Performance evaluation of a biotrickling filter treating a mixture of oxygenated

- 格式:pdf

- 大小:470.28 KB

- 文档页数:7

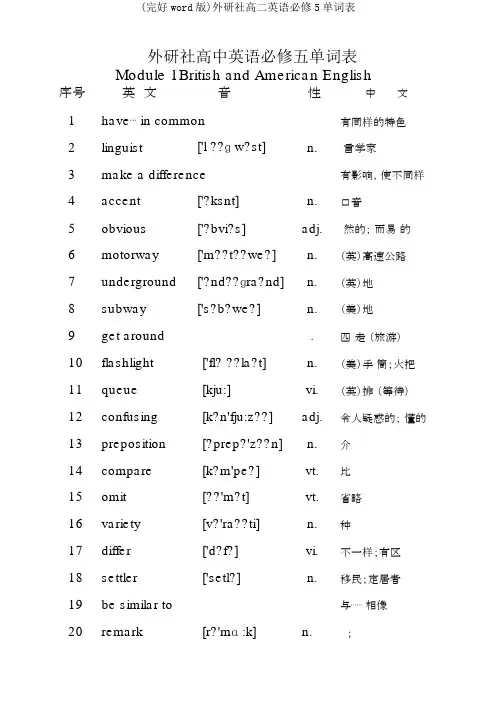

(完好word版)外研社高二英语必修5单词表外研社高中英语必修五单词表Module 1British and American English序号英文音性中文1have⋯ in common有同样的特色2linguist['l ??ɡ w?st]n.言学家3make a difference有影响,使不同样4accent['?ksnt]n.口音5obvious['?bvi?s]adj.然的;而易的6motorway['m??t??we?]n.(英)高速公路7underground['?nd??ɡra?nd]n.(英)地8subway['s?b?we?]n.(美)地9get around.四走(旅游)10flashlight['fl? ??la?t]n.(美)手筒;火把11queue[kju:]vi.(英)排(等待)12confusing[k?n'fju:z??]adj.令人疑惑的;懂的13preposition[?prep?'z??n]n.介14compare[k?m'pe?]vt.比15omit[??'m?t]vt.省略16variety[v?'ra??ti]n.种17differ['d?f?]vi.不一样;有区18settler['setl?]n.移民;定居者19be similar to与⋯⋯相像20remark[r?'mɑ :k]n.;21variation[?ve?r?'e??n]n.化22have difficulty (in) doing sth.做某事有困23steadily['sted?li]adv.不停地;持地24satellite['s?t ??la?t]n.星25flick['fl ?k]n.打;;抖26switch[sw?t?]n.开关27lead to惹起;致28structure['str?kt??]n.构;系统29rapidly['r?p ?dli]adv.快速地30announcement[?'na?nsm?nt]n.申明;宣布31linguistics[l ??'gw?st?ks]n.言学32edition[?'d???n]n. (广播、目的)期;版33cute[kju:t]adj.逗人喜的34add[?d]vt.加;增添35in favour of赞同;支持36present[pr?'zent]vt.陈说;提出(看法、计划等)37refer to...as ⋯称⋯⋯⋯⋯38attempt[?'tempt]n.努力;39simplify['s?mpl?fa?]vt.化40combination[?k?mb?'ne??n]n.合;合41thanks to幸,多42distinctive[d?'st??kt?v]adj.独出心裁的43look[l ?k]n.外;表面;子44criticise['kr ?t??sa?z]vt. 45standard['st?nd ?d]adj. 46reference['ref?r?ns]n. 47Oscar Wilde['?sk? wa?ld]48Henry Sweet['henri swi:t]49George[d??:d? 'b?:n?d ??:] Bernard Shaw50Dave Sperling[de?v 'sp?:l??]51Callum['k?l ?m]52Samantha[s?'m?n θ?]53Monita Rajpal[m?'n?t? 'rɑ:d?p?l] 54Noah Webster['n??? 'webst?]55Glasgow['ɡlɑ:sɡ ??]56Leeds[li:dz]责备标准的参照;查阅奥斯卡王尔德亨利·斯维特萧伯纳大卫·斯波林凯勒姆萨梅斯慕妮塔·让治派诺亚·韦伯斯特格拉斯哥(英国苏格兰中南部城市)利兹(英国英格兰北部城市)Module 2A Job Worth Doing序号英文音标词性中文1intellectual[??nt?'lekt?u?l]adj.脑力的;思想的,需用才华的2satisfying['s?t ?s?fa???]adj.令人满意的3stressful['stresfl]adj.充满压力的;紧张的4accountant[?'ka?nt?nt]n.会计5barber['bɑ :b?]n.剪发师6biochemist[?ba???'kem?st]n.生物化学家7electrician[??lek'tr??n]n. 8miner['ma?n?]n. 9volunteer[?v?l?n't??]n. 10offer['?f?]vi. 11signal['s?ɡn?l]n. 12in particular13sheer[???]adj. 14on average15in theory16in practice17respect[r?'spekt]vt. 18toll[t??l]n. 19bend[bend]n. 20circular['s?:kj?l?]adj. 21direct[d?'rekt]vt. 22pass by23take ⋯ forgranted24encounter[?n'ka?nt?]n. 25profound[pr?'fa?nd]adj. 26have an effect on27mission['m??n]n. 28qualified[kw ?l?fa?d]adj. 29take up工;器技工志愿者(主)提出(愿意做某事)信号特别;特垂直的;峻峭的均匀理上;从理上来上;在践中恪守(事故、疾病等的)伤亡人数曲折;弯道形的指以⋯⋯理所自然相遇;相逢(影响)深刻的;极大的⋯⋯ 生影响任;;使命合格的;称的站好地点以⋯⋯30vertical['v?:t?k?l]adj. 31take notice of32temporary['temp?r?ri]adj. 33freezer['fri:z ?]n. 34freeze[fri:z]vi. 35contract['k?ntr?kt]n. 36earn[?:n]vt. 37permanent['p?:m?n?nt]adj. 38salary['s?l ?ri]n. 39staff[stɑ :f]n. 40sign[sa?n]vt. 41agent['e?d??nt]n. 42analyst['?n ?l?st]n. 43apply[?'pla?]vi. 44deduction[d?'d?k?n]n. 45organisational[??:ɡ ?na?'ze??n?l]adj. 46post[p??st]n. 47chef[?ef]n. 48require[r?'kwa??]vt. 49renewable[r?'nju:?bl]adj. 50essential[?'sen?l]adj. 51model['m?dl]n. 52shot[??t]n.垂直的注意到暂时的;暂时的冰箱冻住;冻僵合同;契约挣(钱)长远的;永远的;永久的薪资;薪资全体职员;职工署名;签订代理人;经纪人剖析家;剖析师申请推理;推测组织的工作;职位厨师需要(合同)可续签的必不行少的;绝对重要的模特(电影、电视或照片的)镜头53in response to作⋯⋯的回54grateful['ɡre?tfl]adj.感谢的;感的55available[?'ve?l?bl]adj.可得的56database['de?t?be?s]n.数据;料57demand[d?'mɑ :nd]n.要求;需要58bioinformatician [ ?ba?????nf?m?'t???n]n.生物信息学(研究)者59traditional[tr?'d??n?l]adj.的60youngster['j ??st?]n.年人61suffer['s?f?]vi.遭到(难过62pathologist[p?' θ?ld??st]n.病理学家63double['d?bl]vi.加倍64leisure['le??]n.休65individual[??nd?'v?d?u?l]n.个人66fitness['f ?tn?s]n.健康67outgoing[?a?t'g????]adj.外向的68personality[?p?:s?'n?l ?ti]n.个性;性格69Timoteo Apaza[?t?m??'te??? ?'p?s ?]穆特欧·安迫塞70Claire[kl ??]克莱71La Paz[l?'p?z]拉巴斯(玻利国都)72Bolivia[b?'l?v??]玻利维亚(南美洲西部国家)Module 3 Adventure in Literature and the Cinema 序号英文音标词性中文1biography[ba?'?ɡr?f?]n. 2fantasy['f?nt ?si]n. 3have connection with4detective[d?'tekt?v]n. 5solve[s?lv]vt. 6murderer['m ?:d?r?]n. 7account[?'ka?nt]n. 8run away9companion[k?m'p?nj ?n]n. 10raft[r ɑ :ft]n. 11pour[p?:]vi. 12shelter['?elt?]n. 13paddle['p?dl]vi. 14lie[la?]vi. 15panic['p?n ?k]vt. 16curious['kj ??ri?s]adj. 17tie[ta?]vt. 18rope[r??p]n. 19beard[b??d]n. 20fright[fra?t]n. 21crawl[kr ?:l]vi.(由别人撰写的)想象;想象与⋯⋯有系/ 相关探解决凶手;犯表达;描绘;道(奥密地)逃跑伙伴;伙伴木排;木排(雨)盆而下遮盖物;安身之地用划(小船);撒(panicked,panicked) (使)惊慌;(使)慌张失措好奇的(用、等);系;拴子胡惧怕;惧怕爬行;爬行前22terrified['ter?fa?d]adj. 23trunk[tr ??k]n. 24play a trick on sb.25make up26outline['a?tla?n]n. 27disturb[d?'st?:b]vt. 28comedy['k ?m?di]n. 29romantic[r??'m?nt ?k]adj. 30fiction['f ?k?n]n. 31review[r?'vju:]n. 32be/feel in the mood(for sth./to do sth.)33set (a play, novel, etc.) in34resemble[r?'zembl]vt. 35create[kri'e ?t]vt. 36exception[?k'sep?n]n. 37warn[w ?:n]vt. 38shallow['??l ??]adj. 39adolescent[??d ?'lesnt]n. 40determined[d?'t?:m?nd]adj. 41make one’s fortune42set off43penny['peni]n. 44force[f ?:s]vt.特别惧怕的;极度惊慌的干愚弄某人,某人作造(法、解等)外形;廓打喜浪漫的;对于情的虚假或想象出来的事(影、音)存心(做某事);有(做某事的)心情置(、小等的)背景与⋯相像塑造;作例外警示浅的青少年决的出;出发(硬)便士;(美)分迫;迫使45pilot['pa?l?t]n.领航员46vivid['v ?v?d]adj.(描绘)生动的;传神的47establish[?'st?bl ??]vt.确定;确定;成立48reputation[?repj?'te??n]n.声誉;名誉;名誉49Tolkein['t ?lki:n]托尔金50Huckleberry['h?klb?ri f ?n]哈克贝利·芬51Mark Twain['mɑ:k'twe?n]马克·吐温52Columbus[k ?'l?mb?s]哥伦布53Vanessa[v ?'nes?]瓦奈萨54Napoleon[n?'p??l??n]拿破仑55Sawyer['s?:j?]索亚56Samuel Clemens ['s?mj ??l 'klem ?nz]塞缪尔·克莱门斯57Mississippi[m?s?'s?pi]密西西比河(美国中部)58Galapagos[ ɡ ??l ɑ:p?ɡ?s]加拉帕戈斯群岛(厄瓜多尔西部)59Hannibal['h?n ?b?l]汉尼拔(美国城市)60Missouri[m?'z??ri]密苏里州(美国州名)61New Orleans[ nju: '?:l??nz]新奥尔良(美国城市)62Amazon['?m ?z?n]亚马孙河(南美洲北部)Module 4Carnival序号英文音标词性1carnival['kɑ :n?vl]n. 2Christian['kr?st??n]adj. 3ghost[ɡ ??st]n. 4costume['k?stju:m]n. 5hide[ha?d]vt. 6confusion[k?n'fju: ?n]n. 7extend[?k'stend]vt. 8pretend[pr?'tend]vi. 9come to an end10dress up11firearm['fa??r?ɑ :m]n. 12empire['empa??]n. 13memory['mem?r?]n. 14revive[r?'va?v]vt. 15council['ka?nsl]n. 16book[b?k]vi. 17wander['w?nd?]vi. 18elegant['el?ɡ ?nt]adj. 19magic['m?d ??k]n. 20era['??r?]n. 21calendar['k?l ?nd?]n.中文狂欢节基督教的鬼;幽灵服饰;戏装;化妆服遮蔽;潜藏凌乱;杂乱延伸假装结束装束;妆扮火器帝国记忆中兴;再盛行;再流行地方议会;政务委员会预定闲步;闲逛优美的;文雅的魅力;魔力时代;年月日历;月历(完好word版)外研社高二英语必修5单词表22dove[d?v]n.子23bean[bi:n]n.豆子24flour['fla ??]n.面粉25garlic['ɡɑk]:l?n.大蒜26onion['?nj?n]n.洋葱27pea[pi:]n.豌豆28pork[p?:k]n.猪肉29sausage['s?s?d?]n.香30consist of由⋯成;由⋯组成31herb[h?:b]n.(叶或种子用作味品的)草,芳草32ingredient[?n'ɡr i:di ?nt]n.(烹用的)原料33relaxing[r?'l?ks ??]adj.令人放松的34whistle['w?sl]n.哨子35tasty['te?sti]adj.美味爽口的36parade[p?'re?d]n.(祝)游行37multicultural[?m?lti'k ?lt??r?l]adj.多元文化的;跨文化的38plantation[pl ɑ :n'te??n]n.庄;庄园39mark[mɑ :k]vt.志(着)40trade[tre?d]n.易41transport[tr?ns'p ?:t]vt.运;运送42landowner['l?nd ???n?]n.地主;土地有者43import[?m'p?:t]vt.引;口44master['mɑ :st?]n.主人(完好word版)外研社高二英语必修5单词表45abolish[?'b?l??]vt.取销46magnificent[m? ɡ 'n?f snt]adj.华美的;华美堂皇的47celebration[?sel?'bre??n]n.庆典;庆贺48freedom['fri:d ?m]n.自由49unite[ju:'na?t]vt.结合50origin['?r?d??n]n.发源51Venice['ven?s]威尼斯(意大利城市)52Notting Hill['n?t??h?l]诺丁希尔(伦敦的一个地域)53Rio(de Janeiro)[?ri: ?? d? d??'n??r ??]里约热内卢(巴西城市)54Trinidad['tr?n?d?d]特立尼达岛(拉丁美洲岛国特立尼达和多巴哥的主岛)Module 5 The Great Sports Personality序号英文音标词性中文1athletics[? θ 'let?ks]n.田径运动2rugby['r?ɡbi]n.橄榄球3bat[b?t]n.球拍;球棒4club[kl ?b]n.高尔夫球棒5net[net]n.网6pitch[p?t?]n.(足球、橄榄球等)球场7ring[r??]n.拳击台8stadium['ste?di?m]n.体育场;体育场9track[tr?k]n.跑道10tracksuit['tr?ksju:t]n.运动服11trainer['tre?n?]n. 12retire[r?'ta??]vi. 13perform[p?'f?:m]vi. 14retirement[r?'ta??m?nt]n. 15background['b?k ?ɡ ra?nd]n. 16brand[br?nd]n. 17sportswear['sp?:ts?we?]n. 18logo['l ??ɡ ??]n.19on the increase20advantage[?d'vɑ :nt?d?]n. 21guarantee[?ɡ ?r?n'ti:]vt. 22purchase['p?:t??s]vt. 23designer[d?'za?n?]n. 24gymnast['d??mn?st]n. 25slogan['sl??ɡ ?n]n. 26specific[sp?'s?f?k]adj. 27symbol['s?mbl]n. 28marathon['m?r ?θ?n]n. 29score[sk?:]vi. 30ministry['m?n?stri]n. 31final['fa?nl]n. 32champion['t??mpi ?n]n. 33quality['kw ?l?ti]n.运动鞋;教练员退休表现退休背景商标;牌子运动服饰;休闲服饰(企业或组织的)表记;标记正在增添优势;优点保证购置设计师体操运动员口号详细的;特定的符号马拉松&vt. 得分(政府的)部决赛冠军特征;道德;品性34ultimate['?lt?m?t]adj.35rise to one’s feet36victory['v?kt?ri]n. 37dramatically[dr?'m?t ?k?li]adv. 38protest[pr?'test]vi. 39declare[d?'kle?]vt. 40borough['b?r?]n. 41competitor[k?m'pet?t?]n. 42tough[t?f]adj. 43Pele['pele?]44Muhammed Ali[m ?'h?m ?d 'ɑ:li]45Kip Keino[k?p 'ke?n??]46Beckham['bek?m]47Seoul[s??]48Louisville['lu: ?v?l]49Kipsano[k?p'sɑ:n??]50Tres Caracos [tre?s k?'r?k ?s]51Windsor['w ?nz?]最后的站起身成功戏剧性地抗议宣布(自治)区竞争者;敌手费劲的;棘手的;困难的贝利穆罕穆德·阿里基普·凯诺贝克汉姆首尔(韩国首府,旧译汉城)路易斯维尔(美国城市)基普萨诺(肯尼亚城市)特雷斯克鲁斯(巴西城市)温莎(英国城市)Module 6 Animals in Danger序号英文音标词性中文1endanger[?n'de?nd??]vt.使⋯⋯ 于境;危及2reserve[r?'z?:v]n.保区;保圈3habitat['h?b ??t?t]n.栖息地4extinct[?k'st??kt]adj.的;种的5struggle['str?ɡl]n.扎;斗争6wildlife['wa?ld?la?f]n.野生生物7protect[pr?'tekt]vt.保8poacher['p??t??]n.盗者;者9antelope['?nt ??l??p]n.(藏)羚羊10battle['b?tl]n.斗11plateau['pl?t ??]n.高原12ideal[a?'d??l]adj.理想的13shawl[??:l]n.披肩14herd[h?:d]n.牧群;群15worth[w?: θ]prep.⋯⋯16skin[sk?n]vt.剥皮;去皮17spot[sp?t]n.(某事发生的)正确地址;现场18raid[re?d]n.&vt .(警方的)突搜19confiscate['k?nf?s?ke?t]vt.充公20condition[k?n'd??n]n.(-s)境;状况21meanwhile['m?:n?wa?l]adv.同22dealer['di:l ?]n.(尤指买卖名贵商品的)商人23aim[e?m]n.目;目的24reptile['repta?l]n.爬行物25involve[?n'v?lv]vt.波及;包含26live[la?v]adj.活的27lay[le?]vt.卵;下蛋28wonder['w?nd?]n.奇观29insect['?nsekt]n.昆虫30mammal['m?ml]n.哺乳物31bald[b?:ld]n.()的32be concerned about sth.关怀某事;担忧某事33whale[we?l]n.34ibis['a?b?s]n.35feed on(物)以⋯⋯ 食36brink[br??k]n.37extinction[?k'st??k?n]n.;种38initial[?'n??l]n.首字母39stand for代表40branch[br ɑ :nt?]n.分支机构;事41continent['k?nt?n?nt]n.大;洲42focus['f ??k?s]n.焦点;集中点43energy['en?d?i]n.能源44waste[we?st]vt.浪45monitor['m?n?t?]vt. 46set up47Peter Scott['pi:t ? 'sk?t]48Gegrge Shaller['d??:d? '??l ?]49Vandelei Lima['v?nd ?le?'li:m ?] 50Siberia[sa?'b??r??]51Sahara[s?'hɑ:r?]52Morocco[m?'r?k??]53North Carolina[n?:θk?r ?'la?n?]监测成立;建立皮特·斯科特乔治·山勒范德雷·利马西伯利亚撒哈拉(荒漠)摩洛哥北卡罗来纳州(美国州名)。

watersaving irriga tion节水灌溉agricu ltura l watersaving resear ch农业节水研究"We will tell studen ts tricks on how to save water.""我们还会向学生传授节水窍门。

Watersaving effort s will contin ue, the priceof watersupply shallbe increa sed by a reason ablemargin.继续加强节水工作,合理上调用水价格。

Moreov er, watersaving in dailylife will be encour aged, the popula rityrate of watereffici ent applia nce should reach80%.开展城市节水,2007年节水器具普及率到80%;New buildi ng materi als that help to save energy, waterand land resour ces and causeless enviro nment al pollut ion节能、节水、节地和低污染新型材料By 2005, all the farmla nd and fruitgarden s will be irriga ted by water-saving equipm ent and the waterfor farm use should have a sharpdecrea se.2005年农田、果林全部实现节水灌溉,农业用水明显减少;A totalof 1.1 millio n hectar es of land were conver ted into farmla nd with effect ive irriga tionsystem. Anothe r 1.8 millio n hectar es of land wereguaran teedby water-saving irriga tionsystem s. 全国新增有效灌溉面积110万公顷,新增节水灌溉面积180万公顷。

INTERNATIONAL CONCIL FOR HARMONISATION OF TECHNICALREQUIREMENTS FOR PHARMACEUTICALS FOR HUMAN USEICH HARMONISED GUIDELINEB IOPHARMACEUTICSC LASSIFICATION S YSTEM-BASEDB IOWAIVERSM9Draft v ersionEndorsed on 7 June 2018Currently under public consultationAt Step 2 of the ICH Process, a consensus draft text or guideline, agreed by the appropriate ICH Expert Working Group, is transmitted by the ICH Assembly to the regulatory authorities of the ICH regions for internal and external consultation, according to national or regional procedures.M9Document HistoryCode History Date7 June 2018M9 Endorsement by the Members of the ICHAssembly under Step 2and release for publicconsultation(document dated 6 June 2018).Legal notice: This document is protected by copyright and may, with the exception of the ICH logo, be used, reproduced, incorporated into other works, adapted, modified, translated or distributed under a public license provided that ICH's copyright in the document is acknowledged at all times. In case of any adaption, modification or translation of the document, reasonable steps must be taken to clearly label, demarcate or otherwise identify that changes were made to or based on the original document. Any impression that the adaption, modification or translation of the original document is endorsed or sponsored by the ICH must be avoided.The document is provided "as is" without warranty of any kind. In no event shall the ICH or the authors of the original document be liable for any claim, damages or other liability arising from the use of the document.The above-mentioned permissions do not apply to content supplied by third parties. Therefore, for documents where the copyright vests in a third party, permission for reproduction must be obtained from this copyright holder.ICH H ARMONISED G UIDELINEB IOPHARMACEUTICSC LASSIFICATION S YSTEM-BASEDB IOWAIVERSM9ICH Consensus GuidelineT ABLE OF C ONTENTS1. Introduction (1)1.1.Background and Objective (1)1.2 Scope (1)2. Biopharmaceutics classification of the drug substance (2)2.1. Solubility (2)2.2. Permeability (3)3. Support of the eligibility of a drug product for a BCS-based biowaiver (4)3.1. Excipients (4)3.2. In vitro dissolution (6)4. Documentation (8)5. Glossary (9)INTRODUCTION11.1.Background and Objective2Two drug products containing the same active substance are considered bioequivalent if their 3bioavailabilities (rate and extent of drug absorption) after administration in the same molar 4dose lie within acceptable predefined limits. These limits are set to ensure comparable in vivo 5performance, i.e., similarity in terms of safety and efficacy. In in vivo bioequivalence studies, 6the pivotal pharmacokinetic parameters AUC (the area under the concentration time curve), 7and C max(the maximum concentration), are generally used to assess the rate and extent of 8drug absorption.9The BCS (Biopharmaceutics Classification System)-based biowaiver approach is intended to 10reduce the need for in vivo bioequivalence studies i.e., it can provide a surrogate for in vivo 11bioequivalence. In vivo bioequivalence studies may be exempted if an assumption of 12equivalence in in vivo performance can be justified by satisfactory in vitro data. The BCS is a 13scientific approach based on the aqueous solubility and intestinal permeability characteristics 14of the drug substance. The BCS categorizes drug substances into one of four BCS classes as 15follows:16Class I: high solubility, high permeability17Class II: low solubility, high permeability18Class III: high solubility, low permeability19Class IV: low solubility, low permeability20This guidance will provide recommendations to support the biopharmaceutics classification of 21drug substances and the BCS-based biowaiver of bioequivalence studies for drug products.221.2 Scope23BCS-based biowaivers may be used to demonstrate bioequivalence for example between 24products used in early clinical development through commercialization, for line extensions of 25the same pharmaceutical form of innovator products, in applications for generic drug products, 26and post-approval changes that would otherwise require in vivo bioequivalence evaluation, in 27accordance with regional regulations.28The BCS-based biowaiver is only applicable to immediate release, solid orally administered 29dosage forms or suspensions designed to deliver drug to the systemic circulation. Drug 30products having a narrow therapeutic index are excluded from consideration for a BCS-based 31biowaiver in this guidance. Fixed-dose combination (FDC) products are eligible for a 32BCS-based biowaiver when all drug substances contained in the combination drug product 33meet the criteria as defined in sections 2 and 3 of this guidance.34352.BIOPHARMACEUTICS CLASSIFICATION OF THE DRUG SUBSTANCE36BCS-based biowaivers are applicable to drug products where the drug substance exhibits high 37solubility and, either high permeability (BCS Class I) or low permeability (BCS Class III).3839A biowaiver is only applicable when the drug substance(s) in test and reference products are40identical. For example, a biowaiver is not applicable when the drug substance in the test 41product is a different salt, ester, isomer, or mixture of isomers from that in the reference 42product. Pro-drugs may be considered for a BCS-based biowaiver when absorbed as the 43pro-drug.44452.1.Solubility46A drug substance is classified as highly soluble if the highest single therapeutic dose is47completely soluble in 250 ml or less of aqueous media over the pH range of 1.2 – 6.8 at 37 ± 481°C. In cases where the highest single therapeutic dose does not meet this criterion but the 49highest strength of the reference product is soluble under the aforementioned conditions, 50additional data should be submitted to justify the BCS-based biowaiver approach.5152The applicant is expected to establish experimentally the equilibrium saturated solubility of 53the drug substance over the pH range of 1.2 – 6.8 at 37 ± 1ºC using a shake-flask technique or 54an alternative method, if justified. At least three buffers within this range, including buffers at 55pH 1.2, 4.5 and 6.8, should be evaluated. In addition, solubility at the pKa of the drug 56substance should be evaluated if it is within the specified pH range. The pH for each test 57solution should be measured after the addition of the drug substance and at the end of the 58equilibrium solubility study to ensure the solubility measurement is conducted under the 59specified pH. The pH should be adjusted if necessary. The lowest measured solubility over the 60pH range of 1.2 – 6.8 will be used to classify the drug substance.6162A minimum of three replicate determinations at each solubility condition/pH is necessary to63demonstrate solubility using a validated stability-indicating method, with appropriate 64compendial references for the media employed.6566In addition, adequate stability of the drug substance in the solubility media should be 67demonstrated. In cases where the drug substance is not stable with >10% degradation over 68the extent of the solubility assessment, solubility cannot be adequately determined and thus 69the drug substance cannot be classified. In this case a BCS-based biowaiver cannot be applied.70In addition to experimental data, literature data may be provided to substantiate and support 71solubility determinations, keeping in mind that peer reviewed articles may not contain the 72necessary details of the testing to make a judgement regarding the quality of the studies.73742.2.Permeability75The assessment of permeability should preferentially be based on the extent of absorption 76derived from human pharmacokinetic studies, e.g., absolute bioavailability or mass balance.7778High permeability can be concluded when the absolute bioavailability is ≥85%. High 79permeability can also be concluded if ≥ 85% of the administered dose is recovered in urine as 80unchanged (parent drug), or as the sum of parent drug, Phase 1 oxidative and Phase 2 81conjugative metabolites. Regarding metabolites in feces only oxidative and conjugative 82metabolites can be considered. Metabolites produced through reduction or hydrolysis should 83not be included, unless it can be demonstrated that they are not produced by microbial action 84within the gastrointestinal tract. Unchanged drug in feces cannot be counted toward the extent 85of absorption, unless appropriate data supports that the amount of parent drug in feces to be 86accounted for absorbed drug material is from biliary excretion, intestinal secretion or 87originates from an unstable metabolite, e.g., glucuronide, sulphate, N-oxide that has been 88converted back to the parent by the action of microbial organisms.8990Human in vivo data derived from published literature (for example, product knowledge and 91previously published bioavailability studies) may be acceptable, keeping in mind that peer 92reviewed articles may not contain the necessary details of the testing to make a judgement 93regarding the quality of the results.9495Permeability can be also assessed by validated and standardized in vitro methods using 96Caco-2 cells(see Annex I). The results from Caco-2 permeability assays should be discussed 97in the context of available data on human pharmacokinetics. In vitro cell permeability assays 98(Caco-2) used in support of high permeability should be appropriately validated and 99standardized as outlined in Annex 1. If high permeability is inferred by means of an in vitro 100cell system, permeability independent of active transport should be proven as outlined in 101Annex I, “Assay Considerations”.102103If high permeability is not demonstrated, the drug substance is considered to have low 104permeability (e.g. BCS class III).105106Instability in the Gastrointestinal Tract107If mass balance studies or in vitro Caco-2 studies are used to demonstrate high permeability, 108additional data to document the drug’s stability in the gastrointestinal tract should be provided, 109unless ≥ 85% of the dose is recovered as unchanged drug in urine. Stability in the 110gastrointestinal tract may be documented using compendial and simulated gastric and 111intestinal fluids or, with suitable justification, other relevant methods. Drug solutions should 112be incubated at 37ºC for a period that is representative of the in vivo contact of the drug 113substance with these fluids, i.e., one hour in gastric fluid and three hours in intestinal fluid. 114Drug concentrations should then be determined using a validated stability indicating assay 115method. Significant degradation (>10 percent) of a drug in this study could suggest potential 116instability.1171183.SUPPORT OF THE ELIGIBILITY OF A DRUG PRODUCT FOR A BCS-BASED 119BIOWAIVER120A drug product is eligible for a BCS-based biowaiver provided that the drug substance(s) 121satisfy the criteria regarding solubility and permeability (BCS Class I and III), the drug 122product is an immediate-release oral dosage form with systemic action, and the drug product 123is a dosage form that is pharmaceutically equivalent to the reference product. In cases where 124the highest single therapeutic dose does not meet the high solubility criterion but the highest 125strength of the reference product is soluble under the required conditions, BCS-based 126biowaivers can be supported based on additional data. An example of such additional data is 127demonstration of dose proportional pharmacokinetics (i.e. AUC and C max) over a dose range 128that includes the highest therapeutic dose.129130Drug products with buccal or sublingual absorption are not eligible for a BCS-based 131biowaiver application. As such, an orodispersible product is eligible for a biowaiver 132application only if there is no buccal or sublingual absorption and the product is labelled to be 133taken with water only.134135In order for a drug product to qualify for a BCS-based biowaiver, criteria with respect to the 136composition (excipients) and in vitro dissolution performance of the drug product should be 137satisfied. The drug product acceptance criteria are described in sections 3.1 and 3.2 below.1381393.1.Excipients140Excipient differences between the proposed test and the reference products should be assessed 141for their potential to affect in vivo absorption. This should include consideration of the drug 142substance properties as well as excipient effects. To be eligible for a BCS-based biowaiver, 143the applicant should justify why the proposed excipient differences will not affect the 144absorption profile of the drug substance under consideration, i.e., rate and extent of absorption, 145using a mechanistic and risk-based approach. The decision tree for performing such an 146assessment is outlined in Figures 1 and 2 in Annex II.147The possible effects of excipients on aspects of in vivo absorption such as solubility, 149gastrointestinal motility, transit time and intestinal permeability including transporter 150mechanisms, should be considered. Excipients that may affect absorption include 151sugar-alcohols, e.g., mannitol, sorbitol, and surfactants, e.g., sodium lauryl sulfate. The risk 152that a given excipient will affect the absorption of a drug substance should be assessed 153mechanistically by considering154•the amount of excipient used,155•the mechanism by which the excipient may affect absorption,156•absorption properties (rate, extent and mechanism of absorption) of the drug 157substance.158159The amount of excipients that may affect absorption in the test and reference formulations 160should be addressed during product development, such that excipient changes are kept to a 161minimum. Small amounts included in the tablet coating or levels below documented 162thresholds of effect for the specific drug substance are of less concern.163164By definition, BCS Class I drugs are highly absorbed, and have neither solubility nor 165permeability limited absorption. Therefore they generally represent a low risk group of 166compounds in terms of the potential for excipients to affect absorption, compared to other 167BCS classes. Consideration of excipient effects for BCS ClassI drug products should focus on 168potential changes in the rate or extent of absorption. For example, if it is known that the drug 169has high permeability due to active uptake, excipients that can inhibit uptake transporters are 170likely to be of concern. For BCS Class I drugs that exhibit slow absorption, the potential fora 171given excipient to increase absorption rate should also be considered.172173For BCS Class I drugs, qualitative and quantitative differences in excipients are permitted, 174except for excipients that may affect absorption, which should be qualitatively the same and 175quantitatively similar, i.e., within ± 10.0% of the amount of excipient in the reference product. 176177BCS Class III drug substances are considered to be more susceptible to the effects of 178excipients. These drugs are poorly permeable and may have site-specific absorption, so there 179are a greater number of mechanisms through which excipients can affect their absorption than 180for BCS Class I drugs. For BCS Class III drugs, all of the excipients should be qualitatively 181the same and quantitatively similar (except for film coating or capsule shell excipients). This 182is defined in Table 1. Examples of acceptable differences in excipients are shown in Annex II. 183184Table 1:Allowable differences in excipients for drug products containing BCS Class III 186drugs.187Excipient class Percent of the amount ofexcipient in the referencePercent difference relative tocore weight (w/w)Excipients which mayaffect absorption:± 10.0%All excipients:Filler ± 10.0%DisintegrantStarch ± 6.0%Other ± 2.0% Binder ± 1.0%LubricantCa or Mg stearate ± 0.5%Other ± 2.0% GlidantTalc ± 2.0%Other ± 0.2%Total % change permitted: 10.0% Note: Core does not include tablet film coat or capsule shell188189For FDC formulations containing only BCS Class I drugs, criteria regarding excipients should 190follow that for a BCS Class I drug. For FDC formulations containing only BCS Class III 191drugs, or BCS Class I and BCS Class III drugs, criteria regarding excipients should follow 192that for a BCS Class III drug. This is applicable to FDCs which are pharmaceutically 193equivalent.1941953.2.In vitro Dissolution196When applying the BCS based biowaiver approach, comparative in vitro dissolution tests 197should be conducted using one batch representative of the proposed commercial 198manufacturing process for the test product relative to one batch of the reference product. The 199test product should originate from a batch of at least 1/10 of production scale or 100,000 units, 200whichever is greater, unless otherwise justified. During a (clinical) development phase, 201smaller batch sizes may be acceptable, if justified. The comparative in vitro dissolution 202experiments should use compendial apparatuses and validated analytical methods.203204The following conditions should be employed in the comparative dissolution studies to 205characterize the dissolution profile of the product:206•Apparatus: paddle or basket207•V olume of dissolution medium: 900 ml or less (it is recommended to use the volume 208selected for the QC test)209•Temperature of the dissolution medium: 37 ± 1°C210•Agitation: paddle apparatus - 50 rpm211basket apparatus - 100 rpm212•At least 12 units of reference and test product should be used for each dissolution 213profile determination.214•Three buffers: pH 1.2, pH 4.5, and pH 6.8. Pharmacopoeial buffers should be 215employed. Additional investigation may be required at the pH of minimum solubility 216(if different from the buffers above). Purified water may be used as an additional 217dissolution medium in some regions.218•Organic solvents are not acceptable and no surfactants should be added.219•Samples should be filtered during collection220•For gelatin capsules or tablets with gelatin coatings where cross-linking has been 221demonstrated, the use of enzymes may be acceptable, if appropriately justified.222223When high variability or coning is observed in the paddle apparatus at 50 rpm, the use of the 224basket apparatus at 100 rpm is recommended. Additionally, use of sinkers in the paddle 225apparatus to overcome issues such as coning may be considered with justification.226227To qualify for a BCS-based biowaiver for BCS Class I drug substances both the test product 228and reference product should display either very rapid (≥85 for the mean percent dissolved in 229≤15 minutes) or rapid (≥85 for the mean percent dissolved in ≤30 minutes) and similar in vitro 230dissolution characteristics under all of the defined conditions. In cases where one product has 231rapid dissolution and the other has very rapid dissolution, statistical similarity of the profiles 232should be demonstrated as below.233234For the comparison of dissolution profiles, where applicable, the similarity factor f2 should be 235estimated by using the following formula:236237f2 = 50 • log {[1 + (1/n)Σt=1n (R t - T t)2]-0.5 • 100}238239In this equation f2 is the similarity factor, n is the number of time points, R(t) is the mean 240percent reference drug dissolved at time t after initiation of the study; T(t) is the mean percent 241test drug dissolved at time t after initiation of the study.242243The evaluation of the similarity factor is based on the following conditions:244• A minimum of three time points (zero excluded)245• The time points should be the same for the two products246• Mean of twelve individual values for every time point for each product.247• Not more than one mean value of ≥85% dissolved for any of the products.248• To allow the use of mean data, the coefficient of variation should not be more than 24920% at early time-points (up to 10 minutes), and should not be more than 10% at 250other time points.251252Two dissolution profiles are considered similar when the f2 value is ≥50. When both test and 253reference products demonstrate that ≥85% of the label amount of the drug is dissolved in 15 254minutes, comparison with an f2 test is unnecessary and the dissolution profiles are considered 255similar. In case the coefficient of variation is too high, f2 calculation is considered not 256accurate and reliable and a conclusion on similarity in dissolution cannot be made.257258To qualify for a BCS-based biowaiver for BCS Class III drug substances both the test product 259and reference product should display very rapid (≥85 for the mean percent dissolved in ≤15 260minutes) in vitro dissolution characteristics under the defined conditions.261262For FDC formulations, dissolution profiles should meet the criteria for all drug substances in 263the FDC to be considered. For FDC formulations containing only BCS I drugs, criteria 264regarding dissolution should follow that for a BCS Class I drug. For FDC formulations 265containing only BCS Class III drugs, criteria regarding dissolution should follow that for a 266BCS Class III drug. For FDCs containing both BCS Class I and BCS Class III drugs the 267dissolution criteria for the applicable BCS class for each component should be applied.268269For products with more than one strength the BCS approach should be applied for each 270strength, i.e., it is expected that test and reference product dissolution profiles are compared at 271each strength.2722734.DOCUMENTATION274The applicant should provide complete information on the critical quality attributes of the test 275drug substance and drug product and as much information as possible for the reference 276product, including, but not limited to: polymorphic form and enantiomeric purity; and any 277information on bioavailability or bioequivalence problems with the drug substance or drug 278product, including literature surveys and applicant derived studies. All study protocols 279including standards, quality assurance and testing methods should be appropriately detailed 280and validated according to current regulatory guidance’s and policies.281The reporting format should include tabular and graphical presentations showing individual 282and mean results and summary statistics. The tabular presentation should include standard 283deviation and coefficient of variation.284The report should include all excipients, their qualitative and, if possible, quantitative 285differences between the test and reference products.286A full description of the analytical methods employed, including validation, e.g. method 287linearity, accuracy and precision, should be provided. A detailed description of all test 288methods andmedia, including test and reference batch information [unit dose (milligram 289and %), batch number, manufacturing date and batch size where known, expiry date, and any 290comments] should also be provided. The dissolution report should include a thorough 291description of experimental settings and analytical methods, including information on the 292dissolution conditions such as apparatus, de-aeration, filtration during sampling, volume, etc. 293In addition, complete information with full description of the methods applied should be 294provided for the Caco-2 cell permeability assay method, if applicable (see Annex I).2952965.GLOSSARY297AUC: Area under the concentration versus time curve298BCS: Biopharmaceutics Classification System299C max: Maximum concentration300FDC: Fixed-dose combination301Pharmaceutically equivalent: Medicinal products containing the same amount of the same 302active substance(s) in the same dosage forms.303pKa: Acid dissociation constant at logarithmic scale304rpm: rotation per minute305306ANNEX I: Caco-2 CELL PERMEABILITY ASSAY METHOD CONSIDERATIONS 307Permeability assays employing cultured Caco-2 epithelial cell monolayers derived from a 308human colon adenocarcinoma cell line are widely used to estimate intestinal drug absorption 309in humans. Caco-2 cells undergo spontaneous morphological and biochemical enterocytic 310differentiation, and express cell polarity with an apical brush border, tight intercellular 311junctions, and several active transporters as in the small intestine. Due to a potential for low 312or absent expression of efflux (e.g., P-gp, BCRP, MRP2) and uptake (e.g., PepT1, OATP2B1, 313MCT1) transporters, the use of Caco-2 cell assays in support of high permeability for BCS 314classification is limited to passively transported drugs (for definition see Assay 315Considerations).316317Method validation318The suitability of the Caco-2 cell assays for BCS permeability determination should be 319demonstrated by establishing a rank-order relationship between experimental permeability 320values and the extent of drug absorption in human subjects using zero, low (<50%), moderate 321(50 – 84%), and high (≥85%) permeability model drugs. A sufficient number of model drugs 322are recommended for the validation to characterize the full permeability range (a minimum 5 323for each permeability category, high, moderate and low is recommended; examples are 324provided in Table 1). Further, a sufficient number (minimum of 3) of cell assay replicates 325should be employed to provide a reliable estimate of drug permeability. The established 326relationship should permit differentiation between low, moderate and high permeability drugs. 327328Caco-2 cell monolayer integrity should be confirmed by comparing transepithelial electrical 329resistance (TEER) measures and/or other suitable indicators, prior to and after an experiment. 330In addition, cell monolayer integrity should be demonstrated by means of compounds with 331proven zero permeability.332333Reporting of the method validation should include a list of the selected model drugs along 334with data on extent of absorption in humans (mean, standard deviation, coefficient of 335variation) used to establish suitability of the method, permeability values for each model drug 336(mean, standard deviation, coefficient of variation), permeability class of each model drug, 337and a plot of the extent of absorption as a function of permeability (mean ± standard deviation 338or 95 percent confidence interval) with identification of the high permeability class boundary 339and selected high permeability internal standard used to classify the test drug substance.340341In addition, a description of the study method, drug concentrations in the donor fluid,342description of the analytical method, equation used to calculate permeability, and where343。

Performance evaluation of new product development from a company perspectiveHelen DrivaCentre for Concurrent Enterprising,School of Mechanical,Materials,Manufacturing &Management,University of Nottingham,Nottingham,UK Kulwant S.PawarCentre for Concurrent Enterprising,School of Mechanical,Materials,Manufacturing &Management,University of Nottingham,Nottingham,UK Unny MenonCal Poly State University,IME Department,San Luis Obispo,California,USAIntroduction Performance measurement is an essential element of effective planning and control.However,the degree of effectiveness of anycontrol strategy will depend on the adequacy of the metrics deployed.Historically,accounting-based measures have been relied on for a wide range of managerial monitoringof organizational performance.However,they are generally less than satisfactory for some organizational activities like new product development (NPD).This paper presents the longitudinal case study results which formed an important part of a larger research project,which examinedperformance measurement for NPD,using a triangulation of survey results from industry and academia,including longitudinalvalidation using in-depth case analysis at UKsites of multi-national firms.The focus of this paper is only on the case studies at tencompanies,which was one key component of the research.Full details of the entire project are available in Driva (1997).The structure of this paper includes an introduction to performance measurement from a NPD perspective,a review of state-of-the-art evident in contemporary literature,and an outline of current practice based on a survey of multinational firms.This isfollowed by a detailed discussion of the findings,with concise insights into ten company-based studies which provide a realistic basis for validation and forming general guidelines on the topic of performance measurement realities.Measuring performancePerformance measurement has been anessential element of management control for many years,but up until recently,the only measures consistently made were forfinancial records.It is generally agreed that financial performance measures are most useful at higher levels of management where they can reflect the success of strategies.According to Johnson (1992),relevance was lost between the 1950s and 1980s whenmanagement used cost accounting to drive marketing strategies and control operations.This view is backed up by Dixon et al .(1990)who consider that ``cost-based measures are inconsistent with the new emphasis on quality,JIT and using manufacturing as a competitive weapon''.Activity based costing (ABC)was initially hailed as the answer to all the problems of accounting systems.It is now widely agreed that ABC should be used as a tool for decision making rather than as a replacement for an existing cost accounting system.Financial measures alone cannot adequately reflect factors such as quality,customer satisfaction and employee motivation.By linking development,operational and financial measures,more meaningful ±and directly useful ±results can be obtained.To date,insufficient attention has been directed linking these measures.Activity in the area of concurrentengineering and performance measurement has increased enormously in the last few years (Driva et al .,1999).Notable work here includes that by Gregory (1993),Crawford (1988),Hronec (1993),Globerson (1985)and Sink and Tuttle (1989).In particular,Globerson compiled a useful ``dos and don'ts''list in the design and development ofanThe current issue and full text archive of this journal is available at /ft[368]Integrated ManufacturingSystems12/5[2001]368±378#MCB University Press [ISSN 0957-6061]KeywordsNew product development,Case studies,Performance measurement,Management controlAbstractThe importance of performancemeasurement is generallyrecognized in the literature and by industry.However,the adequacyof metrics applicable to differentaspects of the organization doesnot appear to have been addressed.Provides fresh insight to fill some of the knowledge gapsin this area with particular focuson evaluating productdevelopment performance from a company perspective.Alsopresents insights gained from tencompany-based longitudinal casestudies,which formed one essential part of a much largerresearch project with details ofthe other aspects of the project in Driva.Received:April 1999Revised:January 2000Accepted:July 2000effective performance measurement system. He recommends that for measures to be successful they must be derived from strategy and relate to specific and realistic goals.One of the most comprehensive global investigations of product development and management practices has been in the automobile industry.The conclusions recorded by Clark and Fujimoto(1991)and by Womack et al.(1990)stated that the auto industry example has far-reaching implications that will touch all R&D manufacturing organisations.However,they stop short of proposing a system of performance measures.One of the first studies to focus specifically on NPD was carried out in Canada by Richardson and Gordon(1980).They surveyed15 manufacturing firms,following up with interviews and a study of case literature in manufacturing policy.From this they reported that the traditional performance measures used by these firms inhibit innovation,with the measures focusing on the plant as a whole rather than individual products.An examination of the strength of relationship between innovation and continued market prosperity was one of several projects on success in NPD and innovation that have been carried out by Professor Hart(1996)at Stirling University (Johne and Snelson,1990).She reported that NPD success is often derived from overall company performance,which can be misleading.Mahajan and Wind(1992)carried out one of the few surveys of tools,methods and``models''used for measuring NPD.The main aim of this research was to determine the role of new product``models''in supporting and improving the NPD process. Marketing activities before and after product development(i.e.detailed market study for market identification,positioning and strategy,pre-market volume forecast,market launch planning,etc.)were the main focus of that research.However,the study revealed that there was a low usage of``models''and methods(including focus groups,conjoint analysis,Delphi,QFD and product life cycle models)among the respondents.Our literature review indicates that performance measurement research to date has been confined primarily to financial metrics,with some recent developments for manufacturing metrics by Maskell(1991), some organizational(Neeley et al.,1995)and business measurement systems(Neeley,1998; Black et al.,1998).Some research has been carried out in product development but this has focused on complexity,success and failure aspects(Griffin and Page,1996)and on strategy aspects(Barczack,1995).Currently, more and more attention is paid to assessing the nature of the relationship between business performance,organizational intellectual capital and knowledge management(Hansen et al.,1999;Klein,1998; Svelby,1997).In summary,the literature review revealed that:.There appears to be a lack of cohesive methodology presently available forassessing performance during productdevelopment using concurrentengineering principles(applied on aconsistent rather than on an ad hoc basis). .Use of currently available tools and techniques to assist in controlling product development activities(such as QFD,balanced scorecard(Kaplan and Norton, 1992)and diagnostic tool(Dixon et al.,1990))is fragmented and only used in some limited parts of the product development process(their limited use was laterconfirmed in our company questionnaire results)..There has been an unclear distinction between``hard''and``soft''measures ofperformance or the implications of using them..Measures of performance in product design and development are primarilyinternal measures that focus oncomparing activities and processes toprevious operations and targets.Owing to the diverse nature of products,processes and customers,external benchmarking in this area is often inappropriate(benchmarking across companies in agroup may be an exception)..Some surveys were not backed up by case studies(e.g.Gupta and Wilemon,1996;Nichols et al.,1994)which preventedfollow through of the findings intopractical situations..There is no one set of measures that will remain definitive over time.Performance measures,as with the organization itself, should be flexible to change.Research methodologyA combination of qualitative and quantitative methods was required to allow for large scale and in-depth information to be collected.The data collection phase used a combination of historical information(a literature review,document analysis and meetings with industry and academics in this area),structured questioning(through postal questionnaires and interviews with academics and companies)and in-depth case[369]and Unny Menon Performance evaluation of new product development from a company perspectiveSystems12/5[2001]368±378studies (including observation,sitting in on meetings and content analysis of documents at company sites).Secondly,ten follow-up cases and an in-depth longitudinal case were carried out to clarify specific needs andproblems in performance measurement.The research process concluded with a synthesis to formulate a framework and a performance measurement tool to aid product design and development.A framework was developed (see Figure 1for a high level conceptual view)to assist firms in implementing performance measures for design and development in a manufacturing environment (Driva et al .,1999).This framework encapsulated the themes brought out by the data analysis.Industrial consultation on the applicability of the proposed framework was a central part ofthe process.Two in-depth industrial studies were carried out to test out the viability of the framework by running it through activities on a real product developmentproject.Actual project scenarios were used to test out the benefits and identify any possible drawbacks.This paper will focus only on the results of the follow-up longitudinal cases,comprising ten companies,in our research.These cases have provided invaluable supporting data to validate our overall research study in an empirical manner as well as providingspecific examples and issues which managers face when designing,developing andimplementing performance measures for NPD in manufacturing firms.Furtherinformation on all other findings from the entire research can be found in Driva (1997).Current practice and future plans in performance measurement:case results from industrial applications in UK multinationalsThis section presents the results from follow-up cases with ten respondents of the company questionnaire.Company profilesPostal questionnaires,while being a valuable source of information,can be open toambiguous interpretation.In order to gain a deeper understanding of answers given,a representative sample of the respondents was selected for interview.An important note to add at this stage is that all ten companies are part of multinational corporations.A profile of the interviewed UK multinational companies is shown in Table I.A two to three hour semi-structuredinterview was carried out in each of the ten companies.All interviewees were the same person at the host companies who responded to the questionnaire survey and all were middle to senior-level managers.Interviews were based around questionnaire responses,but also explored the company's experiences with performance measures for product design and development and their plans for the future.Two in-depth cases are included in this paper,with the remaining eight cases available in Driva (1997).All cases followed the same format;background and overview,with the measures currently used and those for future improvements.The data werecollected on the understanding that they are confidential and would be used only for research purposes.Therefore,company names have been disguised.Figure 1The overall framework for new productdevelopment[370]and Unny MenonPerformance evaluation of new product development from a company perspective Systems12/5[2001]368±378Overview of resultsTables II-IV provide summaries of the results of our study.Table II highlights the popularity of brainstorming,CAD andprocess mapping.An interesting finding was that despite academics'general enthusiasm for QFD as observed during ourquestionnaire survey (Driva,1997),it is not widely used by the companies.Within the case study companies,only three had used it ``to some extent''.This was backed up in the wider questionnaire,with only 25per cent of respondents having used it.Another surprise was the lack of use of internal surveys to gauge staff opinion.This is a useful and relatively easy way to investigate a whole range of issues (including current policy and practices,change management,ideas for improvement,etc.).With the increasedemergence of electronic intranets,this task has been made even simpler.Internalfeedback currently seems to be collected on an ad hoc and/or informal basis,regardless of the size of the companies.Increasingly,firms are using process mapping and/orflowcharting to depict visibly how theyoperate.In terms of the product development process,process mapping is especially useful to identify where bottlenecks occur and hence where performance measures can help.In Figure 2we portray the modes of communication for some types ofperformance measures at our ten companies.Management of the measuresThe way in which the measures are managed,including who brought in performance measures,who reports and who deals with them is summarized in Table III.Allrespondents used cross-functional teams to varying extents and eight were ISO 9000accredited.Senior management accounted for nearly all introductions of performance measurement (90per cent).This was greater than for the questionnaire results (75per cent).With the exception of two firms (out of ten),measures were collected through a combination of automatically generated information (e.g.as part of the accounting system,ISO 9000procedures,etc.)and specially generated for design anddevelopment.This was also higher than the questionnaire average (66per cent).A variety of people were responsible for reporting the measures,ranging fromfinance,IT/MIS and individual departments but with project teams taking responsibility in the majority of cases (60per cent).Again,this was higher than the questionnaires (41per cent).Where they did differ from general opinion was in the introduction of more performance measures.Virtually all stages were mentioned by follow-up caserespondents,but their most popular answer was to introduce additional measures at the feasibility stage (40per cent).This contrasts with the questionnaire respondents who considered that the specification stage was where they were most needed.Table IProfiles of follow-up case companies Ref.No.of employees No.of NPD aNature of No.Sector Site wide D&D projects Interviewee position production 1Chemicals 20010070R&D manager Mass2Engineering 48,0002,500500Project manager Project/batch 3Food 300308Technical director Mass 4Clothing 240740-50Technical director Batch 5Ventilation 3001210-20Technical director Mass 6Automotive 185145255Program manager Mass 7Adhesives 901210Technical manager Batch 8Brewing>3008030+Technical manager Batch9Instrumentation 200204Industrial engineer Batch/mass 10Sports equipment40012100sProject managerBatch/massNote:a Number of new product development projects run at one time Use of tools and techniques Reference No.Tools/techniques 12345678910Total Brainstorming 10CAD,CAM,CAE8Concept testing with customers6Design for X6Fishbone analysis4FMEA3Internal surveys 3QFD3Process mapping/flowcharting7Value analysis6[371]and Unny MenonPerformance evaluation of new product development from a company perspective Systems12/5[2001]368±378Types of performance measures usedThe questionnaire responses revealed that the most widespread measures among the ten companies were the monitoring of thenumber of projects completed per annum (80per cent),the number of field trials prior to production (80per cent),the actual versus target time for project completion (70per cent)and the number of new products released per annum (70per cent).Thepreferred frequency of reporting was almost evenly split between monthly and perproject.Scores of those measures used now are plotted along with those that will be used in future in Figures 3-5.They have been grouped into four categories;cost based (Figure 3),time based (Figure 4),quality/reliability based (Figure 5)and general measures (Figure 6)to aid presentation.The follow-up cases allowed theresearchers to determine the three mostimportant measures that are currently beingused in companies (Table IV)and those they would most like to introduce in the future.As these data are of a very qualitative nature,it was decided to present them as they were described,rather than forcing them into categories.This list clearly shows that time and cost are the most important measures ±as would be expected.What is surprising is the lack of quality measures in the top three.Is this because quality-related issues are toodifficult to measure or do the companies in this survey leave quality measures to the quality department?Perhaps there may be some other reason?This could provide an interesting starting point for further research.Performance measures:some notable opinions from the ten firmsAs with current usage of performance measures,differences existed in what wasManagement of the measurespany name (disguised)Who brought in performance measures?How are measures collected?a Who isresponsible for reporting measures?Who measures are visible to (i.e.who sees them)NPD stage where more measures would be most useful Have ISO 9000?Use of cross-functional teams?1Plastico Division IT managerSpecially formulatedCentrallymanaged by IT All senior and project managers Feasibility No Some of the time 2Global pany-wide task forceMixture Project/team based CEO,team,seniormanagement All stages Yes Some of the time 3Petproducts LtdCorporate-led directive as part of ISO 9000MixtureDepartment/finance based CEO,finance,seniormanagement SpecificationYesAll of the time4Seasonswear Plc Technicaldirector Mixture Project/team based Team,senior management,finance Prototyping and tooling Yes Some of the time 5Airvent LtdMDMixture Project/team basedAll;``anyone who asks''Specification Yes Some of the time6Autosystems Inc.MD Specially formulated Project/team basedAll Detailed design Yes All of the time 7GluecoMDMixture Department basedProject team and project managers FeasibilityYes Some of the time 8Brewmasters UK MDMixtureProject/teamand department based(depending on project)AllConcept design 9002All of the time9Weighdex MD Mixture Department based CEO and senior management Feasibility Yes Some of the time10SportscoProject managerMixtureProject/team basedAll managers Feasibility NoSome of the timeNote:a Some measures were automatically generated from existing reporting information and some were specially formulated,with time spent collecting them [372]and Unny MenonPerformance evaluation of new product development from a company perspective Systems12/5[2001]368±378required for future measures across the ten companies.At Plastico,where they have only recently introduced formal performancemeasurement,the technical manager stated:We currently have an ad hoc system,where people monitor their own project time but realistically the results are questionable.Basically,we would like to be able to manage this area more effectively.At Global Engineering Co.things are more advanced,with performance measures beingintegrated into the new product introduction process.The project manager states:We are not satisfied with the number of measures currently used,we need more measures of performance to addressefficiency of the process and ones to giveearly warning of potential problems,etc.The major barrier to this is the lack of systems in place to support more measurement.The company is increasingly aiming to automate data collection because,as the number of projects increases,the cost of data collection becomes more significant.At Petproducts Ltd,the technical director sees performance measures continuing to play an important role:Our main measure has been and always will be (for the foreseeable future)growth.The key for us over the last five years has been to define additional critical measurements and find ways of assessing this performance in a pragmatic manner.I believe we have achieved this.At Seasonswear Plc,the technical director explained that:There are currently no strategic levelmeasures to compare the company divisions globally but I feel it is only a matter of time before this happens.We may eventually write a bespoke package in-house but this could take some time.We would especially like a ``what-if''scenario to help us schedule activities to avoid bottlenecks around the constrained activities.At Airvent Ltd there are severalimprovements that the technical director wants to make to the measurement system in the future:We are a very engineering-led company.While we want to retain this focus,we need to increase our consideration of the marketing aspects.This will be built in to the ``contract [product specification document].At Glueco,the technical manager wanted to focus on seemingly basic goals:The costing of projects is extremely difficult (especially for projects of indeterminate duration)but we really need to get a better approximation ±its currently very much based on gut feeling.However,we areencountering the usual problems of people feeling like they are being tested and tracked and others complaining that it's a waste of time or simply forgetting to fill out the sheets.Another performance measure that we would like to introduce in future is thenumber of new products released per annum against the increased sales generated.At Brewmasters,the engineering project manager had many ideas for future improvements.He stated:We need to find a way of using our resources more effectively.I would like to formalizeTable IVThree most important performance measures usedNo.of companiesTimeAverage time to market 2On-time delivery of PDP 3Schedule adherence 3CostTotal project cost against budget4Profitability analysis ±performance against objectives 2Product cost1Actual to predicted profit on products1Product development cost as percentage of turnover 1Margin analysis 1Quality and customerNo.and nature of engineering change requests (ECRs)per project1Adherence to original product specification 1Field trials 1GeneralPercentage sales from new products vs total sales 1No.of (new)products released p.a.3No.of successful development projects vs total no.of projects 2Money generated by new products over first two years vs total sales value1No.of products taken up (from project portfolio)vs total no.available1Figure 2Communicating performancemeasures[373]and Unny MenonPerformance evaluation of new product development from a company perspective Systems12/5[2001]368±378suggestions for future improvements (that could be fed back into the procedures).At Sportsco,the NPD manager had this to say about future improvements:I would like to see more performancemeasures at the feasibility stage of product development.Better market information would be the biggest improvement to input into the product specification.Of course this is very difficult to achieve.Auto Systems Inc.and Weighdex are the subject of a more comprehensive discussion which is presented in the following section.In general,the follow-up case companies were more advanced in their awareness ofand use of performance measures for design and development than the companies covered via questionnaire research.This is perhaps to be expected,because those who agree to deeply intrusive studies of this nature may have already taken the first steps towards substantial re-engineering of their development processes targeting for substantial improvements.Case study 1±Auto Systems Inc.Auto Systems Inc.(AS)designs and manufactures the full range of brakingsystems for many of the world's automobile manufacturers.It is part of a globalengineering group,with manufacturing sites across the world.The company operates under a matrix structure,with ``heavy-weight''cross-functional teams assigned to work on projects for different customers.The program manager at AS's UK design center explained how projects are organized:We have two types of teams,those working on a particular product type (e.g.brake discs)and those working with one customer.The performance measurement system was designed and implemented by the program manager.He firmly believes that ``measures of performance are a blunt tool''and that essential measurements are applied only to the areas of performance they are likely to improve.``Basically,they need to be valid to your business,otherwise it is likely that improvements will be made against areas that are not core to the problem and which may in fact cause deterioration in other areas of operation''.It was decided that there were three main criteria.First,there needed to be asignificant amount of resource utilized.Second,there are significant bottlenecks in time.Third,the equipment overhead rate is expensive.An additional consideration was that in order to be measured,activities require having a certain amount ofrepetitiveness,where the order of magnitude of the tasks and their complexity is largely the same.Initially four metrics were selected but,after short-term trials,one of them ±concerned with measuring the number of change notes over a period ±was rejected as being too prone to interpretation.The remaining three are listed below.The three most important performance measures they use are:1Actual vs target time for projectcompletion,i.e.schedule adherence where progress is monitored monthly on all projects.CostmeasuresTimemeasures[374]and Unny MenonPerformance evaluation of new product development from a company perspective Systems12/5[2001]368±3782Product cost,monitored monthly during design and development.This includes shop-floor labour costs and material costs.Variance directly affects profit margin,as once the contract has been tendered,that price has to be maintained.There are two ways of costing time;use the functional budget for engineering (current practice)or on a project basis.The company wants to move towards the project basis as it is a more accurate reflection of its activities.3Total cost of project ±monitored monthly.This includes engineers'hours,any purchases and sub-contractors'hours.Without monitoring,project costs may spiral out of control and affect the potential profitability of the project.Projects are measured by the overallperformance of the project team and not by the performance of an individual or function:``There is no point using measures againstpeople.On the individual level,measures need to be made non-threatening by encouraging investigation of the teammember's role to search for improvements''.Performance was monitored by the project manager and communicated.On the subject of softer measures such as communication,the project manager had this to say:Measures of performance must be something you can physically get in your hand.``Communication''is not solid enough ±even if you have a feeling about what is happening,it's hard to prove.For example,how do you assess the cost of failure if it is attributed to communication?More importantly,communication is the cause rather than the effect,so if anything it should feed into other measures.Case study 2±WeighdexWeighdex is a well-established,small to medium sized company that designs and manufactures a range of mechanical and electronic weighing equipment.Products include bench scales,crane-weighers,counting scales and electronic weighingplatforms,manufactured on a make-to-order basis.They are part of a larger group based in the South of England,with another sister company in USA.The company has grown rapidly over the last ten years and isplanning to double its size again over the next three years.As part of this expansion,world exports,which currently represent approximately 15per cent of business,will be targeted as a major growth area.Additionally,a large part of the business comes from the company's reputation for after-sales service.Weighing is very much a trade-led business.Conforming to safety standards and weighing and measuring legislation is a vital part of the productdevelopment process.The company ISO 9001certified and has a comprehensivecontinuous process improvement program.Most bottlenecks that occur during product development tend to revolve around early errors.The industrial engineer stated:Basically (wrong)decisions or mistakes made at the feasibility and concept design stages manifest themselves in later stages,especially during tooling and pre-production.Of course,problems that are not spotted at the start of a project cost far more to resolve at the end.I would like to see more research done and measures taken earlier to prevent these problems occurring.The three most important performance measures they use are:1Actual to predicted profits on products.Figure 6GeneralmeasuresFigure 5Qualitymeasures[375]and Unny MenonPerformance evaluation of new product development from a company perspective Systems12/5[2001]368±378。

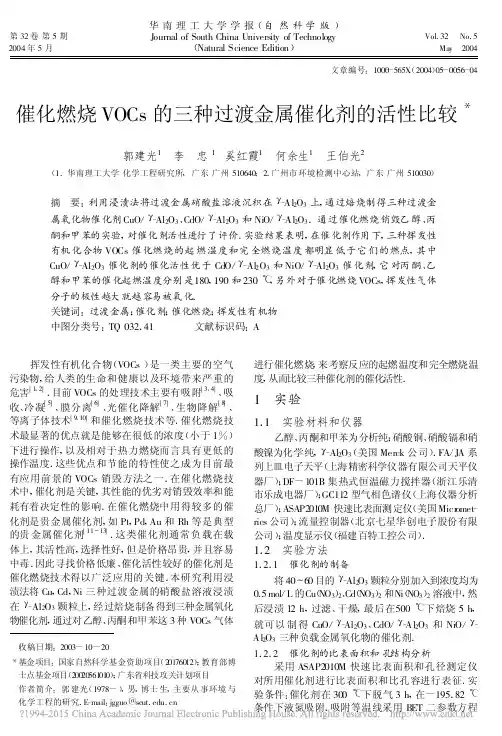

华南理工大学学报(自然科学版)第32卷第5期Journal of South China University of TechnologyVol .32 No .52004年5月(Natural Science Edition )May 2004文章编号:1000-565X (2004)05-0056-04催化燃烧VOCs 的三种过渡金属催化剂的活性比较*郭建光1 李 忠1 奚红霞1 何余生1 王伯光2(1.华南理工大学化学工程研究所,广东广州510640;2.广州市环境检测中心站,广东广州510030)摘 要:利用浸渍法将过渡金属硝酸盐溶液沉积在γ-Al 2O 3上,通过焙烧制得三种过渡金属氧化物催化剂CuO /γ-Al 2O 3、CdO /γ-Al 2O 3和NiO /γ-Al 2O 3.通过催化燃烧销毁乙醇、丙酮和甲苯的实验,对催化剂活性进行了评价.实验结果表明,在催化剂作用下,三种挥发性有机化合物VOCs 催化燃烧的起燃温度和完全燃烧温度都明显低于它们的燃点,其中CuO /γ-Al 2O 3催化剂的催化活性优于CdO /γ-Al 2O 3和NiO /γ-Al 2O 3催化剂,它对丙酮、乙醇和甲苯的催化起燃温度分别是180,190和230℃,另外对于催化燃烧VOCs ,挥发性气体分子的极性越大就越容易被氧化.关键词:过渡金属;催化剂;催化燃烧;挥发性有机物中图分类号:TQ 032.41 文献标识码:A 收稿日期:2003-10-20*基金项目:国家自然科学基金资助项目(20176012);教育部博士点基金项目(20020561010);广东省科技攻关计划项目 作者简介:郭建光(1978-),男,博士生,主要从事环境与化学工程的研究.E -mail :jgguo @scut .edu .cn 挥发性有机化合物(VOCs )是一类主要的空气污染物,给人类的生命和健康以及环境带来严重的危害[1,2].目前VOCs 的处理技术主要有吸附[3,4]、吸收、冷凝[5]、膜分离[6]、光催化降解[7]、生物降解[8]、等离子体技术[9,10]和催化燃烧技术等.催化燃烧技术最显著的优点就是能够在很低的浓度(小于1%)下进行操作,以及相对于热力燃烧而言具有更低的操作温度.这些优点和节能的特性使之成为目前最有应用前景的VOCs 销毁方法之一.在催化燃烧技术中,催化剂是关键,其性能的优劣对销毁效率和能耗有着决定性的影响.在催化燃烧中用得较多的催化剂是贵金属催化剂,如Pt ,Pd ,Au 和Rh 等是典型的贵金属催化剂[11~13].这类催化剂通常负载在载体上,其活性高,选择性好,但是价格昂贵,并且容易中毒.因此寻找价格低廉、催化活性较好的催化剂是催化燃烧技术得以广泛应用的关键.本研究利用浸渍法将Cu ,Cd ,Ni 三种过渡金属的硝酸盐溶液浸渍在γ-Al 2O 3颗粒上,经过焙烧制备得到三种金属氧化物催化剂,通过对乙醇、丙酮和甲苯这3种VOCs 气体进行催化燃烧,来考察反应的起燃温度和完全燃烧温度,从而比较三种催化剂的催化活性.1 实验1.1 实验材料和仪器乙醇、丙酮和甲苯为分析纯;硝酸铜、硝酸镉和硝酸镍为化学纯,γ-Al 2O 3(美国Merck 公司).FA /JA 系列上皿电子天平(上海精密科学仪器有限公司天平仪器厂);DF -101B 集热式恒温磁力搅拌器(浙江乐清市乐成电器厂);GC112型气相色谱仪(上海仪器分析总厂);ASAP2010M 快速比表面测定仪(美国Micr omet -rics 公司);流量控制器(北京七星华创电子股份有限公司);温度显示仪(福建百特工控公司).1.2 实验方法1.2.1 催化剂的制备将40~60目的γ-Al 2O 3颗粒分别加入到浓度均为0.5mol /L 的Cu (NO 3)2、Cd (NO 3)2和Ni (NO 3)2溶液中,然后浸渍12h ,过滤、干燥,最后在500℃下焙烧5h ,就可以制得CuO /γ-Al 2O 3、CdO /γ-Al 2O 3和NiO /γ-Al 2O 3三种负载金属氧化物的催化剂.1.2.2 催化剂的比表面积和孔结构分析采用ASAP2010M 快速比表面积和孔径测定仪对所用催化剂进行比表面积和比孔容进行表征.实验条件:催化剂在300℃下脱气3h ,在-195.82℃条件下液氮吸附.吸附等温线采用B ET 二参数方程处理,计算比表面积及比孔容.1.2.3 催化剂活性评价采用常压固定床催化反应装置,以甲苯、乙醇、丙酮为目标反应物,考察γ-Al 2O 3和制备的三种催化剂的催化燃烧活性.实验流程如图1所示.由空气泵鼓进的空气分成两路,一路空气经过装有有机挥发性化合物液体的鼓泡器后,与另一路空气相混合,然后含有VOCs 的混合气进入固定床催化反应器,在催化床层进行催化燃烧反应.通过控制两路空气流量,可调节进入催化燃烧装置的VOCs 蒸汽浓度,其中反应器的直径为0.9c m ,催化剂装填高度为2cm ,反应气流速为160c m 3/min .通过六通阀取样,将反应后的气体导入到气相色谱仪,用氢火焰检测器(FID )进行定量分析.图1 催化反应实验装置Fig .1 Apparatus for the catal ytic activity tests1—N 2钢瓶;2—空气泵;3—储气瓶;4,5—质量流量控制器;6—气体混和器;7—VOCs 发生器;8—催化燃烧反应器;9—温度显示仪;10—六通阀;11—气相色谱仪;12—色谱工作站;13—尾气2 实验结果与讨论2.1 催化剂比表面积和孔径分析采用ASAP2010M 快速比表面积测定仪,对γ-Al 2O 3和制备的三种催化剂进行比表面及比孔容表征,测定结果如表1所示.从测试结果可以看出,对于同一种载体γ-Al 2O 3负载的三种氧化物催化剂,它们的比表面积和孔径变化不大,这是因为用浸渍方法制备的载体型催化剂,它们的比表面积和孔径基本与载体时相当.所以这三种均以γ-Al 2O 3为载体的催化剂的活性差异主要取决于各个金属氧化物催化剂的活性金属.表1 催化剂的比表面积和孔结构Table 1 Surface areas and pore structure of catalysts催化剂BET 比表面积/(m 2·g -1)比孔容/(cm 3·g -1)CuO /γ-Al 2O 3104.60.2207CdO /γ-Al 2O 3100.80.2280NiO /γ-Al 2O 3103.40.2353γ-Al 2O 3123.80.23702.2 催化剂的活性评价图2反映的是依次用γ-Al 2O 3以及所制备CuO /γ-Al 2O 3,CdO /γ-Al 2O 3,NiO /γ-Al 2O 3三种过渡金属氧化物催化剂对乙醇、丙酮和甲苯三种有机挥发性气体的催化氧化转化率与反应温度的关系.通过对这三种有机挥发性气体催化燃烧时的起燃温度(转化率达到10%)和完全燃烧温度(转化率达到95%)来考察其催化活性.表2列出了γ-Al 2O 3和三种催化剂对三种VOCs 催化氧化的起燃温度和完全燃烧温度.从表2中可以看出,相对于γ-Al 2O 3,三种过渡金属氧化物催化剂对丙酮、乙醇和甲苯催化燃烧的起燃温度和完全燃烧温度均有明显的降低.其中,CuO /γ-Al 2O 3催化剂的活性较高,对丙酮的催化燃烧而言,其活性已达到和超过Luo 等人[11]研制的Mn /Al 2O 3(260℃)和Co /Al 2O 3(280℃).表2 在催化剂作用下三种VOCs 催化燃烧的起燃温度与完全燃烧温度Table 2 Light -off temperature and total conversion temperature ofVOCs under the three prepared catalysts起燃温度/℃完全燃烧温度/℃催化剂 丙酮乙醇甲苯丙酮乙醇甲苯γ-Al 2O 3210240360390400520CuO /γ-Al 2O 3180190230260270350CdO /γ-Al 2O 314018022039038048057 第5期郭建光等:催化燃烧VOCs 的三种过渡金属催化剂的活性比较图2 反应温度与VOCs催化燃烧转化率的关系Fig.2 Relationship between reaction temperatures and conver-sion ratios of VOCs catalytical combustion 通常,丙酮的燃点温度为538℃,乙醇的燃点温度为423℃,甲苯的燃点温度为536℃.本实验中,在过渡金属氧化物催化剂作用下,三种有机挥发性气体的起燃温度明显降低.这是因为根据Mars-Van Krevelen氧化-还原机理[14],即:反应物中的氧并非直接来自气相,而是来自被吸附在金属氧化物催化剂中的氧,气相中的氧只是用来补充反应中在催化剂表面所消耗掉的氧.而这三种过渡金属氧化物CuO,CdO和NiO的金属离子的外层轨道分别为3d10 4s1,4d105s2和3d84s2,具有容易变价的倾向,使其能够在较低的温度下吸附氧,氧化反应的起始温度也较低.从图2中可以看出,对三种VOCs气体的催化燃烧,CuO/γ-Al2O3催化剂的催化活性优于CdO/γ-Al2O3催化剂和NiO/γ-Al2O3催化剂.这是由于CuO 是氧负离子过量型,晶格金属离子是吸附氧的中心,此种类型的金属氧化物能有效地吸附氧这类电子受体[15],所以它对三种VOCs的催化效果较好.另外,由图2还可以看出,三种有机物在同一催化剂上的催化活性差异很大,催化活性基本上是丙酮>乙醇>甲苯,这与三种VOCs分子的结构特点有关,乙醇具有—OH基以及丙酮具有—C O基,分子均呈极性,利用Hyperchem7.0量子化学计算软件进行优化后发现,丙酮、乙醇和甲苯的极性分别为3.011,1.865和0.229,而极性越强越易于被吸附在催化剂活性中心上,使其也更容易被氧化[16].3 结论利用浸渍法制得三种过渡金属氧化物催化剂CuO/γ-Al2O3,CdO/γ-Al2O3和NiO/γ-Al2O3,进行催化燃烧销毁乙醇、丙酮和甲苯,发现这三种VOCs催化燃烧的起燃温度和完全燃烧温度都明显低于它们的燃点温度,其中CuO/γ-Al2O3催化剂的催化活性优于CdO/γ-Al2O3和NiO/γ-Al2O3催化剂,它对丙酮、乙醇和甲苯的催化起燃温度分别是180,190和230℃.另外对于催化燃烧VOCs,挥发性气体分子的极性越大就越容易被氧化.参考文献:[1] Jones A P.Indoor air quality and health[J].At mospheric En-vironment,1999,33(28):4535-4564.[2] 吴永文,李忠,奚红霞,等.VOCs污染控制技术与吸附催化材料[J].离子交换与吸附,2003,19(1):88-95. [3] Pires Jo2o,Carvalho Ana,de Carvalho.Adsorption of volatile58华南理工大学学报(自然科学版)第32卷organic compounds in Y zeolites and pillared clays [J ].Mi -croporous and Mesoporous Materials ,2001,43:277.[4] Isaac Ray .Adsorption with actiued carbon [J ].Chem EngProgress ,1993,89(7):37-41.[5] En gleman ,Victor S .Updates on choices of appropriate tech -nology for control of VOC emissions [J ].Metal fini -shing ,2000,98(6):433-445.[6] John McCliiion .Membrane process capture viryl chloride andother VOC [J ].Chemical Processing ,1994(9):33-36.[7] 王红娟,李忠.半导体多相光催化氧化技术[J ].现代化工,2002,22(2):56-60.[8] Togna A Paul .Biological vapor -phase treatment us ing biliflterand biotricklin g filter peactors :Practical operating regimes [J ].Environ mental Progress ,1994,13(2):94-97.[9] Chang Jen -shih .Recent development of plasma pollution controltechnology :A critical review [J ].Science and Technology of Advanced Materials ,2001(2):571-576.[10] Yan K ,Heesch E J M .Elements of pulsed corona inducednon -thermal plasmas for pollution control and sustainable de -velop ment [J ].Journal of Electrostatics ,2001,51-52:218-224.[11] Luo Meng -fei ,Yuan Xian -xin ,Zheng Xiao -ming .Catalystcharacterization and activity of Ag -Mn ,Ag -Co and Ag -Ce composite oxides for oxidation of volatile organic compounds [J ].Applied Catal ysis A :General ,1998,175:121-129.[12] Gabriele Centi .Supported palladiu m catalysts in environmen -tal catalytic technologies for gaseous emissions [J ].Journal of Molecular Catal y s is A :Chemical ,2001,173:287-312.[13] Minic ò,Simona .In fluence of catalyst pretreatments onvolatile organic compounds oxidation over gold /iron oxide [J ].Applied Catalysis B :Environ mental ,2001,34(4):277-285.[14] 吴越.催化化学[M ].北京:科学出版社,1995.[15] Iamarino M ,Chirone R ,Lisi L .CuO /γ-Al 2O 3catalyst for thecombustion of methane in a fluidized bed reactor [J ].Catal -y s is Today ,2002,75:317-324.[16] Centeno M A .Catalytic combustion of volatile organic com -pounds on Au /CeO 2/Al 2O 3and Au /Al 2O 3catalysts [J ].Ap -plied Catalysis A :General ,2002,234:65-78.Activity Comparison of Three Transition Metal CatalystsUsed in the Catalytic Combustion of VOCsGuo Jian -guang 1 Li Zhong 1 Xi H ong -xia 1 H e Yu -sheng 1 Wang Bo -guang 2(1.Research Institute of Chemical Engineering ,South China Univ .of Tech .,Guan gzhou 510640,Guan gdong ,China ;2.Center of Guangzhou Environmental Monitoring Station ,Guangzhou 510030,Guangdong ,China )Ab stract :Three transition metal catalysts ,CuO /γ-Al 2O 3,CdO /γ-Al 2O 3and NiO /γ-Al 2O 3,were prepared by de -positing transition metal nitrate solutions on γ-Al 2O 3via impregnation .The catalytic activities of these three catalysts were compared by the catalytic combustion experiments of ethanol ,acetone and toluene .E xperimental results show that boththe light -off temperatur e and the total conversion temperature of the catalytic combustion of these three volatile organic compounds (VOCs )are much lo wer than the corresponding burning points ,that CuO /γ-Al 2O 3is of an more excellent catalytic activity than CdO /γ-Al 2O 3and NiO /γ-Al 2O 3,that the light -off temperatures of the catalytic c ombustion of ace -tone ,ethanol and toluene catalyzed by CuO /γ-Al 2O 3are respectively 180,190and 230℃,and that the stronger the polarity of VOCs is ,the easier the corresponding oxidation is .Key words :transition metal ;catalyst ;catalytic combustion ;volatile organic compound59 第5期郭建光等:催化燃烧VOCs 的三种过渡金属催化剂的活性比较。

生物利用度在药物发展过程中的意义英语作文The Significance of Bioavailability in the Drug Development ProcessIntroductionBioavailability plays a crucial role in the development of pharmaceutical drugs. It refers to the degree and rate at which a drug reaches the systemic circulation and is available at the site of action. Understanding and optimizing the bioavailability of a drug is essential for ensuring its therapeutic efficacy and safety. In this article, we will explore the significance of bioavailability in the drug development process.Bioavailablity and Drug AbsorptionOne of the key factors determining the bioavailability of a drug is its absorption. Absorption refers to the process by which a drug enters the bloodstream from its site of administration. Factors such as drug solubility, permeability, and formulation can influence the absorption of a drug. For example, drugs that are poorly soluble or poorly permeable may have low bioavailability, leading to suboptimal therapy.Bioavailability and Drug DistributionAfter absorption, a drug is distributed throughout the body to its target tissues or organs. The distribution of a drug is influenced by factors such as protein binding, tissue permeability, and blood flow. Drugs that are highly bound to plasma proteins may have limited distribution and lower bioavailability. Understanding the distribution of a drug is important for optimizing its dosage and dosing regimen.Bioavailability and Drug MetabolismOnce a drug is absorbed and distributed, it undergoes metabolism in the liver and other tissues. Metabolism can modify the structure of a drug, making it more or less active. The bioavailability of a drug can be affected by its metabolism, as metabolites may have different pharmacokinetic properties than the parent drug. This can impact the efficacy and safety of a drug, highlighting the importance of considering metabolism in the drug development process.Bioavailability and Drug EliminationFinally, a drug is eliminated from the body through processes such as renal excretion, hepatic metabolism, and biliary excretion. The rate of elimination can affect the bioavailability of a drug, as drugs with a short half-life may require more frequent dosing to maintain therapeutic levels.Understanding the elimination of a drug is essential for optimizing its bioavailability and overall pharmacokinetics.Optimizing Bioavailability in Drug DevelopmentIn order to optimize the bioavailability of a drug, researchers can use various strategies during the drug development process. These include selecting appropriate drug formulations, enhancing drug solubility and permeability, and minimizing the impact of metabolism and elimination. By considering bioavailability early in the drug development process, researchers can design drugs with improved efficacy, safety, and patient compliance.ConclusionIn conclusion, bioavailability is a critical factor in the drug development process. Understanding and optimizing the bioavailability of a drug is essential for ensuring its therapeutic effectiveness and safety. By considering factors such as absorption, distribution, metabolism, and elimination, researchers can develop drugs with improved bioavailability and pharmacokinetic properties. Ultimately, by prioritizing bioavailability in drug development, researchers can enhance the quality and impact of pharmaceutical drugs.。

医疗器械生物学评价英文版The biological evaluation of medical devices is a crucial aspect of their development and assessment. It involves the assessment of the biological safety of the device, considering factors such as potential toxicity, irritation, sensitization, and other adverse effects on living tissues. The evaluation is conducted to ensure that the medical device is compatible with the human body and does not pose any undue risk to patients or healthcare providers.The biological evaluation of medical devices is typically conducted in accordance with international standards and guidelines, such as ISO 10993, which provides a framework for assessing the biological safety of medical devices. This evaluation may include various tests and assessments, such as cytotoxicity testing, sensitization testing, and irritation testing, among others.The results of the biological evaluation are essentialfor regulatory submissions and approvals, as they provide critical information about the safety and performance of the medical device. Additionally, they are vital for ensuring that the device meets the necessary quality and safety standards for use in clinical settings.In conclusion, the biological evaluation of medical devices is a comprehensive process that involves the assessment of their biological safety and compatibility with the human body. It is a critical aspect of the development and assessment of medical devices and is essential for ensuring their safety and effectiveness in clinical use.。

英文说文解字英语之说文解字此文是四年前写的,当时对语言文字有一种灵感,故其实此文如果真正用原型意象来改写的话是相当好的一个题材,有兴趣者不妨以雷学为架构,以原型为依托,重新发掘词汇的奥意,会是一个很有趣的历程。

呵呵呵英语之说文解字版权这篇文章本来是写给我在新西兰的一位朋友。

他在那边学英语,抱怨词汇量少,问我有什么好一点的方法记单词。

我以前研究过怎么记单词,故把自己的一点心得写了这篇文章,希望能帮朋友一把。

我的一些同事用我的方法确实也在记词汇方面大有长进。