OrionNPMEvaluationGuide

- 格式:pdf

- 大小:1.85 MB

- 文档页数:83

1目的:1.1制订详尽的工作程序,保证在检验工作中出现的超标、超常结果得到全面分析和正确处理,以符合法规和质量标准要求。

同时保证检验数据可靠,避免误判及检验纠纷。

1.2调查超标、超常检验结果出现的原因,采取预防措施,防止再次出现。

1.3将各类超标、超常检验结果报告公司高级管理层,以提供质量改进的决策依据。

2适用范围:2.1本程序适用质检中心所有检验岗位出现的超标、超常检验结果。

2.2本程序也同时适用于江苏万年长药业合同供应商,根据江苏万年长药业GLP要求,其所属质量保证部检验岗位出现的超标、超常检验结果。

3职责:质检中心经理:负责组织偏差调查,对OOS/OOT结果审核,组织培训防止OOS/OOT结果产生。

检验组组长:负责调查OOS/OOT结果检验员:负责报告OOS/OOT结果4规定:4.1定义:4.1.1超标检验结果 OOS-OutofSpecification :指检验结果超出标准的规定范围。

当两份平行测试榈检验结果一份合格、另一份不合格时,不得将其平均,应视为超标。

4.1.2超常检验结果 OOT-OutofTrend :指检验结果虽符合标准规定,但同此类检品历史上典型的检验结果不一致。

例如:一成分含量历史上典型值为98.0~103.0%,但此次测定结果为96.8%或97.1%,应构成一次超常检验结果。

4.1.3原样复验:指仍采用初始的样品再进行检验。

4.1.4重取样复验:指重新取样进行检验。

4.1.5实验室偏差:指由于任何与检验过程相关的因素所引起的检验结果偏差。

包括取样、样品容器、存放条件、检验操作、计算过程等问题引起的偏差。

4.1.6非实验室偏差:指在排除实验室偏差以外的由于其它任何因素所引起的检验结果偏差。

该类偏差可以分为以下两种:4.1.6.1非生产工艺偏差:系指因操作工未按程序操作、设备故障或用错料等原因引起的检验结果偏差。

4.1.6.2生产工艺偏差:指因生产工艺本身缺陷引起的检验结果偏差,就是人员操作、环境、设备和物料完全正确也不可避免。

网络性能管理系统NPMS1.0产品需求规格说明书武汉和中信息科技有限责任公司版本历史目录0.1. 文档目的 ..............................................................................错误!未定义书签。

0.2. 文档范围 (5)0.3. 读者对象 (5)0.4. 参考文档 (5)0.5. 术语与缩写解释 (5)1.产品介绍 (6)2.产品面向的用户群体 (6)3.产品应当遵循的标准或规范 (6)4.产品范围 (6)5.产品中的角色 (7)6.产品的功能性需求 (7)6.0. 功能性需求分类 (7)6.1. 系统总览S YS O VERVI EW (8)6.1.1.Portlet定制 (8)6.1.2.系统总体Dashboard (9)6.2. 网络实时性能报告R EALTIME N ETWORK (10)6.2.1.网络设备实时性能报告 (10)6.2.2.网络骨干链路实时性能报告 (12)6.2.3.网络源IP实时性能报告 (14)6.2.4.网络目的IP实时性能报告 (16)6.3. 网络历史性能分析 (16)6.3.1.每天总体性能分析报告 (16)6.3.2.TopN源IP报告 (17)6.3.3.TopN目的IP报告 (17)6.3.4.可定制的性能分析报告 (18)6.4. 网络故障管理 (18)6.4.1.网络设备故障监控 (19)6.4.2.网络链路故障监控 (19)6.4.3.DOS攻击定位 (20)6.4.4.网络病毒扫描 (20)6.5. 网络资源对象管理 (21)6.5.1.网络设备分类 (21)6.5.2.骨干链路定义 (22)6.5.3.网络区域分类 (22)6.5.4.网络地址分类 (22)6.6. 系统管理 (23)6.6.1.用户管理 (23)6.6.2.系统日志记录 (23)6.6.3.NPMS系统状态监控 (24)6.6.4.历史数据输出 (24)7.产品的非功能性需求 (25)7.1. 用户界面需求 (25)7.2. 软硬件环境需求 (25)0.1. 文档目的为了阐明NPMS1.0开发项目需要开发完成的功能,特编写本文档。

npm版本表达式解析npm版本表达式是一种用于指定和匹配npm软件包版本的语法,它允许我们在软件包的依赖关系中精确地控制版本范围。

npm使用“语义版本”(SemVer)规范来标识软件包版本,这是一个三部分数字版本号,即主版本号、次版本号和修订版本号,如1.2.3。

npm版本表达式可以用于两个地方:软件包的依赖关系中和版本指令中。

在软件包的依赖关系中,我们可以使用版本表达式来指定我们的软件包所依赖的其他软件包的版本范围。

而在版本指令中,我们可以使用版本表达式来指定我们想要安装的软件包的版本范围。

版本表达式可以分为几种类型:1.指定具体版本号:比如1.2.3表示精确匹配1.2.3版本的软件包。

2.使用通配符:通配符可以替代版本号的某些部分,如*表示匹配任意版本,1.*表示匹配1.x.x系列的版本,1.2.*表示匹配1.2.x系列的版本。

3.使用比较符号:比较符号可以用于指定版本号的比较关系,如<1.2.3表示小于1.2.3的版本,>1.2.3表示大于1.2.3的版本,<=1.2.3表示小于等于1.2.3的版本,>=1.2.3表示大于等于1.2.3的版本。

4.使用波浪号:波浪号可以用于指定兼容的版本范围,即安装最新的兼容版本。

如~1.2.3表示安装最新的1.2.x系列的版本,但不包括1.3.0及以上的版本。

5.使用悲观波浪号:悲观波浪号可以用于指定最新的非破坏性更新版本。

如^1.2.3表示安装最新的1.x.x系列的版本,但不包括2.0.0及以上的版本。

版本表达式还支持逻辑操作符来组合不同的版本范围。

逻辑操作符包括&&(与)、||(或)和!(非)。

我们可以使用这些操作符来表达更复杂的版本范围需求。

例如,"react": ">=15.0.0 && <16.0.0"表示需要安装大于等于15.0.0版本且小于16.0.0版本的react软件包。

Drug Production Validation Guidelines 2003 Edition - EnglishTranslationIntroductionThe Drug Production Validation Guidelines were first published in 2003 to provide a comprehensive framework and set of recommendations for validating pharmaceutical manufacturing processes. This document presents an English translation of the guidelines, which aim to ensure the safety, quality, and efficacy of pharmaceutical products.ScopeThe Drug Production Validation Guidelines apply to all stages of the drug manufacturing process, including the production of active pharmaceutical ingredients (APIs) and finished dosage forms. The guidelines provide direction for both new drug products and existing ones that undergo changes in their manufacturing processes.Purpose of ValidationThe primary purpose of drug production validation is to demonstrate that the manufacturing processes consistently produce pharmaceutical products that meet the predetermined quality attributes, ensuring their safety and efficacy. Validation also helps in identifying and controlling potential sources of variability that may affect the quality of the products.General Principles1. Process DesignThe guidelines emphasize the importance of robust process design, which involves defining critical process parameters and establishing appropriate control strategies. Process design should consider factors such as quality, safety, efficiency, and regulatory requirements.2. Process QualificationProcess qualification involves confirming the suitability and capability of the manufacturing process through a series of documented tests, studies, and evaluations. Three stages of process qualification are identified: installation qualification, operational qualification, and performance qualification.3. Continued Process VerificationOnce a process is qualified, continued process verification is necessary to ensure that the manufacturing process remains in a state of control. This involves ongoing monitoring, analysis of process data, and periodic re-evaluation to identify and address any potential sources of variability or process deviations.Validation Master Plan1. PurposeThe Validation Master Plan (VMP) provides an overview of the entire validation process and establishes the validation strategy for the drug manufacturing facility. It outlines key activities, responsibilities, and timelines for validation activities.2. ContentsThe VMP should include the following sections: - Introduction and scope - Validation policy and objectives - Roles and responsibilities - Validation activities and schedules - Change control procedures - Documentation requirements - Validation protocols and reports - Deviation management - Training requirements Validation Documentation1. Validation ProtocolsValidation protocols are detailed documents that outline the series of tests, experiments, and observations to be performed during the qualification and validation processes. They should describe the acceptance criteria, sampling plan, and test methods.2. Validation ReportsValidation reports summarize the results obtained during the qualification and validation activities. They should include a description of the tests performed, data analysis, conclusions, and any deviations or discrepancies identified.3. Change ControlChange control procedures should be in place to manage any changes to the validated manufacturing processes. The guidelines recommend that any proposed changes be evaluated for potential impact on product quality and documented in change control records.ConclusionThe Drug Production Validation Guidelines provide a robust framework for ensuring the safety, quality, and efficacy of pharmaceutical products through the validation of manufacturing processes. By following these guidelines, drugmanufacturers can mitigate risks, control variability, and produce high-quality pharmaceuticals. It is essential for pharmaceutical companies to adopt and adhere to these guidelines to comply with regulatory requirements and ensure patient safety.。

关于Dotinurad(多替诺德)的标准,可以从以下几个方面进行理解:

1. 药学质量标准:

Dotinurad作为一款药物,必须符合严格的药学质量标准,包括纯度、化学结构确认、含量测定、稳定性测试、微生物限度检查等。

这些标准通常由国家药品监督管理机构如中国NMPA或美国FDA制定,并要求在药品上市前进行全面的检验和验证。

2. 临床疗效与安全性评价标准:

在临床试验阶段,Dotinurad需要达到设定的疗效终点,比如降低血尿酸水平到一定阈值,同时对痛风症状有显著改善作用,并且在安全性和耐受性上满足规定的要求。

这通常通过III期临床试验的结果来评判。

3. 生产工艺及GMP标准:

生产Dotinurad的企业应遵循良好的生产规范(GMP)标准,确保从原料采购、生产过程控制、质量检测到产品放行等各环节都符合国际或国内的相关法规要求。

4. 注册审批标准:

药品上市前需经过国家药品审评中心(如中国的CDE)的严格评审,提交详尽的数据资料,包括药理毒理研究、临床试验数据等,以证明其有效性和安全性,最终获得上市许可。

综上所述,虽然具体的标准细节未给出,但Dotinurad作为治疗高尿酸血症和痛风的新药,其质量和疗效评估必然要符合一系列国内外药品监管体系下的严格标准。

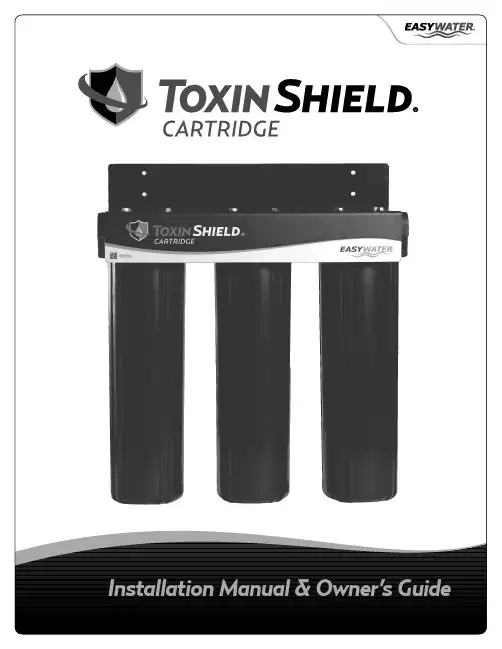

Before Starting Installation (Cont’d)PRODUCT INSTALLATION SEQUENCECARTRIDGE SEQUENCE1. SedimentCartridgeRemoves dirt andsediment particles down to 5 microns in size.3. High PerformanceCarbon CartridgeRemoves chlorine and reduces many pesticides, herbicides, THMs, VOCs and more.2. Unique GranularCarbon CartridgeRemoves chloramines and reduces manyremaining contaminants.22½”27½”Municipal Water MainCity WaterWater Pump Pressure Tank Acid Shield Acid ShieldToxin Shield+Toxin Shield CartridgeLead ShieldLead ShieldNo-Salt Conditioner1100/2200/3500No-Salt Conditioner1100/2200/3500Bacteria ShieldBacteria ShieldIron Shield+1000/2000RevitaLifeRevitaLifePrivate Well WaterTroubleshootingProblemReduced Water Flow or Pressure Quality of Water Decreasing Possible CauseFilter cartridges reaching capacityService flow rate exceedsrecommended flow rateFilter cartridges reaching capacitySolutionReplace filter cartridgesConsider installing 2nd TSCin parallelReplace filter cartridgesInstallation InstructionsIMPORTANT: T oxin Shield Cartridge System is pre-assembled for water to enter on the left and exit on the right (as you face the unit). If your water enters from the right, the filter caps need to be removed from the bracket, and the 3-piece cartridge cap reversed, such that water enters on the right and exits on the left. The sequence of the cartridges is critical to the operation of the system, and will differ with the water flow direction. The proper sequence is:1. Sediment cartridge2. Unique Granular Carbon cartridge3. High Performance Carbon cartridge1) Find a suitable location where the filter can be securely mounted to a wall.Note: Completed system with water weighs in excess of 75 lbs. MUST be securely mounted into wall studs.2) Shut the water supply off, draining water from the plumbing, and cut the plumbing to the correct length.3) A shutoff valve (not included) should be installed before and after the filter, for conveniencewhen changing filter cartridges.4) Install the filter bracket on the wall (inspect for hidden electrical or plumbing lines), insertcartridges into housings in the correct order, and install the housing, use caution to ensure the O-rings are in place. (You may need to use Food Grade Lubricant for threads.) System Start-Up (After installation is complete)1) Open two faucets inside the home.2) Open the shutoff valve located after the filter.3) Open the shutoff valve located before thefilter, and open the home water servicevalve SLOWLY.4) Let water run until air is cleared fromthe lines and the water runs clear.5) Close the two faucets inside the home.6) Check installation for leaks.Limited WarrantyEasyWater, Fishers, IN warrants this EasyWater Toxin Shield Cartridge System (referred to as Filter) as stated herein:From the date of installation, within the warranty period described below, we will repair or replace any part which we find defective because of faulty materials or workmanship. Y ou pay only freight to our factory and local labor charges.-One year on all components, excluding filter cartridgesDamage to any part of Filter because of misuse, misapplication, neglect, alteration, accident, installation or operation contrary to printed instructions, or damage caused by an act of terrorism or any unusual force of nature such as, but not limited to, freezing, flood, hurricane, tornado or earthquake is not covered by this warranty. In all cases, regular parts and service charges will apply.We assume no warranty liability in connection with this Filter other than specified herein. This warranty is in lieu of all other warranties, express or implied, including warranties of fitness for a particular purpose. We do not authorize any person or representative to assume for us any other obligations on the sale of this filter.Should a defect or malfunction occur, contact your EasyWater Authorized Partner Dealer. If you are unable to contact your EasyWater Authorized Partner Dealer, contact EasyWater, at (888) 766-**********************************.Wewillrepairorreplacethepartatnocostifourrepair department determines it to be defective under the terms of the warranty.Feed water quality must meet the requirements for this system on an ongoing basis in order for this warranty to be valid.This warranty is valid for the original purchaser only and gives you specific legal rights. You may have other rights which vary from state to state.EasyWater, Inc9715 Kincaid Drive Suite 1100, Fishers, IN 46140(888) 766-7258。

2021年最新的TL9000要求手册R6.3中文版本TL9000要求手册按R6.3 版翻译,红色字体是R6.3的修改之处。

R6.3 2021 年 10 月 1 日生效4组织环境4.1:理解组织环境:无4.2:理解相关方要求:无.4.4 质量管理体系范围4.3.C.1要求手册和测量手册适用性声明组织必须在它的注册界面中声明确定不适用的要求和任何声明的测量豁免。

注解1: 假如要求(手册)是在组织已经选择的TL9000注册专项之外的范围,对组织而言,声明TL9000 不适用不是必须的。

同样,当要求本身或相关的注解要求表明针对组织的产品或服务类型不适用,对组织而言,声明不适用也不是必须的。

注解2:参见测量手册中的测量豁免定义。

4.3.C.2TL9000概况和范围4.3.C.2 TL9000概况和范围组织寻求认证,必须与认证机构协调,确定:--TL9000的范围描述;--ISO9001的范围描述;--不适用的要求决定;--测量的豁免;--注册的专项选择;--NACE的编号--产品类别;--位置和地址;--ISO 9001的版本;--TL9000要求和测量的版本,和--监督审核和再认证程序( ASRP)的应用。

所有注册必须在QF注册管理系统(RMS)的注册概况中记录和维护。

TL9000管理者必须把相关信息给认可的认证IAF数据库。

被认证公司发行的证书必须参考在概况创建时,TL9000管理者分配的TL编号注册管理系统(RMS)的注册概况。

范围描述必须包括:a)组织被注册的身份,可以包括整个组织,一个组织的单元,或多个单元的结合,和b)被注册所覆盖的产品/产品线,假如不是所有产品/产品线包括的注册中,那么包括或排除的产品/产品线必须被列出;范围描述不需要包括:a)产品类型的编号,b)位置或地址;,c)ISO 9001, 要求手册和测量手册的版本;,d)注册专项的选择,和e)其他在注册概况中被定为个别行业的特征;4.4质量管理体系及其过程:无5领导力5.1领导力和承诺5.1.1总则:无5.1.2客户为中心5.1.2.C.1 客户沟通方法组织必须建立并保持方法以与选定的客户沟通分享期望,并确保产品质量的改进。

欧盟草药良好应用申请的申报要求英文版The European Union has strict regulations in place for the approval of herbal medicinal products. Any company looking to market herbal products within the EU must adhere to these guidelines in order to ensure the safety and efficacy of their products.One of the key requirements for applying for approval of herbal medicinal products in the EU is the submission of a detailed dossier outlining the quality, safety, and efficacy of the product. This dossier must include information on the composition of the product, the manufacturing process, and any relevant clinical studies that have been conducted.In addition to the dossier, companies must also provide evidence of the traditional use of the herbal product in question. This can include historical evidence of the product's use as a medicinal remedy, as well as any other relevant information that supports its safety and efficacy.Once the dossier has been submitted, it will be reviewed by the European Medicines Agency (EMA) and the Committee on Herbal Medicinal Products (HMPC). If the product meets all of the necessary criteria, it will be granted approval for marketing within the EU.In conclusion, the application process for approval of herbal medicinal products in the EU is thorough and rigorous. Companies must provide detailed information on the quality, safety, and efficacy of their products in order to ensure that they meet the necessary standards for approval.欧盟草药良好应用申请的申报要求欧盟对草药药品的批准制定了严格的规定。

DIN 50190标准DIN 50190标准是德国标准学会(Deutsches Institut für Normung,简称DIN)制定的一个标准,用于描述软件项目管理过程中的过程和方法。

该标准于1998年首次发布,是软件项目管理领域的里程碑,为组织提供了可重复和可预测的软件开发过程。

DIN 50190标准主要关注软件开发过程的设计、实施和验证,包括以下几个方面:1. 过程设计:DIN 50190标准为软件开发过程的设计提供了指南,包括过程目标、输入、输出、资源和职责等。

过程设计的目标是确保软件开发过程能够满足组织的业务需求,并能够有效地支持软件开发团队的工作。

2. 过程实施:DIN 50190标准为软件开发过程的实施提供了指南,包括过程的启动、运行和维护。

过程实施的目标是确保软件开发过程能够按照设计的目标和原则有效地运行,并能够持续改进。

3. 过程验证:DIN 50190标准为软件开发过程的验证提供了指南,包括过程的评估、审核和认证。

过程验证的目标是确保软件开发过程能够满足组织的业务需求,并能够达到预定的质量水平。

4. 过程改进:DIN 50190标准为软件开发过程的改进提供了指南,包括过程的评审、分析和优化。

过程改进的目标是确保软件开发过程能够持续改进,并能够达到更高的质量水平。

DIN 50190标准为软件项目管理提供了一个全面的过程和方法框架,可以帮助组织实现软件开发过程的规范化、标准化和持续改进。

该标准适用于各种类型的软件开发项目,包括内部开发项目、外包项目和合作开发项目等。

DIN 50190标准的主要优点包括:1. 过程导向:DIN 50190标准强调过程的重要性,为软件开发过程的设计、实施和验证提供了清晰的指南,有助于实现过程的规范化、标准化和持续改进。

2. 灵活性:DIN 50190标准提供了灵活的过程设计、实施和验证方法,可以根据组织的具体需求和环境进行定制和优化。

3. 适用性:DIN 50190标准适用于各种类型的软件开发项目,可以帮助组织实现软件开发过程的规范化、标准化和持续改进。

Epicor 9 品质保证课程教师培训手册DisclaimerCopyright © 2009 by Epicor Software Corporation. All rights reserved. Printed in the United States of America. No part of this publication may be reproduced in any form without the prior written consent of Epicor Software Corporation. Epicor, Vantage, and Vista are registered trademarks of Epicor Software Corporation. All other trademarks are property of their respective owners. Microsoft product screen shots reprinted with permission from Microsoft Corporation. Epicor Software Corporation makes no representations or warranties with respect to the contents of this document and specifically disclaims any implied warranties of merchantability, satisfactory quality or fitness for any particular purpose. The contents of this document are believed to be current and accurate as of its date of publication. Changes to this document between reprintings and otherimportant information about the software product are made or publishedin release notes, and you are urged to obtain the current release notes for the software product. We welcome user comments and reserve the right to revise this publication and/or make improvements or changes to the products or programs described in this publication at any time without notice. The usage of any Epicor Software shall be pursuant to an Epicor end user license agreement and the performance of any consulting services by Epicor personnel shall be pursuant to Epicor's standard services terms and conditions.ED8239090521-900-9280-5835039.04.503中文翻译:HZ,2009年7月。

EUROPEAN COMMISSIONHEALTH AND CONSUMERS DIRECTORATE-GENERALPublic Health and Risk AssessmentPharmaceuticalsBrussels,SANCO/C8/AM/sl/ares(2010)1064587EudraLexThe Rules Governing Medicinal Products in the European UnionVolume 4Good Manufacturing PracticeMedicinal Products for Human and Veterinary UseChapter 4: Documentation第四章:文件Legal basis for publishing the detailed guidelines:Article 47 of Directive2001/83/EC on the Community code relating to medicinal products for human use and Article 51 of Directive 2001/82/EC on the Community code relating to veterinary medicinal products. This document provides guidance for the interpretation of the principles and guidelines of good manufacturing practice (GMP) for medicinal products as laid down in Directive 2003/94/EC for medicinal products for human use and Directive 91/412/EEC for veterinary use.立法基础:2001/83/EC法令第47款对人用药品的相关要求,2001/82/EC法令第51款兽用药相关的欧共体法规。

m ax 制作 w w w .n w a d m i n .c n网管部落Solarwinds 迁移手册Maxmsn :ningqie@ mail :ningmax@注意:迁移你的orion npm 到一个新的服务器需要至少30分钟到几个小时,这取决于你orion 数据库的大小。

迁移前要做到工作:迁移你的orion npm 系统要遵循一下过程:1 服务器的硬件配置要满足orion npm 的需求。

2一定要使用有管理员权限的用户进行操作。

3 一定要把你以前注册的信息做重置。

你可以通过安装SolarWinds License Manager 来管理你的授权。

你可以在solarwinds 的管理员手册中找到更相信的说明。

4 需要一个临时的存储空间去保存你以前自定义的地图和报表。

你可以用u 盘之类的东西。

迁移orion npm :根据一下步骤逐步迁移orion npm迁移orion npm :1 登陆你当年的solarwinds 服务器。

2 点击start ‐‐‐all programs ‐‐‐solarwinds orion ‐‐‐‐database utilities ‐‐‐database managerm ax 制作 w w w .n w a d m i n .c n网管部落3 如果你的数据库没有出现在里面,那么你需要增加你的数据库到系统中。

操作如下: A 点击add serverB 从下拉菜单选择你想加入的数据库名称。

也可以直接输入数据库所在服务器的ip 地址C 选择登陆认证方式,点击connect to database server4 在你添加近来的数据库上点右键,选择backup database 做数据库备份。

5 选择一个位置存放备份的数据库文件。

6 选择一下任意一种配置方式:A 如果你希望追加你的新的数据库备份到你最后备份的数据库文件,那么选择追加到最后的备份文件B 如果你想覆盖选择的备份文件,那么选择覆盖备份文件。

集成开发环境Orion 3.0用户手册2007 User’s Manual集成开发环境Orion 3.0用户手册版本号:Rev.1.52007.01珠海欧比特控制工程股份有限公司前言本手册是 Orion 3.0 用户手册。

该用户手册是Orion 3.0 集成开发环境附带文档之一,是软件开发人员的必读手册。

该用户手册就使用Orion 3.0 进行嵌入式应用开发的流程进行了详尽描述,每个步骤都给出图例和解释,以方便用户尽快地掌握和熟悉Orion 3.0 集成开发环境。

Orion 3.0集成开发环境包含Orbita EOS, Orion IDE, 以及调试工具软件如DSUMON,Debug monitor等。

Orion 3.0对这些工具进行了集成,使用户在统一的图形界面里进行开发。

Orion 3.0 集成开发环境界面友好,操作简捷,是开发基于SPARC V7/V8系列处理器的嵌入式软件的理想工具。

Orion3.0运行的主机环境为Redhat Linux 7.3/9.0,支持的开发语言包括标准C,C++和汇编语言。

该手册的读者应当具备 C/C++ 编程基础,并且了解嵌入式软件开发过程中的编译、链接、调试等概念。

目录1引言 (1)1.1编写目的 (1)1.2背景 (1)1.3定义 (1)1.4参考资料 (2)2用途 (3)2.1功能 (3)3运行环境 (4)3.1硬件设备 (4)3.2支持软件 (4)4安装与初始化 (5)4.1O RION3.0安装 (5)4.2D EBUG MONITOR 安装 (5)5基本界面概述 (7)5.1启动画面 (7)5.2主界面 (8)5.3菜单 (8)5.4工具栏 (11)6 用ORION 3.0做嵌入式开发 (12)6.1工程向导 (12)6.2编译,连接,运行 (18)6.3配置实时系统 (20)6.4编写代码 (23)6.5调试 (31)6.6生成ROM映像文件 (35)7技术服务 (38)图目录图 5-1 启动画面 (7)图 5-2 主界面 (8)图 5-3 工具栏 (11)图 6-1 工程向导1 (13)图 6-2 工程向导2 (14)图 6-3 工程向导3 (15)图 6-4 工程向导4 (16)图 6-5 工程向导5 (17)图 6-6 新工程开始 (18)图 6-7 编译 (19)图 6-8 连接 (19)图 6-9 运行 (20)图 6-10 Orion通用的选项 (21)图 6-11 动态帮助 (21)图 6-12 Orion API 的选项 (22)图6-13 Orion Linker 选项 (23)图 6-14 建立新类 (24)图 6-15 新类命名 (24)图 6-16 新类加入 (25)图 6-17 添加类的方法/成员 (26)图 6-18 类成员命名 (27)图 6-19 类方法命名 (28)图 6-20 类视图 (29)图 6-21 类的实例 (29)图 6-22 类视图 (30)图 6-23 运行 (31)图6-24 Debug Monitor调试模式示意图 (32)图 6-25 DSU 调试模式示意图 (32)图 6-26 模拟器调试模式提示 (33)图 6-27 调试界面 (34)图 6-28 浮动调试工具栏 (34)图 6-29 观察窗口 (35)图 6-30 ROM 映像文件内存使用示意图 (36)图 6-31 Rom Image 页 (36)图 6-32 ROM映像文件运行例子 (37)1引言1.1编写目的这份手册向读者介绍 Orion 3.0 集成开发环境的基本概念和基本操作,指导读者使用Orion 3.0 开发基于SPARC V7/V8系列处理器的嵌入式软件。

通过人用和兽用药物产品降低动物海绵状脑病传播风险的指南说明(EMA/410/01 rev.3)(2011/C 73/01)本文件提供通过人用和兽用药物产品降低动物海绵状脑病发生风险的指南此次第三版技术修订版的TSE(可传染性动物海绵状脑病) 指导说明已经考虑到了在传播性海绵状脑病领域的技术进步,以及全世界牛海绵状脑病传播的进展情况。

为根据BSE风险对国家和地区进行分类,修订的指南说明将参考世界动物卫生组织(OIE)制定的规则,以代替已有的GBR分类。

同时,对于根据BGR进行分类而没有根据世界动物卫生组织标准尚未分类的国家,在没有证据表明BSE风险有所改变的基础上仍然适用于BGR分类。

新的指南说明中引入了采购和加工用于生产人用或兽医用药品的明胶或牛血液衍生物制品的新标准,同时还有关于胨类标准的新内容。

新指南说明中更换了已出版的指南说明(EMEA/410/01 Rev. 2 published in the Official Journal of the European Union (C 24, 28.1.2004, p. 6)。

修订后指南说明应用日期定于2011年7月1日1、前言1.1背景介绍传染性可传染性动物海绵状脑病(TSEs)是一种慢性退行性神经疾病,以异常细胞糖蛋白(成为PrP或朊病毒蛋白)的异常同工积累为主要特征。

PrP(PrP TSE)的异常同工化和正常PrP(PrPc) 同工化的不同在于对蛋白酶以及热处理变形具有高度的抗性。

PrP TSE被认为是TSE产生传染性的传染媒介。

动物TSE疾病包括:-牛海绵状脑病(BSE)-绵羊和山羊的瘙痒病-鹿和麋鹿的慢性消耗性疾病(CWD)-养殖水貂的传染性貂脑病(TME)-猫和猫科动物的海绵状脑病(FSE,尤其是猫和圈养的大型猫科动物)以及-动物园中外来有蹄类动物海绵状脑病。

人类中,海绵状脑病包括不同形式的克雅氏病(CJD),库鲁病,Gerstmann-Sträussler-Scheinker综合症(GSS),致死性家族性失眠症(FFI)。