epolymer

- 格式:pdf

- 大小:946.09 KB

- 文档页数:8

/Journal of Reinforced Plastics and Composites/content/30/19/1621The online version of this article can be found at:DOI: 10.1177/07316844114268102011 30: 1621 originally published online 7 November 2011Journal of Reinforced Plastics and Composites N. Venkateshwaran, A. ElayaPerumal and M. S. JagatheeshwaranEffect of fiber length and fiber content on mechanical properties of banana fiber/epoxy compositePublished by: can be found at:Journal of Reinforced Plastics and Composites Additional services and information for/cgi/alerts Email Alerts:/subscriptions Subscriptions: /journalsReprints.nav Reprints:/journalsPermissions.nav Permissions:/content/30/19/1621.refs.html Citations:What is This?- Nov 7, 2011OnlineFirst Version of Record- Dec 16, 2011Version of Record >>ArticleEffect of fiber length and fiber contenton mechanical properties of banana fiber/epoxy compositeN.Venkateshwaran,A.ElayaPerumal and M.S.JagatheeshwaranAbstractThe main factors that influence the properties of composite are fiber length and content.Hence the prediction of optimum fiber length and content becomes important,so that composite can be prepared with best mechanical prop-erties.Experiments are carried out as per ASTM standards to find the mechanical properties namely,tensile strength and modulus,flexural strength and modulus,and impact strength.In addition to mechanical properties,water absorption capacity of the composite is also studied.Further,fractured surface of the specimen are subjected to morphological study using scanning electron microscope.The investigation revealed the suitability of banana fiber as an effective reinforce-ment in epoxy matrix.Keywordspolymer composites,banana fiber,mechanical properties,scanning electron microscopeIntroductionNowadays,polymers are used everywhere in the day-to-day life.Plastics found its way when the need for low weight high strength material became important for various applications.The research in thefield of poly-mer and polymer-based components has gained wide-spread recognition owing to its property;however,its bio-degradability is still a matter of concern.Further, glassfiber reinforced polymers(GFRP)have become appealing substitutes for aluminum,concrete,and steel due to its high strength-to-weight ratio,ease of handling,and for being corrosion-free.Moreover, they can also be engineered to get the desired proper-ties.1Since large-scale production and fabrication of glassfiber causes environmental problems and also health hazards,a suitable alternate which is environ-mental friendly is the need of the hour.Naturalfibers that are low cost,lightweight and environmental friendly provide an excellent alternative to glassfiber. Joshi et al.2reviewed the life cycle assessment of natural fiber and glassfiber composite and found that natural fibers are environmentally superior to glassfiber,and also reduces the polymer content as reinforcement. Schmidt and Beyer,Wotzel et al.,and Corbiere et al.carried out some important works using the natural fibers as reinforcement in polymer matrix for use in automobile parts.Schmit and Beyer3have replaced the glassfiber polypropylene(PP)with hemp-PP com-posite for auto-insulation application.Wotzel et al.4 have used hemp-epoxy to replace glassfiber acryloni-trile butadien–styrene(ABS)for usage in auto-side panel.Similarly,Corbiere et al.5replaced glassfiber PP with Curaua PP for transporting pallet.All these studies revealed that the naturalfiber based polymer composite has successfully replaced the glassfiber. Pothan et al.6studied the effect offiber length and con-tent on the mechanical properties of the short banana/ polyester composite.Study shows that30–40mmfiber length and40%fiber loading provides better mechan-ical properties.Idicula et al.7investigated the mechan-ical performance of banana/sisal hybrid composite and Department of Mechanical Engineering,Anna University,Chennai,India.Corresponding author:N.Venkateshwaran,Department of Mechanical Engineering,Anna University,Chennai,IndiaEmail:venkatcad@Journal of Reinforced Plasticsand Composites30(19)1621–1627!The Author(s)2011Reprints and permissions:/journalsPermissions.navDOI:10.1177/0731684411426810the positive hybrid effect for tensile strength was found to be in the ratio of4:1(banana:sisal). Further,the tensile strength of the composite is better when bananafiber is used as skin and sisal as core material.Visco-elastic property of the banana/ sisal(1:1ratio)hybrid composite was studied by Idicula et al.8The study shows that sisal/polyester composite has maximum damping behavior and high-est impact strength as compared to banana/polyester and hybrid composite.Sapuan et al.9prepared the composite by reinforcing woven bananafibers with epoxy matrix.Tensile test result showed that the woven kind of reinforcement has better strength and the same was confirmed using Anova technique also. Venkateshwaran and ElayaPerumal10reviewed the various work in thefield of bananafiber reinforced with polymer matrix composite with reference to phys-ical properties,structure,and application. Venkateshwaran et al.11studied the effect of hybridi-zation on mechanical and water absorption properties. Investigation revealed that the addition of sisal in bananafiber composite upto50%increases the mechanical properties.Sapuan et al.12designed and fabricated the household telephone stand using woven banana fabric and epoxy as resin.Zainudin et al.13studied the thermal stability of banana pseudo-stem(BPS)filled unplastisized polyvinyl chlo-ride(UPVC)composites using thermo-gravimetric analysis.The study revealed that the incorporation of bananafiller decreases the thermal stability of the composite.Zainudin et al.14investigated the effect of bananafiller content in the UPVC matrix.The inser-tion offiller increases the modulus of the composite and not the tensile andflexural strength.Zainudin et al.15studied the effect of temperature on storage modulus and damping behavior of bananafiber rein-forced with UPVC.Uma Devi et al.16studied the mechanical properties of pineapple leaffiber rein-forced with polyester composite.Study found that optimum mechanical properties are achieved at 30mmfiber length and30%fiber content.Dabade et al.17investigated the effect offiber length and weight ratio on tensile properties of sun hemp and palmyra/polyester composite.The optimumfiber length and weight ratio were30mm and around 55%,respectively.From the above literatures,it is evident that the fiber length and content are the important factors that affect properties of the composite.Hence in this work,the effect offiber length and weight percentage on the mechanical and water absorption properties of the bananafiber epoxy composite is investigated. Further,the fractured surface of the composite are subjected to fractography study to evaluate the frac-ture mechanism.ExperimentalFabrication of compositeA molding box made of well-seasoned teak wood of dimensions300Â300Â3mm3is used to make a com-posite specimen.The top,bottom surfaces of the mold and the walls are coated with remover and kept for drying.Fibers of different length(5,10,15,and 20mm)and weight percentage(8,12,16,and20)are used along with Epoxy(LY556)and Hardener (HY951)for the preparation of composite.Testing standardsThe tensile strength of the composite was determined using Tinnus Olsen Universal Testing Machine (UTM)as per ASTM D638standard.The test speed was maintained at5mm/min.In this case,five specimens were tested with variedfiber length andfiber weight ratio.The average value of tensile load at breaking point was calculated.Theflexural strength was determined using the above-mentioned UTM as per ASTM D790procedure.The test speed was maintained between1.3and1.5mm/min. In this case,five samples were tested and the average flexural strength was reported.The impact strength of the composite specimen was determined using an Izod impact tester according to ASTM D256 Standards.In this case,five specimens were tested to obtain the average value.Figures1to5show the effect offiber length and weight content on ten-sile,flexural,and impact properties.Water absorp-tion behavior of banana/epoxy composites in water at room temperature was studied as per ASTM D570to study the kinetics of water absorption. The samples were taken out periodically andFigure1.Effect of fiber length and weight percentage on tensile strength.1622Journal of Reinforced Plastics and Composites30(19)weighed immediately,after wiping out the water from the surface of the sample and using a precise 4-digit balance to find out the content of water absorbed.All the samples were dried in an oven until constant weight was reached before immersing again in the water.The percentage of moisture absorption was plotted against time (hours)and are shown in Figures 6–13.Scanning electron microscopeThe fractured surfaces of the specimens were exam-ined directly by scanning electron microscope Hitachi-S3400N.The fractured portions of the sam-ples were cut and gold coated over the surface uni-formly for examination.The accelerating voltage used in this work was 10kV.Figures 14to 17show the fractured surface characteristics of the compositespecimen.Figure 6.Effect of moisture on fiber content;Fiber length –5mm.Figure 3.Effect of fiber length and weight percentage on flexural strength.Figure 2.Effect of fiber length and weight percentage on tensilemodulus.Figure 4.Effect of fiber length and weight percentage on flexuralmodulus.Figure 5.Effect of fiber length and weight percentage on impact strength.Venkateshwaran et al.1623Figure 12.Effect of moisture on fiber length;Fiber wt%–16.Figure 7.Effect of moisture on fiber content;Fiber length –10mm.Figure 11.Effect of moisture on fiber length;Fiber wt%–12.Figure 10.Effect of moisture on fiber length;Fiber wt%–8.Figure 8.Effect of moisture on fiber content;Fiber length –15mm.Figure 9.Effect of moisture on fiber content;Fiber length –20mm.1624Journal of Reinforced Plastics and Composites 30(19)Results and discussion Mechanical propertiesFor the tensile test,composite specimens are made of fibers of different length (5,10,15,and 20mm)and weight ratio (8,12,16,and 20)were used to calculate the tensile strength.Figures 1and 2show the effect of fiber length and weight ratios on tensile strength and modulus of the composite,respectively.Figure 1shows that the increase in fiber length and weight ratio increases the tensile strength and modulus upto 15mm fiber length and 12%weight ratio.Further increases cause the properties to decrease because of lower fiber–matrix adhesion and the quantity of fiber content being more than matrix.From Figures 1and 2,the maximum tensile strength and modulus oftheFigure 14.SEM micrograph of tensile fracturedspecimen.Figure 15.SEM micrograph of fractured specimen under flexuralload.Figure 16.SEM micrograph of fractured specimen under impactload.Figure 17.Micrograph of poorinterface.Figure 13.Effect of moisture on fiber length;Fiber wt%–20.Venkateshwaran et al.1625composite are16.39MPa and0.652GPa,respectively for thefiber length of5mm and12%weight ratio. Flexural strength and modulus for differentfiber lengths(5,10,15,and20mm)and weight ratios(8, 12,16,and20)are shown in Figures3and4,respec-tively.It was found that the maximumflexural strength and modulus are57.53MPa and8.92GPa,respectively for thefiber length of15mm andfiber weight of16%.The results of the pendulum impact test are shown in Figure 5.As thefiber weight and length increases impact strength also increases upto16%fiber weight ratio and then begin to decrease.The maximum impact strength of 2.25J/m was found for thefiber length 20mm and16%fiber weight.Although the variousfiber lengths and weight per-centage provides the maximum mechanical properties, from Figures10,12,and14it can be concluded that the optimumfiber length andfiber weight percentage is 15mm and16%respectively as the properties variation with15mm and16%are negligible when compared to the maximum mechanical properties provided by differ-entfiber lengths and weight percentage indicated as above.The mechanical properties provided above are better than coir18and palmyra.19Water absorption studyThe effects offiber length and content on the water absorption study are shown in Figures6–13.Figures 6to9show the effect offiber content on the water absorption property of the banana/epoxy composite. It shows that as thefiber content increases the moisture uptake of the composite also increases.This is due to the affinity of the bananafiber towards the moisture. The maximum moisture absorption for the composite is around5%for all length and weight percentage of composite.Figures10to13show the effect offiber length on the water uptake capability of composite.It indicates that the variation of length(5,10,15,and 20mm)does not have much impact as compared with thefiber content.The moisture absorption percentage of bananafiber/epoxy composite seems to be lesser than hempfiber20andflaxfiber21composite. Fractography studyMicrographs of fractured tensile,flexural,and impact specimens are shown in Figures14–17.Figure14shows the micrograph of fractured surface of specimen under tensile load.It clearly indicates that the failure is due to fiber pull out phenomenon.Figure15shows the frac-tured surface of the specimen under bending load. Micrograph also shows the bending offibers due to the application of load.Figure16shows the failure of the composite under impact load.Further,it also shows the striation occurring on the matrix surface and the presence of hole due tofiber pull out.Figure17shows the micrograph of20mmfiber length and20%fiber weight composite specimen.It clearly indicates that the clustering offibers result in poor interface with matrix,and in turn decreases the mechanical properties of the composite.ConclusionBased on thefindings of this investigation the following conclusions can be drawn:.The optimumfiber length and weight ratio are 15mm and16%,respectively for bananafiber/ epoxy composite..Moisture absorption percentage of banana/epoxy composite for all length and weight percentage is around5..Also,the moisture uptake capability of the compos-ite is greatly influenced byfiber content than length. .SEM image shows that increasing thefiber content above16%results in poor interface betweenfiber and matrix.References1.Houston N and Acosta F.Environmental effect of glassfiber reinforced polymers.In:Proceedings of2007Earth Quake Engineering Symposium for Young Researcher, Seattle,Washington,2007.2.Joshi SV,Drzal LT,Mohanty AK and Arora S.Are nat-ural fiber composites environmentally superior to glass fiber reinforced posite Part A2004;35: 371–376.3.Schmidt WP and Beyer HM.Life cycle study on a naturalfiber reinforced component.In:SAE Technical Paper 982195.SAE Total Life-Cycle Conference,1–3 December,1998,Graz,Austria.4.Wotzel K,Wirth R and Flake R.Life cycle studies onhemp fiber reinforced components and ABS for automo-tive parts.Die Angewandte Makromolekulare Chemie1999;272:121–127.5.Corbiere-Nicollier T,Laban BG and Lundquist.Lifecycleassessment of bio-fibers replacing glass fibers as reinforce-ment in plastics.Resour Conserv Recycl2001;33:267–287.6.Pothan LA,Thomas S and Neelakantan NR.Shortbanana fiber reinforced polyester composites:mechanical, failure and aging characteristics.J Reinf Plast Compos 1997;16:744–765.7.Idicula M,Neelakantan NR and Oommen Z.A study ofthe mechanical properties of randomly oriented short banana and sisal hybrid fibre reinforced polyester compos-ites.J Appl Polym Sci2005;96:1699–1709.1626Journal of Reinforced Plastics and Composites30(19)8.Idicula M,Malhotra SK,Joseph K and Thomas S.Dynamic mechanical analysis of randomly oriented short banana/sisal hybrid fibre reinforced polyester pos Sci Technol2005;65:1077–1085.9.Sapuan SM,Leenie A,Harimi M and Beng YK.Mechanical property analysis of woven banana/epoxy composite.Mater Design2006;27:689–693.10.Venkateshwaran N and ElayaPerumal A.Banana fiberreinforced polymer composite-a review.J Reinf Plast Compos2010;29:2387–2396.11.Venkateshwaran N,ElayaPerumal A,Alavudeen A andThiruchitrambalam M.Mechanical and water absorption behavior of banana/sisal reinforced hybrid composites.Mater Design2011;32:4017–4021.12.Sapuan SM and Maleque MA.Design and fabrication ofnatural woven fabric reinforced epoxy composite for household telephone stand.Mater Design2005;26: 65–71.13.Zainudin ES,Sapuan SM,Abdan K and MohamadMTM.Thermal degradation of banana pseudo-stem fibre reinforced unplastisized polyvinyl chloride compos-ites.Mater Design2009;30:557–562.14.Zainudin ES,Sapuan SM,Abdan K and MohamadMTM.The mechanical performance of banana pseudo-stem reinforced unplastisized polyvinyl chloride compos-ites.Polym Plast Technol Eng2009;48:97–101.15.Zainudin ES,Sapuan SM,Abdan K and MohamadMTM.Dynamic mechanical behaviour of bananapseudo-stem filled unplasticized polyvinyl chloride com-posites.Polym Polym Compos2009;17:55–62.16.Uma Devi L,Bhagawan SS and Sabu Thomas.Mechanical properties of pineapple leaf fiber-reinforced polyester composites.J Appl Polym Sci1997;64: 1739–1748.17.Dabade BM,Ramachandra Reddy G,Rajesham S andUdaya kiran C.Effect of fiber length and fiber weight ratio on tensile properties of sun hemp and palmyra fiber reinforced polyester composites.J Reinf Plast Compos 2006;25:1733–1738.18.Harish S,Peter Michael D,Bensely A,Mohan Lal D andRajadurai A.Mechanical property evaluation of natural fiber coir composite.Mater Characterisation2009;60: 44–49.19.Velmurugan R and Manikandan V.Mechanical proper-ties of palmyra/glass fiber hybrid posite Part-A2009;38:2216–2226.20.Dhakal HN,Zhang ZY and Richardson MOW.Effect ofwater absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites.Compos Sci Technol2007;67:1674–1683.21.Alix S,Philippe E,Bessadok A,Lebrun V,Morvan V andMarais S.Effect of chemical treatments on water sorption and mechanical properties of flax fibres.Bioresour Technol2009;100:4742–4749.Venkateshwaran et al.1627。

第27卷 第1期2006年2月特种橡胶制品Special Purpose Rubber Products Vol.27 No.1 February 2006NBR/EPVC 共混物压缩永久变形的研究晏才圣1, 罗权2(11广州市建筑材料工业研究所有限公司,广州 510030;21华南理工大学材料科学与工程学院,广州 510640)摘 要:研究了聚氯乙烯糊树脂(EPVC )用量、增塑剂DOP 用量、硫化体系、交联剂DCP 用量、补强剂品种对NBR/EPVC 共混物压缩永久变形的影响。

结果表明,加入EPVC 使NBR/EPVC 共混物的压缩永久变形显著增大;DOP 也会使共混物的压缩永久变形增大;采用过氧化物硫化体系、半有效硫化体系和有效硫化体系硫化的NBR/EPVC 共混物压缩永久变形较小,在半有效硫化体系中加入交联剂DCP 可进一步降低共混物的压缩永久变形;采用炭黑补强的NBR/EPVC 共混物压缩永久变形比采用白炭黑补强的小。

关键词:聚氯乙烯糊树脂;丁腈橡胶;压缩永久变形中图分类号:TQ33419 文献标识码:A 文章编号:1005-4030(2006)01-0006-03收稿日期:2005-08-26作者简介:晏才圣(1979-),男,湖南浏阳人,硕士,毕业于华南理工大学,主要从事高分子材料改性和加工,阻燃及防火材料的开发和测试技术的研究。

为了获得耐臭氧性能较好的丁腈橡胶(NBR )胶料,常在胶料中共混一定比例的聚氯乙烯(PVC )[1~3]。

NBR 与PVC 的共混物可以用于耐油密封制品。

橡胶密封制品在装配状态下贮存或使用时,由于受机械作用力、介质及空气中氧和温度的共同作用产生累积永久变形,导致压缩永久变形增大而引起泄漏,丧失密封性能。

选择高温下压缩永久变形为评价指标可以对密封制品的贮存寿命进行预期评估[4]。

在NBR/硬质聚氯乙烯(SPVC )共混物制备过程中,需要高温塑化PVC 后才能与NBR 实现共混。

常用的几种卡波姆Carbopol 940:短流变性、高粘度、高清澈度,低耐离子性及耐剪切性,适用于凝胶及膏霜中Carbopol 941:长流变性、低粘度、高清澈度,中等耐离子性及耐剪切,适用于凝胶及乳液Carbopol ETD 2020:丙烯酸酯/C10-30烷基丙烯酸酯交链共聚物,长流变性、低粘度、高清澈度、高耐离子性及耐剪切性,适用清澈凝胶。

Carbopol AQUA SF-1:液体,长流变性、可配制清澈配方,与多种成份具优良的相容性,回酸增稠,可用于表面活性剂体系。

Carbopol Ultrez 21:丙烯酸酯/C10-30烷基丙烯酸酯交链共聚物,短流变性、用于凝胶、洗涤清洁用品、高电解质产品、膏霜、乳液。

Carbopol Ultrez 20:丙烯酸酯/C10-30烷基丙烯酸酯交链共聚物,长流变性、香波、沐浴凝胶、膏霜/乳液、含电解质的护肤、护发凝胶Pemulen TR-1:丙烯酸酯/C10-30烷基丙烯酸酯交链共聚物,增稠型乳化剂、短流变性、用于膏霜、乳液Pemulen TR-2:丙烯酸酯/C10-30烷基丙烯酸酯交链共聚物,增稠型乳化剂、长流变性、用于乳液Carbopol ULTREZ 20聚合物Carbopol® Ultrez 20 PolymerINCI Name: Acrylates/C10-30 Alkyl Acrylate Crosspolymer Carbopol® Ultrez 20 polymer is a hydrophobically(疏水性地)modified cross-linked acrylate copolymer. This polymer offers many substantial benefits for formulators and marketers of personal care products. Like other "Ultrez" grade polymers, Carbopol Ultrez 20 polymer is exceptionally easy to use - it self-wets and disperses within minutes.This rheology (流变学)modifier and stabilizer also provides electrolyte tolerance(耐受性) and unique sensory benefits in formulations. It can be used in systems with moderate surfactant content, making it an ideal choice for many applications.Key Benefits of Carbopol Ultrez 20 PolymerPleasing Sensorial(知觉的,感觉的) Properties:Carbopol Ultrez 20 provides a rich, creamy skinfeelduring the rubout(擦掉,抹掉) phase of applyingoil-in-water based creams and lotions(洗液). Theseproperties are featured in our SensiMap Formulating(明确叙述)Concept.Rapid Wetting:The unique structure of Carbopol Ultrez 20 polymer allows for rapid wetting and improved swelling (膨胀)time without the need for agitation. This processing benefit is offered without compromising the performance that the personal care industry expects from the Carbopol polymer product line.Efficient Thickening(高效增稠): Carbopol Ultrez 20 polymer provides moderate-to-high viscosity with smooth, long flow properties. It's a versatile(通用的) product that can be used when your formulations require viscosity and suspending properties. Carbopol Ultrez 20 polymer performs effectively across a broad pH range, making it a versatile ingredient for many applications.Stability of Ingredients in Surfactant-Containing Formulation s(配方): In shampoo and body wash formulations, Carbopol Ultrez 20 polymer helps to suspend and stabilize beads(珠子,水珠), microcapsules and exfoliants(去角质系列)for excellent product stability and visual appeal(视觉的吸引力). In 2-in-1 formulations, Carbopol Ultrez 20 polymer can stabilize silicone fluids and oils effectively.Aesthetic(美学的;审美的)Properties:Carbopol Ultrez20 polymer exhibits good clarity(透明) in gelformulations, along with providing a smooth,aesthetically pleasing gel(凝胶)quality. In creams andlotions(洗液), it helps to create emulsions(乳剂) withexcellent skin feel.Excellent Clarity: Even at high polymer concentration, Carbopol Ultrez 20 polymer maintains superior clarity.It can be used with confidence(满怀信心地)in systemswhere sparkling(发泡的, 闪烁的)clarity is required. Excellent Electrolyte(电解质) Tolerance:Viscosity, clarity and stability are all maintained in the presence of(在面前)electrolytes with Carbopol Ultrez 20 polymer. It is ideally suited for use in formulations containing higher levels of oils, botanical(来自植物的; 植物的)ingredients, or humectants(湿润剂)like Sodium PCA.Carbopol Ultrez 20 polymer provides excellent performance in a wide range of products, including:ShampoosLotionsBody washesHair and skin gelsBath gelsCreamsCarbopol® Ultrez 20 polymer is a featured ingredient in theCarbopol® Ultrez 20 polymer is recommendedfor .Name: CARBOPOL® ULTREZ 20 POLYMERCompany:Trade Name: CARBOPOL®Description: Like other "Ultrez" grade polymers, Carbopol® Ultrez 20 polymer is exceptionally easy to use-it self wets and disperses within minutes. This new thickener and stabilizer also provides improved electrolyte tolerance and unique sensory benefits. It can be used in systems with a moderate surfactant content, making it an ideal choice for many applications.Documents Data SheetTechnical InformationProduct name : Carbopol Ultrez 21 Polymer Chemical name : Acrylates/C10-30 alkyl acrylate crosspolymerItems PropertiesAppearance:white powderOdor:mild acrylic odorTotal solids:100%pH (in water): 30.5% mucilage(粘液)viscosity at 20 rpm:55, 000 mPa·s0.5% dispersionwetting time: 3 minutes0.5% mucilage* clarity(% Transmission)(传送)~ 95 Characteristics and Application :Carbopol Ultrez 21 Polymer is a hydrophobically(疏水性地) modified crosslinked polyacrylate polymer designed to efficientlyimpart(赋予)thickening, stabilizing, and suspending properties to a variety of personal care applications.Carbopol Ultrez 21 polymer is self wetting crosslinked polyacrylic acid polymer that is synthesized in a cosolvent(共溶剂)ethyl acetate/cyclohexane mixture.It provides greater versatility(多功能,多用途) in formulating because it quickly and easily self wets without any mixing required. Carbopol Ultrez 21 polymer has short flow characteristics with relatively high viscosity compared to other Carbopol polymers.Benefits :Facilitates(使容易) formulating and processing because it is a self-wetting polymer that requires no dispersion agitation.Provides excellent thickening efficiency to form very high clarity gels.Provides shear(切变) thinning(变稀) rheology(流变能力)to enable easy pumping(抽吸)and dispensing(分发; 分配)of finished products via trigger(扳柄)sprayers(喷雾器).Provides yield value(屈服值)to allow for the suspension of a wide variety of insoluble materials or particles(粒子). Yield value enables finished products to have vertical cling(附着) which is an important characteristic for products that are dispensed via a trigger spray(反柄喷雾器) or nozzle(管口, 喷嘴). Stabilizes oil-in-water emulsions.INCL命名:丙烯酸酯/C10-30烷基丙烯酸酯交联聚合物(Acrylates/C10-30 Alkyl Acrylate Crosspolymer)一.工艺操作上的优点:在工艺操作上ULTREZ 20比ETD2020更简便。

一、什么是EM.EPR

E:Expansion 膨胀

M:Mold 模具

E:Evolutional 进化物

P:Polymer 聚合物

R:Realignment 重新组合

二、EM.EPR简介

EM.EPR是由晋江毅恒鞋材有限公司与日本共同开发研制的新型材料替代品。

EM.EPR产品,经过多年研发、试验,将超轻、耐磨与止滑融为一体,已取得同类产品先进水平,所有的物性经过权威机构(SATRA)的测试都已获得通过,耐磨、止滑已达到RUBBER OUTSOLE& PU大底的水平,并突破了耐磨与止滑相对抵触之缺点。

同时,随着消费者对品质要求的提高,对压缩歪需求的进一步提升,现EM.EPR 之压缩歪已超越了所有EVA的传统标准。

三、四大特性

(1)超轻

(2)耐寒

(3)止滑

(4)三重耐磨

四、五大功能

(1)反弹

(2)吸震

(3)支撑

(4)多种质感

(5)可手缝

反弹、吸震

为了适应市场及消费者的要求,EM.EPR可生产高技术高物性的功能鞋底,反弹加吸震及耐磨、止滑底一次发泡成型,其中反弹、吸震经权威机构的测试,已达到同类产品的顶尖水平,同时,可免去为生产功能鞋底的贴合不稳定性及成本上的负担。

可手缝

经长期的研发及测试,EM.EPR是可生产手缝底材,主要原因及特点是拉力、撕裂、剥离强度高于一般M/D标准。

产品已通过多家品牌CLARKS、ROCKPORT、LA NEM、REEBOK、HUSHPUPIESS认定使用,物性比其他材料更佳、比重更轻。

专利名称:POLYMER发明人:TAKAHASHI HIROSHI,ABE KATSUHIRO 申请号:JP4492381申请日:19810327公开号:JPS643218B2公开日:19890120专利内容由知识产权出版社提供摘要:PURPOSE:A polymer rich in reactivity and excellent in heat resistance, rigidity and impact resistance, having structural units, 5-norbornene-2-carboxylate ester group and 5-norbornene-2-carboxylic acid group, at a specified ratio. CONSTITUTION:A polymer consisting of structural units of formulaI, wherein R<1> is H, an alkyl or a phenyl, R<2> is H or an alkyl, and structural units of formula II, wherein R<3> is an alkyl. An ester group-containing norbornene derivative monomer (e.g., methyl 5-norbornene-2-carboxylate) easily undergoes ring-opening polymerization by the help of a metathesis catalyst. The ring-opened polymer obtained by ring-opening polymerization is one consisting of structural units of formula III. The purpose polymer can be prepared by hydrolyzing the ester groups by dissolving the polymer in an organic solvent and adding a proper amount of an alkali to the solution.申请人:MITSUBISHI PETROCHEMICAL CO更多信息请下载全文后查看。

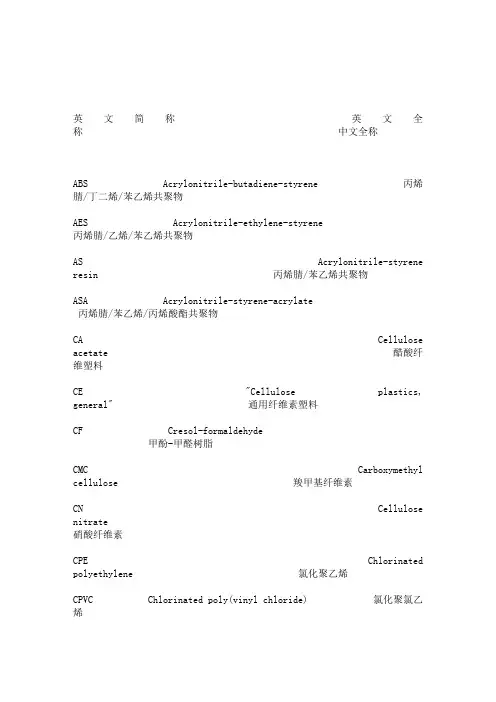

英文简称英文全称中文全称ABS Acrylonitrile-butadiene-styrene 丙烯腈/丁二烯/苯乙烯共聚物AES Acrylonitrile-ethylene-styrene 丙烯腈/乙烯/苯乙烯共聚物AS Acrylonitrile-styrene resin 丙烯腈/苯乙烯共聚物ASA Acrylonitrile-styrene-acrylate 丙烯腈/苯乙烯/丙烯酸酯共聚物CA Cellulose acetate 醋酸纤维塑料CE "Cellulose plastics, general" 通用纤维素塑料CF Cresol-formaldehyde 甲酚-甲醛树脂CMC Carboxymethyl cellulose 羧甲基纤维素CN Cellulose nitrate 硝酸纤维素CPE Chlorinated polyethylene 氯化聚乙烯CPVC Chlorinated poly(vinyl chloride) 氯化聚氯乙烯EP "Epoxy, epoxide" 环氧树脂EPM Ethylene-propylene polymer 乙烯/丙烯共聚物EPS Expanded polystyrene 可发性聚苯乙烯EVA Ethylene/vinyl acetate 乙烯/醋酸乙烯共聚物HDPE High-density polyethylene plastics 高密度聚乙烯HIPS High impact polystyrene 高抗冲聚苯乙烯IPS Impact-resistant polystyre ne 耐冲击聚苯乙烯K树脂 Styrene- butadiene 苯乙烯/丁二烯共聚物LCP Liquid crystal polymer 液晶聚合物LDPE Low-density polyethylene plastics 低密度聚乙烯LLDPE Linear low-density polyethylene 线型低密聚乙烯LMDPE Linear medium-density polyethylene 线型中密聚乙烯MBS Methacrylate-butadiene-styrene 甲基丙烯酸/丁二烯/苯乙烯共聚物MC Methyl cellulose 甲基纤维素MDPE Medium-density polyethylene 中密聚乙烯MF Melamine-formaldehyde resin 密胺-甲醛树脂MPF Melamine/phenol-formaldehyde 密胺/酚醛树脂PA Polyamide (nylon) 聚酰胺(尼龙)PAE Polyarylether 聚芳醚PAEK Polyaryletherketone 聚芳醚酮PAI Polyamide-imide 聚酰胺-酰亚胺PAK Polyester alkyd 聚酯树脂PAN Polyacrylonitrile 聚丙烯腈PASU Polyarylsulfone 聚芳砜PAT Polyarylate 聚芳酯PAUR Poly(ester urethane) 聚酯型聚氨酯PB Polybutene-1 聚丁烯-[1] PBT Poly(butylene terephthalate) 聚对苯二酸丁二酯PC Polycarbonate 聚碳酸酯PE Polyethylene 聚乙烯PEEK Polyetheretherketone 聚醚醚酮PEI Poly(etherimide) 聚醚酰亚胺PEK Polyether ketone 聚醚酮PES Poly(ether sulfone) 聚醚砜PET Poly(ethylene terephthalate) 聚对苯二甲酸乙二酯PEUR Poly(ether urethane) 聚醚型聚氨酯PF Phenol-formaldehyde resin 酚醛树脂PI Polyimide 聚酰亚胺PMMA Poly(methyl methacrylate) 聚甲基丙烯酸甲酯PMS Poly(alpha-methylstyrene) 聚α-甲基苯乙烯POM "Polyoxymethylene, polyacetal" 聚甲醛PP Polypropylene 聚丙烯PPO Poly(phenylene oxide) deprecated 聚苯醚PP-R Polypropylene randon coplymer 无规共聚聚丙烯PPS Poly(phenylene sulfide) 聚苯硫醚PPSU Poly(phenylene sulfone) 聚苯砜PS Polystyrene 聚苯乙烯PSU Polysulfone 聚砜PTFE Polytetrafluoroethylene 聚四氟乙烯PU(或PUR)Polyurethane 聚氨酯PV AL Poly(vinyl alcohol) 聚乙烯醇PVC Poly(vinyl chloride) 聚氯乙烯PVCC chlorinated poly(vinyl chloride)(*CPVC) 氯化聚氯乙烯RP reinforced plastics 增强塑料RTP reinforced thermoplastics 增强热塑性塑料S/AN styrene-acryonitrile copolymer 苯乙烯/丙烯腈共聚物SBS styrene-butadiene block copolymer 苯乙烯/丁二烯嵌段共聚物SMC sheet molding compound 片状模塑料S/MS styrene-α-methylstyrene copolymer 苯乙烯/α-甲基苯乙烯共聚物TMC thick molding compound 厚片模塑料TPE thermoplastic elastomer 热塑性弹性体TPU thermoplastic urethanes 热塑性聚氨酯PVDC Poly(vinylidene chloride) 聚(偏二氯乙烯)PVDF Poly(vinylidene fluoride) 聚(偏二氟乙烯)SAN Styrene-acrylonitrile plastic 苯乙烯/丙烯腈共聚物SB Styrene-butadiene plastic 苯乙烯/丁二烯共聚物Si Silicone plastics 有机硅塑料SMS Styrene/alpha-methylstyrene plastic 苯乙烯/α-甲基苯乙烯共聚物TPE Thermoplastic elastomer 热塑性弹性体UF Urea-formaldehyde resin 脲甲醛树脂UHMWPE Ultra-high molecular weight PE 超高分子量聚乙烯UP Unsaturated polyester 不饱和聚酯缩写代号英文全称中文全称别名ABS Acrylonitrile-butadiene-styrene 丙烯腈/丁二烯/苯乙烯共聚物ABS树脂AES Acrylonitrile-ethylene-styrene 丙烯腈/乙烯/苯乙烯共聚物AES树脂AS Acrylonitrile-styrene resin 丙烯腈/苯乙烯共聚物AS树脂CN Cellulose nitrate 硝酸纤维素赛璐璐EPM Ethylene-propylene polymer 乙烯/丙烯共聚物乙丙树脂EPS Expanded polystyrene 可发性聚苯乙烯发泡聚苯乙烯EVA Ethylene/vinyl acetate 乙烯/醋酸乙烯共聚物EV A树脂GPPS Generral polystyrene 通用聚苯乙烯透明聚苯乙烯HDPE High-density polyethylene plastics 高密度聚乙烯低压聚乙烯HIPS High impact polystyrene 高抗冲聚苯乙烯改性聚苯乙烯K树脂Styrene- butadiene 苯乙烯/丁二烯共聚物K胶LCP Liquid crystal polymer 液晶聚合物LDPE Low-density polyethylene plastics 低密度聚乙烯高压聚乙烯LLDPE Linear low-density polyethylene 线型低密聚乙烯线型高压聚乙烯MF Melamine-formaldehyde resin 密胺-甲醛树脂密胺塑料PA Polyamide (nylon) 聚酰胺尼龙、锦纶PAI Polyamide-imide 聚酰胺-酰亚胺PBT Poly(butylene terephthalate) 聚对苯二酸丁二酯聚酯PC Polycarbonate 聚碳酸酯PE Polyethylene 聚乙烯PEI Poly(etherimide) 聚醚酰亚胺PES Poly(ether sulfone) 聚醚砜聚苯醚砜PET Poly(ethylene terephthalate) 聚对苯二甲酸乙二酯涤纶(线型)树脂PF Phenol-formaldehyde resin 酚醛树脂电木粉、胶木粉PI Polyimide 聚酰亚胺PMMA Poly(methyl methacrylate) 聚甲基丙烯酸甲酯有机玻璃POM "Polyoxymethylene, polyacetal" 聚甲醛PP Polypropylene 聚丙烯PP-R Polypropylene randon coplymer 无规共聚聚丙烯PPO Poly(phenylene oxide) deprecated 聚苯醚聚苯撑氧PPS Poly(phenylene sulfide) 聚苯硫醚聚次苯基硫醚PS Polystyrene 聚苯乙烯PSU Polysulfone 聚砜PTFE(F4)Polytetrafluoroethylene 聚四氟乙烯四氟、塑料王PUR Polyurethane 聚氨酯聚氨基甲酸酯PU Polyurethane 聚氨酯聚氨基甲酸乙酯PVC Poly(vinyl chloride) 聚氯乙烯SAN Styrene-acrylonitrile plastic 苯乙烯/丙烯腈共聚物SAN树脂TPE Thermoplastic elastomer 热塑性弹性体UF Urea-formaldehyde resin 脲甲醛树脂电玉粉UHMWPE Ultra-high molecular weight PE 超高分子量聚乙烯。

SPECIFICATIONSElkay® Polymer 3-1/2" Disposer Flange with Removable BasketStrainer and Rubber StopperModel(s) LKQD35In keeping with our policy of continuing product improvement, Elkay reserves the right to change product specifications without notice. Please visit for the most current version of Elkay product specification sheets. This specification describes an Elkay product with design, quality, and functional benefits to the user. When making a comparison of other producers’ offerings, be certain these features are not overlooked.Elkay REV 12162023 1-800-476-4106 | ******************© 2023 Page 1 LKQD35 Patent /patents LKQD35_spec.pdfPRODUCT SPECIFICATIONSElkay® Polymer 3-1/2" Disposer Flange with Removable Basket Strainer and Rubber Stopper. Overall dimensions are 4-1/2" x 4-1/2" x 2-1/8". Made of Polymer.your Elkay Quartz Classic® or Quartz Luxe® sink∙ POLYMER CONSTRUCTION: Material is fully infused withcolor and will not chip or scratch off from daily use.∙ BASKET STRAINER AND STOPPER: Strainer catches foodand waste from going down the drain. Use stopper to fill sink with water for washing and soaking.∙ CORROSION RESISTANT: Constructed of high-qualitymaterial to resist rust and stains, keeping drain looking greatfor years to come.∙ DISPOSAL READY: Designed for garbage disposals thataccommodate 4-1/2" flange or select InSinkErator disposers. ∙ EASY CLEANING: Wash by hand with a mild detergent andsoft cloth; rinse.A Century of Tradition and Quality.For more than 100 years, Elkay has been making innovativeproducts and providing exceptional customer care. We take pride in offering plumbing products that make life easier, inspire change and leave the world a better place.Product Compliance: ASME A112.18.2/CSA B125.2Drains are listed by IAPMO ® as meeting the applicable requirements of the Uniform Plumbing Code ®, International Plumbing Code ®, and National Plumbing Code of Canada.Clean and Care Manual (PDF)Installation Instructions (PDF) - 1000003753 Warranty (PDF)PART:________________________________QTY: _____________ PROJECT:______________________________________________ CONTACT:______________________________________________ DATE:__________________________________________________ NOTES:_________________________________________________APPROVAL:_____________________________________________。

e10p 分子量e10p是一种聚醚酯类的高分子化合物,具有许多优异的特性和广泛的应用领域。

本文将以简体中文为主要语言,详细介绍e10p的分子量及其相关内容。

首先,我们来了解一下e10p的分子量。

e10p是一种对聚醚酯类的命名,其中的“e”代表乙醇酸(ethylene glycol),“10”代表辛醇酸(octanol),而“p”则代表聚合物(polymer)。

e10p的聚合物结构如下:-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-CH2-CH2-O-这是由乙醇酸和辛醇酸按照一定比例聚合得到的高分子聚合物。

由于其分子链中每隔10个单元就会出现一个辛醇酸单元,因此得名e10p。

e10p的分子量一般指的是其相对分子质量,用Dalton(Da)为单位表示。

相对分子质量是化学物质中所有原子质量的总和。

由于e10p 的分子结构较为复杂,其中既包含了乙醇酸的基团,又包含了辛醇酸的基团,因此计算其分子量需要考虑这两种基团的相对分子质量。

乙醇酸的相对分子质量是62.07 Da,而辛醇酸的相对分子质量是130.23 Da。

根据e10p分子链中每隔10个单元就会出现一个辛醇酸单元的规律,我们可以通过对乙醇酸和辛醇酸的相对分子质量进行加权求和,来计算e10p的平均分子量。

e10p 分子量1. 什么是分子量?分子量是指一个分子中所有原子质量的总和。

它是化学中一个重要的概念,用来描述物质的质量和化学反应的计算。

2. 如何计算分子量?计算分子量需要知道每个原子的相对原子质量(也称为相对原子质量或相对分子质量),然后将它们相加。

相对原子质量可以从元素周期表上找到。

例如,我们来计算一下水(H2O)的分子量:•氢原子(H)的相对原子质量为1•氧原子(O)的相对原子质量为16因此,水(H2O)的分子量为:2(1) + 16 = 183. e10p 是什么?e10p 是一种聚合物,也被称为环氧树脂。

它由环氧基团和酚基团组成,具有优异的物理性能和化学性能。

e10p 的全名是 Epoxy-10-polymer。

4. e10p 分子结构e10p 的分子结构由多个单体组成,其中包含环氧基团和酚基团。

5. e10p 分子量的计算要计算 e10p 的分子量,我们需要知道每个单体的相对原子质量。

假设环氧基团的相对原子质量为 A,酚基团的相对原子质量为 B。

e10p 的分子量可以通过以下公式计算:分子量 = nA + mB其中,n 和 m 是环氧基团和酚基团在 e10p 分子中的数量。

6. e10p 分子量的应用e10p 分子量的准确计算对于研究和生产中的许多方面都是至关重要的。

它可以用于以下方面:a) 物性研究通过准确计算 e10p 的分子量,可以预测其物理性质,例如密度、粘度和热膨胀系数等。

这些信息对于材料设计和工程应用非常重要。

b) 化学反应在化学反应中,需要知道反应物和产物的分子量以进行配比和计算摩尔比。

e10p 的分子量可以帮助确定所需反应物的数量,并优化反应条件。

c) 质控检测在生产过程中,需要对 e10p 进行质控检测以确保产品质量。

通过测量 e10p 的分子量,可以判断产品是否符合规格要求,以及是否存在杂质或变异。

7. 总结e10p 分子量是指 e10p 分子中所有原子质量的总和。

高分子聚合物名词解释高分子聚合物(Polymer)是由大量重复单元(单体)通过化学键连接而成的大分子化合物。

这些重复单元可以是相同的或不同的,它们通过聚合反应(Polymerization)形成长链结构。

高分子聚合物在自然界和人类社会中无处不在,具有重要的应用价值。

以下是一些与高分子聚合物相关的名词解释。

1.单体(Monomer):单体是高分子聚合物的构成单元,它们可以是简单的有机分子,如乙烯、丙烯、苯乙烯等,或者是更复杂的分子。

在聚合反应中,单体分子会失去一部分原子或基团,与其他单体分子形成共价键。

2.聚合反应(Polymerization):聚合反应是指将单体分子转化为高分子聚合物的过程。

这个过程可以是加成聚合(Addition Polymerization),也可以是缩合聚合(Con densation Polymerization)。

3.链增长(Chain Growth):在聚合反应中,随着单体分子不断地加入到正在形成的聚合物链中,聚合物链的长度不断增加,这个过程称为链增长。

4.聚合物链(Polymer Chain):由单体单元通过共价键连接而成的长链结构称为聚合物链。

这些链可以是线性的、分支的或交联的。

5.高分子(Polymer):由大量单体分子通过聚合反应形成的大分子化合物称为高分子。

高分子可以是天然存在的,如蛋白质、淀粉、天然橡胶,也可以是人工合成的,如聚乙烯、聚丙烯、聚苯乙烯等。

6.聚合度(Degree of Polymerization):聚合度是指高分子聚合物中单体单元的重复次数,也就是聚合物链的长度。

7.聚合物网络(Polymer Network):当高分子链通过化学键或物理相互作用形成三维网络结构时,称为聚合物网络。

这种结构通常具有很高的强度和弹性。

8.热塑性聚合物(Thermoplastic Polymer):热塑性聚合物是指那些在加热时可以软化并流动,冷却后又能硬化的聚合物。

聚合物英缩写、全名、中文名对照表英缩写英全名中文名AAS Acrylonitrile-Bcry ate-styrene opolymer 丙烯腈一丙烯酸脂一苯乙烯共聚物ABS Acrylonitrile-butadiene-styrene 丙烯腈一丁二烯丙烯一苯乙烯共聚物ALK Alkyd resin 醇酸树脂AMMA Acrylonitrile-methylmethacrylate copolymer 丙烯腈一甲基丙烯酸甲脂共聚物AMS Alpha methyl styrene a甲基苯乙烯AS Acrylonitrile-styrene copolymer(see SAN) 丙烯腈一苯乙烯共聚物ASA Acrylonitrile styrene-acrylate copolymer(AAS) 丙烯腈一苯乙烯一丙烯酸脂共聚物BMC Bulk moulding compound 预制整体模塑料CA Cellulose acetate 乙酸纤维素CAB Cellulose acetate butyrate 乙酸一丁酸纤维素CAP Cellulose acetate propionate 醋酸一丙酸纤维素CF Casein formaldehyde resin 甲酚一甲醛树脂CFE Polychlorotrfluoroethylene(see PCTFE) 聚三氯氧乙烯CM Chlorinated polyethylene(see CPE) 氯化聚乙烯CMC Carboxymethyl cellulose 碳甲基纤维素CN Cellulose nitrate 酸纤维素CN Cellulose nitrate 酸纤维素COPE Polyether ester elastomer 聚醚脂弹性体CP Cellulose propionate(CAP) 丙酸纤维素CPE Chlorinated polyethylene(PE-C) 氯化聚乙烯CPVC Chlorinated polyvinyl Chloride(PVC-C) 氯化聚氯乙烯CS Casein plastics 酪素塑料CSM &cspr Chorosulfonated polyethylene 然化聚乙烯CTA Cellulose triacetate 三乙酸纤维素DMC Dough moulding tompound 圈状模塑料E/P Ethylene propylene copolymer 乙烯一丙烯共聚物CA-MPR Elastomer alloy melt processable rubber 弹性体合金一可熔融成型橡胶EA-TPV Elastomer alloy thermoplastic vulcanizate 弹性体合金一热塑性硫化料EC Ethylene cellulose 乙基纤维素EEA Ethylene ethylacrylate copolymer 乙烯一丙烯酸乙酯共聚物EP Epoxide or epoxy(cured) 环氧树脂EPDM Ethylene propylene diene terpolymer 乙丙三元共聚物EPS Expandable polystyrene 可发性聚苯乙烯ETFE Ethylene/tetrafluoroethylene 乙烯一四氟乙烯共聚物EV A Ethylene vinyl accetate copolymer 乙烯一乙酸乙烯酯共聚物EV AL/EVOH Ethylene vinyl alcohol copolymer 乙烯一乙烯醇共聚物FEP Fluorinated ethylene propylene(TFE-HEP) 四氟乙烯一六氟丙烯共聚物CPMC Granular polyester moulding compound 粒状聚酯模塑料HDPE High density ployethylene(PE-HD) 高密度聚乙烯HDPE High density ployethylene(PE-HD) 高密度聚乙烯HIPS High impact polystyrene(TPS or IPS) 高抗冲聚苯乙烯HMWPE High molecular weight polyethylene 高分子量聚乙烯LCP Liquid crystal polymer 液晶聚合物LDPE Low Density polyethylene(PE-LD) 低密度聚乙烯LLDPE Linear low density polyethylene 线型低密度聚乙烯MBS Methyl methacrylate-butadiem-styrene copolymer 甲基丙烯酸甲酯一丁二烯一苯乙烯共聚物MC Methyl cellutose 甲基纤维素MDPE Medium density polyethylene(PE MD) 中密度聚乙烯MF Melamine formaldehyde 三聚氰胺一甲醛树脂MPF Melamine phenol formaldehyde resin 三聚氰胺一酚甲醛树脂NC Nitroncellulose 硝基纤维素PA Polyamide or nylon 聚酰胺(尼龙)PA6 Polyamide 6 or nylon 6 尼龙6PA11 Polyamide 11 or nylon 11 尼龙11PA12 Polyamide 12 or nylon 12 尼龙12PA46 Polyamide 46 or nylon 46 尼龙46PA66 Polyamide 66 or nylon 66 尼龙66PA610 Polyamide 610 or nylon 610 尼龙610PAA Polyacrylic acid 聚丙烯酸PAA6 Polyaryl amide or,poly-m-xylene-adipamide(PA MXD6) 鄯减0?PAN Polyacrylonitrile 聚丙烯腈PAN Polyacrylonitrile 聚丙烯腈PB Polybutene-1 聚丁烯-1PBI Polybenzimidazole 聚苯并咪唑PBT Polybutylene terephthalate 聚对苯二甲酸丁二醇酯PC Polycarbonate 聚碳酸脂(防弹胶)PCTFE Polychlorotrifluorethylene 聚三氟氯乙烯PDAP Polydiallyl phthalate 聚鄰苯二酸二烯丙酯PE Polyethylene 聚乙烯PEBA Polyether block amide 酯一酰嵌段共聚物PEC Chorinated polyethlene (see CPE) 氯化聚乙烯PEEK Polyether ether ketone 衙淹?PEEL Polyether ester(YPBO) 醚脂PEI Polyether imide 聚醚酰亚胶PEK Polyether ketone 醚酮PEKK Polyethylene ketone ketone 淹 ?PEOX Polyetylene(oxlde) 聚氧化乙烯PES Polyether sulphone 聚醚砜PET Polyethylene terephthalate 聚对苯二甲酸乙二醇酯PETP (see PET)PF Phenol formaldehyde resin 酚醛树脂PI Polyimide 聚酰胺PMC Polyester moulding compound 聚酯模塑料PMCA Polymethy α-chloacrylate 聚α--氯化丙烯酸甲酯PMCA Pol ymethy α-chloacrylate 聚α--氯化丙烯酸甲酯PMI Polymethacrylimide 聚甲基丙烯酰亚胺PMMA Polymethyl methacrylate(acrylic) 聚甲基丙烯酸甲酯PMMA-T Toughened acrylic 增炀~ 丙烯酸酯PO Polyolefine 聚烯烃POM Polyoxymethylene or,acetal or polyformaldehyde 聚甲醛POM-CO Acetal copolymer 聚甲醛共聚物POM-H Acetal homopolymer 聚甲醛均聚物PP polypropylene 聚丙烯PPC Chlorinated polypropylene 氯化聚丙烯PPE Polyphenylene ether(ss PPO) 聚苯醚PPO Polyphenylene oxide-usually modified 聚苯醚PPOX Polypropylene oxide 聚氧化丙烯PPS Polyphenylene sulphide 聚苯硫醚PPSU Polyethylene sulfone 苯砜PPVC Plasticised polyvinyl chloride(PVC-P) 增塑聚氯乙烯PS Polystyrene(GPPS) 聚苯乙烯PSU Polysulphone 聚砜树脂PTFE Polytetyafluoroethylene 聚四氟乙烯PU Hard polyurethane elastomer 硬聚氨脂弹性体PUR Polyurethane 聚氨脂PV AC Polyvinylacetate 聚乙酸乙烯脂PV AL Polyvinylalcohol 聚乙烯醇PV AL Polyvinylalcohol 聚乙烯醇PVB Polyvinylbutyral 聚乙烯醇缩丁醛PVC Polyvinyl chloride 聚氯乙烯PVCC Chlorinated polyvinyl chloride 氯化聚氯乙烯PVDC Polyvinylidene chloride 聚偏二氯乙烯PVDF Polyvinylidene fluoride 聚偏二氟乙烯PVF Polyvinyl fluorde 聚氟乙烯PVFM Polyvinylformal 聚乙烯醇缩甲醛PVK Polyvinyl carbazole 聚乙烯基咔唑PVP Polyvinyl pyrrolidone 聚乙烯┩橥?SAN Styrene acrylonitrile copolymer 苯乙烯一丙烯腈共聚物(透明大力膠)SBS Styrene butadiene styrene block copolymer 苯乙烯一丁二一苯乙烯嵌共聚物SEBS Styrene butadiene styrene block copolymer(saturated) 苯乙烯一丁二烯一苯乙嵌共聚物(胞和)SI Silicone 聚硅氧烷SMA Styrene_maleic anhydride copolymer 苯乙烯一马来酐共聚物SMC Sheet moulding compound 片状摸塑料SMS Styrene_methylstyrene copolymer 苯乙烯一甲基苯乙共聚物TP-EE Thermoplastic elastomer-either ester 醚酯类热塑性弹性体TP-EPDM Thermoplastic elastomer-based on EPDM 三元乙 鹉z类热塑性弹性体TP-EV A Thermoplastic elastomer-baged on EV A 乙烯乙酸酯共聚物类热塑性弹性体TP-NBR Thermoplastic elastomer-based on NBR ‰嫦鹉z类热塑性弹性体TPE Thermoplastic elastomer rubber 热塑性弹性体TPE Thermoplastic elastomer rubber 热塑性弹性体TPO Thermoplastic polyolefin 热塑性聚烯烃TPO-XL Thermoplastic polyolefin rubber-crosslinked(rubber) 交联热塑跃巯┨ ?膠TPR Thermoplastic rubber(etaslomer) 热塑韵鹉zTPU Thermoplastic polyurethance 热塑性聚氧脂TPV Thermoplastic elastomer or rubber-crosslinked(rubber) 交联热塑性弹性体或橡膠UF Urea formaldehyde 脲醛树脂UHMWPE Ultrahigh molecular weight polyethylene 超高分子量聚乙烯UP Unseturated polyester resin 不胞和聚脂树脂UPVC Unplasticsed polychloride 末增塑聚氧乙烯VC/E Vinylchloride ethylene copolymer 氯乙烯一乙烯共聚物VC/E/MA Vinylchloride ethylene maleic acid copolymer 氯乙烯一乙烯一马来酸共聚物VC/E/V AC 氯乙烯一乙烯一乙酸乙烯酯共聚物VC/MA Vinylchloride maleic acid copolymer 氯乙烯一马来酸共聚物VC/OA Vinylchloride octylacrylate copolymer 氯乙烯一丙烯酸辛酯共聚物VC/P Vinylchloride propylene copolymer 氯乙烯一丙烯共聚物VC/V AC Vinylchloride vinylacetate copolymer 氯乙烯一乙酸乙烯酯共聚物VC/VDC Vinylchloride vinylidene chloride copolymer 氯乙烯一偏氯乙烯共聚物VE Vinyl ester resing 乙烯基酯树脂VLDPE very low density polyethylene 極低密度聚乙烯VC/E/MA Vinylchloride ethylene maleic acid copolymer 氯乙烯一乙烯一马来酸共聚。

e-Polymers 2015; 15(4): 271–278*Corresponding author: Yueqin Yu, State Key Laboratory Base of Eco-chemical Engineering, College of Chemistry and Molecular Engineering, Qingdao University of Science and Technology, Qingdao 266042, P. R. China, Fax: +86 532 84023927, e-mail: qustyu@Jie Wu, Yanmei Zhou, Yang Meng, Jiaxing Zhang, Qingbing Liu, Qimeng Cao: State Key Laboratory Base of Eco-chemical Engineering, College of Chemistry and Molecular Engineering, Qingdao University of Science and Technology, Qingdao 266042, P. R. ChinaJie Wu, Yanmei Zhou, Yang Meng, Jiaxing Zhang, Qingbing Liu, Qimeng Cao and Yueqin Yu*Synthesis and properties of sodium alginate/poly(acrylic acid) double-network superabsorbentDOI 10.1515/epoly-2015-0060Received March 13, 2015; accepted June 3, 2015Abstract: A tough double-network (DN) superabsorbent was synthesized by a two-step method using N ,N -methyl-enebisacrylamide as a covalent cross-linker for one mono-mer [acrylic acid (AA)], Ca 2+ (CaCl 2) as an ionic cross-linker for the other monomer (sodium alginate [SA]) and ammo-nium peroxodisulfate as the redox initiator. The optimized experimental conditions for the absorbency in deionized water were determined according to orthogonal experi-ments. Unlike conventional chemical cross-linked single-network superabsorbents, SA/poly(acrylic acid) (PAA) DN superabsorbents exhibit superb mechanical properties. Compared with the tensile strength of PAA-only superab-sorbents, that of SA/PAA DN superabsorbents showed an approximately 371.9% increase with increasing amount of 6 wt.% SA. We also investigated the capacity of SA/PAA DN superabsorbents to remove heavy metal ions. It was found that the addition of SA can truly increase the metal ion removal capacity of the PAA superabsorbents and that the affinity order was Pb 2+>Z n 2+.Keywords: double network; heavy metal ion removal; sodium alginate; superabsorbent; superb mechanical property.1 IntroductionSuperabsorbents can absorb extremely large amounts of water relative to their own mass in a short time. They are usually formed from three-dimensional cross-linkedpolymer networks of flexible chains (1). Superabsorbents can retain the absorbed water even under some pres-sure, so they are widely used in health, agriculture and horticulture applications (2, 3) owing to their excellent characteristics since the first superabsorbent polymer was reported by the US Department of Agriculture in 1976 (4). Great efforts have been made to modify their swell-ing ability, swelling strength and swelling rate in all areas of their application over the past decades (5–7). In our previous work (8, 9), we reported the synthesis of natu-ral-based superabsorbent, the grafting polymerization of hydrophilic (acrylic acid and acrylamide) monomers onto chitosan, and a biocompatible and biodegradable superabsorbent, poly(maleic anhydride-co-acrylic acid) (P(MA-co-AA)) with N -maleoyl chitosan as a cross-linker, to try to solve the environmental compatibility issues of superabsorbents. But the application field of superabsor-bents is somewhat strictly limited because of their poor mechanical properties (10). Most superabsorbents made from synthetic polymers, such as polyacrylamide and polyacrylate, have outstanding swelling properties, but have low mechanical properties. Intense efforts have been devoted to synthesizing superabsorbents with improved mechanical properties (11–19). Recently, double-network (DN) superabsorbents with high mechanical strength, in which a neutral polymer network with relatively high molecular mass has been incorporated within a swollen heterogeneous polyelectrolyte network (20–23), have shown major improvements, and a series of natural and synthetic DN superabsorbents with excellent properties have been designed.Alginate, an anionic polysaccharide, was chosen as a monomer for this study because it has attractive proper-ties, such as non-toxicity, high swelling ability, and sta-bility over a range of pH-values. Alginate is composed of d-mannuronic acid (M unit) and l-guluronic acid (G unit) irregularly assembled in MM, GG and MG blocks along the chain. The proportion of M and G residues and their mac-romolecular conformation determine the physical proper-ties and affinity of the alginate for heavy metals (24). In an aqueous solution, the G blocks in different alginate chains form ionic cross-links through divalent cations (e.g. Ca 2+, Ba 2+, etc.), resulting in a network in water – an alginate hydrogel (18, 25–27).272 J. Wu et al.: SA/PAA double-network superabsorbents In the present study, we developed a superabsorbent from polymers forming covalently and ionically cross-linked networks. In the superabsorbent, the poly(acrylic acid) chain forms a network by covalent cross-links and the alginate chain forms a network by ionic cross-links of the G unit through Ca 2+. The mechanical properties of the sodium alginate/poly(acrylic acid) (SA/PAA) DN supera-bsorbents were greatly enhanced compared with those of the PAA single-network superabsorbents. The effects of composition, such as SA, ionic cross-linker (Ca 2+) and solid content, on their mechanical properties were inves-tigated. On the basis of the mechanical principle, the mechanical changes in the network were thereby dis-cussed. The Taguchi method (28) was used to optimally synthesize swelling superabsorbents, which provided a simple, efficient and systematic method to obtain the opti-mized conditions. We also described the removal of Zn 2+ and Pb 2+ ions from an aqueous solution by the superab-sorbents. Various parameters influencing the removal of heavy metal ions, such as SA content, treatment time with the solution and initial pH of the solution, were investi-gated in detail.2 Experimental sections2.1 MaterialsSA powder was bought from Qingdao Bright Moon Seaweed Group (Qingdao, Shandong, China). N ,N ′-Methylenebisacrylamide (BIS), acrylic acid (AA), ammo-nium peroxodisulfate (AP), calcium chloride (CaCl 2), zinc nitrate [Zn(NO 3)2], lead nitrate [Pb(NO 3)2], nitrate acid (HNO 3), ethylenediaminetetraacetic acid disodium salt (disodium-EDTA), ammonia water, zinc oxide benchmark reagents (ZnO), hexamethylene tetramine and xylenol orange indicator were purchased from Shanghai Fine Chemical Co. Ltd. (Shanghai, China) and were of analyti-cal grade and used as received without purification. The deionized water used for the experiment was obtained in our local laboratory.2.2 Polymerization procedureThe PAA superabsorbent was prepared as shown in Scheme 1, and the three types of superabsorbents are shown in Figure 1. The procedure of the preparation of SA/PAA DN superabsorbents in water was depicted in detailas an example. Firstly, the BIS cross-linker (0.0184 g) wasScheme 1: Synthesis of the poly(acrylic acid) superabsorbents.totally dissolved in 10 ml of deionized water in a 100-ml beaker by stirring. Then the monomers, SA (0.16 g) and AA (1.75 ml), were added into the beaker, stirred continu-ously and then neutralized with sodium hydroxide solu-tion (5 mol/l, 2.04 ml). Afterwards, the redox initiation system, AP (4%, 0.18 ml), was introduced into the beaker, stirred for 2 min and then the mixture was put in a con-stant temperature water bath (80°C) for 4 h. The product was removed from the bath and then cut into a mass of tiny cubes (1 ×1 cm). The cubes were immersed in an aqueous solution of 29.9 ml 1 wt.% CaCl 2 for 12 h, result-ing in a highly homogeneous and transparent SA/PAA DN superabsorbent cross-linked by Ca 2+. The reaction product was washed with plenty of deionized water (3 ×500 ml, 24 h) and freeze-dried.Experiments were performed to determine the mechanical properties of the superabsorbents using a procedure similar to the one described previously. But the amount of every material increased by the same mul-tiple to make the synthesized superabsorbent films large enough for our experiment on the mechanical properties. After adding all the materials to deionized water and stir-ring, the mixture was cast onto a level glass plate and put in a constant temperature water bath (80°C) for 4 h. The superabsorbent film was sprayed with an aqueous solu-tion of CaCl 2, kept alone for 12 h and then dried at room temperature.2.3 Orthogonal experimentAccording to the basic principle of the synthesis of supera-bsorbents, monomer concentration, weight ratio of SA to (SA+AA), neutralization degree and cross-linker concentra-tion were determined as the key synthesis factors affecting the final properties of superabsorbents. These parametersJ. Wu et al.: SA/PAA double-network superabsorbents 273A B CFigure 1: Schematics of the SA/PAA DN superabsorbents [(A) BIS-cross-linked PAA network; (B) SA going through the PAA network in a physical way; (C) SA/PAA DN of SA cross-linked by Ca2+ and PAA)].Table 1: Orthogonal experimental table of the water absorbency of the superabsorbents.Sample Monomerconcentration (%)Weight ratio of SAto (SA+AA) (%)Neutralizationdegree (%)Cross-linkerconcentration (%)Q (g/g)RSD (%)11010503204.9 1.9 210860475.7 2.5 3106301128.9 1.6 4104402176.4 1.8 51510404205.0 2.1 6158303266.0 2.4 715660275.2 1.7 8154501171.8 2.3 92010302280.2 1.3 10208401584.6 1.7 11206504141.8 1.6 12204603216.4 1.5 132510601330.8 1.9 14258502204.2 1.4 152********.1 2.0 1625430480.3 2.2X 1146.475255.2174.525304.025X 2179.5282.625180.675184.000X 3305.75125.000280.025210.35X 4192.35161.225188.85125.7R159.275157.625105.5178.325 Q, water absorbency of the superabsorbents in deionized water (g/g).274 J. Wu et al.: SA/PAA double-network superabsorbents were varied at four levels, as shown in Table 1. An orthogo-nal array was particularly designed with the symbol of L 16. The columns corresponded to the factors specified in this study, and each column contained four levels. Each row in the array represented a trial condition with the factor levels (8), which are indicated by the numbers in the row.2.4 Water absorbency measurementThe degree of swelling was determined by a gravimetric method. The freeze-dried superabsorbent samples were weighed and immersed for 24 h in water maintained at room temperature. After reaching the swelling equilib-rium, the water on the surfaces of the samples was wiped off using filter papers and then the weight of the swollen samples was calculated again. Relative water absorbency was expressed as follows:100(-)Q W W W = [1]where W 0 and W 1 are the weight of the dry sample and the swollen sample, respectively. The Q -value, which isthe water absorbency of the superabsorbents in deion-ized water, was calculated as grams of water per gram of sample.2.5 Tensile strength and elongation at break Tensile strength (TS) and elongation at break (E ) were meas-ured with an electronic universal testing machine (model MZ-4000D, Jiangsu Mingzhu Testing Machine, China). The cross-head speed was kept constant at 500 mm/min. The unit of TS was mPa, and TS was calculated by dividing the maximum load (N) by the initial cross-sectional area (m 2) of the samples. E was measured using the following formula: E =(l max -l )/l , where l max is the change in length at the maximum load and l is the initial length.2.6 Removal of heavy metal ionsA stock solution containing Zn 2+ or Pb 2+ was prepared by dis-solving metal nitrate salts in deionized water. An SA/PAA DN superabsorbent was added to 20 ml of the stock solution (0.02 mol/l). The amount of residual metal ions in the ali-quots of the withdrawn solution was followed by chemistry titration up to 24 h. The chemistry titration was as follows.The pH (4.5) was adjusted using drops of 0.1 mol/l NaOH, 0.1 mol/l HNO 3 and a pH paper. Then two drops of 0.2 wt.% xylenol orange indicator and 20 wt.% hexamethylene tetramine was added to make the solution look stable mul-berry in color, then more 5 ml hexamethylene tetramine added to the solution. The aliquot was titrated with the standardized EDTA solution (about 0.02 mol/l) that was prepared previously until reaching the end point when the mulberry color changed to light yellow immediately.The metal ion removal capacities of the superabsor-bents were calculated as follows:i t EDTA superabsorbent (-)q V V C M =× [2]where V i is the volume (ml) of the EDTA used by the initial metal ion solution, V t is the volume (ml) of the EDTA used by the metal ion solution after the removal of the metal ions; C EDTA is the concentration (mol/l) of the EDTA solution, M superabsorbent is the weight (g) of the SA/PAA DN superabsorbent and q is the metal ion removal capacity (mmol/g superabsorbent) of the superabsorbent.3 Results and discussion3.1 Orthogonal experiment analysis An orthogonal experiment was carried out by a four- f actorand four-level test, and we set AP/AA to 0.2 wt.% and CaCl 2/SA to 18.7 wt.% in every sample. The experimen-tal layout after assigning the values of the parameters isshown in Table 1. As can be seen in the table, 16 experi-ments were carried out and the water absorbency (Q ) of the 16 samples was measured. Q -values were average values. Five samples were tested for each value, and the relative standard deviation (RSD) was calculated. X was the mean value of the water absorbency of the four superabsorbents obtained by fixing one level for one factor and changing four levels for the other three factors. R was the differ-ence between the maximum and the minimum values ofX in each column, which reflects the amplitude of varia-tion of the swelling ratio along with the change of factors. The contribution of each factor to the water absorbency of the superabsorbents was obtained as follows: cross-linker concentration >m onomer concentration >m onomerweight ratio >n eutralization degree. The optimized values of cross-linker concentration, monomer concentration, weight ratio of SA to (SA+AA), and neutralization degree of AA were 1 wt.%, 20 wt.%, 6% and 40%, respectively. Under optimal conditions, the water absorbency of thesuperabsorbents in deionized water was 584.6 g/g. The outstanding water absorbency property of the superab-sorbents can potentially extend their application in the agricultural and horticultural fields.J. Wu et al.: SA/PAA double-network superabsorbents 2753.2.2 Effect of SA contentAs shown in Table 2, the mechanical properties of the PAA and SA/PAA superabsorbents were measured. Five samples were tested for each TS and E -value, and RSD was calculated. The PAA-only superabsorbents had a TS of 1.96 mPa and an E of 332.2%. With 4 wt.% of SA, the TS of the SA/PAA superabsorbents was 2.84 mPa, which increased by approximately 44.9%. When increasing the content of SA to 6%, the corresponding results were furthered improved and the highest TS obtained was 9.25 mPa. However, TS decreased to 3.41 mPa with a further increase in SA content (8%). It was found that SA played a crucial role in improving the mechanical properties of the material. All the aforementioned results showed that the TS of the SA/PAA superabsorbents increased signifi-cantly with increasing SA content of up to 6 wt.% and then decreased with further increase in SA content.The PAA superabsorbents were weak and exhibited brittle fracture. In contrast, the SA/PAA DN superab-sorbents were very tough. It is known that a single PAA network lacks mechanical strength. The low density and the small friction between the PAA chains were both responsible for the lower mechanical strength of a single PAA network (20). The controlled addition of SA sig-nificantly enhanced the TS (2–6%), which was probably caused by the strong interaction between the polymer matrices and by the moderate density of the cross-link points and hydrogen bonds. However, the decrease in TS with 8 wt.% SA might be due to the aggregation of cross-link points with high surface energy. Therefore, the controlled amount of SA addition was essential for the synthesis of SA/PAA DN superabsorbents with desirable tensile properties.3.2.3 Effect of the ionic cross-link densityWe prepared superabsorbents with various content of CaCl 2 to study the effect of alginate chains. Five samples3.2 M echanical properties of thesuperabsorbents3.2.1 Effect of solid contentThe solid content of the superabsorbents has an important effect on the mechanical properties. Putting the supera-bsorbent films at room temperature changed the solid content as time went on. The solid content increased at a rapid rate during the first 90 h, rising from 20% to 80%. Then it tended towards stability, and the superabsor-bents exhibited brittleness because during that period the superabsorbent films were rigid, brittle and wrinkled on the surface. So the following experiments were performed when the solid content was <80%; that is, the polymers were far removed from the conditions corresponding to equilibrium swelling. In contrast, at a low level of solid content, it was difficult to perform normal mechanical testing on the PAA gels because they were too brittle and weak to be held tightly enough between the two clamps of the machine.Figure 2 shows that the mechanical properties changed greatly with increasing solid content. As shown in the figure, TS increased with increasing solid content. As the superabsorbents tended to be dried, they dwindled in size and this increased the cross-link density of the network. As a result, TS increased and E decreased. So it should be noted that all the PAA and SA/PAA DN superab-sorbents used for the mechanical tests had the same solid content.Solid content (%)T S (M P a )50100150200250300E (%)Figure 2: Effect of solid content on mechanical properties (reaction condition of the superabsorbents: monomer concentration,20 wt.%; SA/(SA+AA), 6 wt.%; neutralization degree, 40%; cross-linker concentration, 2 wt.%; AP/AA, 0.2 wt.%; CaCl 2/SA, 18.7 wt.%; polymerization temperature, 80°C; reaction time, 4 h).Table 2: Effect of SA content on the mechanical properties of the superabsorbents.SA/(SA+AA) (wt.%)TS (mPa)RSD (%)E (%)RSD (%)0 1.960.8332.2 1.72 1.910.6256.2 1.84 2.840.474.5 1.369.250.788.9 1.583.410.5104.6 1.6276 J. Wu et al.: SA/PAA double-network superabsorbentswere tested for each TS and E -value, and the RSD was cal-culated. As shown in Table 3, the TS reached its maximumvalue when CaCl 2/SA content was 18.7 wt.%, about or >9.25 mPa, a 112.2% increase compared to that of SA/PAA superabsorbents without CaCl 2. When the CaCl 2/SA content was <18.7 wt.%, the TS increased with increas-ing CaCl 2 content; In contrast, when the CaCl 2/SA content was above 18.7 wt.%, the TS decreased with increasing CaCl 2 content. The E -value showed a contrary trend withincreasing CaCl 2 content.The results showed that the addition of CaCl 2 couldimprove the mechanical properties of the material. It canbe illustrated that Ca 2+ cross-linking with the carboxylate groups of the G unit on the SA chains resulted in the highdensity of the cross-link points. But TS decreased when the CaCl 2/SA content increased to 37.3 wt% because thehigh density of cross-link points resulted in the aggrega-tion of stress points and in the cracking of the superab-sorbent materials.3.3 Removal of heavy metal ions3.3.1 Effect of SA contentFigure 3 shows the impact of SA content on metal ion removal capacity of the superabsorbents. As shown in the figure, the adsorption capacity of the superabsor-bents was found to be Pb 2+>Z n 2+. The ionic radius of Pb 2+ is bigger than that of Cu 2+, so Pb 2+ is more electro-positive. Pb 2+ ions have a stronger interaction with the superabsorbent than those of Zn 2+ owing to the stronger electrostatic interaction between Pb 2+ and the carboxy-late group (29). As seen from Figure 3, the addition of SA significantly increased the metal ion removal capacity of the superabsorbents. The carboxylate groups of the G residues of SA going through the PAA network exist in the form of -COO -, which can chelate with divalent metal ions to produce a steady complex (known as the “egg box” model), so high SA content helps increase the metal ion removal capacity.Table 3: Effect of CaCl 2 content on the mechanical properties of the superabsorbents.CaCl 2/SA (wt.%)TS (mPa)RSD (%)E (%)RSD (%)0 4.360.6115.5 1.318.79.250.888.9 1.137.3 2.420.5288.5 1.956.03.310.7272.9 1.72.102.152.202.25AB 2.30q (m m o l /l )SA/(SA+AA) (%)05101520q (m m o l /g )SA/(SA+AA) (%)Figure 3: Effect of SA content on metal ion removal capacity (reac-tion condition of the superabsorbents: monomer concentration, 15 wt.%; neutralization degree, 40%; cross-linker concentration, 1 wt.%; polymerization temperature, 80°C; reaction time, 4 h).3.3.2 Effect of treatment time with the solutionFigure 4 shows the effect of treatment time on the removal of Zn 2+ and Pb 2+ ions by the SA/PAA DN superabsorbents. As seen from the figure, the metal ion removal capacity of the superabsorbents increased rapidly during the first 2 h and then slowed down with the increase in treatment time. The removal capacities reached a saturation value within 3 h and almost no longer increased.3.3.3 Effect of initial pH of the solutionSA/PAA superabsorbents were added to the stock solution with a pH-value varying from 2 to 6, and the effect of pH on the removal of Zn 2+, Pb 2+ ions was investigated. Figure 5 shows that the higher the pH in the solution the greaterJ. Wu et al.: SA/PAA double-network superabsorbents 277carboxylate groups of the G unit occurred with increas-ing pH and the interaction between the metal ions and the c arboxylate groups in the solution was strengthened (29). A suitable pH-value (4 and 4.5) was considered to be optimal for Pb 2+ and Zn 2+, since the precipitates of lead hydroxide and zinc hydroxide were formed under the higher pH of the solution, respectively.4 ConclusionsHighly strong SA/PAA DN superabsorbents were prepared successfully based on a two-step method. The optimized synthetic conditions of the superabsorbents were deter-mined by an orthogonal experiment as follows: monomer concentration, 15 wt.%; weight ratio of SA to (SA+AA), 8%; neutralization degree of AA, 40%; and cross-linker concentration, 1 wt%. The deionized water absorbency of the superabsorbents under the optimal conditions was 584.6 g/g.With increasing amount of SA and CaCl 2, the mechan-ical properties of the superabsorbents increased and then decreased. TS attained its highest value when SA content was 6 wt.% and CaCl 2/SA content was 18.7 wt.%, a 371.9% improvement compared to that of the PAA superabsor-bents. The distinctive mechanical property of the SA/PAA DN superabsorbents can be explained in terms of the density of the cross-linkers and by the interaction between the polymer matrices. The outstanding mechani-cal properties of the superabsorbents may extend their application in more fields.Finally, SA/PAA DN superabsorbents were success-fully utilized for the removal of metal ions and the factors influencing the increased removal capacity were deter-mined as follows: increasing amount of SA, treatment time with the solution and initial pH of the solution. The order of the removal efficiency of the metal ions was Pb 2+>Z n 2+.Acknowledgments: This study was supported by the National Key Technology Support Program of China (no. 2014BAC10B01) and by the Key Scientific and Techno-logical Project of China’s Shanxi Province (no. MN2014-10).References 1. Zou XX. Superabsorbent materials. Beijing, China: ChemicalIndustry Press; 2002.2. Raju KM, Raju MP , Mohan YM. Synthesis of superabsorbent copolymers as water manageable materials. Polym Int. 2003;52:768–72.the metal ion removal capacity of the superabsorbents. Since SA chains have ionizable groups (i.e. carboxylategroups), the pH parameter plays an important role in the ion removal capacity, with different ionization degrees.When the pH-value was lowered, the non-ionized car-boxylate groups of the G unit appeared in the solution, which weakened the interaction between the carboxylate groups and the metal ions. Accordingly, ionization of the0.00.51.01.52.02.53.03.5q (m m o l /g )t (h)Figure 4: Effect of time on metal ion removal capacity [reaction con-dition of the superabsorbents: monomer concentration, 15 wt.%; weight ratio of SA to (SA+AA), 20%; neutralization degree, 40%; cross-linker concentration, 1 wt.%; polymerization temperature, 80°C; reaction time, 4 h].1.01.52.0 2.53.03.54.0 4.55.0 5.56.00.51.01.52.02.53.03.54.04.5q (m m o l /g )pHFigure 5: Effect of pH on metal ion removal capacity [reaction condi-tion of the superabsorbents: monomer concentration, 15 wt.%; weight ratio of SA to (SA+AA), 20%; neutralization degree, 40%; cross-linker concentration, 1 wt.%; polymerization temperature, 80°C; reaction time, 4 h].278 J. Wu et al.: SA/PAA double-network superabsorbents3. Shiga T, Hirose Y, Okada A, Kurauchi T. Bending of poly-(vinylalcohol)-poly(sodium acrylate) composite hydrogel in electric fields. J Appl Polym Sci. 1992;44:249–53.4. Weaver MO, Bagley EB, Fanta GF, Doane WM. Highly absorbentstarch-containing polymeric compositions. US Patent, 1976,3981100.5. Taylor NW, Fanta GF, Doane WM, Russell CR. Swelling and rheol-ogy of saponified starch-g-polyacrylonitrile copolymers. Effect of starch granule retreatment and grafted chain length. J Appl Polym Sci. 1978;22:1343–57.6. Lokhande HT, Varadarjan PV, Iyer VJ. Water-superabsorbentp olymers through gamma radiation-induced graft copolymeriza-tion of acrylonitrile on guargum. Appl Polym Sci. 1992;45:2031–6.7. Fanta GF, Burr RC, Doane WM, Russell CR. Saponified starch-g-polyacrylonitrile. Variables in the Ce+4 initiation of graft polym-erization. J Appl Polym Sci. 1982;27:2713–37.8. Yu Y, Liu L, Kong Y. Synthesis and properties of N-maleoylchitosan-cross-linked poly(acrylic acid-co-acrylamide) superab-sorbents. J Polym Environ. 2011;19:926–34.9. Yu Y, Jia F, Li S, Yan S, Leng C, Yuan K. Synthesis and swellingbehavior of superabsorbents cross-linked with N-maleoyl chi-tosan. Int J Polym Mater. 2013;62:450–4.10. Calvert P. Hydrogels for soft machines. Adv Mater. 2009;21:743–56.11. Gong JP, Katsuyama Y, Kurokawa T, Osada Y. Double-networkhydrogels with extremely high mechanical strength. Adv Mater.2003;15:1155–8.12. Huang T, Xu HG, Jiao KX. A novel hydrogel with high mechanicalstrength: a macromolecular microsphere composite hydrogel.Adv Mater. 2007;19:1622–6.13. Sakai T, Matsunaga T, Yamamoto Y, Ito C, Yoshida R, Suzuki S,Sasaki N. Design and fabrication of a high-strength hydrogelwith ideally homogeneous network structure from tetrahedron-like macromonomers. Macromolecules 2008;41:5379–84. 14. Bhattacharya SV, Sen KK, Sen SO, Banerjee S, Kaity S,Ghosh AK, Ghosh A. Synthesis and characterization ofpoly(acrylic acid)/modified bentonite superabsorbent polymer.Int J Polym Mater. 2011;60:1015–25.15. Lin WC, Fan W, Marcellan A, Hourdet D, Creton C. Large strainand fracture properties of poly(dimethylacrylamide)/silicahybrid hydrogels. Macromolecules 2010;43:2554–63.16. Wang QG, Mynar JL, Yoshida M, Lee E, Lee M, Okuro K, KinbaraK, Aida T. Highly-water-content mouldable hydrogels by mixing clay and a dendritic molecular binder. Nature 2010;463:339–43.17. Haque MA, Kurokawa T, Kamita G, Gong JP. Lamellar bilayers asreversible sacrificial bonds to toughen hydrogel: hysteresis,self-recovery, fatigue resistance, and crack blunting. Macromol-ecules 2011;44:8916–24.18. Sun JY, Zhao XH, Illeperuma WRK, Chaudhuri O, Oh KH,Mooney DJ, Vlassak JJ, Suo ZG. Highly stretchable and toughhydrogels. Nature 2012;489:133–6.19. Imran AB, Esaki K, Gotoh H, Seki T, Ito K, Sakai Y, Takeoka Y.Extremely stretchable thermosensitive hydrogels by introducing slide-ring polyrotaxane cross-linkers and ionic groups into the polymer network. Nat Commun. 2014;5:5124.20. Gong JP. Why are double network hydrogels so tough? SoftM atter2010;6:2583–90.21. Tang Q, Sun X, Li Q, Wu J, Lin J, Huang M. A simple route to high-strength hydrogel with an interpenetrating polymer network.e-Polymers 2009;9:1087–92.22. Xin H, Saricilar SZ, Brown H R, Whitten PG, Spinks GM. Effectof First network topology on the toughness of double network hydrogels. Macromolecules 2013;46:6613–20.23. Georgiev G, Dyankova K, Vassileva E, Friedrich k. Synthesis andsome mechanical properties of polysulfobetaine-polyacryla-mide double networks. e-Polymers 2006;6:690–701.24. Haug A, Myklestad S, Larsen B, Smidsrød O. Correlationbetween chemical structure and physical properties of algi-nates. Acta Chem Scand. 1967;21:768–78.25. Morris ER, Rees DA. Competitive inhibition of interchain interac-tions in polysaccharide systems. J Mol Biol. 1980;16:88–91. 26. Rees DA. Polysaccharide shape and their interactions: somerecent advances. Pure Appl Chem. 1981;53:1–14.27. Thomas AD, Erwin JJK, Jose PP, Raewyn MT. Cd(II) Speciation inalginate gels. Environ Sci Technol. 2008;42:7242–7.28. Bardajee GR, Pourjavadi A, Soleyman R, Sheikh N. Novel highlyswelling nanoporous hydrogel based on polysaccharide/protein hybrid backbone. J Polym Res. 2011;18:337–46.29. Güçlü G, Al E, Emik S, Yim TB, Özgümü S, Özyürek M. Removal ofCu2+ and Pb2+ ions from aqueous solutions by star-graft acrylic acid/montmorillonite superabsorbent nanocomposite hydro-gels. Polym Bull. 2010;65:333–46.。