PPF_Development_Guide

- 格式:pdf

- 大小:1.05 MB

- 文档页数:52

Guideline for the Admission of Dietary Supplement Ingredients to the USP–NF Monograph Development ProcessG1.12-00Background The purpose of this Guideline is to set forth the criteria that USP Expert Committee uses to determine whether or not a dietary ingredient qualifies for admission to the process for the development of a quality monograph. The Guideline establishes a Class A and Class B system that categorizes dietary ingredients according to their level of safety concern, and describes the process by which the ingredients are classified. The USP Dietary Supplements Admission Evaluations Joint Standard Setting Subcommittee (DS AE JS3) makes a determination whether or not USP should proceed with monograph development.Subsequent approval of the monograph for inclusion into the United States Pharmacopeia and National Formulary (USP–NF ) is determined by the USP Balloting Process.Selection and Prioritization of Dietary IngredientsThe initial selection and prioritization of dietary ingredients for admission into the USP-NF compendial monograph development process is based on several considerations, including but not limited to the following:1. Extent of use, based upon market sales or other factors2. Historical use3. Knowledge of chemical composition4. Existence of other pharmacopeial standards5. Evidence of benefit6. Interest from a governmental body7. Potential risks to health associated with its use.Classification SystemUSP classifies dietary ingredients as follows:Class A: Admitted to the USP-NF compendial monograph development process Ingredients for which the available evidence does not indicate a serious risk to health* or other public health concern that precludes development of a USP-NF monograph and that could be approved for inclusion in the compendia with or without a cautionary label statement**.Guideline for the Admission of Dietary Supplement Ingredients to theUSP–NF Monograph Development ProcessG1.12-00Class B: Not admitted into the compendial monograph development process Ingredients for which the available evidence indicates a serious risk to health* or other public health concern that precludes development of a monograph for inclusion in the USP-NF .*Serious risk to health means that the use of the Ingredients could:(A) result in: (i) death; (ii) a life–threatening experience; (iii) inpatient hospitalization; (iv) a persistent orsignificant disability or incapacity; or (v) a congenital anomaly or birth defect; or (B) require, based on reasonable medical judgment, a medical or surgical intervention to prevent an outcome described under subparagraph (A).** Cautionary Label StatementIn certain cases the DSAE JS3 may recommend that monograph development proceed under Class A only if a cautionary label statement is included in the monograph. In such cases the monograph will not proceed to ballot until after the DSAE JS3 has had the opportunity to review the draft monograph to ensure that a suitable cautionary label statement is included. Examples of cases of approved monographs where cautionary label statements have been included are provided below. ArticleCautionary label statement that was included Black Cohosh Dosage forms prepared with this article should bear the followingstatement: Discontinue use and consult a healthcare practitioner ifyou have a liver disorder or develop symptoms of liver trouble,such as abdominal pain, dark urine, or jaundice.St. John’s Wort The label bears a statement indicating that “Rare cases of allergicreactions and photosensitivity have been reported with the use ofSt. John’s Wort. St. John’s Wort interacts with numerousmedications. Check with your healthcare provider before using.”Salix Species BarkThe label bears a statement indicating “Not for use in children,women who are pregnant or nursing, or by persons with knownsensitivity to aspirin”.Guideline for the Admission of Dietary Supplement Ingredients to theUSP–NF Monograph Development ProcessG1.12-00Comprehensive USP Admission EvaluationFor comprehensive USP admission evaluation, USP researches and evaluates diverse sources of safety information to determine the classification for dietary ingredients. Some articles may be exempt from comprehensive evaluation as outlined under “Criteria for Exemption from Comprehensive USP Admission Evaluation” below .The sources of information evaluated by USP include, but are not limited to the following:1. Human data: Although dietary ingredients are not required to undergo controlled clinicaltrials before they are marketed,1 the safety profile of an ingredient may be evaluatedusing the following information:a) Clinical safety studies: Sufficiently powered prospective observational studies,clinical trials, dose-escalation studies, systematic reviews, or retrospective meta-analysis of clinical studies provide useful information to evaluate the safety of aningredient.b) Other clinical studies: Although clinical studies may be limited by the small numberof study participants, observation of adverse events under controlled studyconditions generates useful safety information on the ingredient. Information fromrandomized, placebo-controlled, double-blind clinical studies, are valuable.c) Postmarket surveillance: Premarket safety studies sometimes are limited by thenumber of study subjects. When products are in wide use, detection of adverseevents provides a strong surrogate for safety monitoring in the general populationand in consumers who have chronic conditions. Postmarket surveillance alsoprovides valuable information about an ingredient’s safety profile in vulnerablepopulations, e.g., in pregnancy, lactation, the elderly, children, or prescriptionmedication users. Epidemiological reports might be helpful if the dietary ingredients are widely used as a traditional preparation.d) Adverse events: An adverse event associated with a supplement may be reportedby a healthcare practitioner (HCP) in a peer-reviewed journal or may be reportedby the HCP or a consumer to the local Poison Control Center or the United States1 Dietary Supplement Health and Education Act 1994.Available athttps:///About/DSHEA_Wording.aspx Accessed February 09, 2016Guideline for the Admission of Dietary Supplement Ingredients to theUSP–NF Monograph Development ProcessG1.12-00(U.S.) Food and Drug Administration’s (FDA) primary adverse event reportingportal, MedWatch. Since December 22, 2007, dietary supplement manufacturersand distributors are required to submit serious adverse event reports to FDAMedWatch. Valuable information about adverse events also is available from other international regulatory agencies such as Health Canada, the British Medicines and Healthcare Products Regulatory Agency (MHRA), and the Australian TherapeuticGoods Administration (TGA).e) Supplement interactions: Interactions with prescription drugs have significant safetyimplications because of their effects on bioavailability or induction/inhibition ofmetabolizing enzymes. Such interactions may lead to synergism or antagonism ofintended effects.f) Data from other relevant products: When long term safety information is not welldocumented, particularly for new dietary ingredients (NDIs) (ingredients introduced into the market after Oct. 15, 1994), any additional publicly available informationmay be useful in establishing the ingredient’s safety profile. Knowledge aboutchemical constituents may be used during investigations of equivalency amongcommercial dietary supplement products and their traditional counterparts. 2. Non-human data (pharmacological data): Carefully planned and justified in vivo animalstudies and in vitro experiments that investigate potential risks to human health.Information from animal experiments may bridge the knowledge gap regarding the safety of dietary supplement use.a) Reproductive toxicity: Animal experimental data regarding genotoxicity,reproductive and developmental toxicity, and carcinogenicity provide valuablesafety information for the use of the dietary ingredient by pregnant and lactatingmothers. In vitro studies such as the Ames test provide insights into likelygenotoxicity.b) Studies in experimental animals: Studies may provide insights into the mechanismof action of a substance, its purported efficacy, and its effect(s) on target organs. In vitro cell culture studies may provide information about effects at the cellular leveland molecular mediators involved in the observed effects.Guideline for the Admission of Dietary Supplement Ingredients to theUSP–NF Monograph Development ProcessG1.12-00c) Pharmacokinetics: Information about the absorption kinetics, bioavailability,accumulation in vital organs, plasma maximum concentration (C max ), time for half-life (t 1/2), and elimination kinetics, or marker compound kinetics identifies the dose or duration mediated toxicity of a dietary ingredient.d) Safety margin: Information from animal studies regarding the effective dose(ED 50), lethal dose (LD 50), no observed adverse effect level (NOAEL), and lowest observed adverse effect level (LOAEL) are used to determine the relative safetymargin in the use of the dietary ingredient.e) Presence of toxic constituents (or structurally related compounds with establishedtoxicity): Knowledge of chemical components of a dietary ingredient aids in safetyevaluation by identifying potentially toxic constituents, components containingtoxicophores, or constituents known to mimic or modulate endogenousintermediates. Structure-based computational prediction models and in silicoanalysis may be used if available, to make better determinations on toxicity whenaddressing uncertainty with safety data (such as equivocal evidence or missinginformation) from conventional in vivo or in vitro studies.3. Contemporaneous extent of use globally and in the U.S., including patterns of misuse,abuse, and fluctuations of use: Information collected from dietary supplement trade publications and regulatory bulletins helps generate signals of value. Informationregarding the extent of use (global market information) provides insights into the safety profile.4. Historical use: Traditional use documented in authoritative texts—including the context ofuse, dose, duration of use, method of preparation, and traditional cautions—provides valuable information about deviations of the commercial preparations from the traditional use, if any, and unexpected adverse effects. Traditional medical systems such asAyurveda and Traditional Chinese Medicine provide useful information about historical use.5. Regulatory status in the U.S. and other countries:a) Regulatory actions: Information about regulatory actions (including product recallsand safety alerts) from international regulatory agencies may indicate the extent ofadverse event reports, the incidence and methods of detection ofadulteration/contamination, the regional or global nature of adverse events, anddietary supplement–prescription drug interactions.Guideline for the Admission of Dietary Supplement Ingredients to theUSP–NF Monograph Development ProcessG1.12-00b) Regulatory status: The regulation of dietary supplements in the U.S. differs fromother countries. In some European countries, dietary supplement ingredients areregulated as OTC drugs or prescription drugs, which may require registration orpre-market approval. In the U.S. these same ingredients may be regulated asdietary supplements and thus do not require pre-marketing approval by FDA unless they are NDIs. Thus, the intervention of the HCP and the consumption patterns ofthe dietary ingredients by consumers are different in the U.S. and other countries.Accordingly, the qualitative and quantitative information on the safety profileobtained from different countries provides valuable information.c) GRAS/NDI status: FDA may be notified of Generally Recognized as Safe (GRAS)status for some dietary ingredients and the intended conditions of use. GRASnotifications to FDA of dietary ingredients may provide information about availablescientific data and basis of a product’s safety. Similarly, NDI notifications to FDAprovide information about the basis for a product’s safety.6. Existence of pharmacopeial monographs in other pharmacopeias may provide criticalinformation about the standards of purity, adulterants/contaminants, dosage, and caution statements intended to ensure the safe use of dietary ingredients. Examples of such authoritative information include but are not limited to, the World Health Organization (WHO), the European Scientific Cooperative on Phytotherapy (ESCOP), the German Commission E, Indian Pharmacopeia, Pharmacopoeia of the People’s Republic of China, and Health Canada monographs.In analyzing information from the above sources for a dietary ingredient, the limitations of dietary supplement specific issues (detailed in Gardiner et al., 20082,3) are considered. Reports of serious adverse events may be analyzed with an appropriate causality algorithm (such as the WHO-UMC system for standardized case causality assessment). The “odds ratio” for a serious adverse reaction and the signal of safety concern may be estimated from the extent of use, “number needed to harm” or proportional representation ratio.Commensurate with the signal of safety concern, USP may communicate the admission evaluation and classification through publications in peer–reviewed journals, public2 Gardiner P, Sarma DN, Low Dog T, Barrett ML, Chavez ML, Ko R, Mahady GB, Marles RJ,Pellicore LS, and Giancaspro GI. 2008. The state of dietary supplement adverse event reporting in the United States. Pharmacoepidemiology and Drug Safety. 17: 962–970. 3 Dietary Supplements: A Framework for Evaluating Safety. Institute of Medicine & National Research Council; The National Academies Press: Washington, DC, 2005.Guideline for the Admission of Dietary Supplement Ingredients to theUSP–NF Monograph Development ProcessG1.12-00communications, Pharmacopeial Forum notices, USP Dietary Supplement Compendium, or other appropriate means.The AE JS3 will determine the appropriate classification based on the totality of the evidence obtained above for each of the parameters examined. Criteria for Exemption from Comprehensive USP Admission EvaluationA comprehensive literature search and review may not be necessary for dietary ingredients for which a GRAS or an NDI notification was submitted to the FDA, for review and notobjected to by the Agency. USP Admission Classification for such dietary ingredients may be based on the information from the GRAS or NDI notifications, which usually contain themajority of the information that USP assesses as described above. A comprehensive review may be performed for dietary ingredients for which a GRAS or an NDI notification does not contain sufficient information to make an admission evaluation, or where the candidatedietary ingredient for admission is not exactly the same or equivalent to the subject of the NDI or GRAS notification. The following attributes will be reviewed to determine whether an exemption from a comprehensive admission evaluation applies:1. Equivalency of the candidate dietary ingredient to the subject of the NDI or GRASnotification. To determine equivalency, information on the following attributes will be reviewed:a. Identity of the ingredient;b. Physical characteristics of the ingredient i.e., the form of the ingredient reviewedwhether liquid, powder or other, including the particle size characteristics (micro ornanoparticle); and,c. The chemical profile, including the extraction procedure and compounds present inthe ingredient.2. Daily Intake: The maximum amount of the candidate dietary ingredient recommended orsuggested for use in a dietary supplement as determined from publicly availablepublications (for example, from the NIH Office of Dietary Supplements and NationalGuideline for the Admission of Dietary Supplement Ingredients to theUSP–NF Monograph Development ProcessG1.12-00Library of Medicine Dietary Supplement Label Database (DSLD)4), should not exceed the intake level stipulated in the GRAS or NDI notification.This Guideline is intended to allow USP to evaluate safety issues depending on the particular dietary ingredient involved, the level of available safety data, and other relevantconsiderations. For example, even where a dietary ingredient is classified as Class A and is eligible for admission into the USP-NF monograph development process, there may be specific safety concerns that will require future monitoring. USP monitors safety information for all dietary ingredients for which dietary supplement monographs have been developed on an ongoing basis for possible re–evaluation of an article’s admission status.USP’s evaluation of a dietary ingredient under this Guideline is performed for the sole purpose of determining admission into the compendial monograph development process and should not be relied upon as any finding about the intrinsic safety or effectiveness of the dietary ingredient under review.This Guideline supersedes any previous guideline issued by USP on safety criteria and admission classification for dietary supplements. 4 ODS-NLM Dietary Supplement Label Database (DSLD). Available at/dsld/ (Accessed February 09, 2016).。

psfgen User’s GuideVersion1.3.3Justin Gullingsrud and Jim PhillipsSeptember14,2005Theoretical Biophysics GroupUniversity of Illinois and Beckman Institute405N.MathewsUrbana,IL618011Creating PSF Structure FilesThe psfgen structure building tool consists of a portable library of structure andfile manipulation routines with a Tcl interface.Current capabilities include•reading CHARMM topologyfiles•reading psffiles in X-PLOR/NAMD format•extracting sequence data from single segment PDBfiles•generating a full molecular structure from sequence data•applying patches to modify or link different segments•writing NAMD and VMD compatible PSF structurefiles•extracting coordinate data from PDBfiles•constructing(guessing)missing atomic coordinates•deleting selected atoms from the structure•writing NAMD and VMD compatible PDB coordinatefilesWe are currently refining the interface of psfgen and adding features to create a complete molecular building solution.We welcome your feedback on this new tool.2Ordinary Usagepsfgen is currently distributed in two forms.One form is as a standalone program implemented as a Tcl interpreter which reads commands from standard output.You may use loops,variables,etc.as you would in a VMD or NAMD script.You may use psfgen interactively,but we expect it to be run most often with a scriptfile redirected to standard input.The second form is as a Tcl package which can be imported into any Tcl application,including VMD.All the commands available to the standalone version of psfgen are available to the Tcl package;using psfgen within VMD lets you harness VMD’s powerful atom selection capability,as well as instantly view the result of your structure building scripts.Examples of using psfgen both with and without VMD are provided in this document.Generating PSF and PDBfiles for use with NAMD will typically consist of the following steps:1.Preparing separate PDBfiles containing individual segments of protein,solvent,etc.before runningpsfgen.2.Reading in the appropriate topology definitionfiles and aliasing residue and atom names found in thePDBfile to those found in the topologyfiles.This will generally include selecting a default protonation state for histidine residues.3.Generating the default structure using segment and pdb commands.4.Applying additional patches to the structure.5.Reading coordinates from the PDBfiles.6.Deleting unwanted atoms,such as overlapping water molecules.7.Guessing missing coordinates of hydrogens and other atoms.8.Writing PSF and PDBfiles for use in NAMD.22.1Preparing separate PDBfilesMany PDBfiles in the PDB databank contain multiple chains,corresponding to protein subunits,water, and other miscellaneous groups.Protein subunits are often identified by their chain ID in the PDBfile.In psfgen,each of these groups must be assigned to their own segment.This applies most strictly in the case of protein chains,each of which must be assigned to its own segment so that N-terminal and C-terminal patches can be applied.You are free to group water molecules into whatever segments you choose.Chains can be split up into their own PDBfiles using your favorite text editor and/or Unix shell com-mands,as illustrated in the BPTI example below.If you are using VMD you can also use atom selections to write pieces of the structure to separatefiles:#Split a file containing protein and water into separate segments.#Creates files named myfile_water.pdb,myfile_frag0.pdb,myfile_frag1.pdb,...#Requires VMD.mol load pdb myfile.pdbset water[atomselect top water]$water writepdb myfile_water.pdbset protein[atomselect top protein]set chains[lsort-unique[$protein get pfrag]]foreach chain$chains{set sel[atomselect top"pfrag$chain"]$sel writepdb myfile_frag${chain}.pdb}2.2Deleting unwanted atomsThe delatom command described below allows you to delete selected atoms from the structure.It’sfine to remove atoms from your structure before building the PSF and PDBfiles,but you should never edit the PSF and PDBfiles created by psfgen by hand as it will probably mess up the internal numbering in the PSFfile.Very often the atoms you want to delete are water molecules that are either too far from the solute,or else outside of the periodic box you are trying to prepare.In either case VMD atom selections can be used to select the waters you want to delete.For example:#Load a pdb and psf file into both psfgen and VMD.resetpsfreadpsf myfile.psfreadpdb myfile.pdbmol load psf myfile.psf pdb myfile.pdb#Select waters that are more than10Angstroms from the protein.set badwater1[atomselect top"name OH2and not within10of protein"]#Alternatively,select waters that are outside our periodic cell.set badwater2[atomselect top"name OH2and(x<-30or x>30or y<-30or>30or z<-30or z>30)"]#Delete the residues corresponding to the atoms we selected.foreach segid[$badwater1get segid]resid[$badwater1get resid]{delatom$segid$resid}#Have psfgen write out the new psf and pdb file(VMD’s structure and#coordinates are unmodified!).writepsf myfile_chopwater.psfwritepdb myfile_chopwater.pdb33BPTI ExampleTo actually run this demo requires•the program psfgen from any NAMD distribution,•the CHARMM topology and parameterfiles top_all22_prot.inp and par_all22_prot.inp from https:///research/amackere/research.html,and•the BPTI PDBfile6PTI.pdb available from the Protein Data Bank at /by searching for6PTI and downloading the complete structurefile in PDB format.Building the BPTI structureIn this demo,we create thefiles bpti.psf and bpti.pdb in the output directory which can then be used for a simple NAMD simulation.#File:bpti_example.tcl#Requirements:topology file top_all22_prot.inp in directory toppar#PDB file6PTI.pdb in current directory#Create working directory;remove old output filesmkdir-p outputrm-f output/6PTI_protein.pdb output/6PTI_water.pdb#(1)Split input PDB file into segments}grep-v’^HETATM’6PTI.pdb>output/6PTI_protein.pdbgrep’HOH’6PTI.pdb>output/6PTI_water.pdb#(2)Embed the psfgen commands in this scriptpsfgen<<ENDMOL#(3)Read topology filetopology toppar/top_all22_prot.inp#(4)Build protein segmentsegment BPTI{pdb output/6PTI_protein.pdb}#(5)Patch protein segmentpatch DISU BPTI:5BPTI:55patch DISU BPTI:14BPTI:38patch DISU BPTI:30BPTI:51#(6)Read protein coordinates from PDB filepdbalias atom ILE CD1CD;#formerly"alias atom..."coordpdb output/6PTI_protein.pdb BPTI#(7)Build water segmentpdbalias residue HOH TIP3;#formerly"alias residue..."segment SOLV{auto nonepdb output/6PTI_water.pdb}4#(8)Read water coordinaes from PDB filepdbalias atom HOH O OH2;#formerly"alias atom..."coordpdb output/6PTI_water.pdb SOLV#(9)Guess missing coordinatesguesscoord#(10)Write structure and coordinate fileswritepsf output/bpti.psfwritepdb output/bpti.pdb#End of psfgen commandsENDMOLStep-by-step explanation of the script:(1)Split input PDBfile into segments.6PTI.pdb is the originalfile from the Protein Data Bank.It contains a single chain of protein and some PO4and H2O HETATM records.Since each segment must have a separate inputfile,we remove all non-protein atom records using grep.If there were multiple chains we would have to split thefile by hand.Create a secondfile containing only waters.(2)Embed the psfgen commands in this script.Run the psfgen program,taking everything until “ENDMOL”as input.You may run psfgen interactively as well.Since psfgen is built on a Tcl interpreter, you may use loops,variables,etc.,but you must use$$for variables when inside a shell script.If you want, run psfgen and enter the following commands manually.(3)Read topologyfile.Read in the topology definitions for the residues we will create.This must match the parameterfile used for the simulation as well.Multiple topologyfiles may be read in since psfgen and NAMD use atom type names rather than numbers in psffiles.(4)Build protein segment.Actually build a segment,calling it BPTI and reading the sequence of residues from the stripped pdbfile created above.In addition to the pdb command,we could specify residues explicitly.Both angles and dihedrals are generated automatically unless“auto none”is added (which is required to build residues of water).The commands“first”and“last”may be used to change the default patches for the ends of the chain.The structure is built when the closing}is encountered,and some errors regarding thefirst and last residue are normal.(5)Patch protein segment.Some patch residues(those not used to begin or end a chain)are applied after the segment is built.These contain all angle and dihedral terms explicitly since they were already generated.In this case we apply the patch for a disulfide link three separate times.(6)Read protein coordinates from PDBfile.The samefile used to generate the sequence is now read to extract coordinates.In the residue ILE,the atom CD is called CD1in the pdbfile,so we use“pdbalias atom”to define the correct name.If the segment names in the pdbfile match the name we gave in the segment statement,then we don’t need to specify it again;in this case we do specify the segment,so that all atoms in the pdbfile must belong to the segment.(7)Build water segment.Build a segment for the crystal waters.The residue type for water depends on the model,so here we alias HOH to TIP3.Because CHARMM uses an additional H-H bond we must disable generation of angles and dihedrals for segments containing water.Then read the pdbfile.5(8)Read water coordinates from PDBfile.Alias the atom type for water oxygen as well and read coordinates from thefile to the segment SOLV.Hydrogen doesn’t show up in crystal structures so it is missing from this pdbfile.(9)Guessing missing coordinates.The tolopogyfile contains default internal coordinates which can be used to guess the locations of many atoms,hydrogens in particular.In the output pdbfile,the occupancy field of guessed atoms will be set to0,atoms which are known are set to1,and atoms which could not be guessed are set to-1.Some atoms are“poorly guessed”if needed bond lengths and angles were missing from the topologyfile.Similarly,waters with missing hydrogen coordinates are given a default orientation.Write structure and coordinatefiles.Now that all of the atoms and bonds have been created,we can write out the psf structurefile for the system.We also create the matching coordinate pdbfile.The psf and pdbfiles are a matched set with identical atom ordering as needed by NAMD.Using generatedfiles in NAMD.Thefiles bpti.pdb and bpti.psf can now be used with NAMD,but the initial coordinates require minimization first.The following is an example NAMD configurationfile for the BPTI example.#NAMD configuration file for BPTI#molecular systemstructure output/bpti.psf#force fieldparatypecharmm onparameters toppar/par_all22_prot.inpexclude scaled1-41-4scaling1.0#approximationsswitching onswitchdist8cutoff12pairlistdist13.5margin0stepspercycle20#integratortimestep1.0#outputoutputenergies10outputtiming100binaryoutput no#molecular systemcoordinates output/bpti.pdb#outputoutputname output/bptidcdfreq10006#protocoltemperature0reassignFreq1000reassignTemp25reassignIncr25reassignHold300#scriptminimize1000run200004Building solvent around a proteinThe following script illustrates how psfgen and VMD can be used together to add water around a protein structure.It assumes you already have a psf and pdbfile for your protein,as well as a box of water which is large enough to contain the protein.For more information on how atomselections can be used within VMD scripts,see the VMD User’s Guide.proc addwater{psffile pdbfile watpsf watpdb}{#Create psf/pdb files that contain both our protein as well as#a box of equilibrated water.The water box should be large enough#to easily contain our protein.resetpsfreadpsf$psffilereadpsf$watpsfcoordpdb$pdbfilecoordpdb$watpdb#Load the combined structure into VMDwritepsf combine.psfwritepdb combine.pdbmol load psf combine.psf pdb combine.pdb#Assume that the segid of the water in watpsf is QQQ#We want to delete waters outside of a box ten Angstroms#bigger than the extent of the protein.set protein[atomselect top"not segid QQQ"]set minmax[measure minmax$protein]foreach{min max}$minmax{break}foreach{xmin ymin zmin}$min{break}foreach{xmax ymax zmax}$max{break}set xmin[expr$xmin-10]set ymin[expr$ymin-10]set zmin[expr$zmin-10]set xmax[expr$xmax+10]set ymax[expr$ymax+10]set zmax[expr$zmax+10]#Center the water on the protein.Also update the coordinates held#by psfgen.set wat[atomselect top"segid QQQ"]7$wat moveby[vecsub[measure center$protein][measure center$wat]]foreach atom[$wat get{segid resid name x y z}]{foreach{segid resid name x y z}$atom{break}coord$segid$resid$name[list$x$y$z]}#Select waters that we don’t want in the final structure.set outsidebox[atomselect top"segid QQQ and(x<=$xmin or y<=$ymin\or z<=$zmin or x>=$xmax or y>=$ymax or z>=$xmax)"]set overlap[atomselect top"segid QQQ and within 2.4of(not segid QQQ)"]#Get a list of all the residues that are in the two selections,and delete#those residues from the structure.set reslist[concat[$outsidebox get resid][$overlap get resid]]set reslist[lsort-unique-integer$reslist]foreach resid$reslist{delatom QQQ$resid}#That should do it-write out the new psf and pdb file.writepsf solvate.psfwritepdb solvate.pdb#Delete the combined water/protein molecule and load the system that#has excess water removed.mol delete topmol load psf solvate.psf pdb solvate.pdb#Return the size of the water boxreturn[list[list$xmin$ymin$zmin][list$xmax$ymax$zmax]]}5List of Commands•topology<file name>Purpose:Read in molecular topology definitions fromfile.Arguments:<file name>:CHARMM format topologyfile.Context:Beginning of script,before segment.May call multiple times.•pdbalias residue<alternate name><real name>Purpose:Provide translations from residues found in PDBfiles to proper residue names read in from topology definitionfiles.Proper names from topologyfiles will be used in generated PSF and PDB files.This command also exists under the deprecated name alias.Arguments:<alternate name>:Residue name found in PDBfile.<real name>:Residue name found in topologyfile.Context:Before reading sequence with pdb.May call multiple times.•segment<segment ID>{<commands>}Purpose:Build a segment of the molecule.A segment is typically a single chain of protein or DNA, with default patches applied to the termini.Segments may also contain pure solvent or lipid.Arguments:<segment ID>:Unique name for segment,1–4characters.<commands>:Sequence of commands in Tcl syntax to build the primary structure of the segment,8including auto,first,last,residue,pdb,etc.Context:After topology definitions and residue aliases.May call multiple times.Structure informa-tion is generated at the end of every segment command.•auto[angles][dihedrals][none]Purpose:Override default settings from topologyfile for automatic generation of angles and dihedrals for the current segment.Arguments:angles:Enable generation of angles from bonds.dihedrals:Enable generation of dihedrals from angles.none:Disable generation of angles and dihedrals.Context:Anywhere within segment,does not affect later segments.•first<patch name>Purpose:Override default patch applied tofirst residue in segment.Default is read from topology file and may be residue-specific.Arguments:<patch name>:Single-target patch residue name or none.Context:Anywhere within segment,does not affect later segments.•last<patch name>Purpose:Override default patch applied to last residue in segment.Default is read from topology file and may be residue-specific.Arguments:<patch name>:Single-target patch residue name or none.Context:Anywhere within segment,does not affect later segments.•residue<resid><resname>Purpose:Add a single residue to the end of the current segment.Arguments:<resid>:Unique name for residue,1–5characters,usually numeric.<resname>: Residue type name from topologyfile.Context:Anywhere within segment.•pdb<file name>Purpose:Extract sequence information from PDBfile when building segment.Residue IDs will be preserved,residue names must match entries in the topologyfile or should be aliased before pdb is called.Arguments:<file name>:PDBfile containing known or aliased residues.Context:Anywhere within segment.•mutate<resid><resname>Purpose:Change the type of a single residue in the current segment.Arguments:<resid>:Unique name for residue,1–5characters,usually numeric.<resname>:New residue type name from topologyfile.Context:Within segment,after target residue has been created.•patch<patch residue name><segid:resid>[...]Purpose:Apply a patch to one or more residues.Patches make small modifications to the structure of residues such as converting one to a terminus,changing the protonation state,or creating disulphide bonds between a pair of residues.Arguments:<patch residue name>:Name of patch residue from topology definitionfile.<segid:resid>:List of segment and residue pairs to which patch should be applied.Context:After one or more segments have been built.•regenerate[angles][dihedrals]Purpose:Remove all angles and/or dihedrals and completely regenerate them using the segment automatic generation algorithms.This is only needed if patches were applied that do not correct angles and bonds.Segment andfile defaults are ignored,and angles/dihedrals for the entire molecule are regenerated from scratch.9Arguments:angles:Enable generation of angles from bonds.dihedrals:Enable generation of dihedrals from angles.Context:After one or more segments have been built.•multiply<factor><segid[:resid[:atomname]]>[...]Purpose:Create multiple images of a set of atoms for use in locally enhanced sampling.The beta column of the output pdbfile is set to1...<factor>for each image.Multiple copies of bonds,angles, etc.are created.Atom,residue or segment names are not altered;images are distinguished only by beta value.This is not a normal molecular structure and may confuse other tools.Arguments:<factor>:<segid:resid:atomname>:segment,residue,or atom to be multiplied.If:resid is omitted the entire segment is multiplied;if:atomname is omitted the entire residue is multiplied.May be repeated as many times as necessary to include all atoms.Context:After one or more segments have been built,all patches applied,and coordinates guessed. The effects of this command may confuse other commands.•delatom<segid>[resid][atom name]Purpose:Delete one or more atoms.If only segid is specified,all atoms from that segment will be removed from the structure.If both segid and resid are specified,all atoms from just that residue will be removed.If segid,resid,and atom name are all specified,just a single atom will be removed. Arguments:<segid>:Name of segment.<resid>:Name of residue(optional).<atom name>:Name of atom(optional).Context:After all segments have been built and patched.•resetpsfPurpose:Delete all segments in from the structure.The topology definitions and aliases are left intact.Arguments:Context:After one or more segments have been built.•psfcontext[context][new][delete]Purpose:Switches between complete contexts,including structure,topology definitions,and aliases. If no arguments are provided,the current context is returned.If<context>or new is specified,a new context is entered and the old context is returned.If delete is also specified,the old context is destroyed and“deleted<old context>”is returned.An error is returned if the specified context does not exist or if delete was specified and the specified context is the same as the current context. Arguments:<context>:Context ID returned by psfcontext.Context:At any time.•writepsf[charmm][x-plor]<file name>Purpose:Write out structure information as PSFfile.Arguments:charmm:Use CHARMM format(numbers for atom types).x-plor:Use X-PLOR format(names for atom types),the default format required by NAMD.<file name>:PSFfile to be generated.Context:After all segments have been built and patched.•readpsf<file name>Purpose:Read in structure information from PSFfile and adds it to the structure.It is an error if any segments in the PSFfile already exist.Arguments:<file name>:PSFfile in X-PLOR format(names for atom types).Context:Anywhere but within segment.•pdbalias atom<residue name><alternate name><real name>Purpose:Provide translations from atom names found in PDBfiles to proper atom names read in10from topology definitionfiles.Proper names from topologyfiles will be used in generated PSF and PDBfiles.This command also exists under the deprecated name alias.Arguments:<residue name>:Proper or aliased residue name.<alternate name>:Atom name found in PDBfile.<real name>:Atom name found in topologyfile.Context:Before reading coordinates with coordpdb.May call multiple times.•coord<segid><resid><atomname><{x y z}>Purpose:Set coordinates for a single atom.Arguments:<segid>:Segment ID of target atom.<resid>:Residue ID of target atom.<atomname>:Name of target atom.<{x y z}>:Coordinates to be assigned.Context:After structure has been generated.•coordpdb<file name>[segid]Purpose:Read coordinates from PDBfile,matching segment,residue and atom names. Arguments:<file name>:PDBfile containing known or aliased residues and atoms.<segid>:If specified override segment IDs in PDBfile.Context:After segment has been generated and atom aliases defined.•guesscoordPurpose:Guesses coordinates of atoms for which they were not explicitly set.Calculation is based on internal coordinate hints contained in toplogy definitionfiles.When these are insufficient,wild guesses are attempted based on bond lengths of1˚A and angles of109◦.Arguments:None.Context:After stucture has been generated and known coordinates read in.•writepdb<file name>Purpose:Writes PDBfile containing coordinates.Atoms order is identical to PSFfile generated by writepsf(unless structure has been changed).The Ofield is set to1for atoms with known coordinates, 0for atoms with guessed coordinates,and-1for atoms with no coordinate data available(coordinates are set to0for these atoms).Arguments:<file name>:PDBfile to be written.Context:After structure and coordinates are complete.11。

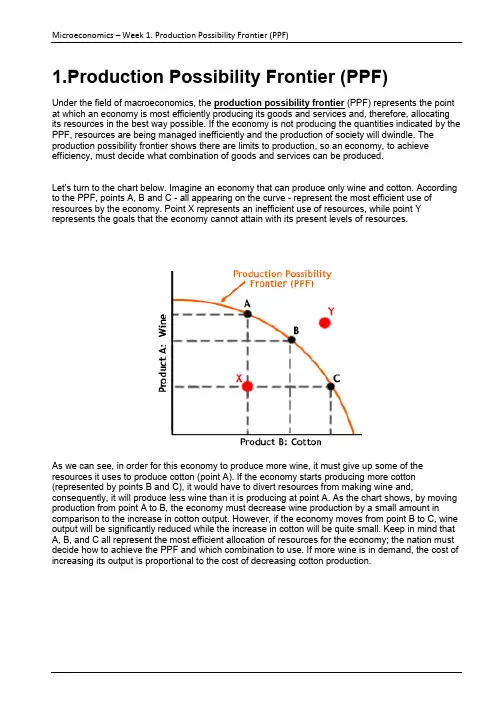

1.Production Possibility Frontier (PPF)Under the field of macroeconomics, the production possibility frontier (PPF) represents the point at which an economy is most efficiently producing its goods and services and, therefore, allocating its resources in the best way possible. If the economy is not producing the quantities indicated by the PPF, resources are being managed inefficiently and the production of society will dwindle. The production possibility frontier shows there are limits to production, so an economy, to achieve efficiency, must decide what combination of goods and services can be produced.Let's turn to the chart below. Imagine an economy that can produce only wine and cotton. According to the PPF, points A, B and C - all appearing on the curve - represent the most efficient use of resources by the economy. Point X represents an inefficient use of resources, while point Y represents the goals that the economy cannot attain with its present levels of resources.As we can see, in order for this economy to produce more wine, it must give up some of the resources it uses to produce cotton (point A). If the economy starts producing more cotton (represented by points B and C), it would have to divert resources from making wine and, consequently, it will produce less wine than it is producing at point A. As the chart shows, by moving production from point A to B, the economy must decrease wine production by a small amount in comparison to the increase in cotton output. However, if the economy moves from point B to C, wine output will be significantly reduced while the increase in cotton will be quite small. Keep in mind that A, B, and C all represent the most efficient allocation of resources for the economy; the nation must decide how to achieve the PPF and which combination to use. If more wine is in demand, the cost of increasing its output is proportional to the cost of decreasing cotton production.Point X means that the country's resources are not being used efficiently or, more specifically, that the country is not producing enough cotton or wine given the potential of its resources. Point Y, as we mentioned above, represents an output level that is currently unreachable by this economy. However, if there were changes in technology while the level of land, labour and capital remained the same, the time required to pick cotton and grapes would be reduced. Output would increase, and the PPF would be pushed outwards. A new curve, on which Y would appear, would represent the new efficient allocation of resources.When the PPF shifts outwards, we know there is growth in an economy. Alternatively, when the PPF shifts inwards it indicates that the economy is shrinking as a result of a decline in its most efficient allocation of resources and optimal production capability. A shrinking economy could be a result of a decrease in supplies or a deficiency in technology.An economy can be producing on the PPF curve only in theory. In reality, economies constantly struggle to reach an optimal production capacity. And because scarcity forces an economy to forgo one choice for another, the slope of the PPF will always be negative; if production of product A increases then production of product B will have to decrease accordingly.2. Opportunity CostOpportunity cost is the value of what is foregone in order to have something else. This valueis unique for each individual. You may, for instance, forgo ice cream in order to have an extra helping of mashed potatoes. For you, the mashed potatoes have a greater value than dessert. But you can always change your mind in the future because there may be some instances when the mashed potatoes are just not as attractive as the ice cream. The opportunity cost of an individual's decisions, therefore, is determined by his or her needs, wants, time and resources (income).This is important to the PPF because a country will decide how to best allocate its resources according to its opportunity cost. Therefore, the previous wine/cotton example shows that if the country chooses to produce more wine than cotton, the opportunity cost is equivalent to the cost of giving up the required cotton production.Let's look at another example to demonstrate how opportunity cost ensures that an individual will buy the least expensive of two similar goods when given the choice. For example, assume that an individual has a choice between two telephone services. If he or she were to buy the most expensive service, that individual may have to reduce the number of times he or she goes to the movies each month. Giving up these opportunities to go to the movies may be a cost that is too high for thisperson, leading him or her to choose the less expensive service.Remember that opportunity cost is different for each individual and nation. Thus, what is valued more than something else will vary among people and countries when decisions are made about how to allocate resources.3. Trade, Comparative Advantage and Absolute Advantage Specialisation and Comparative AdvantageAn economy can focus on producing all of the goods and services it needs to function, but this may lead to an inefficient allocation of resources and hinder future growth. By using specialization, a country can concentrate on the production of one thing that it can do best, rather than dividing up its resources.For example, let's look at a hypothetical world that has only two countries (Country A and Country B) and two products (cars and cotton). Each country can make cars and/or cotton. Now suppose that Country A has very little fertile land and an abundance of steel for car production. Country B, on the other hand, has an abundance of fertile land but very little steel. If Country A were to try to produce both cars and cotton, it would need to divide up its resources. Because it requires a lot of effort to produce cotton by irrigating the land, Country A would have to sacrifice producing cars. The opportunity cost of producing both cars and cotton is high for Country A, which will have to give up a lot of capital in order to produce both. Similarly, for Country B, the opportunity cost of producing both products is high because the effort required to produce cars is greater than that of producing cotton. Each country can produce one of the products more efficiently (at a lower cost) than the other. Country A, which has an abundance of steel, would need to give up more cars than Country B would to produce the same amount of cotton. Country B would need to give up more cotton than Country A to produce the same amount of cars. Therefore, County A has a comparative advantage over Country B in the production of cars, and Country B has a comparative advantage over Country A in the production of cotton.Now let's say that both countries (A and B) specialize in producing the goods with which they have a comparative advantage. If they trade the goods that they produce for other goods in which they don't have a comparative advantage, both countries will be able to enjoy both products at a lower opportunity cost. Furthermore, each country will be exchanging the best product it can make for another good or service that is the best that the other country can produce. Specialization and trade also works when several different countries are involved. For example, if Country C specializes in the production of corn, it can trade its corn for cars from Country A and cotton from Country B. Determining how countries exchange goods produced by a comparative advantage ("the best for the best") is the backbone of international trade theory. This method of exchange is considered an optimal allocation of resources, whereby economies, in theory, will no longer be lacking anything that they need. Like opportunity cost, specialization and comparative advantage also apply to the way in which individuals interact within an economy.Absolute AdvantageSometimes a country or an individual can produce more than another country, even though countries both have the same amount of inputs. For example, Country A may have a technological advantage that, with the same amount of inputs (arable land, steel, labour), enables the country to manufacture more of both cars and cotton than Country B. A country that can produce more of both goods is said to have an absolute advantage. Better quality resources can give a country an absolute advantage as can a higher level of education and overall technological advancement. It is not possible, however, for a country to have a comparative advantage in everything that it produces, so it will always be able to benefit from trade.。

术创新PCR技术在食品微生物检测中的应用与发展魏明斌(黑龙江农业经济职业学院食品药品工程系黑龙江牡丹江157041)摘 要:随着社会经济发展与人民生活水平的提高,食品安全问题受到了社会和人民群众的广泛关注,特别是我国现阶段的发展,使食品安全问题成为备受舆论监督的焦点,可见,食品安全问题在我国已经成为关系到人民身体健康、社会稳定、经济民生的重要问题,而经济市场食品日趋多样化和个性化的发展也对食品安全检测技术提出了更高的目标与要求。

本文从对PCR技术的原理、所需的原料和检测食品微生物的注意事项等几个问题进行阐述,并指出了PCR技术在食品微生物检测中应用的重要意义;然后又从食品食源性菌群检测、食品微生物的有效成分鉴定和转基因食品的鉴定等3个领域的PCR技术应用进行了研究;最后,对PCR技术对食品微生物检测应用发展进行了展望。

关键词:P CR技术微生物检测食品安全DNA聚合酶中图分类号:T S207.3文献标识码:A文章编号:1674-098X(2022)09(a)-0026-03食品安全是我国民生基础性工程的重要组成部分。

当前,在社会经济生活快速发展的今天,食品安全已经为人们所高度关注,特别是食品行业处于快速发展阶段,生产、加工、运输和销售等环节都有可能遭受来自各种环境下的污染,而这之中微生物污染在食品安全中可能尤为严重。

食品的微生物污染可能不仅会导致人的身体受到伤害,严重者甚至可能出现危及生命的情况,因此,对食品的微生物检测工作刻不容缓。

有效的PCR技术可以对食品中的危害物质进行详细的检测,并可以做到及时发现、准确掌握、精准处理,适时做好人们的身体保健工作。

在检测食品的微生物时,在众多的检测技术中,PCR技术更加快捷、方便、易操作,且在我国的食品检测技术中占据了主导地位,成为我国食品检测的关键技术之一,对解决好我国的食品安全起到了重要的作用[1]。

1 PCR技术的相关介绍1.1 PCR技术的概念PCR技术是在20世纪70年代由Khorana提出的原始的设想,而这种技术理论在当时看来是不太可能实现的,直到20世纪80年代才被美国的科学家Kary Mullis正式研究出来[2]。

WHO 第992号技术报告附录3 非无菌工艺验证Annex 3Guidelines on good manufacturing practices: validation,Appendix 7: non?sterile process validationBackgroundThe appendices of the Supplementary guidelines on good manufacturing practices:validation currently comprise the following:Appendix 1. Validation of heating, ventilation and air-conditioning systemsAppendix 2. Validation of water systems for pharmaceutical useAppendix 3. Cleaning validationAppendix 4. Analytical method validationAppendix 5. Validation of computerized systemsAppendix 6. Qualification of systems and equipmentAppendix 7. Non-sterile process validation – revised text reproduced in this Annex1. Background and scope 背景和范围2. Glossary 术语3. Introduction 概述4. Process design 工艺设计5. Process qualification 工艺确认6. Continued process verification 持续工艺确认7. Change management 变更管理References 参考文献1. Background and scope背景和范围Further to the Supplementary guidelines on good manufacturing practices: validation, as published in the World Health Organization (WHO) Technical Report Series, No. 937 (1), additional guidelines to support current approaches to good manufacturing practices (GMP) are published here. These guidelines are intended to further support the concept of process validation linked to quality risk management (QRM) and quality by design principles as described by WHO and the International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH).WHO第937号技术报告中公布了GMP增补指南:验证,此外还公布了一些指南来支持现行的GMP实施方法。

PP-Pure®High Purity Polypropylene (PP) Piping Specification PART 1: GENERAL1.1 SummaryFurnish a complete high purity pigmented PP piping system to include pipe, fittings, specialty fittings and valves.1.2 ReferencesThe following standards apply to products used within this section.ASTM D 1598 ASTM D 1599 DIN 8077ASTM D 2122 ASTM D 2657ASTM D 2837 ASTM D 4101DVS 2207-11 ISO 15494The system design shall meet the requirements of ASME/ANSI B31.3 for design criteria where temperature and pressure fall within the limits of the code.1.3 DefinitionsPolypropylene - PPR grey: Random copolymer polypropylene with pigmentation.PP-Pure®: Asahi/America’s pigmented polypropylene high purity piping system.1.4 System Description and Pressure RatingSystem shall be a PP-Pure® system made of uniform pipe and fitting resin. System pressure ratings shall be based on continuous use of 50 years. PP-Pure® pipe, fittings, and valves shall be based on a Standard Dimensional Ratio (SDR) of 11, 1/2” - 12” (20 - 315mm). Pressure rating for pipe and fittings, unless otherwise noted, shall be rated in accordance with ASTM D2837 and DIN 8077 for hydrostatic design basis. Components are rated to 150psi for all SDR 11 material and 150psi for all applied valves at 68° F.1.5 System Performance RequirementsSystem performance requirements shall handle the following:Operating Pressure: (TBD by Engineer/Project Owner)Operating Temp: (TBD by Engineer/Project Owner)Test Pressure: (TBD by Engineer/Project Owner)Media: (TBD by Engineer/Project Owner)1.6 SubmittalsSubmit the following:A. Product data for the system specified; relative to materials, dimensions of individual components, profiles and finishes.B. Product certificates signed by manufacturer of PP-Pure® piping product, stating compliance to stated requirements.C. Welder certificates, certifying that welders comply with the installation procedures as outlined by ASTM D-2657 & DVS 2207-11. All required training should be scheduled and completed at job start-up.D. Qualification of firms supplying PP-Pure®: Firms must have a minimum of five years experience in design, installationand operation of thermoplastic high purity piping systems.1.7 Quality AssuranceObtain components from a single source having responsibility and accountability to answer and resolve problems regarding proper installation, compatibility, performance, and acceptance.1.8 Delivery, Storage and HandlingA. Deliver all PP-Pure® pipe to arrive on-site double bagged for protection inside polyethylene static-free, non-tear bags forcleanroom applications. See section 2.3.B for quantities per bag.B. Deliver all PP-Pure® fittings to arrive on-site double bagged in boxes, when possible, layered with bubble packing orexpanding Styrofoam to prevent damage.C. Store products on elevated platforms in a dry location with protection from the environment. Failure to protect pipe fromdamage during the project may result in longer start up times, pressure failures or premature breakage.D. Lift, support and transport PP-Pure® piping per manufacturers’ recommendations.1.9 WarrantyWarranty period is one year after date of substantial completion. Asahi/America is not responsible for failures due to installation error or neglect.PART 2: PRODUCTS2.1 ManufacturersSubject to compliance with requirements products which may be incorporated in the work include: The PP-Pure® system as supplied by Asahi/America, Inc. of Lawrence, Massachusetts, 800-343-3618. Produced by Alois Gruber GmbH AGRU of Bad Hall, Austria. 2.2 MaterialPipe, valves and fittings shall be made from resin produced by one supplier. The resin shall meet or exceed the requirements outlined for a random copolymer resin according to DIN 16774 and ASTM D 4101-96a. MFI shall be 1.25 g/10min per 230/5. Resin must be approved for contact with foodstuff as per the FDA CFR, Title 21 (2001) 177.1520, and shall be certified as USP Class VI.Manufacturer shall test all lots to ensure the melt flow index is within allowable range.Traceability of all molded and extruded components must be molded into or otherwise printed on the outside of the pipingcomponent.2.3 PipeA. ProductionAll pipe shall be produced on a dedicated extruder completely within a dedicated clean area. Dimensions and tolerances shall exceed ISO 15494 requirement. Surface finish smoothness is as follows:Size (inch) Size (mm) Result1/2 - 1-1/4 20 - 40 Ra = 39.3µ” (1.0µm)1-1/2 - 12 50 - 315 Ra = 31.5µ” (0.8µm)B. PackagingAll pipes shall have capped ends. Pipe shall be sleeved in a PE bag and heat-sealed on both sides. Pipe is then packed into a second PE bag and heat sealed on both sides. The following chart designates quantities of pipe per second PE bag:Size (inch) Size(mm)Quantity PerTube1/2 20 Five 3/4 25 Four 1 32 Three 1-1/4 40 One 1-1/2 50 One 2 63 One 2-1/2 75 One 3 90 One4 110 One6 160 One8 200 One9 225 One10 250 One12 315 OneC. Pressure RatingAll pipe shall meet the requirements of Section 1.4.2.4 FittingsA. ProductionAll standard fittings 1/2” - 12” (20 - 315mm) shall be injected molded. All fittings are to be molded with equipment in a clean environment. After secondary machining all fittings shall be cleaned for a minimum of one hour in an automated hot DI rinse. The DI rinse water shall be 70° C with resistivity above 18MΩand TOC ≤10PPB. Dimensions and tolerances shall exceed ISO 15494 requirement and shall be molded with a central injection gate. Surface finish smoothness is as follows:Size (inch) Size (mm) Result1/2 - 5 20 - 140 Ra = 11.8µ” (0.3µm)6 - 12 160 - 315 Ra = 19.7µ” (0.5µm)B. PackagingAll molded fittings are to be packaged in a class 100 cleanroom immediately after the cleaning process. All machined fittings are to be packaged in a class 1000 cleanroom. Fittings are to be double bagged, purged with clean dry class 100 air or nitrogen in PE/Nylon composite bags. Bags are to be silicone free and anti-static.C. Specialty FittingsSpecialty fittings are to include restraint fittings, butt fusion instrumentation fittings, sanitary connections, etc. Specialty fittings shall be machined or molded of a compatible resin to the PP-Pure® pipe and fittings and shall be packaged according to the requirements of section 2.4.B.D. Pressure RatingAll fittings, unless otherwise noted, shall meet the requirements of Section 1.4.2.5 ValvesAll valves shall be produced in the same manner as high purity fittingsA. Type-342 Spigot Diaphragm Valve:1/2” - 2” (20mm - 63mm) shall be the Type-342 of the PP-Pure® system. The valves shall be molded using a compatible resin with options for EPDM backed PTFE or EPDM diaphragms. Valve bodies are to be unibody, molded design with a full 150psi rating at 70° F. All metal nuts and bolts must be capped or covered to reduce metal exposure. Top works must include integral lockout device on the handle and position indicator.B. Type-343 Zero Dead Leg Valve:1/2” x 1/2” - 2” x 1” (20mm x 20mm - 63mm x 32mm) reduced dead leg (zero dead leg) valves shall be Type-343 style from the PP- Pure®system. Valves shall be made of PP-Pure®resin. Valve bodies are to be unibody, molded design with a full 150psi rating at 68° F (20° C). All metal nuts and bolts must be capped or covered to reduce metal exposure. Top works must include integral lockout device on the handle and position indicator.C. Flanged Diaphragm Valves:1/2” - 10” (20mm - 250mm) shall be Type-14, Type-15 or Type-G pigmented polypropylene unibody with flanges molded as part of the body. Diaphragm shall be a two-piece style with PTFE and separate EPDM backing. Top works shall include a position indicator and travel stop. Supplied cleaned and double bagged.D. Butterfly Valves:1-1/2” - 12” (50mm - 315mm) shall be Type-57P manual gear operated valves with a polypropylene disc and ANSI 150# bolt pattern. Liners shall be available in EPDM or FKM materials. Supplied cleaned and double bagged.E. Ball Valve:PP-Pure® ball valves shall be available 1/2” - 2” (20mm - 63mm). O-rings are to be FKM or EPDM. Ball valves shall be offered in spigot ends. Supplied cleaned and double bagged.F. Ball Check Valves:1/2” - 4” (20mm - 110mm) shall be polypropylene ball type check with FKM or EPDM seat and seals. Ball check valves shall be offered in spigot ends. Supplied cleaned and double bagged.G. V182 Pressure Regulating Valve with Gauge Guard:1/2” - 4” (20mm - 110mm) shall be polypropylene V182 with EPDM/EPDM or PTFE/FKM diaphragms/seals. 1/2” - 1-1/2”(20mm - 50mm) shall be pressure rated to 150psi at 68° F. 2” - 3” (63mm - 90mm) shall be pressure rated to 90psi at 68° F. 4”(110mm) shall be pressure rated to 60psi at 68° F.H. V186 Back Pressure Regulating Valve:1/2” - 2-1/2” shall be polypropylene V182 with EPDM/EPDM or PTFE/FKM diaphragms/seals. 1/2” - 1-1/2” shall be pressure rated to 150psi at 68° F. 2” shall be pressure rated to 90psi at 68° F.I. Flow Meters:Available in polysulphone (PSU) and polyamide (PA) Frank M123 and M335 flow meters shall be supplied with spigot ends suitable for high purity welding. Flow ranges available up to 135 gallons-per-minute with custom ranges available.2.6 Pipe/Valve Hangers and SupportsA. Support SpacingDesign pipe supports and anchors in accordance with Asahi/America’s recommended support spacing for SDR 11 polypropylene pipe. See Section 4.3 for recommended support spacing for PP-Pure® piping systems.B. Supports and HangersUse Asahi/America’s recommended support types per document Asahi/America Engineering Design Guide. Metallic supports and clamps shall not come directly into contact with plastic piping systems.2.7 Joining EquipmentPP-Pure® installations shall be performed by factory certified and trained installers in accordance with manufacturer’s ISOprocedures, ASTM D 2657 and DVS 2207-11. Date of certification or re-certification shall not exceed two years from the beginning of project. Available joining techniques are as follows:A. Butt FusionProper equipment selection should be based on pipe size and site conditions. Butt fusion equipment should be designed and tested to provide reliable welds. All equipment should utilize electronically controlled heating elements for accurate welding temperatures.Tools should also incorporate planing units to face ends prior to heating. Butt fusion equipment supplied shall weld joints based on force or pressure and not mechanical stops.B. Non-Contact Butt FusionProper equipment selection should be based on installation requirements and line sizes. Tool shall be fully automatic (SP series).SP-S Series:Tool shall be made available in the following modelsSP 110-S 1/2” - 4” (20mm - 110mm)SP 250-S 4” - 10” (110mm - 250mm)SP 315-S 4” - 12” (110mm - 315mm)Tools shall possess electronic planer and infrared heating element. Tools will utilize and measure the welding pressures to join material and not mechanical stops. To avoid improper welded joints, tool shall automatically operate clamps and control joining force. Tools shall possess the following features:1. Computer control and automatic fusion.2. Touch screen for tool operation and parameter selection.3. Restricted access through use of barcode or RFID cards.4. Automatic label printouts after each weld.5. Ability to display and graph weld processes as weld is proceeding.6. Memory storage of welds7. Magnetic clamps to reduce change out time from one size to another.8. Vertical and horizontal adjustment for pipe alignment.C. Beadless FusionSP-B Series:SP 110-B: 1/2” - 4” (20mm - 110mm)Tools shall possess electronic planer and heating element. To avoid improper welded joints, tool shall automatically operate clamps, heater movement, heater closing and control joining force. Tools shall possess identical features as:1. Computer control and automatic fusion.2. Touch screen for tool operation and parameter selection.3. Restricted access through use of RFID cards.4. Automatic label printouts after each weld.5. Ability to display and graph weld processes as weld is proceeding.6. Memory storage of welds7. Magnetic clamps to reduce change out time from one size to another.8. Vertical and horizontal adjustment for pipe alignment.PART 3: EXECUTION3.1 Piping AssemblyA. FacilitiesSubassembly and fabrication work should be conducted in a separate, temporary clean room located within the building.Cleanroom should be equipped with the following to provide a clean installation:1. Provide laminar flow HEPA filters in room ceiling to reach a level of class 10,000.2. The quantity of filters should be determined by providing a minimum of 60 room air changes per hour.3. Nitrogen should be available for purging the pipelines with a positive pressure if the assemblies expand beyond the bounds of theroom.B. ToolsAll fusion tools utilized are to be dedicated for clean build only, and should be kept separate. Special attention should be given to the fusion tools to prevent the possibility of contaminating a weld. The contractor shall lease or purchase all necessary weldingequipment from the manufacturer. At the end of the installation, any necessary equipment needed on-site should be sold to the owner. Contractor is responsible for proper maintenance and care of the fusion tools during construction.C. CertificationInstallers shall be pre-qualified as per section 2.7. Manufacturer shall provide on-site training in the assembly and installation of the PP-Pure® piping system as needed.D. Installation of Flanged ConnectionsFor each flange connection, only Asahi/America seal clean expanded PTFE (e-PTFE) gaskets should be used. Ensure that each gasket is centered according to manufacturer’s recommendation. Apply the recommended backing rings and torques. Ensure correct support of piping in the area of flange connection.3.2 TestingA. InspectionPrior to pressure testing, the system shall be examined for the following items:1. Pipe shall be completed per drawing layout with all pipe and valve supports in place.2. Pipe, valves, and equipment shall be supported as specified, without any concentrated loads on the system.3. Pipe shall be in good conditions, void of any cracks, gouges or deformation.4. Pipe flanges shall be properly aligned. All flange bolts should be checked for correct torques.5. All diaphragm valve bonnet bolts shall be checked for correct torques.6. All joints should be reviewed for appropriate welding technique:Non-Contact: Identity labels shall identify weld certification by the print “welding parameters OK”. Joints should have twobeads 360° around the joint.Butt: To have two beads, 360° around the joint.Manufacturer to supply inspection procedures beyond above recommendations. If any deficiencies appear, the quality control manager shall provide directions for repair.B. Pressure Test1. Test fluid should be deionized water, with quality level set by quality control engineer. In all cases test must be donehydrostatically. Air test is not allowed.2. Filling the system: Open all valves and vents to purge the system of air. Slowly inject the water into the system, making sure thatair does not become trapped in the system.3. Begin pressurizing the system in increments of 10psi. Bring the system up to 100psi and hold. Allow system to hold pressure fora minimum of two hours and up to a recommended 12 hours. Check pressure gauge after one hour. Due to natural creep effects onplastic piping, the pressure will have decreased. If drop is less than 10%, pump the pressure back up. At this time, the system may be fully pressurized to desired test pressure.4. If after one hour the pressure has decreased more than 10%, test is considered a failure. Note the 10% value may need to begreater for larger systems, or systems experiencing significant thermal changes.5. Test is to be witnessed by quality control engineer and certified by the contractor.3.3 Cleaning of PP-Pure® Piping SystemSystem shall be cleaned at completion of project according to requirements set by owner.PART 4: APPENDICESDisclaimer: This information is provided for convenience. For additional information, please consult Asahi/America’s engineering design guide or contact our engineering staff at 781-321-5409.4.1 Material PropertiesTable 1 - Material Properties of PP-Pure ® PPPropertiesCondition Standard Units PP-R P h y s i c a l Density 23° C (73.4° F) ISO 1183 g/cm 3 0.91 Melt Flow Rate230° C/5 kg 190° C/5 kg ISO 1133 g/10min 1.25 0.5 M e c h a n i c a l P r o p e r t i e sTensile stress at yield 50 mm/min ISO 527 MPa 25 Elongation at yield 50 mm/min ISO 527 % 12 Elongation at break 50 mm/min ISO 527 % >300 Impact strength unnotched23° C (73.4° F) ISO 179/1eUkJ/m 2no break 0° C (32° F) no break -20° C (-4° F)40 Impact strength notched23 °C (73.4° F)ISO 179/1eAkJ/m 220 0° C (32° F) 3.5 -20° C (-4° F)2 Ball indentation hardness according to RockwellISO 2039-1 MPa 45 Flexural strength (3.5% flexural stress)ISO 178MPa 20 Modulus of elasticityISO 527 MPa 900 T h e r m a l P r o p e r t i e s Vicat-Softening point VST/B/50 ISO 306 °C °F 65 149 Heat deflection temperature HDT/BISO 75 °C °F 70 158 Linear thermal expansion coefficientDIN 53752 K -1 x 10-4 1.5 Thermal conductivity 20° C (68° F)DIN 52612 W/(m x K)0.24 FlammabilityUL94 DIN 4102 94-HB B2 E l e c t r i c a l P r o p e r t i e s Specific volume resistance VDE 0303 Ω x cm >1016 Specific surface resistanceVDE 0303 Ω>1013 Dielectric constant 1 MHzDIN 53483 2.3 Dielectric strength VDE 0303 kV/mm70 G e n e r a lPhysiologically nontoxic EEC 90/128 Yes FDAYes USP Class VI Yes UV ResistanceNo ColorPP-Pure ® GreyRAL 7032 PolyPure ®Natural4.2 Pressure RatingPermissible operating pressure for PP-Pure® piping systems based on years of operation and temperature. These tables are for water, a safety correction factor shall be applied for chemical service. Consult Asahi/America Engineering staff for chemical recommendation. Additionally, a system reduction factor of 0.8 shall be used for influences such as welding, joints, flange, and bending loads for aboveground installations and 1.0 should be used for below ground installation.Table 2 - Permissible Operating Pressures for PP-Pure® PP (psi)Temperature 1 Year 5 Years10 Years25 Years 50 Years100Years PP 150SDR 11PP 150SDR 11PP 150SDR 11PP 150SDR 11PP 150SDR 11PP 150SDR 11° C ° F10 50 306 289 281 271 265 258 20 68 261 245 239 231 225 219 30 86 222 209 203 196 190 - 40 104 189 176 171 164 160 - 50 122 160 148 144 138 135 - 60 140 135 125 120 116 112 - 70 158 113 104 102 87 74 - 80 176 94 84 71 57 - - 90 194 78 55 46 - - - 95 203 67 45 - - - -4.3 Support SpacingTable 3 - PP-Pure® PP Support Spacing (feet)Pipe Size 68° F/20° C 86° F/30° C104° F/40° C122° F/50° C140° F/60° C158° F/70° C176° F/80° Cmm inch20 1/2 1.7 1.7 1.6 1.5 1.5 1.4 1.425 3/4 2.0 1.9 1.8 1.8 1.7 1.7 1.632 1 2.3 2.3 2.2 2.2 2.1 2.0 1.840 1-1/4 2.7 2.6 2.6 2.5 2.3 2.3 2.250 1-1/2 3.1 3.0 3.0 2.8 2.7 2.6 2.563 2 3.6 3.5 3.4 3.3 3.2 3.1 3.075 2-1/2 3.8 3.7 3.6 3.4 3.3 3.2 3.190 3 4.1 3.9 3.8 3.7 3.6 3.4 3.3110 4 4.6 4.4 4.3 4.2 3.9 3.7 3.4125 4-1/2 4.9 4.8 4.7 4.4 4.2 3.9 3.7140 5 5.2 5.0 4.9 4.7 4.4 4.2 3.9160 6 5.5 5.4 5.2 4.9 4.7 4.4 4.2180 7 5.8 5.7 5.4 5.2 4.9 4.7 4.4200 8 6.2 5.9 5.7 5.4 5.2 4.9 4.7225 9 6.5 6.3 6.0 5.8 5.5 5.3 4.9250 10 6.9 6.6 6.4 6.2 5.9 5.7 5.3280 11 7.3 7.0 6.8 6.5 6.3 6.0 5.7315 12 10.3 10.0 9.7 9.4 8.9 8.5 8.0For gases and fluids with different densities, the conversion factors shown below should be used.LL=LL AA∗ff1f1 – conversion factor (See Table 4)L – new support distance [mm]L A – permissible support distance (See Table 3)Table 4 - External Support Spacing Correction Factors basedon Operating Media Density for PPMaterial SDRConversion factor f1Media density [g/cm3]Gases Water Other Media <0.01 1.00 1.25 1.50PP-Pure® 11 1.30 1.0 0.96 0.92。