Surface fractal dimension of bentonite and its application to determination of swelling properties

- 格式:pdf

- 大小:192.94 KB

- 文档页数:10

武汉理工大学材料科学基础(第2版)课后习题和答案第一章绪论1、仔细观察一下白炽灯泡,会发现有多少种不同的材料?每种材料需要何种热学、电学性质?2、为什么金属具有良好的导电性和导热性?3、为什么陶瓷、聚合物通常是绝缘体?4、铝原子的质量是多少?若铝的密度为2.7g/cm3,计算1mm3中有多少原子?5、为了防止碰撞造成纽折,汽车的挡板可有装甲制造,但实际应用中为何不如此设计?说出至少三种理由。

6、描述不同材料常用的加工方法。

7、叙述金属材料的类型及其分类依据。

8、试将下列材料按金属、陶瓷、聚合物或复合材料进行分类:黄铜钢筋混凝土橡胶氯化钠铅-锡焊料沥青环氧树脂镁合金碳化硅混凝土石墨玻璃钢9、Al2O3陶瓷既牢固又坚硬且耐磨,为什么不用Al2O3制造铁锤?第二章晶体结构1、解释下列概念晶系、晶胞、晶胞参数、空间点阵、米勒指数(晶面指数)、离子晶体的晶格能、原子半径与离子半径、配位数、离子极化、同质多晶与类质同晶、正尖晶石与反正尖晶石、反萤石结构、铁电效应、压电效应.2、(1)一晶面在x、y、z轴上的截距分别为2a、3b、6c,求出该晶面的米勒指数;(2)一晶面在x、y、z 轴上的截距分别为a/3、b/2、c,求出该晶面的米勒指数。

3、在立方晶系的晶胞中画出下列米勒指数的晶面和晶向:(001)与[210],(111)与[112],(110)与[111],(322)与[236],(257)与[111],(123)与[121],(102),(112),(213),[110],[111],[120],[321]4、写出面心立方格子的单位平行六面体上所有结点的坐标。

5、已知Mg2+半径为0.072nm,O2-半径为0.140nm,计算MgO晶体结构的堆积系数与密度。

6、计算体心立方、面心立方、密排六方晶胞中的原子数、配位数、堆积系数。

7、从理论计算公式计算NaC1与MgO的晶格能。

MgO的熔点为2800℃,NaC1为80l℃, 请说明这种差别的原因。

介质分界面的全反射角布儒斯特角布儒斯特角(Brewster's angle)是光线在介质分界面发生全反射的特殊角度。

在这个角度下,入射光线的偏振方向与界面垂直,使得反射光线的偏振方向与界面平行。

这一现象是19世纪初由英国物理学家大卫·布儒斯特发现的,也因此得名。

布儒斯特角的大小可以通过斯涅尔定律(Snell's law)来推导。

斯涅尔定律描述了光在介质分界面的折射现象,即入射光线与界面法线夹角的正弦比等于两个介质的折射率之比。

在特定的折射率条件下,根据斯涅尔定律可以推导出布儒斯特角。

设光线从折射率为n1的介质1通过一个折射率为n2的介质2射入介质2时,入射角为θ1,折射角为θ2。

当光线的入射角等于布儒斯特角时,折射角为90度,即θ2=90°。

根据斯涅尔定律,正弦θ1/n1 = 正弦θ2/n2,代入θ2=90°,可得正弦布儒斯特角sinθp = n2/n1。

布儒斯特角与入射介质和折射介质的折射率有关。

在布儒斯特角下,入射光线的偏振方向与界面垂直,这意味着反射光线的偏振方向与界面平行。

这一现象可以用光的电矢量理论来解释。

光是一种电磁波,包含着电矢量和磁矢量的振动。

当光线从一个介质射入另一个介质时,根据介质的折射率差异,电矢量和磁矢量会以不同的速度传播,导致光线的偏振方向改变。

而在布儒斯特角下,入射角的选择使得电矢量只能沿界面方向振动,从而反射光线的偏振方向与界面平行。

布儒斯特角在光学研究和应用中具有重要意义。

它可以用于优化光学器件的设计,例如激光器、光纤、反射镜等。

在这些应用中,布儒斯特角被用来选择性地传递或反射特定偏振方向的光线,从而提高光学器件的效率和性能。

布儒斯特角还被用于测量介质的折射率。

由于布儒斯特角与折射率之间的关系可以通过正弦函数表达,因此可以通过测量布儒斯特角来确定介质的折射率,这在物理实验和材料研究中有着广泛的应用。

总结起来,布儒斯特角是光线在介质分界面发生全反射的特殊角度。

【高分子专业英语翻译】第五课乳液聚合大部分的乳液聚合都是由自由基引发的并且表现出其他自由基体系的很多特点,最主要的反应机理的不同源自小体积元中自由基增长的场所不同。

乳液聚合不仅允许在高反应速率下获得较高分子量,这在本体聚合中是无法实现或效率低下的,,同时还有其他重要的实用优点。

水吸收了大部分聚合热且有利于反应控制,产物在低粘度体系中获得,容易处理,可直接使用或是在凝聚,水洗,干燥之后很快转化成固体聚合物。

在共聚中,尽管共聚原理适用于乳液体系,单体在水相中溶解能力的不同也可能导致其与本体聚合行为不同,从而有重要的实际意义。

乳液聚合的变化很大,从包含单一单体,乳化剂,水和单一引发剂的简单体系到这些包含有2,3个单体,一次或分批添加,,混合乳化剂和助稳定剂以及包括链转移剂的复合引发体系。

单体和水相的比例允许变化范围很大,但是在技术做法上通常限制在30/70到60/40。

单体和水相比更高时则达到了直接聚合允许的极限,只有通过分批添加单体方法来排除聚合产生的大量的热。

更复杂的是随着胶体数的增加粘度也大大增加,尤其是当水溶性的单体和聚合物易容时,反应结束胶乳浓度降低。

这一阶段常常伴随着通过聚集作用或是在热力学不稳定时凝结作用而使胶粒尺寸增大。

第十课高分子的构型和构象本课中我们将使用根据经典有机化学术语而来的构型和构象这两个词。

构型异构是由于分子中存在一个或多个不对称中心,以最简单的C原子为例,每一碳原子的绝对构型为R型和S型,当存在双键时会有顺式和反式几何异构。

以合成聚合物为例,构型异构的典型问题和R.S型不对称碳原子在主链上的排布有关。

这些不对称碳原子要么来自不对称单体,如环氧丙烷,要么来自对称单体,如乙烯单体,,这些物质的聚合,在每个单体单元中形成至少一个不对称碳原子。

大分子中的构型异构源于侧链上存在不对称的碳原子,例如不对称乙烯单体的聚合,也是可能的,现今已经被广泛研究。

和经典有机化学术语一致,构象,旋转体,旋转异构体,构象异构体,指的是由于分子单键的内旋转而形成的空间排布的不同。

石墨为基础的单一细菌分辨率装置和DNA晶体管:石墨衍生物纳米微型生物成份的界面连接技术摘要建立“大接触面积”与微生物和哺乳动物细胞中的敏感纳米界面将导致生物诊断和生物医学方面有价值的工具和设备的发展。

化学改性石墨(CMG)的纳米结构与他们的微型区域、敏感的电气性能与修改的化学功能是生物细胞和生物分子尺度方面的生物装置的极好的选择。

在此,我们报告一种新型CMG-型的制作和运作:(I)单细菌生物装置(ii)无标签的DNA传感器,及(iii)细菌的DNA/蛋白质和电解质的化学晶体管。

在p型CMG,细菌生物装置与单细菌附件产生的约1400载流子是非常敏感。

同样的,拴在石墨上的单链DNA与它的互补DNA 混合,以便可逆增加空穴密度到5.61 ×1012 cm-2.。

我们进一步证明(a)通过操控表面组织,对装置灵敏的控制(b)通过改变表面极性使极性特异性的转换(c)在厚的CMG的表面和尖的CMG 皱纹上的DNA的优先连接物在过去十年中,已经出现了对制造与电,光,热活跃的纳米材料有关纳米/生物界面的大量研究,这使得生物医学、生物驱使设备、生物检测和诊断学领域极大地前进。

当前一代用零维(0D)纳米粒子、一维(1D)纳米线和二维网络建造的电活性纳米生物装置显示了对分子的(DNA,三磷酸腺苷,蛋白质等)和纳米(病毒等)生物成份的优良检测和接口技术能力。

然而,在区域尺寸不相容在使用个别的零维和一维纳米结构时具有挑战性,这种纳米结构是为与大尺寸的微生物建造强的界面或保留他们在网络上。

化学改性的石墨有二维纳米结构和可调表面化学,它能与生物系统界面在无几何限制和在不损害微生物附着的完整性强烈接触。

最近,化学的和几何学的石墨处理显现出极大的潜力来控制半金属和半导体之间的带间隙。

此外,其低电气噪声(低电荷散射)和弹道输运,石墨纳米结构已合成各种电子和光电子应用产品,如气体传感器、晶体管、太阳能电池和液晶元素。

然而,还没有石墨烯在生物装置上应用的报告。

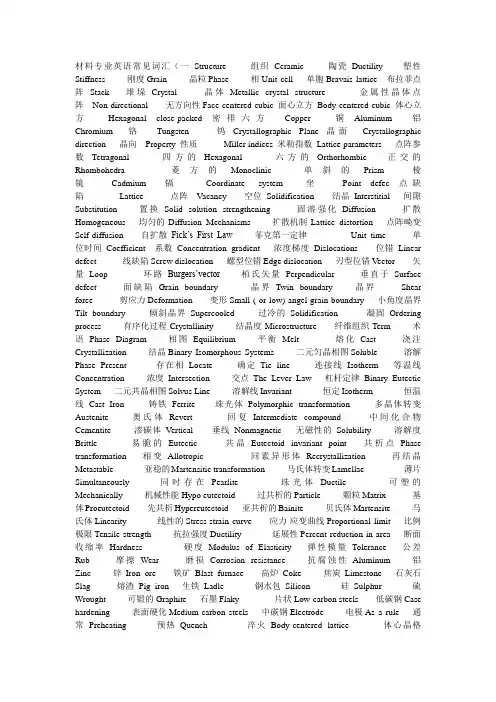

材料专业英语常见词汇(一Structure 组织Ceramic 陶瓷Ductility 塑性Stiffness 刚度Grain 晶粒Phase 相Unit cell 单胞Bravais lattice 布拉菲点阵Stack 堆垛Crystal 晶体Metallic crystal structure 金属性晶体点阵 Non-directional 无方向性Face-centered cubic 面心立方 Body-centered cubic 体心立方 Hexagonal close-packed 密排六方 Copper 铜Aluminum 铝Chromium 铬 Tungsten 钨Crystallographic Plane 晶面 Crystallographic direction 晶向 Property 性质 Miller indices 米勒指数Lattice parameters 点阵参数Tetragonal 四方的Hexagonal 六方的Orthorhombic 正交的Rhombohedra 菱方的Monoclinic 单斜的Prism 棱镜Cadmium 镉 Coordinate system 坐Point defec点缺陷 Lattice 点阵 Vacancy 空位Solidification 结晶Interstitial 间隙Substitution 置换Solid solution strengthening 固溶强化Diffusion 扩散Homogeneous 均匀的Diffusion Mechanisms 扩散机制Lattice distortion 点阵畸变Self-diffusion 自扩散Fick’s First Law菲克第一定律 Unit time 单位时间Coefficient 系数Concentration gradient 浓度梯度Dislocations 位错Linear defect 线缺陷Screw dislocation 螺型位错Edge dislocation 刃型位错Vector 矢量Loop 环路Burgers’vector柏氏矢量Perpendicular 垂直于Surface defect 面缺陷Grain boundary 晶界Twin boundary 晶界 Shear force 剪应力Deformation 变形Small ( or low) angel grain boundary 小角度晶界Tilt boundary 倾斜晶界Supercooled 过冷的Solidification 凝固Ordering process 有序化过程Crystallinity 结晶度Microstructure 纤维组织Term 术语Phase Diagram 相图Equilibrium 平衡Melt 熔化Cast 浇注Crystallization 结晶Binary Isomorphous Systems 二元匀晶相图Soluble 溶解Phase Present 存在相Locate 确定Tie line 连接线Isotherm 等温线Concentration 浓度Intersection 交点The Lever Law 杠杆定律Binary Eutectic System 二元共晶相图Solvus Line 溶解线Invariant 恒定Isotherm 恒温线Cast Iron 铸铁Ferrite 珠光体Polymorphic transformation 多晶体转变Austenite 奥氏体Revert 回复Intermediate compound 中间化合物Cementite 渗碳体Vertical 垂线Nonmagnetic 无磁性的Solubility 溶解度Brittle 易脆的Eutectic 共晶Eutectoid invariant point 共析点Phase transformation 相变Allotropic 同素异形体Recrystallization 再结晶Metastable 亚稳的Martensitic transformation 马氏体转变Lamellae 薄片Simultaneously 同时存在Pearlite 珠光体Ductile 可塑的Mechanically 机械性能Hypo eutectoid 过共析的Particle 颗粒Matrix 基体Proeutectoid 先共析Hypereutectoid 亚共析的Bainite 贝氏体Martensite 马氏体Linearity 线性的Stress-strain curve 应力-应变曲线Proportional limit 比例极限Tensile strength 抗拉强度Ductility 延展性Percent reduction in area 断面收缩率Hardness 硬度Modulus of Elasticity 弹性模量Tolerance 公差Rub 摩擦Wear 磨损Corrosion resistance 抗腐蚀性Aluminum 铝Zinc 锌Iron ore 铁矿Blast furnace 高炉Coke 焦炭Limestone 石灰石Slag 熔渣Pig iron 生铁Ladle 钢水包Silicon 硅Sulphur 硫Wrought 可锻的Graphite 石墨Flaky 片状Low-carbon steels 低碳钢Case hardening 表面硬化Medium-carbon steels 中碳钢Electrode 电极As a rule 通常Preheating 预热Quench 淬火Body-centered lattice 体心晶格Carbide 碳化物Hypereutectoid 过共晶Chromium 铬Manganese 锰Molybdenum 钼Titanium 钛Cobalt 钴Tungsten 钨Vanadium 钒Pearlitic microstructure 珠光体组织Martensitic microstructure 马氏体组织Viscosity 粘性Wrought 锻造的Magnesium 镁Flake 片状Malleable 可锻的Nodular 球状Spheroidal 球状Superior property 优越性Galvanization 镀锌Versatile 通用的Battery grid 电极板Calcium 钙Tin 锡Toxicity 毒性Refractory 耐火的Platinum 铂Polymer 聚合物Composite 混合物Erosive 腐蚀性Inert 惰性Thermo chemically 热化学Generator 发电机Flaw 缺陷Variability 易变的Annealing 退火Tempering 回火Texture 织构Kinetic 动力学Peculiarity 特性Critical point 临界点Dispersity 弥散程度Spontaneous 自发的Inherent grain 本质晶粒Toughness 韧性Rupture 断裂Kinetic curve of transformation 转变动力学曲线Incubation period 孕育期Sorbite 索氏体Troostite 屈氏体Disperse 弥散的Granular 颗粒状Metallurgical 冶金学的Precipitation 析出Depletion 减少Quasi-eutectoid 伪共析Superposition 重叠Supersede 代替Dilatometric 膨胀Unstable 不稳定Supersaturate 使过饱和Tetragonality 正方度Shear 切变Displacement 位移Irreversible 不可逆的金属材料工程专业英语acid-base equilibrium酸碱平衡acid-base indicator酸碱指示剂acid bath酸槽acid(Bessemer)converter酸性转炉acid brick酸性耐火砖acid brittleness酸洗脆性、氢脆性acid burden酸性炉料acid clay酸性粘土acid cleaning (同pickling)酸洗acid concentration酸浓度acid converter酸性转炉acid converter steel酸性转炉钢acid content酸含量acid corrosion酸腐蚀acid deficient弱酸的、酸不足的acid dip 酸浸 acid dip pickler(沉浸式) 酸洗装置acid(dip)tank酸液(浸洗)槽acid drain tank排酸槽acidless descaling无酸除鳞acid medium酸性介质acid mist酸雾acid-proof paint耐酸涂料(漆)acid-proof steel耐酸钢acid-resistant耐酸钢acid-resisting vessel耐酸槽acid strength酸浓度acid supply pump供酸泵acid wash酸洗acid value酸值acid wash solution酸洗液acieration渗碳、增碳Acm point Acm转变点(渗碳体析出温度)acorn nut螺母、螺帽acoustic absorption coefficient声吸收系数acoustic susceptance声纳actifier再生器action line作用线action spot作用点activated atom激活原子activated bath活化槽activated carbon活性碳activating treatment活化处理active corrosion活性腐蚀、强烈腐蚀active area有效面积active power有功功率、有效功率active product放射性产物active resistance有效电阻、纯电阻active roll gap轧辊的有效(或工作)开口度active state活性状态active surface有效(表)面activity coefficient激活系数、活度系数actual diameter(钢丝绳)实际直径actual efficiency实际效率actual error实际误差actual time实时actual working stress实际加工应力actuating device调节装置、传动装置、起动装置actuating lever驱动杆、起动杆actuating mechanism 动作机构、执行机构actuating motor驱动电动机、伺服电动机actuating pressure作用压力actuation shaft 起动轴actuator调节器、传动装置、执行机构acute angle锐角adaptive feed back control自适应反馈控制adaptive optimization自适应最优化adaptor接头、接合器、连结装置、转接器、附件材料科学基础专业词汇:第一章晶体结构原子质量单位Atomic mass unit (amu) 原子数Atomic number 原子量Atomic weight波尔原子模型Bohr atomic model 键能Bonding energy 库仑力Coulombic force共价键Covalent bond 分子的构型molecular configuration电子构型electronic configuration 负电的Electronegative 正电的Electropositive基态Ground state 氢键Hydrogen bond 离子键Ionic bond 同位素Isotope金属键Metallic bond 摩尔Mole 分子Molecule 泡利不相容原理Pauli exclusion principle 元素周期表Periodic table 原子atom 分子molecule 分子量molecule weight极性分子Polar molecule 量子数quantum number 价电子valence electron范德华键van der waals bond 电子轨道electron orbitals 点群point group对称要素symmetry elements 各向异性anisotropy 原子堆积因数atomic packing factor(APF) 体心立方结构body-centered cubic (BCC) 面心立方结构face-centered cubic (FCC)布拉格定律bragg’s law 配位数coordination number 晶体结构crystal structure晶系crystal system 晶体的crystalline 衍射diffraction 中子衍射neutron diffraction电子衍射electron diffraction 晶界grain boundary 六方密堆积hexagonal close-packed (HCP) 鲍林规则Pauling’s rules NaCl型结构NaCl-type structureCsCl型结构Caesium Chloride structure 闪锌矿型结构Blende-type structure纤锌矿型结构Wurtzite structure 金红石型结构Rutile structure萤石型结构Fluorite structure 钙钛矿型结构Perovskite-type structure尖晶石型结构Spinel-type structure 硅酸盐结构Structure of silicates岛状结构Island structure 链状结构Chain structure 层状结构Layer structure架状结构Framework structure 滑石talc 叶蜡石pyrophyllite 高岭石kaolinite石英quartz 长石feldspar 美橄榄石forsterite 各向同性的isotropic各向异性的anisotropy 晶格lattice 晶格参数lattice parameters 密勒指数miller indices 非结晶的noncrystalline多晶的polycrystalline 多晶形polymorphism 单晶single crystal 晶胞unit cell电位electron states(化合)价valence 电子electrons 共价键covalent bonding金属键metallic bonding 离子键Ionic bonding 极性分子polar molecules原子面密度atomic planar density 衍射角diffraction angle 合金alloy粒度,晶粒大小grain size 显微结构microstructure 显微照相photomicrograph扫描电子显微镜scanning electron microscope (SEM)透射电子显微镜transmission electron microscope (TEM) 重量百分数weight percent四方的tetragonal 单斜的monoclinic 配位数coordination number材料科学基础专业词汇:第二章晶体结构缺陷缺陷defect, imperfection 点缺陷point defect 线缺陷line defect, dislocation面缺陷interface defect 体缺陷volume defect 位错排列dislocation arrangement位错线dislocation line 刃位错edge dislocation 螺位错screw dislocation混合位错mixed dislocation 晶界grain boundaries 大角度晶界high-angle grain boundaries小角度晶界tilt boundary, 孪晶界twin boundaries 位错阵列dislocation array位错气团dislocation atmosphere 位错轴dislocation axis 位错胞dislocation cell位错爬移dislocation climb 位错聚结dislocation coalescence 位错滑移dislocation slip 位错核心能量dislocation core energy 位错裂纹dislocation crack位错阻尼dislocation damping 位错密度dislocation density原子错位substitution of a wrong atom 间隙原子interstitial atom晶格空位vacant lattice sites 间隙位置interstitial sites 杂质impurities弗伦克尔缺陷Frenkel disorder 肖脱基缺陷Schottky disorder 主晶相the host lattice 错位原子misplaced atoms 缔合中心Associated Centers. 自由电子Free Electrons电子空穴Electron Holes 伯格斯矢量Burgers 克罗各-明克符号Kroger Vink notation 中性原子neutral atom材料科学基础专业词汇:第二章晶体结构缺陷-固溶体固溶体solid solution 固溶度solid solubility 化合物compound间隙固溶体interstitial solid solution 置换固溶体substitutional solid solution金属间化合物intermetallics 不混溶固溶体immiscible solid solution转熔型固溶体peritectic solid solution 有序固溶体ordered solid solution无序固溶体disordered solid solution 固溶强化solid solution strengthening取代型固溶体Substitutional solid solutions 过饱和固溶体supersaturated solid solution 非化学计量化合物Nonstoichiometric compound材料科学基础专业词汇:第三章熔体结构熔体结构structure of melt过冷液体supercooling melt 玻璃态vitreous state软化温度softening temperature 粘度viscosity 表面张力Surface tension介稳态过渡相metastable phase 组织constitution 淬火quenching退火的softened 玻璃分相phase separation in glasses 体积收缩volume shrinkage材料科学基础专业词汇:第四章固体的表面与界面表面surface 界面interface 同相界面homophase boundary异相界面heterophase boundary 晶界grain boundary 表面能surface energy小角度晶界low angle grain boundary 大角度晶界high angle grain boundary共格孪晶界coherent twin boundary 晶界迁移grain boundary migration错配度mismatch 驰豫relaxation 重构reconstuction 表面吸附surface adsorption表面能surface energy 倾转晶界titlt grain boundary 扭转晶界twist grain boundary倒易密度reciprocal density 共格界面coherent boundary 半共格界面semi-coherent boundary 非共格界面noncoherent boundary 界面能interfacial free energy应变能strain energy 晶体学取向关系crystallographic orientation惯习面habit plane材料科学基础专业词汇:第五章相图相图phase diagrams 相phase 组分component 组元compoonent相律Phase rule 投影图Projection drawing 浓度三角形Concentration triangle冷却曲线Cooling curve 成分composition 自由度freedom相平衡phase equilibrium 化学势chemical potential 热力学thermodynamics相律phase rule 吉布斯相律Gibbs phase rule 自由能free energy吉布斯自由能Gibbs free energy 吉布斯混合能Gibbs energy of mixing吉布斯熵Gibbs entropy 吉布斯函数Gibbs function 热力学函数thermodynamics function热分析thermal analysis 过冷supercooling 过冷度degree of supercooling杠杆定律lever rule 相界phase boundary 相界线phase boundary line相界交联phase boundary crosslinking 共轭线conjugate lines相界有限交联phase boundary crosslinking 相界反应phase boundary reaction相变phase change 相组成phase composition 共格相phase-coherent金相相组织phase constentuent 相衬phase contrast 相衬显微镜phase contrast microscope相衬显微术phase contrast microscopy 相分布phase distribution相平衡常数phase equilibrium constant 相平衡图phase equilibrium diagram相变滞后phase transition lag 相分离phase segregation 相序phase order相稳定性phase stability 相态phase state 相稳定区phase stabile range相变温度phase transition temperature 相变压力phase transition pressure同质多晶转变polymorphic transformation 同素异晶转变allotropic transformation相平衡条件phase equilibrium conditions 显微结构microstructures 低共熔体eutectoid不混溶性immiscibility材料科学基础专业词汇:第六章扩散活化能activation energy 扩散通量diffusion flux 浓度梯度concentration gradient菲克第一定律Fick’s first law 菲克第二定律Fick’s second law 相关因子correlation factor 稳态扩散steady state diffusion 非稳态扩散nonsteady-state diffusion扩散系数diffusion coefficient 跳动几率jump frequency填隙机制interstitalcy mechanism 晶界扩散grain boundary diffusion短路扩散short-circuit diffusion 上坡扩散uphill diffusion 下坡扩散Downhill diffusion互扩散系数Mutual diffusion 渗碳剂carburizing 浓度梯度concentration gradient浓度分布曲线concentration profile 扩散流量diffusion flux 驱动力driving force间隙扩散interstitial diffusion 自扩散self-diffusion 表面扩散surface diffusion空位扩散vacancy diffusion 扩散偶diffusion couple 扩散方程diffusion equation扩散机理diffusion mechanism 扩散特性diffusion property 无规行走Random walk达肯方程Dark equation 柯肯达尔效应Kirkendall equation本征热缺陷Intrinsic thermal defect 本征扩散系数Intrinsic diffusion coefficient离子电导率Ion-conductivity 空位机制Vacancy concentration材料科学基础专业词汇:第七章相变过冷supercooling 过冷度degree of supercooling 晶核nucleus 形核nucleation形核功nucleation energy 晶体长大crystal growth 均匀形核homogeneous nucleation非均匀形核heterogeneous nucleation 形核率nucleation rate 长大速率growth rate热力学函数thermodynamics function 临界晶核critical nucleus临界晶核半径critical nucleus radius 枝晶偏析dendritic segregation局部平衡localized equilibrium 平衡分配系数equilibrium distributioncoefficient有效分配系数effective distribution coefficient 成分过冷constitutional supercooling引领(领先)相leading phase 共晶组织eutectic structure 层状共晶体lamellar eutectic伪共晶pseudoeutectic 离异共晶divorsed eutectic 表面等轴晶区chill zone柱状晶区columnar zone 中心等轴晶区equiaxed crystal zone定向凝固unidirectional solidification 急冷技术splatcooling 区域提纯zone refining单晶提拉法Czochralski method 晶界形核boundary nucleation位错形核dislocation nucleation 晶核长大nuclei growth斯宾那多分解spinodal decomposition 有序无序转变disordered-order transition马氏体相变martensite phase transformation 马氏体martensite材料科学基础专业词汇:第八、九章固相反应和烧结固相反应solid state reaction 烧结sintering 烧成fire 合金alloy 再结晶Recrystallization 二次再结晶Secondary recrystallization 成核nucleation 结晶crystallization子晶,雏晶matted crystal 耔晶取向seed orientation 异质核化heterogeneous nucleation 均匀化热处理homogenization heat treatment 铁碳合金iron-carbon alloy渗碳体cementite 铁素体ferrite 奥氏体austenite 共晶反应eutectic reaction固溶处理solution heat treatment。

《材料科学基础》名词解释AOrowan mechanism (奥罗万机制)位错绕过第二相粒子,形成包围第二相粒子的位错环的机制。

Austenite(奥氏体)碳在γ—Fe中形成的间隙固溶体称为奥氏体。

B布拉菲点阵除考虑晶胞外形外,还考虑阵点位置所构成的点阵.Half—coherent interface(半共格相界)两相邻晶体在相界面处的晶面间距相差较大,则在相界面上不可能做到完全一一对应,于是在界面上将产生一些位错,以降低界面弹性应变能。

这时两相原子部分保持匹配,这样的界面称为半共格界面。

Sheet texture(板织构)轧板时形成的组织的择优取向。

Peritectic reaction(包晶反应)固相和液相生成另一成分的固溶体的反应Peritectic segregation(包晶偏析)新生成的固相的芯部保留残余的原有固相,新相本身成分也不均匀。

Peritectic phase diagram(包晶相图)具有包晶反应的相图Peritectoid reaction(包析反应)由两个固相反应得到一个固相的过程为包析反应。

Cellular structure(胞状结构)成分过冷区很小时,固相突出部分局限在很小区域内,不生成侧向枝晶。

Intrinstic diffusion coefficient(本征扩散系数)依赖热缺陷进行的扩散的扩散系数。

Transformed ledeburite(变态莱氏体)渗碳体和奥氏体组成的莱氏体冷却至727℃时奥氏体发生共析反应转变为珠光体,此时称变态莱氏体.Deformation twins(变形孪晶)晶体通过孪生方式发生塑性变形时产生的孪晶(BCC,HCP)Chill zone(表层细晶区)和低温铸模模壁接触,强烈过冷形成的细小的方向杂乱的等轴晶粒细晶区. Burger's vector(柏氏矢量)表征位错引起的晶格点阵畸变大小和方向的物理量。

Asymmetric tilt boundary(不对称倾斜晶界)晶界两侧晶粒不对称的小角度晶界,界面含两套垂直的刃型位错。

高聚物的固态流变行为G. W. HALLDIN” and Y. C. LOf威斯康辛·麦迪逊大学,机械工程学院。

威斯康辛,麦迪逊 53 706高聚物的固态流变行为在力学行为表现,测试,固态成形中十分重要。

这篇文章包含了一些非常有经济利用价值的高聚物的固态流变曲线,研究了固定型半晶态,可导型半晶态,可导型无定形态,两相无定形态树脂的拉伸,压缩过程。

半结晶态高聚物出现几何级的负荷下降,无定形态高聚物出现了线性应变软化,并使用了覆盖全部应力范围的流动学方程,对全部材料进行了应变软化的模拟。

简介对于高聚物科学来说,一个对热塑性塑料固态流动完全实际的理解和模拟是十分重要的。

这种行为经常在材料评价中出现,对固态成形十分重要[1-5]。

这种技术使用固态流动成形,能够成形超高分子量聚合物[6,7]。

固相流动的显著特征就是流动曲线,显示了应力应变的关系,所有固态研究都需要它,十分有名。

对高聚物来说,流动曲线与工程上的应力应变曲线有所不同,尤其对于半晶态,晶态,无定形热塑性塑料来说,尤为显著。

对大多数可延展,它们在弯曲时显示出应力下降,是由于“几何级的应变软化”,即不稳定的裂纹向内增生的速度,大于应力紧缩的速度。

工程应力减小的时候,真应力却在直线上升,Vincent[8]解释说,负荷下降是由于几何级的应变软化,Marshall和Tompson[9]用热压实验试图解释这种现象。

建于移动变形基础上的金属变形理论早已成熟,在很多情况下可被验证到,对高聚物来说,Imada,et al[l0]假设了三种机理:即α1,α2,β机理,Vincent[8]认为,屈服是由于相连接高分子链断裂形成的,无论无定形高分子之间的交错和二价力的作用。

有些理论建于自由体积[l1]和玻璃化转变温度[l2]之上,却无理论可以将半晶态高聚物和无定形高聚物与真应力联系起来。

Bahadur[13]做了一个流动曲线特征分析,发现PVC、PVDC的屈服点,但PE,PA66,PC,PTFE 却没有,Imada,et al[14]发现真应力升的很快,Brown和Ward[15]也发现了PE在剪切作用下拉伸变形应力下降。

面心立方金属简单剪切织构的发展遵循连续晶格转动原则-概述说明以及解释1.引言1.1 概述概述部分的内容:面心立方金属简单剪切织构是一种重要的晶体结构,在材料科学和工程领域广泛应用。

简单剪切织构是指由于外界作用力引起的晶格畸变,使晶体结构产生相应的变形现象。

连续晶格转动原则是指晶格在变形过程中会连续旋转一定角度,从而实现晶体结构的畸变。

本文旨在探讨面心立方金属简单剪切织构的发展过程,并研究连续晶格转动原则在该过程中的应用。

文章将以介绍面心立方金属的背景和相关概念为起点,包括面心立方结构的特点、简单剪切织构的定义和原理。

接着将详细阐述连续晶格转动原则的概念和作用机制,解释其在面心立方金属简单剪切织构中的重要性。

在结论部分,将回顾面心立方金属简单剪切织构的发展历程,包括相关研究成果和应用案例的介绍。

同时,将探讨连续晶格转动原则在该领域所取得的成就,并展望未来发展方向,探讨可能的研究方向和应用前景。

总结部分将对本文的核心内容进行概括,并强调面心立方金属简单剪切织构发展遵循连续晶格转动原则的重要性。

通过本文的研究和分析,相信能够对面心立方金属简单剪切织构及其应用中的连续晶格转动原则有更深入的了解,为相关领域的深入研究提供参考和指导。

1.2文章结构文章结构部分的内容可以从以下几个方面进行编写:文章结构的目的是为了清晰地呈现出整篇文章的组织框架,使读者在阅读过程中能够理解文章的逻辑结构和内容安排。

首先,文章的结构可以分为引言、正文和结论三个部分。

引言部分主要是对文章的背景、研究目的以及方法进行介绍,帮助读者了解文章的研究背景和意义。

正文部分是文章的核心部分,包含了对面心立方金属的简介、简单剪切织构的概念以及连续晶格转动原则的介绍。

结论部分是对整篇文章的总结和未来发展方向的展望。

其次,引言部分包括概述、文章结构、目的和总结四个子部分。

概述部分可以简要介绍面心立方金属在材料科学领域的重要性和研究现状。

文章结构部分描述了整篇文章的组织框架,向读者展示了文章的主要内容和章节安排。

东北大学材料科学基础(826)名词解释1、晶体[2008年]原子按一定方式在三维空间内周期性地规则重复排列,有固定熔点、各向异性。

2、中间相两组元A和B组成合金时,除了形成以A为基或以B为基的固溶体外,还可能形成晶体结构与A,B两组元均不相同的新相。

由于它们在二元相图上的位置总是位于中间,故通常把这些相称为中间相。

3、亚稳相亚稳相指的是热力学上不能稳定存在,但在快速冷却或加热过程中,由于热力学能垒或动力学的因素造成其未能转变为稳定相而暂时稳定存在的一种相。

4、配位数晶体结构中任一原子周围最近邻且等距离的原子数。

5、再结晶[2002年、2003年、2004年、2006年B]冷变形后的金属加热到一定温度之后,在原变形组织中重新产生了无畸变的新晶粒,而性能也发生了明显的变化并恢复到变形前的状态,这个过程称为再结晶。

(指出现无畸变的等轴新晶粒逐步取代变形晶粒的过程)6、伪共晶[2006年A]非平衡凝固条件下,某些亚共晶或过共晶成分的合金也能得到全部的共晶组织,这种由非共晶成分的合金得到的共晶组织称为伪共晶。

7、交滑移当某一螺型位错在原滑移面上运动受阻时,有可能从原滑移面转移到与之相交的另一滑移面上去继续滑移,这一过程称为交滑移。

8、过时效铝合金经固溶处理后,在加热保温过程中将先后析出GP区,θ″,θ′,和θ。

在开始保温阶段,随保温时间延长,硬度强度上升,当保温时间过长,将析出θ′,这时材料的硬度强度将下降,这种现象称为过时效。

9、形变强化金属经冷塑性变形后,其强度和硬度上升,塑性和韧性下降,这种现象称为形变强化。

10、固溶强化由于合金元素(杂质)的加入,导致的以金属为基体的合金的强度得到加强的现象。

11、弥散强化许多材料由两相或多相构成,如果其中一相为细小的颗粒并弥散分布在材料内,则这种材料的强度往往会增加,称为弥散强化。

12、不全位错[2014年]柏氏矢量不等于点阵矢量整数倍的位错称为不全位错。

13、扩展位错[2007年]通常指一个全位错分解为两个不全位错,中间夹着一个堆垛层错的整个位错形态。

面心立方晶体弗兰克不全位错(Frankel Defect)是固体材料中常见的晶格缺陷之一。

它的形成对材料的性能和特性有着深远的影响,因此深入了解其形成方式对于材料科学和工程具有重要意义。

本文将介绍面心立方晶体弗兰克不全位错的形成方式,以帮助读者更好地理解这一晶格缺陷。

1. 弗兰克不全位错的定义弗兰克不全位错是晶体中一种常见的点缺陷,它是指晶体中原子的位置发生了偏移,而不是出现了新的原子。

具体来说,弗兰克不全位错是由于晶体中一个正离子离开其原位,同时在空隙处留下一个空位,从而导致晶体中出现了偏差。

这种偏差会对晶体的物理性质产生显著影响。

2. 形成方式弗兰克不全位错的形成方式主要有两种:热激活和辐射损伤。

2.1 热激活在晶体中,原子具有一定的热运动。

当晶体受到热激活时,原子会不断地进行热振动,从而有可能发生位置的漂移。

在面心立方晶体中,当一个正离子向外偏离其原位时,会在其原位置留下一个空位,形成弗兰克不全位错。

这种形成方式是晶体中常见的,也是晶体材料在高温条件下产生弗兰克不全位错的重要原因之一。

2.2 辐射损伤另一种形成弗兰克不全位错的方式是辐射损伤。

辐射能量可以导致晶体中发生原子的位移和损伤,从而形成弗兰克不全位错。

这种方式通常发生在受到放射性物质辐射的晶体材料中,例如核反应堆中的燃料元素就会受到中子的辐射,从而导致晶体结构发生变化和损伤。

3. 形成机制弗兰克不全位错的形成机制主要与晶体的结构和原子间的相互作用有关。

在面心立方晶体中,正离子通常被密堆积地排列,因此当一个正离子离开其原位时,会在其原位置留下一个空位。

这种空位随后又会通过扩散等机制在晶体中进行传播,从而导致弗兰克不全位错在晶体中扩展和形成。

4. 总结面心立方晶体弗兰克不全位错的形成方式主要包括热激活和辐射损伤两种机制。

这些形成方式和机制对于材料科学和工程具有重要意义,有助于科学家和工程师更好地理解晶体材料中的晶格缺陷和其对材料性能的影响。

分型面设计英语Fractal Surface Design。

Fractal surface design is a fascinating concept that combines mathematics, art, and technology. It involves creating intricate patterns and textures that exhibit self-similarity at various scales. This article explores the principles and applications of fractal surface design, highlighting its significance in different fields.The concept of fractals was introduced by the mathematician Benoit Mandelbrot in the 1970s. Fractals are complex geometric shapes that exhibit self-similarity, meaning they have the same pattern regardless of the scale at which they are observed. This property makes fractals perfect for creating visually appealing and intricate designs.Fractal surface design finds applications in various fields, including computer graphics, architecture, textiles, and even finance. In computer graphics, fractal algorithms are used to generate realistic landscapes, clouds, and other natural phenomena. Architects incorporate fractal patterns in building facades and interior designs to create visually stunning spaces. Textile designers use fractal patterns to create unique and intricate fabrics. In finance, fractal analysis is used to model and predict complex market behavior.The key to creating successful fractal surface designs lies in understanding the underlying mathematical principles. Fractals are generated using recursive algorithms, where a simple geometric shape is repeatedly transformed and scaled down. Each iteration adds detail to the design, resulting in intricate patterns that exhibit self-similarity. The level of detail and complexity can be adjusted by varying the parameters of the algorithm.One popular fractal algorithm is the Mandelbrot set. It generates a complex and infinitely detailed fractal pattern by iterating a simple equation. The resulting image is a mesmerizing display of intricate shapes and colors. Another well-known fractal algorithm is the Julia set, which produces a different type of fractal pattern with its own unique characteristics.Fractal surface design also involves the use of color and texture to enhance the visual appeal of the patterns. Colors can be assigned based on mathematical properties of the fractal, creating a harmonious and visually pleasing composition. Textures can be added to simulate different materials or to create a tactile experience.In addition to their aesthetic value, fractal surface designs have practical applications. For example, in computer graphics, fractal algorithms are used to generate realistic terrain for video games and simulations. In architecture, fractal patterns can be used to optimize the acoustic properties of a space or to create energy-efficient designs. Textile designers can use fractal patterns to create fabrics with unique visual and tactile qualities.The future of fractal surface design holds exciting possibilities. With advancements in technology, designers can now create and manipulate fractal patterns in real-time, allowing for interactive and dynamic designs. Virtual reality and augmented reality technologies also open up new avenues for experiencing fractal surface designs in immersive environments.In conclusion, fractal surface design is a captivating field that combines mathematics, art, and technology. Its self-similar patterns and intricate details make it visually appealing and versatile. From computer graphics to architecture and textiles, fractal surface design finds applications in various domains. By understanding the underlying mathematical principles and leveraging technology, designers can create stunning and innovative fractal surface designs that push the boundaries of creativity.。

用分形几何来表征粗糙表面的几何形状加工表面的微观几何特征主要包括表面粗糙度和表面波度两部分组成,表面粗糙度是波距L小于1mm的表面微小波纹;表面波度是指波距L在1~20mm之间的表面波纹。

通常情况下,当L/H(波距/波高)﹤50时为表面粗糙度,L/H=50~1000时为表面波度。

表面粗糙度主要是由刀具的形状以及切削过程中塑性变形和振动等因素引起的,它是指已加工表面的微观几何形状误差。

表面波度主要是由加工过程中工艺系统的低频振动引起的周期性形状误差(图5—1中L 2/H 2),介于形状误差(L 1/H 1﹥1000)与表面粗糙度(L 3/H 3﹤50)之间。

加工表面的微观几何特征是表面质量的重要组成部分,而零件的表面质量是又机械加工质量的重要组成部分,表面质量是指:机械加工后零件表面层的微观几何结构及表层金属材料性质发生变化的情况。

经机械加工后的零件表面并非理想的光滑表面,它存在着不同程度的粗糙波纹、冷硬、裂纹等表面缺陷。

虽然只有极薄的一层(0.05~0 .15mm),但对机器零件的使用性能有着极大的影响;零件的磨损、腐蚀和疲劳破坏都是从零件表面开始的,特别是现代化工业生产使机器正朝着精密化、高速化、多功能方向发展,工作在高温、高压、高速、高应力条件下的机械零件,表面层的任何缺陷都会加速零件的失效。

因此,必须重视机械加工表面质量。

下面介绍一些常见的传统表面粗糙度表征的方法。

1.峰谷表征参数:表面粗糙度是表面峰谷高度相对基准面的变化。

常用的表面粗糙度参数有两种,一类是高度分布参数,包括轮廓算术平均偏差Ra(最常用),标准差σ,方均根Rq等。

另一类是极值高度参数,包括轮廓最大高度Rt (最常用),最大高峰Rp,最大深谷Rv,微观不平衡度Rz和平均高度Rpm。

2.空间表征参数:表征凸峰的横向间距参数或空间波长参数是对表面高度信息的补充描述,常用的参数有两种,一是凸峰密度Np,二是相交密度N。

Np是单位长度内轮廓线上所含局部最大凸峰的频数;N是单位长度内轮廓线与平均线相交的次数。

半平面双材料角界面应力奇异性分布规律的探究_物理论文论文导读::本文对半平面双材料角受集中力问题(Bogy [16])的界面应力场作了深入的探究,特别着重于双材料角端点附近的界面应力的奇异性分布规律。

论文关键词:双材料角,应力奇异性,界面应力,应力强度因子0 引言自上世纪八十年代以来,对于双材料角的初始脱粘判据的研究,主要是按照断裂力学[1]的思路进行的,即采用双材料角应力强度因子作为界面强度参数。

迄今的研究表明,用双材料角应力强度因子只能建立固定楔角的双材料角的初始脱粘判据,不能用来建立适用于不同楔角的双材料角的初始脱粘的一般判据。

为了探索建立不同楔角的双材料角的初始脱粘的一般判据的途径,有必要对双材料角端点附近的界面应力的奇异性分布作深入的研究,求得对双材料角应力奇异性的内禀特性的充分了解。

Williams [2]发现在双材料界面的自由边界处存在应力奇异性,而奇异性应力可以用下式表示:????????(1)其中表示界面应力,为场点至界面端点的距离,称为应力强度因子,而则是应力奇异性指数。

Bogy [3-4],Hein [5]采用Airy应力函数和Mellin变换,求解了双材料角的平面特征值问题,得到的奇异性指数不是常数,而是与Dundurs常数及双材料角的二个顶角有关的函数,即(2) 式中Dundurs常数是二种材料的四个弹性常数的组合[6] (3) (4) 式中为剪切模量,为Poisson比,下标1,2标注二种不同材料。

由于,,Dundurs常数只能在()坐标平面上的以(1, 0),(1, 0.5),(-1, 0)和(-1, -0.5)为顶点的平行四边形内取值。

双材料角的奇异性指数一般以复数的形式来表示:。

根据和的值,双材料角可分为三种情形:(1) 无奇异性 (), (2) 奇异性 (), (3) 振荡奇异性 (). 在许多新型材料和结构中常常会遇到双材料角,例如:复合材料,焊接结构,倒装芯片的封装等。

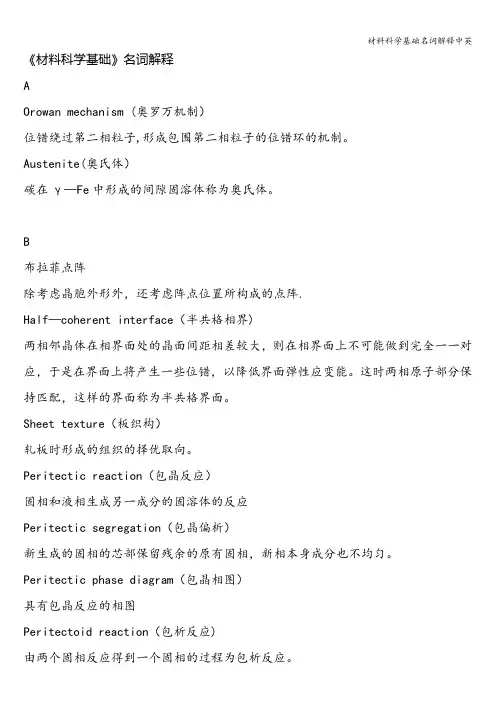

Surface fractal dimension of bentonite and its applicationto determination of swelling propertiesY.F.Xua,b,*,De Õan Sun b ,Yangping Yao b a School of Civil Engineering and Mechanics,Shanghai Jiaotong University,Shanghai 200030,Chinab Venture Business Laboratory,Nagoya Institute of Technology,Nagoya 466-8555,JapanAbstractBentonite with a low hydraulic conductivity is often used as engineered barriers to prevent groundwater contami-nation by leachate from the nuclear waste.When bentonite is immersed into the water solution,swelling deformation and swelling pressure will occur to create a tight contact with confining rock.The swelling deformation and swelling pressure are proportional to the amount of water volume absorbed by bentonite.The water volume absorbed by bentonite is related to its surface fractality.The correlation of the normalized water volume by bentonite volume (V w =V m )to vertical overburden pressure (p )is obtained as V w =V m ¼Kp D s À3,which presents a method to determine the surface fractal dimension of bentonite using the swelling tests.The surface fractal dimensions (D s )of Wyoming ben-tonite and Tsukinuno bentonite are 2.64,2.65,respectively obtained from the swelling tests.The surface fractal di-mension of bentonite can be used to estimate the maximum swelling strain and swelling pressure in the disposal system of nuclear waste.Ó2003Elsevier Ltd.All rights reserved.1.IntroductionBentonite has recently attracted increasing attention as back-filling (buffer)materials for high-level nuclear waste,for its ability to expand and completely fill up openings and to create a tight contact with confining rock.The Swedish disposal program for nuclear waste is shown in Fig.1[1].The deposition hole shown in Fig.1is currently planned to construct to a depth of several hundred meters,and compacted bentonite is planned to use as buffers in this hole.The function of the buffer material is to create an impermeable zone around the canister containing the high-level nuclear waste,since nuclear waste must be kept separate from surrounding environment.To develop buffer materials using compacted bentonite,it is very necessary and important to quantitatively evaluate the swelling characteristics of compacted bentonite.Swelling characteristics previously were evaluated using the diffuse double layer theory (DDL)[2].Bolt found that the initial prediction of DDL theory deviates somewhat from the experimental data,and explained that was the results of the specific surface of clay sample larger than the calculated one [3].Sposito indicated that the DDL theory might not give accurate predictions for bivalent electrolytes [4].Yong and Mohamed also investigated the limitation of the DDL theory in application to the predictions of swelling behaviour [5].The swelling characteristics are proved to relate to the surface area of montmorillonite [6].Fractal approach seems to be a potentially useful tool to study the soil surface texture formation [7,8].Mercury intrusion porosimetry was often used to study the surface fractal dimension in the range of mesoporosity (10 A <r 6250 A )and macro-porosity (r >250 A)[9,10].Avnir and Jaroniec [8]and Yin [11]proposed a convenient method to determine the surface fractal dimension in the micropore size range from a single adsorption isotherm.However,the measurement of the surface*Corresponding author.Address:School of Civil Engineering and Mechanics,Shanghai Jiaotong University,Shanghai 200030,China.0960-0779/04/$-see front matter Ó2003Elsevier Ltd.All rights reserved.doi:10.1016/S0960-0779(03)00047-X Chaos,Solitons and Fractals 19(2004)347–356/locate/chaosfractal dimension using the nitrogen adsorption isotherms is usually tedious and time consuming;typically,one needs to obtain a series of adsorption isotherms,either for a homologous series of adsorbate molecules on the solid of interest or for a single adsorbate on different particle size preparation of solid[8].In the present paper,a simple method is pro-posed to determine the surface fractal dimension of swelling clays.The theoretical relationship between the normalized water volume and vertical overburden pressure is constructed for bentonite.According to the proposed correlation of the normalized water volume to vertical overburden pressure,the surface fractal dimension of bentonite is obtained from the results of the swelling pressure and swelling deformation tests,and conversely the maximum swelling strain and swelling pressure can be evaluated using the surface fractal dimension for the compacted bentonite buffer in the disposal system of nuclear waste.2.Surface fractal dimensionUnless particularly prepared(e.g.,sputter and annealed metal crystals,exfoliated graphite,and etc.),solids tend to have a microscopic surface texture that cannot be reasonably described in terms of height above some standard ref-erence manifold(plane,sphere)[12].This type of situation,originating from absence of globally directive forces(like gravity in geomorphology),is referred to as porosity.It has two important consequences.First,since much of the surface is hidden with respect to any straight-line path in a beam of incoming projectiles,only X-rays and neutrons,or diffusing molecules can effectively probe this relevant surface.Second,even if an atlas of maps of the surface were available,Fourier methods are not applicable for the analysis.Thus,the following two methods are often used to probe the surface texture of these solids.2.1.Mercury intrusion porosimetryThe surface fractal dimension,D s is determined theoretically from the equation[13]AðrÞ¼Cr2ÀD sð1Þwhere AðrÞis the surface area which would be measured using a gauge(or a yardstick)r,C is a constant.Neimark proposed an approach that the role of the gauge is played by an average radius of curvature of the meniscus at the mercury-solid interface,r,when mercury is intruded into the solid pores at the pressure p[10].The average radius of the curvature of the mercury meniscus is related to the pressure p under condition of capillary equilibrium,and is given byr¼2r cos apð2ÞFig.1.Cross section of tunnel with deposition hole of the Swedish disposal program for nuclear waste[1].348Y.F.Xu et al./Chaos,Solitons and Fractals19(2004)347–356where r is surface tension,a is the contact angle.The surface area of the mercury-solid interface can be calculated fromAðrÞ¼Z V0pd Vð3Þwhere V is the volume of the intruded mercury.Substituting Eqs.(2)and(3)into Eq.(1)the surface fractal dimension is obtainedD s¼2þdR Vp d Vð4ÞThe conventional interpretation of mercury intrusion porosimetry is based on the dubious assumption that the pore space is represented as a bundle of parallel,non-intersecting cylindrical tubes of equal length but of different diameter [14].This oversimplified assumption usually leads to an entirely unreliable result[15].2.2.Adsorption isothermConsider a general form of the adsorption isotherm equation on irregular solid,the adsorption volume V ads is givenby[16]V ads¼Zfðr;qÞAðrÞd rð5Þwhere r is the pore radius accessible to adsorption,q is the change in the Gibbs free energy of adsorption,and is written asq¼RT lnP0Pð6Þwhere P and P0are the partial water vapour pressure and the saturated vapour pressure,respectively,R is the gas constant,T is the temperature,fðr;qÞis the function representing the probability of porefilling,and can be approx-imated by[11]fðr;qÞ¼1ð7Þunder the condition of2V mol r cos a=q>r,V mol is the molar volume of adsorbate.Except for very small pores,the condensation in the pore with average radius r is governed by Kelvin equation,q¼2V mol r cos arð8Þwhere V mol is the molar volume of bining Eq.(1)with Eqs.(5)–(8),it is given outV ads¼k1lnP0 PD sÀ3ð9Þwhere k1is a constant.Eq.(9)wasfirst presented by Avnir and Jaroniec[8].Generally,the surface fractal dimension evaluated from adsorption isotherm should provide more reliable information about geometric heterogeneity of the surface than that from mercury intrusion porosimetry,because only physical forces are governing adsorption of these particles[16].The surface fractal dimension of Wyoming bentonite is measured using the mercury intrusion porosimetry and the nitrogen adsorption isotherm(NAI)[17].The physical indexes of Wyoming bentonite is listed in Table1.Exper-iments of the mercury intrusion porosimetry and the nitrogen adsorption isotherm are shown in Fig.2for Wyo-ming bentonite.The surface fractal dimensions measured from the mercury intrusion porosimetry and the nitrogen adsorption isotherm are2.44and2.65,respectively.The surface fractal dimension of Wyoming bentonite measured using the nitrogen adsorption isotherms is larger than that measured using the mercury intrusion porosimetry.The bentonite surface measured by the mercury intrusion porosimetry is approximated by the inscribed equicurvature surface between the mercury and bentonite[10].It is manifested that the inscribed equicurvature surface could not display the roughness of the micropore surface by the fact that the intrusion volume of mercury usually less than the void volume of soilds[18].This result is due to the oversimplified assumption in the interpretation of mercury intrusion porosimetry.Y.F.Xu et al./Chaos,Solitons and Fractals19(2004)347–3563493.Determination of swelling strain and swelling pressureThe swelling process of bentonite is shown in Fig.3due to water uptake.Vertical deformation of bentonite will occur under vertical pressure when lateral deformation is confined.Swelling deformation occurs when vertical pressure is less than swelling pressure (Fig.3a).Swelling pressure is the maximum vertical pressure needed to maintain the original specimen height (Fig.3b).Similarly to the nitrogen adsorption isotherm,the normalized water volume by the volume of bentonite is related to the vapour pressure,and expressed using the surface fractal dimension as follows:V w V m ¼k 2ln P 0PD s À3ð10Þwhere V w is the water volume absorbed by montmorillonite in bentonite,V m is the volume of montmorillonite,k 2is a constant.The water volume absorbed by montmorillonite is calculated from the following equation (Fig.3):V w ¼V v2S r2ð11Þwhere V v2is the void volume after complete swelling,V v2¼V v1þV sw ,V v1and V sw are the void volume before swelling and the swelling volume of bentonite due to water uptake,respectively,S r2is the degree of saturation after complete swelling,and S r2¼100%.In Fig.3,V nm is the volume of non-swelling clay in bentonite.The adsorption isotherm also allows the calculation of water potential as a function of the water content.The relationship between the water potential and the vapour pressure is given by the Kelvin equation [2]:W ¼RT M w ln P P 0ð12ÞTable 1Physical properties of Wyoming bentonite and Tsukinuno bentoniteType Specificgravity G sLiquid limit w L (%)Plastic limit w p (%)Plasticity index I p Content of montmorillonite C m (%)Specific surface area S e (m 2/g)Cation exchange capacity M e (meq/g)Wyoming bentonite 2.7640748359757490.760Tsukinunobentonite2.79473.926.6447.3488100.732350Y.F.Xu et al./Chaos,Solitons and Fractals 19(2004)347–356where W is the water potential.The vertical overburden pressure must be supported by the water potential of mont-morillonite [19].Thus,an assumption can be made that the vertical overburden pressure equals to the water potential,i.e.ÀW ¼p ð13Þwhere p is the vertical overburden pressure.According to Eqs.(10),(12)and (13),the correlation of the normalized water volume to the vertical overburden pressure is given byV w V m /p D s À3ð14ÞEq.(14)presents the relationship between the normalized water volume and the vertical overburden pressure in the swelling deformation tests.The surface fractal dimension of bentonite can be obtained from Eq.(14)using the swelling deformation tests.The correlation of the normalized water content to the vertical overburden pressure can be also derived from the conversation of energy.The follows show how the normalized water content is related to the vertical overburden pressure from the viewpoint of the energy conversation.In the clay–water system,the salt concentration in solution of montmorillonite is larger than that in pure water.The free energy or chemical potential of pure water is less than that of the montmorillonite solution,hence water will be absorbed into the montmorillonite solution [20].The water volume absorbed by bentonite in swelling process is related to its surface texture.From the thermodynamic viewpoint,a balance exists between the decrease in the free energy of water and the increase in the work of vertical overburden pressure,and is given byY.F.Xu et al./Chaos,Solitons and Fractals 19(2004)347–356351C d A s¼p d V wð15Þwhere C is the free energy of water,p is the vertical overburden pressure,d A s is the increase in the surface area of montmorillonite wetted by water,d V w is the increment of the water volume absorbed by montmorillonite.The surface area of montmorillonite is expressed as Eq.(1).According to the Young–Laplace equation,the relationship between the pore radius r and the water potential is given byW¼2r cos arð16Þwhere r is the surface tension,a is the contact angle,r is the pore radius.The normalized water volume by the volume of swelling clay minerals is obtained from Eqs.(1),(12),(13),(15)and(16),and is given byV wV m¼Kp D sÀ3ð17ÞK¼ðD sÀ2ÞC Cð2r cos aÞ2ÀD ss mð18ÞFrom Eq.(18),it is seen that the value of K is related to the solution characteristics and the properties of bentonite.Eq.(18)is derived from the conversation of energy,and with the identical form of Eq.(14).The correlation between the normalized water volume and vertical pressure expressed in Eq.(14)is verified from the conservation of energy.From Fig.3,it is seen that the swelling pressure is the critical overburden pressure at which the swelling strain equals to0.Therefore,from Eq.(17)it is obtained thatp s¼p je s¼0¼1KV wV m1=ðD sÀ3Þð19Þwhere p s is the swelling pressure,e s is the swelling strain.Eq.(19)gives out the relationship between the normalized water volume and swelling pressure.The surface fractal dimension of bentonite can also be measured using the swelling pressure tests.The maximum swelling strain is defined as(Fig.3a)e s max¼V2ÀV1V1Â100%ð20Þwhere V1and V2are the initial andfinal volume of specimens,respectively.The normalized water volume by the volume of montmorillonite is obtained from Eqs.(11)and(20),V w m ¼1mG sdÀ1þe s maxG sdð21Þwhere C m is the content of montmorillonite in bentonite,G s is the specific gravity of montmorillonite,q d is the dry density of compacted specimen.For a specimen with a given dry density q d,the swelling strain e s can be measured under some vertical pressure p in the swelling deformation test.Hence the normalized water volume can be calculated in Eq.(21).Swelling deformation tests of Wyoming bentonite were also conducted by Millins et al.[19].and Studds et al.[21]. The relationship between the normalized water volume and vertical pressure is shown in Fig.4.The surface fractal dimension of Wyoming bentonite can be obtained from the linear relationship of logðV w=V mÞÀlog p.The surface fractal dimensions of Wyoming bentonite are2.64obtained from Fig.4.The surface fractal dimension of Wyoming bentonite from the swelling deformation tests nearly equals to that obtained from the nitrogen adsorption isotherm.Therefore,it is trustworthy that the surface fractal dimension of bentonite is determined from Eqs.(14)and(17)using the results of the swelling tests,which are easily performed in laboratory.The swelling deformation tests and the swelling pressure tests were also conducted on Tsukinuno bentonite.The physical properties of Tsukinuno bentonite are also listed in Table1.The X-ray diffraction plot of the Tsukinuno bentonite is shown in Fig.5.X-ray diffraction spectra(Fig.5)indicate that Tsukinuno bentonite is predominantly Na-montmorillonite with some quartz,feldspar,calcite,clinoptilolite and pyrite.The results of swelling deformation tests and the swelling pressure tests are compiled in Fig.6.The relationship between the normalized water volume and vertical overburden pressure and that between the normalized water volume and swelling pressure can be expressed by the same linear function in log–log plot in Fig.6.It is seen from Fig.6that the experimental data of the swelling 352Y.F.Xu et al./Chaos,Solitons and Fractals19(2004)347–356deformation and swelling pressure tests lie to the same line in log ðV w =V m ÞÀlog p plot.Thus the swelling deformation and swelling pressure tests give the same fractal dimension.The surface fractal dimension of Tsukinuno bentonite is2.63obtained from the results of the swelling deformation tests and the swelling pressure tests.The relationship between the normalized water volume and vertical overburden pressure (Eq.(17))is validated by the results of the swelling deformation tests and the swelling pressure tests in Figs.4and 6.The surface fractal dimension of bentonite can be feasibly determined from Eq.(17)using the results of the swelling deformation tests and swelling pressure tests.Conversely,the maximum swelling strain and swelling pressure can be calculated from Eq.(17)using the surface fractal dimension of bentonite.The maximum swelling strain can be obtained from Eqs.(17)and (21),and is given bye s max ¼C m K q d s p D s À3þq d sÀ1ð22ÞThe swelling pressure can be obtained from Eqs.(19)and (21),and is written asp s ¼C m K G s q d À1 1=ðD s À3Þð23ÞThe calculated behaviours of the maximum swelling strain are shown in Fig.7.Fig.7a shows the relationship between the maximum swelling strain and vertical overburden pressure for different bentonites with the same value ofFig.5.X-ray powder diffraction pattern of Tsukinuno bentonite.Y.F.Xu et al./Chaos,Solitons and Fractals 19(2004)347–356353354Y.F.Xu et al./Chaos,Solitons and Fractals19(2004)347–356Y.F.Xu et al./Chaos,Solitons and Fractals19(2004)347–356355 K.The less the surface fractal dimension of bentonite,the more the change in the maximum swelling strain with vertical overburden pressure.All the curves of e s max vs.p intersect at the vertical overburden pressure of1kPa for different bentonites with the same value of K.Fig.7b displays the relationship between the maximum swelling strain and vertical overburden pressure for the bentonite with the same surface fractal dimension.The larger the value of K,the larger the maximum swelling strain.All the curves of e s max vs.p appear to converge at a large pressure for the bentonite with the same surface fractal dimension.The calculated behaviours of swelling pressure are shown in Fig.8.It is seen from Fig.8a that the larger the surface fractal dimension,the larger the swelling pressure for bentonite with the same value of K.As shown in Fig.8b,the larger the value of K,the larger the swelling paring the results in Fig.8a with those in Fig.8b,it is found that the more effect of the surface fractal dimension than that of K exists on swelling pressure.4.Conclusions(1)The correlation of the normalized water volume to vertical overburden pressure is derived from both the Avnir–Jaroniec adsorption isotherm equation and the conversation of energy,and is used to measure the surface fractal di-mension of bentonite.The surface fractal dimension of bentonite obtained from swelling tests nearly equals to that measured from the nitrogen adsorption isotherms,and larger than that measured by the mercury intrusion porosimetry.A simple and easy method is offered to estimate the surface fractal dimension of bentonite using the swelling tests, including the swelling deformation and swelling pressure tests,which are very easily and conveniently conducted in laboratory.(2)The surface fractal dimension can conversely be used to calculate the maximum swelling strain and swelling pressure.The effect of surface fractal dimension D s and parameter K on the maximum swelling strain and swelling pressure can be evaluated.AcknowledgementsThe authors would like to express their gratitude to Prof.Hajime Matsuoka his kind help.The National Natural Science Foundation of China(Grant No.40201624)and the Japanese Society for the Promotion of Science(JSPS)are sincerely acknowledged for theirfinancial support,too.References[1]Pusch R.Mineral-water interactions and their influence on the physical behaviour of highly compacted Na-bentonite.CanGeotech J1982;19:381–7.[2]Yong RN,Warkentin BP.Soil properties and behaviour.Amsterdam:Elsevier;1975.[3]Bolt GH.Physico-chemical analysis of the compressibility of pure clay.Geotechnique1956;6:86–93.[4]Sposito G.The surface chemistry of soils.New York:Oxford University Press;1984.[5]Yong RN,Mohamed AMO.A study of particle interaction energies in wetting of unsaturated expansive clays.Can Geotech J1992;29:1060–70.[6]DeBruyn C,Collins C,Williams A.The specific surface,water affinity and expansive potential of clays.Clay Miner Bull1957;3:120–8.[7]Pachepsky YA,Polubesova TA,Hajnos M,Sokolowska Z,Jozefaciuk G.Fractal parameters of pore surface area as influenced bysimulated soil degradation.Soil Sci Soc Am J1995;59:68–74.[8]Avnir D,Jaroniec M.An isotherm equation for adsorption on fractal surfaces of heterogeneous porous ngmuir1989;5:1431–3.[9]Friesen WI,Mikula RJ.Fractal dimensions of coal particles.J Coll Interf Sci1987;120:263–71.[10]Neimark A.A new approach to the determination of the surface fractal dimension of porous solids.Physica A1992;191:258–62.[11]Yin Y.Adsorption isotherm on fractally porous ngmuir1991;7:216–7.[12]Pfeifer P,Avnir D,Farin D.Scaling behaviour of surface irregularity in the molecular domain:form adsorption studies of fractalcatalysts.J Stat Phys1984;36:699–715.[13]Mandelbrot BB.The Fractal Geometry of Nature.San Francisco,CA:W.H.Freeman;1982.[14]Drake LC,Ritter HL.Macropore-size distribution in some typical porous substances.Ind Chem Eng Anal Ed1945;17:787–91.[15]Perrier E,Mullon C,Rieu puter construction of fractal soil structures:simulation of their hydraulic and shrinkageproperties.Water Resour Res1995;31:2927–43.356Y.F.Xu et al./Chaos,Solitons and Fractals19(2004)347–356[16]Sokolowska Z,Sokolowski S.Influence of humic acid on surface fractal dimension of kaolin:analysis of mercury porosimetry andwater vapour adsorption data.Geoderma1999;99:233–49.[17]Celies R,Cornejo J,Hermosin MC.Surface fractal dimensions of synthetic clay-hydrous iron oxide associations from nitrogenadsorption isotherms and mercury porosimetry.Clay Miner1996;31:355–63.[18]Diamond S.Pore size distributions in clay.Clays Clay Miner1970;18:7–23.[19]Mollins LH,Stewart DI,Cousens TW.Predicting the properties of bentonite–sand mixtures.Clay Miner1996;31:243–52.[20]Aylmore LAG,Quirk JP.Swelling of clay–water systems.Nature1959;183:1752–3.[21]Studds PG,Stewart DI,Cousens TW.The effects of salt solutions on the properties of bentonite–sand mixtures.Clay Miner1998;33:651–61.。