SQA Manual P2104 edition 7 - July 2005 (Chinese)

- 格式:doc

- 大小:918.00 KB

- 文档页数:30

日本JIS认证目录JIS标准1JISA0001-1999基本模数JISA0002-1999建筑模数术语JISA0003-1999建筑构件的公差JISA0004-1999建筑模数的配合原则JISA0005-1966建筑物开口部构件标准公称尺寸JISA0006-1966建筑用板的标准尺寸JISA0007-1967建筑用铁制框架墙壁构件的标准公称尺寸JISA0008-1967建筑用铁制框架屋顶构件的标准公称尺寸JISA0009-1970建筑物活动隔墙构件的公称尺寸JISA0012-1980住宅卫生设备的模数组合尺寸JISA0013-1980住宅壁式厨房设备的模数组合尺寸JISA0014-1976住宅空调设备的模数组合尺寸JISA0015-1976住宅管道系统的模数组合尺寸JISA0016-1979贮藏组合间墙内容纳机器空间的模数协调尺寸JISA0017-1998厨房设备.组合尺寸JISA0018-1992住宅配套设备单元的模数协调尺寸JISA0030-1994建筑构件性能的分类JISA0101-1994土木工程制图通则JISA0150-1999建筑制图通则JISA0151-1961门、窗符号JISA0201-1971建筑用室内外装饰材料术语JISA0202-2000隔热.词汇JISA0203-1999混凝土术语JISA1101-1998混凝土塌落度的试验方法JISA1102-1999集料的筛分试验方法JISA1103-1997集料的75mm筛选试验方法JISA1104ERRATUM1-2000集料的单容重和集料实积率的测定方法(勘误1)JISA1104-1999集料的单容重和集料实积率的测定方法JISA1104-1999/ERRATUM1-2000集料的体积密度和集料中固体含量的试验方法(勘误1)JISA1105-2001细集料中有机杂质的试验方法JISA1106-1999混凝土弯曲强度的试验方法JISA1107-1993混凝土钻芯样和截梁试样的采取及其试验方法JISA1108-1999混凝土抗压强度的试验方法JISA1109-1999细集料的比重及吸水率的试验方法JISA1110-1999粗集料的比重及吸水率试验方法JISA1111-2001细集料表面湿度的试验方法JISA1112-1997新浇混凝土的筛洗分析方法JISA1113-1999混凝土抗张强度的试验方法JISA1114-1993使用弯曲折断梁块测定混凝土抗压强度的试验方法JISA1115-1998新浇混凝土的取样方法JISA1116-1998新浇混凝土的容重和空气含量的试验方法JISA1118-1997容积法测量新浇混凝土中空气含量的试验方法JISA1119-1998新搅拌混凝土中成分变化率的试验方法JISA1120-1976用德威尔试验机作粗集料的磨损试验方法JISA1121-2001用洛杉矶试验机测定粗集料耐磨性的试验方法JISA1122-1998使用硫酸钠的集料稳定性试验方法JISA1123-1997混凝土泌水的试验方法JISA1125-2001干燥法测定集料的含水总量及表面湿度的试验方法JISA1126ERRATUM1-2001用划痕试验进行粗集料中软质颗粒含量的试验方法(勘误1)JISA1126-2001划痕法测定粗集料中软质颗粒含量的试验方法JISA1127-2001混凝土的动态弹性模量、动态刚性及动态泊松比的共振试验方法JISA1128-1999测定新浇混凝土空气含量试验方法(压力法)JISA1129-1-2001灰浆和混凝土长度变化的试验方法.第1部分:比较器法JISA1129-1993灰浆和混凝土长度变化的试验方法JISA1129-2-2001灰浆和混凝土长度变化的试验方法.第2部分:接触型应变仪法JISA1129-3-2001灰浆和混凝土长度变化的试验方法.第3部分:千分表法JISA1132-1999混凝土样品制备和加工方法JISA1134-1999结构混凝土用轻细集料的吸水率和颗粒密度的试验方法JISA1135-1999结构混凝土用轻粗集料的吸水率和颗粒密度的试验方法JISA1136-1993用离心捣固法浇制的混凝土的抗压强度试验方法JISA1137-1998集料中粘土块含量的试验方法JISA1138-1998实验室内混凝土试样的制作方法JISA1139-1993混凝土立方试件双轴向抗压试验方法JISA1140-1978钢筋混凝土雨水槽和污水槽抗压强度的试验方法JISA1141ERRATUM1-2001集料中密度低于1.95g/cm*3的粒子的试验方法(勘误1)JISA1141-2001集料中密度低于1.95g/cm*3的粒子的试验方法JISA1142-2001用灰浆抗压强度测定细集料中有机杂质含量的试验方法JISA1143ERRATUM1-2001对轻粗集料中漂浮粒子含量的试验方法(勘误1)JISA1143-2001对轻粗集料中漂浮粒子含量的试验方法JISA1144-2001新浇混凝土水中氯化物浓度的试验方法JISA1145-2001用化学方法测试集料碱硅反应性的试验方法JISA1146ERRATUM1-2001用灰浆棒法测试集料碱硅反应性的试验方法(勘误1)JISA1146-2001用灰浆棒法测试集料碱硅反应性的试验方法JISA1147-2001用耐渗透性测试混凝土混合物固结时间的试验方法JISA1148-2001混凝土耐冻结性和耐融化性的试验方法JISA1149-2001混凝土的静态弹性模量测试方法JISA1150-2001混凝土的坍落流试验方法JISA1161-1994多孔混凝土的体积比重、含水率、吸水率及抗压强度的试验方法JISA1162-1973多孔混凝土长度变化的试验方法JISA1171-2000聚合物改良水泥砂浆的试验方法JISA1172-1995聚合物改良水泥砂浆强度的试验方法JISA1173-1978聚合物水泥砂浆塌落度的试验方法JISA1174-1978新浇聚合物改良水泥砂浆的单容重量试验方法和空气含量的试验方法(重量方法)JISA1181-1978强度试验用聚酯树脂混凝土试样的制备方法JISA1182-1995聚酯树脂混凝土抗压强度的试验方法JISA1183-1995用弯曲断梁测定聚酯树脂混凝土抗压强度的试验方法JISA1184-1995聚酯树脂混凝土抗弯强度的试验方法JISA1185-1995聚酯树脂混凝土抗拉强度的试验方法JISA1186-1995聚酯树脂混凝土凝固时间的测定方法JISA1201-2000土质试验用土壤试样的制备方法JISA1202-1999土壤颗粒密度的试验方法JISA1203-1999土壤含水量的测定方法JISA1204-2000土壤粒度分布的试验方法JISA1205-1999土壤液体极限与塑性极限试验方法JISA1207-1990土壤离心含水当量的试验方法JISA1209-2000土壤收缩系数的试验方法JISA1210-1999捣固后土壤的夯实试验方法JISA1211-1998实验室内土壤的加利福尼亚承载比试验方法JISA1214-2001土壤密度的砂置换试验方法JISA1215-2001道路土壤的平面荷载测试方法JISA1216-1998土壤无侧限抗压的试验方法JISA1217-2000土壤压实试验方法JISA1218-1998土壤饱水渗透率的试验方法JISA1219-2001标准浸入试验方法JISA1220-2001荷兰式双重管圆锥浸入试验方法JISA1221-1995瑞典式加重测深试验方法JISA1222-2001现场土壤的加里福尼亚洲式承载率(CBR)试验方法JISA1223-2000土壤中细粒部分含量的试验方法JISA1224-2000沙中最小和最大密度的试验方法JISA1225-2000土壤的散装密度的试验方法JISA1226-2000土壤灼烧损伤的试验方法JISA1227-2000土壤单维固结特性的试验方法JISA1228-2000压实土壤的锥形指数的试验方法JISA1301-1994建筑物木结构部分的防火试验方法JISA1302-1994建筑物不燃烧结构部分的防火试验方法JISA1304-1994建筑构件的耐火试验方法JISA1306-1983用消光法测定烟浓度的方法JISA1311-1994建筑用防火门的防火试验方法JISA1312-1959屋顶的防火试验方法JISA1313-1995卷帘式防火铁门的检查标准JISA1314-1992火炉调节闸板防烟试验方法JISA1321-1994建筑物的内部装修材料及施工方法的不燃性试验方法JISA1322-1966建筑用细薄材料的不燃性试验方法JISA1323-1995建筑工程中焊接及切割火花对薄板的不易燃性试验方法JISA1324-1995建筑材料中水蒸发及渗透的测量方法JISA1325-1995建筑材料的热膨胀系数的测量方法JISA1400-1998散热器、对流式供暖器和类似设备.性能试验方法JISA1401-1963瓦工用水泥砂浆试验方法JISA1402-1977供暖用铸铁散热器和钢板散热器辐射效率的试验方法JISA1404-1994建筑用水泥防水剂的试验方法JISA1405-1998声学.阻抗管中吸音率和阻抗的测定.驻波系数法JISA1406-1974室内通风量的测定方法(二氧化碳法)JISA1407-1994地板滑度的试验方法(摆动式)JISA1408-2001建筑用板的弯曲和冲击试验方法JISA1409-1998混响室中测量吸音率的方法JISA1410-1968塑料建筑材料的风化试验方法JISA1411-1968塑料建筑材料老化的评定方法JISA1412-1-1999隔热保温材料的导热系数测定方法JISA1412-2-1999隔热保温材料的导热系数测定方法,第2部分:热流计设备JISA1412-3-1999热绝缘材料的热阻和相关特性的试验方法.第3部分:循环管设备JISA1414-1994建筑构件板性能的试验方法JISA1415-1999聚合物建筑材料暴露于试验室光源的方法JISA1416ERRATUM1-2000声学.建筑部件隔音的实验室测量方法(勘误1)JISA1416ERRATUM2-2000声学.建筑部件隔音的实验室测量方法(勘误2)JISA1416-2000声学.建筑物元件的气载声音隔绝的实验室测量方法JISA1416-2000/ERRATUM1-2000声学.建筑物元件的气载声音隔绝的实验室测量方法(勘误1)JISA1416-2000/ERRATUM2-2000声学.建筑物元件的气载声音隔绝的实验室测量方法(勘误2)JISA1417ERRATUM1-2000声学.建筑物隔音的现场测量(勘误1)JISA1417-2000声学.建筑物的气载声音隔绝的现场测量JISA1417-2000/ERRATUM1-2000声学.建筑物的气载声音隔绝的现场测量(勘误1)JISA1418-1ERRATUM1-2000声学.建筑物的楼板撞击声音绝缘的测量.第1部分:使用标准轻型撞击源的方法(勘误1)JISA1418-1-2000声学.建筑物的楼板冲击声音隔绝的测量.第1部分:使用标准清型冲击源的的方法JISA1418-1-2000/ERRATUM1-2000声学.建筑物的楼板冲击声音隔绝的测量.第1部分:使用标准轻型冲击源的的方法(勘误1)JISA1418-1995建筑物地板冲击声级的现场测定方法JISA1418-2ERRATUM1-2000声学.建筑物的楼板撞击声音绝缘的测量.第2部分:使用标准重型撞击源的方法(勘误1)JISA1418-2-2000声学.建筑物的楼板冲击声音隔绝的测量.第2部分:使用标准重型冲击源的的方法JISA1418-2-2000/ERRATUM1-2000声学.建筑物的楼板冲击声音隔绝的测量.第2部分:使用标准重型冲击源的的方法(勘误1)JISA1419-1-2000声学.建筑物和建筑元件内声音隔绝的比率.第1部分:气载声音隔绝JISA1419-1992建筑物隔音等级JISA1419-2-2000声学.建筑物和建筑元件内声音隔绝的比率.第2部分:楼板冲击声音隔绝JISA1420-1999稳定状态热传输特性的测定.热盒方法JISA1422-1993测定遮阳装置遮阳系数的简易试验方法JISA1423-1983利用红外线放射温度计测定放射率的简易试验方法JISA1424-1-1998给水设施噪声的实验室试验方法.第1部分:测量方法JISA1424-2-1998给水设施噪声的实验室试验方法.第2部分:排放旋塞和混合阀的安装和操作条件JISA1425-2000太阳能聚集器的热性能试验方法JISA1426-1995太阳能蓄热槽的蓄热性能试验方法JISA1431-1994空调和通风系统的风量测量方法JISA1432-1995涂覆隔热材料的管路热性能测定法(热水循环程序)JISA1435-1991建筑用外壁材料的耐冻性试验方法(冻结融解法)JISA1436-1991建筑用被膜状材料的底层不连接部耐疲劳性试验方法JISA1437-1992建筑用内部装修板类的耐湿性试验方法JISA1438-1992建筑用外壁板类的耐水性试验方JISA1439-1997建筑物封焊和门窗玻璃用密封剂的试验方法JISA1440-1997用固态标准地板上地板覆盖物对TAPAAING机发射冲击声波衰减的实验室测量JISA1450-1997提高的通路地板部件试验方法JISA1451-1994建筑材料及建筑构件的磨耗试验方法(采用回转圆盘磨擦与冲击地板材料的磨耗试验方法)JISA1452-1972建筑材料及建筑构件的磨耗试验方法(落砂法)JISA1453-1973建筑材料及建筑构件的磨耗试验方法(砂纸法)JISA1454-1998试验方法.弹性地板覆盖物JISA1460-2001建筑板的甲醛辐射的测定.干燥器JISA1510-1-2001建筑物门配件的试验方法.第1部分:锁和插销JISA1510-1995销的试验方法JISA1510-2-2001建筑物门配件的试验方法.第2部分:门的配件JISA1510-3-2001建筑物门配件的试验方法.第3部分:暗式关门装置、关门装置和铰链关门装置JISA1511-1995门用合叶的试验方法JISA1512-1995门用合叶(铰链)及闭合器性能的试验方法JISA1513-1996门具和窗.试验方法通则JISA1514-1993防止门、窗结露的试验方法JISA1515-1998窗和门组件.风阻力试验JISA1516-1998窗和门组件.气密性试验JISA1517-1996高压力下门具、窗的水密性试验JISA1518-1996门具的耐砂袋冲击试验JISA1519-1996门具、窗的开关力的测定JISA1520-1988门和窗的隔声现场测量方法JISA1521-1996门具在静荷载力下的对角变形试验JISA1522-1996门窗扇框架的机械变形试验JISA1523-1996门具的静扭转试验JISA1524-1996门具的垂直负荷试验JISA1525-1996门具的重复性开关试验JISA1526-1997门的术语JISA1527-1997门叶.一般平整度的缺陷测量JISA1528-1997门叶.尺寸和垂直度缺陷的测量JISA1529-1997门具.静荷载试验JISA1531-1998家具.表面抗冷液体的评估JISA1550-2000门.重复开关试验JISA1551-1995自动门系统的试验方法JISA1611-1996木砖粘合剂及其中的胶接接头粘合强度的试验方法JISA1612-1996墙和天花板的粘合剂及其中的胶接接头粘合强度的试验方法JISA1701-1994游乐设施(滑坡有轨车)的检查标准JISA1702-1976住宅内设备尺寸的试验方法通则JISA1703-1976住宅内设备维修更换时的工作空间试验方法通则JISA1704-1994住宅内设备渗漏试验方法JISA1705-1976住宅内设施排水试验方法JISA1706-1994住宅内燃烧装置安全性试验方法JISA1707-1994住宅内设备振动的试验方法JISA1708-1994住宅内设备噪声的测定方法JISA1709-1994住宅内设备强度和耐久性的试验方法JISA1710-1994住宅内设备保温绝热性能的试验方法JISA1711-1976住宅内设备电绝缘性能的试验方法JISA1712-1994住宅卫生设备防潮和防水性能的试验方法JISA1713-1994评定住宅空调附属设备的热水供应能力的试验方法JISA1714-1995游乐设施(观览车)的检查标准JISA1715-1995游乐设施(飞行车)的检查标准JISA1716-1995游乐设施(滑水撬板)的检查标准JISA1717-1995游乐设施(旋转木马)的检查标准JISA1718-1994浴池管的试验方法JISA1801-1989混凝土生产控制用试验方法.混凝土用细集料砂当量试验法JISA1802-1989混凝土生产控制用试验方法.细集材的表面含水率的离心力试验法JISA1803-1991混凝土生产管理用试验方法-粗集料的表面含水率试验方法JISA1804-2001混凝土生产管理用试验方法.集料碱性反应性识别的快速试验方法JISA1805-2001混凝土生产管理用试验方法.热水养护法测定混凝土压缩强度的快速试验方法JISA3301-1993木结构校舍构造的设计标准JISA3302-2000建筑物内用废水净化器的人口的估计JISA3304-1994活动房屋结构设计标准JISA4001-1975采暖用铸铁散热器JISA4002-1989带存水弯的地面排水管JISA4003-1995燃油暖风供暖设备JISA4004-1998散热器、对流供暖器和类似设备.定义、分类和要求JISA4006-1994热水锅炉用贮水器JISA4007-1995风扇式对流换热器JISA4008ERRATUM1-2000通风装置(勘误1)JISA4008-1995冷风机装置JISA4009-1997空调管廊部件JISA4101-1994抽水马桶用玻璃纤维增强塑料制污物处理装置结构件JISA4110-1989玻璃纤维增强聚酯造整体式水箱JISA4111-1997住宅用太阳能热水器JISA4112-1995太阳能收集器JISA4113-1995太阳能储热槽JISA4201-1992建筑物避雷装置(避雷针)JISA4301-1983电梯轿厢及井道的尺寸JISA4302-1992电梯、自动扶梯、轻型运货电梯的检查标准JISA4303-1994排烟装置的检查标准JISA4401-1994梳妆台JISA4410-1995住宅用综合卫生间JISA4412-1994住宅用空调设备JISA4413-1991住宅用管道系统JISA4414-1998住宅用贮藏隔板元件JISA4416-1995住宅用浴室设备JISA4417-1995住宅用厕所设备JISA4418-1995住宅用洗手间设备JISA4419-1991浴室用防溢水盆JISA4420-1998厨房设备部件JISA4421-1991室内设备用带存水弯的排水管JISA4422-1992带座浴用水冲洗器的马桶座圈JISA4601-1973木制夹板门JISA4602-1973木制双槽推拉玻璃门JISA4603-1973木制套窗JISA4702ERRATUM1-2000门装置(勘误1)JISA4702-2000门装置JISA4704-1998建筑物用轻质卷帘式百叶门部件JISA4705-1998建筑物用卷帘式百叶门部件JISA4706ERRATUM1-2000窗(勘误1)JISA4706-2000窗框JISA4709-1993滑动铝合金窗用纱窗JISA4710-1996门具和窗的隔热试验JISA4712-1986住宅用钢制及铝合金制正门门具JISA4713-1993住宅用金属套窗JISA4714-1995硬质聚氯乙烯内窗窗框JISA4715-2002分段式升降门的元部件JISA4801-1991钢及铝合金制软百窗JISA4802-1994挂窗帘用的金属导轨横杆JISA4902-1994住宅用金属防火套窗JISA5001-1995铺路用碎石JISA5002-1999结构用轻质混凝土集料JISA5003-1995石材JISA5005-1993混凝土用碎石JISA5006-1995毛石JISA5007-1977珍珠岩JISA5008-1995沥青铺路混合料用石灰石填充料JISA5009-1972蛭石JISA5011-1-1997混凝土用矿渣集料.第1部分:高炉矿渣集料JISA5011-2-1997混凝土用矿渣集料.第2部分:镍铁矿渣集料JISA5011-3-1997混凝土用矿渣集料.第3部分:铜矿渣集料JISA5015-1992道路结构用铁和钢炉渣JISA5101-1950轨道用铺石JISA5102-1995天然石板JISA5105-1993住宅用简易水洗式便器JISA5207-2000卫生陶瓷制品JISA5208-1996陶土瓦JISA5209-1994陶砖JISA5210-1994陶块JISA5211-1977陶制非冲洗式便器JISA5212-1993空心玻璃砖JISA5301-1983自来水厂用石棉水泥管JISA5302-1994钢筋混凝土管JISA5303-1993离心浇制钢筋混凝土管JISA5304-1994铺路用混凝土石板JISA5305-1994钢筋混凝土U形边沟JISA5306-1999混凝土及钢筋混凝土L形路边沟JISA5307-1999混凝界标JISA5308-1998预拌混凝土JISA5309-1995离心浇制的预应力混凝土电杆JISA5310-1995离心浇注钢筋混凝土桩JISA5312-1994装配式混凝土挡土墙JISA5313-1995平板桥用预应力混凝土梁JISA5314-1998球墨铸铁管用砂浆衬里JISA5315-1983输水管道用石棉水泥管的石棉水泥接头JISA5317-1996下水道用增强混凝土检查井井圈JISA5318-1994钢筋混凝土水槽JISA5319-1995轻荷重桥用预应力混凝土梁JISA5321-1994钢筋混凝土电缆沟JISA5322-1993套接式离心浇灌钢筋混凝土管JISA5323-1997挡土墙和护墙用混凝土砌块JISA5325-1990钢筋混凝土板桩JISA5328-1994装配式暗沟盖JISA5333-1993芯式预应力混凝土管JISA5335-1987离心浇注预应力混凝土桩JISA5336-1979后张法离心浇注预应力混凝土桩JISA5337-1995离心浇注高强度预应力混凝土桩JISA5338-1993钢筋混凝土L型挡土墙JISA5341-1982加固的旋转浇制的混凝土沟槽JISA5342-1982加固的旋转浇制的混凝土路缘沟槽JISA5343-1982旋转浇制的混凝土路缘块JISA5344-1982沟槽用加固的旋转浇制的混凝土沟盖JISA5345-2000道路用钢筋混凝土边沟JISA5350-1991玻璃纤维增强的复合管JISA5354-1993混凝土板桩JISA5361ERRATUM1-2000预制混凝土制品.分类、命名和标记的通用规则(勘误1)JISA5361-2000预制混凝土产品.分级,标识和标记的一般规则JISA5362-2001预制混凝土制品.要求的性能和验证方法JISA5363-2001预制混凝土制品.性能试验方法的通用规则JISA5364ERRATUM1-2000预制混凝土制品.材料和制品方法的通用规则JISA5364-2000预制混凝土产品.材料和生产方法的一般规则JISA5365-2000预制混凝土产品.检验方法的一般规则JISA5371ERRATUM1-2000预制无钢筋混凝土制品(勘误1)JISA5371-2000预制非增强混凝土产品JISA5372ERRATUM1-2000预制钢筋混凝土制品(勘误1)JISA5372ERRATUM2-2001预制钢筋混凝土制品(勘误2)JISA5372-2000预制增强混凝土产品JISA5373ERRATUM1-2000预制预应力混凝土制品(勘误1)JISA5373-2000预制预应力混凝土制品JISA5390-2001预制混凝土用塑料隔板JISA5401-1978水泥瓦JISA5402-1994压制水泥屋面瓦JISA5404ERRATUM1-2001水泥粘结的木屑板(勘误1)JISA5404-2001水泥砂木丝板和碎料板JISA5405-1982石棉水泥管JISA5406-2000建筑用混凝土砌块JISA5409-1993预制钢筋混凝土围墙构件JISA5411-1994预制水磨石砌块JISA5412-1995预应力混凝土板(双T型)JISA5414-1993纸浆水泥板JISA5416-1997高压蒸氧加气轻质混凝土装配板JISA5422-1995纤维增强水泥护墙板JISA5423-1995住宅屋面用饰面水泥瓦JISA5425-1983用胶合板增强的石棉水泥板JISA5426-1995与挠性水泥板叠合的刨花水泥板JISA5430-2001纤维增强水泥板JISA5440-2000火山硅酸盐纤维增强多层板JISA5451-1995石棉衬板JISA5502-1971锻钢和锻制不锈钢弹簧铰链JISA5504-1994钢丝网JISA5505-1995金属网JISA5506-1995污水工程用人孔盖JISA5507-1977雨水口箅子盖JISA5508-1992钉子JISA5509-1971滑动门钢轨JISA5512-1979滑动门和滑动窗用滑轮JISA5513-1993镀锌铁丝石笼筐JISA5519-1978石棉水泥管用钢制接头及配件JISA5520-1983输水管道用石棉水泥管的铸铁管接头及其异形管接头JISA5522-1975屋顶排水管(平屋顶用)JISA5523-2000可焊接热轧钢板桩JISA5524-1994抹灰底衬金属板网(直角瓦楞镀锌板网)JISA5525-1994钢管桩JISA5526-1994H形钢桩JISA5527-1978住宅用日本式浴室外接锅炉的循环水管连接配件JISA5528-2000热轧钢板桩JISA5529-1995射钉枪用销钉JISA5530-1994钢管板桩JISA5531-1978木结构用金属附件JISA5532-1994浴盆JISA5533-1993搪瓷排气管JISA5534-1979搪瓷面砖JISA5536-2002弹性地板覆盖物用粘合剂JISA5537-2002固定木砌块用粘合剂JISA5538-2002护墙板和天花板用粘合剂JISA5540-1982建筑用拉线螺旋扣JISA5541-1993建筑用拉线螺旋扣本体JISA5542-1993建筑用紧线器的螺栓JISA5545-1991推位窗用金属附件JISA5547-2002预制泡沫塑料隔热板用粘合剂JISA5548-1993陶磁面砖用有机粘合剂JISA5556-1993U形钉JISA5701-1995玻璃纤维增强塑料波纹板JISA5702-1993硬质聚氯乙烯波纹板JISA5703-1994室内用塑料叠层或印制板材JISA5705-1998地板覆盖物.聚氯乙烯JISA5706-1995未增塑聚氯乙烯檐沟和落水管JISA5708-1994塑料浴盆盖JISA5712-1994带洗涤槽的玻璃纤维增强塑料浴盆JISA5713-1980与加热炉连接的住宅用浴盆JISA5721-1995塑料地板层面板JISA5731-2002回收利用塑料检验室和防雨水掩蔽物JISA5750-2000建筑物中门窗和面板接头用弹性泡沫预制密封垫JISA5751-1995建筑用油性填充料JISA5752-1994金属门窗嵌玻璃用腻子JISA5753-1968木制门窗嵌玻璃用油灰JISA5756-1997建筑衬垫和建筑结构衬垫.密封门窗玻璃和嵌板用预成形固态硬化材料JISA5757-1995建筑用密封材料用途和性能JISA5758-1997建筑物焊封和门窗玻璃用密封剂JISA5759-1998门窗玻璃用粘附薄膜JISA5801-1975建筑用防火木材JISA5901-1997塌塌咪芯材(日本席垫芯材)JISA5902-1997塌塌咪(日本席垫)JISA5905-1994纤维板JISA5908-1994碎料板JISA5914-1997非草编塌塌咪JISA6005-1991屋面沥青油毡JISA6008-2002合成聚合物制屋面薄板JISA6009-1983布基等叠层合成高分子屋面毡JISA6012ERRATUM1-2000织物沥青屋面料(勘误1)JISA6012-1993机织物沥青屋面JISA6012-1993/ERRATUM1-2000机织物沥青屋面(勘误1)JISA6013-1996改性聚合沥青屋项板材JISA6021-2000建筑物的防水薄膜涂层用液态化合物JISA6022-1991弹性屋面沥青油毡(合成纤维基)JISA6023-1991多孔沥青屋面油毡JISA6024-1998建筑物修补用环氧树脂注入胶粘剂JISA6111-1996房屋装饰板JISA6201-1999用于混凝土的飞灰JISA6202-1997混凝土用膨胀掺合剂JISA6203-2000水泥调节剂用聚合物分散剂和可再分散的聚合物粉末JISA6204-2000混凝土用化学添加剂JISA6205-1993钢筋混凝土用防锈剂JISA6206-1997混凝土用基本粒状高炉矿渣JISA6207-2000混凝土用发烟硅酸JISA6301ERRATUM1-2000吸音材料(勘误1)JISA6301-2000吸音材料JISA6301-2000/ERRATUM1-2000吸音材料(勘误1)JISA6305-1978吸音用多孔铝装配板JISA6321-2000夹层地板用石棉缓冲材料JISA6322-1979浮式地面用玻璃棉缓冲材料JISA6501-1994建筑构件(混凝土墙壁装配板)JISA6503-1994建筑构件(钢制墙壁装配板)JISA6504-1994建筑构件(木质壁装配板)JISA6505-1994建筑构件(混凝土地面装配板)JISA6506-1994建筑构件(木质地面装配板)JISA6507-1994建筑构件(钢制地面装配板)JISA6508-1994建筑构件(混凝土屋顶装配板)JISA6509-1994建筑构件(木质屋顶装配板)JISA6510-1994建筑构件(钢制屋顶装配板)JISA6511-2002预应力混凝土空心装配板JISA6512-1992移动式隔墙JISA6513-1994金属制栅栏及门扉JISA6514-1995钢制叠瓦屋顶结构材料JISA6516-1995搪瓷钢壁板JISA6517-2002建筑物中墙和顶棚用钢制罩饰材料JISA6518-1994铁丝网栏栅的元部件JISA6519-1995体育馆地板用钢制罩饰结构材料JISA6601-1996住宅阳台和栏杆用金属组件JISA6602-1996联排式房屋用金属屋顶组件JISA6603-1996钢制贮藏柜JISA6604-1996停车场用金属元部件JISA6701-1983碳酸镁板JISA6711-1997复合金属板壁JISA6901-1997石膏板JISA6902-1995抹灰用熟石灰JISA6903-1995白云石灰泥JISA6904-1997石膏灰泥JISA6905-1993氧化镁水泥(氧化镁含量)JISA6909-2000建筑物的织纹状饰面用涂覆材料JISA6914-1997石膏灰泥板用勾缝材料JISA6916-2000饰面用表面制备材料JISA6921-2001装修用壁纸和墙壁覆盖物JISA6922-1998装修壁纸和墙壁覆盖物用胶粘剂JISA6930-1997住房用塑料薄膜蒸汽阻挡层JISA6931-1994装配板用纸芯JISA7201-1999离心浇制的混凝土桩的施工标准JISA7801-1994防火用水泥砂浆的粉刷方法JISA7802-1994石棉水泥烟囱的安装标准实施规范JISA8101-1998施工机械用仪表的振动和冲击试验方法JISA8102-1978建筑机械用发动机转速计。

新加坡PSB认证新加坡消费品保护法规1991指定新加坡标准,生产力和创新委员作为产品安全职能机构,负责对消费者保护(安全要求)注册方案(CPS)涉及的产品进行许可和注册。

只有带“SAFETY”标志的注册产品才能在新加坡销售。

目前新加坡只要求安全而对EMC只是自愿原则。

安全要求:在IEC标准要求下,产品还要符合热带条件测试。

新加坡电压:AC 230V\ 50Hz验厂:一般需要(如果通过莱茵CB去申请有莱茵的工厂检查报告可以不再工厂检查)。

说明书:要求英文证书有效期:证书有效期为一年。

申请周期:一般3-4周。

瑞士SEV为非欧盟国家,在产品认证方面未加入欧盟的CE制度。

因此瑞士的产品法规有自己的要求,瑞士的SEV低电压产品法规规定:进入瑞士市场的电子电气产品需要取得S-PLUS标志。

此标志包含了产品的安全性也涵盖了电磁兼容(EMC)的要求。

电压:AC 230V/50Hz说明书:法语验厂:无需验厂、意大利语或徳语认证周期:如用CB申请需2-3周。

无CB需4-6周。

波兰(Poland)认证B标志认证是波兰目前的强制性认证。

出口到波兰的电子电气产品都必须通过B标志认证。

B标志涵盖产品安全、电磁兼容和卫生要求。

认证机构:PCBC,BBJ电压:AC 230V/50Hz验厂:需要或指定机构的验厂报告说明书:波兰文认证周期:4-5周申请方式:CB报告或GS报告+EMC报告的基础上申请。

匈牙利(Hungary)匈牙利的电工产品实验是依据关于人身、健康、财产安全的有关规定,按照匈牙利的电气标准而进行的强制实验。

认证机构:Magyar Elektrotechnikai Ellenorzo Intezet-MEEI认证标志:S-Mark MEEI Mark认证要求:安全及EMC都要求电压:AC 230V/50Hz验厂:需要或指定机构的验厂报告说明书:匈牙利文认证周期:S-Mark 1-2 周 (有CB的时间)MEEI 2-3 周 (有CB的时间)申请方式:CB报告或GS报告+EMC报告的基础上申请。

SECHRIST INDUSTRIES, INC.Service Manual Hydraulic and Standard StretchersHydraulic Models:P/N 21465Preventative Maintenance Checklist3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cleaning4 Service Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Caster Cover Installation and Removal5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Caster Assembly Replacement5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Brake Rod Removal6 Brake Ring Removal7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fifth Wheel Removal7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Siderail Latch Adjustment8 Assembly Drawings and Parts Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fixed Height Base Assembly9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Base Assembly with Standard Brakes10, 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Brake Rod Assembly12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Drive Link Assembly13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fifth Wheel Assembly14, 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Caster Assembly16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Push Bar Gurney Assembly17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fixed Height Base Labeling Assembly18 Fixed Height Base Labeling Assembly − Pushbar Gurney19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Hydraulic Base Assembly20−24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Release Pedal Assembly25, 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Pump Pedal Assembly27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .End Control Base Labeling Assembly28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Litter Assembly − Fixed Height Base29−31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Litter Assembly − Hydraulic Base32−35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Folddown Siderail Assembly36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Litter Release Rod Assembly37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Push Handle Assembly38 Transfer Dolly Assembly39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I.V. Pole Assembly40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Warranty41Sechrist IndustriesDeclares that the medical devices described hereafter:Gurney System for the following models:2146521266215022146421487are in conformity with the essential requirements and provisions of Council Directive 93/42/EEC. Conformity has been achieved under Annex VII.Preventative MaintenanceCHECKLISTALL STRETCHERS:All fasteners secure (reference assembly prints)Siderails move and latch properly (Stretchers 21502, 21464, 21465, 21266)All casters lock with brake pedal engagedSteer function working properlyAll casters secure and swiveling properlyGround chain intactI.V. pole intact and operating properlyOxygen bottle holder intact and operating properlyHead rest operates and latches properly (on Stretcher P/N’s 21464, 21465)No rips or cracks in mattress coverLubricate where requiredAccessories and mounting hardware in good condition and working properlyHYDRAULIC STRETCHERS (P/N’S 21465, 21266):No leaks at hydraulic connectionsHydraulic jacks holding properlyHydraulic drop rate set properlyHydraulic oil level sufficientSerial No. ______________ __________________________________________ __________________________________________ ____________________________ Completed By: _________________________________ Date: _____________NOTEReferences to the right or left side of the stretcher refer to the right and left sides of a patient lying face up on the stretcher.CleaningHand wash all surfaces of the stretcher with warm water and mild detergent. Dry thoroughly. DO NOT STEAM CLEAN, PRESSURE WASH, HOSE OFF OR ULTRASONICALLY CLEAN. Using these methods of cleaning is not recommended and may void this product’s warranty.In general, when used in those concentrations recommended by the manufacturer, either phenolic type or quaternary type disinfectants can be used. Iodophor type disinfectants are not recommended for use be-cause staining may result. The following products have been tested by the Herculite Laboratory and have been found not to have a harmful effect WHEN USED IN ACCORDANCE WITH MANUFACTURERS REC-OMMENDED DILUTION.*Quaternary Germicidal Disinfectants, used as directed, and/or Chlorine Bleach products, typically 5.25% So-dium Hypochlorite in dilutions ranging between 1 part bleach to 100 parts water, and 2 parts bleach to 100 parts water are not considered mild detergents. These products are corrosive in nature and may cause dam-age to your stretcher if used improperly. If these types of products are used to clean patient handling equip-ment, measures must be taken to insure the stretchers are rinsed with clean water and thoroughly dried fol-lowing cleaning. Failure to properly rinse and dry the stretchers will leave a corrosive residue on the surface of the stretcher, possibly causing premature corrosion of critical components. Failure to follow the above directions when using these types of cleaners may void this product’s warranty.REMOVAL OF IODINE COMPOUNDSThis solution may be used to remove iodine stains from mattress cover surfaces.1. Use a solution of 1−2 tablespoons Sodium Thiosulfate in a pint of warm water to clean the stained area.Clean as soon as possible after staining occurs. If stains are not immediately removed, allow solution to soak or stand on the surface.2. Rinse surfaces which have been exposed to the solution in clear water before returning bed to service.CASTER COVER INSTALLATION AND REMOVALDouble ProngsSingle ProngProperly AttachedCover1.2.3.Top View (Cut −Away)T op View (Cut −Away)T op View (Cut −Away)Looking through the larger of the two side cut −outs,align the cover with the axle nut or bolt head, as shown.Push down on the opposite side of the cover until the single prong engages the caster horn.Push on the cover with your palm until the double prongs engage.To remove the wheel cover, insert a large screwdriver into the cut −out in the side of the wheel cover and into the space between the double prongs. Pry up the cover to disengage the double prongs and push sharply upward to disengage the single prong.CASTER REMOVAL Required Tools:9/16” Open End Wrench 1.Remove the caster cover.2.While keeping pressure on the caster bolt with your index finger, use a 9/16” open end wrench to removethe nylock hex nut on top of the caster ing the brake ring, lift up on the base assembly and pull the caster assembly down to remove it.4.Reverse steps 1−3 to install the new caster.Required Tools:Hammer7/32” Punch String or Bungee Cords1.Pump the litter up to full height.2.Lift the base hood and support it from the litter using string or bungee cords.3.Remove the hex head cap screws connecting the brake rod supports to the base frame.4.Remove the bolt connecting the drive link assembly to the fifth wheel cam.5.Remove the rue ring cotter and clevis pin connecting the rod end link to the side control link.6.Remove the rue ring cotter connecting the drive link assembly to the bearing pivot support on the baseframe (under the brake ring weldment).7.Remove the three hex washer head screws holding the brake rod assembly to the base frame.8.Remove the slotted spring pins connecting the butterfly “V” pedals, drive link assemblies and side controllink to the brake rod.9.Reverse steps 1−8 to reinstall the brake rod. When reinstalling the brake rod supports, torque the hexhead cap screws to 12−15 ft.−lbs.CAUTIONWhen reattaching the brake rod assembly to the base frame, set the torque specs no higher than 15 ft.−lbs. or damage could occur to the bolts.SIDE CONTROL BRAKE ROD REMOVALRequired Tools:Hammer7/32” Punch Needle Nose Pliers String or Bungee Cords1.Pump the litter up to full height.2.Lift the base hood and support it from the litter using string or bungee cords.3.Remove the rue ring cotter and clevis pin connecting the rod end link to the side control link.4.Remove the four bolts holding the brake rod assembly to the base frame and remove the entire assembly.ing a hammer and 7/32” punch, drive the slotted spring pin out of the butterfly “V” pedal on the patient’sleft side and remove the pedal,ing a hammer and 7/32” punch, drive the slotted spring pin out of the hard stop in the center of thesupport weldment.ing a hammer and 7/32” punch, drive out the slotted spring pin connecting the side control link to theside control brake rod on the patient’s right side.8.Pull on the butterfly “V” pedal on the patient’s right side to remove the side control brake rod from the base.9.Reverse steps 1−8 to reinstall the brake rod. When reinstalling the assembly, torque the hex head capscrews to 12−15 ft.−lbs.CAUTIONWhen reattaching the brake rod assembly to the base frame, set the torque specs no higher than 15 ft.−lbs. or damage could occur to the bolts.Required Tools:9/16” Socket w/Extension3/8” Drive Ratchet Needle−Nose Pliers String or Bungee Cord1.Pump the litter up to full height.2.Lift the base hood and support it from the litter using string or bungee cords.ing needle−nose pliers, unhook the extension springs from the top of the base caster tubes.4.Remove the plastic caster covers.5.While putting pressure on the caster carriage bolt, use a 9/16” socket and a 3/8” drive ratchet to removethe caster nut on both sides of the stretcher.6.Remove the casters.7.Remove the brake rod (see procedure).8.Remove the cotter pin from the clevis pin in the center of the brake ring weldment.9.Remove the cotter pin from the bearing pivot support.10.Remove the 3/4” nylock hex nut from the bearing pivot support.11.Remove the drive link assembly.12.Pull the brake ring down and out away from the stretcher base frame.13.Reverse steps 1−12 to reinstall the brake ring.FIFTH WHEEL ASSEMBLY REMOVALRequired Tools:1/2” Socket3/8” Drive Ratcheting a 1/2” socket and 3/8” drive ratchet, remove the 1/2” bolt holding the fifth wheel cam drive link andfifth wheel drive link to the fifth wheel cam.2.Remove the two 1/2” bolts holding the fifth wheel mounting bracket to the base frame weldment.3.Remove the fifth wheel assembly.4.Reverse steps 1 and 2 to reinstall the fifth wheel. When reinstalling the assembly, torque the hex headcap screws to 12−15 ft.−lbs.CAUTIONWhen reattaching the fifth wheel assembly to the base frame, set the torque specs no higher than 15 ft.−lbs. or damage could occur to the bolts.SIDERAIL LATCH ADJUSTMENTRequired Tools:1/8” Hex Allen WrenchWARNINGThe siderail latches are preset at the factory, and do not normally need adjustment. If adjustment must be done, it is important to follow the procedure below. If adjustment is not done properly, injury to the patient or user could occur.Adjustment Procedure:ing a 1/8” hex Allen wrench, adjust the Allen screw located on the latch assembly opposite the latch.Turning the screw clockwise will DECREASE the amount of ”play” in the latch. Turning counterclockwise will INCREASE the amount. The amount of ”play” in the siderail, when in full up engaged position, should be approximately 1/8 to 3/16 inches.CAUTIONToo much ”play” when the siderail is in the full up engaged position will give the siderail the appearance of being unstable and could also cause premature wearing of the latch system.Too little ”play” will obstruct the latch and keep it from engaging completely in the full up position, which may cause damage to the latch and/or injury to the patient or user.Fixed Height Base Assembly with Standard Brakes Assembly part number 0720−600−210 (reference only)Item Part No.Part Name Qty.A0023−288−000Hex Washer Hd, Screw10B0023−305−000Hex Washer Hd, Screw1C(page 10)Standard Brake Assembly1D(page 14)Fifth Wheel Assembly1E0753−006−148Cam Bearing1F0753−010−007Reservoir Clamp2G0720−201−032Upper Tower (not shown)2Assembly part number 0753−003−005 (reference only)Item Part No.Part Name Qty. A0005−039−000Step Bolt4 B0011−262−000Washer4 C0016−035−000Nylock Hex Nut4 D0016−049−000Nylock Hex Nut2 E0023−288−000Hex Washer Hd. Screw3 F0027−012−000Hitch Pin2 G0028−037−000External Retaining Ring4 H0038−439−000Extension Spring4 J0081−272−000Roller Bearing2 K0753−001−001Base Frame1 L(page 12)Brake Rod Assembly1 M0753−003−006Brake Ring2 N0753−003−066Clevis Pin2 P0753−003−079Caster Tube Brake Pin Guide4 R0753−003−121Brake Cushion4 S0753−003−130Bearing Pivot Support2 T0753−003−131Spacer2 V(page 16)Caster Assembly4 Y0027−019−000Rue Ring Cotter Pin2 Z0753−010−012Ground Chain1 AA0023−025−000H. Washer Hd. Tapping Screw1Brake Rod AssemblyAssembly part number 0753−003−001 (reference only)Item Part No.Part Name Qty.A0026−067−000Slotted Spring Pin2E0753−003−004Brake Rod Support3F(page 13)Drive Link Assembly2G0753−003−014Brake Rod1H0753−003−015Nyliner3J0753−003−099Butterfly “V” Pedal2K(page 13)Drive Link Assembly1M1210−201−335Red Brake Label2N1210−201−336Green Steer Label2R0753−003−133Retainment Spacer10753−003−010 Drive Link AssemblyItem Part No.Part Name Qty. B0753−003−011Brake Rod Drive Link1 C0753−003−061Brake Cam Drive Link2 D0753−003−098Flat Hd. Semi−Tubular Rivet2 E0753−003−102Brake Cam1 0753−006−135 Drive Link AssemblyItem Part No.Part Name Qty. A0753−003−011Brake Rod Drive Link1 B0753−003−098Semi−Tubular Rivet1 C0753−006−1225th Wheel Cam Drive Link1 D0753−006−147Fifth Wheel Drive Link1Item Part No.Part Name Qty. A0003−083−000Hex Hd. Cap Screw1 B0016−035−000Nylock Hex Nut1 C0023−288−000Hex Washer Hd. Screw5 D0025−050−000Rivet2 F0753−006−074Torsion Spring1 G0753−006−075Torsion Spring1 H0753−006−097Drive Shaft Bearing2 J0753−006−106Dampener1 K0753−006−108Thrust Washer1 L0753−006−115Bearing2 M0753−006−120Bumper Mounting Pin1 N0753−006−126Wheel Bracket1 P0753−006−133Cam Pivot Block1 R0753−006−134Fifth Wheel Mounting Bracket1 S0753−006−142Fifth Wheel Cam1 T0753−006−143Cam Bearing1 V0753−006−1495th Wheel Ramp1 W0753−006−152Spring Spacer1 X0753−006−153Roller Stem1 Z0753−006−198Drive Pin1 AA0753−006−223Drive Shaft1 AB0753−006−227Return Spring Hook1 AC0753−006−277Roller1 AD0753−010−045Hood Standoff1 AE1210−001−147Wheel1 AG0753−006−280Dual Lock1 AH0753−006−281Dual Lock1 AJ0011−360−000Washer20753−010−020 8” Caster AssemblyItem Part No.Part Name Qty. A0715−002−025Wheel1 B0003−099−000Hex Hd. Cap Screw1 C0753−010−021Caster Horn w/Bearing1 D0016−060−000Centerlock Nut1Push Bar Gurney AssemblyAssembly part number 0720−565−010 (reference only)Item Part No.Part Name Qty.A0003−093−000Hex Hd. Cap Screw4B0003−017−000Hex Hd. Cap Screw8C0011−004−000Washer8D0016−011−000Flexlock Nut4E0016−028−000Fiberlock Nut8G0037−010−000Square Hole Plug8H0720−500−017Cap2J0720−565−034Upper Tower Assembly2K0720−565−040Push Arm Weldment2Base Labeling Assembly − Fixed Height Stretcher Assembly part number 0720−660−050Item Part No.Part Name Qty.A0004−057−000But. Hd. Cap Screw2B0016−027−000Kep Nut2C0753−010−043Hood1D0946−001−108I.V. Clip2E0946−421−005Grommet2F0720−560−051Sechrist Serial No. Label1G0720−560−052Sechrist Spec. Label2H0720−560−054Gray Stripe Label2J0753−010−410Gray Brake/Steer Label, Head1K0753−010−391Gray Brake/Steer Label, Foot1Base Labeling Assembly − Pushbar GurneyItem Part No.Part Name Qty.A0753−010−046Hood1 B0946−421−005Grommet2 C0720−560−052Sechrist Logo Label2 D0720−560−051Sechrist Spec. Label1 E0921−001−252Serial No. Label1 F0753−010−400Gray Brake/Steer Label, Foot1 G0753−010−410Gray Brake/Steer Label, Head1pump ram as shownrod into release valve assembly as shownrod into release valve assembly as shownin the jack mounting plateItem Part No.Part Name Qty. A0011−023−000Washer2 B0014−071−000Washer2 C0023−288−000Hex Washer Hd. Screw13 D0025−079−000Dome Head Rivet2 E0027−031−000Hair Pin Cotter1 F0038−497−000Extension Spring3 G(page 25)Release Pedal Assembly1 H0753−004−014Head End Release Rod1 J0753−004−015Foot End Release Rod1 K0753−004−030Foot End Release Cable2 M0753−004−032Release Pedal Swivel2 N(page 26)Ft. End Release Pedal Assembly1 P0753−004−127Cable Mounting Plate1 R0753−005−037Pump Connecting Rod1 S0753−005−044Pump Pedal Bushing2 T0753−005−063Foot End Mounting Bracket1 W(page 27)Ft. End Pump Pedal Assembly1 X0753−005−074Pivot Pin1 Y0753−005−075Pump Pedal Link1 Z0753−005−087Return Spring Hook1 AA0753−005−088Wear Strip2 AB0753−005−089Pump Ram Plug2 AC0753−010−015Release Rod Guide1 AD0753−010−115Release Rod Bracket1Release Pedal AssemblyAssembly part number 0721−660−022 (reference only)Item Part No.Part Name Qty.A0025−079−000Rivet4B0721−660−023Release Pedal Weldment2C0753−004−035Release Pedal Bumper Strip2D0753−004−036Release Pedal Bushing4E0753−004−121Release Pedal Mtg. Plate2Foot End Release Pedal AssemblyAssembly part number 0753−004−123 (reference only)Item Part No.Part Name Qty.A0026−132−000Clevis Pin2B0753−004−024Release Pedal, Foot End, Left1C0753−004−025Release Pedal, Foot End, Right1D0753−004−028Release Pedal Return Spring2E0753−004−322Release Pedal Mtg. Plate1F0027−022−000Rue Ring Cotter20753−005−173 Foot End Pump Pedal AssemblyItem Part No.Part Name Qty.A0026−343−000Groove Pin1B0715−001−140Clear Vinyl Tubing1C0753−005−044Pump Pedal Bushing2D0753−005−171Foot End Pedal Weldment1E0715−201−126Plastic Pump Pedal1Base Labeling Assembly − End Control Base Assembly part number 0721−660−050 (reference only)Item Part No.Part Name Qty.A0004−057−000But. Hd. Cap Screw2B0016−027−000Kep Nut2C0753−010−048Base Hood1D0946−001−108I.V. Clip2E1040−010−134Bellows2F0720−560−052Sechrist Logo Label2G0720−560−054Gray Stripe Label2H0721−560−051Sechrist Serial No. Label1J0753−010−052Foot End Pump Pedal Label1K0753−010−053Foot End Release Pedal Label1L0921−001−252Bar Code Label1M0753−010−410Head End Brake/Steer Label1N0753−010−400Foot End Brake/Steer Label1Litter Assembly − Fixed Height StretcherAssembly part number 0720−560−010 (reference only)D e t a i l AItem Part No.Part Name Qty.Item Part No.Part Name Qty. A0003−047−000Hex Hd. Cap Screw6AC0721−026−066Pivot Screw14 B0003−050−000Hex Hd. Cap Screw2AD0721−026−068Upright Cradle6C0003−054−000Hex Hd. Cap Screw2AE0721−026−069Upright Sleeve4D0004−135−000Soc. Hd. Cap Screw4AF0721−026−074Lock Handle2E0004−136−000Soc. Hd. Cap Screw14AH(page 36)Siderail Ass’y, Rt.1F0004−201−000Soc. Hd. Cap Screw4AJ(page 36)Siderail Ass’y, Lt.1H0011−002−000Washer16AK0721−201−020Frame Assembly1J0014−021−000Washer12AL0926−400−142Corner Wheel4K0016−028−000Hex Nut16AN1001−040−012Foot Board Receptacle2L0016−035−000Hex Nut4AP1010−026−069Lock Support2M0021−104−000Set Screw2AR1010−026−080Lock Housing Ass’y, Rt.1N0023−104−000Pan Hd. Self−Tap. Screw8AS1010−026−081Lock Housing Ass’y, Lt.1P0025−038−000Blind Rivet20AT1010−201−027Bumper Channel2R0026−012−000Spring Pin2AW1010−201−236Corner Cover, Hole/Hole1S0028−072−000Ext. Tooth Retaining Ring2AX1010−201−237Corner Cover, Hole/Slot1T0037−010−000Hole Plug6AY1010−201−238Corner Cover, Slot Only1 W0037−059−000Hole Plug2AZ1010−201−239Corner Cover, Hole Only1X0037−074−000Hole Plug6BA1010−700−045Siderail Bumper2Y0038−220−000Compression Spring2BB1210−800−008Patent Label1Z0003−078−000Hex Hd. Cap Screw8BC(page 38)Push Handle Assembly2 AA0720−560−013Handle Soc. Wldmt., Lt.1BD0721−560−019Sechrist Support Wldmt.2AB0720−560−014Handle Soc. Wldmt., Rt.1Assembly part number 0721−660−010 (reference only)SIDERAIL LATCHDETAILItem Part No.Part Name Qty.Item Part No.Part Name Qty. A0003−355−000Hex Hd. Cap Screw2AN0721−026−069Upright Sleeve4 B0003−356−000Hex Hd. Cap Screw4AP0721−026−074Lock Handle2 C0003−359−000Hex Hd. Cap Screw20AR(page 36)Siderail Assembly, Right1 D0004−135−000But. Hd. Cap Screw6AS(page 36)Siderail Assembly, Left1 E0004−136−000But. Hd. Cap Screw14AT0721−031−065Hole Plug4 F0004−196−000Soc. Hd. Cap Screw2AW0721−201−020Litter Frame1 G0004−330−000Soc. Hd. Cap Screw4AX(page 37)Litter Release Rod1 H0011−001−000Washer4AY0721−560−017Rod Guide Weldment1 J0011−077−000Washer4AZ0721−560−019Support Weldment2 K0011−360−000Washer2BA0721−560−021Short Link1 M0014−021−000Washer12BB0721−560−023Turnbuckle1 N0015−012−000Hex Jam Nut1BC0721−660−011Head End Support Tube1 P0016−014−000Fiberlock Hex Nut2BD0721−660−012Foot End Support Tube1 R0016−117−000Stover Hex Lock Nut4BE0721−660−030Litter Stop2 S0016−118−000Stover Hex Lock Nut28BF0753−010−043Hd. End Jack Supt. Tube2 T0021−105−000Set Screw2BG0926−400−142Bumper4 W0023−104−000Pan Hd. Tapping Screw8BH0938−001−401Collar2 X0023−288−000Hex Washer Hd. Screw2BJ1001−040−012Foot Board Receptacle2 Y0025−038−000Rivet20BK1001−201−029Nylon Insert2 Z0026−012−000Slotted Spring Pin2BM1001−401−030Trend Support2 AA0028−023−000External Retaining Ring2BN1010−026−069Lock Support2 AB0033−002−000Knob1BP1010−026−080Lock Housing Ass’y, Lt.1 AC0037−010−000Hole Plug4BQ1010−026−081Lock Housing Ass’y, Rt.1 AD0037−059−000Hole Plug2BR1010−201−027Bumper Channel2 AE0037−074−000Hole Plug6BS1010−201−236Corner Cover, Hole/Slot1 AF0038−220−000Compression Spring2BT1010−201−237Corner Cover, Hole/Hole1 AG0124−001−082Compression Spring2BW1010−201−238Corner Cover, Slot1 AH0720−560−013Handle Socket, Left1BX1010−201−239Corner Cover, Hole1 AJ0720−560−014Handle Socket, Right1BY1210−800−008Patent Label1 AK0721−026−066Pivot Screw14BZ(page 38)Push Handle Assembly2 AM0721−026−068Upright Cradle6Siderail Assembly, Right & LeftJ(Left Side Shown)Assembly part numbers 0721−026−096 (Right)0721−026−097 (Left)ItemPart No.Part NameQty.A 1010−026−015Top Rail 1B 1010−026−083Upright4C 1010−026−084Upright, Bent 1D 1010−026−082Spacer6E 0025−106−000Semi −Tubular Rivet 6F 1010−026−010Round Hole Plug 4H 1010−026−085Upright, Latch 1J1010−026−012Bent Spindle Stop10721−560−015 Litter Release Rod AssemblyItem Part No.Part Name Qty.A0721−560−021Short Link1 B0721−560−022Litter Release Rod1 C0721−560−023Turn Buckle1 D0015−012−000Jam Nut11211−351−010 Push Handle AssemblyItem Part No.Part Name Qty. A1010−354−024Stop Link1 B1211−151−018Sleeve Assembly1 C0026−118−000Roll Pin1Transfer Dolly AssemblyHEADENDItem Part No.Part Name Qty.A N/A Litter Assembly1B HB−233Latch1C HB−274Machine Screw3D HB−275Washer2E HB−276Machine Screw2F HB−279Machine Screw4G HB−284Machine Screw4H HB−305−16Washer20J HB−601−05Track Guide2K HB−601−07Track Cap2L HB−801−02Rear Crossbrace1M HB−801−03Front Crossbrace1N HB−801−04Dolly Track20390−025−000 Standard, Removable I.V. Pole AssemblyItem Part No.Part Name Qty.A0024−023−000Plastic Knob1B0390−003−053Double I.V. Ass’y1C0393−003−043Tube Assembly1D0004−496−000Soc. Hd. Cap Screw1WarrantySECHRIST INDUSTRIES, INC. warrants this product to meet the published specifications and to be free from defects in material and workmanship under normal use for a period of one (1) year from the date of purchase. THE FOREGOING IS IN LIEU OF ANY OTHER WARRANTY, EX-PRESS, IMPLIED OR STATUTORY, INCLUDING WITHOUT LIMITATION ANY WARRANTY OF MERCHANTABILITY. The sole liability of SECHRIST under this warranty is limited to replacing, repairing, or issuing credit at the discretion of SECHRIST for the products, equipment or parts which fail to meet the published specifications or which become defective during the warranty peri-od and which are upon examination by SECHRIST found not to meet the published specifications or to be defective in material or workmanship. SECHRIST will not be liable under this warranty unless the following provisions are strictly complied with: (a) SECHRIST is promptly notified, in writing, upon discovery of the failure of said product or equipment to meet the published specifica-tions or of defects in material or workmanship, (b) the defective product, equipment or part thereof is returned to SECHRIST, transportation charges prepaid by the buyer, (c) the defective part is re-ceived by SECHRIST for examination no later than one (1) month following the expiration of the warranty period and provided (d) that examination by SECHRIST of said product, equipment or part shall disclose to SECHRIST’S satisfaction that such defect has not been caused by improper usage, accident, neglect, alteration, abuse, improper installation or unauthorized repair. Products, equipment or parts replaced under this warranty are warranted only through the terms of the origi-nal warranty. SECHRIST neither assumes nor authorizes any other person or entity to assume for it any other warranty, obligation or liability in connection with its products or equipment whatso-ever, and this warranty can only be changed in writing by a duly authorized representative of SEC-HRIST. SECHRIST makes no representations or warranties whatsoever as to fitness or useful-ness of the products or equipment manufactured by it for any medical treatment, physical condition or other purpose whatsoever. In so event shall SECHRIST be liable for personal injury, property damage or any special or consequential damage to any buyer, user or any other person whomso-ever, including, but not limited to, loss of profits, loss of use of the product or equipment, or for dam-ages of any other kind whatsoever based on a claim for breach of warranty other than a refund of the purchase price of any defective product or equipment. Any authorization for repair or alter-ation by buyer must be in writing from SECHRIST to prevent the voiding of this warranty. In the event SECHRIST or its representatives render any technical advice or service of any kind to buyer or anyone else in connection with the equipment or products covered by this warranty, the buyer hereby releases SECHRIST from all liability of any kind whatsoever as a result thereof; and the warranty as hereinbefore set forth shall not be enlarged or affected by said action by SECHRIST.。

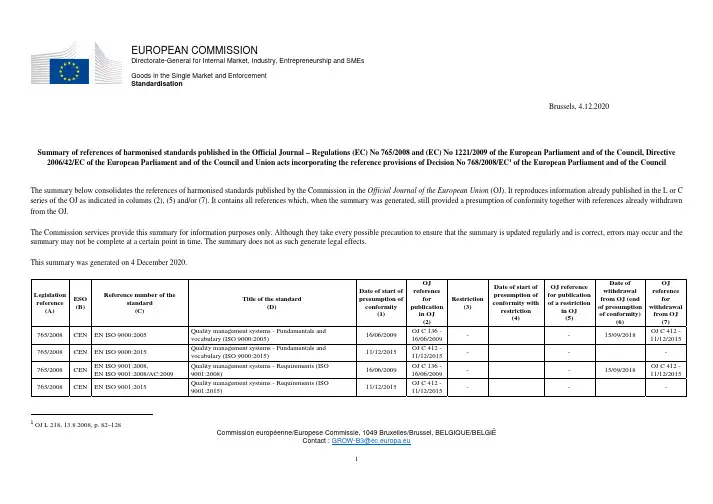

EUROPEAN COMMISSION Directorate-General for Internal Market, Industry, Entrepreneurship and SMEsGoods in the Single Market and Enforcement StandardisationBrussels, 4.12.2020Summary of references of harmonised standards published in the Official Journal – Regulations (EC) No 765/2008 and (EC) No 1221/2009 of the European Parliament and of the Council, Directive 2006/42/EC of the European Parliament and of the Council and Union acts incorporating the reference provisions of Decision No 768/2008/EC 1 of the European Parliament and of the CouncilThe summary below consolidates the references of harmonised standards published by the Commission in the Official Journal of the European Union (OJ). It reproduces information already published in the L or C series of the OJ as indicated in columns (2), (5) and/or (7). It contains all references which, when the summary was generated, still provided a presumption of conformity together with references already withdrawn from the OJ.The Commission services provide this summary for information purposes only. Although they take every possible precaution to ensure that the summary is updated regularly and is correct, errors may occur and the summary may not be complete at a certain point in time. The summary does not as such generate legal effects. This summary was generated on 4 December 2020.Legislationreference(A) ESO(B)Reference number of thestandard (C)Title of the standard(D)Date of start of presumption of conformity (1) OJ reference for publication in OJ (2)Restriction(3) Date of start of presumption of conformity with restriction (4) OJ referencefor publicationof a restrictionin OJ(5)Date ofwithdrawalfrom OJ (end of presumption of conformity)(6) OJ reference for withdrawalfrom OJ (7) 765/2008 CEN EN ISO 9000:2005 Quality management systems - Fundamentals andvocabulary (ISO 9000:2005)16/06/2009 OJ C 136 - 16/06/2009 - - 15/09/2018OJ C 412 -11/12/2015 765/2008 CEN EN ISO 9000:2015 Quality management systems - Fundamentals and vocabulary (ISO 9000:2015)11/12/2015OJ C 412 -11/12/2015- - - 765/2008 CENEN ISO 9001:2008, EN ISO 9001:2008/AC:2009 Quality management systems - Requirements (ISO 9001:2008)16/06/2009OJ C 136 -16/06/2009- - 15/09/2018 OJ C 412 - 11/12/2015 765/2008 CEN EN ISO 9001:2015Quality management systems - Requirements (ISO 9001:2015)11/12/2015 OJ C 412 -11/12/2015- - -1OJ L 218, 13.8.2008, p. 82–128Commission européenne/Europese Commissie, 1049 Bruxelles/Brussel, BELGIQUE/BELGIËContact : *****************.euLegislationreference(A)ESO(B)Reference number of thestandard (C)Title of the standard(D)Date of start of presumption of conformity (1) OJ reference for publication in OJ (2)Restriction(3) Date of start of presumption of conformity with restriction (4) OJ referencefor publicationof a restrictionin OJ(5)Date ofwithdrawalfrom OJ (end of presumption of conformity)(6) OJ reference for withdrawalfrom OJ (7) 765/2008 CEN EN ISO 14001:2004 Environmental management systems - Requirements withguidance for use (ISO 14001:2004)16/06/2009OJ C 136 -16/06/2009- - 15/09/2018 OJ C 412 - 11/12/2015 765/2008 CENEN ISO 14001:2004, EN ISO 14001:2004/AC:2009 Environmental management systems - Requirements with guidance for use (ISO 14001:2004)16/06/2009 OJ C136 - 16/06/2009 - - 15/09/2018OJ C 412 -11/12/2015 765/2008 CEN EN ISO 14001:2015 Environmental management systems - Requirements with guidance for use (ISO 14001:2015)11/12/2015 OJ C 412 -11/12/2015 - - -765/2008 CEN EN ISO 14004:2010 Environmental management systems - General guidelines on principles, systems and support techniques (ISO 14004:2004)05/10/2011 OJ C 292 - 05/10/2011 - - 30/04/2019OJ C 209 -10/06/2016765/2008 CEN EN ISO 14004:2016 Environmental management systems - General guidelines on implementation (ISO 14004:2016)10/06/2016 OJ C 209 - 10/06/2016 - - -765/2008 CEN EN ISO 14015:2010 Environmental management - Environmental assessment of sites and organizations (EASO) (ISO 14015:2001)05/10/2011 OJ C 292 - 05/10/2011 - - -765/2008 CEN EN ISO 14020:2001 Environmental labels and declarations - General principles (ISO 14020:2000)16/06/2009 OJ C 136 - 16/06/2009 - - - 765/2008 CEN EN ISO 14021:2001 Environmental labels and declarations - Self-declared environmental claims (Type II environmental labelling) (ISO 14021:1999)16/06/2009 OJ C 136 - 16/06/2009 - - 30/06/2012OJ C 149 - 25/05/2012 765/2008 CENEN ISO 14021:2001, EN ISO 14021:2001/A1:2011 Environmental labels and declarations - Self-declared environmental claims (Type II environmental labelling) (ISO 14021:1999)25/05/2012 OJ C 149 - 25/05/2012 - - 31/10/2018OJ C 293 -12/08/2016765/2008 CEN EN ISO 14021:2016 Environmental labels and declarations - Self-declared environmental claims (Type II environmental labelling) (ISO 14021:2016)12/08/2016 OJ C 293 - 12/08/2016 - - - 765/2008 CEN EN ISO 14024:2000 Environmental labels and declarations - Type Ienvironmental labelling - Principles and procedures (ISO 14024:1999)16/06/2009 OJ C 136 - 16/06/2009 - - 31/12/2020OJ C 209 - 15/06/2018765/2008 CEN EN ISO 14024:2018 Environmental labels and declarations - Type Ienvironmental labelling - Principles and procedures (ISO 14024:2018)15/06/2018 OJ C 209 - 15/06/2018 - - - 765/2008 CEN EN ISO 14031:1999 Environmental management - Environmental performance evaluation - Guidelines (ISO 14031:1999)16/06/2009 OJ C 136 - 16/06/2009 - - 28/04/2014OJ C 348 - 28/11/2013765/2008 CEN EN ISO 14031:2013 Environmental management - Environmental performance evaluation - Guidelines (ISO 14031:2013)28/11/2013 OJ C 348 - 28/11/2013 - - -765/2008 CEN EN ISO 14040:2006 Environmental management - Life cycle assessment - Principles and framework (ISO 14040:2006)16/06/2009 OJ C 136 - 16/06/2009 - - - 765/2008 CEN EN ISO 14044:2006 Environmental management - Life cycle assessment - Requirements and guidelines (ISO 14044:2006)16/06/2009 OJ C 136 - 16/06/2009 - - 31/12/2020OJ C 209 - 15/06/2018765/2008 CENEN ISO 14044:2006, EN ISO 14044:2006/A1:2018 Environmental management - Life cycle assessment - Requirements and guidelines (ISO 14044:2006) 15/06/2018 OJ C 209 - 15/06/2018 - - -765/2008 CEN EN ISO 14050:2010Environmental management - Vocabulary (ISO 14050:2009)05/10/2011OJ C 292 - 05/10/2011- - -Legislation reference(A) ESO(B)Reference number of thestandard(C)Title of the standard(D)presumption ofconformity(1)forpublicationin OJ(2)Restriction(3)presumption ofconformity withrestriction(4)for publicationof a restrictionin OJ(5)from OJ (endof presumptionof conformity)(6)forwithdrawalfrom OJ(7)765/2008 CEN ENISO14063:2010 Environmental management - Environmentalcommunication - Guidelines and examples (ISO14063:2006)05/10/2011OJ C 292 -05/10/2011- - -765/2008 CEN ENISO14064-1:2012 Greenhouse gases - Part 1: Specification with guidance atthe organization level for quantification and reporting ofgreenhouse gas emissions and removals (ISO 14064-1:2006)28/11/2013OJ C 348 -28/11/2013- -01/07/2022OJ L 408 -04/12/2020765/2008 CEN ENISO14064-1:2019 Greenhouse gases - Part 1: Specification with guidance atthe organization level for quantification and reporting ofgreenhouse gas emissions and removals (ISO 14064-1:2018)04/12/2020OJ L 408 -04/12/2020- - -765/2008 CEN ENISO14064-2:2012 Greenhouse gases - Part 2: Specification with guidance atthe project level for quantification, monitoring andreporting of greenhouse gas emission reductions orremoval enhancements (ISO 14064-2:2006)28/11/2013OJ C 348 -28/11/2013- -01/07/2022OJ L 408 -04/12/2020765/2008 CEN ENISO14064-2:2019 Greenhouse gases - Part 2: Specification with guidance atthe project level for quantification, monitoring andreporting of greenhouse gas emission reductions orremoval enhancements (ISO 14064-2:2019)04/12/2020OJ L 408 -04/12/2020- - -765/2008 CEN ENISO14064-3:2012 Greenhouse gases - Part 3: Specification with guidance forthe validation and verification of greenhouse gas assertions(ISO 14064-3:2006)28/11/2013OJ C 348 -28/11/2013- -01/07/2022OJ L 408 -04/12/2020765/2008 CEN ENISO14064-3:2019 Greenhouse gases - Part 3: Specification with guidance forthe verification and validation of greenhouse gasstatements (ISO 14064-3:2019)04/12/2020OJ L 408 -04/12/2020- - -765/2008 CEN ENISO14065:2012 Greenhouse gases - Requirements for greenhouse gasvalidation and verification bodies for use in accreditationor other forms of recognition25/05/2012OJ C 149 -25/05/2012- -31/12/2013OJ C 258 -07/09/2013765/2008 CEN ENISO14065:2013 Greenhouse gases - Requirements for greenhouse gasvalidation and verification bodies for use in accreditationor other forms of recognition (ISO 14065:2013)07/09/2013OJ C 258 -07/09/2013- - -765/2008 CEN ENISO15189:2012 Medical laboratories - Requirements for quality andcompetence (ISO 15189:2012, Corrected version 2014-08-15)13/03/2013OJ C 074 -13/03/2013- - -765/2008 CEN ENISO15195:2003 Laboratory medicine - Requirements for referencemeasurement laboratories (ISO 15195:2003)05/10/2011OJ C 292 -05/10/2011- -01/07/2022OJ L 408 -04/12/2020765/2008 CEN ENISO15195:2019 Laboratory medicine - Requirements for the competence ofcalibration laboratories using reference measurementprocedures (ISO 15195:2018)04/12/2020OJ L 408 -04/12/2020- - -765/2008 CEN ENISO/IEC17000:2004 Conformity assessment - Vocabulary and generalprinciples (ISO/IEC 17000:2004)16/06/2009OJ C 136 -16/06/2009- - -765/2008 CEN ENISO/IEC17011:2004 Conformity assessment - General requirements foraccreditation bodies accrediting conformity assessmentbodies (ISO/IEC 17011:2004)16/06/2009OJ C 136 -16/06/2009- -31/12/2020OJ C 092 -09/03/2018Legislationreference(A)ESO(B)Reference number of thestandard (C)Title of the standard(D)presumption of conformity (1) for publicationin OJ(2) Restriction(3) presumption of conformity with restriction (4) for publicationof a restrictionin OJ(5)from OJ (endof presumption of conformity)(6) for withdrawalfrom OJ (7)765/2008 CEN EN ISO/IEC 17011:2017 Conformity assessment - Requirements for accreditation bodies accrediting conformity assessment bodies (ISO/IEC 17011:2017)09/03/2018 OJ C 092 - 09/03/2018 - - -765/2008 CEN EN ISO/IEC 17020:2012 Conformity assessment - Requirements for the operation of various types of bodies performing inspection (ISO/IEC 17020:2012)25/05/2012 OJ C 149 - 25/05/2012 - - - 765/2008 CEN EN ISO/IEC 17021:2011 Conformity assessment - Requirements for bodiesproviding audit and certification of management systems (ISO/IEC 17021:2011)05/10/2011 OJ C 292 - 05/10/2011 - - 08/07/2017OJ C 412 -11/12/2015765/2008 CEN EN ISO/IEC 17021-1:2015 Conformity assessment - Requirements for bodiesproviding audit and certification of management systems - Part 1: Requirements (ISO/IEC 17021-1:2015)11/12/2015 OJ C 412 - 11/12/2015 - - -765/2008 CEN EN ISO/IEC 17024:2012 Conformity assessment - General requirements for bodies operating certification of persons (ISO/IEC 17024:2012) 07/09/2013 OJ C 258 - 07/09/2013 - - - 765/2008 CEN EN ISO/IEC 17025:2005,EN ISO/IEC17025:2005/AC:2006 General requirements for the competence of testing and calibration laboratories (ISO/IEC 17025:2005)16/06/2009 OJ C 136 - 16/06/2009 - - 01/07/2021OJ L 408 - 04/12/2020765/2008 CEN EN ISO/IEC 17025:2017 General requirements for the competence of testing and calibration laboratories (ISO/IEC 17025:2017) 09/03/2018 OJ C 092 - 09/03/2018 - - -765/2008 CEN EN ISO/IEC 17029:2019 Conformity Assessment - General principles and requirements for validation and verification bodies (ISO/IEC 17029:2019)04/12/2020 OJ L 408 - 04/12/2020 - - -765/2008 CEN EN ISO 17034:2016 General requirements for the competence of reference material producers (ISO 17034:2016)08/09/2017 OJ C 298 - 08/09/2017 - - -765/2008 CEN EN ISO/IEC 17040:2005 Conformity assessment - General requirements for peer assessment of conformity assessment bodies and accreditation bodies (ISO/IEC 17040:2005)16/06/2009 OJ C 136 - 16/06/2009 - - -765/2008 CEN EN ISO/IEC 17043:2010 Conformity assessment - General requirements for proficiency testing (ISO/IEC 17043:2010)28/11/2013 OJ C 348 - 28/11/2013 - - -765/2008 CEN EN ISO/IEC 17050-1:2010 Conformity assessment - Supplier's declaration of conformity - Part 1: General requirements (ISO/IEC 17050-1:2004, corrected version 2007-06-15) 05/10/2011 OJ C 292 - 05/10/2011 - - -765/2008 CEN EN ISO/IEC 17050-2:2004 Conformity assessment - Supplier's declaration ofconformity - Part 2: Supporting documentation (ISO/IEC 17050-2:2004)16/06/2009 OJ C 136 - 16/06/2009 - - -765/2008 CEN EN ISO/IEC 17065:2012 Conformity assessment - Requirements for bodies certifying products, processes and services (ISO/IEC 17065:2012)07/09/2013 OJ C 258 - 07/09/2013 - - -765/2008 CEN EN ISO/IEC 17067:2013 Conformity assessment - Fundamentals of product certification and guidelines for product certification schemes (ISO/IEC 17067:2013)12/02/2016 OJ C 054 - 12/02/2016 - - - 765/2008 CEN EN ISO 19011:2002 Guidelines for quality and/or environmental management systems auditing (ISO 19011:2002)16/06/2009 OJ C 136 - 16/06/2009 - - 31/05/2012OJ C 149 - 25/05/2012 765/2008 CEN EN ISO 19011:2011Guidelines for auditing management systems (ISO 19011:2011)25/05/2012OJ C 149 - 25/05/2012- - 01/01/2021OJ L 263 -16/10/2019Legislation reference(A) ESO(B)Reference number of thestandard(C)Title of the standard(D)Date of start ofpresumption ofconformity(1)OJreferenceforpublicationin OJ(2)Restriction(3)Date of start ofpresumption ofconformity withrestriction(4)OJ referencefor publicationof a restrictionin OJ(5)Date ofwithdrawalfrom OJ (endof presumptionof conformity)(6)OJreferenceforwithdrawalfrom OJ(7)765/2008 CEN ENISO19011:2018 Guidelines for auditing management systems (ISO19011:2018)16/10/2019OJ L 263 -16/10/2019- - -765/2008 CEN ENISO22870:2006 Point-of-care testing (POCT) - Requirements for qualityand competence (ISO 22870:2006)05/10/2011OJ C 292 -05/10/2011- -30/11/2019OJ C 076 -10/03/2017765/2008 CEN ENISO22870:2016 Point-of-care testing (POCT) - Requirements for qualityand competence (ISO 22870:2016)10/03/2017OJ C 076 -10/03/2017- - -765/2008 CEN ENISO15189:2007 Medical laboratories - Particular requirements for qualityand competence (ISO 15189:2007)05/10/2011OJ C 292 -05/10/2011- -30/11/2015OJ C 074 -13/03/2013765/2008 CEN ENISO/IEC17020:2004 General criteria for the operation of various types of bodiesperforming inspection (ISO/IEC 17020:1998)16/06/2009OJ C 136 -16/06/2009- -01/03/2015OJ C 149 -25/05/2012765/2008 CEN ENISO/IEC17024:2003 Conformity assessment - General requirements for bodiesoperating certification of persons (ISO/IEC 17024:2003)16/06/2009OJ C 136 -16/06/2009- -01/07/2015OJ C 258 -07/09/2013765/2008 CEN EN45011:1998 General requirements for bodies operating productcertification systems (ISO/IEC Guide 65:1996)16/06/2009OJ C 136 -16/06/2009- -15/09/2015OJ C 258 -07/09/2013Column legendReference information on legislation and standards(A) Reference number of a relevant Directive or Regulation under which it was published in the OJ(B) European standardisation organisation that adopted the relevant standard(C) Reference number of a relevant European standard or of a European standard and its amendment(s)(D) Title of a European standardDates and OJ references for establishing a presumption of conformity(1) Date when a presumption of conformity starts or started in cases where a reference was published in the OJ without restriction. This date is usually, but not always, the same as the OJ reference datein column (2)(2) Reference number and date of a relevant publication in the L or C series of the OJ in cases where a reference was published in the OJ without restrictionDates and OJ references for establishing a presumption of conformity with restriction(3) Restriction published in the OJ to restrict a presumption of conformity – this includes restrictions on the basis of formal objections(4) Date when a presumption of conformity with restriction starts or started in cases where a reference was published in the OJ with restriction. This date is usually, but not always, the same as the datein column (5)(5) Reference number and date of a relevant publication in the L or C series of the OJ in cases where a reference was published in the OJ with restrictionDates and OJ references for ending a presumption of conformity(6) Date when a presumption of conformity ends or ended(7) Reference number and date of a relevant publication in the L or C series of the OJ where the date of withdrawal from the OJ (date in column (6)) was published。

2006年3月31日发布(2006年8月31日修订)通用汽车公司顾客特殊要求- ISO/TS16949包括关于PPAP第四版的通用汽车公司特别说明(参见第5章节)注: 为方便起见,关于通用汽车公司顾客特殊要求和PPAP特别说明的先前版本的重大变化已经通过加下划线来突出显示,而2006 年3月31日发行的修订版加灰色阴影来突出。

但机构有责任阅读、理解并应用全部文件。

1. 范围ISO/TS 16949:2002, 第二版, 2002年3月1日 , “品质管理系统 –ISO 9001:2000应用于汽车生产和相关维修件机构的特殊要求”,及本文件规定的汽车顾客-指定部件生产和/或维修机构的通用汽车公司基本品质系统要求。

为确保供应商品质系统要求,满足下列条件的ISO/TS 16949第三方认证,通用汽车公司将接受其视为QS-9000的另一种选择:·这认证范围必须包括 ISO/TS 16949和ISO/TS 16949附加的GM-顾客特殊要求·这认证必须由一家与IATF监督办公室签约的认证机构,依据IATF 认可的汽车业认证计划来实施。

注: 品质系统要求, QS-9000, 第3版 (QS-9000:1998), 截止日期2006年12月14日所有ISO/TS 16949:2002中的要求和本文件中的要求必须在机构的品质管理系统中文件化。

2. 参考文献2.1 戴姆勒克莱斯勒, 福特汽车, 通用汽车品质系统要求 (QS-9000), 第三版, 1998年3月.2.2 戴姆勒克莱斯勒, 福特汽车, 通用汽车生产件批准程序(PPAP), 第四版, 2006年3月.2.3 戴姆勒克莱斯勒, 福特汽车, 通用汽车统计制程管制 (SPC), 第二版, 2005年7月.2.4 戴姆勒克莱斯勒, 福特汽车, 通用汽车产品品质先期策划与控制计划, 1994年6月2.5 戴姆勒克莱斯勒, 福特汽车, 通用汽车测量系统分析(MSA),第三版,2002年3月2.6 戴姆勒克莱斯勒, 福特汽车, 通用汽车潜在失效模式及后果分析, FMEA第三版, 2001年7月2.8 对 ISO/TS 16949:2002的IATF指导,AIAG版本, 2002年.2.9 ISO/TS 16949:2002汽车业认证计划, ISO/TS 16949:2002的获得IATF 认可的规则,第二版, 2004年5月.2.10 ISO/TS 16949:2002标准,第一版, 2002年3月 (2003年12月修正版本)可以应用上述列出的参考文献的最新版本,除非GM采购部门另有规定。

SQA 是供应商质量保证的英文缩写,他体现的是一种 过程管理 模式和 团队合作 精神。

流程优化1、两个延伸:SQA 工作先前延伸到P1;PE 工作向后延伸到P8。

2、SQA 项目前期工作的补充完善:项目前期介入零部件管理,新增加的工作内容主要包括:参与供应商的选择、技术交底、手工样件管理、工装样件管理等 。

3、质量门工作细化:根据奇瑞公司质量门建立SQA 质量门,按照工作类别细化为23项工作内容,根据不同零部件的开发周期及复杂程度,针对每一个零件建立产品开发计划表,共55项项目工作要求。

有效工具的使用质量管理的五大工具为:APQP 、FMEA 、SPC 、MSA 、PPAP 。

SQA 的六大工具分别为:1、使用APQP 状态跟踪表------全程监控每个零件的实时状态;2、明确了SQA 的主战场------供应商现场3、分阶段培训供应商------提高质量意识及能力4、全方位的PSO 审核------对零件开发状态、供应商生产准备、产能等进行确认5、供应商量产前的遏制------提前发现问题,平稳进入正常生产状态。

6、建立开口问题清单--------质量问题的跟踪与关闭APQP 监控等级明确为了保证新产品先期质量策划(APQP )工作的有效性、必要性和适用性,结合奇瑞公司现阶段的项目开发特点,对供应商零部件APQP 监控等级进行了明确:二级监控:对于自身结构复杂、加工工序繁多、关键特性较多、售后问题较多、配合关系复杂的各种总成件或单件;所有安全件、法规件;0级监控:沿用件;标准件;工艺简单的小型冲压件;小型注塑零件; 各类隔音、减震、降噪所使用的零部件;进口、转口贸易零件一级监控:二级和0 级以外的其他零件使用APQP 状态跟踪表1、为便于各项目对零件进行全程管理及风险管理,SQA 使用的系统工具是APQP状态跟踪表,跟踪表共55项工作内容。

2、在评定供应商风险等级和零部件APQP 监控等级基础上,运用风险评估准则,确定 PPAP 提交等级 。

1910.1 Purpose and scope.1910.1目的和范围。

1910.2 Definitions.1910.2定义。

1910.3 Petitions for the issuance, amendment, or repeal ofa standard.1910.3请愿书之核发、修改或废止的一个标准。

1910.4 Amendments to this part.1910.5 Applicability of standards.1910.6 Incorporation by reference.1910.6 Incorporation by reference.1910.7 Definition and requirements for a nationallyrecognized testing laboratory.1910.8 OMB control numbers under the Paperwork Reduction Act. 1910.11 Scope and purpose.1910.12 Construction work.1910.15 Shipyard employment.1910.16 Longshoring and marine terminals.1910.17 Effective dates.1910.18 Changes in established Federal standards.1910.19 Special provisions for air contaminants.1910.21 Definitions.1910.22 General requirements.1910.23 Guarding floor and wall openings and holes.1910.24 Fixed industrial stairs.1910.25 Portable wood ladders.1910.26 Portable metal ladders.1910.27 Fixed ladders.1910.28 Safety requirements for scaffolding.1910.29 Manually propelled mobile ladder stands and scaffolds(towers).1910.30 Other working surfaces.1910.33 Table of contents.1910.34 Coverage and definitions.1910.35 Compliance with NFPA 101-2000, Life Safety Code. 1910.36 Design and construction requirements for exit routes.1910.37 Maintenance, safeguards, and operational features forexit routes.1910.38 Emergency action plans.1910.39 Fire prevention plans.1910.66 Powered platforms for building maintenance.1910.66 Powered platforms for building maintenance.1910.67 Vehicle-mounted elevating and rotating workplatforms.1910.68 Manlifts.1910.94 Ventilation.1910.95 Occupational noise exposure.1910.97 Nonionizing radiation.1910.98 Effective dates.1910.101 Compressed gases (general requirements).1910.102 Acetylene.1910.103 Hydrogen.1910.104 Oxygen.1910.105 Nitrous oxide.1910.106 Flammable and combustible liquids.1910.107 Spray finishing using flammable and combustiblematerials.1910.109 Explosives and blasting agents.1910.1目的和范围。