数字集成电路:电路系统与设计(第二版) (8)

- 格式:pdf

- 大小:736.64 KB

- 文档页数:43

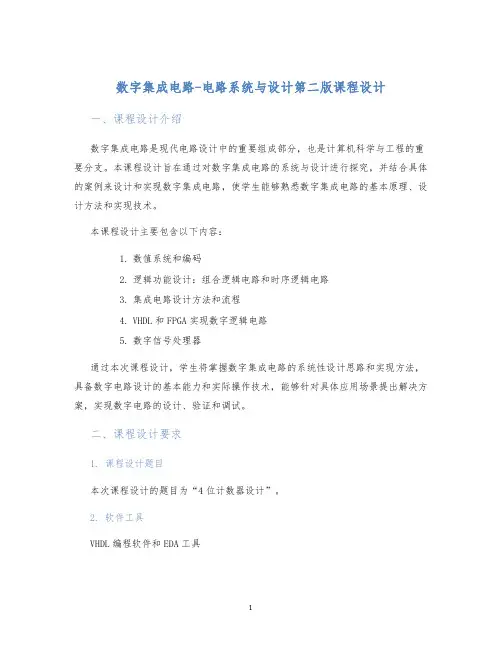

数字集成电路-电路系统与设计第二版课程设计

一、课程设计介绍

数字集成电路是现代电路设计中的重要组成部分,也是计算机科学与工程的重要分支。

本课程设计旨在通过对数字集成电路的系统与设计进行探究,并结合具体的案例来设计和实现数字集成电路,使学生能够熟悉数字集成电路的基本原理、设计方法和实现技术。

本课程设计主要包含以下内容:

1.数值系统和编码

2.逻辑功能设计:组合逻辑电路和时序逻辑电路

3.集成电路设计方法和流程

4.VHDL和FPGA实现数字逻辑电路

5.数字信号处理器

通过本次课程设计,学生将掌握数字集成电路的系统性设计思路和实现方法,具备数字电路设计的基本能力和实际操作技术,能够针对具体应用场景提出解决方案,实现数字电路的设计、验证和调试。

二、课程设计要求

1. 课程设计题目

本次课程设计的题目为“4位计数器设计”。

2. 软件工具

VHDL编程软件和EDA工具

1。

![[精品]数字集成电路分析与设计教学大纲.doc](https://uimg.taocdn.com/14361b0afab069dc5122014d.webp)

数字集成电路分析与设计一、课程基本情况课程编号40260103开课单位微纳电子学系课程名称中文名称数字集成电路分析与设计英文名称Digital Integrated Circuit Analysis and Design教学目的与重点教学目的:1)让学生掌握数字集成电路的工作原理与分析方法2)让学生掌握数字集成电路与系统的设计流程和基本方法3)培养学生实际设计数字集成电路与系统的能力教学重点:1) CMOS反相器的特性,数字集成电路分析与设计的关键问题2)组合逻辑链的性能优化3)互连线的延时模型与分析4)同步时序电路的分析和设计5)数据通路运算单元的分析与设计6)存储器的工作原理的理解与分析课程负责人刘雷波吴行军课程类型□文化素质课□公共基础课□学科基础课□专业基础课■专业课□其它教学方式■讲授为主□实验/实践为主□专题讨论为主□案例教学为主□自学为主□其它授课语言■中文口中文+英文(英文授课>50%)□英文□其他外语学分学时学分 3 总学时48考核方式及成绩评定标准作业:15%,课程设计:15%,期中考试(闭卷):30%,期末考试(闭卷):40%教材及主要参考书中文外文教材数字集成电路一电路、系统与设计(第二版),JanM.Rabaey等著,周润德等译,电子工业出版社。

Jan M. Rabaey etc. “Digital Integrated Circuits , A Design Perspective (Second Edition)", Prentice Hall , 2003.主要参考书CMOS数字集成电路一分析与设计(第3版),Sung-Mo Kang等著,王志功等译,清华大学出版社(影Sung-Mo Kang, Yusuf Leblebici,"CMOS Digital IntegratedCircuits-Analysis and Design(ThirdEdition)".三、课程主要教学内容9.4高级互连技术9. 5综述9.6总结第10章存储器(6学时)(教材第12章)10.1分类10.2结构10.3内核--- 存储单元和阵列10.4外围电路10.5可靠性10.6总结。

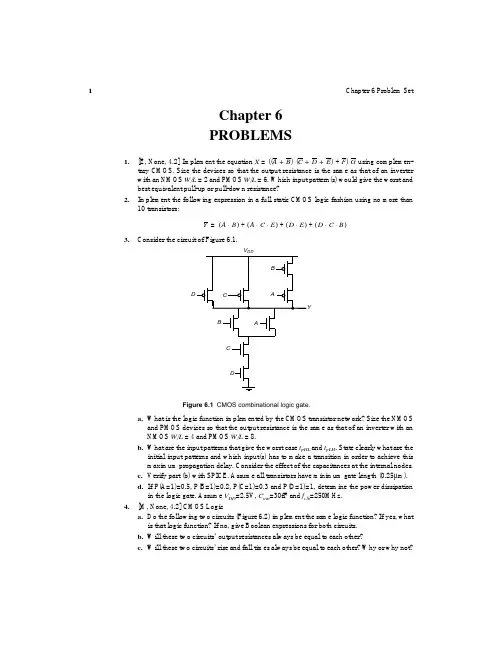

数字集成电路--电路、系统与设计(第⼆版)课后练习题第六.Digital Integrated Circuits - 2nd Ed 11 DESIGN PROJECT Design, lay out, and simulate a CMOS four-input XOR gate in the standard 0.25 micron CMOS process. You can choose any logic circuit style, and you are free to choose how many stages of logic to use: you could use one large logic gate or a combination of smaller logic gates. The supply voltage is set at 2.5 V! Your circuit must drive an external 20 fF load in addition to whatever internal parasitics are present in your circuit. The primary design objective is to minimize the propagation delay of the worst-case transition for your circuit. The secondary objective is to minimize the area of the layout. At the very worst, your design must have a propagation delay of no more than 0.5 ns and occupy an area of no more than 500 square microns, but the faster and smaller your circuit, the better. Be aware that, when using dynamic logic, the precharge time should be made part of the delay. The design will be graded on themagnitude of A × tp2, the product of the area of your design and the square of the delay for the worst-case transition.。

数字集成电路是现代电子产品中不可或缺的一部分,它们广泛应用于计算机、手机、汽车、医疗设备等领域。

数字集成电路通过在芯片上集成大量的数字电子元件,实现了电子系统的高度集成和高速运算。

本文将从电路、系统与设计三个方面探讨数字集成电路的相关内容。

一、数字集成电路的电路结构数字集成电路的电路结构主要包括逻辑门、寄存器、计数器等基本元件。

其中,逻辑门是数字集成电路中最基本的构建元件,包括与门、或门、非门等,通过逻辑门的组合可以实现各种复杂的逻辑功能。

寄存器是用于存储数据的元件,通常由触发器构成;而计数器则可以实现计数和计时功能。

这些基本的电路结构构成了数字集成电路的基础,为实现各种数字系统提供了必要的支持。

二、数字集成电路与数字系统数字集成电路是数字系统的核心组成部分,数字系统是以数字信号为处理对象的系统。

数字系统通常包括输入输出接口、控制单元、运算器、存储器等部分,数字集成电路在其中充当着处理和控制信号的角色。

数字系统的设计需要充分考虑数字集成电路的特性,包括时序和逻辑的正确性、面积和功耗的优化等方面。

数字集成电路的发展也推动了数字系统的不断完善和创新,使得数字系统在各个领域得到了广泛的应用。

三、数字集成电路的设计方法数字集成电路的设计过程通常包括需求分析、总体设计、逻辑设计、电路设计、物理设计等阶段。

需求分析阶段需要充分了解数字系统的功能需求,并将其转化为具体的电路规格。

总体设计阶段需要根据需求分析的结果确定电路的整体结构和功能分配。

逻辑设计阶段是将总体设计转化为逻辑电路图,其中需要考虑逻辑函数、时序关系、并行性等问题。

电路设计阶段是将逻辑电路图转化为电路级电路图,包括门电路的选择和优化等。

物理设计阶段则是将电路级电路图转化为实际的版图设计,考虑布线、功耗、散热等问题。

在每个设计阶段都需要充分考虑电路的性能、面积、功耗等指标,以实现设计的最优化。

结语数字集成电路作为现代电子系统的关键组成部分,对于数字系统的功能和性能起着至关重要的作用。

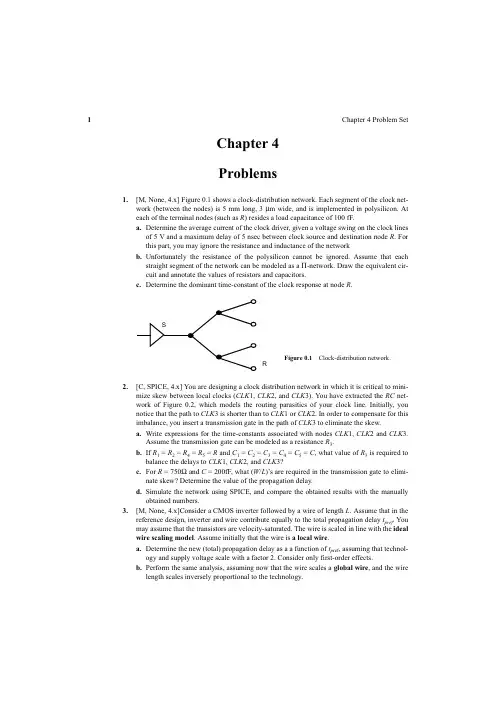

1Chapter 4 Problem SetChapter 4Problems1.[M, None, 4.x] Figure 0.1 shows a clock-distribution network. Each segment of the clock net-work (between the nodes) is 5 mm long, 3 μm wide, and is implemented in polysilicon. Ateach of the terminal nodes (such as R ) resides a load capacitance of 100 fF.a.Determine the average current of the clock driver, given a voltage swing on the clock linesof 5 V and a maximum delay of 5 nsec between clock source and destination node R . Forthis part, you may ignore the resistance and inductance of the networkb.Unfortunately the resistance of the polysilicon cannot be ignored. Assume that eachstraight segment of the network can be modeled as a Π-network. Draw the equivalent cir-cuit and annotate the values of resistors and capacitors.c.Determine the dominant time-constant of the clock response at node R .2.[C, SPICE, 4.x] You are designing a clock distribution network in which it is critical to mini-mize skew between local clocks (CLK 1, CLK 2, and CLK 3). You have extracted the RC net-work of F igure 0.2, which models the routing parasitics of your clock line. Initially, you notice that the path to CLK 3 is shorter than to CLK 1 or CLK 2. In order to compensate for this imbalance, you insert a transmission gate in the path of CLK 3 to eliminate the skew.a.Write expressions for the time-constants associated with nodes CLK 1,CLK 2 and CLK 3.Assume the transmission gate can be modeled as a resistance R 3.b.If R 1 = R 2 = R 4 = R 5 = R and C 1 = C 2 = C 3 = C 4 = C 5 = C , what value of R 3 is required to balance the delays to CLK 1, CLK 2, and CLK 3?c.For R =750Ω and C =200fF, what (W /L )’s are required in the transmission gate to elimi-nate skew? Determine the value of the propagation delay.d.Simulate the network using SPICE, and compare the obtained results with the manually obtained numbers.3.[M, None, 4.x]Consider a CMOS inverter followed by a wire of length L . Assume that in thereference design, inverter and wire contribute equally to the total propagation delay t pref . Youmay assume that the transistors are velocity-saturated. The wire is scaled in line with the idealwire scaling model . Assume initially that the wire is a local wire .a.Determine the new (total) propagation delay as a a function of t p ref , assuming that technol-ogy and supply voltage scale with a factor 2. Consider only first-order effects.b.Perform the same analysis, assuming now that the wire scales a global wire , and the wire length scales inversely proportional to the technology.Figure 0.1Clock-distribution network.SR2Chapter 4 Problem Setc.Repeat b, but assume now that the wire is scaled along the constant resistance model. You may ignore the effect of the fringing capacitance.d.Repeat b, but assume that the new technology uses a better wiring material that reduces the resistivity by half, and a dielectric with a 25% smaller permittivity.e.Discuss the energy dissipation of part a. as a function of the energy dissipation of the orig-inal design E ref .f.Determine for each of the statements below if it is true, false, or undefined, and explain in one line your answer. - When driving a small fan-out, increasing the driver transistor sizes raises the short-circuit power dissipation. - Reducing the supply voltage, while keeping the threshold voltage constant decreases the short-circuit power dissipation.- Moving to Copper wires on a chip will enable us to build faster adders.- Making a wire wider helps to reduce its RC delay.- Going to dielectrics with a lower permittivity will make RC wire delay more impor-tant.4.[M, None, 4.x] A two-stage buffer is used to drive a metal wire of 1 cm. The first inverter is of minimum size with an input capacitance Ci=10 fF and an internal propagation delay t p0=50 ps and load dependent delay of 5ps/fF. The width of the metal wire is 3.6 μm. The sheet resis-tance of the metal is 0.08 Ω/, the capacitance value is 0.03 fF/μm 2and the fringing field capacitance is 0.04fF/μm.a.What is the propagation delay of the metal wire?pute the optimal size of the second inverter. What is the minimum delay through the buffer?c.If the input to the first inverter has 25% chance of making a 0-to-1 transition, and the whole chip is running at 20MHz with a 2.5 supply voltage, then what’s the power con-sumed by the metal wire?5.[M, None, 4.x]To connect a processor to an external memory an off -chip connection is neces-sary. The copper wire on the board is 15 cm long and acts as a transmission line with a charac-teristic impedance of 100Ω.(See F igure 0.3). The memory input pins present a very highimpedance which can be considered infinite. The bus driver is a CMOS inverter consisting ofvery large devices: (50/0.25) for the NMOS and (150/0.25) for the PMOS, where all sizes areClock CLK 1CLK 2CLK 3R 1R 2R 5R 4R 3Model as:Figure 0.2RC clock-distribution network.driver C 1C 3C 4C 5C 2Digital Integrated Circuits - 2nd Ed3 in μm. The minimum size device, (0.25/0.25) for NMOS and (0.75/0.25) for PMOS, has theon resistance 35 kΩ.a.Determine the time it takes for a change in the signal to propagate from source to destina-tion (time of flight). The wire inductance per unit length equals 75*10-8 H/m.b.Determine how long it will take the output signal to stay within 10% of its final value. Youcan model the driver as a voltage source with the driving device acting as a series resis-tance. Assume a supply and step voltage of 2.5V. Hint: draw the lattice diagram for thetransmission line.c.Resize the dimensions of the driver to minimize the total delay.L=15cmMemoryZ=100ΩFigure 0.3The driver, the connecting copper wire and thememory block being accessed.6.[M, None, 4.x] A two stage buffer is used to drive a metal wire of 1 cm. The first inverter is aminimum size with an input capacitance C i=10 fF and a propagation delay t p0=175 ps whenloaded with an identical gate. The width of the metal wire is 3.6 μm. The sheet resistance ofthe metal is 0.08 Ω/, the capacitance value is 0.03 fF/μm2 and the fringing field capacitanceis 0.04 fF/μm.a.What is the propagation delay of the metal wire?pute the optimal size of the second inverter. What is the minimum delay through thebuffer?7.[M, None, 4.x] For the RC tree given in Figure 0.4 calculate the Elmore delay from node A tonode B using the values for the resistors and capacitors given in the below in Table 0.1.Figure 0.4RC tree for calculating the delay4Chapter 4 Problem SetTable 0.1Values of the components in the RC tree of Figure 0.4Resistor Value(Ω)Capacitor Value(fF)R10.25C1250R20.25C2750R30.50C3250R4100C4250R50.25C51000R6 1.00C6250R70.75C7500R81000C82508.[M, SPICE, 4.x] In this problem the various wire models and their respective accuracies willbe studied.pute the 0%-50% delay of a 500um x 0.5um wire with resistance of 0.08 Ω/,witharea capacitance of 30aF/um2, and fringing capacitance of 40aF/um. Assume the driverhas a 100Ω resistance and negligible output capacitance.•Using a lumped model for the wire.•Using a PI model for the wire, and the Elmore equations to find tau. (see Chapter 4, figure4.26).•Using the distributed RC line equations from Chapter 4, section 4.4.4.pare your results in part a. using spice (be sure to include the source resistance). Foreach simulation, measure the 0%-50% time for the output•First, simulate a step input to a lumped R-C circuit.•Next, simulate a step input to your wire as a PI model.•Unfortunately, our version of SPICE does not support the distributed RC model as described in your book (Chapter 4, section 4.5.1). Instead, simulate a step input to yourwire using a PI3 distributed RC model.9.[M, None, 4.x] A standard CMOS inverter drives an aluminum wire on the first metal layer.Assume Rn=4kΩ, Rp=6kΩ. Also, assume that the output capacitance of the inverter is negli-gible in comparison with the wire capacitance. The wire is .5um wide, and the resistivity is0.08 Ω/..a.What is the "critical length" of the wire?b.What is the equivalent capacitance of a wire of this length? (For your capacitance calcula-tions, use Table 4.2 of your book , assume there’s field oxide underneath and nothingabove the aluminum wire)Digital Integrated Circuits - 2nd Ed510.[M, None, 4.x] A 10cm long lossless transmission line on a PC board (relative dielectric con-stant = 9, relative permeability = 1) with characteristic impedance of 50Ω is driven by a 2.5Vpulse coming from a source with 150Ω resistance.a.If the load resistance is infinite, determine the time it takes for a change at the source toreach the load (time of flight).Now a 200Ω load is attached at the end of the transmission line.b.What is the voltage at the load at t = 3ns?c.Draw lattice diagram and sketch the voltage at the load as a function of time. Determinehow long does it take for the output to be within 1 percent of its final value.11.[C, SPICE, 4.x] Assume V DD =1.5V . Also, use short-channel transistor models forhand analy-sis.a.The Figure 0.5 shows an output driver feeding a 0.2 pF effective fan-out of CMOS gates through a transmission line. Size the two transistors of the driver to optimize the delay.Sketch waveforms of V S and V L , assuming a square wave input. Label critical voltages and times.b.Size down the transistors by m times (m is to be treated as a parameter). Derive a first order expression for the time it takes for V L to settle down within 10% of its final voltage pare the obtained result with the case where no inductance is associated with the wire.Please draw the waveforms of V L for both cases, and comment.e the transistors as in part a). Suppose C L is changed to 20pF. Sketch waveforms of V S and V L , assuming a square wave input. Label critical voltages and instants.d.Assume now that the transmission line is lossy. Perform Hspice simulation for three cases:R=100 Ω/cm; R=2.5 Ω/cm; R=0.5 Ω/cm. Get the waveforms of V S , V L and the middle point of the line. Discuss the results.12.[M, None, 4.x] Consider an isolated 2mm long and 1μm wide M1(Metal1)wire over a silicon substrate driven by an inverter that has zero resistance and parasitic output capccitance. How will the wire delay change for the following cases? Explain your reasoning in each case.a.If the wire width is doubled.b.If the wire length is halved.c.If the wire thickness is doubled.d.If thickness of the oxide between the M1 and the substrate is doubled.13.[E, None, 4.x] In an ideal scaling model, where all dimensions and voltages scale with a fac-tor of S >1 :L=350nH/m 10cm C=150pF/m inV DDV DD V S V LC L =0.2pF Figure 0.5Transmission line between two inverters6Chapter 4 Problem Seta.How does the delay of an inverter scale?b.If a chip is scaled from one technology to another where all wire dimensions,including thevertical one and spacing, scale with a factor of S, how does the wire delayscale? How doesthe overall operating frequency of a chip scale?c.Repeat b) for the case where everything scales, except the vertical dimension of wires (itstays constant).。

数字集成电路:电路系统与设计(第二版)简介《数字集成电路:电路系统与设计(第二版)》是一本介绍数字集成电路的基本原理和设计方法的教材。

本书的内容覆盖了数字电路的基础知识、逻辑门电路、组合逻辑电路、时序逻辑电路、存储器和程序控制电路等方面。

通过学习本书,读者可以了解数字集成电路的概念、设计方法和实际应用。

目录1.数字电路基础知识 1.1 数字电路的基本概念 1.2 二进制系统与数制转换 1.3 逻辑运算与布尔代数2.逻辑门电路 2.1 与门、或门、非门 2.2 与非门、或非门、异或门 2.3 多输入门电路的设计方法3.组合逻辑电路 3.1 组合逻辑电路的基本原理 3.2 组合逻辑电路的设计方法 3.3 编码器和译码器4.时序逻辑电路 4.1 时序逻辑电路的基本原理 4.2 同步时序电路的设计方法 4.3 异步时序电路的设计方法5.存储器电路 5.1 存储器的基本概念 5.2 可读写存储器的设计方法 5.3 只读存储器的设计方法6.程序控制电路 6.1 程序控制电路的基本概念 6.2 程序控制电路的设计方法 6.3 微程序控制器的设计方法内容概述1. 数字电路基础知识本章主要介绍数字电路的基本概念,包括数字电路与模拟电路的区别、数字信号的表示方法以及数制转换等内容。

此外,还介绍了数字电路中常用的逻辑运算和布尔代数的基本原理。

2. 逻辑门电路逻辑门电路是数字电路中的基本组成单元,本章主要介绍了与门、或门、非门以及与非门、或非门、异或门等逻辑门的基本原理和组成。

此外,还介绍了多输入门电路的设计方法,以及逻辑门电路在数字电路设计中的应用。

3. 组合逻辑电路组合逻辑电路是由逻辑门电路组成的,本章主要介绍了组合逻辑电路的基本原理和设计方法。

此外,还介绍了编码器和译码器的原理和应用,以及在数字电路设计中的实际应用场景。

4. 时序逻辑电路时序逻辑电路是在组合逻辑电路的基础上引入了时序元件并进行时序控制的电路。

本章主要介绍了时序逻辑电路的基本原理和设计方法,包括同步时序电路和异步时序电路的设计。

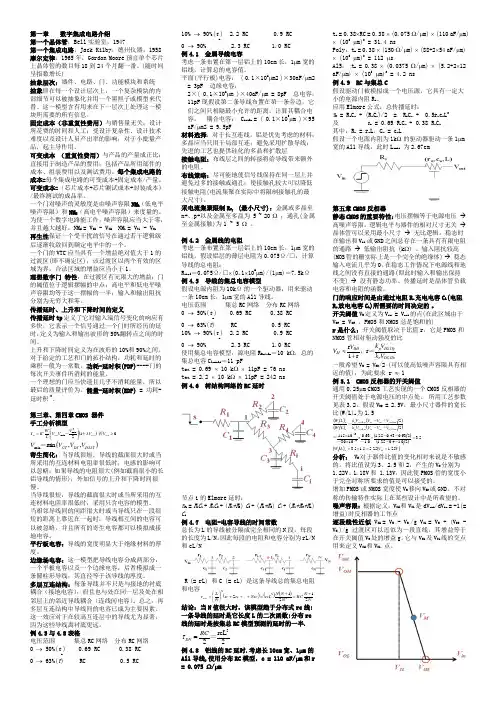

第一章 数字集成电路介绍第一个晶体管,Bell 实验室,1947第一个集成电路,Jack Kilby ,德州仪器,1958 摩尔定律:1965年,Gordon Moore 预言单个芯片上晶体管的数目每18到24个月翻一番。

(随时间呈指数增长)抽象层次:器件、电路、门、功能模块和系统 抽象即在每一个设计层次上,一个复杂模块的内部细节可以被抽象化并用一个黑匣子或模型来代替。

这一模型含有用来在下一层次上处理这一模块所需要的所有信息。

固定成本(非重复性费用)与销售量无关;设计所花费的时间和人工;受设计复杂性、设计技术难度以及设计人员产出率的影响;对于小批量产品,起主导作用。

可变成本 (重复性费用)与产品的产量成正比;直接用于制造产品的费用;包括产品所用部件的成本、组装费用以及测试费用。

每个集成电路的成本=每个集成电路的可变成本+固定成本/产量。

可变成本=(芯片成本+芯片测试成本+封装成本)/最终测试的成品率。

一个门对噪声的灵敏度是由噪声容限NM L (低电平噪声容限)和NM H (高电平噪声容限)来度量的。

为使一个数字电路能工作,噪声容限应当大于零,并且越大越好。

NM H = V OH - V IH NM L = V IL - V OL 再生性保证一个受干扰的信号在通过若干逻辑级后逐渐收敛回到额定电平中的一个。

一个门的VTC 应当具有一个增益绝对值大于1的过渡区(即不确定区),该过渡区以两个有效的区域为界,合法区域的增益应当小于1。

理想数字门 特性:在过渡区有无限大的增益;门的阈值位于逻辑摆幅的中点;高电平和低电平噪声容限均等于这一摆幅的一半;输入和输出阻抗分别为无穷大和零。

传播延时、上升和下降时间的定义传播延时tp 定义了它对输入端信号变化的响应有多快。

它表示一个信号通过一个门时所经历的延时,定义为输入和输出波形的50%翻转点之间的时间。

上升和下降时间定义为在波形的10%和90%之间。

对于给定的工艺和门的拓扑结构,功耗和延时的乘积一般为一常数。

数字集成电路第二版答案【篇一:《数字集成电路》期末试卷a(含答案)】考试试卷 a姓名学号班级任课教师一、填空题(本大题共10小题,每空格1分,共10分)请在每小题的空格中填上正确答案。

错填、不填均无分。

1.十进制数(68)10对应的二进制数等于;2.描述组合逻辑电路逻辑功能的方法有真值表、逻辑函数、卡诺图、逻辑电路图、波形图和硬件描述语言(hdl)法等,其中描述法是基础且最直接。

3.a?1可以简化为4.图1所示逻辑电路对应的逻辑函数l等于。

abc≥1lcy图1图25.如图2所示,当输入c是(高电平,低电平)时,y?ab。

6.两输入端ttl与非门的输出逻辑函数z?ab,当a=b=1时,输出低电平且vz=0.3v,当该与非门加上负载后,输出电压将(增大,减小)。

7.moore型时序电路和mealy型时序电路相比,型电路的抗干扰能力更强。

8.与同步时序电路相比,异步时序电路的最大缺陷是会产生 9.jk触发器的功能有置0、置1、保持和的ram。

二、选择题(本大题共10小题,每小题2分,共20分)在每小题列出的四个备选项中只有一个是符合题目要求的,请将其代码填写在题后的括号内。

错选、多选或未选均无分。

11.十进制数(172)10对应的8421bcd编码是。

【】a.(1111010)8421bcdb.(10111010)8421bcdc.(000101110010)8421bcd d.(101110010)8421bcd12.逻辑函数z(a,b,c)?ab?ac包含【】a.2 b.3c.4d.513.设标准ttl与非门z?ab的电源电压是+5v,不带负载时输出高电平电压值等于+3.6v,输出低电平电压值等于0.3v。

当输入端a、b电压值va=0.3v,vb=3.6v和va=vb=3.6v两种情况下,输出电压值vz分别为。

a.5v,5v c.3.6v,0.3v【】b.3.6v,3.6v d.0.3v ,3.6v14.图3所示电路的输出逻辑函数z1等于。

C H A P T E R5T H E C M O S I N V E R T E R Quantification of integrity,performance,and energy metrics of an inverterOptimization of an inverter design5.1Exercises and Design Problems5.2The Static CMOS Inverter—An IntuitivePerspective5.3Evaluating the Robustness of the CMOSInverter:The Static Behavior5.3.1Switching Threshold5.3.2Noise Margins5.3.3Robustness Revisited5.4Performance of CMOS Inverter:The DynamicBehavior5.4.1Computing the Capacitances5.4.2Propagation Delay:First-OrderAnalysis5.4.3Propagation Delay from a DesignPerspective5.5Power,Energy,and Energy-Delay5.5.1Dynamic Power Consumption5.5.2Static Consumption5.5.3Putting It All Together5.5.4Analyzing Power Consumption UsingSPICE5.6Perspective:Technology Scaling and itsImpact on the Inverter Metrics180Section 5.1Exercises and Design Problems 1815.1Exercises and Design Problems1.[M,SPICE,3.3.2]The layout of a static CMOS inverter is given in Figure 5.1.(λ=0.125µm).a.Determine the sizes of the NMOS and PMOS transistors.b.Plot the VTC (using HSPICE)and derive its parameters (V OH ,V OL ,V M ,V IH ,and V IL ).c.Is the VTC affected when the output of the gates is connected to the inputs of 4similargates?.d.Resize the inverter to achieve a switching threshold of approximately 0.75V .Do not lay-out the new inverter,use HSPICE for your simulations.How are the noise margins affected by this modification?2.Figure 5.2shows a piecewise linear approximation for the VTC.The transition region isapproximated by a straight line with a slope equal to the inverter gain at V M .The intersectionof this line with the V OH and the V OL lines defines V IH and V IL .a.The noise margins of a CMOS inverter are highly dependent on the sizing ratio,r =k p /k n ,of the NMOS and PMOS e HSPICE with V Tn =|V Tp |to determine the valueof r that results in equal noise margins?Give a qualitative explanation.b.Section 5.3.2of the text uses this piecewise linear approximation to derive simplifiedexpressions for NM H and NM L in terms of the inverter gain.The derivation of the gain isbased on the assumption that both the NMOS and the PMOS devices are velocity saturatedat V M .For what range of r is this assumption valid?What is the resulting range of V M ?c.Derive expressions for the inverter gain at V M for the cases when the sizing ratio is justabove and just below the limits of the range where both devices are velocity saturated.What are the operating regions of the NMOS and the PMOS for each case?Consider theeffect of channel-length modulation by using the following expression for the small-signalresistance in the saturation region:r o,sat =1/(λI D ).Figure 5.1CMOS inverter layout.InOutGND V DD =2.5V.Poly Metal1NMOSPMOSPolyMetal12λ182THE CMOS INVERTER Chapter 53.[M,SPICE,3.3.2]Figure 5.3shows an NMOS inverter with resistive load.a.Qualitatively discuss why this circuit behaves as an inverter.b.Find V OH and V OL calculate V IH and V IL .c.Find NM L and NM H ,and plot the VTC using HSPICE.d.Compute the average power dissipation for:(i)V in =0V and (ii)V in =2.5Ve HSPICE to sketch the VTCs for R L =37k,75k,and 150k on a single graph.ment on the relationship between the critical VTC voltages (i.e.,V OL ,V OH ,V IL ,V IH )and the load resistance,R L .g.Do high or low impedance loads seem to produce more ideal inverter characteristics?4.[E,None,3.3.3]For the inverter of Figure 5.3and an output load of 3pF:a.Calculate t plh ,t phl ,and t p .b.Are the rising and falling delays equal?Why or why not?pute the static and dynamic power dissipation assuming the gate is clocked as fast as possible.5.The next figure shows two implementations of MOS inverters.The first inverter uses onlyNMOS transistors.V OH V OL inV outFigure 5.2A different approach to derive V IL and V IH .V outV in M 1W/L =1.5/0.5+2.5VFigure 5.3Resistive-load inverterR L =75k ΩSection 5.1Exercises and Design Problems183a.Calculate V OH ,V OL ,V M for each case.e HSPICE to obtain the two VTCs.You must assume certain values for the source/drain areas and perimeters since there is no layout.For our scalable CMOS process,λ =0.125μm,and the source/drain extensions are 5λfor the PMOS;for the NMOS the source/drain contact regions are 5λx5λ.c.Find V IH ,V IL ,NM L and NM H for each inverter and comment on the results.How can you increase the noise margins and reduce the undefined region?ment on the differences in the VTCs,robustness and regeneration of each inverter.6.Consider the following NMOS inverter.Assume that the bulk terminals of all NMOS deviceare connected to GND.Assume that the input IN has a 0V to 2.5V swing.a.Set up the equation(s)to compute the voltage on node x .Assume γ=0.5.b.What are the modes of operation of device M2?Assume γ=0.c.What is the value on the output node OUT for the case when IN =0V?Assume γ=0.d.Assuming γ=0,derive an expression for the switching threshold (V M )of the inverter.Recall that the switching threshold is the point where V IN =V OUT .Assume that the devicesizes for M1,M2and M3are (W/L)1,(W/L)2,and (W/L)3respectively.What are the limitson the switching threshold?For this,consider two cases:i)(W/L)1>>(W/L)2V DD =2.5V V IN V OUTV DD =2.5V V IN V OUT M 2M 1M 4M 3W/L=0.375/0.25W/L=0.75/0.25W/L=0.375/0.25W/L=0.75/0.25Figure 5.4Inverter ImplementationsV DD =2.5V OUTM1IN M2M3V DD =2.5Vx184THE CMOS INVERTER Chapter 5ii)(W/L)2>>(W/L)17.Consider the circuit in Figure 5.5.Device M1is a standard NMOS device.Device M2has allthe same properties as M1,except that its device threshold voltage is negative and has a valueof -0.4V.Assume that all the current equations and inequality equations (to determine themode of operation)for the depletion device M2are the same as a regular NMOS.Assume thatthe input IN has a 0V to 2.5V swing.a.Device M2has its gate terminal connected to its source terminal.If V IN =0V ,what is the output voltage?In steady state,what is the mode of operation of device M2for this input?pute the output voltage for V IN =2.5V .You may assume that V OUT is small to simplify your calculation.In steady state,what is the mode of operation of device M2for this input?c.Assuming Pr (IN =0)=0.3,what is the static power dissipation of this circuit?8.[M,None,3.3.3]An NMOS transistor is used to charge a large capacitor,as shown in Figure5.6.a.Determine the t pLH of this circuit,assuming an ideal step from 0to 2.5V at the input node.b.Assume that a resistor R S of 5k Ωis used to discharge the capacitance to ground.Deter-mine t pHL .c.Determine how much energy is taken from the supply during the charging of the capacitor.How much of this is dissipated in M1.How much is dissipated in the pull-down resistanceduring discharge?How does this change when R S is reduced to 1k Ω.d.The NMOS transistor is replaced by a PMOS device,sized so that k p is equal to the k n ofthe original NMOS.Will the resulting structure be faster?Explain why or why not.9.The circuit in Figure 5.7is known as the source follower configuration.It achieves a DC levelshift between the input and the output.The value of this shift is determined by the current I 0.Assume x d =0,γ=0.4,2|φf |=0.6V ,V T 0=0.43V ,k n ’=115μA/V 2and λ=0.V DD =2.5VOUTM1(4μm/1μm)IN M2(2μm/1μm),V Tn =-0.4VFigure 5.5A depletion load NMOSinverterV DD =2.5VOutFigure 5.6Circuit diagram with annotated W/L ratios=5pFSection 5.1Exercises and Design Problems 185a.Suppose we want the nominal level shift between V i and V o to be 0.6V in the circuit in Figure 5.7(a).Neglecting the backgate effect,calculate the width of M2to provide this level shift (Hint:first relate V i to V o in terms of I o ).b.Now assume that an ideal current source replaces M2(Figure 5.7(b)).The NMOS transis-tor M1experiences a shift in V T due to the backgate effect.Find V T as a function of V o for V o ranging from 0to 2.5V with 0.5V intervals.Plot V T vs.V oc.Plot V o vs.V i as V o varies from 0to 2.5V with 0.5V intervals.Plot two curves:one neglecting the body effect and one accounting for it.How does the body effect influence the operation of the level converter?d.At V o (with body effect)=2.5V,find V o (ideal)and thus determine the maximum error introduced by the body effect.10.For this problem assume:V DD =2.5V ,W P /L =1.25/0.25,W N /L =0.375/0.25,L =L eff =0.25μm (i.e.x d =0μm),C L =C inv-gate ,k n ’=115μA/V 2,k p ’=-30μA/V 2,V tn0=|V tp0|=0.4V,λ =0V -1, γ=0.4,2|φf |=0.6V ,and t ox =e the HSPICE model parameters for parasitic capacitance given below (i.e.C gd0,C j ,C jsw ),and assume that V SB =0V for all problems except part (e).Figure 5.7NMOS source follower configuration V DD =2.5V V iV oV DD =2.5VV i V oV bias =(a)(b)I o1um/0.25um M1186THE CMOS INVERTER Chapter 5##Parasitic Capacitance Parameters (F/m)##NMOS:CGDO=3.11x10-10,CGSO=3.11x10-10,CJ=2.02x10-3,CJSW=2.75x10-10PMOS:CGDO=2.68x10-10,CGSO=2.68x10-10,CJ=1.93x10-3,CJSW=2.23x10-10a.What is the V m for this inverter?b.What is the effective load capacitance C Leff of this inverter?(include parasitic capacitance,refer to the text for K eq and m .)Hint:You must assume certain values for the source/drain areas and perimeters since there is no layout.For our scalable CMOS process,λ =0.125μm,and the source/drain extensions are 5λfor the PMOS;for the NMOS the source/drain contact regions are 5λx5λ.c.Calculate t PHL ,t PLH assuming the result of (b)is ‘C Leff =6.5fF’.(Assume an ideal step input,i.e.t rise =t fall =0.Do this part by computing the average current used to charge/dis-charge C Leff .)d.Find (W p /W n )such that t PHL =t PLH .e.Suppose we increase the width of the transistors to reduce the t PHL ,t PLH .Do we get a pro-portional decrease in the delay times?Justify your answer.f.Suppose V SB =1V,what is the value of V tn ,V tp ,V m ?How does this qualitatively affect C Leff ?ing Hspice answer the following questions.a.Simulate the circuit in Problem 10and measure t P and the average power for input V in :pulse(0V DD 5n 0.1n 0.1n 9n 20n),as V DD varies from 1V -2.5V with a 0.25V interval.[t P =(t PHL +t PLH )/2].Using this data,plot ‘t P vs.V DD ’,and ‘Power vs.V DD ’.Specify AS,AD,PS,PD in your spice deck,and manually add C L =6.5fF.Set V SB =0Vfor this problem.b.For Vdd equal to 2.5V determine the maximum fan-out of identical inverters this gate candrive before its delay becomes larger than 2ns.c.Simulate the same circuit for a set of ‘pulse’inputs with rise and fall times of t in_rise,fall =1ns,2ns,5ns,10ns,20ns.For each input,measure (1)the rise and fall times t out_rise andV DD =2.5VV IN V OUTC L =C inv-gateL =L P =L N =0.25μmV SB-+(W p /W n =1.25/0.375)Figure 5.8CMOS inverter with capacitiveSection 5.1Exercises and Design Problems 187t out_fall of the inverter output,(2)the total energy lost E total ,and (3)the energy lost due to short circuit current E short .Using this data,prepare a plot of (1)(t out_rise +t out_fall )/2vs.t in_rise,fall ,(2)E total vs.t in_rise,fall ,(3)E short vs.t in_rise,fall and (4)E short /E total vs.t in_rise,fall.d.Provide simple explanations for:(i)Why the slope for (1)is less than 1?(ii)Why E short increases with t in_rise,fall ?(iii)Why E total increases with t in_rise,fall ?12.Consider the low swing driver of Figure 5.9:a.What is the voltage swing on the output node (V out )?Assume γ=0.b.Estimate (i)the energy drawn from the supply and (ii)energy dissipated for a 0V to 2.5V transition at the input.Assume that the rise and fall times at the input are 0.Repeat the analysis for a 2.5V to 0V transition at the input.pute t pLH (i.e.the time to transition from V OL to (V OH +V OL )/2).Assume the input rise time to be 0.V OL is the output voltage with the input at 0V and V OH is the output volt-age with the input at 2.5V .pute V OH taking into account body effect.Assume γ =0.5V 1/2for both NMOS and PMOS.13.Consider the following low swing driver consisting of NMOS devices M1and M2.Assumean NWELL implementation.Assume that the inputs IN and IN have a 0V to 2.5V swing andthat V IN =0V when V IN =2.5V and vice-versa.Also assume that there is no skew between INand IN (i.e.,the inverter delay to derive IN from IN is zero).a.What voltage is the bulk terminal of M2connected to?V in V out V DD =2.5V W L 3μm 0.25μm =p 2.5V0V C L =100fFW L 1.5μm 0.25μm=n Figure 5.9Low Swing DriverV LOW =0.5VOutM1ININ M225μm/0.25μm 25μm/0.25μmC L =1pFFigure 5.10Low Swing Driver188THE CMOS INVERTER Chapter 5b.What is the voltage swing on the output node as the inputs swing from 0V to 2.5V .Showthe low value and the high value.c.Assume that the inputs IN and IN have zero rise and fall times.Assume a zero skewbetween IN and IN.Determine the low to high propagation delay for charging the outputnode measured from the the 50%point of the input to the 50%point of the output.Assumethat the total load capacitance is 1pF,including the transistor parasitics.d.Assume that,instead of the 1pF load,the low swing driver drives a non-linear capacitor,whose capacitance vs.voltage is plotted pute the energy drawn from the lowsupply for charging up the load capacitor.Ignore the parasitic capacitance of the driver cir-cuit itself.14.The inverter below operates with V DD =0.4V and is composed of |V t |=0.5V devices.Thedevices have identical I 0and n.a.Calculate the switching threshold (V M )of this inverter.b.Calculate V IL and V IH of the inverter.15.Sizing a chain of inverters.a.In order to drive a large capacitance (C L =20pF)from a minimum size gate (with inputcapacitance C i =10fF),you decide to introduce a two-staged buffer as shown in Figure5.12.Assume that the propagation delay of a minimum size inverter is 70ps.Also assumeV DD =0.4VV IN V OUTFigure 5.11Inverter in Weak Inversion RegimeSection 5.1Exercises and Design Problems 189that the input capacitance of a gate is proportional to its size.Determine the sizing of thetwo additional buffer stages that will minimize the propagation delay.b.If you could add any number of stages to achieve the minimum delay,how many stages would you insert?What is the propagation delay in this case?c.Describe the advantages and disadvantages of the methods shown in (a)and (b).d.Determine a closed form expression for the power consumption in the circuit.Consider only gate capacitances in your analysis.What is the power consumption for a supply volt-age of 2.5V and an activity factor of 1?16.[M,None,3.3.5]Consider scaling a CMOS technology by S >1.In order to maintain compat-ibility with existing system components,you decide to use constant voltage scaling.a.In traditional constant voltage scaling,transistor widths scale inversely with S,W ∝1/S.To avoid the power increases associated with constant voltage scaling,however,youdecide to change the scaling factor for W .What should this new scaling factor be to main-tain approximately constant power.Assume long-channel devices (i.e.,neglect velocitysaturation).b.How does delay scale under this new methodology?c.Assuming short-channel devices (i.e.,velocity saturation),how would transistor widthshave to scale to maintain the constant power requirement?1InAdded Buffer StageOUTC L =20pF C i =10fF‘1’is the minimum size inverter.??Figure 5.12Buffer insertion for driving large loads.190THE CMOS INVERTER Chapter5DESIGN PROBLEMUsing the0.25μm CMOS introduced in Chapter2,design a static CMOSinverter that meets the following requirements:1.Matched pull-up and pull-down times(i.e.,t pHL=t pLH).2.t p=5nsec(±0.1nsec).The load capacitance connected to the output is equal to4pF.Notice that thiscapacitance is substantially larger than the internal capacitances of the gate.Determine the W and L of the transistors.To reduce the parasitics,useminimal lengths(L=0.25μm)for all transistors.Verify and optimize the designusing SPICE after proposing a first design using manual -pute also the energy consumed per transition.If you have a layout editor(suchas MAGIC)available,perform the physical design,extract the real circuitparameters,and compare the simulated results with the ones obtained earlier.。

IC,这些微小但强大的芯片,是我们电子设备的无名英雄,从我们口袋里的光滑智能无线终端,到我们桌子上的强大的截肢者,甚至我们车上最先进的汽车系统。

当它到数字集成电路时,全部是创建顶尖的系统,来传递心跳的性能,而吸电就像一个花哨的鸡尾酒,永远,永远,投球在可靠性上。

这些电路是数据处理、信号处理和控制系统的摇滚巨星,使得我们技术精湛的世界开始运转。

但是,在所有的滑翔和魅力背后,工作上有大量的脑力。

设计数字集成电路就像开始一个令人惊叹的冒险,任务包括设定舞台有规格,通过模型化将人物带入生命,在模拟中通过脚步化,通过合成来伤害它们的存在,最后通过彻底的验证确保一切的平稳航行。

就像是数字交响乐的策划者,进行电路,系统和设计技术的和谐混合,在区块上创建最高效和可靠的集成电路。

这是一个疯狂的旅程,但有人必须做到这一点!设计数字集成电路需要使用不同的工具和方法来开发和改进数字系统。

首先要弄清楚数字系统需要做什么以及它需要多好的表现我们用维利洛格和VHDL等特殊语言创建模型并测试数字系统。

接下来,我们把模型变成逻辑门列表,我们努力确保设计符合所有要求。

我们用半导体制造来制造实际的电路。

这涉及到根据设计创建布局和建造电路。

数字集成电路领域是一个不断发展和动态的研究领域,其特点是设计方法、技术和应用方面不断取得进展。

随着数字系统继续在各种电子装置和系统中发挥重要作用,对数字集成电路设计专业人才的需求日益增加。

对这一领域感兴趣的个人必须在数字电路、系统和设计原则方面奠定坚实的基础,并随时了解数字集成电路技术的最新发展。

只要具备必要的知识和技能,就能够有助于创造创新的数字集成电路,推动技术进步,提高电子系统的性能。

数字集成电路——电路、系统与设计目录第一部分基本单元第1章引论1.1 历史回顾1.2 数字集成电路设计中的问题1.3 数字设计的质量评价1.4 小结1.5 进一步探讨第2章制造工艺2.1 引言2.2 CMOS集成电路的制造2.3 设计规则——设计者和工艺工程师之间的桥梁2.4 集成电路封装2.5 综述:工艺技术的发展趋势2.6 小结2.7 进一步探讨设计方法插入说明A——IC版图第3章器件3.1 引言3.2 二极管3.3 MOS(FET)晶体管3.4 关于工艺偏差3.5 综述:工艺尺寸缩小3.6 小结3.7 进一步探讨设计方法插入说明B——电路模拟第4章导线4.1 引言4.2 简介4.3 互连参数——电容、电阻和电感4.4 导线模型4.5 导线的SPICE模型4.6 小结4.7 进一步探讨第二部分电路设计第5章CMOS反相器5.1 引言5.2 静态CMOS反相器——直观综述5.3 CMOS反相器稳定性的评估——静态特性5.4 CMOS反相器的性能——动态特性5.5 功耗、能量和能量延时5.6 综述:工艺尺寸缩小及其对反相器衡量指标的影响5.7 小结本文由整理提供5.8 进一步探讨第6章CMOS组合逻辑门的设计6.1 引言6.2 静态CMOS设计6.3 动态CMOS设计6.4 设计综述6.5 小结6.6 进一步探讨设计方法插入说明C——如何模拟复杂的逻辑电路设计方法插入说明D——复合门的版图技术第7章时序逻辑电路设计7.1 引言7.2 静态锁存器和寄存器7.3 动态锁存器和寄存器7.4 其他寄存器类型7.5 流水线:优化时序电路的一种方法7.6 非双稳时序电路7.7 综述:时钟策略的选择7.8 小结7.9 进一步探讨第三部分系统设计第8章数字IC的实现策略8.1 引言8.2 从定制到半定制以及结构化阵列的设计方法8.3 定制电路设计8.4 以单元为基础的设计方法8.5 以阵列为基础的实现方法8.6 综述:未来的实现平台8.7 小结8.8 进一步探讨设计方法插入说明E——逻辑单元和时序单元的特性描述设计方法插入说明F——设计综合第9章互连问题9.1 引言9.2 电容寄生效应9.3 电阻寄生效应9.4 电感寄生效应9.5 高级互连技术9.6 综述:片上网络9.7 小结9.8 进一步探讨第10章数字电路中的时序问题10.1 引言10.2 数字系统的时序分类本文由整理提供10.3 同步设计——一个深入的考察10.4 自定时电路设计10.5 同步器和判断器10.6 采用锁相环进行时钟综合和同步10.7 综述:未来方向和展望10.8 小结10.9 进一步探讨设计方法插入说明G——设计验证第11章设计运算功能块11.1 引言11.2 数字处理器结构中的数据通路11.3 加法器11.4 乘法器11.5 移位器11.6 其他运算器11.7 数据通路结构中对功耗和速度的综合考虑11.8 综述:设计中的综合考虑11.9 小结11.10进一步探讨第12章存储器和阵列结构设计12.1 引言12.2 存储器内核12.3 存储器外围电路12.4 存储器的可靠性及成品率12.5 存储器中的功耗12.6 存储器设计的实例研究12.7 综述:半导体存储器的发展趋势与进展12.8 小结12.9 进一步探讨设计方法插入说明H——制造电路的验证和测试本文由整理提供。

第一章 数字集成电路介绍第一个晶体管,Bell 实验室,1947第一个集成电路,Jack Kilby ,德州仪器,1958 摩尔定律:1965年,Gordon Moore 预言单个芯片上晶体管的数目每18到24个月翻一番。

(随时间呈指数增长)抽象层次:器件、电路、门、功能模块和系统 抽象即在每一个设计层次上,一个复杂模块的内部细节可以被抽象化并用一个黑匣子或模型来代替。

这一模型含有用来在下一层次上处理这一模块所需要的所有信息。

固定成本(非重复性费用)与销售量无关;设计所花费的时间和人工;受设计复杂性、设计技术难度以及设计人员产出率的影响;对于小批量产品,起主导作用。

可变成本 (重复性费用)与产品的产量成正比;直接用于制造产品的费用;包括产品所用部件的成本、组装费用以及测试费用。

每个集成电路的成本=每个集成电路的可变成本+固定成本/产量。

可变成本=(芯片成本+芯片测试成本+封装成本)/最终测试的成品率。

一个门对噪声的灵敏度是由噪声容限NM L (低电平噪声容限)和NM H (高电平噪声容限)来度量的。

为使一个数字电路能工作,噪声容限应当大于零,并且越大越好。

NM H = V OH - V IH NM L = V IL - V OL 再生性保证一个受干扰的信号在通过若干逻辑级后逐渐收敛回到额定电平中的一个。

一个门的VTC 应当具有一个增益绝对值大于1的过渡区(即不确定区),该过渡区以两个有效的区域为界,合法区域的增益应当小于1。

理想数字门 特性:在过渡区有无限大的增益;门的阈值位于逻辑摆幅的中点;高电平和低电平噪声容限均等于这一摆幅的一半;输入和输出阻抗分别为无穷大和零。

传播延时、上升和下降时间的定义传播延时tp 定义了它对输入端信号变化的响应有多快。

它表示一个信号通过一个门时所经历的延时,定义为输入和输出波形的50%翻转点之间的时间。

上升和下降时间定义为在波形的10%和90%之间。

对于给定的工艺和门的拓扑结构,功耗和延时的乘积一般为一常数。