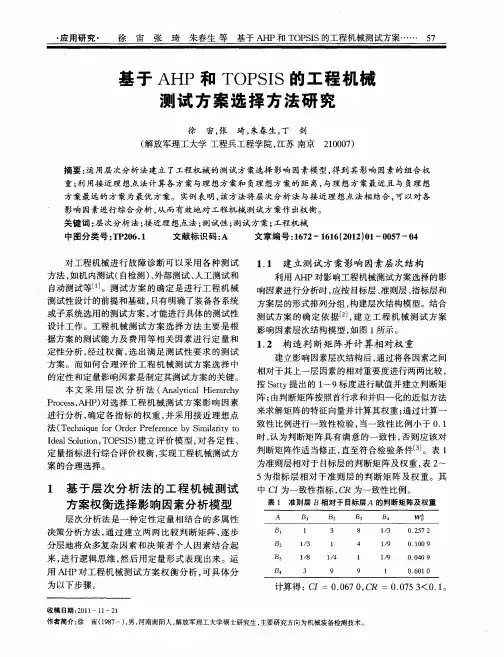

AHP-Based Equipment Selection Model for Construction Projects

- 格式:pdf

- 大小:449.33 KB

- 文档页数:11

价值工程0引言核电站的安全不仅受到公众的关注,而且也是核电站安全、经济运行的基础[1]。

由于核电站存在放射性污染的风险,所以核电建设的安身之基、立命之本就是安全和质量。

在核电站建设管理期间,核安全管理的任务主要落实在项目的技术管理和质量管理上[2]。

为了确保核电站能够安全稳定长期运行,核安全要求贯穿于核电站建设时期的设备设计、制造、安装和调试各个阶段,而核电站设备是各个阶段成果的主要载体,所以核电站安全的重要举措之一就是从源头上提高核安全水平,选择合适的核电站设备供应商。

核电站设备供应商的供货能力直接关系到核电站建设企业能否向最终用户提供满意的产品,在当今市场激烈竞争的环境下,选择合适的供应商对于提高企业的整体竞争力具有非常重要的意义。

1核电站设备供应商评价方法选择应用于供应商选择的方法很多。

层次分析法[3](Analytical Hierarchy Process ,简称AHP )是20世纪70年代初由美国著名的运筹家T.L.萨迪(T.L.Satty )提出。

它将复杂的问题分解成各个组成因素,又将这些因素按支配关系分组形成递阶层次结构。

通过两两比———————————————————————作者简介:林建(1981-),男,福建莆田人,工程硕士,工程师,研究方向为管理科学与工程。

基于AHP 和Fuzzy 法的核电站设备供应商评价与选择Evaluation and Selection of Nuclear Power Plant Equipment Supplier Based on AHP and Fuzzy Theory林建①Lin Jian ;付奇寒②Fu Qihan(①中广核工程有限公司,深圳518124;②大亚湾核电运营管理有限责任公司,深圳518124)(①China Nuclear Power Engineering Company ,LTD.,Shenzhen 518124,China ;②Daya Bay Nuclear Power Operations and Management Co.,LTD.,Shenzhen 518124,China )摘要:核电站设备供应商的选择和评价是一个典型的多指标多层次的综合评价问题。

基于AHP法的维修器材保障能力评价研究作者:李贞新,李有为,王琳,吴新中,徐文龙来源:《物流科技》2010年第10期摘要:以基层级维修机构为研究对象,通过对维修器材保障系统的界定和影响保障能力因素的分析,建立了基于AHP法的维修器材保障能力评价结构模型,并给出了相应的应用算例,算例说明,该模型能够比较科学的对维修器材保障能力作出评价。

关键词:维修器材;保障能力;AHP;评价中图分类号:E237文献标识码:AAbstract: Through defining the supply system of maintenance materials and analyzing the influence factors of support ability, the paper research on the organizational-level maintenance department, established evaluation model of maintenance material support capability, which was based on the AHP method. The related example was also brought out, which testified that the model can scientifically evaluate the maintenance material support capability.Key words: maintenance material; support capability; AHP; evaluation0引言维修器材是实施装备维修保障的重要物质基础[1],是实施换件修理的必要物质条件,能否及时有效地提供维修所需器材,直接影响到装备的可用性。

而在具体实施保障的过程中,保障能力是保证损坏装备及时、有效恢复其性能的关键。

1引言国防科技成果市场化再研发是一种跨越军民两大系统的复杂创新活动。

研究显示,目前中国科技成果转化率仅约25%,产业化比例更是低至不足5%。

由于军民二元管理体制和制度壁垒等障碍,国防科技成果市场化转化率和产业化率可能更低。

2016年,中央印发《关于经济建设和国防建设融合发展的意见》提出:“建立健全规划、项目、投资、绩效评估体系,强化规划刚性约束和执行力”。

国防科技成果再研发作为统筹国防建设和经济高质量发展总体目标的有力手段,既要坚持要素驱动,又要坚持目标导向。

由此,构建基于多主体、面向全过程的国防科技成果再研发评价体系对于加快国防科技成果市场化应用具有直接意义和实践价值。

2文献回顾目前关于国防科技成果再研发的定义,学界缺少权威界定。

本文认为国防科技成果再研发是指为提高生产力水平,对由武器装备预先研究所形成的国防科技成果进行的再次试验、开发、应用、推广直至形成新技术、新工艺、新材料、新产品,发展新产业的系列活动的总和,是基于现存具有特殊社会属性的成果面向市场的兼顾国防安全、社会效益和经济效益的综合复杂创新和面向多主体的JMRH 科技协同创新。

关于科技协同创新的理论研究内容比较丰富、视角多元。

产业经济学视角下,马子健(2018)指出社会技术进步,军民通用技术日渐增多,产生了技术边界模糊,军民产业间的产品和市场逐渐融合,社会资源配置趋于合理化,形成产业全价值链的竞争优势。

在范围经济学看来,梁宇(2018)认为实现范围经济的等价条件是关联产出之间的投入共享,可以通过技术渗透和制度保障消除互动壁垒,稳定、持续地推进军民科技协同创新发展。

姬文波(2017)从新制度经济学视角,基于产权理论指出合适的军民产品的产权安排是生产资源得以有效使用和优化配置的先决条件。

创新经济学理论认为,要突破关键核心技术瓶颈,逐步形成军民科技成果互为转【基金项目】四川省软科学研究项目“创新驱动视角下四川国防科技成果再研发转化的机制与对策研究”(项目编号:2018ZR0142);绵阳市社会科学研究规划项目“建设环高校知识经济圈推进中国(绵阳)科技城加快发展的路径研究”(项目编号:MY2020YB008)。

武器装备需求方案评估研究赵秀玉;王梓然【摘要】在武器装备需求备选方案中,哪些方案对满足作战任务更有效,哪些方案在技术水平方面更有效,这些问题都将影响决策者的最终决策.分析武器装备需求方案评估的特点,建立武器装备需求方案评估指标体系,并将层次分析法和灰色关联分析相结合,建立评估模型,并通过实例分析实现对4种不同方案的优选.%With a number of schemes of weapon equipment requirements, which is effective for campaign objective, and which is effective for technology. These will effect the decision-making. The paper builds up a comprehensive evaluation index system for information systems of weapon equipment, analytic hierarchy process (AHP) for determining criterion weigh is expounded, and then the appraisal and selection model based on AHP and GRAP is built, selects the best project from four schemes of weapon equipment requirements.【期刊名称】《装备学院学报》【年(卷),期】2011(022)002【总页数】4页(P126-129)【关键词】武器装备需求;方案评估;层次分析法;灰色关联分析法【作者】赵秀玉;王梓然【作者单位】装甲兵工程学院信息工程系,北京100072;装甲兵工程学院信息工程系,北京100072【正文语种】中文【中图分类】E92武器装备需求方案评估是装备需求论证过程的重要步骤,对后续武器装备发展规划和采办阶段起着决定性的作用,是决定该需求方案能否最终被接受的关键环节。

·59·兵工自动化Ordnance Industry Automation2021-03 40(3)doi: 10.7690/bgzdh.2021.03.014基于AHP 的装备保障虚拟训练效果评估方法丁 平(中国人民解放军92941部队,辽宁 葫芦岛 125001)摘要:针对目前某型导弹虚拟训练系统培训效果的评估需求,构建一种虚拟训练动态评价模型。

分析虚拟训练影响因素,利用层次分析法,阐述具体评估方法,并应用实例进行验证评估。

结果表明:该方法对人员实际能力水平的评估结果准确、可信,可为完善装备虚拟训练工作与学员培训方案提供参考。

关键词:虚拟训练;综合评估;层次分析法 中图分类号:TP391.98 文献标志码:AEvaluation Method of Equipment Support Virtual Training Effect Based on AHPDing Ping(No . 92941 Unit of PLA , Huludao 125001, China )Abstract: Aiming at the evaluation requirement of the training effect of a certain type missile virtual training system, a dynamic evaluation model of virtual training was constructed. Analyzes the influencing factors of virtual training, using analytic hierarchy process (AHP) to elaborate the specific evaluation method, and verifies the evaluation with an example. The results show that the method is accurate and reliable, and can provide reference for improving the virtual training of equipment and the training scheme of trainees.Keywords: virtual training; comprehensive assessment; analytic hierarchy process0 引言为适应新时代备战需要,弥补传统“实兵+实地+实装”[1]训练模式的不足,促进保障能力的快速生成,前期基于Virtools 虚拟现实引擎研发了某型导弹虚拟训练系统。

基于AHP的装备靠前保障模式效能评估作者:赵华;戴树良来源:《价值工程》2011年第02期摘要:靠前保障是适应未来装备保障发展趋势,贴近部队、贴近装备实施快速保障的一种模式。

通过AHP方法可以定性分析并有效验证靠前保障的部队运行效果。

Abstract: The approaching equipment security is a kind of mode to ensure future development trend of equipment security. It is close to the troops, close to the equipment implementation and can offer the rapid security. Through AHP method we can do qualitative analysis and verified the running effect of approaching security in the army effectively.关键词:靠前保障;AHP;效能评估Key words: approaching security;AHP;performance evaluation中图分类号:E23文献标识码:A文章编号:1006-4311(2011)02-0321-020引言随着大批高科技装备相继列装,部队装备保障工作步入了一个崭新的时期。

适应装备形势的变化与发展,改进装备保障管理模式,加强装备保障能力建设,对提升部队战斗力有重要推动作用。

1装备靠前保障模式中国工程院徐滨士院士在2005年应用高新技术提高维修保障能力会议上首次提出了“靠前维修”的装备保障理念,引领了未来战场装备维修保障管理的趋势。

以此为牵引构建的装备靠前保障管理模式对规范技术力量和保障器材贴近一线部队、靠近装备保障,有序协同保障作业,提高部队装备保障管理能力起到了非常积极的作用。

简述配送中心的作业流程配送中心是指负责接收、存储、分类、分拣以及配送货物的物流中心。

它是物流供应链中环节重要的一部分,扮演着将商品从生产者运送到消费者的关键角色。

配送中心的作业流程主要包括货物接收、入库管理、仓储管理、分拣管理以及配送管理等。

首先,货物接收是配送中心的第一步。

当货物到达配送中心时,需要进行货物的验收和登记。

工作人员要检查货物数量、质量和外包装是否完好,并核对货物的收货单据。

在完成验收后,货物会被分配到相应的存放区域或仓库。

接下来是入库管理。

配送中心的入库管理是为了高效地存放货物,使其易于查找和使用。

通常需要进行货物的分类和标记,以便后续操作。

货物应该按照一定的规则排列,依据货物特性、品种、日期等对货物进行分类,同时在货物上做好标记,方便查找和管理。

在仓储管理环节中,配送中心要对存放在仓库中的货物进行合理的管理。

包括货物的整理、保管和调度。

通过合理规划仓库内货物的存放位置,可以提高仓储效率。

仓库管理还包括对库存进行盘点、核对和调整。

保持准确的库存记录可以帮助配送中心做好库存管理和预测。

分拣管理是配送中心的核心环节之一。

在配送中心内,货物通常需要根据不同的订单进行分拣和打包。

分拣过程中,工作人员需要根据订单的要求将货物按照收货地址、品种等进行分拣,并对分拣结果进行核对和确认。

分拣管理的目标是提高分拣速度和准确率,保证货物能够按时、正确地配送到客户手中。

最后是配送管理。

根据订单的要求,配送中心需要将货物送达到指定的收货地址。

这一过程涉及到货物的装载、线路规划和运输选择。

配送中心通常会采用多种配送方式,例如物流公司的运输车辆或者快递公司的快递员。

在配送过程中,需要对货物的状态进行跟踪和确认,确保货物安全送达。

参考内容:- Kuan C. Understanding order management and fulfillment in the modern supply chain[J]. Manufacturing & Service Operations Management, 2012, 14(4):520-534.- Tomlin B, Zhu J. Operational control of order picking: batch wave release policy in a parallel-aisle warehouse[J]. Manufacturing & Service Operations Management, 2008,10(4):645-665.- Thonemann U W. Relief distribution planning under uncertainty[J]. Manufacturing & Service Operations Management, 2008, 10(3):406-424.- Chen Y F, De N, Venkataramanan M A. Routing with delivery time guarantees: a customer-centric approach[J]. Manufacturing & Service Operations Management, 2015, 17(3):393-404.- Li Y, Gong C. An AHP-based location selection approach for urban distribution center[J]. Operations Research Letters, 2008, 36(5):600-604.。

基于AHP方法的企业家人力资本选择模型研究宗琮【期刊名称】《价值工程》【年(卷),期】2011(030)017【摘要】企业家人力资本是企业发展的核心推动力,企业家人力资本类型与企业核心能力的构建具有内在的匹配性.企业家人力资本选择的核心在于根据企业家所拥有的知识资本、社会资本和精神资本等因素,选择出合适的企业家类型.本文采用AHP方法作为甄选企业家人力资本的选择方法,使得选择在定量化分析的基础上具有科学性,充分发挥企业家人力资本的作用.%Entrepreneur human capital is the core driver of business development, there are inherent matching between entrepreneur human capital types and building core capabilities. The core of entrepreneur human capital is to choose the appropriate type of entrepreneur based on intellectual capital owned by entrepreneurs, social capital and spiritual capital and other factors. This paper took AHP method as a selection method of entrepreneur human capital, to make the choice scientific on the basis of quantitative analysis, and give full play to the role of entrepreneur human capital.【总页数】2页(P114-115)【作者】宗琮【作者单位】云南财经大学统计与数学学院,昆明,650221【正文语种】中文【中图分类】F272【相关文献】1.企业家人力资本与区域经济增长差异——基于动态面板和面板门限模型的实证研究 [J], 李政;佟鑫2.企业家人力资本与企业成长关系研究的创新与探索——《民营企业家人力资本与企业成长绩效实证研究》评介 [J], 张体勤3.创业投资模式下的两类社会资本与技术创新-基于企业家人力资本调节效应的研究 [J], 王雷;赵敬慈4.企业家人力资本影响创新绩效的内外部机制研究——基于知识资本框架 [J], 王敬勇; 丁媛媛5.企业家人力资本价值评估方法研究——基于现金流折现法与模糊数学分部估值法的比较 [J], 许泽想;梅丽霞因版权原因,仅展示原文概要,查看原文内容请购买。

机电设备综合评价体系的研究摘要现代社会对综合评价的应用可以说是相当广泛的,它可以使人们对任何评价对象有一个全面的,系统的比较和衡量,从而有目的的进行选择与评估。

在社会科学、环境监测、经济管理等领域已经得到广泛的应用,对于社会的发展息息相关。

建立一套机电设备的综合评价模型可以对企业或工厂能够充分了解设备的状态提供了一个很好的平台,对企业在选型方面有非常大的帮助,从而使生产更加顺利,有序的进行。

本篇论文通过对层次分析法、主成分分析法、数据包络分析法、模糊综合评价法等多种评价方法的详细阐述和对比,并举例说明其应用过程和应用现状。

最终提出了一种多层次、多因素的机电设备综合评价模式,即设备模糊综合评价,建立了机电设备综合评价模型。

并用实例证明此种方法的可行性与实用性。

关键词:综合评价,层次分析法(AHP),模糊评价法,设备选型Mechanical and Electrical Equipment Comprehensive EvaluationSystemABSTRACTComprehensive evaluation of modern society can be said that a wide range of applications, it allows people to object to any evaluation of a comprehensive, systematic comparison and measurement, and thus the purpose of selection and evaluation. In the social sciences, environmental monitoring, the areas of economic management has been widely used, is closely related to social development. The establishment of a comprehensive evaluation model electrical and mechanical equipment can fully understand the business or factory equipment, the state provides a good platform for enterprises in the selection have a very big help, making production more smoothly and orderly conduct of . This paper on levels of analysis, principal component analysis, data envelopment analysis, fuzzy comprehensive evaluation and other evaluation methods described in detail and contrast, and illustrates its application process and application status. Final A multi-level, multi-factor model comprehensive evaluation of equipment, or equipment, fuzzy comprehensive evaluation, the establishment of a comprehensive evaluation model for mechanical and electrical equipment. With examples to prove the feasibility and practicality of such methods.KEY WORDS: Evaluation,AHP,Fuzzy evaluation,Equipment Selection目录前言 (1)第1章综合评价概述 (2)1.1综合评价的概念 (2)1.1.1综合评价的意义 (3)1.1.2 综合评价标准 (3)1.1.3 综合评价法的特点及步骤 (5)第2章综合评价方法的分类 (7)2.1几种简易的评价方法 (7)2.2 层次分析法 (7)2.2.1 层次分析法梗概 (7)2.2.2层次分析法应用 (8)2.3 主成分分析法 (11)2.3.1主成分分析法概念 (11)2.3.2主成分分析法的基本特征 (12)2.3.3主成分分析法应用 (13)2.4 数据包络分析法 (15)2.4.1数据包络分析法概念 (15)2.4.2DEA法的应用 (15)2.5模糊综合评价法 (17)2.5.1模糊综合评价法概述 (17)2.5.2模糊综合评价法展望 (18)2.6聚类分析法 (18)2.6.1聚类分析法概述 (18)第3章机电设备综合评价模型的建立 (21)3.1 机电设备评价的产生与要素 (21)3.1.1 设备评价的产生 (21)3.1.2 设备评价的要素 (22)3.2 设备评价模型的建立 (24)第4章机电设备综合评价实例 (26)4.1 沥青混凝土拌和楼的综合评价 (26)4.1.1 因素集、评语集和评判对象集的确定 (26)4.1.2 构造因素间的比较判断矩阵 (26)4.1.3 各评价因素权重的确定 (28)4.1.4 综合评判 (29)结论 (32)谢辞 (33)参考文献 (34)附录 (36)外文资料翻译 (39)前言综合评价问题具有广泛性的特点,国内外对综合评价的研究与利用也开展的比较深入,不管是在经济、文化、管理还是在生态、工程等发面都有很大的作用。

基于AHP的高校技术物资供应商选择研究为了减少多目标决策中定性分析的主观性和定量分析的全面性不足,文章从技术、质量、成本、服务水准,以及生产柔性五个评价指标着手,基于AHP方法建立了高校技术物资供应商选择模型,并以航海模拟器的配件采购为例进行了实证分析,从实际使用效果来看,该方法能全面、准确、客观地反映供应商绩效,取得了较好的经济效益和管理效果。

标签:FAHP 供应商选择多目标决策航海模拟器高校技术物资供应商的选择具有技术性强的特点,它有别于企业物资供应商的选择,特别是航海类院校的航海模拟器、轮机模拟器等供应商的选择显得极为突出。

现有文献对供应商评价的方法主要是定性和定量两种方法,定性方法的局限性在于易受主观因素的影响,判断结果的客观性得不到保证,而定量方法的局限在于供应商选择评价的许多指标无法量化,判断结果的全面性得不到保证。

本文在多目标决策问题的AHP方法(层次分析法)的基础上,引入全面质量管理中的“技术”、“质量”、“成本”、“服务”、“柔性”(TQCSF) 的管理思想,建立了FAHP供应商选择模型,并给出了算法案例。

一、供应商选择的FAHP评估模型层次分析方法AHP(AnalyticHierarchyProcess)是美国运筹学家Satty教授于20世纪80年代提出的一种实用的多方案或多目标的决策方法。

它合理地将定性与定量的决策结合起来,按照思维、心理的规律把决策过程层次化、数量化。

它首先将所要分析的问题层次化,根据问题的性质和要达到的总目标,将问题分解成不同的组成因素,按照因素间的相互关系及隶属关系,将因素按不同层次聚集组合,形成一个多层分析结构模型,最终归结为最低层(方案、措施、指标等)相对于最高层(总目标)相对重要程度的权值或相对优劣次序的问题。

1.供应商评价指标体系的建立供应商评价问题涉及因素众多,评价指标多种多样,既有定性的,又有定量,而且指标权重各不相同,选择供应商必须根据实际情况制定适当的选择准则。

Value Engineering 0引言现役装备改造不仅有利于提高武器系统的效能,而且研制周期短,研制费用低,效费比和经济效益明显。

有选择地对现役装备进行现代化改造,已成为武器装备发展的行之有效的途径之一,日益受到世界各国的高度重视。

装备改造受多种因素影响,决策时必须予以充分考虑。

因此,积极开展现役装备改造方案综合评价研究,增强改造决策的科学性和有效性,对于提高装备改造效益具有重要意义[1]。

1评价指标体系构建现役装备改造决策受多种因素的影响和制约,综合来看,主要考虑:装备改造必要性、装备改造系统效能目标值、改造经费预算、改造技术水平、改造规模进度、改造管理保障能力,等等。

因此,构建改造效费综合评价指标体系,必须综合考虑上述因素的影响,做到客观真实。

在广泛征求专家意见的基础上,构建得到评价指标体系,如图1所示。

2模糊综合评价模型现役装备改造决策影响因素具有不确定性的特点,即具有模糊性,应用模糊数学方法去研究处理可具有较好的适用性[2]。

故这里选用模糊综合评判法开展评价研究。

2.1确定评价集评价集是评价专家对评价指标给出评语的集合,是按优劣等级给出的评定。

这里,评语集定义为:v=(v 1,v 2,v 3,v 4){优,良,一般,差}。

2.2确定评价指标权重评价指标权重的确定采用———————————————————————作者简介:淦元柳(1959-),男,江西永修人,本科,高工;徐吉辉(1974-),男,山西闻喜人,博士,教授,硕士生导师。

基于AHP-FSVM 的现役装备改造方案综合评价模型Model of Evaluation of Existing Equipment Modification Capability Based on AHPand Fuzzy Synthetic Evaluation Method淦元柳①GAN Yuan-liu ;徐吉辉②XU Ji-hui ;田浩②TIAN Hao(①空军驻锦州地区军事代表室,锦州121000;①空军工程大学工程学院,西安710038)(①Air Force Jinzhou Military Delegate Office ,Jinzhou 121000,China ;②The Engineering Institute ,Air Force Engineering University ,Xi'an 710038,China )摘要:利用新技术有选择地对现役装备进行现代化改造,已成为武器装备发展的重要途径之一。

基于AHP法的医疗器械供应商评价系统王湘杰;应悦;王志康;娄海芳【摘要】With the application of the method of analytic hierarchy process (AHP), this paper conducts qualitative and quantitative analysis of the most important factors that inlfuence the selection of medical equipment suppliers. The paper calculates the weighting score of each inlfuencing factor, which lays the foundation for the establishment of the medical instrument supplier evaluation system. The system can provide references for the selection of more qualiifed suppliers.%本文应用层次分析(AHP)法,选择重要影响因素对供应商进行定性和定量分析,计算各影响因素权重的得分,在此基础上建立了医疗器械供应商评价系统,为医院择优选择供应商提供参考依据。

【期刊名称】《中国医疗设备》【年(卷),期】2016(031)003【总页数】3页(P144-145,148)【关键词】评价方法;AHP法;供应商评价系统;医疗器械采购【作者】王湘杰;应悦;王志康;娄海芳【作者单位】浙江大学医学院附属第二医院临床医学工程部,浙江杭州 310009;浙江大学医学院附属第二医院临床医学工程部,浙江杭州 310009;浙江大学医学院附属第二医院临床医学工程部,浙江杭州 310009;浙江大学医学院附属第二医院临床医学工程部,浙江杭州 310009【正文语种】中文【中图分类】R197.39;F253.2随着医疗的发展,医用耗材的产品、质量、供应商错综复杂,参差不齐。

AHP-Based Equipment Selection Model for ConstructionProjectsAviad Shapira,M.ASCE,1and Marat Goldenberg2Abstract:Selection of equipment for construction projects,a key factor in the success of the project,is a complex process.Current models offered by the literature fail to provide adequate solutions for two major issues:the systematic evaluation of soft factors,and the weighting of soft benefits in comparison with costs.This paper presents a selection model based on analytic hierarchy process͑AHP͒,a multiattribute decision analysis method,with a view to providing solutions for these two issues.The model has the capacity to handle a great number of different criteria in a way that truly reflects the complex reality,to incorporate the context and unique conditions of the project,and to allow for manifestation of user experience and subjective perception.The model was implemented in an in-house developed system that was improved and validated through testing by senior professionals.The main academic contribution of the study is in the modification of AHP to correspond with the nature of equipment selection and in its utilization as an effective means for the formalization of knowledge possessed by competent,experienced practitioners.On the practical side,the proposed model offers an efficient,convenient tool that forces the users into orderly,methodical thinking,guides them in making logical,consistent decisions,and provides a facility for all necessary computations.DOI:10.1061/͑ASCE͒0733-9364͑2005͒131:12͑1263͒CE Database subject headings:Construction equipment;Cost control;Construction management;Decision making.IntroductionSelecting the right equipment has always been a key factor in the success of any construction project;this is even more so in to-day’s complex,highly industrialized projects͑O’Brien et al. 1996;Schaufelberger1999;Nunnally2000;Harris and McCaffer 2001;Peurifoy et al.2006͒.It is no wonder then that the subject has generated quite a volume of academic studies that attempt to improve both the process and itsfinal product.A study of equip-ment selection models͑Shapira and Goldenberg2005͒has shown that,although they present novel concepts and introduce ad-vanced tools,the majority of the state-of-the-art models͑e.g., Hanna and Lotfallah1999;Zhang et al.1999;Al-Hussein et al. 2000,2001;Tam et al.2001;Sawhney and Mund2001͒:͑1͒limit themselves to dealing with only part of the problem,without systematic consideration of the entire site plan as a whole;͑2͒consider mainly“hard”factors͑such as costs and technical con-straints of the site and project͒,while failing to provide a stage for“soft”͑i.e.,qualitative,intangible,informal͒considerations;͑3͒aim at providing a general,“universal”solution,which re-quires the models to simplify the problem and,consequently,to lose their ability to truly and fully reflect the project’s com-plexity and its unique contextual conditions;and/or͑4͒fail toprovide for the incorporation of the subjective,intuitive judgmentof the decision maker.These conclusions were further supported byfindings of afieldsurvey conducted among successful project managers with expe-rience in the construction of sizable,complex projects͑Shapiraand Goldenberg2005͒.By relying heavily on their vast experi-ence and professional skills,these practitioners managed to makewhat appeared to be“right”decisions in selecting equipment fortheir projects,despite two major obstacles,as attested by them:͑1͒the lack of a method for the systematic evaluation of soft factors;and͑2͒the lack of a structured process for the rationalintegration of cost estimates on the one hand,and soft consider-ations on the other hand.Thus the objective of this study was to develop an equipmentselection model that will both overcome the limitations of exist-ing models,as offered by the current literature,and provide solu-tions for the prevalent issues,as identified in current practices.The characterization of the equipment selection process as anessentially multifaceted problem involving numerous,variegatedconsiderations,often with complex trade-offs among them,im-plied that a suitable solution method might be found among thefamily of multiattribute-decision-analysis͑MADA͒methods ͑Norris and Marshall1995͒.Further analysis and profiling of the selection problem and the identification of the solution method’s desirable capabilities,triggered the consideration of analytic hier-archy process͑AHP͒͑Saaty1980͒as a possible basis for the equipment selection model envisaged.This paperfirst presents the essence of AHP,its suitability forthe equipment selection problem,and its solution mechanism.1Associate Professor,Dept.of Civil and Environmental Engineering, Technion–Israel Institute of Technology,Haifa32000,Israel.2Project Officer,Civil Engineering Division,Israel Air Force; formerly,Graduate Student,Dept.of Civil and Environmental Engineering,Technion–Israel Institute of Technology,Haifa32000, Israel.Note.Discussion open until May1,2006.Separate discussions must be submitted for individual papers.To extend the closing date by one month,a written request must befiled with the ASCE Managing Editor. The manuscript for this paper was submitted for review and possible publication on November11,2003;approved on October28,2004.This paper is part of the Journal of Construction Engineering and Manage-ment,V ol.131,No.12,December1,2005.©ASCE,ISSN0733-9364/ 2005/12-1263–1273/$25.00.The paper then introduces the proposed selection model,with a focus on two modules,which were mentioned as worthy of fur-ther research in the conclusion of the complete report on the subject͑Shapira and Goldenberg2005͒.These two modules,the evaluation of soft factors and the overall evaluation of costs ver-sus soft factors,are regarded by the writers to be the main con-tribution of the present paper.The paper ends with the presenta-tion of the model’s implementation and testing. Fundamentals and Principles of Analytic Hierarchy ProcessAHP ApproachSaaty͑1980͒first introduced AHP as a new approach to dealing with complex economic,technological,and sociopolitical prob-lems,which often involve a great deal of uncertainty.A typical MADA method,AHP was developed to assist in the making of decisions that are characterized by a great number of interrelated and often contending factors.To make such decisions,the relative importance of the factors involved must be properly assessed in order to enable trade-offs among them.The main feature of AHP is its inherent capability of systematically dealing with a vast number of intangible and nonquantifiable attributes,as well as with tangible and objective factors.AHP allows for the incorpo-ration into the decision-making process of subjective judgments and user intuition by producing a common formal and numeric basis for solution.Over the years,AHP has been implemented successfully in various areas.A literature survey found only a few AHP applica-tions in the area of construction,as follows:advanced construc-tion technologies/processes/materials evaluation͑Skibniewski and Chao1992;Hastak1998;Hastak and Halpin2000͒,contrac-tor selection͑Fong and Choi2000͒,procurement selection͑Che-ung et al.2001a͒,alternative dispute resolution͑Cheung et al. 2004͒,and project management͑Al-Harbi2001͒.No AHP appli-cation,however,was found that deals with the selection of con-struction equipment or similar issues.AHP BasicsAccording to Saaty,AHP is based on a two-stage process:first,“decomposing the complexity”by identifying the͑“small”͒fac-tors that make up the͑“big”͒problem and mapping their mutual relationships,and then“synthesizing the relations”by determin-ing the relative weights of the factors and aggregating their cu-mulative effect vis-à-vis a single decision criterion.Five basic AHP elements were identified and are presented briefly below.They are elaborated on later,as required,in relation to the proposed model.Hierarchy ConstructionTo“decompose the complexity,”decision factors are organized in a hierarchy-type structure.The primary goal of the problem͑e.g., successful selection of equipment͒occupies the highest level of the structure,followed by“sets of attributes”that are organized in several more hierarchy levels.A typical second-level attribute set includes all of the secondary goals that together contribute to achieving the primary goal͑e.g.,economy,schedule,efficiency, and safety͒.These,in turn,are directly affected by all of the attributes in the set located one level lower͑e.g.,safety may be affected by winds,power lines,crane overlapping,night work,etc.͒,and so on,as dictated by the nature of the problem.Thus a set is located either under another attribute that is one level higher,or under the primary goal of the problem.Attributes that have no other attributes under them in the hierarchy structure are termed“leaf attributes.”All in all,this hierarchy structure ex-presses the interrelationships between the various decision fac-tors.At the lowest AHP hierarchy level is a set of feasible alter-natives that are to be evaluated.Alternatives must be connected to all of the leaf attributes potentially affecting their evaluation. Pairwise ComparisonsOnce interrelationships between attributes͑i.e.,decision factors͒are mapped by the hierarchy,relative weights of the attributes are determined by comparing them in pairs,separately for each set in the hierarchy.The results for each set are recorded in a separate “decision matrix.”When comparing two attributes,the following must be determined:͑1͒which attribute is more important or has greater influence on the attribute one level higher in the hierarchy ͑e.g.,what affects safety more—winds or power lines;what af-fects safety more—winds or crane overlapping;and so on͒;and ͑2͒what is the intensity of that importance͑e.g.,weak,strong,absolute͒.Verbal intensity assessments are translated into num-bers͑thus,in fact,converting qualitative evaluations into quanti-tative ones͒according to a given scale͑Saaty1980͒.It should be noted that the pairwise-comparison method is perhaps the corner-stone of the entire AHP philosophy,as it allows the user to sys-tematically determine the intensities of interrelationships of a great—practically unlimited—number of decision factors. Relative-Weight CalculationOne of Saaty’s core theorems states that the eigenvector of the decision matrix established in the previous phase͑i.e.,the out-come of the pairwise comparison process͒is the priority vector of the attributes compared,which represents their relative weights with regard to the attribute located one level higher in the hierar-chy.AHP mathematical foundations are relatively simple;the reader is referred to Saaty͑1980͒for a more detailed presentation of the method and its calculation techniques.Several approxima-tion methods can be used to calculate the eigenvector,wជ,of the decision matrix,of which the average of normalized columns ͑ANC͒method is the most accurate͑Saaty1980͒.An ANC cal-culation of w i,the relative weight of the attribute in row i͑which is an element of the eigenvector wជ͒,for a reciprocal nϫn matrix, is as follows:w i=1n·͚j=1na ij͚k=1n a kj͑1͒where a ij=element located in row i and column j of the decision matrix.The screen capture in Fig.3,presented later to illustrate the implementation of the proposed model,serves also as an example for the above calculation procedure.Aggregation of Relative WeightsOnce relative weights are calculated for each set of attributes at every level of the hierarchy and respective local priority vectors are produced,the overall score of each alternative,representing the preference of one alternative over another,can now be ob-tained.Aggregation is achieved by multiplying local priority vec-tors of each set of attributes by the relative weights of the respec-tive attributes immediately above them,starting at the lowest level and ending at the primary goal level.The new vector ob-tained is no longer local but rather inclusive for the entire hierar-chy.The sum total of all such computations for each leaf attributein the hierarchy is1.00.The overall score of the alternatives isobtained by multiplying the local priority vector of the alterna-tives with respect to each leaf attribute by the inclusive priorityvector of that leaf attribute,and summing the products.This scoreenables a comparison between the alternatives on a weightedbasis,representing the entire collection of decision factors in thehierarchy.Consistency RatioThefifth element of AHP,the“Consistency Ratio”͑CR͒measure,is a tool for controlling the consistency of pairwise comparisons.Since one of the advantages of AHP is its ability to allow subjec-tive judgment,and with intuition playing an important role in theselection of the best alternative,absolute consistency in the pair-wise comparison procedure should not be expected.“Absoluteconsistency”means,for example,that if x is more important thany by a factor of2,and y is more important than z by a factor of3, then x should be more important than z by a factor of6.The CR,introduced by Saaty͑1980͒and computed using a formula hedeveloped,enables one to control the extent of inconsistency to amaximum desirable level,for each decision matrix and for theentire hierarchy.Based on numerous empirical studies,Saaty ͑1980͒stated that to be acceptable͑i.e.,for tolerable inconsis-tency͒,the CR must be less than or equal to0.10͑irrespective ofthe nature of the problem͒;if this condition is not fulfilled,arevision of the comparisons is recommended.It must be stressed,however,that an acceptable CR does not guarantee a“good”finalselection outcome.Rather,it ensures only that no intolerable con-flicts exist in the comparisons made,and that the decision is logi-cally sound and not a result of random prioritization.Limitations of AHPThe introduction of AHP and the increase in its popularity encour-aged intensive studies and some criticism of that innovative method.The main issues raised included:͑1͒the likelihood of the occurrence of the“rank reversal”phenomenon,in which an alter-native determined as best is not chosen after all when a certain other alternative is removed from the set of alternatives͑Belton and Gear1983;Dyer1990͒;͑2͒the imposed inconsistency due to the restriction of pairwise comparisons to a1-to-9scale and to the problematic correspondence between the verbal and the numeric scales͑Belton1986;Belton and Goodwin1996͒;and͑3͒the variation in verbal expressions from one person to another,as well as their dependence on the type of elements involved in the comparison͑Pöyhönen et al.1995͒.Saaty͑1990͒;Saaty and Vargas͑1991͒;and Pérez͑1995͒re-sponded to the criticism,showing that AHP principles and scale have a solid theoretical and practical basis.Saaty and Vargas ͑1991͒demonstrated how,in certain applications,“rank reversal”is entirely normal and even desirable,while in other cases,abso-lute measurement of alternatives can be used instead of relative measurement to avoid rank reversal͑as in the proposed model͒. Belton and Goodwin͑1996͒responded to their own critique by concluding that ensuring the user’s full understanding of the ques-tions posed during the pairwise comparisons will guarantee the proper use of AHP.Equipment Selection ModelThe proposed AHP-based equipment selection model does not constitute merely a technical solution for an isolated problem,but rather represents a comprehensive concept of the entire selection process.As outlined in Fig.1,the model comprises three central modules:͑1͒cost evaluation of alternatives;͑2͒benefit evaluation of alternatives;and͑3͒total evaluation of alternatives.Of these three modules,the current paper focuses on the latter two,and thus responds to two major deficiencies in current equipment se-lection practices identified earlier͑Shapira and Goldenberg2005͒, namely the evaluation of alternatives with respect to soft factors, and the integration of both costs and soft factors to produce a single desirable solution.Thus thefirst module,cost evaluation—indispensable but inherently technical,covered extensively by textbooks͑Illingworth1993;Nunnally2000;Harris and McCaf-fer2001;Peurifoy et al.2006͒,and admittedly exercised properly in current practices—is addressed here only to the extent of its implications for the other two modules and its integration within the entire process.Information Gathering and Generation of Alternatives The selection process starts with the preliminary,yet critical phase of information gathering and generation of feasible alterna-tives͑i.e.,those satisfying all threshold requirements͒.Although the current study does not treat this phase specifically,one aspect of it must be stressed,as it might affect the ensuing phases as well as the outcome of the entire selection process͑Goldenberg2002͒: Since the ultimate goal is the best overall production system pos-sible,the scope of the process should extend beyond the mere generation of different equipment alternatives,and should include also an investigation of the possible revision of construction methods͑Nunnally2000͒.Moving from cast-in-place concrete to precast elements,for example,might have a major effect on cran-ing and concrete placingrequirements.Fig.1.Proposed equipment selection modelAHP-Based Benefit EvaluationAs stated earlier,the Benefit Evaluation Module,essentially a modification of the AHP method to suit the problem of equipment selection,is one of the main novelties offered by the current paper.It should be noted,however,that this module may be skipped,at the discretion of the selection team,when a feasible alternative exists that is considerably lower in cost compared to the other alternatives͑as also shown in Fig.1͒.Hierarchy ConstructionHierarchy construction,thefirst phase of the AHP-based benefit evaluation,is also thefirst step that involves adjustment of the solution to the context of the problem,since only decision factors relevant to the project under discussion are determined as at-tributes and grouped into sets at the various hierarchy levels.For example,“Working night shifts”will be an attribute only if night work is indeed planned͑in at least one alternative͒.Hierarchy construction is a typical“trial and error”process.The hierarchy exemplified in Fig.2is a likely outcome of the process,provided all factors are indeed relevant to the examined project.The following should be kept in mind when constructing the hierarchy.•There is no one“correct”hierarchy.Hierarchy construction is subjective and greatly affected by common practices and tra-ditions of the specific construction company,as well as by the experience and preferences of the users.At the same time, hierarchies built in different companies͑or by different users in the same company͒are likely to differ from each other more at lower than at higher levels of the hierarchy.•Similarly,context plays a greater role the lower we go in the hierarchy.In other words,the extent of adjustment to the spe-cific conditions of the project under discussion will not be felt at all at the primary-goal level͑i.e.,“Successful selection of equipment”͒,it might be greater,yet relatively low,at the secondary-goals level͑see Fig.2,Level2͒,and will be most discernable at the decision-factors level͑see Fig.2,Level3͒.•All decision factors in any given set should be clearly relatedto the factor immediately above them,which constitutes the common basis for the pairwise comparisons.•When referring to any attribute in the hierarchy,its name must be closely associated with its exact meaning and perceived as such by the user.Confusing names might lead to errone-ous location of attributes and to inconsistencies in pairwise comparisons.•To avoid duplication,a hierarchy must not include cost factors ͑including soft factors that directly affect costs͒,as these are dealt with in a separate module,and their cumulative influence is also taken into account in the course of the total evaluation.Moreover,certain typical soft factors are likely to have been considered previously in the generation and formulation of alternatives,and hence should not be repeated in the hierarchy.Examples include company policy towards owning of equip-ment versus rental,company project specialization and project forecast,and commercial considerations in cash-flow produc-ing facilities.•The inclusion of factors with regard to which all alternatives are identical should be avoided,even if such factors are essen-tially relevant,so as not to needlessly burden the solution pro-cess.For example,“Noise levels”is a relevant decision factor for projects located in urban areas.If,however,all alternatives are indifferent to noise͑e.g.,only electric powered cranes are used,or no work is planned for irregular hours͒,then there is no need to include“Noise levels”in the hierarchy.•A decision factor is not limited to belonging to only one set, and can appear in two or more sets,provided it has a different type of influence in each set.For example,“Winds”may affect both safety and progress delays,and,if relevant,can appear in two different sets͑see also Fig.2͒.•Proceeding on to the next phase and starting the performance of pairwise comparisons does not necessarily mean that con-struction of the hierarchy has beenfinalized.If difficulties with comparisons are encountered,they may serve as indication that the hierarchy should berevised. Fig.2.Hierarchy for equipment selectionPairwise ComparisonsAt the next phase of the solution,pairs of factors are compared in order to systematically determine the relative influence of the factors on the attribute positioned one level higher in the hierar-chy.The comparisons depend on the constraints of the specific project under discussion,but at this stage,the alternatives them-selves do not yet play a parisons are performed sepa-rately for each set in the hierarchy by responding to a leading question.A typical question for Level2of the hierarchy͑see Fig. 2͒would be,“What might have a greater influence on the suc-cessful selection of equipment͑for the particular project exam-ined͒:work safety or progress delays,and to what extent?”Simi-larly,a typical Level3question would be,“What might have a greater influence on progress delays͑for the particular project examined͒:heavy traffic or labor availability,and to what ex-tent?”In this way,all factors of each set are compared with each other in pairs,resulting in a total of n·͑n−1͒/2such comparisons for a set containing n elements.Note that unlike the previous phase,in which the hierarchy exemplified in Fig.2may indeed serve as a basis for similar cases,the results of the pairwise com-parisons are completely project-dependent and user-dependent; hence no general scheme can be outlined.The main distinction between different cases is the variation in the intensities of the relative influences of the factors,as assessed verbally and then translated into numbers using the given AHP scale͑Saaty1980͒. Pair comparisons constitute,in effect,the input of various project data through which the users can express their specific prefer-ences regarding the given project.For a certain project,progress and schedule may be viewed as dominant,while for another, safety considerations may govern.Moreover,it is quite possible that for the very same project two different users will have dif-ferent preferences due to different experience,perspectives,and attitudes.The decision matrix presented in Fig.3is an example outcome of pairwise comparisons conducted for“Managerial convenience”͑see Fig.2͒.As evident from the matrix,three of the four factors were assessed as being equal͑total of3comparisons for n=3͒, hence the value1͑corresponding to“Two attributes contribute equally to the objective”͒occurs three times in the matrix͑see shaded cells͒.The importance of“Previous experience with equipment”relative to“Managerial convenience”was assessed as inferior to that of the other three factors:by a value of5compared to“Dependence on outsourcing”and“Pieces of equipment to manage”͑i.e.,each is“favored strongly”over“Previous experi-ence”͒,and by a factor of3compared to“Working night shifts”͑i.e.,the latter is“favored slightly”͒.The values in the upper row of the matrix are the reciprocal values of5,5,and3,respectively. Fig.3.Model implementation:screen capture of example pairwise comparisonThe comparison and its outcome are indifferent to the order in which the factors are placed in the hierarchy and then compared to each other.The following guidelines should be observed at this phase.•In order to assure accurate results ͑i.e.,results that truly express the perception of the user ͒,it is advisable,in each comparison,to actually repeat the leading question.When test-ing the model,it was found that users tend to memorize the leading question and to forsake it after several comparisons.This tended to result in CRs that were greater than 0.10͑see “Consistency Ratio”above ͒.When comparisons were repeated with greater adherence to the leading question,CR results improved.•Users should refrain from dealing with more than one pair of factors at a time.Although the tendency to handle all factors in a set at once,and to rate them relative to each other instead of in pairs may seem natural to some users,this practice violates the AHP rationale and procedure and might impair the results.•For each set,the leading question must refer only to the one attribute located immediately above the said ers should pay particular attention when comparing factors that belong to more than one set in the hierarchy ͑and pose a different ques-tion for each set ͒.•As concluded from the testing of the model ͑see “Model Implementation and Testing”͒,users will acquaint themselves with the solution method faster,gain confidence in running the model faster,and use the model more efficiently if pairwise comparisons start with a Level-2set that is “closer to the us-er’s heart”or more comprehensible than other sets.Similarly,the first comparisons within the set ͑i.e.,at Level 3͒should be conducted on factors easily grasped by the user.•Whenever the CR is greater than 0.10,comparisons should be repeated and revised.If the revised comparison does not achieve an acceptable CR ͑i.e.,ഛ0.10͒,the hierarchy should be reexamined.This situation is likely to coincide with confu-sion or difficulty experienced by the users in their responding to the leading question.A likely solution is to correct the lo-cation of a factor in the hierarchy ͑by moving it from one set to another ͒,rephrase the factor,create a new set of factors,or even reconstruct the entire hierarchy.Similar to hierarchy construction,pairwise comparison is a user-induced solution phase.It is accompanied by two concurrent steps,performed without user intervention,in which the results of the comparisons are processed and their consistency checked.These steps are the eigenvector computations,which,at a later phase,serve in the calculation of the final score of each alterna-tive,and CR examination,as mentioned above ͑see “AHP Basics”͒.The results of the eigenvector computations will be as-sembled as shown in Table 1,columns 2and 4.The rest of TableTable 1.Template for Benefits Evaluation of AlternativesLevel 2Level 3Scale for absolute scores Absolute scores Aggregation of relative weightsAttribute Relative weight AttributeRelative weight Score Relative weight Alt.1a…Alt.m aAlt.1b…Alt.m c 1234567…89…10F 1RW ͑F 1͒F 1.1RW ͑F 1.1͒S 1RW ͑S 1͒AS 1͑F 1.1,A 1͒.AS 1͑F 1.1,A m ͒AW 1͑F 1.1,S 1͒.AW m ͑F 1.1,S 1͒S 2RW ͑S 2͒AS 2͑F 1.1,A 1͒AS 2͑F 1.1,A m ͒AW 1͑F 1.1,S 2͒AW m ͑F 1.1,S 2͒S 3RW ͑S 3͒AS 3͑F 1.1,A 1͒AS 3͑F 1.1,A m ͒AW 1͑F 1.1,S 3͒AW m ͑F 1.1,S 3͒..S 1RW ͑S 1͒........S 2RW ͑S 2͒......S 3RW ͑S 3͒....F 1.p RW ͑F 1.p ͒S 1RW ͑S 1͒AS 1͑F 1.p ,A 1͒.AS 1͑F 1.p ,A m ͒AW 1͑F 1.p ,S 1͒.AW m ͑F 1.p ,S 1͒S 2RW ͑S 2͒AS 2͑F 1.p ,A 1͒AS 2͑F 1.p ,A m ͒AW 1͑F 1.p ,S 2͒AW m ͑F 1.p ,S 2͒S 3RW ͑S 3͒AS 3͑F 1.p ,A 1͒AS 3͑F 1.p ,A m ͒AW 1͑F 1.p ,S 3͒AW m ͑F 1.p ,S 3͒....................................F n RW ͑F n ͒F n .1RW ͑F n .1͒S 1RW ͑S 1͒AS 1͑F n .1,A 1͒.AS 1͑F n .1,A m ͒AW 1͑F n .1,S 1͒.AW m ͑F n .1,S 1͒S 2RW ͑S 2͒AS 2͑F n .1,A 1͒AS 2͑F n .1,A m ͒AW 1͑F n .1,S 2͒AW m ͑F n .1,S 2͒S 3RW ͑S 3͒AS 3͑F n .1,A 1͒AS 3͑F n .1,A m ͒AW 1͑F n .1,S 3͒AW m ͑F n .1,S 3͒..S 1RW ͑S 1͒........S 2RW ͑S 2͒......S 3RW ͑S 3͒....F n .q RW ͑F n .q ͒S 1RW ͑S 1͒AS 1͑F n .q ,A 1͒.AS 1͑F n .q ,A m ͒AW 1͑F n .q ,S 1͒.AW m ͑F n .q ,S 1͒S 2RW ͑S 2͒AS 2͑F n .q ,A 1͒AS 2͑F n .q ,A m ͒AW 1͑F n .q ,S 2͒AW m ͑F n .q ,S 2͒S 3RW ͑S 3͒AS 3͑F n .q ,A 1͒AS 3͑F n .q ,A m ͒AW 1͑F n .q ,S 3͒AW m ͑F n .q ,S 3͒Sum of aggregated weights:⌺AW 1͑F i .j ,S k ͒…⌺AW m ͑F i .j ,S k ͒Normalized benefit score of alternatives:͚AW 1ր͚i =1m͚AW i …͚AW m ր͚i =1m ͚AW iaThe values in each cell in columns 7and 8are either 1.0or 0.0.Of the three optional scores for each attribute at Level 3—S 1,S 2,S 3—only one will be assigned the value 1.0,and the other two will be assigned the value 0.0.bColumn 9=2ϫ4ϫ6ϫ7.cColumn 10=2ϫ4ϫ6ϫ8.。