Microstructures and properties of high-entropy alloys

- 格式:pdf

- 大小:16.69 MB

- 文档页数:93

1.1 Metals and Non-metalsWords and termsdefinite-确定的、明确的defect-缺陷plastic deformation塑性变形stress concentrator 应力集中点self-strengthening自强化the tip of a crock裂纹尖端☐Among numerous properties possessed by materials,their mechanical properties,in the majority of cases,are the most essential and therefore,they will be given much consideration in the book.☐在一些主要应用场合,机械性能是材料的各种性能中最重要的性能,因此,本书中将重点讨论。

▪consideration 考虑,需要考虑的事项,报酬☐All critical parts and elements,of which a high reliability (可靠性)is required,are made of metals, rather than of glass,plastics or stone.☐由于各种关键零部件的可靠性要求高,均用金属而不是玻璃、塑料或石头制造。

▪is required 翻译时将英文中的被动语态,改译为汉语中的主动语态。

▪rather than 而不是☐As has been given in Sec.1-1,metals are characterized by the metallic bond(金属键),where positive ions (正离子)occupy the sites of the crystal lattice (晶格)and are surrounded by electron gas(电子云).☐正如Sec1-1中所说,金属主要由金属键组成(其特征主要……)。

材料科学与工程学院费维栋工学博士哈尔滨工业大学材料科学与工程学院副院长教授/博士生导师+86-451-86413908wdfei@主要研究方向[1]多功能金属基复合材料—低热膨胀、高成型性、高塑性、低成本铝基复合材料的界面设计与塑性变形行为与机制研究;高热导、低膨胀、高电导铜基和铝基复合材料的界面设计与性能优化。

[2]功能薄膜材料—主要包括铁磁薄膜、铁电薄膜、压电薄膜的制备、多铁薄膜等的微结构表征和性能分析;铁性薄膜的铁性相变理论、磁电耦合机制的理论与试验研究。

[3]材料的X射线衍射与散射分析理论与方法研究—主要包括:纳米薄膜材料的织构、残余应力、标度特性、生长机制、界面行为等的分析;块体材料织构、残余应力、缺陷等的表征。

社会兼职教育部材料物理与化学专业教学指导委员会委员黑龙江省复合材料学会常务理事《分析与测试技术学报》和《试验技术与试验机》编委全国X射线衍射专业委员会委员东北三省X射线分析学会副主任委员主要学术成果1.W.D.Fei,H.Y.Yue,L.D.Wang,Equicohesive temperature of the interface and matrix and its effect on the tensileplasticity of Al18B4O33whiskers reinforced aluminum composite at elevated temperatures,Materials Chemistry and Physics,2010,119(3),515-5182.Q.G.Chi,W.L.Li,C.Q.Liu,W.D.Fei,Effect of TiOx seed layer on the texture and electric properties in La and Camodified PbTiO3thin films,Thin Solid Films,2009,517(17),4826-48293.Q.G.Chi,W.L.Li,B.Feng,C.Q.Liu and W.D.Fei,Low-temperature crystallization and orientation evolution ofNb-doped Pb(Zr,Ti)O3thin films using a Pb0.8La0.1Ca0.1Ti0.975O3seed layer,Scripta Materialia,2009,60(4),218-2204.W.D.Fei,C.Q.Liu,M.H.Ding,et al.Characterization of fiber texture by omega-scan x-ray diffraction,Review of ScientificInstruments,2009,80(9),0939035.Q.G.Chi,W.L.Li,W.D.Fei,Enhanced performance of sandwich structure Pb0.8La0.1Ca0.1Ti0.975O3thin film for pyroelectricapplications,Materials Letters,2009,63(20),1712-17146.Y.S.Yu,Hai-Bo Li,W.L.Li,Mei Liu,Yu-Mei Zhang and W.D.Fei,Structure and magnetic properties ofmagnetron-sputtered FePt/Au superlattice films,Journal of Physics D:Applied Physics,2008,41,2450037. C.Q.Liu,W.D.Fei,W.L.L,Theory of magnetoelectric coupling in2-2-type magnetostrictive/piezoelectric compositefilm with texture,Journal of Physics D:Applied Physics,2008,41(12),1254048. C.Q.Liu,W.D.Fei,W.L.L,Effects of texture and residual stress on the transition of ferroelectric perovskite thin filmswith C-axis polarization,Thin Solid Films,2008,516(6),1256-12709.H.Y.Yue,W.D.Fei,L.D.Wang,Effects of heat-treatment on interfacial microstructures and tensile properties ofZnAl2O4and ZnO coated Al18B4O33w/Al composites,Materials Science and Engineering A:Structural Material Properties Microstructure and Processing,2008,472(1-2),231-23410.Z.J.Li,W.D.Fei,H.Y.Yue,et al.Hot deformation behaviors of Bi2O3-coated Al18B4O33whisker reinforced aluminummatrix composite with high formability,Composites Science and Technology,2007,67(6),963-97311. F.Yang,W.D.Fei,Z.M.Gao,et al.An alternative micro-area X-ray diffraction method for residual stress measurement ofPb(Zr,Ti)O-3film,Surface&Coating Technology,2007,202(1),121-12512.H.Y.Yue,W.D.Fei,L.D.Wang,Mechanical properties and thermal stability of ZnAl2O4-coated aluminum boratewhiskers reinforced2024Al composite,Journal of Materials Science,2008,43(18),6233-623713.H.Q.Gao,L.D.Wang,W.D.Fei,Interfacial reaction and tensile strength of copper-coated Al18B4O33whisker reinforced6061Al composite,Materials Science and Engineering A:Structural Material Properties Microstructure and Processing,2008,479(1-2),261-26814.Z.J.Li,L.D.Wang,W.D.Fei,Effect of interfacial Bi2O3coating on compressive deformation behavior of aluminumborate whisker-reinforced aluminum composite at elevated temperature,Materials Science and Engineering A: Structural Material Properties Microstructure and Processing,2007,447(1-2),314-31815.H.Y.Yue,W.D.Fei,Z.J.Li,Effects of ZnO coating on the wettability and tensile properties of aluminum boratewhisker-reinforced aluminum composite,Materials Science and Engineering A:Structural Material Properties Microstructure and Processing,2006,441(1-2),197-20116.王黎东,费维栋,含铝和/或镁的复合硅酸盐的制备方法专利号:03132477.017.费维栋,岳红彦,王黎东,含SnO2涂覆陶瓷相增强铝基或镁基复合材料专利号:200510010130.418.费维栋,岳红彦,王黎东,ZnAl2O4包覆硼酸铝晶须增强铝基或镁基复合材料及其制专利号:200510127326.119.费维栋,岳红彦,王黎东,ZnO涂覆的陶瓷相增强铝基或镁基复合材料及其制备方法专利号:200510127309.820.王黎东,费维栋,β-锂霞石的制备方法专利号:200610009821.721.王黎东,费维栋,含β-锂霞石的铜基复合材料专利号:200610009820.222.费维栋,王黎东,一种含β-锂霞石的铜基复合材料的制备方法专利号:200710144909.423.费维栋,李志军,王黎东,三氧化二铋包覆陶瓷相增强铝基复合材料专利号:200510009684.2。

诚信声明本人郑重声明:本论文及其研究工作是本人在指导教师的指导下独立完成的,在完成论文时所利用的一切资料均已在参考文献中列出。

本人签名:年月日毕业设计任务书设计题目:T8钢热处理工艺及组织性能研究系部:机械工程系专业:材料成型及控制工程学号:1120182 37 学生:指导教师(含职称):(副教授)1.课题意义及目标学生应通过本次毕业设计,运用所学过的金属学及热处理等专业知识,了解T8钢的概况;熟悉T8钢的热处理工艺方法;认识T8热处理前后金相组织;找出热处理对T8钢组织和力学性能的影响规律,为优化热处理工艺提高零件质量提供一定的理论依据。

2.主要任务(1)制定T8钢热处理工艺,进行热处理实验。

(2)制备金相试样,观察分析T8钢热处理前后的显微组织。

(3)测定T8钢热处理前后力学性能,包括拉伸性能、硬度、冲击韧性等。

(4)分析热处理工艺、组织结构与力学性能之间的关系。

(5)撰写毕业论文。

结构完整,层次分明,语言顺畅;避免错别字和错误标点符号;格式符合太原工业学院学位论文格式的统一要求。

3.主要参考资料[1] 刘旭麟,高路斯,刘顺华,等.T8钢淬火热处理组织的计算机模拟研究[J].热加工工艺,2006,35(6):44-46.[2] 王英杰,孙国宏. T8钢最佳预处理工艺的选择[J]. 热加工工艺,1995,(4):55-55.[3] 张玉琴,王谦,王玉琴. 改善碳素工具钢组织性能方法探析[J]. 河南冶金,2001,(05):10-10[4]王能为,孙艳. T8钢形变球化退火工艺[J]. 南方金属,2009,(166):23-25[5] 崔忠圻,覃耀春.金属学与热处理[M]. 北京,机械工业出版社,2007:230-308[6] 王佳杰,莫淑华,等,工程材料力学性能[M].北京:北京大学出版社,2013,3[7] 束德林,等,工程材料力学性能[M],机械工业出版社,2003.7[8] 那顺桑,李杰,艾立群,等金属材料力学性能[M],冶金工业出版社2011.74.进度安排审核人: 2015 年 1 月 16 日T8钢热处理工艺及组织性能研究摘要:本次实验主要研究热处理工艺对T8钢力学性能的影响。

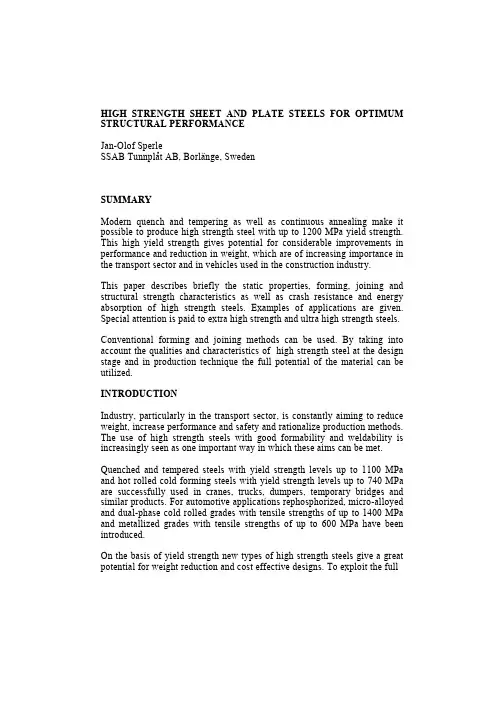

HIGH STRENGTH SHEET AND PLATE STEELS FOR OPTIMUM STRUCTURAL PERFORMANCEJan-Olof SperleSSAB Tunnplåt AB, Borlänge, SwedenSUMMARYModern quench and tempering as well as continuous annealing make it possible to produce high strength steel with up to 1200 MPa yield strength. This high yield strength gives potential for considerable improvements in performance and reduction in weight, which are of increasing importance in the transport sector and in vehicles used in the construction industry.This paper describes briefly the static properties, forming, joining and structural strength characteristics as well as crash resistance and energy absorption of high strength steels. Examples of applications are given. Special attention is paid to extra high strength and ultra high strength steels. Conventional forming and joining methods can be used. By taking into account the qualities and characteristics of high strength steel at the design stage and in production technique the full potential of the material can be utilized.INTRODUCTIONIndustry, particularly in the transport sector, is constantly aiming to reduce weight, increase performance and safety and rationalize production methods. The use of high strength steels with good formability and weldability is increasingly seen as one important way in which these aims can be met. Quenched and tempered steels with yield strength levels up to 1100 MPa and hot rolled cold forming steels with yield strength levels up to 740 MPa are successfully used in cranes, trucks, dumpers, temporary bridges and similar products. For automotive applications rephosphorized, micro-alloyed and dual-phase cold rolled grades with tensile strengths of up to 1400 MPa and metallized grades with tensile strengths of up to 600 MPa have been introduced.On the basis of yield strength new types of high strength steels give a great potential for weight reduction and cost effective designs. To exploit the fullpotential of high strength steels the design philosophy and production techniques must take into accont factors such as formability, weldability, stiffness, buckling, crush resistance and fatigue.In this paper the high strength steels will be presented with focus on the higher strength levels. The above factors are exemplified and discussed on the basis of optimum structural performance in using high strength steels. Most of the test results presented in this paper refer to cold rolled high strength sheet steel, however, many aspects of the use of these steels are generally applicable. Applications are presented where different high strength steels are successfully used.THE MOTIVES FOR USING HIGH STRENGTH STEELSThe driving forces behind the increasing use of high strength steels are often connected to the wish to achieve the best structural performance at the lowest possible weight and cost. In general, overall economy of the final product is usually the deciding factor. This is based on material cost, production economy and, increasingly, Life Cycle Costs - an analysis of all the costs and benefits during the entire life of the product.In such an analysis one should for example consider that by using high strength steel it is possible to reduce material thickness and dead weight of a structure which in turn give higher pay-loads. Lower production weights lead to lower handling costs and less filler material in welding operations. Additionally, modern high strength steels combine several favourable properties such as high strength, weldability, excellent forming and punching characteristics and minor variations in physical properties. All these factors are of primary importance in keeping production costs down. The environmental advantages of low weight and increased pay-load are also extremely important today when fuel consumption, exhaust emissions and the use of finite global resources must be kept to a minimum.The use of high strength steel usually leads to lower material costs since the weight reduction more than compensates for the higher price of high strength steel. This means that there is a strong motivation to use high strength steels outside the transport sector and in structures that are regarded as ”simple” such as shelf systems and hinges.STEEL GRADESAll high strength steel grades produced at SSAB are made by basic oxygen furnace steelmaking followed by continuous casting. Inclusion control is used to increase formability. Steel gradesand mechanical properties are shown in Table I. This paper primarily refers to Extra High Strength, EHS (450 ≤ R e≤ 800 MPa) and Ultra High Strength, UHS (R e > 800 MPa) steels. When placing steels in these groups the yield strength for DP steels is the one after 2 % work-hardening and bake-hardening.Table I: Mechanical properties for high strength steel gradesGrade Steel1typeYieldstrength(MPa)Tensilestrength(MPa)Elongation(%)E c2 minminA5 min A80minWeldox 500 HR-MA 500 570 16 - .39 Weldox 700 HR-MA 700 780 14 - .38 Weldox 900 HR-MA 900 940 12 - .56 Weldox1100 HR-MA 1100 1200 10 - .68 Domex 350 YP HR-MA 350 430 26 - .17 Domex 490 XP HR-MA 490 550 18 - .33 Domex 590 XP HR-MA 590 650 15 - .32 Domex 690 XP HR-MA 690 750 15 - .32 Domex 740 XP HR-MA 740 790 13 - .37 Docol 350 YP CR-MA 350 410 - 22Docol 500 YP CR-MA 500 570 - 12Docol 600 DP CR-DP 350 600 - 16Docol 800 DP CR-DP 500 800 - 8Docol 1000 DP CR-DP 700 1000 - 5Docol 1200 DP CR-DP 1000 1200 4Docol 1400 DP CR-DP 1200 1400 3Dogal 350 YP HDG-MA350 420 - 22Dogal 500 YP HDG-MA500 600 - 101) HR = hot rolled MA = microalloyedCR = cold rolled DP = dual-phaseHDG = hot-dip galvanized2) Ec = C + Mn6+ Cr Mo V++5+ Ni Cu+15(Carbon equivalent, typical values)The Weldox grades are produced in thicknesses 5 - 80 mm. Domex grades are produced in thicknesses 2 - 10 mm and Docol and Dogal in 0.5 to 2 mm.The Weldox grades are either thermomecanically processed (Weldox 500) or quenched and tempered (Weldox 700 - 1100) hot rolled microalloyed steel plates.Domex grades are all hot rolled thermomecanically processed microalloyed strip steels. Docol grades are either cold rolled microalloyed steels (Docol 350 - 500 YP) or cold rolled dual-phase steels (Docol 600 - 1400 DP). Dogal grades, finally, are hot-dip galvanized microalloyed steels.FORMABILITYAll grades mentioned above are intended for cold forming without any extra heating. A low level of non-metallic inclusions and sulphide-shape control are very important for bend formability and edge ductility in hole expansion.A Domex 690 XP hot-rolled grade can be bent without cracks to a bending radius of 1.6xt (t = sheet thickness). The corresponding value for Weldox 700 is 2xt.The dual-phase grades can be work-hardened after forming and bake-hardened after paint baking to increase the yield strength by up to a maximum of 300 MPa. Press-forming can be used even on the tensile strength level 1400 MPa but rollforming is the most suitable method for forming Docol 1200 DP and Docol 1400 DP. The press formability of Docol 600 - 1400 DP in comparison with mild steel is illustrated in Figure 1 [1].Fig 1 Examples from tests in deep drawing and stretch forming of steels DC O4 (mild steel), Docol 600 DP, Docol 800 DP, Docol 1000 DP,Docol 1200 DP and Docol 1400 DPPress hardening using the Plannja process, where boron steel sheets are hot formed in cooled tools, is a very interesting alternative to cold forming for complicated parts of very high strength (R e = 1200 MPa).WELDABILITYAll grades described in this paper can be welded with conventional welding methods. The reason for the good weldability is the lean chemistry of the steels.The most common welding methods for hot rolled steel grades are manual metal arc (MMA) and gas shielded arc welding (MAG). For cold rolled and metallized grades spot welding and MAG-welding are most frequently used. When discussing weldability of high strength steels the matter of most concern is normally cold cracking in the heat affected zone (HAZ). Brittle microstructures such as martensite of high carbon content and high levels of hydrogen together with high restraint forces increase the risk of cold cracking. The carbon equivalent CE, being a measure of the richness in chemical composition, is often used as a value to estimate the susceptibility to cold cracking. If the CE-values given in table I are compared to the CE-value of 0.4 for an ordinary standard high strength steel St 52-3 (R e = 350 MPa) it is obvious that Weldox and Domex extra high strength steels normally show little risk of cold cracking. For plate thicknesses greater than 10 mm preheating is recommended when working with Weldox 900 and 1100. The weldability of Weldox and Domex steels is discussed in more detail in [2] and [3].All Docol cold rolled and Dogal metallized products can be MAG-welded or spot welded, but, it is important to adjust the welding parameters according to the alloy content of each grade. For Docol 1200 DP and 1400 DP only spot welding to mild steel is recommended.MMA- and MAG-welded EHS and UHS steels often show a narrow soft zone in HAZ. In the case of Weldox QT grades and Docol DP grades this is mainly due to tempering and in Domex, Docol and Dogal microalloyed grades due to loss of precipitation hardening in the microstructure. If the soft zone is small in comparison to the thickness of the plate or sheet the strength of the welded joint is not effected due to the high degree of constraint.The width of the soft zone depends mainly on heat input and the thickness. Low heat input is therefore recommended when welding EHS and UHS steels which have a structural load perpendicular to the weld. In such cases it is also advisable to choose a welding wire which matches the strength of the material to be welded.Tensile test results on butt welded joints in Domex cold forming steel and Docol cold rolled steels are shown in Figure 2. It can be seen that the tensile strength of the MAG-welds in Docol DP steels is somewhat lower than the base metal strength when the tensile strength exceeds 800 MPa. The lowertensile strength.STIFFNESSThe use of high strength steel often leads to weight and thickness reductions. Since the Young’s modulus is the same for high strength steel and mild steel the stiffness decreases when the material thickness is reduced. If this reduction is not acceptable the stiffness loss can be compensated by changing the shape of the section.Fig 3 Reduced weight and cost with unchanged stiffnessFigure 3 illustrates that a small increase in section height of a beam can compensate for the stiffness loss associated with a thickness reduction, the stiffness being proportional to the square of the section height. This is a very clear example of the advantage of thinking in terms of the properties of high strength steel at the design stage.BUCKLINGDecreased thickness can result in buckling. The governing parameter for buckling is the width to thickness ratio (w/t) rather than the absolute thickness. This means that the risk of buckling is the same for a 1 mm thick sheet in an automotive structure as in a 20 mm thick bridge structure if the value of w/t is the same. The critical value of the width to thickness ratio, over which buckling will take place before the yield load is reached, is related to the yield strength by(w/t)cr = C √1 Rewhere (w/t)cr = critical width to thickness ratioC = constant depending on overall geometry R e = yield strength (MPa)Cross sections which buckle before the nominal stress in the flanges reaches the yield strength are categorised in cross section class 3 [4]. Cross sections that can be bent plastically without buckling are categorised in section class1 and cross sections in between those limits in section class 2. The value ofC for the limit between section class 2 and 3 is C = 200 for flanges in I, T, CIn order to take full advantage of the properties of high strength steel, cross sections should be in section class 1 or 2. For sections in section class 3 there is, however, still the positive effect of increased yield strength on the load-bearing capacity although it will be somewhat reduced by buckling.FATIGUEWhen introducing high strength steels into fatigue loaded structures it is important to note that the fatigue strength of welded joints does not normally increase with the increasing base metal strength. The reason for this is that the crack-like defects that are present at the weld toes mean that crack propagation will feature in the major part of the fatigue life. Since the crack growth resistance does not differ between mild steel and high strength steel, neither does the fatigue strength of the welded joints. This is illustrated in Figure 5 where we also see that if the stress concentration is low or moderate as in holes, radii and recesses, a decreased thickness and a higher working stress can be balanced by the higher fatigue strength of the high strength steel.The fatigue strength for unnotched base metal is strongly related to the surface roughness. Domex grades normally have a surface roughness R a ≈ 2 and Weldox grades R a = 4 - 8 [5].1002003004005006001002003004005006007008009001000Yield strength (MPa)F a t i g u e s t r e n g t h (M P a )Fig 5 Fatigue strength as a function of yield strengthIn order to achieve optimum performance of high strength steels in fatigue loaded welded structures, welds should be sited in areas of low stress. For spot welds the electrode diameter can be increased and the spot pitch reduced. For butt and fillet welds the toe of the weld can be ground or TIG-dressed in order that the fatigue strength of the weld may be adapted to the high strength steel. [4, 6].CRASH RESISTANCE - ENERGY ABSORPTIONTougher safety standards, for example regarding crash resistance of cars, have highlighted the interest in extra high strength and ultra high strength cold rolled, metallized and thinner hot rolled sheet steels. These steels are effective both for absorbing large amounts of energy, as in the front and rear of a car, and for withstanding high peak loads, as in the structure constituting the passenger compartment.In order to increase knowledge of how yield strength, thickness and overall geometry influence the energy absorption, static and dynamic tests in axial compression and bending have been performed on different sections.These tests, summarized below, are described in more detail in [7, 8, 9]. Axial crush testsStatic and dynamic axial tests have been performed on DP steels. The test specimens were 300 mm long rectangular hollow sections, 60x60x1.2 mm, developing an accordion-like deformation pattern when loaded in axial compression. The specimens were manufactured by joining two formed U-sections together by gas metal arc welding. Impact loads were achieved by accelerating steel pistons in a horizontal tube to the predetermined speed, 50 km/h.As expected, the absorbed energy increases with the increasing tensile strength of the steel grade, Figure 6.A comparison of results for static and dynamic tests confirm that there is a positive effect of crush speed for all steels including UHS-steels. This means that all these steels have a positive strain rate sensitivity.in DP steelsBending testsBending tests related to the application of high strength steels, for example in door intrusion beams, have been performed on rectangular sections 50x30xt mm. The thickness t varied from 1 to 2 mm. Cold rolled dual-phase and microalloyed steels as well as hot rolled microalloyed steels have beentested. The bending tests were carried out using three-point bending. The distance between the supports was 800 mm. During the test the load displacement plot was recorded. The maximum deformation was 150 mm.The maximum ultimate load, P max, as well as the absorbed energy wereFig 7 Maximum load P max vs. yield strength for bending testsBased on results from the axial crash tests and the bending tests we can draw some conclusions as to the gain in energy absorption at unchanged thicknessand reduced weight when using high strength steels instead of mild steels, table II [9].Table II: Gain in energy absorption and weight reduction when using high strength Docol DP steels instead of mild steelsDocol DP grade 600 800 1000 1200 1400Gain in energy absorption % 35 55 75 90 105Weight reduction % 25 30 35 40 45APPLICATIONSBased on the knowledge of how yield strength, plate thickness and overall geometry influence the structural properties and manufacturing properties of different constructions, high strength steels have already been successfully used in many applications.Hot rolled extra high strength steels are used for example in cranes, trucks and earth moving equipment. Figure 8 shows an application where Weldox 700 and Weldox 900 have been used for a mobile crane boom. Note that there are no welds on the flanges. The longitudinal weld situated in the neutral layer gives optimum structural performance in terms of fatigue.The use of Domex 690 XP grade is exemplified with a truck frame, figure 9. Note that rivets are used instead of welds in order to achieve the best fatigue performance.Another application for Domex 690 XP is a side reinforcing bar, which is a part of the Volvo side impact protection system, figure 10.Fig 8 Crane boom in Weldox 700 Fig 9 Truck frame inand Weldox 900 Domex 690 XPFig 10 Door intrusion beam in Fig 11 Back seat of the Volvo Domex 690 XP 850 Docol 600 DPFig 12 Bumper reinforcement Fig 13 Back seat top beam in in Docol 600 DL Dogal 500 YPFigure 10 shows a door beam where the use of Domex 690 XP combines high energy absorption with good cold formability and low weight.Figure 11 shows the back seat of the Volvo 850, where press-formed parts and tubes produced from Docol 600 DP are included to save weight.Figure 12 s hows a bumper reinforcement made of dual-phase grade Docol 600 DL where the low yield ratio gives the good formability to make the part.When corrosion protection is of great importance hot-dip galvanized microalloyed steel grades can be used. Figure 13 shows a transversal safety beam made of Dogal 500 YP which is used in the top of the back seat construction by the SAAB.REFERENCES[1]”Forming Handbook”SSAB Tunnplåt, 1997T[2] NILSSONWelding of DOMEX extra high strength cold forming steelSvetsen, special issue June 1995[3]LARSSON T BHandbook on welding of Oxelösund’s steelsSSAB Oxelösund, 1992[4] ”Sheet Steel Handbook”SSAB Tunnplåt, 1992[5] SPERLE J O AND NILSSON TThe Application of High Strength Steel for Fatigue LoadedStructuresProc. HSLA Steels Conf. on Processing, Properties andApplications, Beijing, 1992[6] SPERLE J OHigh Strength Steel for Light Weight Structures - Strength and PerformanceFatigueRoyal Institute of Technology, 1984[7] SPERLE J O AND LUNDH HStrength and Crush Resistance of Structural Members in High Strength Dual-Phase Steel SheetSc Journal of Metallurgy, 13(1984)6:343-351[8] SPERLE J O AND LUNDH HImproved Energy Absorption with High Strength Dual-PhaseSheetSteelProc. 12th Biennial Congress IDDRG, S Margherita, Italy,24 - 28 May, 1982[9] SPERLE J O AND OLSSON KHigh strength and Ultra High Strength Steels for WeightReduction in Structural and Safety Related ApplicationProc. ISATA Conf., Florence, 1996。

Ta含量对NiCoCrAlY涂层性能的影响陈建国; 张淑婷; 杜开平; 欧阳佩旋【期刊名称】《《热喷涂技术》》【年(卷),期】2019(000)003【总页数】6页(P38-43)【关键词】NiCoCrAlYTa; 涂层; 高温氧化; 抗热震性能【作者】陈建国; 张淑婷; 杜开平; 欧阳佩旋【作者单位】北京航天无人机系统工程研究所北京 100094; 北方工业大学机械与材料工程学院北京 100144; 北京矿冶科技集团有限公司北京 100160【正文语种】中文【中图分类】TG174.40 引言航空发动机的叶片、燃烧室、火焰筒等关键热端部件的高温氧化和腐蚀破坏是影响整机寿命、可靠性和运行安全性的主要因素,在热端部件表面制备MCrA1Y(M:Ni,Co)高温合金防护涂层,是解决这一问题最有效的方法[1-3]。

新一代航空发动机动力系统指标趋于极致化,如进气口温度超过1500℃,叶片使用寿命需超过300h等,MCrAlY高温合金涂层面临更高耐受温度、更长服役寿命和更高可靠性的挑战[4-6]。

为了进一步提高MCrAIY涂层的抗高温氧化及热腐蚀性能,人们进行了大量有益的探索,如对添加改性元素Re,Zr,Hf,Ta,Si等的MCrAIY 涂层体系进行了广泛和深入的研究[7,8],其中添加Ta元素的NiCoCrAlYTa六组元合金涂层已用于航空发动机叶片的防护,显著提高了叶片的高温抗氧化性能[9-11]。

国内外针对含Ta的涂层主要围绕喷涂工艺、涂层抗氧化等性能开展了相关研究,如广东省新材料研究所毛杰[12]等人研究了不同热喷涂工艺对NiCoCrAlYTa涂层的显微结构和性能的影响,其结果表明,不同热喷涂工艺主要对涂层的孔隙率、氧含量、显微硬度产生影响,涂层物相组成未发生明显变化。

而Ta元素在NiCoCrAlY涂层中的分布、Ta含量在高温下对涂层抗氧化性能以及抗热震性能的影响等研究鲜有报道。

因此,本文设计并制备了不同Ta含量的NiCoCrAlYTa涂层,并对合金材料的物相、微观组织、高温抗氧化性能、抗热震性能等进行了实验研究,期望能为MCrA1Y涂层材料在不同环境下的应用提供参考。

Trans. Nonferrous Met. Soc. China 22(2012) 262−267Structure stability and mechanical properties of high-pressure die-cast Mg −Al −Ce −Y-based alloyZHANG Jing-huai 1, LIU Shu-juan 2, LENG Zhe 1, ZHANG Mi-lin 1, MENG Jian 3, WU Rui-zhi 11. Key Laboratory of Superlight Materials & Surface Technology of Ministry of Education,Harbin Engineering University, Harbin 150001, China;2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;3. State Key Laboratory of Rare Earth Resources Utilization, Changchun Institute of Applied Chemistry,Chinese Academy of Sciences, Changchun 130022, ChinaReceived 28 February 2011; accepted 23 June 2011Abstract: With the aim to further improve the mechanical properties of Mg −Al −RE-based alloy, Mg −3.0Al −1.8Ce −0.3Y −0.2Mn alloy was prepared by high-pressure die-casting technique. The microstructure, thermal stability of intermetallic phases and mechanical properties were investigated. The results show that the alloy is composed of fine primary α-Mg dendrites and eutectic in the interdendritic regions. The intermetallic phases in eutectic are Al 11(Ce,Y)3 and Al 2(Ce,Y) with the former being the dominant one. The thermal stability of Al 11(Ce,Y)3 is conditioned. It is basically stable at temperature up to 200 °C within 800 h, while most of the Al 11(Ce,Y)3 intermetallics transform to Al 2(Ce,Y) at higher temperature of 450 °C for 800 h. The alloy exhibits remarkably improved strength both at room temperature and 200 °C, which is mainly attributed to the reinforcement of dendrite boundaries with Al 11(Ce,Y)3 intermetallics, small dendritic arm spacing effect as well as the solid solution strengthening with Y element. Key words: magnesium alloy; Mg −Al −Ce −Y alloy; Al 11RE 3; structure stability; mechanical properties1 IntroductionIn recent years, magnesium alloy in the form of high-pressure die-cast (HPDC) components has attracted much attention in automotive applications as advanced light material. Mg −Al-based alloys such as AZ91D and AM60B are used extensively in some non-critical parts [1]. However, these alloys are unsuitable for more critical components such as transmission and engine parts because of their poor mechanical properties at temperature above 125 °C [2, 3]. Further studies show that it is ascribed to the coarsening of β-Mg 17Al 12 phase in the eutectic region [4] and the discontinuous precipitate of lamellar Mg 17Al 12 from α-Mg matrix [5]. Moreover, a widely accepted view is that both diffusion controlled dislocation climbing and grain boundary sliding are the creep mechanisms in Mg −Al-based alloys [6]. Therefore, the design of alloys with good heatresistance should be based on the reinforcement of both the grain/dendrite boundaries and the α-Mg matrix.The Mg −Al −RE series alloys such as AE42 are the typical heat-resistant alloys designed for lightweight applications in the automotive industry [7]. However, there still appear inconsistencies in the previous reports as to the stability of the main strengthening phase Al 11RE 3 in Mg −Al −RE alloys. PETTERSON et al [8] (AE42 heat treated at 150, 200 and 250 °C for 100 h), HUANG et al [9] (AE42, 450 °C for 15 h), ZHU et al [5] (AE42, 200 °C for 2 weeks), DARGUSCH et al [10] (AE42+1%Sr, 200 °C for 2 weeks) and RZYCHO Ń et al [11] (AE44, 175 °C for 3000 h) reported that the intermetallic phase Al 11RE 3 has high thermal stability, and no decomposition is observed. In contrast, according to the work by POWELL et al [12] (AE42, 175 °C for 1000 h with and without stress) and our recent work [13] (AE44, 200 °C for 100 h under 70 MPa stress), Al 11RE 3 is unstable and partially decomposes to Al 2RE.Foundation item: Project (HEUCFR1128) supported by the Fundamental Research Funds for the Central Universities, China; Project (2010AA4BE031)supported by the Key Project of Science and Technology of Harbin City, China; Projects (20100471015, 20100471046) supported by the China Postdoctoral Science Foundation; Project (LBH-Z09217) supported by the Heilongjiang Postdoctorial Fund, ChinaCorresponding author: ZHANG Jing-huai; Tel: +86-451-82533026; E-mail: jinghuaizhang@ DOI: 10.1016/S1003-6326(11)61169-2ZHANG Jing-huai, et al/Trans. Nonferrous Met. Soc. China 22(2012) 262−267 263In this work, a new heat-resistant HPDC Mg alloy was designed. Relatively low Al content was used to improve the die castability, form high melting point intermetallics and try to avoid the formation of Mg17Al12. Ce with low solid solubility in Mg (0.74%, mass fraction) was added to form large amount of Al−Ce intermetallic particles to reinforce the grain/dendrite boundaries [14]; Y with high solubility in Mg (12.4%, mass fraction) was expected to strengthen the α-Mg matrix [14]. The microstructure, thermal stability of intermetallic and mechanical properties at room temperature and 200 °C of HPDC Mg−Al−Ce−Y-based alloy were investigated.2 ExperimentalThe chemical composition of the experimental alloy was Mg−3.0Al−1.8Ce−0.3Y−0.2Mn (ACY320). The reference alloy prepared under the same condition was Mg−3.3Al−0.2Mn (AM30). Commercial pure Mg and Al were used. Ce, Y and Mn were added in the form of Mg−20%Ce, Mg−20%Y and Al−10%Mn master alloys (mass fraction). Specimens were die cast using a 280 t clamping force cold chamber die-cast machine. About 20 kg raw materials were melted in a mild steel crucible. Pure argon was used as protective gas and refined gas. The molten metal was hand-ladled into the casting machine and the melt temperature prior to casting was about 700 °C. The die was equipped with an oil heating/cooling system and the temperature of the oil heater was set to 220 °C. The chemical compositions of the castings were determined by inductively coupled plasma atomic emission spectrometer.The tensile samples were 70 mm in gauge length and 6 mm in gauge diameter, as shown in Fig. 1. Tensile tests were performed using Instron 5869 tensile testing machine at a strain rate of 1.1×10−3 s−1. The experimental result in the study was the average value of at least four measured specimens. Metallographic sample was cut from the middle segment of the tensile bar. The microstructures and intermetallic phases were characterized by scanning electron microscope (SEM)Fig. 1 Photo of HPDC tensile test bars obtained from ACY320 alloy equipped with an energy dispersive X-ray spectrometer (EDS) and X-ray diffractometer (XRD).3 Results and discussion3.1 MicrostructureIn order to understand the role of Ce and Y additions in the Mg−3Al-based alloy, the microstructure of HPDC AM30 alloy is observed, as shown in Fig. 2(a). It reveals that the AM30 alloy is composed of primary α-Mg dendrites surrounded by interdendritic eutectic. A spot of β-Mg17Al12 intermetallics disperses in the interdendritic regions. The average dendritic arm spacing (DAS) is about 17 μm. The remarkable changes in the microstructure can be observed with the addition of Ce and Y, as shown in Fig. 2(b). The primary α-Mg dendrites in HPDC ACY320 alloy tend to be equiaxed and the average DAS is reduced to 9 μm. More important, the amount of intermetallic compounds in the interdendritic regions is much higher than that in AM30 alloy with the similar Al content.3.2 Intermetallics and their thermal stabilityThe XRD result of the HPDC ACY320 alloy is illustrated in Fig. 3(a). It is known that Mg−Al−Zn (AZ) and Mg−Al−Mn (AM) alloys are mainly composed of α-Mg and β-Mg17Al12 phases [15], the diffraction peaks of β-Mg17Al12 are not emerged due to the addition of Ce and Y. The main secondary phases in ACY320 alloy are Al11(Ce,Y)3 and Al2(Ce,Y), while the diffraction peak of Al11(Ce,Y)3 is much more intense than that of Al2(Ce,Y), which suggests that the former is the dominant one.The magnified SEM images characterizing the secondary phases are shown in Figs. 2(c) and (d). The acicular intermetallics with length of 1−3 μm arrange in a row then the rows form layers roughly, which exhibits outstanding morphology and distribution of the intermetallics. Besides, a few polyhedral intermetallics with size of 1−5 μm can be observed by SEM observations. EDS analyses were used to identify these intermetallics. Figures 2(e) and (f) show the EDS spectra detected from acicular intermetallics and polyhedral intermetallic, respectively. Combined with the XRD result, the acicular intermetallic is identified as Al11(Ce,Y)3 and the polyhedral one corresponds to Al2(Ce,Y). It is worthwhile to note that Al11(Ce,Y)3 has higher content of Ce than Y, while Y content is much higher than Ce in Al2(Ce,Y).To study the thermal stability of Al11(Ce,Y)3 intermetallic, some samples were aged at 200 and 450 °C for 800 h, respectively. The microstructure of ACY320 alloy after heat treatment is shown in Fig. 4. There is no obvious evidence of decomposition of the intermetallics in 200 °C annealed sample, except that a few particlesZHANG Jing-huai, et al/Trans. Nonferrous Met. Soc. China 22(2012) 262−267264Fig. 2 SEM images and EDS analyses of HPDC alloys: (a) SEM images of AM30 alloy; (b, c, d) SEM images of HPDC ACY320 alloy; (e) EDS analyses of acicular intermetallics at point A ; (f) EDS analyses of polyhedral intermetallic at point BFig. 3 XRD patterns of HPDC ACY320 alloys before aging (a), after aging at 200 °C for 800 h (b) and after aging at 450 °C for 800 h (c)show certain coarsening (see Figs. 4(a)−(c)). The XRD patterns also show incognizable changes before and after 200 °C aging by comparing Figs. 3(a) and (b). However, the conspicuous change of microstructure could be observed after age treatment at higher temperature of 450 °C (Figs. 4(d)−(f)). It reveals that most of the acicular intermetallics disappear and give place to fine quadrate-like particles with size of 100−400 nm in interdendritic regions. The XRD pattern illustrated in Fig. 3(c) also changes obviously after 450 °C aging, namely, the intensity of Al 11(Ce,Y)3 peaks decreases and that of Al 2(Ce,Y) peaks increases obviously. In addition, EDS in SEM mode also indicates the Al: (Ce,Y) atom ratio of these small particles is close to 2:1, not 11:3. Therefore, the present study shows a clear evidence ofZHANG Jing-huai, et al/Trans. Nonferrous Met. Soc. China 22(2012) 262−267 265Fig. 4 SEM images of HPDC ACY320 after ageing at 200 °C (a, b, c) and 450 °C for 800 h (d, e, f)the phase transition according to the reaction Al 11(Ce,Y)3 → 3Al 2(Ce, Y) + 5Al [12].The observations reported here suggest that there is a limit to the thermal stability of Al 11RE 3. Up to now, the thermal stability of the main strengthening phase Al 11RE 3 in Mg −Al −RE alloys is still a matter of debate [6, 9−14]. POWELL et al [12] investigated the microstructural stability of die-cast AE42 (Mg −4Al −2RE) alloys which were individually creep tested for 1000 h at 22, 100, 125, 150 and 175 °C. It was reported that the lamellar/acicular phase Al 11RE 3, which dominates the interdendritic microstructure of the alloy, partly decomposes into Al 2RE and Al (forming Mg 17Al 12) at temperature above 150 °C (i.e. 175 °C), and the sharp decrease in the creep resistance is attributed to the reduced presence of the lamellar/acicular Al 11RE 3 and the appearance of Mg 17Al 12. In addition, it was also pointed out that the stress is not a contributing factor to Al 11RE 3 stability. However, ZHU et al [5] reported that intermetallic phaseAl 11RE 3 in die-cast AE42 has high thermal stability with no decomposition observed at temperature up to 200 °C for 336 h, meanwhile, the continuous precipitation of Mg 17Al 12 due to the supersaturation of Al solute was observed in the Mg matrix, which was considered to be responsible for the deterioration in creep resistance at temperatures above 150 °C. In the present work, as for the alloy Mg −3.0Al −1.8Ce −0.3Y −0.2Mn after severe aging treatment at 200 °C for 800 h, neither obvious decomposition of Al 11RE 3 (i.e. Al 11(Ce,Y)3) nor the formation of Mg 17Al 12 is observed. It is considered that following aspects are related to the stability of Al 11RE 3 and the formation of Mg 17Al 12. First, the harsh degree of aging treatment containing aging temperature and time is an important factor for the composition of Al 11RE 3. This may be responsible for the different observation results by POWELL et al (175 °C for 1000 h) and ZHU et al (200 °C for 336 h) in AE42 alloy as well as ACY320 alloy in this study (200 °C for 800 h and 450 °C forZHANG Jing-huai, et al/Trans. Nonferrous Met. Soc. China 22(2012) 262−267 266800 h) at different aging temperatures. Second, the difference of RE components also affects the stability of Al11RE3 [13], which is a factor to explain the difference between Al11RE3 in AE42 and Al11(Ce, Y)3 in ACY320 alloy. Last, the lower Al content in ACY320 (3%) compared with that in AE42 (4%) causes little Al sequestered as soluted in the Mg matrix, which is responsible for no discernible precipitation of Mg17Al12 after aging in ACY320 alloy. The absence of DSC analysis to study phase transition challenges further work.3.3 Mechanical propertiesThe representative tensile stress—strain curves of HPDC ACY320 and AM30 alloys at room temperature and 200 °C are shown in Fig. 5. The tensile properties including ultimate tensile strength, tensile yield strength and elongation to failure are listed in Table 1. The strength increases dramatically by 45−65 MPa both at room temperature and 200 °C, while the elongation still keeps a high level with the addition of Ce and Y to AM30 alloy. The following aspects are considered to be related to the improved strength. The first and also the most important aspect is the formation of large amountFig. 5 Typical tensile stress—strain curves of HPDC alloys at room temperature (a) and 200 °C (b) of Al11(Ce,Y)3 intermetallics which provide considerable reinforcement of dendrite boundaries. Second, since the DAS is finer for the Mg−3Al-based alloys containing Ce and Y, the fine DAS effect can contribute to the observed increase in strength. Another factor is the strengtheningof the α-Mg matrix by solid solution with rare earth elements especially Y. Generally, the ductility is low for the alloy containing large amount of intermetallic particles [16]. However, the elongation of HPDC ACY320 alloy with high volume fraction of intermetallics still keeps a high level. It may be related tothe fine morphology and arrangement of Al11(Ce,Y)3 intermetallics.Table 1 Tensile and compressive properties of HPDC alloys at room temperature and 200 °CRoom temperatureAlloy Tensile yieldstrength/MPaUltimate tensilestrength/MPaElongation/%ACY320 158 255 10 AM30 116 191 9200 °CAlloy Tensile yieldstrength/MPaUltimate tensilestrength/MPaElongation/%ACY320 103 120 22 AM30 60 72 18 4 Conclusions1) With the addition of 1.8% Ce and 0.3% Y to Mg−3%Al-based alloy, the primary Mg dendrites are refined, the intermetallic phase Mg17Al12 is completely suppressed and substituted by Al11(Ce,Y)3 and Al2(Ce,Y) with the former being the dominant one at the interdendritic regions.2) Al11(Ce,Y)3 intermetallics are basically stable at temperature up to 200 °C within 800 h, while most of theAl11(Ce,Y)3 transform to Al2(Ce,Y) at higher temperatureof 450 °C for 800 h. This suggests that the thermal stability of Al11RE3 is conditioned.3) The high-pressure die-cast Mg−3.0Al−1.8Ce−0.3Y−0.2Mn alloy exhibits significantly improved strength at room temperature and 200 °C, which is the results of the reinforcement of dendrite boundaries withAl11(Ce,Y)3 intermetallics, fine dendritic arm spacing effect as well as the solid solution strengthening with Y element.References[1]KULEKEI M K. Magnesium and its alloys applications inautomotive industry [J]. Int J Adv Manuf Tech, 2008, 39(9−10):851−865.ZHANG Jing-huai, et al/Trans. Nonferrous Met. Soc. China 22(2012) 262−267 267[2]WANG Jian-li, PENG Qiu-ming, WU Yao-min, WANG Li-min.Microstructure and mechanical properties of Mg−6Al−4RE−0.4Mnalloy [J]. Transactions of Nonferrous Metals Society of China, 2006,16: s1703−s1707.[3]TONG Guo-dong, LIU Hai-feng, LIU Yao-hui. Effect of rare earthadditions on microstructure and mechanical properties of AZ91magnesium alloys [J]. Transactions of Nonferrous Metals Society ofChina, 2010, 20: s336−s340.[4]BAKKE P, WESTENGEN H. Die casting for highperformance-focus on alloy development [J]. Adv Eng Mater, 2003,5(12): 879−885.[5]ZHU S M, GIBSON M A, NIE J F, EASTON M A, ABBOTT T B.Microstructure analysis of the creep resistance of die-castMg−4Al−2RE alloy [J]. Scripta Mater, 2008, 58(6): 477−480.[6]LUO A A. Recent magnesium alloy development for elevatedtemperature application [J]. Int Mater Rev, 2004, 49(1): 13−30.[7]WANG J, LIAO R, WANG L, WU Y, CAO Z, WANG L.Investigations of the properties of Mg−5Al−0.3Mn−x Ce (x=0−3,wt.%) alloys [J]. J Alloys Compd, 2009, 477(1−2): 341−345.[8]PETTERSEN G, WESTENGEN H, HØIER R, LOHNE O.Microstructure of a pressure die cast magnesium-4wt.% aluminiumalloy modified with rare earth additions [J]. Mater Sci Eng A, 1996,207(1): 115−120.[9]HUANG Y D, DIERINGA H, HORT N, MAIER P, KAINER K U,LIU Y L. Evolution of microstructure and hardness of AE42 alloyafter heat treatments [J]. J Alloys Compd, 2008, 463(1−2): 238−245. [10]DARGUSCH M S, ZHU S M, NIE J F, DUNLOP G L.Microstructural analysis of the improved creep resistance of adie-cast magnesium-aluminium-rare earth alloy by strontium additions [J]. Scripta Mater, 2009, 60(2): 116−119.[11]RZYCHON T, KIELBUS A, CWAJNA J, MIZERA J.Microstructural stability and creep properties of die casting Mg−4Al−4RE magnesium alloy [J]. Mater Charact, 2009, 60(10):1107−1113.[12]POWELL B R, REZHETS V, BALOGH M P, WALDO R A.Microstructure and creep behavior in AE42 magnesium die-castingalloy [J]. JOM, 2002, 54(8): 34−38.[13]ZHANG Jing-huai, YU Peng, LIU Ke, FANG Da-qing, TANGDing-xiang, MENG Jian. Effect of substituting cerium-rich mischmetal with lanthanum on microstructure and mechanicalproperties of die-cast Mg−Al−RE alloys [J]. Mater Design, 2009,30(7): 2372−2378.[14]ZHANG Jing-huai, LIU H F, SUN W, LU H Y, TANG D X, MENG J.Influence of structure and ionic radius on solubility limit in theMg−RE systems [J]. Mater Sci Forum, 2007, 561−565: 143−146. [15]SU Gui-hua, ZHANG Liang, CHENG Li-ren, LIU Yong-bing, CAOZhan-yi. Microstructure and mechanical properties of Mg−6Al−0.3Mn−x Y alloys prepared by casting and hot rolling [J].Transactions of Nonferrous Metals Society of China, 2010, 20(3):383−389.[16]BAE D H, KIM S H, KIM D H, KIM W T. Deformation behavior ofMg−Zn−Y alloys reinforced by icosahedral quasicrystalline particles[J]. Acta Mater, 2002, 50(9): 2343−2356.Mg−Al−Ce−Y基压铸合金的微观结构稳定性和力学性能 张景怀1, 刘淑娟2, 冷哲1, 张密林1, 孟健3, 巫瑞智11. 哈尔滨工程大学超轻材料与表面技术教育部重点实验室,哈尔滨 150001;2. 哈尔滨工业大学材料科学与工程学院,哈尔滨 150001;3. 中国科学院长春应用化学研究所稀土资源利用国家重点实验室,长春 130022摘 要:为进一步提高Mg−Al−RE基合金的力学性能,采用高压压铸技术制备Mg−3.0Al−1.8Ce−0.3Y−0.2Mn合金,并研究其微观组织、金属间相的热稳定性和合金的力学性能。

北科大考博辅导班:2019北京科技大学材料科学与工程考博难度解析及经验分享根据教育部学位与研究生教育发展中心最新公布的第四轮学科评估结果可知,在科教评价网版2017-2018材料科学与工程专业大学排名中,材料科学与工程专业排名第一的是清华大学,排名第二的是北京航空航天大学,排名第三的是武汉理工大学。

作为北京科技大学实施国家“211工程”和“985工程”的重点学科,新金属国家重点实验室的材料科学与工程一级学科在历次全国学科评估中均名列第四。

下面是启道考博辅导班整理的关于北京科技大学材料科学与工程考博相关内容。

一、专业介绍材料科学与工程,在国务院学位委员会学科评议组制定和颁布的《授予博士、硕士学位和培养研究生的学科、专业目录》中,材料科学与工程属于工学学科门类之中的其中一个一级学科,下设3个二级学科,分别是:材料物理与化学、材料学、材料加工工程。

材料科学与工程专业是研究材料成分、结构、加工工艺与其性能和应用的学科。

在现代科学技术中,材料科学是国民经济发展的三大支柱之一。

主要专业方向有金属材料、无机非金属材料、高分子材料、耐磨材料、表面强化、材料加工工程等等。

北京科技大学新金属国家重点实验室的材料科学与工程在博士招生方面,划分为60个研究方向080500 ★材料科学与工程研究方向:01 新型高性能汽车及船舶用铝合金的研究与开发02 极端性能材料的力学理论研究02 铝、镁等轻合金先进制备加工全程工艺优化研究03 可降解生物医用金属材料研究与开发04 金属燃烧机理与抗燃烧合金研究开发05 结构-功能金属间化合物06 难变形材料的强加工和组织精确控制07 新型金属间化合物多孔材料08 高熵高温合金09 非晶软磁合金10 材料基因工程11 金属智能材料12 磁性功能材料13 功能复合材料14 非晶合金的玻璃转变15 外场作用金属塑性加工16 轻合金的耐候性17 高熵合金和陶瓷18 超弹性材料19 塑性流动20 新型钴基与镍基单晶高温合金的高温力学行为21 高温合金热端部件服役损伤评价方法22 高温结构材料的材料基因工程研究方法23 高熵合金24 高性能钢铁材料25 非晶态合金26 功能复合材料27 磁致伸缩材料28 储氢材料29 全固态锂离子电池材料30 先进锆合金及钛合金31 核电关键部件材料服役性能及评价32特殊环境用高性能不锈钢结构材料33 高强韧汽车结构件铝合金34 新一代装甲板/船用铅合金开发和应用35 金属连铸工艺过程模拟和优化36 高强韧航空用铝合金37 新一代高铁/磁悬浮轨道交通用铝合金38 高性能形状记忆合金39 金属智能材料40 磁场、应力场作用下的马氏体相变及多功能特性41 纳米准晶及应用42 高性能高熵合金及微观机理43 电子显微学方法44 金属材料微观力学行为研究45 工程材料部件三维多尺度应力测量与损伤评估46 新型形状记忆合金相变行为与功能47 导热复合材料48 电子封装材料49 航空航天用难熔金属硅化物、钛铝超高温结构材料50 耐液态金属腐蚀材料与多孔材料51 可控电弧丝材熔覆、堆焊与3D打印;热喷涂52 兵器材料失效特征与机理53 兵器材料的设计与制备54 极端工况材料燃烧特征与机理55 高熵合金56 非晶态合金57 金属材料强韧化58 三维原子探针结构表征59 等离子体表面工程60 金属燃烧考试科目:①1001 外语水平考核②2001 专业水平考核③3001 综合素质考核二、考试内容北京科技大学材料科学与工程专业博士研究生招生考试的考核阶段,其中,综合考核内容为:成立学科专家组,根据本学科专业前沿发展趋势和培养要求,采用笔试加面试(多种)方式对申请人的综合应用知识能力、外语应用能力、本学科专业前沿知识及最新研究动态掌握情况等方面进行考核,重点考核申请人是否具有研究潜质、创新精神和创新能力。

A12时效温度对HSLA-100高强船体钢组织性能的影响罗小兵苏航杨才福柴锋钢铁研究总院结构材料研究所北京 100081摘要:采用固溶+时效的热处理方法研究了时效温度对HSLA-100含铜高强船体钢组织性能的影响。

结果表明,试验钢在450℃处出现强度峰值,这是由大量纳米级的Cu析出物(<5nm)和少量Nb(C,N)第二相粒子的析出强化造成的。

过时效状态下,Cu析出粒子尺寸显著增大(10 nm~30 nm),其形状由球状变为杆状或短棒状,晶体结构也由bcc转变为fcc结构,并与基体失去共格关系,沉淀强化作用也逐渐减弱。

时效过程中基体软化和第二相粒子沉淀强化的共同作用决定了含铜高强船体钢的性能变化规律。

关键词:时效温度 HSLA-100 Cu 沉淀强化船体钢Effect of aging temperature on microstructure and properties of HSLA-100 highstrength ship hull steelsLUO Xiaobing, SU Hang , YANG Caifu, CHAI FengCentral Iron and Steel Research Institute, Institute for structural materials, Beijing 100081, China Abstract:Processing of quenching and aging was applied in this paper to research the effect of aging temperature on microstructure and properties of HSLA-100 copper-bearing high strength ship-hull steels. The results indicated that t he strength of tested steels were peaked while aging at 450℃ which attributed to the large amount of fine Cu particles( less than 5nm)and a small number of Nb(C,N) precipitates. The size of Cu particles happened to coarsen(10 nm~30 nm)in the condition of over aging, and it grew to rod-like from spherical in the particle shape, and lost the relationship of coherency to matrix , finally its precipitation strengthening is weakened. In addition, competition between the soften of matrix and the strengthen by second phase determined the aging regularity of copper-bearing high strength ship-hull steels.Keywords:Aging Temperature HSLA-100 Cu Precipitation Strengthening Ship-Hull steels0 前言随着国内外对铜在钢中作用研究的不断深入,Cu的沉淀强化技术被人们广泛应用于船舶、桥梁、汽车、石油化工、压力容器等领域。

FeCoNiCrMn高熵合金动态力学性能与微观结构黄小霞;汪冰峰;刘彬【摘要】采用分离式霍普金森压杆研究了等原子比FeCoNiCrMn高熵合金的动态力学性能及其微观结构.结果表明,FeCoNiCrMn高熵合金的锯齿行为在高应变速率下表现出明显的应变率敏感性.高熵合金在高应变率下的屈服强度随应变率增加而显著增加.当真应变为3.07时,真应力达到1270 MPa,此时FeCoNiCrMn高熵合金帽型样品出现剪切失稳现象,并形成一条宽20μm左右的剪切带.利用光学显微镜、电子探针显微分析仪和透射电子显微镜分析了高熵合金显微组织的演变,发现在剪切带的边界处,位错胞和孪生结构沿剪切方向高度拉长,直径约为150 nm的超细等轴晶粒和纳米孪晶共同存在于剪切带的中心.【期刊名称】《矿冶工程》【年(卷),期】2018(038)003【总页数】4页(P136-139)【关键词】高熵合金;FeCoNiCrMn;粉末冶金;动态力学性能;应变率敏感;微观结构【作者】黄小霞;汪冰峰;刘彬【作者单位】中南大学材料科学与工程学院,湖南长沙410083;中南大学材料科学与工程学院,湖南长沙410083;中南大学粉末冶金研究院,湖南长沙410083【正文语种】中文【中图分类】TG132.32等原子比FeCoNiCrMn高熵合金因其强度高、硬度高、延展性好、耐磨和耐腐蚀等优异性能而备受广大材料研究者的青睐[1-10]。

虽然其静态力学性能研究较为广泛,但动态力学行为的研究还有待完善。

锯齿行为是材料在一定变形温度和应变速率下塑性变形过程中相应应力⁃应变曲线上出现的反复屈服现象[11]。

而剪切局域化则是材料在高应变速率变形下的一种典型现象,剪切局域化的产生意味着材料的损伤[12]。

了解材料高应变速率下的锯齿行为、绝热剪切局域化及其微观结构变化,对材料的应用有重大的意义。

本文主要针对等原子比FeCoNiCrMn高熵合金动态力学性能及其动态变形后的微观结构进行研究。

Microstructure evolution and mechanical properties of1 000 MPa cold rolled dual-phase steelZHAO Zheng-zhi(赵征志), JIN Guang-can(金光灿), NIU Feng(牛枫), TANG Di(唐荻), ZHAO Ai-min(赵爱民) Engineering Research Institute, University of Science and Technology Beijing, Beijing 100083, ChinaReceived 10 August 2009; accepted 15 September 2009Abstract: The microstructure evolution of 1 000 MPa cold rolled dual-phase (DP) steel at the initial heating stages of the continuous annealing process was analyzed. The effects of different overaging temperatures on the microstructures and mechanical properties of 1 000 MPa cold rolled DP steel were investigated using a Gleeble−3500 thermal/mechanical simulator. The experimental results show that ferrite recovery and recrystallization, pearlite dissolution and austenite nucleation and growth take place in the annealing process of ultra-high strength cold rolled DP steel. When being annealed at 800 ℃ for 80 s, the tensile strength and total elongation of DP steel can reach 1 150 MPa and 13%, respectively. The microstructure of DP steel mainly consists of a mixture of ferrite and martensite. The steel exhibits low yield strength and continuous yielding which is commonly attributed to mobile dislocations introduced during cooling process from the intercritical annealing temperature.Key words: cold rolled dual-phase steel; microstructure evolution; recrystallization; mechanical property; overaging temperature1 IntroductionAdvanced high-strength steels (AHSS) have been used in the automotive industry as a solution for the weight reduction, safety performance improvement and cost saving. Among them, the dual-phase (DP) steels, whose microstructure mainly consists of ferrite and martensite, are an excellent choice for applications where low yield strength, high tensile strength, continuous yielding, and good uniform elongation are required [1−4].The continuous annealing process to produce cold rolled DP steels typically has the following stages: heating to the intercritical temperature region, soaking in order to allow the nucleation and growth of austenite, slow cooling to the quench temperature, rapid cooling to transform the austenite into martensite, overaging, and air cooling. The amount and morphology of the constituents formed depend on such annealing parameters. The effects of the retained austenite, ferrite, and martensite morphologies on the mechanical behavior of DP steels have been intensively investigated[5−9]. As we all known, overaging treatment is an important process during the production of dual-phase steel. It can reduce the hardness of martensite and improve the comprehensive mechanical properties of DP steel [10−14].The purpose of the present research was to study the microstructure evolution of cold rolled DP steel at the initial heating stages of the continuous annealing process using a Gleeble simulator. At the same time, the effects of overaging temperature on the mechanical properties of DP steel were also studied. The microstructures of specimens simulated on a Gleeble simulator, were analyzed using scanning electron microscopy (SEM) and transmission electron microscopy (TEM).2 ExperimentalThe chemical compositions of the experimental steel (mass fraction, %) were: 0.14−0.17C, 0.40−0.60Si, 1.70−1.90Mn, 0.02−0.04Nb, 0.40−0.60Cr, ≤0.010P, ≤0.010S, 0.02−0.06Al and balance Fe. Firstly, experimental steels were smelted in a 50 kg vacuum induction furnace. After smelting, experimental steels were forged into 35 mm×100 mm×100 mm cubic samples. The forged slabs were reheated to 1 200 ℃and soaked for 1 h. The hot rolled thickness was 3.5 mm after 6 passes rolling. The finish rolling temperature was about 880 ℃. The coiling temperature was 620 ℃. After being pickled in hydrochloric acid, the hot rolledFoundation item: Project(2006BAE03A06) supported by the National Key Technology R&D Program during the 11th Five-Year Plan Period Corresponding author: ZHAO Zheng-zhi; Tel: +86-10-62332617; E-mail: zhaozhzhi@ZHAO Zheng-zhi, et al/Trans. Nonferrous Met. Soc. China 19(2009) s563−s568 s564bands were cold rolled to the final thickness of 1.0 mm, and the reduction was about 70%. Finally, the cold rolled sheets were cut into the samples for the simulation of continuous annealing experiment.The microstructure evolution at the initial steps of the continuous annealing process was studied using a Gleeble 1500 simulator. The steel was heated at 10 ℃/sto the different heating temperatures (550, 630, 670, 710, 730, 750 and 780 ℃) and held for 20 s followed by water-quenching. The effects of different overaging temperatures on the microstructures and mechanical properties of DP steel were investigated using a Gleeble 3500 simulator. The processing schedules and parameters used are shown in Fig.1. The soaking temperature of intercritical region was set at 800 ℃, soaking time is 80 s; after a slow cooling, the samples were rapidly cooled to 240, 280, 320 and 360 ℃, respectively and soaked for 300 s; at last, the samples were air cooled to the room temperature.Fig.1 Continuous annealing process of DP steelAfter heat treatment, the steel sheet would be cut into standard tensile specimens (length 200 mm, gauge length 50 mm). The tensile test was performed with CMT4105-type tensile test machine to test mechanical properties. The longitudinal cold rolling plane sections of samples after annealing were prepared and etched with 4% natal. The microstructure was analyzed by scanning electron microscopy (SEM). Some samples were analyzed using transmission electron microscopy (TEM).3 Results and discussion3.1 Mechanical properties and microstructures ofsamples after hot-rolling and continuousannealingTable 1 shows the tensile test data for the two samples after hot-rolling and continuous annealing in terms of yield strength, ultimate tensile strength and total elongation. When the annealing temperature is 800 ℃and soaking time is 60 s, the tensile strength reaches 1 110 MPa and the total elongation reaches 12%. Compared with the hot-rolled samples, the yield strength and total elongation of sample after annealing are similar, but the tensile strength increases by about 450 MPa. The yield ratio decreases obviously. The engineering uniaxial tensile stress—strain curve of the sample after continuous annealing is characterized by very uniform plastic flow until necking. There is no physical yield point and yield point extension, that is, the steel exhibits continuous yielding which is commonly attributed to mobile dislocations introduced during cooling from the intercritical annealing temperature. Many dislocation sources come into action at low strain and plastic flow begins simultaneously through the specimen, thereby suppressing discontinuous yielding[15].Table 1 Mechanical properties of samples after hot rolling and annealingConditionYieldstrength/MPaTensilestrength/MPaYieldratio*Totalelongation/% Hot rolling555 665 0.83 16 Annealing540 1110 0.49 12* Yield ratio is defined as the ratio of yield strength to tensile strength.The microstructures of the hot-rolled and cold-rolled samples are shown in Fig.2. It can be observed that hot rolled steel features a band microstructure, i.e. pearlite band in a ferrite grain matrix. The ferrite grain size is measured to be 5.0−9.0 µm. After cold rolling, the microstructure consists of elongated grains of ferrite and deformed colonies of pearlite (Fig.2(b)). After cold-rolling, there is an increase in the stored energy of the steel due to the high dislocation density and this provides the driving pressure for the ferrite recrystallization during annealing process. The total ferrite grain boundary area increases and the cementite laminar structure in pearlite is broken down. The latter has been shown to promote spheroidization of cementite during subsequent annealing process.The SEM micrograph of the sample after annealing is given in Fig.3(a). The microstructure of DP steel consists of a mixture of ferrite, martensite, martensite/austenite constituent. There is also some bainite in the microstructure. The martensite islands are homogeneously distributed in ferrite matrix. The DP steel has finer grain size and the size of ferrite grain and martensite island are about 1.0−2.0 µm. Some martensite islands have a bright white circle around the edge, and the center of martensite is of irregular black structure.ZHAO Zheng-zhi, et al/Trans. Nonferrous Met. Soc. China 19(2009) s563−s568 s565Fig.2 Microstructures of steel after hot rolling (a) and cold rolling (b)Fig.3 SEM images (a) and TEM micrograph (b) of steel after continuous annealingThe main reason is the manganese partitioning will occur during the continuous annealing process. During the heating process, a high-Mn side lap forms around austenite, which makes the hardenability of austenite island edge higher than that of the center. So, it makes high-Mn side lap form around martensite in the cooling process. The volume fraction of martensite is about 40%, which is the main reason for DP steel with a higher strength. After the continuous annealing process, band structure is significantly improved, which plays an important role in improving the performance of DP steel.The fine structures of martensite and ferrite are shown in Fig.3(b) by the TEM observation. The lath martensite is fine, and is relatively clean; at the same time, a very high density of dislocations can be observed in the ferrite grain adjacent to martensite. These dislocations are generated in order to accommodate transformation induced strain built between martensite transformed by quenching and retained ferrite. In addition, they are known to be mobile and play an important role on rapid, extensive strain hardening of DP steel from the onset of its plastic deformation.3.2 Microstructure evolution at initial steps ofcontinuous annealing processThe microstructure evolution at the initial stages of the continuous annealing process is very important for producing the ultra-high strength DP steel. During the annealing process of high strength DP steel, ferrite recovery and recrystallization, pearlite dissolution and austenite nucleation and growth will occur. When the sample is heated to 550 , the℃microstructure has no visible change as compared with the cold rolled sample. The ferrite grain is stretched along the rolling direction significantly; lamellar pearlite is stretched along the rolling direction too. At the same time, there are some carbide particles in the ferrite matrix, as shown in Fig.4(a). At this temperature, the recrystallization nucleus was not found in the structure. So, at this stage the sample is still at the recovery stage. When the heating temperature is 630 , the℃recrystallization nucleus begins to appear in the microstructure. The nucleus of crystal appears mainly nearby the large deformation ferrite (Fig.4(b)). The recrystallization nucleus is fine and equiaxed. Large deformation storage power is present in the large deformation region. So, recrystallization nucleus forms in this region firstly. With the heating temperature increasing, the recrystallization nucleus begins to grow. Therefore, the size of recrystallization is uneven at this stage, as shown in Fig.4(c). When the heating temperature is 670 ℃, the deformation structure still exists in the microstructure. With the temperature increasing, the deformed ferrite grains are replaced by recrystallization ferrite grains. When the heating temperature is 710 , the d℃eformation structure has already vanished, which is replaced by theZHAO Zheng-zhi, et al/Trans. Nonferrous Met. Soc. China 19(2009) s563−s568 s566equiaxed recrystallization grain. So, the process of recrystallization completes basically. In the ferrite recrystallization process, the pearlite transforms to granular from lamellar gradually.When the heating temperature is 730 ,℃it begins to enter the two-phase region; and the ferrite and spheroidised carbides begin to transform to austenite. A small amount of austenite nucleates in the original pearlite region, as shown in Fig.4(e). Austenite nucleates mainly in the ferrite and pearlite grain boundary; and a part of austenite also nucleates in the carbide particles of ferrite. After austenite nucleation, it begins to grow rapidly. At this stage, the pearlite dissolves rapidly. When the temperature reaches 750 , the austenite℃transformation occurs obviously. The bright white particle which distributes in the ferrite matrix is the martensite island. The martensite transforms from austenite during the rapid cooling process. At the same time, a small amount of martensite particles can also be observed in ferrite; and there are still some non-dissolved carbide particles in the ferrite matrix. The initial austenite growing-up is mainly controlled by the carbon Fig.4Microstructure evolutions duringcontinuous heating process: (a) 550 ℃; (b)630 ℃; (c) 670 ℃; (d) 710 ℃; (e) 730 ℃; (f)750 ℃; (g) 780 ℃ZHAO Zheng-zhi, et al/Trans. Nonferrous Met. Soc. China 19(2009) s563−s568 s567diffusion in the austenite, and the diffusion path is along the pearlite/austenite interface. When the annealing temperature is 780 , the austenite volume increase℃s, and the number of carbide particles is reduced gradually. There is only a very small amount of carbide particles distributing in ferrite matrix.3.3 Effect of overaging temperature onmicrostructure and mechanical properties ofDP steelThe overaging is a temper treatment to harden martensite in the dual-phase steel, reduce the hardness of martensite and improve the comprehensive mechanical properties[16]. Fig.5 shows the effect of overaging temperature on the mechanical properties of dual-phase steel. All the samples are intercritically annealed at 800℃ with different overaging temperatures. As can be seen from Fig.5, the highest tensile strength is achieved in the sample overaged at 280 ℃. The yield strength is 560 MPa, the tensile strength is 1 150 MPa, and the total elongation reaches 13%. The good combination of high strength and toughness properties is obtained. And then, with the increase of overaging temperature, the yield strength and tensile strength of samples decrease, while the total elongation increases. When the overaging temperature reaches 360 ℃, the tensile strength decreases, the yield strength does not change significantly. The mechanical properties of sample cannot meet the necessary requirements of CR980DP. At the same time, the stress—strain curve of the steel shows discontinuous yielding behaviour and develops yield plateaus.Fig.6 shows the SEM microstructures with different overaging temperatures. It can be seen that the microstructure mainly consists of dark grey ferrite grains and white martensite. When the overaging temperature is 360 ℃, the martensite boundary is fuzzier than that of sample overaged at 320 ℃, and there are more carbides, which is due to the effects of tempering on the martensite, such as the volume contraction of martensite during the tempering, the changes of the martensite strength and additional carbon clustering or precipitation near the ferrite and martensite interfaces.Fig.5 Effects of different overaging temperatures on mechanical propertiesFig.6 SEM images of microstructures of DP steel overaged at different temperatures: (a) 240 ℃; (b) 280 ℃; (c) 320 ℃; (d) 360 ℃ZHAO Zheng-zhi, et al/Trans. Nonferrous Met. Soc. China 19(2009) s563−s568 s5684 Conclusions1) When the DP steel is annealed at 800 ℃ for 80 s and overaged at 280 ℃, the tensile strength and total elongation of ultra-high strength dual-phase steel can reach 1 150 MPa and 13%, respectively.2) The microstructure of DP steel consists of a mixture of ferrite, martensite, martensite/austenite constituent. There are also some bainites in the microstructure. The martensite islands are homogeneously distributed in ferrite matrix. The ferrite and martensite island grain size are about 1.0−2.0 µm. When the overaging temperature reaches 360 ℃, the tensile strength decreases, the yield strength does not change significantly. The mechanical properties of sample cannot meet the necessary requirements of CR980DP. At the same time, the steel shows discontinuous yielding behaviour and develops yield plateaus.References[1]KANG Yong-lin. Quality control and formability of the mordernMotor plate [M]. Beijing: Metallurgical Industry Press, 1999.[2]LIU Peng, JIN Xian-zhe. The development and research ofautomobile steel plate [J]. Shanxi Metallurgy, 1997(2): 32−33.[3]MA Ming-tu, WU Bao-rong. Dual-phase steel-the physical andmechanical metallurgy [M]. Beijing: Metallurgical Industry Press,1988.[4]LLEWELLYN D T,HILLS D J. Dual phase steels [J]. Ironmakingand Steelmaking, 1996(6): 471−478.[5]SARKAR P P. Microstructural influence on the electrochemicalcorrosion behaviour of dual phase steels in 3.5% NaCl solution [J].Materials Letters, 2005(59): 2488−2491. [6]ROCHA R O, MELO T M F, PERELOMA E V, SANTOS D B.Microstructural evolution at the initial stages of continuous annealingof cold rolled dual-phase steel [J]. Materials Science and EngineeringA, 2005, 391: 296−304.[7]MA C, CHEN D L, BHOLE S D, BOUDREAU G, LEE A, BIRO E.Microstructure and fracture characteristics of spot-welded DP600 steel [J]. Materials Science and Engineering A, 2008, 485: 334−346.[8]SUN Shou-jin, Martin P. Manganese partitioning in dual-phase steelduring annealing [J]. Materials Science and Engineering A, 2000, 276: 167−174.[9]ZHU Xiao-dong, WANG Li. Effect of the continuous annealingparameters on the mechanical properties of cold rolled Si-Mn dualphase steel [C]//CSM 2003 Annual Meeting Proceedings, 2003: 684−688.[10]MOHAMMAD R A, EKRAMI A. Effect of ferrite volume fractionon work hardening behavior of high bainite dual phase (DP) steels [J].Materials Science and Engineering A, 2008, 477: 306−310.[11]HA VV A K Z, CEYLAN K, HUSEYIN A. Investigation of dual phasetransformation of commercial low alloy steels: Effect of holding timeat low inter-critical annealing temperatures [J]. Materials Letters, 2008, 62: 2651−2653.[12]DOU Ting-ting, KANG Yong-lin, YU Hao, KUANG Shuang, LIURen-dong, YAN Ling. Microstructural evolution of cold rolled dualphase steel during initial stages of continuous annealing [J]. Heat Treatment of Metal, 2008, 33(3): 31−35.[13]CHEN Hui-feng, ZHANG Qing-fen, AN Jia-shen. Recrystallizationcharacteristic of IF steel during rapid heating [J]. Journal of East China University of Metallurgy, 1999, 16(1): 21−23.[14]YANG D Z, BROWNEL E L, MATLOCK D K, et al. Ferriterecrystallization and austenite formation in cold rolled intercriticallyannealed steel [J]. Metallurgical Transactions A, 1985, 16A: 1385−391.[15]SULEYMAN G. Static strain ageing behaviour of dual phase steels[J]. Materials Science and Engineering A, 2008, 486: 63−71.[16]KUANG Shuang, KANG Yong-lin, YU Hao, LIU Ren-dong, YANLing. Experimental study on microstructure evolution in continuousannealing of cold-rolled dual phase steels [J]. Iron and Steel, 2007,42(11): 65−73.(Edited by CHEN Ai-hua)。

基金项目:国家重点研发计划项目(2017YFB0304503);国铁集团科技研究开发计划项目(K2018G020)金纪勇,硕士,教授级高级工程师,2011年毕业于中国科学院金属研究所材料工程专业。

E-mail :***************回火工艺对贝氏体钢轨组织性能影响研究金纪勇1,刘宏2,王冬1,陈昕1,刘祥1(1.鞍钢集团钢铁研究院,辽宁鞍山114009;2.鞍钢股份有限公司产品发展部,辽宁鞍山114021)摘要:利用TEM 、磁性分析法、液压伺服万能材料试验机对不同回火温度和二次回火的贝氏体钢轨组织性能进行分析。

结果表明,350℃回火时,贝氏体钢轨残余奥氏体稳定,冲击韧性和-20℃断裂韧性较好;325℃保温10h 二次回火比325℃保温4h 二次回火得到的伸长率及断面收缩率更好,适用于实际生产工艺。

关键词:贝氏体钢轨;回火温度;断裂韧性;伸长率中图分类号:TG113.2文献标识码:A文章编号:1006-4613(2021)02-0019-04Study on Effect of Tempering Process on Microstructures andProperties of Bainite RailJin Jiyong 1,Liu Hong 2,Wang Dong 1,Chen Xin 1,Liu Xiang 1(1.Ansteel Iron &Steel Research Institutes ,Anshan 114009,Liaoning ,China ;2.Product Developing Department of Angang Steel Co.,Ltd.,Anshan 114021,Liaoning ,China )Abstract :The microstructures and properties of a Bainite steel rail with different temperingtemperatures and secondary tempering were analyzed by using TEM,magnetic analysis and hydraulic servo-universal material testing machine.The analytical results demonstrated that when tempered at 350℃,the retained austenite of the bainite rail was stable while its impact toughness and fracture toughness at -20℃were relatively good,and on the other handits elongation and reduction of area by secondary tempering at 325℃for 10h were muchbetter than that by secondary tempering at 325℃for 4h,which was suitable for the actualproduction process.Key words :bainite rail;tempering temperature;fracture toughness;elongation贝氏体钢轨具有韧性好、疲劳强度高和耐磨性好等特点,逐渐成为各研究机构及企业关注的焦点[1-2]。

价值工程0引言通过以等原子或接近等原子的比例添加多种主要元素来最大化金属合金中的构型熵,被认为有利于形成大量固溶体。

这是一种发展高熵合金的新方法[1]。

五等原子钴铬镍面心立方单相固溶体(称为康托尔合金)是迄今为止最常研究的合金体系[2-10]。

不考虑初始假设,一些研究[11-12]指出,构型熵不是形成大量固溶体的唯一因素,但吉布斯自由能也应被视为定义平衡态的决定性因素。

在这方面,已经开发了许多多种元素合金,或复合浓缩合金[13],与康托尔合金相比,这些非等原子设计使合金具有不同的强度/延展性组合[14-17]。

然而,如果保健机构想要得到很好的发展和工业化,则制造过程需要进行优化。

因此,具有重要结果的热机械加工方案被认为是可操作的,不仅是为了在材料成形的同时打破铸造结构,更具体地说,是作为一种中间过程来细化晶粒尺寸、优化微观结构和减少不均匀性[18]。

在这方面,多步等温热锻成功地应用于打破铝铬钴合金和铝铬钴合金的枝晶结构,并形成精细的多相等轴显微组织[19]。

正如所料,与铸态相比,锻态材料的屈服应力、极限抗拉强度和抗拉延展性得到了改善[20]。

到目前为止,已经进行了一些研究,从潜在的恢复机制的角度来研究高温变形特性[21]。

1高熵合金设计准则高熵合金近些年来被受学者喜爱,其通常选用五种组元以上的金属元素,采用粉末冶金或熔炼等操作手段,将合金的成分制备均匀、成为组织性能完备的无序固溶体合金,常采取Al、Ti、V、Co、Cr、Fe、Mn、Ni、Cu等金属元素和C、Si、B等非金属元素来改变高熵合金的性能。

若想合金达到稳定固溶体的标准,通常需要玻尔兹曼公式进行计算,从而达到理想的最大值[22]。

依据热力学原理中,高熵合金相的稳定性与Gibbs自由能之间存在的联系[23],其方程为:ΔG mix=ΔH mix-TΔS mix(1)公式(1)中,ΔH mix为高熵合金体系的混合焓,ΔS mix为高熵合金体系的混合熵;再依据Hume-Ruthery规则,公式如下:ΔH mix=Nv=1,j≠1∑4ΔH mix AB C v C j(2)s=Nv=1∑C v1-r v/N v=1∑C v r v()()√(3)上述公式中,s为存在高熵合金原子半径得差;r v为v 原子的半径;ΔHmixAB为A-B二元合金的混合焓。

航空发动机双性能盘制造技术与机理的研究进展高峻;罗皎;李淼泉【摘要】具有双重组织的双性能涡轮盘和压气机盘因其优秀的综合性能而成为制造高推重比航空发动机的研究热点.介绍国内外航空发动机用高温合金、钛合金双性能盘的研究进展,对双合金双组织双性能盘和单合金双组织双性能盘进行比较,着重分析两类盘在制造过程存在的主要问题,未来双性能盘的研究重点将落在适合双重热处理的粉末合金和钛合金、双重热处理装置改进、超细晶盘坯和双合金连接弱化方面.%Dual property turbine or compressor disk for high thrust-weight ratio areo-engine was in deeply studied due to its dual micro-structure and excellent mechanical properties in recent years. The advance in aero-engine dual property disk of superalloy and titanium alloy was introduced. And dual property disks consisting of two alloys and one alloy were compared. Moreover, the encounter problems in the study were analysed with emphasis. In the future, the research focuses on dual property disks of P/M superalloy and titanium alloy which are suitable for dual microstructure heat treatment (DMHT) , apparatus improvement for DMHT, ultrafine-grained billet and improving the performance of dual alloy disk joints.【期刊名称】《航空材料学报》【年(卷),期】2012(032)006【总页数】7页(P37-43)【关键词】航空发动机;双性能盘;高温合金;钛合金【作者】高峻;罗皎;李淼泉【作者单位】西北工业大学材料学院,西安710072;西北工业大学材料学院,西安710072;西北工业大学材料学院,西安710072【正文语种】中文【中图分类】V223;V215.5提高航空发动机推重比,同时有效保证发动机使用的持久性和可靠性,是发动机设计者的永恒追求。

第23卷第3期中国有色金属学报 2013年3月 V ol.23 No.3 The Chinese Journal of Nonferrous Metals Mar. 2013 文章编号:10040609(2013)03061607高强韧压铸 AlMgSiMn合金的微观组织及力学性能胡祖麒,万 里,吴 晗,刘学强,邹 广,吴树森(华中科技大学 材料成形与模具国家重点实验室,武汉 430074)摘 要:对压铸AlMg x Si2Mn(x=5.7~7.2)合金的微观组织进行分析,测试力学性能以及疲劳性能,研究镁含量对合 金组织和力学性能的影响。

结果表明:随着Mg含量的提高,合金屈服强度和布氏硬度分别提高了10.4%和9%, 伸长率从8.3%降低至4.5%, 抗拉强度则没有明显变化。

疲劳寿命随着Mg含量的提高而提高, 疲劳极限从57MPa 上升至 75 MPa。

合金的微观组织主要由 α(Al)和 Mg2Si 相组成,Fe 相则以颗粒状的 Al3Fe 和不规则形状的 Al15(Fe,Mn)3Si2 存在于晶界。

Mn元素的加入也降低合金的粘模倾向。

关键词:高压压铸;铝镁合金;疲劳性能;微观组织中图分类号:TG249.2 文献标志码:AMicrostructure and mechanical properties of high strength andtoughness die casting AlMgSiMn alloysHU Zuqi, W AN Li, WU Han, LIU Xueqiang,ZOU Guang, WU Shusen(State Key Laboratory of Materials Processing and Die &Mould Technology,Huazhong University of Science and Technology, Wuhan 430074, China)Abstract:Microstructure observation, tensile test and fatigue tests were conducted to investigate the effect of magnesium content on microstructure and mechanical properties of die casting AlMg x Si2 Mn (x=5.7−7.2) alloys. The results indicate that with magnesium content (mass fraction) increasing from 5.7% to 7.2%, the yield strength and brinell hardness increase by 10.4% and 9%, respectively. The elongation decreases from 8.3% to 4.5% and the ultimate tensile strength is stable.The fatigue life of alloys increases with enhanced magnesium contents and the fatigue limit increases from 57MPa to 75MPa.The microstructure of those alloys consists ofα(Al) matrix and Mg2Si. Meanwhile, Al3Fe and Al15(Fe,Mn)3Si2 compounds distribute around grain boundaries.The addition of Mn reduces the die sticking tendency.Key words:high pressures die casting; AlMg alloys; fatigue property; microstructure压铸作为生产效率高、尺寸精度和力学性能优良 的铸造方法,在汽车、机电、通讯等行业得到了越来 越多的应用,如汽车动力零件中的铝合金缸体、铝合 金油底壳、副车架以及通讯腔体等部件均可采用压铸 方法制造 [1−3] 。