l.v. zhigilei

- 格式:pdf

- 大小:211.45 KB

- 文档页数:5

茨维塔耶娃茨维塔耶娃,是俄国作曲家,钢琴家和音乐教育家。

她以其卓越的音乐才华和对钢琴演奏的热爱而闻名于世。

茨维塔耶娃是20世纪最具影响力和最受尊敬的钢琴家之一,她的音乐作品为世人留下了深刻的印象。

她于1904年出生在俄罗斯喀山一个富裕的土地所有者家庭。

她从小就展示出对音乐的浓厚兴趣,父母决定给她提供钢琴教育。

她在乌法音乐学院学习钢琴,并很快展示出非凡的才能。

她的老师们都被她的技巧和灵感深深打动。

茨维塔耶娃的职业生涯在1924年开始迅速崛起。

她参加了第一届列宁格勒国际音乐大赛并荣获第一名,这成为她事业发展的重要契机。

她的演奏技巧和独奏风格为她赢得了无数的赞誉和爱戴。

在20世纪30年代,她开始进行国际巡演。

她的演奏风格独特而富有感染力,她以其出色的技巧和表现力征服了观众。

茨维塔耶娃演奏的音乐富有深情和内涵,触动了听众的内心,将他们带入另一个世界。

她在许多国家和地区演出,包括欧洲、美洲和亚洲。

她在钢琴音乐的演绎上独具一格,她的演奏充满激情和力量,令人难以忘怀。

茨维塔耶娃的音乐才华使她成为了近代钢琴演奏界的巨星。

除了演奏,茨维塔耶娃还是一位杰出的作曲家。

她创作了大量的钢琴曲目,并在自己的演奏会上演奏。

她的作品充满了深情和热情,展现了她对音乐的独特理解和创造力。

然而,正当茨维塔耶娃的事业达到巅峰时,第二次世界大战爆发。

这场战争给世界带来了巨大的动荡和不确定性。

茨维塔耶娃被迫中断了她的巡演并返回苏联。

在战争期间,她积极参与了与军队的合作,为士兵们演奏并提供慰藉。

战争结束后,她重新开始了演奏事业,并继续给世界各地的观众带来无与伦比的音乐享受。

她的音乐表演一直深受欢迎,无论是在音乐厅还是在录音室。

她的演奏风格和独特才华使她在国际上享有盛誉。

茨维塔耶娃一生都致力于音乐教育工作。

她在莫斯科音乐学院担任教授职务,并培养了一代又一代的钢琴家。

她的学生们非常钦佩她对音乐的热爱和对艺术的执着追求。

在1989年的时候,茨维塔耶娃因心脏病去世,享年85岁。

张荔英新加坡画坛先驱张荔英是一位在新加坡画坛享有盛誉的画家,其绘画作品以其精湛的技巧、深邃的内涵和鲜明的个性而著称。

早年经历张荔英出生于上海,在家庭的熏陶下,自幼对艺术产生了浓厚的兴趣。

1962年,她随父母移居新加坡,并开始接受正式的艺术教育。

在1965年至1970年间,她先后在南洋艺术学院、新加坡艺术学会以及美国维吉尼亚艺术学院进行了系统的学习和深造。

创作风格张荔英的作品继承了中国绘画的传统,同时也融合了西方绘画的现代元素。

她运用细腻的笔触和卓越的色彩掌握技法,将自然元素与人类情感有机地结合在一起,使画面具有深厚的意境和思想性。

她对色彩和形式的探索和在作品中的突破,使她的作品在新加坡的艺术圈中备受推崇。

她的艺术成就还为新加坡艺术事业的发展作出了重要的贡献。

代表作品张荔英的代表作品有《朱淑贞在花园》《洛神》和《龙凤》等。

其中《朱淑贞在花园》展现了作者完美运用色彩,令画面充满活力,传递出朱淑贞所带来的快乐和幸福;《洛神》则展现了作者流畅的线条和恰到好处的淡彩运用,令观者感受到了传统与现代的完美融合。

《龙凤》描绘了古老的中国传说中的神物,利用细腻的笔触表现出神物各自的威严和灵气,令人叹为观止。

影响和荣誉张荔英在新加坡的绘画界扮演着重要的角色。

她曾任南洋艺术学院的教授,多次举办个展和联展,并荣获多项艺术奖项,包括1994年新加坡文化奖和2005年东方文化奖。

她的作品在新加坡和国际艺术展览上亮相,并受到了各方的赞誉。

其对传统和现代的融合以及对文化多样性的关注,影响了新加坡的艺术界,在国际上也产生了重要的影响。

结语张荔英是一位在新加坡画坛上有重要贡献的画家,其作品在传承和发扬传统的同时,也展现了技法和思想的革新。

她的艺术传统,丰富了新加坡的文化底蕴,为国家的艺术事业作出了不可磨灭的贡献。

陈志中国名人故事素材故事素材

陈志教授是我国著名的吉他艺术家、教育家、活动家、评论家,是中国古典吉他的奠基人。

陈志现为中央音乐学院古典吉他教授、硕士研究生导师、法国国立巴黎音乐学院、英国伦敦皇家音乐学院客座教授、中国广播吉他乐团团长兼指挥、北京吉他学会理事长、北京陈志古典吉他学校校长,享受国务院特殊津贴的文艺一级专家。

陈志教授的学生们不断在重大的国际吉他比赛中获大奖:其中有王雅梦(1993年在日本东京;1995年在意大利亚历山大里亚;1996年在西班牙马德里)、杨雪霏(1997年在澳大利亚达尔文)、陈川(2002年在香港)。

他们在世界各地音乐会上的表演都得到了很高的评价。

陈志教授多次应邀赴法国、意大利、德国、英国、奥地利、美国、瑞士、比利时、西班牙、葡萄牙、波兰、澳大利亚、日本、马来西亚、香港、澳门、台湾等国家和地区访问、讲学,并经常担任国际吉他比赛的评委。

维果斯基(Lev Vygotsky,1896-1934)前苏联心理学家,“文化-历史”理论的创始人。

1917年毕业于莫斯科大学法律系和沙尼亚夫斯基大学历史哲学系。

1924年到莫斯科心理研究所工作。

维果斯基所处的年代,正是十月革命后苏维埃政权创建的初期。

在意识形态领域,马克思列宁主义与各种资本主义思想发生了激烈的斗争。

年轻的心理学家维果斯基积极参加了这场斗争,一方面反对唯心主义心理学,另一方面尝试建立马克思主义的心理学。

针对行为主义的S-R公式和格式塔心理学的直觉主义,维果斯基对人的高级心理机能进行了研究,并在1925年发表了《意识是行为主义心理学的问题》,明确提出研究意识问题对科学心理学的重大意义。

1931年撰写重要代表作《思维和言语》,详细论述了他对高级心理机能的社会起源与中介结构的理论观点,同时还对皮亚杰关于儿童自我中心言语的观点做了详细评述。

此外,还写有多篇论文阐述教学与发展的关系,提出了“最近发展区”、“教学必须走在发展的前面”等观点。

维果斯基的思想获得了一批年轻心理学家的拥护,鲁利亚和列昂节夫一直追随维果斯基,研究人的高级心理机能的社会历史发生问题。

因此,社会文化-历史学派又称“维列鲁”学派。

1934年维果斯基因患肺结核逝世,年仅38岁。

维果斯基一生留下180多种著作,其心理学思想至今仍有很大影响。

维果斯基所提出的“文化──历史”发展理论认为:人的高级心理机能亦即随意的心理过程,并不是人自身所固有的、而是在与周围人的交往过程中产生与发展起来的,是受人类的文化历史所制约的。

其实现的具体机制是通过物质工具,如刀斧、计算机等,以及精神工具,如各种符号、词和语言等实现的。

高级心理机能不同于低级心理机能的特点是:(1)它们是随意的、主动的,是由主体按照预定的目的而自觉引起的;(2)它们的反映水平是概括的、抽象的,也就是各种机能由于有思维的参与而高级化;(3)它们实现过程的结构是间接的,是以符号或词为中介的;(4)它们的起源是社会文化历史发展的产物,是受社会规律制约的;(5)从个体发展来看它们是在人际的交往过程中产生和不断发展起来的。

匈牙利作曲家里盖蒂逝世

佚名

【期刊名称】《歌剧》

【年(卷),期】2006(000)007

【摘要】一十世纪最伟大的匈牙利作曲家乔治·里盖蒂(Gyorgy Sandor Ligeti)于6月——12日逝世,享年83岁。

【总页数】1页(P39)

【正文语种】中文

【中图分类】J603

【相关文献】

1.里盖蒂的调式和声语言特征——以里盖蒂创作于匈牙利时期的音乐作品为例 [J], 张有川

2.时空的对话——里盖蒂两部《弦乐四重奏》作曲技法的比较分析 [J], 左延芳

3.多重叠映显分隐合——里盖蒂《分歧》中的1/4音作曲技法研究 [J], 左延芳

4.现代音乐作曲家的奏鸣曲式观念——以里盖蒂作品为例 [J], 蒋龙;

5.意大利歌剧的一颗灿烂明星——纪念意大利歌剧作曲家多尼采蒂逝世200周年[J], 朱建;

因版权原因,仅展示原文概要,查看原文内容请购买。

茨威格简介资料范文一:茨威格:一位文学巨匠茨威格(Stefan Zweig)是20世纪初期最杰出的德语文学家之一,也是继海涅后最受欢迎的德国文化名人之一。

他被誉为“欧洲普遍人类的代表”。

茨威格于1881年11月28日出生在奥地利维也纳,成长于一个富裕的犹太家庭。

他早年从事剧作和诗歌写作,但是他的成名作《挪威的宾果》却是一本小说。

这本小说展示了他对人类情感和矛盾的观察和洞察。

在小说的主人公爱情的演化中,茨威格充满了关怀和怜悯,深刻地表现了人类经历的苦涩和幸福。

这也成为茨威格风格的见证。

同样的心理深度和文学价值也体现在他的其他文学作品中。

在茨威格的知名度越来越高之后,第一次世界大战的爆发和他的犹太身份成为了他经历的两个转折点。

为了逃避战争,他和妻子前往瑞士,并开始了自己的流亡生涯。

在流亡期间,他曾游走于欧洲各地。

这期间他写了许多受到读者欢迎的书籍,并成为了一个全球知名的文学巨匠。

但是,这种感人的辉煌之后是茨威格自己先前不可预见的末路。

茨威格和他的妻子因逃离纳粹德国而无所去,最终流亡巴西。

在巴西国内,茨威格的流亡生涯终止了,因为他在1942年自杀身亡。

当时,他正打算回普鲁士以享受“真正意义上的自由”,但是他无法忍受对他所爱的非人性的感官调查。

尽管茨威格的生命短暂,他通过文学成就树立了业界的标杆。

在他的生命中,他写了小说、剧本、散文和回忆录等各种文学作品,一直是不可或缺的文化名人和思想领袖。

他的重要性可以从他在纳粹德国时被禁止的书籍中体现出来,这些作品表明了他对本质和人性僵局的愿景和思想。

他流有道德的手法和文学造诣,引领了许多文学巨匠的发展方向。

要点分析:此范文阐述了茨威格的生平,重点集中在他的成就和贡献,用词清新优美,简明扼要,循序渐进。

写作重点突出了茨威格的独特性并成功地概括了他的主要贡献。

范文二:茨威格:一个值得学习的思想家和文化人茨威格是一个有远见的思想家和杰出的文化人。

他的作品和想法不仅在他自己的时代引领潮流,在今天也散发着巨大的影响力。

【名人故事】牛仔大王李维斯牛仔大王李维斯,这个名字很多人都耳熟能详。

他是美国著名的牛仔服装品牌Levi's 的创始人,也是世界牛仔时尚的先驱者之一。

李维斯的故事鼓舞了无数人追求梦想的勇气和决心。

李维斯原名利维斯·施特劳斯(Levis Strauss),1829年生于德国巴伐利亚州的巴特南大门。

当时,该地区正面临经济和政治的动荡,李维斯的父母决定移民到美国,寻求更好的生活。

1847年,他们一家人来到了旧金山,开始了新的生活。

刚到美国的李维斯,凭借着聪明才智和勤劳的品质,很快融入了这个新的社会。

他的哥哥在纽约开设了一家纺织品公司,而李维斯也去了加利福尼亚州的一家纺织品商店工作。

李维斯的真正辉煌开始于1853年。

当时,一位来自内华达州的挖金矿的人向他提出了一个问题:是否能够给他制作一条牢固耐用的工作裤子。

这位挖金者告诉李维斯,他之前的裤子经常在工作过程中被磨破,需要一种更坚固耐用的材料。

李维斯接受了这个挑战,开始研究制作牢固耐用的工作裤子的方法。

他找到了一种叫做“斜纹布”的材料,这种材料由美国纺织家雅各布·沃夫研发。

斜纹布是一种非常坚固的材料,经过反复的试验和改良,李维斯成功地制作出了一条强韧耐用的裤子。

这条裤子被称为“铜釘裤”,因为裤子上用铜钉固定了裤兜的位置。

李维斯的铜钉裤非常受欢迎,特别是在淘金热中,因为它的品质非常出色,能够耐受金矿工作的辛苦。

为了进一步改良和推广铜钉裤,李维斯在1853年和他的商业合作伙伴雅各布·戈尔曼联合创办了一家公司,命名为“李维斯·施特劳斯和戈尔曼公司”。

他们的目标是将这种牛仔裤推广到全国各地。

随着西部移民的不断增加,牛仔裤成为了西部工人的标志性服装。

李维斯的公司也因此获得了巨大的成功。

他们的产品越来越受欢迎,销售也水涨船高。

李维斯并不满足于此。

他认为牛仔裤还有更大的市场,于是他决定打入国际市场。

他花费了大量的时间和精力,将公司的产品推广到全球各地,特别是在欧洲和亚洲。

走近巴黎:尼古拉盖斯奇埃尔的LV时装秀

法磊

【期刊名称】《中国纤检》

【年(卷),期】2014(000)012

【摘要】2014年巴黎时装周结束了,但也是新的开端。

有时,时尚的周期和生命的轮回是一回事,只是配乐不同而已。

【总页数】2页(P54-55)

【作者】法磊

【作者单位】

【正文语种】中文

【相关文献】

1.“我们必须理解,巴黎提供了“机会——与欧盟委员会前主席若泽曼努埃尔Barroso面试 [J], VERENA MENZEL;

2.走近法国总统宝座的平民之子——尼古拉·萨科奇 [J], 赵静

3.基于亚里士多德三诉诸策略的政治演讲分析r——以埃马纽埃尔·马克龙关于美国退出《巴黎协定》的演讲为例 [J], 单莹

4.创作的焦虑——失衡画家尼古拉斯·德·斯塔埃尔 [J], 金纾

5.桥上的回忆之二渐渐走近埃尔韦·巴赞 [J], 柳鸣九

因版权原因,仅展示原文概要,查看原文内容请购买。

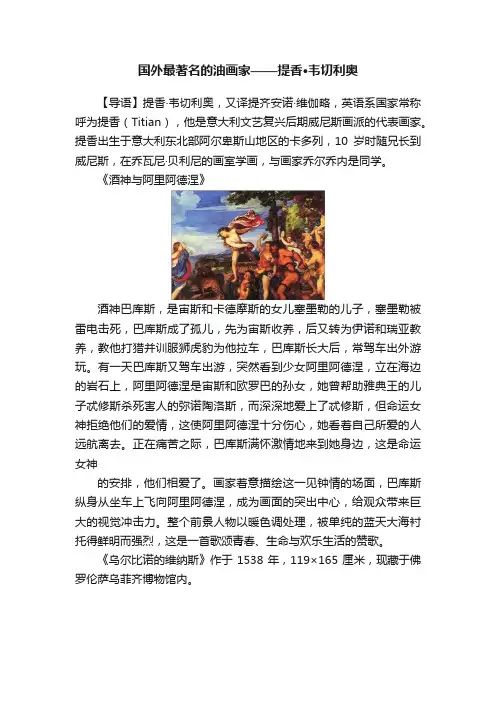

国外最著名的油画家——提香·韦切利奥【导语】提香·韦切利奥,又译提齐安诺·维伽略,英语系国家常称呼为提香(Titian),他是意大利文艺复兴后期威尼斯画派的代表画家。

提香出生于意大利东北部阿尔卑斯山地区的卡多列,10岁时随兄长到威尼斯,在乔瓦尼·贝利尼的画室学画,与画家乔尔乔内是同学。

《酒神与阿里阿德涅》酒神巴库斯,是宙斯和卡德摩斯的女儿塞墨勒的儿子,塞墨勒被雷电击死,巴库斯成了孤儿,先为宙斯收养,后又转为伊诺和瑞亚教养,教他打猎并训服狮虎豹为他拉车,巴库斯长大后,常驾车出外游玩。

有一天巴库斯又驾车出游,突然看到少女阿里阿德涅,立在海边的岩石上,阿里阿德涅是宙斯和欧罗巴的孙女,她曾帮助雅典王的儿子忒修斯杀死害人的弥诺陶洛斯,而深深地爱上了忒修斯,但命运女神拒绝他们的爱情,这使阿里阿德涅十分伤心,她看着自己所爱的人远航离去。

正在痛苦之际,巴库斯满怀激情地来到她身边,这是命运女神的安排,他们相爱了。

画家着意描绘这一见钟情的场面,巴库斯纵身从坐车上飞向阿里阿德涅,成为画面的突出中心,给观众带来巨大的视觉冲击力。

整个前景人物以暖色调处理,被单纯的蓝天大海衬托得鲜明而强烈,这是一首歌颂青春、生命与欢乐生活的赞歌。

《乌尔比诺的维纳斯》作于1538年,119×165厘米,现藏于佛罗伦萨乌菲齐博物馆内。

乌尔比诺的维纳斯的画中人,人们推测是当时的一位贵妇人,名叫艾列奥诺拉乌尔比诺夫人的肖像,所以她不是神,是追求资产阶级生活享乐的上层妇女形象。

画家没有把这个女人画在大自然中,其艺术处理是十分大胆的。

一个普通贵族的室内环境,华丽的床榻,女主人脚边的小狗以及远处正在翻弄衣箱的两个女仆和窗台上的盆花,所有这些细节说明,它是一幅风俗画,它可能是受委托而作。

类似这种画在欧洲其他国家,大概要迟一个世纪,而在威尼斯,上层社会对绘画的感官享受已提到议事日程上了。

此画与乔尔乔内的《睡着的维纳斯》极为相象,也是提香的创作处于最旺盛的年代的杰作。

【名人故事】牛仔大王李维斯李维斯(Levi Strauss)是一位牛仔大王,被誉为“牛仔裤之父”。

他的故事始于19世纪中叶,当时美国正处于西部开拓时期,牛仔裤这种耐用结实的裤子在当时显得尤为重要。

李维斯就是在这个时期,发明了世界上第一条牛仔裤,并为之开创了著名牛仔品牌热门的李维斯牛仔裤。

本文将为大家介绍牛仔大王李维斯的故事。

李维斯出生于1829年,他的父母都是德国移民,在纽约市经营着一家干货店。

年幼的李维斯去世了父母,他随后和两个姐姐一起搬到了德克萨斯州,开始了他的西部探险生涯。

当时的德克萨斯州还没有铁路,而只有马车和驮马。

因此,人们不得不用马或骆驼背上来运货,这就遇到了一些问题。

传统的裤子很容易撕裂,不够结实,而且不透气,无法应对炎热的气候。

为了满足这个市场需求,李维斯开始尝试创造一种更结实、更耐用、更宽松的裤子。

他从法国购买了一些色彩斑斓的刀布织物,这种材料由于纱线结构相对于传统的布料更为紧密,因此更加结实和耐用。

他于是和买家一起设计了这种材料适合的穿着方式,以及如何制作牛仔裤。

这样一来,在1873年,李维斯以织布家族的名义去发行他的第一条牛仔裤,当时是政府为犯人配发物品,但是不久,优秀的耐用性和大方得体的设计成为了全美国牛仔、矿工、工人的首选并在一定程度上代表了美国的文化与精神。

李维斯牛仔裤瞬间成为了当时一种文化象征,成功地占据了市场。

随着市场的壮大,李维斯建立了自己的工厂,并逐步增加了产品线,推出了更多时尚的产品款式,扩大了消费人群。

而且,他也成为一位业务状元,他的企业茁壮成长,迅速拓展到了国际市场,成了一家庞大的时装集团。

很快,李维斯公司就死灰复燃,成为了世界上最大的牛仔裤生产商之一,为全球消费者提供了耐用、具有时尚感的牛仔裤。

就像他的牛仔裤一样,李维斯也是一位坚毅结实的杰出人物。

他的事业与信仰深深地印刻在了他的产品中,他不断地追求创新,不断地突破传统,并赢得了消费者的信任与尊重。

他的成功很大程度上归功于他的信念和中西部开拓时期的努力,使他的公司走向了辉煌的成功之路。

龙源期刊网 林志高艺术赏析作者:来源:《中国经贸》2019年第12期林志高,1954年生于中国福建德化。

双博士学位,历任中国国务院世界艺术研究院院长,中国国务院正部级名誉主席,联合国安理会主席,联合国大会名誉主席,联合国荣誉秘书长等职。

被中共中央、国务院、中央军委授予全国十佳优秀干部。

诗词和书法作品及简历被中央和国家编入《第一文化频道》人物特刊、《2018年国礼挂历》、《2019年新中国功勋人物台历》、2018年第十三届全国人大与政协《两会特刊》和2019年全国人大与政协《两会特刊》以及《一带一路“国家名片”新时代的艺术大师》、《办公室业务》、《中国经贸》、《新中国艺术家档案》等。

林志高的妻子:郑秀玉,1965年生于中国福建德化。

出版《瓷都德化从艺》、《郑成功纪念馆》诗歌和诗词等作品。

2018年第十三届全国人大与政协《两会特刊》和2019年全国人大与政协《两会特刊》以及《一带一路“国家名片”新时代的艺术大师》、《办公室业务》(家照)、《中国经贸》、《新中国艺术家档案》等。

上述事迹及简历多次被国家和世界二百多家网站和全球千家网联播以及各种书报刊登。

林志高与郑秀玉的儿子:林福权,1987年生于中国福建德化。

双博士学位,历任中国国务院世界艺术研究院副院长,联合国大会名誉主席等职。

被中共中央、国务院、中央军委授予全国十佳优秀干部、中国杰出人物、中国中华名人艺术终身荣誉成就奖、中国文化强国先锋人物、全国先进个人、全国先进工作者、爱国精英勋章、人民功臣勋章。

出版《问太阳》、《人生》诗歌和诗词等作品。

《2019年新中国功勋人物台历》、2018年第十三届全国人大與政协《两会特刊》和2019年全国人大与政协《两会特刊》以及《一带一路“国家名片”新时代的艺术大师》、《办公室业务》(家照)、《中国经贸》、《新中国艺术家档案》等。

DOI:10.1007/s00339-004-2607-0Appl.Phys.A 79,977–981(2004)Materials Science &ProcessingApplied Physics Ad.s.ivanov l.v.zhigilei uCombined atomistic-continuum modelfor simulation of laser interaction with metals:application in the calculation of melting thresholds in Ni targets of varying thicknessDepartment of Materials Science &Engineering,University of Virginia,Charlottesville,V A 22904-4745,USAReceived:2October 2003/Accepted:22January 2004Published online:26July 2004•©Springer-Verlag 2004ABSTRACT Thethreshold laser fluence for the onset of surfacemelting is calculated for Ni films of different thicknesses and for a bulk Ni target using a combined atomistic-continuum com-putational model.The model combines the classical molecular dynamics (MD)method for simulation of non-equilibrium pro-cesses of lattice superheating and fast phase transformations with a continuum description of the laser excitation and sub-sequent relaxation of the conduction band electrons based on the two-temperature model (TTM).In the hybrid TTM-MD method,MD substitutes the TTM equation for the lattice tem-perature,and the diffusion equation for the electron temperature is solved simultaneously with MD integration of the equations of motion of atoms.The dependence of the threshold fluence on the film thickness predicted in TTM-MD simulations qual-itatively agrees with TTM calculations,while the values of the thresholds for thick films and bulk targets are ∼10%higher in TTM-MD.The quantitative differences between the predictions of TTM and TTM-MD demonstrate that the kinetics of laser melting as well as the energy partitioning between the thermal energy of atomic vibrations and energy of the collective atomic motion driven by the relaxation of the laser-induced pressure should be taken into account in interpretation of experimental results on surface melting.PACS 61.80.Az;64.70.Dv;02.70.Ns1IntroductionShort-pulse laser irradiation of a metal target caninduce a range of non-equilibrium processes,from strong overheating and fast melting to an explosive boiling and mas-sive material removal (ablation).Experimental analysis of the mechanisms and kinetics of ultrafast laser-induced phase transformations can be performed with optical,X-ray,or elec-tron diffraction time-resolved pump–probe techniques [1–6],whereas the extent of irreversible laser damage can be exam-ined by ex-situ characterization of the target [7–9].A reliable interpretation of experimental observations requires a solid understanding of the fast non-equilibrium pro-cesses occurring in the target material irradiated by a shortu Fax:+1-434/982-5660,E-mail:lz2n@laser pulse.For short,pico-and femtosecond laser pulses,when the time of the laser energy deposition is compa-rable or less than the time needed for electron–phonon thermalization,the method of choice in the majority of theoretical /computational investigations is the so-called two-temperature model (TTM)[10].TTM describes the time evolution of the lattice and electron temperatures by two non-linear differential equations coupled by a term responsible for the energy exchange due to the electron–phonon coupling.Despite the successful applications and popularity of TTM,the inherent limitation of the model is its inability to adequately describe the kinetics of phase transformations oc-curring under highly nonequilibrium conditions induced in the target material by short pulse laser irradiation.In order to overcome this limitation,we are developing a hybrid compu-tational model that combines the MD method for simulation of lattice superheating and fast phase transformations with a continuum TTM description of the laser excitation and subsequent relaxation of the conduction band electrons.The first applications of the TTM-MD model have provided in-sights into the microscopic mechanisms of laser melting and disintegration of Ni and Au films [11,12],photomechanical spallation of bulk Ni targets [13],as well as disintegration and ablation of Cu targets [14].The hybrid model was also used in a recent study of shock-induced heating and melting of a grain boundary region in an Al crystal [15].In this paper we report the results of the application of the TTM-MD model for investigation of the onset of short pulse laser melting in Ni films of different thicknesses and a bulk Ni target.Irradiation parameters are chosen to match the ones used in a recent experimental investigation [1].The threshold laser fluences for the onset of surface melting are calculated with TTM-MD model and compared to the pre-diction of the conventional TTM model.Implications of the simulation results for interpretation of experimental data are discussed.2Combined TTM-MD modelIn the combined model the MD method completelysubstitutes the TTM equation for the lattice temperature.The diffusion equation for electron temperature,T e ,is solved by a finite difference method simultaneously with MD integra-978Applied Physics A –Materials Science &Processingtion of the equations of motion of atoms,TTM:C e (T e )∂T e∂t=∇(K e (T e ,T l )∇T e )−G (T e −T l )+S (z ,t )(1)MD:m i d 2r id t 2=F i +ξm i v T i ,T cell l =N cell i =1m i (v T i )2 (3k B N cell )(2)where in (1)C e is the electron heat capacity,K e is the elec-tron thermal conductivity,G is the electron–phonon coupling constant,and the source term S (z ,t )is used to describe the local laser energy deposition per unit area and unit time dur-ing the laser pulse duration.In (2),m i and r i are mass and position of an atom i ,F i is the force acting on atom i due to the interatomic interactions.An additional term,ξm i v T i ,is added to the ordinary MD equations of motion to account for the electron–phonon coupling.The cells in the finite differ-ence discretization are related to the corresponding volumes of the MD system and the local lattice temperature,T cell l ,is calculated for each cell from the average kinetic energy of the thermal motion of atoms.Thermal velocity of an atom i is defined as v T i =v i −v c ,where v i is the actual velocity of the atom,and v c is the velocity of the center of mass of a cell to which atom i belongs.The coefficient ξin the coup-ling term is calculated for each cell at each MD integration time step and is designed to ensure the energy conservation in the electron-lattice system.The expansion,density variations,and,at higher fluences,disintegration of the irradiated target predicted in the MD part of the model are accounted for in the continuum part of the model.A complete description of the combined TTM-MD model is given elsewhere [12].The hybrid approach,briefly described above,combines the advantages of the two-temperature model and the MD method.The two-temperature model provides an adequate de-scription of the laser energy absorption into the electronic system,energy exchange between the electrons and phonons,and fast electron heat conduction in metals,whereas the MD method is appropriate for simulation of non-equilibrium pro-cesses of lattice superheating,melting,and ablation.In this work we apply the TTM-MD model to study the de-pendence of the threshold fluence for surface melting on the film thickness.Simulations are performed for free-standing Ni films of four different thicknesses,30nm ,50nm ,75nm ,and 100nm ,as well as for a bulk Ni target.The initial MD computational cell is an FCC crystal with lateral dimensions of 3.53×3.53nm .The number of atoms in the computational cell is 34000atoms in 30nm film,56800atoms in 50nm film,85200atoms in 75nm film,and 113600atoms in 100nm film.Periodic boundary conditions are applied in the lateral direc-tions,parallel to (100)free surface(s).In the case of a bulk sample,the MD method is used only in the top 100nm of the target,whereas the diffusion equation for electron tem-perature is solved in a much wider 600nm region,providing an adequate representation of the electronic heat conduction into the bulk of the target.In order to avoid reflection of the pressure waves propagating from the irradiated surface,the dynamic boundary condition [16]is applied at the bottom ofthe MD region.Before applying laser irradiation,all systems are equilibrated at 300K .Laser pulse duration of 200fs is used in the simulations and the absorbed laser fluence rather then the incident fluence is used in the discussion of the simu-lation results.Thermal and elastic properties of the lattice are defined in the TTM-MD model by the inter-atomic potential,de-scribed in this work by the embedded-atom method (EAM)in the form suggested in [17].The parameters used in the TTM equation for the electronic temperature,(1),are as fol-lows [1,11,12],C e =γT e with γ=1065J m −3K −2,K e =K 0T e /T l with K 0=91Wm −1K −1,G =3.6×1017Wm −3K −1.A justification of the choice of the approximation used to de-scribe the dependence of the electron thermal conductivity K e on the electron and lattice temperatures is given in [12].3Results and discussionsSurface melting thresholds predicted in TTM andTTM-MD calculations are shown for Ni targets of differ-ent thickness in Fig.1a.To compare the results of TTM-MD and TTM calculations,the parameters of the model EAM Ni material are used in the TTM equation for the lattice temperature.A series of constant pressure–constant tempera-ture simulations was performed to determine the equation of state of the EAM Ni material,whereas the melting tem-perature was found in liquid-crystal coexistence MD simula-tions.The equilibrium melting temperature at zero pressure,T m ,is found to be 1439K ,the latent heat of melting,H m ,is 2.17×109J m −3,the value of the heat capacity at constant pressure,c p ,increases from 4.08×106J m −3K −1at 300K to 5.32×106J m −3K −1at T m .The temperature dependence of the lattice heat capacity obtained from MD simulations was approximated by a polynomial function and used in TTM cal-culations presented in Fig.1a.In order to make our conclusions usable for quanti-tative interpretation of experimental data,we also per-formed TTM calculations with experimental parameters for Ni,T m =1728K ,H m =2.45×109J m −3[18],and c p =4.1×106J m −3K −1[1].The results of these calculations are shown in Fig.1b [19].To define the melting threshold in a TTM-MD simula-tion,we arbitrary choose the condition at which the number of atoms in the liquid phase corresponds to that in a 2nm layer in the initial crystal before the irradiation.In Fig.1a,the two graphs calculated by TTM correspond to the fluences at which the melting temperature is reached at the very surface of the target (solid line)and the fluences at which the total amount of the melted material in the target is equivalent to a 2nm layer (dashed line).The melting process is included into TTM calculation by a simple assumption that as soon as the melting temperature is reached in a given cell of the finite difference discretization,all the additional energy supplied to the lattice by the heat conduction and transferred from the hot electrons through the electron–phonon coupling goes to the latent heat of melting until all the material in the cell is melted.An alternative to this crude approximation would be to allow overheating and to include a description of the kinet-ics of laser melting based on the classical nucleation theory,e.g.,[20].Recent MD simulations of laser melting [11,12]IVANOV et bined atomistic-continuum model for simulation of laser interaction with metals979FIGURE 1Surface melting threshold versus film thickness calculated with the combined TTM-MD model (data points )and TTM model (dashed and solidlines )for laser irradiation with 200fs laser pulses.The data points for the TTM-MD simulations in a and the dashed line for the TTM calculations show the fluences at which the maximum amount of the melted material corresponds to a 2nm layer in the original target.The solid line shows the fluence at which the melting temperature is reached at the very surface of the target,as predicted by TTM.The dash-dotted line corresponds to the energy needed to homogeneously heat the whole film up to the melting temperature and melt 2nm region of the film.Properties of the model EAM Ni material are used in TTM calculations in a ,experimental properties of Ni [1]are used in b [19]suggest,however,that relaxation of the laser-induced stresses can result in anisotropic deformation of the surface region and reduction of the overheating required for the initiation of the homogeneous melting down to almost zero.Therefore,in this work we decide to not include overheating into the TTM calculations.Note that both overheating and the effect of the relaxation of the laser-induced stresses are naturally included in the TTM-MD model,which does not require any a priori assumptions on the lattice response to the fast laser heating.As we can see from Fig.1a,both TTM-MD and TTM models predict nearly linear increase of the threshold fluence with film thickness up to a certain thickness,L c ,that corres-ponds to the diffusive penetration depth of the excited elec-trons before the electron–phonon equilibration at the thresh-old for melting.The value of L c can be estimated following the method proposed in [21]and the results of the estima-tion are shown by arrows in Fig.1[19].In films thinner than L c ,nearly uniform temperature distributions are established by the time of electron–phonon equilibration.As a result,the threshold fluences for laser melting are defined by the energy density needed to homogeneously heat the film up to the melt-ing temperature and melt a 2nm layer of the film (dash-dotted lines in Fig.1).The maximum depths of melting at the front and back surfaces of a 30nm film are found to be approxi-mately equal to each other,whereas the maximum amount of melted material at the back surface of a 50nm film accounts only for ∼10%of the total amount of the liquid phase.For films thicker than L c ,the electron–phonon equilibration takes place within the electronic diffusion length L c from the irra-diated surface,melting is observed at the front surface only,and the threshold fluence saturates and approaches the value characteristic for a bulk target.While both TTM-MD and TTM predict similar depen-dences of the melting threshold from the film thickness,the threshold values obtained in TTM-MD model for films with thickness significantly above L c are ∼10%higher as com-pared to the ones predicted by TTM.To explain this discrep-ancy,we have to consider the kinetics of the melting process occurring under conditions of the fast laser energy depositionas well as additional channels for partitioning of the deposited energy,not accounted for in TTM but present in a more realis-tic TTM-MD model.The kinetics of energy redistribution in a TTM-MD simu-lation of a partial laser melting of a 100nm Ni film irradiated by a 1ps laser pulse is illustrated in Fig.2.The fluence of 430J /m 2is chosen in this simulation so that the maximum depth of the melted surface region would reach ∼15nm .A larger,as compared to the simulations discussed above,depth of melting allows us to better illustrate,in addition to other channels of the laser energy partitioning,the energy transfer to the latent heat of melting.Following the energy de-position by a 1ps laser pulse,the total energy is conserved for the rest of the simulation.Initially all the laser energy is de-posited into the energy of electrons,E e .The electron–phonon coupling leads to the fast,within ∼20ps ,transfer of more than a half of the deposited laser energy to the thermalen-FIGURE 2Energy partitioning in a 100nm Ni film irradiated with a 1ps laser pulse at an absorbed fluence of 430J /m 2.The thermal energies of theelectrons,E e ,and the atoms,E th a,the energy of the collective atomic motion due to the elastic vibrations of the film,E c a,the energy transferred to the la-tent heat of melting,E m ,and the total energy of the system,E tot ,are shown.Energies are normalized to the total energy absorbed by the film980Applied Physics A–Materials Science&Processingergy of the atomic motion,E th a.The fast temperature increase leads to the buildup of a compressive pressure in the irradiated film.The relaxation of the initial pressure induces a collec-tive atomic motion of the elastic vibrations of thefilm.The energy of the elastic vibrations,E c a,includes contributions of the kinetic and potential energies associated with the collec-tive atomic motion in thefilm.E c a also includes a smaller static component due to a contribution from anisotropic thermoe-lastic stresses that cannot relax by the uniaxial expansion of thefilm in the direction normal to the surface.These static anisotropic stresses remain in the crystalline part of the tar-get even after the relaxation of the elastic oscillations of the film[13].The time dependence of the energy of melting,E m,re-flects the kinetics of the melting process.The energy spent on melting is determined by multiplying the fraction of the liquid phase in the system by the latent heat of melting of the model material.The fraction of the liquid phase is calcu-lated based on the local order parameter defined in[12].In the simulation illustrated by Fig.2,a fast homogeneous melt-ing of∼11nm surface region of irradiatedfilm is followed by a slower heterogeneous melting of additional4nm of thefilm by liquid-solid front propagation.As we can see from Fig.2,the energy transferred from the excited electrons to the lattice splits into three parts, the energy of the thermal motion of the atoms,E th a,the en-ergy of melting,E m,and the energy of the collective atomic motion associated with the relaxation of the laser-induced stresses,E c a.The latter part is not accounted for in a simple TTM model.The energy of the collective motion of atoms can be comparable(up to∼15%in Fig.2)to the energy of the thermal motion of atoms and should be taken into account in the analysis of the energy density needed to melt the mate-rial.Two additional factors are found to have a strong effect on the melting process.First,the material can be significantly (up to∼20%[12])overheated above its equilibrium melting temperature when the time of the laser heating(defined by the laser pulse duration and/or the time of electron–phonon equilibration,whichever is longer)is shorter than the time needed for the melting front propagation from the free sur-face(s)of the target.Second,the fast relaxation of the laser-induced pressure can only proceed in the direction normal to the surface of the target,leading to the uniaxial expansion and associated anisotropic lattice distortions.The anisotropic de-formation of thefilm reduces the lattice stability against the initiation of melting.As a result,the overheating required for the initiation of homogeneous melting can be reduced down to less then T≈1.05T m[11].The net results of all the fac-tors described above is that the thresholds for laser melting of sufficiently thickfilms predicted in the TTM-MD simulations are∼10%higher as compared to the ones obtained in TTM calculations.Although the effects of the overheating and laser-induced collective atomic motion described above are present infilms of any thickness,forfilms thinner or comparable with the electronic diffusion length L c,we observe a good agreement between the predictions of TTM and TTM-MD models.This observation is related to the kinetics of the laser melting pro-cess.In a thickfilm or a bulk target,a fast transient melting of a surface region is followed by recrystallization,whereas in Thickness Time of the maximum melting depth (nm)(ps)TTM TTM-MD3050∼7505018∼750 751540 1001338bulk1334TABLE1Time when the maximum melting depth of2nm is reached in TTM and TTM-MD simulations of surface melting of Nifilms of different thickness and a bulk Ni target irradiated with a200fs laser pulse.For30nm films no recrystallization of the melted regions is observed and the times shown in the table correspond to the saturation in the time dependence of the amount of melted materialafilm thinner than L c the lattice heating proceeds almost ho-mogeneously throughout thefilm and the melted parts of the film remains melted at later times(surface melting is detected at both sides offilms thinner than L c and the melting depths at the front and back sides become closer to each other as thefilm thickness decreases).The predictions of both TTM and TTM-MD calculations forfilms thinner than L c are,therefore,close to the straight dash-dotted lines in Fig.1that correspond to the homogeneous heating of the wholefilm and permanent melt-ing of a surface region(s).An important difference between the TTM and TTM-MD simulations,however,is that the melt-ing of thinfilms(30nm and50nm)takes much longer in the TTM-MD simulations,as shown in Table1.As discussed above and illustrated in Fig.2,in TTM-MD simulations a sig-nificant part of the deposited laser energy goes to the non-thermal energy of the elastic oscillations of thefilm.Gradual dissipation of the oscillations,occurring on the timescale of hundreds of picoseconds,leads to the energy transfer from the energy of the collective atomic motion,E c a,to the energy of the thermal motion of the atoms,E th a,Fig.2.In a thinfilm ho-mogeneously heated up to the melting temperature,the energy transferred from E c a to E th a is further transferred to the latent heat of melting,E m,leading to a gradual advancement of the melting front.As a result,the melting process infilms thinner than L c takes much longer in TTM-MD simulations as com-pared to TTM simulations that do not include a description of the thermoelastic material response to the fast laser heating, Table1.4SummaryIn summary,the quantitative differences between the predictions of TTM and TTM-MD demonstrate that the kinetics of laser melting as well as the energy partitioning be-tween the thermal and collective atomic motions induced by the fast laser energy deposition should be taken into account in interpretation of the experimental results on surface melting.ACKNOWLEDGEMENTS The authors would like to thank Dr.B.Rethfeld of Universit¨a t Essen for insightful comments and discussions and Dr.J.G¨u dde of the Philipps-Universit¨a t Marburg for helpful communication at thefinal stage of the paper preparation.REFERENCES1S.-S.Wellershoff,J.Hohlfeld,J.Güdde,E.Matthias:Appl.Phys.A69, S99(1999)IVANOV et bined atomistic-continuum model for simulation of laser interaction with metals9812M.B.Agranat,S.I.Ashitkov,V.E.Fortov,A.V.Kirillin,A.V.Kostanov-skii,S.I.Anisimov,P.S.Kondratenko:Appl.Phys.A69,637(1999)3B.Lin,H.E.Elsayed–Ali:Surf.Sci.498,275(2002)4K.Sokolowski-Tinten,C.Blome,J.Blums,A.Cavalleri,C.Dietrich,A.Tarasevich,chmann,E.Förster,M.Kammler,M.Horn-von-Hoegen,D.von der Linde:Nature422,287(2003)5B.J.Siwick,J.R.Dwyer,R.E.Jordan,ler:Science302,1382 (2003)6O.P.Uteza,E.G.Gamaly,A.V.Rode,M.Samoc,B.Luther-Davies:in preparation.7S.Preuss,A.Demchuk,M.Stuke:Appl.Phys.A61,33(1995)8T.D.Bennett,C.P.Grigoropoulos,D.J.Krajnovich:J.Appl.Phys.77, 849(1995)9M.Hashida,A.F.Semerok,O.Gobert,G.Petite,Y.Izawa,J.F.Wagner: Appl.Surf.Sci.197–198,862(2002)10S.I.Anisimov,B.L.Kapeliovich,T.L.Perel’man:Sov.Phys.JETP39, 375(1974)11D.S.Ivanov,L.V.Zhigilei:Phys.Rev.Lett.91,105701(2003)12D.S.Ivanov,L.V.Zhigilei:Phys.Rev.B68,064114(2003)13E.Leveugle,D.S.Ivanov,L.V.Zhigilei:Appl.Phys.A,in press14C.Schäfer,H.M.Urbassek,L.V.Zhigilei:Phys.Rev.B66,115404 (2002)15D.S.Ivanov,L.V.Zhigilei,E.M.Bringa,M.De Koning,B.A.Rem-ington,M.J.Caturla,S.M.Pollaine:Proceedings of APS Topical Con-ference on Shock Compression of Condensed Matter,in press (2003)16L.V.Zhigilei,B.J.Garrison:Mat.Res.Soc.Symp.Proc.538,491(1999) 17X.W.Zhou,H.N.G.Wadley,R.A.Johnson, rson,N.Tabat,A.Cerezo,A.K.Petford-Long,G.D.W.Smith,P.H.Clifton,R.L.Mar-tens,T.F.Kelly:Acta Mater.49,4005(2001)18CRC Handbook of Chemistry and Physics,72nd edition,ed.byD.R.Lide,(CRC Press,Boca Raton,FL1991)19Due to a minor difference in the definition of the diffusive penetration depth of excited electrons used in this work and in[1,21],the value of L c is larger by a factor of25/8as compared to the one reported in[1].A more significant quantitative discrepancy is observed between the re-sults of TTM calculations reported in[1]and the results presented in Fig.1b of this paper.In particular,the saturationfluences at which the melting temperature is reached at the surface of thick Ni samples is 220J/m2in[1](Fig.8b)and363J/m2in our calculations(Fig.1b).This discrepancy is due to a mistake in the TTM code used in[1],as identified through private communication with one of the authors of[1], Dr.J.Güdde.New test calculations performed by Dr.Güdde and Dr.Rethfeld agree with the data presented in this paper.20B.Rethfeld,K.Sokolowski-Tinten,D.von der Linde,S.I.Anisimov: Phys.Rev.B65,092103(2002)21P.B.Corkum,F.Brunel,N.K.Sherman,T.Srinivasan-Rao:Phys.Rev.Lett.61,2886(1988)。