Effect of Aging on the Strength of Clinching Galvanized SAE1004 Steel-to-Aluminum AA6111 Joints

- 格式:pdf

- 大小:1.30 MB

- 文档页数:8

2021年1月Journal of Medical Information Jan.2021综述沙库巴曲缬沙坦在心力衰竭中的应用现状王晨青,李婧炜(大理大学药学,云南大理671000)摘要:肾素-血管紧张素-醛固酮系统在心力衰竭发生发展过程中起着关键作用遥尽管既往治疗心力衰竭的药物已经取得了很好的疗效,但心力衰竭患者的死亡率和因心衰再入院率仍比较高遥沙库巴曲缬沙坦是一种双重阻断神经内分泌的抑制剂,研究证明,沙库巴曲缬沙坦较血管紧张素转化酶抑制剂类药物能进一步降低心血管死亡风险,从而改善心衰的治疗效果遥本文主要就沙库巴曲缬沙坦在三种不同类型心衰中有效性和安全性进行综述,旨在为临床治疗心力衰竭提供参考依据遥关键词:沙库巴曲缬沙坦曰心力衰竭曰血浆NT-proBNP中图分类号:R541.6文献标识码:A DOI:10.3969/j.issn.1006-1959.2021.01.011文章编号:1006-1959(2021)01-0037-04The Application Status of Sacubatril Valsartan in Heart FailureWANG Chen-qing,LI Jing-wei(School of Pharmacy,Dali University,Dali671000,Yunnan,China)Abstract:The renin-angiotensin-aldosterone system plays a key role in the development of heart failure.Although the previous drugs for the treatment of heart failure have achieved good results,the mortality and readmission rates of heart failure patients are still relatively high. Sacubitrilvalsartan is a dual-blocking neuroendocrine inhibitor.Studies have shown that sacubitril valsartan can further reduce the risk of cardiovascular death compared with angiotensin-converting enzyme inhibitor drugs,thereby improving the heart therapeutic effect of aging.This article mainly reviews the effectiveness and safety of sacubitril valsartan in three different types of heart failure,aiming to provide a reference for the clinical treatment of heart failure.Key words:Sacubitril valsartan;Heart failure;Plasma NT-proBNP近年来有研究发现心力衰竭(heart failure,HF)是我国患者住院的主要原因,再入院风险高,为社会、家庭都带来了沉重负担叫临床上针对心力衰竭的药物治疗包括如利尿剂(氢氯噻嗪),P受体阻滞剂(如美托洛尔、比索洛尔),醛固酮受体抑制剂(螺内酯),依那普利(ACEI),血管紧张素受体拮抗剂(angiotensin receptor blockers,ARB)等。

家具相关英语大全(资源来自网络)家具展览AAdmiss ion 参观券,入场券An exhibi tionfor profes siona ls of furnit ure and furnis hings produc ed 家具专业人士及厂商展An inaugu ral cooper ation betwee n 与。

的首次合作Appeal to tradebuyers from around the world吸引来自世界各地买家参与Appoin ted travel agent指定旅游代理Articl es exhibi ted 参展内容Attrac tingexhibi tors吸引展商BBooth展位Busine ss cardsfor regist ratio n 名片登记CCost-effect ive 物有所值DD-double occupa ncy 双人房间收费date 日期doorscloseat 闭馆时间during the exhibi tionperiod参展期间EEnjoya discou nt of 10% 享受九折优惠Enjoyfree access享受免费待遇Entran ce 入口Exhibi tionarea 参展面积Exhibi tionhall 展览馆FFirstname 名Free admiss ion with an invita tion凭柬免费入场Furnit ure pavili on 家具展团GGatesa and B A。

B 馆的入口处Govern menttax 政府费Groupvisito rs团体参观者HHong Kong Conven tion% Exhibi tionCentre香港会议展览中心IIndivi dual个人参观者Intern ation al ChinaFurnit ure Expo 中国国际家具展览会Intern ation al Furnit ure Fair. Cologn e 德国科隆国际家具展览会Intern ation al Home Furnis hingFair, High point, NorthCaroli na, USA 美国北卡罗来纳州海波因特(高点)家庭用品展Intern ation al trader s 国际买家Invita tion邀请信,请柬JJob title职务LLaunch a new event举办一项新的活动MMake a busine ss plan 安排商务计划Make a busine ss trip to 。

To improve physical fitness,there are several effective ways to engage in regular exercise.Here are some methods that can be incorporated into your routine:1.Aerobic Exercises:These are activities that increase your heart rate and improve cardiovascular health.Examples include running,swimming,cycling,and brisk walking. Aim for at least150minutes of moderate aerobic activity or75minutes of vigorous activity per week.2.Strength Training:Incorporate weight lifting or bodyweight exercises to build muscle strength.Focus on all major muscle groups and aim for at least two days of strength training per week.3.Flexibility Training:Stretching exercises can improve your flexibility and range of motion.Yoga and Pilates are excellent options for this,as they combine flexibility with strength and balance.4.Balance Training:Activities like Tai Chi or balancespecific exercises can help prevent falls and improve overall stability.This is particularly important for older adults.5.Regular Routine:Establish a consistent workout schedule that suits your lifestyle. Consistency is key to making exercise a habit.6.Variety:Mix up your routine to avoid boredom and to work different muscle groups. This can also prevent plateaus in your fitness progress.7.Proper Nutrition:A balanced diet is essential for fueling your workouts and aiding recovery.Ensure you are consuming enough protein,carbohydrates,and healthy fats. 8.Rest and Recovery:Give your body time to rest and recover.Overtraining can lead to injuries and decreased performance.9.Stay Hydrated:Drink plenty of water before,during,and after your workouts to stay hydrated and support your bodys functions.10.Set Goals:Having clear and achievable fitness goals can motivate you to stay committed to your exercise routine.11.Track Progress:Keep a record of your workouts and improvements.This can help you stay motivated and make adjustments to your routine as needed.12.Seek Professional Guidance:If youre new to exercising or have specific fitness goals, consider working with a personal trainer or fitness professional to ensure youre performing exercises correctly and safely.By incorporating these methods into your lifestyle,you can effectively work towards improving your physical fitness and overall health.Remember,the key to success is consistency and finding activities that you enjoy.。

Optimism is a powerful force that can significantly impact our lives in various ways, including the way we age.An optimistic mindset can make us feel and appear younger, both physically and mentally.Here are some reasons why maintaining a positive outlook can contribute to a more youthful existence.1.Stress Reduction:Optimistic individuals tend to experience less stress because they are better at managing challenging situations.High stress levels can accelerate the aging process by causing inflammation and damaging cells.By reducing stress,optimism can slow down the aging process.2.Improved Immune System:A positive attitude can boost the immune system,making it more effective in fighting off diseases and infections.A robust immune system is crucial for maintaining overall health and can contribute to a more youthful appearance.3.Better Sleep:Optimists often have better sleep patterns.Adequate sleep is essential for the bodys repair processes and for maintaining a youthful complexion.Poor sleep can lead to premature aging and a decline in cognitive function.4.Increased Social Connections:People with an optimistic outlook are more likely to engage in social activities,which can lead to stronger relationships and a support network. Social connections are known to have a positive impact on mental health and can help combat feelings of loneliness,which can contribute to aging.5.Enhanced Physical Activity:Optimism can motivate individuals to be more active,as they are more likely to see the benefits of exercise and participate in physical activities. Regular exercise is one of the best ways to maintain a youthful physique and improve overall health.6.Positive Mental Health:A positive mindset can lead to better mental health,reducing the risk of depression and anxiety.Mental health issues can age a person prematurely, both in terms of appearance and cognitive decline.7.Healthy Lifestyle Choices:Optimistic people are more likely to make healthy lifestyle choices,such as eating a balanced diet,avoiding smoking,and limiting alcohol consumption.These choices can have a direct impact on the aging process.8.Longevity:Studies have shown that optimistic individuals tend to live longer.This is partly because they are more likely to take care of their health and engage in activities that promote longevity.9.Cognitive Function:Maintaining an optimistic outlook can help preserve cognitive function as we age.Positive thinking can stimulate the brain and keep it active,which is essential for preventing agerelated cognitive decline.10.Resilience:Optimists are more resilient in the face of adversity.They are better equipped to bounce back from setbacks,which can help maintain a youthful spirit and prevent the negative effects of stress and disappointment.In conclusion,embracing an optimistic mindset can have a profound effect on how we age.By reducing stress,improving health,and promoting a positive outlook on life, optimism can help us stay young at heart and in body.Its never too late to cultivate a more positive attitude and enjoy the benefits of a more youthful life.。

Effects of aging on the human bodyIntroductionAging is a natural process that occurs in the human body as one grows older. This process affects all systems of the body and can lead to changes in physical appearance, function, and health. This article will discuss the effects of aging on the human body, including the skin, bones, muscles, organs, and immune system.Effects of Aging on the SkinThe skin is the largest organ in the body and is the first to show signs of aging. As one ages, the skin becomes thinner and less elastic, leading to wrinkles and sagging. Age spots, skin tags, and moles can also develop. The skin's ability to produce and hold moisture decreases, resulting in dryness and itching. It also becomes more susceptible to injury and infection.UV radiation from the sun plays a significant role in the skin's aging process. Exposure to the sun's rays can cause skin damage and increase the risk of skin cancer. Therefore, it is crucial to protect the skin from sun damage by wearing protective clothing, hats, and sunscreen with an SPF of 30 or higher.Effects of Aging on the Bones and MusclesAs one ages, bones may become weaker and more fragile, increasing the risk of osteoporosis, a condition in which bones become brittle and prone to fracture. Muscle mass also decreases, leading to reduced strength and mobility.Exercise is vital for maintaining bone density and muscle mass. Weight-bearing exercises, such as walking, running, and weight lifting, can help strengthen bones and muscles. It is also essential to eat a diet high in calcium and vitamin D to support bone health.Effects of Aging on the OrgansThe aging process can affect all organs in the body. The heart, which pumps blood throughout the body, can become weaker and less efficient with age. Blood vessels also become less elastic and more rigid, leading to high blood pressure. The digestive system may also become less efficient, leading to constipation and other digestive issues.The brain can also experience changes with age, including a decline in cognitive function. This decline may result in difficulty with memory, reasoning, and decision-making. However, it is important to note that cognitive decline is not an inevitable part of aging and can be delayed by engaging in mentally stimulating activities.Effects of Aging on the Immune SystemThe immune system is responsible for protecting the body from infections and disease. As one ages, the immune system may become less efficient, resulting in an increased risk of infections and a reduced response to vaccines. The body may also become less able to fight cancer cells, increasing the risk of cancer.To support the immune system, it is essential to maintain a healthy lifestyle. This includes eating a diet high in fruits and vegetables, exercising regularly, and getting adequate sleep.ConclusionIn conclusion, the aging process affects all systems of the body and can lead to changes in physical appearance, function, and health. While some of these changes are inevitable, engaging in a healthy lifestyle, including regular exercise and a healthy diet, can help delay the effects of aging and promote overall health and well-being.。

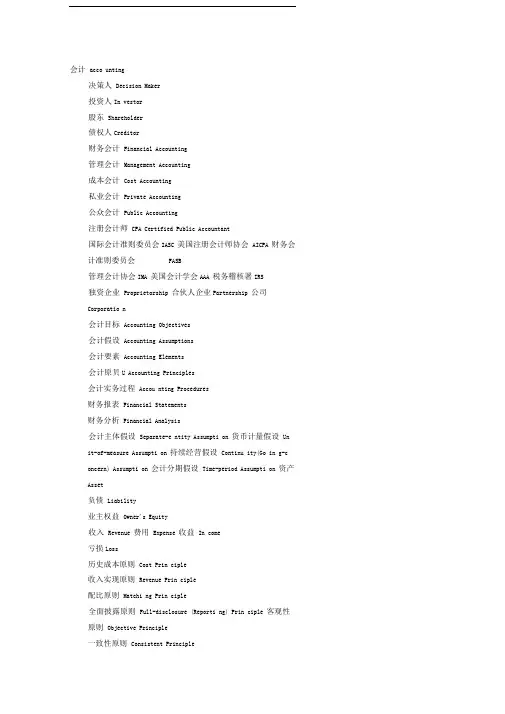

会计acco unting决策人Decision Maker投资人In vestor股东Shareholder债权人Creditor财务会计Financial Accounting管理会计Management Accounting成本会计Cost Accounting私业会计Private Accounting公众会计Public Accounting注册会计师CPA Certified Public Accountant国际会计准则委员会IASC 美国注册会计师协会AICPA 财务会计准则委员会FASB管理会计协会IMA 美国会计学会AAA 税务稽核署IRS独资企业Proprietorship 合伙人企业Partnership 公司Corporatio n会计目标Accounting Objectives会计假设Accounting Assumptions会计要素Accounting Elements会计原贝U Accounting Principles会计实务过程Accou nting Procedures财务报表Financial Statements财务分析Financial Analysis会计主体假设Separate-e ntity Assumpti on 货币计量假设Un it-of-measure Assumpti on 持续经营假设Continu ity(Go in g-c oncern) Assumpti on 会计分期假设Time-period Assumpti on 资产Asset负债Liability业主权益Owner's Equity收入Revenue 费用Expense 收益In come亏损Loss历史成本原则Cost Prin ciple收入实现原则Revenue Prin ciple配比原则Matchi ng Prin ciple全面披露原则Full-disclosure (Reporti ng) Prin ciple 客观性原则Objective Principle一致性原则Consistent Principle可比性原则Comparability Principle重大性原则Materiality Principle稳健性原则Conservatism Principle权责发生制Accrual Basis现金收付制Cash Basis财务报告Financial Report流动资产Current assets流动负债Current Liabilities长期负债Long-term Liabilities投入资本Contributed Capital留存收益Retained Earning(2)会计循环会计循环Accounting Procedure/Cycle会计信息系统Acco un ti ng in formati on System 帐户Ledger 会计科目Accou nt会计分录Journal entry原始凭证Source Document日记帐Journal总分类帐Ge neral Ledger明细分类帐Subsidiary Ledger试算平衡Trial Bala nee现金收款日记帐Cash receipt journal现金付款日记帐Cash disburseme nts journal销售日记帐Sales Journal购货日记帐Purchase Journal普通日记帐General Journal工作底稿Worksheet调整分录Adjusting entries结帐Clos ing en tries(3)现金与应收帐款现金Cash银行存款Cash in bank 库存现金Cash in hand 流动资产Current assets 偿债基金Sinking fund 定额备用金Imprestpetty cash 支票Check(cheque) 银行对帐单Bank statement 银行存款调节表Bank recon ciliati on stateme nt 在途存款Outstanding deposit 在途支票Outstanding check 应付凭单Vouchers payable 应收帐款Account receivable 应收票据Notereceivable 起运点交货价 F.O.B shippi ng poi nt 目的地交货价F.O.B desti nation poi nt 商业折扣Trade discount 现金折扣Cash discount销售退回及折让Sales return and allowa nee 坏帐费用Baddebt expense 备抵法Allowanee method 备抵坏帐Bad debtallowanee损益表法In come stateme nt approach 资产负债表法Bala nee sheet approach 帐龄分析法Aging analysis method 直接冲销法Direct write-off method 带息票据Interest bearing note 不带息票据Non-interest bearing note 出票人Maker 受款人Payee 本金Prin cipal 禾利息率In terest rate 到期日Maturity date 本票Promissory note 贴现Discou nt 背书En dorse拒付费Protest fee com⑷存货存货Inven tory商品存货Merchandise inventory产成品存货Finished goods inventory在产品存货Work in process inventory原材料存货Raw materials inventory起运地离岸价格 F.O.B shipp ing poi nt目的地抵岸价格 F.O.B desti nati on寄销Con sig nment寄销人Con sig nor承销人Con sig nee定期盘存Periodic inventory永续盘存Perpetual inventory购货Purchase购货折让和折扣Purchase allowa nee and disco unts 存货盈余或短缺Inventory overages and shortages 分批认定法Specific identification加权平均法Weighted average先进先出法First-in, first-out or FIFO后进先出法Lost-in, first-out or LIFO移动平均法Moving average成本或市价孰低法Lower of cost or market or LCM市价Market value重置成本Replacement cost可变现净值Net realizable value上限Upper limit下限Lower limit毛禾U法Gross margin method零售价格法Retail method成本率Cost ratio(5)长期投资长期投资Long-term investment长期股票投资In vestme nt on stocks长期债券投资In vestme nt on bonds成本法Cost method权益法Equity method合并法Consolidation method股利宣布日Declarati on date股权登记日Date of record除息日Ex-divide nd date付息日Payment date债券面值Face value, Par value债券折价Discount on bonds债券溢价Premium on bonds票面利率Con tract in terest rate, stated rate市场利率Market interest ratio, Effective rate普通股Com mon Stock优先股Preferred Stock现金股利Cash divide nds股票股利Stock divide nds清算股利J Liquidati ng divide nds到期日Maturity date到期值Maturity value直线摊销法Straight-Line method of amortization实际禾利息摊销法Effective-i nterest method of amortizati on⑹固定资产固定资产Plant assets or Fixed assets原值Origi nal value预计使用年限Expected useful life预计残值Estimated residual value折旧费用Depreciation expense累计折旧Accumulated depreciation帐面价值Carrying value应提折旧成本Depreciati on cost净值Net value在建工程Con struct ion-i n-process磨损Wear and tear过时Obsolesce nee直线法Straight-line method (SL)工作量法Units-of-production method (UOP)力口速折旧法Accelerated depreciation method双倍余额递减法Double-decli ning bala nee method (DDB) 年数总和法Sum-of-the-years-digits method (SYD)以旧换新Trade in经营租赁Operating lease融资租赁Capital lease廉价购买权Bargain purchase option (BPO)资产负债表外筹资Off-bala nce-sheet financing最低租赁付款额Mi nimum lease payme nts(7)无形资产无形资产Intangible assets专利权Pate nts商标权Trademarks, Trade names著作权Copyrights特许权或专营权Fran chises商誉Goodwill开办费Organization cost租赁权Leasehold摊销Amortization(8)流动负债负债Liability流动负债Current liability应付帐款Account payable应付票据Notes payable贴现票据Discount notes长期负债一年内到期部分Current maturities of Iong-term liabilities 应付股利Divide nds payable预收收益Prepayments by customers存入保证金Refundable deposits应付费用Accrual expense增值税value added tax营业税Business tax应付所得税In come tax payable应付奖金Bonuses payable产品质量担保负债Estimated liabilities un der product warra nties 赠品和兑换券Premiums, coup ons and tradi ng stamps 或有事项Contingency 或有负债Contingent或有损失Loss contingencies或有利得Gain contingencies永久性差异Permanent differenee 时间性差异Timing differenee 应付税款法Taxes payable method 纟纳税影响会计法Tax effect acco un ti ngmethod 递延所得税负债法Deferred in come tax liability method(9)长期负债长期负债Long-term Liabilities 应付公司债券Bonds payable 有担保品的公司债券Secured Bonds抵押公司债券Mortgage Bonds 保证公司债券Guara nteed Bonds 信用公司债券Debe nture Bonds 一次还本公司债券Term Bon ds 分期还本公司债券Serial Bonds 可转换公司债券Con vertible Bonds 可赎回公司债券Callable Bonds 可要求公司债券Redeemable Bonds 记名公司债券Registered Bonds 无记名公司债券Coup on Bonds 普通公司债券Ordi nary Bonds 收益公司债券In come Bonds 名义利率,票面利率Nomi nal rate 实际利率Actual rate 有效利率Effective rate 溢价Premium 折价Disco unt 面值Par value 直线法Straight-line method 实际利率法Effectiveinterest method 到期直接偿付Repayme nt at maturity 提前偿付Repayment at advanee 偿债基金Sinking fund 长期应付票据Lon g-term no tespayable 抵押借款Mortgage loan(10)业主权益权益Equity业主权益Owner's equity股东权益Stockholder's equity投入资本Contributed capital缴入资本Paid-in capital股本Capital stock资本公积Capital surplus留存收益Retained earnings核定股本Authorized capital stock实收资本Issued capital stock发行在外股本Outstanding capital stock库藏股Treasury stock普通股Com mon stock优先股Preferred stock累积优先股Cumulative preferred stock非累积优先股Non cumulative preferred stock完全参加优先股Fully participat ing preferred stock 咅B分参加优先股Partially participat ing preferred stock 非部分参加优先股N on partially participat ing preferred stock现金发行Issuanee for cash非现金发行Issua nee for non cash con sideratio n股票的合并发行Lump-sum sales of stock发行成本Issuanee cost成本法Cost method面值法Par value method捐赠资本Donated capital盈余分酉己Distribution of earnings股禾U Divide nd股利政策Divide nd policy宣布日Date of declaration股权登记日Date of record除息日Ex-divide nd date股利支付日Date of payme nt现金股利Cash divide nd股票股利Stock divide nd拨款appropriati on(11)财务报表财务报表Financial Statement资产负债表Bala nee Sheet收益表In come Stateme nt帐户式Account Form报告式Report Form编制(报表)Prepare工作底稿Worksheet多步式Multi-step单步式Single-step(12)财务状况变动表财务状况变动表中的现金基础SCFP.Cash Basis(现金流量表)财务状况变动表中的营运资金基础SCFP.Worki ng Capital Basis (资金来源与运用表)营运资金Working Capital全部资源概念All-resources con cept直接交换业务Direct excha nges正常营业活动Normal operati ng activities财务活动Financing activities投资活动Investing activities(13)财务报表分析财务报表分析An alysis of finan cial stateme nts比较财务报表Comparative finan cial stateme nts趋势百分比Trend percentage比率Ratios普通股每股收益Earnings per share of com mon stock股利收益率Divide nd yield ratio价益比Price-earnings ratio普通股每股帐面价值Book value per share of com mon stock资本报酬率Return on investment总资产报酬率Retur n on total asset债券收益率Yield rate on bonds已获禾利息倍数Number of times in terest earned债券比率Debt ratio优先股收益率Yield rate on preferred stock营运资本Working Capital周转Turnover存货周转率Inventory turnover应收帐款周转率Accou nts receivable turnover流动比率Current ratio速动比率Quick ratio酸性试验比率Acid test ratio(14)合并财务报表合并财务报表Con solidated finan cial stateme nts吸收合并Merger创立合并Consolidation控股公司Pare nt compa ny附属公司Subsidiary company少数股权Minority interest权益联营合并Pooli ng of in terest购买合并Comb in ati on by purchase权益法Equity method成本法Cost method(15)物价变动中的会计计量物价变动之会计Price-level cha nges acco unting一般物价水平会计General price-level accou nti ng货币购买力会计Purchas in g-power acco un ti ng统一币值会计Con sta nt dollar acco unting历史成本Historical cost现行价值会计Current value acco unting现行成本Current cost重置成本Replacement cost物价指数Price-level index国民生产总值物价指数Gross natio nal product implicit price deflator (or GNPdeflator)消费物价指数Co nsumer price in dex (or CPI)批发物价指数Wholesale price in dex货币性资产Monetary assets货币性负债Monetary liabilities货币购买力损益Purchas in g-power gains or losses资产持有损益Holdi ng gains or losses未实现的资产持有损益Un realized hold ing gains or losses1 资产assets 11~ 12 流动资产current assets 111 现金及约当现金cash and cash equivalents 1111 库存现金cash on hand 1112 零用金/周转金petty cash/revolving funds 1113 银行存款cash in banks 1116在途现金cash in tran sit 1117 约当现金cash equivale nts 1118 其它现金及约当现金other cash and cash equivalents 112 短期投资short-terminvestment 1121 短期投资 -股票 short-term investments - stock 期投资-短期票券 short-term investments - short-term notes and bills 投资-政府债券 short-term investments - government bonds 1124 益凭证 short-term investments - beneficiary certificates short-term investments -corporate investments - other 1129 short-term 应收票据 investment to market 1132 notes receivable 应收票据-关系人 1137 票据 other notes receivable tible aeeounts- notes 应 收帐款 aceounts bonds 1128 备抵短期投资跌价损失113 应收票 应收票据贴现notes 1139 receivable receivable应收帐款 allowa nee receivable 1147 备抵呆帐-应收帐款其它应收款 other receivables receivable 1122 短 1123 短期 短期投资-受 短期投资么司债 -其它 short-term 1125 短期投资 allowa nee for reduct ion of 据 notes receivable 1131 discounted notes receivable 1138 其它应收 备抵呆帐—应收票据 allowanee for uncollec- 应收帐款 aceounts receivable 1141 应收分期帐款in stallme nt aceou ntsreceivable - related parties 114 1142aeeounts receivable - related parties 1149 118 forwardexcha nge con tract -关系人for uncollec- tible aeeounts - aeeounts receivable1181应收出售远汇款应收远汇款 -夕卜币 forward exchange contract receivable - foreign currencies 买卖远汇折价 earned reve nue receivable 1182 1183 disco unt on forward ex-cha nge con tract 1184 1185 应收退税款 in come tax refund receivable 其它应收款 其它应收款-关系人 other receivables - related parties 1188 other receivables - other 1189 应收收益 1187 -其它 tible aeeounts - other receivablesmerchandise inventory 1212 goods in tran sit market fini shed 1219 1221 备抵呆帐-其它应收款 121~122 存货 inventories 寄销商品 con sig ned goods 备抵存货跌价损失finished goodsallowa nee 1222 for 1225 1227 allowa nee 1211 1213for uncollec- 商品存货 在途商品inven tory tocon sig nedreduct ion 寄销制成品在制品 work in process 原料raw materialsof 制成品副产品 by-productswork in process - outsourced 12261223委外加工物料 supplies 备抵存货跌价损失goods12241229预付费用 prepaid expenses 1251 prepaidrents 1253 预付保险费 supplies 1255 预付所得税prepaid expenses 126 prepayme nt for purchases 1268 流动资产 other current assets 1228在途原物料materials and supplies in transitallowanee for reduction of inventory to market 125 1252 预付租金用品盘存 office 其它预付费用 other 预付薪资 prepaid payroll prepaid in sura nee 1254 prepaid in come tax 1258 预 付款项 prepayments 1261 其它预付款项 other prepayme nts 预付货款 128~129 其它 1281 (or overpaid payment on 存出保证金 1291 进项税额 VAT paid ( or in put VAT) 1283 暂付款 behalf of others 1285 refundable deposits 1287 递延所得税资产 tax) 1282 留抵税额 temporary payments 1284 员工借支 advances to employees excess VAT paid 代付款 1286 受限制存款 certificate of deposit-restricteddeferred in come tax assets deferred foreig n excha nge losses aceou nt 1294 其它 other current 1293 同业往来 current aeeountassets - other 131292 递延兑换损失 业主(股东)往来 owners(stockholders) current 1298其它流动资产-funds and Iong-termin vestme nts131基金 funds 1311with others基金及长期投资 偿债基金redemption fund (or sinkingfund) 1312 改良及扩充基金fund for improveme nt and expa nsion 1313 意外损失准备基金contingency fund 1314 退休基金pen sion fund 1318 其它基金other funds 132 长期投资Iong-term investments 1321 长期股权投资Iong-term equity investments 1322 长期债券投资Iong-term bond investments 1323 长期不动产投资Ion g-term real estate in-vestme nts 1324 人寿保险现金解约价值cash surre nder value of life in sura nee 1328 其它长期投资otherIon g-term in vestme nts 1329 备抵长期投资跌价损失allowa nee for excess of cost over market value of Ion g-term in vestme nts 14~ 15 固定资产property , pla nt, and equipme nt141 土地land 1411 土地land 1418 土地-重估增值land - revaluatio n in creme nts 142 土地改良物land improveme nts 1421 土地改良物la nd improveme nts 1428 土地改良物-重估增值la nd improveme nts - revaluati on in creme nts。

1.Determination is the key ingredient in achieving ones goals it is the driving force that propels us forward in the face of adversity.2.Resolute determination can turn the seemingly impossible into the possible,and the possible into reality.3.With unwavering determination,even the most daunting tasks can be accomplished with time and effort.4.Determination is the fuel that ignites the fire of ambition,pushing us to reach for the stars.5.A determined mind can overcome any obstacle,for it is the will to succeed that ultimately defines our achievements.6.When faced with challenges,it is our determination that keeps us going,even when the odds seem stacked against us.7.True determination is not just about setting goals,but about the relentless pursuit of those goals,no matter the cost.8.Determination is the bedrock of success without it,even the most talented individuals may falter.9.In life,determination is the compass that guides us through the storms and towards our desired destination.10.Determination is not just a fleeting emotion it is a steadfast commitment to seeing things through to the end.11.The power of determination lies in its ability to inspire and motivate us to push beyond our limits.12.Determination is the silent partner in our success,often unseen but always felt in the culmination of our achievements.13.A determined spirit is one that refuses to accept defeat,even in the face of repeated setbacks.14.Determination is the inner strength that keeps us focused on our goals,even when the path is fraught with difficulties.15.In the pursuit of our dreams,it is determination that often makes the difference between those who succeed and those who do not.16.Determination is the bridge that connects our aspirations with our accomplishments, spanning the gap between hope and reality.17.The flame of determination burns brightest in those who are committed to their cause, undeterred by the trials they face.18.Determination is the wind beneath our wings,lifting us higher and propelling us towards our aspirations.19.With determination as our guide,we can navigate the treacherous waters of life and reach the shores of our dreams.20.Determination is the cornerstone of success,laying the foundation for all our endeavors and ensuring their fruition.。

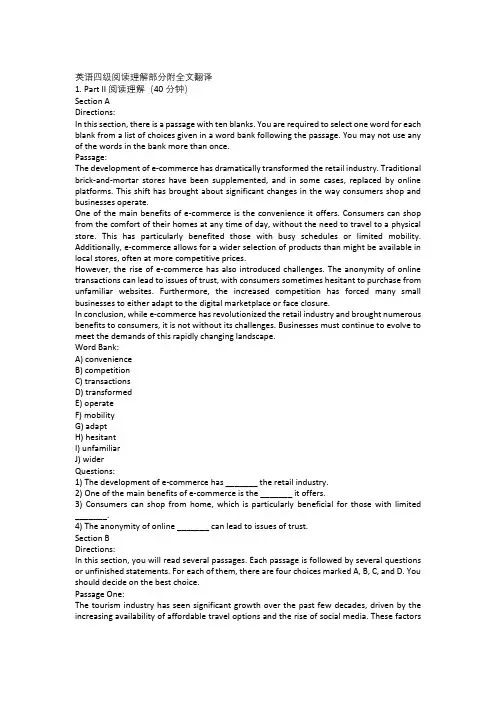

英语四级阅读理解部分附全文翻译1. Part II 阅读理解(40分钟)Section ADirections:In this section, there is a passage with ten blanks. You are required to select one word for each blank from a list of choices given in a word bank following the passage. You may not use any of the words in the bank more than once.Passage:The development of e-commerce has dramatically transformed the retail industry. Traditional brick-and-mortar stores have been supplemented, and in some cases, replaced by online platforms. This shift has brought about significant changes in the way consumers shop and businesses operate.One of the main benefits of e-commerce is the convenience it offers. Consumers can shop from the comfort of their homes at any time of day, without the need to travel to a physical store. This has particularly benefited those with busy schedules or limited mobility. Additionally, e-commerce allows for a wider selection of products than might be available in local stores, often at more competitive prices.However, the rise of e-commerce has also introduced challenges. The anonymity of online transactions can lead to issues of trust, with consumers sometimes hesitant to purchase from unfamiliar websites. Furthermore, the increased competition has forced many small businesses to either adapt to the digital marketplace or face closure.In conclusion, while e-commerce has revolutionized the retail industry and brought numerous benefits to consumers, it is not without its challenges. Businesses must continue to evolve to meet the demands of this rapidly changing landscape.Word Bank:A) convenienceB) competitionC) transactionsD) transformedE) operateF) mobilityG) adaptH) hesitantI) unfamiliarJ) widerQuestions:1) The development of e-commerce has _______ the retail industry.2) One of the main benefits of e-commerce is the _______ it offers.3) Consumers can shop from home, which is particularly beneficial for those with limited _______.4) The anonymity of online _______ can lead to issues of trust.Section BDirections:In this section, you will read several passages. Each passage is followed by several questions or unfinished statements. For each of them, there are four choices marked A, B, C, and D. You should decide on the best choice.Passage One:The tourism industry has seen significant growth over the past few decades, driven by the increasing availability of affordable travel options and the rise of social media. These factorshave made it easier than ever for people to explore new destinations and share their experiences with others.One of the most notable trends in recent years is the rise of "sustainable tourism." This approach emphasizes minimizing the environmental impact of travel while supporting local communities. Sustainable tourism can include practices such as choosing eco-friendly accommodations, participating in conservation efforts, and respecting local cultures. However, the growth of tourism has also led to challenges. Popular destinations can become overcrowded, leading to damage to natural environments and cultural sites. In some cases, the influx of tourists can even disrupt local communities, causing resentment among residents. In conclusion, while tourism offers many benefits, it is important to approach travel responsibly to ensure that destinations can be enjoyed by future generations. Questions:1) What has contributed to the significant growth of the tourism industry?A) The decline in travel costs and the popularity of social media.B) The development of new transportation methods.C) The increase in luxury travel options.D) The promotion of international tourism by governments.2) What is a key aspect of sustainable tourism?A) Visiting as many destinations as possible.B) Minimizing environmental impact and supporting local communities.C) Staying in luxury hotels and resorts.D) Traveling to remote and unspoiled locations.3) What is one of the challenges caused by the growth of tourism?A) The decline in international travel.B) The negative impact on local cultures and environments.C) The rise in travel-related costs.D) The decrease in travel safety.4) How can travelers ensure that destinations remain enjoyable for future generations?A) By visiting only popular tourist spots.B) By choosing environmentally friendly travel options.C) By limiting the duration of their trips.D) By avoiding travel during peak seasons.Passage Two:The concept of work-life balance has become increasingly important in modern society. As technology continues to blur the lines between work and personal life, many people struggle to find time for relaxation and leisure. This issue is particularly prevalent in countries where long working hours are the norm.One of the main challenges of achieving work-life balance is the expectation to be constantly available. With the advent of smartphones and email, employees are often expected to respond to work-related communications outside of regular business hours. This can lead to burnout and decreased job satisfaction.Employers are beginning to recognize the importance of work-life balance for employee well-being and productivity. Some companies have implemented policies such as flexible working hours, remote work options, and mandatory vacation time to help employees achieve a healthier balance.In conclusion, work-life balance is essential for maintaining both physical and mental health. Employers and employees alike must work together to create an environment that supports a healthy balance between work and personal life.Questions:1) What has contributed to the difficulty of achieving work-life balance in modern society?A) The rise of remote work opportunities.B) The increasing demand for skilled labor.C) The expectation to be constantly available.D) The decline in job security.2) What is one of the negative effects of being constantly available for work?A) Increased job satisfaction.B) Higher productivity levels.C) Burnout and decreased job satisfaction.D) Improved work-life balance.3) How are some employers helping employees achieve work-life balance?A) By increasing work hours and reducing vacation time.B) By offering flexible working hours and remote work options.C) By eliminating work-from-home opportunities.D) By requiring employees to work on weekends.4) Why is work-life balance important?A) It helps employees earn more money.B) It allows employees to focus solely on their careers.C) It is essential for maintaining physical and mental health.D) It improves job security.Passage Three:The importance of cybersecurity has grown exponentially as the world becomes more connected through the internet. Cyberattacks are becoming more frequent and sophisticated, targeting everything from personal information to critical infrastructure.One of the most common forms of cyberattacks is phishing, where attackers trick individuals into providing sensitive information by pretending to be a trustworthy source. This can lead to identity theft, financial loss, and damage to an organization's reputation.To combat these threats, both individuals and organizations must take proactive measures. This includes using strong passwords, keeping software up to date, and being cautious of suspicious emails and links. Additionally, governments and businesses are investing in cybersecurity technologies and training to protect against potential threats.In conclusion, cybersecurity is an essential aspect of modern life, requiring constant vigilance and proactive measures to safeguard against the ever-evolving threats in the digital world. Questions:1) What has contributed to the growing importance of cybersecurity?A) The decline in internet usage.B) The increase in cyberattacks targeting critical infrastructure.C) The rise of traditional communication methods.D) The reduction in government regulations.2) What is one of the most common forms of cyberattacks?A) Phishing.B) Malware.C) Ransomware.D) Denial of service.3) What can individuals do to protect themselves from cyberattacks?A) Use weak passwords and share them with others.B) Keep software up to date and be cautious of suspicious emails.C) Ignore cybersecurity threats and rely on antivirus software.D) Avoid using the internet altogether.4) How are governments and businesses addressing cybersecurity threats?A) By reducing investments in cybersecurity technologies.B) By training employees and investing in cybersecurity technologies.C) By eliminating the use of the internet in the workplace.D) By ignoring cybersecurity risks.答案部分1. Part II 阅读理解(40分钟)Section APassage:电子商务的发展已经极大地改变了零售业。

Cultivating Strength Through Struggle Strength is not always born from ease and comfort, but rather from struggleand adversity. It is through facing challenges and overcoming obstacles that individuals cultivate resilience, determination, and a deeper understanding oftheir own capabilities. While the concept of embracing struggle may seem counterintuitive, it is often through these difficult experiences that one cantruly grow and develop both personally and professionally. From a personal perspective, struggle can be a catalyst for self-discovery and growth. When faced with adversity, individuals are forced to confront their limitations and push beyond their comfort zones. This process of pushing past perceived boundaries can lead to a greater sense of self-awareness and confidence. For example, someone who has experienced the loss of a loved one may find themselves navigating through the depths of grief and eventually emerging with a newfound appreciation for life anda deeper understanding of their own emotional resilience. Furthermore, struggle can also serve as a powerful motivator for change. When individuals are confronted with challenges, they are often compelled to reevaluate their priorities and make necessary adjustments in order to overcome the obstacles they face. This can lead to personal growth and the development of new skills and coping mechanisms. For instance, someone who has experienced financial hardship may be motivated topursue new career opportunities or develop a more frugal approach to managingtheir finances, ultimately leading to a greater sense of financial stability and independence. In addition to personal growth, struggle can also foster strength and resilience on a professional level. In the workplace, individuals are often faced with demanding projects, tight deadlines, and high-pressure situations.While these challenges may initially seem daunting, they provide an opportunityfor individuals to demonstrate their ability to persevere in the face of adversity. This can lead to the development of valuable skills such as time management, problem-solving, and effective communication, all of which are essential for professional success. Moreover, struggle can also serve as a source ofinspiration and motivation for others. When individuals openly share their experiences of overcoming adversity, they have the potential to inspire and uplift those who may be facing similar challenges. This sense of solidarity and sharedexperience can create a supportive community where individuals feel empowered to confront their own struggles with courage and resilience. For example, a public figure who has openly shared their journey of overcoming addiction may serve as a source of hope and encouragement for others who are on a similar path to recovery. It is important to acknowledge that while struggle can lead to personal and professional growth, it is not always easy or straightforward. The process of facing and overcoming adversity can be emotionally and physically taxing, and individuals may experience moments of doubt, fear, and frustration along the way. However, it is often through these difficult experiences that individuals can cultivate a deeper sense of empathy, compassion, and understanding for both themselves and others. In conclusion, cultivating strength through struggle is a multifaceted and deeply personal journey that has the potential to foster personal, professional, and emotional growth. By confronting challenges head-on, individuals have the opportunity to develop resilience, self-awareness, and a deeper understanding of their own capabilities. Furthermore, the process of overcoming adversity can inspire and motivate others, creating a supportive community where individuals feel empowered to confront their own struggles with courage and determination. While the path to strength through struggle may be challenging, the rewards of personal growth and emotional resilience are invaluable.。

Playing badminton is a fantastic way to engage in physical activity and enjoy numerous health benefits.Here are some of the advantages of this sport:1.Improves Cardiovascular Health:Badminton is an aerobic exercise that helps to strengthen the heart and improve the circulation of blood throughout the body.2.Enhances Flexibility:The sport requires players to move in various directions, stretching and bending,which improves overall flexibility and range of motion.3.Builds Strength:The repetitive movements involved in badminton,such as swinging the racket and jumping,help to build muscle strength,particularly in the arms,legs,and core.4.Boosts Coordination:The quick reflexes and precise movements needed in badminton enhance handeye coordination and body awareness.5.Reduces Stress:Engaging in physical activities like badminton can release endorphins, which are natural mood lifters that help to reduce stress and anxiety.6.Promotes Social Interaction:Badminton is often played in doubles,encouraging teamwork and social interaction with fellow players.7.Improves Balance:The need to move quickly and maintain body control during the game helps to improve balance and stability.8.Burns Calories:Badminton can be an effective way to burn calories and contribute to weight management.9.Develops Agility:The sport requires players to be quick on their feet,which helps to develop agility and quick thinking.10.Encourages a Healthy Lifestyle:Regular participation in badminton can be part of a broader commitment to a healthy and active lifestyle.11.Accessible to All Ages:Badminton can be enjoyed by people of all ages,making it an inclusive sport for families and communities.12.Cognitive Benefits:The strategic thinking required in badminton can help to improve cognitive function and problemsolving skills.13.Low Impact:Compared to some other sports,badminton is relatively low impact, reducing the risk of injuries associated with highimpact activities.14.Fun and Enjoyable:Above all,badminton is a fun and enjoyable sport that can be played casually or competitively,making it an attractive option for those looking to stay active.By incorporating badminton into your routine,you can experience these benefits and enjoy the games unique combination of speed,skill,and strategy.。

Strength is a quality that is often admired and sought after in individuals.It is the foundation upon which great achievements are built,and it is what allows people to overcome adversity and achieve their goals.In this essay,we will explore the importance of strength in various aspects of life and how it can lead to the creation of glory.Firstly,physical strength is essential for athletes and individuals who engage in sports or physical activities.It enables them to perform at their best and achieve remarkable feats. For example,Olympic athletes train rigorously to build their strength and endurance, which allows them to compete at the highest level and bring glory to their countries.Secondly,mental strength is crucial for individuals who face challenges and obstacles in their personal and professional lives.It helps them to stay focused,persevere,and maintain a positive attitude despite setbacks.People with strong mental fortitude are more likely to bounce back from failures and continue pursuing their dreams,ultimately achieving success and recognition.Thirdly,emotional strength is vital for maintaining healthy relationships and navigating through lifes ups and downs.It allows individuals to express their feelings openly, empathize with others,and provide support when needed.Emotionally strong people are better equipped to handle conflicts,communicate effectively,and build strong bonds with those around them.Moreover,moral strength is the foundation of integrity and ethical behavior.It guides individuals to make the right decisions,even when faced with temptations or pressures. People with strong moral convictions are respected and admired for their honesty, fairness,and commitment to doing what is right.In conclusion,strength in various forms physical,mental,emotional,and moral plays a significant role in shaping an individuals life and achieving glory.By cultivating these qualities,one can overcome challenges,excel in their chosen field,and earn the respect and admiration of others.Embracing strength as a core value can lead to a fulfilling and successful life,filled with accomplishments and recognition.。

Investigating the Effect of Aging onMaterialsIntroductionMaterials are essential for the development of modern society, they provide us with the necessary tools to build our buildings, create our vehicles and develop new technologies. But materials are not invincible, they can degrade over time due to several factors, including exposure to the environment, stress, and aging. Therefore, it is important to investigate the effect of aging on materials to better understand how they will perform over time and ensure their longevity.What is aging?Aging is a natural process that affects all materials, including metals, polymers, ceramics, and composites. It can be defined as the gradual deterioration of material properties due to various mechanisms such as chemical reactions, physical processes like diffusion, and structural changes on the atomic and molecular levels.The aging process is influenced by several factors, including temperature, humidity, exposure to UV radiation, and other environmental factors. Additionally, mechanical and physical stresses can also cause materials to age more quickly.The Effects of Aging on MaterialsAging can affect materials in several ways. One of the most significant effects is the degradation of mechanical properties, including strength, ductility, and toughness. Aging can cause microstructural changes that affect the material's ability to withstand stress and deformation.For example, metals can age due to corrosion, which can cause cracks and other defects that weaken the material's strength. Polymers can also undergo aging through oxidation, which can result in cracking, embrittlement, and loss of strength.Aging can also affect a material's thermal and electrical properties. For example, thermal conductivity may decrease due to the accumulation of impurities or changes in the microstructure. Additionally, aging can cause materials to become less electrically conductive.Methods of Investigating AgingThere are several methods for investigating the effect of aging on materials, including field experiments, laboratory testing, and simulation.Field experiments involve monitoring the performance of materials in real-world environments over a long period of time. This method is useful for investigating the effects of aging on materials in actual service conditions.Laboratory testing involves exposing materials to specific environmental conditions, such as temperature, humidity, and UV radiation, and monitoring their properties over time. This method is useful for simulating the effects of aging on materials in controlled conditions.Simulation involves predicting the aging behavior of materials using computer models. This method is useful for investigating the effect of aging on materials that are difficult or expensive to test in the laboratory or field.ConclusionThe effect of aging on materials is an important area of research that has implications for many industries. Understanding how materials age can help to develop more durable and reliable materials, which can enhance the safety and performance of critical infrastructure and other applications where materials are used. Methods of investigating the effect of aging on materials are diverse, and a combination of laboratory testing, field experiments, and simulation is often used to gain a comprehensive understanding of the aging process.。

2016,24(22):5787-5795.[9] PopovtzerA,BurnsteinH,StemmerS,etal.PhaseIIorgan-preservationtrial:Concurrentcisplatinandradiotherapyforadvancedlaryngealcancerafterresponsetodocetaxel,cisplatin,and5-fluorouracil-basedinductionchemotherapy[J].HeadNeck,2017,39(2):227-233.[10]HuangPW,LinCY,HsiehCH,etal.AphaseIIrandomizedtrialcomparingneoadjuvantchemotherapyfollowedbyconcurrentchemora diotherapyversusconcurrentchemoradiotherapyaloneinadvancedsqua mouscellcarcinomaofthepharynxorlarynx[J].BiomedJ,2018,41(2):129-136.[11]HsiehCH,LinCY,HsuCL,etal.IncorporationofAstragaluspolysaccharidesinjectionduringconcurrentchemoradiotherapyinadvancedpharyngealorlaryngealsquamouscellcarcinoma:preliminaryexperienceofaphaseIIdouble-blind,randomizedtrial[J].JCancerResClinOn col,2020,146(1):33-41.[12]WangY,PangB,ZhangR,etal.UbenimexinducesapoptoticandautophagiccelldeathinratGH3andMMQcellsthroughtheROS/ERKpathway[J].DrugDesDevelTher,2019,13:3217-3228.[13]HeHQ,WuYX,NieYJ,etal.LYRM03,anubenimexderivative,attenuatesLPS-inducedacutelunginjuryinmicebysuppressingtheTLR4signalingpathway[J].ActaPharmacolSin,2017,38(3):342-350.[14]LiC,ZhaiW,WanL,etal.MicroRNA-125aattenuatesthechemoresistanceagainstubenimexinnon-smallcelllungcarcinomaviatargetingtheaminopeptidaseNsignalingpathway[J].JCellBiochem,2020,121(2):1716-1727.[15]XuJW,LiCG,HuangXE,al.Ubenimexcapsuleimprovesgeneralperformanceandchemotherapyrelatedtoxicityinadvancedgastriccancercases[J].AsianPacJCancerPrev,2011,12(4):985-987.[16]张家友,吴亚兵,刘军慧,等.乌苯美司联合TMP方案治疗多发性骨髓瘤的疗效观察[J].肿瘤药学,2017,7(3):328-331,359.[17]李炜,姚忠强,柳仲秋,等.乌苯美司胶囊联合SOX化疗对晚期胃癌患者的临床疗效研究[J].现代生物医学进展,2017,17(23):4495-4497,4470.[18]赵咏梅,李伯海,王建华,等.乌苯美司联合TP方案对晚期非小细胞肺癌患者机体免疫功能的影响[J].临床药物应用,2016,6(23):96-99.[19]ToshiyamaR,KonnoM,EguchiH,etal.Poly(ethyleneglycol)-poly(lysine)blockcopolymer-ubenimexconjugatetargetsaminopeptidaseNandexertsanantitumoreffectinhepatocellularcarcinomastemcells[J].Oncogene,2019,38(2):244-260.[20]GuoQ,SuiZG,XuW,etal.UbenimexsuppressesPim-3kinaseexpressionbytargetingCD13toreverseMDRinHCCcells[J].Oncotar get,2017,8(42):72652-72665.[21]GuoQ,JingFJ,XuW,etal.UbenimexinducesautophagyinhibitionandEMTsuppressiontoovercomecisplatinresistanceinGCcellsbyperturbingthe2011/EMP3/PI3K/AKT/NF-kappaBaxis[J].Aging(AlbanyNY),2019,12(1):80-105.[22]GuoQ,JingFJ,QuHJ,etal.UbenimexReversesMDRinGastricCancerCellsbyActivatingCaspase-3-MediatedApoptosisandSup pressingtheExpressionofMembraneTransportProteins[J].BiomedResInt,2019,2019:4390839.[23]ZhengYB,GongJH,LiY,etal.Inhibitionoftumorcellinvasionandinductionofapoptosisbyubenimex[J].YaoXueXueBao,2012,47(12):1593-1598.[24]HirayamaY,SakamakiS,TakayanagiN,etal.Chemotherapywithubenimexcorrespondingtopatientageandorgandisorderfor18casesofacutemyelogeneousleukemiainelderlypatients--effects,complicationsandlong-termsurvival[J].GanToKagakuRyoho,2003,30(8):1113-1118.[25]LiuS,GaoM,WangX,etal.UbenimexattenuatesacquiredsorafenibresistanceinrenalcellcarcinomabyinhibitingAktsignalinginalipoph agyassociatedmechanism[J].Oncotarget,2016,7(48):79141-79153.(收稿日期:2020-09-28) DOI:10.3969/j.issn.1671-4695.2021.04.013 文章编号:1671-4695(2021)04-0383-05血必净注射液联合抗生素治疗急诊ICU重症肺感染患者临床效果陈兰 范青青 冯佳佳 (如皋市人民医院重症医学科 江苏 如皋 226500)基金项目:江苏省科技厅研究基金资助项目(编号:201207689X) 【摘要】 目的 探讨血必净注射液联合抗生素治疗急诊ICU重症肺感染患者临床效果。

国际老年医学杂志 2023年5月 第44卷第3期 IntJGeriatr,May2023,Vol.44No.32023国际老年医学杂志编辑部 2023bytheEditorialOfficeofInternationalJournalofGeriatrics四川大学护理发展专项基金一般项目(HXHL19021) 通讯作者:方荣华,电子邮箱fangronghua@wchscu cn老年口腔衰弱与肌少症相关性的研究进展蒋 微1,2 张剑书1,2 刘雪莲1,2 方荣华1,2 1四川大学华西医院全科医学中心,成都 610041;2四川大学华西护理学院,成都 610041 [摘 要] 口腔衰弱与肌少症均是与增龄相关的老年健康问题。

口腔衰弱影响食物选择和营养摄入,导致营养不良,进而影响骨骼肌质量,增加肌少症患病风险。

而肌少症又会加速吞咽肌肉萎缩,导致肌少性吞咽困难,从而增加营养不良风险。

本文就老年人口腔衰弱与肌少症相关性进行综述,以提高医护工作者对其重视,从而提高老年人健康水平,促进健康老龄化。

[关键词] 老年人;口腔衰弱;肌少症 doi:10 3969/j issn 1674-7593 2023 03 023ResearchProgressontheCorrelationBetweenOralFrailtyandSarcopeniaintheElderlyJiangWei1,2,ZhangJianshu1,2,LiuXuelian1,2,FangRonghua1,21GeneralPracticeWard/InternationalMedicalCenterWard,GeneralPracticeMedicalCenter,WestChinaHospital,SichuanUniversity,Chengdu 610041;2WestChinaCollegeofNursing,SichuanUniversity,Chengdu 610041Correspondingauthor:FangRonghua,email:fangronghua@wchscu cn [Abstract] Oralfrailtyandsarcopeniaarebothage-relatedhealthproblemsintheelderly.Oralfrailtycanaffectfoodse lectionandnutritionintake,whichmayinducemalnutritionthatcanfurtheraffecttheskeletalmusclemass,eventuallyleadingtotheincreasedriskofsarcopenia.Furthermore,sarcopeniacanalsohaveanegativeimpactonoralhealth,acceleratepharyngealmuscleatrophy,andresultinsarcopenicdysphagia,whichmayincreasetheriskofmalnutrition.Thisarticlereviewsthecorrelationbetweenoralfrailtyandsarcopeniaintheelderly,withthepurposetoraisetheawarenessofhealthcareproviders,soastoimprovethehealthconditionoftheelderly. [Keywords] Elderly;Oralfrailty;Sarcopenia 随着人口老龄化加剧,老年人的生活质量受到广泛关注。

In the realm of personal growth and development,the manifestation of strength and the demonstration of new determination are pivotal aspects that can propel an individual towards achieving their goals and aspirations.Here is an essay that delves into the essence of strength and the importance of cultivating a renewed sense of determination.Title:Unveiling Strength and Resolute DeterminationThe journey of life is fraught with challenges that test our resilience and the strength of our character.It is through these trials that we discover our true potential and the indomitable spirit within us.The display of strength is not merely a physical act but an embodiment of mental fortitude and emotional stability that enables us to face adversities headon.Strength,in its essence,is the ability to endure and overcome obstacles.It is the quiet resolve that keeps us going even when the odds are stacked against us.It is the unwavering belief in our capabilities that fuels our drive to succeed.When we exhibit strength,we are not only asserting our physical prowess but also our mental agility and emotional resilience.Determination,on the other hand,is the relentless pursuit of a goal despite the hurdles that may come our way.It is the force that propels us to keep striving even when the path is fraught with difficulties.Determination is the bedrock of success it is the unwavering commitment to a cause that separates the achievers from the rest.The combination of strength and determination is a powerful catalyst for change.When we are strong,we are better equipped to handle the pressures of life.When we are determined,we are more likely to persist in the face of adversity.Together,these qualities form a formidable force that can break through barriers and achieve the seemingly impossible.Cultivating a new determination requires a shift in mindset.It involves setting clear goals and being willing to put in the hard work required to achieve them.It means accepting that there will be setbacks and failures along the way,but viewing these not as defeats but as opportunities to learn and grow.To demonstrate new determination,one must first acknowledge their strengths. Recognizing what you are capable of is the first step towards leveraging those capabilities to achieve your objectives.It is about understanding your values,your passions,and what truly motivates you to push forward.Moreover,it is essential to develop a plan of action.This plan should be realistic,yet ambitious,and it should outline the steps you need to take to reach your goals.It is also crucial to remain flexible and adapt your plan as circumstances change,demonstrating both strength and adaptability.Another key aspect of demonstrating new determination is the ability to stay focused. Distractions and temptations will inevitably arise,but it is the strength of your resolve that will keep you on track.This focus is a testament to your inner strength and your commitment to your goals.Lastly,it is important to celebrate small victories along the way.Each milestone achieved, no matter how small,is a testament to your strength and determination.These moments of triumph serve to reinforce your belief in your abilities and fuel your drive to continue pursuing your dreams.In conclusion,the display of strength and the demonstration of new determination are integral to personal and professional development.They are the cornerstones of resilience and the key to unlocking our full potential.By embracing these qualities and applying them to our endeavors,we can overcome the challenges that life presents and achieve the success we desire.。

英语作文权力的游戏影评A Critical Analysis of “Game of Thrones”“Game of Thrones” is one of the most popular TV series of all time, with a massive fan following and critical acclaim. However, like any work of art, it is not without its flaws. In this essay, I will provide a critical analysis of the show, examining its strengths and weaknesses.One of the strengths of “Game of Thrones” is its complex and engaging plot. The show is set in a fictional world of Westeros, where several noble houses are vying for power and control. The story is full of political intrigue, backstabbing, and unexpected plot twists, which keep the viewers on the edge of their seats. The characters are also well-developed, with their own motivations, fears, and desires, which makes them more relatable and interesting.Another strength of the show is its production values. The sets, costumes, and special effects are all top-notch, creating a visually stunning and immersive world. The battle scenes are particularly impressive, with realistic choreography and breathtaking visuals. The music and sound design also add to the overall atmosphere of the show, making it a truly epic experience.However, the show also has some weaknesses. One of the main criticisms is its excessive violence and gore. While violence is an integral part of the story, some scenes are overly graphic and gratuitous, which can be disturbing for some viewers. Another criticism is the show’s treatment of female characters. While there are some strong and empowered female characters, there are also many instances of sexual violence and objectification, which has been the subject of much controversy.“Game of Thrones” is a complex and engaging TV series that has both strengths and weaknesses. Its plot and production values are among its strongest assets, while its excessive violence and treatment of female characters are some of its more controversial aspects. Despite these flaws, the show has left a lasting impact on the entertainment industry and has become a cultural phenomenon.。

!临床研究!尼麦角林防治脑梗死后认知功能障碍的临床研究李小凤9胡长林(重庆医科大学附属第二医院神经内科400010)摘要"目的脑梗死后认知功能障碍发生率高达20~309临床亟待防治有效的药物O了解尼麦角林防治脑梗死后认知功能障碍发生的效果以及探讨其作用机理O方法脑梗死患者随机分成治疗组和对照组9治疗组服用尼麦角林O入院1周内和3个月后进行MM SE评分和经颅多谱勒检查O结果3个月后对照组MM SE评分在记忆力\计算能力和回忆能力方面显著下降9大脑血流速度明显下降;而治疗组的评分下降则不明显9大脑血流速度明显提高O结论尼麦角林在防治血管性认知功能障碍方面有显著的效果O改善脑的血供可能是尼麦角林改善脑梗死认知功能障碍的原因之一O关键词"尼麦角林;脑梗死;认知功能;脑血流中图分类号"R743.33;R749.16文献标识码"A文章编号"1671-8348(2006)14-1295-02C li nical trial effect of nicer g oli ne on P revention and treat m ent of co g nitiondist urbance i n P atients w it h cerebral i nf arctionLI Xiao-f en g~U Chan g-linDe P art m ent o f Ne urolo gy Second A f f iliate d~os P it al Chon gg in g Uniuersit y o f M e dic al Sciences Chon gg in g400010China Abstract O b ective The i nci dence of co g niti on dist ur bance af ter cerebral i nf arcti on is about20 -30and eff ecti ve dr u g f or p reventi on and treat m ent of it is ex p ected.T o i nvesti g ate t he eff ect of nicer g oli ne on p reventi on f r o m co g niti on dist ur bance af ter cerebral i nf arcti on and t o ex p l ore its m echanis m.M et hods The p ati ents W it h cerebral i nf arcti on Were di vi ded rando m l y i nt o t Wo g r ou p s treat m ent W it h nicer g oli ne and contr ol.T o m easure MM SE score and cerebral bl ood fl o W W it h TCD W it hi n one Week and af ter t hree mont hs res p ecti vel y.Results The MM SE score and bl ood fl o Wi n contr ol g r ou p decreased obvi ousl y i n m e mor y calcul a-ti on and reco g niti on and t hose i n treat m ent g r ou p di d not chan g e much.Concl us ion N icer g oli ne has g ood eff ect i n p reventi on f r o m vascular co g niti on dist ur bance and i m p r ove m ent of bl ood su pp l y m a y be one of t he m echanis m s.K e y words nicer g oli ne cerebral i nf arcti on co g niti on cerebral bl ood fl o W近年来的流行病学资料显示约20~40的脑梗死患者伴有程度不等的认知功能障碍它不仅增加社会的经济负担而且严重影响老年人的工作生活质量临床亟待能找到防治脑梗死后认知功能障碍发生的有效药物1基础研究的结果表明尼麦角林可以增加海马神经元对葡萄糖的摄取2促进核酸和蛋白质的合成34为了了解尼麦角林防治脑梗死后认知功能障碍发生的效果以及初步探讨其可能的作用机制我们进行了如下的临床观察l临床资料l.l一般资料60例脑梗死患者系1999年10月~2001年4月我科住院的患者诊断均符合第4届全国脑血管病学术会议各类脑血管病诊断标准5均经CT或MR I证实无意识障碍无严重的失语无严重的肝肾功能疾患及其他并发症包括腔隙性脑梗死给每1例患者进行编号记录年龄性别学历既往史如糖尿病高血压高血脂l.2观察及给药方法入选的脑梗死患者随机分成两组治疗组30例服用尼麦角林商品名思尔明每次10m g每日3次连服用3个月对照组30例不服用尼麦角林两组均进行常规的活血化淤治疗及二级预防入院1周内进行MM SE 评分和经颅多普勒超声检查3个月后复查MM SE评分和经颅多普勒超声检查l.3统计方法采用SSPS统计分析软件进行t检验及配对t检验2结果2.l观察对象男33例女27例平均年龄58.1 12.1岁文盲15例小学21例中学21例大学3例高血压37例糖尿病14例高脂血症27例2.2患者的认知功能评定在治疗前患者有认知功能障碍者以DS M-]为标准均未达到痴呆的程度2.2.l脑梗死患者入院1周内的认知功能评定MM SE评分<17分0例17~24分11例24~29分40例30分9例2.2.2尼麦角林治疗前后MM SE评分变化对照组MM SE 评分在记忆力计算能力和回忆能力方面显著下降而治疗组则有明显改善二者差异有统计学意义治疗组和对照组的定向能力3个月后均较入院1周内明显改善但是治疗组和对照组二者差异无统计学意义见表1表1尼麦角林治疗前后MM SE评分变化组别治疗组入院时3个月后对照组入院时3个月后定向能力6.51.58.91.36.31.58.62.0记忆力2.71.2。