Sensors and Actuators B Chemical

- 格式:pdf

- 大小:1.27 MB

- 文档页数:7

半胱氨酸抑制二氧化铈纳米颗粒化学发光石文兵;戚景南;贺薇;万邦江【摘要】在碱性条件下,二氧化铈纳米颗粒能够有效催化过氧化氢-鲁米诺体系的化学发光.然而,当加入半胱氨酸,该体系的化学发光强度得到极大抑制.该文详细讨论发光条件,如二氧化铈纳米颗粒、过氧化氢、鲁米诺等质量浓度及鲁米诺pH对发光强度的影响.在最佳试验条件下,探讨半胱氨酸的抑制特性,在一定范围内抑制强度与半胱氨酸的质量浓度成正比.线性范围为0.01~1.8 μg/mL,(r=0.9946),检出限(3σ)为1.6 ng/mL,对质量浓度为1.0 lg/mL的半胱氨酸进行11次平行测定,RSD为0.72%.该法有望用于测定实际样品中半胱氨酸的含量.【期刊名称】《中国测试》【年(卷),期】2015(041)007【总页数】4页(P37-40)【关键词】半光氨酸;抑制;二氧化铈纳米颗粒;化学发光【作者】石文兵;戚景南;贺薇;万邦江【作者单位】无机特种功能材料重庆市重点实验室,长江师范学院化学化工学院,重庆408100;唐山科技职业技术学院,唐山063001;无机特种功能材料重庆市重点实验室,长江师范学院化学化工学院,重庆408100;无机特种功能材料重庆市重点实验室,长江师范学院化学化工学院,重庆408100【正文语种】中文L-半胱氨酸属于蛋白质氨基酸,在临床医学和医药产业中发挥着重要的生物学作用。

L-半胱氨酸参与多种重要的细胞功能,如蛋白质合成、解毒和新陈代谢等;因此,灵敏、快速和廉价检测半胱氨酸的含量具有重要意义。

近几年,越来越多的方法已用于测定药物、尿液、血清和血浆中L-半胱氨酸含量,如高效液相色谱法(HPLC)[1-2]、分光光度法[3-4]、固相微萃取[5]、比色法[6-7]、电化学法[8]、荧光法[9]。

虽然这些方法大多数具有灵敏度高和选择性好的优点,但它们要么仪器昂贵,要么步骤繁复耗时。

化学发光法(LC)因其灵敏度高、线性范围宽、仪器设备便宜简单、容易实现自动化,广泛应用于不同领域。

sensors and actuators b-chemical模板-回复sensors and actuators in chemical industryIntroduction:In the chemical industry, the use of sensors and actuators plays a crucial role in maintaining efficient operations, ensuring product quality, and enhancing safety measures. Sensors are devices that detect changes in the environment and convert them into an electrical signal, while actuators are mechanisms that control or manipulate physical systems. Together, these two technologies form a fundamental part of process control, enabling automation and optimization in chemical manufacturing. In this article, we will explore the various types of sensors and actuators used in the chemical industry and delve into their applications.1. Sensors in the chemical industry:1.1 Temperature sensors:Temperature sensors are widely used in chemical facilities to monitor and control reaction temperatures. They help to ensure that reactions occur at the desired temperature range to achieveoptimum product yields and reduce the risk of unwanted side reactions. Additionally, temperature sensors aid in maintaining safe operating conditions by triggering alarms and shutdown mechanisms when temperatures exceed predefined limits.1.2 Pressure sensors:Pressure sensors are critical in the chemical industry for maintaining optimal operating conditions and ensuring safety. They help monitor and control pressure levels in storage tanks, pipelines, and reactors. By providing real-time pressure data, these sensors enable operators to take corrective actions promptly, preventing overpressure situations that could lead to equipment failure or even catastrophic incidents.1.3 Flow sensors:Flow sensors are utilized to monitor and regulate the flow rate of liquids or gases during chemical processes. Accurate measurement of flow rates is crucial for maintaining product quality and controlling production volumes. Flow sensors also play a vital role in detecting leaks or blockages in pipelines, preventing potential safety hazards and minimizing product losses.1.4 Level sensors:Level sensors are employed to monitor and control the liquid or solid levels in tanks, vessels, and reactors. They help prevent overflow or underflow situations, ensuring consistent process conditions and preventing environmental pollution. Level sensors also aid in inventory management, enabling timely replenishment of raw materials and avoiding production disruptions.2. Actuators in the chemical industry:2.1 Control valves:Control valves are one of the most commonly used actuators in the chemical industry. They regulate the flow rate, pressure, and temperature of fluids within a system. By responding to signals from sensors or control systems, valves modulate the flow of liquids or gases, allowing precise control over process variables. This enables operators to maintain desired conditions, optimize energy consumption, and ensure product quality.2.2 Motorized valves:Motorized valves are employed to control the opening and closing of fluid passages in chemical plants. They are typically used inlarger pipelines or critical systems where manual valve operation may be impractical or unsafe. Motorized valves can be operated remotely, enhancing operational flexibility and enabling rapid response in emergency situations.2.3 Solenoid valves:Solenoid valves are extensively used in the chemical industry for their fast response time and precise control capabilities. These valves use electromagnetic force to open or close fluid passages, making them ideal for applications that require quick and accurate fluid flow control. Solenoid valves are commonly used in automated systems and are invaluable for process optimization, energy efficiency, and safety enhancement.2.4 Pumps and motors:Pumps and motors are critical actuators used in the chemical industry to move fluids within a process. They provide the necessary pressure and flow required for various operations, such as transferring fluids between vessels, circulating cooling or heating media, and mixing reagents. Efficient and reliable pumps and motors are crucial for maintaining process stability, ensuring product consistency, and minimizing energy consumption.Conclusion:Sensors and actuators are essential components in the chemical industry, enabling efficient and safe operations. They play a vital role in monitoring and controlling process variables, optimizing energy consumption, and ensuring product quality. By providing real-time data and enabling precise control, sensors and actuators contribute to increased productivity, reduced waste, and enhanced safety measures. As technology advances, the application of sensors and actuators in the chemical industry will continue to evolve, revolutionizing manufacturing processes and driving innovation in the field.。

Advanced Materials for Sensors andActuators在当今高科技发展的时代,传感器和执行器等智能装置成为人们生活和工作中不可或缺的一部分。

而这些装置所使用的材料也随着科技的进步而不断更新。

本文将介绍一些先进的传感器和执行器所使用的材料,以及它们在现代科技中的应用。

1. 智能传感器材料随着智能家居、智能医疗和智能交通等领域的快速发展,人们对于传感器的需求也越来越高。

而智能传感器所使用的材料,必须具有高度的灵敏度、稳定性和可靠性。

1.1 纳米材料纳米材料因其尺寸小、比表面大和特殊的物理和化学性质而成为传感器领域的热门材料。

其具有高度的灵敏度和响应速度,可以用于气体、温度、湿度等多种传感器的制备。

1.2 有机材料有机材料由于其可塑性好,可以制备出各种形状和大小的传感器。

它们具有高度的稳定性和可靠性,可以在多种环境条件下工作。

1.3 碳材料碳材料因其良好的导电性能和机械强度,成为制备传感器的优良材料之一。

目前,石墨烯、碳纳米管和纳米钻石等碳材料都在传感器领域得到了广泛的应用。

2. 高效执行器材料执行器是指能够将电能、光能、温度能等形式的输入能量转化成机械力或位移的器件。

高效执行器所使用的材料需要具有良好的电化学性能、热稳定性和机械强度。

2.1 金属氧化物金属氧化物因其良好的电化学性能和可控的工艺成为制备执行器的优良材料之一。

例如,氧化锡、氧化铝、氧化钛等材料都在电动汽车、智能家居和超声波医疗等领域得到了广泛的应用。

2.2 晶体聚合物晶体聚合物是一种具有可逆形变能力的材料。

其具有良好的机械强度和化学稳定性,可以制备出各种形状和大小的执行器。

晶体聚合物的应用涉及到机器人、人工智能和智能医疗等多个领域。

2.3 人工肌肉人工肌肉是一种可逆膨胀材料,可以完成类似于生物肌肉的运动。

其具有良好的机械强度和化学稳定性,在医疗机器人、人机交互和智能家居等领域有广泛的应用前景。

3. 发展趋势在传感器和执行器材料的发展中,改进材料表面性质和生产工艺已成为一个热点和难点。

宋志龙,2011年7月毕业于巢湖学院化学工程与工艺专业;2014年7月毕业于江苏大学化学化工学院,获硕士学位,并获江苏省优秀硕士专业学位论文;2017年9月毕业于华中科技大学光学与电子信息学院,获博士学位;现在江苏大学能源研究院从事博士后工作。

宋志龙同志曾获优秀研究生、优秀毕业生、优秀论文奖、优秀墙报奖、优秀研究生奖学金、研究生国家奖学金等多种奖项。

目前已在《Chemistry of Materials》、《Sensors and Actuators B: Chemical》、《The Journal of Physical Chemistry C》、《Talanta》等国际期刊发表SCI论文19篇,其中第一作者论文4篇,第二作者论文4篇(导师一作2篇)。

多次参加国内外学术会议并做口头报告,参与国家自然科学基金1项以及重点研发计划重点专项1项,授权及申请国家发明专利10项。

目前研究方向主要为胶体量子点、纳米传感与催化、清洁能源与柔性电子器件。

优秀校友二汤磊汤磊,2011年7月毕业于巢湖学院化学工程与工艺专业,获学士学位;2014年7月毕业于南京工业大学化工学院化学工程专业,获硕士学位,现就职于荣盛石化股份有限公司。

目前从事炼油与化工行业,曾涉及氢气/氨气尾气回收装置、氯化氢/二氧化硫回收装置、3×150t/h锅炉烟气脱硫项目等项目。

2015年组织出版《Aspen模拟软件在精馏设计和控制中的应用(原著第二版)》(《Distillation Design and Control Using AspenTM Simulation》),华东理工大学出版社。

2016年组织出版《Aspen Plus热力学计算简明教程》(《Using Aspen Plus in Thermodynamics Instruction》),华东理工大学出版社。

2017年组织出版《Aspen 软件在化工过程分析和模拟中的应用》(《Process Analysis and Simulation in Chemical Engineering》),河海大学出版社。

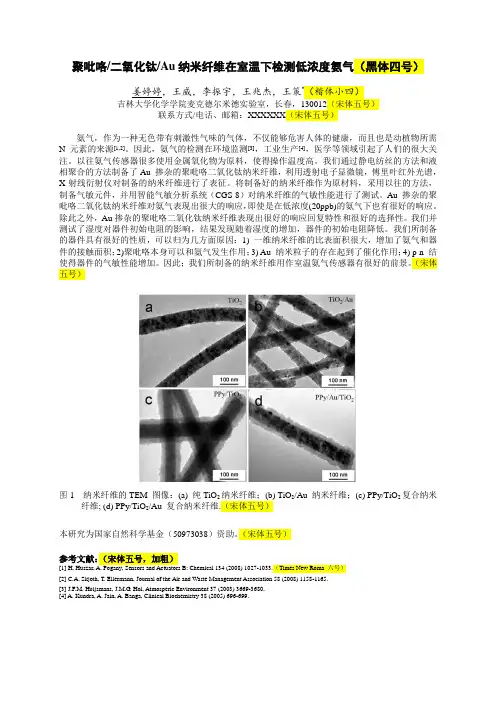

聚吡咯/二氧化钛/Au纳米纤维在室温下检测低浓度氨气(黑体四号)姜婷婷,王威,李振宇,王兆杰,王策*(楷体小四)吉林大学化学学院麦克德尔米德实验室,长春,130012(宋体五号)联系方式/电话、邮箱:XXXXXX(宋体五号)氨气,作为一种无色带有刺激性气味的气体,不仅能够危害人体的健康,而且也是动植物所需N元素的来源[1,2]。

因此,氨气的检测在环境监测[3],工业生产[4],医学等领域引起了人们的很大关注。

以往氨气传感器很多使用金属氧化物为原料,使得操作温度高。

我们通过静电纺丝的方法和液相聚合的方法制备了Au 掺杂的聚吡咯二氧化钛纳米纤维,利用透射电子显微镜,傅里叶红外光谱,X-射线衍射仪对制备的纳米纤维进行了表征。

将制备好的纳米纤维作为原材料,采用以往的方法,制备气敏元件,并用智能气敏分析系统(CGS-8)对纳米纤维的气敏性能进行了测试。

Au 掺杂的聚吡咯二氧化钛纳米纤维对氨气表现出很大的响应,即使是在低浓度(20ppb)的氨气下也有很好的响应。

除此之外,Au掺杂的聚吡咯二氧化钛纳米纤维表现出很好的响应回复特性和很好的选择性。

我们并测试了湿度对器件初始电阻的影响,结果发现随着湿度的增加,器件的初始电阻降低。

我们所制备的器件具有很好的性质,可以归为几方面原因:1) 一维纳米纤维的比表面积很大,增加了氨气和器件的接触面积;2)聚吡咯本身可以和氨气发生作用;3) Au 纳米粒子的存在起到了催化作用;4) p-n 结使得器件的气敏性能增加。

因此;我们所制备的纳米纤维用作室温氨气传感器有很好的前景。

(宋体五号)图1 纳米纤维的TEM 图像:(a) 纯TiO2纳米纤维;(b) TiO2/Au 纳米纤维;(c) PPy/TiO2复合纳米纤维; (d) PPy/TiO2/Au 复合纳米纤维.(宋体五号)本研究为国家自然科学基金(50973038)资助。

(宋体五号)参考文献:(宋体五号,加粗)[1] H. Huszar, A. Pogany, Sensors and Actuators B: Chemical 134 (2008) 1027-1033.(Times New Roma 六号)[2] C.A. Skjoth, T. Ellermann, Journal of the Air and Waste Management Association 58 (2008) 1158-1165.[3] J.F.M. Huijsmans, J.M.G. Hol, Atmosperic Environment 37 (2003) 3669-3680.[4] A. Kundra, A. Jain, A. Banga, Clinical Biochemistry 38 (2005) 696-699.。

第52卷第8期 辽 宁 化 工 Vol.52,No. 8 2023年8月 Liaoning Chemical Industry August,2023收稿日期: 2022-08-21电化学方法检测胆固醇的研究进展飏吕龙,顾婷婷,尚帅,林常瑞(辽宁科技大学 化学工程学院,辽宁 鞍山 114051)摘 要: 随着人类生活质量的提高,胆固醇的检测成为一个重要的研究课题。

电化学方法具有选择性强、检测速度快等优点。

综述了近年来利用电化学方法在有酶和无酶的条件下测定胆固醇含量的电化学原理和最新进展,并对用电化学方法检测胆固醇进行了展望。

关 键 词:胆固醇;有酶;无酶;电化学传感器中图分类号:O657.1 文献标识码: A 文章编号: 1004-0935(2023)08-1193-04胆固醇是一种化学式为C 27H 46O 的环戊烷多氢菲的衍生物。

胆固醇是人体内最普遍存在的化合物,主要存在于大脑的中枢神经组织,另外还存在于肾脏、脾脏、皮肤以及胆汁。

胆固醇能经由多种途径进入身体。

高胆固醇会引起慢性心脏病、高血压、脑血栓等致命的心脑血管病[1-2]。

目前,胆固醇的检测方法有高效液相色谱法[3-4],比色法[5-6]和光谱法[7-8]等,这些检测方法一般存在检测周期长、灵敏度低、选择性、仪器标准化、样品预处理要求高等缺点。

另一方面,电化学方法[9-10]由于具有选择性强、制备方法简单、仪器简单、成本低、操作方便、检测速度快等特点,受到研究者的广泛关注[11]。

电化学检测胆固醇的方法包括包括差分脉冲伏安法(DPV)[12]、安培法[13-14,15-17]、电荷转移(CT)[18]、循环伏安法(CV )[19-22]、线性扫描伏安法 (LSV)[23-24]、电化学发光法(ECL)[25]和电化学阻抗谱(EIS)[26]。

在这些方法中,电流测量法是许多研究中最常用和最敏感的方法[27]。

随着技术的发展,基于各种材料制备出的胆固醇电化学传感器成为研究热点之一。

英文文献|英文期刊数据库|英文硕士论文|英文博士论文论文写作资源SCI论文润色北大核心期刊SCI影响因子化学类英文期刊投稿指南[学术须知] 专业SCI论文修改服务:★先修改后付款;☆语言问题免费重修;★24-72小时交稿;☆正规财务发票;★一分钟下单;☆365日不间断服务化学类英文期刊投稿指南:化学类(Chemistry)1【期刊名称】SENSORS AND ACTUA TORS B: CHEMICAL【所属学科】化学【级别】SCI、EI【期刊主页】/wps/find ... ription#description【投稿方式】email【出版商】elsevier【审稿周期】3-6 months2【期刊名称】Applied Catalysis A: General【所属学科】化学,催化【级别】SCI、EI【投稿主页】/Jour ... 856&Precis=DESC【投稿方式】online submision【影响因子】2.337【出版商】elsevier【审稿周期】3 months【出版周期】half-month journal3【期刊名称】Tetrahedron Letter【所属学科】有机化学Organic Chemistry【级别】SCI【期刊主页】/sci ... c26274c4b9df99e5c0f【投稿方式】email【出版商】elsevier4【期刊名称】Tetrahedron【所属学科】有机化学Organic Chemistry【级别】SCI【期刊主页】/wps/find ... ription#description【投稿方式】email【出版商】elsevier5【期刊名称】The Journal of Organic Chemistry【所属学科】有机化学【级别】SCI【影响因子】6.903【期刊主页】/journals/joceah/index.html【投稿方式】email【出版商】ACS6【期刊名称】Journal of the American Chemical Society【所属学科】化学【级别】SCI【影响因子】3.462【期刊主页】/journals/jacsat/index.html【投稿方式】email【出版商】ACS7【期刊名称】Angewandte Chemie International Edition【所属学科】化学【影响因子】9.161【级别】SCI【期刊主页】/cgi-bin/jhome/26737 【投稿方式】email【出版商】Wiley8【期刊名称】Chemistry - A European Journal【所属学科】化学【级别】SCI【影响因子】4.517【期刊主页】/cgi-bin/jhome/26293 【投稿方式】email【出版商】Wiley 9【期刊名称】European Journal of Organic Chemistry【所属学科】有机化学【级别】SCI【影响因子】2.426【期刊主页】/cgi-bin/jhome/27380 【投稿方式】email【出版商】Wiley10【期刊名称】Journal of Molecular Structure【所属学科】化学,特别是有晶体结构的分子Chemistry【级别】SCI【影响因子】1.0【期刊主页】 ... mp;journal=00222860【投稿方式】email【出版商】elsevier【审稿周期】1-2 week 我师妹的文章是8 天接受的11【期刊名称】The Journal of organic chemistry【所属学科】organic chemistry【级别】SCI【影响因子】3.462【期刊主页】/journals/joceah/index.html【投稿方式】on-line submittion【出版商】American chemistry Society【审稿周期】4-8weeks12【期刊名称】the journal of american chemical society【所属学科】chemistry【级别】SCI【影响因子】6.903【期刊主页】/journals/jacsat/【投稿方式】on-line submittion【出版商】American chemistry Society【审稿周期】4-8weeks13【期刊名称】advanced synthesis & catalysis【所属学科】chemistry【级别】SCI【影响因子】4.482【期刊主页】http///cgi-bin【投稿方式】on-line submittion【出版商】Wiley14【期刊名称】chemical communications【所属学科】chemistry【级别】SCI【影响因子】3.997【期刊主页】/is/journals/current/chemcomm/cccpub.htm 【投稿方式】on-line submittion【出版商】Royal Society of Chemistry【审稿周期】4-8weeks15【期刊名称】Organic &Biomolecular Chmistry【所属学科】有机化学及化学生物学【级别】SCI IF=2.194【期刊主页】/Publishing/Journals/OB/index.asp【投稿方式】email【出版商】RSC【审稿周期】1-2 months16 【期刊名称】Synlett【所属学科】有机化学Organic Chemistry【级别】SCI【期刊主页】/ ... synlett/index.shtml 【出版商】Thieme Stuttgart17【期刊名称】SYNTHESIS【所属学科】有机化学Organic Chemistry【级别】SCI【期刊主页】/ ... nthesis/index.shtml 【投稿方式】email【出版商】Thieme Stuttgart18【期刊名称】Phytochemistry【所属学科】有机化学Organic Chemistry【级别】SCI【期刊主页】/sci ... 7576855b50ec607f058 【投稿方式】email【出版商】elsevier19【期刊名称】Chemical Communications【所属学科】化学【级别】SCI【期刊主页/Publishing/Journals/cc/【投稿方式】email【出版商】RSC20【期刊名称】Green Chemistry【所属学科】化学【级别】SCI【期刊主页】/Publishing/Journals/gc/index.asp【投稿方式】email【出版商】RSC21【期刊名称】Angewandte Chemie International Edition【所属学科】化学【级别】SCI【影响因子】7.996【期刊主页】/cgi-bin/jhome/26737 【投稿方式】email【出版商】Wiley22【期刊名称】Journal of chromatograohy A【所属学科】色谱分析【级别】SCI【影响因子】3.359【期刊主页】/wps/find ... ription#description【投稿方式】email【出版商】elsevier【审稿周期】3-6 months23【期刊名称】Journal of chromatograohy B【所属学科】色谱分析【级别】SCI【影响因子】2.176【期刊主页】/wps/find ... ription#description【投稿方式】email【出版商】elsevier【审稿周期】3-6 months24【期刊名称】Analytical chemistry【所属学科】分析化学【级别】SCI【影响因子】5.450【期刊主页】/journals/ancham/index.html【投稿方式】在线投稿/email【出版商】ACS【审稿周期】unknown25【期刊名称】electrophoresis【所属学科】分析化学【级别】SCI【影响因子】3.743【期刊主页】http://www.wiley-vch.de/publish/en/journals/alphabeticIndex/2027/ 【投稿方式】在线投稿/email【出版商】wiley interscience【审稿周期】2 months26【期刊名称】Journal of chromatography A【所属学科】分析化学【级别】SCI【影响因子】3.359【期刊主页】/wps/find ... ription#description【投稿方式】在线投稿/email【出版商】elsevier【审稿周期】3 months27【期刊名称】JOURNAL OF SEPARA TION SCIENCE【所属学科】分析化学【级别】SCI【影响因子】1.927【期刊主页】http://www.wiley-vch.de/publish/en/journals/alphabeticIndex/2259/ 【投稿方式】在线投稿/email【出版商】wiley interscience【审稿周期】2-3 months28【期刊名称】Journal of pharmaceutical and biomedical analysis【所属学科】分析化学【级别】SCI【影响因子】1.509【期刊主页】/wps/find ... ription#description【投稿方式】在线投稿/email【出版商】elsevier【审稿周期】1-2 month29【期刊名称】Phytochemical Analysis【所属学科】分析化学【级别】SCI【影响因子】1.385【期刊主页】/WileyCDA/WileyTitle/productCd-PCA.html 【投稿方式】主页上无在线投稿【出版商】wiley interscience【审稿周期】2=3 months30【期刊名称】Electrochemistry Communications【所属学科】Electrochemistry【级别】SCI、EI【影响因子】2.926【期刊主页】/sci ... daa82c9a2b982514b77【投稿方式】在线投稿【出版商】ELSEVIER【审稿周期】1 month31【期刊名称】Electrochimica Acta【所属学科】Electrochemistry【级别】SCI、EI【影响因子】2.341【期刊主页】/sci ... abf8e59c12785940620【投稿方式】在线投稿【出版商】ELSEVIER【审稿周期】1 month32【期刊名称】Journal of The Electrochemical Society【所属学科】Electrochemical science and technology【级别】SCI、EI【影响因子】2.356【期刊主页】/JES【投稿方式】在线投稿【出版商】ECS【审稿周期】1-3 months33【期刊名称】Electrochemical and Solid-State Letters【所属学科】Electrochemical science and technology【级别】SCI、EI【影响因子】2.271【期刊主页】/ESL【投稿方式】在线投稿【出版商】ECS【审稿周期】1-3 months34【期刊名称】Organic Letters【所属学科】有机化学【级别】SCI【影响因子】4.19【期刊主页】/journals/orlef7/index.html【投稿方式】在线投稿【出版商】ACS【审稿周期】1 month35 【期刊名称】Organic Letters(影响因子: 4.195), Journal of the American Chemical Society(影响因子: 6.903)【所属学科】chemistry【级别】SCI【期刊主页】/about.html【投稿方式】on-line submittion,/paragonplus/splash/index.html or https:///paragon/index.jsp 【出版商】American chemistry Society36【期刊名称】Analytic Chimic Acta【所属学科】分析化学【级别】SCI、EI【期刊主页】/ACA【投稿方式】email【出版商】elsevier【审稿周期】3-6 months37【期刊名称】Molecules【所属学科】化学【级别】SCI【影响因子】0.676【期刊主页】/molecules/【投稿方式】在线投稿/email/邮寄【出版商】MDPI【审稿周期】3-6 months38【期刊名称】Catalysis Communications【所属学科】化学&催化【级别】SCI【IF】=1.89【期刊主页】/catcom/【投稿方式】online submission【出版商】elsevier【审稿周期】3-6 months39【期刊名称】Applied Catalysis B: Environmental【所属学科】化学&催化&环境科学【级别】SCI【IF】=4.042【期刊主页】/apcatb/【投稿方式】online submission【出版商】elsevier【审稿周期】3-6 months40【期刊名称】Journal of Catalysis【所属学科】化学&催化【级别】SCI【IF】=4.063【期刊主页】/jcat/【投稿方式】online submission【出版商】elsevier【审稿周期】3-6 months41【期刊名称】Journal of Molecular Catalysis A: Chemical 【所属学科】化学&催化【级别】SCI【IF】=2.316【期刊主页】/molcaa/【投稿方式】online submission【出版商】elsevier【审稿周期】3-6 months42【期刊名称】analytical biochemistry【所属学科】分析【级别】SCI【影响因子】2.370【期刊主页】/wps/find ... ription#description 【投稿方式】email【出版商】elsevier【审稿周期】未知43【期刊名称】analyst【所属学科】分析【级别】SCI【影响因子】2.783【期刊主页】/Publishing/Journals/an/index.asp 【投稿方式】email【出版商】皇家化学会【审稿周期】未知44【期刊名称】analytical sciences【所属学科】分析【级别】SCI【影响因子】1.051【期刊主页】http://wwwsoc.nii.ac.jp/cgi-bin/jsac/analsci/toc/【投稿方式】email【出版商】日本分析化学会【审稿周期】未知45【期刊名称】analytical letters【所属学科】分析【级别】SCI【影响因子】0.915【期刊主页】/newjour/a/msg03705.html【投稿方式】email【Publisher】Marcel Dekker, Inc.【审稿周期】未知46【期刊名称】Analytical Communications【所属学科】分析【级别】SCI【影响因子】1.628【期刊主页】/Publishing/Journals/an/index.asp【投稿方式】email【出版商】皇家化学会【审稿周期】未知47【期刊名称】Macromolecules【所属学科】高分子【级别】SCI, 3.898【期刊主页】/macromolecules/【投稿方式】online submision【出版商】ACS【审稿周期】3-6 months48【期刊名称】Talanta【所属学科】分析化学【级别】SCI、EI,2.532(2004 年)【期刊主页】/tal/【投稿方式】submission on line【出版商】elsevier【审稿周期】3-6 months49【期刊名称】ADV ANCES IN CA TALYSIS【所属学科】化学【级别】SCI,EI【影响因子】9.750【期刊主页】/science/bookseries/03600564 【国际刊号】ISSN: 0360-0564【投稿方式】online【出版商】ELSEVIER ACADEMIC PRESS INC【审稿周期】3~6 months50【期刊名称】CA TALYSIS LETTERS【所属学科】化学&材料【级别】SCI,EI【影响因子】1.904【期刊主页】/east/hom ... 40109-70-35504020-0 【国际刊号】ISSN: 1011-372X【出版商】SPRINGER【审稿周期】3~6 months51【期刊名称】European Polymer Journal【所属学科】化学【影响因子】1.419【期刊主页】 ... mp;journal=00143057【投稿方式】online submision【出版商】elsevier【审稿周期】3-6 months52【期刊名称】Polymer degradation and stability【所属学科】化学【级别】SCI【影响因子】1.685【期刊主页】 ... mp;journal=01413910【投稿方式】online submision【出版商】elsevier【审稿周期】3-6 months53【期刊名称】Green Chemistry【所属学科】化学【级别】SCI Impact Factor:3.5【期刊主页】【投稿方式】email【出版商】RSC【审稿周期】3months54【期刊名称】Journal of Polymer Science Part B: Polymer Physics【所属学科】化学主要高分子类【级别】SCI, 1.39【期刊主页】/cgi-bin/jhome/36698【投稿方式】online submision【出版商】Wiley【审稿周期】2 months55【期刊名称】Journal of Applied Polymer Science【所属学科】化学主要高分子类【级别】SCI, 1.3【期刊主页】/cgi-bin/jhome/30035【投稿方式】online submision【出版商】Wiley【审稿周期】2 months56【期刊名称】EUROPEAN POLYMER JOURNAL【简介】This journal publishes results bearing on the physics and chemistry of natural and synthetic macronuclear substances and also reviews articles covering advances in polymer technology.【所属学科】Chemistry ; Physics ; Materials Science【级别】SCI,EI【影响因子】0.720【期刊主页】/wps/find ... ription#description【投稿方式】online submission【出版商】Elsevier【审稿周期】in a month57【期刊名称】Carbohydrate Research【简介】The journal includes normal length research papers, perspectives, notes, rapid communications and book reviews together with notices of meetings concerned w ith carbohydrates.【所属学科】Chemistry【级别】SCI,EI【影响因子】1.43【期刊主页】/Jour ... 829&Precis=DESC【投稿方式】online submission【出版商】Elsevier【审稿周期】2 month58【期刊名称】Carbohydrate Polymers【简介】Carbohydrate Polymers covers the study and exploitation of the industrial applications of carbohydrate polymers in areas such as food, textiles, paper, wood, adhesives, pharmaceuticals, oil field applications and industrial chemistry.【所属学科】Chemistry【级别】SCI,EI【影响因子】1.71【期刊主页】/Jour ... 871&Precis=DESC【投稿方式】online submission【出版商】Elsevier【审稿周期】2 month59【期刊名称】Journal of Physical Chemistry B【所属学科】化学,物理,材料类【级别】SCI【影响因子】3.834 (2004); 3.679 (2003); 3.611 (2002)【期刊主页】/journals/jpcbfk/index.html【投稿方式】on-line submittion【审稿周期】审稿期限是21 天,超过 1 个月编辑会给通讯联系人发信说明情况。

sensors and actuators b-chemical模板"Sensors and Actuators in Chemical Engineering: Enhancing Process Efficiency and Control"Introduction:Chemical engineering plays a crucial role in numerous industries, including pharmaceuticals, petrochemicals, and food processing. The advancement in technology has allowed chemical engineers to employ sensors and actuators in their field to enhance process efficiency and control. This article will delve into the importance of sensors and actuators, their applications in chemical engineering, and the benefits they offer in terms of process optimization, safety, and cost-effectiveness.1. Sensors in Chemical Engineering:Sensors are essential devices that gauge specific parameters in a chemical process. They can measure various factors such as temperature, pressure, flow rate, pH level, conductivity, and concentration of substances. The data provided by sensors helps engineers monitor and control processes, ensuring optimalperformance. For example, temperature sensors allow precise control of reaction rates, while pressure sensors ensure safety by preventing excessive pressure build-up.2. Actuators in Chemical Engineering:Actuators, on the other hand, are devices that act upon the data provided by sensors. They control specific process variables by adjusting valves, pumps, motors, or dampers. Actuators are vital in maintaining process stability and achieving desired results. For instance, actuators may regulate the flow rates of various substances to maintain a precise ratio in a chemical reaction, optimize heat transfer, or handle the movement of materials during a manufacturing process.3. Applications of Sensors and Actuators in Chemical Engineering:a) Process Optimization: By providing real-time data on various process parameters, sensors enable chemical engineers to optimize reaction conditions. This optimization leads to increased product yield, reduced waste generation, and improved energy efficiency. Actuators then respond to the data provided by sensors to controlvariables and maintain optimal conditions. This iterative process helps achieve the best possible outcome.b) Safety Enhancement: Sensors play a crucial role in ensuring the safety of chemical processes. They monitor parameters such as temperature, pressure, and gas concentrations, allowing timely detection of anomalies and potential hazards. Actuators respond to these inputs by taking corrective actions, such as shutting down equipment or adjusting process parameters to prevent accidents or damage to equipment.c) Quality Control: Sensors aid in quality control by continuously monitoring critical product parameters. For example, pH sensors are used to monitor and adjust the acidity of a solution during a chemical reaction, ensuring the desired product quality. Actuators respond to sensor inputs by adjusting process parameters to maintain consistency and compliance with quality standards.d) Environmental Protection: Sensors and actuators also contribute to environmental protection by monitoring and controlling emissions, waste treatment processes, and resource consumption. For example, gas sensors can detect emissions of harmful gases,triggering appropriate actions to minimize their release. Actuators can also optimize process parameters to minimize environmental impact, such as reducing energy consumption or recycling waste materials.4. Benefits of Sensors and Actuators in Chemical Engineering:a) Enhanced Efficiency: By providing real-time data and enabling precise control of process parameters, sensors and actuators improve overall process efficiency. This improvement translates into increased productivity, reduced energy consumption, and optimized resource utilization.b) Improved Safety: The ability of sensors and actuators to detect anomalies and control critical parameters enhances the safety of chemical processes. They help prevent accidents, equipment failures, and the release of hazardous substances.c) Cost-effectiveness: Utilizing sensors and actuators optimizes process conditions, reduces waste generation, and minimizes resource consumption. These benefits lead to cost savings in terms of raw materials, energy, and waste management.d) Automation and Control: Sensors and actuators facilitate process automation, minimizing the need for manual intervention. This automation results in consistent product quality, reduced human errors, and improved overall process control.Conclusion:Sensors and actuators are invaluable tools in chemical engineering, enabling enhanced process efficiency, safety, and control. Their integration into chemical processes allows engineers to monitor and adjust critical parameters in real-time, optimizing conditions for maximum output and minimal waste. Furthermore, sensors and actuators contribute to environmental protection by controlling emissions and resource consumption. Implementing these technologies in chemical engineering is vital for achieving sustainable and cost-effective operations.。

Sensors and Actuators B 133(2008)308–314Contents lists available at ScienceDirectSensors and Actuators B:Chemicalj o u r n a l h o m e p a g e :w w w.e l s e v i e r.c o m /l o c a t e /s nbPotentiometric response of ion-selective membranes with ionic liquids as ion-exchanger and plasticizerBo Peng a ,Jingwei Zhu b ,Xiaojie Liu a ,Yu Qin a ,∗a Department of Chemistry,Renmin University of China,Beijing 100872,ChinabInstitute for Chemical Physics,Beijing Institute of Technology,Beijing 100081,Chinaa r t i c l e i n f o Article history:Received 8December 2007Received in revised form 7January 2008Accepted 21February 2008Available online 4March 2008Keywords:Ion-selective electrode Ionic liquids Ion-exchanger PlasticizerPotentiometric sensora b s t r a c tRoom temperature ionic liquids (RTILs),based on imidazolium,pyridinium and phosphonium cations,have been studied as an anion-exchanger and plasticizer for poly(vinyl chloride)(PVC)-based potentiometric ion-selective membranes.1-Methyl-3-octylimidazolium chloride (MOImCl)and trihexyl-tetradecylphosphonium chloride (THTDPCl)can plasticize PVC to form flexible ion-sensing membranes.PVC–MOImCl membrane without additional ionophore and ion-exchanger demonstrated Nernstian response to sulfate ion with slope of 29.1mV/decade in the concentration range of 10−5to 10−1M.The ionophore-free membrane showed good selectivity toward SO 42−over Cl −,ClO 4−,NO 3−and SCN −.PVC–MOImCl-based electrode have fast response time within 10s and wide pH independent range (3–10).The proposed electrode was used for the determination of sulfate in drinking water samples with satis-factory results.On the other hand,PVC–THTDPCl membrane exhibited stable and Nernstian response to different anions and the selectivity followed the Hofmeister series.Additionally,THTDPCl was found to be a suitable alternative to the traditional anion-exchanger,TDMACl and can be used as ionic additives in ionophore-based ion-selective sensors.©2008Elsevier B.V.All rights reserved.1.IntroductionHighly selective chemical sensors based on molecular recogni-tion and extraction principles are a very important class of sensors.Ion-selective electrodes (ISEs)and optodes in particular have found widespread use in clinical laboratories and are being explored for numerous other applications [1,2].Traditionally,these sensors are based on hydrophobic plasticized polymeric membranes or films that are doped with one or more ionophores in addition to a lipophilic ion-exchanger that plays an important role to the sen-sor response.Ion-exchanger has a selectivity-modifying influence since its concentration in the membrane determines the amount of the exchangeable ions of opposite charge.Hence,by adjusting the molar ratio of ionic sites to ionophore so that the latter is present in excess with respect to the primary ion but in deficiency regarding the interfering ions,the selectivity behavior of ISEs can be improved [3].Various tetraphenylborate derivatives are currently used as cationic additives and lipophilic tetraalkylammonium salts such as tridodecyl methylammonium chloride (TDMACl)are suitable anion exchangers.The hydrophilic counterions of these lipophilic addi-tives are exchanged for the primary ion when the ISE is conditioned in specific aqueous solution.∗Corresponding author.Tel.:+861062512660;fax:+861062516444.E-mail address:qinyu01@ (Y.Qin).For ion-sensing membranes the hydrophobicity of the polymer can assure that spontaneous,non-specific electrolyte extraction from the sample is suppressed.At the same time,the membrane matrix must act as a solvent of low viscosity for all active sens-ing components in the film.Therefore in poly(vinyl chloride)(PVC)membranes it is essential to use external plasticizers (membrane solvents)that can reduce the glass transition temperature of the polymer to below room temperature,increase the elasticity of the polymeric membrane and aid in providing mechanical stability.Furthermore,plasticizers also provide a lipophilic environment within the membrane conducive for improving the solubility of electroactive species (e.g.ionophore and ion-exchanger)[1].For many years,the plasticizers applied in potentiometric sensors are organic solvents such as bis(2-ethylhexyl)phthalate,bis(2-ethylhexyl)sebacate,2-nitrophenyl octyl ether that originated from the plastic industry [4].In recent years,novel polymeric materials have been developed for making sensing membranes without any plasticizer [5–10].Application of plasticizer-free polymer can elim-inate the leaching of membrane solvent and sensing components so that the lifetime of the sensor can be improved.However,it was reported that the diffusion coefficient of plasticizer-free membrane is about two orders of magnitude smaller than that of plasticized PVC membrane [11,12],which may lead to longer response time of plasticizer-free ion sensors,especially for bulk optodes.Room temperature ionic liquids (RTILs)are a class of compounds containing organic cations and anions [13].They are liquid over a0925-4005/$–see front matter ©2008Elsevier B.V.All rights reserved.doi:10.1016/j.snb.2008.02.027B.Peng et al./Sensors and Actuators B133(2008)308–314309wide temperature range and usually exhibit negligible vapor pres-sure,which reduces the possibility of air pollution and loss of materials at ambient conditions.They are air and moisture sta-ble,nonflammable,non-explosive and have high thermal stability. ILs are highly solvating for both organic and inorganic materials. They usually have high electrical conductivity and possess a wide electrochemical window[14].Due to those unique properties,ILs have been successfully used in many applications,including replac-ing traditional organic solvents in chromatography and extraction [15–18],electroanalytical applications[14,19–21]and spectrome-try[22].Notably,due to their ion exchange and polymer plasticizing properties ILs are able to be used as a component in polymeric sensing devices[23–25].Up to date few articles have been published on the utiliza-tion of ILs in ion-selective electrodes or optodes.Shvedene et al. reported the application of BDMImTf2N and DEDPPTf2N in PVC and polymethyl methacrylate(PMMA)membranes[24].Although the membranes did not require any conventional plasticizer,they only exhibited sub-Nernstian response to highly lipophilic anions such as dodecylsulfate and no response reported to common hydrophilic anions.In another paper,Coll et al.observed the selectivity enhancement of sulfate ions by polyazacycloalkane-based(7.11wt.%)membrane(41.84wt.%of powdered PVC, 25.11wt.%of plasticizer NPOE)containing ionic liquid1-butyl-3-methylimidazolium hexafluorophosphate(BMImPF6)(25.94wt.%) [23].The authors observed that NPOE plasticized PVC membranes containing only BMImPF6,exhibited a very poor undefined sub-Nernstian response.Furthermore,a plasticized PVC membrane containing the ionophore without the ionic liquid lost sulfate ion selectivity completely.These results indicated that BMImPF6is essential for polyazacycloalkane-based SO42−electrode;however, the functions of the ionic liquid can hardly be explained by tradi-tional ISE theory.Herein,we reported the investigation of different ILs in ion-selective membranes in order to fully understand their functions as ion-exchanger and plasticizer in potentiometric sen-sors.2.Experimental2.1.ReagentsCation-exchanger sodium tetrakis[3,5-bis(trifluoromethyl) phenyl]borate(NaTFPB)was purchased from Dojindo Laboratories (Gaithersburg,MD)in highest quality.All salts and membrane components anion-exchanger tridodecylmethylammonium chlo-ride,high-molecular weight poly(vinyl chloride),o-nitrophenyl octyl ether(NPOE),bis(2-ethylhexyl)sebacate(DOS),tetrahy-drofuran(THF),1,3-[bis(3-phenylthioureidomethyl)]benzene (sulfate ionophore),ionic liquids1-butyl-3-methylimidazolium tetrafluoroborate(BMImBF4),1-butyl-3-methylimidazolium hexafluorophosphate,1-butyl-3-methylimidazolium hexafluo-rophosphate(BMImCl),1-butyl-4-methylpyridinium chloride (BMPCl),1-methyl-3-octylimidazolium chloride(MOImCl),tri-hexyltetradecyl phosphonium chloride(THTDPCl)were purchased from Fluka(Switzerland).The ionic liquids were further purified as reported[26].All aqueous solutions were prepared by dissolving the appropriate salts or diluting standard solutions as specified in nanopure-purified(18.2M cm)deionized water.2.2.Membrane preparation and EMF measurementsConventional ion-selective membranes were cast by dissolving the ionophore(20mmol/kg,if needed)and the lipophilic ion-exchanger salt TDMACl(5mmol/kg),together with PVC and the plasticizer DOS or NPOE(1:2by weight)to give a total cock-tail mass of140mg,in1.5mL of THF and pouring it into a glass ring(22-mm i.d.)fixed onto a glass slide with rubber bands.The solvent THF was allowed to evaporate overnight.Ion-selective membranes with ILs were prepared by mixing different amount of ILs,PVC and NPOE/DOS(1:2)in THF cocktail.Trihexyltetradecyl phosphonium chloride and1-methyl-3-octylimidazolium chloride plasticized PVC membrane was prepared with20wt.%ionic liq-uid and80wt.%PVC.After conditioning the electrodes overnight in a solution identical to the innerfilling solution,discs6mm in diameter were cut from the parent membranes and mounted into Philips electrode bodies(IS-561,Glasbl¨aserei M¨oller,Zurich, Switzerland).0.01M NaClO4(with10−4M NaCl),0.01M NaCl or 0.01M Na2SO4(with10−4M NaCl)was served as the condition-ing solution and the internalfilling solution of the assembled electrodes.All the electrode potential measurements of sets of at least three replicate membranes disks that were made from the same parent membrane were performed at laboratory ambi-ent temperature versus an Ag/AgCl reference electrode with a 1M LiOAc bridge electrolyte by PXSJ-216Ion Meter(Shanghai, China).To measure the pH response of the electrodes,the sample solu-tion containing10mM boric acid and10mM citric acid(adjusted to pH2with HCl)was dropwisely titrated with0.1M NaOH,while the pH was monitored with a calibrated glass electrode(PB-10, Sartorius,Goettingen,Germany).Drinking water samples with different sulfate concentrations were prepared by adding known amounts of sodium sulfate to blank sample.The working and reference electrodes were immersed in the samples and the concentrations of the analytes were deter-mined by direct potentiometry and using the standard addition technique.To measure the binding constants of the ionophore with sul-fate ion,sandwich membrane experiments were performed as reported[27,28].Briefly,two single membranes were prepared. One of the membranes contained ionic sites TDMACl or THTD-PCl,PVC and plasticizer,the other one had the same composition but with additional sulfate ionophore.Both of the two mem-branes were conditioned in0.01M sodium sulfate solutions and each was measured individually in symmetric cell with the inner filling solution and the sample solution(0.01M sodium sulfate) being identical.The differences of two single membrane potentials were within5mV.The sandwich membrane was made by press-ing two individual membranes(one without ionophore and one with the same components and sulfate ionophore)together imme-diately after blotting them individually dry with tissue paper to avoid an aqueous phase between the two membrane segments. The obtained sandwich membrane was visibly checked for air bubbles before mounting in the same electrode body with the ionophore-containing segment facing the sample solution.The potential difference between the sandwich membrane and sin-gle membrane was used to calculate the stability constant of the ionophore.2.3.SelectivitiesSelectivity coefficients were calculated using an unbiased sepa-rate solution method(SSM)[29]by recording separate calibration curves for all the interfering ions of interest.For PVC–MOImCl and sulfate ionophore-based membranes,the selectivity coefficients were calculated with SO42−as primary ions.For other membranes, Cl−was the primary ion.The selectivity coefficients were deter-mined by using potentials from the highest activities lying within the Nernstian range.310 B.Peng et al./Sensors and Actuators B133(2008)308–314Fig.1.Chemical structures of different ionic liquids,anion-exchanger TDMACl and plasticizer NPOE.3.Results and discussions3.1.Membrane compositionsAs a class of materials,ionic liquids are highly solvating for both organic and inorganic materials.To investigate the potential appli-cations of ILs in potentiometric ion-selective sensors,membranes containing PVC,plasticizers and different types of ILs(structures as shown in Fig.1)were prepared.It was found that imidazolium type of ionic liquids,1-butyl-3-methylimidazolium tetrafluoroborate, 1-butyl-3-methylimidazolium hexafluorophosphate and1-butyl-3-methylimidazolium chloride were not able to plasticize PVC, instead,by mixing them with PVC and conventional plasticizers (NPOE or DOS)we were able to prepare mechanically stable mem-branes.PVC–DOS membranes with different amount of ionic liquids showed decreasedfilm-forming stability,while PVC–NPOE(weight ratio1:2)membrane containing10wt.%ionic liquids are clear and homogenous with enough tensile strength.It is notable that 1-methyl-3-octylimidazolium chloride and trihexyltetradecylpho-nium chloride can plasticize PVC.Without additional plasticizer, the membranes prepared with PVC and MOImCl or THTDPCl exhib-ited goodfilm-forming property and elasticity.On the other hand, 1-butyl-4-methylpyridinium chloride has poor compatibility with PVC and it is difficult to form measurable membranes,even in solvent plasticized polymer matrix.Table1lists the composition of the membranes(Nos.1–7)with good mechanical stability and homogeneity.3.2.Ionic liquids as anion-exchanger in plasticized PVC membranesThe prerequisite for obtaining a theoretical response with ISE membranes is their permselectivity,which means that no sig-nificant amount of counterions may enter the membrane phase. To achieve this the so-called Donnan exclusion,counterions(ion exchangers)confined to the membrane must be present[1].The potentiometrically obtained selectivity of anion-exchanger trido-decyl methylammonium chloride-based membranes displays the Hofmeister series(ClO4−>SCN−>I−∼salicylate>NO3−>Br−> Cl−>HCO3−>CH3COO−>SO42−>HPO42−).For such electrode,the anion selectivity sequence is solely related to the relative anion partition coefficients between water and membrane phases[1].Ionic liquids are consisted of bulky organic cations and inorganic anions.Potentiometric responses of PVC–NPOE membranes with four different ionic liquids were briefly described and compared in Table1.Firstly,BMImPF6-based membrane1was conditioned in 0.01M NaCl solution overnight before the electrode was titrated with different anions.EMF values of the electrodes were sta-ble for each measurement that indicated the exudation of the ionic liquids was negligible after overnight conditioning.How-ever,no obvious response toward anions or cations was observed for the electrodes.It is well known that ion-selective electrode containing anion-exchanger exhibits the Hofmeister series.The extraction of lipophilic anions into organic membrane is relatively easy,while highly hydrophilic anions such as sulfate and phos-phate are poorly extracted from an aqueous solution.Consequently, it is difficult to exchange lipophilic ions out of the membrane phase by more hydrophilic ones.BMImPF6-based PVC–NPOE mem-branes that has been used to prepare selective sulfate ISE[23]were further soaked in10−2M NaClO4.After conditioning the mem-brane showed some potentiometric response toward lipophilic anions with severely sub-Nernstian slopes(−21.8mV/decade for benzoate,−38.3mV/decade for salicylate and−25.1mV/decade for saccharin ions),however,the membrane had no response to other anions including NO3−,Cl−and SO42−.Similar results were observed for BMImBF4-based PVC–NPOE membrane2.After con-ditioning in10−2M NaClO4solution,such membrane showed weak responses to some lipophilic anions including ClO4−,PhCOO−,sal-icylate and saccharin anions in a rather narrow range.The EMF changes are less than40mV during the entire titration range from10−6to0.1M.These results indicated that the cationic part of the BMImBF4and BMImPF6are lipophilic enough to stay in the membrane phase,while the anionic BF4−and PF6−can par-tially be exchanged by more lipophilic anions.Similar results had been reported that ion-selective membranes containing dode-cylethyldiphenylphosphonium bistrifluoromethanesulfonimidate demonstrated potentiometric response toward dodecylsulfate (slope:53mV/dec)and salicylate(slope:44mV/dec)[24],but no data reported for less lipophilic anions.The results suggested that the ionic liquids with large anions might not be suitable for prepa-ration of ion-exchanger-based ISEs especially for the measurement of biologically important hydrophilic anions such as Cl−,SO42−and phosphate ion.We further focused our work on the ionic liquids with chloride ion as anionic counter ion.Membrane3with BMImCl exhibited unstable response mainly due to the high solubility of BMImCl inTable1Compositions of mechanically stable PVC membrane studied in this work and their potentiometric responsesMembrane no.Membrane composition Potentiometric responseIonic liquid PVC(%)NPOE(%)110%BMImBF43060Stable and sub-Nernstian response to lipophilic anions;no response to Cl−,SO42−210%BMImPF63060Stable and sub-Nernstian response to lipophilic anions;no response to Cl−,SO42−310%BMImCl3060Unstable response410%MOImCl3060Stable and sub-Nernstian response to Cl−,SO42−,ClO4−,salicylate510%THTDPCl3060Stable and Nernstian response to Cl−,SO42−,ClO4−,salicylate620%MOImCl800Stable and Nernstian response to SO42−,sub-Nernstian response to other anions 720%THTDPCl800Stable and Nernstian response to Cl−,SO42−,ClO4−,salicylateB.Peng et al./Sensors and Actuators B133(2008)308–314311Fig. 2.Response curves of PVC–NPOE membrane containing10wt.%THTDPCl (membrane5)toward SO42−, ;Cl−, ;salicylate,᭹;ClO4−, after conditioning in 0.01M NaCl solution.aqueous solution.Membrane4that was prepared with MOImCl and PVC–NPOE exhibited responses to Cl−,SO42−,ClO4−,PhCOO−, salicylate-and saccharin anions after conditioning overnight in 0.01M NaCl solution,however,the response slopes were all sub-Nernstian.Although the PVC–NPOE membranes with10wt.% imidazolium type of ILs appeared goodfilm-forming property,this kind of ionic liquids may not be well compatible with NPOE and lead to inferior potentiometric response and selectivity of the sensors.On the other hand,membrane5containing PVC,NPOE and 10wt.%THTDPCl exhibited stable and Nernstian responses to dif-ferent anions from10−5M to10−1M concentration range even for SO42−and Cl−(Fig.2).The response slopes were−30.2mV/decade for SO42−,−58.7mV/decade for Cl−,−61.4mV/decade for ClO4−and−62.0mV/decade for salicylate,respectively.As shown in Table2,the selectivity of THTDPCl-based PVC–NPOE membranes displays the Hofmeister series and similar values compared to TDMACl-based ion-exchanger membrane.It can also be found that the membranes containing THTDPCl as anionic exchangers showed less perchlorate selectivity.It was reported that ionic liquids are able to increase the dielectric constant of the membrane that could make the highly hydrophilic anions such as SO42−easier to be extracted from the water into the membrane phase[23].The overall potentiometric sensing property of the THTDPCl-based membranes is similar to that of membranes with TDMACl.3.3.Ionic liquids as both plasticizer and ion-exchangerAlthough satisfactory results can be obtained from THTDPCl-based PVC membrane with NPOE as plasticizer,the applications of many of traditional plasticizers are often associated with anum-Fig.3.Response curves of PVC–THTDPCl membrane7without additional plasticiz-ers toward SO42−, ;Cl−, ;salicylate,᭹;ClO4−, after conditioning in0.01M NaCl solution.ber of potential problems including limited compatibility,poor stability at high temperatures or under UV radiation,diminished lubricity at low temperatures andflammability[30–33].Reduced plasticizer content resulted from evaporation and exudation may also decrease the solubility of the ionophore and the ion-exchanger within the membrane,thus causing a marked decrease in sensitiv-ity and selectivity[32,34].Ionic liquids are one of the few novel alternatives to traditional plasticizer that have shown promising results in the early stages of investigation.It was recently reported that polyvinyl chloride can be plasticized by phosphonium-based ionic liquids[24,35].In this work we found that MOImCl and THT-DPCl can plasticize PVC and form sensing membranes with good film-forming property and elasticity.However,PVC membranes based on MOImCl or THTDPCl exhibited drastically different poten-tiometric response and selectivity.As shown in Fig.3,PVC–THTDPCl membrane exhibited Nernstian or nearly Nernstian responses to different anions in measuring ranges from10−5M to10−1M,and the slopes were−26.7mV/decade for SO42−,−55.1mV/decade for Cl−,−57.8mV/decade for ClO4−,−61.2mV/decade for salicylate and −61.0mV/decade for saccharin.The response range and selectiv-ity sequence of this NPOE-free membrane is comparable to the traditional PVC–NPOE membrane containing TDMACl(Table2). Less selectivity for lipophilic anions such as ClO4−and salicy-late was also observed for PVC–THTDPCl membrane.Obviously,in such membrane the IL has dual functions of both plasticizer and ion-exchanger.In contrast to THTDPCl,PVC–MOImCl membrane exhibited much improved SO42−selectivity.As shown in Fig.4after conditioning in Na2SO4solution the membrane responded to SO42−from10−5M to10−1M with Nernstian slope29.1mV/decade,while slopes for other anions are all sub-Nernstian and the membrane showed better selectivity toward SO42−than sulfate ionophore I-Table2Slopes and selectivity comparison of PVC–NPOE membranes with THTDPCl(membrane5)or TDMACl and NPOE-free PVC–THTDPCl membrane7Ion J Membrane5(THTDPCl/PVC–NPOE)Membrane7(PVC–THTDPCl)PVC/NPOE TDMAClSlope(mV/dec)log K potCl,J Slope(mV/dec)log K potCl,JSlope(mV/dec)log K potCl,JSO42−−30.2±0.8−1.67±0.2−26.7±1.8−1.53±0.3−28.9±1.0−1.45±0.1 Cl−−58.7±1.20−55.1±1.20−50.8±1.50 Salicylate−−62.0±1.4 2.64±0.2−61.2±0.6 2.57±0.2−62.7±0.6 3.65±0.3 ClO4−−61.4±1.0 3.93±0.3−57.8±1.0 3.79±0.1−62.0±1.7 5.2±0.2 Conditioning and innerfilling solution:0.01M NaCl;primary ion:Cl−.312 B.Peng et al./Sensors and Actuators B 133(2008)308–314Table 3Slopes and selectivity comparison of PVC–MOImCl membrane,PVC–NPOE membranes containing sulfate ionophore and THTDPCl (50mol%)or TDMACl (50mol%)as ion exchangers Ion JMembrane 6(PVC–MOImCl)Sulfate ionophore THTDPCl/PVC–NPOESulfate ionophore TDMACl/PVC–NPOE Slope (mV/dec)log KpotSO 2−4,JSlope(mV/dec)log KpotSO 2−4,J Slope (mV/dec)log KpotSO 2−4,JSO 42−−28.9±0.60−28.3±0.90−32.1±1.00Cl −−27.5±1.6 1.88±0.1−41.8±1.2 2.01±0.3−48.3±1.6 1.76±0.2Salicylate −−33.4±1.2 1.66±0.3−55.2±1.5 4.97±0.1−59.6±0.7 5.06±0.3SCN −−35.8±2.0 1.86±0.2−49.2±0.7 5.80±0.1−57.3±0.6 5.86±0.1ClO 4−−40.0±1.5 1.91±0.3−52.1±1.07.45±0.1−58.1±1.27.12±0.2Conditioning and inner filling solution:0.01M Na 2SO 4+0.1mM NaCl;primary ion:SO 42−.Fig.4.Response curves of PVC–MOImCl membrane 6toward SO 42−,᭹;Cl −, ;NO 3−,×;salicylate, ;ClO 4−,♦after conditioning in 0.01M Na 2SO 4solution.based ISE (Table 3).It is possible that imidazolium type cation of IL can have specific interaction with SO 42−and acts as ionophore that lead to better response and selectivity toward sulfate ion.pH influence on the PVC membrane containing different ionic liquids is studied.As shown in Fig.5,potential of NPOE-free PVC–THTDPCl and PVC–MOImCl membrane are slightly affected by pH in strong acidic solution and both membranes are pHFig.5.pH responses of PVC–THTDPCl ( )and PVC–MOImCl membranes (᭹).independent when pH changes from 3–10.PVC–THTDPCl and PVC–MOImCl membrane without additional plasticizer also shows good reproducibility and fast response time within 10s that is simi-lar to the response time of conventional ISE membranes (see Fig.6).It is the first time reported that ion-selective electrode prepared with PVC and ionic liquids as both ion-exchanger and plasticizer can exhibit Nernstian response to hydrophilic and lipophilic anions.3.4.Ionic liquids as anion-exchanger in ionophore-based membraneFurthermore we prepared the sensor containing neutral sul-fate ionophore [36]and ionic liquid THTDPCl.Forneutral anion ionophores it is essential to have anion-exchanger in the mem-brane to achieve the so-called Donnan exclusion.As shown in Fig.7,the membrane containing sulfate ionophore and THTDPCl (50mol%to ionophore)demonstrated Nernstian response to SO 42−with dynamic range from 10−6M to 10−1M.The response slopes and selectivity of membranes containing THTDPCl and TDMACl were compared in Table 3.THTDPCl-based membrane exhibited Nernstian slopes and similar selectivity to the TDMACl membrane.Although this ionophore was reported to be sulfate-selective,the selectivity we observed was inferior to that of ionophore-free PVC–MOImCl membrane.The complex stability constant of sul-fate ionophore in the two types of membranes with different ion-exchangers was measured by sandwich membrane method.In this method,transient membrane potential measurements on fused segmented sandwich membranes yield information about the activity ratio on both membrane sides.If only one side con-Fig.6.Response time and reproducibility of PVC–MOImCl membrane in 10−3and 10−2Na 2SO 4solutions.B.Peng et al./Sensors and Actuators B133(2008)308–314313Fig.7.Response curves of PVC–NPOE membranes containing sulfate ionophore and THTDPCl toward SO42−, ;Cl−, ;salicylate,᭹;ClO4−, after conditioning in0.01M Na2SO4solution.tains a known concentration of ionophore,information about the binding affinity of this ionophore can be obtained.As reported, the membrane potential E M is determined by subtracting the cell potential for a membrane without ionophore from that of the sand-wich membrane.The sandwich membrane potentials were found to be−251±2mV for TDMACl-based PVC–NPOE membrane and −214±3mV for the same membrane with ionic liquid THTDPCl, which give the apparent stability constants(logˇ)of7.34±0.03 and6.01±0.04,respectively according to Eq.(1)by assuming one sulfate ions binding with one ligand(n=1):E M=RTz I F ln[ˇILn(L T−nR T/Z1)n](1)where L T is the total concentration of ionophore in the membrane segment,R T is the concentration of lipophilic ionic site additives,n is the ion–ionophore complex stoichiometry and R,T,and F are the gas constant,the absolute temperature and the Faraday constant. The ion I carries a charge of Z I.The utilization of ionic liquid is able to influence the dielectric constant of the membrane,which may result in the difference of the stability constant values.The results obtained from both ionophore-based membrane and ionophore-free THTDPCl–PVC–NPOE membrane indicate that the THTDPCl could be used as an alternative anionic exchanger to TDMACl in ion-selective electrodes.3.5.ApplicationsThe new PVC–MOImCl membrane electrode with SO42−selec-tivity was applied for the determination of sulfate in drinking water samples from local market with satisfactory results.The analysis was performed by using the standard addition technique and theTable4Determination of sulfate in drinking water samples with ionophore-free PVC–MOImCl membrane6Added sulfate(mg)Found sulfate(mg)Recovery(%)31.2934.01108.753.2555.79104.873.4975.65102.996.1397.07100.9118.64117.4399.0results are summarized in Table4.Good recoveries were obtained in all samples.4.ConclusionDifferent types of ionic liquids were studied as anion exchangers in potentiometric ion sensors.Trihexyltetradecylphonium chloride was found to be a suitable alternative to the traditional anionic exchanger,TDMACl.PVC–NPOE membranes with THTDPCl as ion-exchanger exhibited similar response and selectivity sequence as TDMACl-based membranes.Furthermore,THTDPCl and MOImCl can also be used as plasticizer in PVC membranes that do not require additional organic solvent.PVC–THTDPCl membrane in which the ionic liquid THTDPCl functions as both ion-exchanger and plasti-cizer,showed comparable response to the traditional plasticized PVC–NPOE membrane containing TDMACl,while PVC–MOImCl membrane exhibited Nernstian response and good selectivity to sulfate.The proposed plasticizer-free membranes were successfully applied in real sample analysis.AcknowledgmentsThe authors wish to thank the starting grant from Renmin Uni-versity of China and National Natural Science Foundation of China (20505017)forfinancial support of this research.References[1]E.Bakker,P.Buhlmann,E.Pretsch,Carrier-based ion-selective electrodes andbulk optodes.1.General characteristics,Chem.Rev.97(1997)3083–3132. [2]P.Buhlmann,E.Pretsch,E.Bakker,Carrier-based ion-selective electrodes andbulk optodes.2.Ionophores for potentiometric and optical sensors,Chem.Rev.98(1998)1593–1688.[3]K.T´oth,n,J.Jeney,M.Horvath,I.Bitter,A.Gru¨n,B.Agai,L.Toke,Chro-mogenic calix[4]arene as ionophore for potentiometric and optical sensors, Talanta41(1994)1041–1049.[4]J.Murphy,Additives for Plastics Handbook,2nd ed.,Elsevier,2001.[5]L.Y.Heng,E.A.H.Hall,Methacrylic–acrylic polymers in ion-selective mem-branes:achieving the right polymer recipe,Anal.Chim.Acta403(2000)77–89.[6]L.Y.Heng,E.A.H.Hall,Producing“self-plasticizing”ion-selective membranes,Anal.Chem.72(2000)42–51.[7]L.Y.Heng,E.A.H.Hall,One-step synthesis of K+-selective methacrylic–acryliccopolymers containing grafted ionophore and requiring no plasticizer,Electro-analysis12(2000)178–186.[8]L.Y.Heng,E.A.H.Hall,Taking the plasticizer out of methacrylic–acrylic mem-branes for K+-selective electrodes,Electroanalysis12(2000)187–193.[9]L.Y.Heng,E.A.H.Hall,Assessing a photocured self-plasticized acrylic membranerecipe for Na+and K+ion selective electrodes,Anal.Chim.Acta443(2001) 25–40.[10]Y.Qin,S.Peper,E.Bakker,Plasticizer-free polymer membrane ion-selectiveelectrodes containing a methacrylic copolymer matrix,Electroanalysis14 (2002)1375–1381.[11]A.J.Michalska, C.Appaih-Kusi,L.Y.Heng,S.Walkiewicz, E.A.H.Hall,Anexperimental study of membrane materials and inner contacting layers for ion-selective K+electrodes with a stable response and good dynamic range,Anal.Chem.76(2004)2031–2039.[12]R.Long,E.Bakker,Optical determination of ionophore diffusion coefficientsin plasticized poly(vinyl chloride)sensingfilms,Anal.Chim.Acta511(2004) 91–95.[13]T.Welton,Room-temperature ionic liquids.Solvents for synthesis and catalysis,Chem.Rev.99(1999)2071–2084.[14]P.A.Z.Suarez,V.M.Selbach,J.E.L.Dullius,S.Einloft, C.M.S.Piatnicki, D.S.Azambuja,R.F.de Souza,J.Dupont,Enlarged electrochemical window in dialkyl-imidazolium cation based room-temperature air and water-stable molten salts,Electrochim.Acta42(1997)2533–2535.[15]S.Carda-Broch,A.Berthod,D.W.Armstrong,Solvent properties of the1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid,Anal.Bioanal.Chem.375(2003)191–199.[16]J.G.Huddleston,R.D.Rogers,Room temperature ionic liquids as novel mediafor‘clean’liquid–liquid extraction,mun.(1998)1765–1766. [17]J.-F.Liu,Y.-G.Chi,G.-B.Jiang,C.Tai,J.-F.Peng,J.-T.Hu,Ionic liquid-basedliquid-phase microextraction,a new sample enrichment procedure for liquid chromatography,J.Chromatogr.A1026(2004)143–147.[18]A.E.Visser,R.P.Swatloski,W.M.Reichert,J.H.Davis Jr.,R.D.Rogers,R.Mayton,S.Sheff,A.Wierzbicki,Task-specific ionic liquids for the extraction of metal ions from aqueous solutions,mun.(2001)135–136.。

2021年1期科技创新与应用Technology Innovation and Application众创空间自参考磁流体磁场传感器研究*赵浩旭,兰云蕾,周志鹏,赵国梁,于洋,武继江*(山东理工大学物理与光电工程学院,山东淄博255000)引言当光波在金属与电介质界面上传播时,在满足一定的条件下,能够激发出表面等离极化激元(surface plas -mon polaritons ,SPPs ),这是一种局域化的电磁表面波传播模式。

基于这种电磁表面波的光学传感器已在多个领域得到广泛的应用,并得到很好的发展[1]。

近年来,一种新型被称为塔姆等离子体激元(Tamm plasmon polaritons ,TPPs )的电磁表面模式也逐步引起了研究者们的研究兴趣[2]。

这种电磁表面波可通过加载有金属薄膜的分布式布拉格反射镜(distributed Bragg reflector ,DBR )的光学结构来激发。

表面等离极化激元的激发对入射光的偏振态有一定的要求,而塔姆等离子体激元这种表面波的激发对入射光的偏振态没有要求,横电偏振光和横磁偏振光均能够激发。

研究表明,一个金属-DBR 光学结构能激发单个塔姆等离子体激元。

近来,人们构造出一种含两个金属-DBR 的光学结构,研究表明该结构可激发两个塔姆等离子体激元。

研究还表明,在一定的结构参数下,所激发的两个塔姆等离子体激元中,其中一个对结构参数的变化不敏感。

基于这一特性,可实现了自参考传感器,并在温度、折射率和血液样品成分的传感测量方面得到很好的应用[3-5]。

作为一个重要的物理参数,磁场的传感测量备受人们的关注。

目前有各种方法可实现磁场的测量。

其中由于光学方法不易受电场干扰的影响而在磁场传感中显示出优异的性能。

在各种光学方法中,基于磁流体(magnetic fluid ,MF )的各类磁场传感器备受研究者的青睐。

磁流体是一种磁性微粒在表面活性剂的作用下均匀弥散于载液中所形成的稳定胶状体系。

牛血红蛋白催化香豆素体系荧光光度法测定过氧化氢单雅琦;陈永宁;张容珲;唐宁莉【摘要】在 pH 3.5的 NaOH -H2 SO4缓冲溶液中,牛血红蛋白催化 H2 O2氧化香豆素生成7-羟基香豆素,导致体系的荧光强度明显增强。

该氧化产物在456 nm 处有最大荧光强度。

实验表明:在456 nm 处,体系的荧光增加值ΔF 与 H2 O2的浓度在3.940×10-7~7.880×10-5 mol/L 范围内呈良好的线性关系,相关系数r 为0.9985,检出限为1.25×10-8 mol/L。

据此建立了一种简单、灵敏度高的检测水样中痕量 H2 O2的荧光新方法。

该方法已用于雨水及消毒液中H2 O2的测定,结果满意。

%In pH 3.5 NaOH -H2 SO4 buffer solution,with bovine hemoglobin as catalyst,coumarin was oxi-dized to produce 7-hydroxycoumarin by hydrogen peroxide,which had strong fluorescence in acid solution.At the length of maximum emission 456 nm,the increased value of fluorescence intensity (ΔF)was linear to the concentration of hydrogen peroxide in the range of 3.940 ×10 -7 -7.880 ×10 -5 mol /L,with a correlation coef-ficient of 0.998 5 and a detec tion limit of 1.25 ×10 -8 mol /L.Based on this,a simple and highly sensitive flu-orometric method was proposed for the determination of trace H2 O2 .This new fluorometric method can be ap-plied to the analysis of H2 O2 in rainwater and disinfectant fluid samples with satisfactory results.【期刊名称】《桂林理工大学学报》【年(卷),期】2016(036)002【总页数】4页(P333-336)【关键词】过氧化氢;牛血红蛋白;香豆素;荧光法【作者】单雅琦;陈永宁;张容珲;唐宁莉【作者单位】桂林理工大学化学与生物工程学院,广西桂林 541004;桂林理工大学化学与生物工程学院,广西桂林 541004;桂林理工大学化学与生物工程学院,广西桂林 541004;桂林理工大学化学与生物工程学院,广西桂林 541004【正文语种】中文【中图分类】O657.3过氧化氢普遍存在于自然生态体系中,是生物和环境系统中存在的一种重要中间产物,在食品科学、医学、化学、生物、环境保护等众多领域应用广泛。

sensors and actuators b chemical不超过5000字Sensors and Actuators are crucial components in the fieldof chemical engineering. These devices play a significant role in monitoring and controlling various chemical processes and reactions. Sensors are responsible for detecting physical or chemical changes in the environment, while actuators are used to initiate a certain action based on the information received from sensors.传感器和执行器是化学工程领域中不可或缺的部件。

这些设备在监测和控制各种化学过程和反应中起着重要作用。

传感器负责检测环境中的物理或化学变化,而执行器则根据传感器接收到的信息来启动某种动作。

Chemical sensors are specialized sensors that are designedto detect the presence of specific chemicals or gases. These sensors work based on various principles such as electrochemical, optical, or catalytic reactions. They can be used to monitor parameters such as temperature, pressure, pH, concentration of a particular chemical species, andmany more.化学传感器是专门设计用于检测特定化学物质或气体存在的传感器。

气相色谱法同时检测复合酸化剂中6种有机酸的方法随着化学工业的快速发展,复合酸化剂作为一种重要的催化剂,在有机合成和化学制品生产过程中发挥着重要作用。

然而,复合酸化剂中常常含有多种有机酸,由于其种类繁多、浓度不同,传统的分析方法往往不适用。

本文将介绍一种采用气相色谱法同时检测复合酸化剂中6种常见有机酸的方法。

2. 方法介绍2.1 样品制备首先,将复合酸化剂样品粉末加入适量的溶剂中,进行超声处理以使样品充分溶解。

然后,用滤纸滤除悬浮物,并将滤液转移至干燥瓶中。

在样品制备过程中,需要注意防止其他杂质的污染和挥发损失。

2.2 色谱条件设置本方法采用气相色谱仪进行分析,使用6种适当的色谱柱进行分离和定量。

根据样品的特性和要求,选择合适的色谱柱类型和尺寸,例如,常用的色谱柱包括DB-5、DB-1、HP-5等。

色谱仪的工作温度、进样量和分析时间等参数也需要根据实际情况进行优化和调整。

2.3 标准曲线制备与定量为了准确地检测样品中的有机酸含量,需要制备一组含有已知浓度的标准溶液,并进行气相色谱分析。

根据标准曲线上的峰面积与浓度的线性关系,可以计算出样品中每种有机酸的浓度。

标准曲线的制备过程需要注意样品的稀释配比和浓度范围的选择。

3. 实验步骤3.1 样品准备将复合酸化剂样品粉末称取适量,加入溶剂中,并进行超声处理使其充分溶解。

3.2 样品处理用滤纸滤除悬浮物,并将滤液转移到干燥瓶中。

保持样品瓶密封,以防止挥发和污染。

3.3 标准曲线制备准备一系列含有已知浓度的标准溶液,并进行气相色谱分析,记录每种有机酸的峰面积和浓度。

3.4 色谱分析将样品和标准溶液以相同的方式进样到色谱仪中,根据标准曲线进行定量分析,计算每种有机酸的浓度。

4. 结果与讨论使用本方法进行分析后,可以得到复合酸化剂中6种有机酸的浓度值。

常见的有机酸包括乙酸、丙酸、戊酸、己酸、庚酸和癸酸。

通过比较不同样品的有机酸含量,可以评估复合酸化剂样品的质量和纯度。

荧光探针可以投稿的文章以下是一些相关的期刊和主题建议:期刊:Sensors and Actuators B: Chemical:该期刊专注于化学传感器和化学元件方面的研究,包括荧光探针等方面的应用。

Analytical Chemistry:这是一个广泛涵盖分析化学领域的期刊,可能刊登与荧光探针相关的分析方法和应用。

Chemical Communications:这个期刊着重于化学领域的快速通讯,也可能包括新型荧光探针的合成和应用研究。

Biosensors and Bioelectronics:关注生物传感器和生物电子学领域,可能刊登与荧光探针在生物传感和检测中的应用。

Journal of Fluorescence:专注于荧光现象和技术的期刊,可能包含荧光探针在不同领域的研究。

Talanta:着眼于分析化学领域的研究,可能包含使用荧光探针进行分析和检测的研究。

主题建议:荧光探针在生物医学研究中的应用:探讨荧光探针在生物医学领域中的最新研究进展和应用,包括荧光成像、荧光共振能量转移(FRET)等技术。

新型荧光探针的设计与合成:介绍新型荧光探针的设计原理、合成方法以及性能评价,探讨其在生物传感、药物筛选等领域的应用前景。

荧光探针在环境监测中的应用:介绍荧光探针在环境监测中的最新研究进展,包括重金属离子、有机污染物等的检测和分析。

荧光探针在食品质量安全检测中的应用:探讨荧光探针在食品质量安全检测中的最新研究和应用,包括农残、添加剂等的检测和分析。

荧光探针在化学和生物分析中的应用:介绍荧光探针在化学和生物分析中的最新研究和应用,包括蛋白质标记、DNA 检测等方面的应用。

当然,这只是一些可供参考的主题建议,具体的投稿还需要根据具体的研究成果和研究内容来确定。

在投稿前,还需要仔细阅读期刊的投稿指南,确保文章符合期刊的要求和格式。