2002 Society for Design and Process Science Printed in the United States of America OBJECT-

- 格式:pdf

- 大小:250.40 KB

- 文档页数:29

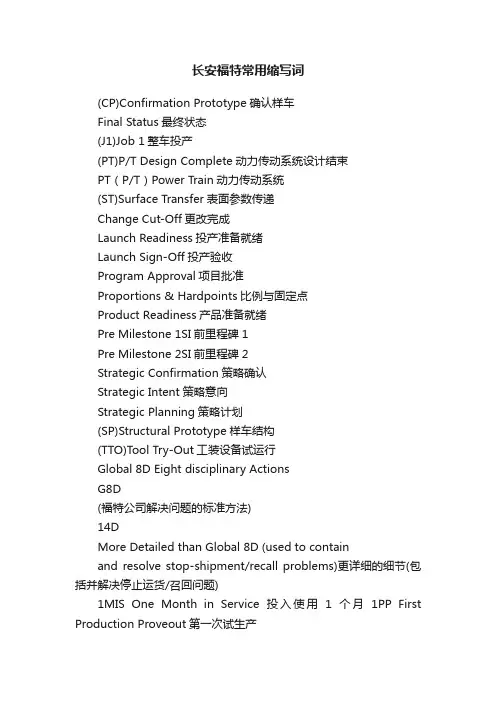

长安福特常用缩写词(CP)Confirmation Prototype确认样车Final Status最终状态(J1)Job 1整车投产(PT)P/T Design Complete动力传动系统设计结束PT(P/T)Power Train动力传动系统(ST)Surface Transfer表面参数传递Change Cut-Off更改完成Launch Readiness投产准备就绪Launch Sign-Off投产验收Program Approval项目批准Proportions & Hardpoints比例与固定点Product Readiness产品准备就绪Pre Milestone 1SI前里程碑1Pre Milestone 2SI前里程碑2Strategic Confirmation策略确认Strategic Intent策略意向Strategic Planning策略计划(SP)Structural Prototype样车结构(TTO)Tool Try-Out工装设备试运行Global 8D Eight disciplinary ActionsG8D(福特公司解决问题的标准方法)14DMore Detailed than Global 8D (used to containand resolve stop-shipment/recall problems)更详细的细节(包括并解决停止运货/召回问题)1MIS One Month in Service投入使用1个月1PP First Production Proveout第一次试生产2PP Second Production Proveout第二次试生产3MIS Three Months in Service投入使用3个月4P Production Process Proveout Program生产程序验证项目AAA American Automobile Association美国汽车工业联合会ABS Affordable Business Structure可承受商业结构ABS Anti skid brake system防抱死制动系统AIAG Automotive Industry Action Group 机动车工业行动小组AIC Accelerated Implementation Centre快速实施中心AIM Automated Issues Matrix问题结构图AIMS Automated Issues Matrix System问题结构图系统AME Advanced Manufacturing Engineering先进制造工艺AMPPE Advanced Manufacturing Pre-Program Engineering 先进项目前制造工艺ANOVA Analysis of Variance多样性分析AP Attribute Prototype设计样车APEAL Automotive Performance Execution and Layout机动车性能实施与规划APQP Advanced Product Quality Planning先进产品质量计划ASQ American Society for Quality美国质量协会AV Appraiser Variation评估者的多样性AVT Advance Vehicle Technology先进车辆技术AWS Analytical Warranty System分析性的保修系统AXOD Automatic Transaxle Overdrive Transmission自动变速驱动桥超速档传动系B&ABody & Assembly Operations (New Term: VehicleOperations)车身与组装操作(新术语:车辆操作)BCG Business Consumer Group消费者工作组BIC Best in Class等级中的最佳BIS Body Shop Information System车身工作间信息系统BLI Business Leadership Initiative领导层初始意向BOM Bill OfMaterials零件清单BTB Bumper-to-Bumper保险杠到保险杠BTS Build-To-Schedule按日程建造BUR Business Unit Review业务小组讨论CAS Capacity Analysis Sheet能力分析表C/E Cause & Effect成因及影响CA Customer Attribute消费者特性CAD Computer Aided Design计算机辅助设计CAE Computer Aided Engineering计算机辅助工程CAP Corrective Action Plan纠正行动计划CBG Consumer Business Group消费者业务小组CB Continuous Build连续性生产CC Critical Characteristic评价特性CC Courtesy Copy抄送CC Carbon Copy副本CCC Customer Concern Classification客户问题分类CCC China compulsory certification中国强制认证CDS Component Design Specification零件设计参数CET Campaignable Events Team召回情况小组CETs Common External Tariff普通关税CETP Corporate Engineering Test Procedures公司工程测试程序CFR Constant Failure Rate连续故障率CHFCIM Computer Integrated Manufacturing计算机综合制造CIWG Continuous Improvement Work Group持续改进工作组CL Centerline中心线CMM Coordinate Measuring Machine协调测量设备CMMS Common Material Management System通用材料管理系统CMMS3Common Manufacturing Management System-3通用制造管理系统-3Code X Pre-build focusing on exterior components制造前关注的外部零件Code Y Pre-build focusing on interior components制造前关注的内部零件CP Cost plan(马自达用语)由ECN引起的价格变动估计CP Common Position通用位置CP Confirmation prototype确认样车(FORD 时间节点)C p Relates the allowable spread of thespecification limits to the measure of theactual variation of the process.将参数限制允许限度下的展开与程序实际多样性联系起来CPE Chief Program Engineer首席项目工程师C pk Measures the process variation with respect tothe allowable specification, and takes intoaccount the location of the process average测量程序的多样性并将其考虑到程序平均性的位置中CPU Cost Per Unit单位成本CQDC Corporate Quality Development Center公司质量开发中心CQIS Common Quality Indicator System一般质量指标系统CR Concern Responses问题回复CRT Component Review Team零件讨论组CSA Corporate Security Administrator公司安全管理员CSI Customer Service Index客户服务指数DCO Duty Cycle Output责任循环结果DCP Dynamic Control Planning动态控制计划DDL Direct Data Link直接数据连接Df Degrees of Freedom自由度DFA Design for Assembly总成设计DFM Design for Manufacturability制造能力设计DFMEA Design Failure Mode Effects Analysis故障模式影响分析设计DFR Decreasing Failure Rate故障下降率DMA Database Maintenance Administrator数据库维护管理人员DOE Design of Experiment试验设计DOM Dealer Operations Manager经销商业务经理DP Design Parameters参数设计DQR Durability Quality and Reliability耐久性质量与可靠性DTD Dock to Dock码头至码头DTD Design to Delivery设计到交付DCV Design Confirmation Vehicle设计确认车DV Design Verification设计验证DVM Design Verification Method设计验证方式DVP Design Verification Plan设计验证计划Design Verification Process and Production设计验证程序和产品验证DVP&PVValidationDVP&R Design Verification Plan & Report设计验证计划和结果DVPR Design Verification & Product Reliability设计验证和产品可靠性DVPV Design Verification and Process Verification设计验证和程序验证EAO European Automotive Operations欧洲机动车协会EASI Engineering And Supply Information工程和供应信息ECAR Electronic Connector Acceptability Rating电子连接接受比率EDI Electronic Data Interchange电子数据交换EESE Electrical and Electronic Systems Engineering电力及电子系统工程EMM Expanded Memory Manager扩展内存管理器EMS Environmental Management System环境管理系统EOL End of Line线的端点EQI Extraordinary Quality Initiative特别初始质量ES Engineering Specifications工程参数ESI Early Supplier Involvement早期供应商参与ESP Extended Service Plan延期服务计划ESTA Early Sourcing Target Agreement早期选点目标协议ESWP Early Sourcing Work Plan早期选点工作计划EV Equipment Variation设备变更F&T Facility & Tooling工装设备FACT Facilitation and Certification Training简易化及认证培训FASS Field Action/Stop Shipment区域行动/停止运货区域行动/停止运货(优先使用缩FA/SS Field Action/Stop Shipment (Preferred Acronym)写)FAO Ford Automotive Operations福特机动车协会FAP Ford Automotive Procedure福特机动车程序FAQ Frequently Asked Questions常见问答FCPA Ford Consumer Product Audit福特客户产品审核FCSD Ford Customer Service Division福特客户售后服务分枝机构FDVS Ford Design Verification System福特设计验证系统FER Fresh Eyes Review其它行业人员论证FER Final Engineering Review最终工程论证FEU Field Evaluation Unit区域评估组FIFO First in First Out先进先出FMEA Failure Mode Effects Analysis故障模式影响分析FMVSS Federal Motor Vehicle Safety Standards美国联邦机动车安全标准FPDS Ford Product Development System福特产品开发系统FPS Ford Production System福特生产系统FPSI Ford Production System Institute福特产品系统学院FPS IT Ford Production System Information Technology福特产品系统信息技术FOB Ford of Britain福特英国FQRs Frequent Quality Rejects经常性质量不合格品FR Functional Requirements功能要求FAO (福特机动车运作) 可靠性指FRG FAO Reliability Guide导FS Final Sign-off最终验收FSIC Ford System Integration Council福特系统综合委员会FSN Ford Supplier Network福特供应商网络FSS Full Service Suppliers全方位服务供应商FTDC Fairlane Training and Development Center培训和发展中心FTEP Ford Technical Educational Program福特技术培训项目FTT First Time Through首次通过FUNC-APPRV Functional Approvals功能批准FVEP Finished Vehicle Evaluation Program下线车辆评估项目GAP Global Architecture Process全球建筑设计程序GC Global Craftsmanship全球技术工艺GCARS Global Craftsmanship Attribute Rating System全球技术特性评分系统GCEQ Global Core Engineering Quality全球核心工程质量GEM Generic Electronic Module通用电子模块GIS1Global Information Standards全球信息标准Global Prototype Inventory Requisition andGPIRS全球样车库存及控制安排SchedulingGPP Global Parts Pricing全球零件定价GQRS Global Quality Research System全球质量调查系统GRC UN-ECE Group des Raporteurs de Ceintures欧盟 ECE 安全带规划小组GRC Government Regulations Coordinator政府法规协调员GR&R Gage Repeatability and Reproducibility量具重复性和再现性GRVW Gross Vehicle Weight车辆质量GSDB Global Supplier Database全球供应商数据库GSSM Global Sourcing Stakeholders Meeting全球选点股东大会GYR Green-Yellow-Red绿-黄-红HB Homologation Build法规车制造HI High-Impact重大影响HIC High-Impact Characteristics重大影响特性HR Human Resources人力资源HTFB Hard Tooled Functional Build成形机功能建造HVAC Heating Ventilating and Air Conditioning加热通风和空调ICA Interim Containment Action过渡性补救措施ICCD Intensified Customer Concern Database强化的客户问题数据库ICCD CRSIntensified Customer Concern Database ConcernResolution Specialist 强化的客户问题数据库解决问题专员IE Industrial Engineer产业工程师IFR Increasing Failure Rate 故障率增长ILVS In-Line Vehicle Sequencing车辆顺序IM Industrial Materials工业材料IP Instrument Panel仪表板IPD In Plant Date进厂日IQ Incoming Quality进货质量IQS2Initial Quality Study初始质量研究IR Internal Reject内部不合格品ISO International Organization for Standardization国际标准化组织ISPC In-Station Process Controls过程质量控制JIT Just in Time及时JPH Jobs Per Hour每小时工作量JSA Job Safety Analysis工作安全分析PSW (零件质量合格验收) 未做好KKK PSW not ready for inspection检测准备KLT Key Life Test关键使用寿命测试KO Kickoff起动LCL Lower Control Limit低控制限值LDEM Lean Design Evaluation Matrix设计评估表LOA Letter of Agreement协议书LP&T Launch Planning & Training投产计划和培训LR Launch Readiness投产准备就绪LRR Launch Readiness Review投产准备就绪论证LS Launch Sign-Off投产验收LSL Lower Specification Limit低参数限制LTDB Light Truck Data Base轻型卡车数据库MBJ1Months Before Job One Job1(投产)前1个月MBO Manufacturing Business Office制造办公室ME Manufacturing Engineering制造工程MIS Months in Service使用中的月份MMSA Material Management System Assessment物料管理系统评定MP Mass Production批量生产MP&L Materials, Planning and Logistics材料、计划与物流MPPS Manufacturing Process Planning System制造程序计划系统MOD Module模块MRB Material Review Board物料论证板MRD Material Required Date物料要求到厂日MS Material Specifications物料参数MS3(MSIII)Material Supply Version III物料供应(第三版)MTC Manage the Change管理变更MY Model Year年度车型NAAO North American Automotive Operations北美汽车工业协会NFM Noise Factor Management噪声管理NIST National Institute of Standards and Testing全国标准和测试协会NMPDC New Model Program Development Center新车型项目开发中心Nova C New Overall Vehicle Audit新车总评审NPPR New Program Product Review供应商技术支持NTEI New Tooled End Items新工具加工成品NVH Noise, Vibration, Harshness噪声、振动、操纵平顺性OCM Operating Committee Meeting工作委员会会议OEE Overall Equipment Efficiency总体设备效率OEM Original Equipment Manufacturer设备最初制造厂ONP Owner Notification Program车主告知程序OS Operator Safety操作者安全OTG Open to Go可进行P Diagrams Parameter Diagrams参数图表PA Program Approval项目批准PAG Premier Automotive Group首要机动车项目组PAL Project Attribute Leadership项目特性领导层PAT Program Activity Team, Program Attribute Team, 项目促进小组、项目特性小组和or Program Action Team项目行动小组PCA Permanent Corrective Action持续改进行动PCF Parts Coordination Fixture零件夹具验证PCI Product Change Information产品变更信息PD Product Development产品开发PDL Program Design Language项目设计语言PD Q1Product Development Q1产品开发Q1PDN2Phased Data NotificationPDSA Plan, Do, Study, Act计划、实践、研讨、实施PFMEA Process Failure Mode Effects Analysis程序故障模式影响分析PI Process Improvement程序改进PIPC Percentage of P pk Indices Process Capable P pk指数程序能力百分比Percentage of Inspection Point That SatisfyPIST满足公差要求的检查点百分比TolerancePM Program Manger项目经理PMA Project Management Analyst项目管理分析PMT Program Management Team or Program Module T eam 项目管理组或项目模式组PO Purchase Order采购订单POC Point of Contact联系点POT Process Ownership Team程序所有者小组P p Process Potential程序潜力PP Pilot ProductPP&T Product Planning & Technology产品计划和技术PPAP Production Part Approval Process生产零件批准程序P pk Process Capability程序能力PPC Product Planning Committee产品计划委员会PPL Program Parts List项目零件清单PPMParts per Million (applied to defectiveSupplier parts)零件的百万分比率(适用于供应商不合格零件)PPPM Program and Pre-Production Management程序和投产前管理PR Public Relations公共关系PR Product Requirement产品要求PR Product Readiness Milestone产品就绪时间节点PSO Production Standard Order制造标准订单PSS Private Switching Service私人转接服务PST Program Steering Team项目指导小组PSW Part Submission Warrant零件质量合格验收PTO Powertrain Operations传动系统操纵件PTR Platinum Resistance Thermometer铂金电阻温度计PV Production Validation产品验证PV Process Variables程序变更PV Part Variation零件变更PVBR Prototype Vehicle Build Requirements样车制造要求PVM Production Validation Method产品验证方法PVP Powertrain Validation Program 传动系统验证程序PVT Product Vehicle Team or Plant Vehicle Team产品车辆组或工厂车辆组QA Quality Assurance质量保证QC Quality Control质量控制QCT Quality Cost Timing质量成本时机选择QFD Quality Function Deployment质量功能配备QFTF Quality Focused Test Fleet质量节点测试行动组QLS Quality Leadership System质量领导体系QMS Quality Management System质量管理体系QOS Quality Operating System质量运作体系QOE Quality of Event质量事件QPM Quality Program Manager质量项目经理QPS Quality Process System质量程序系统QR Quality Reject质量不合格QS-9000Quality Systems – 9000质量体系-9000Quality System Assessment for ProductQSA-PD产品开发质量体系评估DevelopmentQTM Quality Team Member质量小组成员QVA Quality-Focused Value Analysis Workshop车间质量重点价值分析R Range范围RFQ Request For Quotation寻求报价R&M Reliability and Maintainability可靠性及可维护性RMS Resource Management System资源管理系统R&R Repeatability and Reproducibility重复性和再现性R&R Roles and Responsibilities职务与责任R&VT Research & Vehicle Technology研究与车辆技术R/1000Repairs per thousand修理千分率RAP Remote Anti-theft Personality module 防盗遥控器个性化模式Robust Engineering Design Process Enabler积极的工程设计程序计划REDPEPRProjectRIE Reliability Improvement Engineer可靠性改进工程师ROA Return on Assets资产回报率ROCOF Rate of Occurrence of Failure故障发生率RPN Risk Priority Number优先处理风险号码RRCL Reliability and Robustness Check List可靠性与强有力的核对表RRDM Reliability and Robustness Demonstration Matrix可靠性与强有力的演示图表RRR PSW rejected PSW (零件质量合格验收) 不合格RWUP RealWorld Usage Profile现实生活使用记录S Standard deviation标准偏差s2Variance多样性SC Significant Characteristics重要特性Significant Characteristics/CriticalSCs/CCs重要特性/评价特性CharacteristicsSCAC Supplier Craftsmanship Advisory Committee供应商技术顾问委员会SCTs Strategic Commodity Teams策略性商品组SDS System Design Specifications系统设计参数SDS Subsystem Design Specification子系统设计参数SEVA Systems Engineering Value Analysis系统工程价值分析Senko Drawing先行图SHARP Safety and Health Assessment Review Process安全和健康评估讨论程序SI System International des Unit国际单位制SIM Supplier Improvement Metrics供应商改进步骤SMART Synchronous Material and Replenishment Trigger同步物料与补给触发器SME Subject Matter Expert主题专家SMF Synchronous Material Flow同步物料流程SOW Statement of Work工作陈述SP Support PlanSP/AP Structural Prototype/Attribute Prototype结构原形/特性原形SP&PI Strategic Process & Product Improvement策略性程序和产品改进SPC Special Product Committee特殊产品委员会SPC Statistical Process Control统计程序控制SPROM Sample Promise Date承诺的样品到货日SREA Supplier Request for Engineering Approval供应商要求工程批准SRI Supplier Responsible Issues供应商责任SSI Sales Satisfaction Index销售满意度指标SSM Strategic Sourcing Meeting策略选点会议ST Surface Transfer表面转移STA Supplier Technical Assistance供应商技术支持STARS Supplier Tracking and Reporting System供应商跟踪及汇报系统SVC Small Vehicle Center小型车中心TA Target Agreement目标协议TB Training Build训练制造TAP Target Achievement Plan目标完成计划TCM Total Cost Management 总成本管理TED Things Engineers Do工程师任务TEG Tooling and Equipment Group工装及设备组TEM Total Equipment Management全部设备管理TGR Things Gone Right事态发展正确TGW Things Gone Wrong事态发展错误TIS Time in Service服务期限TOC Table of Contents目录TPM Total Productive Maintenance全部生产维护TPPS Torque Process Potential Study扭矩程序潜力研究TQC True Quality Characteristics真实质量特性TRIZ (Russian)Theory of Inventive Problem Solving创造性解决问题的理论(俄罗斯) TRMC Timing, Release and Material Control (also 时效性、发布和物料控制(同known as Tar-Mac)Tar-Mac)TS-16949Technical Specification – 16949技术规范-16949 TSP Technical Skills Program技术性技能项目TTO Tool Try Out工装试运行UCL Upper Control Limit上限控制USL Upper Specification Limit参数上限V/C Very or Completely Satisfied非常或完全满意VC Vehicle Center汽车中心VC BuyerVehicle Center Buyer (now Consumer BusinessGroup Buyer)车辆中心客户(现在为商务集团购买客户)VDI Vehicle Dependability Index车辆可靠性指标VDS Vehicle Design Specifications车辆设计参数VDS Vehicle Descriptor Section车辆描述组VER Vehicle Evaluation Ratings车辆评估等级VFG Vehicle Function Group车辆功能组VIN Vehicle Identification Number车辆识别代码VLD Vehicle Line Director车辆生产线总监VO Vehicle Office车辆办公室VO Vehicle Operations车辆运作VOGO Vehicle Operations General Office车辆运作综合办公室VP Vice President副总裁VPMC Vehicle Project Management Coordinator车辆项目管理协调员VPP Vehicle Program Plan车辆项目计划VQL Vehicle Quality Level车辆质量级别VQR Vehicle Quality Review车辆质量研讨VRT Vehicle Review Team车辆研讨小组VRT Variability Reduction Team减少差异小组VRT Vehicle Reduction Team车辆减产小组WAS Work Analysis Sheet工作分析表WCR Worldwide Customer Requirements全球客户需求WERS Worldwide Engineering Release System全球工程发布系统WIP Work In Progress进行中的工作WMI World Manufacturing Identifier世界制造商识别代码WPRC Warranty Parts Return Center维修部件回收中心Potential Significant and CriticalYS/YC潜在的重要和评价特性CharacteristicsRemark: Editor adds the content in shadow. 备注:阴影部分的内容为编者增加。

九年级英语交通工具练习题30题1<背景文章>Bicycles have a long and fascinating history. The first bicycles were very different from the ones we see today. In the early days, bicycles had huge front wheels and tiny back wheels. These bicycles were called penny-farthings.As time went by, bicycles became more and more advanced. They got better designs, stronger materials, and more comfortable seats. Today, bicycles are not only a means of transportation but also a popular form of exercise and recreation.Bicycles have many advantages. They are environmentally friendly as they don't produce any pollution. They are also cost-effective. You don't need to spend a lot of money on fuel or maintenance. Moreover, riding a bicycle is a great way to stay fit and healthy.In modern society, bicycles play an important role. They are used for commuting to work or school, for running errands, and for enjoying the outdoors. Many cities have built special bike lanes to make cycling safer and more convenient.1. The first bicycles were called ____.A. mountain bikesB. road bikesC. penny-farthingsD. hybrid bikes答案:C。

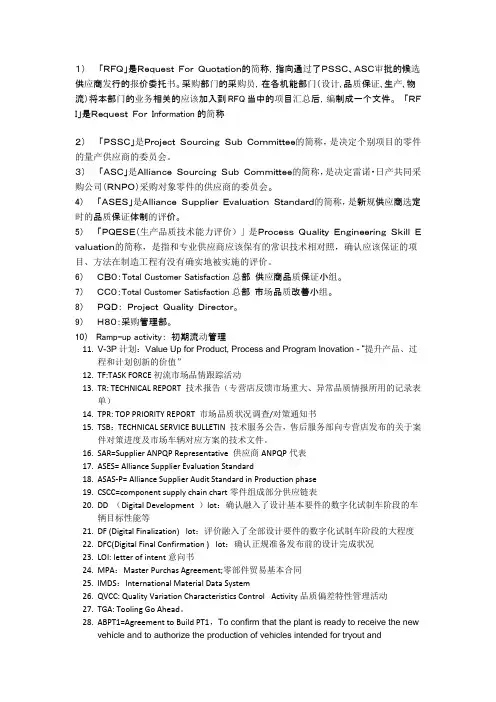

1)「RFQ」是RequestForQuotation的简称,指向通过了PSSC、ASC审批的候选供应商发行的报价委托书。

采购部门的采购员,在各机能部门(设计、品质保证、生产、物流)将本部门的业务相关的应该加入到RFQ当中的项目汇总后,编制成一个文件。

「RFI」是RequestForInformation的简称2)「PSSC」是ProjectSourcingSubCommittee的简称,是决定个别项目的零件的量产供应商的委员会。

3)「ASC」是AllianceSourcingSubCommittee的简称,是决定雷诺・日产共同采购公司(RNPO)采购对象零件的供应商的委员会。

4)「ASES」是AllianceSupplierEvaluationStandard的简称,是新规供应商选定时的品质保证体制的评价。

5)「PQESE(生产品质技术能力评价)」是ProcessQualityEngineeringSkillEvaluation的简称,是指和专业供应商应该保有的常识技术相对照,确认应该保证的项目、方法在制造工程有没有确实地被实施的评价。

6)CB0:Total Customer Satisfaction总部供应商品质保证小组。

7)CC0:Total Customer Satisfaction总部市场品质改善小组。

8)PQD:ProjectQualityDirector。

9)H80:采购管理部。

10)Ramp-up activity:初期流动管理11.V-3P计划:Value Up for Product, Process and Program Inovation - “提升产品、过程和计划创新的价值”12.TF:TASK FORCE初流市场品情跟踪活动13.TR: TECHNICAL REPORT 技术报告(专营店反馈市场重大、异常品质情报所用的记录表单)14.TPR: TOP PRIORITY REPORT 市场品质状况调查/对策通知书15.TSB:TECHNICAL SERVICE BULLETIN 技术服务公告,售后服务部向专营店发布的关于案件对策进度及市场车辆对应方案的技术文件。

世界现代设计史现代设计的萌芽与工艺美术运动设计师汉英翻译The Emergence of Modern Design and the Arts and Crafts Movement in World Modern Design HistoryIntroductionThe history of modern design is marked by the emergence of new ideas and movements that aimed to revolutionize the way objects were designed and produced. Among these influential movements was the Arts and Crafts Movement, which emerged in the late 19th century and left a lasting impact on the world of design. This essay aims to explore the origins of modern design, with a focus on the Arts and Crafts Movement, and its key designers.The Emergence of Modern DesignThe roots of modern design can be traced back to the Industrial Revolution in the 18th and 19th centuries, which brought about significant changes in manufacturing techniques and mass production. As machines began to replace traditional craftsmanship, designers started to question the value and quality of the objects being produced. This gave rise to a new movement that aimed to revive the importance of handcrafted objects and promote individual expression in design.The Arts and Crafts MovementThe Arts and Crafts Movement emerged in the late 19th century as a reaction against the dehumanizing effects of industrialization. Its key proponents, such as William Morris in England and Charles Rennie Mackintosh in Scotland, advocated for a return to the values of medieval craftsmanship, where designers were actively involved in the production process, ensuring high quality and individuality in their creations.Influential Designers of the Arts and Crafts Movement2. Charles Rennie Mackintosh: A key figure in the Glasgow School of Art and a pioneer of Scottish design, Mackintosh's innovative approach integrated elements of Art Nouveau with traditional craftsmanship. His architectural designs, furniture, and interiors showcased his unique style, characterized by clean lines, geometric shapes, and intricate details.The Influence of Modern Design and the Arts and Crafts MovementThe ideas and philosophies of the Arts and Crafts Movement had a profound impact on the development of modern design. Its emphasis on the importance of craftsmanship, simplicity, and functionality resonated with designers worldwide and laid the foundation for future design movements. The movement's focus on social reform and the revival of traditional techniques also paved the way for the rise of the modernist movement, whichaimed to create a harmonious and efficient society through design.ConclusionThe emergence of modern design was rooted in the questioning of traditional manufacturing techniques and the pursuit of individual expression. The Arts and Crafts Movement, with its emphasis on craftsmanship and aesthetics, played a significant role in shaping the direction of modern design. Designers like William Morris and Charles Rennie Mackintosh left a lasting legacy, influencing future generations of designers andinspiring the development of new design movements. Today, their principles continue to inform contemporary design practices, reminding us of the importance of quality, functionality, and the power of individual creativity.。

fidic合同结构英文回答:FIDIC Contract Structure.FIDIC contracts are structured in a modular format,with each module addressing a specific aspect of the construction project. The standard FIDIC suite of contracts consists of the following modules:General Conditions of Contract (GCC): The GCC provides the general framework for the contract, including the roles and responsibilities of the parties, the contractual deadlines, and the dispute resolution process.Conditions of Contract for Construction (CC): The CC provides the specific conditions for the construction works, including the scope of work, the quality standards, and the payment terms.Conditions of Contract for Plant and Design-Build (EPC/Turnkey): The EPC/Turnkey conditions are used for contracts where the contractor is responsible for both the design and construction of the works.Conditions of Contract for Dredging and Reclamation Works (DC): The DC conditions are used for contracts involving dredging and reclamation works.Conditions of Contract for Electrical and Mechanical Plant and Design-Build (EP): The EP conditions are used for contracts involving the supply, installation, and commissioning of electrical and mechanical plant.Conditions of Contract for Subcontracts (SC): The SC conditions are used for subcontracts between the main contractor and subcontractors.The modular structure of FIDIC contracts allows the parties to tailor the contract to the specific requirements of their project. For example, a project that involves dredging and reclamation works would use the GCC, the CC,and the DC conditions.中文回答:FIDIC合同结构。

第8卷 第3期2010年6月实验科学与技术Experi m ent Science and Technol ogyVol 18No 13Jun 12010收稿日期:2010-01-19基金项目:深圳大学精品课程建设项目。

作者简介:郭小勤(1960-),女,硕士,副教授,主要从事控制理论与控制工程领域的教学与科研工作。

基于项目的C D IO 理念在课程教学中的应用郭小勤,曹广忠(深圳大学机电与控制工程学院,广东深圳 518060)摘要:根据C D I O 工程教育理念,结合线性系统理论课程特点,设计了模拟真实工程环境的龙门吊车控制实验项目。

该项目以设计为导向、工程能力培养为目标,构思了以吊运过程平稳性和快速性为总体控制目标的实验教学内容。

在项目实施中,以问题为导向,引导学生主动学习,并在完成项目的整个过程中主动探寻学科知识。

教学实践证明基于项目的教学模式极大地提高了学生学习的积极性和主动性,提高了科学研究能力和工程实践能力。

关 键 词:C D I O 工程教育;线性系统理论;设计导向学习;龙门吊车控制中图分类号:G642·423;TP27114 文献标志码:B 文章编号:1672-4550(2010)03-0083-03Appli cati on of the Project 2based CD I O I dea i n Course Teachi n gG UO Xiao 2qin,CAO Guang 2zhong(College of Electr omechanical and Contr ol Engineering,Shenzhen University,Shenzhen 518060,China )Abstract:The experi m ent p r oject of gantry crane contr ol is designed t o si m ulate p ractical engineering according t o the CD I O engineer 2ing educati on initiative and peculiarity of linear syste m theory course .The p r oject is design 2oriented f or engineering ability training,and its final contr ol goal t o achieve a s mooth and rap id lifting and moving p r ocess was conceived f or the contents of experi m ent teach 2ing .I n the p r oject i m p le mentati on,students are guided t o learning actively by p r oble m s 2oriented method and t o exp l ore acade m icknowledge in p ractice .Teaching p ractice p r oved that the p r oject 2based teaching model greatly enhance students πlearning enthusias mand initiative and i m p r ove the capacity of scientific research and engineering p ractice 1Key words:C D I O engineering educati on;linear syste m theory;design 2oriented learning;gantry crane contr ol1 引 言2000年10月,由美国麻省理工学院和瑞典皇家理工学院等4所大学组成的工程教育改革研究团队提出、并持续发展和倡导了全新的CD I O (Con 2ceiving -Designing -I m p le menting -Operati on )工程教育理念即构思—设计—实现—运行。

中国文化概况英汉对照版中国文化概况英汉对照版一:英文版:Chinese culture, with its rich heritage spanning thousands of years, is one of the oldest and most diverse cultures in the world. It is a blend of traditions, art, philosophy, and customs that have been shaped by the vast and diverse geography of China. From the ancient times of the Yellow Emperor and Confucius to the modern era, Chinese culture has continuously evolved while maintaining its unique identity.At the heart of Chinese culture lies its philosophical traditions, including Confucianism, Taoism, and Buddhism. These philosophies have profoundly influenced the moral and social values of the Chinese people. Confucianism, for instance, emphasizes the importance of family, respect for elders, and the pursuit of knowledge and wisdom.Chinese art, another vital aspect of its culture, encompasses a wide range of styles and mediums, including painting, calligraphy, sculpture, and ceramics. Chinese painting, known for its use of brush and ink, often depicts natural landscapes and scenes from history and mythology. Calligraphy, considered both an art and a way to cultivate one's character, is highly revered in Chinese culture.Cuisine is also a significant part of Chinese culture, characterized by its diversity and emphasis on harmony and balance. Chinese cuisine varies greatly from region to region, with each area having its own unique flavors and specialties. Traditional Chinese medicine, with its holistic approach to health, is another important aspect of the culture.Lastly, Chinese festivals and customs play a crucial role in cultural expression. The Spring Festival, or Chinese New Year, is the most important and widely celebrated festival in China. It is a time for family reunions, feasting, and the giving of red envelopes. Other notable festivals include the Dragon Boat Festival, Mid-Autumn Festival, and Lantern Festival, each with its own traditions and significance.汉语对照版:中国文化,拥有数千年的丰富遗产,是世界上最古老、最多样化的文化之一。

九年级英语人生理想练习题30题1<背景文章>Everyone has their own dreams and ideals. Some people dream of becoming great scientists, while others aspire to be famous artists. However, the pursuit of these ideals is never easy.Take Tom for example. He has always wanted to be a renowned musician. He spends hours every day practicing his instrument. But he faces many challenges. His parents don't support his choice, thinking that music is not a stable career. Moreover, he has to compete with many talented people. Despite these difficulties, Tom is determined to pursue his dream.Another person is Lily. She wants to be a doctor and help those in need. She studies hard to get good grades, but she finds the medical knowledge very difficult to understand. She also worries about the long years of study and training ahead.Despite the challenges, these people are brave enough to chase their dreams. They know that it won't be easy, but they are willing to work hard and persevere.1. Tom wants to be a ___.A. scientistB. artistC. musicianD. doctor答案:C。

食品厂sc生产许可证流程设计英语Food Production Facility SC Production License Process Design.1. Application Submission.The applicant shall submit the following documents to the competent authority:1. Application form.2. Business license.3. Legal representative's identity document.4. Production site layout.5. Equipment list.6. Raw material list.7. Product list.8. Production process flow chart.9. Quality control system.10. Food safety management system.2. Site Inspection.The competent authority shall conduct a site inspection to verify the applicant's production conditions and compliance with relevant regulations.3. Document Review.The competent authority shall review the submitted documents and the site inspection report to assess the applicant's eligibility for the SC production license.4. Issuance of SC Production License.If the applicant meets all the requirements, the competent authority shall issue the SC production license within 20 working days from the date of receipt of the application.5. Post-Issuance Management.After the issuance of the SC production license, the applicant shall:1. Establish and implement a food safety management system.2. Conduct regular self-inspections and record-keeping.3. Cooperate with the competent authority's supervision and inspection.4. Report any changes in production conditions or products.6. Renewal of SC Production License.The SC production license shall be valid for a period of 5 years. The applicant shall apply for renewal at least 6 months before the expiration date. The renewal process follows the same procedure as the initial application.7. Suspension or Revocation of SC Production License.The competent authority may suspend or revoke the SC production license if the licensee:1. Fails to meet the requirements of the relevant regulations.2. Produces or sells unsafe food products.3. Obstructs the competent authority's supervision and inspection.4. Violates other relevant laws and regulations.8. Emergency Measures.In case of a food safety emergency, the competent authority may take emergency measures to protect public health, such as suspending production, recalling products,or closing down the production facility.9. Legal Responsibilities.The licensee shall be legally responsible for thesafety and quality of its food products. Any violation ofthe relevant regulations may result in administrative penalties, fines, or criminal prosecution.Additional Considerations.In addition to the above, the following factors may be considered in the food production facility SC production license process design:Risk assessment: Identifying and assessing potential food safety hazards at each stage of the production process.Traceability: Establishing a system to track food products throughout the supply chain.HACCP principles: Implementing Hazard Analysis and Critical Control Points (HACCP) principles to identify and control food safety risks.International standards: Aligning the production facility and license process with international food safety standards, such as ISO 22000 or FSSC 22000。

systemc中sc_cycle的用法Title: Exploring the Usage of sc_cycle in SystemCIntroduction:SystemC is a widely used modeling and simulation framework for hardware systems. It provides a set of C++ libraries and a simulation kernel to aid the design, verification, and performance analysis of complex electronic systems. Among the many features that SystemC offers, sc_cycle is a key aspect that plays a crucial role in managing the timing and synchronization within the simulated system.In this article, we will discuss the usage of sc_cycle in SystemC. We will explore its purpose, syntax, and several practical examples to highlight its significance in modeling and simulating hardware systems. Whether you are a beginner or an experienced SystemC user, this article aims to provide a comprehensive understanding of sc_cycle and its practical implementation.1. What is sc_cycle?sc_cycle is a member function of the sc_process_handle class in SystemC, which represents a SystemC process. It serves thepurpose of synchronizing the simulation time with the programmed time specified by the user. It allows the designer to control the simulation cycle's length, ensuring proper synchronization and coordination among various modules within the system.2. Syntax and Parameters:The syntax of sc_cycle is as follows:`sc_time sc_cycle(const sc_time& dt = sc_time(1, SC_NS))`The function takes an optional parameter 'dt' of type sc_time, which represents the time duration for which the simulation time should advance. By default, if no parameter is provided, it advances the time by 1 nanosecond (1 ns). However, the user can provide their desired time duration as an argument to customize the cycle length according to the specific requirements of the design.3. Practical Examples:Let's delve into some practical examples to understand the usage and benefits of sc_cycle:Example 1: Basic Usagevoid simple_processor::process() {while (true) {Perform processor operationsSynchronize time for the next cyclesc_cycle();}}In this simple example, a processor module is executing its operations within an infinite loop. After completing each cycle, sc_cycle is called to advance the simulation time by the default duration of 1 ns. This ensures that the simulation stays synchronized with the passage of time in the real-world scenario.Example 2: Customizing Cycle Durationvoid processor::process() {while (true) {Perform processor operationsSynchronize time for the next cyclesc_cycle(sc_time(10, SC_NS)); Advancing simulation time by 10 ns}}In this scenario, the processor module defines a custom cycle duration of 10 ns. By passing `sc_time(10, SC_NS)` as the argument to sc_cycle, the simulation time will be advanced accordingly.Example 3: Dynamic Cycle Length Modificationvoid variable_processor::process() {sc_time cycle_length(1, SC_NS); Initial cycle lengthwhile (true) {Perform variable duration processor operationsModify cycle duration based on specific conditionsif (ConditionA) {cycle_length = sc_time(10, SC_NS);} else if (ConditionB) {cycle_length = sc_time(5, SC_NS);} else {cycle_length = sc_time(1, SC_NS);}Synchronize time for the next cycle using the modified durationsc_cycle(cycle_length);}}This example demonstrates the dynamic nature of sc_cycle, allowing the cycle length to be modified based on specific conditions. In this case, the cycle duration is updated accordingly, ensuring that the simulation accurately reflects the behavior of the hardware system.Conclusion:sc_cycle serves as a vital function within SystemC, enabling designers to manage the timing and synchronization within simulated hardware systems. By offering control over cycle length and the flexibility to modify it dynamically, sc_cycle empowersdesigners with the ability to accurately model real-world scenarios. With a solid understanding of sc_cycle and its utility, designers can enhance their SystemC modeling and simulation capabilities, leading to improved verification and performance analysis of complex hardware systems.。

工艺与设计·PROCESS AND DESIGN1 设计本体与设计学科1.1 设计的本质设计虽然是一个新近的词语,但早在人类造物之初,原始先民第一次将两块石头互相敲击来制造石器,设计就已本质性地存在。

根据这样一种说法,设计似乎是人类与生俱来的能力,只要我们头脑中进行计划、构想、盘算带有预见性的、未来性的、愿望性的内容,就可以叫设计。

在美国学者HerbertA·Simon的概念里,科学是去发现、理解自然、社会的知识,而设计是应用这些知识去创造未来。

科学探究的是事物本身的客观存在,而设计是确定事物的存在方式,是创造性的活动。

我们把设计归结为“人类有目的的创造性活动”,它是设计的最本质意义,是设计活动的本原。

设计活动有两个要素:一是人的目的性,二是创造性,目的是人创造的最终指向①。

1.2 跨学科的设计知识研究应始于设计活动Simon将设计科学界定为研究人工物的科学(The Science of Artificial),认为设计科学是独立于科学与技术以外的第三类知识体系。

科学研究揭示、发现世界的规律“是什么”(Be),关注事物究竟如何;技术手段告诉人们“可以怎样”(Might Be);而设计则综合这些知识去改造世界,关注事物“应该如何”(Should Be)②。

自然科学融入技术研究的是机遇目标的人、事、物关系的总和,在此意义上,设计横跨了科学技术与人文社会两大领域③。

杨砾和徐立在Simon理论的基础上勾勒出设计科学与设计研究诸多领域,以及设计学与其他学科之间的关系。

杨砾的设计学框架讲设计科学模糊地划分为四个知识领域,他认为专业设计知识对其上面 三个层次的研究具有非常强烈的直接影响,反之亦然④。

这是对设计边界模糊性和内容交叉性的一种诠释,设计知识融入到设计活动的每一个角落。

设计作为一门学科,其基本理论是一种与设计师的意识和能力相关的特有知识形式,这种知识形式独立于不同的设计实践专业领域⑤。

国外旧厂房改造的专家发表的著作下载温馨提示:该文档是我店铺精心编制而成,希望大家下载以后,能够帮助大家解决实际的问题。

文档下载后可定制随意修改,请根据实际需要进行相应的调整和使用,谢谢!并且,本店铺为大家提供各种各样类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,如想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by theeditor.I hope that after you download them,they can help yousolve practical problems. The document can be customized andmodified after downloading,please adjust and use it according toactual needs, thank you!In addition, our shop provides you with various types ofpractical materials,such as educational essays, diaryappreciation,sentence excerpts,ancient poems,classic articles,topic composition,work summary,word parsing,copy excerpts,other materials and so on,want to know different data formats andwriting methods,please pay attention!《旧厂房的新生:国外工业遗产改造的探索与实践》——专家杰克逊·史密斯的力作在城市化进程不断加速的今天,如何处理那些承载着历史记忆和文化价值的旧厂房,成为了全球面临的重要议题。

2002 Society for Design and Process SciencePrinted in the United States of AmericaOBJECT-ORIENTED APPROACHIN RE-ENGINEERING: THE STM ICROELECTRONICSMANUFACTURING MODELV. Carchiolo(1)S. D’ambra(2)A. Longheu(1)M. Malgeri(1)(1)Istituto di informatica e TelecomunicazioniUniversità di CataniaV.le A. Doria, 6 – 95100 Catania – ITALY(2)CAM Support Group - STMicroelectronicsStr. Primosole 50 – 95100 Catania – ITALYCurrent manufacturing systems have a very structured production model, expecially when highcomplexity and precision is required, as in semiconductor devices manifacturing. In addition,rapid changes in both production and market requirements may occur, hence great flexibility isalso essential. These goals, together with the requirement of both adding new features as well asremoving some model limitations, often impose to re-engineer periodically existing models,reducing as much as possible the time-to-market of a new product.Re-engineering means first to create an abstract representation of the system (i.e. the abstractmodel) through a reverse engineering process, then this model is re-designed, keeping as muchas possible a high abstraction, so great expandability can be assured, as well as fully exploitingpersonnel know-how, so it is possible to take advantage of their experience about the model.Updating a model generally also requires to improve existing applications, both re-writingsoftware components as well as adding new features to existing components.In this paper, the current model used inside STMicroelectronics facilities to define productionflow (the sequence of operations to be performed in order to make products) is considered. First,the model and its limitations are described, then introducing an updated, enhanced, object-oriented model, with aggregational and constitutional hierarchies used to model and classifyall entities and with a flexible inheritance mechanism used to speed-up and improve the definitionof a production flow.It is also considered which improvements are required on the existing applications, introducingan enhanced environment capable of supporting the enhanced model while preserving at thesame time both technical and economic investments through avoiding radical changes in existingenvironment.Transactions of the SDPS JUNE 2002, Vol. 6, No. 2, pp. 61-891. IntroductionModern manufacturing processes [A. Cichocki et al., 1998; F. Leymann, 1999] are highly structured and automated, so in order to manage them it is necessary a production model which may be quite complex, depending on the requirements of the product being manufactured.Besides, during the use of a model over several years, some questions can occur:• new marketing scenarios may arise, so new kinds of products could be required, or newtechnologies (e.g. chips with a lower consumption) can be developed;• some model limitations may be discovered, even for well-designed models, e.g. a shorter procedure for products manufacturing can be found or repetitive tasks can be discovered;• changes in the production area of the model may occur, for instance a new generation ofproduction machine with advanced capabilities could allow manufacturing operationsimprovements, so time and costs of existing products manufacturing can be reduced.Such situations often requires a periodic re-engineering of existing production model in order to keep it updated. Re-engineering [E. Byrne, 1992] first requires to analyze the currently adopted manufacturing system, identifying its components and their relationships, creating an abstract representation of the system (reverse engineering process [E. Byrne, 1992; Elliot J. Chikofsky and James H. Cross II, 1990], then the model obtained in this way is re-designed through removing its limitations (whenever possible) as well as adding new desired capabilities.General guidelines that should be followed during the re-design phase are:• to keep as much as possible a high-abstraction, achieving expandability and also acting as a base for future re-engineering. For instance, introducing a “production machine” with generalcharacteristics comprehensive of all real machines is better than just modelling all categories of current real machines, so it will be likely that a new type of machine can be modelled easier. Such an abstraction can be achieved using a suitable methodology, e.g. adopting an object-orientedapproach [S. Gossain et al, 1998], in which the concept of class, inheritance and versioning, as well as aggregational and constitutional hierarchies [S. Gossain et al, 1998; Bertino E. and Martino L.R., 1992], allow to model real environments with high abstraction;• to fully exploit the know-how of personnel, taking advantage of their experience about the model.Indeed, when working with a model, on one hand its limitations sometimes leads personnel to resort to expedients (for instance performing manually some unsupported coherence checking on the manufacturing process), in order to bridge the gap between the model and new needs; on the other hand, the way the personnel works may evolve, e.g. reducing the time for setting up a new product using a new shorter sequence of actions. In order to allow the re-engineered model to take into account this experience, it is necessary a complete support for new needs, e.g. providing a tool to define internal rules to automatically guarantee coherence (so users are relieved from using current expedients), and also providing some mechanism (e.g. a customizable wizard) that allowsexperienced users to define working sequences that can be used by inexperienced users during the specification of the manufacturing process, reducing training time.A significant example is the Integrated Circuits (IC) area, where the increasing miniaturization and rapid obsolescence of devices as well as rapid changes in market demand, impose to re-engineer periodically Journal of Integrated Design and Process Science JUNE 2002, Vol. 6, No. 2, 62existing production models in order to get a model which is both sophisticated, so more and more complex devices can be manufactured, and also flexible, so it is open towards new technologies developement and it can rapidly adjust production in reply to market demand (just in time production).We addressed all question described so far considering the STMicroelectronics (ST) [ST Microelectronics – ] environment, in particular analyzing Catania facilities manufacturing model [Longheu A, 1999; Carchiolo V., Longheu A., Malgeri M. and D’Ambra S., 1999; Carchiolo V., Longheu A., Malgeri M. and D’Ambra S., 2000] for production flow definition and management.The production flow is the sequence of logical operations that must be performed in order to make products; we note that such operations just include low-level (i.e. machine devoted) instructions, so an operation like “take X quantity of raw material form repository Y” will not belong to production flow (rather it belongs to a higher-level flow, on which we do not focus here [Carchiolo V., Longheu A., Malgeri M. and D’Ambra S., 1999]).In this case-study paper we first consider the reverse engineering task of the ST model, i.e. we outline the current model, describing any entity together with its links, which are a set of relationships used both to group entities according to a hierarchical classification and to show how different entities form the structure of a larger one. Then we re-design the ST model adopting an object-oriented approach, that is modeling real entities as object classes, placed together into one or more hierarchies, both aggregational (when objects must be simply grouped) or constitutional (when an object consists of others). During re-design we follow the previously described guidelines, crafting an “enhanced” object-oriented model that removes the limitations of current model, in particular:• we give all objects the role suitable for new needs arisen inside ST, also providing each object witha finite state machine to completely describe its behaviour;• we provide an inheritance mechanism for products development, assuring coherence, correctness and reducing setup time for new products, since they will inherit all their common characteristics from a specific “template” (named process). We also provide a three step specification whendeveloping a product, so it is possible to decide what must be inherited from a process and what must be specified for each single product, allowing to set the degree of inheritance.• we introduce a set of operation classes in order to improve the definition and management ofproduction flows, e.g. with the optional operation class we can establish which subsequence of operation must be followed based on the result of an expression. The optional operation can also be used to drive the inheritance between operations belonging to a process and operationsbelonging to its products children, providing a conditional inheritance (see sec. 3).We use object-oriented techniques in the IC manufacturing models context, making it easier to improve the model. Indeed, current manufacturing models are generally “hard-wired” on to the specific production environment, so when changes occur, e.g. when a new kind of technology is developed, it is difficult to modify the model; on the other hand, object-oriented techniques offers a high abstraction through which improvements can be easily added.An object-oriented approach reengineering does not represent a solution for any possible future needs, as when radical changes are required on the core of the model, but it is a way to generalize the specific characteristics of the model, so when new needs arise the abstraction of the model should allow to find a solution as in many cases as possible.Another question that must be considered after an existing model is re-engineered is whether or not the existing software applications are enough to implement the new “enhanced” model.Transactions of the SDPS JUNE 2002, Vol. 6, No. 2, 63We addressed this problem in the ST case, where existing software is not completely suitable for new needs, that are:• to provide a visual environment for a more user friendly production flow definition andmanagement (the existing software works using a character-based interface); this environment should also be cross-platform, since ST intranet presents different operating systems andhardware;• to provide support for defining automatic coherence and correctness rules to check the production flow (with existing software all such controls are manual, hence the training for inexperiencedpersonnel is harder);• to manage several user classes, since the model representation, as well as permissions onproduction flow specification, must be different depending on the specific user group (e.g. design, CAD/CAM, marketing…); with existing software, all users share the same model representation and have the same rights;• to allow a complete sharing of all information about production flow specification inside the STintranet, i.e. in a web-based environment (existing software does not support HTML or XML[XML – /XML; Carchiolo V., Longheu A., Malgeri M. and D’Ambra S., 2000] representation of the model).Given these new needs, on one hand we want to fully exploit existing applications potentiality in order to preserve as much as possible related technical and economic investments, but at the same time complete we want a complete support for all model improvements, hence if some limit is present in the software, it has not to be propagated to the model, influencing the model itself and/or the way it is used (as currently occurs).A compromise between enhanced model requirements and these software applications issues can be reached by enhancing the existing software, without re-writing it whenever possible (e.g. adding a level placed on top of existing software, supporting new required capabilites and acting as an interface to users). Such a goal can be achieved either using general purpose tools, assuring great expandability but with less efficiency, or implementing customized tools, with high efficiency but limited expandability and high costs, since software has to be created ad-hoc; hence, a trade-off between generality-expandibility and specificity-efficiency must be found when enhancing the software.Here we consider such questions, introducing an “enhanced” environment capable of supporting the “enhanced” model, satisfying the requirements described above. In particular, we developed software enhancements using Java platform [Java – ], that fits well in the web-based, cross-platform ST environment, thanks to its networking support, applets, security management, HTML and XML support.The rest of paper is organized as follows: in section 2 we introduce the current model. Then, in section 3 we present the enhanced, object-oriented model, describing objects and their hierarchies, then focusing on process family, product and operation objects, where major improvements are made, and finally describing finite state machine for process families and product objects. In section 4 we consider the existing environment, i.e. software applications used to implement the model, defining improvements needed to support the enhanced model, and finally we present our conclusions in section 5.2. Overview of the STMicroelectronics Current Model.ST Microelectronics Catania M5 facilities produces several families of memories, in particular Flash memories for smartcards, and Eprom and EEprom memories. Capacity for such memories currently Journal of Integrated Design and Process Science JUNE 2002, Vol. 6, No. 2, 64Fig. 1 ST Production model.ranges from 256Kb to 32Mb, while minimum working dimension is less than 0.5mm. In the following we describe the model for the specification of the production flow used for such ICs manufacturing; the model is placed in the context of the entire ST production model [Longheu A, 1999], so we briefly present the latter to better describe the context in which we work.The ST production model can be viewed as a set of macro-operations (Fig.1) starting from the client order, evolving through product manufacturing, to delivering of final required products. In the first step order requests coming from clients are examined by marketing area, where an agreement about quantity, price and delivery time is achieved with clients. Then, in the planning phase, quantity of products are expressed in terms of technical parameters, as the number of slices to manufacture, cycle time constraints and so on. The following steps, represented as white boxes, are performed using the production flow specification model, on which we will focus.The production flow specification setting phase consists in definition of the run-sheet, a document associated with lots (a lot is a group of 25 silicon slices, viewed as a single production unit).The run-sheet contains the sequence of operations that must be carried out on lots in order to make ICs. In the lots startup step we establish which lots must be associated with a given product, based on their crystallographic orientation, electrical resistivity and so on. Then we move to lots processing, the core of Transactions of the SDPS JUNE 2002, Vol. 6, No. 2, 65Fig. 2 Products grouped inside a facility.Fig. 3 A set of products inside a facility.production process, in which several physical and chemical operations (from diffusion to lapping) are performed in order to turn each silicon slice into a set of ICs according to run-sheet specification.After lots processing, we must check if anything went ok performing the Electrical Wafer Sort (EWS), a test in which all faulty chips are marked and discarded. In the assembling phase we separate each single chip from others, packaging it in a plastic or ceramic package, performing a final test on each IC. Finally, storing and delivery phases complete the production process.The production flow specification model currently used to accomplish white boxes phases shown in Fig. 1 is a product-centric model, where product is the logical entity used to represent a real product, and where all products are grouped into the same facility (Fig. 2), that is the plant where production takes place.Each product is characterized by a set of attributes [Longheu A, 1999], e.g. its name, or the material (silicon or germanium) used to make the product, and by an associated production flow (also named route), that is sequence of physical operations that must be carried out by production machines to make ICs belonging to that product (hence, the route is the electronic form of the run-sheet document described previously). Example of production machines are furnaces, ionic planter, etching machines, and photolithographic machine, all used to create silicon wafers (slices), dope them (i.e. increase their electrical conductivity through introducing doping elements as phosphorus or arsenic into silicon), and manifacture IC on doped silicon wafers.To logically classify products, three of its attributes (highlighted in Fig.2) are used: Process family, Technology, Profict and Losses (P&L) family.Journal of Integrated Design and Process Science JUNE 2002, Vol. 6, No. 2, 66Fig. 4 A production flow (route) and its script.The Process family entity is introduced to group products having “similar” routes, i.e. differing for some operation of the sequence or for the value of some parameter belonging to a given operation. Several process families characterized by the same manufacturing process (even if they may have different sequences) are grouped into a technology. Finally, technologies are classified according to the P&L family, an economic parameter.To better explain these parameters, in Fig. 3 we show an example of current hierarchy (lots are not represented), where a set of products manufactured inside M5 facilities is considered.Starting from the bottom left, products BG4X-1 and BG4X-3 represent two flash memories with a capacity of 4Mb, belonging to the same process family, the BG4X. Such products differ for a specific parameter of an operation of their (identical) production flow, indeed it is required a different thickness of the silicon wafer on which they are manufactured, since the BG4X-1 must be assembled on a chip for smartcards (hence, its dimension must be reduced), while BG4X-3 will be assembled on plastic package (where more space is available).Products BG8X00-0 and BG8X00-1 represent two versions of the same logical product, the BG8X00 (a flash memory with 8Mb capacity), belonging to the BG8X process family. Such products have different operations in their production flow (differently from the previous case), indeed some etching phases are made with one operation in the BG8X00-0, while this operation is splitted into two distinct operations in BG8X00-1.Both BG4X and BG8X flash memories process families belong to the same technology T6fsh35, where the T6 prefix indicates the technology generation, in which guidelines for the device geometry are fixed together with the starting minimum working dimension, that is 0.35mm (fsh stands for flash). Starting means that new improved process families created inside this technology may also be manufactured operating at a lower working dimension. Moreover, any time a major change is made on the geometry, a new techology generation is created.We note that production flows for distinct process families (e.g., BG4X and BG8X) may have completely different operations, or they may share some subsequence of operations, or they may have the same operations with different parameters values. So, the same criterias both distinguish process families and separate distinct products inside a process family. The choice on whether a new product is placed into an existing process family or it determines the creation of a new process family is not currently rigorously defined since it is related to corporate internal decisions (e.g., the product may represent a significant evolution of an existing one, since it derives from the application of new technologies, or its production flow is radically different from previous ones, i.e. the most significant operations (core) have been changed). Transactions of the SDPS JUNE 2002, Vol. 6, No. 2, 67Fig. 5 Operation Library.Finally, in Fig. 3 we also have the 16Mb flash memory r-AE16S, belonging to AE16S process family, placed into T6fsh40 technology, whose starting minimum working dimension is 0.40µm. Both T6fsh35 and T6fsh40 are grouped in the same P&L family, P-440, while the 0.40µm EEProm memories technology T6e2p40, which includes the product HX32Na shown in Fig. 3, is placed below a different P&L family (P-455), according to corporate (internal) economic and marketing considerations.Considering operations belonging to a route (Fig.4) mentioned before, they represent abstract actions that must be further specified through a second level of detail, hence, each operation has an associated sub-sequence (script) of events, each of which is an “atomic” action directly linked to production machines.This further specification for operations is needed since e.g. we have diffusion operations, but while this simply means that during the execution of the operation doping elements will be introduced into silicon, all physical and chemical parameters needed to really perform the diffusion phase (i.e. to control furnace machines), as the time of diffusion or the quantity of doping element, will be specified just at low (event) level.Each operation also has a set of attributes in addition to its script [Longheu A, 1999], e.g. short description, used for comments, or workarea, specifying the production area where the operation can be used.Besides, in the current model an operation is used in different routes (i.e. different products), maintaining the same set of values for attributes but with a different associated script, so operations belong to a unique library (Fig. 5) from which we get desidered operation any time a new route is created, then associating the related script (scripts are also stored in a library).The current model described up to now presents several limitations:• the product-centric feature implies that the product is directly placed below the facility entity, while P&L family, technology and process family are viewed as simple product parameters, even if they play a significant role as products classifiers, hence the hierarchy should be better defined, explicitly classifying products;• no mechanism is present to speed-up definition for products having similar operations, so thespecification of a new product is a time-consuming and error-prone task, since it must be created from scratch or, at most, by first copying from a similar existing product, then making changesaccording to specifications;• no support for operations setup is provided; indeed, several operations may share a subset ofevents inside their script, or may have the same script structure with different values for event parameters, so it would be useful some mechanism for operation management;Solutions for these limitations, mentioned in sec.1, impose the re-engineering task leading to the enhanced model shown in the next section. Table 1 provides a summary for all terms introduced so far.Journal of Integrated Design and Process Science JUNE 2002, Vol. 6, No. 2, 68Table 1 Description of the terms introduced.3. The Enhanced Model.3.1. Overview.As mentioned in sec.1, the solution we propose for existing model limitations is the re-engineering through the use of an object-oriented (OO) approach. The first step when creating an OO model is to identify objects, each of which can be defined as an abstraction of a part of the reality being considered. Being this definition highly general, a generic object can represent any entity (e.g., human resources), it may partially overlap with others (several objects may have common features) and may or not have a physical counterpart (this becomes more evident as model description descends from a high abstraction level towards real entities) [S. Gossain et al, 1998].An object can also be used to group others together; this situation, which may also include classical OO inheritance, determines aggregation hierarchy. Another case is that of complex objects [Bertino E. and Martino L.R., 1992], i.e. consisting of other objects; such links creates constitutional hierarchies (also known as aggregation hierarchies [Bertino E. and Martino L.R., 1992]). Finally, several objects can make up a single logical entity, leading to composite objects [Kim W. et al., 1989] (constitutional hierarchies may also include these objects). Aggregation, complex and composite objects, all present in a manufacturing environment, are essential to capture production cycle features.Identifying an object also means choosing which production aspects must be considered as objects. Simple criteria are to select the most significant entities, those that require an identity of their own, and Transactions of the SDPS JUNE 2002, Vol. 6, No. 2, 69Fig. 6 Logical hierarchy of the new model.Fig. 7 The hierarchy of Fig.3 revisited.those that cannot be associated with any other objects. Otherwise, entities can be modeled as attribute of others objects. Finally, after objects identification, it is necessary to determine each object’s attribute and methods.Based on all these considerations, we reconsider existing model, modelling each previously described entity as an object. In particular, we model process family, technology and P&L family, which are currently simple product parameters, as distinct objects placed into a hierarchy based on their role (as defined in sec.2), since we want to give such entities a more central role and also to classify products more explicitly. Hence, we get to Fig. 6 where a new hierarchy is introduced; we note that such hierarchy is aggregational since it is just used to group objects. According to this organization, the flat hierarchy shown in Fig. 3 can be better represented as in Fig. 7.Besides, in the re-engineered (enhanced) model we adopt the existing product definition (see Fig. 4), hence a product has an associated sequence of operations, being a complex object defined in terms of a composite object (its route). In this way, we form a constitutional hierarchy. Really, this definition is exten-ded by introducing two new categories of operations (see section 3.2), in addition to the unique category currently supported, providing in this way major abstraction and flexibility during route definition, also reducing time and cost in product development.In the enhanced model we also make the script for each operation as one of its attributes, since it is required to avoid the current separation between the script and the operation object. In this way operations Journal of Integrated Design and Process Science JUNE 2002, Vol. 6, No. 2, 70Transactions of the SDPS JUNE 2002, Vol. 6, No. 2, 71are modelled in a slightly different manner than current operation . Indeed, in the existing model (see Fig.5), an operation A, identified by its parameters (that do not include the script) is used in different routes,say as operation A 1, ..., A n , associating a different script for each route, i.e. for each operation A i , so operations A i differ just for the script.In the new model, this behaviour is implemented (using OO terminology) first subclassing the operation class (Fig. 8), creating the A operation class, in which its attributes, except for the script, are specified as static (they do not change across instances). Then we instance the A class, creating A 1, ..., A n operations,which can only differ for the script, which is an instance attribute. Any time a new set of attributes (except for the script) is needed, a new subclass of operation class (B, C, ...) is created and then instanced in order to specify the script.We finally associate attributes to each object [Longheu A, 1999] (e.g. also for technology and process family objects). Attributes collect all significant information about an object, even those dispersed throughout the model, i.e. when an attribute is related to another entity or is represented as an entity (the latter is the case of script described above). Since this is not a very significant task, we do not specify here the complete list of attributes for each object.Considering methods, they include object management methods (e.g. constructor), as well as specific methods used to provide each object with its desired behaviour [S. Gossain et al, 1998]. Focusing in particular on object management, or object’s states , when an object is instanced it will be in a created state, then it moves through several states during its life cycle, reaching the final state (obsolescence , see sec.3.2.5) when it will be removed from the production model. All state changes are accomplished using specific methods; hovewer, rather than describe a list of such methods, we introduce (sec. 3.2.5) the most significant states of Finite State Machine (FSM) for process family and product classes. Since no other methods are worth of mentioning (they can be considered as implementation details), we do not consider methods throughout this paper.3.2. Enhanced model core: Process Family and Product.The major improvement with respect to the existing model is the use of inheritance mechanism to model dependences between process family and related products. As mentioned in sec.2, when several products only differ in the values of certain parameters, or for some operation of sequence, it is desirable to avoid the tedious and error-prone work of re-creating what is common among them. The process family definition is extended in order to meet this needs, since in the new model it is not just a simple classifier, but it is a general schema for similar products: creating a process family means to set all common features for this group of products, so they will automatically inherit all that has been defined inside their father process family. Then, to define completely each product, it is required just to specify some operations and/or parameters.Fig. 8 Subclassing operations in the new model.。