Supplier survey

- 格式:doc

- 大小:173.00 KB

- 文档页数:18

Supplier Q + Survey and Audit Kit 供应厂商加强型质量体系的调查和审核United Technologies Corporation联合技朮公司翻译说明由于业务上的需要, 有机会接触到美国United Technologies Corporation(UTC)公司的《Supplier Q + Survey and Audit Kit》(供应厂商加强型质量体系的调查和审核)。

这套资料是UTC公司对供应原材料和元件给该集团的工厂进行质量体系调查和审核、以及后续监测和促进的控制文件。

这套文件包括了对一些朮语的定义; 进行调查和审核的程序与指引; 对质量体系所达到的水平进行评估的分级标准; 并提供了一系列表格, 使评估的结果更直观、更便于分析。

UTC公司之所以将其称为”Q +”, 是因为在这套标准中, UTC公司将质量体系所达到的水平分为四个等级, 达到ISO9000的水准一般只能相当于该套标准的二级, UTC公司要求上游供应厂的质量体系水平必须达到二级以上。

因此, 我们把”Q +”翻译为”加强型质量体系”。

为了便于工作, 亦因为感到这套资料对建立质量体系、实施质量管理和质量保证的工作, 特别是帮助我们制造出口产品的工厂加速实现与国际接轨方面有一定的参考价值, 我们花了相当的精力和时间翻译了这套资料。

但由于时间紧迫、我们的能力与专业水平有限, 再加上标准朮语的表达简洁、专业性和技朮性很强、以及朮语之间不同的连接产生的多变歧义等原因。

尽管我们已极尽所能, 难免存在不少的差错和不足, 敬请批评指正。

亦由于所存在的差错, 我们特此作如下声明:一、该套资料是UTC公司非公幵发行的文件。

使用、参考该套资料必须以英文原义为准, 译文谨供参考。

该套资料的最终汉译解释权属UTC公司。

二、本套资料汉译部分原意仅提供给与译者业务有关的人士参考。

译者保留其译作权。

未经译者同意, 不得翻印、抄袭、引用, 不得公幵发表。

XXX SUPPLIER SURVEY AND AUDIT FORMXXX供方调查和审核表SUPPLIER'S SURVEY DATE : 供方调查日期:SUPPLIER'S NAME :供方名称:ADDRESS:地址:PHONE NO : FAX NO :电话:传真:PRODUCT SUPPLIED :供应的产品REASON FOR THE SURVEY / AUDIT调查 / 审核原因INITIAL AUDIT (NEW SUPPLIER)初步审核(新分承包)现场审核REGULAR AUDIT定期审核PERFORMANCE NOT SATISFACTORY工作不满意之外SELF SURVEY供方自查OTHERS (SPECIFY)其他(特定)AUDIT / SELF SURVEY PERFORMED BY :审核 / 自查执行人REPRESENTATIVES / REVIEW代表 / 审核XXX SUPPLIERXXX 供方XXX SUPPLIER SURVEY AND AUDIT FORMXXX供方调查和审核表Actual Rating ASSESSMENT AREA评估内容Points Points组织机构采购控制进货材料不合格品控制(过程中和最后出货)生产线控制SPC在线检验校验设备维护文件和图纸控制最终产品检验包装和发货培训和教育清洁、搬运、储存TOTALOVERALL RATING%总得分比率FINAL OUTSTANDING (ABOVE 90%) SATISFACTORY (75%-90%) 优异满意RATING NEED IMPROVEMENT (60%-74.9%) POOR (BELOW 60%)需改进不合格(低于60%)RATING SCALEPOINT INTERPRETATION 说明4 - OUTSTANDING 优异的3 - SATISFACTORY 满意2 - NEED IMPROVEMENT 需改进1 - SIGNIFICANT DEFICIENCY 重大缺陷0 - NO SYSTEM 无系统XXX SUPPLIER SURVEY AND AUDIT FORMXXX供方调查和审核表REQUEST FOR CORRECTIVE ACTION纠正措施申请单Supplier response DUE DATE :供方回复到期日:2003.11.30(将回复传回XXX的日期)Supplier response by: 供方回复人:Title: 职位CORRECTIVE ACTION VERIFICATION纠正措施效果确认(由XXX稽核员填写)XXX SUPPLIER SURVEY AND AUDIT FORMXXX供应商调查和审核表EVALUATION RESULT评估结果GENERAL COMMENTS :概述:XXX SUPPLIER SURVEY AND AUDIT FORM XXX供方调查和审核表XXX SUPPLIER SURVEY AND AUDIT FORM XXX供方调查和审核表XXX SUPPLIER SURVEY AND AUDIT FORM XXX供应商调查和审核表Ref : OSPR02 Serial : 01XXX SUPPLIER SURVEY AND AUDIT FORM XXX 供方调查和审核表XXX SUPPLIER SURVEY AND AUDIT FORM XXX供方调查和审核表XXX SUPPLIER SURVEY AND AUDIT FORM XXX供方调查和审核表XXX SUPPLIER SURVEY AND AUDIT FORM XXX 供方调查和审核表XXX SUPPLIER SURVEY AND AUDIT FORM XXX供方调查和审核表XXX SUPPLIER SURVEY AND AUDIT FORM XXX供方调查和审核表XXX SUPPLIER SURVEY AND AUDIT FORM XXX供方调查和审核表XXX SUPPLIER SURVEY AND AUDIT FORM XXX供方调查和审核表XXX SUPPLIER SURVEY AND AUDIT FORM XXX供方调查和审核表XXX SUPPLIER SURVEY AND AUDIT FORM XXX 供方调查和审核表XXX SUPPLIER SURVEY AND AUDIT FORM XXX供方调查和审核表文档来源为:从网络收集整理.word版本可编辑.欢迎下载支持.。

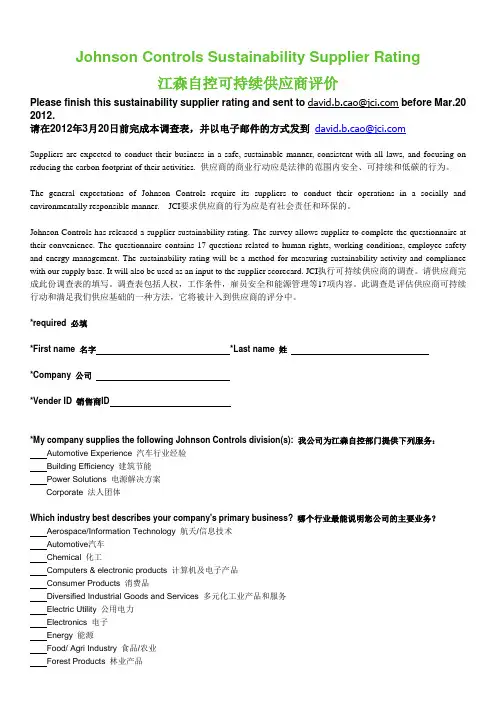

Johnson Controls Sustainability Supplier Rating江森自控可持续供应商评价Please finish this sustainability supplier rating and sent to david.b.cao@ before Mar.20 2012.请在2012年3月20日前完成本调查表,并以电子邮件的方式发到david.b.cao@Suppliers are expected to conduct their business in a safe, sustainable manner, consistent with all laws, and focusing on reducing the carbon footprint of their activities. 供应商的商业行动应是法律的范围内安全、可持续和低碳的行为。

The general expectations of Johnson Controls require its suppliers to conduct their operations in a socially and environmentally responsible manner. JCI要求供应商的行为应是有社会责任和环保的。

Johnson Controls has released a supplier sustainability rating. The survey allows supplier to complete the questionnaire at their convenience. The questionnaire contains 17 questions related to human rights, working conditions, employee safety and energy management. The sustainability rating will be a method for measuring sustainability activity and compliance with our supply base. It will also be used as an input to the supplier scorecard. JCI执行可持续供应商的调查。

尊敬的供应商:您好!为了更好地了解您对我们公司的服务满意度、合作体验以及改进空间,我们特此开展此次调查。

您的宝贵意见将有助于我们提升服务质量,优化合作流程。

请您在百忙之中抽出几分钟时间,完成以下问卷。

感谢您的支持与配合!一、基本信息1. 您所在的公司名称:2. 您在公司担任的职位:3. 您与我公司合作的起始时间:4. 您与我公司合作的领域(如:原材料供应、设备租赁、技术服务等):二、合作满意度5. 您对我公司整体服务质量的满意度(1-5分,5分为最高):1. 非常不满意2. 不满意3. 一般4. 满意5. 非常满意6. 您对我公司以下方面的满意度(1-5分,5分为最高):a. 供货及时性:b. 产品质量:c. 价格竞争力:d. 售后服务:e. 交货周期:f. 付款方式:g. 合作氛围:三、合作体验7. 您认为我公司在以下方面有哪些优势(可多选):a. 产品质量b. 价格优惠c. 售后服务d. 供货及时性e. 合作氛围f. 其他(请注明):8. 您认为我公司在以下方面有哪些不足(可多选):a. 产品质量b. 价格优惠c. 售后服务d. 供货及时性e. 合作氛围f. 其他(请注明):四、改进建议9. 针对我公司在合作过程中存在的不足,您有哪些改进建议?10. 您认为我公司在哪些方面可以进一步提升服务质量?11. 您认为我公司在哪些方面可以加强与您的沟通与协作?五、其他12. 您对我公司有什么其他意见和建议?13. 您认为我公司在行业内的竞争力如何?14. 您对我公司未来发展的信心如何?感谢您抽出宝贵时间填写本次问卷!我们将对您的意见进行认真分析,并努力改进。

祝您工作顺利,生活愉快![调查问卷结束]请您在填写问卷时,尽量确保信息的真实性和准确性。

如有疑问,请联系我们,我们将竭诚为您解答。

再次感谢您的支持与配合!。

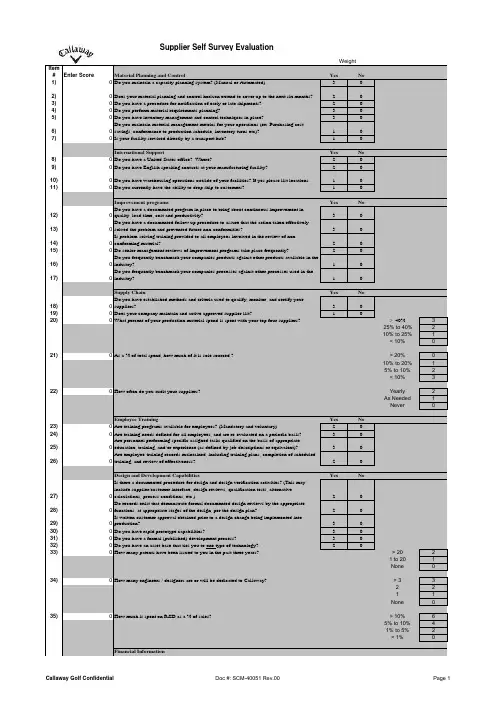

Supplier Self Survey EvaluationItem #Enter Score Material Planning and Control Yes No 1)0Do you maintain a capacity planning system? (Manual or Automated)302)0Does your material planning and control horizon extend to cover up to the next six months?203)0Do you have a procedure for notification of early or late shipments?204)0Do you perform material requirements planning?305)0Do you have inventory management and control techniques in place?306)0Do you maintain material management metrics for your operations (ex. Purchasing costsavings, conformance to production schedule, inventory turns etc)?107)0Is your facility serviced directly by a transport hub?10International Support Yes No8)0Do you have a United States office? Where?209)0Do you have English speaking contacts at your manufacturing facility?2010)0Do you have warehousing operations outside of your facilities? If yes please list locations.1011)0Do you currently have the ability to drop ship to customers?10Improvement programs Yes No12)0Do you have a documented program in place to bring about continuous improvement inquality, lead-time, cost and productivity?3013)0Do you have a documented follow up procedure to assure that the action taken effectivelysolved the problem and prevented future non-conformities?3014)0Is problem-solving training provided to all employees involved in the review of non-conforming material?2015)0Do senior management reviews of improvement programs take place frequently?2016)0Do you frequently benchmark your companies products against other products available inthe industry?1017)0Do you frequently benchmark your companies processes against other processes used inthe industry?10 Supply Chain Yes No18)0Do you have established methods and criteria used to qualify, monitor, and certify yoursuppliers?3019)0Does your company maintain and active approved supplier list?1020)0What percent of your production material spend is spent with your top four suppliers? > 40%325% to 40%210% to 25%1< 10%021)0As a % of total spend, how much of it is sole sourced ?> 20%010% to 20%15% to 10%2< 10%322)0How often do you audit your suppliers?Yearly2As Needed1Never0Employee Training Yes No23)0Are training programs available for employees? (Mandatory and voluntary)2024)0Are training needs defined for all employees, and are re-evaluated on a periodic basis?3025)0Are personnel performing specific assigned tasks qualified on the basis of appropriateeducation, training, and/or experience (as defined by job descriptions or equivalent)?3026)0Are employee-training records maintained, including training plans, completion ofscheduled training, and review of effectiveness?20 Design and Development Capabilities Yes No27)0Is there a documented procedure for design and design verification activities? (This mayinclude supplier/customer interface, design reviews, qualification tests, alternativecalculations, process conditions, etc.)2028)0Do records exist that demonstrate formal documented design reviews by the appropriatefunctions, at appropriate stages of the design, per the design plan?2029)0Is written customer approval obtained prior to a design change being implemented intoproduction?3030)0Do you have rapid prototype capabilities?3031)0Do you have a formal (published) development process?3032)0Do you have an asset base that ties you to one type of technology?2033)0How many patents have been issued to you in the past three years?> 2021 to 201None034)0How many engineers / designers are or will be dedicated to Callaway?> 332211None035)0How much is spent on R&D as a % of sales?> 10%65% to 10%41% to 5%2< 1%0 Financial InformationWeight* Max Score is 111。

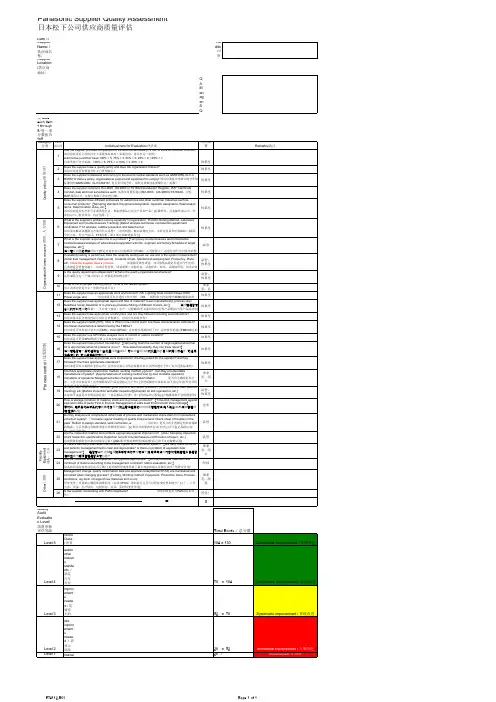

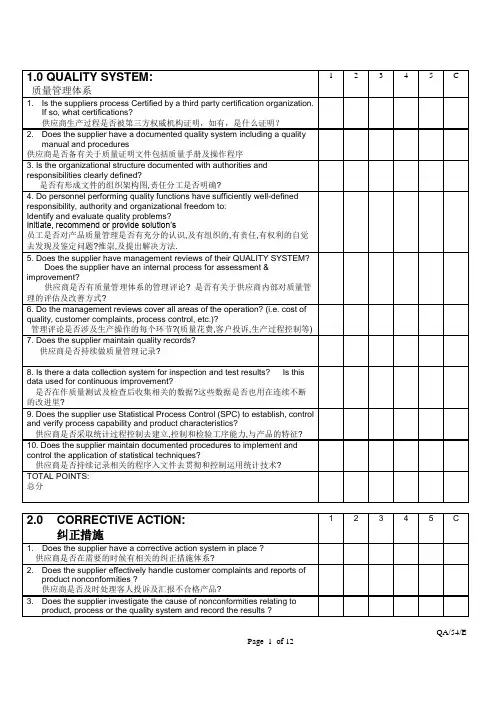

1 2 3 4 5 C 1.0 QUALITY SYSTEM:质量管理体系1. Is the suppliers process Certified by a third party certification organization.If so, what certifications?供应商生产过程是否被第三方权威机构证明,如有,是什么证明?2. Does the supplier have a documented quality system including a qualitymanual and procedures供应商是否备有关于质量证明文件包括质量手册及操作程序3. Is the organizational structure documented with authorities andresponsibilities clearly defined?是否有形成文件的组织架构图,责任分工是否明确?4. Do personnel performing quality functions have sufficiently well-definedresponsibility, authority and organizational freedom to:Identify and evaluate quality problems?Initiate, recommend or provide solution’s员工是否对产品质量管理是否有充分的认识,及有组织的,有责任,有权利的自觉去发现及鉴定问题?推崇,及提出解决方法.5. Does the supplier have management reviews of their QUALITY SYSTEM?Does the supplier have an internal process for assessment &improvement?供应商是否有质量管理体系的管理评论? 是否有关于供应商内部对质量管理的评估及改善方式?6. Do the management reviews cover all areas of the operation? (i.e. cost ofquality, customer complaints, process control, etc.)?管理评论是否涉及生产操作的每个环节?(质量花费,客户投诉,生产过程控制等)7. Does the supplier maintain quality records?供应商是否持续做质量管理记录?8. Is there a data collection system for inspection and test results? Is thisdata used for continuous improvement?是否在作质量测试及检查后收集相关的数据?这些数据是否也用在连续不断的改进里?9. Does the supplier use Statistical Process Control (SPC) to establish, controland verify process capability and product characteristics?供应商是否采取统计过程控制去建立,控制和检验工序能力,与产品的特征?10. Does the supplier maintain documented procedures to implement andcontrol the application of statistical techniques?供应商是否持续记录相关的程序入文件去贯彻和控制运用统计技术?TOTAL POINTS:总分1 2 3 4 5 C2.0 CORRECTIVE ACTION:纠正措施1. Does the supplier have a corrective action system in place ?供应商是否在需要的时候有相关的纠正措施体系?2. Does the supplier effectively handle customer complaints and reports ofproduct nonconformities ?供应商是否及时处理客人投诉及汇报不合格产品?3. Does the supplier investigate the cause of nonconformities relating toproduct, process or the quality system and record the results ?QA/54/E供应商是否调查针对不符合产品,工序,及质量体系的原因,及结果的记录?4. Does the suppliers management initiate action to prevent the occurrenceof any nonconformity’s relating to product, process and quality system ?供应商的管理部门是否做出任何措施防止产品,生产过程及质量体系出现问题?5. Does the supplier have the controls in place to ensure that correctiveaction is taken and is effective ?供应商是否做出相对的控制来确保采取的措施能及时有效的发挥作用?TOTAL POINTS:总分1 2 3 4 5 C 3.0 ENVIRONMENTAL MANAGEMENT SYSTEM:环境保护措施1. Is the Supplier’s process for Environmental Management System certifiedby a third party? If so, what certifications?供应商环境保护过程是否被第三方权威机构证明,如有,是什么证明2. Does the supplier have Environmental Management processes in place?供应商是否有适当的环境保护管理过程?3 Does the supplier have a waste management process & procedure?供应商是否有相应的废物处理过程,及相关的程序?TOTAL POINTS:总分QA/54/ECOMMENTS:备注QA/54/E1 2 3 4 5 C 4.0 ENGINEERING /R&D /DOCUMENT CONTROL:工程研发及文件控制1. Does the supplier have an effective engineering change process ?供应商是否有有效的工程转换过程?2. Does the supplier have electronic data transfer capability (EDI) ? To whatextent ? E-mail capability or a Pro E system for drawing transfer ?供应商是否有电子数据转换能力?什么程度?电子邮件容量及ProE图纸转换软件?3. Does the suppliers documentation control system provide for controlleddistribution of drawings, specification updates and revision control ?供应商有没有对公司受控文件,产品资料,产品图纸资料更新体系?4. Are invalid and/or obsolete documents promptly removed from all points ofissue or use to assure against unintended use ?公司作废的受控文件是否及时地回收处理,以防无意识的使用这些已作废的文件。

Item No.Element Assessed ScoreRemarks 序号审核要素分数(0,1,2,NA)备注-1.1*Is there a Quality System established, implemented andmaintained? 质量体系是否有建立,实施和维护?1.2*Are there Quality Policy and Quality Objectives?是否有制定品质方针和品质目标?1.3*Is there a Documented Quality Manual? 是否有形成文件的品质手册?1.4*Is there a written procedure for documentation review, approval,and release?是否有文件审核,发行的书面程序文件?1.5Are changes to documents reviewed and approved by thefunctional organization(s) that performed the original review and approval?文件变更是否有由原审核部门核准?1.6Are obsolete documents identified to prevent unintended use?作废文件是否有区分以防止误用?1.7Are relevant documents available at the point of use? 相关文件在使用部门是否可用?1.8Is a Master List available showing the current revisions of all pertinent documents? 是否有文件清单记录所有相关文件的当前版本?1.9Are customer furnished drawings identified and controlled by supplier?客户提供的图纸是否有标识并受控?1.10*Is there a documented procedure defining the identification,storage, protection, retrieval, retention time and dispositionquality records? 是否有书面程序规定品质纪录的识别,保存,防护,获取保存期限和处置?Percent 百分比-2.1Are Quality Objectives explained to employees and measured at relevant functions?品质目标是否已向员工传达,并被各部门量2.2Do adequate resources exist to support and continuously improve the quality objectives?是否有充分的资源支持持续提高Is the Quality Dept. functionally separated from production and does it report independent of manufacturing/engineering to top 2.0 Management Responsibility 管理职责1.0 Quality Management System 品质管理体系Subtotal 本部分分数合计SUPPLIER SURVEY 供 应 商 调 查Quality Management System Survey 品质管理体系调查2.3management level? 品质部门是否从职能上与生产分开并独立报告给最高管理层?2.4*Is there a documented internal audit procedure? 是否有形成文件的内部审核程序?2.5Is the internal audit on schedule? 内部审核是否按计划执行?2.6Are there appropriate communication processes within the organization about quality performance and customersatisfaction? 供应商是否就品质绩效及客户满意度进行有效的内部沟通?2.7Does top management regularly review the quality management system for its continuing suitability, adequacy andeffectiveness? 管理层是否定期对品质系统的持续适合性,充分性有效性进行评审?2.8Is there a method which employees can use to communicate to upper management, problems or suggestions to improveQuality? 是否建立员工与管理层就改善品质的问题和建议进行有效沟通的方法?2.9Is there business continual plan(Emergency plan)? 是否有业务持续计划(应急计划)?-3.1Are the necessary competence identified for employeeperforming work affecting product quality? 对于执从事与产品质量相关工作的员工其必要的能力是否有识别?3.2Is there a documented training program? 是否有形成文件的培训程序?3.3Do employees receive job related training? 职员是否有受到工作相关的训练?3.4Have hazardous conditions within the work place been identified and applicable training provided for employees? 工作场所中的危险源是否有标识相关员工是否有培训?3.5Is the effectiveness of training evaluated? 培训的有效性是否有评估?3.6Do records exist that identify the training an employee has received?是否保存了相关的培训记录?3.7Are trainers appropriately qualified? 训练员是否有相关的资格?3.8Are there requirements for retraining/re-certification? 是否有重新培训和认证的要求?39Is there an equipment/tooling preventative maintenance Subtotal 本部分分数合计Percent 百分比3.0 Resource Management 资源管理3.9program available?是否有设备/模具预防保养程序?PQ4.007.000 Rev Q Page 8 of 27序号审核要素分数(0,1,2,NA)备注3.10Is there is an equipment/tooling master list? 是否有设备/模具一览表?3.11Are preventative maintenance intervals defined and is maintenance on schedule?预防保养周期是否有确定并按期执3.12Does the Company have a list of equipment, which require Calibration?公司是否有要求校准的设备清单?3.13Is there a written instruction for calibrating tools and equipment?是否有书面指导书用于校验检验及测试设备和工具?3.14Are records of calibration kept on file? 仪器校验记录是否有存3.15Are the instruments used by production on a calibration program?用于生产的设备/仪器是否纳入校验程序/计划?3.16Is equipment suitably tagged with labels to show calibration status?设备是否贴有显示校验状态的校验标签?3.17Are defective or out of calibration instruments removed from use until repaired or calibrated? 有缺陷的或校准超差的设备在维修和校准前是否被移走以防止误用?3.18Are shop masters calibrated at periodic intervals to secondary standards traceable to NIST or other recognized Standard? 用于校验的工厂标准件是否有定期校验,并可追溯到NIST 或其它承认的标准?3.19Does the inspection and production area reflect adequate and clean working conditions? 检验及生产区域工作环境是否适合和清洁?-4.1Does the supplier have established procedures to review contracts?供应商是否已建立合同评审程序?4.2Is the content adequate to ensure appropriate parties review all customer requirements? 程序内容是否已充分确保相关部门了解所有客户要求?4.3Are review records maintained? 评审记录在是否有保存?Where product requirements such as contract/order/drawing are changed, are the related documents are amended and the relevant personnel are made aware of the changed Subtotal 本部分分数合计Percent 百分比4.0 Product Realization 产品实现4.4relevant personnel are made aware of the changedrequirements? 当产品的要求如合同,订单或图纸变更时,相关文件是否被修订且相关人员了解变更的要求?4.5Are channels for communication and interfacing with thecustomer's organization established? 是否已建立与客户进行有效沟通的渠道?4.6Is reliability data used in the development of new designs? 是否有可靠性数据用于新产品设计开发?4.7Is Quality history fed-back to engineering for improvement in future or current designs? 质量历史记录是否反馈到将来的工程改善或当前的设计?4.8Does the Quality department review new designs? 品质部是否审核新设计?4.9Does the Company have a prototype department? 公司是否有样品制作部门?4.10Does Quality review prototypes? 质量部门是否审核样品?4.11Is there a written procedure to control and verify the design of the product in order to ensure that the specified requirements are met? 是否有书面程序控制和验证产品设计,以确保符合已指定的要求?4.12Is there a written procedure to define the needs andresponsibility for reviewing design input information? 是否有书面程序定义评审设计输入的要求和职责?4.13Are the records of input and review maintained? 设计输入和评审的记录是否保存?4.14Is there a written procedure specifying that the design must be reviewed and verified at appropriate interval? 是否有书面程序说明在适当的阶段设计必须经过评审和验证?4.15Is there a documented procedure to ensure that customers are informed of design changes? 是否有书面程序确保通知客户设计变更?4.16Are Supplier & Customer Product Change Notices (PCN) and Engineering Change Notices (ECN) addressed in your system?对供应商和客户产品和工程变更通知是否有纳入自身系统?4.17Does the Company have a written system for incorporating customer changes into shop drawings? 公司是否有书面系统把客户变更合并到工厂图纸?4.18Are customer specifications interpreted into shop instructions?客户规格是否转译成工厂指导书?4.19Does the supplier have a documented procedure to control purchasing and supplier selection? 是否有文件化的程序来管制采购及供应商选择?序号审核要素分数(0,1,2,NA)备注4.20Is a list of approved suppliers used for material purchased? 是否有认可的供应商清单用于物料采购?4.21Are purchase orders made available to incoming inspection? 对于来料检验是否有对应的采购订单?4.22Are purchase orders supplied with documents defining what is to be purchased?书面订单是否充分已说明采购物料的规格/要4.23Is incoming material inspected upon receipt to assure conformance to requirements? 来料接收之前是否经过检验以确保符合要求?4.24Are written inspection instructions available for each item to be inspected?检验的每个项目是否有书面的检验指导书?4.25Are these instructions under document control? 指导书是否受4.26Are physical and chemical material test reports checked to assure conformance to specifications? 物理及化学物料测试报告是否被检查以确保物料符合规格?4.27Are records maintained of inspection results, including the cause of rejection?检验记录包括拒收原因是否有保存?4.28Is there any procedure used for the materials that are not subjected to inspection?对于免检材料,是否有相应的程序?4.29Does the supplier have a supplier performance rating system?是否有供应商等级评定系统?4.30Is the supplier rating system made available to the purchasing department?供应商等级评定系统在采购部门是否有效可用?4.31Does the incoming inspection department have adequate storage space to hold material until it is inspected? 来料检验部门是否有足够存储空间存放物料直至检验完成?4.32Is non-conforming material identified as such? 不良物料是否有标识?4.33Is non-conforming material held in a specific and controlled area until disposition can be made? 不良物料是否保存在特定的管制区直到不良物料处理完毕?4.34Is there ECO system to control the related production document?是否有使用ECO(工程变更指令)系统管制相关生产文4.35Is the raw material used in production tagged or identified? 是否所有用于生产的原材料都有标识?Are materials properly identified and controlled with the4.36Are materials properly identified and controlled with the inspection and test status throughout the manufacturing process?生产过程中所有物料/产品的检验和测试状态是否标识4.37Can raw material or components of a finished product be traced back to the manufacturer and receipt date? 成品的原材料及部件能否追溯到制造厂商及接收日期?4.38Are there appropriate documents used on production, such as process control plan, traveler/touting ticket, assembly instructions, inspection instructions, set-up instructions, test procedure, workmanship standard? 是否有适当的文件用于生产,如:工艺管制计划,工序记录单,生产指南,检验指南,设备设置指南,测试程序和工艺标准?4.39Are written inspection instructions/acceptance criteria available?书面的检验指导书/接收标准是否有有效可用?4.40Does the supplier have an in-process inspection function? 是否有制程检验职能?4.41Are process capability studies performed in production on a periodic basis to ensure process control? 是否有对生产定期进行工艺能力研究以确保过程受控?4.42Is there a statistical process control program defined for your operation?是否有统计技术SPC应用于生产和检验?4.43Does the supplier have final inspection function? 是否有最终产品检验职能?4.44Does the supplier have reliability function? 是否有信赖性测试职能?4.45Is sample inspection used? 是否使用抽样检验?4.46Are inspection records kept on file? 检验记录是否有存档?4.47Are records of inspection results used for corrective action purposes?检验结果记录是否用于纠正措施目的?4.48Is corrective action taken to prevent the recurrence of defective material?是否有纠正措施以防止不良品再次发生?4.49*Is there a documented procedure for control of nonconforming product?是否有不良品管制程序文件?4.50Are all defective products identified? 所有不良品是否有标识?4.51Are defective products segregated until disposition is made? 不良品在处置之前是否有隔离?4.52Are reworked products submitted for re-inspection? 返工品是否有重新检验?4.53Is there any appropriate procedure for the control of customer-supplied product?是否有适当的程序用于管制客户提供的产品?4.54Is there customer return goods policy/procedure? 是否有客退品处理程序?序号审核要素分数(0,1,2,NA)备注4.55Is there any method used to identify excessive customer returns?是否有方法用于识别过多客户退货?4.56Is there any method used to reduce customer returns? 是否有方法用于减少客户退货?4.57*Is there a documented closed-loop corrective action procedure?是否有文件化的纠正和预防措施程序?4.58Are packaging, storage, handling and labeling instructions available 是否有包装,存储,搬运和标识指南?4.59Is first-in/first-out practiced? 是否实施先进先出原则?4.60Are materials adequately packaged to prevent damage during handling and shipping?包装能否充分防止产品搬运中的破损?4.61Are cartons clearly identified as to contents? 包装箱内容标识是否清楚?4.62Where special packaging specifications are required, is this information readily available to production? 有特殊包装规格要求时生产部是否很容易了解到相关信息?4.63Are cartons containing perishable materials date-stamped? 易腐烂物品的包装箱是否有标识物料生产日期?4.64Are materials, which are subject to deterioration inspected periodically?易变质,退化的物料是否有进行周期性的检查?4.65Are materials removed if the expiration date has been reached?过期物料是否被移走?4.66Are aisles or storage areas clear of obstruction? 过道或存储区障碍物是否被清除?4.67Is material stored in such a manner that it presents no safety or fire hazard?物料是否保存在无安全和火灾危险的地方?-5.1Are methods established to collect customer satisfaction data?是否制定收集客户满意度信息的方法?5.2Are data analyzed and used to improve customer satisfaction?相关资料是否经分析并用于提高客户满意度?5.3Are customer complaint quickly reacted and the supply of parts Subtotal 本部分分数合计Percent 百分比5.0 Customer service, Customer satisfaction 客户服务/满意度secured?对顾客抱怨是否能快速反应并确保产品供应??5.4Is there a Cost of Quality reporting system? 是否有质量成本报告系统?Subtotal 本部分分数合计Percent 百分比。

EASTECH ELECTRONICS (HUI YANG) CO., LTDUL:CE :书面审查公司或子公司:传真:联系方式:东威审查方式现场审查交易年限:品质雇员:设计工程部:总雇员:直接雇员间接雇员:地址审查日期:公司信息公司名称:市:州/乡:邮编:电话:业务分类:主要产品:管理董事长:总经理:制造经理:品质经理:市场/销售经理:财务经理:资金月营业额:总付资金:总股东资金:库存/设施车间面积: _____平方米 ; _____% 占工厂库存周传额:設施條件:职员/设备当前生产量:2kk/day 制造部门:雇员:当前工厂规模:扩充计划:自动装配车间302kk/day 成型铆合车间302kk/day 注塑车间20主要生产设备: 大禹立式注塑机 伊之密卧式注塑机 高速冲床 金龟冲床 自动组装机 自动检验机主要检测设备: 荷重曲线测试仪 接触电阻仪 寿命测试仪 耐压测试仪 高温测试仪 回流焊机 硬度测试仪2kk/day主要分承包商:新城南电镀位置:浙江省乐清市经济开发区检验车间30其它:其它:认证备注:主要客户ISO-9001其它:公司名称:% 业务类型:电话号码 #:联络人:GREE工艺标准TCL 鼓励供货商取得经任命的第三方认证代理的质量体系认证.组织构架图文件确认/要求QA 手册设备清单程序VEASTECH ELECTRONICS (HUI YANG) CO., LTDEASTECH ELECTRONICS (HUI YANG) CO., LTDEASTECH ELECTRONICS (HUI YANG) CO., LTDEASTECH ELECTRONICS (HUI YANG) CO., LTDEASTECH ELECTRONICS (HUI YANG) CO., LTD。

供应商调查问卷说明:填写此份供应商调查问卷是我公司认同过程的一部分,也是贵公司成为我公司将来供应商的先决条件。

请尽可能详细完整地填写,并加盖贵公司公章,并在一周内完成返回给我们。

联系人:电话:传真:1. 产品通用名称:商品名称:批准文号:2. 供应商厂名:地址(街/市/省/邮编):电话/传真:主要联系人姓名/职位:主要联系人电话/传真:公司所有权性质:贵企业是否是一公司的子公司或分部?Yes口No口如果是,请标明公司名3. 工厂与质量负责人员联系方式请填写工厂、生产、质量保证/质量控制负责人姓名及其职位姓名职位联系电话/传真机电子邮箱4. 机构与标准贵公司是否具备药品生产许可并在有效期内?Yes口No口贵公司是否已经GMP认证并在有效期内?Yes口No口如有,标明最近的接受认证时间与授证号贵公司有多少员工从事生产操作?以上产品是否遵循官方标准,如:药典?Yes口No口如有,请写出标准名称产品的放行是否由质量管理部门完成?Yes口No口贵公司是否同意由我公司质量部代表审查贵公司工厂?Yes口No口贵公司是否同意提供产品法规文件的公开部分?Yes口No口5. 技术问题生产问题贵公司是否自己生产以上产品?Yes口No口如果不是,请把此问卷的复印件传给以上产品的制造商继续填写最近的1年至3年中,贵公司的名称,所有权性质,生产地址产品种类或主要的组织架构人员有过变更吗?Yes口No口如果有,请标明是什么时间与何时在你们的制造工厂是否生产或加工其他类产品?Yes口No口如果有,请标出产品名青霉素/头孢Yes口No口细胞毒素Yes口No口类固醇/激素Yes口No口其他危险/有毒物质Yes口No口如果是,采取何种手段避免交叉污染、混淆或标志错误?贵公司的产品是否在同一个工厂内生产?Yes口No口贵公司的产品生产是否使用同一条生产设备线?Yes口No口贵公司的产品/灌装设备是否专用?Yes口No口产品于何时开始商业生产?生产过程中是否用到从动物中获取的起始原料?Yes口No口如果是,是否采取措施以减少受动物传染病影响的风险?Yes口No口是否用到以化学物质/无机物为起始原料?Yes口No口是否用到以植物为起始原料?Yes口No口是否用到以生物制品为起始原料?Yes口No口是否所有生产用原料都建立了质量标准?Yes口No口是否对所有原料都进行了质量检验?Yes口No口是否具备原材料的合格供应商清单?Yes口No口是否保留样本?Yes口No口关键的生产与灌装设备是否经过确认?Yes口No口生产工艺是否经过验证?Yes口No口是否建立了设备的清洁程序?Yes口No口关键设施设备是否经过清洁验证?Yes口No口有何设备?关键设备是否建立了预防维修制度?Yes口No口生产用水是什么?水系统是否经过确认?Yes口No口水质是否定期进行监测?Yes口No口定期监测的周期是多久?厂房:厂房何时建造?是否对厂房的环境控制情况进行确认?Yes口No口生产区盒检测房间是否有清洁SOP?Yes口No口是否有限制进入的规定?Yes口No口质量保证:质量控制是否独立于生产?Yes口No口是否定期进行自检并保留相关的检查记录?Yes口No口是否会执行生产再加工或返工?Yes口No口是否对最终产品的包装/密封系统进行稳定性考察程序?Yes口No口产品是否始终遵循同一经注册的生产工艺/程序生产?Yes口No口若生产工艺有重大变更时贵公司是否会通知我公司?Yes口No口通常一批产品的批量是多少?是否确认了一批产品的均匀性?Yes口No口若果是,如何确认起均匀性的?有原料/包材产品送到工厂外实验室检验吗?Yes口No口是否每一批产品都按照规定的质量标准进行检验?Yes口No口在最终产品中是否存在任何溶剂残留?Yes口No口请标明品种名与处于的水平在最终产品中是否存在任何杂质?Yes口No口请标明品种名与处于的水平产品是否按程序提交微生物污染检测?Yes口No口是否能提供一特定批的检验报告书?Yes口No口是否定期对员工进行GMP培训?Yes口No口是否有GMP培训计划?Yes口No口是否有培训记录?Yes口No口是否定期对培训进行评估?Yes口No口是否建立更改控制程序以确保在生产工艺、分析方法、关键设备中发生变更均得到有效控制与记录?Yes口No口是否有超限结果调查(OOS调查)程序?Yes口No口是否有偏差处理程序?Yes口No口是否有纠正预防措施?Yes口No口是否有工业卫生程序(如厂房、设施、人员、衣服等)?Yes口No口是否有产品质量回顾程序?Yes口No口是否与GMP有关的数据经过电子记录与保存?Yes口No口如果是,该系统是否通过验证?Yes口No口质量控制原料是否均由合格供应商提供?Yes口No口产品检验是否根据规定的质量标准?Yes口No口是否建立了书面且经过批准的检验方法?Yes口No口是否该检验方法经过验证?Yes口No口验证方法是否满足ICH的要求?如(Q2A与Q2B)Yes口No口如果有重大变化,分析方法是否会重新进行验证?Yes口No口如分析方法有变化,贵公司是否会及时通知到客户?Yes口No口即使没有要求需要怎样做?是否有样品处理的书面程序?Yes口No口分析结果与计算是否经两人复合?Yes口No口是否由协议实验室进行分析检验?Yes口No口检验报告书是否能提供所有检验由该测试实验室完成,并且该检验与规定的标准相符合?Yes口No口证书及样品:是否能提供每批产品的检验报告书并且包含所有的分析数据?Yes口No口是否每批样品均保存留样?Yes口No口如果是,请提供存储期是否由QC出具检验报告书并经QA/QC批准?Yes口No口是否进行微生物检查?原料Yes口No口成品Yes口No口空气、墙面、机器/设备Yes口No口水Yes口No口人Yes口No口试剂:是否进行入厂检验?Yes口No口是否有合适的存放条件?(如温度)Yes口No口有效期是否固定?Yes口No口是否对存放环境及有限期进行监控?Yes口No口是否进行有效期的标志?Yes口No口分析仪器:是否经过确认?Yes口No口是否定期校验?Yes口No口是否定期进行维护?Yes口No口是否建立运行记录?Yes口No口是否建立清洁程序?Yes口No口是否有专人管理标准品?Yes口No口6. 包装及运输产品运输时的包装(类型与装量)是什么?每单位的净重:产品是否用垫仓板运输?Yes口No口若果是,请写明垫仓板的种类、尺寸与重量产品包装上是否写明:公司名称,产品名称,批号,净重?Yes口No口请列举一产品的批号,并解释(批编号)含义?请写明产品的有效期/复检期及贮存条件?贵公司是否还遵守其他特定的安全规范?Yes口No口如果有,请写明贵公司是否有特别的运输条件?Yes口No口如果有,请写明贵公司是否使用自己的运输车队?Yes口No口贵公司是否检查所使用的交通工具?Yes口No口请随此问卷附上贵公司的简介、产品质量标准与检测程序。

Business SurveyGENERAL BUSINESSOrganization and ManagementSupport Questions:1. Provide updated organization chart for your business including global organizations.∙Identify who would be designated to GEA account.∙Will they be fully dedicated or part-time?∙What is the tenure of the Engineering organization?∙Who is the ultimate owner of a project with GEA?2. Identify key staff members and responsibilities.3. Outline responsibilities of key staff relative to operation objectives.4. Does supplier have a centralized purchasing organization? No_____ Yes_____Explain:___________________________________________________________________Scoring:1. Limited organization with roles of key players not clearly defined. Company would have difficulty supporting a newprogram start-up without significant staffing and/or plant and equipment expenditures.3. Organization appropriate for scope of current business. Roles are clearly defined and key players have ability to leadcompany to current objectives. Company has ability to grow, but would have to expand staff and facilities toaccommodate.5. Organization is currently staffed to handle additional business. Roles are clearly defined and top positions are staffedwith leaders capable of successfully growing the company. Company is capable and willing to make expenditures to grow business.Comments/Deficiencies:____________________________________________________________________________________ ________________________________________________________________________________________________________ (Category Weight ____4_____) (Category Score__________) = Total Score __________ Operational GoalsSupport Questions:1 What is your company mission? Rank in priority order your company‟s key measurements (sales, availability, etc.,2. What are your current year business objectives?3. Compare current year objectives to historical performance.4. Discuss business reinvestment. Give examples of domestic and international reinvestment.5. Discuss your long term business strategy.6. Are there any outstanding legal issues facing your company that could potentially hamper your ability to supplyproduct under quoted circumstances?7. What countries outside the U.S. do you currently conduct business in?8. Does your company have a legal and policies compliance program?9. Do you use or have you ever used child, forced or prison labor in the manufacture of any products?10.Are there any outstanding regulatory or safety complaints still pending?Scoring:1. Key measurements are neither defined nor communicated beyond staff level. Individual roles andresponsibilities not defined to include accountability for meeting objectives. Goals are limited toshort term with little long term planning evident.3. Key measurements are defined and communicated to all levels, and there is clear accountability for allkey measurements. Long and short term strategic planning is part of total business plan.5. Key measurements are defined in detail and communicated and integrated into work plan of eachemployee. Progress to goals are updated on regular basis to entire business. Strategic long termgrowth is an important part of business plan.Comments/Deficiencies:____________________________________________________________________________________ ________________________________________________________________________________________________________ (Category Weight ____5_____) (Category Score__________) = Total Score _________IndustrySupport Questions:1. Describe your major competencies.2. What type of global competition do you have? Who are they?3. Who are major custo mers and what % of suppliers‟ business do they represent?4. Who are major countries/markets of distribution and what % of business does each represent?5. What are the brand names, market share, and average annual growth rate over the past five yearsfor major products sold in the United States?6. What is the market share for supplier‟s major channels of distribution?7. What is supplier‟s major new product and growth initiatives? (Line extensions, new lines/features/technologies)8. What are your plans to capitalize on these growth opportunities?9. What % of your sales is OEM/private label?10. Name OEM customers and length of time served.- Do you dedicate resources to serve these customers?Scoring:1. Business positioned to maintain small share of total market or niche business, with little funding for planningfor future growth or acquisition. Current product offerings provide limited growth potential.2. Business is positioned well relative to others in industry, although they may not be one of the key suppliers withinthe industry. Product line offerings could provide opportunities for future growth potential.5. Company is clearly an industry leader and accounts for an above average proportion of the total industry outputProduct line offerings are innovative and varied enough to assure their market place leadership.Comments/Deficiencies:____________________________________________________________________________________ ________________________________________________________________________________________________________ (Category Weight ____5_____) (Category Score__________) = Total Score __________ Program ExecutionSupport Questions:1. What major programs are currently underway in your facility?2. What was the last major program your company completed?How long from start to finish?3. What is your history for on-time, on-budget programs?4. Are there any other major programs currently under consideration by your company?5. Outline program management personnel and resources available for program implementation.1.Does supplier utilize a New Product Introduction (N.P.I.) process with scheduled technical and product reviews? Scoring:1. Company has not implemented a mid/major program in recent past. Resources would limit scopeof any program undertaking. GEA would have to lend considerable resources to be assured ofsuccessful implementation.3. Company has successfully implemented mid/major programs in recent past. Resources would limitPrograms to small or mid-sized. GEA would require a detailed implementation plan along withcorrective action program before business could be awarded.5. Company successfully implements mid/major programs on a continuing basis. Resources are eitheravailable or could be obtained to assure successful execution of program. GEA‟s resource involvementwould be limited primarily to program management interface.Comments/Deficiencies:____________________________________________________________________________________ ________________________________________________________________________________________________________ (Category Weight ____5_____) (Category Score__________) = Total Score __________ Customer InterfaceSupport Questions:1. Who are your major customers? Break down sales % by customer.2. How do you service your key customer accounts?3. Do you measure each customer on a separate profit and loss (P&L) statement?4. Do your customers measure you? How?5. How do you measure yourself?6. Give examples of current reports and company performance.7. Do you track the following data internally?a. On-time shipsb. Availability by productc. After-market parts availabilityd. SCR trackingScoring:1. Company works primarily through blanket orders and has minimal contact with customer and supplier base.Quality, delivery and/or other issues are generally reactively handled on case by case basis.3. Company employs a representative who, as the primary customer contact. Personally handles most quality,delivery or customers questions. The representative will involve his plan resources on an as needed basis.Customer/supplier relationships are recognized as being important and are handled in a professional and amiablemanner.5. Customer satisfaction is a key operational objective, and Company has systems in place to measure customerapproval as well as supplier performance. Company has established programs that proactively address customersatisfaction as well as supplier performance.Comments/Deficiencies:____________________________________________________________________________________ ________________________________________________________________________________________________________ (Category Weight ____3_____) (Category Score__________) = Total Score __________Pricing - Also see ‘Productivity’ in Technology sectionSupport Questions:1. Are you willing to share your cost structure with your customers?2. What types of productivity or cost savings programs do you engage in?3. Do you pass on cost savings to your customers?4. Describe the size, organizational structure, and role of your purchasing department.5. What are your primary goals and objectives of your purchasing department and how is it measured?6. What are the qualifications of the personnel in the purchasing department?7. Describe your deflation/cost savings history during the past few years.8. Supply pricing history on several core models.Scoring:1. The current structure and strategy of the company does not support being a low cost producer.3. Company goals include productivity and cost saving initiatives, but efforts are not fully maximized.5. The company aggressively pursues productivity and costs saving initiatives internally and with their supply base byproviding the structure and training to accomplish.Comments/Deficiencies:____________________________________________________________________________________ ________________________________________________________________________________________________________ (Category Weight ____4_____) (Category Score__________) = Total Score __________QUALITYManagement & GoalsSupport Questions:1. What are the Corporate Quality Objectives? How are they communicated to all employees?2. How is Quality Department organized? (See organization chart from General Business Survey)∙Is Quality department organization well defined/functionally sound?∙Are there good lines of responsibility among all functions?∙Who has key contributor expertise and experience?3. What are Quality Goals for the business? Are they documented? Are they challenging?4. What is Service Call Rate (SCR) goal for products?5. What is the SCR for products shipped to the United States?6. What is the SCR of products shipped within the country where products are manufactured?7. How is SCR determined/calculated?8. Is there a long term strategy to achieve SCR goals?9. Has a 6 sigma philosophy been incorporated into new designs and used for problem solving and to identifyopportunities?10. Is there a 6 Sigma movement in the business?11. What level of involvement does the management team have in dealing with quality issues?12. Are quality costs tracked?Scoring:1. Quality organization in place, but there is no evidence of authority, vision, or a strong relationship to businessmeasurements3. Appropriate quality goals in place but the organization is largely inexperienced or not fully staffed. Management iscommitted but resources are not available for needed upgrades.5. Well defined goals and measurements in place; field data and quality costs are understood, acted on, and measured Comments/Deficiencies:____________________________________________________________________________________ ________________________________________________________________________________________________________ (Category Weight ___5____ ) ( Category Score _________) = Total Score __________Planning & DocumentationSupport Questions:1.Is there a comprehensive Quality Manual? Is latest revision up-to-date?2.Is it accessible to all employees, and approved by upper management?3.Are there detailed quality instructions posted at the work stations in the appropriate language?4.Is this facility ISO Approved? 9001? 9002? 9003?5.Is this facility approved by another GE business?6.Who reviews contracts prior to acceptance to ensure customer requirements are understood?∙Evaluate ability of personnel to interpret and communicate in English?∙Evaluate ability of personnel to communicate to GEA? Cross functionally?∙Does sales organization interface with Design Engineering? Manufacturing?7.Are quality plans developed for each product? Who has responsibility?8.Are critical specifications and characteristics identified and control plans developed?9.Are critical processes identified and quality plans developed to 6 sigma process capability?Scoring:1. Quality manual exists but is not complete or primarily covers policies not procedures that can be executed. Minimalquality planning evident.3. Quality manual is well documented but there is little evidence of quality planning in the system and process controlsare not covered adequately.5. Manual is well documented and followed. Quality system includes quality planning, process control, auditing, andreliability testing.Comments/Deficiencies:____________________________________________________________________________________________________________________________________________________________________________________________ (Category Weight ___5___) (Category Score ________) = Total Score _________Change Control/ProceduresSupport Questions:1. What is product specification change procedure? Who is responsible? Is it documented?2. What is process for change control in factory?3. Who physically changes documents or computer files? Is there a master file?4. How are manufacturing drawings and specifications controlled to the latest revision?5. Who insures drawings and specifications from their suppliers are to the latest revision?6. If Engineering and Sales organizations are located in another city/country, how are changes controlled?Scoring:1. There is no formal change control procedure and factory processes do not sufficiently document3. Change procedures for internal changes and drawings only. Suppliers not controlled.5. Well defined process for handling drawing, process, and material changesComments/Deficiencies:____________________________________________________________________________________________________________________________________________________________________________________________ (Category Weight ____5_____) (Category Score __________) = Total Score __________Process Control & Statistical Process ControlSupport Questions:1.List Major in-process inspections/tests∙Do process control plans include acceptance criteria? Characteristic Instrume (Refer to appropriate Product specific survey) ______________________________________________________________________2. Are process instructions and equipment calibration procedures posted at appropriate locations?3. What is the procedure to adjust process equipment between model changes?4. What is the procedure to adjust test/measurement equipment between model changes?5. Are control plans developed and maintained to monitor process outputs?∙Sub-assemblies?∙Finishes?∙Major fabrication?∙Primary assembly and test?6. Do the control plans include:∙Critical-to-quality characteristics? Who is responsible for monitoring?∙Frequency?∙What type of measurements? Type gages used?∙Data recorded? Stat6. Have short and long term capability studies been performed?7. Are assignable cause variations investigated and corrected? Who has responsibility?8. Are appearance standards in place? Is lighting adequate for inspection?9. Are station aids used at CTQ and complex operations?Scoring:1. Ineffective process control system with no understanding or use of SPC.3. Adequate process control techniques in place. Operators understand and work to station instructions.5. Extensive evidence of effective use of statistical control of critical processes. SPC charts being utilized.Comments/Deficiencies:____________________________________________________________________________________________________________________________________________________________________________________________ (Category Weight ____5_____) (Category Score __________) = Total Score __________MetrologySupport Questions:1. Is there a documented gage calibration program?2. Is inspection, measurement, and test equipment capable of the required accuracy/precision?∙Measure at increments 1/10 of tolerance minimum?∙Are gages stored and handled to protect accuracy and fitness for use?3. Are gage R&R (repeatability and reproducibility) studies performed?∙What percent of tolerance is considered acceptable?4. Are calibration records complete for production test equipment?Instrument/TesterLocation?Frequency?__________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ ___________________________________5. Have appropriate actions been taken when measuring and test equipment is found to be out of calibration?∙Have previous test results been checked for validity?∙Is upstream material held for retest?∙Customers notified if suspect material has been shipped?6. Is there a documented gage maintenance program?Scoring:1. Inspection, measurement, and test equipment are not capable of required accuracy/precision and are not calibratedregularly.3. Inspection, measurement, and test equipment are capable of the required accuracy/precision, but documentation andconsistency lacking in some instances.5. Inspection, measurement, and test equipment are capable of the required accuracy/precision and are strictlymonitored and changed as appropriate. Gages and instruments are scheduled for calibration and acceptance R&Rstudies are performed and on file.Comments/Deficiencies:____________________________________________________________________________________________________________________________________________________________________________________________ (Category Weight___5____) (Category Score _________) = Total Score ________Corrective Action / Problem SolvingSupport Questions:1. Is control provided for identification, documentation, evaluation, segregation and disposition of in-process non-conforming product?2. Is non-conforming finished product impounded? Is the customer notified?3. Does written formal procedures exist for problem solving that defines the problem and root cause?4. Do corrective actions have date of temporary fix, permanent fix, and owner?5. Are corrective and preventative actions reviewed by management and the customer?6. How does the Quality organization monitor long term issues - failures from 1-10 years?7. How is field failure information accumulated, including repairs, defective parts, application, and installation?Scoring:1. Little formal procedures exist for corrective actions to resolve problems or control non-conforming material.3. Procedures exist and responsibility assigned, but follow through apparently lacking. Minimal field failure information.5. Formal problem solving and corrective action process is used with containment action, defining root cause, verifyingcorrective action and system changes. Field failure data is obtained and acted on.Comments/Deficiencies:____________________________________________________________________________________________________________________________________________________________________________________________ (Category Weight ____5_____) (Category Score ___________) = Total Score __________Outgoing Quality AssuranceSupport Questions:1. What tests are performed after final assembly? (Refer to appropriate Product specific survey)2. Is there an end-of-the-line audit for products? Characteristics measured? Frequenc∙Safety tests?∙Functional tests?3. Is there a grading system? Describe?4. Is product performance tested by lot? Is data provided to the customer?5. Is product life tested or “stress” tested on a scheduled basis?What tests are performed?6. Is a appearance standards board/room maintained to compare outgoing product versus established standards?Scoring:1. In-line and audit testing are inconsistent and do not ensure 100% function or safety.3. Product is tested 100% in-line for basic functions, but critical characteristics are not formally audited.5. Product is 100% tested in-line, critical tests and consumer cues are audited by sample plan, and product performanceis tested per GEA requirements.Comments/Deficiencies:____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________ (Category Weight ____5_____) (Category Score __________) = Total Score __________Personnel/TrainingSupport Questions:1. What is average factory personnel turnover rate?2. What is minimum educational level for factory personnel? Average?3. What is the training process for new personnel? Hours? TypeTraining?4. Who is responsible to ensure training is documented, accurate, complete, and up-to-date?5. Are there any factory Quality Awareness Programs? Quality Circles?6. Is there a training program for quality personnel?∙Type training? SPC? Scoring:1. Minimal …on job training‟ with limited or no supervision3. Good …on job training‟ with supervision and experienced operators, but little formal quality/gage instruction.5. Formal and mandatory training program in company policies/procedures and normal and specialized job training.Comments/Deficiencies:____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________(Category Weight ____5_____) (Category Score __________) = Total Score __________PRODUCTION SUPPORTInventory ManagementSupport Questions:1. How is inventory measured and tracked? How is it controlled?2. How is schedule attainment measured?3. How many days of RIP (raw, in-process) and finished goods inventory are carried?4. What is the supplier‟s capability to inventory finished goods? How many units?Location?5. What is the supplier‟s capability to inventory components? Quantify.6. What is supplier‟s inventory turns?How are turns calculated?7. What is supplier‟s willing to consign finished inventories at customer‟s location? Is this a current practice?8. How is Materials Department organized? (See organization chart from General Business Survey)9. What training is provided for materials personnel?What type experience or certification is required? e.g. APICS -American Production Inventory Control Society.Scoring:1. Minimal inventory control processes and inability to inventory finished products, minimal manpowerand inventory management focus.3. Inventory control processes being used, some capability to inventory finished products, sufficientstaffing and focus on inventory management.5. Inventory control processes in place and fully utilized, highly capable of storing and managing finished goodsinventories, well organized staffing with focus on meeting business objectives.Comments/Deficiencies:____________________________________________________________________________________ ________________________________________________________________________________________________________ (Category Weight ____5_____) (Category Score__________) = Total Score __________ Scheduling/Quick ResponseSupport Questions:1. What procedures/processes and systems are used to schedule your manufacturing facility? What is the frequency ofschedule updates? What software packages are used?2. Does the supplier have Electronic Data Interchange (EDI) and Internet capability? If yes, what is it used for? If not,are plans in place to implement?3. Does supplier understand which components, materials, subassemblies, and manufacturing processes restrict theirflexibility to respond to customers mix and volume changes?∙What are issues and what actions are being taken to address them?∙Are safety stocks carried - provide any studies performed.4. What is the supplier‟s customer on-time fill rate (quantity ordered versus quantity shipped)?5. What is supplier‟s customer on-time delivery (order date versus date product received)?6. How flexible is supplier‟s factory?a. What is supplier‟s manufacturing cycle time for products?b. What is supplier‟s response time to make product volume or mix changes after notification?c. How often does supplier cycle product? Daily, weekly, monthly?6. How is obsolescence controlled and measured?Scoring:1. Scheduling performed manually with no use of material systems, Electronic Data Interchange (EDI), or the Internet. Limitedunderstanding of issues restricting flexibility or capability to correct. Not capable of meeting customer needs.3. Material systems, Electronic Data Interchange (EDI), and the Internet being used adequately. Supplier plant isreasonably flexible and issues impacting are understood, but only limited actions are taken. Customers needs metfrequently.5. Highly proficient and evident use of material systems, Electronic Interchange Data (EDI), and the Internet. Supplier‟sfactory is flexible and issues impacting are fully understood and proactively addressed. Customers needs fully met.Comments/Deficiencies:____________________________________________________________________________________ ________________________________________________________________________________________________________(Category Weight _____5____) (Category Score __________) = Total ScoreFacility/Equipment/Layout/CapacitySupport Questions:1.What are the primary processes performed in supplier‟s factory - e.g. assembly, metal fabrication, injection molding2.What waste, practices, and inefficiencies are evident when walking the flow of the plan from incoming materialsto outgoing product shipments?3. How would you rate the layout, cleanliness, lighting, and work environment of the plant?4. What expansion capabilities does the supplier have?5. Does supplier have any current plans to expand or upgrade the manufacturing facility?6. Does supplier have any plans to purchase or upgrade equipment? Why and when?7. Would products from other customers impact su pplier‟s ability to support GE production needs, e.g. seasonalproducts.8. Does the supplier have a documented capacity plan which includes overtime capability and supplier and internallimitations?9. What is the annual capacity of the manufacturing facility and what is currently being utilized?10. What is the typical age and condition of supplier‟s equipment, fixturing, and tooling?11. How much of supplier‟s production capacity would be allocated to GE?12. Has the supplier identified and formalized tooling, equipment, and labor constraints relative to capacity? Is a plandeveloped in the event additional capacity is needed?13. How many days/week and shifts do assembly and support operations work?14. Does supplier have a formalized and comprehensive preventative maintenance program? Are records kept onmaintenance, repairs, and modifications?Scoring:1. Inefficient plant layout with poor material and process flow and cleanliness. Limited understanding of factorsrestricting production and no contingency plans to address increased or spiked demands from customers. Lack ofpreventative maintenance reflected in tools and equipment condition.3. Plant layout and material/process flow adequate. Understand factors effecting production and generally have someplans in place to respond to changing customer volumes, although not always timely. Preventative maintenanceroutines in place and tools and equipment in acceptable condition.5. Upgrade or new facility with state-of-the-art and efficient material/process layout and flow. Excellent lighting,cleanliness, and work environment. Supplier thoroughly understands and documents factors restricting productionand actively works issues. Contingency plans are in place to quickly respond to changing customer volumes. Welldocumented preventative maintenance program that is strictly adhered to results in tools and equipment being in likenew condition.Comments/Deficiencies:____________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________(Category Weight ____5_____) (Category Score __________) = Total Score __________ToolingSupport Questions:1. Who is responsible for managing all tooling activities?2. Does supplier design and build its own tooling or purchase from external suppliers? What type tooling does supplierbuild?3. How many tool designers and builders does supplier employ? What are their qualifications?。