01 CONFIGURING OF SUPPLY CHAIN NETWORKS BASED ON CONSTRAINT SATISFACTION, GENETIC AND FUZZY

- 格式:pdf

- 大小:285.73 KB

- 文档页数:10

供应链关系英语作文下载温馨提示:该文档是我店铺精心编制而成,希望大家下载以后,能够帮助大家解决实际的问题。

文档下载后可定制随意修改,请根据实际需要进行相应的调整和使用,谢谢!并且,本店铺为大家提供各种各样类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,如想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by theeditor. I hope that after you download them,they can help yousolve practical problems. The document can be customized andmodified after downloading,please adjust and use it according toactual needs, thank you!In addition, our shop provides you with various types ofpractical materials,such as educational essays, diaryappreciation,sentence excerpts,ancient poems,classic articles,topic composition,work summary,word parsing,copyexcerpts,other materials and so on,want to know different data formats andwriting methods,please pay attention!Supply chain relationships are super important. It'slike a web that connects everything. Suppliers, manufacturers, distributors, and customers they all depend on each other. Without a good supply chain, things can get really messed up.In a supply chain, communication is key. Everyone needs to be in the loop. If there's a problem at one end, it can cause a ripple effect throughout. It's like a domino effect.And trust is crucial too. If you don't trust your suppliers or partners, it can lead to all sorts of issues. You need to be able to rely on them to do their job right.Then there's the issue of efficiency. You want the supply chain to move smoothly and quickly. Any delays or bottlenecks can cost time and money. It's all about keeping things flowing.Sometimes there are unexpected challenges. Like a natural disaster or a sudden change in the market. You have to be able to adapt and adjust quickly to keep the supply chain going.。

Supply Chain Management, 5e (Chopra/Meindl)Chapter 5 Network Design in the Supply Chain5.1 True/False Questions1) Supply chain network design decisions include the location of manufacturing, storage, or transportation-related facilities and the allocation of capacity and roles to each facility. Answer: TRUEDiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainAACSB: Analytic SkillsLearning Outcome: Compare common approaches to supply chain design2) Decisions concerning the role of each facility are significant because they determine the amount of rigidity the supply chain has in changing the way it meets demand.Answer: FALSEDiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainAACSB: Analytic SkillsLearning Outcome: Compare common approaches to supply chain design3) Facility location decisions have a long-term impact on a supply chain's performance because it is cost effective to shut down a facility or move it to a different location.Answer: FALSEDiff: 1Topic: 5.1 The Role of Network Design in the Supply ChainAACSB: Analytic SkillsLearning Outcome: Compare common approaches to supply chain design4) Capacity allocation decisions have a significant impact on supply chain performance because they tend to stay in place for several years.Answer: TRUEDiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainAACSB: Analytic SkillsLearning Outcome: Compare common approaches to supply chain design5) The allocation of supply sources and markets to facilities has a significant impact on performance because it affects total production, inventory, and transportation costs incurred by the supply chain to satisfy customer demand.Answer: TRUEDiff: 1Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design6) The allocation of supply sources and markets to facilities does not need to be reconsidered ona regular basis so that the allocation can be changed as market conditions or plant capacities change.Answer: TRUEDiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design7) Network design decisions have a significant impact on performance because they determine the supply chain configuration and set constraints within which inventory, transportation, and information can be used to either decrease supply chain cost or increase responsiveness. Answer: TRUEDiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design8) Firms focusing on cost leadership tend to find the lowest cost location for their manufacturing facilities, but only if that means locating very far from the markets they serve.Answer: FALSEDiff: 1Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design9) If production technology displays significant economies of scale, many local locations are the most effective.Answer: FALSEDiff: 2Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design10) If facilities have lower fixed costs, many local facilities are preferred because this helps lower transportation costs.Answer: TRUEDiff: 2Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design11) If the production technology is very inflexible and product requirements vary from one country to another, a firm has to set up local facilities to serve the market in each country. Answer: TRUEDiff: 3Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design12) If the technology is flexible, it becomes more difficult to consolidate manufacturing in a few large facilities.Answer: FALSEDiff: 3Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design13) Tariffs have a minor influence on location decisions within a supply chain.Answer: FALSEDiff: 2Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design14) High tariffs lead to more production locations within a supply chain network, with each location having a lower allocated capacity.Answer: TRUEDiff: 3Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design15) When designing supply chain networks, companies must build appropriate flexibility to help counter fluctuations in exchange rates and demand across different countries.Answer: TRUEDiff: 2Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design16) Inventory and facility costs increase as the number of facilities in a supply chain increase. Answer: TRUEDiff: 2Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design17) Transportation costs increase as the number of facilities is increased.Answer: FALSEDiff: 2Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design18) A firm may increase the number of facilities beyond the point that minimizes total logistics cost to improve the response time to its customers.Answer: TRUEDiff: 1Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design19) When faced with a network design decision, the goal of a manager is to design a network that minimizes the firm's costs while satisfying customer needs in terms of demand and responsiveness.Answer: FALSEDiff: 3Topic: 5.3 Framework for Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design20) The supply chain network is designed to maximize total profits, taking into account the expected margin and demand in each market, various logistics and facility costs, and the taxes and tariffs at each location.Answer: TRUEDiff: 1Topic: 5.3 Framework for Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design21) Decisions concerning the role of each facility are significant because they determine the amount of flexibility the supply chain has in changing the way it meets demand.Answer: TRUEDiff: 1Topic: 5.1 The Role of Network Design in the Supply ChainAACSB: Analytic SkillsLearning Outcome: Compare common approaches to supply chain design22) Network design decisions have a significant impact on performance because they determine the supply chain configuration and set constraints within which the other supply chain drivers can be used either to decrease supply chain cost or to increase responsiveness.Answer: TRUEDiff: 1Topic: 5.1 The Role of Network Design in the Supply ChainAACSB: Analytic SkillsLearning Outcome: Compare common approaches to supply chain design23) If facilities have higher fixed costs, many local facilities are preferred because this helps lower transportation costs.Answer: FALSEDiff: 1Topic: 5.2 Factors Influencing Network Design DecisionsAACSB: Analytic SkillsLearning Outcome: Compare common approaches to supply chain design5.2 Multiple Choice Questions1) Supply chain network design decisions includeA) only the location of manufacturing, storage, or transportation-related facilities.B) only the allocation of capacity and roles to each facility.C) both the location of manufacturing, storage, or transportation-related facilities and the allocation of capacity and roles to each facility.D) neither the location of manufacturing, storage, or transportation-related facilities nor the allocation of capacity and roles to each facility.E) none of the aboveAnswer: CDiff: 1Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design2) Supply chain network design decisions classified as facility role are concerned withA) what processes are performed at each facility.B) where facilities should be located.C) how much capacity should be allocated to each facility.D) what markets each facility should serve and which supply sources should feed each facility.E) none of the aboveAnswer: ADiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design3) Supply chain network design decisions classified as facility location are concerned withA) what processes are performed at each facility.B) where facilities should be located.C) how much capacity should be allocated to each facility.D) what markets each facility should serve and which supply sources should feed each facility.E) none of the aboveAnswer: BDiff: 1Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design4) Supply chain network design decisions classified as capacity allocation are concerned withA) what processes are performed at each facility.B) where facilities should be located.C) how much capacity should be allocated to each facility.D) what markets each facility should serve and which supply sources should feed each facility.E) none of the aboveAnswer: CDiff: 1Topic: 5.1 The Role of Network Design in the Supply Chain5) Supply chain network design decisions classified as market and supply allocation are concerned withA) what processes are performed at each facility.B) where facilities should be located.C) how much capacity should be allocated to each facility.D) what markets each facility should serve and which supply sources should feed each facility.E) none of the aboveAnswer: DDiff: 1Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design6) Decisions concerning the role of each facility are significant becauseA) they determine the amount of flexibility the supply chain has in demanding change.B) they determine the amount of flexibility the supply chain has in changing the way it meets demand.C) they determine the amount of capacity the supply chain has in changing the way it meets demand.D) they determine the amount of inventory the supply chain has in demanding change.E) None of the above are true.Answer: BDiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design7) Facility location decisions have a long-term impact on a supply chain's performance becauseA) it is very expensive to shut down a facility or move it to a different location.B) it is not expensive to shut down a facility or move it to a different location.C) it is advisable to shut down a facility or move it to a different location.D) it is cost effective to shut down a facility or move it to a different location.E) none of the aboveAnswer: ADiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design8) Capacity allocation decisions have a significant impact on supply chain performance becauseA) capacity decisions tend to be permanent.B) capacity decisions tend to be changed frequently.C) capacity decisions do not tend to stay in place for several years.D) capacity decisions tend to stay in place for several years.E) none of the aboveAnswer: DDiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design9) Allocating too much capacity to a location results inA) permanent damage.B) poor utilization, and as a result, higher costs.C) high utilization, and as a result, higher costs.D) poor utilization, and as a result, lower costs.E) high utilization, and as a result, lower costs.Answer: BDiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design10) Allocating too little capacity results inA) temporary damage.B) good responsiveness if demand is not satisfied or low cost if demand is filled from a distant facility.C) good responsiveness if demand is not satisfied or high cost if demand is filled from a distant facility.D) poor responsiveness if demand is not satisfied or low cost if demand is filled from a distant facility.E) poor responsiveness if demand is not satisfied or high cost if demand is filled from a distant facility.Answer: EDiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design11) The allocation of supply sources and markets to facilities has a significant impact on performance becauseA) it cannot affect total production, inventory, and transportation costs incurred by the supply chain to satisfy customer demand.B) it cannot affect customer demand.C) it affects total production, inventory, and transportation costs incurred by the supply chain to satisfy customer demand.D) it cannot satisfy customer demand.E) none of the aboveAnswer: CDiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design12) The allocation of supply sources and markets to facilities should be reconsidered on a regular basis so thatA) the allocation can be held constant as market conditions or plant capacities expand.B) the allocation can be changed as market conditions or plant capacities stagnate.C) the allocation can be held constant as market conditions or plant capacities change.D) the allocation can be changed as market conditions or plant capacities change.E) none of the aboveAnswer: DDiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design13) Network design decisions have a significant impact on performance because theyA) determine the supply chain configuration.B) determine the supply chain conflagration.C) set constraints within which inventory, transportation, and information can be used to either decrease supply chain cost or increase responsiveness.D) set constraints within which inventory, transportation, and information can be used to either increase supply chain cost or decrease responsiveness.E) A and C onlyAnswer: EDiff: 3Topic: 5.1 The Role of Network Design in the Supply Chain14) Customer order entry isA) the point in time when the customer has access to choices and makes a decision regarding a purchase.B) the customer informing the retailer of what they want to purchase and the retailer allocating product to the customer.C) the process where product is prepared and sent to the customer.D) the process where the customer receives the product and takes ownership.E) none of the aboveAnswer: BDiff: 2Topic: 5.1 The Role of Network Design in the Supply ChainLearning Outcome: Compare common approaches to supply chain design15) Which of the following is not a factor influencing network design decisions in supply chains?A) Strategic factorsB) Tactical factorsC) Macroeconomic factorsD) Political factorsE) Infrastructure factorsAnswer: BDiff: 2Topic: 5.1 The Role of Network Design in the Supply Chain16) Firms focusing on cost leadership tend toA) locate facilities close to the market they serve.B) locate facilities very far from the market they serve.C) find the lowest cost location for their manufacturing facilities.D) select a high-cost location to be able to react quickly.E) none of the aboveAnswer: CDiff: 2Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design17) Firms focusing on responsiveness tend toA) locate facilities close to the market they serve.B) locate facilities very far from the market they serve.C) find the lowest cost location for their manufacturing facilities.D) select a high-cost location to be able to react slowly.E) none of the aboveAnswer: ADiff: 2Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design18) Which of the following is not one of Kasra Ferdows' classifications of possible strategic roles for various facilities in a global supply chain network?A) Offpost facilityB) Source facilityC) Server facilityD) Contributor facilityE) Outpost facilityAnswer: ADiff: 2Topic: 5.2 Factors Influencing Network Design Decisions19) A facility that serves the role of being a low-cost supply source for markets located outside the country where the facility is located isA) an offshore facility.B) a source facility.C) a server facility.D) a contributor facility.E) an outpost facility.Answer: ADiff: 2Topic: 5.2 Factors Influencing Network Design Decisions20) A facility that also has low cost as its primary objective, but its strategic role is broader than that of an offshore facility isA) an offshore facility.B) a source facility.C) a server facility.D) a contributor facility.E) an outpost facility.Answer: BDiff: 2Topic: 5.2 Factors Influencing Network Design Decisions21) A facility built because of tax incentives, local content requirement, tariff barriers, or high logistics cost to supply the region from elsewhere with the objective to supply the market where it is located isA) an offshore facility.B) a source facility.C) a server facility.D) a contributor facility.E) an outpost facility.Answer: CDiff: 2Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design22) A facility located primarily to obtain access to knowledge or skills that may exist within a certain region isA) an offshore facility.B) a source facility.C) a server facility.D) a contributor facility.E) an outpost facility.Answer: EDiff: 2Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design23) A facility that serves the market where it is located but also assumes responsibility for product customization, process improvements, product modifications, or product development isA) an offshore facility.B) a source facility.C) a server facility.D) a contributor facility.E) an outpost facility.Answer: DDiff: 2Topic: 5.2 Factors Influencing Network Design Decisions24) A facility that creates new products, processes, and technologies for the entire network isA) an offshore facility.B) a source facility.C) a server facility.D) a lead facility.E) an outpost facility.Answer: DDiff: 2Topic: 5.2 Factors Influencing Network Design Decisions25) Production technology displays significant economies of scale,A) many high-capacity locations are the most effective.B) few high-capacity locations are the most effective.C) few high-capacity locations are the least effective.D) few low-capacity locations are the most effective.E) few low-capacity locations are the least effective.Answer: BDiff: 2Topic: 5.2 Factors Influencing Network Design Decisions26) If facilities have lower fixed costs,A) a few high-capacity facilities are preferred because this helps lower transportation costs.B) a few local facilities are preferred because this helps lower transportation costs.C) many high-capacity facilities are preferred because this helps lower transportation costs.D) many local facilities are preferred because this helps lower transportation costs.E) one central facility is preferred because this helps lower transportation costs.Answer: DDiff: 2Topic: 5.2 Factors Influencing Network Design Decisions27) If the production technology is very inflexible and product requirements vary from one country to another, a firm has to set upA) local facilities to serve the market in each country.B) a few high-capacity facilities to serve the market in each country.C) many local facilities because this helps lower transportation costs.D) a few high-capacity facilities because this helps lower transportation costs.E) many high-capacity facilities because this helps lower transportation costs.Answer: ADiff: 3Topic: 5.2 Factors Influencing Network Design Decisions28) If the technology is flexible,A) it becomes more difficult to consolidate manufacturing in a few large facilities.B) it becomes more difficult to distribute manufacturing in many local facilities.C) it becomes easier to consolidate manufacturing in a few large facilities.D) it becomes easier to consolidate manufacturing in many local facilities.E) the firm should have one central facility.Answer: CDiff: 3Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design29) Duties that must be paid when products and/or equipment are moved across international, state, or city boundaries are referred to asA) taxes.B) tax incentives.C) tariffs.D) incentives.E) none of the aboveAnswer: CDiff: 2Topic: 5.2 Factors Influencing Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design30) If a country has very high tariffs,A) companies either do not serve the local market or set up manufacturing plants within the country to save on duties.B) companies do not serve the local market.C) companies set up manufacturing plants within the country to save on duties.D) companies will not serve the local market or set up manufacturing plants within the country to save on duties.E) companies will serve the local market by setting up regional manufacturing plants. Answer: ADiff: 2Topic: 5.2 Factors Influencing Network Design Decisions31) Developing countries often create free trade zones whereA) duties and tariffs are imposed as long as production is used primarily for export.B) duties and tariffs are imposed as long as production is used primarily for import.C) duties and tariffs are relaxed as long as production is used primarily for export.D) duties and tariffs are relaxed as long as production is used primarily for import.E) duties and tariffs are increased as long as production is used primarily for export.Answer: CDiff: 1Topic: 5.2 Factors Influencing Network Design Decisions32) Building some over-capacity in the supply chain network and making the capacity flexible allows a firm to alter production flows within the supply chain toA) produce less in facilities that have a lower cost based on current exchange rates.B) produce more in facilities that have a lower cost based on current exchange rates.C) produce more in facilities that have a higher cost based on current exchange rates.D) produce less in facilities that have the same cost based on current exchange rates.E) None of the above are accurate.Answer: BDiff: 2Topic: 5.2 Factors Influencing Network Design Decisions33) Total logistics costs are a sum of theA) inventory and facility costs.B) transportation and facility costs.C) inventory and transportation costs.D) inventory, transportation, and facility costs.E) inventory, transportation, and faculty costs.Answer: DDiff: 2Topic: 5.2 Factors Influencing Network Design Decisions34) The facilities in a supply chain network mustA) at least maximize total logistics cost.B) at least equal the number that maximizes total logistics cost.C) at least equal the number that minimizes total logistics cost.D) at least minimize total logistics cost.E) none of the aboveAnswer: CDiff: 1Topic: 5.2 Factors Influencing Network Design Decisions35) When faced with a network design decision, the goal of a manager is to design a network thatA) maximizes the firm's profits.B) minimizes the firm's costs.C) satisfies customer needs in terms of demand and responsiveness.D) maximizes the firm's profits while satisfying customer needs in terms of demand and responsiveness.E) none of the aboveAnswer: DDiff: 2Topic: 5.3 Framework for Network Design Decisions36) Which of the following is not a phase in the design of a global supply chain network?A) Define a supply chain strategyB) Define the regional facility configurationC) Select desirable sitesD) Location choicesE) Implement supply chain strategyAnswer: EDiff: 2Topic: 5.3 Framework for Network Design DecisionsLearning Outcome: Compare common approaches to supply chain design37) Which of the following is the first phase in the design of a global supply chain network?A) Define a supply chain strategyB) Define the regional facility configurationC) Select desirable sitesD) Location choicesE) Implement supply chain strategyAnswer: ADiff: 2Topic: 5.3 Framework for Network Design Decisions38) The objective of the first phase of network design is toA) maximize total profits, taking into account the expected margin and demand in each market.B) select a precise location and capacity allocation for each facility.C) select a set of desirable sites within each region where facilities are to be located.D) identify regions where facilities will be located, their potential roles, and their approximate capacity.E) specify what capabilities the supply chain network must have to support a firm's competitive strategy.Answer: EDiff: 3Topic: 5.3 Framework for Network Design Decisions39) The objective of the second phase of network design is toA) maximize total profits, taking into account the expected margin and demand in each market.B) select a precise location and capacity allocation for each facility.C) select a set of desirable sites within each region where facilities are to be located.D) identify regions where facilities will be located, their potential roles, and their approximate capacity.E) specify what capabilities the supply chain network must have to support a firm's competitive strategy.Answer: DDiff: 3Topic: 5.3 Framework for Network Design Decisions40) The objective of the third phase of network design is toA) maximize total profits, taking into account the expected margin and demand in each market.B) select a precise location and capacity allocation for each facility.C) select a set of desirable sites within each region where facilities are to be located.D) identify regions where facilities will be located, their potential roles, and their approximate capacity.E) specify what capabilities the supply chain network must have to support a firm's competitive strategy.Answer: CDiff: 3Topic: 5.3 Framework for Network Design Decisions41) It is very important that long-term consequences be thought through when making facility decisions, becauseA) network designers can use this fact to influence the role of the new facility and the focus of people working there.B) facilities last a long time and have an enduring impact on a firm's performance.C) it is astounding how often tax incentives drive the choice of location.D) the location of a facility has a significant impact on the extent and form of communication that develops in the supply chain network.E) the quality of life at selected facility locations has a significant impact on performance. Answer: BDiff: 3Topic: 5.3 Framework for Network Design Decisions42) The implications of culture should not be glossed over becauseA) tariffs and tax incentives should be carefully considered.B) facilities last a long time and have an enduring impact on a firm's performance.C) it is astounding how often tax incentives drive the choice of location.D) the location of a facility has a significant impact on the extent and form of communication that develops in the supply chain network.E) the quality of life at selected facility locations has a significant impact on performance. Answer: ADiff: 3Topic: 5.5 Making Network Design Decisions in Practice。

Logistics and Supply ChainManagement Organizations nowadays have become more conscious about staying ahead of the competition and gaining an edge in the market. Even in the most competitive market, companies, in order to ensure sustainability, in the long run, need to integrate its business process and operations so as to reach their target goals. Logistics and supply chain management is one of the keys that open the gate of success for any business. This article presents an overview of logistics management and supply chain management. We will help you in giving moredetails on Logistics and Supply Chain Management.Logistics and supply change management is used by the organizations to plan and control the activities and operations as well as coordinate amid the companies either in the same or adjacent industries. Though both these terms at times are used interchangeably, however, the supply chain management is an overall concept that connects the numerous processes of an organization to attain competitive advantages in the industry.On the other hand, logistic is the movement as well as the flow of products, services together with information within the supply chain. The logistics focus on the activities of the same company whereas the supply chain has widened focus due to the involvement of multiple enterprises such as manufacturers, suppliers as well as retailers.Logistics ManagementThe logistics work primarily for the requirement of the customers while supply chain management aims towards attaining competitive advantage for an organization. Therefore, it canbe said that logistic management is a crucial element of supply chain management. It enhances the aspects of the strategy, planning as well as implementation, thereby reducing the cost to provide maximum satisfaction to the customers.The role of logistics and supply chain management is to ensure that the product is delivered to the right customer at the right price as well as at the right time without any discrepancy or delay. Besides this, it involves activities such as transportation, warehousing,controlling stock and monitoring the inflow and outflow of goods from the organization.Supply Chain ManagementSupply chain engages activities such as operations and procurements which are necessary for efficient and effective running of business. It plays a vital role in the success of the company as it aims to accomplish the needs and demands, driving outstanding values from customers, enhancing the responsiveness of organization, building network resiliency and facilitating financial success.Thus, logistic management is an important part of the supply chain management as it involves carrying out of management in addition to information from the point of origin to the consumption-point.Planning and Controlling ActivitiesPlanning and controlling activities are among the most important functions of logistics and supply chain management.Activities and objectives are created under planning and implementing the same effectively under control. These two paradigms works forreconciliations between what is needed by the market and what can actually be delivered by the operation resources.Supply chain management involves the process that helps in the movement of the raw material from the beginning of the production till the deliverance of the goods to the end users. It has been found that in various companies, operational supply chain decisions are made more than a number of times affecting how products could be manufactured or developed, moved as well as sold.In an attempt to meet the challenges in delivering the goods to customers, companies have adopted automated logistics and supply chain management processes for efficient and significant impact on bottom lines.In order to attain a better profit margin, there are a few other important benefits of adopting an appropriate logistics and supply chain management technique or strategy, both into the factory, the warehouse and distribution channels. The intricacies of the supply chain vary with the business along with the obscurity and the quality of items being produced.Functioning of the Logistics and Supply ChainIt is the customers who start the chain of events while they make purchase decisions that have been offered by any company for sale. Logistics and supply chain management system not only enhances the service quality but also amplify productivity through the extraction of wastes.One of the most important things in the logistics and supply chain management process is to ensure that each activity adds value for the end users. If the product needs to be produced, the sales orders must include a prerequisite that is required to be fulfilled with the use of productionfunction. We will provide you proper guidance on Logistics and Supply Chain Management.PlanningThe planning department makes a production plan that includes the manufacturing details of the product in accordance with the demand of the customer and their orders. To manufacture the products the company then purchases the raw material.The planning department works at the administrative level of the organization. This department refers the project team who createthe master plan as well as sector plan along with many other planning efforts that works as the guiding information for the organization to help regulate those plans.PurchasingThe purchasing department receives a list of raw materials and services required by the production department to complete the customer’s orders. The purchasing process is considered crucial as it works as a tool to identify the requirements of the customers, evaluate the needs efficiently, identify thesuppliers, make sure payment occurs effectively and drive improvement continuously.The raw material is received from the suppliers; it is then checked for quality and accuracy and later moved into the warehouse.Inventory ManagementThe inventory management is important because it resists stock-outs, handle multiple locations and ensure appropriate accounting. Inventory is a term related to the stocking of the materials and represents those various levels from raw material to finished products. Based onthe production plan, the raw materials are moved to the production area.These raw materials are used to manufacture the finished product and then sent to the warehouse and stocked for shipping. Implementing a lean logistics and supply chain management in the production process is a key element that helps in developing long-term value and relationship with customers as well as increasing the overall organizational performance.ProductionThe production department in a company is responsible to handle a group of activities that involves the manufacturing process of the goods. This department is the largest group within the organization. It is responsible for transforming input into the final output using a set of the process needed for production.The production manager is responsible for ensuring that the raw material is obtained and transformed into finished good in an efficient way. From there the finished good is sent to the warehouse. The warehouse is considered as the key function as well as a destination in theoverall planning and implementation of supply chain management. It aims to receive and distribute the goods or materials. For many companies, it is concerned as a strategic function.PackagingOn the other hand, the packaging is also a key function in logistics and supply chain management. It is used for protecting finished good from damaging and allows for effective distribution of the products to the appropriate customers. It plays the role of product prompteras it communicates to the customers the information with regard to the goods.For a successful logistics and supply chain management, the packaging system is required to be connected with the activities of marketing, production as well as logistics. As soon as the finished products arrive in the warehouse, then the shipping department settles on the most competent methods to deliver the products to the right customers before or on the date as specified.This is the overall functioning of the logistics and supply chain management. It requires a lot ofefforts from the organization’s end to maintain a balance between the supply and demand of any product or service.A number of companies have segmented their logistics management streamlined it with the supply chain so as to enhance customer relationship together with lowering down their huge operational costs which might otherwise create a burden on the management. Both logistics and supply chain management are interlinked and so, it will not be wrong saying that one process cannot exist devoid of the other.We will now explain you about Inbound and Outbound Logistics.Inbound and Outbound LogisticsLogistics and Supply Chain Management enhances various activities such as inventory handling, as well as the packaging process of the products, transportation, and warehousing, delivery to the customers.There is no doubt that the smooth functioning of the organizations depends on the efficient management of supply and demand which in turn have a significant impact the overall imageand reputation of the organization in the eyes of the customers. In this era of globalization, the Logistics and Supply Change Management has become the most important tool to gain the competitive advantage of global market opportunities.Inbound operationsThe managers of inbound logistics as well as of outbound logistics play a vital role in the Logistics and Supply Chain Management. The inflow of the resources that a company needs to produce its products or render services is managed by the inbound logistics managers.They are responsible for building a relationship among the suppliers as well as retailers.Besides this they manage activities that are necessary for the manufacturing of products such as accessing raw materials, negotiating the price of materials and arranging fast delivery of the products that customers have ordered whereas the manager of outbound logistics deals with two issues including transportation and storage of the goods. They are responsible to implement the cost-saving strategies for the company along with maintaining the orders of the customers.Outbound operationsTo ensure that the good that is produced remains impeccable and safe to use, these managers use warehousing technique. The products may need to be transported as per the imminent demand of the customers and this makes the transportation a critical point which is affected by a number of factors such as a change in the price of fuel or delay delivery. So the outbound logistics manager needs to deal with factors that lead to proper transportation of the ordered products.The traditional organization used to treat them separately but at present, there is a certain value added functionalities associated with them due to their interdependency. In simple words, it is said that the Logistics and Supply Change Management helps in facilitating the manufacturing and marketing operations in an organization.Challenges in the Logistics and Supply Change ManagementAt present, in all the organization Logistics and Supply Change Management plays a vital role in the smooth working and success of a company.It represents various management functions in the organization. Either big companies or small firms all have somehow ort the other adopted effective Supply Chain Management techniques so as to meet their target objectives. However, in the era of globalization, almost all companies all around the world face some challenges in their management system.Though appropriate Logistics and Supply Chain Management provides the companies, especially manufacturing units’ competitive advantage as well as a business advantage;however, there are challenges too in the way of implementation of the system.Due to the increase in the market competition, the Logistics and Supply Chain Management System is facing an increasing number of challenges in the way of creating and running the management system efficiently and effectively. Globalization, consumers changing preferences, market growth, extreme work stress, growing demand of customers are among the major challenges the organizations face in the smooth running of the logistics management.Processing Enormous Amount of Data and InformationProduction of goods goes in a long process and managers are required to maintain a large amount of the details on daily basis. Due to globalization, the information about the suppliers as well as customers from the different location needs to be recorded appropriately and accurately.The managers’ needs to ensure the details about raw materials provided; security of the good, packaging, warehousing, shipment, labor agreement, taxes and pricing of the materialsand many others work’s details. These involve process that are not only complex but also time consuming which as a result leads to the distractions and stress.The long process sometimes also becomes tedious that diverts the mind of the managers from ensuring accuracy of the details.Details with regard to raw materials that need to be obtained from the retailers, suppliers as well as partners even including the customers are in both structures as well as in unstructured format which makes it difficult for the managers to identify, evaluate and produce information fromsuch disorganized pieces of detail. This makes Logistics and Supply Chain Management more complex.Manpower ManagementManpower management is one of the main hidden responsibilities of the managers in the organizations. It is one of the toughest tasks for the inbound logistic managers. They are responsible to maintain human approach and relationship among the workforce and simultaneously with aim to attain more success.Well! it is not as simple as it sounds, rather it worsens the work environment when the employees or staffs at remote locations are not managed appropriately.Offering Segmented,Customized ServicesThe logistics management involves the activities such as packaging of goods in a proper and attractive way and transportation of good to the right customer as per their demand.The organization needs to ensure that it must meet the demand of the local as well international standard of manufacturing,handling, and packaging as well as shipping of the products. Besides this, we have also heard about the changing trends in customers taste and preference. That too creates a burden on the big organization to deal with these demands.The organizations are continuously trying their best to fulfill the necessity of the customer and providing them maximum satisfaction but this is not as easy to do as to hear. Company has to keep enhancing the features and update itself with the new technologies for manufacturing and delivering the goods and render services associated with it according to the preferencesof the customers. Again a complex situation arises for the managers while ensuring appropriate implementation of logistics and supply chain management.Cutting Transportation CostIt is for sure that companies try to deliver the orders placed by the customers on time or before the expected time. Nevertheless transporting the goods to the customers living in the different geographical location is not easy for the company as it involves the various factors, particularly the escalation in freight charges or even a minor increase in the price of fuel. This isanother challenge for companies in the adoption of cost effective logistics and supply chain management.Besides this, companies also face major threat while handling their cost control protocol. Increase in the operating cost also causes extreme pressure on the financial managers as they have to update themselves with new technologies, deal with the increasing labor wages for the global rate production as well as with the increasing commodity prices. The managements often face problems in cost saving for the organization.ConclusionGetting enormous advantages from the logistics and supply chain management is the desire of every company as it involves huge investments so that they can reap the benefits. It is also true that each stage of the supply chain delivers food from the origin (farm) to your dinner table. Supply chains combine integrated logistics, product innovation strategy, and production approach along with forecasting demand. Besides this, the process that is followed in the supply chain management will put the manufacturers and dealers in a great positionthat enables them, to foresee or predict demand in addition to making their moves or planning their strategies accordingly.Moreover, when the business is competent to pool resources better or capable of streamlining the whole production as well as distribution processes, it directly improves the bottom line along with enhancing the productivity and the overall output. Thus, the entrepreneurs and the managers along with the entire team can stay ahead of the competition and enjoy greater profits as well.Therefore, it is essential that companies should understand the implication and importance of a well-organized logistics and supply chain management as well as hire managers to streamline the process that enables the organization to attain productive results.。

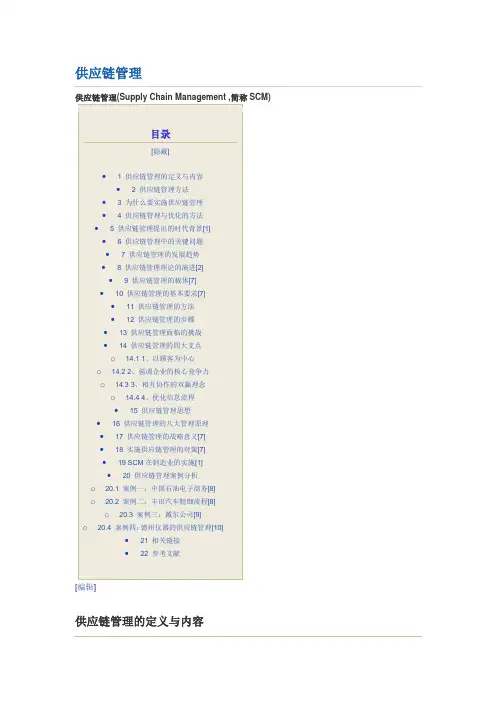

供应链管理供应链管理(Supply Chain Management ,简称SCM)目录[隐藏]∙ 1 供应链管理的定义与内容∙ 2 供应链管理方法∙ 3 为什么要实施供应链管理∙ 4 供应链管理与优化的方法∙ 5 供应链管理提出的时代背景[1]∙ 6 供应链管理中的关键问题∙7 供应链管理的发展趋势∙8 供应链管理理论的演进[2]∙9 供应链管理的载体[7]∙10 供应链管理的基本要求[7]∙11 供应链管理的方法∙12 供应链管理的步骤∙13 供应链管理面临的挑战∙14 供应链管理的四大支点o14.1 1、以顾客为中心o14.2 2、强调企业的核心竟争力o14.3 3、相互协作的双赢理念o14.4 4、优化信息流程∙15 供应链管理思想∙16 供应链管理的八大管理原理∙17 供应链管理的战略意义[7]∙18 实施供应链管理的对策[7]∙19 SCM在制造业的实施[1]∙20 供应链管理案例分析o20.1 案例一:中国石油电子商务[8]o20.2 案例二:丰田汽车精细流程[8]o20.3 案例三:戴尔公司[9]o20.4 案例四:德州仪器的供应链管理[10]∙21 相关链接∙22 参考文献[编辑]供应链管理的定义与内容供应链管理(Supply Chain Management ,简称SCM):就是指在满足一定的客户服务水平的条件下,为了使整个供应链系统成本达到最小而把供应商、制造商、仓库、配送中心和渠道商等有效地组织在一起来进行的产品制造、转运、分销及销售的管理方法。

供应链管理包括计划、采购、制造、配送、退货五大基本内容。

计划:这是SCM的策略性部分。

你需要有一个策略来管理所有的资源,以满足客户对你的产品的需求。

好的计划是建立一系列的方法监控供应链,使它能够有效、低成本地为顾客递送高质量和高价值的产品或服务。

采购:选择能为你的产品和服务提供货品和服务的供应商,和供应商建立一套定价、配送和付款流程并创造方法监控和改善管理,并把对供应商提供的货品和服务的管理流程结合起来,包括提货、核实货单、转送货物到你的制造部门并批准对供应商的付款等。

什么是供应链物流英语作文Supply chain logistics is the backbone of modern commerce, connecting manufacturers, suppliers, retailers, and consumers in a seamless network of transportation, storage, and distribution.Efficient supply chain management requires coordination and collaboration among multiple stakeholders, including suppliers, manufacturers, distributors, and retailers, to ensure timely delivery of goods to meet customer demand.Transportation plays a crucial role in supply chain logistics, with various modes such as trucks, trains, ships, and planes used to move goods from one point to another. Effective transportation management is essential for optimizing delivery schedules and reducing costs.Inventory management is another key aspect of supply chain logistics, involving the monitoring and control of stock levels to prevent stockouts or overstock situations.By implementing inventory management best practices, companies can improve efficiency and reduce carrying costs.Warehousing is an integral part of supply chain logistics, providing storage facilities for goods before they are distributed to their final destination. Proper warehouse management is essential for ensuring quick and accurate order fulfillment.Technology plays a vital role in modern supply chain logistics, with tools such as RFID, GPS, and WMS used to track and monitor goods throughout the supply chain. By leveraging technology, companies can improve visibility, traceability, and efficiency in their operations.Supply chain logistics is a dynamic and evolving field, with constant changes in consumer preferences, market trends, and technological advancements driving the need for continuous improvement and innovation. Companies that adapt to these changes and embrace new technologies will gain a competitive edge in the global marketplace.。

供应链相关知识英语作文Title: Understanding Supply Chain Management。

Supply chain management (SCM) plays a pivotal role in modern business operations, ensuring the seamless flow of goods and services from raw material suppliers to end consumers. In this essay, we will delve into the key concepts, challenges, and strategies involved in supply chain management.1. Definition of Supply Chain Management:Supply chain management encompasses the planning, procurement, production, logistics, and distribution processes involved in delivering products or services to customers. It involves coordinating various stakeholders, including suppliers, manufacturers, distributors, retailers, and customers, to optimize efficiency and meet customer demands.2. Key Components of Supply Chain Management:a. Procurement: This involves sourcing raw materials, components, or services from suppliers at the right price, quality, and quantity.b. Production: Once materials are procured, they are transformed into finished products through manufacturing processes.c. Logistics: Logistics involves the movement and storage of goods from production facilities to distribution centers and ultimately to customers.d. Distribution: Distribution entails delivering products to retailers or directly to end consumers through various channels, such as wholesalers, warehouses, or e-commerce platforms.e. Inventory Management: Effective inventory management ensures the right amount of stock is maintained to meet demand while minimizing excess inventory and associatedcosts.f. Information Systems: Information systems, such as Enterprise Resource Planning (ERP) systems and supply chain management software, facilitate communication and coordination among supply chain partners.3. Challenges in Supply Chain Management:a. Globalization: Managing supply chains across geographically dispersed locations introduces complexities related to transportation, customs regulations, andcultural differences.b. Supply Chain Disruptions: Events such as natural disasters, pandemics, or political unrest can disrupt the flow of goods and services, highlighting the importance of risk management and contingency planning.c. Demand Volatility: Fluctuations in customer demand can lead to inventory imbalances or stockouts, necessitating agile and responsive supply chain strategies.d. Supplier Reliability: Dependence on suppliers exposes organizations to risks such as supplier bankruptcies, quality issues, or supply shortages.e. Environmental Sustainability: Increasing pressure to reduce carbon footprint and adopt sustainable practices throughout the supply chain requires organizations to rethink sourcing, production, and distribution processes.4. Strategies for Effective Supply Chain Management:a. Collaboration: Foster collaboration and transparency among supply chain partners to improve communication, share information, and jointly address challenges.b. Inventory Optimization: Employ advanced forecasting techniques and inventory optimization models to minimize excess inventory while ensuring product availability.c. Risk Management: Develop risk mitigation strategies, such as dual sourcing, inventory buffers, or businesscontinuity plans, to mitigate the impact of supply chain disruptions.d. Technology Adoption: Embrace digital technologies such as IoT, blockchain, and artificial intelligence to enhance visibility, traceability, and efficiency across the supply chain.e. Sustainable Practices: Integrate environmental sustainability into supply chain operations by optimizing transportation routes, reducing packaging waste, and sourcing from eco-friendly suppliers.5. Conclusion:In conclusion, supply chain management is a multifaceted discipline that requires careful planning, coordination, and adaptation to navigate the complexities of today's global business environment. By understanding the key components, challenges, and strategies of supply chain management, organizations can enhance theircompetitiveness, resilience, and sustainability in an ever-evolving marketplace.。

supply chain英语作文Supply chain management (SCM) is a critical aspect of modern business operations. In today’s interconnected world, where companies operate in a global marketplace, the efficiency and effectiveness of the supply chain can determine the success or failure of a business. This essay explores the importance of supply chain management, its key components, and the benefits it brings to businesses.Supply chain management involves the coordination and management of all activities involved in sourcing, procurement, conversion, and logistics. It encompasses the planning and management of all activities involved in sourcing and procurement, conversion, and all logistics management activities. Importantly, it also includes coordination and collaboration with channel partners, which can be suppliers, intermediaries, third-party service providers, and customers. Inessence, SCM integrates supply and demand management within and across companies.1. Sourcing and ProcurementSourcing and procurement involve selecting suppliers that provide goods and services needed for production. Effective procurement strategies ensure that the materials are of high quality and cost-effective. Building strong relationships with suppliers is crucial to secure reliable and timely supplies, which can significantly impact production schedules and overall business efficiency.2. Manufacturing and ProductionThis component covers the transformation of raw materials into finished products. Efficient manufacturing processes are essential to maintain high productivity levels, reduce waste, and ensure the quality of the final product. Thisrequires meticulous planning and control, from scheduling production runs to maintaining machinery and equipment.3. Logistics and DistributionLogistics involves the transportation and storage of goods. It ensures that products are delivered to customers on time and in the right condition. Efficient logistics require a well-organized transportation network and effective inventory management to balance supply and demand. Warehousing also plays a critical role in logistics, providing storage solutions that help manage inventory levels and meet customer needs promptly.4. Demand Planning and ForecastingAccurate demand planning and forecasting are vital to avoid overproduction or underproduction. By predicting customer demand, businesses can better manage their inventory levels, reduce holding costs, and ensure that they meet customer needs without delay. Advanced analytical toolsand data management systems are often used to improve the accuracy of demand forecasts.5. Returns ManagementReturns management, or reverse logistics, deals with handling returned products. This includes processes for returning goods, restocking, refurbishing, and recycling. Efficient returns management can enhance customer satisfaction and recovery of value from returned products, thus contributing to overall supply chain efficiency.1. Cost ReductionOne of the primary benefits of effective supply chain management is cost reduction. By optimizing procurement, production, and logistics processes, businesses can reduce costs related to raw materials, production delays, transportation, and warehousing. Efficient supply chains also minimize the need forexcess inventory, which reduces holding costs and capital expenditure.2. Improved EfficiencyEffective SCM enhances the efficiency of business operations. Streamlined processes, improved coordination, and real-time data sharing among supply chain partners enable businesses to respond quickly to changes in demand and supply conditions. This agility leads to improved production schedules, faster delivery times, and better customer service.3. Enhanced Customer SatisfactionA well-managed supply chain ensures that products are available to customers when they need them. Timely delivery and high-quality products improve customer satisfaction and loyalty. Additionally, effective returns management processes ensure that any issues are resolved swiftly, further enhancing the customer experience.4. Risk MitigationEffective supply chain management helps businesses identify potential risks and develop strategies to mitigate them. By diversifying suppliers, maintaining safety stock, and developing contingency plans, companies can reduce the impact of disruptions such as natural disasters, supplier failures, or geopolitical issues. This resilience ensures business continuity and protects the company’s reputation.5. Competitive AdvantageIn today’s competitive business environment, a well-managed supply chain can provide a significant competitive advantage. Companies that can deliver products faster, more reliably, and at lower costs than their competitors are more likely to succeed. Efficient SCM allows businesses to respond swiftly to market changes, capitalize on new opportunities, and maintain a strong market position.In conclusion, supply chain management is a vital component of modern business operations. It encompasses a range of activities, from sourcing and procurement to logistics and distribution, all aimed at delivering products to customers efficiently and effectively. The benefits of effective SCM, including cost reduction, improved efficiency, enhanced customer satisfaction, risk mitigation, and competitive advantage, highlight its importance in achieving business success. As global markets continue to evolve, the role of supply chain management will only become more critical, making it essential for businesses to invest in optimizing their supply chain processes.。

供应链管理英文作文英文:Supply chain management is a crucial aspect of any business, as it involves the coordination and management of all activities involved in the production and delivery of goods to customers. Effective supply chain management can lead to increased efficiency, reduced costs, and improved customer satisfaction.One important component of supply chain management is inventory management. By keeping track of inventory levels and predicting demand, businesses can ensure that they have enough stock on hand to meet customer needs without overstocking and wasting resources. For example, a clothing retailer may use data analysis to predict which items will be popular during a certain season and order the appropriate amount of inventory to meet that demand.Another key aspect of supply chain management islogistics. This involves the transportation and storage of goods from the manufacturer to the end customer. Effective logistics management ensures that products are delivered on time and in good condition. For example, a foodmanufacturer may use temperature-controlled trucks to transport perishable goods to ensure that they arrive atthe grocery store in good condition.In addition to inventory management and logistics, supply chain management also involves supplier management. This includes selecting and managing suppliers to ensurethat they meet quality standards and can deliver goods on time. For example, a car manufacturer may work closely with a specific supplier to ensure that the components they receive meet their quality standards and are delivered on time to avoid production delays.Overall, effective supply chain management is essential for the success of any business. By managing inventory, logistics, and suppliers, businesses can improve efficiency, reduce costs, and provide better service to their customers.中文:供应链管理是任何企业的重要组成部分,它涉及到生产和交付商品给客户的所有活动的协调和管理。