Single-crystal laser deposition of superalloys-processing–microstructure maps

- 格式:pdf

- 大小:1.22 MB

- 文档页数:12

《光电技术》专业英语词汇1.Absorption coefficient 吸收系数2.Acceptance angle 接收角3.fibers 光纤4.Acceptors in semiconductors 半导体接收器5.Acousto-optic modulator 声光调制6.Bragg diffraction 布拉格衍射7.Air disk 艾里斑8.angular radius 角半径9.Airy rings 艾里环10.anisotropy 各向异性11.optical 光学的12.refractive index 各向异性13.Antireflection coating 抗反膜14.Argon-ion laser 氩离子激光器15.Attenuation coefficient 衰减系数16.Avalanche 雪崩17.breakdown voltage 击穿电压18.multiplication factor 倍增因子19.noise 燥声20.Avalanche photodiode(APD) 雪崩二极管21.absorption region in APD APD 吸收区域22.characteristics-table 特性表格23.guard ring 保护环24.internal gain 内增益25.noise 噪声26.photogeneration 光子再生27.primary photocurrent 起始光电流28.principle 原理29.responsivity of InGaAs InGaAs 响应度30.separate absorption and multiplication(SAM) 分离吸收和倍增31.separate absorption grading and multiplication(SAGM) 分离吸收等级和倍增32.silicon 硅33.Average irradiance 平均照度34.Bandgap 带隙35.energy gap 能级带隙36.bandgap diagram 带隙图37.Bandwidth 带宽38.Beam 光束39.Beam splitter cube立方分束器40.Biaxial crystals 双轴晶体41.Birefringent 双折射42.Bit rate 位率43.Black body radiation law 黑体辐射法则44.Bloch wave in a crystal 晶体中布洛赫波45.Boundary conditions 边界条件46.Bragg angle 布拉格角度47.Bragg diffraction condition 布拉格衍射条件48.Bragg wavelength 布拉格波长49.Brewster angle 布鲁斯特角50.Brewster window 布鲁斯特窗51.Calcite霰石52.Carrier confinement 载流子限制53.Centrosymmetric crystals 中心对称晶体54.Chirping 啁啾55.Cladding覆层56.Coefficient of index grating 指数光栅系数57.Coherence 连贯性pensation doping 掺杂补偿59.Conduction band 导带60.Conductivity 导电性61.Confining layers 限制层62.Conjugate image 共轭像63.Cut-off wavelength 截止波长64.Degenerate semiconductor简并半导体65.Density of states 态密度66.Depletion layer 耗尽层67.Detectivity 探测率68.Dielectric mirrors 介电质镜像69.Diffraction 衍射70.Diffraction grating 衍射光栅71.Diffraction grating equation 衍射光栅等式72.Diffusion current 扩散电流73.Diffusion flux 扩散流量74.Diffusion Length 扩散长度75.Diode equation 二极管公式76.Diode ideality factor 二极管理想因子77.Direct recombination 直接复合78.Dispersion 散射79.Dispersive medium 散射介质80.Distributed Bragg reflector 分布布拉格反射器81.Donors in semiconductors 施主离子82.Doppler broadened linewidth 多普勒扩展线宽83.Doppler effect 多普勒效应84.Doppler shift 多普勒位移85.Doppler-heterostructure 多普勒同质结构86.Drift mobility漂移迁移率87.Drift Velocity 漂移速度88.Effective density of states 有效态密度89.Effective mass 有效质量90.Efficiency 效率91.Einstein coefficients 爱因斯坦系数92.Electrical bandwidth of fibers 光纤电子带宽93.Electromagnetic wave 电磁波94.Electron affinity 电子亲和势95.Electron potential energy in a crystal 晶体电子阱能量96.Electro-optic effects 光电子效应97.Energy band 能量带宽98.Energy band diagram 能量带宽图99.Energy level 能级100.Epitaxial growth外延生长101.Erbium doped fiber amplifier 掺饵光纤放大器102.Excess carrier distribution 过剩载流子扩散103.External photocurrent 外部光电流104.Extrinsic semiconductors 本征半导体105.Fabry-Perot laser amplifier 法布里-珀罗激光放大器106.Fabry-Perot optical resonator 法布里-珀罗光谐振器107.Faraday effect 法拉第效应108.Fermi-Dirac function 费米狄拉克结109.Fermi energy 费米能级110.Fill factor 填充因子111.Free spectral range 自由谱范围112.Fresnel’s equations菲涅耳方程113.Fresnel’s optical indicatrix 菲涅耳椭圆球114.Full width at half maximum半峰宽115.Full width at half power半功率带宽116.Gaussian beam 高斯光束117.Gaussian dispersion 高斯散射118.Gaussian pulse 高斯脉冲119.Glass perform玻璃预制棒120.Goos Haenchen phase shift Goos Haenchen相位移121.Graded index rod lens 梯度折射率棒透镜122.Group delay 群延迟123.Group velocity 群参数124.Half-wave plate retarder 半波延迟器125.Helium-Neon laser氦氖激光器126.Heterojunction 异质结127.Heterostructure 异质结构128.Hole 空穴129.Hologram 全息图130.Holography 全息照相131.Homojunction 同质结132.Huygens-Fresnel principle惠更斯-菲涅耳原理133.Impact-ionization 碰撞电离134.Index matching 指数匹配135.Injection 注射136.Instantaneous irradiance 自发辐射137.Integrated optics 集成光路138.Intensity of light 光强139.Intersymbol interference 符号间干扰140.Intrinsic concentration本征浓度141.Intrinsic semiconductors 本征半导体142.Irradiance 辐射SER 激光144.active medium 活动介质145.active region 活动区域146.amplifiers 放大器147.cleaved-coupled-cavity解理耦合腔148.distributed Bragg reflection 分布布拉格反射149.distributed feedback 分布反馈150.efficiency of the He-Ne 氦氖效率151.multiple quantum well 多量子阱152.oscillation condition 振荡条件ser diode 激光二极管sing emission 激光发射155.LED 发光二极管156.Lineshape function 线形结157.Linewidth 线宽158.Lithium niobate铌酸锂159.Load line 负载线160.Loss coefficient 损耗系数161.Mazh-Zehnder modulator Mazh-Zehnder型调制器162.Macrobending loss 宏弯损耗163.Magneto-optic effects 磁光效应164.Magneto-optic isolator 磁光隔离165.Magneto-optic modulator 磁光调制166.Majority carriers 多数载流子167.Matrix emitter 矩阵发射168.Maximum acceptance angle 最优接收角169.Maxwell’s wave equation 麦克斯维方程170.Microbending loss 微弯损耗171.Microlaser 微型激光172.Minority carriers 少数载流子173.Modulated directional coupler 调制定向偶合器174.Modulation of light 光调制175.Monochromatic wave 单色光176.Multiplication region 倍增区177.Negative absolute temperature 负温度系数 round-trip optical gain 环路净光增益179.Noise 噪声180.Noncentrosymmetric crystals 非中心对称晶体181.Nondegenerate semiconductors 非简并半异体182.Non-linear optic 非线性光学183.Non-thermal equilibrium 非热平衡184.Normalized frequency 归一化频率185.Normalized index difference 归一化指数差异186.Normalized propagation constant 归一化传播常数187.Normalized thickness 归一化厚度188.Numerical aperture 孔径189.Optic axis 光轴190.Optical activity 光活性191.Optical anisotropy 光各向异性192.Optical bandwidth 光带宽193.Optical cavity 光腔194.Optical divergence 光发散195.Optic fibers 光纤196.Optical fiber amplifier 光纤放大器197.Optical field 光场198.Optical gain 光增益199.Optical indicatrix 光随圆球200.Optical isolater 光隔离器201.Optical Laser amplifiers 激光放大器202.Optical modulators 光调制器203.Optical pumping 光泵浦204.Optical resonator 光谐振器205.Optical tunneling光学通道206.Optical isotropic光学各向同性的207.Outside vapor deposition管外气相淀积208.Penetration depth 渗透深度209.Phase change 相位改变210.Phase condition in lasers 激光相条件211.Phase matching 相位匹配212.Phase matching angle 相位匹配角213.Phase mismatch 相位失配214.Phase modulation 相位调制215.Phase modulator 相位调制器216.Phase of a wave 波相217.Phase velocity 相速218.Phonon 光子219.Photoconductive detector 光导探测器220.Photoconductive gain 光导增益221.Photoconductivity 光导性222.Photocurrent 光电流223.Photodetector 光探测器224.Photodiode 光电二极管225.Photoelastic effect 光弹效应226.Photogeneration 光子再生227.Photon amplification 光子放大228.Photon confinement 光子限制229.Photortansistor 光电三极管230.Photovoltaic devices 光伏器件231.Piezoelectric effect 压电效应232.Planck’s radiation distribution law 普朗克辐射法则233.Pockels cell modulator 普克尔斯调制器234.Pockel coefficients 普克尔斯系数235.Pockels phase modulator 普克尔斯相位调制器236.Polarization 极化237.Polarization transmission matrix 极化传输矩阵238.Population inversion 粒子数反转239.Poynting vector能流密度向量240.Preform 预制棒241.Propagation constant 传播常数242.Pumping 泵浦243.Pyroelectric detectors 热释电探测器244.Quantum efficiency 量子效应245.Quantum noise 量子噪声246.Quantum well 量子阱247.Quarter-wave plate retarder 四分之一波长延迟248.Radiant sensitivity 辐射敏感性249.Ramo’s theorem拉莫定理250.Rate equations速率方程251.Rayleigh criterion 瑞利条件252.Rayleigh scattering limit 瑞利散射极限253.Real image 实像254.Recombination 复合255.Recombination lifetime 复合寿命256.Reflectance 反射257.Reflection 反射258.Refracted light 折射光259.Refractive index 折射系数260.Resolving power分辩力261.Response time 响应时间262.Return-to-zero data rate 归零码263.Rise time 上升时间264.Saturation drift velocity 饱和漂移速度265.Scattering 散射266.Second harmonic generation 二阶谐波267.Self-phase modulation 自相位调制268.Sellmeier dispersion equation色列米尔波散方程式269.Shockley equation肖克利公式270.Shot noise肖特基噪声271.Signal to noise ratio 信噪比272.Single frequency lasers 单波长噪声273.Single quantum well 单量子阱274.Snell’s law斯涅尔定律275.Solar cell 光电池276.Solid state photomultiplier 固态光复用器277.Spectral intensity 谱强度278.Spectral responsivity 光谱响应279.Spontaneous emission 自发辐射280.stimulated emission 受激辐射281.Terrestrial light 陆地光282.Theraml equilibrium热平衡283.Thermal generation 热再生284.Thermal velocity 热速度285.Thershold concentration 光强阈值286.Threshold current 阈值电流287.Threshold wavelength 阈值波长288.Total acceptance angle 全接受角289.Totla internal reflection 全反射290.Transfer distance 转移距离291.Transit time 渡越时间292.Transmission coefficient 传输系数293.Tramsmittance 传输294.Transverse electric field 电横波场295.Tranverse magnetic field 磁横波场296.Traveling vave lase 行波激光器297.Uniaxial crystals 单轴晶体298.UnPolarized light 非极化光299.Wave 波300.Wave equation 波公式301.Wavefront 波前302.Waveguide 波导303.Wave number 波数304.Wave packet 波包络305.Wavevector 波矢量306.Dark current 暗电流307.Saturation signal 饱和信号量308.Fringing field drift 边缘电场漂移plementary color 补色310.Image lag 残像311.Charge handling capability 操作电荷量312.Luminous quantity 测光量313.Pixel signal interpolating 插值处理314.Field integration 场读出方式315.Vertical CCD 垂直CCD316.Vertical overflow drain 垂直溢出漏极317.Conduction band 导带318.Charge coupled device 电荷耦合组件319.Electronic shutter 电子快门320.Dynamic range 动态范围321.Temporal resolution 动态分辨率322.Majority carrier 多数载流子323.Amorphous silicon photoconversion layer 非晶硅存储型324.Floating diffusion amplifier 浮置扩散放大器325.Floating gate amplifier 浮置栅极放大器326.Radiant quantity 辐射剂量327.Blooming 高光溢出328.High frame rate readout mode 高速读出模式329.Interlace scan 隔行扫描330.Fixed pattern noise 固定图形噪声331.Photodiode 光电二极管332.Iconoscope 光电摄像管333.Photolelctric effect 光电效应334.Spectral response 光谱响应335.Interline transfer CCD 行间转移型CCD336.Depletion layer 耗尽层plementary metal oxide semi-conductor 互补金属氧化物半导体338.Fundamental absorption edge 基本吸收带339.Valence band 价带340.Transistor 晶体管341.Visible light 可见光342.Spatial filter 空间滤波器343.Block access 块存取344.Pupil compensation 快门校正345.Diffusion current 扩散电流346.Discrete cosine transform 离散余弦变换347.Luminance signal 高度信号348.Quantum efficiency 量子效率349.Smear 漏光350.Edge enhancement 轮廓校正351.Nyquist frequency 奈奎斯特频率352.Energy band 能带353.Bias 偏压354.Drift current 漂移电流355.Clamp 钳位356.Global exposure 全面曝光357.Progressive scan 全像素读出方式358.Full frame CCD 全帧CCD359.Defect correction 缺陷补偿360.Thermal noise 热噪声361.Weak inversion 弱反转362.Shot noise 散粒噪声363.Chrominance difference signal 色差信号364.Color temperature 色温365.Minority carrier 少数载流子366.Image stabilizer 手振校正367.Horizontal CCD 水平CCD368.Random noise 随机噪声369.Tunneling effect 隧道效应370.Image sensor 图像传感器371.Aliasing 伪信号372.Passive 无源373.Passive pixel sensor 无源像素传感器374.Line transfer 线转移375.Correlated double sampling 相关双采样376.Pinned photodiode 掩埋型光电二极管377.Overflow 溢出378.Effective pixel 有效像素379.Active pixel sensor 有源像素传感器380.Threshold voltage 阈值电压381.Source follower 源极跟随器382.Illuminance 照度383.Refraction index 折射率384.Frame integration 帧读出方式385.Frame interline transfer CCD 帧行间转移CCD 386.Frame transfer 帧转移387.Frame transfer CCD 帧转移CCD388.Non interlace 逐行扫描389.Conversion efficiency 转换效率390.Automatic gain control 自动增益控制391.Self-induced drift 自激漂移392.Minimum illumination 最低照度393.CMOS image sensor COMS图像传感器394.MOS diode MOS二极管395.MOS image sensor MOS型图像传感器396.ISO sensitivity ISO感光度。

氧化锡纳米结构的制备及光致发光性能李立珺【摘要】利用热蒸发法成功制备出了两种氧化锡纳米结构.利用X射线衍射法、拉曼光谱、扫描电子显微镜和透射电子显微镜对两种纳米结构的晶格结构和表面形貌做了详细分析,结果表明所制纳米结构为金红石型氧化锡晶体结构,氧化锡纳米结构的形貌与实验中所用的源材料有着很大的关系.以氧化锡和碳粉的混合物为源,制备出的纳米线长且直,直径在50~200nm之间,以氧化亚锡和碳粉为源,制备出的纳米结构短且多弯折,直径在150nm左右.研究了所制氧化锡纳米材料的室温光致发光性能,发光峰位于590、630和677nm处.【期刊名称】《功能材料》【年(卷),期】2013(044)009【总页数】4页(P1269-1271,1276)【关键词】氧化锡;纳米结构;热蒸发法;X射线衍射;光致发光【作者】李立珺【作者单位】西安邮电大学电子工程学院,陕西西安710121【正文语种】中文【中图分类】TB334;O782+.91 引言SnO2作为一种重要的宽禁带半导体功能材料,由于具有优异的光学、电学特性,在气敏传感器[1]、透明导电材料[2]、紫外探测器[3]、场发射器件[4]等众多领域具有广阔的潜在应用前景,引起了人们的广泛关注。

由于特殊的物理属性和在纳米级器件上的应用,近年来一维纳米结构已经引起了人们强烈的兴趣。

SnO2纳米结构的研究也取得了重大的进展。

通常制备SnO2纳米结构的方法有水热合成法[5]、化学气相沉积法[6],激光脉冲沉积法[7]和热蒸发法[8-12]。

其中热蒸发法最为常用,该方法制备的产品纯度高,均一性好,可通过改变反应条件实现可控制性生长。

目前,已通过控制实验温度、气压、气流量、催化剂等工艺条件制备出了不同形貌的纳米结构,如纳米片[8]、纳米线[9]、纳米带[10]、之字状结构[11]及鱼骨状结构[12]等。

通过改变源材料配比,也能影响到纳米结构形貌的变化,而目前相关报道较少。

本文通过改变源材料配比,利用热蒸发法成功制备出了两种不同形貌的氧化锡纳米结构,进行了形貌和结构表征,并初步研究了所制两种氧化锡纳米结构的室温光致发光性能。

第49卷第6期2021年6月硅酸盐学报Vol. 49,No. 6June,2021 JOURNAL OF THE CHINESE CERAMIC SOCIETY DOI:10.14062/j.issn.0454-5648.20200617Sb2Te3基热电薄膜的研究进展易文1,2,赵永杰1,王伯宇1,周志方2,李亮亮2,李静波1(1. 北京理工大学材料学院, 北京 100081;2. 清华大学材料学院,北京 100084)摘要:基于热电薄膜的微型热电器件在微区制冷、温差发电等领域具有广阔应用前景。

具有高功率因子、ZT值的热电薄膜对微型热电器件的性能至关重要。

Sb2Te3基材料是室温下性能优异的p型热电材料。

然而,目前Sb2Te3基薄膜的热电性能仍然不能满足实际应用的需求。

简述了热电材料研究的相关背景,介绍了Sb2Te3的晶体结构,概述了Sb2Te3基薄膜的常用制备技术,从提高功率因子和降低热导率2方面综述了提高Sb2Te3基薄膜热电性能的方法。

重点介绍了材料组织、微观结构与热电性能的关系,即缺陷、择优取向、纳米颗粒、超晶格、有机无机杂化等对Sb2Te3基薄膜热电性能的影响。

此外,对Sb2Te3基热电薄膜的发展方向予以展望。

关键词:热电薄膜;碲化锑;热电性能;功率因子;热导率中图分类号:TB34 文献标志码:A 文章编号:0454–5648(2021)06–1111–14网络出版时间:2021-04-06Research Progress on Antimony Telluride Based Thermoelectric Thin FilmsYI Wen1,2, ZHAO Yongjie1, WANG Boyu1, ZHOU Zhifang2, Li Liangliang2, Li Jingbo1(1. School of Materials Science and Engineering, Beijing Institute of Technology, Beijing 100081, China;2. School of Materials Science and Engineering, Tsinghua University, Beijing 100084, China)Abstract: Micro thermoelectric devices based on thermoelectric films have promising applications in various fields such as micro-zone refrigeration and power generation. Thermoelectric films with high power factor and large ZT values are critical materials in these devices. Sb2Te3-based materials are outstanding p-type thermoelectric materials at room temperature. However, the thermoelectric properties of Sb2Te3-based thin films cannot meet the requirement of practical applications. The research background of thermoelectric materials is briefly introduced, the crystal structure of Sb2Te3 is discussed, the preparation techniques of Sb2Te3-based thin films are outlined, and the methods of improving the power factor and reducing the thermal conductivity of Sb2Te3-based thin films are summarized. In particular, the effects of microstructure on thermoelectric properties are focused on to elucidate the mechanism of improving thermoelectric properties of the films, which includes defects, preferential orientation, nanoparticles, superlattice, organic-inorganic hybridization, and so on. In addition, the future research directions for Sb2Te3-based thermoelectric thin films are discussed.Keywords:thermoelectric thin film; antimony telluride; thermoelectric property; power factor; thermal conductivity当前,能源危机、全球变暖、环境污染等问题日益严重,因此,寻找资源丰富、环境友好的新能源材料,并实现能源的高效利用至关重要[1-3]。

纳米材料和纳米结构P hysical V apor D eposition物理气相沉积第七讲Physical Vapor Deposition (PVD)物理气相沉积一、Definition定义Film deposition by condensation(凝结) from vapor phase(气相)从气相凝结的薄膜沉积二、Three Steps of PVD:(PVD的三个步骤:)1、Generating a vapor phase by evaporation or sublimation(用蒸发或升华生成一个气相)1、Electron-beam evaporation(电子束蒸发)2、Molecular-beam epitaxy(分子束外延)3、Thermal evaporation(热蒸发)4、Sputtering (溅射)5、Cathodic arc plasma deposition(阴极电弧等离子沉积)6、Pulsed laser deposition(脉冲激光沉积)2、Transporting the material from the source to the substrate(把原材料导入基底;)3、Formation of film by nucleation and diffusion(集结和扩散作用形成薄膜;)三、Application(应用)1、Coatings of electronic materials(电子材料的镀膜)Insulator绝缘体Semiconductor半导体Conductor导体Superconductor(超导体)2、Nanometer scale multilayer structures(纳米尺寸的层结构)Advanced electronic devices先进电子设备Abrasion resistant coatings耐磨涂料四、Concerned Problems(关注问题)*Contamination at the interfaces or intermixing(在物质界面和混合下的污染情况) * Multi-material systems involved(相关的复合材质系统;)* Cost of equipment and maintenance(器材和维护费用)* Complexion of operation(运算情况)五、Systems Described in This Section(此节中描述的系统)Sputtering(溅射法)Pulsed laser deposition(脉冲激光沉积法)1 Sputtering(溅射)1-1 Principle of Sputtering(溅射原理)1-2 Sputtering System(溅射系统)1-3 Preparing Multilayer Structures by Sputtering(溅射法备制多分子层结构) 1-4 Current Status of Sputtering(溅射法的近况)1-11-1 Principle of Sputtering(溅射原理)1、Ejection of Atoms from the Target(靶物质原子的喷溅)* Accomplished by an energetic particle bombarding a target surface with sufficient energy (50 eV – 1 000 eV)(在足够电压下(大概50---1000eV),高能量粒子撞击靶物质表面来完成喷溅。

纳米结构与纳米材料基础词汇纳米科学技术Nano-ST自上而下top down自下而上bottom up纳米物质Nanostructured materials国家纳米技术推进计划National Nanotechnology Initiative--NNI纳米科学nanoscience纳米技术狭义的nanotechnology纳米工程nanoengineering超薄膜ultrathin films体材料bulk materials纳米技术nano scale technology纳米科学nano scale science纳米材料nanostructure materials或nanomaterials纳米结构nanostructure1.纳米材料nanomaterial2. 纳米晶或纳米相nanocrystalline or nanophase3.纳米非晶态材料nano amorphous materials4. 纳米半导体材料nano semiconductors5.纳米陶瓷材料nano ceramic materials6.纳米复相材料nanomultiphase materials7.纳米结构nanostructural8. 纳米技术nanotechnology9.纳米组装体系nanostructured assembling system10. 胶体化学colloid chemistry11.人造超原子artificial superatoms12. 原子簇cluster13.超微粒子ultra-fine particle14. 人造原子artificial atoms15.扫描隧道显微镜scanning tunneling microscope, STM 16.化学气相沉积chemical vapor deposition CVD17.激光诱导化学气相沉积laser induced chemical vapor deposition LICVD18.性质property19. 力学性质mechanical property20.光学性质optics property21. 电学性质electronics property22.磁学性质magnetic property22. 纳米结构块体nanaostructureed bulk23.纳米复合材料nano-composite materials24. 纳米簿膜材料nanofllm materials25.溶胶—凝胶法Sol-Gel26. 碳纳米管carbon nano-tube27.同轴纳米电缆coaxial nanocable28. 抗折强度flexural strength29.微观形貌microstructure30. 透射电镜TEM tunneling electric microscope31.介观固体mesoscopy solid32.气体蒸发法gas evaporation method33.气体冷凝法gas-condensatin method34. 蓝移blue shift35.红移red shift36.磁性液体magnetic fluid37.纳米生物材料nano-biomaterials38.单晶single crystal39.多晶polycrystal40. 粘度viscosity41.抗拉强度tensile strength42.抗压强度compressive strength43.晶界crystal boundary44.纳米超导体nanosuperconductor45.半导体semiconductor46.介电性能dielectric performance47.纳米器件nano-device48.纳米机器人nanorobert49.微机电系统MEMS microelectric mechanics system50.化合物compound51.电子特性electronic character52.量子点quantum dot53纳米阵列nanoarray54.表面效应surface effect55.量子尺寸效应quantum size effect56.散射dispersion57.吸收absorb58.量子理论quantum theory59.能带理论energy bind theory60.催化catalysis61.纳米结构陶瓷nano-structural ceramics62.界面boundary63. 制备方法produced method64.液相法liquid-phase method65. 固相法solid-phase method66.共沉淀法co-precipitate method67. 纤维fiber68.超细粉末ultra-fine powder69. 团聚agglomerate70.量子芯片quantum chip77. 一维one dimension78.二维two dimension79. 三维three dimension80.强度strength81. 结构陶瓷structural ceramics 82.塑性形变plastic deformation83.脆性断裂brittle fracture84.量子quantum85.机理mechanism86.功能陶瓷functional ceramics87.功能玻璃functional glass88.金属Metal89.合金Alloy90.硬度hardness91分散disperse92.表面活性剂surface activity reagent93.表面修饰surface modify94. 纳米线nano-line95. 纳米丝nano-thread96.纳米棒nano-rod97. 氢键hydrogen valent98.纳米自组装nano-self- assembling99. 结构与性能composition structure performance100.多量子阱自组装self- assembling multi-quantum-well structure纳米尺度nanoscale纳米基元nano-unit纳米结构单元nanostructure unit纳米材料nanomaterial纳米技术nanotechnology纳米结构体系nanostructure system纳米组装体nanostructure assembling system 纳米器件nanodevice碳纳米管carbon nanotubes,CNTs原子团簇atom cluster单分散颗粒[系] monodispersed particle纳米颗粒nanoparticle团粒aggregate纳米粉体nano-powder纳米纤维nano-fibre纳米薄膜nano-film纳米块体nano-bulk纳米孔nano-pore纳米晶体材料nanocrystalline material 纳米非晶材料amorphous nanomaterial纳米准晶材料quasi-crystal nanomaterial金属纳米材料metallic nanomaterial无机非金属纳米材料inorganic non-metallic nanomaterial高分子纳米材料polymer nanomaterial纳米复合材料nanocomposites结构纳米材料structured nanomaterial功能纳米材料functional nanomaterial生物医用纳米材料biomedical nanomaterial 小尺寸效应small-size effect表面效应surface effect量子尺寸效应quantum size effect宏观量子隧道效应macroscopic quantum tunneling effect,MQT惰性气体沉积法inert gas deposition物理粉碎法physics grinding高能球磨法high energy ball mill溅射法sputtering物理粉碎法physics grinding 爆炸法explosion 喷雾法spraying冷冻干燥法freeze drying化学气相沉积法chemical vapor deposition,CVD沉淀法precipitation水热合成法hydrothermal synthesis溶胶-凝胶法sol-gel辐射化学合成法radiation chemical synthesis快速凝固法rapidly quenching强烈塑性变形法severe(intense) plastic deformation非晶晶化法amorphous solid crystallization 溅射法sputtering非晶晶化法crystallization of amorphous solid原位复合法in-situ composite插层复合法intercalation hybrids微乳液法micro emulsion模板合成法template synthesis自组装法self-assembly石墨电弧放电法graphite arc discharge快速凝固法rapidly quenching表面处理surface treatment表面修饰surface decoration稳定化处理passivating treatmentX射线衍射法X-ray diffractometry ,XRD扫描探针显微镜scanning probe microscopy, SPM扫描隧道显微镜scanning tunneling microscopy, STM扫描近场光学显微镜scanning near-field optical microscopy, SNOM原子力显微镜atomic force microscopy, AFM 扫描电容显微镜scanning capacitance microscopy, SCM磁力显微镜magnetic force microscopy, MFM扫描热显微镜scanning thermal microscopy, STHMX射线衍射法X-ray diffractometry ,XRDX射线衍射线宽化法X-ray diffractometry line broadening, XRD-LBX射线小角度散射法small angle X-ray scattering, SAXS透射电子显微镜法transmission electron microscopy ,TEM 透射电镜法TEM method扫描电子显微镜法scanning electron microscopy , SEM扫描电镜法SEM method拉曼光谱法raman spectrometry红外吸收光谱法infrared absorption spectroscopy穆斯堡尔谱法mossbauer spectrometry光子相关谱法photon correlation spectroscopyBET法BET压汞仪法mercury porosimetry纳米压痕仪nano impress,NI4.6.16扫描探针显微法scanning probe microscopy, SPM扫描隧道电子显微法scanning tunneling electron microscopy,STM扫描近场光学显微法scanning near-field optical microscopy,SNOM原子力显微法atomic force microscopy,AFM扫描电容显微法scanning capacitance microscopy, SCM扫描热显微法scanning thermal microscopy, STHM场离子显微法field ion microscopy, FIM磁力显微法magnetic force microscopy, MFM激光干涉仪laser interferometer激光衍射/散射法laser diffraction and scattering离心沉降法centrifugal sedimentation。

1. semiconductor: 半导体,常温下导电性能介于导体(conductor)与绝缘体(insulator)之间的材料。

2. light-emitting diode (LED): 发光二极管3. laser diode (LD): 半导体激光器4. photodiode: 光电二极管5. electrons: 电子6. holes: 空穴7. energy gap: 能隙8. photon: 光子9. insulator: 绝缘体10. transistor: 晶体管11. solar cell: 太阳能电池12. quantum dot: 量子点13. doping: 掺杂。

14. Pauli exclusion principle: 泡利不相容原理。

15. Fermi level: 费米能级16. valence band: 价带17. conduction band: 导带18. optical fiber: 光纤19. energy level: 能级。

20. electron–hole pair: 电子-空穴对。

21. impurity: 杂质。

22. dopant: 掺杂剂。

23. intrinsic (pure) semiconductor: 纯半导体。

24. p-type semiconductor: P 型半导体25. n-type semiconductor: N 型半导体。

26. p–n junction: PN 结27. space charge region(depletion layer): 空间电荷区(耗尽层)。

28. forward-bias voltage: 正向偏置电压29. ground state: 基态30. upper level: 上能级31. lower level: 下能级33. electromagnetic radiation:电磁辐射。

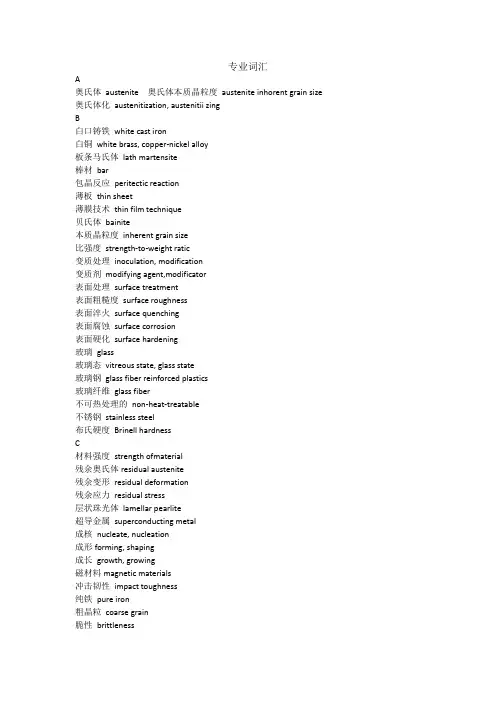

专业词汇A奥氏体austenite 奥氏体本质晶粒度austenite inhorent grain size 奥氏体化austenitization, austenitii zingB白口铸铁white cast iron白铜white brass, copper-nickel alloy板条马氏体lath martensite棒材bar包晶反应peritectic reaction薄板thin sheet薄膜技术thin film technique贝氏体bainite本质晶粒度inherent grain size比强度strength-to-weight ratic变质处理inoculation, modification变质剂modifying agent,modificator表面处理surface treatment表面粗糙度surface roughness表面淬火surface quenching表面腐蚀surface corrosion表面硬化surface hardening玻璃glass玻璃态vitreous state, glass state玻璃钢glass fiber reinforced plastics玻璃纤维glass fiber不可热处理的non-heat-treatable不锈钢stainless steel布氏硬度Brinell hardnessC材料强度strength ofmaterial残余奥氏体residual austenite残余变形residual deformation残余应力residual stress层状珠光体lamellar pearlite超导金属superconducting metal成核nucleate, nucleation成形forming, shaping成长growth, growing磁材料magnetic materials冲击韧性impact toughness纯铁pure iron粗晶粒coarse grain脆性brittleness脆性断裂brittle fracture淬火quenching, quench淬透性hardenability淬硬性hardenabilityD带材baud, strip单晶single crystal, unit crystal单体monomer, element氮化层nitration case氮化物nitride刀具cutting tool导磁性magnetic conductivity导电性electric conductivity导热性heat conductivity, thermal conductivity导体conductor等离子堆焊plasma surfacing等离子弧喷涂plasma spraying等离子增强化学气相沉积Plasma chemical vapour deposition (PCVD) 等温转变曲线isothermal transformation curve低合金钢low alloy steel低碳钢low carbon steel低碳马氏体low carbon?martensite低温回火low tempering点阵常数grating constant, lattice constant电镀electroplating, galvanize电弧喷涂electric arc spraying电子显微镜electron microscope定向结晶directional solidification S端淬试验end quenching test断口分析fracture analysis断裂强度breaking strength, fracture strength断裂韧性fracture toughness断面收缩率contraction of cross sectional area,锻造forge, forging, smithing多晶体polycrystalE二次硬化secondaryhardening二元合金binary alloy, two-component alloyF防锈的rust-proot, rust resistant非金属non-metal, nonmetal非晶态amorphous stats分子键molecular bond分子结构molecular structure分子量molecular weight酚醛树脂bakelite, phenolic resin粉末治金powder metallurgy粉末复合材料particulate composite腐蚀corrosion, corrode, etch, etching腐蚀剂corrodent, corrosive, etchant复合材料composite materialG感应淬火inductionquenching刚度rigidity, stiffness钢steel钢板steel plate钢棒steel bar钢锭steel ingot钢管steel tube, steel pipe钢丝steel wire钢球steel ball杠杆定理lever rule, lever principle高分子聚合物high polymer, superpolymer 高合金钢high alloy steel高锰钢high manganess steel高频淬火high frequency quenching高速钢high speed steel ,quick-cutting steel 高碳钢high-carbon steel高碳马氏体high carbon martensite高弹态elastomer高温回火high tempering各向同性isotropy各向异性anisotropy, anisotropism工程材料engineering material工具钢tool steel工业纯铁industrial pure iron工艺technology共价键covalent bond共晶体eutectic共晶反应eutectic reaction共析体eutectoid共析钢eatectoid steel功能材料functional materials固溶处理solid solution treatment固溶强化solution strengthening固溶体solid solution固相solid phase光亮热处理bright heat treatment滚珠轴承钢ball bearing steel过饱和固溶体supersaturated solid solution过共晶合金hypereutectic alloy过共析钢hypereutectoid steel过冷over-cooling, supercooling过冷奥氏体supercooled austenite过冷度degree of supercooling过热overheat, superheatH焊接welding, weld航空材料aerial material合成纤维synthetic fiber合金钢alloy steel合金化alloying合金结构钢structural alloy steel黑色金属ferrous metal红硬性red hardness滑移slip, glide滑移方向glide direction, slip direction滑移面glide plane, slip plane滑移系slip system化合物compound化学气相沉积chemical vapour eposition (CVD) 化学热处理chemical heat treatmentJ基体matrix机械混合物mechanical mixture机械性能mechanical property激光热处理heat treatment with a laser beam 激光laser激光熔凝laser melting and consolidation激光表面硬化surface hardening by laser beam 加工硬化work hardening加热heating胶粘剂adhesive结构材料structural material结晶crystallize, crystallization结晶度crystallinity金属材料metal material金属化合物metallic compound金属键metallic bond金属组织metal structure金属结构metallic framework金属塑料复合材料plastimets金属塑性加工metal plastic?working金属陶瓷metal ceramic金相显微镜metallographic microscope, metalloscope金相照片metallograph晶胞cell晶格crystal lattice晶格常数lattice constant晶格空位lattice vacancy晶粒crystal grain晶粒度grain size晶粒细化grain refining晶体结构crystal structure聚四氟乙烯polytetrafluoroethy lene (PTFE)聚合度degree of polymerization聚合反应polymerization绝热材料heat-insulating material绝缘材料insulating materialK抗拉强度tensile strength抗压强度compression strength颗粒复合材料particle composite扩散diffusion, diffuseL老化aging莱氏体ledeburite冷变形cold deformation冷加工cold work, cold working冷却cool, cooling冷作硬化cold hardening离子ion粒状珠光体granular pearlite连续转变曲线continuous cooling transformation(CCT) curve 孪晶twin crystal孪生twinning, twin螺旋位错helical dislocation洛氏硬度Rockwell hardnessM马氏体martensite (M)密排六方晶格close-packed xagonal lattice (C.P.H.)面心立方晶格face-centred cubic lattice (F.C.C.)摩擦friction磨损wear, abrade, abrasion模具钢die steelMf 点martensite finishing pointMs点martensite starting pointN纳米材料nanostructuredmaterials耐磨钢wear-resisting steel耐磨性wearability, wear resistance耐热钢heat resistant steel , high temperature steel内耗internal friction内应力internal stress尼龙nylon粘弹性viscoelasticity凝固solidify, solidification扭转强度torsional strength扭转疲劳强度torsional fatigue strengthP泡沫塑料foamplastics, expanded plastics配位数coordination number喷丸硬化shot-peening疲劳强度fatigue strength疲劳寿命fatigue life片状马氏体lamellar martensite, plate type martensite普通碳钢ordinary steel, plain carbon steelQ气体渗碳gas carburizing切变shear切削cut, cutting切应力shearing stress球化退火spheroidizing annealing球墨铸铁nodular graphite cast iron, spheroidal graphitecast iron 球状珠光体globular pearlite屈服强度yielding strength, yield strength屈强比yielding-to-tensile ratio屈氏体troolstite (T)去应力退火relief annealingR热处理heat treatment热加工hot work, hot working热喷涂thermal spraying热固性thermosetting热塑性hot plasticity热硬性thermohardening柔顺性flexibility人工时效artificial ageing刃具cutting tool刃型位错edge dislacation, blade dislocation韧性toughness溶质solute溶剂solvent蠕变creep蠕墨铸铁quasiflake graphite cast iron软氮化soft nitridingS扫描电镜scanning electronmicroscope (SEM)上贝氏体upper bainite渗氮nitriding渗硫sulfurizing渗碳carburizing, carburization渗碳体cementite (Cm)失效failure石墨graphite (G)时间-温度转变曲线time temperature transformation (TTT) curve 时效硬化age-hardening实际晶粒度actual grain size使用寿命service life使用性能usability树枝状晶dendrite树脂resin双金属bimetal, duplex metal水淬water quenching, water hardening, water quench松弛relax , relaxation塑料plastics塑性plasticity, ductility塑性变形plastic deformation索氏体sorbite (S)T弹簧钢spring steel弹性elasticity, spring弹性变形elastic deformation弹性极限elastic limit弹性模量elastic modulus碳素钢carbon steel碳含量carbon content碳化物carbide碳素工具钢carbon tool steel陶瓷ceramic陶瓷材料ceramic material体心立方晶格body-centered cubic lattice (B.C. C.)体型聚合物three-dimensional polymer调质处理quenching and tempering调质钢quenched and tempered steel铁碳平衡图iron-carbon equilibrium diagram透明(结晶)陶瓷crystalline ceramics同素异构转变allotropic transformation涂层coat, coating退火anneal, annealing托氏体troostite (T)W弯曲bend, bending完全退火full annealing微观组织microstructure维氏硬度Vickers hardness未经变质处理的uninoculated温度temperature无定形的amorphous物理气相沉积physical vapour deposition (PVD)X下贝氏体lower bainite线型聚合物linear polymer纤维fibre, fiber纤维增强复合材料filament reinforced composite显微照片metallograph,microphotograph, micrograph 显微组织microscopic structure, microstructure橡胶rubber相phase相变phase transition相图phase diagram消除应力退火stress relief annealing形状记忆合金Shape memory alloys形变deformation性能performance, propertyX射线结构分析X-ray structural analysisY压力加工press work亚共晶铸铁hypoeutectic cast iron亚共析钢hypoeutectoid steel氧化物陶瓷oxide ceramics延伸率elongation percentage盐溶淬火salt both quenching液相liquid phase应变strain应力stress应力场强度因子stress intensity factror应力松弛relaxation of stress硬质合金carbide alloy, hard alloy油淬oil quenching, oil hardening有机玻璃methyl-methacrylate, plexiglass 有色金属nonferrous metal匀晶uniform grain孕育处理inoculation, modificationZ再结晶退火recrystallization annealing载荷load增强塑料reinforced plastics针状马氏体acicular martensite正火normalize, normalization致密度tightness支化型聚合物branched polymer智能材料intelligent materials中合金钢medium alloy steel轴承钢bearing steel轴承合金bearing alloy珠光体pearlite (P)柱状晶体columnar crystal铸造cast , foundry自然时效natural ageing自由能free energy组元component, constituent组织structureα钛合金αtitanium alloy。

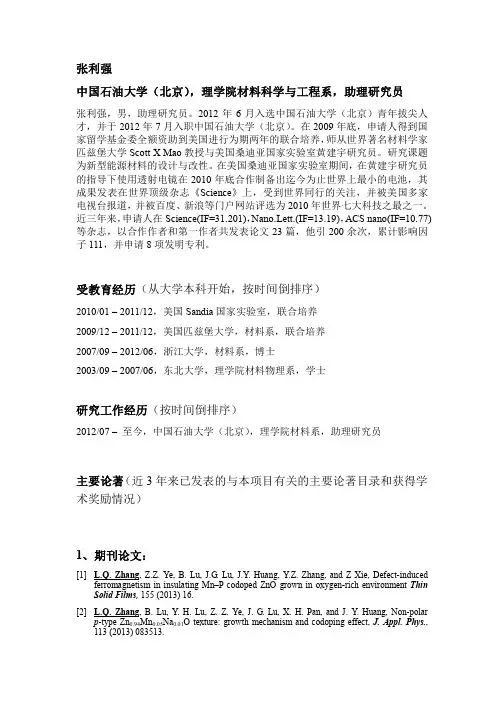

张利强中国石油大学(北京),理学院材料科学与工程系,助理研究员张利强,男,助理研究员。

2012年6月入选中国石油大学(北京)青年拔尖人才,并于2012年7月入职中国石油大学(北京)。

在2009年底,申请人得到国家留学基金委全额资助到美国进行为期两年的联合培养,师从世界著名材料学家匹兹堡大学Scott X Mao教授与美国桑迪亚国家实验室黄建宇研究员。

研究课题为新型能源材料的设计与改性。

在美国桑迪亚国家实验室期间,在黄建宇研究员的指导下使用透射电镜在2010年底合作制备出迄今为止世界上最小的电池,其成果发表在世界顶级杂志《Science》上,受到世界同行的关注,并被美国多家电视台报道,并被百度、新浪等门户网站评选为2010年世界七大科技之最之一。

近三年来,申请人在Science(IF=31.201),Nano.Lett.(IF=13.19),ACS nano(IF=10.77)等杂志,以合作作者和第一作者共发表论文23篇,他引200余次,累计影响因子111,并申请8项发明专利。

受教育经历(从大学本科开始,按时间倒排序)2010/01 – 2011/12,美国Sandia国家实验室,联合培养2009/12 – 2011/12,美国匹兹堡大学,材料系,联合培养2007/09 – 2012/06,浙江大学,材料系,博士2003/09 – 2007/06,东北大学,理学院材料物理系,学士研究工作经历(按时间倒排序)2012/07 – 至今,中国石油大学(北京),理学院材料系,助理研究员主要论著(近3年来已发表的与本项目有关的主要论著目录和获得学术奖励情况)1、期刊论文:[1]L.Q. Zhang, Z.Z. Ye, B. Lu, J.G. Lu, J.Y. Huang, Y.Z. Zhang, and Z Xie, Defect-inducedferromagnetism in insulating Mn–P codoped ZnO grown in oxygen-rich environment Thin Solid Films, 155 (2013) 16.[2]L.Q. Zhang, B. Lu, Y. H. Lu, Z. Z. Ye, J. G. Lu, X. H. Pan, and J. Y. Huang, Non-polarp-type Zn0.94Mn0.05Na0.01O texture: growth mechanism and codoping effect, J. Appl. Phys., 113 (2013) 083513.[3]L.Q. Zhang, X.H. Liu, Y.-C. Perng, J. Cho, J.P. Chang, S.X. Mao, Z.Z. Ye, and J.Y. Huang,Direct observation of Sn crystal growth during the lithiation and delithiation processes of SnO2 nanowires,Micron, 43 (2012) 1127.[4]L.Q. Zhang, Y.Z. Zhang, Z.Z. Ye, J.G. Lu, B. Lu, B. He, The effects of group-I elementsco-doping with Mn in ZnO dilute magnetic semiconductor, J. Appl. Phys.,111 (2012) 123524.[5]L.Q. Zhang, X.H. Liu, Y. Liu, S. Huang, T. Zhu, L.J. Gui, S.X. Mao, Z.Z. Ye, C. M. Wang, J.P. Sullivan, J.Y. Huang, Controlling the Lithiation-Induced Strain and Charging Rate in Nanowire Electrodes by Coating, ACS Nano, 5 (2011) 4800-4809.[6]L.Q. Zhang, Z.Z. Ye, J.Y. Huang, B. Lu, H.P. He, J.G. Lu, Y.Z. Zhang, J. Jiang, J. Zhang,K.W. Wu, W.G. Zhang, Fabrication and properties of p-type K doped Zn1-x Mg x O thin film, J.Alloys Compd.,509 (2011) 7405-7409.[7]L.Q. Zhang, Z.Z. Ye, B. Lu, J.G. Lu, Y.Z. Zhang, L.P. Zhu, J.Y. Huang, W.G. Zhang, J.Huang, J. Zhang, J. Jiang, K.W. Wu, Z. Xie, Ferromagnetism induced by donor-related defects in Co-doped ZnO thin films, J. Alloys Compd.,509 (2011) 2149-2153[8]L.Q. Zhang, Z.Z. Ye, B. Lu, J.G. Lu, Y.Z. Zhang, L.P. Zhu, J. Zhang, J. Jiang, K.W. Wu, B.He, Fabrication and properties of Li-doped ZnCoO diluted magnetic semiconductor thin films. Superlattices Microstruct.,50 (2011) 261-268[9]L.Q. Zhang, Z.Z. Ye, S.S. Lin, Y.Z. Zhang, B. Lu, H. P. He, L. X. Chen, J. G. Lu, J. Jiang,K.W. Wu, J.Y. Huang, L. P. Zhu, The fabrication of Na doped p-type Zn1−x Mg x O films by pulsed laser deposition, Appl. Phys. A, 106 (2011) 191-196[10]L.Q. Zhang, Z.Z. Ye, J.G. Lu, B. Lu, Y.Z. Zhang, L.P. Zhu, J. Zhang, D. Yang, K.W. Wu, J.Huang, Z. Xie, Influence of p-type and n-type dopants on the magnetic properties of ZnCuO based diluted magnetic semiconductor thin films,J. Phys. D: Appl. Phys.,43 (2010) 015001.[11]H.W. Huang, L.Q. Zhang, W.K. Wu, Q. Yu, R. Chen, H.S. Yang, X.S. Peng, Z.Z. Ye,Hetero-metal cation control of CuO nanostructures and their high catalytic performance for CO oxidation Nanoscale, 24 (2012) 7832-7841[12]Lu B, L.Q. Zhang, Y.H. Lu, Z.Z. Ye, J.G. Lu, X.H. Pan, J.Y. Huang, Ferromagneticenhancement and magnetic anisotropy in nonpolar-oriented (Mn, Na)-codoped ZnO thin films. Appl. Phys. Lett.,101 (2012) 083513.[13]X.H. Liu, L.Q. Zhang, L. Zhong, Y. Liu, H. Zheng, J.W. Wang, J.-H. Cho, S.A. Dayeh, S.T.Picraux, J.P. Sullivan, S.X. Mao, Z.Z. Ye, J.Y. Huang, Ultrafast Electrochemical Lithiation of Individual Si Nanowire Anodes,Nano Lett., 11 (2011) 2251-2258[14]X.H. Liu, L. Zhong, L.Q. Zhang, A. Kushima, S. X. Mao, J. Li, Z.Z.Ye, J.P. Sullivan, J.Y.Huang, Lithium fiber growth on the anode in a nanowire lithium ion battery during charging, Appl. Phys. Lett., 98 (2011) 183107[15]X.T. Wang, L.P. Zhu, L.Q. Zhang, J. Jiang, Z.G. Yang, Z.Z. Ye, B. He, Properties of Nidoped and Ni–Ga co-doped ZnO thin films prepared by pulsed laser deposition J. Alloys Compd.,509 (2011) 3282 -3285.[16]W.G. Zhang, Bin Lu, L.Q. Zhang, J.G. Lu, M. Fang, K.W. Wu, B.H. Zhao, Z.Z. Ye, Influenceof preparation condition and doping concentration of Fe-doped ZnO thin films: Oxygen-vacancy related room temperature ferromagnetism, Thin Solid Films, 519 (2011) 6624-6628.[17]H.W. Huang, Q. Yu, Y.H. Ye, P. Wang, L.Q. Zhang, M.X. Gao, X.S. Peng, Z.Z. Ye, Thincopper oxide nanowires/carbon nanotubes interpenetrating networks for lithium ion batteries Crystengcomm, 14:21(2012) 7294-7300[18]J.Y. Huang, L. Zhong, C.M. Wang, J.P. Sullivan, W. Xu, L.Q. Zhang, S.X. Mao, N.S. Hudak,X.H. Liu, A. Subramanian, H.Y. Fan, L. Qi, A. Kushima, J. Li,In Situ Observation of theElectrochemical Lithiation of a Single SnO2Nanowire Electrode,Science, 330 (2010) 1515-1520[19]X.H. Liu, H. Zheng, L. Zhong, S. Huang, K. Karki, L.Q. Zhang, Y. Liu, A. Kushima, W.T.Liang, J.W. Wang, J.-H. Cho, E. Epstein, S.A. Dayeh, S.T. Picraux, T. Zhu, J. Li, J.P. Sullivan, J. Cumings, C. Wang, S.X. Mao, Z.Z. Ye, S. Zhang, J.Y. Huang, Anisotropic Swelling and Fracture of Silicon Nanowires during Lithiation, Nano Lett.,11 (2011) 3312-3318.[20]W.G. Zhang, Bin Lu, L.Q. Zhang, Y.H. Ye, and Z.Z. Ye, Growth Orientation and Propertiesof ZnCoO Thin Films,J. Mater. Sci. Eng.,29 (2011) 679-683.[21]H.P. He, S.S. Lin, G.D. Yuan, L.Q. Zhang, W.F. Zhang, L.B. Luo, Y.L. Cao, Zhizhen Ye, andS.-T. Lee, Single-Crystalline Sodium-Doped p-Type ZnO and ZnMgO Nanowires via Combination of Thin-Film and Nano Techniques, J. Phys. Chem. C, 115 (2011) 19018-19022.[22]J. Jiang, X.T. Wang, L.P. Zhu, L.Q. Zhang, Z.G. Yang, and Z.Z. Ye,Electrical and magneticproperties of ZnNiO thin films deposited by pulse laser deposition.J. Zhejiang Uni-Sci A (Appl Phys & Eng),12 (2011) 561-566.[23]J. Jiang, L.P. Zhu, H.P. He, Y. Li, Y.M. Guo, L. Cao, Y.G. Li, K.W. Wu, L.Q. Zhang, and Z.Z.Ye, Structural and optical properties of ZnCdO/ZnO multiple quantum wells grown on sapphire substrates using pulsed laser deposition, J. Appl. Phys.,112 (2012) 083513.2、会议论文:[1]L.Q. Zhang, X.H. Liu, Y. Liu, S. Huang, T. Zhu, L.J. Gui, S. X. Mao, Z. Z. Ye, C. M. Wang, J. P. Sullivan, J. Y. Huang, Controlling the Lithiation Induced Strain and Charging Rate in Nanowire Electrodes by Coating,2012 TMS symposium on Mechanical Behavior at Nanoscale. Orlando, FL, USA. 2012.03.15. Poster.3、专著:[1] 叶志镇,吕建国,张银珠,何海平,马全宝,张利强等,《氧化锌掺杂与制备方法》第六章ZnO基稀磁半导体, 浙江大学出版社, 25.7万字, 20094、专利:[1]叶志镇,张利强,张银珠,吕建国,何海平,朱丽萍,Co-Ga共掺的ZnO基稀磁半导体薄膜及其制备方法, 中国, 申请号: 200910095453.6[2]叶志镇,张利强,黄靖云,张银珠,朱丽萍,汪雷,蒋杰,薛雅,张俊,一种Mg-Na共掺的ZnO基发光二极管及其制备方法, 中国, 申请号: 200910100826.4[3]叶志镇,张利强,黄靖云,张银珠,一种垂直结构ZnO基多量子阱发光二极管及其制备方法, 中国, 申请号: 200910100985.4[4]叶志镇,张利强,蒋杰,黄靖云,张银珠,张维广,张俊,朱丽萍,一种Mg-K共掺的ZnO基发光二极管及其制备方法, 中国, 申请号: 201010220372.7[5]叶志镇,张利强,吕建国,何海平,朱丽萍,张银珠,一种非极性ZnO晶体薄膜的生长方法, 授权时间: 2010.8.25, 中国, 授权号: ZL200810164207.7[6]崔立山,张利强,邵阳,姜大强,杨峰,杜敏疏,郭云鹏,郭方敏,一种应用形状记忆合金赋予薄膜大弹性应变的方法, 中国, 申请号: 201310001136.X[7]张利强,崔立山,邵阳,姜大强,杨峰,杜敏疏,郭云鹏,郭方敏,利用形状记忆合金表面浮凸实现薄膜拉伸弹性应变的方法, 中国, 申请号: 201310000764.6[8]张利强,崔立山,张俊松,姜大强,邵阳,郭云鹏,一种形状记忆合金复合材料制成的锂离子电池及制备方法, 中国, 申请号: 201210448229.2。

YBCO超导材料及其带材的结构和制备方法王醒东,刘勇,张立永,袁卿瑞,徐华【摘要】摘要:YBCO(YBa2Cu3O7-δ)是一种新型的超导材料,在过去几十年里被广泛研究。

本文概述了YBCO的研究意义,并在国内外研究文献的基础上论述了YBCO的结构、总结了YBCO带材的多种制备方法及各自优缺点。

其中详细介绍了脉冲激光沉积法、溅射法、金属有机化学气相沉积法、溶胶-凝胶法和三氟乙酸盐金属有机物沉积法。

【期刊名称】广州化工【年(卷),期】2011(039)023【总页数】4【关键词】关键词:YBCO;带材;结构;制备自1911年荷兰科学家Onnes发现超导现象以来,由于其独特的物理特性,已经引起了广泛的研究。

目前研究重点主要集中在一代铋-锶-钙-铜-氧(Bi-Sr-Ca-Cu-O,简写BSCCO)和二代钇-钡-铜-氧(Y-Ba-Cu-O,简写YBCO)高温超导材料上。

BSCCO超导材料已经得到了实用化,目前已部分应用于电力引线、超导磁体、超导变压器和超导电缆等电力设备上。

尽管BSCCO 材料已经实现商业化,但仍没有大规模应用,主要原因有两个:(1)临界电流容易受到磁场的影响;(2)BSCCO带材采用银作为原材料,成本高、价格贵。

因此,人们逐渐将目光转移到二代YBCO超导材料上,YBCO是首个被发现的临界温度高于液氮沸点的超导材料。

由于YBCO材料成型时,是被涂覆或沉积在柔软基带上,所以二代钇钡铜氧材料又被称为涂层导体(coated conductor,CC导体或第二代高温超导带材)。

与第一代铋系超导材料相比,YBCO超导材料具有各向异性较弱,电流密度高,临界温度高,交流损耗低,不需要贵金属银等优点,因此越来越受到更多重视。

目前YBCO高温超导材料主要应用于强电、微波、红外、弱磁场探测、开关元件等领域[1-3]。

1 YBCO材料及其带材结构YBCO材料具有层状钙钛矿(ABO3)结构,它的分子式为YBa2Cu3O7-δ(简写为Y123或YBCO)。

铌镁酸铅-钛酸铅薄膜的钙钛矿结构及介电特性张德强;蔡长龙;纪红芬;林大斌【摘要】为了提高铌镁酸铅-钛酸铅(Pb(Mg1/3Nb2/3)O3-PbTiO3,PMN-PT)薄膜的铁电特性,采用单一醇盐溶胶-凝胶法制备了PMN-PT薄膜,分析了铌镁酸铅-钛酸铅薄膜的钙钛矿结构纯度及介电特性.结果表明:PMN-PT薄膜具有(100)择优取向,钙钛矿结构纯度达到97.7%,晶粒尺寸为95~105 nm;室温下,其相对介电常数达到1 135,介电损耗低于4%,弥散相变温度为85~120℃.【期刊名称】《西安工业大学学报》【年(卷),期】2018(038)002【总页数】6页(P169-174)【关键词】铌镁酸铅-钛酸铅薄膜;溶胶-凝胶;钙钛矿结构;介电特性【作者】张德强;蔡长龙;纪红芬;林大斌【作者单位】西安工业大学光电工程学院,西安710021;西安工业大学光电工程学院,西安710021;西安工业大学光电工程学院,西安710021;西安工业大学光电工程学院,西安710021【正文语种】中文【中图分类】TQ139.1铌镁酸铅-钛酸铅((1-x)[Pb(Mg1/3Nb2/3)O3]-xPbTiO3,(1-x)PMN-xPT)固溶体作为一种综合性能非常优异的新型铁电材料,因在准同型相界附近x=0.3时,具有较高的介电常数、热释电系数、压电系数、机电耦合系数以及优异的铁电性等[1-2],是压电/铁电器件领域的研究热点.目前,对于热释电型红外探测器、压电探测器和微机电系统(Micro-Electro-Mechanical System,MEMS)微制冷器,研究较多的材料有钛酸锶钡(BaxSr1-xTiO3,BST)、钛酸锶铅(PbxSr1-xTiO3,PST)、锆钛酸铅(PbxZr1-xTiO3,PZT)和钛酸铅(PbTiO3,PT)等.但是相比这些传统铁电材料,铌镁酸铅-钛酸铅(Pb(Mg1/3Nb2/3)O3-PbTiO3,PMN-PT)材料性能更加稳定,已经被证明是多层电容器、换能器、热释电探测器、MEMS微制冷器和非线性光器件的前景材料.现阶段关于PMN-PT材料的研究主要集中在固体陶瓷和单晶特性方面,而对薄膜材料的制备和特性研究相对较少,这是由于在PMN-PT钙钛矿结构形成的过程中往往伴随着铅元素的挥发导致焦绿石相的生成,而焦绿石相的含量严重影响着薄膜材料的电学特性.纯钙钛矿结构的制备有一定难度,但是随着集成电路的发展,高集成小型化的微电子器件需求越来越高,薄膜微器件是未来的发展趋势.因此,对于PMN-PT薄膜的研究具有重要意义.目前制备PMN-PT薄膜的方法主要有脉冲激光法(Pulse Laser Deposition,PLD)、射频磁控溅射法(Radio Frequency Magnetron Sputtering,RF-MS)、溶胶-凝胶法及金属有机物化学气相沉积法(Metal-Organic Chemical Vapor Deposition,MOCVD)[3-5].一般而言,在RF-MS制备薄膜的过程中,溅射气压、功率、靶基距、溅射气氛及衬底温度等多种参数对最终薄膜形成的材料成分具有非常重要的影响,但是磁控溅射法的薄膜组分和结构的均匀性很难控制,沉积薄膜的速率较慢;MOCVD这种方法制备的薄膜一般具有很高的质量,但是过高的成本限制了其在生产上面的应用,仅有少数的学者用化学气相沉积法来研究PMN-PT薄膜的性质;PLD法制备的薄膜化学成分和靶材的化学成分很接近,膜表面上常有细微液滴凝固形成的颗粒状突起而使表面质量不甚理想,不易于制备大面积薄膜.相比这些方法,溶胶-凝胶法因工艺成本较低、工艺过程相对简单,并且容易精确控制薄膜组分.该方法能在较低温度下沉积所要结构相的薄膜,且沉积系统相对简单.文献[6]采用射频磁控溅射方法制备出PMN-PT薄膜并研究了在Pt/Ti/SiO2/Si(100)衬底上TiO2种子层对不同组分(1-x)PMN-xPT介电特性的影响,结果表明当x=0.3~0.5时,其相对介电常数可达1 000~1 300,介电损耗低于4%.文献[7]采用双醇盐溶胶-凝胶法制备出了厚度为1.5 μm的0.7PMN-0.3PT薄膜,在700 ℃的退火工艺下制备(100)晶向PMN-PT薄膜的压电系数达170~183 pC·N-1.文献[8]采用PLD法在La0.5Sr0.5CoO3/LaAlO3衬底上制备出(001)择优取向的0.7PMN-0.3PT薄膜,探讨基底和组分对PMN-PT薄膜结构和电学特性影响.文献[9]采用双醇盐溶胶-凝胶法在Pt/Si衬底上制备了钙钛矿结构0.68PMN-0.32PT薄膜,其纯度达到95%,具有(110)择优取向;对室温下厚度为0.8 μm薄膜进行测试,结果表明其相对介电常数达950.文献[10]采用溶胶-凝胶法在800 ℃退火温度下制备了(100)/(110)混合晶向的0.7PMN-0.3PT组分薄膜.文献[11]采用溶胶-凝胶法在Pt/Ti/SiO2/Si衬底上制备出厚度为220 nm且具有(111)择优取向的PMN-PT薄膜,研究了低频电压变化下的逆磁电耦合效应.目前,制备大尺寸PMN-PT薄膜的工艺存在制备成本过高、工艺过程复杂以及制备面积较小等问题.文中采用单一醇盐溶胶-凝胶法制备直径为∅10.16 cm的PMN-PT薄膜,通过调整退火工艺过程中不同退火温度和退火时间,研究了薄膜钙钛矿相及薄膜表面形貌变化,表征了其介电特性.1 实验材料及方法以三水合醋酸铅[Pb(CH3COO)·3H2O]、乙醇铌[Nb(OC2H5)5]、四水合乙酸镁[Mg(CH3COO)2·4H2O]和钛酸四正丁酯[Ti(OC4H9)4]为原料,乙二醇甲醚[C3H8O2]为溶剂,乙酰丙酮[C5H8O2]为稳定剂和螯合剂,以冰醋酸[C2H4O2]作为催化剂.由于退火过程中Pb元素挥发,对原料用量进行精确调整,因此在前驱液的配制过程中需要进行铅补偿,根据前期探索性实验采取Pb过量25%.在Pb过量的情况下,Ti要保持含量不变,否则过量的Pb和Ti影响最终PMN-PT组分.乙醇铌的含量要精确,加入量太少使溶液不均匀产生不相溶区,加入量过多则对水解反应有抑制作用[12].Mg元素过量5%以增大晶粒尺寸且有利于消除焦绿石相[13].将Pb(CH3COO)·3H2O溶于C3H8O2中加热并保持在100 ℃,充分搅拌呈澄清透明状后保持10 min,此后自然冷却至室温,标记为A溶液;将Mg(CH3COO)2·4H2O溶于C3H8O2中,加入适量C2H4O2后加热并保持在110 ℃,充分搅拌呈澄清透明状后保持10 min,此后自然冷却至室温,标记为B溶液;在A溶液中加入C5H8O2后再加入Nb(OC2H5)5,室温充分搅拌至澄清,颜色为很浅的淡黄色,标记为C溶液;在B溶液中加入C5H8O2后再加入Ti(OC4H9)4,室温充分搅拌至澄清透明;将C溶液和B溶液混合,充分搅拌后定容得到最终PMN-PT溶液,pH值为4~5,陈化24 h后等待使用.采用KW-4A型匀胶机进行旋涂,每层旋涂后进行快速热退火处理,以制备出预期厚度的PMN-PT薄膜,具体过程如下:① 取退火温度为220 ℃,保温4 min,使有机溶剂挥发;② 取退火温度为400 ℃,热解4 min,完全去除有机物;③ 在最佳退火温度下以最佳退火时间完成最终结晶退火;④ 重复上述步骤以得到达到预期厚度的PMN-PT薄膜.采用日本电子公司JSM-6390A型高分辨场发射扫描电子电镜(Scanning Electron Microscope,SEM)对薄膜表面形貌进行表征,断面特征采用日立SU1510型钨灯丝扫描电子显微镜观察.采用日本岛津XRD-6000型X射线衍射(X-Ray Diffraction,XRD)仪,铜Kα辐射,波长为1.540 56×10-4 μm进行物相结构表征.采用Agilent E4980A型精密测试仪表征介电频谱-温谱特性.2 实验结果与分析2.1 PMN-PT薄膜物相结构不同退火温度下PMN-PT薄膜的XRD测试结果如图1所示,2θ为衍射角.其中,在550 ℃,600 ℃,650 ℃和700 ℃退火温度下得到的PMN-PT薄膜的主要物相成分为PMN-PT,在39.92°,44.68°位置的衍射峰属于基底Pt的衍射峰;在29.36°,34.08°和48.96°位置的衍射峰属于样品中杂相Pb2(Nb0.67Ti0.33)2O6.67(PDF-#71-0704)的衍射峰.这是由于温度在550 ℃时焦绿石相还未完全转化为钙钛矿相,而温度高于600 ℃时伴随着Pb元素的严重挥发钙钛矿相又开始向焦绿石相转变.从整个衍射图谱看,制备的PMN-PT薄膜呈(100)择优取向.在最优退火温度下研究了不同退火时间(1 min,3 min,5 min和10 min)对PMN-PT薄膜物相结构的影响,其不同退火时间下PMN-PT薄膜的XRD测试结果如图2所示.退火温度600 ℃、保温时间1 min时焦绿石相还没有完全转化为钙钛矿相,此时各个晶向衍射峰强度相对较弱,PMN-PT薄膜呈随机取向;当保温时间为3 min时,可看到此时钙钛矿相相对焦绿石相衍射峰强达到最大,基本为纯钙钛矿相,并且呈现(100)择优取向;在保温时间大于5 min时,由于加热时间过长造成Pb元素的大量挥发,此时钙钛矿相又开始向焦绿石相转化,在图2中可看出钙钛矿相纯度在降低.图1 不同退火温度下PMN-PT薄膜的XRD测试结果Fig.1 XRD test results of PMN-PT film in different annealing temperature图2 不同退火时间下PMN-PT薄膜的XRD测试结果Fig.2 XRD test results of PMN-PT film in different annealing time钙钛矿相的纯度[14]为WPMN-PT=Ipero/(Ipero+Ipyro )×100%(1)式中:WPMN-PT为钙钛矿相结构的纯度;Ipero为钙钛矿结构的最强衍射峰值;Ipyro为焦绿石相的最强衍射峰值.通过式(1)计算可以得到各个退火温度和各个保温时间下PMN-PT钙钛矿相的值,其不同退火工艺下PMN-PT薄膜钙钛矿结构的纯度如图3所示.在500 ℃,550 ℃,600 ℃,650 ℃,700 ℃和750 ℃退火温度下钙钛矿相含量分别为88%,96.84%,97.70%,95.33%,90.79%和83.12%;退火温度为600 ℃时,在1 min,2 min,3 min,4 min,5 min和10 min保温时间下钙钛矿相含量分别为75.4%,89.26%,97.70%,86.46%,80.77%和77.07%;因此确定600 ℃为最佳退火温度,3 min为最佳保温时间,钙钛矿相的纯度为97.70%.图3 不同退火工艺下PMN-PT薄膜钙钛矿结构的纯度Fig.3 Perovskite structure purity of PMN-PT film with different annealing processes根据Jade物相分析软件可以计算出最佳工艺条件下晶格常数为a=0.400 76 nm,b=0.402 18 nm,c=0.400 27 nm,β=90.11°,这是单斜晶系,空间群为Pm,此结果与文献[15]中粉末中子衍射所得结果近似,晶格常数差别在3%以下,造成这种差别的原因主要是降温过程中晶格畸变的结果.2.2 PMN-PT薄膜微观形貌图4(a)为在退火结晶温度为600 ℃,每层退火1 min下PMN-PT薄膜的SEM表面形貌,此时PMN-PT薄膜物相结构正由焦绿石相向钙钛矿相结构转变,由图4(a)中可以看到部分未长大的PMN-PT薄膜晶粒,这些晶粒是焦绿石相[14],并且可以观察到孔洞现象.图4(b)为在退火结晶温度为600 ℃,每层退火时间为3 min下PMN-PT薄膜的SEM表面形貌,从图4(b)中可以看出在此条件下得到了平整均匀且较为致密的薄膜,晶粒尺寸多在95~105 nm之间.退火3 min下PMN-PT薄膜截面如图4(c)所示,PMN-PT薄膜厚度达到500 nm.图4 PMN-PT薄膜SEM表面形貌及薄膜截面Fig.4 PMN-PT film surface morphology and sectional view of SEM2.3 PMN-PT薄膜的介电特性分析在室温下,测试样品介电特性,相对介电常数[2]为(2)式中:C为薄膜样品的电容;d为薄膜样品厚度;ε0为真空介电常数;A为样品上电极面积.实验中采用硬掩膜的方法通过磁控溅射镀制金上电极,掩膜版孔径为0.3 mm.对退火温度为600 ℃,保温时间为3 min条件下获得的PMN-PT薄膜进行电容测试,PMN-PT薄膜介电常数和介电损耗随频率的变化如图5所示,从图5中可以看出室温下,最大相对介电常数为1 135.电压频率为1~200 kHz时,样品的介电损耗为0.031~0.048;电压频率在100 kHz以内,损耗变化相对缓慢,这是因为在低频下,电场变化缓慢,极化与电场变化保持同步,介电损耗变化不大,而电压频率大于100 kHz时,电场变化快,极化滞后于电场变化,介电损耗变化较大.PMN-PT薄膜的介电温谱测试结果如图6所示.在样品未做极化处理的情况下,在升温过程中,温度从20 ℃升高至220 ℃;在85~120 ℃时,不同电压频率下(1 kHz,10 kHz和100 kHz)的相对介电常数-温度曲线均出现了高温峰且弥散.这是由于铌镁酸铅(PMN)相变属于典型的弥散相变,钛酸铅(PT)相变属于普通的一级相变,而PMN-PT作为固溶体,其组分处于两者之间,相变特性表现为过渡的性质.因此PMN-PT的组分以PMN为主,相变以弥散相变为主.相对介电常数-温度关系并不遵守居里-外斯定律,而遵守Smolenskii弥散相变规律.图5 PMN-PT薄膜介电常数和介电损耗随频率的变化Fig.5 PMN-PT thin film dielectric constant and loss vary with frequency图6 PMT-PT薄膜的介电温谱测试结果Fig.6 Test results of dielectric constant-temperature of PMN-PT film3 结论采用溶胶-凝胶法制备了PMN-PT薄膜,分析了PMN-PT薄膜的相结构、微观形貌和介电性能,得到的结论为1) 制备0.7PMN-0.3PT薄膜的最佳快速热退火工艺为退火温度600 ℃,保温时间为3 min.XRD测试结果表明PMN-PT薄膜钙钛矿相纯度可达97.70%,呈(100)择优取向.SEM测试结果表明薄膜晶粒尺寸在95~105 nm之间,薄膜厚度为0.5 μm.2) 介电-温谱测试结果表明在室温下,相对介电常数达到1 135,介电损耗低于4%,相变温度在85~120 ℃范围内.单一醇盐溶胶-凝胶法实现了高质量大尺寸PMN-PT铁电材料薄膜的制备,可用于新型热释电探测器.参考文献:【相关文献】[1] FERRI A,DA C A,SAITZEK S,et al.Local Piezoelectric Hysteresis Loops for the Study of Electrical Properties of 0.7Pb(Mg1/3Nb2/3)O3-0.3PbTiO3 Thin Films:Bottom Electrode Dependence and Film Thickness Effect[J].Ferroelectrics,2008,362(1):21.[2] CHANG W Y,HUANG W,BAGAL A,et al.Study on Dielectric and Piezoelectric Properties of 0.7Pb(Mg1/3Nb2/3)O3-0.3PbTiO3 Single Crystal with Nano-patterned Composite Electrode[J].Journal of Applied Physics,2013,114(11):114103.[3] YAO Q,WANG F,LEUNG C M,et al.Ferroelectric and Dielectric Properties ofLa0.6Sr0.4CoO3 Buffered 0.7Pb(Mg1/3Nb2/3)O3-0.3PbTiO3 Thin Film by Pulsed Laser Deposition[J].Journal of Alloys and Compounds,2014,588:290.[4] ZHOU Q,ZHANG Q,XU B,et al.In-plane Polarized 0.7Pb(Mg1/3Nb2/3)O3-0.3PbTiO3 Thin Films[J].Journal of the American Ceramic Society,2002,85(8):1997.[5] KIGHELMAN Z,DAMJANOVIC D,SETTER N.Electromechanical Properties and Self-polarization in Relaxor Pb(Mg1/3Nb2/3)O3 Thin Films[J].Journal of AppliedPhysics,2001,89(2):1393.[6] JIANG M C,HONG T J,WU T B.Deposition and Characterization of FerroelectricPb[(Mg1/3Nb2/3)xTi1-x]O3 Thin Films by RF Magnetron Sputtering[J].Japanese Journal ofApplied Physics,1994,33(11):6301.[7] PARK J H,XU F,TROLIER M S.Dielectric and Piezoelectric Properties of Sol-gel Derived Lead Magnesium Niobium Titanate Films with Different Textures[J].Journal of Applied Physics,2001,89(1):568.[8] WANG J,WONG K H,CHAN H L W,et position Control and Electrical Properties of PMN-PT Thin Films Around the Morphotropic Boundary[J].Applied Physics A,2004,79(3):55.[9] KUMAR P,SONI A,PATEL R K,et al.Effect of Substrates on Phase Formation in PMN-PT 68/32 Thin Films by Sol-gel Process[J].Materials Chemistry and Physics,2008,110(1):7.[10] RYO N,HIROMITSU K.Preparation of 0.7Pb(Mg1/3Nb2/3)O3-0.3PbTiO3Thin Films viaa Polyvinyl-pyrrolidone Assisted Aqueous Sol-gel Process and DielectricProperties[J].Journal of the American Ceramic Society,2010,90(11):3632.[11] FENG M,HU J M,WANG J J,et al.Converse Magnetoelectric Coupling inNiFe/Pb(Mg1/3Nb2/3)O3-PbTiO3Nanocomposite Thin Films Grown on SiSubstrates[J].Applied Physics Letters,2013,103(19):192903.[12] 符春林.铁电薄膜材料及其应用[M].北京:科学出版社,2009.FU Chunlin.Ferroelectric Thin Film Materials and Applications[M].Beijing:Science Press,2009.(in Chinese)[13] PARK J H,YOON K H,DONG H K.Dielectric and Electrical Properties of Preferentially(111)Oriented Zr-Rich 0.1Pb(Mg1/3Nb2/3)O3-0.9Pb(ZrxTi1-x)O3Thin Films by Chemical Solution Deposition[J].Thin Solid Films,2001,396(1/2):84.[14] 王冲.PMN-PT系热释电红外传感材料的制备与性能研究[D].宁波:宁波大学,2010.WANG Chong.Study on the Preparation and Properties of Pyroelectric Infrared Sensing Materials for PMN-PT System[D].Ningbo:Ningbo University,2010.(in Chinese)[15] SINGH A K,PANDEY D,ZAHARKO O.Powder Neutron Diffraction Study of Phase Transitions in and a Phase Diagram of (1-x)[Pb(Mg1/3Nb2/3)O3]-xPbTiO3[J].Physical Review B,2006,74(2):24101.。

Mid-Infrared Fiber LasersMarkus Pollnau1and Stuart D.Jackson21Advanced Photonics Laboratory,Institute for Biomedical Imaging,Optics and Engineering,Swiss Federal Institute of Technology1015Lausanne,Switzerlandmarkus.pollnau@epfl.ch2Optical Fibre Technology Centre,Australian Photonics CRC.The University of Sydney206National Innovation Centre,Australian Technology ParkEveleigh NSW1430,Australias.jackson@.auAbstract.The current state of the art in mid-infraredfiber lasers is reviewed in this chapter.The relevantfiber-host materials such as silicates,fluorides,chalco-genides,and ceramics,thefiber,pump,and resonator geometries,and the spectro-scopic properties of rare-earth ions are sers at transitions ranging from1.9to4µm occurring in the rare-earth ions Tm3+,Ho3+,and Er3+and their population mechanisms are discussed on the basis of the fundamental spectroscopic properties of these ions.Continuous-wave,fundamental-mode power levels ranging from a few mW near4µm up to≈10W near2µm have been demonstrated in recent years.Power-scaling methods and their limitations,the possibilities to op-timize the population mechanisms and increase the efficiencies of these lasers,as well as the prospects of future mid-infraredfiber lasers in a number of rare-earth ions at transitions in the wavelength range beyond3µm and extending to5µm are described.1IntroductionSince the introduction of the double-cladfiber more than a decade ago and with the recent technological advances in thefields offiber fabrication and beam-shaped high-power diode lasers,the performance of diode-pumpedfiber lasers has steadily improved.Today,fiber lasers can compete with their cor-responding bulk crystalline systems in certain applications,especially when transverse-fundamental-mode,continuous-wave(CW)laser operation at out-put powers in the milliwatt to multiwatt range is required.The increased recent interest infiber lasers emitting at mid-infrared wavelengths between 2and3µm primarily relates to the high potential of these wavelengths for applications in laser microsurgery.Due to the high absorption of water in the spectral region at2.7–3.0µm,high-quality laser cutting or ablation has been demonstrated in biological tissues.In addition,laser wavelengths near 2µm could be suitable for tissue welding.A number of other potential laser applications in the mid-infrared spectral region,e.g.environmental trace-gas I.T.Sorokina,K.L.Vodopyanov(Eds.):Solid-State Mid-Infrared Laser Sources,Topics Appl.Phys.89,219–255(2003)c Springer-Verlag Berlin Heidelberg2003220Markus Pollnau and Stuart D.Jacksondetection,are currently becoming increasingly important.In all these appli-cations fiber lasers may find their niches.The high development costs of fabricating fibers with sufficiently low losses in the mid-infrared spectral region has impeded the necessary research efforts in the field of mid-infrared fiber lasers.The currently available fiber materials that are suitable as host materials for specific rare-earth-doped fiber lasers in the spectral region 2–5µm will be introduced in Sect.2.More than any other idea,the invention of the double-clad fiber geometry has accelerated the output-power scaling and hence the success of fiber lasers.The various aspects of the fiber,pump,and resonator geometries will be de-scribed in Sect.3.A significant number of spectroscopic investigations has led to a better understanding of the population mechanisms of rare-earth-doped laser systems.The fundamental spectroscopic properties of rare-earth ions in solid-state host materials will be reviewed in Sect.4.Equipped with this general information,the performance of the most important mid-infrared fiber laser transitions in the wavelength range 2–3µm can be understood in detail.Sect.5will be devoted to the Tm 3+fiber lasers at 1.9and 2.3µm,whereas the Ho 3+fiber lasers at 2.1and 2.9µm will be discussed in Sect.6.An impressive example of the variety of population mechanisms and operational regimes in a single system is the Er 3+2.7µm fiber laser transition that will be investigated in Sect.7.At wavelengths beyond 3µm,it becomes increasingly difficult to find suitable host materials for actively doped laser systems.This statement holds true for glass fibers in the same way as for crystalline materials.The prospects of future mid-infrared fiber lasers in this wavelength range will be discussed in Sect.8.Besides general introductions to the different topics of lasers [1,2]that include many aspects relevant also to mid-infrared fiber lasers,a comprehen-sive introduction to the field of rare-earth-doped fiber lasers can be found in [3].2Fiber MaterialsThe choice of the fiber material involves a number of considerations:the maximum phonon energy,the environmental durability,the draw ability,the rare-earth solubility,and the purity of the starting materials.The maximum phonon energy of the glass sets the overall infrared transparency range of the fiber and the multiphonon relaxation rates which influence the quantum efficiency.The multiphonon relaxation rates for the common fiber glasses as a function of the energy gap between energy levels are shown in Fig.1.The optical transparency range relates to both the size of the band gap and also the infrared absorption cut-off,hence to the vibrational frequency νof the anion–cation bonds of the glass.For an ordered structure,ν=(1/2π) k/M ,(1)Mid-Infrared Fiber Lasers221101010M u l t i p h o n o n R e l a x a t i o n R a t e (s -1)Energy Gap (cm )Fig.1.Calculated and measured multiphonon relaxation rates as a function of the energy gap between energy levels for glasses with different maximum phonon energies.(Data taken from [4,5])where M =m 1m 2/(m 1+m 2)is the reduced mass for two bodies m 1,m 2vibrating with an elastic restoring force k .While for disordered structures like glass,this is not an accurate expression,nevertheless,it does highlight the important contributions to the glass transparency.The relative cation–anion bond strength is intimated by the field strength Z /r 2,where Z is the valence state of the cation or anion and r is the ionic radius.Generally,glasses composed of large anions and cations with low field strengths display high transparency in the mid-infrared spectral region.The important physical properties of the popular glasses used for optical fibers are shown in Table 1.Table 1.Properties of popular fiber materialsFibermaterialMax.phonon energy (cm −1)Infrared transparency (µm)Propagation losses (λat minimum)(dB/km)Thermal conductivity (W/K m)Silica1100[4]<2.50.2(1.55µm) 1.38[6]ZBLAN550[7]<6.00.05(2.55µm)0.7–0.8[8]GLS 425[5]<8.00.5(3.50µm)0.43–0.5[9]2.1SilicatesThis glass is perhaps the most important material used for optical fiber pro-duction [3,10],however,the maximum phonon energy is high (≈1100cm −1)and has so far limited the emission wavelength of mid-infrared fiber lasers us-ing this material to ≈2.2µm [11].Silica is robust and involves the very effec-222Markus Pollnau and Stuart D.Jacksontive modified chemical vapor deposition(MCVD)technique forfiber fabrica-tion.Reducing the OH−content in the glass,which has two main absorption peaks in the range1.3–2.0µm[12],improves the near-to-mid-infrared utility. Rare-earth ions such as Nd3+and Er3+which have highfield strengths have low solubility in silicate glass which can lead to clustering and micro-scale phase separation.2.2FluoridesThe use offluoride glasses,especially the heavy-metalfluorides[13,14],as host materials for mid-infraredfiber lasers has found wide acceptance.The most common form of heavy-metalfluoride glass is thefluorozirconate(ZrF4) composition and the most widespreadfluoridefiber material is ZBLAN[15], a mixture of53mol.%ZrF4,20mol.%BaF2,4mol.%LaF3,3mol.%AlF3, and20mol.%NaF.Since it can be readily drawn into single-mode optical fiber[16]it is particularly important to mid-infraredfiber lasers[17].The large atomic weight of the zirconium atom combined with relatively weak bonding provides a maximum phonon energy for ZBLAN of≈550cm−1and allows for high infrared transparency up to≈6µm.Multiphonon relaxation, however,becomes significant for transitions at wavelengths longer than≈3µpared to silica,ZBLAN has a lower damage threshold and a lower level of inhomogeneous spectral-line broadening(Sect.4.1)because the rare-earth ion is placed in sites of a less perturbed network.The crystal-field strength is also comparatively weaker[18].An overview of the spectroscopic properties of rare-earth ions doped into ZBLAN has been given in[7].2.3ChalcogenidesChalcogenides are composed of the chalcogen elements S,Se and Te[19,20,21]. They are environmentally durable,have a low toxicity and have reasonably large glass forming regions.When the rare-earth ions are doped into these glasses[22],the radiative transition probabilities and,therefore,the absorp-tion and emission cross-sections are high as a result of the high refractive in-dex(≈2.6)of the glass and the high degree of covalency of the rare-earth ion with the surrounding medium.Maximum phonon energies of300–450cm−1 produce low rates of multiphonon relaxation,see Fig.1,and therefore high quantum efficiencies.The low thermal conductivity,see Table1,is however an important factor to be considered in the design of chalcogenide-based lasers. Of the large number of rare-earth chalcogenides studied for luminescent emis-sion,the most important glasses are the sulfide glasses GaLaS(GLS)[23]and GeGaS[24]because of the reasonably high rare-earth solubility.2.4CeramicsStudies into the use of ceramics as host materials for the rare earths have recently made a lot of progress[25].These ceramics are composed of nano-Mid-Infrared Fiber Lasers223 crystallites of materials such as Y3Al5O12(YAG)and can be produced ina simple and cost-efficient process at relatively low temperatures.This allows the fabrication of materials with very high melting points[26]that are difficultto grow by other techniques such as the Czochralski method[27].This class ofmaterials is also available infiber geometry[28].Ceramicfibers combine the characteristics of crystalline materials such as high absorption and emissioncross-sections,large thermal conductivity,and even the possibility of doping with transition-metal ions[28]with the convenience of guiding the pump andsignal light in afiber.Currently,the losses of thesefibers are comparativelyhigh,but further improvement can be expected.3Fiber,Pump,and Resonator GeometriesThe light oscillating in afiber-laser resonator can be either free running or deliberately modulated depending on whether CW or pulsed output,re-spectively,is desired.Consequently,a large number of techniques for pulsedoperation including Q-switching and mode locking offiber lasers have been explored.These techniques have been investigated intensively for the commonlaser transitions at1µm in Nd3+and Yb3+and at1.5µm in Er3+,and are usually described in combination with these lasers.The smallfiber size limitsthe peak power through the damage-threshold intensity(propagating powerper core area)and,hence,crystalline lasers in bulk geometries or optical parametric processes are often preferred when high-energy short pulses areneeded.This argument accounts especially for mid-infrared ZBLAN-basedfiber lasers,because thesefibers possess a lower damage threshold compared to silicafibers.The description of mid-infraredfiber lasers is,therefore,con-fined to CW operation and specific techniques for pulsed operation offiber lasers are not discussed in this chapter.In an analogous way to the optical excitation of bulk gain media,dopedopticalfibers can be either end pumped(core pumped)or side pumped (cladding pumped).The former method is less scalable since it relies onthe use of expensive high-beam-quality pump sources because core areas areusually<100µm2.On the other hand,the larger cladding area(>104µm2) allows for high-power diode-array pumping[29,30,31,32,33].The obvious sim-plicity of the core-pumping method negates further explanation and we will concentrate on the cladding-pumping technique:one of the most important developments infiber-laser technology.3.1Fiber Designs for Cladding PumpingIn the design offibers for cladding pumping,the core of thefiber is gener-ally made to guide a single-transverse LP01mode.The shape of the mul-timode pump cladding,see Fig.2,however,remains somewhatflexible and can be shaped with a number of considerations in mind.The pump cladding,224Markus Pollnau and Stuart D.Jackson (a)(b)(d)CorePump cladding Outer cladding Jacket Fig.2.Principal double-clad fiber geometries which include (a )circular shaped pump cladding with axially positioned core,(b )circular shaped pump cladding with off-axially positioned core,(c )rectangular shaped pump cladding and (d )D-shaped pump claddingwhich in turn is surrounded by a low-refractive-index transparent polymer or glass,provides a high numerical aperture (NA)of 0.3–0.55for the pump cladding.There are three main double-clad-fiber layouts:circular,circular with offset core,and rectangular as shown schematically in Fig.2.Maxi-mum pump-light absorption sees the core near the outer edge of the circular pump cladding [34]because a portion of the launched light is skew to the fiber axis and produces an inner caustic and never crosses the central re-gion of the pump cladding.Scrambling these skew rays by bending [35]or by using a graded and slightly elliptical pump cladding [36]increases the pump-absorption efficiency as does spatially varying refractive-index fluctuations in inhomogeneous pump claddings [37].Inner caustics can be avoided by rectilinearly shaping the pump cladding [38]which has the ancillary advantage of matching the shape of diode-array output.The overall absorption coefficient of the fiber is reduced by the ratio of the core area to the area of the pump cladding [34].The propagation losses for the rectangular-shaped pump cladding are higher and the effective numerical aperture lower as compared to the circular shape [39];however,in certain cases higher dopant concentrations can provide shorter fiber lengths that also lead to reduced nonlinear effects.A D-shaped or trun-cated circular pump cladding [40],see Fig.2d,is also effective while be-ing easier to make than rectangular preforms.The circular-multimode pump cladding may also have the gain medium distributed in a ring around the edge of the pump cladding either discretely or continuously in multi-core [41]and M-profile [42]arrangements,respectively.The effective absorption coef-ficient is now further increased while maintaining high-beam-quality output.A large-mode-area core [43]can also increase the effective absorption coeffi-cient of the fiber.Recently,double-clad pump schemes have been demonstrated also with holey fibers [44].These structures offer the additional advantage of single-mode guiding over a broad spectral range [45].Mid-Infrared Fiber Lasers 2253.2Fiber-Laser ResonatorsTypical free-running fiber-laser resonators are shown schematically in Fig.3.In the simplest resonator,see Fig.3a,the pump light passes through a dichroic mirror that is highly reflective for the oscillating laser light.Fresnel reflection at the cleaved output end facet of the fiber can provide sufficient feedback for laser oscillation;however,with an output-coupler mirror –and pump retro-reflector –placed at the output end of the fiber the optical efficiency can be maximized.In an alternative arrangement,the pump light can be launched into the output end of the fiber,see Fig.3b.A dichroic mirror oriented at 45◦to the fiber axis extracts the laser output and a broadband highly reflecting mirror is placed at the rear fiber end.To scale the output power,each end of the fiber can be pumped,see Fig.3c.Periodic V-grooves [46]or prism coupling [47]along the fiber to distribute the pump access allow one to further scale the output power and are useful for pumping fiber ring resonators.Spectrally combining the output from a number of separate fiber lasers is also a promising power-scaling technique [48,49,50].The highest reported fiber-laser output powers of 110W in a singly Yb 3+-doped fiber [51]and 150W in a Nd 3+,Yb 3+-codoped fiber [52]have been obtained using arrangements as shown schematically in Fig.3c.Bragg gratings can substitute the fiber-butted mirror if spectrally well-defined output is required.PumpPump Pump Pump Output Output OutputMM M MMFiberFiberFiber(a)(b)(c)Fig.3.Schematic diagram of resonators used for free-running fiber lasers with (a )a single-end co-propagating pump,(b )a single-end counter-propagating pump and (c )dual end pumps.M represents the mirror226Markus Pollnau and Stuart D.Jackson3.3Thermal IssuesAs higher pump powers become available from laser-diode systems,it is gen-erally recognized that thermal and thermo-optical issues set limitations to the power scalability of end-pumped bulk-laser systems.Owing to the unfavor-able temperature dependence of thermal and thermo-optical parameters[53], the large heat load in the crystal leads,firstly,to a significant temperature increase in the rod,secondly,to strong thermal lensing with pronounced spherical aberrations,and ultimately,to rod fracture in a high-average-power end-pumped system.Due to its geometry,thefiber provides potentially high pump-and signal-beam intensities without the drawbacks of significant thermal and thermo-optical effects.Its large surface-area-to-volume ratio means that the heat generated from multiphonon relaxation in the core is dissipated effectively by radiation and convection from the outer surface of thefiber.This is es-pecially true for single-clad,core-pumped single-modefibers where this ratio is highest[54].Double-cladfibers have a relatively smaller surface-area-to-volume ratio and thermal issues need to be taken into account[6,55,56]. Thermal management will be required when very high output powers are desired.In particular,for high-power mid-infrared operation,thermal man-agement may be very important because of the decreased quantum efficiency and the consequently higher amount of heat dissipation.4Spectroscopic and Laser Propertiesof Rare-Earth IonsThe structure of a glass is less well defined as compared to a crystalline mate-rial.The local variation of the chemical environment of active ions in a glass has a number of consequences.Most important,the active ions may undergo chemical reactions during the fabrication process and be incorporated in the host in several oxidation states with different spectroscopic properties.Oxi-dation states other than the desired one may act as impurities that introduce undesired optical effects such as parasitic pump absorption,the reabsorption of oscillating laser light,the lifetime quenching of the laser ion,and the trap-ping of the excitation energy.A stable oxidation state of the optically active ion is thus highly desirable.The necessity of a stable oxidation state excludes a number of transition-metal ions from the list of suitable dopants in glass environments.This is one of the possible reasons why examples of transition-metal-ion-doped lasers in glass hosts are rare.On the other hand,most of the rare-earth ions prefer to stabilize in the trivalent oxidation state and are, therefore,suitable candidates as glass andfiber dopants.This chapter will, therefore,concentrate on the rare-earth ions as active dopants offiber lasers.Mid-Infrared Fiber Lasers227 4.1Spectra of Rare-Earth Ions in GlassesThe optical transitions of lanthanide(rare-earth)ions in the visible and in-frared spectral region occur within the4f subshell.This subshell is shielded by the outer5s and5p subshells and the influence of the host material isrelatively small compared to,e.g.,the3d transitions in transition-metal ions.The electronic structure of trivalent rare-earth ions derives from the perturba-tion of the4f energy level in the central-field approximation by the noncen-trosymmetric electron–electron interaction,the spin–orbit interaction,andthe crystal-field splitting(Stark effect);see the example of the energy-level scheme of Er3+in Fig.4.The spin–orbit multiplets are commonly denotedby their2S+1L J terms in Russell–Saunders coupling,although the4f elec-trons of lanthanide ions exhibit intermediate coupling and the total angularmomenta J of the spin–orbit multiplets are linear combinations of the totalorbital angular momenta L and total spins S.Single crystal-field(Stark)tran-sitions between two spin–orbit multiplets cannot be distinguished in glasses at ambient temperature,because inhomogeneous spectral-line broadening oc-curs due to the local variation of the ligand electricfield.Also homogeneous (lifetime)broadening mechanisms are relevant in a number of glasses.This spectral-line broadening makes glasses the preferred hosts when broadband,Fig.4.Energy-level scheme of triva-lent erbium indicating the splitting ofthe4f11configuration in the central-field approximation by the noncen-trosymmetric electron–electron inter-action,the spin–orbit interaction,andthe Stark splitting by the local elec-tricfield of the host material(indi-cated only for selected spin–orbit mul-tiplets)228Markus Pollnau and Stuart D.Jacksoncontinuous tunability of lasers is desired.On the other hand,the spectral-line broadening leads to lower absorption and emission cross-sections for the same transition in glasses compared to single-crystalline hosts.The reducedcross-sections lead to generally higher pump threshold of laser transitions inglasses,a fact that is compensated infiber geometry because a high pump confinement is achieved over the wholefiber length.4.2Intraionic ProcessesGenerally,the probability of an allowed electric-dipole transition is seven or-ders of magnitude larger than that of an allowed magnetic-dipole transition.Since electric-dipole transitions within the4f subshell are parity forbidden,the intensities of radiative transitions in rare-earth ions are weak and the radiative lifetimes of the emitting states are long,typically in the ms range.Mixing of the4f states with higher-lying(typically5d)electronic states of opposite parity at ion sites without inversion symmetry,however,means thatelectric-dipole transitions become partially allowed and are usually the dom-inant transitions between4f electronic states.The oscillator strengths f and integrated absorption and emission cross-sectionsσof these spin–orbit mul-tiplet-to-multiplet transitions can be calculated with the help of the semi-empirical Judd–Ofelt theory[57,58].If the degree of inhomogeneous spectral-line broadening is relatively small and the absorption and emission spectraremain structured,as is the case for ZBLAN,the cross-sectionsσ(λ)at in-dividual wavelengths that are relevant to pump absorption and stimulatedemission of narrow laser lines must be determined experimentally.Besides ground-state absorption(GSA),excited-state absorption(ESA) of pump photons,see Fig.5a,can play a significant role infiber lasers,specif-ically in the case of high-intensity core pumping.An experimental examplewill be given later in Sect.7.1.Since the absorption increases exponentially with the absorption coefficientα(λP)=Nσ(λP),ESA becomes relevant forthe population dynamics of a laser when(a)the ESA and GSA cross-sectionsσ(λP)are comparable at the pump wavelengthλP and(b)the population density N of the excited state in which the second pump-absorption steporiginates becomes a significant fraction of the density of ions in the ground state,i.e.,a large degree of ground-state bleaching must be present for ESA to play a significant role.A radiative transition from an excited state i to a lower-lying state j is characterized by the radiative rate constant A ij.If the decay occurs to sev-eral lower-lying states,the overall radiative rate constant A i is the sum of all individual rate constants.The branching ratio of each radiative transition is defined asβij=A ij/A i.Radiative decay of excited states is in competition with nonradiative decay by interaction with vibrations of the host material, called multiphonon relaxation.The rate constant of a multiphonon relaxation process decreases exponentially with the energy gap to the next lower-lying state and with the order of the process,i.e.,the number of phonons required(a)Ion (b)12Donor Ion Acceptor IonAcceptor Ion (c)Sensitizing Ion ALaser Ion B(d)1Laser Ion AQuenching Ion B (e)Donor Ion Acceptor Ion(f)1Donor Ion Acceptor Ion Fig.5.Intra-and interionic processes infiber lasers:(a)excited-state absorption (ESA);(b)energy migration;(c)sensitization and(d)quenching of a laser ion by an ion of a different type;(e)cross-relaxation and(f)energy-transfer upconversionto bridge the energy gap[59,60].This fact is illustrated in Fig.1for differ-ent glasses.The rate constant of multiphonon relaxation increases with host temperature.The measurable luminescence lifetimeτi of an excited state i is the inverse of the sum of the overall radiative rate constant A i and the rate constant of multiphonon relaxation,W i.The radiative quantum efficiency is defined asη=A i/(A i+W i).The influence of multiphonon relaxations is stronger in oxides as com-pared tofluorides because of the smaller atomic mass m2of the anion and the larger elastic restoring force k,see(1),due to stronger covalent bonds in oxides[3],both resulting in larger maximum phonon energies in oxides.A brief example:The luminescence lifetime of the4I11/2upper laser level of the erbium3µm laser(Sect.7)is partly quenched by multiphonon relaxation. Typically,nonradiative decay becomes dominant iffive or less phonons are required to bridge the energy gap.With an energy gap between the4I11/2and the next lower lying4I13/2levels of≈3400–3500cm−1,radiative decay pre-vails for phonon energies below≈600cm−1,roughly the maximum phonon energy of ZBLAN,see Table1.Fluorides are,therefore,preferred over oxides as host materials for most of the mid-infrared laser transitions.Like absorption,the strength of a stimulated-emission process is char-acterized by the emission cross-sectionσ(λL)of the laser transition.From a simple analysis,for one resonator round-trip of oscillating laser photons, the productτσ(λL)withτthe luminescence lifetime of the upper laser level, is identified as a“figure of merit”for a possible laser transition.The larger this product,the lower is the expected pump threshold of the laser transition. This“figure of merit”,however,does not take into account the numerous par-asitic effects that can occur in the population dynamics of a laser system,such as pump ESA,reabsorption of laser photons,and energy-transfer processes. It is often these parasitic processes that lead to surprising performance char-acteristics–as likely in the negative as in the positive sense–and make the interpretation of rare-earth-doped solid-state lasers challenging.Examples will be discussed in Sects.5–7.4.3Interionic ProcessesIn addition to intraionic excitation and decay mechanisms,radiative en-ergy transfer due to reabsorption of emitted photons by other active ions in the sample and nonradiative energy-transfer processes due to multipole–multipole or exchange interactions between neighboring active ions can occur. Radiative energy transfer leads to an increase in the luminescence lifetime. Among the nonradiative energy-transfer processes,most common is the elec-tric dipole–dipole interaction,which can occur as a direct[61]or phonon-assisted[62]energy transfer.A direct energy transfer requires spectral reso-nance between the involved emission and absorption transitions whereas an indirect transfer can also be nonresonant,i.e.,an existing energy gap between the emission and absorption transitions involved in the transfer is bridged by。

Supplemental MaterialsPhase structure and field-dependent charge injectionBiFeO3 thin films with the thickness of 200 nm were deposited on (100) SrTiO3 single-crystal substrates at 700°C using pulsed laser deposition. During deposition, the flowing oxygen pressure was adjusted to be 50mTorr, and the pulsed KrF excimer laser beam (wavelength 248 nm) was focused to reach a laser fluence of 1-2 J/cm2 on the ceramic target surface. For the investigation of the effect of the film leakage current on the preferred domain orientations, three Fe-enriched bismuth ferrite ceramic targets were prepared with nominal chemical compositions of BiFeO3, BiFe1.05O3and BiFe1.1O3. With the increase in the Fe content, we can observe the reflection from an impurity phase of Bi2Fe4O9in BiFe1.1O3.1Before electrical measurements, the 150 nm-thick epitaxial LaNiO3 conductive layer was pre-grown as a lower electrode using ULV AC ACS-4000-C4 magnetron sputtering. The crystal structures were investigated by X-ray diffraction (Bruker X-ray Diffractometer D8 discover) with Cu Kα1 and Kβ radiations, as shown in Fig. S1. The film surface was studied with a Veeco MultiMode-V atomic force microscopy (AFM) operated in tapping mode, as shown in Fig. S2. The plate-like grains change into big islands with much rougher film surface in releasing epitaxial stresses with the further increase in the film thickness.2Before measurements, each film is susceptible to the repetitive bipolar voltage stressing at ±10 V/300 ns for 10-15 cycles to achieve a stable measurement. Theupper circular Au electrodes with the diameters of 5-100 μm were deposited on the films through lithography. The input domain switching pulses are supplied by an Agilent 33250A arbitrary waveform generator with a rise time of 5 ns, and the switching current is monitored through an in-series LC WR 6200A oscilloscope with the internal resistance of 50 Ω.Fig. S1 XRD patterns of bismuth ferrite thin films with different Fe excesses.Fig. S2 AFM micrograph of a 200 nm-thick BiFe1.1O3 thin film.The process of charge compensation is discussed here. The accumulated opposite charges contradict initial immobile trapped charges with the density of σ0, for example, the positively charge oxygen vacancies V O⋅⋅and negatively charged Fe Fe' (Fe3+→Fe2+) separately piled up near top and bottom electrodes with density distribution functions of ρO(x) and ρFe(x), respectively, as shown in Fig. S3(a), whereσ0=d(x) dx Oρ⎰= d(x) dx Feρ⎰. These immobile charges can compensate for the domain boundary charges for the as-grown films, which become uncompensated to generate an internal field immediately after polarization reversal, as shown in Fig. S3(b). Under a negative field stressing of the film for time t, the two immobile charges can be compensated by two opposite injected charges of electrons and holes near top and bottom electrodes with density distribution functions of ρe(x) and ρh(x),as shown in Fig. S3(c). In this case, E i disappears as σ0 =d(x) dx eρ⎰= d(x) dx hρ⎰. However, if the two distribution functions between injection charges and immobile charges cannot overlap together, and the small portion of the injected charges near the interfaces could be smoothed out of the film thickness after the removal of the stressing field due to the built-in heterogeneous interfacial field, as shown in Fig. S3(d).Fig. S3 The sketched boundary charge compensation of the preferred domains by the opposite immobile charges of V O⋅⋅ and Fe Fe' as well as deeply trapped electrons and holes near top (x=0) and bottom electrodes (x = d), respectively, for (a) the as-grown films with the two immobile charge distribution functions of ρO(x) and ρFe(x), (b) the film with the presence of an internal field due to the appearance of uncompensated immobile charges immediately after polarization reversal, (c) the film with one-side electron or hole injection at a negative basing voltage to compensate for the immobile charge with a density distribution function of ρe(x) or ρh(x), and (d) the reducedinjection charge densities ofd(x) dx eρ⎰and d(x) dx hρ⎰near electrodes after removal of the biasing voltage.References1Z. M. Tian, S. L. Yuan, X. L. Wang, X. F. Zheng, S. Y. Yin, C. H. Wang, and L. Liu, J. Appl. Phys. 106, 103912 (2009).2H. W. Jang, D. Ortiz, S. H. Baek, C. M. Folkman, R. R. Das, P. Shafer, Y. B. Chen, C. T. Nelson, X. Q.Pan, R. Ramesh, and C. B. Eom, Adv. Mater. 21, 817 (2009).。

第38卷 第7期中 国 激 光Vo l.38,N o.72011年7月CHINESE JOURNAL O F LASERSJuly,2011结晶器铜合金表面激光原位制备纳米颗粒增强钴基梯度涂层陈岁元 董 江 陈 军 梁 京 刘常升(东北大学材料各向异性与织构工程教育部重点实验室,辽宁沈阳110004)摘要 在Co 基熔覆涂层材料成分与结构设计的基础上,利用脉冲激光诱导原位反应技术,在结晶器Cu 合金基体材料上制备陶瓷相增强Co 基梯度涂层。

利用分析技术对制备涂层的组织结构、成分、性能和涂层形成机理进行了系统研究。

结果表明,设计成分的梯度变化成功制备出具有3层梯度的Co 基合金涂层,实现了涂层组织与性能的梯度变化。

梯度涂层里没有裂纹和气孔缺陷,涂层与Cu 合金基体形成冶金界面结合。

激光诱导原位生成了纳米级Cr -N-i Fe -C,M o N i 4,Cr 7C 2,WC 1-x 等颗粒,起到了增强Co 基合金梯度涂层的作用。

梯度涂层各层的陶瓷颗粒数量呈现由第1层到第3层逐渐增多的趋势,硬度由铜合金基体的94H V 逐渐增加到最外层涂层的523H V 。

涂层中石墨具有改善梯度涂层摩擦性能的作用。