Diffusion lengths of silicon solar cells from luminescence images

- 格式:pdf

- 大小:1.45 MB

- 文档页数:10

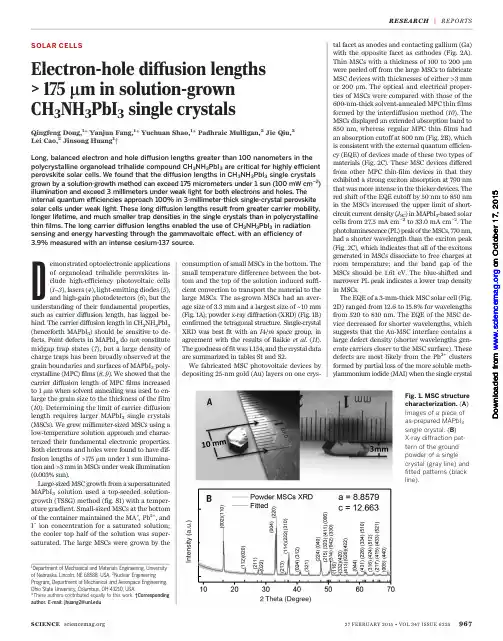

of organolead trihalide perovskites in-clude high-efficiency photovoltaic cells (1–3),lasers (4),light-emitting diodes (5),and high-gain photodetectors (6),but the understanding of their fundamental properties,such as carrier diffusion length,has lagged be-hind.The carrier diffusion length in CH 3NH 3PbI 3(henceforth MAPbI 3)should be sensitive to de-fects.Point defects in MAPbI 3do not constitute midgap trap states (7),but a large density of charge traps has been broadly observed at the grain boundaries and surfaces of MAPbI 3poly-crystalline (MPC)films (8,9).We showed that the carrier diffusion length of MPC films increased to 1m m when solvent annealing was used to en-large the grain size to the thickness of the film (10).Determining the limit of carrier diffusion length requires larger MAPbI 3single crystals (MSCs).We grew millimeter-sized MSCs using a low-temperature solution approach and charac-terized their fundamental electronic properties.Both electrons and holes were found to have dif-fusion lengths of >175m m under 1sun illumina-tion and >3mm in MSCs under weak illumination (0.003%sun).Large-sized MSC growth from a supersaturated MAPbI 3solution used a top-seeded solution-growth (TSSG)method (fig.S1)with a temper-ature gradient.Small-sized MSCs at the bottom of the container maintained the MA +,Pb 2+,and I –ion concentration for a saturated solution;the cooler top half of the solution was super-saturated.The large MSCs were grown by thesmall temperature difference between the bot-tom and the top of the solution induced suffi-cient convection to transport the material to the large MSCs.The as-grown MSCs had an aver-age size of 3.3mm and a largest size of ~10mm (Fig.1A);powder x-ray diffraction (XRD)(Fig.1B)confirmed the tetragonal structure.Single-crystal XRD was best fit with an I 4/m space group,in agreement with the results of Baikie et al .(11).The goodness of fit was 1.154,and the crystal data are summarized in tables S1and S2.We fabricated MSC photovoltaic devices by depositing 25-nm gold (Au)layers on one crys-tal facet as anodes and contacting gallium (Ga)with the opposite facet as cathodes (Fig.2A).Thin MSCs with a thickness of 100to 200m m were peeled off from the large MSCs to fabricate MSC devices with thicknesses of either >3mm or 200m m.The optical and electrical proper-ties of MSCs were compared with those of the 600-nm-thick solvent-annealed MPC thin films formed by the interdiffusion method (10).The MSCs displayed an extended absorption band to 850nm,whereas regular MPC thin films had an absorption cutoff at 800nm (Fig.2B),which is consistent with the external quantum efficien-cy (EQE)of devices made of these two types of materials (Fig.2C).These MSC devices differed from other MPC thin-film devices in that they exhibited a strong exciton absorption at 790nm that was more intense in the thicker devices.The red shift of the EQE cutoff by 50nm to 850nm in the MSCs increased the upper limit of short-circuit current density (J SC )in MAPbI 3-based solar cells from 27.5mA cm −2to 33.0mA cm −2.The photoluminescence (PL)peak of the MSCs,770nm,had a shorter wavelength than the exciton peak (Fig.2C),which indicates that all of the excitons generated in MSCs dissociate to free charges at room temperature;and the band gap of the MSCs should be 1.61eV.The blue-shifted and narrower PL peak indicates a lower trap density in MSCs.The EQE of a 3-mm-thick MSC solar cell (Fig.2D)ranged from 12.6to 15.8%for wavelengths from 520to 810nm.The EQE of the MSC de-vice decreased for shorter wavelengths,which suggests that the Au-MSC interface contains a large defect density (shorter wavelengths gen-erate carriers closer to the MSC surface).These defects are most likely from the Pb 2+clusters formed by partial loss of the more soluble meth-ylammonium iodide (MAI)when the single crystalSCIENCE 27FEBRUARY 2015•VOL 347ISSUE 62259671Department of Mechanical and Materials Engineering,University of Nebraska,Lincoln,NE 68588,USA.2Nuclear Engineering Program,Department of Mechanical and Aerospace Engineering,Ohio State University,Columbus,OH 43210,USA.*These authors contributed equally to this work.†Corresponding author.E-mail:jhuang2@Fig.1.MSC structure characterization.(A )Images of a piece of as-prepared MAPbI 3single crystal.(B )X-ray diffraction pat-tern of the ground powder of a single crystal (gray line)and fitted patterns (black line).RESEARCH |REPORTSo n O c t o b e r 17, 2015w w w .s c i e n c e m a g .o r g D o w n l o a d e d f r o mis removed from solution.Our recent density functional theory calculation verified that the Pb 2+clusters on the MAPbI 3surface tend to form charge traps (6).The internal quantum effici-ency (IQE)of the 3-mm MSC device (derived by dividing EQE by the transmittance of the Au electrode;see Fig.2D and fig.S2)was near unity (95T 7%).The electrons generated in the very thin pe-rovskite layer near the Au anode must traverse the whole crystal to be collected by the Ga cathode,indicating that the electron diffusion length in MSCs is greater than the crystal thick-ness (~3mm).We also replaced Ga by a semi-transparent Au (25nm)/C 60(25nm)layer as the cathode so that photogenerated charges would be located at the cathode side.Again,the value of J SC measured at 0.1%sun was comparable with incident light from both sides,which in-dicates that the hole diffusion length in MSCs is also longer than the MSC thickness.The dependence of responsivity (R )and J SC on light intensity (I L )for thick devices is sum-marized in Fig.2,E and F,respectively [see fig.S3for photocurrent density –voltage (J ph -V )curves].Under 1sun,the open-circuit voltage V oc was 0.62V,versus ~1.00V in optimized MPC thin-film devices,again indicating a strong charge recombination in the MSC devices under strong illumination.For thick MSC devices,R decreased from 35mA W −1to 0.19mA W −1when the in-tensity of white illuminated light increased from 0.003mW cm −2to 100mW cm −2because of in-creased charge recombination for higher I L .Fitting of J sc with I L as J sc ºI L b gave a value of b (recombination parameter)of 0.5T 0.01,which suggests that second-order charge recombina-tion dominated in the thick MSC devices for I L >0.003mW cm −2,as seen previously (12,13).Re-ducing the MSC thickness to 200m m recovered large R (Fig.2E)at 1sun and increased b to 0.88,which indicates that the carrier diffusion length of MSCs is near 200m m for 1sun illumination.We could characterize the carrier mobility m and carrier lifetime t r because the carrier diffu-sion length L D is determined by L D =(k B T m t r /e )1/2,where k B ,T ,and e are the Boltzmann constant,absolute temperature,and elementary charge,re-spectively.The device dark current (J D )was mea-sured to derive the trap density and carrier mobilities.The MSCs were sandwiched by two Au electrodes deposited by thermal evaporation to form hole-only devices.As shown in Fig.3A,the linear J D -V relation (green line)indicates an ohmic response at the low bias (<2.1V).A trap-filling process was identified by the marked in-crease of the current injection at a bias range of 2.1to 10.7V.The voltage at which all the traps are filled (trap-filled limit voltage V TFL )was deter-mined by the trap density (14):V TFL¼en t L 22ee 0ð1Þwhere L is the thickness of the MSCs,e (=32)is relative dielectric constant of MAPbI 3,and e 0is the vacuum permittivity.The trap density n t in MSCs was calculated to be 3.6×1010cm −3.Forfilms were also fabricated with PEDOT:PSS and Au as the hole injection electrodes (fig.S4).The calculated hole trap density in the MPC thin films was 2.0×1015cm −3,which is almost five orders of magnitude greater than in the MSCs.Thermal admittance spectroscopy (fig.S5)confirmed the reduction in trap density by two to three orders of magnitude in MSCs.Thus,the extraordinary carrier diffusion length in the MSCs is the result of largely suppressed trap density.When operat-ing in the trap-free space charge limit current (SCLC)regime above 10.7V,the dark current of the MSC was well fitted (Fig.3A,green line)by the Mott-Gurney law:J D ¼9ee 0m V 2b8L3ð2Þwhere V b is applied voltage.A large hole mobil-ity of 164T 25cm 2V −1s −1was derived from the curve fitting.The uncertainties we reportedmeasurements on 10nominally identical de-vices.Hall effect measurements revealed that the MSC was slightly p-doped,with a low free hole concentration of 9(T 2)×109cm −3(see supple-mentary materials).The hole mobility from Hall effect measurement was 105T 35cm 2V −1s −1,in agreement with the SCLC results.Similarly,the electron trap density and electron mobility of MSCs were measured with the electron-only de-vices,which had phenyl-C 61-butyric acid methyl (PCBM):C 60/Ga as both electrodes.A low elec-tron trap density of 4.5×1010cm −3was derived (Fig.3B),comparable to the hole trap density,and the electron mobility was 24.8T 4.1cm 2V −1s −1.Finally,we used time-of-flight (ToF)to verify the high electron mobilities of 24.0T 6.8cm 2V −1s −1(Fig.3,C and D).The electron and hole mobil-ities in MSCs are several times the intrinsic band transport mobility in MPC thin films (10)and polycrystals (15)measured by the Hall effect method96827FEBRUARY 2015•VOL 347ISSUE 6225 SCIENCERESEARCH |REPORTSand those measured by transient terahertz spec-troscopy (16),both of which measure band trans-port mobility.However,ToF and SCLC mobilities are sensitive to the presence of charge traps in the materials.The excellent agreement of Hall mobility with ToF and SCLC mobilities in the single-crystal MAPbI 3devices indicates that the band-tail states in the organolead trihalide pe-rovskite single crystals are negligible.We measured t r in MSCs with transient pho-tovoltaic (TPV)and impedance spectroscopy (IS)at different values of I L (Fig.4);at 1sun,the TPV and IS values of t r were 82T 5m s and 95T 8m s,respectively,more than 10times the t r values in the best thin-film devices with so-phisticated surface passivation (10).Combining the measured mobility and lifetime of MSCs,the hole diffusion length is 175T 25m m under 1sun.The measured bulk carrier lifetime can be un-derestimated because of the presence of surface charge recombination,so the bulk carrier diffu-sion length should exceed this value.Reducing the bias light intensity to 0.1sun increased t r to 234and 198m s by TPV and IS measurements,respectively,indicating a longer carrier diffusion length under weaker light intensity.The long carrier diffusion length of MAPbI 3can find direct application in x-ray and gamma-ray sensing and in radiation energy harvesting.Radiation is generally much weaker than 1sun but should penetrate the entire device.Details pertaining to the carrier diffusion length extrapo-lation under weak light,radiation measurement,simulation,and estimation of gammavoltaic ef-ficiency can be found in the supplementary mate-rials.We extrapolated a carrier recombination lifetime of 2.6T 0.2s and carrier diffusion length sum of 33T 5mm under a light intensity of 0.003mW cm −2from our 1sun data.The presence of surface recombination should reduce the carrier diffusion length,and the measured >3mm elec-tron and hole diffusion length under weak light is thus reasonable.We exposed the 3-mm MSC device to intense gamma radiation and measured the electric current generation.A cesium-137gam-ma irradiator of 102Ci yielded a persistent current of 36.3T 0.3nA,which corresponds to a photon-to-electron conversion efficiency of 3.9%and agrees with the theoretic estimation.The demonstrated high carrier mobility,car-rier lifetime,and diffusion length of the MSCs described above point to several new directions for the application of MAPbI 3materials in print-able electronics,lasers,and solar cells (4).The high PL quantum yield of MAPbI 3and the ex-cellent overlap of the PL spectra with the ab-sorption spectrum of the single crystal allow photon recycling in thick perovskite crystals by reabsorbing the emission (4,5).The demonstra-tion of a charge diffusion length that greatly exceeds the absorption depth of photons with energy larger than the band gap of perovskites implies that IQEs of essentially 100%can be achieved under the low internal electric fields at device working condition.REFERENCES AND NOTES1.S.D.Stranks et al .,Science 342,341–344(2013).2.M.M.Lee,J.Teuscher,T.Miyasaka,T.N.Murakami,H.J.Snaith,Science 338,643–647(2012).3. A.Mei et al .,Science 345,295–298(2014).4.G.Xing et al .,Nat.Mater.13,476–480(2014).5.Z.K.Tan et al .,Nat.Nanotechnol.9,687–692(2014).6.R.Dong et al .,Adv.Mater.10.1002/adma.201405116(2015).7.J.Kim,S.H.Lee,J.H.Lee,K.H.Hong,J.Phys.Chem.Lett.5,1312–1317(2014).8.N.K.Noel et al .,ACS Nano 8,9815–9821(2014).9.I.A.Shkrob,T.W.Marin,J.Phys.Chem.Lett.5,1066–1071(2014).10.Z.Xiao et al .,Adv.Mater.26,6503–6509(2014).11.T.Baikie et al .,J.Mater.Chem.A 1,5628–5641(2013).12.J.S.Manser,P.V.Kamat,Nat.Photonics 8,737–743(2014).13.S.D.Stranks et al .,Phys.Rev.A 2,034007(2014).14.R.H.Bube,J.Appl.Phys.33,1733–1737(1962).15.C.C.Stoumpos,C.D.Malliakas,M.G.Kanatzidis,Inorg.Chem.52,9019–9038(2013).16.C.Wehrenfennig,G.E.Eperon,M.B.Johnston,H.J.Snaith,L.M.Herz,Adv.Mater.26,1584–1589(2014).SCIENCE 27FEBRUARY 2015•VOL 347ISSUE 6225969Fig.3.Carrier mobility characterization of MSCs.(A and B )Current-voltage curve for a hole-only MSC device (A)and an electron-only MSC device (B).The insets show the device structure of hole-only and electron-only MSC devices,respectively.Three regions can be identified according to different values of the exponent n :n =1is the ohmic region,n =2is the SCLC region,and in between is the trap-filled limited region.(C )Schematic illustration of the device for the time-of-flight measurement.(D )The transient current curves of the MSC device show the normalized transient photocurrent under various reverse biases.The carrier transit time is determined by the intercept of the pretransit and posttransit asymptotes of the photocurrent,marked by solid blue circles.Inset shows the charge transit time versus the reciprocal of bias;the solid line is a linear fit to the data.Fig.4.Carrier recombination lifetime characterization of MSCs.(A and B )Impedance spectroscopies (A)and transient photovoltaic curves (B)of the MSC devices under 1sun and 0.1sun illumination,re-spectively,with incident light from the semitransparent Au anode.The TPV decay curves were fitted by a single-exponential decay function.The inset of (A)is the extracted charge recombination lifetime from IS measurement of the MSC device and the MPC thin film at various applied voltage biases under 1sun illumination.The inset of (B)is the extracted charge recombination lifetime from TPV measurement of the MSC device under various light bias intensities.RESEARCH |REPORTSACKNOWLEDGMENTSSupported by U.S.Department of Energy award DE-EE0006709(solar cell)and Defense Threat Reduction Agency award HDTRA1-14-1-0030(radiation detector).J.H.conceived the idea and supervised the project;Q.D.grew thesingle crystals and fabricated the devices;Q.D.,Y.F.,and Y.S.P.M.,J.Q.,and L.C.measured the devices under gamma ray irradiation and did the simulation;and J.H.wrote the paper.SUPPLEMENTARY MATERIALS/content/347/6225/967/suppl/DC1Figs.S1to S11Tables S1and S2References (17–21)27December 2014;accepted 20January 2015Published online 29January 2015;water is a promising means of storing solar energy in a way that compensates for the intermittency of sunlight as a primary source of power (1,2).It can be realized by apply-ing a hybrid system in which a solar cell powers an electrolyzer [photovoltaic (PV)electrolysis].Pho-toelectrolysis (PE)uses photocatalyst electrodes with additional electrical power provided by a photovoltaic element.Photocatalysis (PC)involves light-irradiated catalysts (typically catalyst pow-ders suspended in water)for water splitting (3).Recently reported “solar-to-hydrogen ”(STH)ef-ficiencies for PV electrolysis systems exceed 10%(4–6).State-of-the-art PE systems yield STH values of 2to 3%(7)but are believed to provide a cheaper solution for H 2production.PC is the simplest water-splitting approach,more ame-nable to cheap,large-scale applications of H 2generation.Unfortunately,despite intense efforts during the past 40years (8–15),current direct photocatalysts for water splitting still face several challenging issues:(i)Currently reported cata-lysts suffer from low quantum efficiency (QE)in the visible range,with STH efficiencies less thanof rare and expensive materials;(iii)various pho-tocatalysts show poor stability [e.g.,inorganic sulfide and (oxy)nitride-based photocatalysts are less stable and more susceptible to oxida-tion than water];(iv)O 2release from semi-conductor catalysts is difficult,so that the use of sacrificial reagents is required;(v)the overall four-electron water oxidation to O 2encounters a large overpotential;and (vi)the kinetically com-peting two-electron reaction to H 2O 2often poisons the photocatalysts (19).Overall water splitting to H 2and O 2requires a high free energy of 113.38kcal/mol (20,21).The challenge lies mainly in the release of diatomic O 2,which involves four electron and four pro-ton transfers for the eventual formation of an O-O bond.The concerted four-electron process for oxygen evolution (1.23eV)is thermodyna-mically more favorable than the two-electron process for H 2O 2formation (1.78eV).However,detailed analysis (see supplementary text)shows that a higher reaction rate may be achieved in a system where water is first oxidized via a two-electron reaction to H 2O 2and H 2,followed by H 2O 2decomposition to O 2and H 2O.For this stepwise two-electron/two-electron water splitting to H 2and O 2to be viable and practical,the photo-catalyst applied should be capable of promoting generation as well as subsequent decomposition of H 2O 2with high efficiencies and low overpo-tentials,so as to allow considerable reduction in the energy cost for production of H 2and O 2overall water splitting.Here,we report that nanocomposites of carbon nanodots embedded a C 3N 4matrix perform as an excellent photo-fulfilling the above requirements.C 3N 4is commercially available (e.g.,from Carbo-and can be easily fabricated (e.g.,from urea)19).It is an Earth-abundant and low-cost photo-capable of generating H 2and H 2O 2from even in the absence of catalytic metals,with a low QE (19,22–26).C 3N 4belongs to oldest reported polymer materials prepared chemists (by Berzelius in ~1830)and first “Melon ”(27).In 2006it was determined the visible light activity of TiO 2after treat-with urea was due to “Melon ”(28).In 2009,and colleagues described in detail the properties,electronic structure,and photo-activity of C 3N 4(29).Following this work,groups attempted to optimize the catalytic of C 3N 4,motivated by its relatively low gap energy E g of 2.7eV,and high valence and conduction band positions (29)[1.8–0.9eV versus reversible hydrogen electrode Many heterojunction composites with semiconductors as well as photocatalyst were investigated.The latter included systems with a variety of oxides (30)and sulfides (31)along with pure metals (19)and even graphene (32)and carbon nanotubes (33).Different prep-aration methods were studied in an effort to increase the surface area of C 3N 4and to improve its catalytic activity.The QE values obtained using C 3N 4as a catalyst for water splitting to H 2and O 2have been low (maximum 3.75%at 420nm and less than 0.5%for 500nm),and generally the use of a sacrificial reagent has been necessary (19,24,26,30–32,34).The efficiency at 700nm can be largely increased by applying dye mol-ecules,but again a sacrificial reagent is a must (35).During water splitting C 3N 4suffers from poi-soning by the produced H 2O 2,which is difficult to remove from the C 3N 4surface (19).Different methods including stirring,bubbling,and/or ad-dition of chemical agents have been attempted for regeneration of the poisoned C 3N 4catalyst (19).Carbon nanodots (CDots;monodisperse graph-ite particles less than 10nm in diameter)exhibit unique photo-induced electron transfer,photo-luminescence,and electron reservoir properties (36).In particular,CDots possess high catalytic activity (by chemical catalysis;no light is needed)for H 2O 2decomposition (37).Given the photo-catalytic properties of CDots and C 3N 4,we hypoth-esized that a combination of CDots and C 3N 4could constitute a high-performance composite photocatalyst for water splitting via the stepwise two-electron/two-electron process:(i)2H 2O →H 2O 2+H 2;(ii)2H 2O 2→2H 2O +O 2.97027FEBRUARY 2015•VOL 347ISSUE 6225 SCIENCE1Jiangsu Key Laboratory for Carbon-based FunctionalMaterials and Devices,Institute of Functional Nano and Soft Materials (FUNSOM),Soochow University,Suzhou 215123,China.2Department of Materials Science and Engineering,Technion,Israel Institute of Technology,Haifa 3200003,Israel.*Corresponding authors.E-mail:zhkang@ (Z.K.);apannale@ (S.-T.L.);shayli@tx.technion.ac.il (Y.L.)RESEARCH |REPORTSDOI: 10.1126/science.aaa5760, 967 (2015);347 Science et al.Qingfeng Dong single crystals 3PbI 3NH 3m in solution-grown CH µElectron-hole diffusion lengths > 175This copy is for your personal, non-commercial use only.clicking here.colleagues, clients, or customers by , you can order high-quality copies for your If you wish to distribute this article to othershere.following the guidelines can be obtained by Permission to republish or repurpose articles or portions of articles): October 17, 2015 (this information is current as of The following resources related to this article are available online at/content/347/6225/967.full.html version of this article at:including high-resolution figures, can be found in the online Updated information and services, /content/suppl/2015/01/28/science.aaa5760.DC1.htmlcan be found at:Supporting Online Material /content/347/6225/967.full.html#related found at:can be related to this article A list of selected additional articles on the Science Web sites /content/347/6225/967.full.html#ref-list-1, 3 of which can be accessed free:cites 20 articles This article /content/347/6225/967.full.html#related-urls 3 articles hosted by HighWire Press; see:cited by This article has been/cgi/collection/app_physics Physics, Appliedsubject collections:This article appears in the following registered trademark of AAAS.is a Science 2015 by the American Association for the Advancement of Science; all rights reserved. The title Copyright American Association for the Advancement of Science, 1200 New York Avenue NW, Washington, DC 20005. (print ISSN 0036-8075; online ISSN 1095-9203) is published weekly, except the last week in December, by the Science o n O c t o b e r 17, 2015w w w .s c i e n c e m a g .o r g D o w n l o a d e d f r o m。

2008年5月电工技术学报Vol.23 No. 5 第23卷第5期TRANSACTIONS OF CHINA ELECTROTECHNICAL SOCIETY May 2008 硅太阳能电池串联电阻的一种估算新方法廖志凌1, 2阮新波1(1. 南京航空航天大学航空电源重点实验室南京 2100162. 江苏大学电气信息工程学院镇江 212013)摘要硅太阳能电池等效串联电阻会影响其正向伏安特性和短路电流,而对开路电压没有影响,另外串联电阻的增大会使太阳能电池的填充因子和光电转换效率降低。

研究计算太阳能电池串联电阻具有重要的实际意义。

提出一种估算太阳能电池串联电阻的新方法,利用太阳能电池生产厂商提供的在标准测试条件下的四个技术参数(短路电流I sc,开路电压V oc,最大功率点电流I m和电压V m)进行计算,同时通过引入相应补偿系数来考虑太阳光强和电池温度变化时对串联电阻的影响。

理论估算结果与实验测量结果比较,两者误差在工程应用允许的精度6%以下。

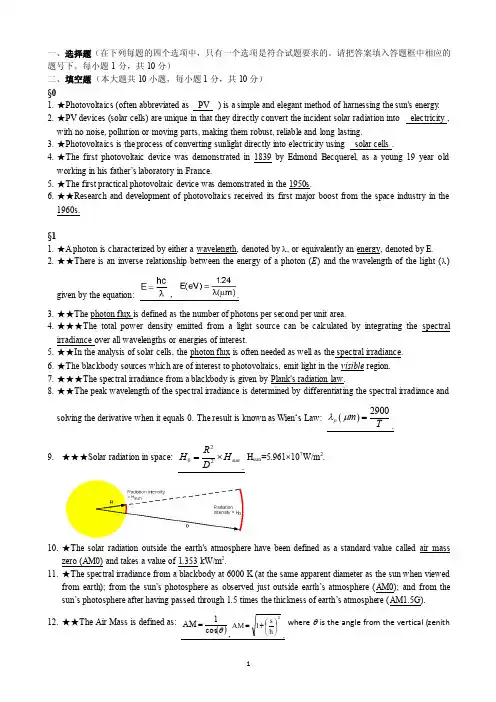

关键词:硅太阳能电池光伏发电串联电阻估算方法中图分类号:TK513A New Method on Computing Series Resistance of Silicon Solar CellsLiao Zhiling1, 2 Ruan Xinbo1(1. Nanjing University of Aeronautics and Astronautics Nanjing 210016 China2. Jiangsu University Zhenjiang 212013 China)Abstract The equivalent series resistance of silicon solar cell can influence its straight volt-ampere property and short-circuit current, but have no influence on open-circuit voltage. Moreover, the increase of series resistance can reduce the solar cell’s fill factor and conversion efficiency.Research on computing the series resistance of silicon solar cell has the important meaning. A new method on computing series resistance of silicon solar cells is proposed, which uses only four electrical parameters (the short-circuit current I sc, the open-circuit voltage V oc, the current of maximum power point I m, the voltage of maximum power point V m) under standard test conditions provided by manufacture. And the influence of variational solar radiation and solar cell temperature on series resistance of solar cell is taken into account with three additional compensation parameters. According to the comparison between theoretic computing datum and experimental datum of silicon solar cells, the result is satisfactory and the difference is found to be less than 6 percent.Keywords:Silicon solar cell,photovoltaic,series resistance,computing method1引言当今世界能源结构是以煤炭、石油和天然气等化石能源为主体,而化石能源是不可再生能源,大量耗用终将枯竭。

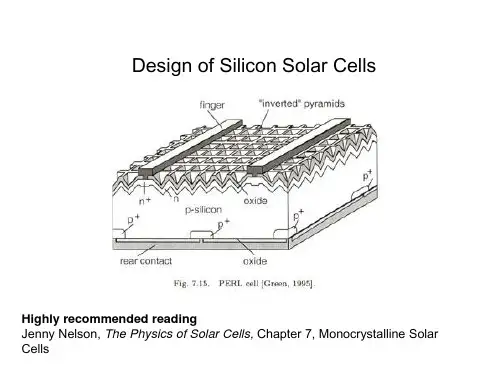

PERFORMANCE INSTABILITY IN N-TYPE PERT SILICON SOLAR CELLS Jianhua Zhao1, Jan Schmidt2, Aihua Wang1, Guangchun Zhang1, Bryce S. Richards1 and Martin A. Green11. Centre of Excellence for Advanced Silicon Photovoltaics and Photonics,University of New South Wales, Sydney, NSW 2052, Australia2. Institut für Solarenergieforschung Hameln/Emmerthal (ISFH),Am Ohrberg 1, D-31860 Emmerthal, GermanyABSTRACTPERT (passivated emitter, rear totally-diffused) cellson CZ and FZ n-type silicon substrates have demonstratedhigh efficiencies of 21.1% and 21.9%, respectively.Performance loss has been observed in these cells afterover two-year storage. A further loss was observed whenthese cells were illuminated under one-sun intensity usingELH halogen projection lamps. The lightly doped boronemitters and strong surface depletion might be the causefor such loss, which appear to have an electrostatic originand to be largely reversible.1.INTRODUCTIONFabricating solar cells on n-type CZ silicon substratesforms part of an international effort to solve thedegradation problem for cells on boron doped p-type CZsilicon substrates [1]. PERT cells on CZ and FZ n-typesilicon substrates (see Fig. 1) have demonstrated highefficiencies of 21.1% and 21.9%, respectively [2]. Fig. 1shows the structure of n-PERT cells. BBr3 liquid sourcediffusion is used to form the boron doped emitters. Thefront surfaces of these cells are further passivated by athermally grown 200Å thin silicon dioxide (SiO2), and asubsequent “alneal” (aluminium anneal) process. Thealneal process provides excellent surface passivation, andhence these n-PERT cells give high open-circuit voltages,V oc, close to 700 mV [2].p+pn-siliconthin oxide (~200Å) oxiderear contact finger"inverted" pyramidsn+n+n+double layerantireflectioncoatingnnFig. 1. PERT cell structure on n-type substrate.Directly after fabrication, these cells showed stable performance after a short period of illumination and a few weeks storage. The effective carrier lifetime measurement of such substrate passivated by TCA grown SiO2 have also shown stable performance after a few weeks storage and a few hours illumination by ELH lamps at one-sun intensity.2.DEGRADATION DURING STORAGE OF N-PERT CELLSHowever, in a recent study into these n-type PERT cells which were made two to three years ago, it was found that most of the cells have suffered large losses in their V oc up to 100 mV (see Fig. 2(a)). The cells in the left part in Fig. 2(a) were fabricated earlier than the cells in the right, with about one year time span. The latest cells in Fig.2(a) were made about 2 years ago. These cells were stored in a nitrogen box kept in a dimmed room light condition. It is seen that the earlier cells degraded much more than the later cells. The cells degraded by severely an average of 38 mV in V oc.(a)(b)Fig. 2. Comparison of performance loss after a few years storage of (a) PERT cells on n-type substrates, and (b) PERL cells on p-type substrates. The solid triangles are the performance before storage, and the hollow squares are those after storage.Due to the observation of the performance loss in the n-PERT cells, similar test were made to some even earlier fabricated PERL (passivated emitter, rear locally-diffused) cells on p-type substrates (see Fig. 2(b)). All these p-PERL cells, which were fabricated 3 to 9 years ago showed much smaller and more uniform changes, with little relation to the fabrication time and cell performance.The average V oc reduction of these p-PERL cells after N2 storage is 4.2 mV. However, because the short-circuit current density, J sc, of some unscribed cells was not properly calibrated due to the peripheral current collection, a large error was generated by the direct V oc comparison after storage. This error can be reduced when V oc reduction is corrected to an average 2.5 mV, assuming the cell J sc has no degradation. This assumption is reasonable for p-PERL cells, since V oc is much more sensitive than J sc to the changes in total recombination rate.3.FURTHER ILLUMINATION DEGRADATIONThe stability of un-encapsulated n-PERT and other types of cells was further examined by illuminating them under one-sun intensity from ELH lamps. Such ELH lamps possess a very small UV component, which results in similar conditions when encapsulated under glass. A further degradation has been observed (see Fig. 3).ocillumination by ELH lamps.In Fig. 3, the solid triangles from cell Wn10-3a represent the V oc of a PERT cell on an n-type FZ substrate. This cell had a high V oc of 693 mV after fabrication 3 years ago. Its V oc has degraded to 686 mV after 3 years storage in nitrogen. After 11 hours one-sun illumination, its V oc has further quickly degraded to 675.5 mV. Even this value was still degrading without reaching saturation when the experiment was stoped. This represents close to 20 mV degradation after storage and a short time illumination. It is clearly one of the least stable cells among all the tested cells.It is possible that the small UV component in the light source could generate electrical charges in the space between the ELH lamp and the cell, which can deposit on the cell surface. Hence, at the end of the degradation curve, the cell surface was charged with negative corona charging. Charged surfaces can vary the surface recombination velocity, but not affect the bulk recombination. After illumination degradation, the charged V oc could not recover to the value at fabrication, which shows some physical change has occurred.It was thought that the change may be associated with the 200Å thin passivation oxide, or with the inverted pyramid structure giving (111) surfaces. Hence, one planar n-PERL cell, X1-159R, with 1100Å thick passivation oxide made 10 years ago and stored in an office cabinet was also tested (not shown in Fig. 3). However, the V oc of this planar cell had degraded from about 690 mV at fabrication to the present 593mV. This gives about 100 mV in V oc degradation during 10 year storage. It makes it clear that a planar surface with thick passivation oxide does not help for the n-type cell stability.The illuminated V oc curves of the earlier rear boron emitter cells on n-type substrates, X1-294L and X1-294R, are also shown in Fig. 3. The initial V oc data of these cells could not be found, but they should be close to 690 mV, according to similar cells made at that time. Both cells had relatively large storage degradation of about 15 mV. It is interesting that these cells showed even greater illumination degradation rate, and did not reach saturation after losing a further 20 mV in 23 hours of illumination.A positive corona charging at the end of illumination recovered V oc to its fabrication value of over 690 mV for cell X1-294L. This suggests no permanent changes to this cell, with the voltage changes attributed to a changing electrostatic environment.The p-PERT cells [3] with an entire rear light boron diffusion on SEH 1.2 Ω-cm FZ(B) substrate has a similar rear surface condition as the rear boron n-PERL cells, X1-294L and X1-294R. One of these p-PERT cells, Ws8-4a, with very high initial V oc of 708.2 mV, was tested. It gives 7.7 mV storage degradation, and further 6.8 mV degradation in 38-hour illumination. It is clear that this p-PERT cell is much more stable than the n-PERT and n-PERL cells. Electrostatic charging restored the cell voltage to its original value, again suggesting no permanent change.A couple of p-PERL cells [3], Wh15-1f and Wh15-1d, were also tested. Wh15-1f showed a slightly less storage and illuminated V oc degradation than the p-PERT cell. The other p-PERL cell, Wh15-1d, had relatively large 8.8 mV storage V oc degradation. This cell was illuminated initially in short circuit conditions for the first 20 hours, and then changed to open circuit conditions. This cell gave a very stable illumination performance and circuit condition did not seem affect its performance. At the endof degradation curves, positive charges are deposited onto the surfaces all the p-type PERL and PERT cells. This recovered cell V oc to their original values. Hence, this verifies that the V oc reduction was due to the surface charge change, instead of any permanent degradation.To be noted here is that high efficiency p-PERL cells had been encapsulated and exposed to outdoor direct sunlight in stability tests in 1991 and 1996. Minimum V oc degradation was observed during those tests. From the present illuminated V oc degradation tests, it seems that the cells storage in nitrogen for long time may enhance the illuminated degradation. Hence, it is planned to have some n-PERT cells encapsulated as the previous p-PERL cells for outdoor sunlight illumination test. However, once the cell is encapsulated, it will be difficult to measure the cell temperature, which might generate large errors inV oc measurement.For comparison, the previous illumination measurement of p-PERT cells on CZ(Ga) substrates, Ws4-4c, Ws4-4e, Ws12-3c and Ws12-3e [4], is also shown in Fig. 3. These cells exhibited virtually no V oc change.4.BORON PROFILES BY SRA AND SIMS TESTSThe boron emitter profiles of the n-PERT cells were recently tested by SRA (spreading resistance analysis) (see Fig. 4). SIMS (Secondary Ion Mass Spectrometry) testalso showed similar boron profiles for cell Wn10-3. In Fig. 4, the high noise levels in Wn16-3 and Wn10-3 by SRA is due to the rough bright etched wafers surfaces, which distorted the depth positions when a flat bevel is used to enlarge the depth profile. In contrast, cell Wn1-6 has a very smooth boron profile due to its mechanically polished mirror surface finish.5.2. IQE Measurement of Different Cells1.E +141.E +151.E +161.E +171.E +181.E +190.511.5D epth (m ic ron)C a r r i e r C o n c e n t r a t i o n (c m -3)2The IQE (internal quantum efficiency) of different cells were also measured at UNSW and compared to the initial measurement results from Sandia many years ago when the cells were freshly made (see Fig. 6). It can be seen that the p-PERL cell, W4-19-6e, and rear boron emitter n-PERL cell, X1-280R, exhibited very little change in their short-wavelength IQE. On the contrary, the front boron emitter n-PERT cell, Wn10-6a, showed a significant reduction in the short-wavelength IQE, corresponding to a significant increase of the surface recombination in this cell. Using PC-1D simulation, this represents a surface recombination velocity of 25000 cm/s. Correspondingly, the V oc of this cell has degraded from 699 mV at fabrication, to 657.5 mV. This cell was measured at Sandia, and gives a higher degradation than the other cells stored in nitrogen at UNSW. It is not sure if the transportation to Sandia, or storage in air has caused this extra degradation.Fig. 4. Boron emitter profiles for a few n-PERT cells tested by SRA (spreading resistance analysis).In spite of the distortion in the profiles, the SRA results give some important information. Firstly, most of the profiles have rather light boron doping levels, as a result from searching for the highest cell efficiencies. Secondly, most of the cells have deep junctions. Thirdly and maybe the most importantly, there is a profound surface depletion in the boron profiles. Such surface depletion might significantly enhance the effect of surface recombination to the cell performance, and hance reduce the cell stability, under electrostatic changes at the surface.fabrication, and at UNSW after storage for a few years.5.3. Corona Charging Test5. OTHER EXPERIMENTS ON SURFACEPASSIVATION QUALITY Corona charging can deposit either positive or negative electrical charges onto the solar cell surface and hence changes the surface recombination rate. Fig.7. shows the corona charging result for an n-PERT cell, Wn10-3e.5.1. LBIC TestSpatially resolved LBIC (light beam induced current) measurements were performed at a wavelength of 633 nm to investigate the emitter uniformity. Low and uneven LBIC results (see Fig. 5) have been seen in the test pattern for these n-PERL cells. A previous study using Lock-in Thermography at Max Planck Institute of Microstructure Physics, Halle, also showed a highly non-uniform boron emitter and higher temperature rise than p-PERL cells [2].Wn8-3cResolution: 55.6umLaser wavelength: 633 nm With Bias LightFig. 7. Corona charging of an n-PERT cell.From the initial degraded state of 661 mV for V oc , the negative charges lifted V oc to 692.4 mV, which is 4.8 mV higher than when the cell was freshly fabricated. The positive charge initially reduce V oc , and then increase it again to a saturation value of 689.5 mV. Charging theFig. 5. LBIC image of the n-PERT cell emitter.thick oxide planar n-PERL cells and rear boron emitter n-PERL cells gave similar results as shown in Fig. 7. The corona charging experiment confirms that the V oc loss is due to electrostatic effects at the cell surface, while the bulk carrier lifetime does not degrade at all.It has been suggested that the lightly doped n-type surface might be easily inverted which generates a shunting channel [5]. However, charging the peripheral areas of the n-PERT cells did not affect the cell performance. It was confirmed that all the V oc change during charging comes from the cell active area, possibly due to the low substrate resistivity in these cells.5.4. SiN x Passivation ExperimentDepositing SiN x film with remote plasma has been used to improve the surface passivation for silicon cells [6]. Hence, such SiN x films have been deposited on to the n-PERT cells, some with passivating SiO 2 layer removed. It was found that the cells performance recovered to their original V oc in 690 mV range for SiN x /SiO 2 passivation. Unfortunately, the performances of these SiN x /SiO 2 passivated cells degraded even more quickly than the standard n-PERT cells with the SiO 2 surface passivation, both during shipping and during exposure to light.Fig. 9. PC-1D simulation results show that a heavier and shallow front boron emitter can markedly improve cell stability.7. CONCLUSIONSThe analysis on the emitter doping profiles by SRA (spreading resistance analysis) and SIMS (Secondary Ion Mass Spectrometry) has revealed very light emitter boron profiles and significant boron depletion at the emitter surface of n-type PERT cells. The boron surface depletion may have enhanced the instability of these cells. Changing the surface conditions using the corona charging strongly affects the cell performance. Depositing silicon nitride passivation layer with a remote plasma source can also recover some of the degradation, particularly for SiN x /SiO 2 passivation. Unfortunately, the SiN x /SiO 2 passivated cells still degrade fast after the SiN x deposition. It is expected that a heavier emitter boron profile with less surface boron depletion may significantly improve the performance of such cells, by improving tolerance to changing surface electrostatic conditions.6. PC-1D SIMULATIONThe performance of the front boron emitter n-PERT cells has been simulated with PC-1D (see Fig. 8). The surface boron depletion detected by SRA and SIMS measurement are incorporated into the calculation by including a secondary lighter and shallower n+ diffusion to compensate some surface boron. This surface depletion effect has significantly reduced V oc for certain front surface recombination velocities. Also, the simulated result shows V oc is expected to degrade much earlier than J sc if surface recombination velocity increases. This is the case for the n-PERT cells, in which the V oc was the most degraded factor, while their J sc remained basically unchanged during V oc degradation.ACKNOWLEDGMENTThe authors would like to thank P. Verlinden at Origin Energy for discussions about the n-type cells.REFERENCES[1] T. Saitoh, et al. "Light Degradation and Control ofLow-Resistivity CZ-Si Solar Cells --An International Joint Research--", Technical Digest of the 11th International Photovoltaic Science and Engineering Conference, Sapporo, Japan, pp.553-556, Sept., 1999. [2] J. Zhao, A. Wang, P.P. Altermatt, M. A. Green, J. P.Rakotoniaina and O. Breitenstein, “High Efficiency PERT Cells on N-Type Silicon Substrates”, Proceedings of the 29th IEEE Photovoltaic Specialist Conference, New Orleans, pp.218-221, May, 2002. [3] J. Zhao, A. Wang and M.A. Green, “24.5%Efficiency Silicon PERT Cells on MCZ Substrates and 24.7% Efficiency PERL Cells on FZ Substrates”, Progress in Photovoltaics, Vol. 7, pp. 471-474, 1999. Fig. 8. PC-1D simulation of the n-PERT cell performance. [4] J. Zhao, A. Wang, M.A. Green, “High EfficiencyPERT Cells on a Variety of Single Crystalline Silicon Substrates”, Proceedings of the 16th European Photovoltaic Solar Energy Conference and Exhibition, Glasgow, UK, pp.1100-1103, May, 2000.A further simulation with PC-1D has shown that an increased boron doping level is beneficial to n-PERT cell stability. Another fact is that the surface depletion in the boron profile is reduced for heavier boron diffusion, according to the SRA measurement (see Fig. 4.). This further improves the cell stability. If the boron junction depth can also be reduced, both V oc and J sc degradations can be reduced (see Fig. 9).[5] P. Verlinden, Private communication, 2003.[6] A. Hubner, A.G. Aberle and R. Hezel, “20% EfficientBifacial Silicon Solar Cells, Conf. Record 14th European Photovoltaic Solar Energy Conference, pp. 92, 1997.。

SURFACE PASSIVATION OF BORON DIFFUSED EMITTERS FOR HIGH EFFICIENCYSOLAR CELLSJan Benick1, Bram Hoex2, O. Schultz and Stefan W. Glunz11Fraunhofer Institute for Solar Energy Systems, Heidenhofstr. 2, 79110 Freiburg, Germany 2Department of Applied Physics, Eindhoven University of Technology, P.O. Box 513, 5600 MB Eindhoven, TheNetherlandse-mail: jan.benick@ise.fraunhofer.deABSTRACTIn order to utilize the full potential of solar cells fabricated on n-type silicon, it is necessary to achieve an excellent passivation on boron-doped emitters. As SiO2, the most effective passivation for highly doped n-type surfaces, does not show a sufficient performance on highly boron doped surfaces some effects that possibly lead to this gap in performance are investigated. Especially the question of boron redistribution during oxidation is the focus of this work.The field effect induced either by corona charge or fixed charge in the surface layer is known to strongly affect the surface passivation quality on silicon solar cells. Typical passivation layers used for high-efficiency solar cells as SiO2 and SiN x feature a built-in positive charge. For highly doped p-type surfaces however, it is shown experimentally that the passivation quality is strongly enhanced by a high density of negative charge. Thus, the negative-charge dielectric Al2O3 is applied as surface passivation layer on high efficiency n-type c-Si solar cells. An independently certified solar cell efficiency of 23.2 % confirms the excellent passivation quality of this negatively charged dielectric on a boron emitter.INTRODUCTIONn-type silicon has an enormous potential for widescale application in the photovoltaic industry. The relative tolerance to common impurities (e.g. Fe) [1] potentially results in higher minority carrier diffusion lengths compared to p-type c-Si substrates. Furthermore, n-type c-Si does not suffer from the boron-oxygen related, light- induced degradation (LID), which p-type Czochralski-grown silicon is known for [2].In order to benefit from these advantages of the bulk material, a sufficient technology for passivation of boron emitters must be developed. However, on device level the excellent passivation quality as achieved for highly doped n-type emitters has not been realized so far for highly boron-doped p-type c-Si. Thus, the effects leading to this gap in performance have to be further investigated.PASSIVATION WITH THERMAL SIO2SiO2, the most effective passivation for highly dopedn-type surfaces [3], does not show a sufficient performance on highly boron doped surfaces [4] [5] [6] [7].In order to investigate the passivation quality of thermalSiO2 on highly boron-doped solar cell emitters, n-typePERL [3] (passivated emitter with rear locally diffused)solar cells (shown in Fig. 1) were fabricated on 〈100〉1 Ω cm, FZ, n-type c-Si wafers with a thickness of 250 µm.These cells (A = 4 cm2) feature a front surface withinverted pyramids and evaporated Al/Ti/Pd/Ag contacts,thickened by electroplating. The rear surface exhibits local phosphorus BSFs (R sheet≈ 20 Ω/sq) and is covered with a100 nm thick thermal SiO2 and a 2 µm thick aluminumlayer. BBr3 diffusion at 890°C results in a homogenousboron emitter with a sheet resistance of 130 Ω/sq and asurface doping concentration of approximately 8×1019 cm-3. This front-side boron emitter is passivated either by a105 nm thick thermal SiO2 (Fig. 1a) or a stack systemconsisting of a thin (30 nm) SiO2 followed by a 40 nm thickSiN x layer (Fig. 1b).(a) (b)Fig. 1 PERL solar cell structure on n-type silicon. (a)The boron emitter is passivated by a 105 nm thick thermalSiO2. (b) The boron emitter is passivated by a layer stackof a 30 nm thick thermal SiO2 followed by a 40 nm thickSiN x antireflection layer.The one-sun parameters of these cells are summarized in Table 1. The solar cells passivated by the SiO 2/SiN layer stack show a higher conversion efficiency (20.4 %) compared to the solar cells passivated by the 105 nm thick thermal SiO 2 (19.5 %). This gain in performance can be attributed to a higher short-circuit current due to better antireflection characteristics of the layer stack system as shown in Fig. 2. The open-circuit voltage (V oc ), a measure for passivation quality, is the same for both passivation layers. The relatively low values of only 638 mV reached for these cells indicate a poor passivation quality which is assumed to be due to an insufficient passivation of the boron emitter by the thermal SiO 2.Table 1 Results of n -type PERL solar cells passivated by thermal SiO 2 (AM1.5G, 100 mW/cm 2, 25°C). Passivation layerV oc [mV]j sc [mA/cm 2]FF [%] η [%] av. 636.7 ± 3.6 39.2± 0.3 78.4 ± 0.319.6 ± 1.0SiO 2 + SiNbest 638.139.780.6 20.4 av. 636.3 ± 1.4 37.8± 0.2 79.6± 0.219.1 ± 0.5105 nm SiO 2best 638.538.080.3 19.5The strong drop of the internal quantum efficiency (IQE) in the short wavelength range (below ~600 nm) for both passivation systems confirms this assumption of an insufficient passivation of the boron emitter.I Q Ewavelength [nm]Fig. 2 IQE and reflection of n -type PERL solar cells passivated by thermal SiO 2.As the solubility of the boron is higher in SiO 2 than in Si the oxidation process might cause a surface depletion of the boron emitter as described by other researchers [7] [8]. Such a surface depletion would be detrimental for surface passivation. To investigate this effect, FZ n -type Si wafers with identical boron emitters (R sheet = 130 Ω/sq) were oxidized at different temperatures resulting in SiO 2thicknesses between 10 and 105 nm. The resulting boron profiles were measured by electrochemical capacitance-voltage profiling (ECV) (see Fig. 3). A surface depletion of the boron emitter could only be observed for the oxidation process that resulted in a very thin (10 nm) SiO 2. The diffusion profiles of the remaining boron emitters which received an oxidation process that led to a thicker SiO 2, do not show a significant surface depletion. As the SiO 2 passivation layers which are applied at our solar cells exceed this critical thickness the effect of surface depletion of the boron emitter is probably not the reason for the poor passivation quality measured at the solar cells.10101010d o p i n g c o n c e n t r a t i o n [c m -3]depth [µm]Fig. 3 Diffusion profiles of the initial boron emitter before oxidation and after passivation with different thermal SiO 2.The sheet resistivities (R sheet ) of all of these boron emitters show a strong increase with increasing thickness of the thermal SiO 2 (see Table 2). This increase in R sheet is assumed to be due to a diffusion of the boron from the emitter into the SiO 2. To verify this presumption the total boron concentration of the emitters was determined by integrating the measured boron profiles (see Table 2). It can be observed that the total boron concentration decreases while the R sheet (i.e. the thickness of the thermal SiO 2) increases. Thus it is proven that there is a strong loss of the emitter total boron concentration (up to 70 % for the 105 nm thick thermal SiO 2) due to a diffusion of the boron into the SiO 2.For this reason a very high boron concentration within the SiO 2 layers is expected. To investigate this, the boron concentration in the SiO 2 layer and in the boron emitter is measured by SIMS. Fig. 4 shows the initial boron emitter as well as the boron distribution in the thermal SiO 2 and in the resulting emitter. In the displayed example the boron distribution after growing of a 27 nm thick thermal SiO 2 (as also applied on solar cells) is shown. A very high boron concentration above 1020 cm -3 can be observed in the oxide layer.Table 2 Increase in R sheet and total boron loss of theemitter after different oxidation processes.SiO 2 thickness[nm]-- 8 17 27 105R sheet [Ω/sq] 133 141 153 157 218 Normalized totalboron doping [%]100 84 67 65 32 The measurement of the boron concentration within the thermal SiO 2, especially if as thin as ~30 nm, is not routinely done. Thus the reliability of this measurement has to be verified. The total boron of the thermal SiO 2 and the resulting boron emitter is compared to the total boron of the initial emitter. This was done by integrating themeasured doping profiles. The derived total boron of 8.1×1014 cm -2 for the thermal SiO 2 (3.2×1014 cm -2) and theresulting boron emitter (4.9×1014 cm -2) is in very good agreement to the 8.2×1014 cm -2 determined for the initialemitter. Thus, the measured profiles are reliable. The extracted boron loss of ~40 % additionally is in good agreement with the values given in table 2.101010101010d o p i n g c o n ce n t r a t i o n [c m -3]depth [µm]Fig. 4 Distribution of boron in the initial emitter and for the thermal SiO 2 together with the resulting boron emitter after oxidation.This very high boron concentration within the passivating SiO 2 is assumed to contribute significantly to the low level of surface passivation observed for thermal grown SiO 2 on highly boron doped surfaces.FIELD EFFECT PASSIVATIONTo derive an effective surface passivation the surface recombination velocity has to be kept as low as possible. To reach this two methods are available. The first is the reduction of interface states, e.g. dangling bonds. This is the dominant mechanism when thermal SiO 2 or a-Si:H is applied as the passivation layer. The second approach is the reduction of one carrier type (preferable minority carriers) at the semiconductor surface [9]. This can be reached by an electrical field induced either by a fixedcharge density within the dielectric layer (e.g. SiN x ) used for passivation or by applying corona charge on an insulating layer.To investigate the effect of a high charge density on surface passivation quality, corona charges have been applied on SiO 2 (105 nm) passivated surfaces.Symmetrical n +/p /n + and p +/n /p + lifetime samples (1 Ω cmn - or p -type c -Si) have been prepared and subsequently acharge density in the range between -4 to 4×1012 cm -2 wasapplied. The quasi-steady-state photo-conductance(QSSPC) method [10] is used to measure effective lifetime τeff . The implied V oc was extracted from the QSSPC data as proposed by Sinton [11]: 2)(i dop oc n n N n q kT V implied Δ+Δ=(1)where Δn is the excess carrier density, k the Boltzmann constant, T the temperature, q the elementary charge, N dopthe bulk doping concentration and n i the intrinsic carrier density. 600625650675700-4-3-2-11234i m p l i e d V o c [m V ]surface potential [V]surface charge density [1012 cm -2]Fig. 5 The effect of surface charge density on surface passivation quality. Both the boron and phosphorus emitters have comparable sheet resistivities of approximately 140 Ω/sq with surface doping concentrations of 6×1018 cm -3 for the boron and8×1018 cm -3for the phosphorus emitter. Both emitters are passivated by a thermally grown 105 nm thick SiO 2.The observed detrimental effect of positive charges on the passivation of highly doped p -type surfaces can be explained by the surface depletion of the majority carriers (i.e. the holes) induced by these positive charges. This surface depletion enhances the minority carrier (i.e. the electron) concentration at the surface, which leads to an enhanced surface recombination. The opposite effect occurs when a negative charge density is applied. In this case an accumulation layer is induced, which provides an effective field effect passivation at the p -type surface. By applying a negative charge density of -4×1012 cm -2 theimplied V oc is increased from below 650 mV (without surface charging) to approximately 690 mV. An analogue effect, but with opposite polarity, can be observed for highly n -type doped surfaces.In order to prove the beneficial influence of such charges also at the device level, a high density of negative charges was applied on high efficiency (PERL) n -type solar cells passivated by a 105 nm thick thermal SiO 2. The initially poor internal quantum efficiency (see Fig. 6) of these solar cells could be greatly enhanced by applying negative charges at the SiO 2 passivated boron emitter.i n t e r n a l q u a n t u m e f f i c i e n c y I Q Ewavelength λ [nm]Fig. 6 Measured and simulated (PC1D) internal quantum efficiencies for a solar cell with and without anapplied high density of negative charges.For one representative solar cell the influence of surfacecharges was calculated by numerical modeling with PC1D[12]. As is shown in Fig. 7 the experimental V oc values foran increased surface charge density can be reproduced bythe PC1D model when the same surface charge density isapplied.V o c [m V ]surface charge density [1012 cm -2]Fig. 7 Measured and simulated (PC1D) values for the open circuit voltage when negative charges are applied at the solar cell surface.Applying a charge density of -3.5×1012 cm -2 on the same cell, the initial V oc could be increased from 623 to 665 mV. As the j sc at the same time raised from 36.0 to 39.6 mA/cm 2 the conversion efficiency of 18.1 % was increased to 21.1 %.With respect to these findings the ideal dielectric layer to passivate a boron emitter would be a dielectric that feature a high density of fixed negative charges.One dielectric layer that meets these specifications is the negative-charge dielectric Al 2O 3. Recently, Hoex et al. [13] measured emitter saturation current densities below 10 fA/cm 2 on highly doped p -type c -Si surfaces of unmetalized lifetime samples passivated by Al 2O 3. On highefficiency n -type PERL solar cells passivated by thisdielectric layer we recently reached an open circuit voltage of 703.6 mV that led to a independently confirmed conversion efficiency of 23.2 % [14].CONCLUSIONSThermal grown SiO 2 is not sufficient to effectively passivate highly boron doped surfaces as proven by the low level of surface passivation (V oc ~ 640 mV) achieved on high efficiency n -type solar cells passivated with athermal SiO 2 (105 nm thick single layer or SiO 2/SiN x layerstack). Surface depletion of the boron emitter (as known to be detrimental for passivation) due to the higher solubilityof the boron in the SiO 2 could not be observed for theapplied SiO 2 passivated boron emitters. Instead a strong total boron loss in the emitter leading to a very high boronconcentration within the SiO 2 (>1020 cm -3) was observed even for thin SiO 2 layers. This very high boron concentration within the passivating SiO 2 is assumed to contribute to the low level of surface passivation observed for thermal grown SiO 2 on highly boron doped surfaces. To increase the passivation quality built-in charges in the dielectric layer can be beneficial. Our study shows that positive charges have a beneficial effect on highly n -doped surfaces while a negative charge is appropriate for highly p -doped surfaces. Thus, the negative-charge dielectric Al 2O 3 is applied as surface passivation layer on high efficiency n -type c -Si solar cells. An independently certified solar cell efficiency of 23.2 % confirms the excellent passivation quality of this negatively charged dielectric for passivation of boron emitters on device level. ACKNOWLEDGEMENTSThe authors would like to thank S. Seitz, T. Leimenstoll,and E. Schäffer for process technology and measurements.The work was supported by the German Federal Ministryfor the Environment, Nature Conservation and NuclearSafety under contract number 0329849A …Th-ETA“ REFERENCES[1] D. Macdonald and L. J. Geerligs, "Recombinationactivity of interstitial iron and other transition metal point defects in p- and n-type crystalline silicon," Appl. Phys. Lett. 85, 2004, pp. 4061-3.[2] S. W. Glunz, S. Rein, J. Y. Lee, and W. Warta, "Minority carrier lifetime degradation in boron-doped Czochralski silicon," J. Appl. Phys.90, 2001, pp. 2397-404.[3] J. Zhao, A. Wang, P. P. Altermatt, S. R. Wenham, and M. A. Green, "24% efficient PERL silicon solar cell: recent improvements in high efficiency silicon cell research," Proc. 1st WCPEC, Hawaii, USA, 1994, pp. 87-99.[4] R. R. King and R. M. Swanson, "Studies of diffused boron emitters: saturation current, bandgap narrowing, and surface recombination velocity," IEEE Trans. Electron Devices38, 1991, pp. 1399-409.[5] A. Cuevas, M. Stuckings, J. Lau, and M. Petravic, "The recombination velocity of boron diffused silicon surfaces," Proc. 14th EC PVSEC, Barcelona, Spain, 1997, pp. 2416-9.[6] P. P. Altermatt, H. Plagwitz, R. Bock, J. Schmidt, R. Brendel, M. J. Kerr, and A. Cuevas, "The surface recombination velocity at boron-doped emitters: comparison between various passivation techniques," Proc. 21st EU PVSEC, Dresden, Germany, 2006, pp. 647-50.[7] J. Zhao, J. Schmidt, A. Wang, G. Zhang, B. S. Richards, and M. A. Green, "Performance instability in n-type PERT silicon solar cells," Proc. 3rd WCPEC, Osaka, Japan, 2003, pp. 923-6.[8] J. Libal, R. Petres, T. Buck, R. Kopecek, G. Hahn, R. Ferre, M. Vetter, I. Martín, K. Wambach, I. Roever, and P. Fath, "N-type multicrystalline silicon solar cells: BBr3-diffusion and passivation of P+-diffused silicon surfaces," Proc. 20th EC PVSEC Barcelona, Spain, 2005, pp. 793-6.[9] S. W. Glunz, D. Biro, S. Rein, and W. Warta, "Field-effect passivation of the SiO2-Si interface," J. Appl. Phys. 86, 1999, pp. 683-91.[10] R. A. Sinton, A. Cuevas, and M. Stuckings, "Quasi-steady-state photoconductance, a new method for solar cell material and device characterization," Proc. 25th IEEE PVSC, Washington DC, USA, 1996, pp. 457-60. [11] R. A. Sinton and A. Cuevas, "Contactless determination of current-voltage characteristics and minority-carrier lifetimes in semiconductors from quasi-steady-state photoconductance data," Appl. Phys. Lett.69, 1996, pp. 2510-2.[12] P. A. Basore, D. T. Rover, and A. W. Smith, "PC-1D version 2: enhanced numerical solar cell modelling," Proc. 20th IEEE PVSC, Las Vegas, Nevada, USA, 1988, pp. 389-96.[13] B. Hoex, J. Schmidt, R. Bock, P. P. Altermatt, M.C. M. van de Sanden, and W. M. M. Kessels, "Excellent passivation of highly doped p-type Si surfaces by the negative-charge-dielectric Al2O3," Appl. Phys. Lett.91, 2007, pp. 112107/1-3.[14] J. Benick, B. Hoex, R. Van de Sanden, E. Kessels, O. Schultz, and S. Glunz, "High efficiency n-type Si cells based on Al2O3-passivated boron emitters," Appl. Phys. Lett., 2008, pp. submitted.。

Exciton annihilation and diffusion in semiconducting polymersP. E. Shaw, A. J. Lewis, A. Ruseckas, I. D. W. SamuelOrganic Semiconductor Centre, SUPA, School of Physics and Astronomy, University of St Andrews, North Haugh, St Andrews, Fife KY16 9SS, United KingdomABSTRACTWe show that time-resolved luminescence measurements at high excitation densities can be used to study exciton annihilation and diffusion, and report the results of such measurements on films of P3HT and MEH-PPV. The results fit to an exciton-exciton annihilation model with a time independent annihilation rate γ, which was measured to be γ = (2.8±0.5)x10-8 cm3s-1 in MEH-PPV and γ = (5.2±1)x10-10 cm3s-1 in P3HT. This implies much faster diffusion in MEH-PPV. Assuming a value of 1 nm for the annihilation radius we evaluated the diffusion length for pristine P3HT in one direction to be 3.2 nm. Annealing of P3HT was found to increase the annihilation rate to (1.1±0.2)x10-9 cm3s-1 and the diffusion length to 4.7 nm.Keywords: Annihilation, Diffusion, Time-resolved, Fluorescence, Annealing, P3HT, MEH-PPV1.INTRODUCTIONThe properties of conjugated polymers make them promising materials for use in organic photovoltaic cells 1. Their high absorption coefficient, capability of charge transport, and solution-processing make them versatile materials that can be incorporated into a range of possible device structures. Photoexcitation of the polymer results primarily in singlet exciton formation2 with a relatively high binding energy in the range of 0.3 to 1 eV 3, 4. This factor means that dissociation of the excitons does not readily occur and that a charge-accepting material is required to provide an interface at which separation can occur.In organic solar cells this can be achieved by either depositing the polymer film directly onto a flat layer of charge accepting material,5 or by blending the two together to form a bulk heterojunction 6. This last approach has proved most effective with reported efficiencies of ~5% 7. In either case the performance will depend critically on the ability of the exciton to diffuse to an interface.From the time of generation the exciton diffuses by a random walk process through the polymer matrix. The rate of diffusion is known as the diffusion coefficient and will vary from polymer to polymer. The distance traveled by an exciton during its lifetime is the diffusion length. Longer diffusion lengths are desirable for solar cell materials.An important technique for measuring exciton diffusion is via the diffusion to a quencher method 8-11. Varying thicknesses of the polymer of interest are deposited onto a quenching surface such as a fullerene or TiO2 12. The properties of the quenching surface are essential for the effectiveness of this method. The quencher must be smooth, stable and capable of readily accepting charges in the vicinity. In addition the thickness of the polymer must be determined accurately – for example by spectroscopic ellipsometry.Of all the excitons generated within the polymer by photoexcitation a fraction of these will be close to the interface and likely to be quenched. By varying the thickness of the polymer film the extent of the quenching will also change, the effect of which can be detected by both steady-state and time-resolved measurements of the photoluminescence (PL). In both cases a reference film of the same thickness, deposited onto a non-quenching substrate, is also required for comparison. A value for the diffusion coefficient is typically calculated by fitting to the data with a diffusion model.An alternative technique is via exciton-exciton annihilation. At high exciton densities two excitons may fuse to form a higher energy exciton, which rapidly decays to the original excited state by phonon emission. This process requires the two excitons to be in close proximity to each other; so its rate depends on the density of excitons and how rapidly theyOrganic Photovoltaics VII, edited by Zakya H. Kafafi, Paul A. Lane,Proc. of SPIE Vol. 6334, 63340G, (2006) · 0277-786X/06/$15 · doi: 10.1117/12.681573diffuse. By measuring the rate of decay of photoluminescence as a function of excitation density, exciton annihilation and diffusion can be studied. An advantage of this method is that it does not require a quencher and is therefore less complex. In this paper we apply this technique to study exciton dynamics in the conjugated polymers P3HT and MEH-PPV, which are promising materials for light-emitting devices 13, 14, organic photovoltaics 15, 16 and field effect transistors 17, 18.2.EXPERIMENTAL METHODThe P3HT was supplied by Merck and has a regio-regularity of 98.5%. Solutions were prepared in chloroform and initially heated to 50° C for two hours while stirring to assist the dissolution of the polymer. All films were spin-coated onto fused silica substrates, which had been cleaned in an ultrasonic bath with acetone and propan-2-ol. Annealing was performed in the inert atmosphere of a glove box at 140° C for 2 hours.Time-resolved measurements were performed with the sample stored in a vacuum of ~5x10-5 mbar and excited from the polymer side. For the P3HT measurements excitation was in the form of 100 fs duration pulses of 505 nm wavelength at a frequency of 5 kHz. The low repetition rate ensures there is full relaxation of the excited states in the polymer between successive excitations. Time-resolved PL measurements were captured over the wavelength range of 610-730 nm with a Hamamatsu streak camera coupled with a Chromex imaging spectrograph. The diameter of the excitation spot was measured to be 280 µm with a beam profiler. The absorbance spectra were measured with a Varian Cary 300 spectrophotometer. Film thickness was calculated from the absorbance to be 48 nm.The data for the MEH-PPV was obtained by exciting the film with 100 fs pulses of 400 nm wavelength at a repetition rate of 50 kHz. The diameter of the excitation spot was measured to be 0.5 mm with the emission over the wavelength range 550-680 nm captured by the streak camera. Film thickness was calculated from the absorbance to be 35 nm.3.RESULTSThe structures of the materials studied, together with their absorption spectra are shown in figure 1. The time-resolved PL decays for MEH-PPV for a range of exciton densities are displayed in Fig. 2. The initial excitation density isresults in a single photoexcitation. At the lowest density (5x1016 cm -3) the decay is mono-exponential with a 1/e lifetime of 140 ps, but as the exciton density increases the decay becomes more rapid due to exciton-exciton annihilation. This can be modeled by the following rate equation:2)(n n dtt dn γκ−−= (1)where n(t) is the time dependent exciton density, κ is the exciton decay rate in the absence of annihilation and γ is the annihilation rate. Assuming the annihilation rate is time-independent, the solution to equation (1) is:)]exp(1)[0(1)exp()0()(t n t n t n κκγκ−−+−=(2)eeeP L I n t e n s i t y (n o r m a l i s e d )-3κκκγ−⎟⎟⎠⎞⎜⎜⎝⎛+=)exp()0(1)(1t n t n (3)From equation (3) the 1/n(t) dependence on exp(κt) is expected to be linear, which turns out to be true for MEH-PPV (Fig. 3), confirming that the annihilation rate γ is indeed time-independent. The gradient and intercept of the data give a value for γ = (2.8±0.5)x10-8 cm 3 s -1.1.21.62.02.42.80.05.0x10-181.0x10-171.5x10-172.0x10-171/n (t )Exp (κt)Fig. 3. Linearised annihilation data for a 38 nm MEH-PPV film. Excitation densities are given in cm -3.Time-resolved measurements of the PL decay of P3HT reveal an initial rapid decay component that prevents the full decay from being considered as mono-exponential (Fig. 4). However, the remainder of the decay is close to mono-exponential and so can be fitted to with the model if the initial ~50 ps are omitted. A value for the initial excitation n(0) is required to calculate the annihilation rate γ from the gradient and this was obtained by extrapolating the decay back to t = 0 as illustrated in Fig. 4. This approach yields a value for n(0) consistent with a time independent decay rate, which is what is assumed in the model.1.0x10181.0x1019n (t )Time (ps)Fig. 4. Exciton density as a function of time and initial excitation density for a P3HT film excited with 505 nm pulsesThe linearised results for the pristine film are presented in Fig. 5 with the extrapolated initial excitation densities in the inset. Linear fits agree well with the data and yield consistent values for the annihilation rate, the average of which was (5.2±1)x10-10 cm 3s -1.1/n (t )exp(κt)Fig. 5. Linearised annihilation data for pristine P3HT. The extrapolated n(0) are given in the inset.exp(κt)Fig. 6. Linearised annihilation data for annealed P3HT. The extrapolated n(0) are given in the inset.4. DISCUSSIONThe results reveal that the annihilation rate is faster in MEH-PPV than it is in P3HT by more than an order of magnitude, implying that the exciton diffusion rate must also be faster in MEH-PPV than it is in P3HT.The annihilation rate is related to the diffusion coefficient, D , by equation (4) where R a is the annihilation radius.D R a πγ4= (4)The annihilation radius is a critical variable in the determination of D , however it is one that is not easily measured experimentally. It corresponds to the separation at which the process of annihilation between two excitons is faster than diffusion and therefore likely to occur.The distance that an exciton can diffuse will be limited by its lifetime τ and is the diffusion length L D . For diffusion towards a quenching interface (in one direction):τD L D =(5)For the purpose of all the calculations presented for P3HT the value of R a was set to 1 nm. This is consistent with what others have assumed in the literature 21, 22 for this polymer. For the pristine film this gives D = (4.1±0.8)x10-4 cm 2s -1 and the diffusion length is estimated to be 3.2 nm using this value and the lifetime at low excitation intensities of 250 ps.For the annealed film the diffusion coefficient and diffusion length were calculated to be (8.8±2)x10-4 cm 2s -1 and 4.7 nm respectively, again assuming a value of 1 nm for R a . The doubling of the annihilation rate (and diffusion coefficient) shows that adjustments to processing can be used to enhance exciton diffusion. The benefits of thermally annealing P3HT/PCBM blends have been extensively reported 23, 24 and generally attributed to better mixing of the PCBM and the polymer matrix. The results presented here indicate that a proportion of this enhancement may be due to a reordering of the P3HT.For MEH-PPV the annihilation rate was calculated to be (2.8±0.5)x10-8 cm 3s -1, which gives a diffusion coefficient D = 2.2x10-2 cm 2s -1 for a value of R a of 1 nm. With a lifetime of 140 ps the diffusion length L D is therefore 18 nm. This value is at the high end of what has been reported 25, but the result is strongly influenced by the value assigned to the annihilation radius. It is possible that the annihilation radius of MEH-PPV is much bigger than it is for P3HT and increasing R a to 4 nm yields a diffusion coefficient of (5.6±1.0)x10-3 cm 2s -1 and a value for L D of 8.8 nm. Values reported so far in the literature for MEH-PPV, obtained via diffusion to an interface experiments, suggest a diffusion length in the range of 6-14 nm 11, 25, 26, which would be consistent with a larger value for R a .An estimate for the diffusion length can be obtained from the exciton density at which the onset of annihilation is detected. Assuming a uniform exciton distribution n(0) and that diffusion is isotropic then each exciton can be approximated as a sphere of radius L 3D , where L 3D is the sum of the 3-dimensional diffusion length and the annihilation radius. This calculation provides an upper limit for the diffusion length.1)0(3433=D L n π (6)In MEH-PPV the onset occurred at approximately n(0) = 1017 cm -3, which gives a value of L 3D ~ 13 nm. For P3HT the corresponding value of n(0) is higher at approximately 1018 cm -3, resulting in L 3D ~ 6 nm, which fits with the view that both the diffusion length and the annihilation radius are small and agrees well with the values calculated from the annihilation rate. The calculated diffusion length of 3.2 nm is consistent with that reported by Kroeze et al 22 of 2.6-5.3 nm and that of ~ 5 nm by Theander et al 10 for a similar polythiophene.The calculation of the diffusion coefficient from the annihilation rate is influenced by the value chosen for the annihilation radius and there is no reason why this should be the same for both MEH-PPV as P3HT. The low onset of annihilation may not be due solely to an increase in the diffusion coefficient, but could also be a consequence of a large annihilation radius too.5.CONCLUSIONSWe have shown that exciton annihilation is a useful technique for the study of solar cell materials. Exciton annihilation and diffusion is faster in MEH-PPV than in P3HT. In P3HT the rate of annihilation and diffusion can be doubled by thermal annealing, indicating that refinements to processing can enhance exciton diffusion.ACKNOWLEDGEMENTSThe authors would like to thank EPSRC for financial support.REFERENCES1Nelson, J., Current Opinion in Solid State and Materials Science2002, 6, 87.2Greenham, N. C.; Samuel, I. D. W.; Hayes, G. R.; Phillips, R. T.; Kessener, Y.; Moratti, S. C.; Holmes, A. B.;Friend, R. H., Chemical Physics Letters1995, 241, 89.3Frankevich, E. L.; Lymarev, A. A.; Sokolik, I.; Karasz, F. E.; Blumstengel, S.; Baughman, R. H.; Horhold, H.H., Physical Review B1992, 46, (15), 9320.4Scheidler, M.; Lemmer, U.; Kersting, R.; Karg, S.; Riess, W.; Cleve, B.; Mahrt, R.; Kurz, H.; Bassler, H.;Gobel, E.; Thomas, P., Physical Review B1996, 54, (8), 5536.5Oregan, B. and Gratzel, M., Nature1991, 353, (6346), 737.6Halls, J. J. M.; Walsh, C. A.; Greenham, N. C.; Marseglia, E. A.; Friend, R. H.; Moratti, S. C.; Holmes, A. B., Nature1995, 376, (6540), 498.7Li, G.; Shrotriya, V.; Huang, J. S.; Yao, Y.; Moriarty, T.; Emery, K.; Yang, Y., Nature Materials2005, 4, (11), 864.8Scully, S. R. and McGehee, M. D., Journal of Applied Physics2006, 100, 034907.9Gregg, B.; Sprague, J.; Peterson, M., Journal of Physical Chemistry B1997, 101, (27), 5362.10Theander, M.; Yartsev, A.; Zigmantas, D.; Sundstrom, V.; Mammo, W.; Andersson, M. R.; Inganas, O., Physical Review B2000, 61, (19), 12957.11Markov, D. E.; Hummelen, J. C.; Blom, P. W. M.; Sieval, A. B., Physical Review B2005, 72, 045216.12van Hal, P. A.; Christiaans, M. P. T.; Wienk, M. M.; Kroon, J. M.; Janssen, R. A. J., Journal of Physical Chemistry B1999, 103, (21), 4352.13Nguyen, T.; Kwong, R.; Thompson, M.; Schwartz, B., Applied Physics Letters2000, 76, (17), 2454.14Kim, Y. and Bradley, D. D. C., Current Applied Physics2005, 5, (3), 222.15Kim, Y.; Cook, S.; Tuladhar, S. M.; Choulis, S. A.; Nelson, J.; Durrant, J. R.; Bradley, D. D. C.; Giles, M.;McCulloch, I.; Ha, C.; Ree, M., Nature Materials2006, 5, 197.16Kawata, K.; Burlakov, V. M.; Carey, M. J.; Assender, H. E.; Briggs, G. A. D.; Ruseckas, A.; Samuel, I. D. W., Solar Energy Materials and Solar Cells2005, 87, 715.17Sirringhaus, H.; Tessler, N.; Friend, R., Science1998, 280, (5370), 1741.18Sirringhaus, H.; Brown, P. J.; Friend, R. H.; Nielsen, M. M.; Bechgaard, K.; Langeveld-Voss, B. M. W.;Spiering, A. J. H.; Janssen, R. A. J.; Meijer, E. W.; Herwig, P.; de Leeuw, D. M., Nature1999, 401, (6754),685.19Liu, Y.; Summers, M. A.; Edder, C.; Fréchet, J. M. J.; McGehee, M. D., Advanced Materials2005, 17, (24), 2960.20Kim, Y.; Choulis, S. A.; Nelson, J.; Bradley, D. D. C.; Cook, S.; Durrant, J. R., Applied Physics Letters2005, 86, 063502.21Dicker, G.; de Haas, M. P.; Siebbeles, L. D. A.; Warman, J. M., Physical Review B2004, 70, 045203.22Kroeze, J. E.; Savenije, T. J.; Vermeulen, M. J. W.; Warman, J. M., Journal of Physical Chemistry B2003, 107, (31), 7696.23Kim, Y.; Choulis, S. A.; Nelson, J.; Bradley, D. D. C.; Cook, S.; Durrant, J. R., Journal of Materials Science 2005, 40, (6), 1371.24Li, G.; Shrotriya, V.; Yao, Y.; Yang, Y., Journal of Applied Physics2005, 98, 043704.25Burlakov, V. M.; Kawata, K.; Assender, H. E.; Briggs, G. A. D.; Ruseckas, A.; Samuel, I. D. W., Physical Review B2005, 72, 075206.26Halls, J. J. M.; Pichler, K.; Friend, R. H.; Moratti, S. C.; Holmes, A. B., Applied Physics Letters1996, 68, (22), 3120.。