EPC Information Service (EPCIS)

- 格式:pdf

- 大小:381.63 KB

- 文档页数:9

EPC系统的构成EPC系统是一个非常先进的、综合性的复杂系统,其最终目标是为每一单品建立全球的、开放的标识标准。

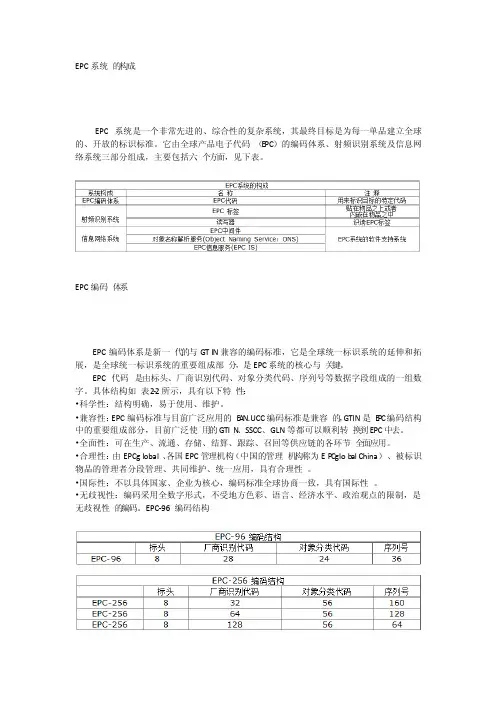

它由全球产品电子代码(E PC)的编码体系、射频识别系统及信息网络系统三部分组成,主要包括六个方面,见下表。

EPC编码体系EPC编码体系是新一代的与GTIN兼容的编码标准,它是全球统一标识系统的延伸和拓展,是全球统一标识系统的重要组成部分,是EPC系统的核心与关键。

EPC代码是由标头、厂商识别代码、对象分类代码、序列号等数据字段组成的一组数字。

具体结构如表2-2所示,具有以下特性:•科学性:结构明确,易于使用、维护。

•兼容性:EPC编码标准与目前广泛应用的E A N.UCC编码标准是兼容的,GTIN是E P C编码结构中的重要组成部分,目前广泛使用的GTIN、SSCC、GLN等都可以顺利转换到EPC中去。

•全面性:可在生产、流通、存储、结算、跟踪、召回等供应链的各环节全面应用。

•合理性:由EPCglobal、各国EPC管理机构(中国的管理机构称为EP Cglob al China)、被标识物品的管理者分段管理、共同维护、统一应用,具有合理性。

•国际性:不以具体国家、企业为核心,编码标准全球协商一致,具有国际性。

•无歧视性:编码采用全数字形式,不受地方色彩、语言、经济水平、政治观点的限制,是无歧视性的编码。

EPC-96 编码结构当前,出于成本等因素的考虑,参与EPC测试所使用的编码标准采用的是64位数据结构,未来将采用96位的编码结构。

EPC射频识别系统EPC射频识别系统是实现EPC代码自动采集的功能模块,主要由射频标签和射频读写器组成。

射频标签是产品电子代码(EPC)的物理载体,附着于可跟踪的物品上,可全球流通并对其进行识别和读写。

EPC网络中ONS安全分析及解决方案作者:谢雷来源:《软件导刊》2013年第05期摘要:分析了ONS系统架构中存在的安全问题,综合DES和RSA加密算法的优点,提出了基于DES和RSA的混合加密方案,并将其应用于ONS查询过程中的数据通信,有效地防止了偷听等攻击行为,加强了各ONS组件之间交互的可信性和安全性。

关键词:EPC;对象命名服务;混合加密中图分类号:TP309 文献标识码:A 文章编号:1672-7800(2013)005-0130-030、引言EPC网络(又称为物联网)是当今的热门研究领域,在此网络中,可以识别任何事物及其在物流链中的位置,以达到降低成本、提高物流供应链管理水平的目的。

近年来物联网飞速发展,其通信安全也受到了广泛关注。

物联网的安全研究主要分为两类:一类研究RFID阅读器通讯和RFID标签;另一类研究EPC Global网络安全。

文献分析了EPC G10bal网络体系中0NS系统存在的安全隐患,并给出了解决方案,由于此方案需要与VPN技术结合,因此局限于大规模应用;文献提出了基于DNS安全扩展的解决方案,以加强ONS系统内部的安全,此方案能够保证0NS内部的安全,但当0NS与EPC系统中的其它组件进行交互时,可能会出现窃听、欺骗等安全威胁。

目前数据加密技术有两种:一是对称加密,采用相同的密钥加解密,如DES、IDEA、AES算法等;二是非对称加密,加密解密使用不同的密钥,如RSA、椭圆曲线算法等。

这两类加密算法在速度、安全性和密钥的管理上各有优缺点,优势互补。

因此,本文提出了基于DES和RSA的混合加密方案,并将DES—RSA混合加密技术应用于ONS查询过程中的数据通信,使得各ONS组件之间交互时更加可信和安全。

1、EPC网络EPC网络由EPC编码标准、射频识别系统及信息网络系统组成,如图1所示。

(1)EPC编码标准。

EPC编码标准是由版本号、厂商识别代码、对象分类代码及序列号等字段组成的一串数字,其作用是为每个对象提供唯一标识。

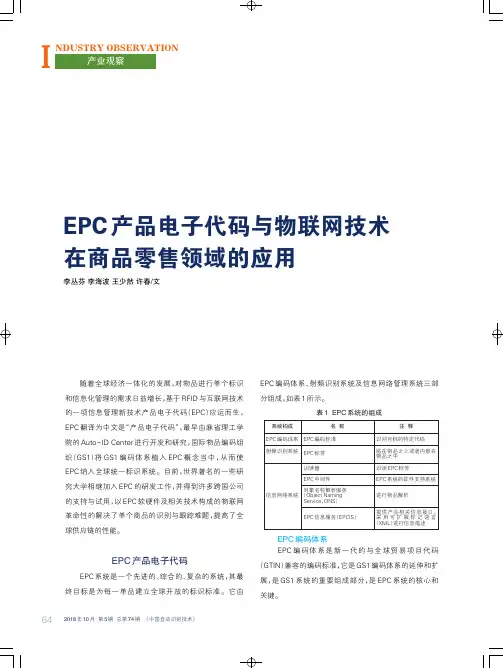

2018年10月第5期总第74期《中国自动识别技术》随着全球经济一体化的发展,对物品进行单个标识和信息化管理的需求日益增长,基于RFID 与互联网技术的一项信息管理新技术产品电子代码(EPC )应运而生,EPC 翻译为中文是“产品电子代码”,最早由麻省理工学院的Auto-ID Center 进行开发和研究,国际物品编码组织(GS1)将GS1编码体系植入EPC 概念当中,从而使EPC 纳入全球统一标识系统。

目前,世界著名的一些研究大学相继加入EPC 的研发工作,并得到许多跨国公司的支持与试用,以EPC 软硬件及相关技术构成的物联网革命性的解决了单个商品的识别与跟踪难题,提高了全球供应链的性能。

EPC 产品电子代码EPC 系统是一个先进的、综合的、复杂的系统,其最终目标是为每一单品建立全球开放的标识标准。

它由EPC 编码体系、射频识别系统及信息网络管理系统三部分组成,如表1所示。

表1EPC 系统的组成EPC 编码体系EPC 编码体系是新一代的与全球贸易项目代码(GTIN )兼容的编码标准,它是GS1编码体系的延伸和扩展,是GS1系统的重要组成部分,是EPC 系统的核心和关键。

EPC 产品电子代码与物联网技术在商品零售领域的应用李丛芬李海波王少然许春/文系统构成EPC 编码体系射频识别系统信息网络系统名称EPC 编码标准EPC 标签识读器EPC 中间件对象名称解析服务(Object Naming Service,ONS )EPC 信息服务(EPCIS )注释识别目标的特定代码贴在物品之上或者内嵌在物品之中识读EPC 标签EPC 系统的软件支持系统进行物品解析提供产品相关信息接口,采用可扩展标记语言(XML )进行信息描述产业观察INDUSTRY OBSERVATION642018年10月第5期总第74期《中国自动识别技术》EPC 编码是由标头、管理者代码、对象分类代码、序列号等数据字段组成的一组数字,96位EPC 代码具体结构如表2所示。

The Communicating Language in EPCglobal: PML物联网中的通信语言:PMLPML:物体标记语言摘要:随着RFID 的大规模应用,EPC 物联网也得到了很大的发展。

在此物联网络中,相互通信的公共语言是PML。

PML是在XML的基础上扩展而来,用于描述自然物体、处理过程及环境情况。

本文详细地讲述了PML 语言的概念、组成、设计,并给出了其应用实例。

EPC的6个组成部件:EPC编码标准EPC标签阅读器SavantONSEPC信息服务器(EPCIS,旧称PML服务器)PML设计现实生活中的产品丰富多样,难以用一个统一的语言来客观的描述每一个物体。

然而,自然物体都有着共同的特性,如体积、重量;企业、个人交易时有着时间、空间上的共性。

例如,苹果、橙子、统一鲜橙多,它们三者都属于食品饮料,而苹果、橙子同属于农作物,鲜橙多又是橙子加工后的商品;人们交易一箱苹果的时间、地点又是相同的。

但是,自然物体的一些相关信息(如生产地、保质期)不会变化。

同时,EPC物联网是建立在现有的互联网上的。

为此,作为描述物体信息载体的PML 语言,其设计有着独特的要求。

(1)开发技术PML 首先使用现有的标准(如XML、TCP/IP)来规范语法和数据传输,并利用现有工具来设计编制PML 应用程序。

PML 需提供一种简单的规范,通过通用默认的方案,使方案无需进行转换,即能可靠传输和翻译。

PML 对所有的数据元素提供单一的表示方法,如有多个对数据类型编码的方法,PML 仅选择其中一种,如日期编码。

(2)数据存储和管理PML 只是用在信息发送时对信息区分的方法,实际内容可以任意格式存放在服务器(SQL 数据库或数据表)中,即不必一定以PML 格式存储信息。

企业应用程序将以现有的格式和程序来维护数据,如Aaplet 可以从互联网上通过ONS来选取必需的数据,为便于传输,数据将按照PML 规范重新进行格式化。

EPC系统详细介绍EPC(Engineering, Procurement, and Construction)系统是指工程、采购和施工三个环节的一体化管理系统。

它是一种综合管理方法,包含了项目的规划、设计、采购、施工和交付等各个阶段。

EPC系统在建设行业中被广泛应用,可以提高工程质量、加快工程进度、降低成本、提高管理效率等一系列好处。

EPC系统的核心是整合各个环节的信息和资源,实现工程项目的一体化管理。

它包括工程规划、工程设计、采购计划、供应商管理、施工管理、质量控制、安全管理、进度控制、成本控制等一系列子系统。

通过这些子系统的协同工作,能够实现工程项目从规划到竣工的全过程管理。

首先,EPC系统的工程规划子系统可以帮助项目经理进行项目的整体规划。

它能够帮助项目经理确定项目目标、项目范围和项目需求,制定项目计划,并进行资源分配和风险评估。

在规划阶段,EPC系统能够帮助项目经理预见潜在问题,提前采取措施,从而保证项目能够按照预期目标实施。

其次,EPC系统的工程设计子系统能够帮助设计师进行工程设计。

它提供了一套完整的设计工具,能够进行布置设计、结构设计和设备选择等工作。

设计师可以通过EPC系统对设计进行模拟和测试,预测设计的效果,并在需要时进行调整。

同时,系统还能够提供设计文档和图纸管理,确保设计的正确性和完整性。

另外,EPC系统的施工管理子系统能够实现对施工过程的全面管理。

它能够帮助施工人员进行施工计划、资源分配和进度控制,确保施工进程和质量的控制。

系统还能提供施工现场的安全管理和质量管理功能,保证施工过程的安全和质量水平。

此外,EPC系统还具备成本控制和财务管理的功能。

项目经理可以通过系统进行成本预测、成本分析和成本控制,确保项目在预算范围内进行。

系统还能够提供供应商和工程合同的付款管理,实现对工程项目的财务管理。

总的来说,EPC系统是一种综合管理系统,能够对工程项目进行全过程管理。

它通过整合各个环节的信息和资源,实现工程项目的一体化管理,提高工程质量、加快工程进度、降低成本、提高管理效率等一系列好处。

epc模式是什么意思何谓epc模式,我们可以看看它的解答是什么?下面是店铺给大家整理的epc模式是什么意思,供大家参阅!epc模式是什么意思EPC为Engineering Procurement and Construction或Engineer,Procure and Construct的缩写,可译为设计——采购——施工(交钥匙)项目合同条件。

一般情况下由承包商实施所有的设计、采购和建造工作,完全负责项目的设备和施工,雇主基本不参与工作。

即在"交钥匙"时,提供一个配套完整、可以运行的设施。

EPC的其它含义主要特点EPC是一种进无余量精确成形的工艺。

其特点是采用遇金属即消失的泡沫塑料做模样,既无分型又无分型芯。

模样无起模斜度,铸件无飞边毛刺,还减小了由于型芯块组合而造成的尺寸误差。

铸件尺寸精度和表面粗糙度可分别达到IT5—IT7,Ra=6.3~12.5μm,接近熔模精密铸造水平。

由于采用干砂,根除了由于水分,粘结剂和附加物带来的缺陷,铸造废品率显著下降,铸件质量显著提高。

该工艺对工人的操作水平要求不高,对铸造行业很有吸引力。

容易实现清洁生产。

低温下聚苯乙烯(EPS)对环境完全无害,浇注时排出的有机物也少;EPS有机物排放量仅占浇注铁液质量的0.3%。

而自硬砂为0.5%。

同时生产有机排放物的时间短,地点集中,易于收集,可以采用负压抽吸式燃烧净化处理,燃烧产物净化后对环境无公海,旧砂回用率在95%以上。

与传统铸造方法相比。

EPC法的噪声,一氧化碳气体和硅石粉尘危害明显减小,工人劳动强度大大降低,劳动环境显著改善,容易实现机械化,自动化的清洁生产。

为主见结构设计提供了充分的自由度。

原先要由多个零件加工组装的构件,采用EPC工艺后可以通过分片制模然后粘合的办法整体铸出,而且型芯可以省去,孔、洞可以直接铸出,这就大大节约了加工装配的费用,同时也可以减少加工装备的投资。

一般说来,与传统铸造工艺相比,EPC技术设备投资可减少30%~50%,铸件成本可下降10%~30%。

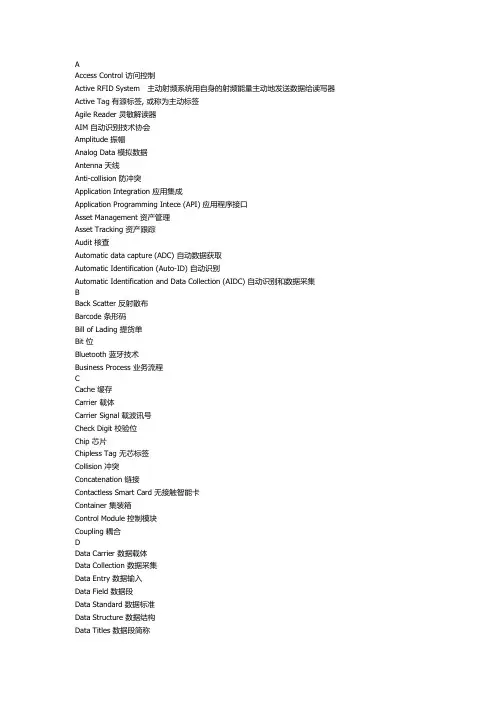

AAccess Control 访问控制Active RFID System主动射频系统用自身的射频能量主动地发送数据给读写器Active Tag 有源标签, 或称为主动标签Agile Reader 灵敏解读器AIM 自动识别技术协会Amplitude 振幅Analog Data 模拟数据Antenna 天线Anti-collision 防冲突Application Integration 应用集成Application Programming Intece (API) 应用程序接口Asset Management 资产管理Asset Tracking 资产跟踪Audit 核查Automatic data capture (ADC) 自动数据获取Automatic Identification (Auto-ID) 自动识别Automatic Identification and Data Collection (AIDC) 自动识别和数据采集BBack Scatter 反射散布Barcode 条形码Bill of Lading 提货单Bit 位Bluetooth 蓝牙技术Business Process 业务流程CCache 缓存Carrier 载体Carrier Signal 载波讯号Check Digit 校验位Chip 芯片Chipless Tag 无芯标签Collision 冲突Concatenation 链接Contactless Smart Card 无接触智能卡Container 集装箱Control Module 控制模块Coupling 耦合DData Carrier 数据载体Data Collection 数据采集Data Entry 数据输入Data Field 数据段Data Standard 数据标准Data Structure 数据结构Data Titles 数据段简称Decode 解码Die 模块Distributed Architecture 分布式结构Distributed Architecture 分布式架构Distribution Center 分发中心DUN-14 (Despatch Unit Number) 储运单元代码Dynamic Data 动态数据EEAN International 国际物品编码协会EAN UCC Company Prefix EAN·UCC厂商识别代码EAN UCC Prefix EAN·UCC前缀码Electromagnetic Compatibility (EMC) 电磁兼容能力Electromagnetic Interference (EMI) 电磁干扰Electromagnetic Spectrum 电磁波频谱Electromagnetic Waves 电磁波Electronic Article Surveillance (EAS) 商品电子防盗系统Electronic Data Interchange (EDI) 电子数据交换Electronic Invoice 电子发票Electronic Product Code (EPC) 电子产品码Encode 编码Enterprise Application Integration (EAI) 企业应用集成Enterprise Resource Planning (ERP) 企业资源规划EPC Information Service (EPCIS) EPC信息服务European Article Numbering (EAN) 欧洲商品编码Excite 激发Extensible Markup Language (XML)可扩展标识语言Extension Digit 扩展位FFast Moving Consumer Goods 快速消费品FCC 美国联邦传播委员会Firmware 固件Fixed Measure Trade Item 定量贸易项目GGlobal Commercial Initiative 全球商业联盟Global Location Number 全球位置码Global Tag (GTAG) 全球标准标签(G标签)Global Trade Identification Number (GTIN) 全球贸易识别号码Global Trade Item Number 全球贸易项目代码GTIN 全球贸易项目代码HHigh Frequency (HF) 高频House Way Bill Number 货运代理人运单号IInductive Coupling 感应耦合Industrial, Scientific and Medical (ISM) Bands 工业,科学和医药频段Infrastructure 基础设施Integrated Circuit (IC) 集成电路International Standards Organization (ISO) 国际标准化组织International Telecommunications Union (ITU) 联合国国际电信联盟Internet of things 物联网Interrogator 询问器Interrogator (see Reader) 讯问器 (参照解读器)Inventory 库存ISO 国际标准化组织Item 产品Item Model 产品型号Item Number 产品编号Item Reference 项目参考Item Reference Number 项目代码LLine-of-sight Technology 可视传输技术Logistic Measures 物流计量Logistic Unit 物流单元Logistics 物流Low Frequency (LF) 低频MMagnification 放大系数Manufacturer 制造商Manufacturer’s ID 制造商标识Manufacturer’s Number 制造商代码Microchip 微芯片Microchip 微芯片Micron 微米Microwave Tags 微波标签Middleware 中间件Modulation 调制Multiple Access Schemes 多路配置Multiplexer 多路转换器NNanoblock 纳块Nominal Range 标称范围Null Spot 无效点OObject Naming Service (ONS) 对象名解析服务PPackaging and Labeling 包装和标记Packaging Type 包装类型Pallet 运输托盘Passive RFID system被动射频系统Passive Tag 无源标签, 或称被动标签Physical Markup Language (PML) 物理标识语言Platform 平台PML Server 物体标示语言服务器PML Server PML服务器Protocol 协议Prototype 原型Proximity Sensor 近距离传感器RRadio Frequency (RF) Spectrum 无线电频谱Radio Frequency Identification (RFID) 射频识别Radio Wave 射频信号Read Range 解读范围Read Rate 读取速度Reader 解读器, 或称阅读器, 读写器Reader Collision 解读器冲突Reader Field 解读器区域Read-Only Tag 只读标签Read-Write Tag 读写标签Receiver 接收器Retailer 零售商Return on Investment (ROI) 投资回报Returnable Asset 可回收资产RFID Tag 射频标签SScanner 扫描器Semi-passive RFID System半主动射频系统Semi-Passive Tag 半无源电子标签, 或称半被动式电子标签Sensor 感应器Short Range 短距离Simultaneous identification 同时识别功能Smart Card 智能卡Smart Label 智能标签Static Data 静态数据Supplier 供应商Supply Chain Management (SCM) 物流管理System Implementation 系统实施TTag 标签Tag Collision 标签冲突Temporal Data 暂态数据Track and Trace 跟踪与追踪Trade Measures 贸易计量Transmitter 发射器Transponder 转发器UUHF 超高频Uniform Code Council (UCC) 美国统一代码协会Uniform Product Code (UPC) 通用产品代码WWafer 晶片Warehouse Management 仓库管理Write Rate记录速度。

RFID技术常用词语解释AAgile reader灵敏解读器是可以解读不同类型RFID标签的解读器通称,例如由不同厂商制造的,或可以工作在不同频率下的解读器。

Amplitude振幅无线电波的最大高度。

Analog data模拟数据由连续改变的物理量所表示的信息,如电磁波(见下文)的长度或高度。

Antenna天线发射或接收电磁波的装置。

Anti-collision防冲突一项用来防止一个解读器场中的多个标签,或者重叠场中的多个解读器互相冲突的技术。

典型的防冲突算法是通过保证标签或解读器不在同一时间传输信号来工作的。

Automatic data capture (ADC) 自动数据获取(ADC)采集数据并不依靠人的干预而直接输入到计算机系统中的方法(见自动识别和数据采集)Automatic identification and data collection (AIDC)自动识别和数据采集(AIDC)一个很广泛的术语,包括不通过键盘而把数据直接录入到计算机系统的方法。

这包括条码扫描,射频识别,声音识别及其他技术。

BBar Code条码使机器自动识别带标签物体而采用的技术。

因为对机器来说,条码更容易解读。

条码使用的最大缺点是,它不能区分这一瓶罐头与另一瓶罐头,并且扫描头必须对着可视面来识读标签。

Bit位数字信息的最小单位-一个单独的1或0。

一个96位的EPC由一串96个1和0的字符组成。

CCache缓存用来存储并快速检索最近访问数据的存储器。

Chip芯片见微芯片Collision冲突无线电信号的互相干扰。

标签或解读器的信号可能发生冲突(见下文)。

Coupling耦合电路之间能量的传递。

电感耦合和电容耦合是解读器和标签之间能量传递(也包括数据)的两个方法。

DDie模块一块微小的正方形的硅,集成电路蚀刻在上面-我们一般称之为硅芯片。

Distributed architecture分布式架构指同时在分散遍布一个机构中的不同计算机上工作的软件,而不是在一台中心计算机上工作的软件。

epc名词解释

EPC是英语Enterprise Resource Planning(企业资源计划)的

缩写,是一种综合企业信息化管理系统。

它包括采购、生产、销售、物流、财务和人力资源等全方位的业务模块,通过整合管理企业的内外部信息和资源,实现制造、交付和服务的数字化一体化,提高企业的管理水平和竞争力,提升企业的效率和盈利能力。

在EPC系统中,各个模块之间是高度集成的,数据共享、信

息流畅。

EPC系统可以帮助企业实现供应链的协同与一体化,及时了解自身的生产销售状况、库存量和资金流,可有效决策和调节。

EPC的实施需要企业重新规划组织架构、流程、数据、技术

和人员等方面,是一项具有挑战性和复杂性的项目。

企业需要按照自己的实际情况和需求,选择合适的EPC方案和供应商,并进行系统规划、数据清洗和转换、用户培训等工作,以确保EPC系统的平稳上线和应用。

EPC系统的实施和应用,可以直接影响到企业的发展和竞争力。

因此,企业需要做好前期调研、规划、准备工作,并加强对EPC系统的监管和维护,确保系统的稳定性和可靠性。

《基于物联网的EPC信息服务查询机制的研究》篇一一、引言随着物联网技术的飞速发展,各类物品的电子标识与信息追踪变得尤为重要。

其中,EPC(Electronic Product Code)信息服务在物联网领域的应用日渐广泛。

EPC不仅提供了对物品的唯一标识,更实现了物品信息的快速查询与共享。

因此,研究基于物联网的EPC信息服务查询机制,对于提高物品管理效率、优化资源配置以及促进物联网技术的进一步发展具有重要意义。

二、EPC信息服务及其在物联网中的应用EPC信息服务是基于EPC编码体系构建的,通过对物品的电子标识进行识别,实现物品信息的采集、存储和查询。

在物联网中,EPC信息服务可以应用于各类物品的追踪、追溯、管理与维护,提高物流效率,优化资源配置,并有效减少人为错误和操作失误。

三、基于物联网的EPC信息服务查询机制(一)机制概述基于物联网的EPC信息服务查询机制主要包括:EPC编码体系、信息采集与传输、信息存储与处理以及信息查询与共享等部分。

该机制通过物联网技术实现对物品信息的实时采集、传输、存储和查询,从而为各类用户提供便捷的EPC信息服务。

(二)编码体系EPC编码体系是EPC信息服务的基础。

在物联网中,每个物品都有一个唯一的EPC编码,用于标识该物品的身份。

此外,EPC编码还包含了物品的相关信息,如生产日期、制造商等。

通过识别EPC编码,可以实现对物品信息的快速获取和追踪。

(三)信息采集与传输信息采集与传输是EPC信息服务查询机制的重要组成部分。

在物联网中,各类传感器和标签负责对物品信息的实时采集,然后将这些信息通过无线网络传输到数据中心。

这些信息包括物品的状态、位置、数量等。

通过数据中心的统一管理和处理,实现对物品信息的实时更新和共享。

(四)信息存储与处理在数据中心中,信息被存储并进行相应的处理。

数据中心负责维护一个完整的数据库系统,包括EPC编码与物品信息的映射关系。

通过大数据分析和云计算等技术手段,实现物品信息的实时分析和挖掘,为决策者提供数据支持。

静s翟碰ncR。

p眦特别报道

如果有一天,世界上的万事万物(包括人)无论何时、无论何地都能彼此相联,互相交流,那将是一个怎样的景象?这就是物联网为我们描绘的未来蓝图。

物联网是

产品电子代码EPC的实物互联网,是在计算机互联网的基础上,利用射频技术、无线

数据通信等技术,构造的一个实现全球物品信息实时共享的“InternetofThings”。

EPC

和物联网的产生是信息社会及经济贸易发展的智慧结晶,是高科技领域一项革命性的

新技术,必将对自动识别技术行业带来一场革命。

目前,互联网软、硬件环境的初步形成和EPC的快速发展为物联网的实现创造了前提条件,而射频技术的逐渐成熟为物联网的实现提供了技术支持。

世界发达国家和

地区高度重视物联网的发展,纷纷积极推动EPC技术在本国和本地区的研究与应用。

美国商业零售巨头沃尔玛要求排名前1oo位的供应商,从2005年1月1El起在物流单

元上使用EPC;El本在2004年5月将向国际标准化组织(ISO)提供日本起草的EPC国

EPC系统简介

刊名:

自动识别技术与应用

英文刊名:AUTOMATIC IDENTIFICATION TECHNOLOGY & APPLICATION

年,卷(期):2004(2)

本文链接:/Periodical_zdsbjsyyy200402008.aspx。

EPC Information Service (EPCIS)Mark HarrisonCambridge Auto-ID LabInstitute for ManufacturingUniversity of CambridgeMark.Harrison@1.IntroductionThis presentation provides an overview of our Java web service prototypes of the EPC Information Service (EPCIS) and the EPCIS Discovery Service (formerly known as Dynamic ONS), as well as an update on the latest thinking from the SAG EPCIS working group.2.EPC Information Service (EPCIS)The EPC Information Service provides a uniform programmatic interface to allow various clients to capture, secure, and access EPC-related data and the business transactions with which that data is associated. In the revised architecture of the EPC Network, EPCIS largely replaced the role of the PML Server / PML Service and also aspects of the Physical Markup Language.The original EPC network architecture envisioned by the Auto-ID Centre, consisted of a collection of technology components, including tags and readers, Savant, the Object Name Service (ONS) and the Physical Markup Language (PML). The version 1.0 specifications released in September 2003 described each of these components as building blocks. This is illustrated in Figure 1.In the last year, the technical action groups have been working on a revised set of specifications to form the basis for the EPCglobal Network standards. In many cases, there is a major shift of emphasis away from defining components and towards defining interfaces that may be implemented by various components. This approach should make it much easier to test and certify compliance with particular standards, especially when the functionality of various components expands – e.g. smart readers which also implement sophisticated filtering. The revised architecture is illustrated conceptually in Figure 2.[ conceptual diagram – not authoritative ].Figure 2. Revised EPC Network Architecture (September 2004)[ conceptual diagram – not authoritative ].The key to affordable global adoption of the EPC Network was always to use relatively simple passive RFID tags with very limited memory capacity and to store the additional EPC-related data in networked databases. Initially, David Brock proposed the Physical Markup Language (PML) as an XML schema for representing all of the EPC-related data, including physical attributes of objects, such as dimensions, mass – as well as observations and sensor measurements. In order to make this work more manageable, theeffort on PML was refocused to concentrate on a well-defined PML Core, to mark up thelow-level event data captured from the EPC Network of sensors, including identity sensors such as RFID readers.3.Web ServicesMore recently, with increasing adoption of web service technology, there is much greater emphasis on direct programmatic access to the precise item of data of interest, eliminating the need for client applications to parse through large markup documents to extract the information they require.A classical use of a web service is in a stock quote monitoring program. While various websites such as provide human-readable web pages of information about stock prices, together with graphs and forecasts, a stock quote monitoring program often only requires rapid access to a numeric value – the instantaneous (or time-delayed) stock price – and it is disadvantageous if it must search through (parse) the entire document merely to extract a simple numeric value hidden somewhere within the document.Web services are usually defined in terms of WSDL (Web Services Description Language) files, which are XML documents which define the methods or functions which are available, as well as the input parameters and data types and the returned data type. WSDL files also can include transport bindings to specify how the message is sent over the network – these include the endpoint – the networked data object which provides those methods – and the proxy – the URI address which handles calls to that object.4.Categories of EPCIS data and relationshipsThere are many categories of EPC-related data. Some of these are attribute data, such as the mass or dimensions of an object or its date of manufacture. Other relations are dynamically built up over time, such as the history of where an object has been observed within a factory, distribution centre or retail store.Of the attribute data, some are defined at product-class level, while others are defined at instance level (i.e. may be different for each instance of a product class, e.g. date of manufacture, expiry date).For the timestamped historical data, we want to be able to determine both the current state of an object (e.g. its current location, temperature), as well as its history (trace of locations visited, temperature history). We may also want to be able to query the data using keys other than the EPC of the object. For example, in a product recall scenario, we might want to find out the identities of all objects which passed through a particular contaminated location within a particular time range. Since the Tag Data Standards specification v1.1r1.24 defines how to encode a Global Location Number (GLN) into an EPC – so locations are also valid EPCs – and the location EPC would be the main parameter for such a query, with a list of object EPCs being returned.5.Business LogicAnother important distinguishing feature of EPCIS is that it is the lowest level in the EPC Network architecture where ‘business logic’ may be introduced. The output of the filtering platform (‘Application Level Events’) says nothing about the interpretation in terms of business events. For example, an ALE report may indicate that a pallet and several cases were seen together (within a particular event cycle timeframe) at a particular location, such as a dock door. However, that information alone does not imply that the cases were aggregated onto the pallet – nor that it represents a particular shipment, nor whether it was being despatched or received. ALE merely provides raw observation reports from the sensor network, which need to be combined with additional context information in order to construct ‘business events’ upon which applications such as ERP, WMS systems can act.EPCIS can serve as a repository for storing both the low-level observation reports from ALE, as well as higher-level business logic relations, such as a particular shipment arriving and consisting of a particular list of cases, aggregated to a particular pallet.6.EPCIS as a platform to support multiple underlying databases Just as one of the original aims of Savant was to provide a platform into which several vendors of reader could ‘plug-in’, with the output being significant ‘detection events’ communicated in a standard format to applications. This is illustrated in Figure 3.Figure 3. Savant as a ‘platform’ for interfacing to EPC readers from multiple vendors. The platform provides a uniform interface to client applications, in just the same way that an operating system provides vendor-unspecific print functions to applications, while vendor-specific printer drivers translate commands into vendor-specific code.In the same way, EPCIS is designed as a platform with a uniform query and update interface to applications, while the actual implementation details and data binding to existing databases and information systems is not specified by EPCIS. EPCIS should therefore support simultaneous binding to multiple databases and information systems from multiple vendors, as well as EPCIS as a managed application service, like webhosting or DNS provision. This is illustrated in Figure 4.Figure 4. Applications use the EPCIS as a standard interface to EPC-related data, even though it may be stored in underlying databases and information systems of different types and from different vendors. Applications may need to access multiple EPCIS services across the supply chain to handle more complex queries which require information from several custodians of the object.In order to accommodate various types of data relationships such as observations, measurement, containment, associations with particular transactions, EPCIS is being designed as a modular framework, with a very lightweight core functionality, which merely described which ‘profiles’ or relationship types are implemented on any particular instantiation providing an EPCIS interface. From the list of profile IDs, it is then possible to query for the profile interface definition, most likely in terms of a WSDL file.From this, an application then knows which methods (functions) are available to it, howto construct the commands for performing queries or updates – and how to connect to the EPCIS interface over the network.7.Security technologiesUntil this point, we have not mentioned security. EPCIS provides an opportunity for trading partners to share information and massively increase the visibility of product flows within supply chains. However, it is essential that this can be done in a secure way, so that companies can be assured that they retain control of who has access to which subsets of their data. There are various aspects of security that need to be considered:Authentication – who is making the request, who is providing the data in responseAccess control – does the requestor have the correct role-based access privileges to entitle them to read (or even update) that specific informationFederation and single sign-in – the underlying information accessed via EPCIS may be fragmented not only across a supply chain, but also within a company, across several underlying systems.Web services security is developing and much of the current interest is around XML Digital Signatures, which allow both the sender and receiver to mutually authenticate that they are conversing with each other. Regarding access control, technologies such as XACL and XACML (XML Access Control Markup Langauge) allow fine-grained policies to be defined about which roles are allowed read / update permission to particular subsets of data. For federation, technologies such as SAML (Security Assertion Markup Language) allow different systems to exchange tokens which confirm that a particular user has the right to access particular information.8.Coordination role by client applicationsOf course, the EPCIS proposed at this stage has neither any artificial intelligence built in, nor does it attempt to proxy requests to other EPCIS instances on behalf of the client making the request. EPCIS can usually only provide access to data that it can access locally. It is the role of client applications to break down complex queries which need to contact multiple EPCIS services and to co-ordinate the sequence of queries and combination of the results. This is completely analogous to the way that a web browser client may request a web page, which itself contains images held on different webservers – in this case, the client application (web browser) needs to separately retrieve those images from the other webservers, in order to build up the full picture for the web page. Furthermore, the instance-level data is fragmented across the unique supply chain path followed by each individual object. For example, a distribution company may hold records of the temperature history of perishable goods while in transit. The Object Name Service (ONS) does not provide serial-level pointers to EPCIS, nor is the DNS technology on which it is based suitable for dynamically updated serial-level pointersacross the supply chain. The EPCIS Discovery Service provides a mechanism for each custodian to update a registry, so that each can indicate on a per-EPC basis that they hold some data related to a particular EPC. This is what was formerly known as ‘Dynamic ONS’ or the custodian sequence registry. There are of course opportunities for the registry to not only hold a list of EPCIS URLs for a given EPC – but also associated timestamps or even a flag to indicate whether an individual serialised object is marked for recall, thus enabling more pro-active finer-grained product recalls, even before the recalled objects have reached the end of their supply chain paths.9.Our latest prototypesWe have developed prototypes of the PML Server/Service for over two years. Our latest prototypes are implemented using the Java Web Services Development Pack (JWSDP 1.3) from Sun Microsystems, together with a PostgreSQL relational database for storing the underlying data. After writing get…() and set…() methods to query and update the timestamped relations. we then use the JAXRPC tools to automatically generate the WSDL files which describe the web service – and also in the client-side code which accesses our prototypes of EPCIS and the EPCIS Discovery Service. We have developed web page interfaces for viewing the tables of relationships. These display both the current state and historical trace of relationships for Observations, Measurements, Containment and Transactions.The next stages of our development work will involve making our prototypes more modular / profile-based, supporting queries and updates of attribute data, using well-defined XML schema and Xpath/XQL queries and the use of the various emerging web service security technologies mentioned above to provide authenticated fine-grained access controls to only selected parts of the data.We also intend to learn more about Resource Description Framework (RDF) technologies, since these will be relevant for automating inferencing based on the kinds of fundamental simple relationship assertions accessed via EPCIS.。