Carbon-enhanced Lead Acid Battery

- 格式:pdf

- 大小:2.94 MB

- 文档页数:33

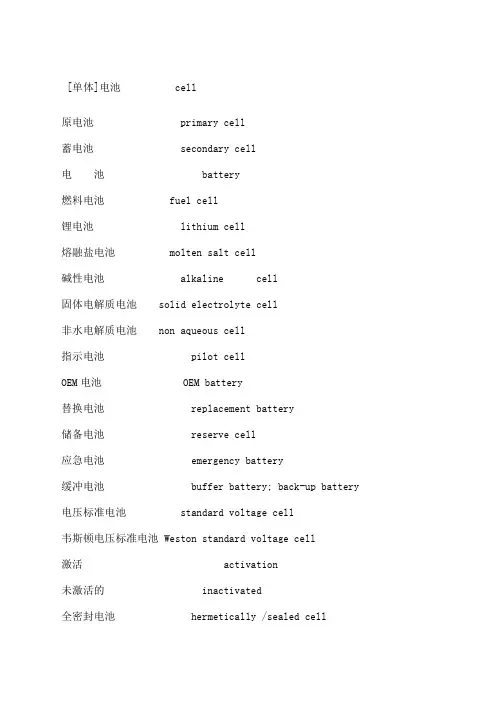

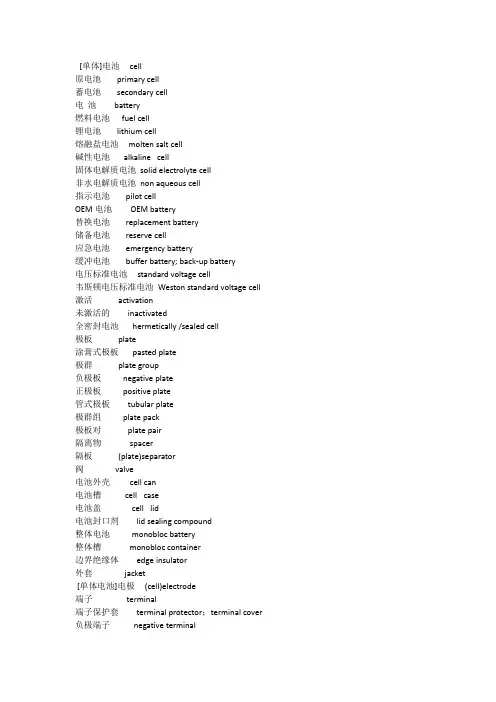

[单体]电池cell原电池primary cell蓄电池secondary cell电池battery燃料电池fuel cell锂电池lithium cell熔融盐电池molten salt cell碱性电池alkaline cell固体电解质电池solid electrolyte cell非水电解质电池non aqueous cell指示电池pilot cellOEM电池OEM battery替换电池replacement battery储备电池reserve cell应急电池emergency battery缓冲电池buffer battery; back-up battery 电压标准电池standard voltage cell韦斯顿电压标准电池 Weston standard voltage cell激活activation未激活的inactivated全密封电池hermetically /sealed cell极板plate涂膏式极板pasted plate极群plate group负极板negative plate正极板positive plate管式极板tubular plate极群组plate pack极板对plate pair隔离物spacer隔板(plate)separator阀valve电池外壳cell can电池槽cell case电池盖cell lid电池封口剂lid sealing compound整体电池monobloc battery整体槽monobloc container边界绝缘体edge insulator外套jacket[单体电池]电极(cell)electrode端子terminal端子保护套terminal protector;terminal cover负极端子negative terminal正极端子positive terminal电极的活性表面active surface of an electrode阳极anode阴极cathode电解质electrolyte电解质爬渗electrolyte creep电解质保持能力electrolyte containment泄漏leakage活性物质active material活性物质混合物active material mix电池组合箱battery tray输出电缆output cable连接件connector矩形(的)prismatic圆柱形电池cylindrical cell扣式电池button cell; coin cell 电化学反应electrochemical reaction 电极极化electrode polarization 反极polarity reversal cell reversal 结晶极化crystallization polarization活化极化activation polarization阳极极化anodic polarization阴极极化cathodic polarization浓差极化concentration polarization; mass transfer polarization 欧姆极化ohmic polarization反应极化reaction polarization阳极反应anodic reaction阴极反应cathodic reaction副反应side reaction; secondary reaction;容量(电池的)capacity(for cells or batteries)额定容量rated capacity剩余容量residual capacity体积(比)容量volumetric capacity温度系数temperature coefficient(of the capacity)质量(比)容量gravimetric capacity面积(比)容量areic capacity电池能量battery energy(电池)体积(比)能量volumic energy(related to battery)(电池)放电discharge(of a battery)放电电流discharge current放电率discharge rate短路电流(电池的)short-circuit current(related to cells or batteries) 自放电self discharge放电电压(电池的)discharge voltage(related to cells or batteries)闭路电压closed circuit voltage负载电压(拒用)on load voltage (deprecated)初始放电电压initial discharge voltage初始闭路电压initial closed circuit voltage初始负载电压(拒用)initial on load voltage(deprecated)终止电压end-of-discharge voltage; final voltage; cut-off voltage; end-point voltage标称电压nominal voltage开路电压(电池的)open-circuit voltage(related to cells or batteries)开路电压温度系数temperature coefficient of the open-circuit voltage 比特性specific characteristic荷电保持能力charge retention容量保持能力capacity retention表观内阻internal apparent resistance剩余活性物质residual active mass使用质量service mass并联parallel connection并串联parallel series connection串联series connection串并联series parallel connection标称值nominal value电池耐久性battery endurance贮存试验storage test使用寿命service life贮存寿命storage life; shelf life连续工作试验continuous service test金属-空气电池air metal battery碱性锌-空气电池alkaline zinc air battery碱性锌-二氧化锰电池alkaline zinc manganese dioxide battery锌-氧化银电池zinc silver oxide battery中性锌-空气电池neutral electrolyte zinc air battery氯化锌电池zinc chloride battery锌-碳电池zinc carbon battery诸如勒克朗谢电池或氯化锌电池之类的原电池。

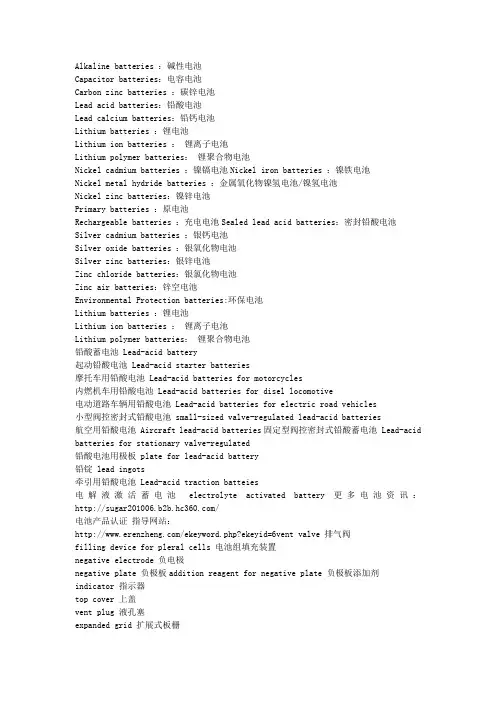

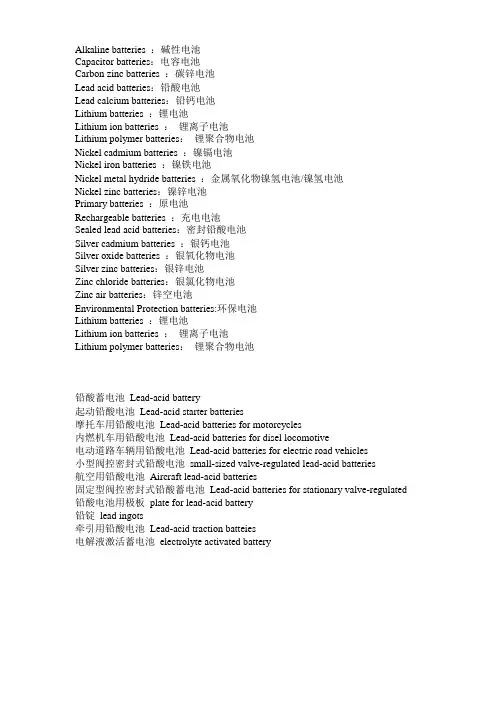

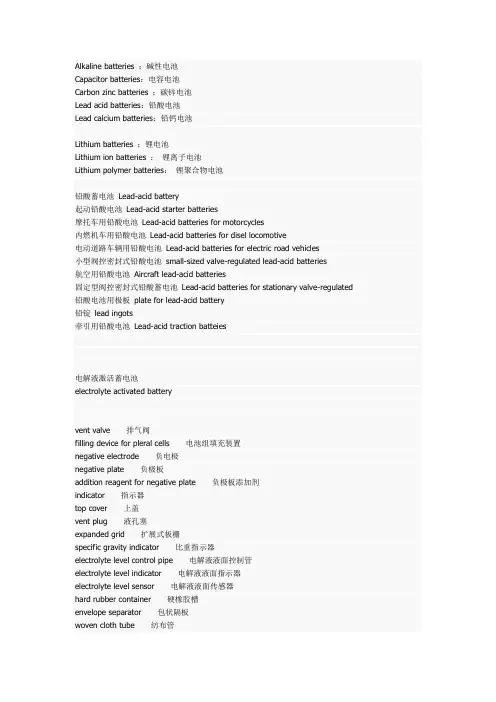

Alkaline batteries :碱性电池Capacitor batteries:电容电池Carbon zinc batteries :碳锌电池Lead acid batteries:铅酸电池Lead calcium batteries:铅钙电池Lithium batteries :锂电池Lithium ion batteries :锂离子电池Lithium polymer batteries:锂聚合物电池Nickel cadmium batteries :镍镉电池Nickel iron batteries :镍铁电池Nickel metal hydride batteries :金属氧化物镍氢电池/镍氢电池Nickel zinc batteries:镍锌电池Primary batteries :原电池Rechargeable batteries :充电电池Sealed lead acid batteries:密封铅酸电池Silver cadmium batteries :银钙电池Silver oxide batteries :银氧化物电池Silver zinc batteries:银锌电池Zinc chloride batteries:银氯化物电池Zinc air batteries:锌空电池Environmental Protection batteries:环保电池Lithium batteries :锂电池Lithium ion batteries :锂离子电池Lithium polymer batteries:锂聚合物电池铅酸蓄电池 Lead-acid battery起动铅酸电池 Lead-acid starter batteries摩托车用铅酸电池 Lead-acid batteries for motorcycles内燃机车用铅酸电池 Lead-acid batteries for disel locomotive电动道路车辆用铅酸电池 Lead-acid batteries for electric road vehicles小型阀控密封式铅酸电池 small-sized valve-regulated lead-acid batteries航空用铅酸电池 Aircraft lead-acid batteries固定型阀控密封式铅酸蓄电池 Lead-acid batteries for stationary valve-regulated铅酸电池用极板 plate for lead-acid battery铅锭 lead ingots牵引用铅酸电池 Lead-acid traction batteies电解液激活蓄电池electrolyte activated battery更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=6vent valve 排气阀filling device for pleral cells 电池组填充装置negative electrode 负电极negative plate 负极板addition reagent for negative plate 负极板添加剂indicator 指示器top cover 上盖vent plug 液孔塞expanded grid 扩展式板栅specific gravity indicator 比重指示器electrolyte level control pipe 电解液液面控制管electrolyte level indicator 电解液液面指示器electrolyte level sensor 电解液液面传感器hard rubber container 硬橡胶槽envelope separator 包状隔板woven cloth tube 纺布管spongy lead 海绵状铅partition 隔壁over the partition type 越过隔壁型through the partition type 贯通隔壁贯通型separator 隔板(1)battery rack(2)battery stand(3)battery stillage 蓄电池架/蓄电池底垫active material 活性物质glass fiber separator 玻璃纤维隔板glass mat 玻璃纤维绵glass mat tube 玻璃纤维绵管spacing washer 间隔垫圈reinforced fiber separator 强化纤维隔板polarity mark plate 极性标记板pole 极柱pole insulator 极柱绝缘子pole nut 极柱螺母plate 极板plate foot 极板足plate supporter 极板支撑件element 极板群/极群组pole bolt 极柱螺栓plate lug 极板耳dilute sulfuric acid 稀硫酸steel can 金属罐steel container 金属蓄电池槽(1)madribs(2)element rest 鞍子/极群组座tubular plate 管状极板gelled electrolyte 胶体电解液更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=6grid板栅caution label 警告标签synthetic resin separator 合成树脂隔板plastics container 塑料蓄电池槽synthetic fiber separator 合成纤维隔板connector sunken type 沉没型连接器connetor exposed type 露出型连接器safety valve test 安全阀测试ampere-hour efficency 安时效率one charge distance range 一次充电行程gas recombination on negative electrode typecut-off discharge 终止放电/截止放电阴极气体再化合型/阴极气体复合型(1)specific characteristic (2)energy density (1)比特性(2)能量密度recovering charge 恢复充电(1)open circuit voltage(2)off-load voltage 开路电压/空载电压overcharge 过充电gassing 析气overcharge life test 过充电寿命试验accelerated life test 加速寿命试验active material utilization 活性物质利用率theoretical capacity of active material 活性物质的理论容量over discharge 过放电intermittent discharge 间歇放电full charge 完全充电full discharge 完全放电reverse charge 反充电/反向充电quick charge 快速放电allowable minimum voltage 允许最小电压equalizing charge 均衡充电creeping 蠕变group voltage 组电压shallow cycle endurance 轻负荷寿命/轻负荷循环寿命characteristic of electrolyte decrease 电解液减少特性nominal voltage 标称电压high rate discharge 高率放电high rate discharge characteristic 高率放电特性5 second voltage at discharge 放电 5 秒电压(1)cold cranking ampere(2)cold cranking performance(1)冷启动电流(2)冷启动性能cycle life test 循环寿命测试maximum voltage at discharge 最大放电电压30 second voltage at discharge 放电 30 秒电压residual capacity 残存容量(1)hour rate(2) discharge rate (1)小时率(2)放电率更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=6(1) self discharge (2) local action (1)自放电(2)局部自放电(1) self discharge rate(2) local action rate (1)自放电率(2)局部自放电率actual capacity 实际容量(1)starting capability(2)cranking ability 启动能力cranking current 启动电流battery clamp test 电池夹钳测试power density 功率密度momentary discharge 瞬间放电modified constant voltage charge 修正恒定电压充电initial capacity 初始容量gas recombination by catalyser type 触媒气体复合式initialcharge 初始充电viberation test 振动试验predetermined voltage 预定电压total voltage 总电压activation test for dry charged battery 干式荷电蓄电池活化试验salting 盐析earthquake-proof characteristics 防震性能dielectric voltage withstand test 电介质耐压试验short time discharge 短时间放电escaped acid mist test 酸雾逸出测试terminal voltage 端子电压cell voltage 单电池电压step charge阶段充电short-circuit current 短路电流storage test 保存测试high rate discharge at low temperature 低温高率放电rated voltage 额定电压rated capacity 额定容量fixed resistance discharge 定阻抗放电constant voltage charge 恒压充电constant voltage life test 恒压寿命测试constant current charge 恒流充电constant voltage constant current charge 恒流恒压充电constant current discharge 恒流放电constant watt discharge 恒功率放电low rate discharge characteristics 低率放电特征trickle charge 涓流充电trickle charge current 涓流充电电流trickle charge life test 涓流充电寿命测试thermal runaway 热失控driving pattern test 运行测试capacity in driving pattern test 运行测试更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=6boost charge急充电floating charge浮充电floating charge voltage 浮充电电压floating charge current 浮充电电流(1)mean voltage (2)average voltage 平均电压on-load voltage 负载电压discharge duration time 放电持续时间(1)final voltage(2)cut-off voltage(3)end voltagedepth of discharge 放电深度discharge voltage 放电电压discharge current 放电电流discharge current density 放电电流密度discharge watt-hour 放电瓦时discharge characteristics 放电特性discharged ampere-hour 放电安时explosion proof test 防爆测试auxiliary charge 补充电maintenance factor 维护率storage characteristics 保存特性终止电压/截止电压gas recombinating efficiencycharge 充电气体复合效率/气体再化合效率charge acceptance test 充电可接受性试验start-of-charge current 充电开始电流charge efficiency 充电效率end-of-charge voltage 充电结束电压specific gravity of electrolyte at the end of charge充电结束时电解液比重charge voltage 充电电压charge current 充电电流charged watt-hour 充电瓦时charge characteristic 充电特性charge ampere-hour 充电安时deep cycle endurance 重负荷循环寿命/重复合寿命weight engergy density 重量能量密度rubber pad 橡胶垫lower level line 下液面线side terminal 侧端子collective exhaust unit 公共的排放单元sintered plaque 烧结极板sintered separator 烧结隔板sintered plate 烧结极板catalyst plug 催化塞spine 芯骨strap 带更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=6spacer 隔离物insulating tube绝缘管intercell connector连接线/连接条connector cover连接管盖float mounted plug 浮动安装的栓(1)pasted plate (2)grid type plate 涂膏式极板braidd tube 编织管(1)flame-arrester vent plug (2)flam-retardant vent plug 安全塞explosion and splash proof construction 防爆防溅结构baffle 保护板pocket type plate 袋式极板bottom hole-down 底孔向下(固定)bolt fastening terminal 螺栓连接端子male blade 阳片monoblock container 整体槽positive electrode 正极positive plate 正极板leading wire terminal 引线端子retainer mat 止动垫片ribbed separator 肋隔板(1)jumping wire (2)inter low wire 跳线end plate 端板filling plug 注液塞plante plate 形成式极板/普朗特极板tubular plate 管式极板low electric resistance separator 低电阻隔板tapered terminal post 锥形接线柱electrolyte 电解液container 蓄电池槽/蓄电池壳set of container 成套蓄电池槽level-scope mounted plug 透视塞/透视栓handle 手柄jug 取液管(1)connector;(2)plug concent (1)连接器;(2)插座式连接器connector wire 连接线connecting bar 连杆connecting bar cover 连杆帽lead 引线/连接线edge insulator 绝缘卡side frame 侧框架battery cubicle 蓄电池箱perforated separator 多孔隔板burning rod (铅)焊条terminal 端子更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=6terminal connector 端子连接条terminal cover 端子盖terminal base 端子座tab 接线片lead bushing 铅套corrugated separator 波形隔板(1)lead dioxide;(2)lead peroxide (1)二氧化铅;(2)过氧化铅(1)woven separator;(2)nonwoven separator (1)织物隔板;(2)非织物隔板vent hole 通气孔exhaust tube 排气管antipolar mass 反极性物质output cable 输出电缆microporous rubber separator 微孔像胶隔板specific gravity indicator 比重计leaf separator 叶片式隔板lid sealing compound 密封剂/封口剂sealing gasket 密封衬垫/垫圈lid 蓄电池盖set of lid 系列的盖方通盖板cover board底板solepiece钢珠steel ball压钢珠press steel ball防爆阀valve preventing explosion大电流(倍率)放电discharge in high rate current标称电压Normal voltage标称容量normal capacity放电容量discharge capacity充电上限电压limited voltage in charge放电下限电压更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=6terminating voltage in discharge 恒流充电constant current charge恒压充电constant voltage charge恒流放电constant current discharge放电曲线discharge curve充电曲线charge curve放电平台discharge voltage plateau容量衰减capacity attenuation起始容量initial discharge capacity流水线pipelining传送带carrying tape焊极耳welding the current collector卷绕wind叠片layer贴胶带stick tape点焊spot welding超声焊ultrasonic weldingThe terminating voltage in discharge of the battery is 3.0 volt. The limited voltage in charge of the battery is 4.2 volt.三元素Nickle-Cobalt-Manganese Lithium Oxidethree elements materials钴酸锂Cobalt Lithium Oxide锰酸锂Manganese Lithium Oxide石墨graphite更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=6烘箱oven真空烘箱vacuum oven搅拌机mixing devicevacuum mixing device涂布机coating equipment裁纸刀paper knife ,,,,,,cutting knife分条机equipment for cutting big piece to much pieces辊压机roll press equipment电阻点焊机spot welding machine超声点焊机ultrasonic spot welding machine卷绕机winder自动叠片机auto laminating machine激光焊机laser welding machine注液机infusing machine真空注液机vacuum infusion machine预充柜pre-charge equipment化成柜formation systems分容柜grading systems测试柜testing systems内阻仪battery inner resistance tester万用表multimeter转盘式真空封口机turntable type vacuum sealing machine更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=6自动冲膜机automatic aluminum membrane shaper序号首字母英文中文1 A aging 老化2 B battery charger3 black-fleck 黑斑4 C cap 盖板充电器5 capacity density 能量密度6 capacity grading 分容7 cathode tab welding 极耳超焊8 cell 电芯9 charge(capacity) retention 荷电(容量)保持10 checking code 检码11 concave spot 凹点12 constant current charge 恒流充电13 constant current discharge 恒流放电14 constant voltage charge 恒压充电15 corrective measures 纠正措施16 crack 裂纹17 cut-off voltage 终止电压18 cycle life 循环寿命19 D dark trace 暗痕20 degrade 降级21 dent 凹痕22 discharge depth 放电深度23 distortion 变形24 drape 打折25 E Electrical and MechanicalServices Department 机电部26 electrolyte 电解,电解液27 empaistic 压纹28 end-off voltage 放电截止电压29 environmentally friendly 对环境友好30 equipment first inspection 设备首检31 erode 腐蚀32 explosion-proof line 防爆线33 F first inspection 首检34 formation 化成35 fracture 断裂36 I inspection 检验37 insulate 绝缘38 internal resistance 内阻更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=639 J jellyroll 卷芯40 joint 接缝,结合点41 L laser deflecting 偏光42 laser reticle 激光刻线43 laser welding-flatwise weld 激光焊接-平焊laser welding-standing weld 激光焊接-立焊44 leakage 漏液45 leak-checking 测漏46 leaving out of welding 漏焊47 limited charge voltage 充电限制电压48 local action 自放电49 M margin turnly 翘边50 measuring the dimension of cells 电芯卡尺寸51 meet requirement 达到要求52 memory effects 记忆效应53 N nick 划痕54 nominal voltage 标称电压55 notice-board confirmation 看板确认56 nugget 硬块57 O obverse 正面58 open circuit voltage 开路电压59 over charge 过充60 over discharge 过放61 over the thickness 超厚62 P particle 颗粒63 PE membrane PE 膜64 pit 坑点65 placing cells into the box 电芯装盒66 point inspection 点检67 preventive measures 预防措施68 pricking the tapes 扎孔69 process inspection 制程检验70 put the battery piled up 将电芯叠放在一起71 Q qualified products 合格品72 quality assurance 质量保证73 quality control 质量控制74 quality improvement 质量改进75 quality match 品质配对76 quality planning 质量策划77 R rated capacity 额定容量78 recharge 再充电79 refitting the can of cell 电芯壳口整形80 requirment 要求81 reverse 背面,反面更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=682 rework 返工83 ringing cells into pyrocondensation films84 S safety vent 安全阀85 sand aperture 砂眼86 scar 疤痕87 secondary battery 二次电池88 select appearance 选外观sharp-set 批锋89 short circuit checking 测短路90 smudginess 污物91 spot welding by laser 激光点焊92 spot welding place 点焊位置93 spraying the code 喷码94 spur 毛刺95 sticking the PVC cover boards 贴面垫96 storing 陈化97 storing with high voltage 高压储存98 T tabs deflection 极耳歪斜99 tabs excursion 极耳错位100 technics requiment 工艺要求101 U ultrasonic welding 超声波焊接102 ultrasonic welding strength 超焊强度103 unqualified products 不合格品104 W wave 波浪105 working procedure 工序套热缩膜Voltage:Units of measuring electrical current, all batteries are rated in volts DC. (DirectCurrent). This determines how much energy is needed to power your equipment. Voltage plateau:(电压平台)A slow decrease in voltage over a long period of time. As a rule, the plateau extendsfrom the first voltage drop at the start of the discharge to the bend of the curveafter which the voltage drops rapidly at the end.Nominal Voltage(标称电压)The voltage of a battery, as specified by the manufacturer, discharging at aspecified rate and temperature.Working voltage(工作电压)The working voltage of a cell or battery begins at its electrical connections as soon as an electrical consumer is connected to it.Discharging voltage, average voltage (放电电压)更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=6The average discharging voltage is the average value of the dischargingvoltageduring the entire discharging process with a related discharging current.Open circuit voltage (OCV 开路电压)The voltage of a battery when there is no current flowing.Closed-Circuit Voltage (CCV 闭路电压)The potential or voltage of a battery when it is discharging or charging.State of charge:The rate of charge capacity vs. whole capacity.Initial voltage(起始电压)A battery's initial voltage is the working voltage when discharging begins. End-point voltage (End voltage, Cutoff voltage, Final voltage)截止电压Specified closed circuit voltage at which a service output test is terminated. End-of-discharge voltageThe battery voltage when discharge is terminated.End-of-charge voltageThe battery voltage when charge is terminated.Cutoff voltage (V)The battery voltage at which charge or discharge is terminated.Definition: Capacity(容量)The capacity of a cell is defined as how manymilli-amp-hours (mAh) of current the cell canstore and subsequently deliver.One milli-amp (mA) is 1/1000th of an Amp. Somelarger cell capacities are expressed in Amp-hours(Ah).“Rated capacity” is varies with discharge rate,temperature, and cutoff voltage.Rated capacity is different from power or energyExample:If a cell is rated at 1000 mAh, then it can deliverthe following:1000 mA of current for 1 hour500 mA of current for 2 hours200 mA of current for 5 hours2000 mA of current for 1/2 hourDefinition: Energy Density(能量密度,包括体积比能量和质量比能量)The energy density of a cell is a measure of howmuch energy can be stored in the cell per unitvolume or per unit weight.E (watt-hours) = cell voltage x capacity rating更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=6? Energy density per unit volume is called the“volumetric energy density” and is expressed interms of watt-hours/liter (wh/l).Energy density per unit weight is called the“gravimetric energy density” and is expressedin terms of watt-hours/kilogram (wh/kg).These measurements are useful when you aretrying to determine which cell has the mostcapacity per unit volume or weight.1.Self Discharge自放电2.Uniformity of the Li-ion Batteries3.steel strap 钢带4.Burst vent 防爆阀5.Filling port 注液孔锂离子电池的一致性6.spirally wound type cylindrical wound type7.foil 箔圆柱形8.parallel-plate prismatic design 方形叠片式设计Ageing (老化)-Permanent loss of capacity with frequent use orthe passage of time due to unwanted irreversible chemical reactions in the cell.Anode(阳极) - The electrode in an electrochemical cell where oxidation takes place,releasing electrons.During discharge the negative electrode of the cell is the anode.During charge the situation reverses and the positive electrode of the cell is the anode.Cathode(阴极) - The electrode in an electrochemical cell where reduction takesplace, gaining electrons.During discharge the positive electrode of the cell is the cathode. During chargethe situation reverses andthe negative electrode of the cell is the cathode.Cycle (循环)- A single charge and discharge of a battery.Depth of discharge DOD (放电深度)- The ratio of the quantity of electricity orcharge removed from a cell on discharge to its rated capacity.Internal impedance(交流内阻) - Resistance to the flow of AC current within a cell.It takes into account the capacitive effect of the plates forming the electrodes.Internal resistance(直流内阻)- Resistance to the flow of DC electric current withina cell,causing a voltage drop across the cell in closed circuit proportional to the currentdrain from the cell.A low internal impedance is usually required for a high rate cell.更多电池资讯:/电池产品认证指导网站:/ekeyword.php?ekeyid=6锂离子电池的内阻英语概念到底用哪个概念,是Internal resistance还是Internalimpedance,一些电池说明书内阻用 Internal resistance,也有的用 Internal impedance,我认为 Internal impedance 较好些,因为国内测的电池内阻基本都是交流内阻,而外文也有这样定义的(我在别的帖子也粘贴过):Internal impedance(交流内阻) - Resistance to the flow of AC current within a cell.It takes into account the capacitive effect of the plates forming theelectrodes.Internal resistance(直流内阻)- Resistance to the flow of DC electric current withina cell,causing a voltage drop across the cell in closed circuit proportional to the currentdrain from the cell.A low internal impedance is usually required for a high rate cell.在 IEC6196002 中,只定义为 Internal resistance,而用交流的方法测得的内阻,叫Internala.c. resistance(交流内阻)用直流的方法测得的内阻,叫 Internal d.c. resistance(直流内阻),其实 Internal a.c.resistance 测得就是阻抗,这样看来不如用 Internal impedance(交流内阻)和 Internal resistance (直流内阻)这两个概念把它们进行分清,以免混淆。

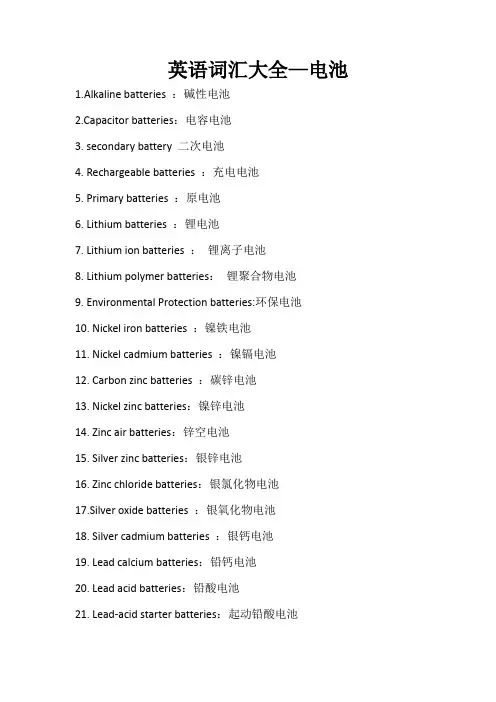

英语词汇大全—电池1.Alkaline batteries :碱性电池2.Capacitor batteries:电容电池3. secondary battery 二次电池4. Rechargeable batteries :充电电池5. Primary batteries :原电池6. Lithium batteries :锂电池7. Lithium ion batteries :锂离子电池8. Lithium polymer batteries:锂聚合物电池9. Environmental Protection batteries:环保电池10. Nickel iron batteries :镍铁电池11. Nickel cadmium batteries :镍镉电池12. Carbon zinc batteries :碳锌电池13. Nickel zinc batteries:镍锌电池14. Zinc air batteries:锌空电池15. Silver zinc batteries:银锌电池16. Zinc chloride batteries:银氯化物电池17.Silver oxide batteries :银氧化物电池18. Silver cadmium batteries :银钙电池19. Lead calcium batteries:铅钙电池20. Lead acid batteries:铅酸电池21. Lead-acid starter batteries:起动铅酸电池22. Lead-acid traction batteies:牵引用铅酸电池23. Aircraft lead-acid batteries:航空用铅酸电池24. Sealed lead acid batteries:密封铅酸电池25. Lead-acid batteries for stationary valve-regulated:固定型阀控密封式铅酸蓄电池26. small-sized valve-regulated lead-acid batteries:小型阀控密封式铅酸电池27. Lead-acid batteries for motorcycles:摩托车用铅酸电池28. Lead-acid batteries for disel locomotive:内燃机车用铅酸电池29. Lead-acid batteries for electric road vehicles:电动道路车辆用铅酸电池。

[单体]电池cell原电池primary cell蓄电池secondary cell电池battery燃料电池fuel cell锂电池lithium cell熔融盐电池molten salt cell碱性电池alkaline cell固体电解质电池solid electrolyte cell非水电解质电池non aqueous cell指示电池pilot cellOEM电池OEM battery替换电池replacement battery储备电池reserve cell应急电池emergency battery缓冲电池buffer battery; back-up battery电压标准电池standard voltage cell韦斯顿电压标准电池Weston standard voltage cell 激活activation未激活的inactivated全密封电池hermetically /sealed cell极板plate涂膏式极板pasted plate极群plate group负极板negative plate正极板positive plate管式极板tubular plate极群组plate pack极板对plate pair隔离物spacer隔板(plate)separator阀valve电池外壳cell can电池槽cell case电池盖cell lid电池封口剂lid sealing compound整体电池monobloc battery整体槽monobloc container边界绝缘体edge insulator外套jacket[单体电池]电极(cell)electrode端子terminal端子保护套terminal protector;terminal cover 负极端子negative terminal正极端子positive terminal电极的活性表面active surface of an electrode阳极anode阴极cathode电解质electrolyte电解质爬渗electrolyte creep电解质保持能力electrolyte containment泄漏leakage活性物质active material活性物质混合物active material mix电池组合箱battery tray输出电缆output cable连接件connector矩形(的)prismatic圆柱形电池cylindrical cell扣式电池button cell;coin cell电化学反应electrochemical reaction电极极化electrode polarization反极polarity reversal cell reversal结晶极化crystallization polarization活化极化activation polarization阳极极化anodic polarization阴极极化cathodic polarization浓差极化concentration polarization; mass transfer polarization欧姆极化ohmic polarization反应极化reaction polarization阳极反应anodic reaction阴极反应cathodic reaction副反应side reaction; secondary reaction;容量(电池的)capacity(for cells or batteries)额定容量rated capacity剩余容量residual capacity体积(比)容量volumetric capacity温度系数temperature coefficient(of the capacity)质量(比)容量gravimetric capacity面积(比)容量areic capacity电池能量battery energy(电池)体积(比)能量volumic energy(related to battery)(电池)放电discharge(of a battery)放电电流discharge current放电率discharge rate短路电流(电池的)short-circuit current(related to cells or batteries)自放电self discharge放电电压(电池的)discharge voltage(related to cells or batteries)闭路电压closed circuit voltage负载电压(拒用)on load voltage (deprecated)初始放电电压initial discharge voltage初始闭路电压initial closed circuit voltage初始负载电压(拒用)initial on load voltage(deprecated)终止电压end-of-discharge voltage; final voltage; cut-off voltage; end-point voltage 标称电压nominal voltage开路电压(电池的)open-circuit voltage(related to cells or batteries)开路电压温度系数temperature coefficient of the open-circuit voltage比特性specific characteristic荷电保持能力charge retention容量保持能力capacity retention表观内阻internal apparent resistance剩余活性物质residual active mass使用质量service mass并联parallel connection并串联parallel series connection串联series connection串并联series parallel connection标称值nominal value电池耐久性battery endurance贮存试验storage test使用寿命service life贮存寿命storage life; shelf life连续工作试验continuous service test金属-空气电池air metal battery碱性锌-空气电池alkaline zinc air battery碱性锌-二氧化锰电池alkaline zinc manganese dioxide battery锌-氧化银电池zinc silver oxide battery中性锌-空气电池neutral electrolyte zinc air battery氯化锌电池zinc chloride battery锌-碳电池zinc carbon battery诸如勒克朗谢电池或氯化锌电池之类的原电池。

Alkaline batteries :碱性电池Capacitor batteries:电容电池Carbon zinc batteries :碳锌电池Lead acid batteries:铅酸电池Lead calcium batteries:铅钙电池Lithium batteries :锂电池Lithium ion batteries :锂离子电池Lithium polymer batteries:锂聚合物电池Nickel cadmium batteries :镍镉电池Nickel iron batteries :镍铁电池Nickel metal hydride batteries :金属氧化物镍氢电池/镍氢电池Nickel zinc batteries:镍锌电池Primary batteries :原电池Rechargeable batteries :充电电池Sealed lead acid batteries:密封铅酸电池Silver cadmium batteries :银钙电池Silver oxide batteries :银氧化物电池Silver zinc batteries:银锌电池Zinc chloride batteries:银氯化物电池Zinc air batteries:锌空电池Environmental Protection batteries:环保电池Lithium batteries :锂电池Lithium ion batteries :锂离子电池Lithium polymer batteries:锂聚合物电池铅酸蓄电池Lead-acid battery起动铅酸电池Lead-acid starter batteries摩托车用铅酸电池Lead-acid batteries for motorcycles内燃机车用铅酸电池Lead-acid batteries for disel locomotive电动道路车辆用铅酸电池Lead-acid batteries for electric road vehicles小型阀控密封式铅酸电池small-sized valve-regulated lead-acid batteries航空用铅酸电池Aircraft lead-acid batteries固定型阀控密封式铅酸蓄电池Lead-acid batteries for stationary valve-regulated 铅酸电池用极板plate for lead-acid battery铅锭lead ingots牵引用铅酸电池Lead-acid traction batteies电解液激活蓄电池electrolyte activated batteryvent valve 排气阀filling device for pleral cells 电池组填充装置negative electrode 负电极negative plate 负极板addition reagent for negative plate 负极板添加剂indicator 指示器top cover 上盖vent plug 液孔塞expanded grid 扩展式板栅specific gravity indicator 比重指示器electrolyte level control pipe 电解液液面控制管electrolyte level indicator 电解液液面指示器electrolyte level sensor 电解液液面传感器hard rubber container 硬橡胶槽envelope separator 包状隔板woven cloth tube 纺布管spongy lead 海绵状铅partition 隔壁over the partition type 越过隔壁型through the partition type 贯通隔壁贯通型separator 隔板(1)battery rack(2)battery stand(3)battery stillage 蓄电池架/蓄电池底垫active material 活性物质glass fiber separator 玻璃纤维隔板glass mat 玻璃纤维绵glass mat tube 玻璃纤维绵管spacing washer 间隔垫圈reinforced fiber separator 强化纤维隔板polarity mark plate 极性标记板pole 极柱pole insulator 极柱绝缘子pole nut 极柱螺母plate 极板plate foot 极板足plate supporter 极板支撑件element 极板群/极群组pole bolt 极柱螺栓plate lug 极板耳dilute sulfuric acid 稀硫酸steel can 金属罐steel container 金属蓄电池槽(1)madribs(2)element rest 鞍子/极群组座tubular plate 管状极板gelled electrolyte 胶体电解液grid 板栅caution label 警告标签synthetic resin separator 合成树脂隔板plastics container 塑料蓄电池槽synthetic fiber separator 合成纤维隔板connector sunken type 沉没型连接器connetor exposed type 露出型连接器safety valve test 安全阀测试ampere-hour efficency 安时效率one charge distance range 一次充电行程gas recombination on negative electrode type 阴极气体再化合型/阴极气体复合型cut-off discharge 终止放电/截止放电(1)specific characteristic (2)energy density (1)比特性(2)能量密度recovering charge 恢复充电(1)open circuit voltage(2)off-load voltage 开路电压/空载电压overcharge 过充电gassing 析气overcharge life test 过充电寿命试验accelerated life test 加速寿命试验active material utilization 活性物质利用率theoretical capacity of active material 活性物质的理论容量over discharge 过放电intermittent discharge 间歇放电full charge 完全充电full discharge 完全放电reverse charge 反充电/反向充电quick charge 快速放电allowable minimum voltage 允许最小电压equalizing charge 均衡充电creeping 蠕变group voltage 组电压shallow cycle endurance 轻负荷寿命/轻负荷循环寿命characteristic of electrolyte decrease 电解液减少特性nominal voltage 标称电压high rate discharge 高率放电high rate discharge characteristic 高率放电特性5 second voltage at discharge 放电5 秒电压(1)cold cranking ampere(2)cold cranking performance(1)冷启动电流(2)冷启动性能cycle life test 循环寿命测试maximum voltage at discharge 最大放电电压30 second voltage at discharge 放电30 秒电压residual capacity 残存容量(1)hour rate(2) discharge rate (1)小时率(2)放电率(1) self discharge (2) local action (1)自放电(2)局部自放电(1) self discharge rate(2) local action rate (1)自放电率(2)局部自放电率actual capacity 实际容量(1)starting capability(2)cranking ability 启动能力cranking current 启动电流battery clamp test 电池夹钳测试power density 功率密度momentary discharge 瞬间放电modified constant voltage charge 修正恒定电压充电initial capacity 初始容量gas recombination by catalyser type 触媒气体复合式initialcharge 初始充电viberation test 振动试验predetermined voltage 预定电压total voltage 总电压activation test for dry charged battery 干式荷电蓄电池活化试验salting 盐析earthquake-proof characteristics 防震性能dielectric voltage withstand test 电介质耐压试验short time discharge 短时间放电escaped acid mist test 酸雾逸出测试terminal voltage 端子电压cell voltage 单电池电压step charge 阶段充电short-circuit current 短路电流storage test 保存测试high rate discharge at low temperature 低温高率放电rated voltage 额定电压rated capacity 额定容量fixed resistance discharge 定阻抗放电constant voltage charge 恒压充电constant voltage life test 恒压寿命测试constant current charge 恒流充电constant voltage constant current charge 恒流恒压充电constant current discharge 恒流放电constant watt discharge 恒功率放电low rate discharge characteristics 低率放电特征trickle charge 涓流充电trickle charge current 涓流充电电流trickle charge life test 涓流充电寿命测试thermal runaway 热失控driving pattern test 运行测试capacity in driving pattern test 运行测试boost charge 急充电floating charge 浮充电floating charge voltage 浮充电电压floating charge current 浮充电电流(1)mean voltage (2)average voltage 平均电压on-load voltage 负载电压discharge duration time 放电持续时间(1)final voltage(2)cut-off voltage(3)end voltage 终止电压/截止电压depth of discharge 放电深度discharge voltage 放电电压discharge current 放电电流discharge current density 放电电流密度discharge watt-hour 放电瓦时discharge characteristics 放电特性discharged ampere-hour 放电安时explosion proof test 防爆测试auxiliary charge 补充电maintenance factor 维护率storage characteristics 保存特性gas recombinating efficiency 气体复合效率/气体再化合效率charge 充电charge acceptance test 充电可接受性试验start-of-charge current 充电开始电流charge efficiency 充电效率end-of-charge voltage 充电结束电压specific gravity of electrolyte at the end of charge 充电结束时电解液比重charge voltage 充电电压charge current 充电电流charged watt-hour 充电瓦时charge characteristic 充电特性charge ampere-hour 充电安时deep cycle endurance 重负荷循环寿命/重复合寿命weight engergy density 重量能量密度rubber pad 橡胶垫lower level line 下液面线side terminal 侧端子collective exhaust unit 公共的排放单元sintered plaque 烧结极板sintered separator 烧结隔板sintered plate 烧结极板catalyst plug 催化塞spine 芯骨strap 带spacer 隔离物insulating tube 绝缘管intercell connector 连接线/连接条connector cover 连接管盖float mounted plug 浮动安装的栓(1)pasted plate (2)grid type plate 涂膏式极板braidd tube 编织管(1)flame-arrester vent plug (2)flam-retardant vent plug 安全塞explosion and splash proof construction 防爆防溅结构baffle 保护板pocket type plate 袋式极板bottom hole-down 底孔向下(固定)bolt fastening terminal 螺栓连接端子male blade 阳片monoblock container 整体槽positive electrode 正极positive plate 正极板leading wire terminal 引线端子retainer mat 止动垫片ribbed separator 肋隔板(1)jumping wire (2)inter low wire 跳线end plate 端板filling plug 注液塞plante plate 形成式极板/普朗特极板tubular plate 管式极板low electric resistance separator 低电阻隔板tapered terminal post 锥形接线柱electrolyte 电解液container 蓄电池槽/蓄电池壳set of container 成套蓄电池槽level-scope mounted plug 透视塞/透视栓handle 手柄jug 取液管(1)connector;(2)plug concent (1)连接器;(2)插座式连接器connector wire 连接线connecting bar 连杆connecting bar cover 连杆帽lead 引线/连接线edge insulator 绝缘卡side frame 侧框架battery cubicle 蓄电池箱perforated separator 多孔隔板burning rod (铅)焊条terminal 端子terminal connector 端子连接条terminal cover 端子盖terminal base 端子座tab 接线片lead bushing 铅套corrugated separator 波形隔板(1)lead dioxide;(2)lead peroxide (1)二氧化铅;(2)过氧化铅(1)woven separator;(2)nonwoven separator (1)织物隔板;(2)非织物隔板vent hole 通气孔exhaust tube 排气管antipolar mass 反极性物质output cable 输出电缆microporous rubber separator 微孔像胶隔板specific gravity indicator 比重计leaf separator 叶片式隔板lid sealing compound 密封剂/封口剂sealing gasket 密封衬垫/垫圈lid 蓄电池盖set of lid 系列的盖方通盖板cover board底板solepiece钢珠steel ball压钢珠press steel ball防爆阀valve preventing explosion大电流(倍率)放电discharge in high rate current标称电压Normal voltage标称容量normal capacity放电容量discharge capacity充电上限电压limited voltage in charge放电下限电压terminating voltage in discharge恒流充电constant current charge恒压充电constant voltage charge恒流放电constant current discharge放电曲线discharge curve充电曲线charge curve放电平台discharge voltage plateau容量衰减capacity attenuation起始容量initial discharge capacity流水线pipelining传送带carrying tape焊极耳welding the current collector卷绕wind叠片layer贴胶带stick tape点焊spot welding超声焊ultrasonic weldingThe terminating voltage in discharge of the battery is 3.0 volt. The limited voltage in charge of the battery is 4.2 volt.三元素Nickle-Cobalt-Manganese Lithium Oxidethree elements materials钴酸锂Cobalt Lithium Oxide锰酸锂Manganese Lithium Oxide石墨graphite烘箱oven真空烘箱vacuum oven搅拌机mixing devicevacuum mixing device涂布机coating equipment裁纸刀paper knife ,,,,,,cutting knife分条机equipment for cutting big piece to much pieces 辊压机roll press equipment电阻点焊机spot welding machine超声点焊机ultrasonic spot welding machine卷绕机winder自动叠片机auto laminating machine激光焊机laser welding machine注液机infusing machine真空注液机vacuum infusion machine预充柜pre-charge equipment化成柜formation systems分容柜grading systems测试柜testing systems内阻仪battery inner resistance tester万用表multimeter转盘式真空封口机turntable type vacuum sealing machine自动冲膜机automatic aluminum membrane shaper序号首字母英文中文1 A aging 老化2 B battery charger 充电器3 black-fleck 黑斑4 C cap 盖板5 capacity density 能量密度6 capacity grading 分容7 cathode tab welding 极耳超焊8 cell 电芯9 charge(capacity) retention 荷电(容量)保持10 checking code 检码11 concave spot 凹点12 constant current charge 恒流充电13 constant current discharge 恒流放电14 constant voltage charge 恒压充电15 corrective measures 纠正措施16 crack 裂纹17 cut-off voltage 终止电压18 cycle life 循环寿命19 D dark trace 暗痕20 degrade 降级21 dent 凹痕22 discharge depth 放电深度23 distortion 变形24 drape 打折25 E Electrical and MechanicalServices Department 机电部26 electrolyte 电解,电解液27 empaistic 压纹28 end-off voltage 放电截止电压29 environmentally friendly 对环境友好30 equipment first inspection 设备首检31 erode 腐蚀32 explosion-proof line 防爆线33 F first inspection 首检34 formation 化成35 fracture 断裂36 I inspection 检验37 insulate 绝缘38 internal resistance 内阻39 J jellyroll 卷芯40 joint 接缝,结合点41 L laser deflecting 偏光42 laser reticle 激光刻线43 laser welding-flatwise weld 激光焊接-平焊laser welding-standing weld 激光焊接-立焊44 leakage 漏液45 leak-checking 测漏46 leaving out of welding 漏焊47 limited charge voltage 充电限制电压48 local action 自放电49 M margin turnly 翘边50 measuring the dimension of cells 电芯卡尺寸51 meet requirement 达到要求52 memory effects 记忆效应53 N nick 划痕54 nominal voltage 标称电压55 notice-board confirmation 看板确认56 nugget 硬块57 O obverse 正面58 open circuit voltage 开路电压59 over charge 过充60 over discharge 过放61 over the thickness 超厚62 P particle 颗粒63 PE membrane PE 膜64 pit 坑点65 placing cells into the box 电芯装盒66 point inspection 点检67 preventive measures 预防措施68 pricking the tapes 扎孔69 process inspection 制程检验70 put the battery piled up 将电芯叠放在一起71 Q qualified products 合格品72 quality assurance 质量保证73 quality control 质量控制74 quality improvement 质量改进75 quality match 品质配对76 quality planning 质量策划77 R rated capacity 额定容量78 recharge 再充电79 refitting the can of cell 电芯壳口整形80 requirment 要求81 reverse 背面,反面82 rework 返工83 ringing cells into pyrocondensation films 套热缩膜84 S safety vent 安全阀85 sand aperture 砂眼86 scar 疤痕87 secondary battery 二次电池88 select appearance 选外观sharp-set 批锋89 short circuit checking 测短路90 smudginess 污物91 spot welding by laser 激光点焊92 spot welding place 点焊位置93 spraying the code 喷码94 spur 毛刺95 sticking the PVC cover boards 贴面垫96 storing 陈化97 storing with high voltage 高压储存98 T tabs deflection 极耳歪斜99 tabs excursion 极耳错位100 technics requiment 工艺要求101 U ultrasonic welding 超声波焊接102 ultrasonic welding strength 超焊强度103 unqualified products 不合格品104 W wave 波浪105 working procedure 工序Voltage:Units of measuring electrical current, all batteries are rated in volts DC. (Direct Current). This determines how much energy is needed to power your equipment. Voltage plateau:(电压平台)A slow decrease in voltage over a long period of time. As a rule, the plateau extends from the first voltage drop at the start of the discharge to the bend of the curve after which the voltage drops rapidly at the end.Nominal Voltage(标称电压)The voltage of a battery, as specified by the manufacturer, discharging at a specified rate and temperature.Working voltage(工作电压)The working voltage of a cell or battery begins at its electrical connections assoon as an electrical consumer is connected to it.Discharging voltage, average voltage (放电电压)The average discharging voltage is the average value of the discharging voltage during the entire discharging process with a related discharging current.Open circuit voltage (OCV 开路电压)The voltage of a battery when there is no current flowing.Closed-Circuit Voltage (CCV 闭路电压)The potential or voltage of a battery when it is discharging or charging.State of charge:The rate of charge capacity vs. whole capacity.Initial voltage(起始电压)A battery's initial voltage is the working voltage when discharging begins. End-point voltage (End voltage, Cutoff voltage, Final voltage)截止电压Specified closed circuit voltage at which a service output test is terminated. End-of-discharge voltageThe battery voltage when discharge is terminated.End-of-charge voltageThe battery voltage when charge is terminated.Cutoff voltage (V)The battery voltage at which charge or discharge is terminated.Definition: Capacity(容量)? The capacity of a cell is defined as how manymilli-amp-hours (mAh) of current the cell canstore and subsequently deliver.? One milli-amp (mA) is 1/1000th of an Amp. Somelarger cell capacities are expressed in Amp-hours(Ah).? “Rated capacity” is varies with discharge rate,temperature, and cutoff voltage.? Rated capacity is different from power or energy? Example:? If a cell is rated at 1000 mAh, then it can deliverthe following:? 1000 mA of current for 1 hour? 500 mA of current for 2 hours? 200 mA of current for 5 hours? 2000 mA of current for 1/2 hourDefinition: Energy Density(能量密度,包括体积比能量和质量比能量)? The energy density of a cell is a measure of howmuch energy can be stored in the cell per unitvolume or per unit weight.? E (watt-hours) = cell voltage x capacity rating? Energy density per unit volume is called the“volumetric energy density” and is expressed interms of watt-hours/liter (wh/l).? Energy density per unit weight is called the“gravimetric energy density” and is expressedin terms of watt-hours/kilogram (wh/kg).? These measurements are useful when you aretrying to determine which cell has the mostcapacity per unit volume or weight.1.Self Discharge 自放电2.Uniformity of the Li-ion Batteries 锂离子电池的一致性3.steel strap 钢带4.Burst vent 防爆阀5.Filling port 注液孔6.spirally wound type cylindrical wound type 圆柱形7.foil 箔8.parallel-plate prismatic design 方形叠片式设计Ageing (老化)- Permanent loss of capacity with frequent use orthe passage of time due to unwanted irreversible chemical reactions in the cell.Anode(阳极)- The electrode in an electrochemical cell where oxidation takes place, releasing electrons.During discharge the negative electrode of the cell is the anode.During charge the situation reverses and the positive electrode of the cell is the anode.Cathode(阴极)- The electrode in an electrochemical cell where reduction takes place, gaining electrons.During discharge the positive electrode of the cell is the cathode. During chargethe situation reverses andthe negative electrode of the cell is the cathode.Cycle (循环)- A single charge and discharge of a battery.Depth of discharge DOD (放电深度)- The ratio of the quantity of electricity or charge removed from a cell on discharge to its rated capacity.Internal impedance(交流内阻)- Resistance to the flow of AC current within a cell. It takes into account the capacitive effect of the plates forming the electrodes.Internal resistance(直流内阻)- Resistance to the flow of DC electric current within a cell,causing a voltage drop across the cell in closed circuit proportional to the currentdrain from the cell.A low internal impedance is usually required for a high rate cell.锂离子电池的内阻英语概念到底用哪个概念,是Internal resistance 还是Internal impedance,一些电池说明书内阻用Internal resistance,也有的用Internal impedance,我认为Internal impedance 较好些,因为国内测的电池内阻基本都是交流内阻,而外文也有这样定义的(我在别的帖子也粘贴过):Internal impedance(交流内阻)- Resistance to the flow of AC current within a cell.It takes into account the capacitive effect of the plates forming the electrodes.Internal resistance(直流内阻)- Resistance to the flow of DC electric current withina cell,causing a voltage drop across the cell in closed circuit proportional to the currentdrain from the cell.A low internal impedance is usually required for a high rate cell.在IEC6196002 中,只定义为Internal resistance,而用交流的方法测得的内阻,叫Internal a.c. resistance(交流内阻)用直流的方法测得的内阻,叫Internal d.c. resistance(直流内阻),其实Internal a.c. resistance 测得就是阻抗,这样看来不如用Internal impedance(交流内阻)和Internal resistance (直流内阻)这两个概念把它们进行分清,以免混淆。

Alkaline batteries :碱性电池Capacitor batteries:电容电池Carbon zinc batteries :碳锌电池Lead acid batteries:铅酸电池Lead calcium batteries:铅钙电池Lithium batteries :锂电池Lithium ion batteries :锂离子电池Lithium polymer batteries:锂聚合物电池铅酸蓄电池Lead-acid battery起动铅酸电池Lead-acid starter batteries摩托车用铅酸电池Lead-acid batteries for motorcycles内燃机车用铅酸电池Lead-acid batteries for disel locomotive电动道路车辆用铅酸电池Lead-acid batteries for electric road vehicles小型阀控密封式铅酸电池small-sized valve-regulated lead-acid batteries航空用铅酸电池Aircraft lead-acid batteries固定型阀控密封式铅酸蓄电池Lead-acid batteries for stationary valve-regulated 铅酸电池用极板plate for lead-acid battery铅锭lead ingots牵引用铅酸电池Lead-acid traction batteies电解液激活蓄电池electrolyte activated batteryvent valve 排气阀filling device for pleral cells 电池组填充装置negative electrode 负电极negative plate 负极板addition reagent for negative plate 负极板添加剂indicator 指示器top cover 上盖vent plug 液孔塞expanded grid 扩展式板栅specific gravity indicator 比重指示器electrolyte level control pipe 电解液液面控制管electrolyte level indicator 电解液液面指示器electrolyte level sensor 电解液液面传感器hard rubber container 硬橡胶槽envelope separator 包状隔板woven cloth tube 纺布管spongy lead 海绵状铅partition 隔壁over the partition type 越过隔壁型through the partition type 贯通隔壁贯通型separator 隔板(1)battery rack(2)battery stand(3)battery stillage 蓄电池架/蓄电池底垫active material 活性物质glass fiber separator 玻璃纤维隔板glass mat 玻璃纤维绵glass mat tube 玻璃纤维绵管spacing washer 间隔垫圈reinforced fiber separator 强化纤维隔板polarity mark plate 极性标记板pole 极柱pole insulator 极柱绝缘子pole nut 极柱螺母plate 极板plate foot 极板足plate supporter 极板支撑件element 极板群/极群组pole bolt 极柱螺栓plate lug 极板耳dilute sulfuric acid 稀硫酸steel can 金属罐steel container 金属蓄电池槽(1)madribs(2)element rest 鞍子/极群组座tubular plate 管状极板gelled electrolyte 胶体电解液grid 板栅caution label 警告标签synthetic resin separator 合成树脂隔板plastics container 塑料蓄电池槽synthetic fiber separator 合成纤维隔板connector sunken type 沉没型连接器connetor exposed type 露出型连接器safety valve test 安全阀测试ampere-hour efficency 安时效率one charge distance range 一次充电行程gas recombination on negative electrode type 阴极气体再化合型/阴极气体复合型cut-off discharge 终止放电/截止放电(1)specific characteristic (2)energy density (1)比特性(2)能量密度recovering charge 恢复充电(1)open circuit voltage(2)off-load voltage 开路电压/空载电压overcharge 过充电gassing 析气overcharge life test 过充电寿命试验accelerated life test 加速寿命试验active material utilization 活性物质利用率theoretical capacity of active material 活性物质的理论容量over discharge 过放电intermittent discharge 间歇放电full charge 完全充电full discharge 完全放电reverse charge 反充电/反向充电quick charge 快速放电allowable minimum voltage 允许最小电压equalizing charge 均衡充电creeping 蠕变group voltage 组电压shallow cycle endurance 轻负荷寿命/轻负荷循环寿命characteristic of electrolyte decrease 电解液减少特性nominal voltage 标称电压high rate discharge 高率放电high rate discharge characteristic 高率放电特性5 second voltage at discharge 放电5秒电压(1)cold cranking ampere(2)cold cranking performance (1)冷启动电流(2)冷启动性能cycle life test 循环寿命测试maximum voltage at discharge 最大放电电压30 second voltage at discharge 放电30秒电压residual capacity 残存容量(1)hour rate(2) discharge rate (1)小时率(2)放电率(1) self discharge (2) local action (1)自放电(2)局部自放电(1) self discharge rate(2) local action rate (1)自放电率(2)局部自放电率actual capacity 实际容量(1)starting capability(2)cranking ability 启动能力cranking current 启动电流battery clamp test 电池夹钳测试power density 功率密度momentary discharge 瞬间放电modified constant voltage charge 修正恒定电压充电initial capacity 初始容量gas recombination by catalyser type 触媒气体复合式initialcharge 初始充电viberation test 振动试验predetermined voltage 预定电压total voltage 总电压activation test for dry charged battery 干式荷电蓄电池活化试验salting 盐析earthquake-proof characteristics 防震性能dielectric voltage withstand test 电介质耐压试验short time discharge 短时间放电escaped acid mist test 酸雾逸出测试terminal voltage 端子电压cell voltage 单电池电压step charge 阶段充电short-circuit current 短路电流storage test 保存测试high rate discharge at low temperature 低温高率放电rated voltage 额定电压rated capacity 额定容量fixed resistance discharge 定阻抗放电constant voltage charge 恒压充电constant voltage life test 恒压寿命测试constant current charge 恒流充电constant voltage constant current charge 恒流恒压充电constant current discharge 恒流放电constant watt discharge 恒功率放电low rate discharge characteristics 低率放电特征trickle charge 涓流充电trickle charge current 涓流充电电流trickle charge life test 涓流充电寿命测试thermal runaway 热失控driving pattern test 运行测试capacity in driving pattern test 运行测试boost charge 急充电floating charge 浮充电floating charge voltage 浮充电电压floating charge current 浮充电电流(1)mean voltage (2)average voltage 平均电压on-load voltage 负载电压discharge duration time 放电持续时间(1)final voltage(2)cut-off voltage(3)end voltage 终止电压/截止电压depth of discharge 放电深度discharge voltage 放电电压discharge current 放电电流discharge current density 放电电流密度discharge watt-hour 放电瓦时discharge characteristics 放电特性discharged ampere-hour 放电安时explosion proof test 防爆测试auxiliary charge 补充电maintenance factor 维护率storage characteristics 保存特性gas recombinating efficiency 气体复合效率/气体再化合效率charge 充电charge acceptance test 充电可接受性试验start-of-charge current 充电开始电流charge efficiency 充电效率end-of-charge voltage 充电结束电压specific gravity of electrolyte at the end of charge 充电结束时电解液比重charge voltage 充电电压charge current 充电电流charged watt-hour 充电瓦时charge characteristic 充电特性charge ampere-hour 充电安时deep cycle endurance 重负荷循环寿命/重复合寿命weight engergy density 重量能量密度rubber pad 橡胶垫lower level line 下液面线side terminal 侧端子collective exhaust unit 公共的排放单元sintered plaque 烧结极板sintered separator 烧结隔板sintered plate 烧结极板catalyst plug 催化塞spine 芯骨strap 带spacer 隔离物insulating tube 绝缘管intercell connector 连接线/连接条connector cover 连接管盖float mounted plug 浮动安装的栓(1)pasted plate (2)grid type plate 涂膏式极板braidd tube 编织管(1)flame-arrester vent plug (2)flam-retardant vent plug 安全塞explosion and splash proof construction 防爆防溅结构baffle 保护板pocket type plate 袋式极板bottom hole-down 底孔向下(固定)bolt fastening terminal 螺栓连接端子male blade 阳片monoblock container 整体槽positive electrode 正极positive plate 正极板leading wire terminal 引线端子retainer mat 止动垫片ribbed separator 肋隔板(1)jumping wire (2)inter low wire 跳线end plate 端板filling plug 注液塞plante plate 形成式极板/普朗特极板tubular plate 管式极板low electric resistance separator 低电阻隔板tapered terminal post 锥形接线柱electrolyte 电解液container 蓄电池槽/蓄电池壳set of container 成套蓄电池槽level-scope mounted plug 透视塞/透视栓handle 手柄jug 取液管(1)connector;(2)plug concent (1)连接器;(2)插座式连接器connector wire 连接线connecting bar 连杆connecting bar cover 连杆帽lead 引线/连接线edge insulator 绝缘卡side frame 侧框架battery cubicle 蓄电池箱perforated separator 多孔隔板burning rod (铅)焊条terminal 端子terminal connector 端子连接条terminal cover 端子盖terminal base 端子座tab 接线片lead bushing 铅套corrugated separator 波形隔板(1)lead dioxide;(2)lead peroxide (1)二氧化铅;(2)过氧化铅(1)woven separator;(2)nonwoven separator (1)织物隔板;(2)非织物隔板vent hole 通气孔exhaust tube 排气管antipolar mass 反极性物质output cable 输出电缆microporous rubber separator 微孔像胶隔板specific gravity indicator 比重计leaf separator 叶片式隔板lid sealing compound 密封剂/封口剂sealing gasket 密封衬垫/垫圈lid 蓄电池盖set of lid 系列的盖1.精滤器secondary filter high efficiency filter2、反渗透装置主机reverse osmosis unit3、反渗透膜reverse osmosis membrane4、数显示电导仪digital conductivity apparatus5、面板式流量计panel type flow meter6、混合离子交换器mixed-ion exchanger7、配套树脂supporting resin8、732阴树脂732 negative resin9、酸碱再生装置acid and alkali regenerative unit10、直线型铅碇输送机linear type lead ingot conveyer11、自动恒温熔铅炉melting furnace with automatic constant temperature12、铅棒冷却槽lead stick cooling tank13、铅粉视密度lead powder apparent density14、卸料阀discharge valve15、布风屏cloth besel锂离子电池专业英语和大家分享一下,有不足的欢迎大家补充!方通盖板cover board底板solepiece钢珠steel ball压钢珠press steel ball防爆阀valve preventing explosion大电流(倍率)放电discharge in high rate current标称电压Normal voltage标称容量normal capacity放电容量discharge capacity充电上限电压limited voltage in charge放电下限电压terminating voltage in discharge恒流充电constant current charge恒压充电constant voltage charge恒流放电constant current discharge放电曲线discharge curve充电曲线charge curve放电平台discharge voltage plateau容量衰减capacity attenuation起始容量initial discharge capacity流水线pipelining传送带carrying tape焊极耳welding the current collector卷绕wind叠片layer贴胶带stick tape点焊spot welding超声焊ultrasonic weldingThe terminating voltage in discharge of the battery is 3.0 volt. The limited voltage in charge of the battery is 4.2 volt.三元素Nickle-Cobalt-Manganese Lithium Oxidethree elements materials钴酸锂Cobalt Lithium Oxide锰酸锂Manganese Lithium Oxide石墨graphite烘箱oven真空烘箱vacuum oven搅拌机mixing devicevacuum mixing device涂布机coating equipment裁纸刀paper knife ,,,,,,cutting knife分条机equipment for cutting big piece to much pieces 辊压机roll press equipment电阻点焊机spot welding machine超声点焊机ultrasonic spot welding machine卷绕机winder自动叠片机auto laminating machine激光焊机laser welding machine注液机infusing machine真空注液机vacuum infusion machine预充柜pre-charge equipment化成柜formation systems分容柜grading systems测试柜testing systems内阻仪battery inner resistance tester万用表multimeter转盘式真空封口机turntable type vacuum sealing machine自动冲膜机automatic aluminum membrane shaper序号首字母英文中文1 A aging 老化2 B battery charger 充电器3 black-fleck 黑斑4 C cap 盖板5 capacity density 能量密度6 capacity grading 分容7 cathode tab welding 极耳超焊8 cell 电芯9 charge(capacity) retention 荷电(容量)保持10 checking code 检码11 concave spot 凹点12 constant current charge 恒流充电13 constant current discharge 恒流放电14 constant voltage charge 恒压充电15 corrective measures 纠正措施16 crack 裂纹17 cut-off voltage 终止电压18 cycle life 循环寿命19 D dark trace 暗痕20 degrade 降级21 dent 凹痕22 discharge depth 放电深度23 distortion 变形24 drape 打折25 E Electrical and MechanicalServices Department 机电部26 electrolyte 电解,电解液27 empaistic 压纹28 end-off voltage 放电截止电压29 environmentally friendly 对环境友好30 equipment first inspection 设备首检31 erode 腐蚀32 explosion-proof line 防爆线33 F first inspection 首检34 formation 化成35 fracture 断裂36 I inspection 检验37 insulate 绝缘38 internal resistance 内阻39 J jellyroll 卷芯40 joint 接缝,结合点41 L laser deflecting 偏光42 laser reticle 激光刻线43 laser welding-flatwise weld 激光焊接-平焊laser welding-standing weld 激光焊接-立焊44 leakage 漏液45 leak-checking 测漏46 leaving out of welding 漏焊47 limited charge voltage 充电限制电压48 local action 自放电49 M margin turnly 翘边50 measuring the dimension of cells 电芯卡尺寸51 meet requirement 达到要求52 memory effects 记忆效应53 N nick 划痕54 nominal voltage 标称电压55 notice-board confirmation 看板确认56 nugget 硬块57 O obverse 正面58 open circuit voltage 开路电压59 over charge 过充60 over discharge 过放61 over the thickness 超厚62 P particle 颗粒63 PE membrane PE膜64 pit 坑点65 placing cells into the box 电芯装盒66 point inspection 点检67 preventive measures 预防措施68 pricking the tapes 扎孔69 process inspection 制程检验70 put the battery piled up 将电芯叠放在一起71 Q qualified products 合格品72 quality assurance 质量保证73 quality control 质量控制74 quality improvement 质量改进75 quality match 品质配对76 quality planning 质量策划77 R rated capacity 额定容量78 recharge 再充电79 refitting the can of cell 电芯壳口整形80 requirment 要求81 reverse 背面,反面82 rework 返工83 ringing cells into pyrocondensation films 套热缩膜84 S safety vent 安全阀85 sand aperture 砂眼86 scar 疤痕87 secondary battery 二次电池88 select appearance 选外观sharp-set 批锋89 short circuit checking 测短路90 smudginess 污物91 spot welding by laser 激光点焊92 spot welding place 点焊位置93 spraying the code 喷码94 spur 毛刺95 sticking the PVC cover boards 贴面垫96 storing 陈化97 storing with high voltage 高压储存98 T tabs deflection 极耳歪斜99 tabs excursion 极耳错位100 technics requiment 工艺要求101 U ultrasonic welding 超声波焊接102 ultrasonic welding strength 超焊强度103 unqualified products 不合格品104 W wave 波浪105 working procedure 工序Voltage:Units of measuring electrical current, all batteries are rated in volts DC. (Direct Current). This determines how much energy is needed to power your equipment.Voltage plateau:(电压平台)A slow decrease in voltage over a long period of time. As a rule, the plateau extends from the first voltage drop at the start of the discharge to the bend of the curve after which the voltage drops rapidly at the end.Nominal Voltage(标称电压)The voltage of a battery, as specified by the manufacturer, discharging at a specified rate and temperature.Working voltage(工作电压)The working voltage of a cell or battery begins at its electrical connections as soon as an electrical consumer is connected to it.Discharging voltage, average voltage (放电电压)The average discharging voltage is the average value of the discharging voltage during the entire discharging process with a related discharging current.Open circuit voltage (OCV开路电压)The voltage of a battery when there is no current flowing.Closed-Circuit Voltage (CCV闭路电压)The potential or voltage of a battery when it is discharging or charging.State of charge:The rate of charge capacity vs. whole capacity.Initial voltage(起始电压)A battery's initial voltage is the working voltage when discharging begins. End-point voltage (End voltage, Cutoff voltage, Final voltage)截止电压Specified closed circuit voltage at which a service output test is terminated. End-of-discharge voltageThe battery voltage when discharge is terminated.End-of-charge voltageThe battery voltage when charge is terminated.Cutoff voltage (V)The battery voltage at which charge or discharge is terminated.Definition: Capacity(容量)? The capacity of a cell is defined as how manymilli-amp-hours (mAh) of current the cell canstore and subsequently deliver.? One milli-amp (mA) is 1/1000th of an Amp. Somelarger cell capacities are expressed in Amp-hours(Ah).? “Rated capacity” is varies with discharge rate,temperature, and cutoff voltage.? Rated capacity is different from power or energy? Example:? If a cell is rated at 1000 mAh, then it can deliverthe following:? 1000 mA of current for 1 hour? 500 mA of current for 2 hours? 200 mA of current for 5 hours? 2000 mA of current for 1/2 hourDefinition: Energy Density(能量密度,包括体积比能量和质量比能量)? The energy density of a cell is a measure of howmuch energy can be stored in the cell per unitvolume or per unit weight.? E (watt-hours) = cell voltage x capacity rating? Energy density per unit volume is called the“volumetric energy density” and is expressed interms of watt-hours/liter (wh/l).? Energy density per unit weight is called the“gravimetric energy density” and is expressedin terms of watt-hours/kilogram (wh/kg).? These measurements are useful when you aretrying to determine which cell has the mostcapacity per unit volume or weight.1.Self Discharge 自放电2.Uniformity of the Li-ion Batteries 锂离子电池的一致性3.steel strap 钢带4.Burst vent 防爆阀5.Filling port 注液孔6.spirally wound type cylindrical wound type 圆柱形7.foil 箔8.parallel-plate prismatic design 方形叠片式设计Ageing (老化)- Permanent loss of capacity with frequent use orthe passage of time due to unwanted irreversible chemical reactions in the cell.Anode(阳极)- The electrode in an electrochemical cell where oxidation takes place, releasing electrons.During discharge the negative electrode of the cell is the anode.During charge the situation reverses and the positive electrode of the cell is the anode.Cathode(阴极)- The electrode in an electrochemical cell where reduction takes place, gaining electrons.During discharge the positive electrode of the cell is the cathode. During charge the situation reverses andthe negative electrode of the cell is the cathode.Cycle (循环)- A single charge and discharge of a battery.Depth of discharge DOD (放电深度)- The ratio of the quantity of electricity or charge removed from a cell on discharge to its rated capacity.Internal impedance(交流内阻)- Resistance to the flow of AC current within a cell. It takes into account the capacitive effect of the plates forming the electrodes.Internal resistance (直流内阻)- Resistance to the flow of DC electric current within a cell, causing a voltage drop across the cell in closed circuit proportional to the current drain from the cell.A low internal impedance is usually required for a high rate cell.锂离子电池的内阻英语概念到底用哪个概念,是Internal resistance还是Internal impedance,一些电池说明书内阻用Internal resistance,也有的用Internal impedance,我认为Internal impedance较好些,因为国内测的电池内阻基本都是交流内阻,而外文也有这样定义的(我在别的帖子也粘贴过):Internal impedance(交流内阻)- Resistance to the flow of AC current within a cell. It takes into account the capacitive effect of the plates forming the electrodes.Internal resistance (直流内阻)- Resistance to the flow of DC electric current within a cell, causing a voltage drop across the cell in closed circuit proportional to the current drain from the cell.A low internal impedance is usually required for a high rate cell.在IEC6196002中,只定义为Internal resistance,而用交流的方法测得的内阻,叫Internal a.c. resistance(交流内阻)用直流的方法测得的内阻,叫Internal d.c. resistance(直流内阻),其实Internal a.c. resistance测得就是阻抗,这样看来不如用Internal impedance(交流内阻)和Internal resistance (直流内阻)这两个概念把它们进行分清,以免混淆。

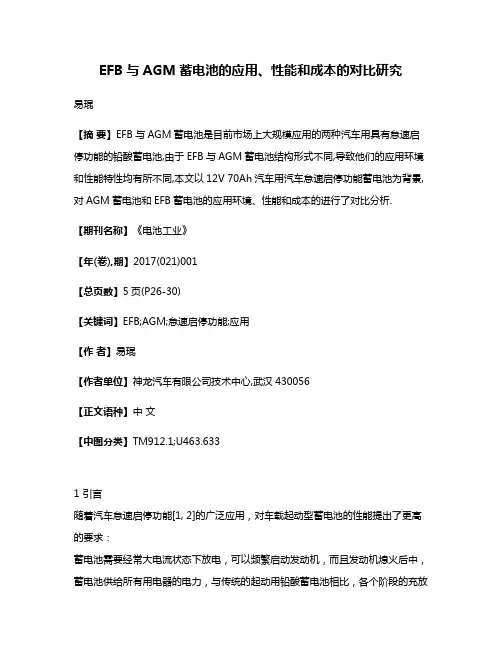

EFB与AGM蓄电池的应用、性能和成本的对比研究易琨【摘要】EFB与AGM蓄电池是目前市场上大规模应用的两种汽车用具有怠速启停功能的铅酸蓄电池,由于EFB与AGM蓄电池结构形式不同,导致他们的应用环境和性能特性均有所不同,本文以12V 70Ah汽车用汽车怠速启停功能蓄电池为背景,对AGM蓄电池和EFB蓄电池的应用环境、性能和成本的进行了对比分析.【期刊名称】《电池工业》【年(卷),期】2017(021)001【总页数】5页(P26-30)【关键词】EFB;AGM;怠速启停功能;应用【作者】易琨【作者单位】神龙汽车有限公司技术中心,武汉430056【正文语种】中文【中图分类】TM912.1;U463.6331 引言随着汽车怠速启停功能[1, 2]的广泛应用,对车载起动型蓄电池的性能提出了更高的要求:蓄电池需要经常大电流状态下放电,可以频繁启动发动机,而且发动机熄火后中,蓄电池供给所有用电器的电力,与传统的起动用铅酸蓄电池相比,各个阶段的充放电量均有增加;同时,要求蓄电池应具有较高的耐久性能以及更长的循环寿命。

为提高燃油效率,必须在减速和刹车制动时利用产生的再生制动能量充电,要求在0~10s的短时间内提高蓄电池的充电接受能力。

富液加强型蓄电池(EFB)和贫液阀控吸附式玻璃纤维棉隔板铅酸蓄电池[1](AGM)作为具有怠速启停功能的起动型蓄电池,在实际中都得到了广泛应用。

本文对目前投入实际应用的具有怠速启停功能的这两种起动型蓄电池进行初步的对比分析。

2 EFB与AGM蓄电池概述2.1 贫液阀控吸附式玻璃纤维棉隔板铅酸蓄电池(AGM)AGM蓄电池,全称为贫液阀控吸附式玻璃纤维棉隔板铅酸蓄电池是一种贫液电池,也是一种阀控蓄电池(Valve Regulated Lead-Acid Battery)。

采用吸附式玻璃纤维棉(Absorbed Glass Mat)作隔板[3~6],电解液吸附在极板和隔板中,采取贫电液设计,电池内无流动的电解液,电池可以立放工作,也可以卧放工作。

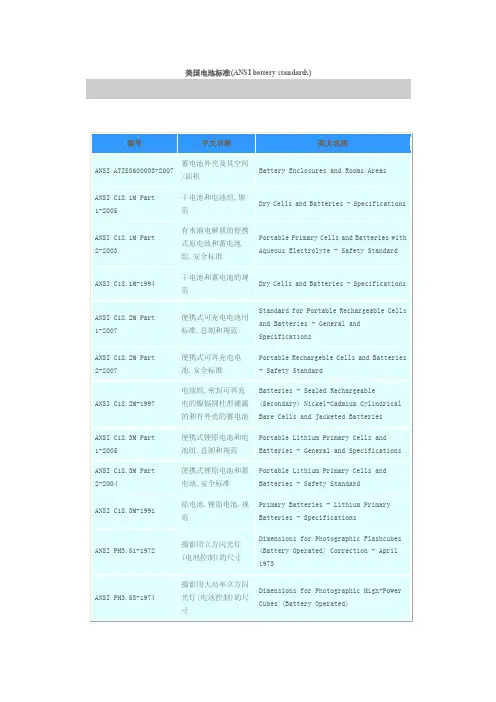

美国电池标准(ANSI battery standards)编号中文名称英文名称ANSI ATIS0600003-2007 蓄电池外壳及其空间/面积Battery Enclosures and Rooms/AreasANSI C18.1M Part 1-2005 干电池和电池组.规范Dry Cells and Batteries - SpecificationsANSI C18.1M Part 2-2003 有水溶电解质的便携式原电池和蓄电池组.安全标准Portable Primary Cells and Batteries withAqueous Electrolyte - Safety StandardANSI C18.1M-1994 干电池和蓄电池的规范Dry Cells and Batteries - SpecificationsANSI C18.2M Part 1-2007 便携式可充电电池用标准.总则和规范Standard for Portable Rechargeable Cellsand Batteries - General andSpecificationsANSI C18.2M Part 2-2007 便携式可再充电电池.安全标准Portable Rechargeble Cells and Batteries- Safety StandardANSI C18.2M-1997 电池组.密封可再充电的镍镉圆柱形裸露的和有外壳的蓄电池Batteries - Sealed Rechargeable(Secondary) Nickel-Cadmium CylindricalBare Cells and Jacketed BatteriesANSI C18.3M Part 1-2005 便携式锂原电池和电池组.总则和规范Portable Lithium Primary Cells andBatteries - General and SpecificationsANSI C18.3M Part 2-2004 便携式锂原电池和蓄电池.安全标准Portable Lithium Primary Cells andBatteries - Safety StandardANSI C18.3M-1991 原电池.锂原电池.规范Primary Batteries - Lithium PrimaryBatteries - SpecificationsANSI PH3.51-1972 摄影用立方闪光灯(电池控制)的尺寸Dimensions for Photographic Flashcubes(Battery Operated) Correction - April1973ANSI PH3.58-1974 摄影用大功率立方闪光灯(电池控制)的尺寸Dimensions for Photographic High-PowerCubes (Battery Operated)ANSI T1.330-1997 电信.电信环境用的阀调的铅酸电池Telecommunications - Valve-regulatedlead-acid batteries used in thetelecommunications environmentANSI T1.405-2002 电信.网络与用户装置接口.利用环路反向电池信令的直接向内拨号模拟音频转换访问线路Telecommunications -InstallationInterfaces - Direct-Inward-DialingAnalog Voicegrade Switched Access UsingLoop Reverse-Battery SignalingANSI T1.411-2001 电信.网络与用户装置接口.使用网络提供的反向电池信令的模拟音频增强型911转换访问线路Telecommunications - Network-to-CustomerInstallation Interfaces - AnalogVoicegrade Enhanced 911 Switched AccessUsing Network-Provided Reverse-BatterySignalingANSI T1.411a Supplement-1996 电信.载体和用户装置之间的接口.用网络提供的蓄电池信令发送进行模拟声音级增强的911转换存取.补充件Telecommunications - Interface betweencarriers and customer installations -Analog voicegrade enhanced 911 switchedaccess using network-providedreserve-battery signaling; SupplementANSI T1.414-1998 电信.网络与用户装置接口.使用环路反向电池信令的增强型模拟音频PSAP访问线路Telecommunications - Network to CustomerInstallation Interfaces - Enhanced 911Analog Voicegrade PSAP Access Using LoopReverse-Battery SignalingANSI/ASME PTC50-2002 燃料电池动力系统性能Fuel Cell Power Systems PerformanceANSI/ASTM D7148-2006 用电解槽测量系统中用碳极测定碱性蓄电池隔板的离子(电阻率)用试验方法Test Method for Determining the Ionic(resistivity) (er) of Alkaline BatterySeparator Using a Carbon Electrode in anElectrolyte Bath Measuring SystemANSI/ASTM E1021-1995 光伏电池光谱响应的测量方法Test Methods for Measuring the SpectralResponse of Photovoltaic CellsANSI/ASTM E1036/E 1036M-1996 利用比对电池测定非浓缩地面光伏电池模拟器电特性的方法(米制)Test Methods for Electrical Performanceof Non-Concentrator TerrestrialPhotovoltaic Modules and Arrays UsingReference Cells (Metric)ANSI/ASTM E1039-1999 球面发光条件下校准和表征非浓缩地面光Test Method for Calibration andCharacterization of Non-Concentrator伏比对电池特性试验方法Terrestrial Photovoltaic Reference Cells Under Global IrradiationANSI/ASTM E1125-1999 利用平行光谱校准初级非浓缩地面光伏比对电池的试验方法Test Method for Calibration of PrimaryNon-Concentrator TerrestrialPhotovolatic Reference Cells Using aTabular SpectrumANSI/ASTM E1362-1999 非浓缩光伏副基准比对电池校准试验方法Test Method for Calibration ofNon-Concentrator Photovoltaic SecondaryReference CellsANSI/ASTM E1596-1999 光伏电池模拟器太阳能辐射风化试验方法Test Method for Solar RadiationWeathering of Photovoltaic ModulesANSI/ASTM E1597-1999 海洋环境用光伏电池模拟器盐水浸没压力和温度测试方法Test Method for Saltwater PressureImmersion and Temperature Testing ofPhotovoltaic Modules for MarineEnvironmentsANSI/ASTM E2047-1999 光伏电池阵列绝缘完整性试验方法Test Method for Wet Insulation IntegrityTesting of Photovoltaic ArraysANSI/ASTM E948-1995 利用比对电池进行非浓缩地面光伏电池的电特性的方法Test Methods for Electrical Performanceof Non-Concentrator TerrestrialPhotovoltaic Cells Using Reference CellsANSI/ASTM E973M-1996 光伏器件和光伏比对电池光谱失配参数测定方法Test Method for Determination of theSpectral Mismatch Parameter between aPhotovoltaic Device and a PhotovoltaicReference Cell (Metric)ANSI/CSA AmericaFC1-2004燃料电池动力装置Fuel Cell Power Plants (same as CGA 12.10)ANSI/CSA FC3-2004 便携式燃料电池动力系统Portable Fuel Cell Power SystemsANSI/EIA 540J000-2000 电子设备用电池支架的分规范Sectional Specification for BatteryHolders for Use in Electronic EquipmentANSI/EIA 540J0AA-2000 电子设备用的圆柱形电池支架标准外形的详细规范Detail Specification for CylindricalBattery Holders, Standard Profile, foruse in Electronic EquipmentANSI/EIA 540J0AB-2001 用于电子设备的币式电池座的详细规范Detail Specification for Coin CellBattery Holders for Use in ElectronicEquipmentANSI/EIA-540J000-2000 电子设备用蓄电池座分规范Sectional Specification for BatteryHolders for Use in Electronic EquipmentANSI/EIA-540J0AA-2000 电子设备用圆柱形电池安装座,标准形状详细规范Detail Specification for CylindricalBattery Holders, Standard Profile, foruse in Electronic EquipmentANSI/EIA-540J0AB-2001 电子设备用硬币式蓄电池座详细规范Detail Specification for Coin CellBattery Holders for Use in ElectronicEquipmentANSI/IEEE 1013-2007 单机光电(PV)系统用酸性铅蓄电池尺寸选定的推荐实施规程Recommended Practice for Sizing Lead-AcidBatteries for Stand-Alone Photovoltaic(PV) SystemsANSI/IEEE 1106-2005 固定设施用带泄漏口的镍镉蓄电池组的安装、维护、测试及更换的推荐实施规程Recommended Practice for Installation,Maintenance, Testing, and Replacement ofVented Nickel-Cadmium Batteries forStationary ApplicationsANSI/IEEE 1115-2000 固定电池组用镍镉蓄电池组规格选择Recommended Practice for SizingNickel-Cadmium Batteries for StationaryApplicationsANSI/IEEE 1184-2006 不可间断电源系统用电池的指南Guide for Batteries for UninterruptiblePower Supply SystemsANSI/IEEE 1187-2002 固定用途的阀调节铅酸蓄电池的安装设计和安装的推荐实施规程Recommended Practice for InstallationDesign and Installation of ValveRegulated Lead-Acid Storage Batteries forStationary ApplicationsANSI/IEEE 1188-2005 固定设备用的阀调节铅酸蓄电池的维修、试验和更换的推荐实施规程Recommended Practice for Maintenance,Testing and Replacement of ValveRegulated Lead-Acid Batteries forStationary ApplicationsANSI/IEEE 1189-1996 固定设备用的阀调节铅酸(VRLA)蓄电池的选择指南Guide for the Selection ofValve-Regulated Lead-Acid (VRLA)Batteries for Stationary ApplicationANSI/IEEE 1361-2003 独立的光电系统中使用的铅酸蓄电池的选择、充电、试验和评定指南Guide for Selection, Charging, Test andEvaluation of Lead-Acid Batteries Used inStand-Alone Photovoltaic (PV) SystemsANSI/IEEE 1375-1998 固定蓄电池组系统的保护指南Guide for Protection of StationaryBattery SystemsANSI/IEEE 1491-2005 固定装置中选择和使用蓄电池监控设备的指南Guide for Selection and Use of BatteryMonitoring Equipment in StationaryApplicationsANSI/IEEE 1536-2002 铁路运输车辆蓄电池物理接口标准Standard for Rail Transit Vehicle BatteryPhysical InterfaceANSI/IEEE 1568-2003 铁路客运工具用镍镉蓄电池电量大小的推荐规程Recommended Practice for ElectricalSizing of Nickel-Cadmium Batteries forRail Passenger VehiclesANSI/IEEE 1578-2007 固定蓄电池电解质溢出处理和管理的推荐实施规程Recommended Practice for StationaryBattery Electrolyte Spill Containment andManagementANSI/IEEE 1625-2004 便携式计算机用可再充电电池Rechargeable Batteries for PortableComputingANSI/IEEE 1725-2006 移动电话用可再充电电池标准Standard for Rechargeable Batteries forCellular TelephonesANSI/IEEE 450-2002 发电站和变电站的大型铅蓄电池组的维护、试验和更换实施规程Maintenance, Testing, and Replacement ofLarge Lead Storage Batteries forGenerating Stations and Substations,Practice forANSI/IEEE 463-2006 电解电池线性工作区的电气安全规程标准Standard for Electrical Safety Practicesin Electrolytic Cell Line Working ZonesANSI/IEEE 484-2002 固定设备用大型铅酸蓄电池组安装设计和安装的实施规程Recommended Practice for InstallationDesign and Installation of VentedLead-Acid Batteries for StationaryApplicationsANSI/IEEE 485-1997 固定装置用的铅酸电池规格选择的推荐实施规程Recommended Practice for Sizing Lead-AcidBatteries for Stationary ApplicationsANSI/IEEE 535-2006 核电站用1E类铅蓄电池的合格证明标准Standard for Qualification of Class 1ELead Storage Batteries for Nuclear PowerGenerating StationsANSI/IEEE 937-2007 光电(PV)系统用铅酸蓄电池组安装和维护实施规程Recommended Practice for Installation andMaintenance of Lead-Acid Batteries forPhotovoltaic (PV) SystemsANSI/SAE J1494-1997 蓄电池升压器电缆Battery Booster CablesANSI/SAE J1495-1998 蓄电池阻燃通风系统Test Procedure for Battery Flame的试验程序Retardant Venting SystemsANSI/SAE J1766-1998 电动和混合电动车蓄电池系统的推荐实施规程.碰撞完整性试验Recommended Practice for Electric andHybrid Electric Vehicle Battery Systems -Crash Integrity TestingANSI/SAE J2380-1998 电动车蓄电池组的振动试验Vibration Testing of Electric VehicleBatteriesANSI/SAE J240-1993 汽车蓄电池的寿命试验Automotive Storage Batteries, Life TestforANSI/SAE J537-1994 蓄电池组Storage BatteriesANSI/SCTE 48-3-2004 用GTEM电池测量编织同轴引入电缆的屏蔽效果的试验规程Test Procedure for Measuring ShieldingEffectiveness of Braided Coaxial DropCable Using the GTEM CellANSI/UL 1236-2006 装载发电机启动器蓄电池用蓄电池充电器的安全标准Standard for Safety for Battery Chargersfor Charging Engine-Starter BatteriesANSI/UL 1564-2006 工业蓄电池充电装置安全标准Standard for Safety for IndustrialBattery ChargersANSI/UL 1839-2007 汽车蓄电池电瓶线的安全标准Standard for Safety for AutomotiveBattery Booster CablesANSI/UL 218A-2004 柴油发动机驱动的离心消防泵用蓄电池接触器Battery Contactors for Use in DieselEngines Driving Centrifugal Fire PumpsANSI/UL 2267-2006 工业电瓶货车设备用燃料电池电源系统安全标准Standard for Safety for Fuel Cell PowerSystems for Installation in IndustrialElectric TrucksANSI/UL 583-2007 工业用蓄电池电力货车标准Standard for Electric-Battery-PoweredIndustrial TrucksANSI/UL 745-4-36-2006 电池组手动工具的特殊要求安全标准Standard for Safety for ParticularRequirements for Battery Operated HandMotor ToolsASME PTC 50-2002 燃料电池电源系统性能(Fuel cell power systems performance)ASTM C 876-1991 混凝土中未涂覆的预应力钢筋的半电池电势的试验方法Test Method for Half-Cell Potentials ofUncoated Reinforcing Steel in ConcreteASTM D 7129-2005 接合蓄电池隔板中氨的测定的标准试验方法Standard Test Method for Determination ofAmmonia Trapping in a Grafted BatterySeparatorASTM D 7131-2005 接合蓄电池隔板中离子交换能力测定的标准试验方法Standard Test Method for Determination ofIon Exchange Capacity (IEC) in GraftedBattery SeparatorASTM D 7148-2007 电解槽测量系统中使用碳极测定碱性蓄电池隔板的离子电阻系数(ER)用标准试验方法Standard Test Method for Determining theIonic Resistivity (ER) of AlkalineBattery Separator Using a CarbonElectrode in an Electrolyte BathMeasuring SystemASTM E 1036-2002 使用标准电池的非聚能地面光电模件和阵列电气性能的标准试验方法Standard Test Methods for ElectricalPerformance of NonconcentratorTerrestrial Photovoltaic Modules andArrays Using Reference CellsASTM E 1040-2005 非集中大地光电参比电池物理特性的标准规范Standard Specification for PhysicalCharacteristics of NonconcentratorTerrestrial Photovoltaic Reference CellsASTM E 1125-2005 用表列光谱校准初级非集中大地光电参比电池的标准试验方法Standard Test Method for Calibration ofPrimary Non-Concentrator TerrestrialPhotovoltaic Reference Cells Using aTabular SpectrumASTM E 1362-2005 非集中光电二次参比电池校准的标准试验方法Standard Test Method for Calibration ofNon-Concentrator Photovoltaic SecondaryReference CellsASTM E 2236a-2005 无聚集器多结光电池和组件的电性能和光谱灵敏度测量的标准试验方法Standard Test Methods for Measurement ofElectrical Performance and SpectralResponse of NonconcentratorMultijunction Photovoltaic Cells andModulesASTM E 948a-2005 在模拟日光下使用参比电池的光电电池电性能的标准试验方法Standard Test Method for ElectricalPerformance of Photovoltaic Cells UsingReference Cells Under Simulated SunlightASTM E 973a-2005 测定光电装置与光电参比电池之间光谱不Standard Test Method for Determination ofthe Spectral Mismatch Parameter Between a协调参数的标准试验方法Photovoltaic Device and a Photovoltaic Reference CellASTM G 95-2007 管道涂层的阴极剥离试验用标准试验方法(附着电池法)Standard Test Method for CathodicDisbondment Test of Pipeline Coatings(Attached Cell Method)IEEE 1013-2000 光电系统用铅酸蓄电池尺寸测量的推荐实施规程(Recommended practice for sizinglead-acid batteries for photovoltaic (PV)systems)IEEE 1106-1995 发电站及变电所用镍-镉蓄电池组的维护,试验及更换用推荐规程(Recommended practice for installation,maintenance, testing, and replacement ofvented nickel-cadmium batteries forstationary applications)IEEE 1115-2000 静态用镍-镉电池组规格的推荐操作规程(Recommended practice for sizingnickel-cadmium batteries for stationaryapplications)IEEE 1144-1996 光电系统用校准镍-镉蓄电池组的推荐规程(Recommended practice for sizingnickel-cadmium batteries forphotovolatic (PV) systems)IEEE 1184-1994 不间断电源系统电池尺寸的规定和选择(Selection and sizing of batteries foruninterruptible power systems)IEEE 1187-2002 固定设备用的阀调节铅酸蓄电池的安装设计和安装的推荐性实施规程(Recommended practice for installationdesign and installation ofvalve-regulated lead-acid storagebatteries for stationary applications)IEEE 1188-1996 发电站用阀调节铅酸(VRLA)蓄电池组的保养、试验和更新的推荐规程(Recommended practice for maintenance,testing, and replacement ofvalve-regulated lead-acid (VRLA)batteries for stationary applications)IEEE 1189-1996 固定设备用调节阀铅酸(VRLA)蓄电池的选择指南(Guide for selection of valve-regulatedlead-acid (VRLA) batteries for stationaryapplications)IEEE 1375-1998 固定蓄电池组的保护指南(Guide for the protection of stationarybattery systems)IEEE 1536-2002 铁路运输车辆蓄电池物理接口(Rail transit vehicle battery physicalinterface)IEEE 450-2002 通气固定铅蓄电池组的维护、试验及更换(Maintenance, testing, and replacement ofvented lead-acid batteries for stationaryapplications)IEEE 484-2002 发电站用透气式铅酸蓄电池组设计、安装推荐规程(Recommended practice for installationdesign and installation of ventedlead-acid batteries for stationaryapplications)IEEE 485-1997 固定设施用酸性铅蓄电池尺寸测定推荐规程(Recommended practice for sizinglead-acid batteries for stationaryapplications)IEEE 535-1986 核电站用1E级铅蓄电池组的鉴定(Qualification of class 1E lead storagebatteries for nuclear power generatingstations)IEEE 650-1990 核电站1E级固定式电池充电器和逆变器的合格鉴定(Qualification of class 1E static batterychargers and inverters for nuclear powergenerating stations)IEEE 937-2000 光电系统用铅酸蓄电池组的安装及维护推荐规程(Recommended practice for installationand maintenance of lead-acid batteriesfor photovoltaic (PV) systems)UL 1236-2002 充电的发动机起动电池组用蓄电池充电器(Battery chargers for chargingengine-starter batteries )UL 1564-1993 工业蓄电池充电器(Industrial battery chargers )UL 1642-1995 锂蓄电池组(Lithium batteries )UL 1989-1996 备用蓄电池组(Standby batteries )UL 2054-1997 家用和商用蓄电池组(Household and commercial batteries ) UL 2089-2003 车辆用蓄电池适配器(Vehicle battery adapters )UL 218A-2004 柴油机中驱动离心点火泵用电池接头标准(Standard for battery contactors for usein diesel engines driving centrifugalfire pumps )UL 745-3-1995 由蓄电池供电的便携工具(Portable battery operated tools )UL 745-4-1-1995 由蓄电池供电的电钻的特殊要求(Particular requirementsbattery-operated drills )UL 745-4-11-1995 由蓄电池供电的往复式锯的特殊要求(Particular requirements forbattery-operated reciprocating saws )UL 745-4-14-1995 由蓄电池供电的刨刀(Particular requirements for的特殊要求battery-operated planers )UL 745-4-17-1995 由蓄电池供电的刻纹机和修剪机特殊要求(Particular requirements forbattery-operated routers and trimmers )UL 745-4-2-1995 由蓄电池供电的旋具和套筒扳手特殊要求(Particular requirements forbattery-operated screwdrivers and impactwrenches )UL 745-4-3-1995 由蓄电池供电的研磨机、磨光器和盘形砂轮机特殊要求(Particular requirements forbattery-operated grinders, polishers,and disk-type sanders )UL 745-4-35-1995 由蓄电池供电的污水清洁器特殊要求(Particular requirements forbattery-operated drain cleaners )UL 745-4-36-1995 由蓄电池供电的手持式电动工具特殊要求(Particular requirements forbattery-operated hand motor tools )UL 745-4-4-1995 由蓄电池供电的砂轮机特殊要求(Particular requirements forbattery-operated sanders )UL 745-4-5-1995 由蓄电池供电的圆盘锯和圆盘刀具特殊要求(Particular requirements forbattery-operated circular saws andcircular knives )UL 745-4-6-1995 由蓄电池供电的锤子的特殊要求(Particular requirements forbattery-operated hammers )UL 745-4-8-1995 由蓄电池供电的剪刀和步冲轮廓机特殊要求(Particular requirements forbattery-operated shears and nibblers )编号中文名称英文名称。

第4卷第6期2015年11月 储 能 科 学 与 技 术 Energy Storage Science and Technology V ol.4 No.6Nov. 2015特约评述铅碳电池储能技术陶占良,陈 军(先进能源材料化学教育部重点实验室,天津化学化工协同创新中心,南开大学化学学院,天津 300071)摘 要:储能技术在太阳能、风能等可再生能源发电、智能电网/微网建设等方面有着广阔的应用前景。

铅酸电池具有价格低、较高电压、性能稳定、宽工作温度范围等优势,占据着固定储能市场的主导地位。

但在智能电网、混合动力车的实际应用中,电池必须在不同的充电状态下操作,特别是在高倍率部分荷电模式。

在这种操作模式下,硫酸盐沉积物积聚在电极表面,限制了铅酸电池的容量和循环寿命。

铅碳电池是由铅酸电池和超级电容器组合形成的新型储能装置,它抑制了放电过程中负极板表面硫酸盐的不均匀分布和充电时较早的析氢现象,具有铅酸电池高能量和超级电容器高功率的优点,在部分荷电态大功率充放电状态具有较高的循环寿命,适合高倍率循环和瞬间脉冲放电等工作状态。

本文介绍了铅碳电池的基本概念及原理,并对铅碳电池储能技术的发展历程和现状进行了总结。

关键词:储能;铅酸电池;铅碳电池;负极材料doi: 10.3969/j.issn.2095-4239.2015.06.002中图分类号:TK 02;TM 912.2 文献标志码:A 文章编号:2095-4239(2015)06-546-10Lead carbon ultrabatteries for energy storageTAO Zhanliang , CHEN Jun(Key Laboratory of Advanced Energy Materials Chemistry, Ministry of Education, Collaborative Innovation Center of ChemicalScience and Engineering, College of Chemistry, Nankai University, Tianjin 300071, China)Abstract: Energy storage technologies show broad application prospects in renewable energy systems such as wind and solar energy, and in the construction of smart grid/micro grids. Lead-acid batteries have dominated the market in stationary energy storage due to their advantages of low price, high-unit voltage, stable performance, and a wide operating temperature range. However, lead-acid batteries under hybrid electric veheciles (HEV) and renewable-energy applications must be operated at different state-of-charge windows. In particular, under high-rate partial-state-of-charge (HRPSoC) duty, lead-acid batteries fail prematurely due to the sulfation of the negative plates. Lead carbon ultrabatteies are a new hybrid energy storage device, which combines a lead acid battery and an asymmetric supercapacitor in single unit, with the advantage of both high energy of lead acid battery and high power of supercapacitor. The uneven distribution of lead sulfate across the cross-section of negative plate during discharge and the early evolution of hydrogen during charge should be suppressed. There fore, lead carbon ultrabatteies have longer cycling life in a wider state-of-charge window, which is suitable for high rate cycling and pulse applications. The concept and the basic principles of lead carbon ultrabatteries and its recent developments are summarized.Key words: energy storage; lead-acid battery; lead carbon ultrabattery; negative active material储能技术在以太阳能、风能发电为主力能源的收稿日期:2015-07-09;修改稿日期:2015-08-31。