2008-Usability factors to be considered in a simulation tool while designing production system

- 格式:pdf

- 大小:118.84 KB

- 文档页数:8

英译汉Europe Pushes to Get Fuel From Fields欧洲推动从田地获取燃料ARDEA, Italy — The previous growing season, this lush coastal field near Rome was filled with rows of delicate durum wheat, used to make high-quality pasta. Today it overflows with rapeseed, a tall, gnarled weedlike plant bursting with coarse yellow flowers that has become a new manna for European farmers: rapeseed can be turned into biofuel.意大利阿尔代尔——在先前的发展时期,靠近罗马的那些肥沃的沿海田地种满了成排的硬粒小麦,这些小麦用于制作高质量的意大利面。

现如今这片土地种植了油菜籽,这是一种高高的、粗糙的像野草一样的植物,开着粗俗的黄花,然而这已成为欧洲农民新的甘露:油菜籽可以变成生物燃料。

Motivated by generous subsidies to develop alternative energy sources —and a measure of concern about the future of the planet — Europe’s farmers are beginning to grow crops that can be turned into fuels meant to produce fewer emissions than gas or oil. They are chasing their counterparts in the Americas who have been raising crops for biofuel for more than five years. 发展可替代能源资源会有丰厚的补助,同时这也是为地球的未来考虑,受到这两方面因素的激励,欧洲的农民开始种植可以变成燃料的农作物,这种燃料比汽油或燃油排放更清洁。

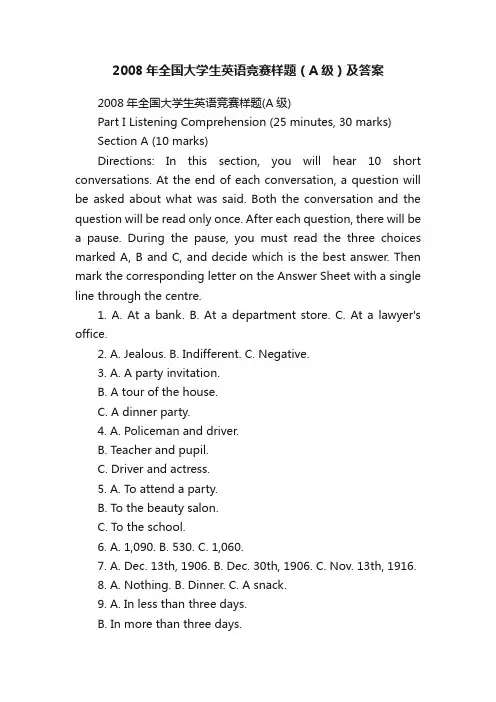

2008年全国大学生英语竞赛样题(A级)及答案2008年全国大学生英语竞赛样题(A级)Part I Listening Comprehension (25 minutes, 30 marks)Section A (10 marks)Directions: In this section, you will hear 10 short conversations. At the end of each conversation, a question will be asked about what was said. Both the conversation and the question will be read only once. After each question, there will be a pause. During the pause, you must read the three choices marked A, B and C, and decide which is the best answer. Then mark the corresponding letter on the Answer Sheet with a single line through the centre.1. A. At a bank. B. At a department store. C. At a lawyer's office.2. A. Jealous. B. Indifferent. C. Negative.3. A. A party invitation.B. A tour of the house.C. A dinner party.4. A. Policeman and driver.B. Teacher and pupil.C. Driver and actress.5. A. To attend a party.B. To the beauty salon.C. To the school.6. A. 1,090. B. 530. C. 1,060.7. A. Dec. 13th, 1906. B. Dec. 30th, 1906. C. Nov. 13th, 1916.8. A. Nothing. B. Dinner. C. A snack.9. A. In less than three days.B. In more than three days.C. In three days.10. A. To a friend's house.B. To the kindergarten.C. Do some shopping.Section B (5 marks)Directions: In this section, you will hear one long conversation. The conversation will be read only once. At the end of the conversation, there will be a one-minute pause. During the pause, you must read the five questions, each with three choices marked A, B and C, and decide which is the best answer. Then mark the corresponding letter on the Answer Sheet with a single line through the centre.11. What does Susan have to do on Saturday morning?A. Walk the dog.B. Clean the house.C. Go to the doctor's.12. What will Susan do at noon?A. Go shopping.B. Watch TV.C. Go to the dentist's.13. What time is Susan meeting with Julie?A. 12:30 am.B. 2:00 pm.C. 4:30 pm.14. How does Susan feel about her schedule on Saturday?A. Exciting.B. Disappointing.C. Exhausting.15. Why can't they watch a video at Susan's house?A. The machine doesn't work.B. They can't decide on a video.C. Susan's mother is going to use it.Section C (5 marks)Directions: In this section, you will hear 5 short news items. After each item, there will be a pause. During the pause, you must read the question and then the three choices marked A, B and C, and decide which is the best answer. Then mark the corresponding letter on the Answer Sheet with a single line through the centre.16. Who got to move to the next step?A. Andre Agassi.B. Rogen Fidow.C. Roger Federer.17. What did the gunman force the charity to do?A. Delay the operation in this area.B. Operate on their own staff.C. Attack the Sans Frontieres.18. Why were the Iraqi detainees made to pick up garbage?A. Because the serviceman abused the detainees.B. Because the commander gave the order to the serviceman.C. Because the detainees were accused.19. Where did the clash happen?A. In the West Bank.B. Near Israeli.C. Near Ariel.20. Why do the Israeli forces threaten to carry out a massive offensive against the Palestinians?A. Because Israeli troops were besieged by the Palestinians.B. Because the military operation began since last November.C. Because Palestinians killed Israelis in a suicide attack.Section D (10 marks)Directions: In this section, you will hear a short passage. There are ten missing words or phrases in it. Fill in the blanks with the exact words or phrases you hear on the tape. Remember to write the answers on the Answer Sheet.There are two types of people in the world. Although they have (21)________ degrees of health and wealth and other comforts of life, one becomes happy, and the other becomes (22) ________. This arises from the different ways in which they consider things, persons, and events, and the resulting effects upon their minds.People who are to be happy fix their attention on the (23) ________ of things, the pleasant part of convention, the fine weather. They enjoy all the (24) ________ things. Those who are to be unhappy think and speak only of the (25) ________ things. Therefore, they are continually (26) ________. By their remarks, they sour the pleasure of society, offend many people, and make themselves (27) ________ everywhere. If this turn of mind were found in nature, such unhappy persons would be the more to be pitied. The tendency to criticize and to be disgusted is perhaps taken up originally (28) ________. It grows into a habit, unknown to its possessors. The habit may be strong, but itmay be cured when those who have it are convinced of its bad effects (29) ________. I hope this little warning may be of service to them, and help them change this habit. Although in fact it is chiefly (30) ________, it has serious consequences in life since it brings on deep sorrow and bad luck.Part II Vocabulary and Structure (10 minutes, 15 marks) Directions: There are 15 incomplete sentences in this section. For each blank there are four choices marked A, B, C and D. Choosethe one that bestcompletes the sentence. Then mark the corresponding letter on the Answer Sheet with a single line through the centre.31. Essentially, a theory is an abstract, symbolic representation of________ reality.A. what it is conceivedB. that is conceivedC. what is conceived to beD. that is being conceived of32. New York City collects garbage ________ $209 per family per year.A. at the cost ofB. at sacrifice ofC. in demand ofD. in support of33. I would just as soon ________ rudely to her.A. you not speakB. you won't speakC. you not speakingD. you didn't speak34. ________ so many people been out of work as today.A. More than ever beforeB. Never before haveC. In the past, there never haveD. Formerly, there never were35. We got home late last night, ________, early this morning.A. namelyB. in other wordsC. or ratherD. in any case36. The miners escaped the danger by ________.A. a hair breadthB. hair breadthC. hair's breadthD. a hair's breadth37. Praise is like warm sunshine. It not only brings joy to ________ who are praised but also adds pleasure to ________ who praise.A. these; theseB. we; usC. them; themD. those; those38. When our imports ________ our exports, we say we have a favorable trade balance; however, when our imports and exports are the other way round we say we have an unfavorable trade balance.A. fall shortB. fall short ofC. run out ofD. are lack of39. ________ that distinguish human beings from other primates are related to the ability of people to stand upright and walk on two legs.A. Many of the physical characteristicsB. Of the many physical characteristicsC. The physical characteristicsD. There are many physical characteristics40. Classical logic is characterized by a concern for the structure and elements of argument ________ that thought,language, and reality are interrelated.A. based on the beliefB. on the belief basedC. belief based on theD. the based belief on41. ________ fashioned from a wick floating in a bowl of oil functioned according to the principle of capillary action.A. All lamps earlyB. Lamps all earlyC. All early lampsD. Early all lamps42. In 1964 ________ of Henry Osaka Tanner's paintings was shown at the Smithsonian Institution.A. was a major collectionB. that a major collectionC. a collection was majorD. a major collection43. Traditionally, ________ on Thanksgiving Day in New England.A. when served is sweet ciderB. when sweet cider is servedC. is served sweet ciderD. sweet cider is served44. Richard: This class is so boring. When will it end?Drew: I don't know. I don't think I can take it much longer.Teacher: ________Richard: Oh, nothing. We were discussing the text.A. Hey you two! What are you talking about?B. Do one of you know what the answer to this problem is?C. Am I boring you two?D. The two of you go to the principal's office right now!45. Delivery man: I have a package here for Beverly Beaver.Beverly: That is me. ________Delivery man: Yes, please sign here on the line.Beverly: Thank you. These must be the new drapes I ordered.A. Where is the receipt?B. Do you have the sender's address?C. Do you take a credit card?D. Do I have to sign for it?Part III Reading Comprehension (20 minutes, 40 marks)Section A (5 marks)Directions: There is one passage in this section with 5 questions. For each question, there are four choices marked A, B, C and D. You should decide on the best choice. Then mark the corresponding letter on theAnswer Sheet with a single line through the centre.Questions 46-50 are based on the following passage.No matter what our work is, we all have to face that choice - in my field no less than in others. There may not be a more important field for the dissemination of values in our country than the entire communicationsindustry - most strikingly, television. Networks are very sensitive to that fact, and they employ dozens of censors to prevent all of us from using language on television that an eight year old might have to explain to his parents. But the point that censors miss, I think, is that it is not so much what we say that teaches as what we don't say. Even programs that attempt to make a moral point don't always make the point that they intended to. Because when we sense we are being sole something, we automatically defend ourselves against it. I thinkit may be the unspoken assumptions that mold an audience.Look at the way, for instance, that violence is treated on television. It is not only the quantity that offends. There probably is no more violence on television than there is in a Shakespearean tragedy. But on television you find unfelt violence and in Shakespeare you tend to find felt violence. In Shakespeare the characters react with a human response: They fear, they hurt, they mourn. Most of the time on television, violence is dealt with by sweeping it under the rug as fast as possible and by having people go on about their business as if nothing had happened. (If I can't have less violence, I want at least a better grade of violence.) One of the unspoken assumptions is that violence can be tolerated as long as you ignore it and have no reaction to it. But that seems to me to be dangerously close to psychopathic behavior.I wonder if there is any connection between the long acceptance by our people of the Vietnam War and the thousands and thousands of deaths that we have seen on television over the years that were never mourned, never even paused for except to sell shampoo for sixty seconds.Maybe our greatest problem is that we have two separate sets of value systems that we use - the one we talk about and the one we live by. We seem to place a very high value on fairness and on human concerns. And yet we stillhave widespread discrimination based on race, sex and religion. You still don't find Jews, blacks or other minorities in any significant numbers in decision-making positions in the banking industry, for instance. You think that's an accident? I think somebody puts a value on that. And you don't find women in any significant numbers in decision-making capacities in any industry.Why? Because we place a higher value on appeasing the fragile male ego than we do on fairness and decency. Maybe what we need is a declaration of interdependence.Questions:46. It can be concluded from the first paragraph that ________.A. we won't buy things that are recommendedB. we become defensive whenever we are taught to do somethingC. television is the most important part of the communication industryD. TV programs can never successfully convey a moral point47. What is the author's attitude toward violence on television?A. He thinks that violence on television should be totally banned.B. Violence on television is more tolerable than the one in Shakespeare's plays.C. Violence can be tolerated if you pretend that it doesn't exist.D. Violence, if unavoidable, should be presented on television in a more appropriate way.48. The word “appeasing” (line 6 in paragraph 3) most probably means ________.A. attackingB. accusingC. soothingD. satisfying49. By citing the examples of the Jews, blacks, and other minorities in the last paragraph, the author aims to show that ________.A. it's an accident that they are out-numbered in the decision-making positions in the banking industryB. they stand for one set of value systemC. what we talk about and what we actually do might be totally differentD. fairness is well respected in our life50. The author's tone in writing the text is ________.A. neutralB. matter-of-factC. criticalD. questioningSection B (15 marks)Directions: There is one passage in this section with 10 questions. Go over the passage quickly and answer the questions on the Answer Sheet.For questions 51 - 55, markY (for YES) if the statement agrees with the information given in the passage;N (for NO) if the statement contradicts the information given in the passage;NG (for NOT GIVEN) if the information is not given in the passage.For questions 56 - 60, complete the sentences with the information given in the passage.You hear the same complaint all the time as people get older: “My memory is terrible.” Is it all in the mind, or do real changes take place in the brain with age to justify such grumbling (抱怨)? The depressing answer is that the brain's cells, the neurons, die and decline in efficiency with age.Professor Arthur Shimamura, of the University of Californiaat Berkeley, says there are three main ways in which mental function changes. The first is mental speed, for example how quickly you can react to fast-moving incidents on the road. Drivers in their late teens react quickly but tend to drive too fast, while the over sixties are more cautious but react more slowly. The near-inevitable slowing with age also partly explains why soccer players are seen as old in their thirties, while golf professionals are still in their prime at that age. This type of mental slowing results from a reduction in the efficiency with which the brain's neurons work.The fact that adults find it harder to learn musical instruments than children points to a second type of mental loss with age - a reduction in learning capacity. The parts of the brain known as the temporal lobes control new learning, and are particularly vulnerable to the effects of aging. This means that, as we get older, we take longer to learn a new language, and slower to master new routines and technologies at work, and we have to rely more on diaries and other mental aids.“Working memory” is the third brain system which is vulnerable to the effects of aging. Working memory is the brain's “blackboard”,where we juggle from moment to moment the things we have to keep in mind when solving problems, planning tasks and generally organizing our day-to-day life. Absent-mindedness occurs at all ages because of imperfections in the working memory system - so, for instance, you may continually lose your glasses, or find yourself walking into a room of your house only to find that you cannot remember what you came for.Such absent-mindedness tends to creep up on us as we age and occurs because our plans and intentions, which are chalkedup on the mental blackboard, are easily wiped out by stray thoughts and other distractions. Stress and preoccupation can also cause such absent-mindedness, in addition to age-related changes in the brain. The frontal lobes of the brain - located behind the forehead and above the eyes - are where the working memory system is located. Like the temporal lobes, which handle new learning, the frontal lobes are more vulnerable to the aging process than other parts of the brain.The news, however, is not all bleak. Although neurons reduce in number with age, the remaining neurons send out new and longer connection fibers (dendrites) to maintain connections and allow us to function reasonably well with only relatively small drops in ability.This and other evidence suggests that the principle “use it or lost it” might apply to the aging brain. Professor Shimamura studied a group of university professors who were still intellectually active, and compared their performance on neuropsychological tests with that of others of their age group, as well as with younger people. He found that on several tests of memory, the mentally active professors in their sixties and early seventies were superior to their contemporaries, and as good as the younger people.Research on animals provide even stronger evidence of the effects of stimulation on the brain structure. Professor Bryan Kolb, of the University of Lethbridge in Canada, has shown that animals kept in stimulating environments show sprouting (生长) and lengthening of the connecting nerve fibers in comparison with animals kept in unstimulating environments.The beneficial effects of continued mental activity are shown by the fact that older contestants in quiz shows are just as fastand accurate in responding to general knowledge questions as younger competitors, suggesting that at least part of their intellectual apparatus is spared the effects of aging because of practice and skill.Such findings lead to the intriguing possibility of “mental fitnesstra ining” to accompany jogging and workouts for the health conscious. Research in Stockholm by Professor Lars Backman and his colleague has shown that older people can be trained to use their memory better, with the effects of this training lasting several years.Just as people go bald or grey at different rates, so the same is true for their mental faculties. Why this should be the case for memory and other mental functions is not yet clear. If Professor Shimamura is right, then the degree to which people use and stretch their mental faculties may also have a role to play.Questions:51. The passage gives a description of several methods of testing mental ability.52. Professor Shimamura identified a number of areas in which mental function may change.53. As the temporal lobes of the brain are affected by aging, it becomes harder to pick up new skills.54. Research indicates that physical training can help to improve memory.55. Taking part in quizzes is the best way to stimulate the brain.56. Absent-mindedness is not necessarily ________.57. Scientists do not understand why people's ________ decline at different rates.58. If a person is under stress, ________ may become more frequent.59. When the frontal lobes of the brain are affected by aging, there is a gradual deterioration in ________.60. If an animal's brain is kept active and stimulated, ______________. Section C (10 marks)Directions: In this section, there is one passage followed by 5 questions. Read the passage carefully, then answer the questions in a maximum of 10 words. Remember to write the answers on the Answer Sheet.Questions 61 - 65 are based on the following passage.Alarmed by a 20-year decline in student achievement, American schools are considering major upheavals in the career structure of teachers, school boards around the country are planning to abandon traditional salary schedules and single out outstanding teachers for massive pay rise.The idea is regarded with deep suspicion by the United States' biggest teachers' unions, the National Education Association and the American Federation of Teachers. They say the creation of a cadre of elite teachers will sour professional relationships and encourage teachers to compete instead of cooperate; they also question whether a fair way can be devised to tell which teachers really do perform better than their colleagues.But heightened public anxiety about secondary education appears to have given the master teacher concept unstoppable political momentum. Florida and Tennessee are racing to introduce ambitious statewide master teacher schemes before the end of the year. Less grandiose proposals to pay teachers on the basis of merit instead of seniority have already beenimplemented in countless school districts. And the Secretary of Education, Mr. Terrel Bell, recently promised substantial incentive grants to states which intend to follow their example.Low pay is believed to be the single most important reason for the flight from teaching. The average salary of a teacher in the United States is just under $19,000, much less than that of an engineer ($34,700) and not much more than that of a secretary($16,500). To make ends meet it is common for teachers to take second jobs in the evening and in their summer holidays, and women, who used to make up the bulk of teacher candidates are turning to better paid professions.The unions insist that the answer to this problem is to increase the basic pay of all teachers, but most states would find that too expensive, they would be better able to afford schemes that confine pay increases to a small number of exceptional teachers. Champions of the idea say it would at least hold out the promise of high pay and status to bright graduates who are confident of their ability to do well in the classroom, but are deterred by the present meager opportunities for promotion.One of the first large-scale tests of this approach will come in Tennessee, where a year of painstaking negotiations has just overcome bitterunion opposition to a wide-ranging master teacher scheme. Tennessee promised that they will allocate $300 million as education budget. In return for a chance to earn bigger salaries and faster promotion, teachers will subject themselves to closer scrutiny.The Tennessee plan will make it harder for poor teachers to join the profession. Beginners will have to serve a probationary year before qualifying, and another three apprentice years beforereceiving tenure. Apprentice teachers who fail to reach a required standard will not be allowed to stay on. Survivors will be designated “career teachers” and given a chance to climb through three career rugs and earn bonuses of up to $7,000. Advancement will not be automatic. The performance of each teacher will be closely assessed by committees of teachers drawn from other districts.Questions:61. What support is the federal government offering to states that set upa master teacher scheme?62. What's the purpose of the master teacher scheme?63. In the state of Tennessee, how will teachers be assessed?64. What is the main idea of the text?65. What can be inferred from the text about the master teacher scheme?Section D (10 marks)Directions: In this section, there is one passage followed by a summary. Read the passage carefully and complete the summary below by choosing no more than three words from the passage. Remember to write the answers on the Answer Sheet.Questions 66 - 70 are based on the following passage.The United KingdomBritain (or Great Britain) is an island that lies off the north-west coast of Europe. The nearest country is France, which is 20 miles away and from which Britain is separated by the English Channel. The island is surrounded by the Atlantic Ocean to the west, and the North Sea to the east. It comprises the mainlands of England, Wales and Scotland, that is, three countries. Scotland is in the north, while Wales is in the west. Ireland, which is alsoan island, lies off the west coast of Britain. It consists of Northern Ireland and the Irish Republic. Britain together with Northern Ireland constitute the United Kingdom (UK). Thus, the United Kingdom is composed of four countries, the largest of which is England. The capital city is London, which is situated in south-east England.The UK has a total area of about 244,100 square kilometres (94,248 square miles). About 70% of the land area is devoted to agriculture, about 7% is wasteland, moorland and mountains, about 13% is devoted to urban development, and 10% is forest and woodland. The northern and western regions of Britain, that is Scotland and Vales, are mainly mountainous and hilly. Parts of the north-west and centre of England also consist of mountains and hills.Britain has a generally mild and temperate climate. It is, however, subject to frequent changes. It has an average annual rainfall of about 120 centimetres (47 inches).In 1998 the population of the United Kingdom was nearly 59 million. The density of population was approximately 240 people per square kilometre. However, in England, where 83% of the population live, the density was much higher, about 363 per square kilometre.In the UK, English is the first language of the vast majority of people. However, in western Wales, Welsh is the first language for many of the people. In Scotland only a small number of people speak Gaelic.In Britain about 66% of the population say that they are Christian, while fewer than 5% say that they belong to other religions.Summary:Britain is an island that (66) ________ the Atlantic Ocean and the North Sea. It comprises the mainlands of England, Wales and Scotland. Ireland(67) ________ the west coast of Britain. It (68) ________ Northern Ireland and the Irish Republic. The United Kingdom consists of Britain together with Northern Ireland. The capital city is London which (69) ________ south-east England.In 1998 the population of the UK was nearly 59 million. The density of population was 240 people per square kilometre. In the UK English is the first language of most people. In western Wales, Welsh (70) ________ many of the people, but few people in Scotland speak Gaelic.Part IV Cloze (15 minutes, 15 marks)Section A (5 marks)Directions: There are 5 blanks in the passage. For each blank, some letters of the word have been given (not exceeding 3 letters). Read the passage below and think of the word which best fits each blank. Use only one word in each blank. Remember to write the answers on the Answer Sheet.Language is learned primarily through communication with other people. Research shows that the more communication children (71) exp________ at home, the better developed their language skills will be. Children need to talk well in order to learn well. This is especially important for the development of native language skills since the language is often reinforced by the child's environment outside school.However, the (72) qu________ of communication is just as or more important than quantity alone. The language adults use helps children become aware of the many different aspects of objects and events around them. For example, during a shoppingtrip to the market or store, adults can develop children's concepts by bringing their attention to the shapes, colors, sounds, textures, and sizes of objects and events around them. Parents can do this naturally through conversation without (73) di________ teaching. In other words, conversation with children in everyday situations expands their minds and develops their thinking skills.In addition to conversing with children, adults can help prepare their children to succeed in school by (74) en________ them to take an active interest in books and in the print that surrounds them in the environment. The child's first major task in school is learning to read. Children who come to school with knowledge that the print aroundthem carries important meaning and with an interest in books an d stories will usually (75) su________ in learning to read rapidly. Section B (10 marks)Directions: There are 10 blanks in the passage. Use the word given in each blanket to form a word that fits in each blank. Remember to write the answers on the Answer Sheet.Forensic science (法庭科学) means (76) ________ (use) science to solve crime. But what exactly does a forensic scientist do?At the scene of crime, the crime scene (77) ________ (investigator) will thoroughly examine the area. They will look for fingerprints and palm prints; marks of tools and weapons; marks from shoes; fibers from (78) ______ (cloth); body fluids.Increasingly, CSIs (= crime scene investigators) are using specialized techniques, on site, to determine which areas to concentrate their investigation on.A forensic pathologist (法医)specializes in examining dead bodies to determine how and when death occurred. As well as (79) ________ (examine) the body,。

2008年新托福独立写作北美考题2008.1.12Do you agree or disagree with the following statement?The government should focus on environmental problems instead of on economic development.利弊型—拆分法Agree—环境问题Water pollutionResources deficiencyAir pollutionDisagree—经济发展2008.1.18Do you agree or disagree with the following statement?People are happier when they finish a challenging or difficult job than when they complete an essay task.事实型,比较类—拆场景AgreeDisagree2008.1.27Do you agree or disagree with the following statement?Successful people accept new things and take risks rather than hold on to the things that they have done well.成功类2008.2.1Do you agree or disagree with the following statement?Being creative is more important in finding the best solution to a problem than planning carefully.2008.2.8Do you agree or disagree with the following statement?Advertisements targeting children aged between 2 and 5 should be banned.2008. 2.15Do you agree or disagree with the following statement?It’s important for families to have meals together regularly.2008.2.23Do you agree or disagree with the following statement?Technology makes people’s lives simpler rather than makes people’s lives more complicated. 2008.3.1Do you agree or disagree with the following statement?To solve the present and future problems, it’s necessary to understand the past.2008. 3.7Do you agree or disagree with the following statement?People today spend too much time on enjoyment. We do what we like to do rather than what we should do.2008.3.14Do you agree or disagree with the following statement?The environmental issue is too complex to be solved by the individuals.2008.3.29Do you agree or disagree with the following statement?It’s important to have rules about the types of clothing that people wear at work and at school.2008. 4.26Do you agree or disagree with the following statement?The government should give priority to healthcare rather than to environmental problems.2008. 5.3Do you agree or disagree with the following statement?Technology had made children less creative than the children were in the past.2008.5.9Do you agree or disagree with the following statement?The government should spend more money on improving access to the Internet than to public transportation.2008.5.16Do you agree or disagree with the following statement?Telephone has greater influence on people’s lives than TV.2008.5. 30Do you agree or disagree with the following statement?People today are not as friendly as people were in the past.2008.6.6Do you agree or disagree with the following statement?Playing computer games is a waste of time for children.2008. 6.21Do you agree or disagree with the following statement?Good looks and clothing are more important to success than good ideas.2008. 6.28Do you agree or disagree with the following statement?People should live in a city or country all their lives than to move to another place.2008.7.11Do you agree or disagree with the following statement?Today, people don’t understand their children as well as the parents did 50 years ago.2008. 8.2Do you agree or disagree with the following statement?It was easier to achieve success in the past than it is today.2008.8.16Do you agree or disagree with the following statement?Most businesspeople are motivated only by the desire for more money.2008.8.23Do you agree or disagree with the following statement?A serious and strict teacher is more effective than a teacher who is humorous and easygoing.2008.9.5Which source is more dependable for news, TV or newspapers?2008.9.21Do you agree or disagree with the following statement?Children should play and study rather than learn how to do household chores.2008.9.27Do you agree or disagree with the following statement?Printed books have greater effect on society than TV does.2008.10.12Do you agree or disagree with the following statement?In order to succeed, we should be more like others than be different from others.2008.10.17Do you agree or disagree with the following statement?People get more benefits from traveling in their own country than traveling in a foreign country.2008.10.25Do you agree or disagree with the following statement?Students who can keep their own rooms organized are more likely to succeed.2008. 10.31Do you agree or disagree with the following statement?It is more fun to see a movie in a cinema with other people than watch a movie at home.2008.11.8Do you agree or disagree with the following statement?Scientists should be responsible for the negative impacts that is brought about by their discoveries or inventions.2008.11.14Do you agree or disagree with the following statement?Children should only play sports for fun rather than play sports in competitions or contests.2008.11.22Do you agree or disagree with the following statement?Students are more influenced by teachers than by their parents.2008.12.5Do you agree or disagree with the following statement?Sports teach us lessons about life.2008.12.7Do you agree or disagree with the following statement?Spending time alone is the best way to relieve stress.2008.12.10Do you agree or disagree with the following statement?People who have interests in different things cannot be friends.2008.12.12Do you agree or disagree with the following statement?Sports and exercises are more important to elderly people than to young people.2008.12.20Do you agree or disagree with the following statement?People should be allowed to use cell phones on public transportation such as buses and trains.。

2008考研英语作文真题In the modern era, the environment has become a significant concern for humanity. The rapid industrialization and urbanization have led to a series of environmental issues that are threatening the very existence of our planet. This essay aims to underscore the importance of environmental protection and the role each individual can play in preserving our natural resources.First and foremost, the environment is the foundation upon which all life depends. Without clean air, water, and fertile soil, the ecosystem would collapse, leading to the extinction of numerous species, including humans. Therefore, it is imperative that we take proactive measures to protect the environment.Secondly, environmental protection is not just a moral obligation but also an economic necessity. A healthy environment supports sustainable development, ensuring that future generations can enjoy the same resources that we do today. Investing in renewable energy, for example, not only helps reduce pollution but also creates new job opportunities and drives innovation.Moreover, the collective efforts of individuals can make a significant impact on environmental protection. Simple actions such as recycling, conserving water, and reducing waste can contribute to a cleaner and greener planet. It isthrough these small, everyday choices that we cancollectively make a difference.In conclusion, the importance of environmental protection cannot be overstated. It is a responsibility that falls on each of us to ensure the survival and prosperity of our planet. By recognizing the value of our natural resources and taking steps to protect them, we can secure a brighter future for all.。

2008年10月SAT真题解析阅读Section 21. 此题为简单同义重复,空格处因填写与“significant impact”同方向的词会,答案C(influential)正确。

2. 此题逻辑关系为同义重复,二空与“someone shrouded in mystery”同方向,故答案B正确。

3. 题干中冒号提示本题逻辑关系为同义重复。

空格处因填与“she wrote more than…”同方向词汇。

答案C(a prolific)正确。

4. 题干中一共三重逻辑关系。

借助于逻辑关系词even,一空与conventional 同义重复,二空借助that从句同义重复。

一二空之间借助nevertheless反义重复。

故答案E正确。

5. 题干中两个for均提示本题为同义重复中因果关系。

空格处应填“implementing sweeping…”内容同方向的词汇。

答案D(precipitately)正确。

Questions 6-10 are based on the following passages.Passage 1Every age, after his own, has gone in search of Shakespeare. The first biography was written in 1709. Now it is a poor year for the Shakespeare business when two or three more do not show up on bookstore shelves. We want to know who he was hoping that the narrative of his life will somehow explain the genius of his writing. But it never does. We find him but who we find only adds to the mystery. How is it that a man without a university education, a glover's son from a small Warwickshire market town, could have written the plays and poems that have spoken to generations of readers and theatergoers?Passage 2Stratford. Shakespeare's hometown, has become an almost sacred place of pilgrimage, with tourists waddling reverently around the spectacularly tasteless cathedral of the Shakespeare Memorial Theatre. An impressionable few of them are even moved to doff their caps or discardtheir ice creams. Shakespeare's familiar high-domed head, an image that is quite possibly not him at all, has adorned everything from TV beer commercials to British currency. He is the presiding genius of the national spirit, a kind of hero in a neck ruff. Without him industries would crash and ideologies crumble. It is even rumored that he also wrote plays.分析: Passage1 对Shakespeare是正面的态度。

Section1 1. Since one of Professor Roche's oft-repeated adages was that familiarity leads to ___, his students were quite surprised to find him so ___ Return of the Native, a novel he had taught for over 30 years. A love...enthusiastic over B contempt...disdainful of C knowledge...conversant with D boredom...excited by E admiration...confused by 参考答案:D 句中的Return of the Native由其后同位结构(⼀本他讲了三⼗多年的⼩说)可推论其即意味着familiarity,因⽽学⽣所感到惊讶的内容(即空格2)应和 familiarity会带来的内容(即空格1)形成反义,因⽽排除ABC(均为同义);⽽E选项的admiration和confused并不构成反义;⽽D选项的boredom和excited可构成反义(厌倦与兴奋)。

参考译⽂: 由于罗希教授(Professor Roche)常挂在嘴边的格⾔之⼀就是熟悉会带来厌倦,因⽽他的学⽣当发现他对《本⼟⼈的回归》这⼀他已讲了三⼗多年的⼩说仍会兴奋时倍感惊讶。

2. Reason was once believed to be ___ human, but lately this assumption of intellectual superiority has come under increasingly skeptical scrutiny: most researchers now at least ___ the notion that some animals can think. A logically…ridicule B unique…entertain C scarcely…embrace D quintessentially…balk at E peculiarly…scoff at 参考答案:B 句中有两层关系,⾸先,由but后内容(⼈类的智⼒优越性愈来愈受到怀疑和审视)推论出前句内容应为推理被认为是⼈类的能⼒,因⽽空格1应表肯定,由此可排除C(scarcely表否定);其次,从冒号所起的解释作⽤可推论出⼤多数研究⼈员应⽀持动物能够思考的观点,,因⽽空格2应表肯定,由此可排除 ADE(选项2均表否定)。

2008考研英语一真题In 2008, the Graduate Student Entrance Examination in English (English 1) posed significant challenges to test-takers. This article aims to provide a comprehensive analysis of this particular exam, covering its structure, content, and tips for effective preparation.Section I: Listening comprehension (30 points)This section consisted of four parts: long conversations, short conversations, passage dictation, and news broadcast. Each part tested candidates' ability to understand spoken English, including their comprehension of vocabulary, grammar, and overall context. To excel in this section, it is essential to practice listening to authentic English audio materials, such as news broadcasts, podcasts, and movies.Section II: Vocabulary and language (20 points)This section assessed candidates' knowledge of English vocabulary, idioms, and grammatical structures. The questions required test-takers to choose the correct word, phrase, or sentence completion to demonstrate their mastery of English language usage. To excel in this section, it is crucial to expand vocabulary through reading English newspapers, books, and online articles. Furthermore, dedicating time to learning and memorizing essential idioms and phrasal verbs is highly recommended.Section III: Reading comprehension (50 points)The reading comprehension section tested candidates' ability to understand and analyze written English passages. The question typesincluded true or false statements, multiple-choice questions, and sentence completion exercises. To perform well in this section, it is necessary to improve reading speed without compromising comprehension. Additionally, enhancing reading skills through frequent practice and exposure to a variety of topics is highly beneficial.Section IV: Translation (15 points)This section required candidates to translate a given Chinese text into English. To excel in this section, it is vital to master both Chinese and English language skills, including proper grammar, vocabulary, and sentence structure of both languages. Regular translation drills and extensive reading in both languages can significantly improve overall performance.Section V: Writing (55 points)The writing section consisted of two parts: sentence translation and essay writing. The sentence translation part required candidates to translate a given English sentence into Chinese. In the essay writing part, candidates were asked to write an essay on a given topic within the specified time limit. To succeed in this section, it is essential to enhance both writing skills and critical thinking abilities. Practicing timed essay writing and reviewing various essay structures can be beneficial for effective preparation.Overall, the 2008 Graduate Student Entrance Examination in English (English 1) demanded a comprehensive understanding of English language proficiency. To excel in this exam, candidates should focus on enhancing listening, vocabulary, reading, translation, and writing skills. Diligent practice and exposure to various English language resources will undoubtedly contribute to achieving success in this challenging examination.。

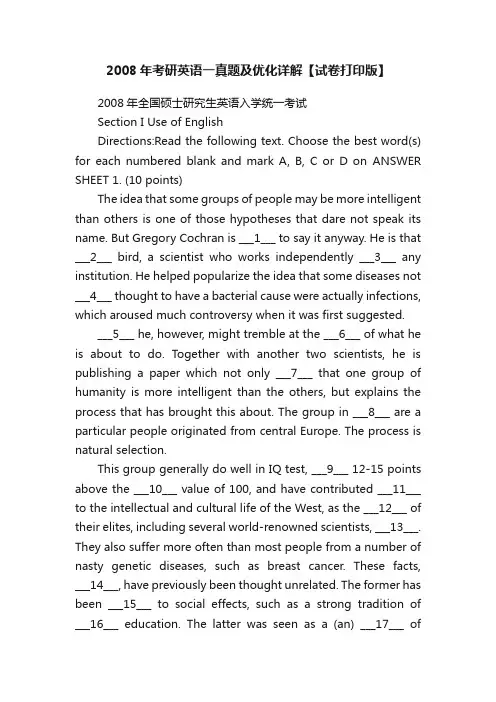

2008年考研英语一真题及优化详解【试卷打印版】2008年全国硕士研究生英语入学统一考试Section I Use of EnglishDirections:Read the following text. Choose the best word(s) for each numbered blank and mark A, B, C or D on ANSWER SHEET 1. (10 points)The idea that some groups of people may be more intelligent than others is one of those hypotheses that dare not speak its name. But Gregory Cochran is ___1___ to say it anyway. He is that ___2___ bird, a scientist who works independently ___3___ any institution. He helped popularize the idea that some diseases not ___4___ thought to have a bacterial cause were actually infections, which aroused much controversy when it was first suggested.___5___ he, however, might tremble at the ___6___ of what he is about to do. Together with another two scientists, he is publishing a paper which not only ___7___ that one group of humanity is more intelligent than the others, but explains the process that has brought this about. The group in ___8___ are a particular people originated from central Europe. The process is natural selection.This group generally do well in IQ test, ___9___ 12-15 points above the ___10___ value of 100, and have contributed ___11___ to the intellectual and cultural life of the West, as the ___12___ of their elites, including several world-renowned scientists, ___13___. They also suffer more often than most people from a number of nasty genetic diseases, such as breast cancer. These facts, ___14___, have previously been thought unrelated. The former has been ___15___ to social effects, such as a strong tradition of ___16___ education. The latter was seen as a (an) ___17___ ofgenetic isolation. Dr. Cochran suggests that the intelligence and diseases are intimately ___18___. His argument is that the unusual history of these people has ___19___ them to unique evolutionary pressures that have resulted in this ___20___ state of affairs.1. [A] selected [B] prepared [C] obliged [D] pleased2. [A] unique [B] particular [C] special [D] rare3. [A] of [B] with [C] in [D] against4. [A] subsequently [B] presently [C] previously [D] lately5. [A] Only [B] So [C] Even [D] Hence6. [A] thought [B] sight [C] cost [D] risk7. [A] advises [B] suggests [C] protests [D] objects8. [A] progress [B] fact [C] need [D] question9. [A] attaining [B] scoring [C] reaching [D] calculating10. [A] normal [B] common [C] mean [D] total11. [A] unconsciously [B] isproportionately [C] indefinitely [D] unaccountably12. [A] missions [B] fortunes [C] interests [D] careers13. [A] affirm [B] witness [C] observe [D] approve14. [A] moreover [B] therefore [C] however [D] meanwhile15. [A] given up [B] got over [C] carried on [D] put down16. [A] assessing [B] supervising [C] administering [D] valuing17. [A] development [B] origin [C] consequence [D] instrument18. [A] linked [B] integrated [C] woven [D] combined19. [A] limited [B] subjected [C] converted [D] directed20. [A] paradoxical [B] incompatible [C] inevitable [D] continuousSection II Reading ComprehensionPart ADirections:Read the following four texts. Answer thequestions below each text by choosing A, B, C or D. Mark your answers on ANSWER SHEET 1. (40 points)Text 1While still catching-up to men in some spheres of modern life, women appear to be way ahead in at least one undesirable category. “Women are particularly susceptible to developing depression and anxiety disorders in response to stress compared to men,” according to Dr. Yehuda, chief psychiatrist at New York’s Veteran’s Administrat ion Hospital.Studies of both animals and humans have shown that sex hormones somehow affect the stress response, causing females under stress to produce more of the trigger chemicals than do males under the same conditions. In several of the studies, when stressed-out female rats had their ovaries (the female reproductive organs) removed, their chemical responses became equal to those of the males.Adding to a woman’s increased dose of stress chemicals, are her increased “opportunities” for stress. “It’s n ot necessarily that women don’t cope as well. It’s just that they have so much more to cope with,” says Dr. Yehuda. “Their capacity for tolerating stress may even be greater than men’s,” she observes, “it’s just that they’re dealing with so many more things that they become worn out from it more visibly and sooner.”Dr. Yehuda notes another difference between the sexes. “I think that the kinds of things that women are exposed to tend to be in more of a chronic or repeated nature. Men go to war and are exposed to combat stress. Men are exposed to more acts of random physical violence. The kinds of interpersonal violence that women are exposed to tend to be in domestic situations, by,unfortunately, parents or other family members, and they tend not to be one-shot deals. The wear-and-tear that comes from these longer relationships can be quite devastating.”Adeline Alvarez married at 18 and gave birth to a son, but was determined to finish college. “I struggled a lot to get the college degree. I was living in so much frustration that that was my escape, to go to school, and get ahead and do better.” Later, her marriage ended and she became a single mother. “It’s the hardest thing to take care of a teenager, have a job, pay the rent, pay the car payment, and pay the debt. I lived from paycheck to paycheck.”Not everyone experiences the kinds of severe chronic stresses Alvarez describes. But most women today are coping with a lot of obligations, with few breaks, and feeling the strain. Alvarez’s experience demonstr ates the importance of finding ways to diffuse stress before it threatens your health and your ability to function.21. Which of the following is true according to the first two paragraphs?[A] Women are biologically more vulnerable to stress.[B] Women are still suffering much stress caused by men.[C] Women are more experienced than men in coping with stress.[D] Men and women show different inclinations when faced with stress.22. Dr. Yehuda’s research suggests that women[A] need extra doses of chemicals to handle stress.[B] have limited capacity for tolerating stress.[C] are more capable of avoiding stress.[D] are exposed to more stress.23. According to Paragraph 4, the stress women confront tends to be[A] domestic and temporary.[B] irregular and violent.[C] durable and frequent.[D] trivial and random.24. The sentence “I lived from paycheck to paycheck.” (Line 6, Para. 5) shows that[A] Alvarez cared about nothing but making money.[B] Alvarez’s salary barely covered her household expenses.[C] Alvarez got paychecks from different jobs.[D] Alvarez paid practically everything by check.25. Which of the following would be the best title for the text?[A] Strain of Stress: No Way Out?[B] Responses to Stress: Gender Difference[C] Stress Analysis: What Chemicals Say[D] Gender Inequality: Women Under StressText 2It used to be so straightforward. A team of researchers working together in the laboratory would submit the results of their research to a journal. A journal editor would then remove the a uthors’ names and affiliations from the paper and send it to their peers for review. Depending on the comments received, the editor would accept the paper for publication or decline it. Copyright rested with the journal publisher, and researchers seeking knowledge of the results would have to subscribe to the journal.No longer. The Internet –and pressure from funding agencies, who are questioning why commercial publishers are making money from government-funded research by restrictingaccess to it – is making access to scientific results a reality. The Organization for Economic Co-operation and Development (OECD) has just issued a report describing the far-reaching consequences of this. The report, by John Houghton of Victoria University in Australia and Graham Vickery of the OECD, makes heavy reading for publishers who have, so far, made handsome profits. But it goes further than that. It signals a change in what has, until now, been a key element of scientific endeavor.The value of knowledge and the return on the public investment in research depends, in part, upon wide distribution and ready access. It is big business. In America, the core scientific publishing market is estimated at between $7 billion and $11 billion. The International Association of Scientific, Technical and Medical Publishers says that there are more than 2,000 publishers worldwide specializing in these subjects. They publish more than 1.2 million articles each year in some 16,000 journals.This is now changing. According to the OECD report, some 75% of scholarly journals are now online. Entirely new business models are emerging; three main ones were identified by the report’s authors. There is the so-called big deal, where institutional subscribers pay for access to a collection of online journal titles through site-licensing agreements. There is open-access publishing, typically supported by asking the author (or his employer) to pay for the paper to be published. Finally, there are open-access archives, where organizations such as universities or international laboratories support institutional repositories. Other models exist that are hybrids of these three, such as delayed open-access, where journals allow only subscribers to read a paper for the first six months, before making it freely available to everyone who wishes to see it. Allthis could change the traditional form of the peer-review process, at least for the publication of papers.26. In the first paragraph, the author discusses[A] the background information of journal editing.[B] the publication routine of laboratory reports.[C] the relations of authors with journal publishers.[D] the traditional process of journal publication.27. Which of the following is true of the OECD report?[A] It criticizes government-funded research.[B] It introduces an effective means of publication.[C] It upsets profit-making journal publishers.[D] It benefits scientific research considerably.28. According to the text, online publication is significant in that[A] it provides an easier access to scientific results.[B] it brings huge profits to scientific researchers.[C] it emphasizes the crucial role of scientific knowledge.[D] it facilitates public investment in scientific research.29. With the open-access publishing model, the author of a paper is required to[A] cover the cost of its publication.[B] subscribe to the journal publishing it.[C] allow other online journals to use it freely.[D] complete the peer-review before submission.30. Which of the following best summarizes the text?[A] The Internet is posing a threat to publishers.[B] A new mode of publication is emerging.[C] Authors welcome the new channel for publication.[D] Publication is rendered easier by online service.Text 3In the early 1960s Wilt Chamberlain was one of only three players in the National Basketball Association (NBA) listed at over seven feet. If he had played last season, however, he would have been one of 42. The bodies playing major professional sports have changed dramatically over the years, and managers have been more than willing to adjust team uniforms to fit the growing numbers of bigger, longer frames.The trend in sports, though, may be obscuring an unrecognized reality: Americans have generally stopped growing. Though typically about two inches taller now than 140 years ago, today’s people –especially those born to families who have lived in the U.S. for many generations – apparently reached their limit in the early 1960s. And they aren’t likely to get any taller. “In the general populatio n today, at this genetic, environmental level, we’ve pretty much gone as far as we can go,” says anthropologist William Cameron Chumlea of Wright State University. In the case of NBA players, their increase in height appears to result from the increasingly common practice of recruiting players from all over the world.Growth, which rarely continues beyond the age of 20, demands calories and nutrients –notably, protein –to feed expanding tissues. At the start of the 20th century, under-nutrition and childhood infections got in the way. But as diet and health improved, children and adolescents have, on average, increased in height by about an inch and a half every 20 years, a pattern known as the secular trend in height. Yet according to the Centers for Disease Control and Prevention, average height –5′9″for men, 5′4″for women –hasn’t really changed since 1960.Genetically speaking, there are advantages to avoiding substantial height. During childbirth, larger babies have moredifficulty passing through the birth canal. Moreover, even though humans have been upright for millions of years, our feet and back continue to struggle with bipedal posture and cannot easily withstand repeated strain imposed by oversize limbs. “There are some real constraints that are set by the genetic architecture of the individual organism,” says anthropologist William Leonard of Northwestern University.Genetic maximums can change, but don’t expect this to happen soon. Claire C. Gordon, senior anthropologist at the Army Research Center in Natick, Mass., ensures that 90 percent of the uniforms and workstations fit recruits without alteration. She says that, unlike those for basketball, the length of military uniforms has not changed for some time. And if you need to predict human height in the near future to design a piece of equipment, Gordon says that by and large, “you could use today’s data and feel fairly confident.”31. Wilt Chamberlain is cited as an example to[A] illustrate the change of height of NBA players.[B] show the popularity of NBA players in the U.S..[C] compare different generations of NBA players.[D] assess the achievements of famous NBA players.32. Which of the following plays a key role in body growth according to the text?[A] Genetic modification.[B] Natural environment.[C] Living standards.[D] Daily exercise.33. On which of the following statements would the author most probably agree?[A] Non-Americans add to the average height of the nation.[B] Human height is conditioned by the upright posture.[C] Americans are the tallest on average in the world.[D] Larger babies tend to become taller in adulthood.34. We learn from the last paragraph that in the near future[A] the garment industry will reconsider the uniform size.[B] the design of military uniforms will remain unchanged.[C] genetic testing will be employed in selecting sportsmen.[D] the existing data of human height will still be applicable.35. The text intends to tell us that[A] the change of human height follows a cyclic pattern.[B] human height is becoming even more predictable.[C] Americans have reached their genetic growth limit.[D] the genetic pattern of Americans has altered.Text 4In 1784, five years before he became president of the United States, George Washington, 52, was nearly toothless. So he hired a dentist to transplant nine teeth into his jaw – having extracted them from the mouths of his slaves.That’s a far different image from the cherry-tree-chopping George most people remember from their history books. But recently, many historians have begun to focus on the roles slavery played in the lives of the founding generation. They have been spurred in part by DNA evidence made available in 1998, which almost certainly proved Thomas Jefferson had fathered at least one child with his slave Sally Hemings. And only over the past 30 years have scholars examined history from the bottom up. Works of several historians reveal the moral compromises made by the nation’s early leaders and the fragile nature of the country’s infancy. Mor e significantly, they argue that many of the Founding Fathers knew slavery was wrong – and yet most didlittle to fight it.More than anything, the historians say, the founders were hampered by the culture of their time. While Washington and Jefferson privately expressed distaste for slavery, they also understood that it was part of the political and economic bedrock of the country they helped to create.For one thing, the South could not afford to part with its slaves. Owning slaves was “like having a large bank account,” says Wiencek, author of An Imperfect God: George Washington, His Slaves, and the Creation of America. The southern states would not have signed the Constitution without protections for the “peculiar institution,” including a clause that counted a slave as three fifths of a man for purposes of congressional representation.And the statesmen’s political lives depended on slavery. The three-fifths formula handed Jefferson his narrow victory in the presidential election of 1800 by inflating the votes of the southern states in the Electoral College. Once in office, Jefferson extended slavery with the Louisiana Purchase in 1803; the new land was carved into 13 states, including three slave states.Still, Jefferson fre ed Hemings’s children –though not Hemings herself or his approximately 150 other slaves. Washington, who had begun to believe that all men were created equal after observing the bravery of the black soldiers during the Revolutionary War, overcame the strong opposition of his relatives to grant his slaves their freedom in his will. Only a decade earlier, such an act would have required legislative approval in Virginia.36. George Washington’s dental surgery is mentioned to[A] show the primitive medical practice in the past.[B] demonstrate the cruelty of slavery in his days.[C] stress the role of slaves in the U.S. history.[D] reveal some unknown aspect of his life.37. We may infer from the second paragraph that[A] DNA technology has been widely applied to history research.[B] in its early days the U.S. was confronted with delicate situations.[C] historians deliberately made up some stories of Jefferson’s life.[D] political compromises are easily found throughout the U.S. history.38. What do we learn about Thomas Jefferson?[A] His political view changed his attitude towards slavery.[B] His status as a father made him free the child slaves.[C] His attitude towards slavery was complex.[D] His affair with a slave stained his prestige.39. Which of the following is true according to the text?[A] Some Founding Fathers benefit politically from slavery.[B] Slaves in the old days did not have the right to vote.[C] Slave owners usually had large savings accounts.[D] Slavery was regarded as a peculiar institution.40. Washington’s decision to free slaves originated from his[A] moral considerations.[B] military experience.[C] financial conditions.[D] political stand.Part BDirections:In the following article, some sentences have been removed. For Questions 41—45, choose the most suitable onefrom the list A-G to fit into each of the numbered blanks. There are two extra choices,which do not fit in any of the blanks. Mark your answers on ANSWER SHEET 1. (10 points)The time for sharpening pencils, arranging your desk, and doing almost anything else instead of writing has ended. The first draft will appear on the page only if you stop avoiding the inevitable and sit, stand up, or lie down to write.41.__________Be flexible. Your outline should smoothly conduct you from one point to the next, but do not permit it to railroad you. If a relevant and important idea occurs to you now, work it into the draft.42.__________Grammar, punctuation, and spelling can wait until you revise. Concentrate on what you are saying. Good writing most often occurs when you are in hot pursuit of an idea rather than in a nervous search for errors.43.__________Your pages will be easier to keep track of that way, and, if you have to clip a paragraph to place it elsewhere, you will not lose any writing on the other side.If you are working on a word processor, you can take advantage of its capacity to make additions and deletions as well as move entire paragraphs by making just a few simple keyboard commands. Some software programs can also check spelling and certain grammatical elements in your writing.44.__________These printouts are also easier to read than the screen when you work on revisions.Once you have a first draft on paper, you can delete material that is unrelated to your thesis and add material necessary to illustrate your points and make your paper convincing. The student who wrote “The A & P as a State of Mind” wisely dropped a paragraph that questioned whether Sammy displays chauvinistic attitudes toward women.45.__________Remember that your initial draft is only that. You should go through the paper many times –and then again –working to substantiate and clarify your ideas. You may even end up with several entire versions of the paper. Rewrite. The sentences within each paragraph should be related to a single topic. Transitions should connect one paragraph to the next so that there are no abrupt or confusing shifts. Awkward or wordy phrasing or unclear sentences and paragraphs should bemercilessly poked and prodded into shape.[A] To make revising easier, leave wide margins and extra space between lines so that you can easily add words, sentences, and corrections. Write on only one side of the paper.[B] After you have clearly and adequately developed the body of your paper, pay particular attention to the introductory and concluding paragraphs. It’s probably best to write the introduction last, after you know precisely what you are introducing. Concluding paragraphs demand equal attention because they leave the reader with a final impression.[C] It’s worth remembering, however, that though a clean copy fresh off a printer may look terrific, it will read only as well as the thinking and writing that have gone into it. Many writers prudently store their data on disks and print their pages each time they finish a draft to avoid losing any material because ofpower failures or other problems.[D] It makes no difference how you write, just so you do. Now that you have developed a topic into a tentative thesis, you can assemble your notes and begin to flesh out whatever outline you have made.[E] Although this is an interesting issue, it has nothing to do with the thesis, which explains how the setting influences Sammy’s decision to quit his job. Instead of including that paragraph, she added one that described Lengel’s crabbed response to the girls so that she could lead up to the A & P “policy” he enforces.[F] In the final paragraph about the significance of the setting in “A & P,” the student brings t ogether the reasons Sammy quit his job by referring to his refusal to accept Lengel’s store policies.[G] By using the first draft as a means of thinking about what you want to say, you will very likely discover more than your notes originally suggested. P lenty of good writers don’t use outlines at all but discover ordering principles as they write. Do not attempt to compose a perfectly correct draft the first time around.Part CDirections:Read the following text carefully and then translate the underlined segments into Chinese. Your translation should be written clearly on ANSWER SHEET 2. (10 points) In his autobiography, Darwin himself speaks of his intellectual powers with extraordinary modesty. He points out that he always experienced much difficulty in expressing himself clearly and concisely, but (46) he believes that this very difficulty may have had the compensating advantage of forcing him tothink long and intently about every sentence, and thus enabling him to detect errors in reasoning and in his own observations. He disclaimed the possession of any great quickness of apprehension or wit, such as distinguished Huxley. (47) He asserted, also, that his power to follow a long and purely abstract train of thought was very limited, for which reason he felt certain that he never could have succeeded with mathematics. His memory, too, he described as extensive, but hazy. So poor in one sense was it that he never could remember for more than a few days a single date or a line of poetry. (48) On the other hand, he did not accept as well founded the charge made by some of his critics that, while he was a good observer, he had no power of reasoning. This, he thought, could not be true, because the “Origin of Species” is one long argument from the beginning to the end, and has convinced many able men. No one, he submits, could have written it without possessing some power of reasoning. He was willing to assert that “I have a fair share of invention, and of common sense or judgment, such as every fairly successful lawyer or doctor must have, but not, I believe, in any higher degree.” (49) He adds humbly that perhaps he was “superior to the common run of men in noticing things which easily escape attention, and in observing them carefully.”Writing in the last year of his life, he expressed the opinion that in two or three respects his mind had changed during the preceding twenty or thirty years. Up to the age of thirty or beyond it poetry of many kinds gave him great pleasure. Formerly, too, pictures had given him considerable, and music very great, delight. In 1881, however, he said: “Now for many years I cannot endure to read a line of poetry. I have also almost lost my taste for pictures or music.” (50) Darwin was convincedthat the loss of these tastes was not only a loss of happiness, but might possibly be injurious to the intellect, and more probably to the moral character.Section III WritingPart A51. Directions:You have just come back from Canada and found a music CD in your luggage that you forgot to return to Bob, your landlord there. Write him a letter to1) make an apology, and2) suggest a solution.You should write about 100 words on ANSWER SHEET 2.Do not sign your own name at the end of the letter. Use “Li Ming” instead.Do not write the address. (10 points)Part B52. Directions:Write an essay of 160-200 words based on the following drawing. In your essay, you should1) describe the drawing briefly,2) explain its intended meaning, and then3) give your comments.You should write neatly on ANSWER SHEET 2. (20 points)2008年考研英语真题参考答案详解1.【答案】B【解析】测试语义逻辑衔接。

![2008年12月20日大学英语六级A卷真题满分答案6[1]](https://uimg.taocdn.com/cbc1613b87c24028915fc343.webp)

2008年12月20日大学英语六级A卷真题满分答案6[1]Part VIndividuals and businesses have legal protection for intellectual property they create and own . intellectual proper _62_from creative thinking and may include products, 63 processes, and ideas. Intellectual property is protected 64 misapproprition(盗用)Misappropriation is taking the Intellectual propetty of others withour ____65____ compensation and using it for monetary gain.Legal protection is provided for the ___66___of intellectual propetty. The three common types of legal protection are patents, copyrights, and trademarks.Patents provide exclusive use of inventions. If the u.s patent office __67__ a patent, it is confirmind that the intellectual property is ___68____. The patent prevents others from making ,using, or selling the invention without the owner’s __69___ for a period of 20 years.Copyright are similar to patents __70___that they are applied to artistic works. A copyright protects the creator of an __72___artisitic or intellectual work, such as a song or a novel. A copyright gives the owner wxclusive rights to copy, __72___ display, or perform the work . the copyright prevents others from using and selling the work , the __73___ of a copyright is typically the lifetime of the author62 retrievesdeviatesresultsdeparts63servicesreserversassumptionsmotions64forwithbyfrom65 sound partial due random 66users owners masters executives 67 affords affiliates funds grants68sober unique universal 69 perspective permission conformity consensus 70 except besides eyond despite71 absolute alternative original orthodox 72stimulaatenominatedistribute73rangelengthscaleextent74 an additional 70 years. 74 A) plus C) viaTrademarks are words, names, or symbols that B) versus D) untilIdentify the manufacturer of a product and 75 it 75 A) distract C) distinguish from similar goods of others. A servicemark is B)differ D) disconnect similar to a trademark 76 is used to identify 76 A) or C) soservices. A trademark prevents others from using B) but D) whereasthe 77 or a similar word, name, or symbol to 77 A) identical C) literalB) analogical D) paralleltake advantage of the recognition and 78 of the 78 A) ambiguity C) popularity brand or to create confusion in the marketplace. B) utility D) proximity79 registration, a trademark is usually granted 79 A) From C) BeforeB) Over D) Uponfor a period of ten years. It can be 80 for 80 A)recurred C) recalled B) renewed D) recoveredadditional ten-year periods indefinitely as 81 as 81 A)long C) far the mark’s use continues. B)soon D) well。

AP® Physics C: Electricity and Magnetism2008 Free-Response QuestionsThe College Board: Connecting Students to College SuccessThe College Board is a not-for-profit membership association whose mission is to connect students to college success and opportunity. Founded in 1900, the association is composed of more than 5,000 schools, colleges, universities, and other educational organizations. Each year, the College Board serves seven million students and their parents, 23,000 high schools, and 3,500 colleges through major programs and services in college admissions, guidance, assessment, financial aid, enrollment, and teaching and learning. Among its best-known programs are the SAT®, the PSAT/NMSQT®, and the Advanced Placement Program® (AP®). The College Board is committed to the principles of excellence and equity, and that commitment is embodied in all of its programs, services, activities, and concerns.College Board, Advanced Placement Program, AP, AP Central, SAT, and the acorn logo are registered trademarks of the College Board. PSAT/NMSQT is a registered trademark of the College Board and National Merit Scholarship Corporation.Permission to use copyrighted College Board materials may be requested online at:/inquiry/cbpermit.html.Visit the College Board on the Web: .AP Central is the official online home for the AP Program: .PHYSICS C: ELECTRICITY AND MAGNETISMSECTION IITime-45 minutes3 QuestionsDirections: Answer all three questions. The suggested time is about 15 minutes for answering each of the questions, which are worth 15 points each. The parts within a question may not have equal weight. Show all your work in the pink booklet in the spaces provided after each part, NOT in this green insert.2008E1. A metal sphere of radius a contains a charge +Q and is surrounded by an uncharged, concentric, metallic shell of inner radiusb and outer radius c, as shown above. Express all algebraic answers in terms of the given quantities and fundamental constants.(a) Determine the induced charge on each of the following and explain your reasoning in each case.i.The inner surface of the metallic shellii.The outer surface of the metallic shell(b) Determine expressions for the magnitude of the electric field E as a function of r, the distance from the center of the inner sphere, ineach of the following regions.i.r < aii. a < r < biii. b < r < civ. c < r(c) On the axes below, sketch a graph of E as a function of r.(d) An electron of mass m e carrying a charge –e is released from rest at a very large distance from the spheres. Derive an expression for thespeed of the particle at a distance 10c from the center of the spheres.**=In the original printed version, the di stance was given as “10 r”.2008E2. In the circuit shown above, A and B are terminals to which different circuit components can be connected.(a) Calculate the potential difference across R2immediately after the switch S is closed in each of the following cases.i. A 50 Ω resistor connects A and B.ii. A 40 mH inductor connects A and B.iii.An initially uncharged 0.80 µF capacitor connects A and B.(b) The switch gets closed at time t = 0. On the axes below, sketch the graphs of the current in the 100 Ω resistor R3versus time t for the threecases. Label the graphs R for the resistor, L for the inductor, and C for the capacitor.ItOFigure 12008E3. The circular loop of wire in Figure 1 above has a radius of R and carries a current I . Point P is a distance of R/2 above the center of the loop. Express algebraic answers to parts (a) and (b) in terms of R, I, and fundamental constants.(a)i. State the direction of the magnetic field B 1 at point P due to the current in the loop. ii. Calculate the magnitude of the magnetic field B 1 at point P.Figure 2 Figure 3A second identical loop also carrying a current I is added at a distance of R above the first loop, as shown in Figure 2 above. (b) Determine the magnitude of the net magnetic fieldB net at point P .A small square loop of wire in which each side has a length s is now placed at point P with its plane parallel to the plane of each loop, as shown in Figure 3 above. For parts (c) and (d), assume that the magnetic field between the two circular loops is uniform in the region of the square loop and has magnitudeB net .(c) In terms of B net and s , determine the magnetic flux through the square loop.(d) The square loop is now rotated about an axis in its plane at an angular speed ω. In terms of B net , s , and ω, calculate the induced emf in the loop as a function of time t , assuming that the loop is horizontal at t = 0 .II。