Verification of Compensation Requirements for the SEPIA Cooperative Authoring System

- 格式:pdf

- 大小:101.41 KB

- 文档页数:15

Approval Guide无线设备FCC认证认识(官网直译)OverviewRadio Frequency (RF) devices are required to be properly authorized under 47 CFR Part 2 prior to being marketed or imported into the United States. The Office of Engineering and Technology (OET)administers the equipment authorization program under the authority delegated to it by theCommission. This program is one of the principal ways the Commission ensures that RF devices used inthe United States operate effectively without causing harmful interference and otherwise comply with the Commission’s rules.All RF devices subject to equipment authorization must comply with theCommission’s technical requirements prior to importation or marketing.无线射频认证遵循47条例Part 2章节Equipment that contains an RF device must be authorized in accordance with the appropriate procedures specified in Part 2, Subpart J as summarized below (with certain limited exceptions). These requirements not only minimize the potential for harmful interference, but also ensure that the equipment complies withthe rules that address other policy objectives – such as human RF exposure limits and hearing aid compatibility (HAC) with wireless handsets.设备含无线装置认证流程遵循Part 2.Subpart JThe Commission has three different approval procedures for equipment authorization, and the specificprocedure to be followed is based on the type of equipment being authorized.?Certification?Declaration of Conformity (DoC)?Verification共计三种认证类别,Verification(自我认证)、Declaration of Conformity(符合性声明)、Certification(证书认证)Obtaining an Equipment AuthorizationThe following steps summarize the process to obtain the required equipment authorization for yourproduct (device):Step 1 – Determine if device is a Radio Frequency (RF) device subject to the FCC rules.?If a device is subject to FCC rules, determine the specific type of equipment authorization that applies to the device. Become familiar with all the basic marketing, equipment authorization, andimportation rules. In some instances, a device may have different functions resulting in the devicebeing subject to more than one type of approval procedure.Step 2 – Determine all applicable technical and administrative rules that apply tothe device requiring an equipment authorization.The technical requirements are generally specified in the applicable FCC rule parts and the administrativerules are specified in Part 2, Subpart J.NOTE – Determining all applicable technical and administrative rules requires a technicalunderstanding of the electrical functions of the device and an understanding of the FCCrules. For assistance, we recommend that you work with one of the Accredited TestingLaboratories or TCBs. Questions can also be submitted through the Knowledge Database(KDB).Step 3 – Perform the required tests to ensure the device complies with theapplicable technical requirements (as determined in Step 2).The type of testing facility (laboratory) used to demonstrate compliance is based on the required approval procedure.VerificationEquipment approved using the Verification procedure is required to be tested, however, it is not required to use a FCC Recognized Testing Laboratory. The test laboratory used is required to maintain a record of the measurement facilities as specified in Section 2.948.自我认证无需FCC认可实验室出具报告,但需要有样品测试数据。

Verification Program: A comprehensive guide IntroductionIn today’s competitive digital landscape, it is essential to ensure the reliability and accuracy of software systems. Verification programs play a crucial role in validating the functionality and performance of various software applications. This document aims to provide a comprehensive guide to verification program design, emphasizing the utilization of English for better understanding and collaboration among international teams.Table of Contents1.What is Verification?2.Why is Verification Important?3.Types of Verification4.Key Components of a Verification Program–Test Planning–Test Design–Test Execution–Test Reporting5.Verification Program Workflow6.Challenges in Verification7.Best Practices for Successful Verification8.Conclusion1. What is Verification?Verification is the process of evaluating software systems to determine whether they comply with the specified requirements. It involves conducting systematic tests, inspections, and analyses to ensure that the software behaves as intended and meets the customer’s expectations.2. Why is Verification Important?Effective verification is critical to the success of software systems. It helps identify defects, ensures compliance with regulations and standards, and enhances the overall quality of the software. By thoroughly testing and validating the software, potential issues and risks can be mitigated, resulting in increased user satisfaction and reduced development costs.3. Types of VerificationThere are various types of verification techniques employed in software development. Some common types include:•Static Testing: This technique involves analyzing the software code or documentation without executing it. It includes techniques like code reviews, inspections, and walkthroughs.•Dynamic Testing: Unlike static testing, dynamic testing involves the execution of software to test its behavior. This includes techniques such as unit testing, integration testing, system testing, and acceptance testing.•Model-based Testing: This approach involves creating a model of the system and generating test scenarios based on the model.•Performance Testing: Performance testing focuses on evaluating system performance under different load conditions to identify performance bottlenecks and ensure optimal performance.4. Key Components of a Verification ProgramTest PlanningTest planning involves defining the objectives, scope, and resources required for the verification process. It includes tasks such as identifying test scenarios, creating test plans, and allocating resources.Test DesignTest design encompasses the creation of test cases and test scenarios based on the specified requirements. It involves defining inputs, expected results, and test execution steps.Test ExecutionTest execution involves running the test cases and scenarios on the software system and validating the actual results against the expected results. It includes tasks like test environment setup, test data generation, and test execution.Test ReportingTest reporting is the process of documenting and communicating the results of the verification process. It includes generating test reports, defect reports, and providing recommendations for further improvement.5. Verification Program WorkflowA typical verification program follows the following workflow:1.Define Verification Objectives: Clearly define the objectives andgoals of the verification program.2.Identify Verification Scope: Determine the scope of the verificationprogram, including the software modules and functionalities to be tested.3.Plan Verification Activities: Develop a detailed test plan, includingtest scenarios, test cases, and resource allocation.4.Execute Verification Tests: Execute the test cases and scenarios,ensuring that each step is documented and executed as planned.5.Analyze Test Results: Analyze the test results and identify anydeviations from expected outcomes.6.Report and Document: Generate test reports, defect reports, anddocumentation that summarize the results and findings.7.Perform Root Cause Analysis: Investigate the root causes of anydefects or issues encountered during the verification process.8.Iterate and Improve: Incorporate lessons learned from theverification process and implement necessary improvements for future cycles.6. Challenges in VerificationWhile verification plays a crucial role in software development, several challenges need to be addressed:•Complexity: As software systems become more complex, verification becomes more challenging, as it involves testing various functionalities andcomponents.•Time and Resource Constraints: Limited time and resources can impede the thoroughness of the verification process.•Requirement Changes: Changes in project requirements can affect the scope and planning of the verification program.•Lack of Standardization: A lack of standardized verification practices can hinder effective collaboration among international teams.7. Best Practices for Successful VerificationTo overcome the challenges and ensure successful verification, developers can follow these best practices:•Early Verification: Start the verification process as early as possible, even during the software requirements gathering phase.•Clearly Defined Requirements: Ensure that requirements are well-documented and clearly understood by all stakeholders.•Utilize Test Automation: Automation can improve the efficiency and effectiveness of the verification process.•Collaboration and Communication: Foster effective communication and collaboration among team members to exchange ideas and share insights.•Standardized Practices: Establish standardized verification practices across teams to ensure consistency and facilitate collaboration.ConclusionVerification programs are essential for the successful development and deployment of software systems. By following this comprehensive guide, software developers can design and implement effective verification programs that minimize defects, meet customer expectations, and enhance overall software quality. Emphasizing the use of English is crucial to facilitate collaboration among international teams and ensure clarity in communication.。

The Importance of Verification Planning in EnsuringProduct Quality and EfficiencyIn today's highly competitive manufacturing environment, verification planning is crucial to ensuring product quality, enhancing production efficiency, and maintaining customer satisfaction. This article explores the key elements of verification planning and how it can be used to improve overall performance.Background and PurposeVerification planning is a systematic approach to validating the quality, performance, and reliability of products, processes, or systems. Its primary goal is to identify any potential issues early on and address them before they impact the final product or process. By identifying and rectifying problems during the verification stage, companies can avoid costly production delays, reduce warranty claims, and maintain brand reputation.Scope and Objects of VerificationThe scope of verification planning typically covers products, processes, and systems that are critical to the overall operation of a business. This may include product prototypes, production equipment, software systems, and even entire supply chains. Verification objects can range from individual components to complex integrated systems.Verification Methods and StepsVerification planning involves a multi-step process that typically begins with a thorough understanding of the product or process's requirements and specifications. This is followed by the selection of appropriate verification methods, such as testing, simulation, or analysis. These methods are then applied to the verification objects to assess their performance and identify any deviations from the specified requirements.Outcome Analysis and Improvement SuggestionsAfter the verification process is complete, a detailed analysis of the results is conducted to identify any issues or discrepancies. Based on this analysis, improvement suggestions are made to address the identified problems and enhance the product or process's performance. These suggestions may involve modifications to the design, changes in production processes, or updates to quality control procedures.Timing and Resource AllocationEffective verification planning requires careful consideration of timing and resource allocation. Each stage of the verification process should be assigned a reasonable time frame to ensure that the overall project remains on track. Additionally, resources such as personnel, equipment, and funding should be allocated based on the specific needs of each verification phase.Communication, Coordination, and CollaborationEffective communication, coordination, and collaboration are essential for the success of verification planning. Establishing clear lines of communication between different departments and teams ensures that information flows freely and that any issues or concerns can be addressed promptly. Additionally, cross-departmental collaboration can help identify and address potential problems more efficiently.Strategy for Applying Successful OutcomesOnce the verification process has been completed and successful outcomes have been achieved, it is crucial to develop a strategy for applying these successes to other similar projects or scenarios. This may involve sharing lessons learned across departments or even across different businesses within the same organization. By leveraging successful outcomes from one project to improve future projects, companies can continuously enhance their overall performance and competitiveness.Risk Assessment and Mitigation MeasuresAs with any planning process, it is essential to identify potential risks and challenges and develop corresponding mitigation measures. This may involve identifying potential bottlenecks in the verification process, assessing the impact of changes in raw material suppliers or regulations, or preparing for unexpected delays in the production schedule. By anticipatingand planning for these risks, companies can minimize their impact on the verification process and overall project outcomes.Conclusion and OutlookVerification planning is a crucial component of ensuring product quality and production efficiency in modern manufacturing environments. By carefully planning and executing the verification process, companies can identify and address potential issues early on, improve product performance and reliability, and maintain customer satisfaction. To optimize verification planning, companies need to invest in the right resources, establish effective communication channels, collaborate across departments, and continuously learn from past projects. By doing so, companies can ensure that their products and processes remain competitive in today's rapidly evolving marketplace.。

DIRECTIVE NUMBER: CPL 02-00-150 EFFECTIVE DATE: April 22, 2011 SUBJECT: Field Operations Manual (FOM)ABSTRACTPurpose: This instruction cancels and replaces OSHA Instruction CPL 02-00-148,Field Operations Manual (FOM), issued November 9, 2009, whichreplaced the September 26, 1994 Instruction that implemented the FieldInspection Reference Manual (FIRM). The FOM is a revision of OSHA’senforcement policies and procedures manual that provides the field officesa reference document for identifying the responsibilities associated withthe majority of their inspection duties. This Instruction also cancels OSHAInstruction FAP 01-00-003 Federal Agency Safety and Health Programs,May 17, 1996 and Chapter 13 of OSHA Instruction CPL 02-00-045,Revised Field Operations Manual, June 15, 1989.Scope: OSHA-wide.References: Title 29 Code of Federal Regulations §1903.6, Advance Notice ofInspections; 29 Code of Federal Regulations §1903.14, Policy RegardingEmployee Rescue Activities; 29 Code of Federal Regulations §1903.19,Abatement Verification; 29 Code of Federal Regulations §1904.39,Reporting Fatalities and Multiple Hospitalizations to OSHA; and Housingfor Agricultural Workers: Final Rule, Federal Register, March 4, 1980 (45FR 14180).Cancellations: OSHA Instruction CPL 02-00-148, Field Operations Manual, November9, 2009.OSHA Instruction FAP 01-00-003, Federal Agency Safety and HealthPrograms, May 17, 1996.Chapter 13 of OSHA Instruction CPL 02-00-045, Revised FieldOperations Manual, June 15, 1989.State Impact: Notice of Intent and Adoption required. See paragraph VI.Action Offices: National, Regional, and Area OfficesOriginating Office: Directorate of Enforcement Programs Contact: Directorate of Enforcement ProgramsOffice of General Industry Enforcement200 Constitution Avenue, NW, N3 119Washington, DC 20210202-693-1850By and Under the Authority ofDavid Michaels, PhD, MPHAssistant SecretaryExecutive SummaryThis instruction cancels and replaces OSHA Instruction CPL 02-00-148, Field Operations Manual (FOM), issued November 9, 2009. The one remaining part of the prior Field Operations Manual, the chapter on Disclosure, will be added at a later date. This Instruction also cancels OSHA Instruction FAP 01-00-003 Federal Agency Safety and Health Programs, May 17, 1996 and Chapter 13 of OSHA Instruction CPL 02-00-045, Revised Field Operations Manual, June 15, 1989. This Instruction constitutes OSHA’s general enforcement policies and procedures manual for use by the field offices in conducting inspections, issuing citations and proposing penalties.Significant Changes∙A new Table of Contents for the entire FOM is added.∙ A new References section for the entire FOM is added∙ A new Cancellations section for the entire FOM is added.∙Adds a Maritime Industry Sector to Section III of Chapter 10, Industry Sectors.∙Revises sections referring to the Enhanced Enforcement Program (EEP) replacing the information with the Severe Violator Enforcement Program (SVEP).∙Adds Chapter 13, Federal Agency Field Activities.∙Cancels OSHA Instruction FAP 01-00-003, Federal Agency Safety and Health Programs, May 17, 1996.DisclaimerThis manual is intended to provide instruction regarding some of the internal operations of the Occupational Safety and Health Administration (OSHA), and is solely for the benefit of the Government. No duties, rights, or benefits, substantive or procedural, are created or implied by this manual. The contents of this manual are not enforceable by any person or entity against the Department of Labor or the United States. Statements which reflect current Occupational Safety and Health Review Commission or court precedents do not necessarily indicate acquiescence with those precedents.Table of ContentsCHAPTER 1INTRODUCTIONI.PURPOSE. ........................................................................................................... 1-1 II.SCOPE. ................................................................................................................ 1-1 III.REFERENCES .................................................................................................... 1-1 IV.CANCELLATIONS............................................................................................. 1-8 V. ACTION INFORMATION ................................................................................. 1-8A.R ESPONSIBLE O FFICE.......................................................................................................................................... 1-8B.A CTION O FFICES. .................................................................................................................... 1-8C. I NFORMATION O FFICES............................................................................................................ 1-8 VI. STATE IMPACT. ................................................................................................ 1-8 VII.SIGNIFICANT CHANGES. ............................................................................... 1-9 VIII.BACKGROUND. ................................................................................................. 1-9 IX. DEFINITIONS AND TERMINOLOGY. ........................................................ 1-10A.T HE A CT................................................................................................................................................................. 1-10B. C OMPLIANCE S AFETY AND H EALTH O FFICER (CSHO). ...........................................................1-10B.H E/S HE AND H IS/H ERS ..................................................................................................................................... 1-10C.P ROFESSIONAL J UDGMENT............................................................................................................................... 1-10E. W ORKPLACE AND W ORKSITE ......................................................................................................................... 1-10CHAPTER 2PROGRAM PLANNINGI.INTRODUCTION ............................................................................................... 2-1 II.AREA OFFICE RESPONSIBILITIES. .............................................................. 2-1A.P ROVIDING A SSISTANCE TO S MALL E MPLOYERS. ...................................................................................... 2-1B.A REA O FFICE O UTREACH P ROGRAM. ............................................................................................................. 2-1C. R ESPONDING TO R EQUESTS FOR A SSISTANCE. ............................................................................................ 2-2 III. OSHA COOPERATIVE PROGRAMS OVERVIEW. ...................................... 2-2A.V OLUNTARY P ROTECTION P ROGRAM (VPP). ........................................................................... 2-2B.O NSITE C ONSULTATION P ROGRAM. ................................................................................................................ 2-2C.S TRATEGIC P ARTNERSHIPS................................................................................................................................. 2-3D.A LLIANCE P ROGRAM ........................................................................................................................................... 2-3 IV. ENFORCEMENT PROGRAM SCHEDULING. ................................................ 2-4A.G ENERAL ................................................................................................................................................................. 2-4B.I NSPECTION P RIORITY C RITERIA. ..................................................................................................................... 2-4C.E FFECT OF C ONTEST ............................................................................................................................................ 2-5D.E NFORCEMENT E XEMPTIONS AND L IMITATIONS. ....................................................................................... 2-6E.P REEMPTION BY A NOTHER F EDERAL A GENCY ........................................................................................... 2-6F.U NITED S TATES P OSTAL S ERVICE. .................................................................................................................. 2-7G.H OME-B ASED W ORKSITES. ................................................................................................................................ 2-8H.I NSPECTION/I NVESTIGATION T YPES. ............................................................................................................... 2-8 V.UNPROGRAMMED ACTIVITY – HAZARD EVALUATION AND INSPECTION SCHEDULING ............................................................................ 2-9 VI.PROGRAMMED INSPECTIONS. ................................................................... 2-10A.S ITE-S PECIFIC T ARGETING (SST) P ROGRAM. ............................................................................................. 2-10B.S CHEDULING FOR C ONSTRUCTION I NSPECTIONS. ..................................................................................... 2-10C.S CHEDULING FOR M ARITIME I NSPECTIONS. ............................................................................. 2-11D.S PECIAL E MPHASIS P ROGRAMS (SEP S). ................................................................................... 2-12E.N ATIONAL E MPHASIS P ROGRAMS (NEP S) ............................................................................... 2-13F.L OCAL E MPHASIS P ROGRAMS (LEP S) AND R EGIONAL E MPHASIS P ROGRAMS (REP S) ............ 2-13G.O THER S PECIAL P ROGRAMS. ............................................................................................................................ 2-13H.I NSPECTION S CHEDULING AND I NTERFACE WITH C OOPERATIVE P ROGRAM P ARTICIPANTS ....... 2-13CHAPTER 3INSPECTION PROCEDURESI.INSPECTION PREPARATION. .......................................................................... 3-1 II.INSPECTION PLANNING. .................................................................................. 3-1A.R EVIEW OF I NSPECTION H ISTORY .................................................................................................................... 3-1B.R EVIEW OF C OOPERATIVE P ROGRAM P ARTICIPATION .............................................................................. 3-1C.OSHA D ATA I NITIATIVE (ODI) D ATA R EVIEW .......................................................................................... 3-2D.S AFETY AND H EALTH I SSUES R ELATING TO CSHO S.................................................................. 3-2E.A DVANCE N OTICE. ................................................................................................................................................ 3-3F.P RE-I NSPECTION C OMPULSORY P ROCESS ...................................................................................................... 3-5G.P ERSONAL S ECURITY C LEARANCE. ................................................................................................................. 3-5H.E XPERT A SSISTANCE. ........................................................................................................................................... 3-5 III. INSPECTION SCOPE. ......................................................................................... 3-6A.C OMPREHENSIVE ................................................................................................................................................... 3-6B.P ARTIAL. ................................................................................................................................................................... 3-6 IV. CONDUCT OF INSPECTION .............................................................................. 3-6A.T IME OF I NSPECTION............................................................................................................................................. 3-6B.P RESENTING C REDENTIALS. ............................................................................................................................... 3-6C.R EFUSAL TO P ERMIT I NSPECTION AND I NTERFERENCE ............................................................................. 3-7D.E MPLOYEE P ARTICIPATION. ............................................................................................................................... 3-9E.R ELEASE FOR E NTRY ............................................................................................................................................ 3-9F.B ANKRUPT OR O UT OF B USINESS. .................................................................................................................... 3-9G.E MPLOYEE R ESPONSIBILITIES. ................................................................................................. 3-10H.S TRIKE OR L ABOR D ISPUTE ............................................................................................................................. 3-10I. V ARIANCES. .......................................................................................................................................................... 3-11 V. OPENING CONFERENCE. ................................................................................ 3-11A.G ENERAL ................................................................................................................................................................ 3-11B.R EVIEW OF A PPROPRIATION A CT E XEMPTIONS AND L IMITATION. ..................................................... 3-13C.R EVIEW S CREENING FOR P ROCESS S AFETY M ANAGEMENT (PSM) C OVERAGE............................. 3-13D.R EVIEW OF V OLUNTARY C OMPLIANCE P ROGRAMS. ................................................................................ 3-14E.D ISRUPTIVE C ONDUCT. ...................................................................................................................................... 3-15F.C LASSIFIED A REAS ............................................................................................................................................. 3-16VI. REVIEW OF RECORDS. ................................................................................... 3-16A.I NJURY AND I LLNESS R ECORDS...................................................................................................................... 3-16B.R ECORDING C RITERIA. ...................................................................................................................................... 3-18C. R ECORDKEEPING D EFICIENCIES. .................................................................................................................. 3-18 VII. WALKAROUND INSPECTION. ....................................................................... 3-19A.W ALKAROUND R EPRESENTATIVES ............................................................................................................... 3-19B.E VALUATION OF S AFETY AND H EALTH M ANAGEMENT S YSTEM. ....................................................... 3-20C.R ECORD A LL F ACTS P ERTINENT TO A V IOLATION. ................................................................................. 3-20D.T ESTIFYING IN H EARINGS ................................................................................................................................ 3-21E.T RADE S ECRETS. ................................................................................................................................................. 3-21F.C OLLECTING S AMPLES. ..................................................................................................................................... 3-22G.P HOTOGRAPHS AND V IDEOTAPES.................................................................................................................. 3-22H.V IOLATIONS OF O THER L AWS. ....................................................................................................................... 3-23I.I NTERVIEWS OF N ON-M ANAGERIAL E MPLOYEES .................................................................................... 3-23J.M ULTI-E MPLOYER W ORKSITES ..................................................................................................................... 3-27 K.A DMINISTRATIVE S UBPOENA.......................................................................................................................... 3-27 L.E MPLOYER A BATEMENT A SSISTANCE. ........................................................................................................ 3-27 VIII. CLOSING CONFERENCE. .............................................................................. 3-28A.P ARTICIPANTS. ..................................................................................................................................................... 3-28B.D ISCUSSION I TEMS. ............................................................................................................................................ 3-28C.A DVICE TO A TTENDEES .................................................................................................................................... 3-29D.P ENALTIES............................................................................................................................................................. 3-30E.F EASIBLE A DMINISTRATIVE, W ORK P RACTICE AND E NGINEERING C ONTROLS. ............................ 3-30F.R EDUCING E MPLOYEE E XPOSURE. ................................................................................................................ 3-32G.A BATEMENT V ERIFICATION. ........................................................................................................................... 3-32H.E MPLOYEE D ISCRIMINATION .......................................................................................................................... 3-33 IX. SPECIAL INSPECTION PROCEDURES. ...................................................... 3-33A.F OLLOW-UP AND M ONITORING I NSPECTIONS............................................................................................ 3-33B.C ONSTRUCTION I NSPECTIONS ......................................................................................................................... 3-34C. F EDERAL A GENCY I NSPECTIONS. ................................................................................................................. 3-35CHAPTER 4VIOLATIONSI. BASIS OF VIOLATIONS ..................................................................................... 4-1A.S TANDARDS AND R EGULATIONS. .................................................................................................................... 4-1B.E MPLOYEE E XPOSURE. ........................................................................................................................................ 4-3C.R EGULATORY R EQUIREMENTS. ........................................................................................................................ 4-6D.H AZARD C OMMUNICATION. .............................................................................................................................. 4-6E. E MPLOYER/E MPLOYEE R ESPONSIBILITIES ................................................................................................... 4-6 II. SERIOUS VIOLATIONS. .................................................................................... 4-8A.S ECTION 17(K). ......................................................................................................................... 4-8B.E STABLISHING S ERIOUS V IOLATIONS ............................................................................................................ 4-8C. F OUR S TEPS TO BE D OCUMENTED. ................................................................................................................... 4-8 III. GENERAL DUTY REQUIREMENTS ............................................................. 4-14A.E VALUATION OF G ENERAL D UTY R EQUIREMENTS ................................................................................. 4-14B.E LEMENTS OF A G ENERAL D UTY R EQUIREMENT V IOLATION.............................................................. 4-14C. U SE OF THE G ENERAL D UTY C LAUSE ........................................................................................................ 4-23D.L IMITATIONS OF U SE OF THE G ENERAL D UTY C LAUSE. ..............................................................E.C LASSIFICATION OF V IOLATIONS C ITED U NDER THE G ENERAL D UTY C LAUSE. ..................F. P ROCEDURES FOR I MPLEMENTATION OF S ECTION 5(A)(1) E NFORCEMENT ............................ 4-25 4-27 4-27IV.OTHER-THAN-SERIOUS VIOLATIONS ............................................... 4-28 V.WILLFUL VIOLATIONS. ......................................................................... 4-28A.I NTENTIONAL D ISREGARD V IOLATIONS. ..........................................................................................4-28B.P LAIN I NDIFFERENCE V IOLATIONS. ...................................................................................................4-29 VI. CRIMINAL/WILLFUL VIOLATIONS. ................................................... 4-30A.A REA D IRECTOR C OORDINATION ....................................................................................................... 4-31B.C RITERIA FOR I NVESTIGATING P OSSIBLE C RIMINAL/W ILLFUL V IOLATIONS ........................ 4-31C. W ILLFUL V IOLATIONS R ELATED TO A F ATALITY .......................................................................... 4-32 VII. REPEATED VIOLATIONS. ...................................................................... 4-32A.F EDERAL AND S TATE P LAN V IOLATIONS. ........................................................................................4-32B.I DENTICAL S TANDARDS. .......................................................................................................................4-32C.D IFFERENT S TANDARDS. .......................................................................................................................4-33D.O BTAINING I NSPECTION H ISTORY. .....................................................................................................4-33E.T IME L IMITATIONS..................................................................................................................................4-34F.R EPEATED V. F AILURE TO A BATE....................................................................................................... 4-34G. A REA D IRECTOR R ESPONSIBILITIES. .............................................................................. 4-35 VIII. DE MINIMIS CONDITIONS. ................................................................... 4-36A.C RITERIA ................................................................................................................................................... 4-36B.P ROFESSIONAL J UDGMENT. ..................................................................................................................4-37C. A REA D IRECTOR R ESPONSIBILITIES. .............................................................................. 4-37 IX. CITING IN THE ALTERNATIVE ............................................................ 4-37 X. COMBINING AND GROUPING VIOLATIONS. ................................... 4-37A.C OMBINING. ..............................................................................................................................................4-37B.G ROUPING. ................................................................................................................................................4-38C. W HEN N OT TO G ROUP OR C OMBINE. ................................................................................................4-38 XI. HEALTH STANDARD VIOLATIONS ....................................................... 4-39A.C ITATION OF V ENTILATION S TANDARDS ......................................................................................... 4-39B.V IOLATIONS OF THE N OISE S TANDARD. ...........................................................................................4-40 XII. VIOLATIONS OF THE RESPIRATORY PROTECTION STANDARD(§1910.134). ....................................................................................................... XIII. VIOLATIONS OF AIR CONTAMINANT STANDARDS (§1910.1000) ... 4-43 4-43A.R EQUIREMENTS UNDER THE STANDARD: .................................................................................................. 4-43B.C LASSIFICATION OF V IOLATIONS OF A IR C ONTAMINANT S TANDARDS. ......................................... 4-43 XIV. CITING IMPROPER PERSONAL HYGIENE PRACTICES. ................... 4-45A.I NGESTION H AZARDS. .................................................................................................................................... 4-45B.A BSORPTION H AZARDS. ................................................................................................................................ 4-46C.W IPE S AMPLING. ............................................................................................................................................. 4-46D.C ITATION P OLICY ............................................................................................................................................ 4-46 XV. BIOLOGICAL MONITORING. ...................................................................... 4-47CHAPTER 5CASE FILE PREPARATION AND DOCUMENTATIONI.INTRODUCTION ............................................................................................... 5-1 II.INSPECTION CONDUCTED, CITATIONS BEING ISSUED. .................... 5-1A.OSHA-1 ................................................................................................................................... 5-1B.OSHA-1A. ............................................................................................................................... 5-1C. OSHA-1B. ................................................................................................................................ 5-2 III.INSPECTION CONDUCTED BUT NO CITATIONS ISSUED .................... 5-5 IV.NO INSPECTION ............................................................................................... 5-5 V. HEALTH INSPECTIONS. ................................................................................. 5-6A.D OCUMENT P OTENTIAL E XPOSURE. ............................................................................................................... 5-6B.E MPLOYER’S O CCUPATIONAL S AFETY AND H EALTH S YSTEM. ............................................................. 5-6 VI. AFFIRMATIVE DEFENSES............................................................................. 5-8A.B URDEN OF P ROOF. .............................................................................................................................................. 5-8B.E XPLANATIONS. ..................................................................................................................................................... 5-8 VII. INTERVIEW STATEMENTS. ........................................................................ 5-10A.G ENERALLY. ......................................................................................................................................................... 5-10B.CSHO S SHALL OBTAIN WRITTEN STATEMENTS WHEN: .......................................................................... 5-10C.L ANGUAGE AND W ORDING OF S TATEMENT. ............................................................................................. 5-11D.R EFUSAL TO S IGN S TATEMENT ...................................................................................................................... 5-11E.V IDEO AND A UDIOTAPED S TATEMENTS. ..................................................................................................... 5-11F.A DMINISTRATIVE D EPOSITIONS. .............................................................................................5-11 VIII. PAPERWORK AND WRITTEN PROGRAM REQUIREMENTS. .......... 5-12 IX.GUIDELINES FOR CASE FILE DOCUMENTATION FOR USE WITH VIDEOTAPES AND AUDIOTAPES .............................................................. 5-12 X.CASE FILE ACTIVITY DIARY SHEET. ..................................................... 5-12 XI. CITATIONS. ..................................................................................................... 5-12A.S TATUTE OF L IMITATIONS. .............................................................................................................................. 5-13B.I SSUING C ITATIONS. ........................................................................................................................................... 5-13C.A MENDING/W ITHDRAWING C ITATIONS AND N OTIFICATION OF P ENALTIES. .................................. 5-13D.P ROCEDURES FOR A MENDING OR W ITHDRAWING C ITATIONS ............................................................ 5-14 XII. INSPECTION RECORDS. ............................................................................... 5-15A.G ENERALLY. ......................................................................................................................................................... 5-15B.R ELEASE OF I NSPECTION I NFORMATION ..................................................................................................... 5-15C. C LASSIFIED AND T RADE S ECRET I NFORMATION ...................................................................................... 5-16。

passing the verification检定合格-回复Verification is a crucial process in various domains, ensuring the authenticity, accuracy, and reliability of information, products, or services. This article will delve into the steps involved in passing verification, using the theme "passing the verification检定合格" as a guiding principle. By understanding these steps, individuals and organizations can navigate through the verification process successfully.Step 1: Understand the Verification RequirementsTo pass verification, it is vital to comprehend the specific requirements imposed by the verifying entity. These requirements may differ based on the industry, purpose, or nature of the verification. Familiarize yourself with the guidelines, standards, and protocols that need to be adhered to.Step 2: Gather the Necessary DocumentationOnce the verification requirements are known, the next step is to gather all the necessary documentation. This documentation may include identification documents, certificates, licenses, permits, or any other relevant paperwork. Ensure that all documents are up to date, accurate, and comply with the specific verificationrequirements.Step 3: Prepare for Verification InspectionsIn many cases, verification involves on-site inspections or audits to verify compliance with certain standards or regulations. Therefore, it is imperative to prepare for these inspections thoroughly. This may involve conducting internal audits, ensuring the availability of required facilities or equipment, and training staff members to handle the verification process professionally.Step 4: Implement Necessary Changes or ImprovementsBased on the findings of internal audits or in preparation for verification inspections, it may be necessary to implement changes or improvements. Identify any areas that require attention and take appropriate actions to rectify them. This may involve upgrading equipment, updating procedures, or enhancing training programs to comply with the verification requirements.Step 5: Submit Application for VerificationOnce all the necessary documentation is gathered, and preparations are complete, it is time to submit the application for verification. Ensure that the application is completed accuratelyand all required documents are attached appropriately. Pay attention to any deadlines or submission requirements specified by the verifying entity.Step 6: Cooperate with the Verifying EntityDuring the verification process, cooperation with the verifying entity is crucial. Respond promptly to any requests for additional information, attend scheduled inspections or audits, and address any concerns or questions raised by the verifiers. Demonstrating transparency, professionalism, and a willingness to cooperate can positively influence the verification outcome.Step 7: Address any Identified Non-ConformitiesIn some cases, verification may uncover non-conformities or areas of improvement. It is essential to address these identified issues promptly and effectively. Develop corrective measures and implement them to rectify any discrepancies or shortcomings. Demonstrating a proactive approach towards resolving non-conformities improves the chances of successfully passing verification.Step 8: Receive Verification ResultsAfter completing the verification process, the next step is to await the verification results. Depending on the verifying entity, these results may be provided in the form of a certificate, a report, or a compliance statement. Carefully review the outcome and take necessary action based on the results received.Step 9: Maintain Compliance and Renew Verification Verification is not a one-time process; it is essential to maintain ongoing compliance to continue meeting the required standards or regulations. Regularly assess and enhance your processes, procedures, and systems to ensure continuous compliance. Additionally, monitor verification expiry dates and initiate the renewal process within the stipulated timelines to avoid any interruption in verification status.Step 10: Leverage Verification StatusOnce the verification is successfully passed and maintained, it is vital to leverage the verification status. Promote your verified status through appropriate channels to enhance your credibility, reputation, and market standing. This can lead to numerous benefits, including increased customer trust, improved business opportunities, and a competitive advantage.In conclusion, passing verification requires careful navigation through multiple steps. Understanding the specific verification requirements, gathering necessary documentation, preparing for inspections, implementing changes, submitting applications accurately, cooperating with the verifying entity, addressing non-conformities promptly, and maintaining ongoing compliance are all crucial elements in achieving successful verification. By following these steps, individuals and organizations can fulfill the necessary criteria and obtain the desired verification status.。

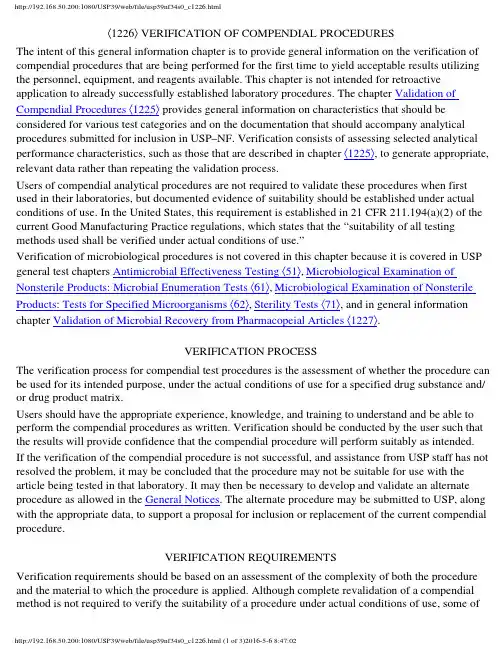

〈1226〉 VERIFICATION OF COMPENDIAL PROCEDURESThe intent of this general information chapter is to provide general information on the verification of compendial procedures that are being performed for the first time to yield acceptable results utilizing the personnel, equipment, and reagents available. This chapter is not intended for retroactive application to already successfully established laboratory procedures. The chapter Validation of Compendial Procedures 〈1225〉 provides general information on characteristics that should be considered for various test categories and on the documentation that should accompany analytical procedures submitted for inclusion in USP–NF. Verification consists of assessing selected analytical performance characteristics, such as those that are described in chapter 〈1225〉, to generate appropriate, relevant data rather than repeating the validation process.Users of compendial analytical procedures are not required to validate these procedures when first used in their laboratories, but documented evidence of suitability should be established under actual conditions of use. In the United States, this requirement is established in 21 CFR 211.194(a)(2) of the current Good Manufacturing Practice regulations, which states that the “suitability of all testing methods used shall be verified under actual conditions of use.”Verification of microbiological procedures is not covered in this chapter because it is covered in USP general test chapters Antimicrobial Effectiveness Testing 〈51〉, Microbiological Examination of Nonsterile Products: Microbial Enumeration Tests 〈61〉, Microbiological Examination of Nonsterile Products: Tests for Specified Microorganisms 〈62〉, Sterility Tests 〈71〉, and in general information chapter Validation of Microbial Recovery from Pharmacopeial Articles 〈1227〉.VERIFICATION PROCESSThe verification process for compendial test procedures is the assessment of whether the procedure can be used for its intended purpose, under the actual conditions of use for a specified drug substance and/ or drug product matrix.Users should have the appropriate experience, knowledge, and training to understand and be able to perform the compendial procedures as written. Verification should be conducted by the user such that the results will provide confidence that the compendial procedure will perform suitably as intended.If the verification of the compendial procedure is not successful, and assistance from USP staff has not resolved the problem, it may be concluded that the procedure may not be suitable for use with the article being tested in that laboratory. It may then be necessary to develop and validate an alternate procedure as allowed in the General Notices. The alternate procedure may be submitted to USP, along with the appropriate data, to support a proposal for inclusion or replacement of the current compendial procedure.VERIFICATION REQUIREMENTSVerification requirements should be based on an assessment of the complexity of both the procedure and the material to which the procedure is applied. Although complete revalidation of a compendial method is not required to verify the suitability of a procedure under actual conditions of use, some ofthe analytical performance characteristics listed in chapter 〈1225〉, Table 2, may be used for the verification process. Only those characteristics that are considered to be appropriate for the verification of the particular procedure need to be evaluated. The process of assessing the suitability of a compendial analytical test procedure under the conditions of actual use may or may not require actual laboratory performance of each analytical performance characteristic. The degree and extent of the verification process may depend on the level of training and experience of the user, on the type of procedure and its associated equipment or instrumentation, on the specific procedural steps, and on which article(s) are being tested.Verification should assess whether the compendial procedure is suitable for the drug substance and/or the drug product matrix, taking into account the drug substance's synthetic route, the method of manufacture for the drug product, or both, if applicable. Verification should include an assessment of elements such as the effect of the matrix on the recovery of impurities and drug substances from the drug product matrix, as well as the suitability of chromatographic conditions and column, the appropriateness of detector signal response, etc.As an example, an assessment of specificity is a key parameter in verifying that a compendial procedure is suitable for use in assaying drug substances and drug products. For instance, acceptable specificity for a chromatographic method may be verified by conformance with system suitability resolution requirements (if specified in the procedure). However, drug substances from different suppliers may have different impurity profiles that are not addressed by the compendial test procedure. Similarly, the excipients in a drug product can vary widely among manufacturers and may have the potential to directly interfere with the procedure or cause the formation of impurities that are not addressed by the compendial procedure. In addition, drug products containing different excipients, antioxidants, buffers, or container extractives may affect the recovery of the drug substance from the matrix. In these cases, a more thorough assessment of the matrix effects may be required to demonstrate suitability of the procedure for the particular drug substance or product. Other analytical performance characteristics such as an assessment of the limit of detection or quantitation and precision for impurities procedures may be useful to demonstrate the suitability of the compendial procedure under actual conditions of use.Verification is not required for basic compendial test procedures that are routinely performed unless there is an indication that the compendial procedure is not appropriate for the article under test. Examples of basic compendial procedures include, but are not limited to, loss on drying, residue on ignition, various wet chemical procedures such as acid value, and simple instrumental determinations such as pH measurements. However, for the application of already established routine procedures to compendial articles tested for the first time, it is recommended that consideration be given to any new or different sample handling or solution preparation requirements.Pharmacopeial Forum: Volume No. 36(6) Page 1775。

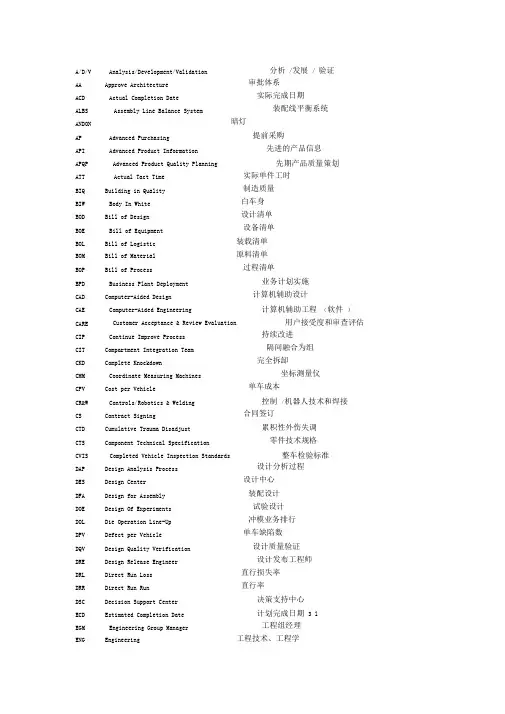

A/D/V Analysis/Development/Validation 分析/发展/ 验证审批体系AA Approve Architecture实际完成日期ACD Actual Completion Date装配线平衡系统ALBS Assembly Line Balance SystemANDON 暗灯提前采购AP Advanced PurchasingAPI Advanced Product Information 先进的产品信息APQP Advanced Product Quality Planning 先期产品质量策划ATT Actual Tact Time 实际单件工时制造质量BIQ Building in QualityBIW Body In White 白车身设计清单BOD Bill of Design设备清单BOE Bill of Equipment装载清单BOL Bill of LogisticBOM Bill of Material 原料清单过程清单BOP Bill of Process业务计划实施BPD Business Plant DeploymentCAD Computer-Aided Design 计算机辅助设计CAE Computer-Aided Engineering 计算机辅助工程(软件)CARE Customer Acceptance & Review Evaluation 用户接受度和审查评估持续改进CIP Continue Improve Process隔间融合为组CIT Compartment Integration Team完全拆缷CKD Complete Knockdown坐标测量仪CMM Coordinate Measuring MachinesCPV Cost per Vehicle 单车成本CR&W Controls/Robotics & Welding 控制/机器人技术和焊接合同签订CS Contract SigningCTD Cumulative Trauma Disadjust 累积性外伤失调零件技术规格CTS Component Technical SpecificationCVIS Completed Vehicle Inspection Standards 整车检验标准设计分析过程DAP Design Analysis Process设计中心DES Design Center装配设计DFA Design for Assembly试验设计DOE Design Of ExperimentsDOL Die Operation Line-Up 冲模业务排行单车缺陷数DPV Defect per Vehicle设计质量验证DQV Design Quality Verification设计发布工程师DRE Design Release EngineerDRL Direct Run Loss 直行损失率直行率DRR Direct Run Run决策支持中心DSC Decision Support CenterECD Estimated Completion Date 计划完成日期 3 l工程组经理EGM Engineering Group ManagerENG Engineering 工程技术、工程学精选文库EOA End of Accelerati on停止加速EPC&L En gi neeri ng P roduction Control & Logistics 工程生产控制和后勤EQF Early Quality Feedback 早期质量反馈EWO Engin eeri ng Work Order 工程工作指令 FA Final App roval 最终认可 FE Functional Evaluati on功能评估FEDR Fu nctio nal Evaluation Dis position Rep ort 功能评估部署报告FFF Free Form Fabricati on 自由形态制造FIN Finan cial 金融的FPS Fixed Poi nt Stop 定点停FTP File Tran sfer P rotocol 文件传送协议 FTQ First Time Quality 一次送检合格率GA Gen eral Assembly 总装GA ShopGeneral Assembly Sho p总装车间P ai nt Sho p 涂装车间 Body Sho p 车身车间 Press Shop 冲压车间GCAGD&T GDSGM GMA PGME GMIO GMIQ GMPTG GMS GP GQTS GSB HVAC IC ICD Global Customer AuditGeometric Dime nsioning & Tolera ncingGlobal Delivery SurveyGeneral Motors GM Asia P acific Gen eral Motors Europe Gen eral Motors Intern ati onal Op erati ons General Motors In itial Quality Gen eral Motors Po wertra in Group Global Manu facturi ng System Gen eral P rocedureGlobal Quality Track ing System Global Strategy Board全球顾客评审 几何尺寸及精度 全球发运检查 通用汽车 通用亚太 通用汽车欧洲 通用汽车国际运作 通用汽车初始质量 通用汽车动力组 通用全球制造系统 通用程序全球质量跟踪系统 全球战略部加热、通风及空调IE ILRS IO IOM IOS IPC IPTV IQS IR ISP ITPHeati ng. Ven tilati on ,and Air Con diti oning 初始租约 界面控制文件工业工程 间接劳动报告系统 国际业务 检验操作方法 检验操作概要 国际产品中心 每千辆车的故障率 初始质量调查 事故报告综合计划 综合培训方法In itiate CharterIn terface Con trol Docume nt In dustrial Engin eeri ngIn direct Labor Reporting System Intern ati onal Op erati ons Insp ecti on Op eratio n MethodInspection Op erati on Summary Intern ati onal Product Cen ter In cide nts Per Thousa nd Vehicles In itial Quality Survey In cide nt ReportIn tegrated Scheduli ng Project In tegrated Training Process精选文库In terior Tech nical Sp ecificati on Draw ing Intern ati onal Uniform Vehicle Audit Job Eleme nt Sheet Job Issue SheetJust in Time Job per hourKey Con trol CharacteristicsKey Characteristics Desig natio n System Key p roduct Characteristic Look atMetal Fabricati on Divisi on Manu facturi ng Op erati onsManu facturi ng In tegrati on Engin eer Material Labor Bala nee System Manu facturi ng Engin eeri ng Milford Proving Grou nd Master P rocess In dex Master Parts List Material Planning System Material Required DateMaterial Safety Data Sheets Manu facturi ng System Engin eer Mea n Time Betwee n Failures Manu facturi ng Tech nical Sp ecificati on Motor Vehicle Safety Sta ndards North America n Market An alysis North America n Op erati ons NAO Contain erization Numerically Con trolled Notice of Authorizati on NAO Strategy Board Orga ni zati on and Empio yee Development Occu patio nal Safety & HealthOccup atio nal Safety & Health Act Product ion Con trol and Logistics金属预制件区 制造过程)制造综合工程师 物化劳动平衡系统制造工程 试验场 主程序索引 主零件列表 原料计划系统物料需求日期 化学品安全数据单制造系统工程 平均故障时间 生产技术规范汽车发动机安全标准 北美市场分析 北美业务NAO 货柜运输数字控制 授权书 北美业务部组织和员工发展 职业安全健康T职业安全与健康法案职业安全健康管理体系 职业安全标准 生产结果 产品临时授权绩效评估委员会 项目评估和控制条件 产品装配文件零件准备跟踪系统问题信息生产控制和支持ITSD lUVA JESJIS JIT JPH KCC KCDS KPC LT MFD MFG MIE MLBS MNG MPG MPI MPL MPS MRD MSDS MSE MTBF MTS MVSS NAMA NAO NAOC NC NOA NSB OED OSH OSHA OSHMS OSHS PA PAA PAC P ACE PAD P ARTS PC PCLOccup atio nal Safety & Health Man ageme nt System Occup ati onal Safety & Health Stan dards Producti on Achieveme nt P roduct Actio n Authorizati on P erforma nee Assessme nt CommitteeProgram Assessme nt and Con trol En viro nment P roduct Assembly Docume nt Part Readi ness Track ing System Problem Communi cati on内部技术规范图 国际统一车辆审核 工作要素单 工作要素单 准时制 每小时工作量关键控制特性关键特性标识系统关键产品特性精选文库Process Con trol Man ager Problem Communi cati on Report P roduct Data Man ageme nt Product Descri pti on System Product Development TeamP roduct ion Engin eeri ng Dep artme nt P roduct Evaluati on P rogram PersonnelP rogram Executi on Team P rogram Man ageme nt People In volveme nt Product ion Launch ProcessProcess Modeli ng In tegrati on Program Manu facturi ng Man ager P roduct Manu facturability Requireme ntsP roducti on Order Man ageme nt System Point of Pu rchase P ush PullP roductio n Part App roval P rocess Personal P rotective Equipment P roblems Per Hun dred P roblems Per Millio n P ractical P roblem Solvi ng P erforma nee ReviewP roblem Reporting and Resoluti onProblem Resoluti on and Track ing System Po rtfolio Strategy Cou ncil Plant Support Team Primary Tryout P roduct ion Trial Run Purchas ing Quality AuditQuality Assessme nt Process Quality Build Concern Quality CharacteristicQuality Con trol Op erati on Sheets Quality Engin eerQuality Engin eeri ng Team Quality Function Deployment Quality, Reliability and Durability Quality System Quality Review CharterRequired CompI eti on DatePCM PCR PDM PDS PDT PED PEP PER PET PGM PI PLP PMI PMM PMR POMS POP PP PPAP PPE PPH PPM PPS PR PR/R P RTS PSC PST PTO PTR PUR QA QAP QBC QC QCOS QE QET QFD QRD QS QUA RCRCD工艺控制负责人 问题交流报告 产品资料管理 产品说明系统 产品发展小组 产品工程部 产品评估程序 人员项目执行小组项目管理 人员参与 生产启动程序 加工建模一体化 项目制造经理 产品制造能要求 产品指令管理小组 采购点 推拉生产零部件批准程序个人防护用品百辆车缺陷数 百万辆车缺陷数 实际问题解决 绩效评估问题报告和解决 问题解决跟踪系统 部长职务策略委员会 工厂支持小组 第一次试验生产试运行 采购 质量评审质量评估过程 质量体系构建关系 质量特性质量风险控制 质量工程师质量工程小组 质量功能配置 质量、可靠性和耐久力 质量体系质量评估特许 必须完成日期精选文库RFQ Request For Quotati on 报价请求RGM Reliability Growth Man ageme nt 可靠性增长小组RONA Retur n on Net Assets 净资产评估RPO Regular Product ion Op ti on 正式产品选项RQA Routi ng Quality Assessme nt 程序安排质量评定RT&TM Rigorous Tracki ng and Throughout Ma nageme nt 严格跟踪和全程管理SDC Strategic Decisi on Cen ter 战略决策中心SF Styli ng Freeze 造型冻结SIL Si ngle Issue List 单一问题清单SIP Stan dardized Insp ecti on Process 标准化检验过程SL System Layouts 系统规划SLT Short Leadi ng Team 缩短制造周期SMB P Synchronous Math-Based Process 理论同步过程SMT Systems Man ageme nt Team 系统管理小组SNR 坏路实验SOP Start of P roduct ion 生产启动SOP Safe Op erati ng Practice 安全操作规程SOR Stateme nt of Requireme nts 技术要求SOS Stan dardizati on Op erati on Sheet 标准化工作操作单SOW Stateme nt of Work 工作说明SPA Shipping Priority Audit 发运优先级审计SPC Statistical Process Con trol 统计过程控制SPE Surface and Protot ype Engin eeri ng 表面及原型工程SPO Service P arts Op erati ons 配件组织SPT Sin gle Point Team 专一任务小组SQA Supp lier Quality Assura nee 供应商质量保证(供应商现场工程师)SQC Supp lier Quality Con trol 供方质量控制SQD Supp lier Quality Development 供应方质量开发SQE Supp lier Quality Engin eer 供方质量工程师SQ IP Su pp lier Quality Imp roveme nt P rocess 供应商质量改进程序SSLT Subsystem Leadersh ip Team 子系统领导组SSTS Subsystem Tech ni cal Sp ecificati on 技术参数子系统STD Stan dardizati on 标准化STO Secon dary Tryout 二级试验SUI 安全作业指导书SUW Sta ndard Unit of Work 标准工作单位SWE Simulated Work En viro nment 模拟工作环境TAG Timi ng An alysis Group 定时分析组TBD To Be Determ ined 下决定TCS Tract ion Con trol System 牵引控制系统TDC Tech no logy Devel opment Centre 技术中心TDMF Text Data Man ageme nt Facility 文本数据管理设备TG Tooli ng 工具TIMS Test In cide nt Man ageme nt System 试验事件管理系统精选文库TIR Test In cide nt Report 试验事件报告TMIE Total Manu facturi ng In tegrati on Engin eer 总的制造综合工程TOE Total Own ersh ip Exp erie nee 总的物主体验TPM Total Product ion Maintenance 全员生产维护TSM Trade Study Methodology 贸易研究方法TT Tact Time 单件工时TVDE Total Vehicle Dime nsional Engin eer 整车外型尺寸工程师TVIE Total Vehicle In tegrati on Engin eer 整车综合工程师TWS Tire and Wheel System 轮胎和车轮系统UAW Un ited Auto Workers 班组UCL Uniform Criteria List 统一的标准表UDR Un verified Data Release 未经核对的资料发布UPC Uniform Parts Classificati on 统一零件分级VAE Vehicle Assembly Engin eer 车辆装配工程师VCD Vehicle Chief Desig ner 汽车首席设计师VCE Vehicle Chief Engin eer 汽车总工程师CVCRI Validati on Cross-Refere nee In dex 确认父叉引用索引VDR Verified Data Release 核实数据发布VDS Vehicle Descri pti on Summary 汽车描述概要VDT Vehicle Development Team 汽车发展组VEC Vehicle Engin eeri ng Cen ter 汽车工程中心VIE Vehicle In tegrati on Engin eer 汽车综合工程师VIN Vehicle Ide ntificatio n Number 车辆识别代码VIS Vehicle In formati on System 汽车信息系统VLE Vehicle Li ne Executive 总装线主管VLM Vehicle Launch Man ager 汽车创办经理VOC Voice of Customer 顾客的意见VOD Voice of Desig n 设计意见VS Validatio n Statio n 确认站VSAS Vehicle Syn thesis An alysis and Simulation 汽车综合、分析和仿真VSE Vehicle System Engin eer 汽车系统工程师VTS Vehicle Tech ni cal Sp ecificati on 汽车技术说明书WOT Wide Open Throttle 压制广泛开放WPO Work Place Organi zati on 工作场地布置WWP Worldwide Purchas ing 全球采购COMMWIP Correctio n 纠错浪费。

德累斯顿工业大学本科硕士博士申请条件德累斯顿工业大学是德国一所著名的大学,也是德国最大的工业大学之一,学校有超过120门学位课程,有优质的教育。

按教育水平划分,德累斯顿工业大学的申请可分为大学第一学位(first university degree)申请、大学另一学位(another university degree)申请和博士学位申请。

大学第一学位包括学士学位、毕业文凭和国家考试(Staats examen),另一学位主要指硕士学位。

下面出guo为大家并翻译德累斯顿工业大学各阶段的留学申请,一起来看看吧。

一、Requirements for courses that lead to a first university degree1.Which university entrance qualification (HZB) do I need for a course that will lead to a first university degree?(1). University entrance qualification (HZB) for applicants with German nationalityThe general higher education entrance qualification (Abitur) allows you to study any degree course.The subject-related higher education entrance qualification allows you to study certain degree courses. Possible disciplines of study are usually shown on the certificate.Applicants who have already suessfully pleted a degree in Germany are allowed to study any degree course.Holders of certain qualifications for professional advanced education (e.g. master craftsman qualification) are allowed to study all undergraduate courses after consultation with TU Dresden.Those with a vocational qualification with a pleted apprenticeship and at least three years professional experience can take an entrance examination at TU Dresden. Upon suessful pletion and after consultation, they are allowed to study at TU Dresden only in the course for which they applied. Those with a vocational qualification (must have a training qualification) have the university entrance qualification after studying for 2 semesters at a state or state-approved university.Attention: The advanced technical college certificate (also known as the Fachabitur) is not a subject-related higher education entrance qualification and therefore does not allow you to study at an academic institution in the Free State of Saxony. In Saxony the advanced technical college certificate only allows you to study at a university of applied sciences.(1)德国学生的大学入学资格持有普通高等教育入学资格证书,你可以学习任何学位课程。

安全验证英语In today's digital age, where technology has woven itself into the fabric of our daily lives, the importance ofsecurity verification in English cannot be overstated. It is a crucial mechanism that ensures the safety and integrity of our online interactions.Security verifications come in various forms, such astwo-factor authentication (2FA), which requires users to provide two types of identification before accessing an account. This could be something you know, like a password, and something you have, such as a code sent to your mobile device.Another common method is CAPTCHA, which stands for "Completely Automated Public Turing test to tell Computers and Humans Apart." This is a test designed to determine whether the user is a human or a bot, helping to prevent automated software from accessing secure areas of websites.Biometric verification is also becoming increasingly popular. This involves using unique physical or behavioral characteristics, such as fingerprints, facial recognition, or voice patterns, to verify a user's identity.The implementation of these security measures in English is essential for several reasons. Firstly, it protects sensitive information from unauthorized access. Secondly, ithelps to prevent identity theft and fraud. Lastly, it ensures that the digital environment remains a safe space for communication and transactions.In conclusion, as we continue to rely on technology for various aspects of our lives, the role of securityverification in English will only grow in importance. It is the key to maintaining trust in our digital systems and safeguarding our personal and professional data.。

质量管理体系术语(中英文对照)receipt (入厂)接受,验收,进货han dli ng 搬运packagi ng 包装storage 保存protecti on 保护comparis on 比较iden tificati on 标识replaceme nt of ide ntificati on mark标识标志更换maintenance of ide ntificati on 标识的保持records of identification control标识控制记录ten der 标书suppleme ntal 补充nonconforming product 不合格品con trol of nonconforming product不合格品控制con trol procedure of nonconforming products不合格品控制程序tendency of noncon forma nee 不合格倾向purchas ing 采购verification of purchased product采购的产品验证purchas ing process 采购过程【三】purchas ing con trol procedure采购控制程序purchas ing in formati on 采购信息reference in structi ons 参照细贝Ustockhouse 仓库measureme nt, an alysis and improveme nt 测量,分析和改进measureme nt result 测量结果con trol procedure of mon itori ng and measuri ng devices测量设备控制程序pla nning 策戈Upreservati on of product 产品保护【四】con trol procedure for maintenan ce, replaceme nt and records of product ide ntificati on产品标识的保持,更换及记录控制程序procedure for product ide ntificati on and traceability 产品标识禾口可追溯性程序con formity of product 产品的符合性mon itori ng and measureme nt of product 产品的监督和测量product pla n 产品方案con trol procedure for product preservati on method of product release 产品放行方法con formity of product,product con formity product realizati on 产品实现pla nning of product realizati on产品实现策划【五】product characteristics 产品特性in put to product requirements产品要求的输入product status 产品状态final accepta nee of product 产品最后验收procedure 程序产品防护控制程序产品符合性program docume nts 程序文件procedure for con ti nual improveme nt of quality man ageme nt system持续改进质量体系程序adequacy 充分性storage locati on 存放地点【六】age ncy personnel 代理人员submissi on of tenders 递交标书adjustme nt 调整,调节statutory and regulatory requireme nts法律法规要求rework, vt 返工repair, vt 返修subc on tractor 分承包方annex 附录mproveme nt acti ons 改进措施【七】on-the-job training 岗位技能培训respon sibility of in dividual departme nt and post 各部门, 各岗位职责change identification 更改标记cha nge order nu mber 更改单编号process sheets 工艺单process specificati on 工艺规程procedure(process card) 工艺规程(工艺卡)process characteristics 工艺特性Job Description工种描述单Formatwork en viro nment 工作环境【八】impartiality 公正性supplier 供方supplier evaluati on procedure供方评价程序supplier provided special processes供方提供的特殊过程verification at supplier's premises供方现场验证supply cha in 供应链criteria for supplier selection, evaluation and re-evaluation 供应商选择、评估和再评估准则com muni cati on 沟通customer 顾客【九】customer property 顾客财产control procedure for customer property 顾客财产控制程序customer feedback 顾客反馈Customer Service Con tact Form顾客服务联系表customer cum muni cati ons 顾客沟通customer satisfacti on 顾客满意statistical an alysis of customer satisfacti on顾客满意度统计分析customer compla int 顾客投诉iden tificai on of customer requireme nts 顾客要求的识别man ageme nt review 管理评审【十】records from man ageme nt review管理评审记录man ageme nt review con trol procedure管理评审控制程序man ageme nt represe ntative 管理者代表specified limits of acceptability规定的可接受界限specified use 规定的用途process 过程complexity of processes 过程的复杂性mon itori ng and measureme nt ofprocesses operati on of process 过程的运行过程的监视和测量status of processes 过程的状态process approach 过程方法process con trols 过程控制process control docume nts 过程控制文件process performa nee 过程业绩appropriate ness 合适性cha nges to con tractor 合同的更改con tract review con trol procedure合同评审控制程序in ternet sales 互联网销售en viro nmen tai con diti ons 环境条件【十二】mono gram pragram requireme nts会标纲要要求type of activities 活动类型inf rastructure 基础建设inf rastructure 基础设施fun dame ntals and vocabulary 基础与词汇control of records 记录控制tech ni cal specificai on 技术规范process trace sheet 力口工跟踪单mon itori ng and measureme nt 监视和测量mon itori ng and measuri ng device监视和测量装置【十三】control of monitoring and measuring devices制check method 检查方法freque ncy of checks 检查频次calibrati on status 检定状态in specti on and test con trol procedure检验和试验控制程序iden tificati on procedure for in specti on and test status 验状态标识程序in specti on wit ness point 检验见证点in specti on hold point 检验停止点buildi ngs 建筑物delivery 交付【十四】post-delivery activities 交付后的活动delivery activities 交付活动in terface 接口accepta nee of con tract or orders接受合同或定单type of medium 介质类型experie nee 经验correcti on acti on 纠正措施Corrective action response time纠正措施答复时间,纠正措施响应时间man ageme nt procedure for corrective acti ons corrective acti on resp onse times纠正措施响应时间【十五】developme nt activity 开发活动监视和测量装置控检验和试纠正措施管理程序traceability mark 可追溯性标志objectivity 客观性Customer Service Log 客户服务记录簿control feature 控制特性,控制细节control features 控制细则periodic assessme nt of stock库存定期评估justificati on 理由routi ne 例程,惯例,常规in ternal com muni cati on 内部沟通【十六】in ternal audit 内部审核in ternal audit procedure 内部审核程序in ternally con trolled sta ndard 内控标准internal audit 内审results of internal and exter nal audits 内外部审核结果compete nee 能力trai ning 培训trai ning n eeds 培训需要evaluate 评价records of the results of the review评审结果的记录【十七】review output 评审输出review in put 评审输入Purchase Requisiti on 请购单authority 权限validati on 确认con cessi on 让步huma n resources 人力资源job trai ning of personnel 人员岗位培训qualificati on of pers onnel 人员资格equipme nt con trol procedure设备控制程序【十八】device type 设备类型order of desig n cha nges 设计更改通知单设计和开发控制程序desig n and developme nt con trol proceduredesig n and developme nt 设计开发desig n and developme nt pla nning设计开发策划con trol of desig n and developme nt cha nges设计开发更改控制desig n and developme nt review设计开发评审desig n and developme nt validati on设计开发确认desig n and developme nt outputs设计开发输出desig n and developme nt in puts设计开发输入【十九】desig n and developme nt verificati on设计开发验证desig n validati on 设计确认desig n docume ntati on 设计文件编制desig n accepta nee criteria 设计验收准贝Udesig n verificati on 设计验证audit program 审核大纲con duct of audits 审核行为audit criteria 审核准贝Uproducti on process control 生产过程控制producti on process con trol procedure生产过程控制程序【二十】producti on and service provisi on生产和服务提供control of producti on and service provisi on 生产和服务提供的控制validati on of processes for producti on and service provisi on 生产和服务提供过程的确认producti on order 生产令iden tificati on and traceability识别和可追溯性iden tificati on and traceability maintenance and replaceme nt 识别和可追溯性维护与替换in validate 使失效market survey 市场调研suitability 适宜性scope 适用范围【二^一】terms and defi niti ons 术语与定义an alysis of data 数据分析seque nee 顺序transfer of own ership 所有权转移system docume nt 体系文件statistical tech nique 统计方法outsource(vt) a process 夕卜包过程exter nal source 夕卜部来源docume nts of exter nal origi n 夕卜来文件【二十二】outsource, vt 夕卜协unique ide ntificati on 唯一的标识maintenance 维护Docume nt Cha nge Co ntrol 文件更改控制Request For Docume nt Change (RDC)文件更改需求单control of docume nts 文件控制docume ntati on requireme nts 文件要求enquiry 问询,询价field nonconfor mity an alysis现场不符合分析releva nee 相关性【二十三】in teracti on 相互作用detail design 详细设计,详图设计,零件设计,施工设计sales departme nt 销售部sales con tract 销售合同checklist 校验表,一览表,检查一览表calibrati on 校准submissi on of acti on pla ns行动计划的递交docume nted procedures 形成文件的程序docume nted stateme nt 形成文件的声明performa nee requireme nts 性能要求【二十四】licensee responsibilities许可证持有者责任accepta nee criteria 验收准贝U verificati on arran geme nt 验证安排verificati on results 验证结果customer focus以客户为关注点,以客户为焦点aware ness 意识in troduction 引言,概述,介绍no rmative referen ces 引用标准applicati on 应用visit to user 用户访问【二十五】review of requireme nts related to the product 有关产品的要求评审compete nt 有能力的effective ness 有效性determ in ati on of requireme nts related to the 与产品有关的要求的确定customer-related processes与顾客有关的过程preve ntive acti on 预防措施man ageme nt procedure for preve ntive acti ons 预防措施管理程序pla nn ed results 预期的结果inten ded use 预期的用途procedure for compete nee, kno wledge and training of pers onnel 员工能力,知识和培训程序【二十六】pers onnel training procedure员工培训程序support ing services 支持性服务fun cti ons 职能部门respon sibility 职责assig nment of respon sibility 职责分工workma nship 制造工艺manu facturi ng accepta nee criteria制造验收准则quality policy 质量方针quality programs 质量纲领quality man ageme nt system 质量管理体系【二十七】quality man ageme nt system pla nning 质量管理体系策划performa nee of the quality man ageme nt systemquality pla n 质量计戈Uquality records 质量记录quality objectives 质量目标quality audit 质量审核quality manual 质量手册quality problem han dli ng form质量问题处理单quality requireme nts 质量要求allocati on table of quality resp on sibilities 【二十八】resource man ageme nt 资源管理allocati on of resources 资源配置质量管理体系业质量职能分配表gen eral requireme nts 总要求,一般要求con stitue nt part 组成部件orga ni zati on 组织con ti nual improveme nt of the orga ni zati组织的持续改进on size of organi zati on 组织的规模Organi zati onal Diagram 组织机构图final accepta nee 最终验收work in structi ons 作业指导书。