INSTITUTE OF PHYSICS PUBLISHING MEASUREMENT SCIENCE AND TECHNOLOGY

- 格式:pdf

- 大小:270.05 KB

- 文档页数:9

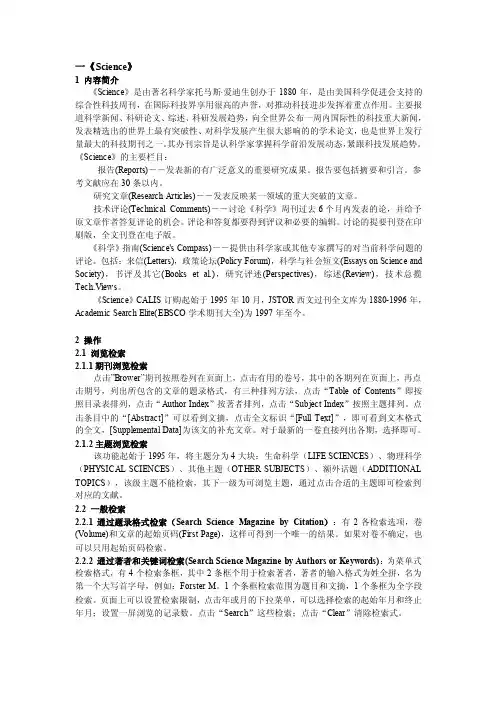

一《Science》1 内容简介《Science》是由著名科学家托马斯·爱迪生创办于1880年,是由美国科学促进会支持的综合性科技周刊,在国际科技界享用很高的声誉,对推动科技进步发挥着重点作用。

主要报道科学新闻、科研论文、综述、科研发展趋势,向全世界公布一周内国际性的科技重大新闻,发表精选出的世界上最有突破性、对科学发展产生很大影响的的学术论文,也是世界上发行量最大的科技期刊之一。

其办刊宗旨是认科学家掌握科学前沿发展动态,紧跟科技发展趋势。

《Science》的主要栏目:报告(Reports)――发表新的有广泛意义的重要研究成果。

报告要包括摘要和引言。

参考文献应在30条以内。

研究文章(Research Articles)――发表反映某一领域的重大突破的文章。

技术评论(Technical Comments)――讨论《科学》周刊过去6个月内发表的论,并给予原文章作者答复评论的机会。

评论和答复都要得到评议和必要的编辑。

讨论的提要刊登在印刷版,全文刊登在电子版。

《科学》指南(Science's Compass)――提供由科学家或其他专家撰写的对当前科学问题的评论。

包括:来信(Letters),政策论坛(Policy Forum),科学与社会短文(Essays on Science and Society),书评及其它(Books et al.),研究评述(Perspectives),综述(Review),技术总揽Tech.Views。

《Science》CALIS订购起始于1995年10月,JSTOR西文过刊全文库为1880-1996年,Academic Search Elite(EBSCO学术期刊大全)为1997年至今。

2 操作2.1 浏览检索2.1.1期刊浏览检索点击”Brower”期刊按照卷列在页面上,点击有用的卷号,其中的各期列在页面上,再点击期号,列出所包含的文章的题录格式,有三种排列方法,点击“Table of Contents”即按照目录表排列,点击“Author Index”按著者排列,点击“Subject Index”按照主题排列。

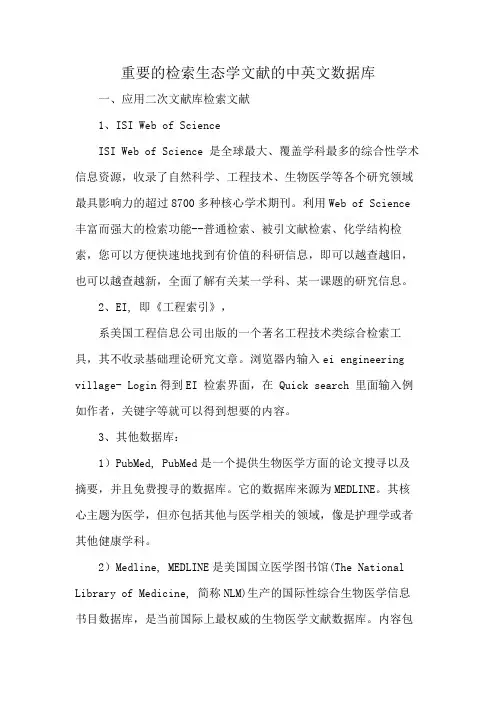

重要的检索生态学文献的中英文数据库一、应用二次文献库检索文献1、ISI Web of ScienceISI Web of Science 是全球最大、覆盖学科最多的综合性学术信息资源,收录了自然科学、工程技术、生物医学等各个研究领域最具影响力的超过8700多种核心学术期刊。

利用Web of Science 丰富而强大的检索功能--普通检索、被引文献检索、化学结构检索,您可以方便快速地找到有价值的科研信息,即可以越查越旧,也可以越查越新,全面了解有关某一学科、某一课题的研究信息。

2、EI, 即《工程索引》,系美国工程信息公司出版的一个著名工程技术类综合检索工具,其不收录基础理论研究文章。

浏览器内输入ei engineering village- Login得到EI 检索界面,在 Quick search 里面输入例如作者,关键字等就可以得到想要的内容。

3、其他数据库:1)PubMed, PubMed是一个提供生物医学方面的论文搜寻以及摘要,并且免费搜寻的数据库。

它的数据库来源为MEDLINE。

其核心主题为医学,但亦包括其他与医学相关的领域,像是护理学或者其他健康学科。

2)Medline, MEDLINE是美国国立医学图书馆(The National Library of Medicine, 简称NLM)生产的国际性综合生物医学信息书目数据库,是当前国际上最权威的生物医学文献数据库。

内容包括美国《医学索引》(Index Medicus, IM)的全部内容和《牙科文献索引》(Index to Dental Literature)、《国际护理索引》(International Nursing Index)的部分内容3)CSA, CSA是加拿大标准协会(Canadian Standards Association)的简称。

它成立于1919年,是加拿大首家专为制定工业标准的非盈利性机构。

在北美市场上销售的电子,电器,卫浴,燃气等产品都需要取得安全方面的认证。

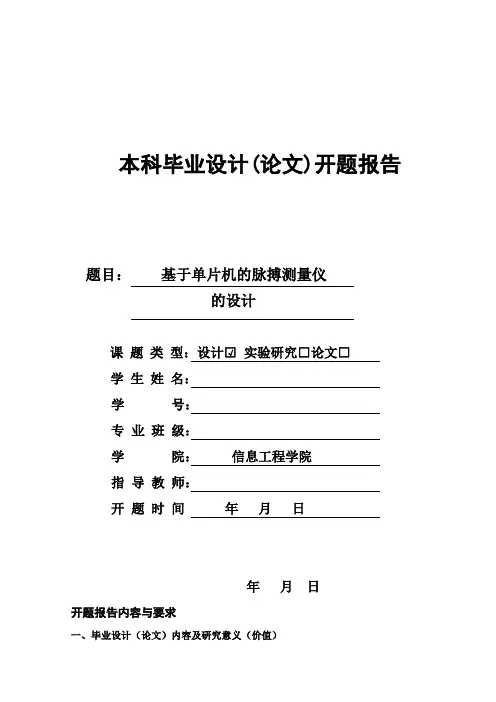

本科毕业设计(论文)开题报告题目:基于单片机的脉搏测量仪的设计课题类型:设计□√实验研究□论文□学生姓名:学号:专业班级:学院:信息工程学院指导教师:开题时间年月日年月日开题报告内容与要求一、毕业设计(论文)内容及研究意义(价值)随着科技发展的不断提高,生命科学和信息科学的结合越来越紧密,出现了各种新颖的脉搏测量仪器,特别是电子脉搏仪的出现,使脉搏测量变得非常方便。

脉诊在我国已具有2600多年临床实践,是我国传统中医的精髓,但祖国传统医学采用“望、闻、问、切”的手段进行病情诊断,受人为的影响因素较大,测量精度不高。

科技的创新,脉搏测试不再局限于传统的人工测试法或听诊器测试法,脉搏测量可利用电子仪器测量出精度更就的数据。

人体脉搏信号中包含丰富的生理信息,也逐渐引起了临床医生的很大兴趣,达到了方便、快捷、准确的测量脉搏的目的。

随着电子测量技术的迅速发展,现代电子测量仪器以极快的速度向数字化、自动化的方向发展。

制成的脉搏测量仪器性能良好,结构简单,有较好的应用和推广价值。

脉搏测量仪的设计,必须是通过采集人体脉搏变化引起的一些生物信号,然后把生物信号转化为物理信号,使得这些变化的物理信号能够表达人体的脉搏变化,最后要得出每分钟的脉搏次数,就需要通过相应的硬件电路及芯片来处理物理变化并存储脉搏次数。

在硬件设计中一般的物理信号就是电压变化。

本系统的组成包括传感器、信号处理、单片机电路、显示电路、键盘输入等部分。

二、毕业设计(论文)研究现状和发展趋势(文献综述)随着科学技术的发展,脉搏测量技术也越来越先进,对脉搏的测量精度也越来越高,国内外先后研制了不同类型的脉搏测量仪,脉搏测试不再局限于传统的人工测试法或听诊器测试法,脉搏测量可利用电子仪器测量出精度更就的数据。

人体脉搏信号中包含丰富的生理信息,也逐渐引起了临床医生的很大兴趣,达到了方便、快捷、准确在测量脉搏的目的。

随着电子测量技术的迅速发展,现代电子测量仪器以极快的速度向数字化、自动化的方向发展。

The Effect Of Phase Distortion On InterferometricMeasurements Of Thin Film Coated Optical SurfacesJon Watson, Daniel SavageOptimax Systems, 6367 Dean Parkway, Ontario, NY USA*********************©Copyright Optimax Systems, Inc. 2010This paper discusses difficulty in accurately interpreting surface form data from a phase shifting interferometer measurement of a thin film interference coated surfaces.PHASE-SHIFTING INTERFEROMETRYPhase-shifting interferometry is a metrology tool widely used in optical manufacturing to determine form errors of an optical surface. The surface under test generates a reflected wavefront that interferes with the reference wavefront produced by the interferometer 1. A phase-shifting interferometer modulates phase by slightly moving the reference wavefront with respect to the reflected test wavefront 2 . The phase information collected is converted into the height data which comprises the surface under test3.Visibility of fringes in an interferometer is a function of intensity mismatch between the test and reference beams. Most commercially available interferometers are designed to optimize fringe contrast based on a 4% reflected beam intensity. If the surface under test is coated for minimum reflection near or at the test wavelength of the interferometer, the visibility of the fringe pattern can be too low to accurately measure.OPTICAL THIN-FILM INTERFERENCE COATINGSOptical thin-film interference coatings are structures composed of one or more thin layers (typically multiples of a quarter-wave optical thickness) of materials deposited on the surface of an optical substrate.The goal of interference coatings is to create a multilayer film structure where interference effects within the structure achieve a desired percent intensity transmission or reflection over a given wavelength range.The purpose of the coating defines the design of the multilayer structure. Basic design variables include:• Number of layers• Thickness of each layer• Material of each layerThe most common types of multilayer films are high reflector (HR) and anti-reflection (AR) coatings. HR coatings function by constructively interfering reflected light, while AR coatings function by destructively interfering reflected light. These coatings are designed to operate over a specific wavelength range distributed around a particular design wavelength.To produce the desired interference effects, thin-film structures are designed to modulate the phase of the reflected or transmitted wavefront. The nature of the interference effect depends precisely on the thickness of each layer in the coating as well as the refractive index of each layer. If the thickness and index of each layer is uniform across the coated surface, the reflected wavefront will have a constant phase offset across the surface. However, if layer thicknesses or index vary across the coated surface, then the phase of thereflected wavefront will also vary. Depending on the design of the coating and the severity of the thickness or index non-uniformity, the distortion of the phase of the reflected wavefront can be severe. 4Layer thickness non-uniformity is inherent in the coating process and is exaggerated by increasing radius of curvature of the coated surface.5 All industry-standard directed source deposition processes (thermal evaporation, sputtering, etc) result in some degree of layer thickness non-uniformity.5 Even processes developed to minimize layer non-uniformity, such as those used at Optimax, will still result in slight layer non-uniformity (within design tolerance).TESTING COATED OPTICS INTERFEROMETRICALLYPhase-shifting interferometers use phase information to determine the height map of the surface under test. However, surfaces coated with a thin-film interference coating can have severe phase distortion in the reflected wavefront due to slight layer thickness non-uniformities and refractive index inhomogeneity. Therefore, the measured irregularity of a coated surface measured on a phase shifting interferometer at a wavelength other than the design wavelength, may not represent the actual irregularity of the surface. Even using a phase shifting interferometer at the coating design wavelength does not guarantee accurate surface irregularity measurements. If a coating has very low reflectance over any given wavelength range (such as in the case of an AR coating), the phase shift on reflection with wavelength will vary significantly in that range.7 Figure 1 shows an example of how the phase can vary with coating thickness variations.Figure 1In this particular case, if a point at the lens edge has the nominal coating thickness and the coating at lens center is 2% thicker, expect ~38° phase difference in the measurement (~0.1 waves). This will erroneous be seen as height by the interferometer, despite the actual height change in this case being less than 7nm (~0.01 waves). Also, depending on coating design, low fringe visibility may inhibit measurements.There is an extreme method to determine the irregularity of a thin-film interference coated surface by flash coating it with a bare metal mirror coating. A metal mirror coating is not a thin-film interference coating, and the surface of the mirror represents the true surface, This relatively expensive process requires extra time, handling, and potential damage during the metal coating chemical strip process.CONCLUSIONS•There can be practical limitations to getting accurate surface form data on coated optical surfaces due to issues with phase distortion and fringe visibility.•The issues are a function of thin film coating design particulars and the actual deposition processes.1 R.E. Fischer, B. Tadic-Galeb, P. Yoder, Optical System Design, Pg 340, McGraw Hill, New York City, 20082 H.H. Karow, Fabrication Methods For Precision Optics, Pg 656, John Wiley & Sons, New York City, 19933 MetroPro Reference Guide OMP-0347J, Page 7-1, Zygo Corporation, Middlefield, Connecticut, 20044 H.A. Macleod, Thin Film Optical Filters, Chapter 11: Layer uniformity and thickness monitoring, The Institute of Physics Publishing, 2001.5 R.E. Fischer, B. Tadic-Galeb, P. Yoder, Optical System Design, Pg 581, McGraw Hill, New York City, 2008。

综合检索报告综合检索报告姓名 __ ___ 班级 __ __ 学号 _______检索课题(中文) ______人造金刚石的合成______________(英文)_______ The synthesis of synthetic diamond __________________一、检索策略1、检索词:主题词(中文):人造金刚石(英文): synthetic diamond相关词:(中文)___金刚石______ (英文)___ diamond _____副主题词:(中文)__人造______(英文)___ synthetic _____副主题词:(中文)___合成_____(英文)___ synthesis _____2、构造检索式(布尔逻辑表达式或网络检索式)金刚石and人造and合成二、检索来源(本文所查数据库名或其它来源)万方数据库数据库维普数据库欧洲专利局美国专利局中国专利局CALIS学位论文系统 OhioLINK ETDs学位论文谷歌图书网亚马逊图书网三、检索结果:分别写出篇名、作者、文献来源(期刊指刊名、年、卷期;专利指专利号;学位论文指授予单位,标准指标准号等文摘形式)及摘要(有原文请注明),所有数据库均检索近6年的文献。

1、中文期刊(找5篇):(必备)①《人造大单晶金刚石合成技术及应用研究现状》摘要:随着近几年人造金刚石技术研究的再次发展,大单晶金刚石合成技术成为相关研究者新的研究方向.本文结合当前人造金刚石合成现状,详细介绍了金刚石的合成技术发展,各人研究机构的研究进度,生产设备及合成方法.大单晶金刚石的应用情况等.作者:王东胜王志勇董耀华来源:《广东建材》(4)②《绝缘片在粉末工艺合成人造金刚石中的试验研究》摘要:本文介绍了一种用氧化铝陶瓷基片制作的绝缘片,应用在粉末工艺合成人造金刚石中.通过在六面顶压机上进行人造金刚石高温、超高压合成的对比实验,结果表明:绝缘片能有效地改善合成腔体内部的温度分布差异,为金刚石的成核生长提供良好的环境.具有绝缘片的粉末合成块在粉末合成工艺中较没有绝缘片粉末合成块合成工艺更稳定.同时由于合成腔体的温场均匀,合成的金刚石颜色、透明度、单产都有很大提高.为进一步提高金刚石的品位进行了实验摸索.作者:李丹孟继承张景鑫朱凤福周连科文献来源:《人工晶体学报》(1)③《高品级人造金刚石合成工艺特点的探讨》摘要:通过对高品级金刚石理想合成区间和实际生产区间的探讨分析,阐述了高品级金刚石合成过程中温度与压力的匹配与控制的关键技术,对合理制定高品级金刚石合成工艺不无益处.作者:刘立新赵岩文献来源:《超硬材料工程》(2)④《金刚石合成设备的技术进展》摘要:近年来,随着以粉末合成块为代表的人造金刚石合成工艺的迅速推广,大压机更新换代发展势头迅猛。

国内的话力学杂志有《力学进展》、《力学与实践》等。

给lz一些国际的期刊。

国际知名的力学期刊刊名原文名创刊年附注《应用数学和力学》(中国) (AppliedMa hematics and Mechanics) 1980《应用数学和力学》编辑委员会《热应力杂志》(美)Journal of Thermal Stresses 1978 美国Hemispheres Publishing Co.《国际非线性力学杂志》(英) International Journal of Non-Linear Mechanics 1966 英国Pergamon Press Ltd.《国际固体与结构杂志》International Journal of Solids and Structures 1965 英国Pergamon Press Ltd.《国际多相流杂志》(英)International Journal of Multiphase Flow 1973 英国Pergamon Press Ltd.《地震工程与结构动力学》(英)Earthquake Engineering Structural Dynamics 1972 英国John Wiley Sons Ltd.《国际热与热流杂志》(英) International Journal of Heat and FluidFlow 1979 英国Mechanical Engineering Publi-CationsLtd.《国际地震工程与土壤动力学杂志》(英)International Journal of Earthquake Engineering Soil Dynamics1981 英国CML Publications《工程断裂力学》(英)Engineering Fracture Mechanics 1968 英国Pergamon Press Ltd.《国际压力容器与管道杂志》(英)The International Journal Of Pressure Vessels Piping 1973 英国Applied Science Publishers Ltd.《国际工程数值方法杂志》(英)International Journal for Numerical Methodsin Engineering 1969 英国John Wiley Sons Ltd.《工程材料与结构的疲劳》(英)Fatigue of Engineering Materials and Structures 1978 英国Pergamon Press Ltd《国际疲劳杂志》(英) International Journal of Fatigue 1979 英国IPC Science and Technology Press.《国际岩石力学与采矿学及地质力学文摘》(英)International Journal of Rock Mechanics MiningScienc Geomechanics ABSTRACTS 1964 英国Pergamon Press Ltd.《水利》(法)La Houille Blanche 1902 法国《理论与应用力学杂志》(法)Journal de Mecanique Theorique et Appliquee (Le) 1962 法国Centrale des revues DunodGauthier-Villars《工程师文献》(联邦德国)Ingenieur-Archiv 1929 联邦德国Springer-Verlag 《岩石力学与岩石工程》(奥地利)Rock Mechanics Rock Engineering 1929 奥地利Springer-Verlag《固体力学文献》(荷兰)Solid Mechanics Archives 1976 荷兰Martinus Nijhoff Publishers.《应用力学和工程技术中的计算机方法》(荷兰)Computer Methods in Applied Mechanics and Engineering 1972 荷兰Elsevier Science Publishers.《风工程和工业空气动力学杂志》(荷兰)Journal of Wind Engineering and Industrial Aerodynamics 1975 荷兰Elsevier Scientific Publishing Company(原名为Journal of Industrial Aerodynamics,1980年改为现名)《国际断裂杂志》(荷兰)International Journal of Fracture 1965 荷兰Martinus Nijhoff Publishers《水利学研究杂志》(荷兰)Journal of Hydraulic Research 1963 荷兰International Assiciation for Hydraulic Research《非牛顿流体力学杂志》(荷兰)Journal of Non-Newtonian Flluid Mechanics 1975 荷兰Elsevier Scientific Publishing Company《波动》(荷兰)Wave Motion 1979 荷兰North-Holland Publishing Co.《土木工程学报》(中国)China Civil Engineering 1954 中国土木工程学会China Civil Engineering Society《力学学报》(中国)Acta Me-chanica Subuca 1957 中国力学学会《力学学报》编辑委员会(The Editorial Board of ACTAMECHANIC A SINICA,the Chinese Society of Theoretical and Applied Mechanics)《力学译丛》(中国)1964 中国科学技术情报研究所分所《力学进展》(中国)1982 中国科学院力学研究所《应用力学》(中国)1982 中国科学技术情报研究所分所《固体力学学报》(中国)Acta Mechanica Solida Sinica 1980 《固体力学》学报编辑委员会员《应用数学和力学》(中国)Applied Mathematics and Mechanics 1980 《应用数学和力学》编辑委员会《建筑结构学报》(中国)Jour-nal of Building Structures 1980 中国建筑学会《上海力学》(中国)1980 《上海力学》编辑部《爆炸与冲击》(中国)1981 《爆炸与冲击》编辑部《振动与冲击》(中国)1982 《振动与冲击》编辑委员会《空气动力学学报》(中国)Acta Aerodynamica Sinica 1983 《空气动力学学报》编辑委员会《数学物理学报》(中国)1981 《数学物理学报》编辑委员会《实验应力分析学会会报》(美)Proceedings of the Society for Experimental StressAnalysis 1943 美国实验应力分析学会(Society for Experimental Stress Analysis)《实验力学》(美)Experimental Mechanics 1961 美国实验应力分析学会(Society for Experimental Stress Analysis)《结构力学杂志》(美)Journal of Structural Mechanics 1972 美国Marcel Dekker Ine.《流变学杂志》(美)Journal of Rheology 1957 美国John Wiley Sons Inc. Publishers.《液压与气体力学》(美)Hydraulics Pneumatics; Magazine of Fluid Power and Control Systems 1948 美国Penton/IPC《流体物理学》(美)Physics of Fluids 1958 美国物理学会(American Institute of Physics)《流体力学年评》(美)Annual Review of Fluid Mechanics 1969 美国Annual Review Inc.《应用力学杂志》(美)Journal of AppliedMechanics 1935 美国机械工程师学会(American Society ofMechanical Engineers)《实验应力分析学会年度春季会议录》(美)Proceedingsof the SESA Annual Spring Meeting 美国实验应力分析学会(Society for Experimental Stress Analysis)《聚合物科学杂志》(美)Journal of Polymer Science 1946 美国John Wiley Sons Inc Publishers《生物工程学杂志》(美)Journal of BiomechanicalEngineering 1977 美国机械工程师学会(American Society ofMechanical Engineers)《复合材料杂志》(美)Journal of Composite Materials 1967 美国Technomic Publishing Company Inc.《流体工程学杂志》(美)Journal of FluidsEngineering 1973 美国机械工程师学会(American Society ofMechanical Engineers)《美国土木工程师学会会报--工程力学组杂志》(美)Proceedings of the American Society of CivilEngineers- Journal of the Engineer Mechanics Division 1873 美国机械工程师学会(American Society of Civil Engineers)《自动车工程师学会汇刊》(美)SAE Transactions 1906 自动车工程师学会(Society of Automotive Engineers)《船舶研究杂志》(美)Journal of ShipResearch 1893 造船与轮机工程师协会(Society of NavalArchitects Marine Engineers)《美国航空与航天学会志》(美)AIAA Journal 1930 美国航空与航天学会(American Institute of Aeronautics Astronautics)《苏联流体力学研究》(美)Fluid Mechanics-Soviet Research 1972 美国Scripta Publishing Co.《流体动力学》(美)Fluid Dynamics 1966 美国Plenum Publishing Co.《伦敦皇家学会会报,A辑:数学及物理科学》(英)Proceedings of the Royal Society of London,A:Mathematical Physical Sciences 1854 英国皇家学会(The Royal Society of London)《伦敦皇家学会哲学汇刊,A 辑数学与物理科学》(英)Philosophical Transactions of the RoyalSociety of London,SeriesA:Mathematical PhysicalSciences 1854 英国皇家学会(The Royal Society of London)1887年(第178卷)起分A,B两辑出版《力学研究通讯》(英)Mechanics Research Communications 1974 英国Pergamon Press Ltd《生物流变学》(英)Biorheology 1963 英国Pergamon Press Ltd.《生物力学杂志》(英)Journal of Biomechanics 1968 英国Pergamon Press Ltd.《材料科学杂志》(英)Journal of Materials Science 1966 英国Chapman and Hall Ltd.《应变》(英)Strain 1964 英国应变测量学会(British Society for Strain Measurement)《工程设计应变分析杂志》(英)Journal of Strain Analysis for Engineering Design 1965 英国Mechanical EngineeringPublications Ltd.《力学研究》(英)Research Mechanica 1980 英国Applied Science Publishers《计算机与结构》(英)Computers Structures 1971 英国《计算机与流体》(英)Computers Fluid 1971 英国Pergamon Press Ltd. 《水力气体机械动力》(英)Hydraulic Pneumatic Mechanical Power 1955 英国Trade Technical Press Ltd. Ltd.《飞机工程》(英)Aircraft Engineering 1929 英国Bunhill Publications Ltd. 《航空季刊》(英)Aeronautical Quarterly 1949 英国皇家学会(Royal Aeronautical Society)《航空杂志》(英)Aeronautical Journal 1897 英国皇家学会(Royal Aeronautical Society)《星际航行学报》(英)ActaAstronautica 1955 英国1974年改为现名,1955~1973年刊名为Astronautica Acta,Pergamon Press Ltc.《应用数学与力学杂志》(英)Journal of Applied Mathematics Mechanics 1958 英国1974年改为现名,1955~ 1973年刊名为AstronauticaActa,Pergamon Press Ltd《理性力学与分析文献》(联邦德国)Archive for Rational Mechanics and Analysis 1957 联邦德国springer-Verlag《流变学学报》(联邦德国)Rheologica Acta 1958 联邦德国Dr. Dietrich Steinkopff Verlag《流体力学实验》(联邦德国)Experiments in Fluid 1983 联邦德国springer-Verlag《油压力学与气体力学》(联邦德国)Olhydraulik und Pneumatik 1957 联邦德国Krausskopf Verlagsgruppe《数学生物学杂志》(联邦德国)Journal of Mathematical Biology 1974 联邦德国springer-Verlag《热力学与流体力学》(联邦德国)Warme-und Stoffubertragung 1968 联邦德国springer-Verlag《法国流变学小组手册》《通报》(法)Cahiers et Bulletin du Groupe Franais de rheologie 1965 法国《法国科学院会议周报,A-B辑:数理科学》(法)Comptes Rendus Hebdomadaires des Seances deL’Academie des Sciences, Series A et B:”Sciences Mathematiques,Sciences Physiques” 1835 法国Centrale des Revues Dunod Gauthier-Villars《应用力学纪事》(法)Journal de Mecanique Appliquee 1977 法国Centrale des Revues Dunod Gauthier-Villars《力学》(意)Mechanica 1966 意大利Pitagora Editrice《力学学报》(奥地利)Acta Mechanica 1965 奥地利Springer-Verlag《弹性体杂志》(荷)Journal of Elasticity 1971 荷兰artinus Nijhoff Publishers《天体力学》(荷)Celestial Mechanics 1969 荷兰Publishing Co.《工程数学杂志》(荷)Journal of Engineering Mathematics 1966 荷兰Martinus Nijhoff Publishers《材料力学》(荷)Mechanics of Materials 1981 荷兰North-Holland Publishing Co.《澳大利亚地质力学杂志》(澳)The Australian Geomechanics Journal 1971 澳大利亚《加拿大航空与空间杂志》(加)Canadian Aeronautics SpaceJournal 1955 加拿大,1962年改为现名,1955~1961年刊名为:Canadian Aeronautics Journal.《核工程与设计》(瑞士)Nuclear Engineering and Design 1965 瑞士Elsevier Sequoia .《应用数学与力学杂志》(民主德国)ZAMM-Zeitschrift fur Angewandt Mathematikund Mechanik 1921 民主德国Akademic-Verlag《理论与应用力学》(波兰)Mechanika Teoretyczna i Stosowana 1964 波兰PWN《工程汇刊》(波兰)Rozprawy Inzynierskie 1953 波兰PWN《力学文献集》(波兰)Archives of Mechanics 1849 波兰PWN《罗马尼亚技术科学杂志, 应用力学辑》(罗)Revue Roumaine des sciences Techniques,Serie Mecanique Appliquee1956 罗马尼亚科学出版社《应用力学研究》(罗)Studii si Cerctari de Mecanica Applicata 1942 罗马尼亚科学出版社《日本应用力学全国会议录》(日)Proceedings of the Japan National Congress of Applied Mechanics 1953 日本中央科学社《材料》(日)Journal of the Society of Materials Science 1952 日本材料学会《日本机械学会论文集》(日)Transactions of the Japan Society of Mechanical Engineer 1935 日本机械学会《土木协会论文报告集》(日)Proceedings of the Japan Society of Civil Engineers 1944 日本土木工学会《日本造船协会志》(日)Bulletin of the society of Naval Archiects of Japan 1915 日本造船协会《流体工程学》(日)流体工学1965 日本产业开发社(原名:学,1965~)《日本材料强度学会志》日本材料强度学会志1967 日本材料强度学会《力学研究所报告》(日)力学研究所报告1967 日本力学研究所《日本流变学会志》(日)日本一学会志1973 日本流变学会《应用数学与力学》(苏联)1936 苏联《苏联科学院通报:固体力学》(苏)1966 苏联,美国出版有英译本《磁流体力学》(苏)1965 苏联,美国出版有英译本《燃烧与爆炸物理学》(苏)1965 苏联《应用力学与物理学杂志》(苏)1960 苏联,美国出版有英译本《应用力学》(苏)1955 苏联《复合材料力学》(苏)1965 苏联《建筑力学与建筑物计算》(苏)1959 苏联《莫斯科大学力学通报》(美)Moscow University Mechanics Bulletin 1969 美国Allerton Press Inc (译自俄文)《得克萨斯大学巴尔科研究中心年报》(美)Annual Repoet-Balcones Research Center, Texas at Austin 美国《剑桥哲学会数学汇刊》(英)Re Mathematical Proceedings of the Cambridge Philosophical Society 1977 英国Cambridge ,1977年改为现名,1843~1976 年名为Proceedings of Cambridge Philosophical Society;Mathematical Physical Sciences《力学与应用数学季刊》(英)Quarterly Journal of Mechanics and Applied Mathematics 1948 英国《流体力学杂志》(英)Journal of Fluid Mechanics 1956 英国Cambridge 《应用力学研究所报告》(日)Reports of Research Institute for Applied Mathematics 1952 日本九州大学应用力学研究所《东京大学航天研究所报告》ISAS (Institute of Space Aeronautical Science,Univ. Tokyo) 日本东京大学航天研究所《布加勒斯特乔治乌德治工学院通报:力学辑》(罗)Buletinul Institutului Politehnic“Gheorghe Gheorghiu-Dij” 1949 罗马尼亚《列宁格勒大学通报:数学,力学和天文学类》(苏)1946 苏联《莫斯科大学通报:数学力学类》(苏)1946 苏联《国外科技资料馆藏目录━数学,力学》(中国) 中国科学技术情报研究所《力学文摘━流体力学部分》(中国)1958 中国科学技术情报研究所重庆分所翻译,苏联科学院科学情报研究所文摘编辑委员会编辑《力学文摘━一般力学部分》(中国)1958 中国科学技术情报研究所重庆分所翻译,苏联科学院科学情报研究所文摘编辑委员会编辑《力学文摘━弹性力学部分》(中国)1958 中国科学技术情报研究所重庆分所翻译,苏联科学院科学情报研究所文摘编辑委员会编辑《数学文摘》(美)Mathematical Reviewswith Index toMathematical Reviews 1940 美国数学会American Mathematical Society《冲击与振动研究辑要》(美)Shock and Vibration Digest 1969 美国冲击与振动情报中心《流变学通报》(美)Rheology Bulletin 1937 美国物理学会American Institute ofPhysics《应用力学文摘》(美)Applied Mechanics Reviews 1948 美国机械工程师协会American Society of Mechanical Engineers《地震工程文摘杂志》(美)Abstracts Journal in Earthquake Engineering 1968 美国加利福尼亚大学伯克利分校地震工程研究中心Univ. of California, Berkeley, Earthquake Engineering Research Center《工程索引》(美)Engineering Index (Annual) 1884 美国Engineering Index Inc.《美国土木工程师学会汇刊》(美)Transactions of the American Society of Civil百度文库- 好好学习,天天向上Engineering 1852 美国土木工程师学会American Society of Civil Engineering 《科学引文索引》(美)Science Citation Index 1961 美国科学情报研究所Institute of Scientific Information《土木工程水利文摘》(英)Civil Engineering HydraulicsAbstracts 1968 英国流体力学研究协会British Hydromechanics Research Association《流变学文摘》(英)Rheology Abstracts 1940 英国Pergamon Press 《固体-液体流文摘》(英)Solid-Liquid FlowAbstracts 1973 英国流体力学研究协会British HydromechanicsResearch Association《工业空气动力学文摘》(英)Industrial Aerodynamics Abstracts 1970 英国流体力学研究协会British Hydromechanics《流体动力学文摘》(英)Fluid Power Abstracts 1965 英国流体力学研究协会Hydromechanics Research Association《英国土木工程师协会文摘》(英)ICE Abstracts 1972 英国流体力学研究协会,1974 年改为现名(The Institution of Civil Engineers)《法国全国科学研究中心文摘通报,第130辑:数学,物理,光学,声学,力学,热学》(法)Bulletin Signaletique du 130 hysique Mathematique, Optique, Acoustique, Mecanique, Chaleur 1961 法国全国科学研究中心《科学技术文献速报:机械工学编》(日)Currdnt Bibliography on Science Technology 1975 日本科学技术情报中心(日本科学技术情报)《文摘杂志:力学(综合本)》(苏)1953 苏联全苏科学技术情报研究所《力学与实践》(中国)1979 《力学与实践》编辑委员会《美国物理学杂志》(美)American Journal of Physics 1933 美国物理学会American Institute-11。

物理文献及其查阅方法倪致祥主讲一、查阅物理文献的意义科学的发展是连续的,有一个积累的过程。

我们学习的所有知识都是前人的成果,任何一项创造发明都是在前人基础上取得的,牛顿曾经说过,“如果我比笛卡儿看的远些,那是因为我站在巨人们的肩上的缘故”。

因此,查阅文献对于正在学习物理课程的大学生来说是一种必不可少的基本能力。

一般来说,学会查阅物理文献具有下列重要意义:1、帮助学习:我们所学习的课本内容是前人科学研究的成果,也是后人教学研究的对象。

文献中有许多关于课本知识的背景内容和专题研讨的资料,通过对资料的检索和学习,可以帮助我们更好地掌握书本内容。

2、拓宽知识:课本的容量是非常有限的,狭窄的专业化教育已经不能适应这个知识爆炸的时代。

主动提高自己的学习能力,树立终身学习的观念,是新时代对现代人的要求。

利用图书馆和计算机网络来进行信息检索,是我们及时更新知识、拓宽知识面的有效手段。

3、促进创新:任何人从事某一特定领域的学术活动,或开始做一项新的科研工作,往往先要花费大量的时间对有关文献进行全面的调查研究,摸清是否已经有人在做同样的工作,取得一些什么成果,存在什么问题,以避免重复劳动。

只有知新,才能够创新。

另一方面,许多文献中的内容都是前人的创造性成果,通过对文献的查阅,可以学习和了解创新的思想和方法,活跃自己的思维,激发灵感。

二、物理文献的分类1、按性质分类物理文献按性质可分为一次文献、二次文献和三次文献。

一次文献指原始文献。

期刊论文多数是未经重新组织的原始文献,即一次文献。

特别是专业期刊的出版周期短、刊载速度快,能够及时地反映科学技术的新成果和新进展,是一次文献的主要来源。

科技报告、学位论文、会议资料及专利说明书等,也是一次文献的重要来源。

二次文献指书目、索引、文摘等检索工具。

是将分散的无组织的原始资料经过加工整理、简化、组织等工作,如著录文献特征、摘录内容要点,使之系统化,以便查找与利用。

二次文献的重要性在于它可以作为查找一次文献的线索。

探索物理学的前沿学术期刊物理学是自然科学中的重要分支,它通过研究物质和能量的性质以及它们之间的相互作用,揭示了宇宙的奥秘。

而学术期刊则是学术界交流和分享研究成果的重要平台。

在物理学领域,探索前沿学术期刊是科学家追求学术进步的重要途径之一。

本文将探索物理学的前沿学术期刊,旨在介绍几个顶尖学术期刊,以及为什么它们在物理学界备受推崇。

一、Nature PhysicsNature Physics(自然物理学)是一份由自然出版集团(Nature Publishing Group)出版的月刊。

作为一个跨学科期刊,Nature Physics 专注于物理学的基础和前沿研究。

它涵盖了从基础物理学到交叉学科领域的广泛范围,包括凝聚态物理学、理论物理学、光学与光子学等等。

Nature Physics以其高质量的研究论文和独特的观点文章而闻名,这些文章不仅具有深度,而且具有广泛的影响力。

二、Physical Review LettersPhysical Review Letters(物理评论快报)是由美国物理学会(American Physical Society)出版的一份拥有世界领先地位的物理学期刊。

它以其及时、具有突破性的研究成果而获得了极高的声誉。

Physical Review Letters在各个领域的物理学研究中都有影响力,而且经常发布一些重要的突破性发现。

物理评论快报以其严谨的评审流程和学术标准而闻名,为物理学家们提供了一个展示和分享研究成果的重要平台。

三、ScienceScience(科学)是一份由美国科学促进会(AAAS)出版的杂志,它是一个跨学科的综合性科学期刊,涵盖了自然科学、生命科学、医学、工程学、计算机科学等领域。

尽管Science并不是一个专注于物理学的期刊,但它经常刊登一些物理学的顶尖研究成果,以及涉及物理学交叉学科的重要文章。

Science的影响因子非常高,被认为是科学界的顶级期刊之一。

物理与光电工程学院研究培养方案大连理工大学2012年6月目录物理学一级学科培养方案 (3)博士研究生 (3)学术型硕士研究生 (13)光学工程一级学培养方案 (31)博士研究生 (31)学术型硕士研究生 (15)全日制专业学位硕士 (37)电子科学与技术一级学科培养方案 (44)博士研究生 (49)学术型硕士研究生 (49)大连理工大学博士研究生培养方案物理学一级学科(一级学科(专业)代码:0702授予理学博士学位)一、培养目标本学科专业培养能够从事理论物理学、等离子体物理学、凝聚态物理学、光学,原子分子物理,生物物理学、神经信息学方面的教学、科研及管理工作的高层次人才。

学位获得者应具备坚实的物理理论基础和系统深入的专门知识;能熟练地运用一门外语进行专业学术交流;具备严谨的治学态度和刻苦钻研精神;具备独立从事科学研究工作的能力,并能够在科学或专门技术上取得创造性的成果。

二、学科群、专业及研究方向简介本学科点包括国家重点学科:等离子体物理;辽宁省重点学科:理论物理,等离子体物理。

2003年获得物理学一级学科博士学位授予权,设有物理学一级学科博士后流动站;•等离子体物理1998年获得博士授予权, 2001年被评为“国家重点学科”,2007年再次被评为国家重点学科;理论物理1986年获得硕士授予权,2000年获得博士授予权,2008年获批辽宁省重点建设学科。

本学科群依托教育部三束材料改性重点实验室和辽宁省先进光电技术重点实验室,设有理论物理研究所等十余个研究机构,拥有先进大型研究设备近百台(套),在“十一五”期间,共承担了各类课题100余项,包括国家自然科学基金重点项目,面上项目,青年基金项目,国际重大合作项目;“973”重点基础研究计划(课题)、国家重大研究计划ITER专项(课题),02专项(课题),“863”科技攻关项目;国防项目及预研项目;教育部骨干教师和博士点基金项目;辽宁省自然科学基金项目以及企业委托项目。

I NSTITUTE OF P HYSICS P UBLISHING M EASUREMENT S CIENCE AND T ECHNOLOGY Meas.Sci.Technol.15(2004)451–459PII:S0957-0233(04)69214-9Calibrated measurement of the behaviour of mechanical junctions from micrometre to subnanometre scale:the friction force scannerDaniel Sidobre1and Vincent Hayward2,31Laboratoire d’Analyse et d’Architecture des Syst`e mes,7avenue du Colonel Roche,31077Toulouse,France2Centre for Intelligent Machines,3480University Street,McGill University,Montreal,H3A2A7,CanadaE-mail:daniel.sidobre@laas.fr and hayward@cim.mcgill.caReceived16September2003,infinal form20November2003,accepted forpublication8December2003Published20January2004Online at /MST/15/451(DOI: 10.1088/0957-0233/15/2/020)AbstractWe describe an instrument called a friction force scanner(FFS)able toperform calibrated measurements of the behaviour of mechanical junctionswith more than four orders of magnitude of resolution for both displacementand force.A probe carrier is suspended byfibres in an arrangement thatprovides exactly two degrees of freedom of motion.The suspension makesit possible to measure the carrier displacement by interferometry.A noveldifferential electrostatic actuator with linear response mounted on the carrierwas used to precisely determine the force experienced by a junction.Thesingle-stage design is easily calibrated and can be used for forcemeasurement and scanning,allowing the study of friction at multiple lengthscales.Measurements involving mica–mica and steel–steel junctions arereported while using the instrument in open loop.Keywords:friction force instruments,atomic force microscopy,atomic scalefriction,electrostatic actuators,fibre suspensions1.IntroductionThe mechanisms that form the basis of friction remain largely unexplained.Several models have been proposed in the recent years,appealing notably to phenomena involving phonons[1],‘third bodies’[2],and recently fracture creation and healing[3].This provides motivation for developing instruments capable of detailed measurements of the behaviour of mechanical junctions.Such instruments are also useful for applications in tribology and otherfields[4–6].Common designs are related to atomic force microscopy [7,8],whereby the behaviour of a junction is observed by measuring the deformations of aflexible cantilevered probe interacting with a sample.Recently,an instrument was 3Author to whom any correspondence should be addressed.designed to investigate the behaviour of junctions using a probe and a sample,each supported by leaf springs arranged orthogonally[9].Another instrument is the interfacial force microscope that uses electrostatically driven feedback to create rigid displacement[10].Magnetically activated probe designs that can boost sensitivity and decoupling of normal and tangential measurements have also been described[11].Most instruments balance the net force experienced at a junction by strain forces resulting from the deformation offlexures. Measurement of displacement[12],together with calibration of theflexural response,makes it then possible to evaluate the net force at the junction.In this paper,we describe an instrument called the friction force scanner(FFS)which uses electrostatic energy instead of strain energy.It has a single stage and yet achieves a0957-0233/04/020451+09$30.00©2004IOP Publishing Ltd Printed in the UK451D Sidobre and V Haywardvery large range.The probe interacting with the sample ismounted on a carrier supported by afibre suspension which has several advantages over previous designs.The suspension provides nearly perfect kinematic guidance in order to reduce the number of degrees of freedom to exactly two,simplifying modelling and calibration.The precise guidance makes it possible to detect the probe movements by interferometry. It also has a displacement range sufficient to permit the same stage to be used for interaction force measurement and scanning at multiple scales,hence taking advantage of the range of the interferometer.By design,the tunable suspension compliance is linear over the operating range,and parasitic terms due to mechanical hysteresis and gravity are eliminated. The suspended probe carrier has two electrostatic comb actuators acting in the normal and the tangential directions.A novel linearized differential electrostatic actuator provides calibrated force measurement over the entire operating range.The instrument was operated in the quasi-static range. Without controlling environmental factors other than taking ordinary precautions,it achieved better than2×10−7N of force resolution in a±2×10−4N range.Position was measured by a commercially available interferometer (precision optical displacement sensor or PODS from MPB Technologies Inc.,Montreal)that gives0.1nm of tangential displacement resolution[13].The movement range was larger than1µm;thus we could investigate the behaviour of mechanical junctions over four orders of magnitude for force and displacement simultaneously.2.Instrument design2.1.SuspensionSuspensions can be realized with leaves or withfibres.Leaves are often used in pairs to create the approximation of a sliding joint.However,the compliance of a suspension based on leafs in a desired direction depends on stiffness in the other directions,so design tradeoffs are introduced.In addition, compliance varies with deflection due to the bending shape mode,complicating calibration.The suspension must provide two directions of movement corresponding to the normal and tangential relative displacements of two samples.Therefore it must create four constraints,one in translation and three in rotation.Fibres seem unsuitable atfirst sight because they cannot be used to create these constraints simultaneously.To see that,consider that a singlefibre defines a translational constraint at one point.Severalfibres parallel to one another also create one translational constraint but two rotational constraints as well.Two differentfibre directions are required to constrain three rotations;therefore the problem has no solution. It is nevertheless possible to achieve an arbitrarily close approximation.Referring tofigure1(a),a carrier holding a probe is suspended with three parallelfibres to constrain it to planar motions.A fourth orthogonally crossingfibre defines a centre of rotation.This approximates two translational freedoms at the tip.It is the tension of thefibres which determines the suspension compliance.Section2.3further describes the mechanism which was implemented to provide for tunable tension and for a linear compliant behaviour over a wide range of suspensiondeflections.(b)Figure2.There is a balanced unipolar actuator acting in the normal direction,and a differential bipolar actuator in the lateral direction. The precise guidance allows the use of inteferometry to measure lateral displacements.Precise guidance allowed us to use interferometry directly since a mirror attached to the carrier has a nearlyfixed orientation.The geometry of the realized carrier is shown infigure1(b).With30mm between the probe and the rotation centre,the displacement error in the normal direction is about 0.0167nm for a tangential movement of1µm.A stiffness of20N m−1(typical tuning)yields a normal force error of 0.33×10−9N.By design,the inertial coefficients are close in the normal and tangential directions(about10−3kg).Figure2shows schematically the elements of the system seen from the back.In the normal direction z,a unipolar actuator is divided into two sections in order to provide a normal force component coinciding with the tip.They are represented side by side in thefigure for clarity,but452Friction force scannera(a)(b)Figure3.(a)Unipolar comb actuator.(b)Differential bipolar comb actuator.in the constructed instrument,the two sections are stacked vertically.In the tangential direction x,the force is given by a bipolar differential actuator.The adjustable tension in each fibre allows for tunable compliance.The tension in the two frontfibres is equalized by a rocker mechanism,eliminating spurious torque.The geometry of the carrier(figure1(b))and of the capacitors was so designed that its centre of mass,the point where the electrostatic forces act,as well as the point where the elastic forces act,all coincide with the location of the junction under test,eliminating all static and dynamic couplings.Thus, denoting the tangential displacement by x and the normal displacement by z,the dynamics of the system is well described by two decoupled second order differential equations involving forces acting at the junction:F t=m t¨x−a t−k t x−b t˙x,F n=m n¨z−a n−k n z−b n˙z.(1)F t and F n are the measured tangential and normal components of the force experienced by the junction,m t¨x and m n¨z are decoupled inertial terms,a t and a n are independently specified by the actuators,k t x and k n z are two known forces due to the compliance of the suspension,and b t˙x and b n˙z are viscous damping terms.2.2.Electrostatic comb actuatorsComb actuators generally produce a force which is quadratically related to the voltage applied.This complicates device calibration because the incremental change of force depends on the operating point.Consider a unipolar actuator as infigure3(a),with a guided moving armature(1)meshing with afixed armature(2). Given the electric potentials v1and v2of the armatures,the electrostatic energy isE=12(c11v21+c22v22+2c12v1v2),(2) where the c i j represent capacities.Ignoring the boundary effects,the capacity of any one pair of armatures is 0 r l n z0/a, where 0is the permittivity of vacuum, r the relative permittivity of air,l n and z0represent the length and width of the armatures’opposing surfaces,and a the gap between them.Calling z the displacement of the moving armatures,N n the number of gaps and posing c n=(N n 0 r l n)/a givesc11=c22=c12=c n(z0+z).(3)The actuator force is∂E/∂z=12c n(v21+v22+2v1v2).Here,v1is assigned to afixed voltage,and v2is assigned to an input control voltage v n,so that the normal force produced by the actuator isa n=c n(12v21+12v2n+v1v n).(4)Position adjust screwDirection of gravityspringTension adjust screw Figure4.Deformation and loading of suspensionfibre.In the tangential direction,a novel bipolar differential electrostatic actuator was used to linearize the response and simplify calibration(seefigure3(b)).It has a guided moving armature(1)and twofixed armatures(2)and(3).Given the three voltages v1,v2,v3,the electrostatic energy isE=12(c11v21+c22v22+c33v23+2c12v1v2+2c13v1v3+2c23v2v3).(5) Posing c t=(N t 0 r l t)/a to reflect the geometry of the actuator, given the displacement x,c11=2c t x0,c22=c12=c t(x0−x),c33=c13=c t(x0+x),c23≈0.(6)The actuator force is∂E/∂x=12c t(−v22+v23−2v1v2+2v1v3). Controlling the voltages so that v2and v3are opposites of each other,assigning them to a control voltage such that v3=v t and v2=−v t,andfixing v1,yields an actuator force equal toa t=2c t v1v t.(7)Thus,the force produced is proportional to v t.The voltage v1 may also be used to adjust the actuator constant.2.3.Elastic forcesFigure4shows the principle of the positioning and tensioning mechanism.Thefibres are attached at one end to a positioning mechanism and at the other to an adjustable leaf spring that allows the tension to be set independently.The elastic forces due to carrier deflection result from the deformation of the tensioning leaf springs,from thefibre deformation,and from the suspended mass subject to gravity.It can be shown that the force arising fromfibre deformation is orders of magnitude smaller than that arising from the other terms,and hence can be neglected.The tensions in the two frontfibres are equal because they are on the same load path created by the rocker mechanism(figure2).For small angles,the stiffness of the suspension in the tangential direction is k t=(4T t−mg)/l0, where T t is the tension in thefibres,mg the weight of the carrier that they support,and l0their half length.In the normal direction,the stiffness of the crossed backfibres having tension T n adds to that of the frontfibres,but almost no mass is supported,so k n=k t+4T n/l0.The stiffnesses can be independently set by adjusting T n and T t,according to the application.For most tunings,the suspension design achieves a compliance ratio of at least1000between the free and the constrained directions.Leaf springs have a stiffness which depends on deflection. The arrangement has the effect of decoupling the compliance of the leaves from the displacements of the carrier.Call d the leaf deflection needed to create a tension T,and d453D Sidobre and VHayward(a)(b)Figure5.(a)View of instrument with microscope,the viewing mirror,and the sample moved back.The probing tip inside the carrier’s cavity can be viewed with the microscope to monitor the contact between the sample and the probe.The two front glassfibres may be seen but are partially hidden by the locking mechanism used for transport and tip mounting.(b)At the back of the frame,the two crossingfibres constrain the carrier stem.The electrical groundingfilament can also be seen.time (s)x(nm)time (s)101112x(nm)frequency (Hz)–100102030405060–551077.27.47.67.820040060080010001005152025(a)(b)(c)Figure6.(a)Measurement made with the junction at rest.(b)Enlarged view of the signal from time10to12s.(c)Power spectrum below 25Hz.the incremental leaf deflection due to carrier displacement:T=k leaf(d+ d)(d+ d).By geometry, d is of the sameorder as x or z.If the leaf is selected so that d d,then Tis nearly constant,and so is the suspension compliance.2.4.CalibrationFrom the mass of the moving part and from its displacement,the stiffnesses were found by measuring the natural frequenciesin the tangential and normal directions.For the particulartuning used in section3,the measured natural frequencies were7.008and11.05Hz corresponding to3.5and8.7N m−1in thetangential and normal directions,respectively.The actuatorswere then calibrated.The result of calibration for the tangentialbipolar actuator was a t=1.30×10−6v t.The coefficient of theunipolar actuator acting in the normal direction could be knownonly approximatively.The maximum tangential force was±0.2mN.Forces could be modulated asfinely as permitted bythe driving voltages.This is limited in the present realizationby the resolution of the16-bit digital-to-analogue convertersused in the prototype.454Friction force scannertime (s)x (n m )12100200300400time (s)x (n m )150152154156158 1.831.8351.841.8451.85(a)(b)Figure 7.Mica–mica junction.(a)Response to a periodic tangential force over a period of about two seconds.(b)Same data,but zoomed-in by a factor of two orders of magnitude from time 1.83to 1.85s (raw measurements).time (s)F t (m N )x (nm)50100150200x (nm)F t (m N )–0.1–0.050.050.1–0.1–0.050.050.100.10.20.30.40.5050100150200(a)(b)Figure 8.(a)Time domain recording of large scale hysteresis for one normal force (dashed curve:tangential force;solid curve:tangential displacement).(b)Four loops as displacement–force phase plots with the same tangential force but different normal forces.F c =50Hz.2.5.ConstructionThe device was composed of an aluminium frame supporting the fibre tensioning mechanisms and the fixed actuator armatures (figure 5(a)).Much care was exercised to minimize hysteresis by careful fibre attachment design and by using long glass fibres (0.13mm diameter)that underwent very little strain.The sample was supported by micrometric translation and rotary stages for accurate positioning.Electrical connection to the moving carriage was provided by a tungsten incandescent lamp filament attached near the centre of rotation to minimize its movement and hence the perturbations it might introduce (figure 5(b)).Actuator voltages v n ,v t ,and −v t were set by three precision high voltage operational amplifiers driving the actuators via low-pass passive filters (±200V ,1kHz cut-off).These amplifiers were driven by 16-bit analogue-to-digital converters.The armature voltages were also converted with 16-bit resolution via precision resistor bridges.It is these voltages that were used to measure the force supplied by the actuators,once they were calibrated.2.6.ScalingSince future versions of similar instruments could be greatly miniaturized,it is interesting to examine the factors that affect the measurement range as a function of scale.Recall that theinstrument obeys two decoupled equations of the formF =m ¨x −a −kx −b ˙x ,(8)where the force F is the quantity to be measured,andwhere the other terms are known from calibrated quantities and displacement measurements.The instrument can be operated in three modes defined by the natural frequency f 0=1/2π√k /m .In the quasi-static mode I below f 0,the elastic term kx in equation (8)dominates.Therefore,the force supplied by the actuators must balance both the force to be measured and the elastic force due to deflection.In the resonant mode II atf 0,the elastic term kx and the inertial term m ¨xcancel each other.The sensitivity is only a function of damping which is very low:the force supplied by the actuators equates almost exactly to the force to be measured.In the third mode III abovef 0,the inertial term m ¨xdominates,rising quadratically with the operating frequency.Mode III is useful for measurements at high velocity or with tunings with high compliance.Thus,any instrument of this kind is governed by design tradeoffs which are different in each mode.In mode I,the maximum scanning distance x M ,the suspension stiffness k ,and the actuator saturation a M are related through x M =ka M ,an expression that defines the basic operational range.In mode III,the tradeoff involves scanning distance,inertia,and actuator saturation.For a455D Sidobre and V Haywardtime (s)V t (V)x (nm)X (nm)F t (m N )X (nm)F t (m N )X (nm)F t (m N )(a)(b)(c)(d)Figure 9.Small scale hysteretic behaviour test of a steel junction.(a)Tangential voltage (dashed curve)and corresponding displacement (solid curve).(b)Major hysteresis loop (18nm),(c)minor loop (2nm),(d)second order minor loop (70pm).F c =8.3Hz.Table 1.Maximum values of static and dynamic terms for each measurement example.In all cases,the inertial term isoverestimated since these values were computed by finite difference from the unfiltered displacement signal.The same holds for the damping term.In addition,the value used for b was estimated from the free response at large velocities.This value is probably much lower during measurements.Max a t Max [kx ]Max [b ˙x ]Max [m ¨x ]Figures (N)(N)(N)(N)5(a)2.2×10−57.1×10−71.8×10−79.5×10−65(b)a 2.0×10−62.5×10−70.7×10−72.0×10−66(b)1.3×10−43.3×10−71.2×10−77.5×10−87(b)2.8×10−51.7×10−87.0×10−101.0×10−97(c)6.0×10−61.0×10−85.0×10−101.0×10−97(d)3.4×10−67.3×10−93.5×10−101.0×10−97(d)b0.7×10−61.0×10−98.0×10−101.0×10−98(a)and (b)c 1.2×10−51.1×10−50.8×10−51.4×10−58(c)and (d)d 2.2×10−62.1×10−60.5×10−60.1×10−69(a)4.5×10−52.9×10−60.7×10−63.7×10−89(b)and (c)4.5×10−50.5×10−64.0×10−82.5×10−9a Rough estimate of the actuator force.bIndicates difference between maximum and minimum values in the minor loop.cAt large displacement,almost all the actuator force is used to balance the elastic term.dFigure compensated for the elastic term.maximum scanning distance x M ,the upper frequency limit is 1/2π√a M /(mx M ).These factors vary as a function of the scale defined by a characteristic length l .The meso-scale instrument presently constructed is such that l ∼10−2m,m ∼10−3kg,b ∼10−1N s m −1(in air),a M ∼10−4N,x M ∼10−5m,and k ∼10N m −1;thus,f 0∼10Hz.We now can estimate the performance of a system that would be scaled down,say by two orders of magnitude to the level of a MEMS device (l ∼10−4m).The moving mass would vary as l 3.At a smaller scale,the suspension fibres would be replaced by beams.Unlike the meso-scale device reported here in which stiffness can be tuned,the stiffness would then be dominated by beam deflection which would decrease linearly with l .So the resonance frequency would scale as √k /m ∝ l /l 3=1/l .A micro-scale device could be predicted to resonate at 1kHz.The actuator meshing length would decrease with l but the gap distance would decrease with l too,so these two factors cancel each other.Based on the Paschen law and on data reported for MEMS devices [14,15],the maximum voltage could be invariant with scale,so the maximum actuator force would also be invariant.In mode I,the maximum scanning distance would scale with l .For a MEMS scale device,this would give x M ∼10−7m.In mode III,for the same scanning distance,the frequency limitdue to actuator saturation would vary as √a M /(mx M )∝l −2.For a MEMS scale device this would give a maximum frequency of 100kHz.3.Measurements examplesThe system was placed in an enclosed 2ton optical table pneumatically isolated from the ground and protected with a heavy hood from acoustic vibrations.An additional elastic456Friction force scannertime (s)V n (V)x (in 1000 nm)time (s)V n (V )x (nm)time (s)V n (V )x (in 1000 nm)time (s)F t (m N )–110–100–90–802468101214–4–3–2–10123–106–104–102–10024681012–600–400–20002004006.577.58–0.002–0.0010.0010.002024681012(a)(b)(c)(d)Figure 10.(a)and (b)Effect of normal force for displacements at two length scales.(c)Enlargement of (a)when the normal force becomes large.(d)The tangential friction force drops to a small value when the tangential displacement is the largest in (b).F c =8.3Hz.suspension made of six 1m latex hoses was used to further reduce the noise level.The additional suspension had a resonance at 2Hz and its free oscillations decayed in 2s.After a stabilization period,measurements were then made with the carriage freely suspended.There were at least three sources of noise:mechanical vibration and sound,the interferometer intrinsic noise and thermal drift.A very low damping coefficient of 0.05N s m −1could be estimated.To evaluate the noise floor,displacement recordings were made with the junction at rest (figure 6).The interferometer noise was in the range 0.1–0.2nm with a component probably due to thermal drift,because the thermal expansion term of the supporting structure was of the order of 1.6nm /thousandth of degree centigrade.These tests indicated that indeed details at subnanometre scale can be measured.In the measurements reported below,the force and displacement signals were frequency-limited by transforming them in the Fourier domain,truncating the spectrum below a given frequency F c ,and then reconstructing the time-domain signal (thus preserving the phase information).The cutoff frequency is indicated in the captions of the experimental figures.Measurements were made for two cylindrical mica surfaces contacting orthogonally and for a sharp steel point interacting with a polished flat steel surface.Friction forces were measured for displacements in the range of 0.1–10000nm for various kinds of force trajectories.The measurements where all made in mode I.For each example,table 1collects the relative importance of the static anddynamic terms.In most cases,displacements,velocities,and accelerations were sufficiently low to identify the actuator force with the force experienced at the junction.A selection of results,here briefly discussed,show a variety of effects and phenomena.3.1.Mica on mica sticking and sliding frictionSamples were made of sheets of mica each bonded to two steel half cylinders of 1.0mm radius.They were touching at a right angle.A sinusoidal signal of period 2.5s was applied tangentially.The resulting displacement is shown in figure 7(a)measured at a rate of 35000samples s −1.After a sliding initial transient until time 1.0s,the contact comes to rest while oscillating with period 0.2s until time 1.75s,probably because of the compliance in the contact.It then breaks away to come to rest again with a similar oscillatory behaviour.Zooming-in inside a portion of the sliding motion reveals very small oscillations with an amplitude of about one nanometre (figure 7(b)).rge scale hysteresis as a function of normal force Figure 8shows four force–displacement hysteresis loops obtained with the same periodic tangential force applied to the mica–mica junction,but with four different normal forces.Figure 8(a)show one such measurement in the time domain.Figure 8(b)shows the four phase diagrams of friction force457D Sidobre and V Haywardtime (s)x (n m )time (s)x (n m )time (s)x (n m )200400600800010203040506050100272829305010015037383940(a)(b)(c)Figure 11.(a)The steel junction experiences a periodic tangential force.While the displacement extrema are normally smooth,for example (b)from time 27to 30s,the last extremum (c)before junction failure leading to slipping is extremely active during time 37to 30s (raw measurements).versus ck of calibration prevented us from knowing exactly the magnitude of the normal force component.3.3.Hysteresis at various scalesFigure 9(a)shows a tangential force trajectory composed of three sinusoidal arcs of decreasing amplitude,each a tenth the size of the previous one.This was used to examine the hysteretic behaviour of the same junction at three length scales,creating three loops each one-tenth the size of the previous.The same data are shown in figures 9(b)–(d)as phase diagrams.A sharp increase in junction stiffness would typically be observed for hysteresis loops at subnanometre scale,as seen in smallest minor hysteresis loop in figure 9(d).3.4.Effect of the normal forceThe influence of the normal force on junction behaviour is shown in figures 10(a)and (b)for displacements at two different scales.A sharp steel point interacted with a polished steel flat surface with a sinusoidal tangential actuator force.The dashed lines represent the voltage applied to the normal actuator.We could not know the force magnitude for lack of calibration,but the actuator response was linearized while operating around 100V .This indicates an inverse relationship between the normal force and the tangential displacement.Many details are contained in figure 10(a)with large tangential displacements of up to ±4µm.One of them is shown in figure 10(c)where the tangential displacement becomes very small.Figure 10(b)shows a similar experiment,but at a smaller length scale with displacements of about ±0.5µm.Figure 10(d)shows how the tangential force vanishes when the contact is broken.In plotting the tangential force,the elastic term was not neglected since the displacement is large (see table 1).3.5.Transition to slidingFigure 11(a)shows the same junction experiencing a sinusoidal tangential force of period 10s.The bond progressively fails before a transition from sticking to sliding.Signs of failure slowly gain amplitude in the cycles prior to a transition to sliding at time 48s,as seen in figures 11(b)and (c),for times 27–30and 37–40s respectively.After failure at time 48s,the junction slips by 600nm and then slips back to ‘bond’again exactly at the location of failure.The tangential displacement had a varying amplitude although the force experienced by the junction was periodic.4.DiscussionThe FFS is distinct from previous designs in several aspects.Electrostatic forces are used instead of bending stresses to balance the force experienced by a junction.The probe is mounted on a carrier suspended by fibres arranged to constrain its movement to two degrees of translational freedom with a high degree of decoupling and linearity of the compliant behaviour.A quasi-ideal kinematic guidance,a new electrostatic actuator responding linearly to voltage,and the use of interferometry yield a large range of calibrated458。