太阳能跟踪器 Solar Tracker 外文翻译

- 格式:doc

- 大小:66.00 KB

- 文档页数:16

新能源产业专业词汇1.单晶硅片 mono-crystalline silicon wafer多晶硅片 polycrystalline silicon wafer晶向 orientation少数载流子寿命 lifetime导电类型 conductivity type位错密度 dislocation硅单晶片厚度 thickness硅单晶片的弯曲度 surface camber准方单晶硅片 : quasi-square mono-crystalline silicon wafer2.太阳电池 solar cell3.薄膜太阳电池 film solar cell4.光电转换 photo-electricity conversion5.太阳电池组件 solar module多晶硅太阳电池组件 polycrystalline solar module单晶硅太阳电池组件mono-crystalline solar module6.太阳能户用系统solar home system(分为:太阳能直流户用系统;太阳能交流户用系统;太阳能交直流户用系统)7.太阳能电站solar power station(分为:离网型太阳能电站 off-grid solar power station ;并网型太阳能电站 grid-connected solar power station )8.太阳能热水器solar water heater9.太阳能热水系统:solar heating system10.太阳能直流式热水系统 : solar direct heating system11.太阳能强迫循环热水系统 solar compelling cycle heatingsystem12.太阳能自然循环热水系统 solar spontaneously cycle heatingsystem13.真空管太阳能集热器 vacuum tube solar centralized heatingsystem14.平板型太阳能集热器 flat type solar centralized heatingsystem15.全玻璃真空太阳能集热器full-glass vacuum solarcentralized heating system16.热管式真空管太阳集热器heat-tube vacuum solarcentralized heating system17.采光面积 : lighting area18.太阳能幅照度 solar radiant intensity19.太阳能控制器:solar controller20.太阳能逆变器:solar inverter21.太阳能通讯基站 solar telecommunication power systems22.石油和天然气管道太阳能阴极保护电站:solar power stationsfor cathode protection of the oil and gas feeding pipes23.太阳能电池方阵 solar array24.太阳能通讯电源 solar communication power station25.太阳能自动跟踪装置 solar automatic tracker26.太阳能移动电源车(站) solar mobile electrical vehicle(station)27.光伏水泵 solar pump28.太阳能杨水系统 solar pumping system29.光—网---柴互补系统complementary system for solar–grid-diesel oil30.风---光互补系统 complementary system for solar - wind31.太阳能交通信号灯 solar traffic signal light32.太阳能交通警示标志 solar traffic warning symbol33.太阳能道钉 solar road mark34.太阳能庭院灯 solar garden light35.太阳能路灯 solar street light36.太阳能草坪灯 solar lawn light37.太阳能广告牌 solar billboard38.太阳能电话亭 solar telephone booth39.综合楼 Management and Control building40.管理区Living quarter41.132kV升压站 132kV substation42.支架 The mounting structure43.围栏 Railing44.围墙 Enclosure45.平面布置图 layout46.水泵房 Water Pump House47.门卫室 Guard house48.砂砾碎石Graded crushed gravel49.泥结碎石 Glay mixing gravel50.场地平整 ground leveling51.原始高程(自然地面高程)Natural Ground Level.(简写:N.G.L)52.升压变压器 Step-up transformer53.逆变器 Inverter54.临设区域 The laydown area55.边界线 Boundary line56.等高线 Gontour57.子方阵 Sub-arrays58.电缆 cable59.汇流箱 Combiner Box60.发电单元Generating Unit61.主控室 Local control room62.33KV配电室 33KV Switchgear room63.电缆沟 Cable Trenchesyout drawing 平面布置图65.主变压器 Main transformer66.SVC reactive compensation device SVC无功补偿装置67.Ground connection transformer 接地变压器68.guard room 门卫室69.SF6 breaker SF6 断路器70.132kv current transformer 132KV电流互感器71.132kv disconnecting switch 132KV隔离开关72.132kv zinc oxide arrester 132KV氧化锌避雷器73.132kv voltage transformer 132KV电压互感器74.Meter Panel 电度表屏75.太阳能扬水和照明综合应用系统:the comprehensive utilization system of solar pumping and lighting76.变频调速交流异步电机:high-efficient frequency conversion alternating asynchronous motors(这个产品不是太阳能产品)77.送电到乡: Power Supply to Township78.丝绸之路光明工程: Silk Road Brightness Project79.太阳能亮化工程 solar brightness project80.太阳能与建筑一体化 integrate solar energy with building81.活动Activity82.活动定义:Activity Definition83.活动描述/说明:AD=Activity Description84.活动历时估算:Activity Duration Estimating85.箭线网络图(双代号网络图):AOA=Activity-On-Arrow86.节点式网络图(单代号网络图):AON=Activity-on-Node87.已执行工作实际成本:ACWP=Actual Cost of Work Performed88.实际完成日期:AF=Actual Finish Date89.实际开始日期:AS=Actual Start Date90.行政收尾:Administrative Closure91.箭线:Arrow92.箭线图示法:ADM=Arrow Diagramming Method93.逆推计算法:Backward Pass94.横道图:Bar Chart95.基准计划:Baseline96.完工预算:BAC=Budget At Completion97. 概算:Budget Estimate98.已执行预算成本:BCWP=Budgeted Cost of Work Performed99.计划执行预算成本:BCWS= Budgeted Cost of Scheduled 100.日历单位:Calendar Unit101.变更控制委员会:CCB=Chang Control Board102.沟通规划:Communications Planning103.并行工程:Concurrent Engineering104.意外费用:Contingencies105.意外准备金:contingency Allowance106.意外规划:Contingency Planning107.意外储备:Contingency Reserve108.合同:Contract109.合同管理:Contract Administration110.合同收尾:Contract Close-out111.控制:Control112.控制图:Control Chart113.纠正措施:Corrective Action114.费用预算:Cost Budgeting115.费用控制:Cost Control116.费用做算:Cost Estimating117.质量成本:Cost of Quality118.费用绩效指数:CPI=Cost Performance Index119.费用偏差:CV=Cost Variance120.赶工:Crashing121.关键工序:Critical Activity122.关键路线:Critical Path123.关键路线法:CPM=Critical Path Method124.当前完成日期:Current Finish Date125.当前开始日期:Current Start Date126.数据日期:DD=Data Date127.交付物:Deliverable128.依赖关系:Dependency129.虚活动:Dummy Activity130.延续时间:DU=Duration131.延续时间压缩:Duration Compression132.最早完工日期:EF=Early Finish Date133.最早开始日期:ES=Early Start Date134.挣值法:EV=Earned Value135.挣值分析:Earned Value Analysis136.人工量:Effort137.估算:概算:Estimate138.在完成时的费用估算:EAC=Estimate At Completion 139.到完成时的估算:ETC=Estimate To Complete140.单节点事件图:Event-on-Node141.例外报告:Exception Report142.完成日期:Finish Date143.完成到完成关系:FF=Finish-to-Finish144.完成到开始关系:FS=Finish-to-Start145.时差:机动时间:浮动时间:Float146.顺推计算法:Forward Pass147.自由时差:FF=Free Float148.职能经理:Functional Manager149.职能组织:Functional Organization150.甘特图:Gantt Chart151.图解评审技术:GERT=Graphical Evaluation and Review Technique152.集合工作:Hammock153.悬摆:Hanger154.信息分发:Information Distribution155.立项:Initiation156.成本/进度综合报告:Integrated Cost/Schedule Reporting 157.邀标:IFB= Invitation for Bid158.关键事件进度计划:Key Event Schedule160.滞后量:Lag161.最晚完成日期:LF=Late Finish Date162.最晚开始日期:LS=Late Start Date163.提前量:Lead164.全生命期成本估算:Life-cycle Costing165. 产品经理:Line Manager166. 逻辑图:Logic Diagram167.逻辑关系:Logical Relationship168.回路:Loop169.管理储备量:Management Reserve170.主进度计划:Master Schedule171.矩阵型组织:Matrix Organization172.里程碑:Milestone173.里程碑进度计划:Milestone Schedule174.现代项目管理:MPM=Modern Project Management175.监控:Monitoring176.蒙托卡罗分析:Monte Carlo Analysis177.次关键工作:Near-Critical Activity178.网络:Network179.网络分析:Network Analysis180.网络逻辑:Network Logic181.网络路线:Network Path182. 节点:Node183.组织分解结构:OBS=Organizational Breakdown Structure 184.组织规划:Organizational Planning185.整体变更控制:Overall Change Control186.重叠:Overlap187.参数估算法:Parametric Estimating188.线路:Path189.线路时差:Path Float190.完成百分比:PC=Percent Complete191.执行报告:Performance Reporting192.执行机构:Performing organization193.计划评审技术图:PERT Chart194.计划的完成日期:PF=Planned Finish Date195.计划的开始日期:PS=Planned Start Date196.优先图示法:PDM=Precedence Diagramming Method197.优先关系:Precedence Relationship198.紧前工作:Predecessor Activity199.采购规划:Procurement Planning200.工程:Program201.计划评审技术:PERT=Program Evaluation and Review Technique 202.项目:Project203.项目许可证、项目章程:Project Charter204.项目沟通管理:Project Communication Management205.项目费用管理:Project Cost Management206.项目人力资源管理:Project Human Resource Management 207.项目综合管理:Project Integration Management208.项目生命周期:Project Life Cycle209.项目管理:PM=Project Management210.项目管理知识体系:PMBOK=Project Management Body of Knowledge211.项目管理软件:Project Management Software212.项目管理团队:Project Management Team213.项目经理:PM=Project Manager214.项目网络图:Project Network Diagram215.项目阶段:Project Phase216.项目计划:Project Plan217.项目计划开发:Project Plan Development218.项目计划实施:Project Plan Execution219.项目规划:Project Planning220.项目采购管理:Project Procurement Management221.项目质量管理:Project Quality Management222.项目风险管理:Project Risk Management223.项目进度计划:Project Schedule224. 项目范围管理:Project Scope Management225.项目团队成员:Project Team Member226.项目时间管理:Project Time Management227.项目型组织:Project Organization228.质量保证:QA=Quality Assurance229.质量控制:QC=Quality Control230.质量规划:Quality Planning231.剩余持续时间:RDU=Remaining Duration232.请求建议书:RFP=Request for Proposal233.请求报价单:RFQ=Request for Quotation234.储备量:Reserve235.资源平衡:Resource Leveling236.资源约束进度计划:Resource-Limited Schedule237.资源规划:Resource Planning238.责任分配矩阵:RAM=Responsibility Assignment Matrix 234.责任图:Responsibility Chart235.责任矩阵:Responsibility Matrix236.保留金:Retain age237.突发事件:Risk Event238.风险识别:Risk Identification239.风险应对控制:Risk Response Control240.风险应对开发:Risk Response Development241.曲线:S-Curve242.进度计划:Schedule243.进度计划分析:Schedule Analysis244.进度计划压缩:Schedule Compression245.进度计划控制:Schedule Control246.进度执行指数:SPI=Schedule Performance Index247.进度偏差:SV=Schedule Variance248.计划完成日期:SF=Scheduled Finish Date249.计划开始日期:SS=Scheduled Start Date 250.范围:Scope251.范围基准计划:Scope Baseline252.范围变更:Scope Change253.范围变更控制:Scope Change Control 254.范围定义:Scope Definition255.范围规划:Scope Planning256.范围验证:Scope Verification257.时差:Slack 258.询价:Solicitation259.询价规划:Solicitation260.工作人员招募:Staff Acquisition261.项目相关者:Stakeholder262.开始日期:Start Date263.开始到完成关系:Start-to-Finish264.开始到开始关系:Start-to-Start265.工作说明:SOW=Statement of Work266.子网:Subnet 267.子网络:Subnet Work268.后续工作:Successor Activity269.目标完成日期:TC=Target Completion Date 270.目标时度计划:Target Schedule271.任务:Task 272.团队建设:Team Development273.团队成员:Team members274.时标网络图:Time-Scaled Network Diagram 275.目标完成日期:TF=Target Finish Date 276.目标开始日期:Ts=Target Start Date277.总时差:TF=Total Float278.全面质量管理:TQM=Total Quality Management 279. 权变措施:Workaround280.工作分解结构:WBS=Work Breakdown Structure 281.工作包:Work Package。

太阳能发电外文翻译文献(文档含中英文对照即英文原文和中文翻译)Design of a Lead-Acid Battery Charging and Protecting IC in Photovoltaic SystemZENG De-you,LING Chao-dong,LI Guo-gang1.IntroductionSolar energy as an inexhaustible, inexhaustible source of energy more and more attention. Solar power has become popular in many countries and regions, solar lighting has also been put into use in many cities in China. As a key part of the solar lighting, battery charging and protection is particularly important. Sealed maintenance-free lead-acid battery has a sealed, leak-free, pollution-free, maintenance-free, low-cost, reliable power supply during the entire life of the battery voltage is stable and no maintenance, the need for uninterrupted for the various typesof has wide application in power electronic equipment, and portable instrumentation. Appropriate float voltage, in normal use (to prevent over-discharge, overcharge, over-current), maintenance-free lead-acid battery float life of up to 12 ~ 16 years float voltage deviation of 5% shorten the life of 1/2. Thus, the charge has a major impact on this type of battery life. Photovoltaic, battery does not need regular maintenance, the correct charge and reasonable protection, can effectively extend battery life. Charging and protection IC is the separation of the occupied area and the peripheral circuit complexity. Currently, the market has not yet real, charged with the protection function is integrated on a single chip. For this problem, design a set of battery charging and protection functions in one IC is very necessary.2.System design and considerationsThe system mainly includes two parts: the battery charger module and the protection module. Of great significance for the battery as standby power use of the occasion, It can ensure that the external power supply to the battery-powered, but also in the battery overcharge, over-current and an external power supply is disconnected the battery is to put the state to provide protection, the charge and protection rolled into one to make the circuit to simplify and reduce valuable product waste of resources. Figure 1 is a specific application of this Ic in the photovoltaic power generation system, but also the source of this design.Figure1 Photovoltaic circuit system block diagramMaintenance-free lead-acid battery life is usually the cycle life and float life factors affecting the life of the battery charge rate, discharge rate, and float voltage. Some manufacturers said that if the overcharge protection circuit, the charging rate can be achieved even more than 2C (C is the rated capacity of the battery), battery manufacturers recommend charging rate of C/20 ~ C/3. Battery voltage and temperature, the temperature is increased by 1 °C, single cell battery voltage drops 4 mV , negative temperature coefficient of -4 mV / ° C means that the battery float voltage. Ordinary charger for the best working condition at 25 °C; charge less than the ambient temperature of 0 °C; at 45 °C may shorten the battery life due to severe overcharge. To make the battery to extend the working life, have a certain solar battery array Charge controllercontroller Dischargecontroller DC load accumulatorunderstanding and analysis of the working status of the battery, in order to achieve the purpose of protection of the battery. Battery, there are four states: normal state, over-current state over the state of charge, over discharge state. However, due to the impact of the different discharge current over-capacity and lifetime of the battery is not the same, so the battery over discharge current detection should be treated separately. When the battery is charging the state a long time, would severely reduce the capacity of the battery and shorten battery life. When the battery is the time of discharge status exceeds the allotted time, the battery, the battery voltage is too low may not be able to recharge, making the battery life is lower. Based on the above, the charge on the life of maintenance-free lead-acid batteries have a significant impact, while the battery is always in good working condition, battery protection circuit must be able to detect the normal working condition of the battery and make the action the battery can never normal working state back to normal operation, in order to achieve the protection of the battery.3.Units modular design3.1The charging moduleChip, charging module block diagram shown in Figure 2. The circuitry includes current limiting, current sensing comparator, reference voltage source, under-voltage detection circuit, voltage sampling circuit and logic control circuit.Figure2 Charging module block diagramdriverV oltage amplifierV oltage sampling comparatorStart amplifierState level control Charging indicator Logicalmodule Undervoltage detection circuitR- powerCurrent sampling comparator Limitingamplifier Power indicatorThe module contains a stand-alone limiting amplifier and voltage control circuit, it can control off-chip drive, 20 ~30 mA, provided by the drive output current can directly drive an external series of adjustment tube, so as to adjust the charger output voltage and current . V oltage and current detection comparator detects the battery charge status, and control the state of the input signal of the logic circuit. When the battery voltage or current is too low, the charge to start the comparator control the charging. Appliances into the trickle charge state when the cut-off of the drive, the comparator can output about 20 mA into the trickle charge current. Thus, when the battery short-circuit or reverse, the charger can only charge a small current, to avoid damage to the battery charging current is too large. This module constitutes a charging circuit charging process is divided into two charging status: high-current constant-current charge state, high-voltage charge status and low-voltage constant voltage floating state. The charging process from the constant current charging status, the constant charging current of the charger output in this state. And the charger continuously monitors the voltage across the battery pack, the battery power has been restored to 70% to 90% of the released capacity when the battery voltage reaches the switching voltage to charge conversion voltage Vsam charger moves to the state of charge. In this state, the charger output voltage is increased to overcharge pressure V oc is due to the charger output voltage remains constant, so the charging current is a continuous decline. Current down to charge and suspend the current Ioct, the battery capacity has reached 100% of rated capacity, the charger output voltage drops to a lower float voltage VF.3.2 Protection ModuleChip block diagram of the internal protection circuit shown in Figure 3. The circuit includes control logic circuit, sampling circuit, overcharge detection circuit, over-discharge detection comparator, overcurrent detection comparator, load short-circuit detection circuit, level-shifting circuit and reference circuit (BGR).Figure3 Block diagram of battery protectionThis module constitutes a protection circuit shown in Figure 4. Under the chip supply voltage within the normal scope of work, and the VM pin voltage at the overcurrent detection voltage, the battery is in normal operation, the charge and discharge control of the chip high power end of the CO and DO are level, when the chip is in normal working mode. Larger when the battery discharge current will cause voltage rise of the VM pin at the VM pin voltage at above the current detection voltage Viov, then the battery is the current status, if this state to maintain the tiov overcurrent delay time, the chip ban on battery discharge, then the charge to control the end of CO is high, the discharge control side DO is low, the chip is in the current mode, general in order to play on the battery safer and more reasonable protection, the chip will battery over-discharge current to take over the discharge current delay time protection. The general rule is that the over-discharge current is larger, over the shorter the discharge current delay time. Above Overcharge detection voltage, the chip supply voltage (Vdd> Vcu), the battery is in overcharge state, this state is to maintain the corresponding overcharge delay time tcu chip will be prohibited from charging the battery, then discharge control end DO is high, and charging control terminal CO is low, the chip is in charging mode. When the supply voltage of the chip under the overdischarge detection voltage (Vdd <Vdl,), then the battery is discharged state, this state remains the overdischarge delay time tdl chip will be prohibited to discharge the battery at this time The charge control side CO is high, while the discharge control terminal DO is low, the chip is in discharge mode. Sampling circuitOver discharge detection comparatorControl logic circuit Level conversion circuit Overcharge detection comparator Over-current detection comparator2 Over-current detection comparator1Over-current detection circuitLoad short detection circuitFigure4 Protection circuit application schematic diagram4.Circuit DesignTwo charge protection module structure diagram, the circuit can be divided into four parts: the power detection circuit (under-voltage detection circuit), part of the bias circuit (sampling circuit, the reference circuit and bias circuit), the comparator (including the overcharge detection /overdischarge detection comparator, over-current detection and load short-circuit detection circuit) and the logic control part.This paper describes the under-voltage detection circuit (Figure 5), and gives the bandgap reference circuit (Figure 6).Figure5 Under-voltage detection circuitProtectionmoduleBiasing circuit Reference circuit Bleeder circuit difference amplifier Output circuitAmplifierAmplifierFigure6 A reference power supply circuit diagramBattery charging, voltage stability is particularly important, undervoltage, overvoltage protection is essential, therefore integrated overvoltage, undervoltage protection circuit inside the chip, to improve power supply reliability and security. And protection circuit design should be simple, practical, here designed a CMOS process, the undervoltage protection circuit, this simple circuit structure, process and easy to implement and can be used as high-voltage power integrated circuits and other power protection circuit.Undervoltage protection circuit schematic shown in Figure 5, a total of five components: the bias circuit, reference voltage, the voltage divider circuit, differential amplifier, the output circuit. The circuit supply voltage is 10V; the M0, M1, M2, R0 is the offset portion of the circuit to provide bias to the post-stage circuit, the resistance, Ro, determine the circuit's operating point, the M0, M1, M2 form a current mirror; R1 M14 is the feedback loop of the undervoltage signal; the rest of the M3, M4 and M5, M6, M7, M8, M9, M10, M11, M12, M13, M14, composed of four amplification comparator; M15, DO, a reference voltage, the comparator input with the inverting input is fixed (V+), partial pressure of the resistance R1, R2, R3, the input to the inverting input of the comparator, when the normal working of the power supply voltage, the inverting terminal of the voltage detection is lost to the inverting terminal voltage of the comparator is greater than V+. Comparator output is low, M14 cutoff, feedback circuit does not work; undervoltage occurs, the voltage divider of R1, R2, R3, reaction is more sensitive, lost to the inverting input voltage is less than V when the resistor divider, the comparator the output voltage is high, this signal will be M14 open, the voltage across R into M at both ends of the saturation voltage close to 0V, thereby further driving down the R1> R2, the partial pressure of the output voltage, the formation of the undervoltage positive feedback. Output, undervoltage lockout, and plays a protective role.5. Simulation results and analysisThe design of the circuit in CSMC 0.6 μm in digital CMOS process simulation and analysis of the circuit. In the overall simulation of the circuit, the main observation is that the protection module on the battery charge and discharge process by monitoring Vdd potential and Vm potential leaving chip CO side and DO-side changes accordingly. The simulation waveform diagram shown in Figure 7, the overall protection module with the battery voltage changes from the usual mode conversion into overcharge mode, and then return to normal working mode, and then into the discharge mode, and finally back to normal working mode. As the design in the early stages of the various parameters to be optimized, but to provide a preliminary simulation results.Figure7 Overvoltage and under-voltage protection circuit simulation waveform6.ConclusionDesigned a set of battery charging and protection functions in one IC. This design not only can reduce the product, they can reduce the peripheral circuit components. The circuit uses the low-power design. This project is underway to design optimization stage, a complete simulation can not meet the requirements, but also need to optimize the design of each module circuit.光伏系统中蓄电池的充电保护IC电路设计曾德友,凌朝东,李国刚1.引言太阳能作为一种取之不尽、用之不竭的能源越来越受到重视。

定日镜优化设计的优点定日镜(Solar Tracker)是一种能够跟随太阳运动的设备,用于优化太阳能收集效率的设计。

在太阳能发电系统中,定日镜的优化设计是非常重要的,它能够提高太阳能的吸收和利用效率,从而提高整个系统的能量产出。

本文将从多个方面介绍定日镜优化设计的优点。

定日镜优化设计可以提高太阳能收集效率。

太阳能是一种非常重要的可再生能源,广泛应用于太阳能发电系统中。

定日镜的优化设计可以让太阳能板始终朝向太阳,最大限度地吸收太阳能,提高能量转换效率。

通过跟踪太阳的运动,定日镜可以保持太阳能板与太阳垂直,最大程度地减少光线的反射和散射损失,使得光能可以更充分地被吸收和转换为电能。

定日镜优化设计可以提高太阳能发电系统的稳定性。

太阳能发电系统的运行稳定性对于长期稳定的能源供应至关重要。

定日镜通过跟踪太阳的运动,可以确保太阳能板始终朝向太阳,减少因太阳位置变化而引起的能量波动。

定日镜还可以通过及时调整太阳能板的角度,适应不同季节和天气条件下太阳的高度和位置变化,保持系统的稳定输出。

定日镜优化设计可以增加太阳能发电系统的产能。

通过最大限度地吸收太阳能,定日镜可以提高太阳能板的输出功率,增加系统的发电量。

定日镜的跟踪功能可以使太阳能板在一天中不同时间段都能保持最佳的入射角度,最大程度地提高能量转换效率。

这种增加产能的优点对于大规模商业太阳能发电系统尤其重要,可以提高系统的经济效益。

定日镜优化设计还可以减少能源系统的投资成本。

太阳能发电系统的建设和维护成本是一个重要的考虑因素。

通过使用定日镜,可以减少太阳能板的数量,因为每个太阳能板的发电量会得到最大化利用,降低了系统的投资成本。

定日镜优化设计可以减少对环境的影响。

太阳能是一种清洁、环保的能源形式,使用定日镜可以最大限度地利用太阳能,减少对传统能源的依赖。

定日镜的优化设计可以使太阳能发电系统的能源转换过程更加高效,从而减少对环境的污染和损害。

通过使用太阳能发电系统,可以减少温室气体排放,降低气候变化的风险,对环境保护起到积极的促进作用。

(文档含英文原文和中文翻译)中英文对照外文翻译英文原文Solar TrackerThe Solar Tracker team was formed in the fall of 2005 from five students in an ME design team, and a Smart House liaison. We continued the work of a previous solar tracker group. The task was to design a prototype tracking device to align solar panels optimally to the sun as it moves over the course of the day. The implementation of such a system dramatically increases the efficiency of solar panels used to power the Smart House. This report examines the process of designing and constructing the prototype, the experiences and problems encountered, and suggestions for continuing the project.1.IntroductionSolar tracking is the process of varying the angle of solar panels and collectors to take advantage of the full amount of the sun‟s energy. This is done by rotating panels to be perpendicular to the sun‟s angle of incidence. Initial tests in industry suggest that this process can increase the efficiency of a solar power system by up to 50%. Given those gains, it is an attractive way to enhance an existing solar power system. The goal is to build a rig that will accomplish the solar tracking and realize the maximum increase in efficiency. The ultimate goal is that the project will be cost effective – that is, the gains received by increased efficiency will more than offset the one time cost of developing the rig over time. In addition to the functional goals, the Smart House set forth the other following goals for our project: it must not draw external power (self-sustaining), it must be aesthetically pleasing, and it must be weatherproof.The design of our solar tracker consists of three components: the frame, the sensor, and the drive system. Each was carefully reviewed and tested, instituting changes and improvements along the design process. The frame for the tracker is an aluminum prismatic frame supplied by the previous solar tracking group. It utilizes an …A-frame‟ design with the rotating axle in the middle. Attached to the bottom of this square channel axle is the platform which will house the main solar collecting panels. The frame itself is at an angle to direct the panels toward the sun (along with the inclination of the roof). Its rotation tracks the sun from east to west during the day.The sensor design for the system uses two small solar panels that lie on the same plane as the collecting panels. These sensor panels have mirrors vertically attached between them so that, unless the mirror faces do not receive any sun, they are shading one of the panels, while the other is receiving full sunlight. Our sensor relies on this difference in light, which results in a large impedance difference across the panels, to drive the motor in the proper direction until again, the mirrors are not seeing any sunlight, at which point both solar panels on the sensor receive equal sunlight and no power difference is seen.After evaluation of the previous direct drive system for the tracker, we designed a belt system that would be easier to maintain in the case of a failure. On one end of the frame is a motor that has the drive pulley attached to its output shaft. The motor rotates the drive belt which then rotates the pulley on the axle. This system is simple and easily disassembled. It is easy tointerchange motors as needed for further testing and also allows for optimization of the final gear ratio for response of the tracker.As with any design process there were several setbacks to our progress. The first and foremost was inclement weather which denied us of valuable testing time. Despite the setbacks, we believe this design and prototype to be a very valuable proof-of-principle. During our testing we have eliminated many of the repetitive problems with the motor and wiring so that future work on the project will go more smoothly. We also have achieved our goal of tracking the sun in a …hands-off‟demo. We were able to have the tracker rotate under its own power to the angle of the sun and stop without any assistance. This was the main goal set forth to us by the Smart House so we believe our sensed motion prototype for solar tracking will be the foundation as they move forward in the future development and implementation of this technology to the house.2. Defining the ProblemT he project was to complete the “REV 2” design phase of the solar tracker to be used on the Smart House. While the team was comprised of members from the ME160 senior design course, the customer for this project was to be the Smart House organization. Jeff Schwane, a representative from the Smart House, was our liaison and communicated to our group the direction Smart House leadership wished us to proceed.At our first meeting with Jeff and Tom Rose, the following needs were identified:1.Track the sun during the daye no external power source3.Weather proof4.Cost effective power gain5.Must look good6.Solar panel versatile i.e. can fit different types of panelsWith these needs in hand, we constructed a Quality Function Deployment chart. This chart can be found in Appendix A. The QFD showed the major areas of concern might have been: number of panels/size of panels, internal power requirements, motor torque required.At our first meeting we were also able to set up our goals for the semester. Having a working prototype capable of tracking the sun was to be the main goal for the end of the semester, but we soon found that in order to accomplish this, we would be forced to omit portions of the design criteria in hopes they would be worked out later. This would result in the optimization of platform space on the roof to be irrelevant, with our goal being to have one platform track. It also led to the assumption that our base would not need to be tested for stability or required to be fastened to the roof. With an idea of where we were to begin, from scratch with the possibility of using the frame from the “REV 1” design, and an idea of where we were to finish, with a moving prototype, we constructed the Gantt chart that can be found in Appendix B. Our group planned to meet with Jeff once a week to make sure we were on track with the needs of the Smart House. Jeff would also meet with Tom Rose, the director of Smart House, at least once a week in order to keep everyone on the same page. With our goals in mind we embarked on the process of idea generation.3. Concepts and Research3.1 Tracking TypeOur group used a brainstorming approach to concept generation. We thought of ideas for different solar tracking devices, which proved difficult at times due to the existing frame and concept presented to us by Smart House. Other concepts were generated through research of pre-existing solar tracking devices. Originally our concept generation was geared towards creating a completely new solar tracker outside of the constraints of the previous structure given to us by Smart House. This initial brainstorming generated many concepts. The first one was a uni-axial tracking system that would track the sun east to west across the sky during the course of a day and return at the end of the day. This concept presented the advantage of simplicity and presented us with the option to use materials from the previous structure (which was also intended to be a uni-axial tracker) in construction. Another more complex concept was to track the sun bi-axially which would involve tracking the sun both east to west and throughout the seasons. The advantage of this concept was a more efficient harvesting of solar energy. The third concept was to only track throughout the seasons. This would provide small efficiency gains but nowhere near the gain provided by tracking east to west.The different structures we came up with to accomplish tracking motion included a rotating center axle with attached panels, hydraulic or motorized lifts which would move the main panel in the direction of the sun, and a robotic arm which would turn to face the sun. The clear efficiency gains coupled with the simplicity of design of the uni-axial tracking system and the existence of usable parts (i.e. motor and axle) for the rotating center axle structure, led us to the choice of the East to West tracking, rotating center axle concept.3.2 StructureOnce the method of motion was chosen, it was necessary to generate concepts for the structural support of the axle. Support could be provided by the triangular prismatic structure which was attempted by the previous Smart House solar tracker group or through the use of columns which would support the axis on either side. While the prismatic structure presented the advantage of mobility and an existing frame, the columns would have provided us with ease of construction, simple geometric considerations, and ease of prospective mounting on the roof. Due to the heightened intensity of time considerations, the previous financial commitment to the prismatic structure by Smart House, and our limited budget, the presence of the pre-existing frame proved to be the most important factor in deciding on a structure. Due to these factors we decided to work within the frame which was provided to us from the previous Solar Tracker group.3.2 Tracking MotionOnce the structural support was finalized we needed to decide on a means to actualize this motion. We decided between sensed motion, which would sense the sun‟s position and move t o follow it, and continuous clock type motion, which would track the sun based on its pre-determinedposition in the sky. We chose the concept of continuous motion based on its perceived accuracy and the existence of known timing technology. During the evaluation stage, however, we realized that continuous motion would prove difficult. One reason was the inability to draw constant voltage and current from the solar panels necessary to sustain consistent motion, resulting in the necessity for sensing the rotation position to compensate. Continuous motion also required nearly constant power throughout the day, which would require a mechanism to store power. Aside from these considerations, the implementation of a timing circuit and location sensing device seemed daunting. After consulting Dr. Rhett George, we decided on a device using two panels and shading for sensed motion.4. Analysis and Embodiment4.1 Structure GeometryThe geometry of the frame was created in order to allow the solar panels to absorb light efficiently. This was done by allowing rotation in the east-west direction for tracking the sun daily and a 36° inclination (Durham‟s latitude) towards the south. Because this frame was designed to be placed on a roof with a slope of 25°, the actual incline of the frame was made to be 11°.The geometry of the existing platform structure was modified. This was done in order to incorporate the results from the Clear Day Model supplied to us by Dr. Knight. This model led to the conclusion that the platform should track to up to 60° in both directions of horizontal. Thus, the angle range of the frame had to be increased. The sides of the frame were brought in to increase the allowable angle of rotation, and they were brought in proportionally to maintain the inclination angle of 11°. Also, crosspieces were moved to the inside of the frame to allow greater rotation of the platform before it came into contact with the support structure.The panels used for sensing and powering rotation were placed on the plane of the platform. Mirrors were placed perpendicular to and in between the panels to shade one and amplify the other in order to produce a difference to power the motor. The sensing panels were placed outside the platform area to maintain the largest area possible for collecting panels. A third sensing panel was mounted nearly vertical and facing east to aid rotation back towards the sun in the morning. This panel was attached to the frame under the platform, so that during most of the day, it‟s shaded with mi nimal effects on sensed rotation.Minimizing the torques on the motor was a main concern in order to minimize the motor power needed. The platform designed for the placement of the collecting solar panels was placed under the rotational shaft so that the panels would be aligned with it the rotational axis. Since the main panels comprise the majority of the weight putting these in the plane of the rotational axis reduces torque on the shaft. The sensing panels were placed symmetrically about the axis of rotation in order to preventadditional torque on the motor. The third panel was attached to the frame instead of the platform or rotational shaft so as to also avoid any torque.4.2 MaterialsMaterials selection for most of the frame was simple because it had already been constructed. The mirrors used for the amplification and shading of the sensing panels were also already purchased and available for use. Additional parts for attachment of the panels and mirrors to the frame were taken from the scrap pieces available in the machine shop. In our selection of sensing panels, size and power needed to be balanced effectively. The panels were to be as small as possible in order to add minimal stress and weight to the frame but also needed to be powerful enough to power the rotation of the platform. Therefore, the most powerful of the intermediate sized panels available were selected. The panels purchased also appeared to be the most reliable of our options.4.3 Drive MechanismAfter designing a prototype and testing it, the motor purchased and used by the previous solar tracker group was slipping. It was removed, and the installation of a gear system with another simple motor was suggested and attempted. Professor Knight supplied some gears as well as some belts and pulleys. One end of the shaft was lathed so that one of the pulleys could be set on it, and spacers were bought so that a 6V motor we had available could power another pulley. These pulleys were to be connected by a belt. This motor demonstrated insufficient strength to turn the rotational shaft. The original motor, once detached, was taken apart and examined. Itappeared to be working again so a new pulley was purchased to fit it and was attached in the place of the 6V motor.5. Detailed Design5.1 FrameThe frame was designed from one inch square aluminum tubing, and a five foot long, two inch square tube for the axle. It is constructed with a rigid base and triangular prismatic frame with side supporting bars that provide stability. The end of the axle is attached to a system of pulleys which are driven by the motor. It is easily transported by removing the sides of the base and folding the structure.5.2 SensorOur sensing panels are bolted to the bottom of the main solar panel frame and braced underneath with half inch L-brackets. The mirrors are attached to the inside of the sensing panels and braced by L-brackets as well. The whole structure attaches easily to the main panel frame which is attached to the main axle using four 2-inch U-bolts. A third panel is bolted to the structure to return the main panels direction towards the horizon of sunrise.5.3 How the Sensor WorksOur sensor creates movement of the motor by shading one of the panels and amplifying the other when the system is not directly facing the sun. The two sensing panels are mounted parallel to the main panels symmetrically about the center axle with two mirrors in between them. The shading on one of the panels creates high impedance, while the amplified panel powers the motor. This happens until the panels receive the same amount of sunlight and balance each other out (i.e. when the sensing panels and main panels are facing the sun.). We initially attempted using a series configuration to take advantage of the voltage difference when one of the panels was shaded (Appendix C). This difference, however, was not large enough to drive the motor. We subsequently attempted a parallel configuration which would take advantage of the impedance of the shaded panel (Appendix C) and provide the current needed to drive the motor. Once the sensing mechanism has rotated from sunrise to sunset, the third panel, which is usually shaded, uses sunlight from the sunrise of the next day to power the motor to return the panels towards the direction of the sun.6. Prototype TestingInitial testing was done using just the sensing component and a 6V motor. The panels were tilted by hand to create shading and amplification. A series configuration of the sensing panels was initially tested and proved ineffective. Data acquisition showed a maximum of a 2V difference across the motor, which was insufficient to power it. Upon testing the panels individually, it was discovered that the open voltage across each individual panel would only vary between 21.5V and 19.5V when fully amplified and fully shaded, respectively. The current running through each panel, however, was seen to fluctuate between nearly 0 amps when shaded, up to 0.65 amps when fully amplified. Therefore, in order to take advantage of the increase in impedance of the solar panels due to shading, we chose to put our sensing panels in parallel with each other and the motor. Tests with this configuration turned the motor in one direction, stopped when the sensing panels were nearly perpendicular to the sun, and reversed direction as the panels rotated past perpendicular. We found the angle range necessary to stop the motor to be very small. It was also observed that the panels rotated to slightly past perpendicular when they ceased motion. This error may be due to a difference in the innate resistance in each individual sensing panel. When tested it was found that one panel had a resistance of 52 kΩ, and the other panel resistance was 53 kΩ. Other testing found the voltage and current provided by the sensing solar panels to the motor to be consistent at all points, excluding when the solar panels are directly facing the sun. Through testing it was concluded that resistance may need to be added to one of the panels to compensate for the differences in the internal resistances of the individual panels, and a voltage regulator needs to be added to decrease the voltage seen across the motor. The original motor was prone to failure as its slippage caused the breakdown of our initial prototype after testing. This led to the institution of the pulley and belt driven system which would allow for easier maintenance givenmotor failure or slippage. The success of our initial testing and prototype proved to us the efficacy of our solar tracker design.7. ConclusionThroughout this project we enlisted the support of multiple resources (i.e. ME and EE professors, previous Smart House teams). We learned early on that a clear problem definition was essential to efficient design and progress. We struggled initially as we tried to design a tracking device that was different from the previous solar tracker group‟s attempt, without fully weighing the size of their investment and the advantages of using the existing frame for our purposes. As we worked with the fixed frame construction from the previous group we learned that variability of design is key, especially when in the initial phases of prototyping. After many setbacks in testing of the solar panels, we learned that when working with solar panels, much time needs to be set aside for testing due to the unpredictability of the weather.The actual implementation of using the prototype in its intended location on the Smart House roof requires weather-proofing to protect the wiring and electrical connections from the elements, housing for the motor, a bracing system to attach the structure to the roof, and possible redesign to eliminate excess height and simplify overall geometry. The efficiency of the sensor system could be improved by widening the mirrors or by placing blinders along the sides of the panels to decrease the effects of reflected and refracted light incident on the shaded sensing panel.中文译文太阳能跟踪器简介太阳能跟踪队成立于2005年秋季,设计团队由五名队员组成,我们还负责与智能家居的联络工作。

A1、absorptions coefficient——吸收系数, 吸收强度(α-吸收系数)2、aperture diameter width——开口直径,指槽式聚光镜抛物槽的开口直径大小3、axis——轴4、azimuth——方位角,方位角又称地平经度(Azimuth (angle)缩写Az),是在平面上量度物体之间的角度差的方法之一。

是从某点的指北方向线起,依顺时针方向到目标方向线之间的水平夹角。

5、absorptance——吸收率6、assembly——组装7、Alternating current——交流电8、AM, air mass的缩写, 空气质量.直射阳光光束透过大气层所通过的路程,以直射太阳光束从天顶到达海平面所通过的路程的倍数来表示。

9、Anneal——退火10、as-built drawing——竣工图B1、bypass valve——旁路阀2、biomass——生物质,太阳能电站混合供电系统中用到的生物质发电技术C1、concentrating Solar Power——聚光式太阳能发电,简称CSP,又叫做STP(Solar Thermal Power)——光热太阳能发电2、concentrator——聚光器或聚光镜3、collector——集热器,直接将太阳能转化为热能,使用高储热的物质诸如水或油等,之后使用热交换器使用所搜集的热量。

是聚光太阳能设备的总称,其中包括,concentrator(聚光镜)和receiver(接收器).4、collecting loop 集热回路,槽式太阳能集热回路包括两种模式,一种是双回路系统,包括导热油(HTF系统)和(水蒸汽系统),另一种叫DSG系统,直接产生蒸汽系统。

两种系统的区别在于,第一种是由导热油做为热量转换的中间介质,而后者是太阳能直接转化为水蒸气的热能。

第一种系统效率低于第二种,第二种技术对集热管要求较高。

(Skyfuel公司在文件中介绍的便是采用南北向布置的双回路带储能的槽式发电系统。

太阳能产业行业术语光伏产业链PV industry chain多晶硅原料-----单晶硅棒----单晶硅片----晶体硅电池----电池封装----系统集成----工程安装polycrystalline silicon raw material ---mono-crystalline silicon ingot---mono-crystalline silicon wafer---crystalline silicon cell—cells encapsulation---system integration---construction installation单词:1.单晶硅片mono-crystalline silicon wafer多晶硅片polycrystalline silicon wafer晶向orientation少数载流子寿命lifetime导电类型conductivity type位错密度dislocation硅单晶片厚度thickness硅单晶片的弯曲度surface camber准方单晶硅片: quasi-square mono-crystalline silicon wafer2.太阳电池solar cell3.薄膜太阳电池film solar cell4.光电转换photo-electricity conversion5.太阳电池组件solar module多晶硅太阳电池组件polycrystalline solar module单晶硅太阳电池组件mono-crystalline solar module6.太阳能户用系统solar home system(分为:太阳能直流户用系统;太阳能交流户用系统;太阳能交直流户用系统)7.太阳能电站solar power station(分为:离网型太阳能电站off-grid solar power station ;并网型太阳能电站grid-connected solar power station )8.太阳能热水器solar water heater9.太阳能热水系统:solar heating system10.太阳能直流式热水系统: solar direct heating system11.太阳能强迫循环热水系统solar compelling cycle heating system12.太阳能自然循环热水系统solar spontaneously cycle heating system13.真空管太阳能集热器vacuum tube solar centralized heating system14.平板型太阳能集热器flat type solar centralized heating system15.全玻璃真空太阳能集热器full-glass vacuum solar centralizedheating system16.热管式真空管太阳集热器heat-tube vacuum solar centralizedheating system17.采光面积: lighting area18.太阳能幅照度solar radiant intensity19.太阳能控制器:solar controller20.太阳能逆变器:solar inverter21.太阳能通讯基站solar telecommunication power systems22.石油和天然气管道太阳能阴极保护电站:solar power stations forcathode protection of the oil and gas feeding pipes23.太阳能电池方阵solar array24.太阳能通讯电源solar communication power station25.太阳能自动跟踪装置solar automatic tracker26.太阳能移动电源车(站)solar mobile electrical vehicle (station)27.光伏水泵solar pump28.太阳能杨水系统solar pumping system29.光—网---柴互补系统complementary system for solar –grid-dieseloil30.风---光互补系统complementary system for solar - wind31.太阳能交通信号灯solar traffic signal light32.太阳能交通警示标志solar traffic warning symbol33.太阳能道钉solar road mark34.太阳能庭院灯solar garden light35.太阳能路灯solar street light36.太阳能草坪灯solar lawn light37.太阳能广告牌solar billboard38.太阳能电话亭solar telephone booth短语:太阳能扬水和照明综合应用系统:the comprehensive utilization system of solar pumping and lighting变频调速交流异步电机:high-efficient frequency conversion alternating asynchronous motors(这个产品不是太阳能产品)送电到乡: Power Supply to Township丝绸之路光明工程:Silk Road Brightness Project太阳能亮化工程solar brightness project太阳能与建筑一体化integrate solar energy with building。

光伏发电板(电池) (Cell-photovoltaic)太阳能发电板中最小的组件.光伏发电系统平衡(BOS or Balance of System - photovoltaic) 光伏发电系统除发电板矩阵以外的部分. 例如开关, 控制仪表, 电力温控设备, 矩阵的支撑结构, 储电组件等等.光伏矩阵或发电板阵(Array - photovoltaic) 太阳能发电板串联或并联连接在一起形成矩阵.阻流二极管(Blocking Diode)用来防止反向电流, 在发电板阵中, 阻流二极管用来防止电流流向一个或数个失效或有遮影的发电板(或一连串的太阳能发电板) 上. 在夜间或低电流出的期间, 防止电流从蓄电池流向光伏发电板矩阵."旁路二极管(Bypass Diode)是与光伏发电板并联的二极管. 用来在光电板被遮影或出故障时提供另外的电流通路.充电显示器(表) (Charge Monitor/Meter) 用以测量电流安培量的装置, 安培表.充电调节器(Charge Regulator)"用来控制蓄电池充电速度和/或充电状态的装置, 连接于光伏发电板矩阵和蓄电池组之间. 它的主要作用是防止蓄电池被光伏发电板过度充电, 同时监控光伏发电矩阵和/或蓄电池的电压."组件(Components)指用于建立太阳能电源系统所需的其他装置.交直流转换器(Converter) 将交流电转换成直流电的装置.晶体状(Crystalline)具有三维的重复的原子结构.直流电(DC)"两种电流的形态之一, 常见于使用电池的物件中, 如收音机, 汽车, 手提电脑, 手机等等."无序结构(Disordered)减小并消除晶格的局限性. 提供新的自由度, 从而可在多维空间中放置其他元素. 使它们以前所未有的方式互相作用. 这种技术应用多种元素以及复合材料它们在位置, 移动及成分上的不规则可消除结构的局限性, 因而产生新的局部规则环境. 而这些新的局部环境决定了这些材料的物理性质, 电子性质以及化学性质. 因此使得合成具有新颍机理的新型材料成为可能.电网连接- 光伏发电(Grid-Connected - photovoltaic) 是一种由光伏发电板阵向电网提供电力的光伏发电系统. 这些系统可由供电公司或个别楼宇来运作.直流交流转换器(Inverter)用来将直流电转换成交流电的装置.千瓦(Kilowatt)1000 瓦特, 一个灯泡通常使用40至100 瓦特的电力.百万瓦特(Megawatt)1,000,000 瓦特光伏发电板(Module - photovoltaic) 光伏电池以串联方式连在一起组成发电板.奥佛电子(Ovonic)[以S. R. 奥佛辛斯基(联合太阳能公司创始人)及电子的组合命名] - 用来描述我们独有的材料, 产品和技术的术语.奥佛辛斯基效应(Ovshinsky effect) 一种特别的玻璃状薄膜在极小电压的作用下从一种非导体转变成一种半导体的效应..并联连接(Parallel Connection)一种发电板连接方法. 这种连接法使电压保持相同, 但电流成倍数增加峰值输出功能(Peak Power)持续一段时间(通常是10 到30 秒)的最大能量输出.光伏(Photovoltaic - PV)光能到电能的直接转换.光伏发电板(电池) (Photovoltaic Cell) 经过特殊处理可将太阳能辐射转换成电力的半导体材料.卷到卷工序(Roll-to-Roll Process) 将整卷的基件连续地转变成整卷的产品的工序.串联连接(Series Connection)电流不变电压倍增的连接方式.太阳能(Solar)来自太阳的能量.太阳能收集器(Solar Collectors)用以捕获来自太阳的光能或热能的装置. 太阳收集器用于太阳能热水器系统中(常见于住家), 而光伏能收集器则是用于太阳能电力系统.太阳能加热(Solar Heating) 利用来自太阳的热能发电的技术或系统. 太阳能收集器用于太阳能热水器系统中(常见于住家), 而光伏能收集器则是用于太阳能电力系统中太阳能发电模块或太阳能发电板(Solar Module or Solar Panel) 一些由太阳能发电板单元所组成的太阳能发电板板块.稳定能量转换效率(Stabilized Energy Conversion Efficiency) 长期的电力输出与光能输入比例.系统, 平衡系统(Systems; Balance of Systems)"太阳能电力系统包括了光伏发电板矩阵和其它的部件. 这些部件可使这些太阳能发电板得以应用在需要可控直流电或交流电的住家和商业设施中. 用于太阳能电力系统的其它部件包括:接线和短路装置, 充电调压器,逆变器, 仪表和接地部件."薄膜(Thin-Film)在基片上形成的很薄的材料层.瓦特(Watts)用电压乘以电流的值来衡量的电力度.MWpMWp 的具体解释:M 是兆瓦,1MW 是1000KW ,WP 是太阳能电池的瓦数,是指在1000W/ 平方光照下的太阳能电池输出功率,与实际太阳光照照强度有区别.伏特(Volts)电动势能单位•能促使一安培的电流通过一欧姆的电阻•电压(Voltage)电势的量. 电压表(Voltage Meter)用以测量电压的装置.屋顶光伏屯源系统Rt K)f-UK>untedPVpciwersystern独立家庭电源系统Off- gi idhi)int?p<>ivei systt*i TI小述太阳能发屯系统Resident L4JtlureuPVp<jw or ay stem光伏建筑一体化BIPVproducts太阳能境电在1 芒馆、学校中的应用Appl icat ionsof solarPV 1 nhote 1 sandschc ml a移动信号塔太阳能发电猥胃So larPVp< iwersystemsformobi 1 ecomiitur] i cations i gnalstat i ons移动通f方垒汨T工放汕电源PVpt用systpnisf<>rGS\fljnsesttil ioils小型并网光伏社站sjna】lon^gridPVpowerstation人平井网光伙i|l?[S liirg&i en]-^ridPVp(i'WPrstci t iori乡tft公路太阳能路灯灼应用Solarstreet 1 ightsforrura 1 roadsA L R I 能建设新农村工程Solarprojec tssfornowvil Iagos城rfl A阳能庭院灯的応ffl SolargardenL ight sforci t ies乡镇太阳能庭院灯的应用So 1 ar gar de n 1 i gh t s f or town s郊区太阳能冲坪灯工程Sol ar 1 awn 1 i gh t s f<)r suburbs太阳能交通";弓灯匸程 Installationof solar trafficsigns成乡风光互补路灯丈例WindanclI^hybridstre?!! ights卜区风光互补系统 WindandPVhybridpowersysteinsforresidentialareas入力发屯系统的应用Windgeneratingsysterns人阳能方血专业术语「I1英文对照诠脅[原文地址]比伏发电板(电池)(Cell-photovoltaic)太阳能发屯板屮最小的组件.光伏发电系统平衡(BOS or Balance of System 一photovoltaic)光伏发屯系统除发电板矩阵以外的部分.例如开关,控制仪丧,电力温控设备,矩P 芟撑结构,储电组件等等.此伏矩阵或发电板阵(Array - photovoltaic)太阳能发电板串联或并联连接在一起形成矩阵.目流二极管(Blocking Diode)您影的发电板(或一连小的太阳能发电板)上.在夜间或低电流出的期间,防止电流》社池流向光伏发电板矩阵・"旁路二极管(Bypass Diode)足与光伏发电板并联的二极管・用來在光电板被遮影或川故障时捉供刃外的电流通学充电显示器(表)(Charge Monitor/Meter'用以测量屯流安培量的装置,安培表.充电调节器(Charge Regulator)"川來悴制薔电池充电速度利/或充电状态的装置,连接于光伏发电板矩阵和蒂电池彳nJ.它的主要作用足防止需电池被光伏发电板过度充屯,同时监拧光伏发屯矩阵和/或他的电压・"组件(Components)指用于建立太阳能电源系统所需的戏他装置.交直流转换器(Converter)将交流电转换成直流电的装買.晶体状(Crystalline)具有三维的重复的原子结构.直流电(DC)"两种电流的形态Z- 常见于使用电池的物件中,如收音机,汽车,手提电脑,T无序结构(Disordered)减小并消除晶格的局限性.提供新的自山度,从而可在多维空间屮放置戏他兀素・{ 门以丽所未冇的力武互相作用.这种技术应用多种兀素以及复介材科.它们在位胃,I 及成分I】的不规则诃消除姑构的局限性,因而产生新的局部规则环境.而这此新的局* 竟决定了这些材料的物理性质,电了性质以及化学性质.冈此使得合成具冇新颍机理G 型材料成为可能.电网连接-光伏发电(Grid-Connected - photovoltaic)是一种由光伏发电板阵向电网捉供电力的光伏发电系统.这映系统可曲供电公司或彳 *宇来运作.I直流交流转换器(Inverter)用来将恵流电转换成交流电的装置.千瓦(Kilowatt)1000瓦特,一个灯泡通常使用40至100瓦恃的屯力.13■万瓦特(Megawatt)1, 000, 000 瓦特光伏发电板(Module - photovoltaic)光伏电池以串联方式连在一起组成发电板,奧佛电了(Ovonic)[以S. R•奥佛辛斯基(联合太阳能公司创始人)及电子的组合命名]-用來描述我们勺材料,产品和技术的术语.奥佛辛斯基效应(Ovshinsky effect)一种特别的玻璃状薄膜在极小电压的作用卜从一种非导体转变成一种半导体的效应… | 并联连接(Parallel Connection)一种发电板连接力法.这种连接法使电爪保持相同,但电流成倍数增加峰值输出功能(Peak Power)持续一段时间(通常是10到30秒)的敲大能量输出.光伏(Photovoltaic PV)光能到电能的宜接转换.光伏发电板(电池)(Photovoltaic Cell)经过特殊处理可将太阳能辐射转换成电力的半导体材料.卷到卷工序(Roll-to-Roll P roe ess)将整卷的基件连续地转变成整卷的产品的工序.巾联连接(Series Connection)电流不变电压倍增的连接方式.太阳能(Solar)米自太阳的能量.太阳能收集器(Solar Collectors)用以捕快來自太阳的光能或热能的装胃.人阳收集器用于K阳能热水器系统小(常贝「家人1ft]光伏能收集器则是用于太阳能电力系统.I太阳能加热(Solar Heating)利用來自人阳的热能发电的技术或系统.太阳能收集器用丁太阳能热水器系统小(常七家),血光伏能收集器则是用于太阳能电力系统中太阳能发屯模块或太阳能发屯板(Solar Module or Solar Panel)一些山太阳能发电板单元所组成的太阳能发电板板块.稳定能量转换效率(Stabilized Energy Conversion Efficiency)长期的电力输出与光能输入比例.系统,平衡系统(Systems; Balance of Systems)"人阳能电力系统包括了光伏发电板矩阵和其它的部件.这些部件可使这些太阳能发写以应用在需喪吋控玄流电或殳流电的住家和商业设施川・用于太阳能电力系统的!代乍但括:接线和短路装置,充电调圧器•逆变器,仪表和接地部件・"薄膜(Thin-Film)在基片上形成的很鞠的材料层.瓦特(Watts)用电压乘以电流的值來衡量的电力度.MWpMWp的具体解释:M是兆瓦,1MV是1000KW , WP是太阳能电池的瓦数,是指在1000W/平!«卜的太阳能电池输出功率,与实际太阳光照照戲度冇区別•伏特(Volts)电动势能单位.能促使一安培的电流通过一欧姆的屯阻.屯压(Vol tage)电势的•量.电压表(Vo 1 tage Me ter)用以测虽电压的装置.甸立国的太阳能屯池专业英语Ampere的缩写,安培amorph silicon的缩写,含氢的,非结晶性硅.absorption,吸收.ibsorption of the photons:光吸收;为能量大于禁带宽度的光子入射时.太阳电池内r能量从价带迁到导____________________________________________________;卜产生电子——空穴对的作用.称为光吸收•\b s or p t i on scoef f i c i en t,吸收系数,吸收强度.C,交流电.k安培小时.\cceptor,接收者,在半导体中可以接收一个电了.\lternating current,交流电•简称“交流.-般扌旨人小和力向随时I可作周期性变化衣或电流.它的最基木的形式是正弦屯流.我国交流电供电的标准频率规定为50赫兹,交流电随时间变化农可以是多种多样的。

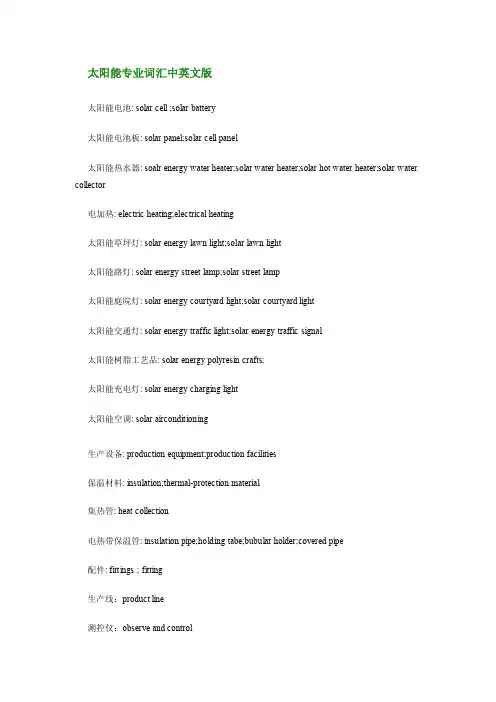

太阳能专业词汇中英文版太阳能电池: solar cell ;solar battery太阳能电池板: solar panel;solar cell panel太阳能热水器: soalr energy water heater;solar water heater;solar hot water heater;solar water collector电加热: electric heating;electrical heating太阳能草坪灯: solar energy lawn light;solar lawn light太阳能路灯: solar energy street lamp;solar street lamp太阳能庭院灯: solar energy courtyard light;solar courtyard light太阳能交通灯: solar energy traffic light;solar energy traffic signal太阳能树脂工艺品: solar energy polyresin crafts;太阳能充电灯: solar energy charging light太阳能空调: solar airconditioning生产设备: production equipment;production facilities保温材料: insulation;thermal-protection material集热管: heat collection电热带保温管: insulation pipe;holding tabe;bubular holder;covered pipe配件: fittings ; fitting生产线:product line测控仪:observe and control水位:waterwater level,water line水温: water temperature ;water temperature光控开关:photoswitch蓄电池: accumulator, secondary, cellstorage, battery,storage cell承压:pressure进水口: infall出水口:osculum,outlet,water outlet,dischatge port,drainage opening,delivery port,water outlet,delivery gate,drain outlet发光二极管:light-emittig diode, LED太阳能供电系统:solar power system控制器:controller;director;control逆变器:inverter;invertor;电线:electrical wire;current lead ;electric line;flex;wire;cord;shoestring;power cord冷阴极灯管:CCFL冷阴极灯:cold cathode lamp节能灯:energy-saving lamp支架:bracket;support;不锈钢:stainless steel反光板:inlluminator铸铝:cast aluminium;aluminum casting;cast aluminum聚光灯/投光灯:spoting light霓虹灯:neon light;neon sign锂电池:lithium cell;lithium power镍镉电池:nickel cadmium cell;nickel-cadmium cell;nickel cadmium battery镍氢电池:nickel hydrogen cell铅酸电池:lead-acid cell;lead-acid battery;灯柱:light staff;lamp post;light staff;lighting column;lighting standard输出电压:output voltage输出电流:current output ;outgoing current ;output current非晶硅:amorphous silicon;non crystallosilicon ;noncrystallosilicon多晶硅:multicrystal silicon; polycrystalline silicon; silicon polycrystal单晶硅:monocrystalline silicon;single crystalline silicon短路电压:short circuit voltage短路电流:shore circuit current ;short circuit current额定功率:nominal power ;normal power ;power rating ;rated horse power ;rated power 硅胶:silica gel环氧树脂:araldite ;epoxide resin ;epoxy resin亮度:brightnesslighteness;lum;luminance;luminosity光强:intensity of light ;lighting intensity ;luminous intensity电压:electric pressure;electric voltage;voltage电流:electric current ;electrical current直流:direct current交流:alternating current ;interflow水箱:water tank;storage cistern;内胆:internal bladder保温层:insulating blanket ;insulating coat ;insulating layer ;insulation course ;thermal barrier ;thermal insulation layer。

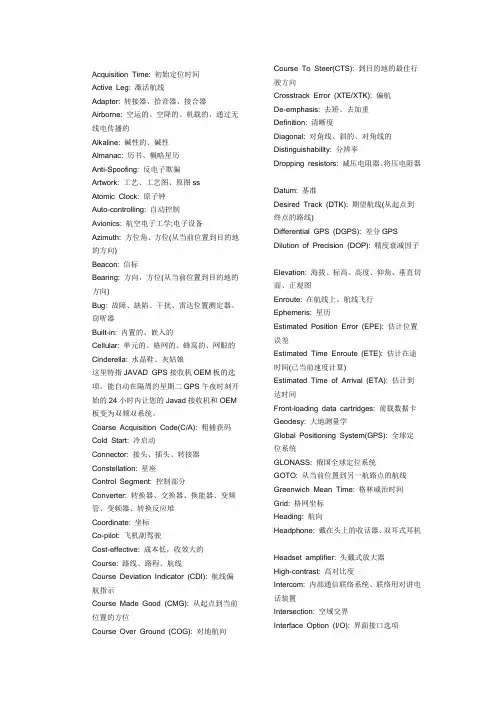

Acquisition Time: 初始定位时间Active Leg: 激活航线Adapter: 转接器、拾音器、接合器Airborne: 空运的、空降的、机载的、通过无线电传播的Alkaline: 碱性的、碱性Almanac: 历书、概略星历Anti-Spoofing: 反电子欺骗Artwork: 工艺、工艺图、原图ssAtomic Clock: 原子钟Auto-controlling: 自动控制Avionics: 航空电子工学;电子设备Azimuth: 方位角、方位(从当前位置到目的地的方向)Beacon: 信标Bearing: 方向,方位(从当前位置到目的地的方向)Bug: 故障、缺陷、干扰、雷达位置测定器、窃听器Built-in: 内置的、嵌入的Cellular: 单元的、格网的、蜂窝的、网眼的Cinderella: 水晶鞋、灰姑娘这里特指JAVAD GPS接收机OEM板的选项,能自动在隔周的星期二GPS午夜时刻开始的24小时内让您的Javad接收机和OEM 板变为双频双系统。

Coarse Acquisition Code(C/A): 粗捕获码Cold Start: 冷启动Connector: 接头、插头、转接器Constellation: 星座Control Segment: 控制部分Converter: 转换器、交换器、换能器、变频管、变频器、转换反应堆Coordinate: 坐标Co-pilot: 飞机副驾驶Cost-effective: 成本低,收效大的Course: 路线、路程、航线Course Deviation Indicator (CDI): 航线偏航指示Course Made Good (CMG): 从起点到当前位置的方位Course Over Ground (COG): 对地航向Course To Steer(CTS): 到目的地的最佳行驶方向Crosstrack Error (XTE/XTK): 偏航De-emphasis: 去矫、去加重Definition: 清晰度Diagonal: 对角线、斜的、对角线的Distinguishability: 分辨率Dropping resistors: 减压电阻器、将压电阻器Datum: 基准Desired Track (DTK): 期望航线(从起点到终点的路线)Differential GPS (DGPS): 差分GPS Dilution of Precision (DOP): 精度衰减因子Elevation: 海拔、标高、高度、仰角、垂直切面、正观图Enroute: 在航线上、航线飞行Ephemeris: 星历Estimated Position Error (EPE): 估计位置误差Estimated Time Enroute (ETE): 估计在途时间(已当前速度计算)Estimated Time of Arrival (ETA): 估计到达时间Front-loading data cartridges: 前载数据卡Geodesy: 大地测量学Global Positioning System(GPS): 全球定位系统GLONASS: 俄国全球定位系统GOTO: 从当前位置到另一航路点的航线Greenwich Mean Time: 格林威治时间Grid: 格网坐标Heading: 航向Headphone: 戴在头上的收话器、双耳式耳机Headset amplifier: 头戴式放大器High-contrast: 高对比度Intercom: 内部通信联络系统、联络用对讲电话装置Intersection: 空域交界Interface Option (I/O): 界面接口选项Initialization: 初始化Invert Route: 航线反转Jack: 插座、插孔Keypad: 键盘、按键Kinematic: 动态的L1 Frequency: GPS信号频率之一(1575.42 MHz)L2 Frequency: GPS信号频率之一(1227.6 MHz)Latitude: 纬度、纬线Leg (route): 航段,航线的一段Liquid Crystal Display (LCD): 液晶显示器Local Area Augmentation System (LAAS):局域增强系统Localizer: 定位器、定位发射机、定位信标Longitude: 经度、经线Long Range Radio Direction Finding Syst em (LORAN): 罗兰导航系统Magnetic North: 磁北Magnetic Variation: 磁偏角Map Display: 地图显示Meter: 米Mount: 安装、支架、装配、管脚、固定件Multiplexing Receiver: 多路复用接收机Multipath: 多路径Nautical Mile: 海里(1海里=1.852米). Navigation: 导航Navigation Message: 导航电文NAVigation Satellite Timing and Ranging (NAVSTAR) Global Positioning System: G PS系统的全称National Marine Electronics Association (NMEA): (美国)国家航海电子协会NMEA 0183: GPS接收机和其他航海电子产品的导航数据输出格式North-Up Display: GPS屏幕显示真北向上Observatory: 观象台、天文台Offset: 偏移量Omnidirectional: 全向的、无定向的Orientation: 方位、方向、定位、倾向性、向东性Panel: 仪表盘、面板Panel-mount: 配电盘装配Parallel Channel Receiver: 并行通道接收机P-Code: P码Photocell: 光电管、光电池、光电元件Pinpoint: 极精确的、准确定位、准确测定、针尖Pixel: 象素Position: 位置Position Fix: 定位Position Format: 位置格式Power-on: 接通电源Pre-amplifier: 前置放大器Prime Meridian: 本初子午线Pseudo-Random Noise Code: 伪随机噪声码Pseudorange: 伪距Rack: 齿条、支架、座、导轨Resolution: 分辨率Route: 航线RS-232: 数据通信串口协议Radio Technical Commission for Maritime Services (RTCM): 航海无线电技术委员会,差分信号格式Selective Availability (SA): 选择可用性Sidetone: 侧音Source: 信号源、辐射体Space Segment: 空间部分Speed Over Ground (SOG): 对地航速Specifcation: 详述、说明书、规格、规范、特性Split Comm: 分瓣通信Squelch:静噪音、静噪电路、静噪抑制电路Statute Mile: 英里(1英里=1,609米) Straight Line Navigation: 直线导航Strobe: 闸门、起滤波作用、选通脉冲、读取脉冲TracBack - 按航迹返航Track-Up Display - 航向向上显示Track (TRK): 航向Transceiver:步话机、收发两用机Transponder: 雷达应答机、(卫星通讯的)转发器、脉冲转发机Transducer: 渔探用探头、传感器Triangulation: 三角测量True North: 真北Turn (TRN): 现时航向和目的地之间的夹角Two-way: 双向的、双路的、双通的Universal Time Coordinated (UTC): 世界协调时间Universal Transverse Mercator (UTM): 通用横轴墨卡托投影U.S.C.G.: 美国海岸警卫队User Interface: 用户自定义界面User Segment: 用户部分Velocity Made Good (VMG): 沿计划航线上的航速Viewing angles: 视角Waypoint: 航路点Wide Area Augmentation System (WAAS):广域差分系统World Geodetic System - 1984(WGS-84): 1984年世界大地坐标系Windshield: 防风玻璃、防风罩Y-Code: 加密的P码Yoke: 架、座、轭、磁轭、磁头组、偏转线圈火箭发射常见用词神舟号 Shenzhou (Divine Vessel)载人飞船 manned spaceship/ spacecraft载人航天 manned space flight载人航天计划 manned space program航天飞机 space shuttle无人飞船 unmanned spaceship / spacecraft 试验太空船 Experimental Spacecraft多级火箭 multistage rocket太空舱 capsule返回式卫星 recoverable satellite通信卫星 communication satellite遥感卫星 remote sensing satellite运载火箭 carrier rocket; rocket launcher 长征二号F运载火箭 Long March II F carrier rocket有效载荷能力 payload capability近地轨道 low Earth orbit气象卫星 weather satellite; meteorological satellite太阳同步轨道卫星 satellite inSun-synchronous orbit 同步轨道卫星 geosynchronous satellite 轨道舱 orbital module返回舱 re-entry module推进舱 propelling module指令舱 command module服务舱 service module登月舱 lunar module发射台 launch pad紧急供氧装置 emergency oxygen apparatus 空间物理探测 space physics exploration 国际空间站 International Space Station 太阳能电池板 solar panel太空升降舱 space elevator哈勃太空望远镜 Hubble Space Telescope 月球车 lunar rover外太空 outer space; deep space银河系 Milky Way阿波罗号宇宙飞船 Apollo美国航空航天管理局 NASA(The National Aeronautics and Space Administration)。

全新版大学进阶英语第二册第一单元课文中英对照Living Off the Grid: How a Family of City-Dwellers Discovered the Simple LifeBy Alison Zeuschel1 After living in the 24-hour city of Las Vegas, Nevada for nearly ten years, my family and I decided to slow things down. My daughter wanted a horse. My husband wanted property. My son wanted a dirt bike. I wanted our family to be more self-sufficient.2 None of us felt that this could be accomplished where we were living and we all agreed that a move to the country would be great for everyone.3 Before long we set about looking for a home in Yucca, Arizona, a very small town of less than 1,000 people. It was while I was scanning listings from our real estate agent that I first learned of it. There was a home for sale there on 40 acres. When I called to inquire about the property, I was informed that there was no electricity available in the area. What? No electricity? I almost dismissed the idea immediately.4 The property was off the grid. It was not connected whatsoever to any utilities — power, water or sewer. Power was supplied by a wind turbine and solar panels. Water had to be hauled in and stored in two tanks located on the property. Forty acres would give us plenty of room for all of our animals and give my husband and son space to ride their ATVs. Besides, what better way is there to become more self-sustainable? After giving it some thought, we decided to put in an offer and moved in on Thanksgiving Day.5 When we first moved to the property, we did some remodeling and stayed in our motor home. We were confronted with real challenges at the time. The power kept going out, the main water line to the house broke, the plumbing backed up into the front yard and the generator died.6 But the setbacks just made us work harder. We slowly got things fixed and moved into the houseafter 38 days in the RV. The next challenge was to become familiar with your power system, and to learn the ins and outs of hauling your own water and generating your own power.7 Our off-the-grid system consists of eight solar panels (1,000 watts) that are mounted on a sun tracker rack. We also have a wind turbine that generates 3,000 watts in 24 mph winds. The energy generated by the wind and sun is stored in 16 6v golf cart batteries. We also have two 2,500-gallon above-ground water tanks and a 250-gallon propane tank. Every weekend, we haul two 275-gallon water tanks to the nearby town of Yucca and fill them with water, which we then pump into our big water tanks.8 While living here for the past four months has been a big adjustment, there are many benefits to living off the grid. I think one of the greatest is teaching my kids the importance of conservation. They used to take water, power and gas for granted. The first week we were here, we used almost 1,000 gallons of water. With only a 5,000-gallon water tank, it didn’t take them long to understand that we had to use less water. We started taking quicker showers, doing only full loads of laundry, turning off the water while brushing our teeth or shaving.9 Over-consumption is even more clearly demonstrated by our electricity usage. We have a digital readout of how many volts of DC power we have stored in our batteries at any given time. If you turn on a light or the TV, the number goes down. In order to protect the batteries, the system is set up to shut the inverter off if the volts get too low. Then the power goes out. When we first moved in, we lost power almost daily. After this happens a few times, it becomes clear very quickly just how often you waste electricity. Everything from lights and ceiling fans to computers and radios were left on when they were not in use. The cell phone chargers were plugged in even when they weren’t charging anything. All of this uses unnecessary power. We aresteadily learning to be more diligent with our power usage.10 In addition, we are also trying to make other changes. They include reducing the amount of trash we generate by recycling and composting, growing our own organic vegetables, and reusing and repurposing things that we would normally toss. We also want to produce our own eggs and goat’s milk in the near future.11 Overall, going off the grid has been great for our family. We have learned how to conserve power and water and to really appreciate what the earth gives to us every day. I hope that once my kids move out of the house, they will keep the habits that they have learned by living off the grid.脱离电网的生活:一家城市居民如何发现了简单生活艾莉森·佐谢尔1在内华达州的不眠之城拉斯维加斯生活了将近十年之后,我和我的家人决定放慢生活节奏。

1 主题内容与适用范围本标准规定了太阳能热利用中一部分关于天文与辐射的术语。

本标准适用于太阳能热利用中对太阳辐射的研究与测量。

2 引用标准GB 3102.6 光及有关电磁辐射的量和单位GB 4270 热工图形符号与文字代号3 天文3.1 天球celestial sphere为研究天体的位置和运动而辅设的一个半径为无限长的假想球体。

其中心按需要可设在观测点、地心、日心或银心等。

天体的位置即指沿天球中心至该天体方向在球面上的投影。

3.2 天轴celestial axis天球的自转轴。

它通过天球中心并平行于地球自转轴。

3.3 天极celestial pole天轴与天球相交的两个交点的统称。

3.4 北天极celestial north pole北半天球上的天极。

3.5 南天极celestial south pole南半天球上的天极。

3.6 天顶zenith观测点铅垂线向上延长与天球相交的交点。

3.7 天底nadir观测点铅垂线向下延长与天球相交的交点。

3.8 天赤道celestial equator通过天球中心并垂直于天轴的平面与天球相交的大圆。

3.9 天球子午圈celestial meridian天球上通过天顶和天极的大圆。

同义词天球子午线3.10 时圈hour circle天球上通过两天极的任一大圆。

同义词赤经圈right ascension circle3.11 地平面horizontal plane地球表面观测点以铅垂线为法线的切平面。

3.12 地平圈horizontal circle通过天球中心并垂直于天顶-天底连线的平面与天球相交的大圆。

同义词地平线horizon3.13 地平经圈vertical circle天球上通过天顶和天底的任一大圆。

3.14 角距离angular distance天球大圆上任意两点所对应的圆心角。

3.15 天球坐标系celestial coordinate system为确定天体在天球上的投影位置和运动而引入的球面坐标系。

A1、absorptions coefficient——吸收系数, 吸收强度(α-吸收系数)2、aperture diameter width——开口直径,指槽式聚光镜抛物槽的开口直径大小3、axis——轴4、azimuth——方位角,方位角又称地平经度(Azimuth (angle)缩写Az),是在平面上量度物体之间的角度差的方法之一。

是从某点的指北方向线起,依顺时针方向到目标方向线之间的水平夹角。

5、absorptance——吸收率6、assembly——组装7、Alternating current——交流电8、AM, air mass的缩写, 空气质量.直射阳光光束透过大气层所通过的路程,以直射太阳光束从天顶到达海平面所通过的路程的倍数来表示。

9、Anneal——退火10、as-built drawing——竣工图B1、bypass valve——旁路阀2、biomass——生物质,太阳能电站混合供电系统中用到的生物质发电技术C1、concentrating Solar Power——聚光式太阳能发电,简称CSP,又叫做STP(Solar Thermal Power)——光热太阳能发电2、concentrator——聚光器或聚光镜3、collector——集热器,直接将太阳能转化为热能,使用高储热的物质诸如水或油等,之后使用热交换器使用所搜集的热量。

是聚光太阳能设备的总称,其中包括,concentrator(聚光镜)和receiver(接收器).4、collecting loop 集热回路,槽式太阳能集热回路包括两种模式,一种是双回路系统,包括导热油(HTF系统)和(水蒸汽系统),另一种叫DSG系统,直接产生蒸汽系统。

两种系统的区别在于,第一种是由导热油做为热量转换的中间介质,而后者是太阳能直接转化为水蒸气的热能。

第一种系统效率低于第二种,第二种技术对集热管要求较高。

(Skyfuel公司在文件中介绍的便是采用南北向布置的双回路带储能的槽式发电系统。

solar connector翻译翻译:太阳能连接器。

用法:太阳能连接器是用于连接太阳能电池板,将太阳能转化成电能的组件。

它是太阳能发电系统的重要部分,常常使用在各种太阳能电站、太阳能路灯、太阳能水泵、家庭太阳能发电系统等领域。

双语例句:1. Solar connectors are essential components for solar power systems.太阳能连接器是太阳能发电系统的重要组成部分。

2. The solar panels are connected with solar connectors to convert sunlight into electrical energy.太阳能电池板通过太阳能连接器连接,将阳光转化为电能。

3. With the help of solar connectors, solar power generation has been widely used in various fields.在太阳能连接器的帮助下,太阳能发电已经被广泛应用于各个领域。

4. Using high-quality solar connectors can ensure the safety and stability of the solar power generation system.使用高质量的太阳能连接器可以确保太阳能发电系统的安全和稳定性。

5. There are various types of solar connectors, including MC4, Anderson, and Amphenol.太阳能连接器有多种类型,包括MC4, Anderson和Amphenol。

6. Solar connectors come in different sizes, shapes, and colors to meet different needs.太阳能连接器有不同的尺寸、形状和颜色,以满足不同的需求。