Dynamics of viscoplastic deformation in amorphous solids

- 格式:pdf

- 大小:615.32 KB

- 文档页数:16

第26卷第12期2005年12月焊接学报TRANSACTIONS OF THE CHINA WELDING INSTITUTIONVol.26 No.12December 2005T91钢TIG+MIG焊接接头性能及组织常铁军1,龚正春2,李子峰1,王长柏1(1.哈尔滨工程大学机电学院,哈尔滨150001;2.哈尔滨锅炉厂有限责任公司,哈尔滨150046)摘要:对采用TIG+MIG焊的T91钢焊接接头进行了力学性能、持久强度和高温时效试验,并对T91钢TIG+MIG焊接接头的显微组织及断口的断裂特征进行了观察和分析。

结果表明,T91钢TIG+MIG焊接接头的韧脆转变温度(FATT)为-13℃,625℃17958h高温持久试验为70MPa,外推105h高温持久强度为46.48MPa。

焊接接头的高温性能取决于其组织的变化,以M23C6为主的合金碳化物对持久强度起了重要作用。

关键词:T91钢;韧脆转变温度;显微组织;持久强度中图分类号:TG401 文献标识码:A 文章编号:0253-360X(2005)12-59-04常铁军0 序言改进型9Cr1Mo钢是美国橡树岭国家实验室(ORNL)和美国燃烧工程公司(CE)于1976年共同研究开发的综合性能优良的动力工程锅炉用耐热钢。

在随后的1977~1984年间,橡树岭国家实验室、燃烧工程公司、法国Vallourec公司先后分别或联合对改进型9Cr1Mo钢进行了大量试验研究。

因此1983年ASTM将改进型9Cr1Mo钢列入SA2l3标准,钢号为T91;1984年ASME将其列入SA335标准,钢号为P91,并规定T91和P91钢可用于动力锅炉的压力管道及集气管[1,2]。

20世纪90年代初国内开始研制和生产T91钢管,并列入国家标准GB5310-1995《高压锅炉用无缝钢管》,钢号为10Cr9Mo1VNb[3]。

T91钢系马氏体耐热钢,焊接性较差,焊接中要重点防止冷裂纹及根部合金元素氧化过烧;另一方面它有良好的塑性和韧性,对焊接有利。

Continued Fractions and DynamicsStefano Isola【期刊名称】《应用数学(英文)》【年(卷),期】2014(5)7【摘要】Several links between continued fractions and classical and less classical constructions in dynamical systems theory are presented and discussed.【总页数】24页(P1067-1090)【关键词】Continued;Fractions;Fast;and;Slow;Convergents;Irrational;Rotations;Farey;a nd;Gauss;Maps;Transfer;Operator;Thermodynamic;Formalism【作者】Stefano Isola【作者单位】Dipartimento di Matematica e Informatica, Università degli Studi di Camerino, Camerino Macerata, Italy【正文语种】中文【中图分类】O1【相关文献】1.Quantitative Poincare recurrence in continued fraction dynamical system [J], PENG Li;TAN Bo;WANG BaoWei2.MULTIFRACTAL ANALYSIS OF THE CONVERGENCE EXPONENT INCONTINUED FRACTIONS [J], 房路路;马际华;宋昆昆;吴敏3.Continued Fraction Method for Approximation of Heat Conduction Dynamics in a Semi-Infinite Slab [J], Jietae Lee;Dong Hyun Kim4.Gravity Field Imaging by Continued Fraction Downward Continuation: A Case Study of the Nechako Basin(Canada) [J], ZHANG Chong;ZHOU Wenna;LV Qingtian;YAN Jiayong5.On Continued Fractions and Their Applications [J], Zakiya M. Ibran;EfafA. Aljatlawi;Ali M. Awin因版权原因,仅展示原文概要,查看原文内容请购买。

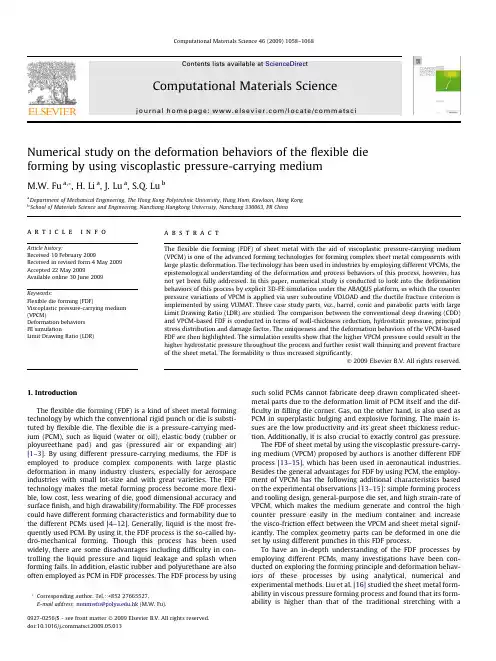

Numerical study on the deformation behaviors of the flexible die forming by using viscoplastic pressure-carrying mediumM.W.Fu a,*,H.Li a ,J.Lu a ,S.Q.Lu ba Department of Mechanical Engineering,The Hong Kong Polytechnic University,Hung Hom,Kowloon,Hong Kong bSchool of Materials Science and Engineering,Nanchang Hangkong University,Nanchang 330063,PR Chinaa r t i c l e i n f o Article history:Received 10February 2009Received in revised form 4May 2009Accepted 22May 2009Available online 30June 2009Keywords:Flexible die forming (FDF)Viscoplastic pressure-carrying medium (VPCM)Deformation behaviors FE simulationLimit Drawing Ratio (LDR)a b s t r a c tThe flexible die forming (FDF)of sheet metal with the aid of viscoplastic pressure-carrying medium (VPCM)is one of the advanced forming technologies for forming complex sheet metal components with large plastic deformation.The technology has been used in industries by employing different VPCMs,the epistemological understanding of the deformation and process behaviors of this process,however,has not yet been fully addressed.In this paper,numerical study is conducted to look into the deformation behaviors of this process by explicit 3D-FE simulation under the ABAQUS platform,in which the counter pressure variations of VPCM is applied via user subroutine VDLOAD and the ductile fracture criterion is implemented by using VUMAT.Three case study parts,viz.,barrel,conic and parabolic parts with large Limit Drawing Ratio (LDR)are studied.The comparison between the conventional deep drawing (CDD)and VPCM-based FDF is conducted in terms of wall-thickness reduction,hydrostatic pressure,principal stress distribution and damage factor.The uniqueness and the deformation behaviors of the VPCM-based FDF are then highlighted.The simulation results show that the higher VPCM pressure could result in the higher hydrostatic pressure throughout the process and further resist wall thinning and prevent fracture of the sheet metal.The formability is thus increased significantly.Ó2009Elsevier B.V.All rights reserved.1.IntroductionThe flexible die forming (FDF)is a kind of sheet metal forming technology by which the conventional rigid punch or die is substi-tuted by flexible die.The flexible die is a pressure-carrying med-ium (PCM),such as liquid (water or oil),elastic body (rubber or ployureethane pad)and gas (pressured air or expanding air)[1–3].By using different pressure-carrying mediums,the FDF is employed to produce complex components with large plastic deformation in many industry clusters,especially for aerospace industries with small lot-size and with great varieties.The FDF technology makes the metal forming process become more flexi-ble,low cost,less wearing of die,good dimensional accuracy and surface finish,and high drawability/formability.The FDF processes could have different forming characteristics and formability due to the different PCMs used [4–12].Generally,liquid is the most fre-quently used PCM.By using it,the FDF process is the so-called hy-dro-mechanical forming.Though this process has been used widely,there are some disadvantages including difficulty in con-trolling the liquid pressure and liquid leakage and splash when forming fails.In addition,elastic rubber and polyurethane are also often employed as PCM in FDF processes.The FDF process by usingsuch solid PCMs cannot fabricate deep drawn complicated sheet-metal parts due to the deformation limit of PCM itself and the dif-ficulty in filling die corner.Gas,on the other hand,is also used as PCM in superplastic bulging and explosive forming.The main is-sues are the low productivity and its great sheet thickness reduc-tion.Additionally,it is also crucial to exactly control gas pressure.The FDF of sheet metal by using the viscoplastic pressure-carry-ing medium (VPCM)proposed by authors is another different FDF process [13–15],which has been used in aeronautical industries.Besides the general advantages for FDF by using PCM,the employ-ment of VPCM has the following additional characteristics based on the experimental observations [13–15]:simple forming process and tooling design,general-purpose die set,and high strain-rate of VPCM,which makes the medium generate and control the high counter pressure easily in the medium container and increase the visco-friction effect between the VPCM and sheet metal signif-icantly.The complex geometry parts can be deformed in one die set by using different punches in this FDF process.To have an in-depth understanding of the FDF processes by employing different PCMs,many investigations have been con-ducted on exploring the forming principle and deformation behav-iors of these processes by using analytical,numerical and experimental methods.Liu et al.[16]studied the sheet metal form-ability in viscous pressure forming process and found that its form-ability is higher than that of the traditional stretching with a0927-0256/$-see front matter Ó2009Elsevier B.V.All rights reserved.doi:10.1016/matsci.2009.05.013*Corresponding author.Tel.:+852********.E-mail address:mmmwfu@.hk (M.W.Fu).Computational Materials Science 46(2009)1058–1068Contents lists available at ScienceDirectComputational Materials Sciencej o u r n a l h o m e p a g e :www.elsevier.c o m /l o c a t e /c o m m a t s cihemispherical solid metal punch.Hama et al.[17]simulated the sheet hydroforming based on the static FEM code and identified the difference of thickness distribution between the hydro-mechanical forming and the conventional press forming with the friction increasing effect.Choi et al.[18]developed an analytical model of hydro-mechanical deep drawing based on the experi-mental results.By using the analytical model,the effects of process conditions were studied including temperature,hydraulic pres-sure,blank holder force and punch speed conditions.In addition,Zhang et al.[19]studied the hydro-mechanical deep drawing of aluminum and mild steel cups experimentally and numerically.Singh et al.[11,20]investigated the effects of various parameters including pre-bulging pressure,cutoff pressure and oil gap,on the thickness distribution and surface finish in hydro-mechanical deep drawing.They also proposed a modified die to enhance the Limit Drawing Ratio (LDR)via the simulation of 2D explicit FE model.Zhao et al.[21]proposed a novel device for hydro-mechan-ical reverse deep drawing with axial pushing effect for cylindrical cups and identified the effects of different process parameters on the forming of deep drawing through FE ng et al.[22,23]proposed a new method,namely,hydrodynamic deep drawing assisted by radial pressure for improving the formability for the low plasticity sheet metal.All of these effects aim at improving the sheet metal drawability/formability of FDF by using the corresponding PCM.For the FDF using VPCM,which is called the VPCM-based FDF in this paper,there are fewer publications.In the authors’previous publication [13–15],the exploratory study on this process was conducted experimentally to identify the advantages of the VPCM-based FDF.However,the quantitative research is needed to reveal in-depth understanding of the deformation behaviors and the panorama of the process.In tandem with this goal,this pa-per thus devotes to conducting the quantitative exploration of this process via FE simulation,together with experimental method.Firstly,an explicit 3D-FE model of the VPCM-based FDF process is developed under the ABAQUS platform.The key procedure is presented including modeling of the counter pressure variation in process and implementation of ductile fracture criterion.Then by using the validated FE model of the FDF process for a barrel part,the forming characteristics between the conventional deep drawing (CDD)and VPCM-based FDF are compared in terms of wall-thickness reduction,hydrostatic pressure variation,principal stress distributions and damage factor.Thus the uniqueness of the VPCM-based FDF is highlighted.Through the case study of three typical workpieces including barrel,conic and parabolicgeometries,the panorama of the process and the deformation behaviors are extensively revealed.2.Working rationale of VPCM-based FDF 2.1.Forming procedure and experimentFig.1shows the forming schematics of the VPCM-based FDF process and a general-purpose die structure.The workpieces with different complex shapes can be formed in this die set by only changing the punch,blank-holder and flange.During the forming process,when the punch moves down at reasonable speed,the high pressure generated by the VPCM makes the sheet-metal de-form following the geometry shape of punch.Upon the completion of deformation,the sheet-metal part is ejected by ejectors.In this process,the blank-holding force is generated by a rigid bland-holder,which can be adjusted to fit the different mechanical prop-erties of sheet-metal and the geometry complexity of the work-pieces.The maximum VPCM pressure inside the container can be conveniently controlled via the control of punch velocity and the adjustment of throttle valve diameter according to the material properties,sheet-metal formability and workpiece geometry com-plexity.Ideally,the VPCM process should possess the following characteristics:(1)relatively high strain-rate sensitivity;(2)low adhesion to the metal surface and good ability to be easily shed from the workpieces and die;(3)good viscosity and property stability;(4)good cohesion,i.e.,difficult to splash;(5)harmless to human health and no pollution to environment;and (6)good re-cyclicability.In this research,the experiment is carried out in a hydraulic press with a capability of 1250kN.To control the forming velocity,a pressure-compensating hydraulic system is designed and imple-mented as an auxiliary device to be installed in the hydraulic sever system of the hydraulic press.The objective is to adjust the form-ing speed,by which the VPCM pressure can be effectively con-trolled.Based on the experimental results,the most preferable forming velocity is identified to be 9–12mm/s.The VPCM is aPunchBlank holderContainerBlankVPCMFig.1.The forming principle and die structure of VPCM-based FDF process.Table 1Composition of 08Al sheet metal (in weight%,the balance is Fe).C Si Mn P S Ni Cr Cu Al 60.0860.030.35–0.4560.02060.0360.0160.0360.150.02–0.07M.W.Fu et al./Computational Materials Science 46(2009)1058–10681059visco-material between the liquid and solid.The details composi-tion is not declosed.The sheet-metal is a widely-used low carbon deep drawing steel 08Al.The detailed composition of the material is shown in Table 1.The workpieces fabricated by this process are the three cup-type workpieces as shown in Fig.2including barrel part,conic part and parabolic part.The geometrical and forming parameters are summarized in Table 2.2.2.Formability and ductile fracture criterionThe formability of sheet metal is represented by the LDR,which is defined as the ratio of the maximum diameter of workpiece and the original blank diameter asR ¼d =D ð1Þwhere d and D are the maximum diameter of the workpiece and the original blank diameter,respectively.By employing the VPCM-based FDF,the LDRs are 0.38for barrel part,0.44for parabolic part and 0.38for conic part.For the barrel part,the conventional draw-ing coefficient is only 0.55–0.57[13].In the VPCM-based FDF process,the ductile fracture is the major deformation defect,which determines the formability of sheet me-tal.A ductile fracture criterion is thus implemented into the FE modeling to predict the fracture damage in the forming process.In order to predict ductile fracture,a number of numerical proce-dures have been developed to predict the fracture initialization.Basically,these methods are categorized into two types:(1)decou-pled criterion;(2)coupled criterion.For the coupled criteria such as Gurson’s porous model [24]and Continuum Damage Mechanics (CDM)model [25],the yield surface of material is allowed to mod-ified by the density changes and void growth induced by the accu-mulation of damage.However,due to the complexity in obtaining experimental data for setting up the damage constitutive laws based on coupled approaches [26],most of the applications re-ported in the literature as well as the numerical implementations found in commercial softwares are still restricted to the decoupled ductile fracture criteria.The decoupled criteria are based on plastic strain and consider the effect of hydrostatic stress in representing the physical behavior of the material.The basic idea of these duc-tile criteria is that fracture occurs when the criterion reaches a crit-ical value.In this study,the Brozzo model [27]is employed,in which the accumulation of damage is formulated as a mathematic function as shown in Eq.(2).Ze f2r 1r 1r m de ¼C ðr 1>0Þð2Þwhere r 1–the largest principal stress,r m –(mean)hydrostaticstress,C –critical damage value at fracture,e f –critical strain at fracture,de ðD e Þ–effective strain increment.The critical damage value can be obtained from experiment.The left side of the equation represents the fracture tendency along the forming history,which is defined as damage factor in this paper.The above criterion is implemented into FE model by using the user defined subroutine VUMAT in ABAQUS [28],in which Eq.(2)can be numerically calculated by Eq.(3).X n i ¼12r 13ðr 1Àr m ÞD e ¼C ðr 1>0Þð3Þwhere n is the number of increments.3.Establishment of 3D-FE models for VPCM-based FDFBased on the nonlinear platform of ABAQUS/Explicit [28],a ser-ies of 3D-FE models are developed to simulate the VPCM-based FDF process.3.1.Modeling of the entire forming systemConsidering the symmetrical features of billet and die geome-tries,material and process behaviors and the boundary conditions,the quarterly FE models for the three case study parts are gener-ated as shown in Figs.3and 4.Table 2Geometrical and forming parameters in VPCM-based FDF.Items Barrel parts Parabolic part (mm)Barrel parts with conical bottom (mm)1Drawing coefficient 0.380.440.382Original blank diameter140mm 110mm 140mm 3Wall initial thickness 0.6mm 0.6mm 0.6mm 4Maximum diameter of the part 53.2mm 48.4mm 53.2mm 5Stroke 90mm 70mm 92mm 6Velocity10mm/s 10mm/s 10mm/s 7Clearance of sheet-blank holder2mm 2mm 2mm 8Clearance of punch-container flange 3.5mm 3.5mm 3.5mm 9Punch radius 3mm 3mm 3mm 10Flange radius3mm 3mm 3mm 11Blank holder radius3mm3mm3mm1060M.W.Fu et al./Computational Materials Science 46(2009)1058–1068The blank is defined as a 3D deformable shell and the die com-ponents are designated as the discrete rigid bodies with an assumption that they will not have any deformation in the forming process.In addition,a 4-node 3D bilinear rigid quadrilateral ele-ment is adopted to model the individual die components including punch,blank holder and container.A 4-node doubly curved thin shell element with reduced integration,hourglass control and fi-nite membrane strain is used to model the blank as shown in Fig.4,at which five integration points by using the Simpson inte-gration rule are used.The average element size of the deformable body mesh is 1mm and the adaptive mesh with refinement is ap-plied in the simulation process.The contact conditions between the metal sheet and the dies are treated by the contact surfaces and the contact pairs including blank holder-blank,container flange-blank and punch-blank.For the sheet metal,the elastic–plastic material model with Hill aniso-tropic quadratic yield function is employed and the strain harden-ing power law as shown in Eq.(4)is used.The material properties of the sheet metal are listed in Table 3.r ¼K e nð4ÞFurthermore,the mass scaling feature is also utilized to im-prove the computation cost with influencing inertia effect.The forming parameters are shown in Table 2.3.2.Modeling issues related to VPCMThe counter VPCM pressure is the key parameter in VPCM-based FDF process.To model the VPCM variations more accurately,the loading path of the VPCM pressure and the friction conditionsshould be treated reasonably.Two different modeling approaches are proposed in this research as follows:(1)In this approach,the VPCM is modeled directly with the solid deformable body with viscoplastic property as shown in Fig.5a.The 2D 4-node bilinear axisym-metric quadrilateral element CAX4R with thereducedFig.3.3D-FE simulation model for the barrel sheet metal part.(a)FE simulation of the die structure;(b)mesh model of the sheetmetal.Fig.4.3D-FE simulation models for the conic and parabolic parts (a)FE simulation model for the conic sheet metal part ;(b)FE simulation model for the parabolic sheet metal part.Table 3Mechanical properties of 08Al sheet material.Materials08Al Ultimate tension strength (MPa)315Fracture elongation (%)44Poisson’s ratio0.27Initial yield stress (MPa)180Strain hardening exponent 0.234Strength coefficient K (MPa)553.47Young’s modulus (GPa)210Density (kg/m 3)7800Normal anisotropy exponent1.8M.W.Fu et al./Computational Materials Science 46(2009)1058–10681061integration and hourglass control is used to discrete the VPCM.The constitutive relationship of the VPCM is shown as Eq.(5).r ¼241_e0:2ð5ÞSince the VPCM undergoes severe plastic deformation inthe VPCM-based FDF process,the severe distortion in VPCM occurs as shown in Fig.5b,even though the Arbi-trary Lagrangian Eulerian (ALE)adaptive meshing [28]is adopted to provide the control of mesh distortion of VPCM.(2)Regarding the second approach,the pressure variation ofthe VPCM with stroke is used to define the loading path of the VPCM counter pressure inside the container,asshown in Fig.6.These pressure variation curves are obtained via experiment.With the downward movement of the punch,the VPCM pressure increases slowly in the beginning due to the existence of the air in VPCM and container,and then increases rapidly.For the three type case parts,when the punch stroke is near 20mm,the pressure reaches a stable stage.At this stage,the pres-sure increases slowly and the VPCM volume generated by the downward movement of the punch is nearly equal to the volume flowing out from the throttle valve and the gap between the blank and container flange.The working pressure,which is the value at the stable stage in the pressure loading path as shown in Fig.6,can be esti-mated by the following equation [14]:p ¼t r b =gð6Þwhere t is the sheet-metal thickness,r b is the strength limit of sheet-metal and g is the empirical factor and fitted as 28.To exactly and effectively interpolate the VPCM pressure into the FE models and reasonably apply the boundary condition,a instant two-segment approach is proposed to treat the pressure loading as shown in Fig.7.Once the sheet metal is drawn into the VPCM container,the pressure loading path shown in Fig.6is applied to the sheet surface and the range of the sheet area can be mathemat-ically defined as the circle with the radius of the container flange ra-dius d 1.The radius is constrained by Eq.(7).For the other area of the sheet metal,the area can be defined as the ring with the width of d 2as shown in Eq.(8).The pressure of this area is regarded as smaller than the stress applied to the sheet metal flowing into the con-tainer.Here the value of the pressure is designated as the initial pressure magnitude in Fig.6.The above dynamic boundary condi-tions are realized by the user subroutine VDLOAD of ABAQUS [28].ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiCurCood ðPoinit ;xi Þ2þCurCood ðPoinit ;zi Þ2q 6d 1ð7ÞD Àd 16d 2ð8Þwhere the CurCood (Poinit ,xi )and CurCood (Poinit ,zi )are the coordi-nates of material points in the direction X and Z ,respectively.In VPCM-based FDF,the VPCM can flow out of the gap between the sheet metal and flange.The VPCM lubrication film between this interface provides a perfect lubrication that reduces the drawing force and the scratching of the part surfaces.The friction coefficient between the blank and container flange is thus very small.The de-tailed contact conditions and friction information aresummarizedFig.5.Illustration of VPCM modeling in VPCM-based FDF process (a)original FE model of VPCM;(b)severe plastic deformation of VPCM.1062M.W.Fu et al./Computational Materials Science 46(2009)1058–1068in Table 4.The Coulomb friction model is used to represent the fric-tion behavior between sheet metal and die as Eq.(9).s ¼l pð9Þwhere s is the frictional shear force,l the friction coefficient,p the pressure force on the contact surface.3.3.Verification of FE simulation resultsThe verification of the FE simulation results by using the energy conservation principle and the comparison of the sheet metal thickness reduction predicted by experiment and simulation were performed.The sheet metal thickness reduction is defined as theratio of the amount of wall-thickness reduction and the original sheet-metal thickness described as Eq.(10):D t ¼ðt Àt 0Þ=t 0Â100%ð10Þwhere t and t 0are the thickness after and before deformation.For explicit simulation of quasi-static forming process,it is known that the kinetic energy should be monitored to ensure that the ratio of kinetic energy to internal energy does not get too large-typically less than 10%[28].Throughout the entire explicit dy-namic plastic analysis,the kinetic energy maintains minor value compared with the internal energy variation as shown in Fig.8.The inertia effects can thus be neglected and the quasi-static pro-cess is ensured according to the energy conservation principle.From Figs.9and 10,it is found that the FE simulation agrees with the experimental ones well with the relative error less than 5%.The discrepancy is mainly caused by the idealized friction con-ditions in the simulation.4.Results and discussionBased on the above validated FE modeling,the process perfor-mance and the deformation behaviors in VPCM-based FDF process can further be explored extensively and quantitatively revealed.4.1.Formability comparison between VPCM-based FDF and CDD processTo compare the deformation behaviors of VPCM-based FDF and the convention deep drawing (CDD),the simulations are conducted for CDD process as shown in Fig.11.Since the formability of the FDF process is determined by the ductile fracture of sheet metal,both the wall-thickness reduction and the maximum damage fac-tor are thus chosen as indices for comparison of the two processes.Fig.12shows the comparison results.It is found that the gen-eral trend of the wall-thickness reduction and the maximum dam-age factor along the deformed part profile are similar.That is because the general stress and strain states are similar between VPCM-based FDF and CDD process as shown in Fig.13.But obvi-ously the wall-thickness reduction and damage factor in VPCM-based FDF are much smaller than those of the CDD process.The reasons are discussed as follows:(1)Due to the existence of the high VPCM pressure,the sheet-metal forms a ‘convex ridge’and then flows into the con-tainer as shown in Fig.7a.This flow pattern of sheet-metal is different from the CDD,at which the metal flowsdirectlyFig.7.Processing of VPCM pressure boundary conditions (a)side view;(b)top view.Table 4Contact conditions in various contact interfaces.Contact interfaceFriction coefficient 1Blank holder/blank 0.052Punch/blank 0.33Container/blank0.001M.W.Fu et al./Computational Materials Science 46(2009)1058–10681063along the corner of theflange.The degree of bending of the metal sheet near theflange corner for VPCM-based FDF issmaller than CDD process,which positively reduces the wall-thickness reduction.In addition,the friction between the sheet-metal and die(flange)is reduced due to the exist-ing of the VPCM at the contact interface,which further reduces the radial tensile stress r r in the deep drawing pro-cess and thus makes the wall-thickness reduction become smaller and more uniform distributed along the metal sheet profile.Furthermore,it is known that the friction effect on formability is great in CDD process.However,in VPCM-based FDF,the effect of friction between the sheet metal and punch is small.Fig.14shows the wall-thickness reduc-tion variations for different friction coefficient.It is found that the wall-thickness reduction almost remains invariable with friction coefficient0.1,0.2and0.3,respectively.This implies that the VPCM pressure plays a vital role in control-ling the wall-thickness distribution in VPCM-based FDF process.(2)It is known that the‘pre-bulging pressure’is necessary in FDFprocess by using other medium such as hydro-mechanical deep drawing[9].Both the‘pre-bulging pressure’and the ‘cutoff pressure’are required to be determined before the oncoming forming process.The‘pre-bulging pressure’means that at the primary stage of sheet metal hydro-mechanicalFig.11.Simulation of conventional deep drawing process of sheet metal(a)original3D FE model for CDD process;(b)deformation in CDD process.Fig.9.Parts fabricated by VPCM-based FDF and predicted result by simulation(a)experimental part;(b)simulation part.1064M.W.Fu et al./Computational Materials Science46(2009)1058–1068forming,one pre-bulging unit is used to increase the pressure in die cavity actively;meanwhile,the punch is fixed at a cer-tain position.The ‘cutoff pressure’refers to the maximum work pressure for sheet metal forming.But for VPCM-based FDF,the VPCM is just needed to be filled into the container before the punch is moved down to the desired depth.The deformation of the viscoplastic VPCM itself provides a coun-ter pressure to hold the sheet metal firmly along the punch shape.The VPCM pressure increases gradually with the stroke as mentioned in Fig.6.On the other hand,the simula-tion shows that the larger acceleration of the counter pres-sure at the beginning improves the formability and reduces the wall-thickness reduction of workpiece.To realize this objective,the following methods were taken in this research:(a)increasing the strain-rate sensitivity of the VPCM to generate the ‘convex ridge’;(b)selecting the optimal throttlevalve diameter to better control the VPCM flow during the forming process;and (c)completely filling the VPCM to the container.After implementation of these methods,the pressure in the medium container can be established quickly.(3)The high counter-pressure generated by VPCM changes thedeformation pattern,which can be explained by the hydro-static pressure P formulated by Eq.(11).P ¼À13trace ðr Þ¼À13r ij d ijð11Þwhere r ij is stress components,d ij is the Kronecker delta,i ,j =1,2,3.P is the mean stress.The hydrostatic pressure stress P is used to rep-resent the anti-fracture ability.In the tensile stress state,it is known that the higher the hydrostatic pressure,the better the deformation formability.The higher hydrostatic pressure could preventtheparison between CDD and FDF viasimulation.Fig.13.Stress and strain states in deep drawing process.M.W.Fu et al./Computational Materials Science 46(2009)1058–10681065coalescing of the microvoids and therefore avoid the possible duc-tile fracture.Fig.15shows the distributions of hydrostatic pressure stress for the CDD and VPCM-based FDF processes.It is found that both processes have a very similar P distribution.However,the hydrostatic pressure variation in VPCM-based FDF is larger than that in CDD in the entire forming process.It is more significant for the above phenomenon at the latter forming stages.(4)The high pressure of VPCM also helps increase the homoge-neous distribution of stress and strain,which may further reduce the wall-thickness reduction.Fig.16shows the prin-cipal stress distribution contours of both processes at the stroke of28mm.It is found that,though the maximum ten-sile stresses for both processed are similar,the distribution of both the radial tensile stress r r and hoop compressive stress r h in VPCM-based FDF is more uniform than those in conventional DD process.This is because the strain-rate sensitivity and viscoplastic property of VPCM resist the great local deformation in the workpiece.The VPCM pressure thus improves the deformation uniformity and leads to more uni-form wall-thickness distribution.In addition,it is also noted that,under the same forming conditions,the wrinkling instability occurs at the sheet metalflange in CDD process.But there is no such phenomenon occurring in VPCM-based FDF due to the high pressure generated by VPCM between the blank and containerflange.4.2.Deformation behaviors of conic and parabolic partsThrough controlling the counter pressure in VPCM-based FDF process,the deformation of various complex geometry parts with greater LDR can be realized.In addition to the barrel part men-tioned previously,the forming of conic and parabolic case parts is also conducted as shown in Fig.2.The deformation profilesof Fig.15.Hydrostatic pressure distribution in CDD and VPCM-basedFDF.parison of stress distribution between VPCM-based FDF and CDD processes(a)r r and r h distribution in CDD process;(b)r r and r h distribution in VPCM-based FDF process.1066M.W.Fu et al./Computational Materials Science46(2009)1058–1068。

机械英语考试试题及答案一、选择题(每题2分,共20分)1. The term "mechanical engineering" refers to:A. The study of machinesB. The design and manufacture of mechanical systemsC. The operation of machineryD. The maintenance of mechanical equipment答案:B2. What is the function of a bearing in a mechanical system?A. To reduce frictionB. To increase efficiencyC. To provide powerD. To transmit motion答案:A3. The process of converting thermal energy into mechanical energy is known as:A. ElectrificationB. CombustionC. ThermodynamicsD. Hydrodynamics答案:C4. In mechanical design, the principle of "KISS" stands for:A. Keep It Simple, StupidB. Keep It Short and SimpleC. Keep It Simple and SafeD. Keep It Simple, Smart答案:A5. A gear train is used to:A. Change the direction of motionB. Increase the speed of rotationC. Decrease the speed of rotationD. All of the above答案:D6. What does CAD stand for in mechanical engineering?A. Computer-Aided DesignB. Computer-Aided DraftingC. Computer-Aided DevelopmentD. Computer-Aided Diagnostics答案:A7. The SI unit for force is:A. NewtonB. JouleC. PascalD. Watt答案:A8. What is the purpose of a flywheel in a mechanical system?A. To store energyB. To increase speedC. To reduce noiseD. To dissipate heat答案:A9. The term "hydraulics" is associated with the study of:A. Fluid dynamicsB. Solid mechanicsC. Structural analysisD. Thermal engineering答案:A10. The process of cutting a material to a specific shape is known as:A. MachiningB. CastingC. ForgingD. Extrusion答案:A二、填空题(每空1分,共10分)11. The formula for calculating the moment of a force is \( F \times d \), where \( F \) is the force and \( d \) is the_______.答案:distance from the pivot12. A _______ is a device that converts linear motion into rotational motion.答案:crank13. In a four-stroke internal combustion engine, the four strokes are intake, compression, _______, and exhaust.答案:power14. The _______ of a material is its ability to resist deformation under load.答案:stiffness15. The term "overhaul" in mechanical maintenance refers to a thorough inspection and _______ of a machine or its parts.答案:repair16. The _______ of a machine is the study of how forces act on and within a body.答案: statics17. A _______ is a type of machine that uses a screw to convert rotational motion into linear motion.答案:screw jack18. The _______ of a system is the point around which the system rotates.答案:pivot19. The _______ of a lever is the ratio of the effort arm to the load arm.答案:mechanical advantage20. The _______ is a type of bearing that allows for rotation with minimal friction.答案:ball bearing三、简答题(每题5分,共30分)21. Explain the difference between static and dynamic equilibrium in mechanical systems.答案:Static equilibrium refers to a state where the net force and net moment acting on a body are zero, resulting in no acceleration. Dynamic equilibrium occurs when the net force is zero, but the body is in motion with constant velocity.22. What is the purpose of a clutch in a vehicle?答案:A clutch is used to engage and disengage the power transmission from the engine to the transmission system, allowing the vehicle to start, stop, and change gears smoothly.23. Describe the function of a governor in an engine.答案:A governor is a device that automatically controls the speed of an engine by regulating the fuel supply or the valve settings, ensuring the engine operates within safespeed limits.24. What are the three primary types of joints in structural engineering?答案:The three primary types of joints are pinned joints, fixed joints, and sliding joints, each serving different purposes in connecting and supporting structural elements.25. Explain the。

卷筒式伸杆机构展开过程仿真实现方法研究吴健;王春洁;李广耀【摘要】以卷筒式伸杆机构为研究对象,研究了其展开过程的动力学仿真方法.首先,建立卷筒式伸杆机构展开过程的原理样机与理论计算模型,基于样机试验数据与MATLAB数值计算结果,确定机构在不同展开高度下的伸展运动状态.之后,在机构运动状态分析结果的基础上,利用有限元方法与MATLAB-VC进行混合编程方法建立了机构展开过程的参数化动力学仿真模型,并利用OpenGL的双缓存模式实现了仿真结果的可视化.最后,综合模型建立、数据传递、仿真结果可视化等方面建立了卷筒式伸杆机构的动力学仿真平台,有效提高了机构的设计效率与质量.【期刊名称】《机械设计与制造》【年(卷),期】2019(000)005【总页数】5页(P42-46)【关键词】卷筒式伸杆机构;动力学建模;有限元分析;仿真结果可视化;仿真平台【作者】吴健;王春洁;李广耀【作者单位】北京航空航天大学机械工程及自动化学院,北京 100191;北京航空航天大学机械工程及自动化学院,北京 100191;虚拟现实技术与系统国家重点实验室,北京 100191;北京航空航天大学机械工程及自动化学院,北京 100191【正文语种】中文【中图分类】TH16;TP391.91 引言大型可展开机构已广泛应用于天线,伸展臂等空间装置,并在各种空间探测任务中起到了重要的作用,因此,可展开机构的研究工作正被广泛地进行。

文献[1]介绍了一种双间隙可展开机构及其动力学建模仿真方法。

文献[2]针对盘绕式展开机构的基本构型和原理展开研究,阐述了该形式的机构具有刚度大,强度高,重量轻等特点。

卷筒式伸杆机构作为一种新型展开机构,除了具有上述机构的优点以外,其结构更加简单,展开方式更为方便,因此具有较为广阔的发展前景。

由此,研究卷筒式伸杆机构的工作原理以及对其进行动力学分析具有重要意义。

文献[3]基于ANSYS软件提出了大变形复合材料薄板的动力学仿真分析方法,文献[4-6]探究了金属、碳纤维等材料大变形过程的动力学分析方法。

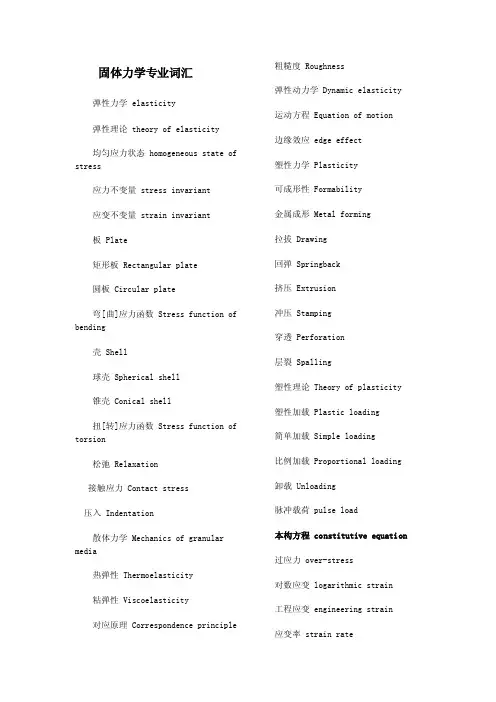

固体力学专业词汇弹性力学 elasticity弹性理论 theory of elasticity均匀应力状态 homogeneous state of stress应力不变量 stress invariant应变不变量 strain invariant板 Plate矩形板 Rectangular plate圆板 Circular plate弯[曲]应力函数 Stress function of bending壳 Shell球壳 Spherical shell锥壳 Conical shell扭[转]应力函数 Stress function of torsion松弛 Relaxation接触应力 Contact stress压入 Indentation散体力学 Mechanics of granular media热弹性 Thermoelasticity粘弹性 Viscoelasticity对应原理 Correspondence principle 粗糙度 Roughness弹性动力学 Dynamic elasticity 运动方程 Equation of motion边缘效应 edge effect塑性力学 Plasticity可成形性 Formability金属成形 Metal forming拉拔 Drawing回弹 Springback挤压 Extrusion冲压 Stamping穿透 Perforation层裂 Spalling塑性理论 Theory of plasticity 塑性加载 Plastic loading简单加载 Simple loading比例加载 Proportional loading 卸载 Unloading脉冲载荷 pulse load本构方程 constitutive equation 过应力 over-stress对数应变 logarithmic strain工程应变 engineering strain应变率 strain rate有限应变 finite strain塑性应变增量 plastic strain increment永久变形 permanent deformation应变软化 strain-softening刚塑性材料 rigid-plastic material理想塑性材料 perfectl plastic material材料稳定性 stability of material应变强化 strain-hardening屈服 Yield屈服条件 yield condition塑性动力学 dynamic plasticity滑移线 slip-lines结构力学 structural mechanics结构分析 structural analysis结构动力学 structural dynamics空间结构 space structure结点法 method of joints截面法 method of sections复合材料力学 mechanics of composites复合材料 composite material纤维复合材料 fibrous composite层板 Laminate膨胀 Expansion压实 Debulk脱层 Delamination纤维应力 fiber stress层应力 ply stress层应变 ply strain短纤维 chopped fiber长纤维 continuous fiber纤维方向 fiber direction纤维断裂 fiber break纤维拔脱 fiber pull-out断裂力学 fracture mechanics弹塑性断裂力学 elastic-plastic fracture mecha-nics, EPFM断裂 Fracture脆性断裂 brittle fracture蠕变断裂 creep fracture裂纹 Crack裂缝 Flaw缺陷 Defect割缝 Slit短裂纹 short crack表面裂纹 surface crack裂纹钝化 crack blunting有效应力张量 effective stress tensor内聚区 cohesive zone塑性区 plastic zone张拉区 stretched zone热影响区 heat affected zone, HAZ应力腐蚀 stress corrosion损伤 Damage累积损伤 accumulated damage脆性损伤 brittle damage宏观损伤 macroscopic damage微观损伤 microscopic damage疲劳 Fatigue应力疲劳 stress fatigue蠕变疲劳 creep fatigue腐蚀疲劳 corrosion fatigue疲劳损伤 fatigue damage疲劳失效 fatigue failure疲劳断裂 fatigue fracture疲劳裂纹 fatigue crack疲劳寿命 fatigue life疲劳破坏 fatigue rupture交变应力 alternating stress应变疲劳 strain fatigue计算结构力学 computational structural mechanics广义位移 generalized displacement广义应变 generalized strain广义应力 generalized stress节点 node, nodal point[单]元 Element二维元 two-dimensional element一维元 one-dimensional element三维元 three-dimensional element轴对称元 axisymmetric element三角形元 triangular element四边形元 quadrilateral element四面体元 tetrahedral element曲线元 curved element位移矢量 displacement vector载荷矢量 load vector面积坐标 area coordinates体积坐标 volume coordinates前处理 pre-processing后处理 post-processing组合结构 composite structure。

7Thermal and Residual StressesI. INTRODUCTION Thermal stresses arise in components that are subject to temperature gradients, and the thermal transients associated with engine operations are of particular concern. Residual stresses arise because of nonuniform plastic deformation, and they are important in that thev affect resistance to fatigue and stress corrosion cracking, and also can cause distortion during machining and heat treating. This chapter briefly reviews how these types of stress are developed. II. THERMAL STRESS, THERMAL STRAIN, AND THERMAL SHOCKA. Thermal Stresses Consider the bimetallic strip shown in Fig. 7-1. In order to avoid bending during heating, equal amounts of material 1 are placed on either side of material 2. The initial length of the strip is L 0, and the area of material 1 is designated as A 1, and that of material 2 as A 2. The corresponding coefficients of expansion are α1 and α2.Fig. 7-1. A bimetallic strip.If the strips were free to expand due to a temperature change of △T, the lengths of each material would be(7-1)(7-2)As long as the stresses are in the elastic range, there will be no residual effects when the temperature returns to its initial value,and the above equations hold. However, if the stresses exceed the yield strength of the materials involved, a state of residual stress will develop when the temperature returns to its initial value. For example, if material 2 in the above example had a lower coefficient of expansion and a relatively low yield stress, it could undergo plastic extension as the temperature increased. Subsequently, when the temperature was lowered, material 2 would be left in a state of residual compression, and material 1 would be in residual tension.).1(),1(202101T L L T L L ∆+=∆+=ααB. Thermal-Mechanical Cyclic StrainsTransient thermal strains of a cyclic nature can arise in jet engine components such as disks, blades, and vanes. Figure 7-2 is a simplified thermal-mechanical cycle for blades in a gas turbine (1). Under cruise conditions, the blades are at 600°C. When engine power is increased, the surface temperature rises to 1100°C in 105 seconds. Fig. 7-2a. Engine power is then returned to the cruise condition, and the temperature falls to 600°C in another 105 seconds. The rate of heating and cooling is 4.76 °C/sec. The total strain is the sum of the strain due to thermal expansion plus the strain due to the thermal stresses developed. The mechanical strain versus time plot, shown in Fig. 7-2b, includes both elastic and plastic strains. On heating, the outer surface initially goes into compressive strain, but then the strain reduces to zero as the interior of the blade heats up. On cooling, the reverse procedure occurs. Figure 7-2c shows the counterclockwise diamond cycle that is the thermal-mechanical hysteresis loop for this transient thermal history. The corresponding stress versus mechanical strain hysteresis loops for single crystals in the [001] and [111] orientations are shown in Fig. 7-3. It is noted that the mean stress for the cycle is close to zero.For the [001] orientation, plastic deformation (or viscoplastic deformation) is pro-nounced at a strain of —0.8. For the [111] orientation, plastic deformation begins at a strain of —0.25. Such thermal mechanical histories are complex, but they are also obviously important in assessing the fatigue life of such components.Fig. 7-2.Thermal-mechanical cycle, (a) Temperature versus time, (b) Strain versus time. (c) Thermal-mechanical hysteresis loop. (From Remy, 1. Reprinted from Low Cycle Fatigue and Elasto-Plastic Behaviour of Materials, edited by K.-T. Rie and P. D. Portella, pp. 119-130, Copyright 1998, with permission of Elsevier Science.)Fig. 7-3. Stress versus mechanical strain hysteresis loops for [001] and [111] thermal mechanical fatigue (TMF) single crystal specimens of AM1 superalloy using the cycle depicted in Fig. 7-2. Comparison between a viscoplastic model (solid line) and experiment (symbols). (After Remy, 1. Reprinted from Low Cycle Fatigue and Elastic-Plastic Behaviour of Materials, edited by K.-T. Rie and P. D. Portella, pp. 119-130. Copyright 1998. with permission of Elsevier Science.)C. Thermal ShockThermal shock denotes the rapid development of a steep temperature gradient and accompanying high stresses that can result in the fracture of brittle materials. It can occur either on heating or cooling. For example, the sudden shutdown of turbine engine can result in cracking of protective platinum-aluminide coatings due to the tensile stresses that develop as the surface cools and tries to shrink but is restrained by the interior.An example of thermal shock that occurs during heating is as follows. Consider a glass bowl whose thermal conductivity is low.1. A hot liquid is poured into the bowl.2. The inside surface of the wall tries to expand because of the sudden rise in temperature.3. A biaxial compressive stress develops on the inside surface because expansion of the is resisted by thesurounding, still cool, wall material.4. This compressive stress system sets up a balancing tensile stress system in the outer, still cool portion of thewall.5. Fracture can initiate in the outer region if the magnitude of the tensile stress developed is sufficient to nucleate a crack at a weak point.III. RESIDUAL STRESSES CAUSED BY NONUNIFORM PLASTIC DEFORMATIONResidual stresses arise because of a gradient in plastic deformation caused either by mechanical deformation or by a thermal gradient caused during cooling of a metal or alloy from a high temperature to a low temperature. The sign of the residual stress is always opposite in sign to the sign of the applied stress that gave rise to the residual stress. Residual stresses are important in fatigue and stress corrosion cracking where they can be either beneficial or detrimental. If residual stresses are present prior to heat treatment or machining, they can be detrimental because they can result in distortion (warping).A. An Example of Mechanically Induced Residual Stresses: Springback after Bending into the Plastic Range (2) In sheet bending, the width w is much greater than the thickness /, and width changes are negligible. Therefore, bending can be considered to be a plane-strain operation with εv = 0, εz = — εx . Let z be the distance measured from the mid-plane of the s heet in the thickness direction, and let r be the radius of curvature of the mid-plane. The value of e v varies linearly from — t/2r at the inside of the bend (z = —t/2) to zero at the mid-plane (z = 0), to +t/2r at the outside of the bend (z = t/2). Figure 7-4 shows the stress through the cross section. The principal of superposition is used to show that unloading can be considered to be the reverse of loading, so that for purely elastic bending there is no residual stress after unloading.Fig. 7-4. Strip bending, elastic strains.Next, assume that the material is elastic ideally plastic, that is, there is no strain hardening in the plastic range. If the tensile yield stress is Y, the flow stress in plane strain o-0 will be 1. 15 Y. Figure 7-5 shows the stress distribution throughout the sheet for fully plastic behavior. Except for an elastic core at mid-plane (which will be neglected), the entire section will be at a stress, σx = ±σ0.Fig. 7-5. Strip bending, plastic strains on loading, elastic on unloading.To calculate the bending moment M needed to create this fully plastic bend, note that dF x = σx w dz, and that dM = z dF x = z σx wdz. Therefore, the fully plastic bending moment is⎰⎰+--===2/2/2/020)67(42t t t x x t w zdz w zdz w M σσσ(Note that the elastic bending moment that is needed to have σx just equal to σ0 would be w σ0 (t 2/6), so that the fully plastic bending moment is 50% higher.)When the external moment is released, the internal moment must go to zero. As the material springs back elastically, the internal residual stress distribution must result in a zero bending moment. Since the unloading is elastic,)77(.1'2-∆=∆-=∆x x x E v E εεσM — △M= 0 after springback, and therefore equating M and △M givesOrThe resulting residual stress)117(.31'3''11''00000/-⎪⎭⎫ ⎝⎛-=⎪⎭⎫ ⎝⎛-=⎪⎭⎫ ⎝⎛--=∆-=∆-=t z tE z E r r E E xx x x σσσσεσσσσOn the outside surface, z = t/2, and the residual stress cr'x equals —σ0/2. On the inside surface, the residual stress is +σ0/2. The distribution of stresses is shown in Fig. 7-5.Note that the sign of the residual stress is opposite to the sign of the stress that caused it. Also, plastic deformation is required, but the plastic deformation must be nonuniform. There is no residual stress associated with a tensile bar that has been uniformly stretched into the plastic region. On the other hand, residual stresses will develop at notches, and so on, if the material at the base of the notch is strained into the plastic range while the surroundings remain elastic.An important state of residual stress is that formed at the tip of a growing fatigue crack due to an overload in plane specimens. During fatigue crack growth, if a 100% overload is applied, the fatigue crack will subsequently undergo a period of reduction in rate of crack growth as the crack penetrates the plastic zone created by the overload. This slowdown is related to an increased level of com-pressive residual stress brought about by the overload. This residual stress is largely a plane stress, surface regions, and is brought about by the lateral contraction of material at the surface that occurs in the overload plastic zone. In ductile materials, this lateral contraction leads to the formation of an obvious dimple immediately ahead of the crack tip. The compressive stress develops as the load is reduced from the overload level, and for now. because of the lateral contraction, there is more material in planes parallel to and just below the surface of the overload plastic zone than before the overload. As the crack grows through the overload zone, these residual stresses are released, giving rise to an increased level of crack closure in the wake of the crack tip (see Chapter 10), which results in a slowing down of the rate of fatigue crack propagation. The extent of the slowdown in crack rate is a function of the overload level and the thickness of the specimen, being much more pronounced in thin as compared to thick specimens. The reason for this difference is that, in thick specimens, plane-strain conditions prevail throughout most of the specimen's thickness, and the lateral contraction associated with plane stress is absent under plane-strain conditions. Hence, the level of enhanced residual compressive stress due to an overload is much less in thick specimens than in thin. Surface compressive residual stresses are beneficial in fatigue and in stress corrosion cracking. For this reason, they are often deliberately introduced, by shot-peening, for example. Any cracks that form are retarded in their growth rates, much as in the case of an overload.B. Case Study: Shaft of a Golf ClubAt a golf driving range in Connecticut the shafts (tapered hollow tubes) of the clubs were sometimes bent or otherwise damaged in use and had to be replaced. A supply of replacement shafts was kept in a storage shed, which was at times damp and humid. The shafts were made of a low-alloy steel that had been chrome plated, which protected the exterior of the shaft from corrosion. Whereas a new shaft is sealed to the club head as well as at the grip end. and thereby protected from corrosion on the inside of the shaft, the replacement shafts were not sealed, and as a result the interiors of these replacement shafts underwent corrosion over a period of time.A golfer was driving balls with a club whose shaft was a replacement. As he struck a ball, the shaft fractured, and the end he was holding struck him in the eye. Fortunately, the damage to his eye was not serious, and he recovered completely. Upon examination of the shaft it was noted that the fracture origin was at a small dent in the shaft that preexisted the accident. The fracture had initiated at this dent on the inside of the shaft. The fracture origin, shown in Fig. 7-6, was more planar and brittle in appearance than was the fracture away from the origin, shown in Fig. 7-7, which exhibited the dimples characteristic of ductile fracture. It was concluded that the fracture was due to hydrogen embrittlement,⎭⎝⎭⎝)97(,'1112'4320-⎪⎭⎫ ⎝⎛-=r r t wE t w σ)107(,'3'110-=⎪⎭⎫ ⎝⎛-tE r r σwhichwas associated with corrosion and the seemingly innocuous dent which, because of springback, resulted in a residual tensile stress on the inside of the shaft at the periphery of the dent. When the dent was formed, material on the inside near the periphery of the dent went into compression, and material near the center of the dent went into tension. Upon springback, the signs of the stresses were reversed, and a residual tensile stress was left on the inside surface at the periphery of the dent.Fig.7-6. Macroscopic view of the area of the fracture origin in a failed golf shaft. The rough area at bottom is the corroded inside surface of the shaft.(Reprinted from Material Characterization, Vol.26,A.J.McEvily and I. Le May,pp.253-268,Copyright 1991,with permission of Elsevier Science.)Fig.7-7. Macroscopic view of fracture surface awwy from fracture origin in failed golf shaft. (Reprinted from Material Characterization, Vol.26,A.J.McEvily and I. Le May,pp.253-268,Copyright 1991,with permission of Elsevier Science.)IV. RESIDUAL STRESSES DUE TO QUENCHING On cooling a metal part from an elevated temperature, residual stresses may be developed. For example, if a massive piece of copper is cooled rapidly, the surface layers will cool before the interior, thus setting up tensile strains and stresses in the surface that are counterbalanced by compressive stresses in the interior. At elevated temperatures, these tensile and compressive stresses are relaxed due to the low yield strength of the material. However, at a later point in the cooling process, the already cooled surface layer will be subjected to compression as the interior finally cools and shrinks. In general, the resultant compressive stress in the surface layers is beneficial, except when machining follows and distortion results from the nonuniform removal of the surface.When steel is quenched to form martensite at a low temperature, the transformation from austenite to martensite is associated with a volume expansion of the order of 1-3%. At the surface, this initially results in a compressive stress, as in the case of copper, but when the underlying layer finally cools and expands, the surface is put into tension. These tensile stresses can be reduced by using a steel of lower hardenability so that the interior does not got through a martensitic transformation, but instead transforms to bainite at a higher temperature.B. Quench CrackingIn a steel, there is always the possibility of immediate quench cracking, due to the level of tensile residual stresses developed when untempered martensite is formed. However, cold cracking (or delayed cracking) is the more probable event, and for this reason, alloy steel parts that have been quenched are quickly transferred to tempering furnances or salt baths in order to mnimize the time available for cold cracking to develop. If cracks develop on quenching into water and the part is then transferred to a salt bath for tempering, an explosive reaction can occur as the water trapped in the cracks transforms into steam. Therfore, personnel carrying out this operation need to wear protective face masks and protective clothing.It is also possible to develop quench cracks above the quench temperature if, during the quench of a material with low ductility, the tensile surface stresses that develop due to the temperture gradient in the material exceed the resistance to cracking of the material, as indicated in Fig. 7-8.Fig. 7-8. A schematic of thermal stress versus resistance to cracking as a function of temperature.To avoid the development of residual stresses, heat-treating procedures are used that minimize the temperature gradients responsible for the residual stresses. Such methods are:(a) Martempering: The steel is rapidly cooled to a temperature above the M s and held to allow a uniformtemperature to develop before further cooling to martensite.(b) Austempering: The steel is rapidly cooled to a temperature above the M s and held there until the transformation tobainite is complete before further slow cooling to room temperature.V. RESIDUAL STRESS TOUGHENINGIf the outer surface of the bowl discussed above in the section on thermal shock had been treated to have a residual compressive stress in the surface region, the resistance to thermal shock would have increased. Glass can be toughened by diffusing large atoms into the surface to develop residual compressive stresses on cooling as, for example, in Corningware. Tempered glass is created by cooling rapidly from an elevated temperature to develop compressive surface residual stresses, much as in the case of a block of copper. This type of glass is used in the side windows of automobiles. When such glass breaks, it fractures into many small fragments. However, the glass used in windshields is not tempered. A windshield consists of a sandwich of two sheets of glass between which is bonded a sheet of plastic. In a crash, the windshield is intended to be flexible enough to reduce head injuries, but be resistant enough to overall fracture to prevent front seat occupants from being ejected through the windshield. In this case the glass generally breaks into large shards that remain attached to the plastic membrane.VI. RESIDUAL STRESSES RESULTING FROM CARBURIZING, NITRIDING, AND INDUCTIONHARDENINGA. CarburizingCarburizing is carried out in the austenitic range and can lead to the development of a compressive residual stress at the surface in a low-alloy steel during quenching for the following reason (3, 4). Carbon is one of the elements that depresses the M s temperature of a steel. The M s temperature of the carburized surface layer, therefore, can be much lower than that of the interior because of the differential in carbon contents. On quenching, the interior, even though at a higher temperature than the surface, is the first to transform due to its higher M s temperature. Later on, the surface transforms and tries to expand but is now restrained by the already transformed interior. As a result, the surface is left in a state of residual compression, as indicated in Fig. 7-9.Fig. 7-9. Effect of carburization on the residual stresses in a quenched and tempered (1 hr at 180-200°C) 0.93 Cr-0.26 C steel (After Ebert, 3, and Krause, 4).B. NitridingNitriding is carried out at an elevated temperature below the eutectoid temperature for time periods of the order of 9-24 hours, and during the nitriding process any prior residual stresses are relaxed. The purpose of nitriding is to improve the surface wear and fatigue properties. Since the temperatures are lower than in carbur-izing and no phase transformation is involved, problems with distortion are minimized, an important consideration when heat treating carefully machined parts such as crankshafts. The formation of nitrides leads to a beneficial compressiveresidual stress in the surface even after the usual slow cooling because of a lower coefficient of expansion of the nitrides.C. Induction HardeningInduction hardenmg is a surface-hardening process in which only the surface layer ot a suitable ferrous workpiece is heated by electrical induction to above the transformation temperature and immediately quenched. Compressive residual stresses develop as the surface layers transform from austenite on quenching.VII. RESIDUAL STRESSES DEVELOPED IN WELDINGIn welding operations, the parts being joined often provide a large heat sink, and therefore cooling rates are rapid. As a result, untempered martensite may form in a residual tensile stress field and lead to weld cracking, either through cold cracking or quench cracking. The susceptibility to weld cracking increases as the number of unfavorable welding conditions increases. For example, a medium-carbon steel welded wuh an electrode not of the low-hydrogen type, and without preheat or postheat. may perform satisfactorily even though there may be a HAZ containing a region of martensite about 1/16 inch thick if joint restraint is low and cyclic loading m service is limited. However, if the section thickness is doubled, the level of residual stress rises due to greater constraint, and the thickness of the martensitic zone is increased due to a higher cooling rate, and cracking may develop. Even the use of low-hydrogen electrodes may not prevent cracking of the thicker section but the use ot a 315℃ (600°F) preheat will prevent cracking by retarding the rate of cooling, and thereby reducing the level of the residual stresses and the amount of marten-site formed.On cooling below the M s temperature, two forms of martensite can form depending upon carbon content. In low-carbon steels, the martensite is made up laths that contain a high density of dislocations. In higher carbon steel, the martensite is made up of plates that also contain a high dislocation content, but in addition may be twined. Preheating is used to reduce the cooling rate in order to minimize the likelihood of the formation of brittle martensite, particularly the twinned martensite. The preheat temperature increases with carbon content and with the thicknessOf the plates being welded, With recommended preheat temperatures ranging from 100°F for a 0.2 wt % C steel up to 600°F for a 0.6 wt % C steelPostweld heating of a weldment serves two purposes. One is to relieve the residual stresses that may have been developed during the welding process. The second is to temper both the weld deposit and HAZ to improve their fracture toughness. It is now mandatory that weldments in all nuclear components and in most pressure vessels be postweld heat treated (PWHT). These postweld heat treatments are carried out at a temperature of the order of 650°C (1200°F) for one hour.(a)Stresses parallel to weld (b)Stresses transverse to weldFig. 7-10. Transverse and longitudinal residual stresses developed at a butt weld. (From Gurney, 5. With permission of the Cambridge University Press.)The residual stresses that are developed both parallel to and transverse to a butt weld due to shrinkage of the weld metal on cooling are shown in Fig. 7-10 (5). To minimize distortion, weld passes were made from each edge of the plate toward the center, which accounts for the transverse residual stress distribution, since the last weld metal to solidify was in the central region of the butt weld. The residual stress developed during welding can sometimes be beneficial. For example, the fatigue strength of steel lap welded joints for automotive use was improved by using low transformation temperature (M.s200°C, M f20°C) welding wire (10Cr-10Ni), which induced compressive residual stresses in the surface layers. The fatigue strength at 108 cycles was increased from 300 MPa to 450 MPa by this procedure (6).VIII. MEASUREMENT OF RESIDUAL STRESSESThe two main methods for the determination of the magnitude of residual stress, the x-ray method and the metal removal method, were described in Chapter 5. Another example of the metal removal method is known as the boring-out method. This method can be used to determine residual stress levels in cannon or other cylindrical bodies. In the case of a cannon barrel, as a last step in the manufacturing process, a pressure is developed within the barrel of sufficient magnitude to expand the interior of the barrel into the plastic range. When the pressure is removed, a beneficial state of residual compressive stress is developed on the inner surface, a process known as autofrettage. The determination of the magnitude of the residual stresses by the boring-out method involves the machining away of successive layers from the interior of the barrel. As each layer is removed, some of the residual stress is relieved. As a result, on the outer surface of the barrel, longitudinal and cir-cumferential strains develop which are measured by strain gauges. From these measurements the magnitude of the initial residual stress state can be deduced.X. SUMMARYTHe thermal stresses that arise in engineered items, such as the turbine disks of jet aircraft engines, are no longer a major problem because of improvements in materials as well as better design procedures. Nevertheless, their presence must be taken into account. Problems with thermal cracking during heat treatment continue. Residual stresses are still a problem because their presence may not be recognized until a cracking problem associated with them develops.REFERENCES(1) L. Remy, in Low Cycle Fatigue and Elasto-Plastic Behavior of Materials, ed. by K.-T. Rie and D. P. Portella. Elsevier, Oxford. UK.1998, pp. 119-130.(2) W. F. Hosford and R. M. Caddell. Metal Forming, 2nd ed., Prentice-Hall, Engelwood Cliffs. NJ, 1993.(3) L. J. Ebert, The Role of Residual Stresses in the Mechanical Performance of Case Car-burized Steel. Met Trans. A. vol. 9A. 1978.pp. 1537-I551.(4) G. Krauss, Principles of Heat Treatment of Steel. ASM. Materials Park. OH, 1980.(5) T. R. Gurney, Fatigue of Welded Structures. Cambridge University Press, Cambridge, UK, 1968. p. 58.(6) A. Ohta, Y. Maeda. and N. Suzuki, in Proc. 25th Symp. on Fatigue, Japan Soc. Mats. Sci., 2000, pp. 284-287.。

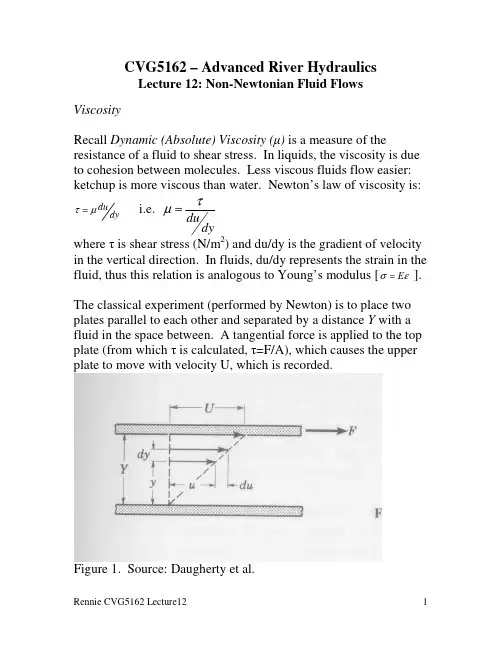

CVG5162 – Advanced River HydraulicsLecture 12: Non-Newtonian Fluid Flows Viscosity Recall Dynamic (Absolute) Viscosity ( ) is a measure of the resistance of a fluid to shear stress. In liquids, the viscosity is due to cohesion between molecules. Less viscous fluids flow easier: ketchup is more viscous than water. Newton’s law of viscosity is: dy duµτ= i.e. dydu τµ=where is shear stress (N/m 2) and du/dy is the gradient of velocity in the vertical direction. In fluids, du/dy represents the strain in the fluid, thus this relation is analogous to Young’s modulus [εσE = ]. The classical experiment (performed by Newton) is to place two plates parallel to each other and separated by a distance Y with a fluid in the space between. A tangential force is applied to the top plate (from which is calculated, =F/A), which causes the upper plate to move with velocity U, which is recorded. Figure 1. Source: Daugherty et al.With the no-slip assumption, the fluid particles next to each plate will assume the velocity of the plate. For laminar steady flow, the velocity gradient in the fluid between the plates will be linear.(i.e. du/dy is constant).Fluids for which does not depend on du/dy are described as Newtonian. Most common fluids are Newtonian. However, particularly relevant for some geophysical flows, fluids with very high suspended sediment concentration can be non-Newtonian. If one assumes that a fluid has zero viscosity (and therefore zero friction), the fluid is termed an ideal fluid. Note that an ideal fluid will not undergo strain due to the applied stress, thus it would maintain zero velocity between the two plates.Figure 2. Source: Daugherty et al.Viscosity of a fluid decreases with temperature, because cohesion diminishes. The dynamic viscosity of water at 20ºC is 1.005E-3 N s/m 2. Kinematic Viscosity ( ) is the dynamic viscosity divided by density: ρµν=. The kinematic viscosity of water at 20ºC is 1.007E-6 m 2/s. Turbulent eddy viscosity We have also seen that turbulence adds an extra apparent (eddy) viscosity (νT ), which is due to the increased transfer of momentum between fluid layers as a result of the turbulent motion (i.e. the Reynolds stress): ()dy du uv dy du T νννρτ+=−= Non-Newtonian Fluid We can see from Figure 2 above, that a Non-Newtonian fluid does not have a linear relation between shear stress and strain. In other words, the viscosity coefficient µ is not a constant – it varies with the shear stress applied. Some non-Newtonian fluids are relatively straight-forward, in that the instantaneous shear depends only on du/dy (as in the figure above). These are described as ‘time independent’, ‘purely viscous’, ‘inelastic’, or ‘generalized Newtonian fluids’ (GNF) (Chabbra and Richardson 1999, p.5). In more complex time-dependent non-Newtonian fluids the instantaneous apparent viscosity also depends on the flow history and previous shear rate.An important distinction between types of time-independent non-Newtonian fluids is whether or not they display a yield strength (i.e. whether a threshold stress is required to initiate strain (deformation) of the fluid, i.e. the stress required to get the fluid moving). See Figure 3. Note that the field of rheology bridges non-Newtonian fluids, plastic solids, and soils. Typically, the viscosity of a time-independent non-Newtonian fluid is specified as a function that depends on du/dy. Secondly, a yield stress term may be included. A viscoplastic is a fluid that displays a yield stress. A Bingham-plastic is a viscoplastic with a linear relation between shear and strain once yield shear is obtained:+=dy du y ηττ where τy is the yield stress (the stress required to initiate strain), and η is the dynamic viscosity (the slope of the line after the yield stress). A shear-thinning or pseudo-plastic fluid has no yield stress, but a relatively high viscosity at low strain. A shear-thickening or dilatant fluid has no yield stress, but a relatively low viscosity at low strain (high viscosity at high strain).Figure 3. Source: Chhabra and Richardson 1999. Note that pseudo-plastic fluid and shear-thinning fluid are synonomous. Figure 1.5 applies to polymer solutions, but shows how apparent viscosity decreases with increasing strain rate for a pseuodplastic fluid.Water-Sediment Mixtures The behaviour of fluids with high suspended sediment volumetric concentration (C s ) encompasses the range from Newtonian, to pseudo-plastic, to Bingham plastic, to yield-pseudoplastic depending on sediment concentration. Furthermore, individual clays have different electrochemical properties, and therefore different rheology. The analysis of high C s flows is thus complex. Julien and Lan (1991) provided a succinct summary of research until that time. Bagnold (1954) initiated this research field, and proposed that at high C s , fluid shear would be dominated by interparticle friction and collisions. He found that under very high rates of shear (i.e. high du/dy) and high C s , the shear stress increases as a second power of du/dy. Thus, the fluid can be described as a yield-pseudo plastic with convexivity to the shear stress (see Figure 4). The increased particle interactions at higher du/dy results in increased apparent viscosity (i.e. shear thickening). An empirical power-law equation (Herschel and Bulkley 1926) can be used for the shear in high clay-water suspensions at high du/dy (Govier and Aziz 1987, cited in O’Brien and Julien 1988):n y dy du a +=ττNote that n=2 based on the Bagnold observations. Alternatively, O’Brien and Julien (1988) found that under lower du/dy, the shear stress varies linearly with du/dy, thus at low du/dy the fluid mixture can be described as a Bingham plastic. They also argued that these are more realistic shear rates (du/dy) for geophysical flows. Note that both the yield stress and the dynamic viscosity increase exponentially with sediment concentration – three orders or magnitude increase between C s = 0.1 and 0.4 (O’Brien and Julien 1988)Julien and Lan provide the following summary plots: Figure 4. Source: Julien and Lan (1991)Figure 5. Source: Julien and Lan (1991)O’Brien and Julien (1985), cited in Julien and Lan (1991), proposed the following:2 ++=dy du dy du y ζηττwhere the first term is for the yield stress, the second for viscous (dynamic) stress, and the third term for the ‘turbulent-dispersive’ stress, which accounts for both turbulence and particle-particle interactions, both of which are presumed to vary as a second power with du/dy.Note that 2212s s d a l λρρζ+=, where ρ and l are mixture density and mixing length, a 1 is Bagnold’s empirical constant, λ varies with sediment concentration, and ρs and d s are sediment density and grain size. Note that the first term works out to be the turbulent Reynolds stress, and the second term is Bagnold’s stress due to particle interactions.Julien and Lan (1991) non-dimensionalized their model (see paper) to collapse the various data sets:Figure 6. Source: Julien and Lan (1991)TemperatureCoussot and Piau (1994) found little change in mud suspension rheological behaviour for temperatures ranging from 0°C to 20°C.Thixotropic Non-Newtonian FluidChanson (2006) presented a model for 1D dam-break flow of a high C s thixotropic fluid. A thixotropic fluid is a solid gel-like substance when at rest, but liquefies when agitated. The precise definition of thixotropy is a fluid which undergoes a decreasing apparent viscosity (i.e. reduced shear stress) when exposed to a constant rate of shear (i.e. du/dy) (Chhabra and Richardson 1999). Thus, viscosity is time-dependent. Mud suspensions tend to display thixotropy (Figure 7).Figure 7. Source: Chhabra and Richardson (1999)Chanson utilized a model by Coussot et al. (2002) for the viscosity of a thixotropic fluid:()n o a λµµ+×= whereλαθλ×∂∂×−=∂∂yV t 1 and the four terms µo , n, θ, and α are constants for a given fluid. Note that the viscosity in this model is time dependent. In general , numerical modelling of non-Newtonian fluids involves defining a relation that describes the viscosity of the fluid as a function of the fluid properties and flow (particularly du/dy). This equation must then be included in the set of equations to be solved. References Chanson, H., Jarny, S., and Coussot, P. (2006). "Dam break wave of thixotropic fluid." J. Hydraulic Eng., 132(3), 280-293. Chhabra, R., and Richardson, J. (1999). Non-Newtonian Flow in the Process Industries: Fundamentals and Engineering Applications , Butterworth Heinemann, Oxford. Daugherty, R. L., Franzini, J. B., and Finnemore, E. J. (1985). Fluid Mechanics with Engineering Applications, Eighth Edition , McGraw-Hill Book Company, New York. Julien, P. Y., and Lan, Y. (1991). "Rheology of hyperconcentrations." J. Hydraulic Eng., 117(3), 346-353. O'Brien, J., and Julien, P. (1988). "Laboratory analysis of mudflow properties." J. Hydraulic Eng., 114(8), 877-887.。