Crystal transformation from the a- to the b-form upon tensile

- 格式:pdf

- 大小:335.57 KB

- 文档页数:8

材料英语作文河流到达海洋而是沿途的风景全文共3篇示例,供读者参考篇1The Winding Path to the Sea: A River's JourneyThey say that a river's destiny is not a better destiny, but rather the journey itself. As a high school student living in a small town nestled along the banks of the Willamette River in Oregon, I've come to understand the profound truth in those words.The Willamette carves its path through valleys and canyons, cities and farmlands, ever pushing forward yet meandering with a sense of grace and patience. From its humble origins as a trickle of snowmelt high in the Cascade Mountains, it grows in strength and determination with each new tributary that feeds its flow.In my youth, I would spend endless summer days wandering the river's edge, my toes digging into the cool, damp soil. The Willamette was my loyal companion, a steadfast presence that colored the background of my formative years. Yet I failed to fully grasp its magnificence until I reached an age where I could reflect on the river's greater purpose.A river's journey is one of fusion - a uniting of waters from high and low, a singular path created by the joining of many streams. The Willamette collects the liquid stories of the Coastal and Cascade ranges, growing swollen with snow runoff, rain, and the outpourings of smaller brooks and creeks. Each new confluence introduces a fresh narrative, altering the river's flow while adding to its complexity.As the Willamette winds northward through Oregon's fertile valleys, it acts as an artery of life. Lush greenery lines the banks, bowing respectfully toward the riverside as if in humble gratitude for the river's life-giving waters. Farms and vineyards flourish on the nutrient-rich soils, sustained by the Willamette's bounty. Even cities like Portland have evolved along the river's sinuous curves, their skylines reflecting in the waters that enabled their existence.To travel beside a river is to bear witness to a grand transformation. The higher I ascend along its path, the more I'm transported through epochs of ecological evolution. From the lush rainforests of its headwaters to the arid high desert landscapes in the east, the Willamette's banks host anever-changing ecosystem parade.The river is also a study in raw, unbridled power. I've witnessed its fury during the spring floods, raging currents tearing away at the banks and obliterating all in their wake. Like the human experience, the river's journey oscillates between peace and upheaval, calm and chaos. Yet it continues ever forward with an indomitable sense of purpose.For as the Willamette flows, so too does the march of civilization. Pioneer settlements emerged along the banks, their sehr inhabitants recognizing the river's importance as a source of food, water, and transportation. Even today, the reaction has to be carried from interior Oregon to the Pacific ports, the river's currents supporting commerce and cultural exchange.Often at night, I'll sit quietly and listen to the Willamette's song - the eternal rush of water over rocks and fallen logs. It's a lyrical melody that spans eons, dating back to the very origins of this magnificent waterway. The more I attune my senses, the more the river's rhythm becomes a part of my own innermost beat and breath.In those transcendent moments, I'm reminded that the Willamette's journey is truly the journey of life itself. It is a river of dreamers and pioneers, of prospectors and homesteaders. It haswitnessed epochs of volcanic catastrophe and regrowth, the comings and goings of great forests and deserts and peoples.Most importantly, the Willamette's ceaseless flow teaches us that no purpone or destination holds more significance than our daily experiences. It is the journey - with all its meanderings and oscillations between turbulence and peace - that holds the ultimate meaning.For me, the Willamette's path will eventually culminate in the vast expanse of the Pacific Ocean. Its waters will merge with the sea's rolls and currents, dispersing across planet Earth in a new cycle. Yet the river's true legacy lies not in that final destination, but in every mile along the way. Itlawksoes in the sunbeams glittering on the waters, the rushes swaying gently in the riverside breezes, and the splendor of another perfect sunset reflecting from its mirrored surface.The journey of a river is a metaphor for the human condition - a compelling call to cherish each passing current, rapid, andof our existence. Like the Willamette, we are constantly in motion yet shaped by the scenery waking across our paths. Our individual stories accte to form the greater river of humankind, ever ebbing and merging toward new conceptions and experiences.So go ahead and dip your toes into the metaphoric waters of your own life's river. Let the currentsonly carry you forward while opening your soul to the profound revelations unfolding at every bend. The ultimate destination matters little compared to the beauty witnessed in the journey itself.篇2The Winding Path to the Sea: A River's JourneyHave you ever really stopped to ponder the incredible journey that a river takes from its humble beginnings high up in the mountains all the way down to the vast, salty expanse of the ocean? It's a voyage filled with twists and turns, obstacles to overcome, and ever-changing scenery that paints a breathtaking tapestry of nature's grandeur. Join me as we trace the footsteps of a river, for it is not the ultimate destination that matters most, but rather the sights and experiences along the way.Our adventure begins at the river's source, a crystal-clear spring bubbling forth from the rocky embrace of a towering peak. Here, the water is pure and icy cold, untainted by the world below. As it trickles down the mountainside, it collects into a merry stream, dancing over mossy boulders and carving its way through the rugged terrain. The air is crisp and invigorating,filled with the scents of pine and wild flowers, a true feast for the senses.Gradually, the stream grows bolder, swelling with the contributions of countless tributaries that join its ranks. The once-gentle trickle transforms into a rushing torrent, crashing over craggy outcroppings and plunging into deep, narrow gorges. The thunderous roar of the water echoes through the valley, a primal symphony that resonates within our very bones. Here, the river is a force to be reckoned with, carving its path with relentless determination, sculpting the landscape with each passing year.As we descend further, the terrain begins to level out, and the river's fury subsides into a more tranquil flow. Emerald-green banks line its shores, dotted with willows that dip their slender branches into the cool, clear depths. Sunlight dances across the rip篇3The Journey of a River to the OceanI remember the first time I truly appreciated the sheer magnificence of a river. It was during a hiking trip with my family in the mountains, where a pristine stream gurgled and tumbledover rocks, its crystal-clear waters reflecting the dappled sunlight filtering through the canopy of trees. That day, I discovered that a river's true splendor lies not merely in its destination but in the journey itself – the ever-changing landscapes it traverses, the life it sustains, and the stories it whispers to those willing to listen.A river's voyage begins high up in the mountains, where melting snow and rainfall converge to form tiny rivulets. These delicate streams, no wider than a footpath, trickle down the slopes, weaving through crevices and cracks in the rock. As they descend, they merge and swell, gaining strength and momentum, until they become a formidable torrent carving its path through the rugged terrain.In the upper reaches, the river is a wild and untamed force, its waters cascading over towering cliffs in a breathtaking display of power. The roar of the falls echoes through the valleys, a primordial symphony that has played for eons. Here, the river's course is dictated by the immovable giants of stone, sculpting intricate patterns and forming deep pools where rainbows of mist dance in the sunlight.As the river continues its descent, it enters a more tranquil phase, meandering through verdant meadows and lush forests. Its banks are lined with a tapestry of vibrant wildflowers, theirpetals swaying gently in the breeze. The air is rich with the scents of pine and earth, and the melodic calls of birds accompany the river's soothing murmur.In these stretches, the river becomes a lifeline for countless species. Deer and elk come to quench their thirst, while bears and otters hunt for fish in the shallows. Dragonflies flit across the surface, their iridescent wings catching the light, and waterfowl glide gracefully, leaving rippling trails in their wake. The river sustains an entire ecosystem, a delicate balance of interdependence that has existed for millennia.As the river winds its way through the foothills and valleys, it encounters human settlements – quaint villages and bustling towns that have sprung up along its banks. Here, the river becomes a vital artery, providing water for drinking, irrigation, and industry. Its waters power mills and factories, turning great wooden wheels that once drove the local economy.In these urban stretches, the river takes on a different character, its banks lined with stone walls and promenades. Bridges arch gracefully overhead, connecting communities on either side, while parks and public spaces offer respite from the hustle and bustle of city life. The river becomes a gathering place,a hub of recreation and leisure, where people come to fish, swim, or simply bask in its tranquil beauty.Yet, even as it meanders through urban landscapes, the river retains its wild essence, a living reminder of nature's enduring presence. Its waters reflect the ever-changing sky, mirroring the vibrant hues of sunrise and sunset, the billowing clouds of an approaching storm, or the twinkling stars of a clear night.And so, the river continues its journey, winding its way through a tapestry of landscapes, each more captivating than the last. It passes through fertile farmlands, where fields of golden wheat and verdant vineyards stretch as far as the eye can see. It carves through arid deserts, where its waters become a lifeline for hardy plants and animals adapted to the harsh conditions.Finally, after traversing countless miles and overcoming innumerable obstacles, the river reaches its ultimate destination – the vast, unending expanse of the ocean. Here, its waters mingle with the salty brine, losing their individual identity but becoming part of a greater, more profound cycle.As I stand on the shore, watching the river's final moments before it merges with the sea, I am struck by the sheer majesty of its journey. From its humble beginnings as a trickle high in themountains to its triumphant arrival at the ocean, the river has witnessed and shaped the very fabric of the land.Its waters have nourished life, carved landscapes, and borne witness to the ebb and flow of civilizations. It has been a constant companion, a thread weaving through the tapestry of history, carrying with it the stories of all those who have walked along its banks.And as I gaze out over the vast expanse of the ocean, I realize that the river's journey is not truly over. Its waters will evaporate, rise into the clouds, and one day fall back to the earth as rain or snow, beginning the cycle anew. The river's voyage is an eternal one, a perpetual dance between land and sea, a testament to the enduring rhythm of nature.In that moment, I am filled with a profound sense of awe and reverence for the river and all that it represents. It is a reminder that life itself is a journey, a winding path filled withever-changing landscapes and experiences. And like the river, we must embrace the beauty and wonder of the voyage, for it is in the journey that we truly find meaning and fulfillment.。

adhesive[胶]allotropic[同素异形的amorphous[无定形的,非晶的anion[负离子]apuy[适当地]austenite[奥氏体]bainte「贝氏体binary isomorphous system[二元匀晶系统]Burgers vector[柏氏矢量]cadmium[镉]canon[正离子]carbide[碳化物Cast Iron[铸铁cementite[渗碳体]ceramic[陶瓷]chloride[氯chromium[铬]composite materials[复合材料cordinate system[坐标系统covalent bond[共价键crystal structure[晶体结构]crystallinity[结晶度ddiy[塑性deteriorative[劣化]dislocation[位错]edge dislocation[刃形位错]equilibrium[平衡]eutectic[共晶的eutectoid[共析的ferrite[铁素体fractional[分数的,部分的,相对的gain[晶粒grain boundary[晶界hase[相hexagonal dose-packed[密排六方的hexagonal[六方的]hypereutectoid[过共析hypoeutectoid[亚共析ion[硅Ionic Dond[离子键]isotherm[等温线lamellae[薄片]lattice[空间点阵,晶格]lever law[杠杆定律liquidus line[液相线martensite[马氏体]martensitic transformation[马氏体相变metallic bond[金属键]microstucture[显微组织monoclinic[单斜的nickel[镍nitride[氮化物]non-crystalline[非晶的]orthorhombic[正交的]parentheses[括孤]pearlite[珠光体periodic table[元素周期表phase diagram[相图]」phase transformation[相交]」point defect[点缺陷]polarize[极化polyethylene[聚乙烯polymerization[聚合]prism[棱镜]proeutectoid[先共析体provoke[诱发]reciprocal[倒数recrystallization[再结晶rhombohedral[菱方的screw dislocation[螺形位错]skew[歪斜]smal-(or low)angle grain boundary[小角度晶界sodium[钠solar cell [太阳能电池]solid solution strengthening[固溶强化solidus line[固相线solute[溶质solvus line[溶解度曲线spiral[螺旋形的]stifness[刚度]strucure[组织]synthesis[合成tetragonal[四方的tetrahedron[四面体thermoplastics[热塑性塑料]thermosets[热固性塑料tie linc[连接线]tilt boundary[倾侧晶界]translucent[半透明的]triclinic[三斜的troley[石油twin boundary[李晶界unit cell[晶胞vacancy[空位valence electron[价电子]Van de Waals bond[范德华键①材料科学是研究材料的加工、组织、性能和功能之间关系的科学。

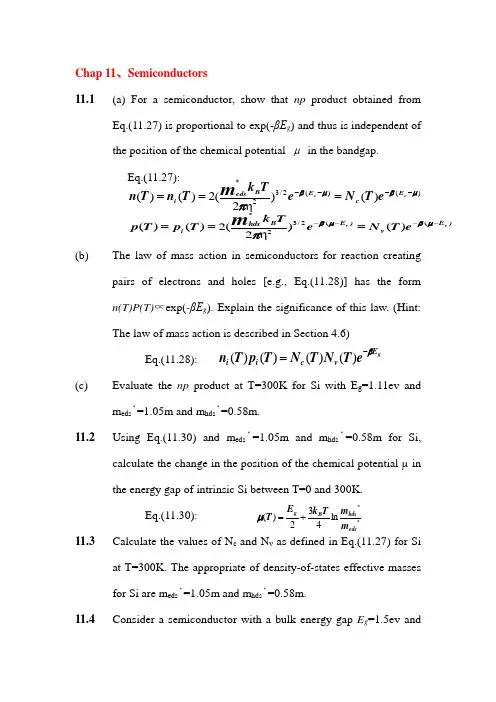

Chap 11、Semiconductors11.1 (a) For a semiconductor, show that np product obtained fromEq.(11.27) is proportional to exp(-βE g ) and thus is independent of the position of the chemical potential μ in the bandgap.Eq.(11.27):(b) The law of mass action in semiconductors for reaction creatingpairs of electrons and holes [e.g., Eq.(11.28)] has the form n(T)P(T)∝exp(-βE g ). Explain the significance of this law. (Hint: The law of mass action is described in Section 4.6)Eq.(11.28): (c) Evaluate the np product at T=300K for Si with E g =1.11ev andm eds ﹡=1.05m and m hds ﹡=0.58m.11.2 Using Eq.(11.30) and m eds ﹡=1.05m and m hds ﹡=0.58m for Si,calculate the change in the position of the chemical potential µ in the energy gap of intrinsic Si between T=0 and 300K.Eq.(11.30): 11.3 Calculate the values of N c and N v as defined in Eq.(11.27) for Siat T=300K. The appropriate of density-of-states effective masses for Si are m eds ﹡=1.05m and m hds ﹡=0.58m.11.4 Consider a semiconductor with a bulk energy gap E g =1.5ev andgE v c i i e T N T N T p T n β-=)()()()()()(2/32)()2(2)()(μβμβπ----*===c c E c E B eds i e T N e T k T n T n m )()(2/32)()2(2)()(v v E v E B h ds i e T N e T k T p T p m ----*===μβμβπ **+=eds hdsB g m m T k E T ln 432)(μwith m e﹡=m h﹡=0.1m. Calculate the increase in the energy gap ofthis semiconductor when it is incorporated into the followingstructures:(a) A quantum well (d=2) with L x=10nm.(b) A quantum wire (d=1) with L x=L y=10nm(c) A quantum dot (d=0) with L x=L y=L z=10nm11.5 A Hall effect measurement is carried out on a rectangular barof a semiconductor with dimensions L x=0.04m (the directionof current flow ) and L y=L z=0.002m. When a current I x=5mAflows in the +x direction and a magnetic field B z=0.2T isapplied in the +z direction, the following voltages aremeasured: V x=6V and V y=+0.3mV (i.e., increasing in the +ydirection). Determine the following properties of thesemiconductor bar from these data :(a) The sign of the dominant charge carriers.(b) The concentration of the dominant charge carriers.(c) The electrical conductivity σ.(d) The mobility µ of the dominant charge carriers.11.6Using Eq.(11.59), estimate the increase △n in the electronconcentration in an n-type semiconductor due to the uniformabsorption of light with α=105m-1, I0=1W/m2, and hω=1e V, aquantum efficiency η=1, and a minority-carrier lifetime ηp=10-3s.Eq.(11.59): 11.7 Using the definition of the Hall mobility µH =︱ζR H ︱and theexpression for R H for an intrinsic semiconductor given in Eq.(11.49), show that µH =︱µh -µe ︱.Eq.(11.49): 11.8 Consider the structural transformation of a binary crystal ABfrom the hexagonal wurtzite crystal structure to the cubic zincblende crystal structure in which the density of the atoms remains constant. Find the lattice constant of the resulting cubic crystal if the lattice constants of the initial wurtzite crystal are a =0.3400nm and c =0.5552nm.11.11 List all of the local tetrahedral bonding units, A-B 4, which arepresent in the ternary semiconducting compounds Cu 2SiTe 3, Cu 3PS 4, and CuSi 2P 3. Note that each tetrahedron must contain an average of four bonding electrons per atom.11.13 Derive the expression for the shift △E of the electron energybands from one side of a p-n junction to the other under zero bias as given in Eq.(11.93). Calculate the magnitdde of the built-in electric potential V B =△E/e for Si at T=300K for N d =N a =2×1024m -3. Using these same parameters, calculate the depletion width d and the maximum electric field Q/∈A for a Si p-n junction at T=300 K.ωτηατω pp L I G p n 0)(==∆=∆)(e h eh H ne R μμμμ+-=Eq.(11.93): .Chap 12、Metals and Alloys 12.1 Referring to Section 12.5, show that the condition for the tangencyof the Fermi sphere to the Brillouin zone boundary for the FCC lattice is N =1.36.12.2 Derive Eq.:12.3 Derive Eq.:Chap 13、Ceramics13.1 For the silicon oxynitride compound Si 2N 2O, assume that Si, N,and O atoms have their usual valences (4, 3, and 2) and that the N and O atoms do not form covalent bonds with each other. (a) Given a local bonding unit Si-N x O y for Si with x+y =4,determine x (and y ) for this crystal structure.(b) What are the local bonding units for N and O?13.2 For the Si x N y O z ternary phase diagram, locate the followingcompounds :SiO 2, Si 3N 4, Si 2N 2O, and Si 3N 2O 3.13.3 Find the average number of bridging oxygens, b, and nonbridgingoxygens, n, for the following glasses:(a)CaO•SiO 2, and(b) soda-lime(i.e., 2CaO•3Na 2O•15SiO 2) n ia d B v c a d B g N N T k N N N N T k E E 2ln ln =+=∆)163253(02222∈-=πF F k e m k N U )]1(356[82202ws c ws Coul r r r Nze U --∈=πChap 14、Polymers14.1 A polymer whose viscoelastic properties are described byEq.(14.40) (i.e., the Maxwell model) is subjected to a time-dependent stress σ=σ0exp(-i ωt). Find the steady-state strain. Compare this result to that of a polymer that obeys the Voigt model, given by Eq. (14.37).Eq.(14.40): Eq. (14.37): 14.2 Consider an elastomer consisting of monomers that are opticallyanisotropic [i.e., they have a polarizability α11(ω) for light parallel to the chain axis and α┴(ω) for light polarized perpendicular to the chain axis]. Assume that there are N chains per unit volume. Let )(ωn be the mean index of refraction of the material. The elastomer is stretched with a steching parameter s , as defined in Secti on 14.5. Show that the elastomer will have a birefringence given by)]()()[1()(]2)([452)()()(112211ωαωαωωπωωωδ⊥--⊥--+=-=s s n n N n n nObtain an expression for the stress optical coefficient. C≡δn(ω)/ζ, where ζ is the applied stress.Chap 15、Dielectric and Ferroelectric Materials∙∙=+εησσG ηστεε=+∙15.1 Given the Landau free-energy density for a ferroelectric of the form Where b>c. Let a=a 0(T-T C ) and assume that b and c are constant. Find P z and χ as a function of T for the state of thermal equilibrium. 15.2 Design a piezoelectric actuator that can be used to sweep anSTM head over the surface of a solid. What is the area that can practically be covered?15.3 Adapt Weiss molecular field theory (see Chapter 9) to describe aferroelectric. Assume that there are just two orientations for the electric-dipole moment of a unit cell and that NN cells interact via an exchange interaction. Obtain the hysteresis curve and values for the coercive field E c , saturation polarization P sat , and remanent polarization P rem .15.4 BaTiO 3 is a paraelectric for T>T C =130℃ and has a Curie constantC=76,000K.(a)If the lattice constant for the cubic unit cell of BaTiO 3 is a=0.401nm, calculate the electric-dipole moment µ of this unit cell. (b)What would the corresponding polarization P=µn be at T=0 K?Chap 16、Superconductors16.1 (a) Derive expression for the difference in entropy△S(T)=S n (T)-S s (T) and the difference in specific heatZ y x x z z y z y x o EP P P P P P P c P P P b P a g g -+++++++=)(2)(422222224442△C(T)=C n (T)-C s (T) between the normal and superconducting states in terms of the critical magnetic field H c (T) and its first derivative dH c /dT and second derivative d 2H c /dT 2. [Hint: Use Eq.(16.3) and standard thermodynamic relationships.](b) Evaluate these expressions for △S(T) and △C(T) for the case where H c (T) can be approximated by H c0[1-(T/T c )2] and show that : (ⅰ) △S(T c )=△S(0)=0(ⅱ) △S(T)>0 for 0<T<T c(ⅲ)△C(T c )=-4µ0H c02/T c . Calculate △C(T c ) from this expressionusing T c = 1.175 K and H c0 = 105 Oe = 8360 A/m for Al and compare with the measured result -225 Jm -3K -1 for Al.(ⅳ) △C=0 for T=T c /3 and T=0K.Eq.(16.3): 16.2 (a) Using Eq.(16.5), calculate the condensation energy in J/m 3 and ineV per electron at T=0K for the superconductor Pb for which H c0=6.39×104A/m.(b) Compare your result from part (a) with the expression ε(0)(ε(0)/E F ) where the superconducting energy gap 2ε(0) = 2.6 meV for Pb. Here ε(0)/E F is the fraction of conduction elections whose energies are actually affected by the condensation .Eq.(16.5): 16.3 Consider the London penetration depth λL defined in Eq.(16.10).⎰+=-=H s s s s H T G dH H M T G T H G 02002),0()(),0(),(μμ2)(),0(),0(20T H T G T G c s n μ=-(a) Calculate λL (0K) for the superconducting Al, Pb, and Nb. (b) If a superconductor has a London penetration depth λL (0K)=200nm, what is the concentration n s of superconducting electrons at T=0.5T c .Eq.(16.10): 16.4 When transport current i flows through a superconducting wireof radius R, its path is confined to a region of thickness λ, the penetration depth, just inside the surface of the wire.(a) In this case show that the critical current density J c =i c /A eff is independent of R and can be expressed in terms of the critical field H c by J c =H c /λ. Here A eff is the effective area through which the current flows, with A eff <<πR 2.(b) Calculate J c for superconducting Pb at T=0K. [Note: H c0 = 803 Oe = 63919 A/m and λ(0) = 39 nm](c) Sketch J c (T)/J c (0) from T = 0 K to T c using the temperature dependencies of H c and λ given in Eqs.(16.6) and (16.11), respectively .Eq.(16.6):Eq.(16.11): 16.5 A type Ⅱ superconductor has T c =125k, ΘD =250K, and κ(T c )=50. Onthe basis of standard theories [free-electron model, Debye model, BCS theory, G-L theory, Pauli limit for H c2 given in Eq.(16.33)], 20)()(e T n mT s L μλ=)1()(220c c c T T H T H -=4)/(1)0()(c L L T T T -=λλestimate the following:(a)The superconducting energy gap 2ε(0).(b) The upper critical field H c2(0)=H p .(c)The co herence length ξ(0) and the penetration depth λ(0).(d)The thermodynamic critical field H c0=H c (0).(e)The coefficients γ and A of the electronic and phonon contributions to the specific heat , γT and AT 3, respectively.Eq.(16.33): 16.7 Use Eq.(16.20) to find the limiting values of λ(l ) and ξ(l ) (a) in theclean limit where the electron mean free path l >>ξ0, and (b) in the dirty limit where l <<ξ0.Eq.(16.20): and 16.8 (a) Calculate the density of vortices per unit area B/Φ0 for thefollowing values of B, the average flux density present in the mixed state of a superconductor. Take H c2=1.6MA/m.(i) B = μ0H c2/2. (ii) B ≈ B c2 = μ0H c2.(b)Calculate the average separation d between the vortices from your answers in part (a) and compare your answers with the conherence length ξ. [Hint: You can obtain ξ with the help of Eq.(16.22).]Eq.(16.22): 16.10 Calculate the number of holes N hole per Cu ion in the CuO 2copper-oxygen layers in the superconductor YBa 2Cu 3O 7-x for the Bp T T H μμε0)()(≈l l 11)(10+=ξξll ξλλ+∞=1)()()(2)(2002T T H c ξπμΦ=cases of x = 0, 0.25, and 0.5. Assume the following ionic charge states for the ions in this structure: Y 3+, Ba 2+, Cu 2+, and O 2-.16.11 For the compound with the chemical formula La 1.7Sr 0.3CuO 3.9:(a)what is the total number of electrons per formula unit outside closed shells?(b)How many electrons are contributed by each ion to the CuO 2 layers?(c)what is the average valence of the copper atoms?(d)Assuming that all copper ions have a charge of +2e, what is the number of holes per formula unit?16.12 Derive Eq.(16.33) for the Pauli limiting field H p by settingG n (H)=G s (H) at H=H p and using the Pauli paramagneticsusceptibility χp =µ0µB 2ρ(E F ) of the conduction electrons in thenormal state. [Hint: Use G n (H)-G n (0)=-µ0χp H 2/2, and the BCS resultG n (0)-G s (0)=ρ(E F )ε(0)2/2.]Eq.(16.33):Chap 17、Magnetic Materials17.1 Consider a single-domain uniaxial ferromagnetic particlemagnetized along its easy axis with M=M s in zero applied magnetic field. The magnetic anisotropy energy density is given by E a =K sin 2θ where K >0 and θ is the angle between the B p T T H μμε0)()(≈magnetization M and the easy axis. A magnetic field H is now applied at 90° to the easy axis.(a)Show that the sum of the anisotropy and magnetostatic energy densities for this particle is u(θ)=K sin 2θ-µ0MHsinθ.(b)Find the angle θ be tween M and the easy axis as a function of the magnitude of the field H by minimizing uwith respect to θ .(Note that it will be important to check for the stability of the solution by requiring that ∂2u/∂θ2>0.)(c) Show that the resulting magnetization curve (i.e., the plot of thecomponent of M in the direction of H versus the applied field H ) is a straight line (with slop χ=µ0M 2s /2K ) up to H =H k =2k/µ0M s , at which point the magnetization is saturated in the direction of H . Here H k is the effective magnetic anisotropy field in Eq.(17.14).Eq.(17.14): 17.4 Prove that when the shape anisotropy constant K s is <0 (i.e., whenN ⊥<N 11), the magnetization M for a ferromagnetic film will lie in the plane of the film .17.5 Calculate the radius at which a spherical Fe particle behavessuperparamagnetically at T =300K by setting K 1V=K B T , where K 1≈4.2×104J/m 3 is the first-order magnetocrystalline anisotropy coefficient for Fe and V is the volume of the sphere.17.6 Calculate t he increase in temperature ΔT of a magnetic material withsK M KH 02μ=a square magnetization loop, with M s =1370KA/m and H c =1100kA/m, when the loop is traversed once, Assume that the material is thermally-isolated from its surroundings and that its specific heat is 4×106J/m 3K.17.7 For a magnetically isotropic m aterial with magnetostriction λ, provethat B 2(C 11-C 12)=2B 1C 44. Show, in fact, that if the material is also elastically isotropic, then B 1=B 2. (Hint: See Section 10.8)17.8 Show that B (t) and M (t) both lag the applied magnetic fieldH(t )=H 0e -iωt by the same phas e angle δ when µ0H 0<<B 0cosδ. [Hint: Start by substituting the expressions for B (t) and M (t) from Eq.(17.33) into the expression B =µ0(H+M).]Eq.(17.33): andChap 18、Optical Materials18.1 Suppose that a quantum dot has the shape of a two-dimensionalcircular disk. A model that is often used to describe the potential of an electron confined in such a dot is V(r)=m ﹡ω02r 2/2. Suppose a magnetic induction B is imposed perpendicular to the plane of the dot. Show that the electron energy levels are given by the formula where n=0, 1, 2,…………and l=……, -2, -1, 0, 1, 2,……..18.2 Consider a Lorentz oscillator model for an electron moving in )(0)(δω+-=t i e B t B )(0)(φω+-=t i e M t M **-+++=m eB l m eB l n E l n 2)2()()12(220, ωone-dimensional anharmonic potential described by the Toda potential V(x)=Ae -ax +Bx, where A, a and B are constants. The equation of motion isDerive expressions for the linear polarization P , at frequency ω and the nonlinear polarization at frequency 2ω, P (2ω).18.3 Consider a particle of mass m moving in the anharmonicsymmetric potential V(x)=Acosh[a(x-x o )] subject to a damping force –γv and a driving force qE cosωt . Find the Fourier coefficients for the dipole moment at frequencies ω and 3ω. 18.4 Using Vegard′s law , derive an expression for the bandgap energyE g (x,y) of a layer of In 1-x Ga x As y P 1-y which is lattice matched to an InP substrate. Compare your expression with the experimental result given in Eq.(18.15) and comment on any differences.Eq.(18.15): E g =1.35-0.72y+0.12y 2 eVt qE e e aA dtdx dt x d m o ax ax ωγcos )()(22+-=+--。

托福阅读TPO20(试题+答案+译文)第3篇:FossilPreservationTPO是我们常用的托福模考工具,对我们的备考很有价值,下面小编给大家带来托福阅读TPO20(试题+答案+译文)第3篇:Fossil Preservation。

托福阅读原文【1】When one considers the many ways by which organisms are completely destroyed after death, it is remarkable that fossils are as common as they are. Attack by scavengers and bacteria, chemical decay, and destruction by erosion and other geologic agencies make the odds against preservation very high. However, the chances of escaping complete destruction are vastly improved if the organism happens to have a mineralized skeleton and dies in a place where it can be quickly buried by sediment. Both of these conditions are often found on the ocean floors, where shelled invertebrates (organisms without spines) flourish and are covered by the continuous rain of sedimentary particles. Although most fossils are found in marine sedimentary rocks, they also are found in terrestrial deposits left by streams and lakes. On occasion, animals and plants have been preserved after becoming immersed in tar or quicksand, trapped in ice or lava flows, or engulfed by rapid falls of volcanic ash.【2】The term "fossil" often implies petrifaction, literally a transformation into stone. After the death of an organism, the soft tissue is ordinarily consumed by scavengers and bacteria. The empty shell of a snail or clam may be left behind, and if it is sufficiently durable and resistant to dissolution, it may remain basically unchanged for a long period of time. Indeed, unaltered shells of marine invertebrates are known from deposits over 100million years old. In many marine creatures, however, the skeleton is composed of a mineral variety of calcium carbonate called aragonite. Although aragonite has the same composition as the more familiar mineral known as calcite, it has a different crystal form, is relatively unstable, and in time changes to the more stable calcite.【3】Many other processes may alter the shell of a clam or snail and enhance its chances for preservation. Water containing dissolved silica, calcium carbonate, or iron may circulate through the enclosing sediment and be deposited in cavities such as marrow cavities and canals in bone once occupied by blood vessels and nerves. In such cases, the original composition of the bone or shell remains, but the fossil is made harder and more durable. This addition of a chemically precipitated substance into pore spaces is termed "permineralization."【4】Petrifaction may also involve a simultaneous exchange of the original substance of a dead plant or animal with mineral matter of a different composition. This process is termed " replacement" because solutions have dissolved the original material and replaced it with an equal volume of the new substance. Replacement can be a marvelously precise process, so that details of shell ornamentation, tree rings in wood, and delicate structures in bone are accurately preserved.【5】Another type of fossilization, known as carbonization, occurs when soft tissues are preserved as thin films of carbon. Leaves and tissue of soft-bodied organisms such as jellyfish or worms may accumulate, become buried and compressed, and lose their volatile constituents. The carbon often remains behind as a blackened silhouette.【6】Although it is certainly true that the possession of hardparts enhances the prospect of preservation, organisms having soft tissues and organs are also occasionally preserved. Insects and even small invertebrates have been found preserved in the hardened resins of conifers and certain other trees. X-ray examination of thin slabs of rock sometimes reveals the ghostly outlines of tentacles, digestive tracts, and visual organs of a variety of marine creatures. Soft parts, including skin, hair, and viscera of ice age mammoths, have been preserved in frozen soil or in the oozing tar of oil seeps.【7】The probability that actual remains of soft tissue will be preserved is improved if the organism dies in an environment of rapid deposition and oxygen deprivation. Under such conditions, the destructive effects of bacteria are diminished. The Middle Eocene Messel Shale (from about 48 million years ago) of Germany accumulated in such an environment. The shale was deposited in an oxygen-deficient lake where lethal gases sometimes bubbled up and killed animals. Their remains accumulated on the floor of the lake and were then covered by clay and silt. Among the superbly preserved Messel fossils are insects with iridescent exoskeletons (hard outer coverings), frogs with skin and blood vessels intact, and even entire small mammals with preserved fur and soft tissue.托福阅读试题1.The word "agencies" in the passage (paragraph 1) is closest in meaning tobinations.B.problems.C.forces.D.changes.2.In paragraph 1, what is the author's purpose in providingexamples of how organisms are destroyed?A.To emphasize how surprising it is that so many fossils exist.B.To introduce a new geologic theory of fossil preservation.C.To explain why the fossil record until now has remained incomplete.D.To compare how fossils form on land and in water.3.The word "terrestrial" in the passage (paragraph 1) is closest in meaning tond.B.protected.C.alternative.D.similar.4.Which of the sentences below best expresses the essential information in the highlighted sentence in the passage (paragraph 2)? Incorrect choices change the meaning in important ways or leave out essential information.A.When snail or clam shells are left behind, they must be empty in order to remain durable and resist dissolution.B.Although snail and clam shells are durable and resist dissolving, over time they slowly begin to change.C.Although the soft parts of snails or clams dissolve quickly, their hard shells resist dissolution for a long time.D.Empty snail or clam shells that are strong enough not to dissolve may stay in their original state for a long time.5.Why does the author mention "aragonite" in the passage (paragraph 2)?A.To emphasize that some fossils remain unaltered for millions of years.B.To contrast fossil formation in organisms with soft tissue and in organisms with hard shells.C.To explain that some marine organisms must undergo chemical changes in order to fossilize.D.To explain why fossil shells are more likely to survive than are fossil skeletons.6.The word "enhance" in the passage (paragraph 3) is closest in meaning toA.control.B.limit.bine.D.increase.7.Which of the following best explains the process of permineralization mentioned in paragraph 3?A.Water containing calcium carbonate circulates through a shell and deposits sediment.B.Liquid containing chemicals hardens an already existing fossil structure.C.Water passes through sediment surrounding a fossil and removes its chemical content.D.A chemical substance enters a fossil and changes its shape.8.The word "precise" in the passage (paragraph 4) is closest in meaning toplex.B.quick.C.exact.D.reliable.9.Paragraph 5 suggests which of the following about the carbonization process?A.It is completed soon after an organism dies.B.It does not occur in hard-shell organisms.C.It sometimes allows soft-tissued organisms to bepreserved with all their parts.D.It is a more precise process of preservation than is replacement.10.The word "prospect" in the passage (paragraph 6) is closest in meaning topletion.B.variety.C.possibility.D.speed.11.According to paragraph 7, how do environments containing oxygen affect fossil preservation?A.They increase the probability that soft-tissued organisms will become fossils.B.They lead to more bacteria production.C.They slow the rate at which clay and silt are deposited.D.They reduce the chance that animal remains will be preserved.12.According to paragraph 7, all of the following assist in fossil preservation EXCEPTA.the presence of calcite in an organism's skeleton.B.the presence of large open areas along an ocean floor.C.the deposition of a fossil in sticky substances such as sap or tar.D.the rapid burial of an organism under layers of silt.13. Look at the four squares [■] that indicate where the following sentence can be added to the passage. Where would the sentence best fit? Click on a square [■] to insert the sentence in the passage. But the evidence of past organic life is not limited to petrifaction. ■【A】Another type of fossilization, known as carbonization, occurs when soft tissues are preserved as thinfilms of carbon. ■【B】Leaves and tissue of soft-bodied organisms such as jellyfish or worms may accumulate, become buried and compressed, and lose their vola tile constituents. ■【C】The carbon often remains behind as a blackened silhouette.■【D】14. Directions: An introductory sentence for a brief summary of the passage is provided below. Complete the summary by selecting the THREE answer choices that express the most important ideas in the passage. Some answer choices do not belong in the summary because they express ideas that are not presented in the passage or are minor ideas in the passage. This question is worth 2 points. The remains of ancient life are amazingly well preserved in the form of fossils.A.Environmental characteristics like those present on ocean floors increase the likelihood that plant and animal fossils will occur.B.Fossils are more likely to be preserved in shale deposits than in deposits of clay and silt.C.The shells of organisms can be preserved by processes of chemical precipitation or mineral exchange.D.Freezing enables the soft parts of organisms to survive longer than the hard parts.paratively few fossils are found in the terrestrial deposits of streams and lakes.F.Thin films of carbon may remain as an indication of soft tissue or actual tissue may be preserved if exposure to bacteria is limited.托福阅读答案1.agency代理,中介,作用,所以答案是force,选C。

Unit 1 Translation.1."材料科学〞涉与到研究材料的结构与性能的关系.相反,材料工程是根据材料的结构与性质的关系来涉与或操控材料的结构以求制造出一系列可预定的性质.2.实际上,所有固体材料的重要性质可以分为六类:机械、电学、热学、磁学、光学、腐蚀性.3.除了结构与性质,材料科学与工程还有其他两个重要的组成部分,即加工与性能.4.工程师或科学家越熟悉材料的各种性质、结构、性能之间的关系以与材料的加工技术,根据以上的原则,他或她就会越自信与熟练地对材料进行更明智的选择.5.只有在少数情况下,材料才具有最优或最理想的综合性质.因此,有时候有必要为某一性质而牺牲另一性能.6.Interdisciplinary dielectric constantSolid material<s> heat capacityMechanical property electromagnetic radiationMaterial processing elastic modulus7.It was not until relatively recent times that scientists came to understand the relationships between the structural elements of materials and their properties.8. Materials engineering is to solve the problem during the manufacturing and application of materials.9.10.Mechanical properties relate deformation to an applied load or force.Unit 21.金属是电和热很好的导体,在可见光下不透明;擦亮的金属表面有金属光泽.2.陶瓷是典型的导热导电的绝缘体,并且比金属和聚合物具有更高的耐热温度和耐恶劣环境性能.3.用于高科技领域的材料有时也被称为先进材料.4.压电陶瓷在电场作用下膨胀和收缩;反之,当它们膨胀和收缩时,他们也能产生一个电场.5.随着能够观察单个原子或者分子的扫描探针显微镜的出现,操控和移动原子和分子以形成新结构成为可能,因此,我们能通过一些简单的原子水平的构建就可以设计出新的材料.6.advanced materials ceramic materialshigh-performance materials clay mineralsalloy implantglass fibre carbon nanotube7.Metallic materials have large numbers of nonlocalized electrons and many properties of metals are directlyattributable to these electrons.8.Many of polymeric materials are organic compounds with very large molecular structures.9.Semiconductors hace electrical properties that are intermediate between the electrical conductors<viz. metalsand metal alloys> and insulators<viz. ceramics and polymers>.10.Biomaterials must not produce toxic substances and must be compatible with body tissues.Unit 31.金属的行为〔性质〕不同于陶瓷的行为〔性质〕,陶瓷的行为〔性质〕不同于聚合物的行为〔性质〕. 2.原子结构主要影响化学性质、物理性质、热学性质、电学性能、磁性能、光学性能.微结构和宏观结构虽也能影响这些性能但是他们主要影响力学性能和化学反应速率.3.金属的强度表明原子是通过强的键结合在一起的.4.元素的原子序数表明该元素的原子核内带正电的质子数.而原子的原子量则表明该原子核中质子数与中子数.5.Microstructure macrostructureChemical reaction atomic weightBalanced electrical charge positively charged proton6. 100 atoms form thousands of different substances ranging from the air we breathe to the metal used to supporttall buildings,7.The facts suggests that metallic atoms are held together bu strong bonds.8. Microstructure which includes features that cannot be seen with the naked eye,but using a microscope.Macrostructure includes features that can be seen with the naked eye.9. The atomic weight is the sum of proton number and neutron number in the nucleus.Unit 41.当密度小于水的密度时,物体将漂浮在水面上,当密度大于水的密度时,物体会沉降.相似的,当比重小于1时,物体将漂浮在水面上,当比重大于1时,物体会沉降.2.由于相互排斥而往相反的方向移动,导致磁通量密度比真空中小,这种材料为反磁性材料.3.使磁通量密度提高1倍以上小于或等于10倍的材料叫顺磁性材料,使磁通量密度提高10倍以上的材料叫铁磁性材料.4.某些铁磁性材料,特别是一些粉末状或夹层铁,钢或镍合金的相对导磁率可高达1000000.反磁性材料的相对导磁率小于1,但是到目前还没有哪种材料的相对导磁率远小于1.5.当顺磁性或铁磁性的芯插入线圈时,其磁感应系数等于相对磁导率乘以空芯时的磁感应系数. 6.specific gravity boiling point magnetic inductioncoefficient of thermal conductivity glass transition temperaturenon-ferrous metals linear coefficient of thermal expansionmass per unit of volume7. Properties that describe how a substance changes into a completely different substance are called chemicalproperties.8. Phase is a physical property of matter and matter can exist in four phases: solid, liquid, gas and plasma.9. At some temperature below the melting point, polymers start to lose their crystalline structure but the moleculesremain linked in chains, which tesults in a soft and pliable material.10. In engineering applications, permeability is often expressed in relative, rather than in absolute.Unit 51. 金属的力学性能决定了材料的使用X围与期望的服役寿命.2. 因此,一般多测几次以得到力学性能,报导的数值一般是平均值或者计算的统计最小值.3.材料的承载方式极大地影响了材料的力学性能,也决定了材料失效形式,以与在失效前是否有预警. 4.然而,受力弯曲时会产生一个应力分布,应力大小与到轴线的垂直距离有关.5.材料受到低于临界压力即屈服强度的力时,材料才会发生弹性形变.6.Test specimen static loading force normal axisEngineering strain critical stress yield strength stress areaStress- strain curve7. Temperatures below room temperature generally cause an increase in strength properties of metallic alloys;while ductility, fracture toughness, and elongation usually decrease.8. From the respective of what is happening within a material, stress is the internal distribution of forces withina body that balance and react to the loads applied to it.9. Engineering strain is defined as the amount of deformation in the direction of the applied force divided bythe initial length of the material.10. A material with high strength and high ductility will hace more toughness than a material with low strengthand high ductility.Unit 61. 随着影响我们星球上人类生存条件的社会问题的即将出现,材料科学与工程界有责任和机遇通过解决未来世界的需求—在能量、交通、住房、饮食、回收和健康方面的需求来改变世界.2. 不发达国家的人口增长率远高于1.4%的世界平均人口增长率.3. 全球能源使用的预算在2025以前将以每年1.7%速度增长,这比世界人口增长率快多了.4. 此外,发达地区的人均能量使用量是不发达地区人均能量使用量的九倍以上.5. gross domestic product materials science and engineering market economySocietal issues economic index sanitationGross national product popilation growth rate6. Some things that have been constant over time are human innovation and creativity, the engineer’s ability toaddress societal needs, and the entrepreneurial spirit of engineering.7. We have witnessed the re-shaping of our lives through revolutions that hace taken place in medicine,telecommunications, and transportantion industries.8. Eighteen percent of the world’s population lacks access to safe drinking water and nearly 40% has no access tosanitation.9. Materials and society are interlinked, and it is only rational that we should see a close relation between the MSEresearch agenda and societal issues that affect the human condition on the globe.Unit 71.从化学角度来说,金属是一类容易失电子以形成正离子的元素,它与其他金属原子形成金属键.2.金属键的无方向性被认为是金属具有延展性的主要原因.3.存在着共价键的晶体只有在原子之间的键断裂的情况下变形,从而导致晶体破裂.4.合金特别是为满足更高应用要求的合金比如喷气发动机,可能含有十种以上的元素.5.delocalized electron electronic structurealkaline earth metal chemical cellnuclear charge electric conductivity6.Metals are sometimes described as a lattice of positive ions surrounded by a cloud of delocalized electrons.7.Metals in general have superior electric and thermal conductivity, high luster and density, and the ability to bedeformed under stress without cleaving.8.An alloy is a mixture of two or more elements in solid solution in which the major component is a metal.bining different ration of metals as alloys modifies the properties of pure metals to produce desirablecharacteristics.Unit 81.超耐热合金的发展非常依赖于化学与加工的创新,并主要受到航空和能源工业的推动.2.抗蠕变性能主要取决于晶体结构内位错速度的放缓.3.超耐热合金在加工方面的发展使超耐热合金的操作温度大幅度提高.4.单晶高温合金是运用改进的定向凝固技术而形成单晶的,因此在材料中并无晶界.5.faced-centred cubic crystal structure turbine entry temperaturemetallic materials phase stabilitynuclear reactor synthesis of nanoparticle6.Superalloys typically hace an sustenitic faced-centered cubic crystal structure.7.Superalloys are used where there is a need for high temperature strength and corrosion/oxidation resistance.8.Superalloys are widely used in aircraft ,submarines, nuclear reactors and military electric motors.9.At high temperatures the gaseous aluminum chloride<or fluoride> is transfereed to the surface of part anddiffuseds inside.Unit 91.腐蚀过程从本质上说是一个电化学的过程,有着与电池相同的本质特征.2. 从矿物中提炼金属所需能源的问题与后续的腐蚀和能量释放直接相关.3. 当电子与中和的正离子〔如电解液中的氢离子〕发生反应时,阴极处电子得以平衡.4.Protective film circuitFree electron electron transferMetal cation anode reaction5.Some metals, such as gold and silver, can be found in the earth in their natural, metallic state, and they havelittle tendency to corrode.6.Oxidation is the process of stripping electrons from an atom and reduction occurs when an electron is addedto an atom.7.If the surface becomes wet, corrosion may take place through ionic exchange in the surface water layerbetween the anode and cathode.8.Corrosion is commonly classification based on the appearance of the corroded material.Unit 101. 我们要观察〔研究〕这些性能,看它们与我们所期望的陶瓷的组成有多匹配.2. 在高于玻璃化转变温度的高温下,玻璃不再具有脆性行为,而表现为粘稠液体.3. 它们显示出优异的力学性能、抗腐蚀/氧化性能,或电学、光学抑或是磁学性能.4. 一般认为,先进是最近100年才发展起来的,而传统的基于粘土的陶瓷早已在25000多年前就被使用了.5. the glass transition temperature ionic-covalent bondStress distribution coefficient of thermal expansionGlass optical fibre materials science and engineeringSolid-oxide fuel cells electron microscopy6. Diamond, which is classified as a ceramic, has the highest thermal conductivity of any known material.7. Ceramic are stronger in compression than in tension, whereas metals have comparable tensile and compressivestrength.8. Ceramics generally have low toughness, although combining them in composites can dramatically improvethis property.9. The functions of ceramic products are dependent on their chemical composition and microstructure, whichdetermines their properties.Unit 111. 材料科学与工程领域经常是根据四大方面—合成与加工,结构与组成,性质与性能之间的相互联系来定义的.2.我们不仅要考虑具有完美晶格和理想结构〔的情况〕,我们也要考虑材料中不可避免的结构缺陷的存在,甚至是无定形的.3. 通过热压可使孔径减小从而得到高密度产品.4. 在运输时,厂方要提供关于产品危害方面的信息.5. crystalline ceramics grain boundaryAlkaline earth oxide oxide additiveTriple point saturation magnetizationTelevision tube the color scale6.To understand the behavior and properties of any material, it is essential to understand its structure.7.The grain size is determined by the size of the initial powder particles and the way in which they wereconsolidated.8.Transparent or translucent ceramics require that we limit the scattering of light by pores and second-phaseparticles.9.Alumina ceramics are used as electrical insulators because of theie high electrical resistivity and lowdielectric constant.Unit 121. 材料的选择是任何组分设计至关重要的环节,尤其在植入体和其它医疗器械方面是特别重要的.2. 我们能进行承载应用的三种主要材料是金属、聚合物和陶瓷.3. 高密度、高纯度的氧化铝被大量的用于植入物,特别是在需要承载压力的髋关节修复和牙移植中.4. 在陶瓷或陶瓷复合材料中,氧化锆的磨损率远远高于氧化锆铝的磨损率.5. controlled reaction stress shieldingTotal hip prosthese strain-to-failure ratioMechanical stress flexural strengthMartensitic transformation6.Biomaterial is a non-viable material used in a medical device intended to interact with biological systems.7.These repairs become necessary when the existing part becomes diseased, damaged, or just simply wears out.8.Because of its low density, cancellous bone has a lower E and higher strain-to-failure ratio than cortical bone.9.Eliminating stress shielding, by reducing E, is one of the primary motivations for the development ofbioceramic composites.10.There are questions concerning the long-term effect of radiation emission from zirconia ceramics.Unit 131. 聚合物的俗名叫塑料,这个词指的是一大类具有许多性质和用途的天然材料和合成材料.2. 聚合物合成是一个把叫做单体的小分子通过共价键的结合形成链的过程.3. 支化聚合物分子是由一条带有一个或多个侧基或支链的主链组成.一些特殊的支化聚合物有星型聚合物、梳状聚合物和刷状聚合物.4. 某些生物聚合物是由一系列不同的胆识结构却相关的单体组成的,例如聚核苷酸是由核苷组成的.5. persistence length cross-linkPolar monomer nucleic acidPolymerization polyelectrolyte6.Most commercially important polymers today are entirely synthetic and produced in high volume, onappropriately scaled organic synthetic techniques.7.Some biological polymers are composed of a variety of different but structurally related monomers, suchas polynucleotides composed of nucleotide sbunits.8. A polymer molecule with a high degree of crosslinking is referred to as a polymer network.9.In polymers, however, the molecular mass may be expressed in terms of degree of polymerization,essentially the number of monomer Units which comprise the polymer.Unit 141. 大量合成的聚合物具有碳-碳骨架,这是因为碳原子具有与其它原子形成更强更稳定的键的优异性能.2. 它们在一定X围内软化,这与完好晶体相具有非常明确的熔点不同.3. 分子量取决于其合成时的条件,因此分子量可能分布很宽或分布很窄.4. Goodyear 很偶然的发现了在橡胶中加入硫磺并加热这个混合物能使橡胶变硬,对氧化和化学进攻能力的敏感性降低.5. thermosetting plastic cross-sectional areaPolymerization reaction double bondChemical composition carboxylic acidMelting point degradation by oxidation6.Polymer with different chemical composition has different physical and chemical property.7. A thermosetting plastic is shaped through irreversible chemical processes and therefore cannot be reshapedreadily.8.Natural rubber is not a useful polymer because it is too soft and too chemically reactive.9.Various substances may be added to polymers to provide protection against the effects of sunlight or againstdegradation by oxidation.Unit 151. 逐渐增强的环境意识促使包装薄膜与其加工既要方便使用又要具有环境友好的特点.2. 显而易见,实现这些性能对控制和改进机械性能和阻隔性能是非常重要的.3. 在羧酸、醇、醛、酮的含氧生物降解过程中,由水和热引发的过氧化反应可以使之降解成低摩尔质量的物质,这就是碳氢聚合物力学性能降低的主要原因.4. 用持久耐用的聚合物做短期使用的包装材料并不合理,另外也是因为包装材料被食物污染后再进行物理回收是不切合实际的.5. natural gas packaging materialsAroma compound bioplastic materialChemical structure the life cycle of biomass6. Bacteria , fungi, enzymes start the bioassimilation giving rise to biomass and CO2 that finally form the humus.7. The bioplastic aim is to imitate the life cycle of biomass, which includes conservation of fossil resources, waterand CO2 production.8. During the oxo-degradation of carboxylic acid, molecules of alcohols, aldehydes and ketones degradable withlow molar mass are produced by peroxidation initiated by heat or light .9. While most of the commercialized biopolymer materials are biodegradable, these are not fully compostable inreal composting conditions, which vary with temperature and relative humidity.Unit 161. 比如,多相金属在微观尺度上是复合材料.但一般意义上的复合材料是指通过键的作用使两种或多种不同的材料结合在一起的材料..2. 最常见的是,复合材料有一个连续的叫基体的本体相,还有一个分散的非连续的叫增强相的相.3. 先进材料采用了树脂与纤维的复合材料,一般为碳/石墨,凯芙拉或玻璃纤维与环氧树脂的复合材料.纤维具有高的硬度,而聚合物树脂基体能保持复合材料的结构.4. 如果复合材料设计和制备合理的话,复合材料就既具有增强相的强度又具有基体的韧性从而得到了性能的理想组合,这是任何一种组分单独存在时所具备的性能.5. composite material reinforcement materialFiberglass matrix materialStrengthening mechanism conventional material6. A composite is commonly defined as a combination of two or more distinct materials, each of which retainsits own distinctive properties, to create a new material with properties that cannot be achieved by any of the components acting alone.7.Carbon-epoxy composties are two thirds the weight of aluminum, and two and a half times as stiff.Composites are resistant to fatigue damage and harsh enviroments, and are repairable.8.According to the conception of composite , reinforced plastics, metal-matrix composites, ceramic-matrixcomposites and concrete are composites.9.In fiber-reinforced composites, the fiber is the primary load-bearing component. Fiberglass and carbon fibercomposites are examples of fiber-reinforced composites.Unit 171. 震荡、撞击或者重复的周期性应力能导致两层的界面处发生薄层分离,这种情况叫剥离.2.3. 事实上,工业材料既要质轻又要牢固的要求是推动复合材料发展的主要动力.4. 提到飞机,值得铭记的是复合材料不像金属〔如铝〕那样在压力的作用下会完全解体.5. orthotropic thermosetThermoplastic Young’s ModulusMechanical property constants extreme enviroment6.In contrast, isotropic material < for example, aluminuim or steel>, in standard wrought forms, typicallyhave the same stiffness regardless of the directional orientation of the applied forces and /or moments.7.The greatest advantage of composite materials is strength and stiffness combined with lightness.8.This makes them ideal for use in products thar are exposed to extreme enviroments such as boats,chemical-handling equipments and spacecrafts.posites will never totally replace tranditional materials like steel, but in many cased they are just whatwe need.Unit 181. 具有相分离的聚合物共混材料经常出现纳米尺度的相.2 在过去几十年里研究的基于溶胶-凝胶化学的有机-无机纳米复合材料已基本淡出纳米复合材料的研究.3. 理解粒子的性质随着尺寸降低到纳米级别而发生改变,这对于优化所得到的纳米复合材料很重要.4. 廉价石墨的生产尚未实现,石墨的广泛使用呕待石墨合成技术的突破.5. electro-optical property bactericidal propertyBlock copolymer interfacial phenomenaExfoliated graphene morphology control6.The field of nanotechnology is one of the most popular areas for current research and development inbasically all technical discillines.7.Nanoscale is considered where the dimensions of the particle, platelet or fiber modification are in the rangeof 1~100nm.8.These improvements are key to future aircraft and wind energy turbine applications.9.Nanostructured surfaces have been noted to yield superhydrophobic character and exceptional adhesion.。

材料专业英语常见词汇The saying "the more diligent, the more luckier you are" really should be my charm in2006.材料专业英语常见词汇一Structure 组织Ceramic 陶瓷Ductility 塑性Stiffness 刚度Grain 晶粒Phase 相Unit cell 单胞Bravais lattice 布拉菲点阵Stack 堆垛Crystal 晶体Metallic crystal structure 金属性晶体点阵 Non-directional 无方向性Face-centered cubic 面心立方Body-centered cubic体心立方 Hexagonal close-packed 密排六方 Copper 铜Aluminum 铝Chromium 铬 Tungsten 钨Crystallographic Plane晶面 Crystallographic direction 晶向 Property性质 Miller indices米勒指数 Lattice parameters 点阵参数Tetragonal 四方的Hexagonal 六方的Orthorhombic 正交的Rhombohedra 菱方的Monoclinic 单斜的Prism 棱镜 Cadmium 镉 Coordinate system 坐 Point defec点缺陷Lattice 点阵 Vacancy 空位Solidification 结晶Interstitial 间隙Substitution 置换Solid solution strengthening 固溶强化Diffusion 扩散Homogeneous 均匀的Diffusion Mechanisms 扩散机制Lattice distortion 点阵畸变Self-diffusion 自扩散Fick’s First Law 菲克第一定律 Unit time 单位时间Coefficient 系数Concentration gradient 浓度梯度Dislocations 位错Linear defect 线缺陷Screw dislocation 螺型位错Edge dislocation 刃型位错Vector 矢量Loop 环路Burgers’vector 柏氏矢量Perpendicular 垂直于Surface defect 面缺陷Grain boundary 晶界Twin boundary 晶界 Shear force 剪应力Deformation 变形Small or low angel grain boundary 小角度晶界Tilt boundary 倾斜晶界Supercooled 过冷的Solidification 凝固Ordering process 有序化过程Crystallinity 结晶度Microstructure 纤维组织Term 术语Phase Diagram 相图Equilibrium 平衡Melt 熔化Cast 浇注Crystallization 结晶Binary Isomorphous Systems 二元匀晶相图Soluble 溶解Phase Present 存在相Locate 确定Tie line 连接线Isotherm 等温线Concentration 浓度Intersection 交点The Lever Law 杠杆定律Binary Eutectic System 二元共晶相图Solvus Line 溶解线Invariant 恒定Isotherm 恒温线Cast Iron 铸铁Ferrite 珠光体Polymorphic transformation 多晶体转变Austenite 奥氏体Revert 回复Intermediate compound 中间化合物Cementite 渗碳体Vertical 垂线Nonmagnetic 无磁性的Solubility 溶解度Brittle 易脆的Eutectic 共晶Eutectoid invariant point 共析点Phase transformation 相变Allotropic 同素异形体Recrystallization 再结晶Metastable 亚稳的Martensitic transformation 马氏体转变Lamellae 薄片Simultaneously 同时存在Pearlite 珠光体Ductile 可塑的Mechanically 机械性能Hypo eutectoid 过共析的Particle 颗粒Matrix基体Proeutectoid 先共析Hypereutectoid 亚共析的Bainite 贝氏体Martensite 马氏体Linearity 线性的Stress-strain curve 应力-应变曲线Proportional limit 比例极限Tensile strength 抗拉强度Ductility 延展性Percent reduction in area 断面收缩率Hardness 硬度Modulus of Elasticity 弹性模量Tolerance 公差Rub 摩擦Wear 磨损Corrosion resistance 抗腐蚀性Aluminum 铝Zinc 锌Iron ore 铁矿Blast furnace 高炉Coke 焦炭Limestone 石灰石Slag 熔渣Pig iron 生铁Ladle 钢水包Silicon 硅Sulphur 硫Wrought 可锻的Graphite 石墨Flaky 片状Low-carbon steels 低碳钢Case hardening 表面硬化Medium-carbon steels 中碳钢Electrode 电极As a rule 通常Preheating 预热Quench 淬火Body-centered lattice 体心晶格Carbide 碳化物Hypereutectoid过共晶Chromium 铬Manganese 锰Molybdenum 钼Titanium 钛Cobalt 钴Tungsten 钨Vanadium 钒Pearlitic microstructure 珠光体组织Martensitic microstructure 马氏体组织Viscosity 粘性Wrought 锻造的Magnesium 镁Flake 片状Malleable 可锻的Nodular 球状Spheroidal 球状Superior property 优越性Galvanization 镀锌Versatile 通用的Battery grid 电极板Calcium 钙Tin 锡Toxicity 毒性Refractory 耐火的Platinum铂Polymer 聚合物Composite 混合物Erosive 腐蚀性Inert 惰性Thermo chemically 热化学Generator 发电机Flaw 缺陷Variability 易变的Annealing 退火Tempering回火Texture 织构Kinetic 动力学Peculiarity 特性Critical point 临界点Dispersity 弥散程度Spontaneous 自发的Inherent grain 本质晶粒Toughness 韧性Rupture 断裂Kinetic curve of transformation 转变动力学曲线Incubation period 孕育期Sorbite 索氏体Troostite 屈氏体Disperse 弥散的Granular 颗粒状Metallurgical 冶金学的Precipitation 析出Depletion 减少Quasi-eutectoid 伪共析Superposition 重叠Supersede 代替Dilatometric 膨胀Unstable 不稳定Supersaturate 使过饱和Tetragonality 正方度Shear 切变Displacement 位移Irreversible 不可逆的金属材料工程专业英语acid-base equilibrium酸碱平衡 acid-base indicator酸碱指示剂 acid bath酸槽 acidBessemerconverter 酸性转炉 acid brick酸性耐火砖 acid brittleness酸洗脆性、氢脆性 acid burden酸性炉料acid clay酸性粘土 acid cleaning同pickling酸洗 acid concentration酸浓度 acid converter酸性转炉 acid converter steel酸性转炉钢 acid content酸含量 acid corrosion酸腐蚀 acid deficient弱酸的、酸不足的 acid dip酸浸acid dip pickler沉浸式酸洗装置 aciddiptank酸液浸洗槽acid drain tank排酸槽acidless descaling无酸除鳞acid medium酸性介质acid mist酸雾acid-proof paint耐酸涂料漆acid-proof steel耐酸钢acid-resistant耐酸钢acid-resisting vessel耐酸槽acid strength酸浓度acid supply pump供酸泵acid wash酸洗acid value酸值acid wash solution酸洗液acieration渗碳、增碳Acm point Acm转变点渗碳体析出温度acorn nut螺母、螺帽acoustic absorption coefficient声吸收系数acoustic susceptance声纳actifier再生器action line作用线action spot作用点activated atom激活原子activated bath活化槽activated carbon活性碳activating treatment活化处理active corrosion活性腐蚀、强烈腐蚀active area有效面积active power有功功率、有效功率active product放射性产物active resistance有效电阻、纯电阻active roll gap轧辊的有效或工作开口度active state活性状态active surface有效表面activity coefficient激活系数、活度系数actual diameter钢丝绳实际直径actual efficiency实际效率actual error实际误差actual time实时actual working stress实际加工应力actuating device调节装置、传动装置、起动装置actuating lever驱动杆、起动杆actuating mechanism 动作机构、执行机构actuating motor驱动电动机、伺服电动机actuating pressure作用压力actuation shaft起动轴actuator调节器、传动装置、执行机构acute angle锐角adaptive feed back control自适应反馈控制adaptive optimization自适应最优化adaptor接头、接合器、连结装置、转接器、附件材料科学基础专业词汇:第一章晶体结构原子质量单位 Atomic mass unit amu 原子数 Atomic number 原子量 Atomic weight波尔原子模型 Bohr atomic model 键能 Bonding energy 库仑力 Coulombic force共价键 Covalent bond 分子的构型 molecular configuration电子构型electronic configuration 负电的 Electronegative 正电的 Electropositive基态 Ground state 氢键 Hydrogen bond 离子键 Ionic bond 同位素 Isotope金属键 Metallic bond 摩尔 Mole 分子 Molecule 泡利不相容原理 Pauli exclusion principle 元素周期表 Periodic table 原子 atom 分子 molecule 分子量 molecule weight极性分子 Polar molecule 量子数 quantum number 价电子 valence electron范德华键 van der waals bond 电子轨道 electron orbitals 点群 point group对称要素 symmetry elements 各向异性 anisotropy 原子堆积因数 atomic packing factorAPF 体心立方结构 body-centered cubic BCC 面心立方结构 face-centered cubic FCC布拉格定律bragg’s law 配位数 coordination number 晶体结构 crystal structure晶系 crystal system 晶体的 crystalline 衍射 diffraction 中子衍射 neutron diffraction电子衍射 electron diffraction 晶界 grain boundary 六方密堆积 hexagonal close-packed HCP 鲍林规则 Paulin g’s rules NaCl型结构 NaCl-type structureCsCl型结构Caesium Chloride structure 闪锌矿型结构 Blende-type structure纤锌矿型结构 Wurtzite structure 金红石型结构 Rutile structure萤石型结构 Fluorite structure 钙钛矿型结构 Perovskite-type structure尖晶石型结构 Spinel-type structure 硅酸盐结构 Structure of silicates岛状结构 Island structure 链状结构 Chain structure 层状结构 Layer structure架状结构 Framework structure 滑石 talc 叶蜡石 pyrophyllite 高岭石 kaolinite石英 quartz 长石 feldspar 美橄榄石 forsterite 各向同性的 isotropic各向异性的 anisotropy 晶格 lattice 晶格参数 lattice parameters 密勒指数 miller indices 非结晶的 noncrystalline多晶的 polycrystalline 多晶形 polymorphism 单晶single crystal 晶胞 unit cell电位 electron states化合价 valence 电子 electrons 共价键 covalent bonding金属键 metallic bonding 离子键Ionic bonding 极性分子 polar molecules原子面密度 atomic planar density 衍射角 diffraction angle 合金 alloy粒度,晶粒大小 grain size 显微结构 microstructure 显微照相 photomicrograph扫描电子显微镜 scanning electron microscope SEM透射电子显微镜 transmission electron microscope TEM 重量百分数 weight percent四方的 tetragonal 单斜的monoclinic 配位数 coordination number材料科学基础专业词汇:第二章晶体结构缺陷缺陷 defect, imperfection 点缺陷 point defect 线缺陷 line defect, dislocation面缺陷 interface defect 体缺陷 volume defect 位错排列 dislocation arrangement位错线 dislocation line 刃位错 edge dislocation 螺位错 screw dislocation混合位错 mixed dislocation 晶界 grain boundaries 大角度晶界 high-angle grain boundaries 小角度晶界 tilt boundary, 孪晶界 twin boundaries 位错阵列 dislocation array位错气团 dislocation atmosphere 位错轴dislocation axis 位错胞 dislocation cell位错爬移 dislocation climb 位错聚结 dislocation coalescence 位错滑移 dislocation slip位错核心能量 dislocation core energy 位错裂纹 dislocation crack位错阻尼 dislocation damping 位错密度 dislocation density原子错位 substitution of a wrong atom 间隙原子 interstitial atom晶格空位 vacant lattice sites 间隙位置 interstitial sites 杂质 impurities弗伦克尔缺陷 Frenkel disorder 肖脱基缺陷 Schottky disorder 主晶相 the host lattice错位原子 misplaced atoms 缔合中心 Associated Centers. 自由电子 Free Electrons电子空穴Electron Holes 伯格斯矢量 Burgers 克罗各-明克符号 Kroger Vink notation中性原子 neutral atom材料科学基础专业词汇:第二章晶体结构缺陷-固溶体固溶体 solid solution 固溶度 solid solubility 化合物 compound间隙固溶体 interstitial solid solution 置换固溶体 substitutional solid solution金属间化合物 intermetallics 不混溶固溶体 immiscible solid solution转熔型固溶体 peritectic solid solution 有序固溶体 ordered solid solution无序固溶体 disordered solid solution 固溶强化 solid solution strengthening取代型固溶体 Substitutional solid solutions 过饱和固溶体 supersaturated solid solution非化学计量化合物 Nonstoichiometric compound材料科学基础专业词汇:第三章熔体结构熔体结构 structure of melt过冷液体 supercooling melt 玻璃态 vitreous state软化温度 softening temperature 粘度 viscosity 表面张力 Surface tension介稳态过渡相 metastable phase 组织 constitution 淬火 quenching退火的 softened 玻璃分相 phase separation in glasses 体积收缩 volume shrinkage材料科学基础专业词汇:第四章固体的表面与界面表面 surface 界面 interface 同相界面 homophase boundary异相界面 heterophase boundary 晶界 grain boundary 表面能 surface energy小角度晶界 low angle grain boundary 大角度晶界 high angle grain boundary共格孪晶界 coherent twin boundary 晶界迁移 grain boundary migration错配度 mismatch 驰豫 relaxation 重构 reconstuction 表面吸附 surface adsorption表面能 surface energy 倾转晶界 titlt grain boundary 扭转晶界 twist grain boundary倒易密度 reciprocal density 共格界面 coherent boundary 半共格界面 semi-coherent boundary 非共格界面 noncoherent boundary 界面能 interfacial free energy应变能 strain energy 晶体学取向关系 crystallographic orientation惯习面habit plane材料科学基础专业词汇:第五章相图相图 phase diagrams 相 phase 组分 component 组元 compoonent相律 Phase rule 投影图 Projection drawing 浓度三角形 Concentration triangle冷却曲线 Cooling curve 成分 composition 自由度 freedom相平衡 phase equilibrium 化学势 chemical potential 热力学 thermodynamics相律 phase rule 吉布斯相律 Gibbs phase rule 自由能 free energy吉布斯自由能 Gibbs free energy 吉布斯混合能 Gibbs energy of mixing吉布斯熵 Gibbs entropy 吉布斯函数 Gibbs function 热力学函数 thermodynamics function 热分析 thermal analysis 过冷 supercooling 过冷度 degree of supercooling杠杆定律 lever rule 相界 phase boundary 相界线 phase boundary line相界交联 phase boundary crosslinking 共轭线 conjugate lines相界有限交联 phase boundary crosslinking 相界反应 phase boundary reaction相变 phase change 相组成 phase composition 共格相 phase-coherent金相相组织 phase constentuent 相衬 phase contrast 相衬显微镜 phase contrast microscope 相衬显微术 phase contrast microscopy 相分布 phase distribution相平衡常数 phase equilibrium constant 相平衡图 phase equilibrium diagram相变滞后 phase transition lag 相分离 phase segregation 相序 phase order相稳定性 phase stability 相态 phase state 相稳定区 phase stabile range相变温度 phase transition temperature 相变压力 phase transition pressure同质多晶转变 polymorphic transformation 同素异晶转变 allotropic transformation相平衡条件 phase equilibrium conditions 显微结构 microstructures 低共熔体 eutectoid不混溶性 immiscibility材料科学基础专业词汇:第六章扩散活化能 activation energy 扩散通量 diffusion flux 浓度梯度 concentration gradient菲克第一定律Fick’s first law 菲克第二定律Fick’s second law 相关因子 correlation factor 稳态扩散 steady state diffusion 非稳态扩散 nonsteady-state diffusion扩散系数 diffusion coefficient 跳动几率 jump frequency填隙机制 interstitalcy mechanism 晶界扩散 grain boundary diffusion短路扩散 short-circuit diffusion 上坡扩散 uphill diffusion 下坡扩散 Downhill diffusion互扩散系数 Mutual diffusion 渗碳剂 carburizing 浓度梯度 concentration gradient浓度分布曲线 concentration profile 扩散流量 diffusion flux 驱动力 driving force间隙扩散 interstitial diffusion 自扩散 self-diffusion 表面扩散 surface diffusion空位扩散 vacancy diffusion 扩散偶 diffusion couple 扩散方程 diffusion equation扩散机理 diffusion mechanism 扩散特性 diffusion property 无规行走 Random walk达肯方程 Dark equation 柯肯达尔效应 Kirkendall equation本征热缺陷 Intrinsic thermal defect 本征扩散系数 Intrinsic diffusion coefficient离子电导率 Ion-conductivity 空位机制 Vacancy concentration材料科学基础专业词汇:第七章相变过冷 supercooling 过冷度 degree of supercooling 晶核 nucleus 形核 nucleation形核功 nucleation energy 晶体长大 crystal growth 均匀形核 homogeneous nucleation非均匀形核 heterogeneous nucleation 形核率 nucleation rate 长大速率 growth rate热力学函数 thermodynamics function 临界晶核 critical nucleus临界晶核半径 critical nucleus radius 枝晶偏析 dendritic segregation局部平衡 localized equilibrium 平衡分配系数 equilibrium distributioncoefficient有效分配系数 effective distribution coefficient 成分过冷 constitutional supercooling引领领先相 leading phase 共晶组织 eutectic structure 层状共晶体 lamellar eutectic伪共晶 pseudoeutectic 离异共晶 divorsed eutectic 表面等轴晶区 chill zone柱状晶区 columnar zone 中心等轴晶区 equiaxed crystal zone定向凝固 unidirectional solidification 急冷技术 splatcooling 区域提纯 zone refining单晶提拉法 Czochralski method 晶界形核 boundary nucleation位错形核 dislocation nucleation 晶核长大 nuclei growth斯宾那多分解 spinodal decomposition 有序无序转变 disordered-order transition马氏体相变 martensite phase transformation 马氏体 martensite材料科学基础专业词汇:第八、九章固相反应和烧结固相反应 solid state reaction 烧结 sintering 烧成 fire 合金 alloy 再结晶 Recrystallization 二次再结晶 Secondary recrystallization 成核 nucleation 结晶 crystallization子晶,雏晶 matted crystal 耔晶取向 seed orientation 异质核化 heterogeneous nucleation均匀化热处理 homogenization heat treatment 铁碳合金 iron-carbon alloy渗碳体 cementite 铁素体 ferrite 奥氏体austenite 共晶反应 eutectic reaction 固溶处理 solution heat treatment。

孪晶建立方法To start with, the process of establishing twins crystals, also known as twinning, is a fascinating phenomenon in the field of crystallography. Twinning occurs when two or more crystals share a common lattice orientation and grow together, resulting in a distinct mirror-image relationship between them. This phenomenon can have a significant impact on the physical and optical properties of the crystals, making them highly sought after in various industries, such as jewelry making, electronics, and pharmaceuticals.首先,孪晶建立的过程,也称为孪晶,是晶体学领域中一种迷人的现象。

当两个或更多的晶体具有共同的晶格取向并一起生长时,就会出现孪晶,导致它们之间存在明显的镜像关系。

这种现象可以显著影响晶体的物理和光学性质,使它们在珠宝制作、电子和制药等各个行业中备受追捧。

From a scientific perspective, twinning occurs due to specific crystallographic orientations that result in symmetrical relationships between the crystals. This phenomenon can be induced by various factors, such as external stress during the crystal growth process or specific lattice arrangements that favor twinning. Understanding theunderlying mechanisms of twinning is crucial for controlling and manipulating the growth of twinned crystals for desired properties and applications. Scientists and researchers continue to study and explore the intricacies of twinning to unlock its full potential in material science and technology.从科学角度来看,孪晶是由于特定的晶体学取向而导致晶体之间存在对称关系。

翻译1.电极电位决定离子浓度Electrode potential depends on the concentration of the ions.2.探索矿物中汞浓度的绝对因素被发现The determination of trace concentrations of mercury in mineral is describe.3.由于目前高品质的矿石可能耗尽,富集过程是十分重要的A concentration process is important now that the depletion of high grade ores is possibility.4.用这种加工方法会浪费一些材料The machining of forgings by this method entails some loss of material.5.阿基米德最先发现固体排水的原理Archimedes first discovered the principle that water is displaced by solid bodies.6.火箭被发明应用于宇宙勘探Rocket have found application for the exploration of the universe.5.要特别注意软管,确保不被磨损Particular attention should be given to ensure that chafing does not occur.7.所有动植物的生长都需要碳All plant and animals need for growth.8.加热可以提高液体温度The temperature of the liquid is raised by the application of heat.9.夯锤由压缩空气驱动的可提高生产率Rammers driven by compressed air can increase the production rates.10.今天计算机广泛应用于解决数学问题,这些问题与天气预报和卫星送入轨道有关Today the electronic computer is widely used in solving mathematical problems having to do with weather forecasting and putting satellites into orbit.11.生产中少量产品时,数控机是极为有用的,录用生产零件必须资料的磁带可以存放起来,需要时还可重新使用和修改Numerical control machines are most useful when quantities of products to be produced are low or medium;the tape containing the information required to produce the part can be stored ,reused or modified when required.12.如果没有吸引力,电子会以直线方向飞离质子If there were no attraction,the electron would fly away from the proton in a straight line13.如果飞机速度降到一定水平以下就会突然失去升力A sudden loss lift will be experienced in case the aircraft speed falls below a certain level.14.假如油泵失灵,运转部件就会过热In case of an oil-pump failure,the moving parts will be overheat.15.万一有雾,飞机可以由指挥塔引导降落至跑道In the event of fog ,aircraft can be guided down to the runway from the control tower16.这部发动机可以高速运转,条件是把震动降低The engine can be run at very high speeds on condition the vibration can be damped out17.让水冷却十分钟再测温度Allow the water to cool for10minutes and the make the temperature.18不能行走的机器人能学会做工并孜孜不倦的工作,今天在世界各地的工厂里得到了使用Non-mobile robots,capable of learning to perform an industrial task and then of being left to perform it tirelessly,are even now in use in industrial plants all over the world.20.由于未能记住这些符号,使许多学生无法掌握他们选修的课程Failure to fix these symbols in mind keeps students from mastering the mathematical subject they take up.21假如速率或方向改变了,速度也会随之改变Velocity changes if either speed or the direction changes.22石油和天然气仍将是我们燃料的主要来源Oil and gas will continue to be our chief source of fuel23驱动这个机器的发动机是50马力的感应电动机The power unit for driving the machine is a 50-hp induction motor24一个物体的速度不会超过光速A material object can not have a speed greater than the speed of light.半导体器件,称为晶体管,在许多应用中是更换管Semiconductor device,called transistors,are replacing tubes in many applications严禁乱拆,以免损坏零件It is forbidden to dismantle it without permission so as to avoid any damage to its parts25.需要明确是磁力和电力是不同的It should be realized that magnetic forces and electric forces are not the same26 .除去水中的矿物质叫做软化The removal of minerals from water is called softening27.只有爱因斯坦的相对论能解释这种现象Einstein’s relativity theory is the only one which can explain such phenomena。