Resolution of Near-Field Microwave Target Detection and Imaging by Using Flat LHM Lens

- 格式:pdf

- 大小:602.11 KB

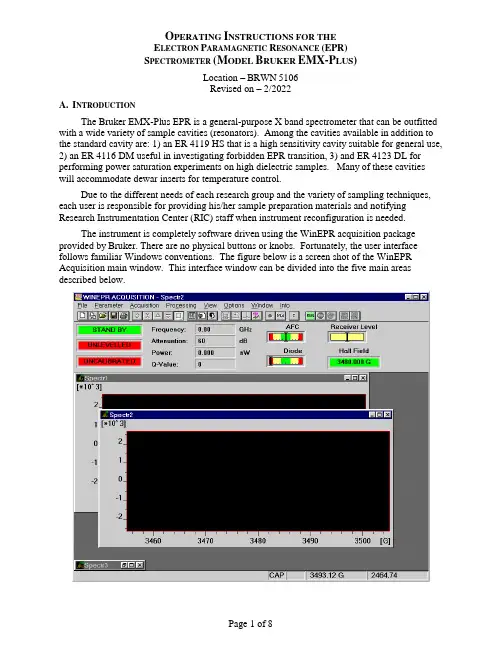

- 文档页数:8

专利名称:Near-field scanning microwave microscopeusing dielectric resonator发明人:Kie Jin Lee,Joo Young Kim,Hyun JunYoo,Jong Il Yang,Song Hui Kim申请号:US11116010申请日:20050427公开号:US20050246129A1公开日:20051103专利内容由知识产权出版社提供专利附图:摘要:Provided is a near-field microscope using a dielectric resonator, which makes it possible to minimize influences by external environments, and to enhance its sensitivity,resolution and function by adjusting the distance between a sample and an apex of a probe. The near-field microscope includes a wave source, a dielectric resonator, a probe, a distance adjusting unit, and a detector. The wave source generates a wave, and a frequency of the wave is adjustable by the wave source. The dielectric resonator propagates the wave from the wave source, and a resonance frequency, impedance, a Q factor and an electromagnetic wave mode of the wave is freely adjustable. The probe scans the wave output from the dielectric resonator on a sample. The distance adjusting unit measures a distance between the probe and the sample and maintains the distance to a predetermined value. The detector detects a wave that propagates through the probe, interacts with the sample and then propagates through the probe and the dielectric resonator.申请人:Kie Jin Lee,Joo Young Kim,Hyun Jun Yoo,Jong Il Yang,Song Hui Kim地址:Seoul KR,Paju-city KR,Suwon-city KR,Seoul KR,Daejeon-city KR国籍:KR,KR,KR,KR,KR更多信息请下载全文后查看。

傅里叶变换红外光谱仪英文Fourier Transform Infrared SpectrometerIntroduction:The Fourier Transform Infrared (FTIR) spectrometer is an essential tool in the field of spectroscopy. It utilizes the mathematical technique known as Fourier transform to analyze infrared light, enabling scientists to study the molecular composition and structure of various substances. In this article, we will explore the principles behind the Fourier Transform Infrared Spectrometer and its applications in scientific research.Principles of Fourier Transform Infrared Spectroscopy:Fourier Transform Infrared Spectroscopy is based on the interaction between infrared light and matter. When a substance is exposed to infrared radiation, the energy absorbed by the molecules causes them to vibrate. These vibrations are specific to each molecule and are dependent on the molecular bonds present within the substance.The spectrometer operates by passing an infrared beam through the sample and measuring the amount of light absorbed at different wavelengths. This absorption spectrum is then transformed using Fourier analysis, producing a highly detailed and accurate representation of the substance's molecular structure.Advantages of Fourier Transform Infrared Spectroscopy:1. High Speed and Sensitivity: Fourier Transform Infrared Spectroscopy offers rapid analysis times due to its ability to gather a full range ofwavelengths simultaneously. This allows for efficient data collection, making it ideal for high-throughput applications. Additionally, the technique is highly sensitive, capable of detecting even small quantities of sample material.2. Broad Analytical Range: FTIR spectroscopy covers a wide range of wavelengths, from near-infrared (NIR) to mid-infrared (MIR). This versatility enables the analysis of various substances, including organic and inorganic compounds, polymers, pharmaceuticals, and biological samples.3. Non-destructive Analysis: One of the key advantages of FTIR spectroscopy is that it is a non-destructive technique. Samples do not require any special preparation and can be analyzed directly, allowing for subsequent analysis or retesting if required.Applications of Fourier Transform Infrared Spectrometers:1. Pharmaceutical Analysis: FTIR spectroscopy plays a vital role in drug discovery and development. It is used to identify and characterize the molecular composition of active pharmaceutical ingredients (APIs), excipients, and impurities. By comparing spectra, scientists can ensure the quality and purity of pharmaceutical products.2. Environmental Analysis: Fourier Transform Infrared Spectrometers are employed in environmental monitoring to analyze air, water, and soil samples. It aids in detecting pollutants, identifying unknown substances, and assessing the impact of human activities on the environment.3. Forensic Science: FTIR spectroscopy has proven to be a valuable tool in forensic science. It assists in the analysis of various evidence, such asfibers, paints, and drugs. FTIR spectra can provide crucial information in criminal investigations, helping to identify unknown substances and link them to potential sources.4. Food and Beverage Industry: The FTIR spectrometer allows for the analysis of food quality, safety, and authenticity. It can identify contaminants, detect adulteration, and verify product labeling claims. Both raw materials and finished products can be analyzed using this technique, ensuring compliance with industry regulations.Conclusion:The Fourier Transform Infrared Spectrometer has revolutionized the field of spectroscopy by providing accurate and detailed information about a substance's molecular structure. Its speed, sensitivity, and versatility make it a crucial analytical tool in various scientific disciplines. With ongoing advancements in technology, FTIR spectroscopy continues to contribute to new discoveries and advancements in research.。

Laser rangefinderA long range laser rangefinder is capable of measuring distance up to 20 km; mounted on a tripod with an angular mount. The resulting system also provides azimuth and elevation measurements.A laser rangefinder is a device which uses a laser beam to determine the distance to an object. The most common form of laser rangefinder operates on the time of flight principle by sending a laser pulse in a narrow beam towards the object and measuring the time taken by the pulse to be reflected off the target and returned to the sender. Due to the high speed of light, this technique is not appropriate for high precision sub-millimeter measurements, where triangulation and other techniques are often used.PulseThe pulse may be coded to reduce the chance that the rangefinder can be jammed. It is possible to use Doppler effect techniques to judge whether the object is moving towards or away from the rangefinder, and if so how fast.PrecisionThe precision of the instrument is determined by the rise or fall time of the laser pulse and the speed of the receiver. One that uses very sharp laser pulses and has a very fast detector can range an object to within a few millimeters.RangeDespite the beam being narrow, it will eventually spread over long distances due to the divergence of the laser beam, as well as due to scintillation and beam wander effects, caused by the presence of air bubbles in the air acting as lenses ranging in size from microscopic to roughly half the height of the laser beam's path above the earth.These atmospheric distortions coupled with the divergence of the laser itself and with transverse winds that serve to push the atmospheric heat bubbles laterally may combine to make it difficult to get an accurate reading of the distance of an object, say, beneath some trees or behind bushes, or even over long distances of more than 1 km in open and unobscured desert terrain.Some of the laser light might reflect off leaves or branches which are closer than the object, giving an early return and a reading which is too low. Alternatively, over distances longer than 1200 ft (365 m), the target, if in proximity to the earth, may simply vanish into a mirage, caused by temperature gradients in the air in proximity to the heated surface bending the laser light. All these effects have to be taken into account.CalculationThe distance between point A and B is given byD=ct/2where c is the speed of light in the atmosphere and t is the amount of time for the round-trip between A and B.gwhere「is the delay which made by the light traveling and , is the angular frequency of optical modulation.Then substitute the values in the equation D=ct/2,D=1/2 ct=1/2 c4/m=c/(4nf) (Nn+A^)=c/4f(N+AN)=U(N+)in this equation, U stands for the unit length.A Q stands for the delay part which does not fulfill n.AN stands the decimal value.DiscriminationSome instruments are able to determine multiple returns, as above. These instruments use waveform-resolving detectors, which means they detect the amount of light returned over a certain time, usually very short. The waveform from a laser pulse that hits a tree and then the ground would have two peaks. The first peak would be the distance to the tree, and the second would be the distance to the ground.Using wavefront sensing, it is possible to determine both the closest and the farthest object at a given point. This makes it possible for aircraft-mounted instruments to see "through" dense canopies[c1arifica t ion needed Please explain how lasers see througl and10ft her semi-reflective surface such as the ocean, leading to many applications for airborne instruments such as:1.Creating "bare earth" topographic maps - removing all trees2.Creating vegetation thickness maps3.Bathymetry(measuring topography under the ocean)4.Forest firehazardTechnologiesTime of flight - this measures the time taken for a light pulse to travel to the target and back. With the speed of light known, and an accurate measurement of the time taken, the distance can be calculated. Many pulses are fired sequentially and the average response is most commonly used. This technique requires very accurate sub-nanosecond timing circuitry.Multiple frequency phase-shift - this measures the phase shift of multiple frequencies on reflection then solves some simultaneous equations to give a final measure.Interferometry - the most accurate and most useful technique for measuring changes in distance rather than absolute distances.ApplicationsMilitaryAn American soldier with a GVS-5 laser rangefinder.A Dutch ISAF sniper team displaying their Accuracy International AWSM .338 Lapua Magnum rifle and Leica/Vectronix VECTOR IV laser rangefinder binoculars.Rangefinders provide an exact distance to targets located beyond the distance of point-blank shooting to snipers and artillery. They can also be used for military reconciliation and engineering. Handheld military rangefinders operate at ranges of 2 km up to 25 km and are combined with binoculars or monoculars. When the rangefinder is equipped with a digital magnetic compass (DMC) and inclinometer it is capable of providing magnetic azimuth, inclination, and height (length) of targets. Some rangefinders can also measure a target's speed in relation to the observer. Some rangefinders have cable or wireless interfaces to enable them to transfer their measurement(s) data to other equipment like fire control computers. Some models also offer the possibility to use add-on night vision modules. Most handheld rangefinders use standard or rechargeable batteries.The more powerful models of rangefinders measure distance up to 25 km and are normally installed either on a tripod or directly on a vehicle or gun platform. In the latter case the rangefinder module is integrated with on-board thermal, night vision and daytime observation equipment. The most advanced military rangefinders can be integrated with computers.To make laser rangefinders and laser-guided weapons less useful against military targets, various military arms may have developed laser-absorbing paint for their vehicles. Regardless, some objects don't reflect laser light very well and using a laser rangefinder on them is difficult.3-D ModellingThis LIDAR scanner may be used to scan buildings, rock formations, etc., to produce a 3D model. The LIDAR can aim its laser beam in a wide range: its head rotates horizontally, a mirror flips vertically. The laser beam is used to measure the distance to the first object on its path.Laser rangefinders are used extensively in 3-D object recognition, 3-D object modelling, and a wide variety of computer vision-related fields. This technology constitutes the heart of the so-called time-of-fligh D scanners. In contrast to the military instruments described above, laser rangefinders offer high-precision scanning abilities, with either single-face or 360-degree scanning modes.A number of algorithms have been developed to merge the range data retrieved from multiple angles of a single object to produce complete 3-D models with as little error as possible. One of the advantages that laser rangefinders offer over other methods of computer vision is that the computer does not need to correlate features from two images to determine depth information as in stereoscopic methods.Laser rangefinders used in computer vision applications often have depth resolutions of tenths of millimeters or less. This can be achieved by using triangulation or refraction measurement techniques as opposed to the time of flight techniques used in LIDAR.ForestryLaser rangefinder TruPulse used for forest inventories (in combination with Field-Map technology)Special laser rangefinders are used in forestry. These devices have anti-leaf filters and work with reflectors. Laser beam reflects only from this reflector and so exact distance measurement isguaranteed. Laser rangefinders with anti-leaf filter are used for example for forest inventories.SportsLaser rangefinders may be effectively used in various sports that require precision distance measurement, such as golf, hunting, and archery. Some of the more popular manufacturers are: Opti-logic Corporation, Bushnell, LaserTechnology, Trimble, Leica, Newcon Optik, Nikon, and Swarovski Optik.Industry production processesAn important application is the use of laser Range finder technology during the automation of stock management systems and production processes in steel industry.SafetyLaser rangefinders for consumers are laser class 1 devices and therefore are considered eyesafe. Some laser rangefinders for military use exceed the laser class 1 energy levels.HistoryDevelopment of the methods used in modern printed circuit boards started early in the 20th century. In 1903, a German inventor, Albert Hanson, described flat foil conductors laminated to an insulating board, in multiple layers. Thomas Edison experimented with chemical methods of plating conductors onto linen paper in 1904. Arthur Berry in 1913 patented a print-and-etch method in Britain, and in the United States Max Schoop obtained a patent111 to flame-spray metal onto a board through a patterned mask. Charles Durcase in 1927 patented a method of electroplating circuit patterns.The Austrian Jewish engineer Paul Eisler invented the printed circuit while working in England around 1936 as part of a radio set. Around 1943 the USA began to use the technology on a large scale to make proximity fuses for use in World War II . After the war, in 1948, theUSA released the invention for commercial use. Printed circuits did not become commonplace in consumer electronics until the mid-1950s, after the Auto-Sembly process was developed by the United States Army.Before printed circuits (and for a while after their invention), point-to-point construction was used.For prototypes, or small production runs, wire wrap or turret board can be more efficient. Predating the printed circuit invention, and similar in spirit, was John Sargrove's 1936 -947 Electronic Circuit Making Equipment (ECME) which sprayed metal onto a Bakelite plastic board. The ECME could produce 3 radios per minute.During World War II, the development of the anti-aircraft proximity fuse required an electronic circuit that could withstand being fired from a gun, and could be produced in quantity. The Centralab Division of Globe Union submitted a proposal which met the requirements: a ceramic plate would be screenprinted with metallic paint for conductors and carbon material for resistors, with ceramic disc capacitors and subminiature vacuum tubes soldered in place.Originally, every electronic component had wire leads, and the PCB had holes drilled for each wire of each component. The components' leads were then passed through the holes and soldered to the PCB trace. This method of assembly is called through-hole construction. In 1949, Moe Abramson and Stanislaus F. Danko of the United States Army Signal Corps developed the Auto-Sembly process in which component leads were inserted into a copper foil interconnection pattern and dip soldered. The patent they obtained in 1956 was assigned to the U.S. Army. [4] With the development of board lamination and etching techniques, this concept evolved into the standard printed circuit board fabrication process in use today. Soldering could be done automatically by passing the board over a ripple, or wave, of molten solder in a wave-soldering machine. However, the wires and holes are wasteful since drilling holes is expensive and the protruding wires are merely cut off.In recent years, the use of surface mount parts has gained popularity as the demand for smaller electronics packaging and greater functionality has grown.References[1]M. Samules, S. Patterson, J. Eppstein, R. Fowler, Low cost handheld lidar system for automotive speed detection and law enforcement, Proc. SPIE 1633 (1992) 147-159.[2]Z.X. Jia, K. Gong, Y.J. Huo, Optoelectronic system for high-speed flier velocity measurement based on laser scattering, Opt. Eng. 48 (2009) 043601.[3]H. Surmann, A. Nuchter, J. Hertzberg, An autonomous mobile robot with a 3D laser range finder for 3D exploration and digitalization of indoor environments, Robot. Auton. Syst. 45(2003)181-198.[4]V. Sequeiraa, J. Goncalves, M. Ribeiro, 3D environment modelling using laser range sensing, Robot. Autom. 16 (1995) 81-91.[5]K. Mdtta, J. Kostamovaara, R. Myllyla, Profiling of hot surfaces by pulsed time -of- flight laser range finder techniques, Appl. Opt. 32 (1993) 5334-5347.[6]M.C. Amann, T. Bosch, M. Lescure, R. Myllyla, Laser ranging: a critical review of usual techniques for distance measurement, Opt. Eng. 40 (2001) 10-19.[7]T. Ruotsalainen, P. Palojarvi, J. Kostamovaara, A wide dynamic range receiver channel fora pulsed time-of-flight laser radar, IEEE J. Solid-State Circuits 36 (2001) 1228-1238.[8]S. Kurtti, J. Kostamovaara, An integrated optical receiver with wide-range timing discrimination characteristics, in: Proceedings 31st European Solid- State Circuits Conference, Grenoble, France, 2005, pp. 435-438.[9]J. Nissinen, I. Nissinen, J. Kostamovaara, Integrated receiver including both receiver channel and TDC for a pulsed time-of-flight laser rangefinder with cmlevel accuracy, IEEE J. Solid-State Circuits 44 (2009) 1486-1497.[10]W.M.C. Sansen, R.G. Meyer, An integrated wide-band variable-gain amplifier with maximum dynamic range, IEEE J. Solid-State Circuits 9 (1974) 159-166.[11]H. Ikeda, T. Ohshima, M. Tsunotani, T. Ichioka, T. KimuraA, An auto-gain control transimpedance amplifier with low noise and wide input dynamic range for 10-Gb/s optical communication systems, IEEE J. Solid-State Circuits 36 (2001) 1303-1308.[12]S. Yamashita, S. Ide, K. Mori, A. Hayakawa, N. Ueno, K. Tanaka, Novel cell-AGC technique for burst-mode CMOS preamplifier with wide dynamic range and high sensitivity for ATM-PON system, IEEE J. Solid-State Circuits 37 (2002) 881C886.[13]J. Nissinen, J. Kostamovaara, Laser pulser for a time-of-flight laser radar, Rev. Sci. Instrum. 68 (1997) 2253-2258.激光测距仪长距离激光测距仪测量距离可达20公里,安装在同一个角度或安装在三脚架上,所形成的系统也可测量方位角和仰角测量。

Microwave Sintering of MetalsTopics CoveredBackgroundOverviewMicrowave Heating of MetalsMicrowave vs.Conventional HeatingWhich Metals can be Microwave Sintered?Which Metals have been Microwave Sintered?Microwave Sintering DevicesPotential for Microwave Sintering of MetalsWhy does Microwave Sintering Produce better Properties compared to Conventional Processing?Microwave Sintering MechanismsBackgroundMicrowave energy has been in use for a variety of applications for over50years.Some of the early applications include communication,navigation and drying of food items.At present,industrial uses of microwaves include wood processing,vulcanisation of rubber,meat tempering,and medical therapy.In the past two decades,the remarkable success of domestic microwave ovens has revolutionised home cooking.OverviewThe use of microwaves in ceramic processing is a relatively recent development.They can be applied effectively and efficiently to heat and sinter ceramic objects.The most recent development in microwave applications is in sintering of metal powders,a surprising application,in view of the fact that bulk metals reflect microwaves. However,reflection by a metal occurs only if it is in a solid,nonporous form and is exposed to microwaves at room temperature.Metal in the form of powder will absorb microwaves at room temperature and will be heated very effectively and rapidly.This technology can be used to sinter various powder metal components,and has produced useful products ranging from small cylinders,rods,gears and automotive components in30-90min.Microwave Heating of MetalsMicrowave heating and sintering is fundamentally different from the conventional sintering,which involves radiant/resistance heating followed by transfer of thermal energy via conduction to the inside of the body being processed.Microwave heating is a volumetric heating involving conversion of electromagnetic energy into thermal energy,which is instantaneous,rapid and highly efficient.The microwave part of the electromagnetic spectrum corresponds to frequencies between300MHz and300GHz. However,most research and industrial activities involve microwaves only at2.45GHz and915MHz frequencies. Based on their microwave interaction,most materials can be classified into one of three categories-opaque, transparent and absorbers.Bulk metals are opaque to microwave and are good reflectors-this property is used in radar detection.However,powdered metals are very good absorbers of microwaves and heat up effectively, with heating rates as high as100°C min-1.Most other materials are either transparent or absorb microwaves to varying degrees at ambient temperature.The degree of microwave absorption,and consequently of heating, changes dramatically with temperature.Microwave vs.Conventional HeatingThe use of microwave energy for materials processing has major potential,and real advantages over conventional heating.These include:· Time and energy savings· Rapid heating rates· Considerably reduced processing time and temperature· Fine microstructures and hence improved mechanical properties and better product performance· Lower environmental impact.Which Metals can be Microwave Sintered?Until recently,microwave heating has been applied to sinter only oxide ceramics and semi-metals like carbides and nitrides.However,our research reveals that in powdered form,virtually all metals,alloys,and intermetallics will couple and heat efficiently and effectively in a microwave field,and their green parts will produce highly sintered bodies with improved mechanical properties.For example,in our exploratory experiments we tried two common commercial steel compositions,namely Fe-Ni-C(FN208)and Fe-Cu-C(FC208).These formed highly sintered bodies in a total cycle time of about90min at temperature range of1100-1300°C with a soaking time of 5-30min in forming gas(a mixture of N2and H2)atmosphere.Mechanical properties such as the modulus ofrupture(MOR)and hardness of microwave processed samples were significantly higher than the conventional samples-in the case of FN208,the MOR was60%higher.The densities of microwave processed samples were close to the theoretical densities,and the net shape of the green body was preserved without significant dimensional changes.Which Metals have been Microwave Sintered?Many commercial powder-metal components of various alloy compositions,including iron and steel,copper, aluminum,nickel,molybdenum,cobalt,tungsten,tungsten carbide,tin,and their alloys have been sintered using microwaves,producing essentially fully dense bodies.Figure1illustrates some of the metallurgical parts processed using microwave technology.The biggest commercial steel component that has been fully sintered in our system so far is an automotive gear of10cm in diameter and about2.5cm in height.Figure1.Metallic parts produced by microwave sintering such as gears cylinders,rods and discs. Microwave Sintering DevicesA typical microwave sintering apparatus operates at a2.45GHz frequency with power output in the range of1-6 kW.The sintering chamber consists of ceramic insulation housing(batch system)or an alumina tube insulated with ceramic insulation from outside,figure2.The primary function of the insulation is to preserve the heat generated in the workpiece.The temperatures are monitored by optical pyrometers,IR sensors and/or sheathed thermocouples placed close to the surface of the sample.The system is equipped with appropriate equipment to provide the desired sintering atmosphere,such as H2,N2,Ar,etc,and is capable of achieving temperatures up to1600°C.Figure2.Schematic of a microwave sintering furnace.The technology can be easily commercialised by scaling up the existing microwave system or designing a continuous system capable of sintering parts of various shapes and sizes.Potential for Microwave Sintering of MetalsThe implications of microwave sintering of metals are obvious in the field of powder metal technology.Metal powders are used in a diverse range of products and applications in various industries,including the automotive industry,aerospace,and heavy machinery.The challenging demands for new and improved processes and materials of high integrity for advanced engineering applications require innovation and new technologies.Finer microstructures and near-theoretical densities in special powder metal components are still elusive and widely desired.Increasing cost is also a concern of the industry.Microwave processing offers a new method to meet these demands of producing fine microstructures and better properties,and potentially at lower cost.Why does Microwave Sintering Produce better Properties compared to Conventional Processing?There are two main reasons why the microwave process yields better mechanical properties,especially in the case of powder metals-it produces a finer grain size,and the shape of the porosity,if any,is quite different than in a conventional part.In microwave-processed powder metal components,we have observed round-edged porosities producing higher ductility and toughness.Microwave Sintering MechanismsSo far,there has been little effort devoted to understanding the mechanisms and the science behind microwave sintering of metals.However,it is obvious that the microwave-metal interactions are more complex than those working actively in the field had expected.There are many factors that contribute significantly to the total microwave heating of powdered metals.The sample size and shape,the distribution of the microwave energy inside the cavity,and the magnetic field of the electromagnetic radiation are all important in the heating and sintering of powder metals.This research is just at the early stages,and it will be a long time before the exact mechanisms are elucidated.Primary author:Prof.Dinesh AgrawalSource:Materials World,Vol.7no.11pp.672-73November1999.For more information on Materials World please visit The Institute of Materials.Date Added:Oct9,2001Microwave Processing and Engineering CenterMicrowave Processing and Engineering Center106Materials Research Laboratory,The Pennsylvania State UniversityUniversity ParkPennsylvania,16802PH:1(814)865-4548Email:************Visit Microwave Processing and Engineering Center WebsitePrimary ActivityService ProviderCompany BackgroundThis center is the world’s leading institution in the study of the interaction of solid matter with microwave radiation.It has published some150+papers and patents covering a sequence of remarkable discoveries:Increasing the kinetics of all reactions involving the most important materials of modern materials science:BaTiO3;all ferrites,silicon,etc.The practice and principles of Anisothermal reactions in any multiphase systemThe physical separability of the E&H fields at microwave frequenciesThe remarkable differences between the E&H fields in interaction with matter,including...The ability to de-crystallize many of the most significant crystalline phases of material technology in a few seconds without meltingApplication of microwave energy to process metallic materialsMost of the Center support has come from two dozen companies and the Defense Dept,since its science is so “transformative”that the“peers”have yet to catch up with it!!Submission DateSeptember20,2001Sales ContactProf Dinesh AgrawalDirector。

DatasheetNarda FieldManNarda FieldMan ®All-in-one electromagnetic field meter ranging from 0 Hz to 90 GHzThe Narda FieldMan performs highly accurate measure-ments of non-ionizing high-frequency radiation and low-frequency fields. Equipped with digital probes for measuring electric or magnetic field strengths, it covers the range from static and low-frequency fields in medical and industrial applications to mobile radio frequencies and millimeter waves. Flat frequency response probes (“flat probes”), as well as so-called shaped probes that evaluate the field strength on the basis of a human safety standard are available. Probes with built-in FFT analysis enable spectral measurements along with time domain analyses up to frequencies of 400 kHz. All probes have a digital interface that transmits the measurement data to the basic device in a fail-safe manner. This eliminates the need to calibrate the basic unit.›Non-directional measurement using isotropic probes for applications in the frequency range 0 Hz (DC) to 90 GHz›Large sunlight readable color display 5” diagonal with 1280x720 HD resolution›Digital probe interface for broadband and selective probes – no more meter calibration›Powerful time and frequency domain analysis for low frequency fields up to 400 kHz including Weighted Peak measurements›WiFi/Bluetooth interface for remote operation via smartphone app (Option)›Built-in GPS receiver and rangefinder for easy location determination (Option)›Fast data transmission ›optical interface ›Ethernet ›USB-CApplicationsThe Narda FieldMan is used to make precision measurements to establish human safety, particularly in workplace environments where high electric or magnetic field strengths are likely to occur. An essential task is to demonstrate compliance with generalsafety regulations, such as FCC, IEEE, ICNIRP or EMF Directive 2013/35/EU. Examples of measurement environments are:›Radiocommunication base stations (e.g. IEC / EN 62232)›Broadcasting systems (e.g. IEC 62577)›Radar and satellite communications systems ›Induction heating and melting (e.g. EN 50519)›Household appliances (e.g. IEC / EN 62233)›Electric welding equipment (e.g. IEC / EN 62822)›Railroad operations (e.g. EN 50500)›Automotive operations (e.g. IEC 62764)›Energy supply systems (e.g. IEC / EN 62110)›Electrical medical devices (e.g. IEC / EN 60601)›TEM cells and absorber chambers to demonstrate electromagnetic compatibility (EMC)Digital ProbesA large number of isotropic field probes are available for theFieldMan. All of them transmit their information and measurement data as a digital signal to the FieldMan, either via an electrical USB interface or via an optical COM interface. In this way,interference is significantly reduced compared to high-resistance analog interfaces. The specially developed screw connectors and electrical contacts are extremely robust and resilient.The probes are automatically recognized after connection to the FieldMan. Sensors inside the probe record the temperature of the measuring location and transmit it to the FieldMan display. In addition to the automatic offset correction, the temperature measurement is also used to compensate for the typicaltemperature dependency of the sensor diodes. The advantages are uninterrupted measurements without zero adjustment and higher measurement accuracy over wide temperature ranges. An automatic self-test function can even detect possible errors in the sensor system, which means that additional checking with a test generator is superfluous. Only the digital probes arecalibrated. You can continue to use your FieldMan during this time.There are probes for many different applications with theappropriate frequency and level ranges. The following table gives an overview of common areas of application.Frequency rangeDC up to1 kHzUp to400 kHzUp to400 kHz Up to 30 MHz Up to 1 GHz Up to 6 GHz Up to 40 GHz Up to 90 GHz Up to 50 GHz Field type, magnetic (H) or electric (E)H E+HHHHEEEE ShapedProbe modelsHP-01EHP-50F/G BFD-400-1 (100 cm 2) BFD-400-3 (3 cm 2) HFD-3061 HFD-0191 EFD-0391 EFD-0392 EFD-0691 EFD-0692 EFD-1891 EFD-4091 EFD-5091 EFD-6091EFD-9091EAD-5091EBD-5091ECD-5091EDD-50915G mobile radio / telecommunications Broadcast radio / TVSatellite communications RadarIndustry: Heating and temperingIndustry: Plastics weldingIndustry: Semiconductor productionMedicine: Diathermy, hyperthermyLeak locationHousehold appliances Electric welding equipmentRailroad operationsAutomotive operationsEnergy supply systems Electric medical devicesAccredited calibration includedProbe interfaceOptical connectionDigital probe interfaceFig. 1. Areas of application and suitable probe modelsUse and benefitDuring the development of the FieldMan, special attention was paid to achieving simple, well-structured and fluid operation. The arrangement of many display elements known from smartphones, the self-explanatory symbols and the FieldMan processes, which are perfectly tailored to the measurement tasks, offer maximum ease of use. The large, anti-glare HD color display shows the measured values numerically and graphically with all important additional information in a clear form and is easy to read even in bright sunlight. From simple broadband measurements to sophisticated time signal recording in real time or spectral frequency analysis of low-frequency fields, you have the right operating modes at your disposal.Measurement results can be commented on by text or voice and can be saved as a screen copy at the push of a button. Built-in sensors record the current environmental conditions as well as the position data and automatically add them to the measurement result. The built-in distance meter (option) shows you the measuring height above the ground, which makes the exact positioning of the measuring device much easier. For a better overview, the measurement results can be assigned to freely definable projects, which is particularly helpful when the measurement locations change frequently. If you want todocument your measurement results with photos and videos, the FieldMan smartphone app will help you. For example, the app wirelessly transfers media files created with the smartphone to the project directory on the FieldMan SD memory card. A newly developed, extremely powerful PC software "Narda-TSX" is available for documenting the measurement results, media and other information. It is Narda's new software platform for device configuration, measurement data evaluation and documentation, which in addition to the FieldMan will also support other Narda products in the future.Fig. 2. FieldMan display and controlsFig. 3. The FieldMan is supplied with a robust transport caseProbe connectionBrightness sensor LoudspeakerMicrophone, humidity sensor Status bar Probe information Measurement informationMeasurement isotropic Measurement single axes Statistical values Interface panelMeasurement graphic: Time curve, spectrum or bar graph Softkey symbolsSoftkeys Save key Back key Navigation keyStatus LEDDefinitions and ConditionsConditionsUnless otherwise noted, specifications apply after 30 minutes warm-up time within the specified environmental conditions. The product is within the recommended calibration cycle.Specifications with limitsThese describe product performance for the given parameter covered by warranty. Specifications with limits (shown as <, ≤, >, ≥, ±, max., min.) apply under the given conditions for the product and are tested during production, considering measurement uncertainty.Specifications without limitsThese describe product performance for the given parameter covered by warranty. Specifications without limits represent values with negligible deviations, which are ensured by design (e.g. dimensions or resolution of a setting parameter). Typical values (typ.)These characterize product performance for the given parameter that is not covered by warranty. When stated as a range or as a limit (shown as <, ≤, >, ≥, ±, max., min.), they represent the performance met by approximately 80% of the instruments. Otherwise, they represent the mean value. The measurement uncertainty is not taken into account. Nominal values (nom.)These characterize expected product performance for the given parameter that is not covered by warranty. Nominal values are verified during product development but are not tested during production. UncertaintiesThese characterize the dispersion of the values attributed to the measurands with an estimated confidence level of approximately 95%. Uncertainty is stated as the standard uncertainty multiplied by the coverage factor k=2 based on the normal distribution. The evaluation has been carried out in accordance with the rules of the “Guide to the Expression of Uncertainty in Measurement” (GUM).Specifications MetricsElectric and magnetic fieldsMeasurement control and result display for the following probes and analyzers.Frequency range and level range depending on the probe/ analyzer. Broadband probes 100 kHz to 90 GHz (see list of digital broadband probes)Selective probes 1 Hz to 400 kHz, B-field (see list of digital selective probes)Probe model EHP-50F/G 1 Hz to 400 kHz, E-field and B-field (FFT-Analyzer, see separate datasheet)Probe model HP-01 0 Hz to 1 kHz, B-field (Magnetometer/ FFT-Analyzer, see separate datasheet)Electric field units V/m, mW/cm2, W/m2, % of standard (depending on the connected probe)Magnetic field units A/m, Tesla, Gauss, mW/cm2, W/m2, % of standard (depending on the connected probe)Temperature 1Logging of the ambient temperature at the time of measurement (-40 °C to +85 °C) in °C or °F Humidity 1Logging of the ambient relative humidity at the time of measurement (0% to 100% RH)Air pressure Logging of the ambient air pressure at the time of measurement (300 to 1100 hPa)Distance (Option) An ultrasonic rangefinder on the bottom side measures the distance to ground or to an object (0.25 m to 4 m) in m, ft, in or yd. Coverage ratio ≈ Distance / 4.Geolocation (Option) Built-in GNSS receiver for determining latitude, longitude and altitude (MSL).72 channels with the support of GNSS systems (GPS / QZSS, Galileo, GLONASS, BeiDou) and the SBAS extension system (WAAS, EGNOS, MSAS, GAGAN).Position accuracy: Autonomous 2.5 m CEP.DisplayDisplay type Sunlight readable 5” color TFT-LCD anti-glare display (HD 1280 x 720 pixels) Brightness Manual control or automatic control via brightness sensorOperating languages Largely language-independent measurement control via symbols.Menu languages: English, German, more are planned.1 The permissible operating range of the device and probe must not be exceeded. The temperature sensor is located in the probe.Operating ModesMode description Field Strength Broadband field measurements. Numerical results with time curve or bar graph display.Spatial Average Procedure for spatial averaging of broadband measurements over several measurement positions. Timer Logging Time-controlled broadband measurement of the field strength in a definable period.Spectrum FFT analysis with spectrum display, marker evaluation and display of the broadband level. Shaped Time Domain Time domain assessment (WPM, WRM) with digital filtering related to a selected safety limit. Scope Triggered measurement of the field curve over time with pretrigger feature.Available modes Broadband ProbesDigital Interface100 kHz to 90 GHzSelective ProbesDigital Interface1 Hz to 400 kHzModel EHP-50F/GOptical Interface1 Hz to 400 kHzModel HP-01Optical InterfaceDC to 1 kHzField Strength ☑☑☑☑Spatial Average ☑☑☑☑Timer Logging ☑☑☑☑Spectrum ☑☑☑Shaped Time Domain ☑☑Scope ☑FeaturesProbe features Recognition Probes are automatically recognized after being plugged in.Operating principle Measurement signals are sampled and processed inside the probe and provided as digital values. Offset compensation Automatic offset compensation enables gapless RF measurements without zero adjustment.Self-test Functional test including the sensor function of each measuring axis for digital interface probes.Signal detection RMS detection, Peak detection for WPM measurementsand selectable detection RMS/Peak with BDF-400 probes.Numerical display Total field (isotropic) and field components X, Y, Z (for probes up to 18 GHz).Result types Field Strength Actual, Max, Min, Avg (average) and Max Avg Spectrum Actual or Max or AvgShaped Time Domain Actual, Max and MinScope Actual, Max and marker for dB/dtAverage mode Moving average over time of the square values of the field strength.Averaging time Field Strength,Timer Logging 1 s, 3 s, 10 s, 30 s, 1 min, 3 min, 6 min, 10 min, 30 min, 1 h, 6 h, or 24 h Spectrum 4, 8, 16, 32 or 64 number of averagesGraphical display with marker function Field Strength Actual and Avg trace vs. time, time span selectable from 48 s to 24 hours.Spatial Average Bar graph of results for each measurement position (≤100) and the spatial average line. Timer Logging Timeline during measurement, results as a graph vs. time after measurement.Spectrum Frequency spectrum and selectable limit line. All axes are measured, one can be displayed. Shaped Time Domain Exposure index (WPM or WRM) in % vs. time, time span selectable from 4 min to 24 h. Scope Sign-based recorded signal with 25 % pretrigger. Recording time selectable from 1 ms to 30 s.Screenshots Manually initiated screenshot or automatically when saving a measurement result.Comments Voice and/or text comments can be assigned to a measurement result.Alarm Alarm sound and alarm message when an adjustable field strength is exceeded.Audible field indicator Acoustic hotspot search with field strength-dependent audio frequency (available for RF-probes).Scheduled measurements Mode Timer Logging with automatic wake-up and shutdown after measurement. Start time pre-selection: up to 24 h or immediate startTimer duration: up to 100 hStorage interval: 1s to 6 min (in 11 steps, up to 32000 intervals)Correction factors Post-processing for broadband probes to increase the accuracy at a known field frequency(direct frequency entry, interpolation between calibration points)Probe interface Digital probe interface for direct connection or via the optional extension cable.Optical port Serial, full duplex, ≥ 1 Mbit/s, to connect the Field Analyzer EHP-50F/G, the Magnetometer HP-01or the Digital Probe Repeater. Recommended interface for PC controlled measurements.USB 2.0 USB-C connection for battery charging, remote control and data transfer.Ethernet Gigabit Ethernet LAN connectivity for remote control and data transfer.Bluetooth (Option) BT 4.0 for remote control via smartphone app (Android).WiFi (Option) WLAN connectivity for remote control and data transfer.AUX MMCX connector, reserved for future use.Result StorageStorage triggers Manual (by keypress) or scheduled (Timer Logging Mode).Storage medium Removable micro SD card for storing measurement data, setups and comments.Storage capacity Up to 128 GB.16 GB micro SD card included.Screenshots Screenshots can be saved for documentation as PNG files.Voice recorder Voice comments can be added to measurement results (recording and playback).Text editor Text comments can be added to measurement results (integrated virtual keyboard).Photos / videos (WiFi/BT Option) Photos and videos from a smartphone can be transferred to the device using the FieldMan app.Printouts (WiFi/BT Option) Saved measurement results can be printed locally by using the FieldMan Android app for on-sitedocumentation (requires a compatible wireless printer).General SpecificationsRecommended calibration interval Calibration of the basic unit is not required. Only the probes are calibrated.Power supply internal Li-Ion rechargeable battery pack, included and replaceable external USB-C PD (maximum 12 V / 3A, compatible with BC1.2 and QC 3.0)Operating time (nom.) 16 hours (with broadband probes and analyzers)Charging time (nom.) 4 hours (80% charged in 2½ h)RF Immunity 200 V/m (100 kHz to 60 GHz); can be below the permissible measuring range of a probe. Operation in static magnetic fields ≤ 30 mT (to avoid high force on the device)Dimensions (H x W x D) 51 mm x 93 mm x 312 mm without probeWeight 695 g (without probe)Country of origin GermanyEnvironmental ConditionsRange of application Suitable for outdoor use and an operating altitude of up to 5000 mOperating temperature -20 °C to +50 °C during normal operation with battery0 °C to 40 °C during the charging process with an external chargerHumidity < 29 g/m³ (< 93 % RH at +30 °C), non-condensingIngress protection IP54 (probe screwed on, protective flap closed, stand folded in)Climatic conditions Storage 1K4 (IEC 60721-3) extended to -30 °C to +70 °C (battery removed)1K3 (IEC 60721-3) extended to -20 °C to +50 °C (battery inserted) Transport 2K3 (IEC 60721-3) extended to -30 °C to +70° COperating 7K2 (IEC 60721-3) extended to -20 °C to +50 °CMechanical conditions Storage 1M3 (IEC 60721-3) Transport 2M3 (IEC 60721-3) Operating 7M3 (IEC 60721-3)EMC European Union Complies with Directive 2014/53/EU, EN 301489-1, EN 301489-17 and EN 61326 -1 Immunity IEC/EN: 61000-4-2, 61000-4-3, 61000-4-4, 61000-4-5, 61000-4-6, 61000-4-8, 61000-4-11 Emissions IEC/EN: 61000-3-2, 61000-3-3, IEC/EN 55011 (CISPR 11) Class BSafety Complies with European Low Voltage Directive 2014/35/EU and IEC/EN 61010-1 Material Complies with European RoHS Directive 2011/65/EU and (EU)2015/863ORDERING INFORMATIONInstrument SetsDescription Part number FieldMan Basic Set-Probes are not included –Includes:›FieldMan Basic Unit›Hard Case for FieldMan and up to 5 Probes ›Power Supply USB-C PD, AU/EU/UK/US Plugs ›Cable, 2x USB-C(M), 3 A, 2 m›Shoulder Strap, 1 m ›Marking Rings for FieldMan Probes›Quick Start Guide›Safety Instructions›USB Stick: Manuals and Documents›Software Narda-TSX (free download)2460/101Digital Broadband ProbesDescription Part number Probe HFD-3061, H-Field, 300 kHz–30 MHz 2462/05 Probe HFD-0191, H-Field, 27 MHz–1 GHz 2462/06 Probe EFD-0391, E-Field, 100 kHz–3 GHz 2462/01 Probe EFD-0392, E-Field, High Power, 100 kHz–3 GHz 2462/12 Probe EFD-0691, E-Field, 100 kHz–6 GHz 2462/14 Probe EFD-0692, E-Field, 600 MHz–6 GHz 2462/20 Probe EFD-1891, E-Field, up to 18 GHz2462/02 Probe EFD-4091, E-Field, up to 40 GHz 2462/19 Probe EFD-5091, E-Field, 300 MHz–50 GHz, Thermocouple2462/03 Probe EFD-6091, E-Field, 100 MHz–60 GHz2462/17 Probe EFD-9091, E-Field, 100 MHz–90 GHz2462/18 Probe EAD-5091, FCC 1997 Controlled, Shaped, 300 kHz–50 GHz, E-Field 2462/07 Probe EBD-5091, IEEE 2019 Restricted, Shaped, 3 MHz–50 GHz, E-Field 2462/21 Probe ECD-5091, SC 6 2015 Controlled, Shaped, 300 kHz–50 GHz, E-Field 2462/16 Probe EDD-5091, ICNIRP 2020 Occ, Shaped, 300 kHz–50 GHz, E-Field 2462/22 Note: Separate data sheets are available for the probesDigital Selective ProbesDescription Part number Probe BFD-400-1, B-Field, 100 cm2, 1 Hz–400 kHz, selective 2463/01 Probe BFD-400-3, B-Field, 3 cm2, 1 Hz–400 kHz, selective2463/02 Note: Separate data sheets are available for the probesField AnalyzersDescription Part number EHP-50F E&H Field Analyzer Set, 1 Hz–400 kHz (no Transport Case included) 2404/105 EHP-50F E&H Field Analyzer Set, 1 Hz–400 kHz, Stand-alone/PC use 2404/104 HP-01 Magnetometer Set DC–1 kHz 2405/101OptionsDescription Part number Option, Narda-TSX Live Measurements, for FieldMan Digital Probes (expected from Q3 2023) 2460/95.01 Option, GPS/ Range Finder for FieldMan 2460/95.11 Option, WiFi/ Bluetooth for FieldMan (expected from Q4 2023) 2460/95.12AccessoriesDescription Part number Digital Broadband Probe Repeater 2464/01 Test-Generator 27 MHz 2244/90.38 Tripod, Non-Conductive, 1.65 m, with Carrying Bag 2244/90.31 Tripod, Benchtop, 0.16 m, Non-Conductive 2244/90.32 Tripod Extension, 0.50 m, Non-Conductive (for 2244/90.31) 2244/90.45 Handle, Non-Conductive, 0.42 m 2250/92.02 Car Charger Adapter, USB-C PD 2259/92.28 Cable, Digital Probe Extension, 2 m 2460/90.02 Cable, Digital Probe to USB 2.0 (Type A), 3 m 2460/90.03 Cable, FO Duplex (1000 µm) RP-02, 2 m 2260/91.02 Cable, FO Duplex (1000 µm) RP-02, 5 m 2260/91.09 Cable, FO Duplex (1000 µm) RP-02, 10 m 2260/91.07 Cable, FO Duplex (1000 µm) RP-02, 20 m 2260/91.03 Cable, FO Duplex (1000 µm) RP-02, 50 m 2260/91.04 Cable, FO Duplex, F-SMA to RP-02, 0.3 m 2260/91.01 O/E Converter RS232, RP-02/DB9 2260/90.06 O/E Converter USB, RP-02/USB 2260/90.07 Cable, Adapter USB 2.0 - RS232, 0.8 m 2260/90.53Narda Safety Test Solutions GmbH Sandwiesenstrasse 772793 Pfullingen, GermanyPhone +49 7121 97 32 0****************** Narda Safety Test SolutionsNorth America Representative Office435 Moreland RoadHauppauge, NY11788, USAPhone +1 631 231 1700******************Narda Safety Test Solutions S.r.l.Via Benessea 29/B17035 Cisano sul Neva, ItalyPhone +39 0182 58641****************************Narda Safety Test Solutions GmbHBeijing Representative OfficeXiyuan Hotel, No. 1 Sanlihe Road, Haidian100044 Beijing, ChinaPhone +86 10 6830 5870********************® Names and Logo are registered trademarks of Narda Safety Test Solutions GmbH - Trade names are trademarks of the owners.。

感应近场测试英语

【原创实用版】

目录

1.感应近场测试的概述

2.感应近场测试的应用领域

3.感应近场测试的英语表达

4.感应近场测试的实例分析

正文

感应近场测试是一种用于测量电磁场中近场区域的技术,其英文表述为“near-field sensing”。

近场指的是距离电磁场源较近的区域,一般而言,距离源小于波长的区域可视为近场。

感应近场测试在众多领域中都有着广泛的应用,如通信、雷达、无线充电等。

在英语中,与感应近场测试相关的词汇还包括“near-field measurement”、“near-field scanning”和“near-field probing”等。

这些词汇描述了在近场区域进行测量、扫描和探查的方法和技术。

举个实例来说明感应近场测试的应用。

在无线通信领域,感应近场测试可用于评估手机等移动设备的天线性能。

通过测量近场区域的电磁场分布,可以得到设备的天线方向图和天线增益等信息。

这些信息对于优化无线通信系统的性能至关重要。

总之,感应近场测试作为一种测量电磁场中近场区域的技术,在多个领域中都有着广泛的应用。

第1页共1页。

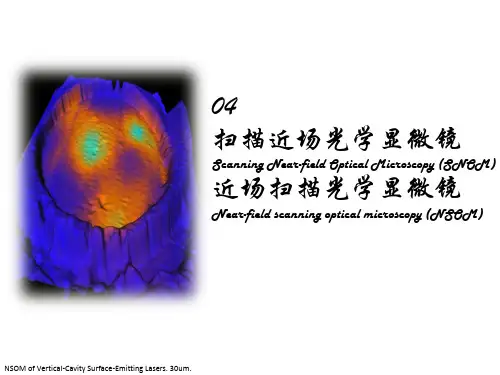

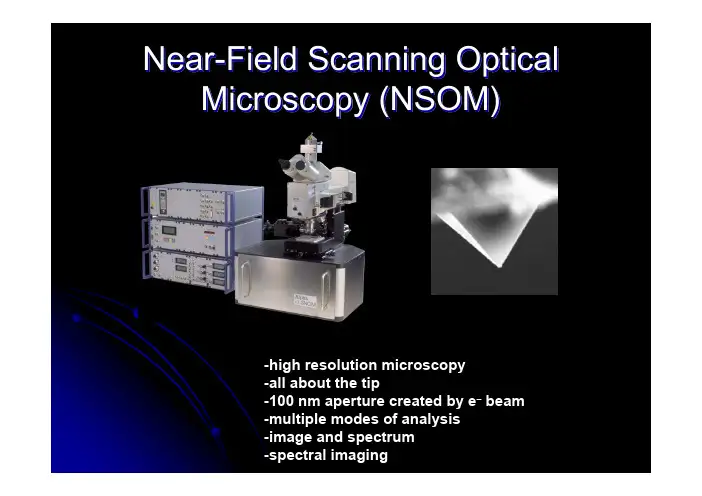

Near-Field Scanning Optical Near-Field Scanning Optical Microscopy (NSOM)-high resolution microscopy-all about the tip-100 nm aperture created by e–beam-multiple modes of analysis-image and spectrum-spectral imagingaperture < wavelength near-fieldtapered optical fibernear-fieldBasic Principle of NSOM ¾normally diffraction limited in far field imaging, i.e., cannot image smaller then wavelength of light used for imaging¾resolution limit between objects in a light microscope: d > λ/ (2sinθ), giving best case resolution of ½excitation wavelength¾with aperture of NSOM, image in near field can get resolution of < 50 nm¾Light through sub-wavelength diameteraperture and illuminates a sample that is placedwithin its near field¾distance to sample is much less than thewavelength of the light¾resolution achieved is far better than that whichconventional optical microscopes can attainBasic Principle of NSOM—cont’d Basic Principle of NSOM—cont’daperture Problems-not reproducible manufacturing process-low optical throughput-shear-force distance control-very fragileNSOM Tip Production —pulled fiber-hollow SiO2tip with aluminium coating-light is focussed from the backside into tip-beam deflection feedback—microfabricated cantilever-aperture diameter < 100 nmAdvantages-batch process-reproducible-different aperture sizes possible-very reliable-beam deflection feedback-easy to use (soft in z-direction)-high transmission coefficient—microfabricated cantileverNSOM Schematicend-capNSOM Cantilever Sensortop video view bottom video viewTransmission NSOMcolor labeled with toluidine blue 532 nm excitationSamples courtesy of Prof.Dr.Shohei Yamashina, Departement of Anatomy, Kitasato University, Japan 25 µmTopography Transmission NSOM Transmission NSOM-Zoom25 µm N = Nucleus Nc = Nucleolus Ec =Euchromatin Hc = Heterochromatin Mn =Nuclear membraneWITec Wissenschaftliche Instrumente und Technologie GmbH, D-89081 Ulm, Germany, Hörvelsinger Weg 6,fon 0700 94832 366,www.WITec.de, info@WITec.de. All rights reserved.Biosensing with NSOMHistological microtome cuts of rat liverN = NucleusEr = ErythrocyteC = CapillaryBA = Blood-Air-BarriereLa = Lung alveole5 µm1 µm5 µm ErErBAAmN LaCA = Axoplasma with Neurotubuli andNeurofilamentsM = Myelinated axonMl = Less-myelinated axonEn = Endoneurium (loosen connective2 µm Zy Nc NZy I I1 µm 1 µm 5 µmMMMlMl En En S AThe chromosomes exist of twochromatides (1+2), tied together at thecineotocher (C).Helical DNA is visible in the darkareas (H).1 µm CH121 µm2 µm2 µm2 µm25 µm x 25 µmSamples courtesy of Prof. Dr. Shohei Yamashina, DepartementHistological microtome cut of rat liver imaged in liquidcolor labeled with toluidine blue 532 nm excitation 2 µmHNSINcHB BSamples courtesy of H. Schmid, University of Ulm, GermanyOther Applications of NSOM200 nm200 nm2-phase polymer mixture for LED applications Fluorescence NSOM Topography5µm1 µmexcitation: λ=457nmdetection λ>490nmSample: U Cambridge, UK, excitation 488 nm.TopographyFluorescence10 microns scan rangeSpectral NSOMPolymer Mixture for Display Technology2 µmH.Aoki and S.Ito, Departement of Polymer Chemistry, Kyoto University, JapanB BCC12 x 12 µmBCCH.Aoki and S.Ito, Departement of Polymer Chemistry,Kyoto University, Japan1 x 1 µm500 x 500 nm21 nm FWHM100 nmF. Vargas,G. Tarrach, Universidad de Chile, and G. de Schaetzen, University of Leuven1 micron 1 micronAl test sample, 450 nm latex spheres2 µm20 micronsDNA dropletexcitation: 488 nm,detection:fluorescenceλ> 590 nm,Reflection NSOM5 micron 1 micron 1 micronReflection NSOMCompact Disk Topography Reflection NSOM1 µm1 µmVertical cavity surface emitting lasers -VCSELNSOM830,25nm21000Background829,53nm60000 145000 280000 210000 140000 800000 130000 610000 180000 80000 1200015 microns scan rangeA view from Nanoworld。

微波反射技术的英文表达Title: Microwave Reflection Technology: Bridging the Gap Between Theory and ApplicationMicrowave reflection technology, a cornerstone in the field of electromagnetic engineering, plays a pivotal role in modern communication systems and radar technology. This essay delves into the core principles of microwave reflection, its diverse applications, and the challenges it presents to researchers and engineers.At the heart of microwave reflection technology lies the concept of electromagnetic wave reflection. When microwaves encounter a surface, a portion of the energy is reflected back, while the rest is absorbed or transmitted. The behavior of these reflected waves is governed by the laws of physics, particularly the Fresnel equations, which describe the reflection and transmission coefficients at the interface between two media.The reflection coefficient, denoted by Γ, is a complex number that quantifies how much of the incident wave is reflected. It depends on the properties of the media, such as the dielectric constant and conductivity, as well as the angle ofincidence and the polarization of the wave. Understanding and manipulating these variables is crucial for optimizing the performance of microwave systems.The applications of microwave reflection technology span various domains, each leveraging its unique properties to solve complex problems.Radar Technology: Radar systems, which rely on microwave reflection for object detection, have been revolutionized by the ability to analyze reflected signals. By measuring the phase and amplitude of the reflected signals, radar can accurately determine the position, velocity, and even the shape of distant objects, making it indispensable in military, meteorological, and civilian navigation applications Microwave Imaging: In medical diagnostics, microwave reflection is used in imaging technologies such as microwave tomography and radar imaging. These systems can detect anomalies in the human body by analyzing the reflected microwave signals, offering a non-invasive alternative toX-rays.Quality Control in Manufacturing: In industries that require non-destructive testing, microwave reflection is used to inspect materials for defects and ensure quality. Thetechnology can detect changes in the material's properties, such as moisture content and density, without causing damage.Despite its widespread applications, microwave reflection technology faces significant challenges that hinder its full potential. These include the complexity of designing systems that can efficiently manipulate microwave signals, the need for accurate models to predict wave behavior in complex environments, and the integration of microwave technology into emerging fields such as 5G communications and quantum computing.Future advancements in microwave reflection technology will likely focus on miniaturization, integration with other technologies, and the development of intelligent systems capable of dynamic adaptation to changing conditions. Research into new materials and manufacturing techniques will also play a critical role in overcoming current limitations and expanding the capabilities of microwave systems.In conclusion, microwave reflection technology, with its foundational principles and broad applications, is a vital area of research and development. As we continue to push the boundaries of what is possible, the future of microwavereflection technology promises to be as exciting as it is transformative.。

汉英词汇索引B白光散斑照相测量术white light speckle photography白光信息处理Write light information processing曝光exposure曝光时间exposure time本征函数characteristic function边端性质terminal property变形反射镜器件Deformable Mirror Devices(DMD)边缘全息edge-lit holograms表面形变空间光调制器Deformable Surface Spatial Light Modulator 标量衍射scalar diffraction波长复用wavelength multiplexing波长选择性wavelength selectivity波前记录Wavefront recording波前再现Wavefront reconstruction布喇格角Bragg angle布喇格失配参量Bragg-mismatch parameter布喇格条件Bragg conditionC参考光束Reference beam参物比light intensity ratio of reference to objective持续光谱烧孔persistent spectral hole-burning抽样定理sampling theorem抽样函数sampled function传递函数transfer function相干传递函数coherent transfer function,非相干传递函数incoherent transfer function串扰噪音cross-talk noise磁光空间光调制器Magnetic-Optical Spatial Light Modulator存储容量storage capacityD等效波长equivalent wavelength电编址Electrically Addressed电光效应electro-optic effect电荷耦合器件Charge-Coupled-Device(CCD)点扩散函数point spread function电子散斑干涉electronic speckle interferometry叠加积分superposition integral定影fix动态范围参量dynamic-range parameter对比度contrast读出光Read out Light多量子阱Multiple Quantum Well(MQW)E二次曝光全息干涉术duoble exposure holographic interferometry 二次散斑场secondary speckle fieldF法拉第效应Faraday Effect放大率magnification范西特-泽尼克定理Van Cittert-zernike theorem菲涅耳近似Fresnel approximation菲涅耳衍射公式Fresnel diffraction formula飞行时间法time of flight分辨率resolution分块全息存储block-oriented holographic storage分数傅里叶变换fractional Fourier transform分数傅里叶变换阶order of fractional Fourier transform分数傅里叶谱fractional Fourier spectrum傅里叶变换Fourier transform傅里叶变换轮廓术Fourier Transform Profilometry(FTP) 复合光栅Multi-grating夫琅和费近似Fraunhofer approximation夫琅和费衍射公式Fraunhofer diffraction formula复振幅complex amplitudeG( 值 film gamma各态历经性ergodicity,共轭像Conjugate image共同体积复用common-volume multiplexing光编址Optically Addressed光波耦合wave coupling光刀light knife光导热塑Photothemoplastic光分束器Beam splitter光功率谱密度power spectral density of the light beam 光计算Optical Computing光漫射器Optical diffuser光密度photographic density光栅矢量grating vector光栅相移grating phase shift光瞳pupil出瞳exit pupil入瞳entrance pupil光瞳函数pupil function广义光瞳函数generalized pupil function光学传递函数optical transfer function(OTF)调制传递函数modulation transfer function(MTF)相位传递函数phase transfer function(PTF)部分相干传递函数partial-coherent transfer function光学粗糙表面optical rough surface光学互连Optical Interconnection光学矩阵运算Optical Matrix光学神经网络Optical Neural Network光学图像识别Optical pattern recognition光学微分Optical differentiation光学信息处理Optical information processing相干光学信息处理Coherence Optical information processing非相干光学信息处理incoherence Optical information processing 光折变晶体Photorefractive crystal光折变效应photorefractive effect光致聚合物Photopolymer光致抗蚀剂Photoresist关联存储器associative memoryHH-D曲线 Hurter-Driffield curve灰雾 gross fog混合场效应hybrid field effect互谱密度函数cross-spectral density functionJ剪切散斑干涉术shearing speckle interferometry假彩色编码Pseudocolor coding夹层全息术sandwich holography角度复用angle multiplexing角度选择性angular selectivity角谱angular spectrum结构照明structured illumination基尔霍夫公式Kirchhoff formula解析信号 analytic signal截止频率cutoff frequency激光片光 laser sheet激光散斑laser speckle激光三角法Laser triangulation机器视觉machine vision,级联系统cascade system,基元函数elementary function,基元全息图 elementary hologramK克尔效应Kerr Effect亥姆霍兹方程Helmholtz equation空间不变线性系统 space-invariant linear system空间带宽积space-bandwidth product空间复用spatial multiplexing空间光调制器Spatial Light Modulator(SLM)空间滤波器Spatial filter空间频率spatial frequency空间频谱spatial frequency spectrum归一化频谱normalized frequency spectrum像强度频谱frequency spectrum of image intensity空间位相检测spatial phase detection空域函数spatial function,L量子限制斯塔克效应Quantum Restricted Stark Effect(QRSE) 灵敏度矢量sensitivity vecto卤化银乳胶Silver halide emulsion滤波函数filtering functionM脉冲响应impulse response莫尔轮廓术moiré topographyN奈奎斯特抽样间隔Nyquist sampling spacing内容寻址的存储器content-addressable memory逆滤波器Inverse filter铌酸锂lithium niobateP平稳性stationary频谱混叠 spectral overlapping匹配滤波器Matched filter普克尔斯读出光调制器---Pockels Readout Optical Modulator (PROM) 普克尔斯效应---Pockels EffectQ强度脉冲响应intensity impulse response强度自相关函数intensity autocorrelation finction全场滤波whole field filtering全息存储holographic storage全息电影holographic movie全息光学元件Holographic Optical Element全息记录介质Holographic recording media全息术Holography计算全息术Computer Generated Holography视频全息video holography合成全息术synthetic holography全息图Hologram彩虹全息图rainbow hologram彩色全息图color hologram反射全息图Reflection Hologram菲涅耳全息图Fresnel hologram夫琅和费全息图Fraunhofer hologram傅里叶变换全息图Fourier transform hologram离轴全息图Off-axis hologram模压全息图embossing hologram平面全息图Plane Hologram体积全息图Volume Hologram体视全息图holographic stereograms透射全息图Transmission Hologram位相全息图Phase hologram无透镜傅里叶变换全息图Lensless Fourier transform hologram 像(面)全息图Image plane hologram振幅全息图Amplitude hologram全息--散斑干涉术holo-speckle interferometry全息象差holographic abberrations全息注塑holograms formed by injectingR瑞利分辨判据Rayleigh criterion of resolution,S散斑场speckle field客观散斑场objective speckle field主观散斑场subjective speckle field散斑干涉术speckle interferometry散斑照相测量术speckle photography散射基元scattering element三维传感three-dimensional sensing被动三维传感passive three-dimensional sensing主动三维传感 active three-dimensional sensing三维面形测量 three-dimensional shape measurement三维显示three-dimensional display色模糊color blur色散dispersion时间平均time average时间平均全息干涉术time-average holographic interferometry实像real image实物仿形 solid modeling双光子吸收bi-photon absorption双目视觉 binocular vision数据传输速率data transfer rate顺序曝光sequential exposure数字散斑干涉术digital speckle interferometry数字散斑照相术digital speckle photography数字微反射镜器件Digital Micromirror Device(DMD)数字象素全息 digital pixel holograms调制Theta modulation倏逝波evanescent wave,T同步扫描 synchronized scanning调制度测量轮廓术modulation measurement profilometry (MMP)铁电液晶ferroelectric liquid crystal体光栅volume grating透镜的位相变换phase transformation of lens,透射率Transmittance图象传感器image sensor图像消模糊Image deblurringW外差全息干涉术heterodyne holographic interferometry完善洗牌Perfect Shuffle微分滤波器Differential filter微通道板Microchannel Plate (MCP)微通道板空间光调制器Microchannel Spatial Light Modulator(MSLM) 位相编码复用phase-encoding multiplexing位相测量剖面术Phase Measuring Profilometry(PMP)位相共轭phase conjugation位相展开phase unwrapping物光束Object beamX限带函数bandlimited function限幅散斑技术clipped speckle technique像素pixel信息流量throughput线模糊blur caused by extended light sources线全息图slit holograms线性性质linear property相干性coherence复相干度complex degree of mutual coherence复相干因子complex coherence factor of the light复自相干度complex degree of self coherence互强度mutual intensity互相干函数mutual coherence function空间相干性spatial coherence时间相干性temporal coherence相干长度coherence length相干面积coherence area相干时间coherence time自相干函数self coherence function相关分析方法correlation analysis相移phase-shifting步进相移stepping phase shifting连续相移continue phase shifting相移全息干涉术phase shifting holographic interferometry 显影development写入光Write Light信噪比signal-noise ratio系综平均statistical average,虚像virtual imageY赝像Pseudoscopic image衍射diffraction,近场衍射near-field diffraction,远场衍射far-field diffraction,衍射孔径diffraction aperture,衍射受限diffraction-limited,衍射效率Diffraction Efficiency液晶光阀Liquid Crystal Light Valve原始像Original image圆型复高斯随机变量circular complex Gaussian random variable Z增量曝光incremental exposure子波干涉wavelet interference自泵浦相位共轭镜self-pumped phase-conjugate mirror针孔滤波器Pinhole filter正弦光栅 sinusoidal grating折射率调制度refractive index modulation指向矢orientation vector重铬酸明胶Dichromated gelatin逐点滤波pointwise filtering准单色条件quasimonochromatic conditions准外差全息干涉术quasi- heterodyne holographic interferometry 着陆台landing pads自电光效应器件Self-Electro-optical Effect Devices(SEED)综合孔径雷达Synthetic Aperture Radar组页器page composer。