13 PREPARATION OF LEAD DIOXIDE ELECTRODE (A REVIEW)

- 格式:doc

- 大小:36.50 KB

- 文档页数:4

二氧化铅论文:二氧化铅的制备及其超级电容器性能研究【中文摘要】超级电容器是近年来出现的一种介于电池和传统电容器之间的新型储能器件,它具有传统电池无法比拟的高功率密度、长循环寿命、环境友好等优点,随着新型绿色环保电动汽车的兴起以及各种电子通讯技术的发展,能源危机和环境保护成为人类可持续发展的战略核心,对于能源储存与转换元器件的要求越来越高,也使得超级容器的发展被提升到了一个新的高度。

高能量、大功率的超级电容器更显示了其前所未有的应用前景,现已成为世界各国的研究热点。

本论文根据大量的文献调研,紧跟该领域的国际前沿,从活性碳材料和金属氧化物材料着手,通过改进材料的制备方法,优化电极制作技术,研制出超级电容器用活性碳电极和二氧化铅薄膜电极,并组装成混合超级电容器。

将材料的表征手段和电化学研究手段相结合,对材料的相关性能进行了测试,为研制混合超级电容器提供了实验依据和理论基础。

主要研究内容如下:1、采用活性碳作为超级电容器的电极材料,组装成对称双电层超级电容器,研究其活性碳电极在5.3 mol L-1 H2SO4(1.28 g cm-3)、2 mol L-1 KCl和2 mol L-1 LiNO3不同电解液中的电化学性能,测试其比电容大小,利用恒流充放电和电化学阻抗谱等手段,测试对称活性碳双电层超级电容器在5.3 mol L-1 H2SO4电解液条件下的电容特性,在100 mAg-1的电流密度下能达到32.4 Fg-1。

2、采用石墨片作为正极集流体,采用恒电流法在石墨片上沉积二氧化铅电极,并通过SEM和XRD研究了二氧化铅电极的形貌和结构特性。

以二氧化铅电极为正极,活性碳电极为负极,5.3 mol L-1 H2SO4作为电解液,组装成混合超级电容器,并进行了恒流充放电和交流阻抗等电化学测试。

结果表明:沉积电流对电极的电化学性能影响很大,在25 mA cm-2电流密度下沉积的二氧化铅电极不仅具有高比电容而且具有较好的循环稳定性,其与活性碳电极组装成混合超级电容器时,在150 mAg-1电流密度下比电容能达到128.4 Fg-1,恒流充放电循环3700次后其容量保持率仍能达到70%。

山东农业大学应用化学专业申报山东省教育厅2007年度高等学校特色专业申报书附件目录附件一、教师发表专业研究论文………………………….附件二、教师发表教研论文……………………………….附件三、教师科研课题……………………………………附件四、教师教学研究课题………………………………附件五、教师教研奖励及部分获奖证书…………………附件六、近几年编写教材统计……………………………附件七、本科学生承担的科技创新项目和SRT项目……附件八、本科学生在SRT项目和科技创新项目研究及毕业论文中发表和已投稿论文目录……………………………………..附件一化学与材料科学学院2003.5-2008.5教师发表专业研究论文1.艾仕云(1). Study on production of hydroxyl free radical and its reaction with salicylic acid at lead dioxide electrode. J.Electroanal. Chem., 2005, 578, 223-2292. 艾仕云(1).Electrochemical deposition and properties of nanometer-structure Ce-dopedlead dioxide film electrodes. Chin. J. Chem.2005, 23, 71-753.艾仕云(1).Preparation of fluorine-doped lead dioxide modified electrodes forelectroanalytical applications. Electroanalysis, 2003, 15, 1403-14074.艾仕云(1). Study on lead dioxide modified electrode and its application in detection of phenols. Chin. J. of Chem. 2003, 21, 157-1615. 艾仕云(1).P reparation of Ce-PbO2 modified electrode and its application in detection ofanilines. Talanta, 2004, 62, 445-4506. 艾仕云(1). Electrocatalytic sensor for the determination of chemical oxygen demandusing a nanometer lead dioxide modified electrode. Electroanalysis, 2004, 16, 404-409 7.艾仕云(1). Study on photocatalytic oxidation for determination of chemical oxygen demand using nano TiO2-K2Cr2O7co-existed system. Anal. Chim. Acta, 2004, 509, 237-2418.艾仕云(1).Determination of reactive intermediates during anodic oxygen-transfer reactions at lead dioxide. Chemical Research in Chinese Universities, 2004, 20, 289-293 9.艾仕云(3). Liquid chromatography with amperometric detection using funtionalized multi-wall carbon nanotube modified electrode for the determination of monoamine neurotransmitters and their metabolites. J. Chromatography B, 2003, 791, 217-22510.艾仕云(4).Liquid chromatography with amperometric detection at a nano crystallineCe-doped PbO2 film modified electrode for simultaneous determination of (R)-Salsolinol, (R)-N-methylsalsolinol and monoamine neurotransmitters in Parkinsonian patients’ cerebrospinal fluid. The Analyst, 2004, 129, 229-23411.艾仕云(4).Simultaneous determination of the monoamine neurotransmitters and glucose in rat brain by microdialysis sampling coupled with liquid chromatography-dualelectrochemical detector. J. Chromatography B, 2003, 785, 327-33612.艾仕云(3). Immobilization of uricase on ZnO nanorods for a reagentless uric acidbiosensor. Anal. Chim. Acta, 2004, 519, 155-16013.艾仕云(5). Amperometric determination of chemical oxygen demand with flow injectionanalysis using F-PbO2 modified electrode. Anal. Chim. Acta, 2005, 548, 199-20414.艾仕云(1).一种新的光催化氧化体系用于化学需氧量测定的研究. 高等学校化学学报, 2004, 25, 823-82615.艾仕云(1).均一形貌的ZnO纳米棒的制备及其光催化性能研究,无机化学学报,2005,21, 270-27216.艾仕云(1).Separation of inorganic anions and cations by high-speed ion chromatography.Current Analytical Chemistry, 2006, 2(4), 389-396.17.艾仕云(1). 纳米二氧化钛膜光催化分-解电化学法联用测定水体中的总磷. 分析化学, 2006, 34(8), 1068-1072.18.艾仕云(*).纳米TiO2光催化氧化甘氨酸及其氧化机理的研究. 山东大学学报(理学版), 2006, 41(4), 148-151.19.艾仕云(*).季胺化功能高分子絮凝剂的制备及其性能研究. 山东大学学报(理学版),2006, 41(5), 134-137, 150.20.艾仕云(*). 新型季磷盐的合成及其杀菌性能研究. 山东科技大学学报(自然科学版)2006, 25(3), 71-73.21.艾仕云(*).纳米金/丝素复合膜修饰电极制备及对对苯二酚的电催化作用. 分析化学,2007, 35(3), 386-389.22.艾仕云(*).AMPS接枝聚乙烯醇高吸水性树脂的合成. 化学世界,2007, 48(1), 18-22.23.艾仕云(*).纳米金/丝素复合膜修饰电极制备及对对苯二酚的电催化作用. 山东农业大学学报(自然科学版), 2007, 38(1), 49-52.24.艾仕云(3).掺铈纳米二氧化铅修饰电极色谱电化学用于单胺类神经递质的研究. 化学学报, 2003, 61, 1030-103525.艾仕云(1).纳米CuO/TiO2 的光催化降解及其应用的研究. 华东师范大学学报(自然科学版), 2003, 48, 62-6726.艾仕云(1).纳米TiO2–有机物体系光催化还原Cr(VI)的研究, 分子催化, 2003, 17,29-3327.艾仕云(1).羟基丙叉-1,1-二磷酸二钠的合成及表征. 华东师范大学学报(自然科学版), 2003, 48, 138-14128.艾仕云(1).无机氧化物对纳米TiO2光诱导电子转移及羟基自由基的ESR验证. 华东师范大学学报(自然科学版), 2004, 49, 76-8129.艾仕云(1).纳米PbO2修饰电极电催化氧化性能的研究. 分子催化,2004,18, 366-37030.艾仕云(2).二氧化锡修饰电极测定水体化学耗氧量的研究, 化学传感器, 2003, 22,32-3731.艾仕云(2).纳米TiO2– KMnO4协同体系光催化测定地表水化学需氧量的研究. 化学传感器, 2003, 22, 34-3932.艾仕云(2). 用MnSO4-Ce(SO4)2协同催化快速测定COD的研究, 重庆环境科学,2003, 11, 29-30:33.艾仕云(2). 分子筛附载纳米TiO2催化降解有机磷农药废水, 净水技术, 2004, 23, 7-934.艾仕云(3). 用分子筛组装Bi2O3催化快速测定COD的研究. 山东农业大学学报(自然科学版), 2005, 36, 363-36635.董静(1). 改进的自乳化溶剂挥发法制备的核-壳型Me.PEG-PLA纳米粒的表征, 药学学报, 2004, 9, 677-68036.董静(2). Characterization and release of triptolide-loaded poly(D,L-lactic acid)nanoparticles. European Polymer Journal, 2005, 2, 375-38237.董静(2). Anti-inflammatory effects of triptolide loaded poly(D,L-lactic acid) nanoparticleson adjuvant-induced arthritis. Journal of Ethnopharmacology, 2005, 3, 219-22538.高吉刚.(1).Fluorometric Method for Quantitative Determination of Glucose and ItsApplication to Human Serum. Analytical science, 2005, 21, 409-41239.高吉刚.(1).草莓和肥桃中过氧化氢酶活性的荧光法测定,山东农业大学学报2006,37(4), 573-57640.高吉刚.(1).The fluorescence properties of N2,N3-Ethenoguanosine and its interaction withBSA. 第40届国际化学会论文集, 2005.10.2141.高吉刚.(1).植物激素吲哚乙酸模板聚合物的分子识别特性的研究. 分析化学, 2003,31, 1173-117742.侯菊英(1).Barium divanadium tellutrite,Acta cryst.C61, 2005, i59-i6043.侯菊英(1).A new noncentrosymmetric tellurite:BaMo2Te2O11(H2O) with {Mo(1)Mo(2)O10}n spiral chains,J. Molecular structure, 2006, 785, 37-4244.侯菊英(1).A New Noncentrosymmetric Tellurite: BaMo2Te2O11(H2O) with{Mo(1)Mo(2)O10}n spiral chains, Journal of molecular structure, 785(2006),37-42 45.姜林(*).取代苯甲醛缩氨基硫脲的合成及其对昆虫酚氧化酶的抑制活性.化学试剂,2007,29,34-36.46.姜林(1). .N-(6-氯吡啶-3-基)羰基-2-取代芳基磺酰胺的合成、结构及除草活性研究. 有机化学, 2006, 26(2), 203-20647.姜林(1). Synthesis and Crystal Structure of Ferroc- ene sulfonyl hexa hydro pyridine. 结构化学, 2006, 15(3), 257-26048.姜林(1).4-(2′-呋喃甲基)氨基嘧啶衍生物的合成及生理活性. 化学研究与应用,2005,17(2), 118-22949.姜林(1).Synthesis and Crystal Structure of 6-(3΄- Indolyl)-8-(p-cl-phenyl)-10,10- dimethyl 10H –pyrido [1,2-a]-Indolium Perchlorate. 结构化学, 2004, 23(12), 1371-1375 50.姜林(2). N-(4-取代嘧啶-2-基)苄基磺酰脲和苯氧基磺酰脲的3D-QSAR研究. 高等学校化学学报, 2004, 25(11), 2031-203351.姜林(2). 碳酸盐水化学平衡体系Coates 信号流图模型与Mathcad 求解. 化学通报,2004, 2, w01252.姜林(1). 磺酰脲类除草剂研制与应用. 山东农大学报, 2003, 34(4), 597-59953.姜林(1). N-(吡啶-2’-基羰基)-2-取代芳基磺酰胺的合成及除草活性. 应用化学,2003,20(1), 77-7954.贾寿华(1).分光光度法测定α-甲基葡萄糖苷中的葡萄糖, 日用化学工业, 2003,4,261-26355.贾寿华(1). δ-层状结晶二硅酸钠的技术经济分析,化工进展,2006, 1, 113-11456.李懋峰(1). A Novel Borophosphate Coordination Polymer with Sandwich-typeSupramolecular Architecture. Chinese Chemical Letters, 2004, 15(7), 863-86657.李懋峰(1) Crystal structure of trans-bis(triphenylphospine tetrachlorotitanum (IV),TiCl4[(C6H5)3PO]2. Z. Kristallogr, 2006, 221, 41-4258.路福绥(*). 三氟氯氰菊酯微乳剂配方筛选及其形成规律的研究,农药,2007(2),100-10259.路福绥(*),农药水悬浮剂的研究开发,第六届全国农药交流会论文集,2006.10,18-2260.路福绥(*). 不同反离子对高效氯氰菊酯微乳液影响的研究, 化学学报, 2006, 3, 367-37061.路福绥(*).不同因素对高效氯氟氰菊酯微乳液相图的影响. 物理化学学报, 2006, 4,475-48062.路福绥(*).醇对高效氯氟氰菊酯微乳液相图的影响, 应用化学, 2006, 5, 503-50763.路福绥(*).三氟氯氰菊酯微乳剂配方筛选及其形成规律的研究, 农药, 2005,12,547-54864.路福绥(*).高效氯氢菊酯微乳剂影响因素的研究, 山东农业大学学报,2004, 6, 277-27965.陆盘芳(2). 海泡石纤维化学松解工艺研究, 矿物研究与开发, 2004, 24(4), 25-3066.陆盘芳(2). 改性海泡石填充不饱和聚酯复合材料的热性能的研究.泰山学院学报,2004, 26(3), 63-6567. 兰孝征(1). Microencapsulation of n-eicosane as energy storage material . CHINESEJOURNAL OF CHEMISTRY,2004, 22 (5), 411-41468. 兰孝征(1)Low-temperature heat capacity and thermochemical study on [Er2 (His⋅H+) (H2O)8] (ClO4)6⋅4H2O. THERMOCHIMICA ACTA, 2004, 416 (1-2), 55-5869.兰孝征(1). Low-temperature heat capacity and thermodynamic properties of [Re2(Ile)4(H2O)8](ClO4)6 (Re = Nd, Er, Ile = isoleucine) .THERMOCHIMICA ACTA, 2003, 402 (1-2), 183-19170. 兰孝征(1). Low-temperature heat capacity and thermal decomposition of crystalline[Ho(Thr)(H2O)5]Cl3 .CHINESE JOURNAL OF CHEMISTRY, 2003, 21 (8), 1043-1046 71.兰孝征(2). Thermodynamic investigation of crystalline K2Cr2O7 and aqueous K2Cr2O7solution. INTERNATIONAL JOURNAL OF THERMAL SCIENCES, 2003, 42 (7), 657-664 72. 兰孝征(2). Microencapsulation of n-hexadecane as a phase change material in polyureaACTA PHYSICO-CHIMICA SINICA , 2004, 20 (1), 90-9373. 兰孝征(3). Preparation and characterization of microencapsulated hexadecane used forthermal energy storage. CHINESE CHEMICAL LETTERS, 2004, 15 (6), 729-73274. 兰孝征(3), Low-temperature heat capacity and thermodynamic functions of nanoCo2O3.CHINESE JOURNAL OF INORGANIC CHEMISTRY. 2003, 19 (3), 325-328 75. 兰孝征(4)Studies on thermal decomposition mechanism and kinetics of aspirin . ACTAPHYSICO-CHIMICA SINICA, 2004, 20 (1), 50-5476. 兰孝征(4). Low-temperature heat capacities and thermodynamic properties of crystallineisoproturon . JOURNAL OF THERMAL ANALYSIS AND CALORIMETRY. 2003, 74 (3), 867-87477. 兰孝征(4). Calorimetric study and thermal analysis of berberine sulphate. JOURNAL OFTHERMAL ANALYSIS AND CALORIMETRY, 2003, 74 (1), 335-34078. 兰孝征(4). Heat capacities and thermodynamic properties of lanthanum/holmiumperchlorate complexes with glycine . CHINESE JOURNAL OF CHEMISTRY, 2003, 21 (4), 396-39979. 兰孝征(4). Standard enthalpy of formation and heat capacities of 3,5-di-tert- butylsalicylic acid. THERMOCHIMICA ACTA , 2003, 404 (1-2), 89-9580. 兰孝征(4). Thermodynamic properties of [H2O (Ala)4(H2O)8]Cl6(Ala = alanine) .ACTA PHYSICO-CHIMICA SINICA, 2003, 19 (5), 445-44981. 兰孝征(3). Calorimetric study and thermal analysis of [Gd4/3Y2/3(Gly)6 (H2O)4](ClO4)6·5H2O and [ErY(Gly)6(H2O)4](ClO4)6·5H2O (Gly : glycin). THERMOCHIMICA ACTA, 2003, 401 (2), 233-23882. 兰孝征(4). Calorimetric study and thermal, analysis of [ErY(Ala)4(H2O)8](ClO4) 6(Ala=alanine). JOURNAL OF THERMAL ANALYSIS AND CALORIMETRY. 2003, 71 (2), 623-62883. 兰孝征(4). Low-temperature heat capacity and thermodynamic properties of crystalline[Re(Gly)3(H2O)2Cl3·2H2O (RE = Pr, Nd, Gly = Glycine), THERMOCHIMICA ACTA, 2003, 397 (1-2), 67-7384. 李丽芳(1). Zn-Al类水滑石零净电荷点及等电点研究, 化学学报, 2004, 62(4), 429-43285. 李丽芳(1) . Zn-Al类水滑石的合成及表征. 精细化工, 2004, 21(3), 161-16486. 李丽芳(1). Zn-Al类水滑石结构正电荷对内禀电离平衡常数的影响, 物理化学学报,2004, 20(5), 459-46287. 李丽芳(1) .金属元素对类水滑石物质阴离子交换性能影响的研究,山东大学学报,2004, 39(2), 90-9488. 李丽芳(4). Studies on Intrinsic Ionization Constant of Fe-Al-Mg Hydrotalcite-LikeCompounds, Journal of Colloid and Interface Sci.2003, 257, 244-24989. 李丽芳(3). ―Mg-Fe-HTlc/高岭土悬浮体流变性研究‖, 化学学报, 2005, 63(8), 693-69690.刘连伟(1). 阻抑动力学光度法测定食物中痕量草酸.应用化学, 2004, 21(3) 316-31891.刘连伟(1). 胶束增敏阻抑动力学光度法测定痕量水杨酸.分析试验室, 2003, 22(增刊),591-59392.刘葵(1). 过氧化氢酶催化反应中以靛蓝胭脂红为供氢体的研究. 山东农业大学学报,2003, 34(2), 278-28093.刘葵(1). 加碘食盐中微量碘的离子选择性电极测定. 分析试验室, 2006, 25(6),46-4894.刘葵(2). 利用混合线性分析分光光度法同时测定微量铜、锌、镍. 分析试验室, 2004,23(4), 67 -6995.刘葵(3). 混合线性分析法同时测定安痛定注射液中三组分含量.分析化学, 2003,31(12), 1476-147896.李长城(1).N–(2–氯吡啶–3–基)羰基–2–取代芳基磺酰胺的合成及除草活性的研究.化学试剂, 2006, 28(4), 225-22697.苗延虹(1).Determination of adenosine disodium triphosphate (A TP) usingnorfloxacin-Tb3+as a fluorescence probe by spectrofluorimetry, Journal of Luminescence,2006,116,67-7298.苗延虹(1).Determination of adenosine disodium triphosphate (A TP) usingoxytetracycline -Eu3+as a fluorescence probe by spectrofluorimetry, Spectrochimica Acta Part A,2004,SAA4635,1-5.99孟庆喜(1). Density Functional Studies on Copper-Catalyzed Asymmetric Cyclopro- panation of Diazoacetate with Alkene. Journal of Molecular Structure: THEOCHEM, 2004, 711(1-3), 193-199100孟庆喜(1). The Computational Study on the Mechanism of Rhodium(I)-Catalyzed Asymmetric Carbonylative [4+1] Cycloaddition with (R, R)-Me-DuPHOS -type ligand. A DFT Study. Journal of Molecular Structure: THEOCHEM, 2005, 726(1-3), 47-54101.孟庆喜(1). Density Functional Computations of Enantio -selective Alkynylation of Aldehyde Catalyzed by Chiral Zinc(II)-Complexes. Journal of Molecular Modeling, 2006, 12(4), 494-502102.孟庆喜(1). Density Function Studies on the PtCl2-catalyzed Asymmetric Cycloisomerization Reaction of Hydroxylated Enyne. International Journal of Quantum Chemistry, 2006, 106(7), 1569-1579103.孟庆喜(1). O(3P)与C2H2反应机理的量子化学研究.西南师范大学学报, 2005, 30(3), 495-499104.孟庆喜(1). FC(O)O自由基与NO2反应的量子化学研究.化学学报, 2005, 63(8), 686-692105.孟庆喜(2). Quantum Chemical Study on Reaction of Acetaldehyde with Hydroxyl Radical. Chinese Journal of Chemistry, 2004, 22(8), 792-797106.曲祥金(1). Electrochemical Behavior and Detection of Plant Hormone 6-Benzyl Adenine in Acetate Buffer at Mercury Electrode. Analytical Sciences,2005, 21(10), 1223-1226107.钱萍(1). 应用ABEEM/MM模型研究水分子团簇(H2O)n (n=7-10)的性质,中国科学B辑,2006, 36(4), 284-298.108.钱萍(1). 应用ABEEM/MM模型研究水分子团簇(H2O)n (n=11-16)的性质,物理化学学报,2006, 22(05), 561-568.109.钱萍(2). A study of N-Methylacetamide in water clusters: Based on atom-bond electron- egativity equalization method fused into molecular mechanics, J. Chem. Phys.2006, 125, 064311.110.裘立群(*). 用反相高效液相色谱-紫外检测法测定1-脱氧野尻霉素的含量. 蚕业科学, 2006, 32 (1), 146-149111.裘立群(2). 原汁苹果醋中的有机酸.食品与发酵工业, 2004, 30(8), 92-95112.裘立群(2). 色谱法测定肉及肉制品中敌草隆、绿麦隆、秀去津和西玛津残留量. 色谱, 2004, 22(1), 88-92113裘立群(3). 高效液相色谱法测定氟草烟在大蒜、玉米中的残留, 色谱, 2004, 22(1), 92-95114.盛锋(1). 丝瓜籽中色素的提取与光热稳定性的研究. 食品与发酵工业, 2003, 29(4), 62-66115.宋少芳(1). 微乳液凝胶固定化脂肪酶催化 -单硬脂酸甘油酯水解反应活性. 应用化学,2006, 23(2), 188-192116.宋少芳(1). AOT-水-正庚烷微乳液中脂肪酶催化拆分消旋布洛芬的研究. 分析试验室,2006, 25(3), 59-62117.宋少芳(1). 微乳液凝胶固定化脂肪酶立体选择性研究. 山东农业大学学报,2003,34(4), 519-522118.宋少芳(3). Effect of Cationic Surfactant on the Inhibition of Ligninase by Hydrogen Peroxide. Chinese Chemical Letters, 2003, 14(8), 836-839119.宋少芳(3). Kinetics of the H2O2-dependent ligninase-catalyzed oxidation of veratryl alcohol in the presence of cationic surfactant studied by spectrophotometric technique.Spectrochimica Acta Part A, 2003, 59, 2547-2551120.宋少芳(3). 非离子表面活性剂存在下过氧化氢对木素过氧化物酶的抑制动力学研究.山东大学学报,2003, 38(2), 108-111121.苏秀荣(1)酸奶发酵剂中嗜热链球菌与保加利亚乳杆菌生长关系的微量量热法研究.食品与发酵工业,2002, 28(9), 38-41122.苏秀荣(1). 微量量热法研究酸奶菌种的适宜生长温度及最佳生长温度.微生物学杂志,2003, 23(5), 15-17123.孙华(1).氰戊菊酯微乳剂形成规律的研究. 农药, 2004, 12, 546-548124.孙华(1).氰戊菊酯微乳液相行为及其结构转变. 应用化学, 2005, 7, 780-783125.孙衍华(1). 阻抑速差催化光度法测定色氨酸和酪氨酸.分析化学, 2004, 32(8), 1067-1069126.孙衍华(1). 溴氧化法测定五倍子中单宁的研究.分析试验室, 2004, 23(8), 34-36 127.孙衍华(1). 盐酸提取、双氧水氧化、8-羟基喹啉沉淀紫外光度法测定乳制品中Fe、Zn、Mg.分析试验室, 2005, 24(12), 47-50128.孙衍华(2). 蜂蜜中糖的薄层展开剂的研究与应用,色谱, 2003, 21(4), 489129.孙衍华(2). 一种能直接染色鉴定氨基酸的薄层展开剂及其应用. 色谱, 2004, 22(5), 566130.孙衍华(2). 碘氧化法测定五倍子中的单宁. 应用化学, 2005, 22(2), 227-229131.孙衍华(2). 鸡蛋清溶菌酶提取工艺的改进.食品与发酵工业, 2004, 30(5), 85-87 132.孙衍华(2). 标准加入法快速测定精制食盐中的碘.山东农业大学学报, 2005, 36(2), 255-257133.万福贤(1). 氨基酸衍生的寡聚DTPA酯钆(Ⅲ)配合物对大鼠肝区的MRI弛豫增强.华中科技大学学报(医学版), 2005, 34(6), 685-688134.万福贤(2).两亲性双核钆(Ⅲ)配合物的合成与肝选择MRI增强.高等学校化学学报,2005, 26(8), 1391-1394135.万福贤(2). 非离子型L-赖氨酸长链酯-双EDTA酰胺钆配合物的合成与弛豫效能.无机化学学报,2005, 21(8), 1237-1241136.万福贤(2). 新型胺羧单酯-酰胺钆配合物的合成及其对大鼠肝区T1弛豫增强作用.无机化学学报,2004, 20(4), 389-393137. 万福贤(3). L-赖氨酸长链烷基酯双DTPA酰胺钆(Ⅲ)配合物的合成、表征与弛豫效能.光谱学与光谱分析,2006, 26(4), 670138.万福贤(2). 靶向性磁共振成像造影剂的研究进展.化学试剂,2004, 26(6), 329-332 139.万福贤(3). 新型四酰胺基铝酞菁的制备及其在体光动力抗癌活性研究.中国激光,2005, 32(8), 1155-1160140.万福贤(3).δ-层状结晶二硅酸钠的技术经济分析.化工进展,2006,(印刷中) 141.王日为(2). 茶树荧光性绿斑病叶细胞中的晶体研究,茶叶科学,2005, 2, 23-26 142王艳芳(1). 脂肪酶在聚乙二醇而丙烯酸交联聚合物上的固定化. 浙江大学学报, 2004, 31(5), 557-559143.汪军(1). 南水北调东线引水工程山东境内农田土壤重金属元素现状评价,. 山东农业大学学报, 2004, 35(1), 59- 64144.汪军(1). 泰山泉水水质分析. 山东农业大学学报, 2004, 35(4), 492-495145.汪浩(1). 聚乙烯接枝不饱和硅烷工艺研究. 电线电缆,2004, 5, 33-36146.汪浩(1). 甘油和水共增塑大豆蛋白质塑料性能. 山东农业大学学报,2005, 4, 529-534147.汪浩(1). 制备工艺对大豆蛋白质塑料性能的影响. 食品与生物技术学报,2006, 2, 93-96148.殷焕顺(1). 易溶性铜酞菁磺酸酯的合成及其凝聚性能.化学研究, 2003, 33(5), 12-16149.殷焕顺(1). 酞菁在高新技术领域中的应用. 精细化工中间体,2003, 14(3), 31-34 150.殷焕顺(1). 金属酞菁的固相法合成. 染料与染色,2004, 41(3),150-152151.殷焕顺(1). 铜酞菁磺酸苯酯的光谱性质研究. 染料与染色,2005, 42(5), 19-20 152.殷焕顺(1). 锡酞菁及其磺化衍生物的合成及性质研究. 电子元件与材料,2005,25(4), 53-56153.殷焕顺(2). 常温下合成铜酞菁聚甲级丙烯酸甲酯的合成. 精细化工中间体,2005,35(4), 39-41154.殷焕顺(2).酞菁类化合物在太阳能电池中的应用,电源技术,2006,30(11),940-942155.张丽丽(1).化学发光分析法应用新进展.理化检验,2004, 4, 243-248156.张丽丽(2).交联聚合 -环糊精-邻香草醛苯甲酰腙的合成及其应用.化学学报,2004,62(4), 399-404157.张丽丽(2). 一氟苯甲酸的电化学合成方法.中国专利,公开号CN 1472364A,2004.2 158.张丽丽(2). 氟代苯甲醛的电化学合成方法.中国专利,公开号CN 1563496A,2005.1 159.张丽丽(3). Study and Application of Flow Injection Spectrofluorimetry with a Fluorescent Probe of 2-(2-Pyridil)-benzothiazoline for Superoxide Anion Radicals.Analytical Biochemistry, 2004, 326(2), 176-182160.张丽丽(3). Rapid flow injection spectrofluorimetric method for determination of cadmium。

Semiconductor Manufacturing Technology半导体制造技术Instructor’s ManualMichael QuirkJulian SerdaCopyright Prentice HallTable of Contents目录OverviewI. Chapter1. Semiconductor industry overview2. Semiconductor materials3. Device technologies—IC families4. Silicon and wafer preparation5. Chemicals in the industry6. Contamination control7. Process metrology8. Process gas controls9. IC fabrication overview10. Oxidation11. Deposition12. Metallization13. Photoresist14. Exposure15. Develop16. Etch17. Ion implant18. Polish19. Test20. Assembly and packagingII. Answers to End-of-Chapter Review QuestionsIII. Test Bank (supplied on diskette)IV. Chapter illustrations, tables, bulleted lists and major topics (supplied on CD-ROM)Notes to Instructors:1)The chapter overview provides a concise summary of the main topics in each chapter.2)The correct answer for each test bank question is highlighted in bold. Test bankquestions are based on the end-of-chapter questions. If a student studies the end-of-chapter questions (which are linked to the italicized words in each chapter), then they will be successful on the test bank questions.2Chapter 1Introduction to the Semiconductor Industry Die:管芯 defective:有缺陷的Development of an Industry•The roots of the electronic industry are based on the vacuum tube and early use of silicon for signal transmission prior to World War II. The first electronic computer, the ENIAC, wasdeveloped at the University of Pennsylvania during World War II.•William Shockley, John Bardeen and Walter Brattain invented the solid-state transistor at Bell Telephone Laboratories on December 16, 1947. The semiconductor industry grew rapidly in the 1950s to commercialize the new transistor technology, with many early pioneers working inSilicon Valley in Northern California.Circuit Integration•The first integrated circuit, or IC, was independently co-invented by Jack Kilby at Texas Instruments and Robert Noyce at Fairchild Semiconductor in 1959. An IC integrates multiple electronic components on one substrate of silicon.•Circuit integration eras are: small scale integration (SSI) with 2 - 50 components, medium scale integration (MSI) with 50 – 5k components, large scale integration (LSI) with 5k to 100kcomponents, very large scale integration (VLSI) with 100k to 1M components, and ultra large scale integration (ULSI) with > 1M components.1IC Fabrication•Chips (or die) are fabricated on a thin slice of silicon, known as a wafer (or substrate). Wafers are fabricated in a facility known as a wafer fab, or simply fab.•The five stages of IC fabrication are:Wafer preparation: silicon is purified and prepared into wafers.Wafer fabrication: microchips are fabricated in a wafer fab by either a merchant chip supplier, captive chip producer, fabless company or foundry.Wafer test: Each individual die is probed and electrically tested to sort for good or bad chips.Assembly and packaging: Each individual die is assembled into its electronic package.Final test: Each packaged IC undergoes final electrical test.•Key semiconductor trends are:Increase in chip performance through reduced critical dimensions (CD), more components per chip (Moore’s law, which predicts the doubling of components every 18-24 months) andreduced power consumption.Increase in chip reliability during usage.Reduction in chip price, with an estimated price reduction of 100 million times for the 50 years prior to 1996.The Electronic Era•The 1950s saw the development of many different types of transistor technology, and lead to the development of the silicon age.•The 1960s were an era of process development to begin the integration of ICs, with many new chip-manufacturing companies.•The 1970s were the era of medium-scale integration and saw increased competition in the industry, the development of the microprocessor and the development of equipment technology. •The 1980s introduced automation into the wafer fab and improvements in manufacturing efficiency and product quality.•The 1990s were the ULSI integration era with the volume production of a wide range of ICs with sub-micron geometries.Career paths•There are a wide range of career paths in semiconductor manufacturing, including technician, engineer and management.2Chapter 2 Characteristics of Semiconductor MaterialsAtomic Structure•The atomic model has three types of particles: neutral neutrons(不带电的中子), positively charged protons(带正电的质子)in the nucleus and negatively charged electrons(带负电的核外电子) that orbit the nucleus. Outermost electrons are in the valence shell, and influence the chemical and physical properties of the atom. Ions form when an atom gains or loses one or more electrons.The Periodic Table•The periodic table lists all known elements. The group number of the periodic table represents the number of valence shell electrons of the element. We are primarily concerned with group numbers IA through VIIIA.•Ionic bonds are formed when valence shell electrons are transferred from the atoms of one element to another. Unstable atoms (e.g., group VIIIA atoms because they lack one electron) easily form ionic bonds.•Covalent bonds have atoms of different elements that share valence shell electrons.3Classifying Materials•There are three difference classes of materials:ConductorsInsulatorsSemiconductors•Conductor materials have low resistance to current flow, such as copper. Insulators have high resistance to current flow. Capacitance is the storage of electrical charge on two conductive plates separated by a dielectric material. The quality of the insulation material between the plates is the dielectric constant. Semiconductor materials can function as either a conductor or insulator.Silicon•Silicon is an elemental semiconductor material because of four valence shell electrons. It occurs in nature as silica and is refined and purified to make wafers.•Pure silicon is intrinsic silicon. The silicon atoms bond together in covalent bonds, which defines many of silicon’s properties. Silicon atoms bond together in set, repeatable patterns, referred to asa crystal.•Germanium was the first semiconductor material used to make chips, but it was soon replaced by silicon. The reasons for this change are:Abundance of siliconHigher melting temperature for wider processing rangeWide temperature range during semiconductor usageNatural growth of silicon dioxide•Silicon dioxide (SiO2) is a high quality, stable electrical insulator material that also serves as a good chemical barrier to protect silicon from external contaminants. The ability to grow stable, thin SiO2 is fundamental to the fabrication of Metal-Oxide-Semiconductor (MOS) devices. •Doping increases silicon conductivity by adding small amounts of other elements. Common dopant elements are from trivalent, p-type Group IIIA (boron) and pentavalent, n-type Group VA (phosphorus, arsenic and antimony).•It is the junction between the n-type and p-type doped regions (referred to as a pn junction) that permit silicon to function as a semiconductor.4Alternative Semiconductor Materials•The alternative semiconductor materials are primarily the compound semiconductors. They are formed from Group IIIA and Group VA (referred to as III-V compounds). An example is gallium arsenide (GaAs).•Some alternative semiconductors come from Group IIA and VIA, referred to as II-VI compounds. •GaAs is the most common III-V compound semiconductor material. GaAs ICs have greater electron mobility, and therefore are faster than ICs made with silicon. GaAs ICs also have higher radiation hardness than silicon, which is better for space and military applications. The primary disadvantage of GaAs is the lack of a natural oxide.5Chapter 3Device TechnologiesCircuit Types•There are two basic types of circuits: analog and digital. Analog circuits have electrical data that varies continuously over a range of voltage, current and power values. Digital circuits have operating signals that vary about two distinct voltage levels – a high and a low.Passive Component Structures•Passive components such as resistors and capacitors conduct electrical current regardless of how the component is connected. IC resistors are a passive component. They can have unwanted resistance known as parasitic resistance. IC capacitor structures can also have unintentional capacitanceActive Component Structures•Active components, such as diodes and transistors can be used to control the direction of current flow. PN junction diodes are formed when there is a region of n-type semiconductor adjacent to a region of p-type semiconductor. A difference in charge at the pn junction creates a depletion region that results in a barrier voltage that must be overcome before a diode can be operated. A bias voltage can be configured to have a reverse bias, with little or no conduction through the diode, or with a forward bias, which permits current flow.•The bipolar junction transistor (BJT) has three electrodes and two pn junctions. A BJT is configured as an npn or pnp transistor and biased for conduction mode. It is a current-amplifying device.6• A schottky diode is formed when metal is brought in contact with a lightly doped n-type semiconductor material. This diode is used in faster and more power efficient BJT circuits.•The field-effect transistor (FET), a voltage-amplifying device, is more compact and power efficient than BJT devices. A thin gate oxide located between the other two electrodes of the transistor insulates the gate on the MOSFET. There are two categories of MOSFETs, nMOS (n-channel) and pMOS (p-channel), each which is defined by its majority current carriers. There is a biasing scheme for operating each type of MOSFET in conduction mode.•For many years, nMOS transistors have been the choice of most IC manufacturers. CMOS, with both nMOS and pMOS transistors in the same IC, has been the most popular device technology since the early 1980s.•BiCMOS technology makes use of the best features of both CMOS and bipolar technology in the same IC device.•Another way to categorize FETs is in terms of enhancement mode and depletion mode. The major different is in the way the channels are doped: enhancement-mode channels are doped opposite in polarity to the source and drain regions, whereas depletion mode channels are doped the same as their respective source and drain regions.Latchup in CMOS Devices•Parasitic transistors can create a latchup condition(???????) in CMOS ICs that causes transistors to unintentionally(无心的) turn on. To control latchup, an epitaxial layer is grown on the wafer surface and an isolation barrier(隔离阻障)is placed between the transistors. An isolation layer can also be buried deep below the transistors.Integrated Circuit Productsz There are a wide range of semiconductor ICs found in electrical and electronic products. This includes the linear IC family, which operates primarily with anal3og circuit applications, and the digital IC family, which includes devices that operate with binary bits of data signals.7Chapter 4Silicon and Wafer Preparation8z Semiconductor-Grade Silicon•The highly refined silicon used for wafer fabrication is termed semiconductor-grade silicon (SGS), and sometimes referred to as electronic-grade silicon. The ultra-high purity of semiconductor-grade silicon is obtained from a multi-step process referred to as the Siemens process.Crystal Structure• A crystal is a solid material with an ordered, 3-dimensional pattern over a long range. This is different from an amorphous material that lacks a repetitive structure.•The unit cell is the most fundamental entity for the long-range order found in crystals. The silicon unit cell is a face-centered cubic diamond structure. Unit cells can be organized in a non-regular arrangement, known as a polycrystal. A monocrystal are neatly arranged unit cells.Crystal Orientation•The orientation of unit cells in a crystal is described by a set of numbers known as Miller indices.The most common crystal planes on a wafer are (100), (110), and (111). Wafers with a (100) crystal plane orientation are most common for MOS devices, whereas (111) is most common for bipolar devices.Monocrystal Silicon Growth•Silicon monocrystal ingots are grown with the Czochralski (CZ) method to achieve the correct crystal orientation and doping. A CZ crystal puller is used to grow the silicon ingots. Chunks of silicon are heated in a crucible in the furnace of the puller, while a perfect silicon crystal seed is used to start the new crystal structure.• A pull process serves to precisely replicate the seed structure. The main parameters during the ingot growth are pull rate and crystal rotation. More homogeneous crystals are achieved with a magnetic field around the silicon melt, known as magnetic CZ.•Dopant material is added to the melt to dope the silicon ingot to the desired electrical resistivity.Impurities are controlled during ingot growth. A float-zone crystal growth method is used toachieve high-purity silicon with lower oxygen content.•Large-diameter ingots are grown today, with a transition underway to produce 300-mm ingot diameters. There are cost benefits for larger diameter wafers, including more die produced on a single wafer.Crystal Defects in Silicon•Crystal defects are interruptions in the repetitive nature of the unit cell. Defect density is the number of defects per square centimeter of wafer surface.•Three general types of crystal defects are: 1) point defects, 2) dislocations, and 3) gross defects.Point defects are vacancies (or voids), interstitial (an atom located in a void) and Frenkel defects, where an atom leaves its lattice site and positions itself in a void. A form of dislocation is astacking fault, which is due to layer stacking errors. Oxygen-induced stacking faults are induced following thermal oxidation. Gross defects are related to the crystal structure (often occurring during crystal growth).Wafer Preparation•The cylindrical, single-crystal ingot undergoes a series of process steps to create wafers, including machining operations, chemical operations, surface polishing and quality checks.•The first wafer preparation steps are the shaping operations: end removal, diameter grinding, and wafer flat or notch. Once these are complete, the ingot undergoes wafer slicing, followed by wafer lapping to remove mechanical damage and an edge contour. Wafer etching is done to chemically remove damage and contamination, followed by polishing. The final steps are cleaning, wafer evaluation and packaging.Quality Measures•Wafer suppliers must produce wafers to stringent quality requirements, including: Physical dimensions: actual dimensions of the wafer (e.g., thickness, etc.).Flatness: linear thickness variation across the wafer.Microroughness: peaks and valleys found on the wafer surface.Oxygen content: excessive oxygen can affect mechanical and electrical properties.Crystal defects: must be minimized for optimum wafer quality.Particles: controlled to minimize yield loss during wafer fabrication.Bulk resistivity(电阻系数): uniform resistivity from doping during crystal growth is critical. Epitaxial Layer•An epitaxial layer (or epi layer) is grown on the wafer surface to achieve the same single crystal structure of the wafer with control over doping type of the epi layer. Epitaxy minimizes latch-up problems as device geometries continue to shrink.Chapter 5Chemicals in Semiconductor FabricationEquipment Service Chase Production BayChemical Supply Room Chemical Distribution Center Holding tank Chemical drumsProcess equipmentControl unit Pump Filter Raised and perforated floorElectronic control cablesSupply air ductDual-wall piping for leak confinement PumpFilterChemical control and leak detection Valve boxes for leak containment Exhaust air ductStates of Matter• Matter in the universe exists in 3 basic states (宇宙万物存在着三种基本形态): solid, liquid andgas. A fourth state is plasma.Properties of Materials• Material properties are the physical and chemical characteristics that describe its unique identity.• Different properties for chemicals in semiconductor manufacturing are: temperature, pressure andvacuum, condensation, vapor pressure, sublimation and deposition, density, surface tension, thermal expansion and stress.Temperature is a measure of how hot or cold a substance is relative to another substance. Pressure is the force exerted per unit area. Vacuum is the removal of gas molecules.Condensation is the process of changing a gas into a liquid. Vaporization is changing a liquidinto a gas.Vapor pressure is the pressure exerted by a vapor in a closed container at equilibrium.Sublimation is the process of changing a solid directly into a gas. Deposition is changing a gas into a solid.Density is the mass of a substance divided by its volume.Surface tension of a liquid is the energy required to increase the surface area of contact.Thermal expansion is the increase in an object’s dimension due to heating.Stress occurs when an object is exposed to a force.Process Chemicals•Semiconductor manufacturing requires extensive chemicals.• A chemical solution is a chemical mixture. The solvent is the component of the solution present in larger amount. The dissolved substances are the solutes.•Acids are solutions that contain hydrogen and dissociate in water to yield hydronium ions. A base is a substance that contains the OH chemical group and dissociates in water to yield the hydroxide ion, OH-.•The pH scale is used to assess the strength of a solution as an acid or base. The pH scale varies from 0 to 14, with 7 being the neutral point. Acids have pH below 7 and bases have pH values above 7.• A solvent is a substance capable of dissolving another substance to form a solution.• A bulk chemical distribution (BCD) system is often used to deliver liquid chemicals to the process tools. Some chemicals are not suitable for BCD and instead use point-of-use (POU) delivery, which means they are stored and used at the process station.•Gases are generally categorized as bulk gases or specialty gases. Bulk gases are the relatively simple gases to manufacture and are traditionally oxygen, nitrogen, hydrogen, helium and argon.The specialty gases, or process gases, are other important gases used in a wafer fab, and usually supplied in low volume.•Specialty gases are usually transported to the fab in metal cylinders.•The local gas distribution system requires a gas purge to flush out undesirable residual gas. Gas delivery systems have special piping and connections systems. A gas stick controls the incoming gas at the process tool.•Specialty gases may be classified as hydrides, fluorinated compounds or acid gases.Chapter 6Contamination Control in Wafer FabsIntroduction•Modern semiconductor manufacturing is performed in a cleanroom, isolated from the outside environment and contaminants.Types of contamination•Cleanroom contamination has five categories: particles, metallic impurities, organic contamination, native oxides and electrostatic discharge. Killer defects are those causes of failure where the chip fails during electrical test.Particles: objects that adhere to a wafer surface and cause yield loss. A particle is a killer defect if it is greater than one-half the minimum device feature size.Metallic impurities: the alkali metals found in common chemicals. Metallic ions are highly mobile and referred to as mobile ionic contaminants (MICs).Organic contamination: contains carbon, such as lubricants and bacteria.Native oxides: thin layer of oxide growth on the wafer surface due to exposure to air.Electrostatic discharge (ESD): uncontrolled transfer of static charge that can damage the microchip.Sources and Control of Contamination•The sources of contamination in a wafer fab are: air, humans, facility, water, process chemicals, process gases and production equipment.Air: class number designates the air quality inside a cleanroom by defining the particle size and density.Humans: a human is a particle generator. Humans wear a cleanroom garment and follow cleanroom protocol to minimize contamination.Facility: the layout is generally done as a ballroom (open space) or bay and chase design.Laminar airflow with air filtering is used to minimize particles. Electrostatic discharge iscontrolled by static-dissipative materials, grounding and air ionization.Ultrapure deiniozed (DI) water: Unacceptable contaminants are removed from DI water through filtration to maintain a resistivity of 18 megohm-cm. The zeta potential represents a charge on fine particles in water, which are trapped by a special filter. UV lamps are used for bacterial sterilization.Process chemicals: filtered to be free of contamination, either by particle filtration, microfiltration (membrane filter), ultrafiltration and reverse osmosis (or hyperfiltration).Process gases: filtered to achieve ultraclean gas.Production equipment: a significant source of particles in a fab.Workstation design: a common layout is bulkhead equipment, where the major equipment is located behind the production bay in the service chase. Wafer handling is done with robotic wafer handlers. A minienvironment is a localized environment where wafers are transferred on a pod and isolated from contamination.Wafer Wet Cleaning•The predominant wafer surface cleaning process is with wet chemistry. The industry standard wet-clean process is the RCA clean, consisting of standard clean 1 (SC-1) and standard clean 2 (SC-2).•SC-1 is a mixture of ammonium hydroxide, hydrogen peroxide and DI water and capable of removing particles and organic materials. For particles, removal is primarily through oxidation of the particle or electric repulsion.•SC-2 is a mixture of hydrochloric acid, hydrogen peroxide and DI water and used to remove metals from the wafer surface.•RCA clean has been modified with diluted cleaning chemistries. The piranha cleaning mixture combines sulfuric acid and hydrogen peroxide to remove organic and metallic impurities. Many cleaning steps include an HF last step to remove native oxide.•Megasonics(兆声清洗) is widely used for wet cleaning. It has ultrasonic energy with frequencies near 1 MHz. Spray cleaning will spray wet-cleaning chemicals onto the wafer. Scrubbing is an effective method for removing particles from the wafer surface.•Wafer rinse is done with overflow rinse, dump rinse and spray rinse. Wafer drying is done with spin dryer or IPA(异丙醇) vapor dry (isopropyl alcohol).•Some alternatives to RCA clean are dry cleaning, such as with plasma-based cleaning, ozone and cryogenic aerosol cleaning.Chapter 7Metrology and Defect InspectionIC Metrology•In a wafer fab, metrology refers to the techniques and procedures for determining physical and electrical properties of the wafer.•In-process data has traditionally been collected on monitor wafers. Measurement equipment is either stand-alone or integrated.•Yield is the percent of good parts produced out of the total group of parts started. It is an indicator of the health of the fabrication process.Quality Measures•Semiconductor quality measures define the requirements for specific aspects of wafer fabrication to ensure acceptable device performance.•Film thickness is generally divided into the measurement of opaque film or transparent film. Sheet resistance measured with a four-point probe is a common method of measuring opaque films (e.g., metal film). A contour map shows sheet resistance deviations across the wafer surface.•Ellipsometry is a nondestructive, noncontact measurement technique for transparent films. It works based on linearly polarized light that reflects off the sample and is elliptically polarized.•Reflectometry is used to measure a film thickness based on how light reflects off the top and bottom surface of the film layer. X-ray and photoacoustic technology are also used to measure film thickness.•Film stress is measured by analyzing changes in the radius of curvature of the wafer. Variations in the refractive index are used to highlight contamination in the film.•Dopant concentration is traditionally measured with a four-point probe. The latest technology is the thermal-wave system, which measures the lattice damage in the implanted wafer after ion implantation. Another method for measuring dopant concentration is spreading resistance probe. •Brightfield detection is the traditional light source for microscope equipment. An optical microscope uses light reflection to detect surface defects. Darkfield detection examines light scattered off defects on the wafer surface. Light scattering uses darkfield detection to detectsurface particles by illuminating the surface with laser light and then using optical imaging.•Critical dimensions (CDs) are measured to achieve precise control over feature size dimensions.The scanning electron microscope is often used to measure CDs.•Conformal step coverage is measured with a surface profiler that has a stylus tip.•Overlay registration measures the ability to accurately print photoresist patterns over a previously etched pattern.•Capacitance-voltage (C-V) test is used to verify acceptable charge conditions and cleanliness at the gate structure in a MOS device.Analytical Equipment•The secondary-ion mass spectrometry (SIMS) is a method of eroding a wafer surface with accelerated ions in a magnetic field to analyze the surface material composition.•The atomic force microscope (AFM) is a surface profiler that scans a small, counterbalanced tip probe over the wafer to create a 3-D surface map.•Auger electron spectroscopy (AES) measures composition on the wafer surface by measuring the energy of the auger electrons. It identifies elements to a depth of about 2 nm. Another instrument used to identify surface chemical species is X-ray photoelectron spectroscopy (XPS).•Transmission electron microscopy (TEM) uses a beam of electrons that is transmitted through a thin slice of the wafer. It is capable of quantifying very small features on a wafer, such as silicon crystal point defects.•Energy-dispersive spectrometer (EDX) is a widely used X-ray detection method for identifying elements. It is often used in conjunction with the SEM.• A focused ion beam (FIB) system is a destructive technique that focuses a beam of ions on the wafer to carve a thin cross section from any wafer area. This permits analysis of the wafermaterial.Chapter 8Gas Control in Process ChambersEtch process chambers••The process chamber is a controlled vacuum environment where intended chemical reactions take place under controlled conditions. Process chambers are often configured as a cluster tool. Vacuum•Vacuum ranges are low (rough) vacuum, medium vacuum, high vacuum and ultrahigh vacuum (UHV). When pressure is lowered in a vacuum, the mean free path(平均自由行程) increases, which is important for how gases flow through the system and for creating a plasma.Vacuum Pumps•Roughing pumps are used to achieve a low to medium vacuum and to exhaust a high vacuum pump. High vacuum pumps achieve a high to ultrahigh vacuum.•Roughing pumps are dry mechanical pumps or a blower pump (also referred to as a booster). Two common high vacuum pumps are a turbomolecular (turbo) pump and cryopump. The turbo pump is a reliable, clean pump that works on the principle of mechanical compression. The cryopump isa capture pump that removes gases from the process chamber by freezing them.。

Positive ElectrodeKR Bullock,Coolohm,Inc.,Blue Bell,PA,USA &2009Elsevier B.V.All rights reserved.Positive Plate ConstructionPositive electrodes are classified as Plante´,Faure´or pasted,and tubular.Bipolar plates have a positive elec-trode on one side and a negative electrode on the other side,with an electronic conductor between the two plates.Plante´plates are made by cycling a high-surface-area lead electrode in acid to form a thick corrosion layer of lead dioxide acting as active mass on the surface.These designs are used exclusively in industrial applications where very long life is desired and a high specific energy is not required.Tubular positive plates are generally used in com-bination with pasted negative plates.The tubular struc-ture has good deep cycle life,but this design is not as versatile as the pasted plate.Tubular plates and bipolar designs are covered in the article entitled Secondary Batteries–Lead–Acid Sys-tems:Electrode Design and Bipolar Batteries in this encyclopedia.Most lead–acid batteries(LABs)sold today have pasted electrodes.They are made by applying a paste onto a current collector called a‘grid’.There are four ways of making the grid:(1)casting molten lead or lead alloy in a book mold,(2)slitting and expanding,(3)punching a lead sheet,and(4)continuous casting of grids as a rolled sheet. Because pure lead is a very soft material,antimony has been added since the1880s to strengthen the lead and reduce grid growth.Unfortunately,antimony also accel-erates water loss by poisoning the negative plate.Lead–calcium alloys were developed by H.E.Haring and U.B. Thomas in1935to minimize gassing and grid corrosion. The use of lead–calcium alloys led to the introduction,in the1970s,of low-maintenance batteries that do not re-quire water addition.Valve-regulated LABs sometimes use pure lead alloyed with a small amount of tin to keep gas formation at a minimum.This lead is soft enough to permit the construction of cylindrical cells.These cells are made by winding a stack of pasted positive and negative plate strips,separated by a porous,absorptive glass mat, into a jelly-roll configuration while the plates are still wet.The lead paste applied to the grid is prepared by mixingfinely divided lead and lead oxide–called‘leady litharge’or‘gray oxide’or‘battery oxide’–withfibers,water,and diluted sulfuric acid.This mixture is then‘hydro set’at high temperatures and humidities.This process forms a hardened porous structure composed of lead oxide particles and basic lead sulfates formed by the reaction of sulfuric acid with the oxide.When the positive plate is charged or‘formed’in sulfuric acid,active material is oxidized to lead dioxide(PbO2).Lead paste is resistive to the current applied during thisfirst charge because lead sulfate is an insulator and the lead oxides and basic lead oxides are semiconductors.‘Red lead’,a lead oxide mixture that contains both lead(II)oxide(PbO)and lead tetraoxide (Pb3O4),is frequently used in the paste mix to enhance its conductivity and thereby accelerate paste oxidation.Pasted plates are used where low-cost,high specific energy or power,or special grid or plate structures are required. They are the most common plate designs used in auto-motive batteries,which is the largest market for LABs.Traditional grids are rectilinear designs with a corner tab that attaches to the top lead connectors in the cell or battery.Although lead is a good conductor,the thickness of the lead is limited by its weight.The thinner the lead becomes,however,the shorter will be the operating time up to a point where the grid is no longer functional. These considerations result in a wide variety of grid designs and thicknesses that accommodate the required discharge rate and the charging conditions in a specific application.For example,automotive batteries typically have thin grids,allowing more plates to be put in the battery to accommodate high discharge rates.Radial grid wires from the tab to the opposite sides of the plate shorten the current path to improve the current-carrying capacity of the battery.Standby power batteries,on the contrary,are generally made with thick grids to tolerate long times onfloat charge.Operating PrinciplesCharge and Discharge Reactions and Half-Cell PotentialsThe cathode or positive electrode of a fully charged lead–acid cell is composed mainly of a porous lead di-oxide material in contact with a current collector that is typically made of lead metal.On discharge,the lead di-oxide reacts with aqueous sulfuric acid to form lead sulfate and water:PbO2þ3HþþHSO4Àþ2eÀ"PbSO4þ2H2O½I590The reaction is reversible on charge.Charge and dis-charge processes have a dissolution/precipitation mech-anism.The Pb2þions dissolve and reprecipitate on the surface of the electrode.Since the Pb2þions are only slightly soluble in sulfuric acid,the product maintains the porous structure of the plate over many cycles.The solubility of lead sulfate decreases with acid concentration and increases with temperature.Table1 shows the concentrations of lead sulfate dissolved in saturated sulfuric acid solutions as a function of these variables.The thermodynamics of the positive plate reaction are well characterized.The standard potential for the posi-tive electrode versus a hydrogen electrode is1.690V.The half-cell potentials for the lead dioxide,lead sulfate electrode vary with temperature and acid concentration, given in moles sulfuric acid per1000g water.Half-cell potentials have been reported at varying acid concen-trations from0.1to8molal(m)at temperatures from0to 551C.This cell is written asCell I:ðPtÞH2j H2SO4ðmÞj PbSO4j b-PbO2ðPtÞThe mercurous sulfate–mercury electrode is frequently used as the reference electrode to study the half-cell reactions in the LAB.The standard potential for this cell is0.6125.This reference electrode is written asCell II:ðPtÞH2j H2SO4ðmÞjj Hg2SO4jðHgÞIts half-cell potentials have been reported for acid con-centrations from0.1to7.199m and temperatures from5 to551C.Tables2and3show the potentials for Cells I and II,respectively.When the positive half-cell potential is measured using a mercurous sulfate–mercury refer-ence electrode,the open-circuit voltage(OCV)equals the potential of Cell I minus the potential of Cell II at the appropriate acid concentration and temperature for each cell.Although cadmium rods are sometimes used toTable1Solubility of lead sulfate in saturated sulfuric acidsolutionsMass%H2SO4Mass%PbSO4Â100001C251C351C501C10.000.120.160.380.9620.000.050.120.280.8030.000.040.120.200.4640.000.040.120.180.23Reproduced from Crockford HD and Brawley DJ(1934)Journal of theAmerican Chemical Society56:2600.Table2The potentials(V)of the lead dioxide electrode(Cell1)Acid concentration278.16K283.16K293.16K298.16K308.16K318.16K328.16K 0.1000m 1.57410 1.57173 1.56730 1.56509 1.56086 1.55683 1.55284 0.1996m 1.59097 1.58893 1.58480 1.58284 1.57887 1.57510 1.57146 0.2917m 1.60031 1.59833 1.59450 1.59266 1.58896 1.58544 1.581970.4717m 1.61237 1.61065 1.60720 1.60550 1.60232 1.59924 1.596171.129m 1.63738 1.63606 1.63336 1.63195 1.62948 1.62701 1.624552.217m 1.66364 1.66259 1.66045 1.65943 1.65720 1.65518 1.653203.900m 1.69856 1.69743 1.69524 1.69420 1.69212 1.69013 1.688264.973m 1.71984 1.71864 1.71603 1.71491 1.71260 1.71056 1.708786.095m 1.74035 1.73891 1.73640 1.73516 1.73285 1.73073 1.728567.199m 1.75965 1.75820 1.75560 1.75425 1.75187 1.74964 1.74740Reproduced from Beck WH,Dobson JV,and Wynne-Jones WFK(1960)The potentials of the mercurous sulphate/mercury electrode.Transactions of the Faraday Society56:1172.Table3The potentials(V)of the mercurous sulfate–mercury electrode(Cell II)Acid concentration278.16K288.16K298.16K308.16K318.16K328.16K 0.1003m0.738660.738200.737750.737290.736780.73629 0.1745m0.725470.724610.723860.723010.722090.72116 0.3877m0.705890.704580.703200.701800.700250.69850 0.5530m0.697030.695360.693680.692010.690070.688580.9776m0.680990.679120.676760.674530.672410.670281.872m0.658370.655820.653450.650650.647760.64491 3.911m0.619770.617250.614300.611550.608570.60633 5.767m0.595380.587170.584740.582030.579200.57614 7.972m0.559850.557310.554900.552660.550420.54842 Reproduced from Beck WH,Singh KP,and Wynne–Jones WFK(1959)The behaviour of the lead dioxide electrode.Part6–The potentials of the lead dioxide/lead sulphate electrode.Transactions of the Faraday Society55:331.Secondary Batteries–Lead–Acid Systems|Positive Electrode591measure the half-cell potentials of the LAB,they are not recommended for precise work.The standard potential of the lead–acid cell is2.048V at251C.A third-order polynomial equation has been fitted to the data to get the following relationship be-tween the OCV V and the acid molality m at251C:m¼517:8557À729:8575Vþ331:772V2À47:832189V3 To obtain accurate values,OCV must be measured on a well-equilibrated cell using a voltmeter with a high input impedance.Variations in acid concentration and tem-perature can change the voltages at the electrode sur-faces.The half-cell potential of the positive electrode changes more with acid concentration than that of the negative electrode.In addition,water formed during positive plate discharge decreases the voltage by diluting the acid concentration at the positive plate,especially at high discharge rates.Chemical Reactions that Limit Shelf LifeThe self-discharge reactions that limit shelf life have been defined in both traditionalflooded and valve-regulated lead–acid(VRLA)batteries.They are the same in both battery types.The only exception is the oxidation of additives such as antimony from the lead alloy in some flooded batteries.Low-maintenance and VRLA batteries use lead alloys that contain stable materials such as tin and sometimes calcium.Oxygen evolution:PbO2þH2SO4-PbSO4þ12O2ðgÞþH2O½II Oxidation of organics,R:2PbO2þRþ2H2SO4-2PbSO4þCO2ðgÞþ2H2OþR0½III Sulfation of residual lead(II)oxide(primarily in newly formed cells):PbOþH2SO4-PbSO4þH2O½IV Corrosion of the lead current collector:PbO2þPbþ2H2SO4-2PbSO4þ2H2O½V Oxidation of alloying metals in the lead current collector, for example antimony:5PbO2þ2Sbþ6H2SO4-5PbSO4þðSbO2ÞSO4þ6H2O½VI The reduction of lead dioxide by hydrogen is negligible on open circuit,but it can occur at very high voltages and temperatures.Overcharge ReactionsAs the battery approaches the end of charge,the recharge reaction becomes less efficient and the positive electrode begins to evolve oxygen:H2O-2Hþþ12O2ðgÞþ2eÀ½VII Organic materials that dissolve from the negative plate expander materials or the separators will oxidize to carbon dioxide:Organics-CO2þH2OþneÀ½VIII where n is the number of electrons and eÀthe electronic charge.Lead carbonates and basic lead carbonates that form during battery processing may be oxidized:PbCO3þH2O-PbO2þCO2þ2Hþþ2eÀ½IX Lead oxides,lead sulfates,and basic lead sulfates that were not converted to lead dioxide during the initial battery formation charge may oxidize to lead dioxide. Examples of these reactions arePbOþH2O-PbO2þ2Hþþ2eÀ½X PbSO4þ2H2O-PbO2þ2HþþH2SO4þ2eÀ½XI Basic lead sulfates may also be oxidized.Water is lost on overcharge in aflooded cell,because hydrogen that forms at the negative plate will vent from the cell.The charge voltage is typically reduced to a low ‘tapered’current to terminate the charge and reduce water loss.Adequate ventilation is an important safety consideration during overcharge.When a VRLA cell is overcharged at a constant voltage,oxygen recombination at the negative plate will keep the positive plate at a higher voltage than in a flooded cell under the same conditions.The higher positive plate voltage will produce more oxygen for re-combination,which will cause the internal temperature of the cell to rise.As the temperature rises,increasing vapor pressure of the acid as well as the oxygen and hydrogen formed at the plates may cause the pressure-relief valves on the battery to vent.This can be controlled by reducing the voltage or using a low‘tapered’current to charge the cell.It is also important to have a reliable pressure-relief valve on the cell that will reseal after opening.Manufacturers provide instructions for proper charging of their products under various conditions.Positive Plate Failure ModesThe following failure modes that limit the life of the positive plate are discussed in this section:•corrosion of the positive plate current collector with the formation of a resistive barrier layer between the grid and active material;592Secondary Batteries–Lead–Acid Systems|Positive Electrode•grid growth owing to excessive corrosion;•shedding of the active lead dioxide material from thepositive plate;•formation of a short between the positive and negativeplates;•loss of positive plate surface area,porosity,or chem-ical conductivity;and •contamination of the lead grid,electrolyte,or oxidematerial.Various battery designs and improved materials have overcome these sources of degradation and,consequently, have pushed cycle life farther.With each new advance-ment or application,a new primary failure mode must be understood and overcome.Positive Grid CorrosionThe lead grid will also slowly corrode,as discussed under failure modes.Grid corrosion can occur at any potential on the positive plate.The products of corrosion depend on the ionic environment at the grid surface and inside the corrosionfilm,as well as the potential.Lead oxide forms on the lead when conditions are basic,and lead sulfate forms when conditions are acidic and sulfate ion is available:PbþH2O-PbOþ2Hþþ2eÀ½XIIPbþH2SO4-PbSO4þ2Hþþ2eÀ½XIII Basic lead sulfates may also form.Table4lists the compounds that have been found in the positive plate environment.Lead sulfate forms a semipermeable membrane at the surface of the corrosion layer,where acid is available. Lead oxide forms underneath the lead sulfatefilm next to the grid by oxidation of lead in a solid-state process. Impediments to the diffusion of sulfate,hydrogen,and oxygen ions within thefilm cause variations in the cor-rosion products across thefilm.Figure1shows which product is formed at the lowest potential under each set of conditions and at what po-tential that compound is oxidized.Below pH1.9,the equilibria involve HSO4À.Above this pH,the equilibria for SO42Àare used.pS is defined as the negative of the log activity of the dominant sulfate ion at a given pH.The conditions at thefilm/solution interface are on the left face of the three-dimensional cube shown in Figure1.As the positive plate discharges,the acid concentration and voltage decrease.At the corrosion film/solution interface at pH0,the compound lead(II) sulfate(PbSO4),or lead dioxide will be stable,depending on the potential.This agrees with the normal charge and discharge reactions in the LAB.The negative electrode potential will become more positive and the total cell voltage will decrease as the sulfate ion concentration decreases.The right-hand face of the cube in Figure1shows what can happen within the corrosionfilm on the positive plate.At the low potentials seen at the negative plate and shown at the bottom of the diagram,the lead grid is stable.However,at the potentials of the positive plate,the lead grid will slowly oxidize to form the sulfate and oxide species shown in Table4.Which lead(II)species form is controlled by both the hydrogen and the sulfate ion activities in the corrosion film.Tetrabasic lead sulfate,4PbOÁPbSO4,is not stable at room temperature.The lead hydroxide(Pb(OH)2), region of the diagram represents all three lead(II)species shown in Table4.Two lead(II)species,lead(II)hy-droxide and3PbOÁPbSO4ÁH2O,will oxidize under basic conditions to lead tetraoxide at a slightly lower potentialTable4Compounds in the Pb/H2SO4/H2O systemLead PbBasic lead sulfates PbOÁPbSO43PbOÁPbSO4ÁH2O4PbOÁPbSO4Lead(II)oxides Pb(OH)2PbO(red)Higher valence oxides Pb2O3¼PbOÁPbO2Pb3O4¼2PbOÁPbO2PbO2Reproduced with permission from Bullock KR(1980)Effect of anion activity on electrochemical equilibria:Three-dimensional potential-pH diagram for Pb/H2SO4/H2O system.Journal of the Electrochemical Society127:662.−−E(V)3O4Figure1Potential(E)of lead compounds in the positive plate of a lead–acid battery(LAB)as a function of hydrogen and sulfate ion concentrations.Reproduced with permission from Bullock KR(1980)Effect of anion activity on electrochemical equilibria:Three-dimensional potential-pH diagram for Pb/H2SO4/H2O system.Journal of the Electrochemical Society127: 662.Secondary Batteries–Lead–Acid Systems|Positive Electrode593than they will oxidize to lead dioxide.A very small sta-bility region for lead tetraoxide is shown in Figure1. The compound Pb2O3has a very small stability region within the lead tetraoxide region,which is not shown because its equilibrium properties are not well understood.Temperature,acid concentration,and half-cell po-tential all have an effect on the corrosion rate and the materials formed.The highest corrosion rates are at overcharge and open-circuit potentials.Grid Growth and ShortingThe corrosion products shown above are all larger than lead.As they form on the grid,the volume expands and stresses the softer lead underneath.These mechanical stresses deform and expand the grid,causing the active material to lose contact with the current collector.When grid growth becomes excessive,some of the material may fall off the grid.Plate growth sometimes causes shorting if the positive plate expands enough to touch a negative component.The grid may also force the lead connections upward until the top of the battery case breaks.Softer materials such as pure lead or lead–calcium alloys will deform more than the harder lead–antimony alloys.This failure mode is generally found in batteries on a prolongedfloat or trickle current charge,where the grid corrodes at a low level for a very long time.It has been overcome in standby power batteries by grid designs that grow uniformly inward toward the active material rather than away from the material and toward the battery case. This grid design concept wasfirst accomplished in a cylindrical design that was suspended horizontally in the AT&T Round Cell.The grid concept was later extended to a rectangular design by engineers at Bell Laboratories. Shedding of the Positive Active Material and Shorting of the PlatesShedding is a common failure mode in deep discharge cycling applications such as vehicle propulsion or utility load leveling.It is also common in automotive batteries where high discharge rates produce variations in the material usage,acid concentrations,and potentials across the plates.The positive active material increases in size during discharge when lead sulfate is formed and de-creases in size during charge when lead dioxide is formed.These volumetric changes cause mechanical stresses in the plate.The materials gradually break apart and shed off the plate.In aflooded battery,the particles will fall to the bottom of the cell and build up as a layer of lead sulfate. Gas evolution during overcharge or mechanical stirring may cause some of the particles to move to the top and settle on the tops of the plates.If the particles touch the negative plate,they will be reduced to lead and may gradually build a conductive bridge or‘short’between the positive and negative plates.This can lead to rapid discharge and cell failure.Extra space is often designed at the bottom of cells in automotive or deep-cycling applications to prevent shorting by this mechanism.A nonconductive shield is also sometimes placed on top of the plate stack to keep the shed material from settling on the plates.Another cause of material shedding is acid stratifi-cation,with higher concentrations at the bottom of the cell.This generally occurs when aflooded cell is deep cycled with minimal overcharge.The active material in the more concentrated acid at the bottom of the cell will soften and shed,even though the material at the top may remain in good condition.Overcharge to produce gas bubbles that stir the electrolyte can prevent stratification but will accelerate other failure modes,such as grid corrosion,and reduce the energy efficiency of the battery. Moreover,the gas bubbles that form on the plates during overcharge exert large pressures on a microscale that can cause some breakup of the active material.Mechanical circulation of the acid is effective,but increases the cell volume and is therefore not practical in most applications.The most effective way to reduce shedding and shorting is to compress a glass mat or other soft separator material against the positive plate to hold the material in place.Valve-regulated lead–acid batteries that have electrodes tightly compressed against a glass mat separ-ator do not shed,but may have some softening of the active material because of acid stratification.Valve-regulated lead–acid batteries with gelled electrolyte also have less shedding,because the gelled electrolyte reduces acid stratification.Flooded batteries have much better cycle life when good separator systems are used to compress the active material.Loss of Positive Plate Surface Area,Porosity,or Chemical ConductivityShedding and softening of the active material is one source of the loss of positive active material and capacity, as discussed above.Another cause for capacity loss is the formation of large lead sulfate crystals that are difficult to recharge,called‘sulfation’.This failure can occur on either plate.It is caused by discharging the plate to form lead sulfate,and then letting the battery sit in a state of discharge for a time that varies with the temperature. Lead sulfate is an insulator that will recrystallize to form large crystals that do not easily recharge.When the current cannot reach the active material,the plates be-come covered with white lead sulfate crystals,and the porosity of the plate decreases.Long periods of time on open circuit also cause sulfation.594Secondary Batteries–Lead–Acid Systems|Positive ElectrodeBoth mechanisms are accelerated by high tempera-tures.Charging the battery soon after use and periodically recharging it during storage at high ambient temperatures is the best method of preventing this failure mode.Various approaches to recharging this‘hard sulfate’have been proposed.One method is a low current trickle charge with a high voltage cutoff.This allows the voltage to increase to a level that overcomes the plate resistance and slowly recharge the sulfate.This method takes many days to accomplish and will not work if the crystals get too large.Contamination of the Lead Grid,Acid,or Active MaterialMetallic ions and organic materials that accelerate failure sometimes contaminate aflooded battery when water is added to it.Contaminants generally accelerate corrosion, self-discharge,or gas evolution and water loss.Failure by contamination is less of a problem in low-maintenance or VRLA designs if manufacturers maintain good quality control over the materials they use in their manu-facturing processes.Unlikeflooded batteries,water can-not be added to these designs to replace the water lost by gas evolution.Specifications for battery acid and water should be carefully followed.Metal ions such as arsenic and antimony can be re-leased from the lead grid by corrosion processes.They increase cycle life in deep discharge applications,but also accelerate self-discharge and gas evolution with water loss as the battery ages.The concentrations of these materials are usually controlled in VRLA batteries and low-maintenance batteries,which are sensitive to me-tallic impurities that increase gassing rates.Additives Used in Positive Plates and GridsA variety of conductive and nonconductive materials have been suggested as additives to the positive active material to reduce cell weight or extend life.Fillers for plastic–metal composite grids,protectivefilms that would protect the grid from corrosion,and porous,conductive, carbon-foam plates that replace the grid are all under development.These materials must have good stability and conductivity and adhere well to the active materials. The brittleness of the lead dioxide and volumetric changes in its structure during cycling must be con-sidered when new materials are evaluated.The materials must also be electrochemically stable at positive plates in a strong acid environment.Conductive AdditivesLead is a metallic conductor,and lead dioxide is a semiconductor with conductivity up to1000siemens per centimeter(S cmÀ1)at room temperature.Thirty-five percent sulfuric acid has a conductivity of0.8S cmÀ1. Because of the high conductivity of these materials,a fully charged LAB has a resistance of only a few milliohms.Unfortunately,the lead(II)compounds are not so conductive.Lead sulfate is an insulator,and the lead(II) oxides and basic lead sulfates are semiconductors.Before the cell is given itsfirst charge,called‘formation’,battery pastes are mixtures of these materials.Plate formation cannot proceed until a conductive pathway is formed.D.Pavlov and coworkers have shown that in acid solutions,the materials next to the current collector are first converted to conductive lead and lead dioxide. Formation then proceeds toward the center of each pellet.Lead sulfate is the last material to be converted in the formation process.The rate of formation is thus limited by the nonconductive nature of the lead oxide in the positive plate.The capacity of a discharged positive plate that is covered with an insulating layer of lead sulfate crystals is limited by the rate of diffusion of acid to the underlying lead dioxide.The total capacity of the lead dioxide is also limited by the need to maintain a stable,conductive structure in the plate to conduct current from the re-action site to the current collector.If the plate becomes too heavily sulfated,it will be impossible to recharge.Conductive additives that are stable in the positive plate are used to overcome this problem.The ideal additive has a conductivity that is at least as high as carbon,a long-range order to minimize the amount of material needed,and stability within the positive plate during formation.It must also not contaminate or de-grade the battery during subsequent use.Many con-ductive materials oxidize in the positive plate because of its high potentials and the strongly oxidizing properties of lead dioxide and sulfuric acid.A traditional way to enhance the conductivity of the positive plate during formation is to use25–100wt%of red lead which contains lead tetraoxide.When sulfuric acid is added to this oxide to make a paste,the red lead reacts to form lead dioxide and lead sulfate.Plates made of red lead have poor cycle life unless the positive active material is highly compressed.This has limited the use of red lead inflat-plate designs,such as those used for automotive batteries.An alternative is to oxidize the surface to conductive lead oxide with ozone gas or so-lutions of persulfates or peroxides.Much lower quantities of lead dioxide are needed with this approach than when red lead is added to the plate,and the normal battery paste can be used.Carbon is added to the negative plate and has been tested in the positive plate,but it is not generally used in positive plates because it oxidizes to carbon dioxide. Conductive polymers doped with anions or intrinsicallySecondary Batteries–Lead–Acid Systems|Positive Electrode595。

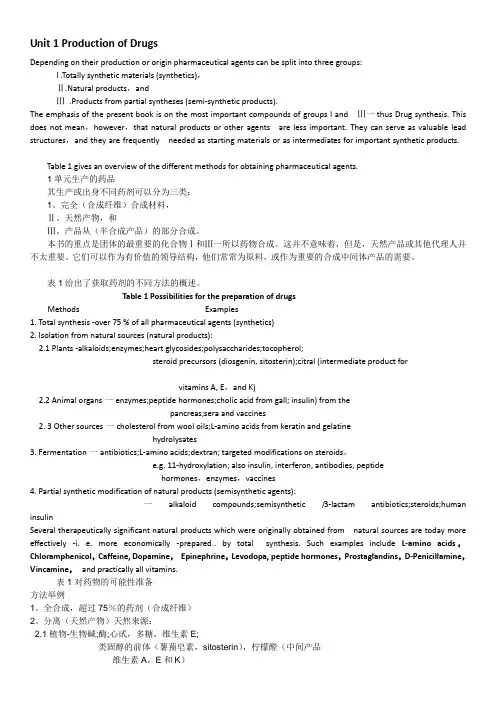

Unit 1 Production of DrugsDepending on their production or origin pharmaceutical agents can be split into three groups:I .Totally synthetic materials (synthetics),Ⅱ.Natural products,andⅢ.Products from partial syntheses (semi-synthetic products).The emphasis of the present book is on the most important compounds of groups I and Ⅲ一thus Drug synthesis. This does not mean,however,that natural products or other agents are less important. They can serve as valuable lead structures,and they are frequently needed as starting materials or as intermediates for important synthetic products.Table 1 gives an overview of the different methods for obtaining pharmaceutical agents.1单元生产的药品其生产或出身不同药剂可以分为三类:1。

完全(合成纤维)合成材料,Ⅱ。

天然产物,和Ⅲ。

产品从(半合成产品)的部分合成。

本书的重点是团体的最重要的化合物Ⅰ和Ⅲ一所以药物合成。

这并不意味着,但是,天然产品或其他代理人并不太重要。

它们可以作为有价值的领导结构,他们常常为原料,或作为重要的合成中间体产品的需要。