Steamturbinemodel (3)

- 格式:pdf

- 大小:1.06 MB

- 文档页数:18

the development of steam power托福阅读

【释义】

the development of steam power

蒸汽动力的发展

【例句】

1With analysis of implement and type selection for steam turbine power supply on LNG ship,the authors forecast the development of new-generation propulsion equipment for LNG ship in future.

作者通过蒸汽轮机动力装置在LNG船上的应用及选型分析,对未来新一代LNG船推进装置的发展趋势进行展望。

2Based on the analysis of two typical turbines(WR-21and GT25000)and other relevant information,the present situation and development trends of naval gas and steam power plants are discussed.

通过二个典型机型(WR-21,GT25000)及其他有关资料的介绍,论述了舰船燃气及蒸汽动力装置的现状与发展趋势。

3With the fast development of the construction in pithead power plant,the large air cooling steam turbine has been widely used in China.

随着我国坑口电站的建设速度加快,大功率空冷机组正成为目前市场的主流产品。

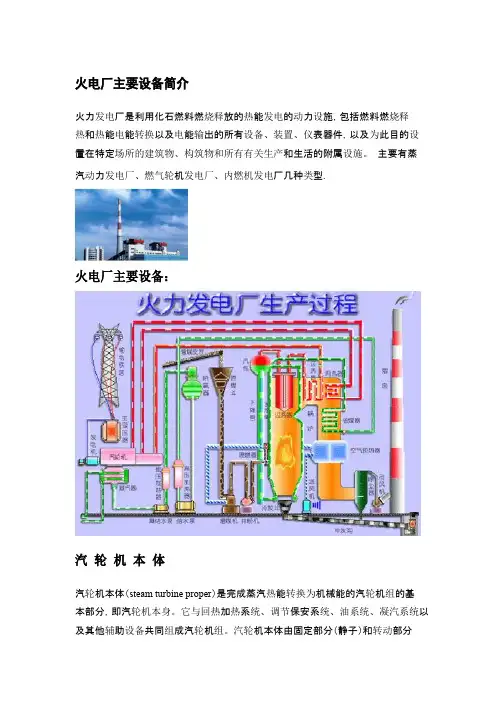

火电厂主要设备简介火力发电厂是利用化石燃料燃烧释放的热能发电的动力设施,包括燃料燃烧释热和热能电能转换以及电能输出的所有设备、装置、仪表器件,以及为此目的设置在特定场所的建筑物、构筑物和所有有关生产和生活的附属设施。

主要有蒸汽动力发电厂、燃气轮机发电厂、内燃机发电厂几种类型.火电厂主要设备:汽轮机本体汽轮机本体(steam turbine proper)是完成蒸汽热能转换为机械能的汽轮机组的基本部分,即汽轮机本身。

它与回热加热系统、调节保安系统、油系统、凝汽系统以及其他辅助设备共同组成汽轮机组。

汽轮机本体由固定部分(静子)和转动部分(转子)组成。

固定部分包括汽缸、隔板、喷嘴、汽封、紧固件和轴承等。

转动部分包括主轴、叶轮或轮鼓、叶片和联轴器等。

固定部分的喷嘴、隔板与转动部分的叶轮、叶片组成蒸汽热能转换为机械能的通流部分。

汽缸是约束高压蒸汽不得外泄的外壳。

汽轮机本体还设有汽封系统。

锅炉本体锅炉设备是火力发电厂中的主要热力设备之一。

它的任务是使燃料通过燃烧将化学能转变为热能,并且以此热能加热水,使其成为一定数量和质量(压力和温度)的蒸汽。

由炉膛、烟道、汽水系统(其中包括受热面、汽包、联箱和连接管道)以及炉墙和构架等部分组成的整体,称为“锅炉本体”。

“热力系统及辅助设备汽轮机部分的辅助设备有凝汽器、水泵、回热加热器、除氧器等。

把锅炉、汽轮机及其辅助设备按汽水循环过程用管道和附件连接起来所构成的系统,叫做发电厂的热力系统。

发电厂的热力系统按照不同的使用目的分为“原则性热力系统”、“全面性热力系统”、汽轮机组热力系统”等。

发电机本体在发电厂中,同步发电机是将机械能转变成电能的唯一电气设备。

因而将一次能源(水力、煤、油、风力、原子能等)转换为二次能源的发电机,现在几乎都是采用三相交流同步发电机。

在发电厂中的交流同步发电机,电枢是静止的,磁极由原动机拖动旋转。

其励磁方式为发电机的励磁线圈FLQ(即转子绕组)由同轴的并激直流励磁机经电刷及滑环来供电。

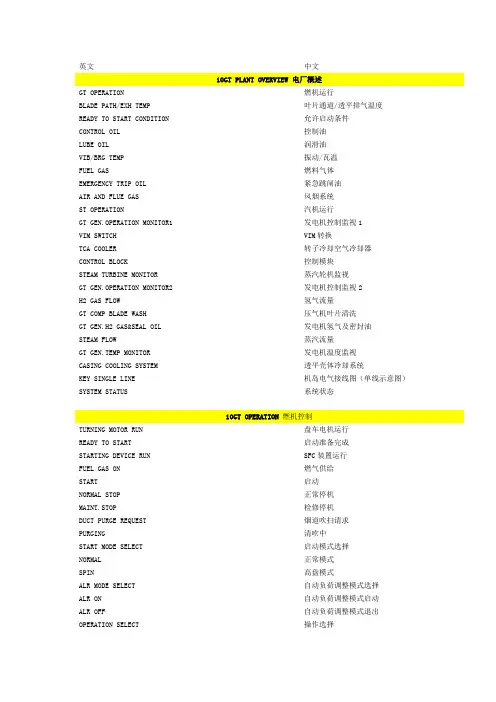

英文中文10GT PLANT OVERVIEW 电厂概述GT OPERATION 燃机运行BLADE PATH/EXH TEMP 叶片通道/透平排气温度READY TO START CONDITION 允许启动条件CONTROL OIL 控制油LUBE OIL 润滑油VIB/BRG TEMP 振动/瓦温FUEL GAS 燃料气体EMERGENCY TRIP OIL 紧急跳闸油AIR AND FLUE GAS 风烟系统ST OPERATION 汽机运行GT GEN.OPERATION MONITOR1 发电机控制监视1VIM SWITCH VIM转换TCA COOLER 转子冷却空气冷却器CONTROL BLOCK 控制模块STEAM TURBINE MONITOR 蒸汽轮机监视GT GEN.OPERATION MONITOR2 发电机控制监视2H2 GAS FLOW 氢气流量GT COMP BLADE WASH 压气机叶片清洗GT GEN.H2 GAS&SEAL OIL 发电机氢气及密封油STEAM FLOW 蒸汽流量GT GEN.TEMP MONITOR 发电机温度监视CASING COOLING SYSTEM 透平壳体冷却系统KEY SINGLE LINE 机岛电气接线图(单线示意图)SYSTEM STATUS 系统状态10GT OPERATION燃机控制TURNING MOTOR RUN 盘车电机运行READY TO START 启动准备完成STARTING DEVICE RUN SFC装置运行FUEL GAS ON 燃气供给START 启动NORMAL STOP 正常停机MAINT.STOP 检修停机DUCT PURGE REQUEST 烟道吹扫请求PURGING 清吹中START MODE SELECT 启动模式选择NORMAL 正常模式SPIN 高盘模式ALR MODE SELECT 自动负荷调整模式选择ALR ON 自动负荷调整模式启动ALR OFF 自动负荷调整模式退出OPERATION SELECT 操作选择COORDINATION ON 协调控制选择COORDINATION OFF 协调控制退出OPERATION MODE SELECT 运行模式选择GOVERNOR 转速控制LOAD LIMIT 负荷限制FUEL GAS CALORIE METER 燃气热值计算仪SFC SELECT SFC选择AGC AND PRIMARY FREQUENCY REGULATION AGC和一次调频AGC ON AGC投入AGC OFF AGC退出PRIM.FREQ.RUGULATION ON 一次调频投入PRIM.FREQ.RUGULATION OFF 一次调频退出FLAME #18/19 ON #18、#19有火焰检测信号LP BLV CLS 低压防喘阀关位MP BLV CLS 中压防喘阀关位HP BLV CLS 高压防喘阀关位RTD SPEED 可并网转速GEN.ON 发电机并网CONTROL MODE SELECTION 控制模式选择BP TEMP 叶片通道温度控制模式EXH TEMP 透平排气温度控制模式FUEL LIMIT 燃料限制模式GT COMP ON-LINE BLADE WASH SELECT 压气机在线水洗控制CPFM 燃烧室压力波动监视ADVANCED CPFM AUTO ADJUSTMENT CONTROL 先进CPFM自动调整控制GAS RESET 天然气复位OIL RESET 油燃料复位EXCLUSION 限制MARGIN LOW 裕量低LOAD HOLD 负荷保持GT LOAD OPERATION 燃机负荷控制ALR SET 自动负荷调整设定GOVERNOR SET 转速调节器设定LOAD LIMIT SET 负荷限制设定OVER SPEED TRIP TEST 超速跳闸试验OST TEST ON/OFF 超速跳闸试验启动/结束MAIN/BACKUP EOST SELECT 主/后备电超速模式选择10GT READY TO START CONDITION准备启动条件AUX READY 辅机准备AUX RUN 辅机运行IGV CLOSE 压气机入口导叶关闭GT SPIN PERMISSIVE(HRSG CONDITION) 燃机高盘允许(锅炉侧条件)LUBE OIL PRESS OK 润滑油压正常AIR FILTER NORMAL 进气滤网正常COMB.BYPASS VLV OPEN 燃烧室旁路阀开位SFC READY SFC准备好CONTROL OIL PRESS OK 控制油压正常GENERATOR READY 发电机正常GEN.H2 READY 发电机氢气系统正常INST AIE PRESS OK 仪用气压力正常CONDENSER VACUUM NORMAL 凝汽器真空正常AUX.BOILER OUT PRESS OK 辅助蒸汽供给压力正常GT TRIP RESET(SPIN) 燃机跳闸复位(高盘模式)RE-START OK 重启动允许CASING METAL DIFF TEMP OK(SPIN) 壳体金属温差正常(高盘模式)GT TRIP RESET(NORMAL) 燃机跳闸复位(正常模式)FLAME OFF 无火焰信号IGNITER AVAIL 点火装置可用CASING METAL DIFF TEMP OK(NORMAL) 壳体温差正常(正常模式)GAS LEAK NON.ALARM 燃气泄露无报警HRSG READY 余热锅炉准备好TCA COOLER READY TCA冷却器准备好GT EXH.DUCT NO PURGE RQ 燃机排烟通道无清吹请求指令ST RTS OK 汽机启动准备已完成FUEL GAS PRESS OK 燃料压力正常GAS CONTROL VLV NORMAL 燃气控制阀正常FGH READY 燃气加热器正常10GT BLADE PATH/ EXT TEMP DIAGRAM叶片通道/排烟温度画面BLADE PATH TEMP 叶片通道温度VARIATION 偏差EXHAUST TEMP 排气温度AVG 平均值COMB.BYPASS VLV 燃烧室旁路阀开度COMP.IN TEMP 压气机进口温度COMP.OUT.TEMP 压气机出口温度COMB.PRESS 燃烧室压力BLADE PATH TEMP VARITION 叶片通道温度偏差COMB.SHELL PRESS RATIO 燃烧室壳体压比RANGE SELECT 范围选择FLAME 火焰10GT VIBRATION/BEARING TEMP DIAGRAM振动/瓦温画面EXCITER 励磁机DRAIN TEMP 轴承回油温度METAL TEMP 瓦温10GT CONTROL OIL DIAGRAM控制油画面CLOSED COOLING WATER 闭式冷却水DP HIGH 滤网压差高CONTROL OIL RETURN FILTER 控制油回油滤网CONTROL OIL RESERVOIR 控制油箱CONTROL OIL CLEANING UNIT 控制油净化装置CONTROL OIL PUMP 控制油泵COP SELECT 控制油泵首选选择CONTROL OIL SUPPLY FILTER 控制油供油滤网PRESS HIGH 压力高SERVO VALVE 伺服阀EMG.OIL LINE 安全油管路HPCV 高压主蒸汽控制阀HPSV 高压主蒸汽关断阀IPCV 中压主蒸汽控制阀IPSV 中压主蒸汽关断阀LPCV 低压主蒸汽控制阀LPSV 低压主蒸汽关断阀BYPASS FB 燃烧室旁路开度反馈FG PILOT FLOW CV 燃料模块值班燃料流量控制阀FG MAIN A/B FLOW CV 燃料模块主燃料流量A/B控制阀FG POTHAT FLOW CV 燃料模块顶环燃料流量控制阀FG MAIN A/B PRESS CV 燃料模块主燃料A/B压力控制阀10GT EMERGENCY TRIP OIL DIAGRAM紧急跳闸油画面CONTROL OIL TANK 控制油油箱MANUAL TRIP VALVE 手动跳闸按钮TRIP SV TEST 跳闸伺服阀试验10GT LUBE OIL DIAGRAM润滑油画面LUBE OIL RESERVOIR 润滑油箱MAIN LUBE OIL PUMP 主润滑油泵LUBE OIL HEATER 润滑油加热器EOP 直流润滑油泵LUBE OIL CLEANING UNIT 润滑油净化装置OIL MIST SEPARATION 油烟分离器LUBE OIL MIST VAPOR EXTRACTOR 润滑油排油烟风机LOP SELECT 润滑油泵预选GT LUBE OIL COOLER 燃机润滑油冷却器COOLING WATER SUPPLY 冷却水进水COOLING WATER RETURN 冷却水回水LUBE OIL TEMP CV 润滑油温度控制阀LUBE OIL REGULATING VALVE 润滑油压力调整阀DC JACKING OIL PUMP 直流顶轴油泵AC JACKING OIL PUMP 交流顶轴油泵TURNING CEAR MOTOR 盘车马达运行THRUST 推力轴承10GT FUEL GAS DIAGRAM燃气画面FUEL GAS 燃料气体GT FG FLOW METER 燃机燃气流量计FG EMERGENCY VENT VLV 燃气紧急放散阀FG TEMP CV 燃气温度控制阀FUEL GAS HEATER 燃气加热器DRAIN LEVEL 疏水液位IP CEO 中压省煤器FGH INLET ISOL VLV 性能加热器进水隔离阀FGH FEED WATER FLOW CV (COND SIDE) 性能加热器给水流量控制阀(凝汽器侧)COND DUMP 回凝气器FGH FEED WATER FLOW CV (HRSG SIDE) 性能加热器给水流量控制阀(锅炉侧)) FG INLET FILTER 燃料进气滤网DIFF PRESS 滤网差压FG SHUT OFF VLV 燃气关断阀FG SUPPLY PRESS .CV 燃气供给压力控制阀FG VENT VALVE 燃气放散阀FG PILOT FLOW CV 燃气值班流量控制阀FG MAIN FLOW CV 燃气主流量控制阀FG TOPAHT FLOW CV 燃气顶环流量控制阀INSTRUMENT AIR 仪用气FG NOZZLE PURGE AIR SHUT OFF VALVE 燃气喷嘴清吹空气关断阀FG TOPHAT NOZZLE PURGE AIR SUPPLY 燃气顶环喷嘴吹扫空气供给阀FG MAIN NOZZLE PURGE AIR SUPPLY 燃气主喷嘴吹扫空气供给阀FG PILOT NOZZLE PURGE AIR SUPPLY 燃气值班喷嘴吹扫空气供给阀PILOT 值班TOPHAT 顶环GT COMB.20 SECTION 燃机20个燃烧室部分GT PKG VENT FAN GAS DETECT LEVEL 燃机罩壳风机泄漏气体浓度GT FG UNIT GAS DETECT LEVEL 燃料单元泄漏气体浓度10GT AIR AND FUEL GAS SYSTEM DIAGRAM 空气及燃气系统画面AMBIENT TEMP 环境温度BAROMETIRC PRESS 大气压力INSTRUMENT AIR PRESS 仪用空气压力AMBIENT HUMIDITY 环境湿度R.C.A TEMP 转子冷却空气温度D.C TEMP 轮盘间隙温度BRG.SEAL AIR PRESS 轴承密封空气压力R.C.A TEMP AVG 转子冷却空气温度平均值D.C TEMP AVG 轮盘间隙温度平均值P.CASING METAL TEMP 燃兼压缸金属温度TUMB.CASING METAL 透平壳体金属温度FAN SELECT 风机预选GT PACKAGE VENT FAN 燃机罩壳风机GT PKG VENT FAN DIFF PRESS 燃机罩壳风机压差GT FG UNIT VENT FAN 燃料模块通风风机GT FG UNIT VENT FAN DIFF PRESS 燃料模块通风风机压差AIR FILTER DIFF PRESS 进气滤网差压AIR FILTER INSIDE PRESS 进气滤网内侧压力COMP.BLADE WASHING UNIT 压气机叶片水洗模块INDEX DIFF PRESS 压差指数INLET MANIF.STATIC PRESS 进气总管静压GT COOLING AIR DRAIN VLV TCA冷却器气侧疏水阀EXH GAS DUCT GAS DETECT LEVEL 排气通道气体泄漏检测浓度10GT CONTROL BLOCK DIAGRAM 控制模块画面SPEED CONTROL SPREF 速度控制指令LOAD CONTROL LDREF 负荷控制指令TEMP CONTROL BPREF 温度控制指令FUEL LIMIT 负荷限制指令IGV CONTROL IGVREF IGV开度指令BYPASS VALVE CONTROL BYREF 燃烧室旁路阀控制指令GVCSO 转速控制输出指令LDCSO 负荷控制输出指令BPCSO 叶片通道控制输出指令EXCSO 排气控制输出指令FLCSO 流量限制控制输出指令IGVCSO IGV控制输出指令BYCSO 旁路控制输出指令MFCSO 主燃料控制输出指令MFCLCSO 先导燃料控制输出指令FUEL GAS DISTRIBUTION 燃料分配DEMAND 指令FEEDBACK 反馈FLAME VOLTAGE 点火电压FUEL GAS SUPPLY PRESS CONTROL PRESS REF 燃气供给压力控制阀压力控制指令FUEL GAS SUPPLY TEMP CONTROL TEMP REF 燃气供给温度控制阀温度控制指令FUEL GAS SUPPLY PRESS CV OUTLET PRESS 燃气供给压力控制阀后压力FUEL GAS SUPPLY PRESS CV OUTLET TEMP 燃气供给温度控制阀后温度CALORIE METER 热值仪DENSITY 密度LHV 低位热值PL RATION BIAS 值班燃料变化偏差TH RATION BIAS 顶环燃料变化偏差BV BIAS 燃烧室旁路阀变化偏差10GT GENERATION OPERATION MONITOR1 发电机控制监视1 REACTIVE POWER 无功功率LEAD 超前LAG 滞后GENERATION OUTPUT 发电机输出功率10GT GENERATION OPERATION MONITOR2 发电机控制监视2 GEN.CONTROL 发电机控制模式GEN.SYN.MODE 发电机同期并网模式AVR MODE 自动电压控制模式VOLTAGE CONSTANT 电压恒定模式FIELD CONSTANT 励磁恒定模式PSS MODE 电力系统稳定控制器模式APFR MODE 自动功率因数调整模式GEN.VOLTAGE CONTROL 发电机电压控制TO SWITCH YARD LINE 至厂级母线开关MAIN TR 主变压器GMCB 发电机主断路器UNIT AUX TR 机组厂用变UNIT BOARD 厂用电母线TO SFC HARMONIC FILTER 至SFC谐波滤波器ECS 励磁控制系统EXC TR 励磁变压器OTHER UNIT BOARD 其他机组厂用电母线USED FOR OTHER UNIT 其他机组用SFC SELECT SFC选择REACTIVE POWER 无功功率GEN.VOLTAGE 发电机定子电压GEN.CURRENT 发电机定子电流POWER FACTOR 功率因数FREQUENCY 频率FIELD VOLTAGE 励磁电压FIELD CURRENT 励磁电流GEN.ROTOE TEMP 发电机转子温度10GT GENERATION TEMPERATURE MONITOR 发电机温度监视S.R.OUTLET AIR TEMP 碳刷小室出口空气温度S.R.INLET AIR TEMP 碳刷小室进口空气温度GEN.COLD GAS TEMP 发电机冷氢温度GEN.WARM GAS TEMP 发电机热氢温度GAS PURITY 氢气纯度GAS PRESS 氢气压力EXCITER END 励磁端TURBINE END 透平端DRAIN OIL TEMP 回油温度GEN.STATOR TEMP 发电机定子温度WINDING 定子线圈温度CORE 定子铁心温度10GT GENERATION H2 GAS/SEAL OIL MONITOR 发电机氢气/密封油监视S.R.HOUSING SPACE HEATER 碳刷小室空间加热器SEAL OIL PUMP 密封油泵SEAL OIL COOLER 密封油冷却器EMERG.SEAL OIL PUMP 事故密封油泵VACUUM TANK 真空密封油箱HYDROGEN DRAIN REGULATOR 排氢调节油箱LOOP SEAL TANK 循环密封油箱VAPOR EXTRACTOR 密封油排油烟风机VACUUM PUMP 密封油真空泵BEARING OIL SUPPLY 轴承滑油供给MIAN OIL TANK 主油箱10GT GENERATION H2 GAS FLOW 发电机氢气流量LIQUID DETECTOR 发电机回油液位检测H2 GAS PRESS./PURITY MONOTORING UNIT 氢气压力/纯度监视单元H2 GAS DRYER 氢气干燥机H2 GAS SUPPLY UNIT INLET PRESS LOW 氢气供给模块进气压力低10GT COMPRESSOR BLADE WASHING SYSTEM 压气机叶片水洗系统GT ON-LINE WASHING SUPPLY VALVE 燃机在线水洗供给阀GT ON-OFF WASHING SUPPLY VALVE 燃机离线水洗供给阀DEMINERALIZED WATER 除盐水COMPRESSOR BLADE WASHING TANK 压气机叶片清洗水箱ORIFICE 节流孔板GT BLADE WASHING DRAIN PIT 燃机叶片水洗疏水坑燃机壳体冷却系统GT CASING COOLING AIR SHUT OFF VALVE 燃机壳体冷却空气关断阀TO FUEL GAS NOZZLE PURGE AIR 至燃气喷嘴吹扫空气GT TURBINE CASING METAL TEMP 燃机壳体金属温度10GT TCA COOLER DIAGRAM TCA冷却器画面COMPRESSOR DISCHARGE 压气机排气DP BALANCE VALVE FOR BFP MIN.FLOW 给水泵最小流量压差平衡阀GT COOLING AIR 燃机冷却空气GT COOLING AIR COOLER 燃机冷却空气冷却器HP BFP 高压给水泵TCA COOLER FW FCV(COND SIDE) TCA冷却器给水控制阀(凝汽器侧)CONDENSER 凝汽器HP ECO INLET MODULATING VALVE 高压省煤器进水调整门10ST OPERATION 汽机控制ST START MODE 汽机启动模式START CONDITION ESTABLISH 启动条件满足ST LOAD UP COMPLETED 汽机加载完毕ST STATUS 汽机状态STRESS CONTROL MODE 应力控制模式ROTOR THERMAL STRESS 转子热应力EXTRACTION MODE 供热模式HP/IP PRESS CONTROL MODE 高/中压应力控制模式LP PRESS CONTROL MODE 低压应力控制模式VALVE OPERATION 主汽阀控制HP/IP/LP VALVE TEST 高中低主汽阀试验10ST STEAM TURBINE MONITOR 蒸汽透平监视SHAFT ECCENITRICITY 轴偏心度HP.T.SHELL/ROTOR DIFF.EXPANSION 高压缸胀差LP.T.SHELL/ROTOR DIFF.EXPANSION 低压缸胀差HP.CASING EXPANSION 高压缸膨胀值ST ROTOR POSITION 汽机转子轴向位移HP STOP VALVE INNER METAL TEMP 高压隔离阀内部金属温度HP STOP VALVE OUTER METAL TEMP 高压隔离阀外部金属温度HP CONTROL VALVE INNER METAL TEMP 高压控制阀内部金属温度HP CONTROL VALVE OUTER METAL TEMP 高压控制阀外部金属温度HP TURBINE INLET STEAM TEMP 高压缸进口蒸汽温度HP TURBINE INLET METAL TEMP 高压缸进口金属温度HIP TURBINE OUTER CASING METAL TEMP 高中压缸外部壳体金属温度IP SIDE UPPER/IP SIDE LOWER 中压缸上部/下部HP SIDE UPPER/HP SIDE LOWER 高压缸上部/下部HIP TURBINE ENDWALL METAL TEMP 高中压缸端壁金属温度IP TURBINE EXHAUST STEAM TEMP 中压缸排汽温度IP CONTROL VALVE INNER METAL TEMP 中压控制阀内部金属温度IP CONTROL VALVE OUTER METAL TEMP 中压控制阀外部金属温度IP TURBINE BLADE RING METAL TEMP 中压缸叶片环金属温度IP EXHAUST UPPER/IP EXHAUST LOWER 中压排汽缸上部/中压排汽缸下部HIP TURBINE CASING FLANGE METAL TEMP 高中压缸壳体法兰金属温度HIP TURBINE CASING BOLT METAL TEMP 高中压缸壳体螺栓金属温度LP TURBINE EXHAUST FLOW GUIDE METAL TEMP 低压缸胀差LP TURBINE LAST STAGE STATIONARY BLADE METAL TEMP 低压缸末级叶片金属温度LP TURBINE EXHAUST TEMP 低压缸排汽温度LP TURBINE GLAND STEAM TEMP 低压缸轴封蒸汽温度LP TURBINE INLET STEAM TEMP 低压缸进口蒸汽温度CONDENSER VACUUM 凝汽器真空HP TURBINE INLET STEAM PRESSURE 高压缸进气蒸汽压力IP TURBINE EXHAUST STEAM PRESSURE 中压汽轮机排汽压力10ST STEAM FLOW 汽机蒸汽流量LP EXTRACTION 低压抽汽IPSV PRESSURE BALANCE SHUT-OFF VALVE 中压主汽阀压力平衡关断阀HRSG REHEATER 余热锅炉再热器CAL FLOW 计算流量ACT FLOW 实际流量10GT KEY SINGLE LINEMCC INCOMING LINE-1 CURRENT MCC进线电流MCC BUS SECTION VOLTAGE MCC母线电压EMCC BUS VOLTAGE EMCC母线电压110V DC DISTRUBUTION BUS VOLTAGE 110V直流分配母线电压UPS DISTRUBUTION BUS VOLTAGE UPS分配母线电压操作框SV INC INH 阀门控制指令闭锁增SV DEC INH 阀门控制指令闭锁减。

This PDF offers an advanced interactive experience.For the best viewing experience, please use Acrobat Reader X or higher.Siemens Steam TurbineSST-300Version /steamturbinesPower diagnostics center Expert network teamreportsknow-how infoData analysis MonitoringDomain knowledgeUse of advanceddiagnostic tools and techniquesEngineering know-howdataadvanced informationoptimizationproposalsreportsOnline diagnosticsOffline diagnosticsAnomaly detectionpower plantPower diagnostics center Expert network teamreportsknow-howinfo Data analysisMonitoringDomain knowledgeUse of advanceddiagnostic tools and techniques Engineering know-howdataadvancedinformation optimization proposals reportsOnline diagnosticsOffline diagnosticsAnomaly detection54321Option of remote monitoringAs all SST-300 are provided with remote monitoring, Siemens offers service contracts for condition-based maintenance, customized for the specific operating status of each machine to reduce outage and overhaul costs.Using the remote monitoring technology, customers are able to get fast telephone assistance and secure remote support, online help, advanced troubleshoot-ing and intervention, provided by specialists personnel who are familiar with the plant’s design and under-stand its operation.Additionally, we offer comprehensive spare-part ser-vice, repairs and maintenance solutions designed to increase the reliability and availability of the plant. Our retrofit solutions return turbines to the state of the art even after a normal operating life. Long-term mainte-nance contracts assure prolonged plant operation at predefined costs.Example for arrangements:SST-300 with downward radial exhaust[5] Exhaust[4] Base frame [3] Gearbox[2] Rotor and reaction blading[1] Turbine casingSST-300 size 40• Power output: up to 25 MW • Speed: up to 10,950 rpm•Controlled extractions possible (single or double, adaptive stage, nozzle control, throttle control)*all data are approximate and project-relatedTechnical dataSST-300 size 50• Power output: up to 45 MW • Speed: up to 9,004 rpm•Controlled extractions possible (single or double, adaptive stage, nozzle control, throttle control)Uncontrolled extractions (up to 5):• Pressure up to 70 bar(a) / 1016 psi •Temperature 450°C / 842 °FControlled extractions (up to 2) • Pressure up to 25 bar(a) / 363 psi •Temperature 390°C / 734 °FLive steam conditions (ESV inlet):• Pressure up to 140 bar(a) / 2031 psi •Temperature 540°C / 1004 °FExhaust steam pressure:• Back pressure up to 16 bar(a) / 232 psi • District heating up to 3 bar(a) / 43 psi •Condensing up to 0.5 bar(a) / 7 psiUnit solutionThe unit solution consists of the simple base frame for steam turbine (only core turbine is placed on it), oil-type base frame for gearbox, and generator which is placed directly a concrete foundation.Semi package solutionThe semi package solution consists of only one base frame with integrated oil unit, carrying tur-bine and gearbox; but the generator is directly placed on concrete.Full package solutionThe full package solution consists of only one base frame with integrated oil unit, carrying the turbine, gear box, and generator.65432 1Switch to printable overview[5] New York, USA[4] Aberdeen, USA[3] Mielec, Poland[2] Irvine, UK [1] Lincoln, UKThis new facility (in operation since 2014), commissioned by Lincolnshire County Council, built by CNIM and oper-ated by FCC Environment Ltd, provides a safe, sustainable and affordable waste treatment solution to dispose of household waste, with a useful and profitable by-product – electricity.It burns 150,000 t of waste a year and has an electrical power output of 15.25 MW and a heat power of 10 MW.Lincolnshires´s Energy from Waste FacilityLincoln, UKSteam turbine: SST-300Power output: 15.25 MW Speed: 6,800 rpmLive steam pressure: 58 bar / 841 psi Live steam temperature: 397° C / 746° F Exhaust steam pressure: 0.07 bar / 1 psiwatch video online[6] Phukhieo, Chaiyaphum, ThailandE–mail:**************************。

考试指南详解I. 阅读理解1. 模拟试题Model Test 1Passage 1主题:任何年龄我们都可能犯错误......1. 他感觉到没能完全理解他朋友的真实感觉2. 有时候这些文字表明说话者有点嫉妒3. 我们犯的错既不是为钱也不是为人4. 避免误会别人的意思5. 并非所有的人Passage 2主题:孩子的吸烟问题......6. 他感觉到没能完全理解他朋友的真实感觉7. 有时候这些文字表明说话者有点嫉妒8. 我们犯的错既不是为钱也不是为人9. 避免误会别人的意思10. 并非所有的人Passage 3略Passage 4主题:剑桥大学......16. 因为整个城市都是大学17. 他们挑选自己的学生18. 有很多特别的图书馆19. 这篇文章没有告诉我们20. 直到1948年他们才开始授予学位模拟试题Model Test 2Passage 1主题:驾车前排座位安全问题...... 1. 警察报告2. 减少交通事故的死亡率3. 让14周岁以下的孩子系上安全带4. 倒车入库的人5. 由于健康的原因不系安全带Passage 2主题:私立学校......6. 不一定比公立学校好7. 私立学校的学校环境很安静8. 公立学校不开设宗教课程9. 特别的校服10. 大部分的美国孩子自由发展Passage 3主题:动物和植物对环境的适应......11. 比别的更适应环境12. 周围环境13. 适应环境14. 某种活的生物适应其睡眠习惯15. 某种生物能为自己创造环境Passage 4主题:铁路......16. 质量糟糕的铁路和不可靠的刹车系统17. 给西部带来了工业和农业的快速发展18. 洲际铁路线:生命线19. 7年20. 需要把东西部连接起来模拟试题Model Test 3Passage 1主题:中学生地理知识调研......1. 研究人与社会群体2. 一半来自巴蒂魔的学生不能在地图上标识美国3. 社会学习有助于帮助学生做一个好的市民4. 来自1916念得报告清楚表明5. 以前的调研报告Passage 2略Passage 3主题:气候......11. 气候12. 恐龙的死亡13. 更冷14. 例子15. 山顶Passage 4主题:感冒......16. 流感17. 病毒18. 伴着人一生的19. 一步步蔓延扩张20. 抗病毒的蛋白质模拟试题Model Test 4Passage 1主题:生态平衡......1. 对生态平衡的破坏是由于化学所致的争辩2. 科学家们预期DDT长期影响3. 把帮助农民的益虫也杀死了4. 对于他来说虫害更为严重5. DDT能控制所有的害虫Passage 2主题:无线电的用途......6. 电视是一种无线电7. 海上船只互相传递信息8. 现代的无线电技术可用于海上,空中和陆地9. 很容易携带10. 无线电的用途Passage 3主题:两个弱智儿童的生活......11. 安娜的生活条件很差12. 形成了一些好习惯更冷13. 不仅跟母亲还跟所有的家庭成员们隔绝14. 学得很慢15. 过着正常的生活Passage 4主题:公共利益法......16. 当事人17. 付钱很少或者不付18. 不公平19. 刑事案件和民事案件20. 一个窃贼被抓捕模拟试题Model Test 5Passage 1主题:孩子的时间观念问题......1. 家长不太懂如何教给孩子时间问题2. 孩子们如果知道如何识别时间会准时3. 劣势4. 分针和时针5. 制作成孩子们不容易损坏的 Passage 2主题:污染......6. 对在这个国家的生活不满意7. 不现实8. 城市9. 城市生活条件需要改进10. 他们的收入Passage 3略Passage 4主题:历史上的考试......16. 考试多为口语表达17. 现代的考试多为书写和限时的18. 反对态度19. 大约19世纪20. 从中世纪以来考试的改变2. 阅读专项练习Passage 1美国与英国小孩上学的年龄情况,公立学校及私立学校的差别1. 五岁2. 免费3 留级4. 包含公立学校和私立学校5. 班里有分组一起讨论学习Passage 2 动物和人的差别1. 以上三种都包含2. 有些动物两只眼睛会分别看到不同的画面3. 大脑4. 人类可以使用手、眼睛和大脑的智慧同时运作来处理事情5. 不平稳的Passage 3略Passage 4 一个男人在美国的经历1. 在中心公园与朋友见面2. 他以为后面那个是小偷3. 他认为那个人很可能又跟着他跑4. 他认为他找到了犯罪人5. 第一个头了第二个的五元钱Passage 5年轻人第一次找工作1. 在大学里学的东西无法满足新的生活需求)2. 发生,出现3. 找一个你尊敬的人,仔细观察他在不同情况时的行动4. 做事的方法5. 从一个案例中学来的Passage 6电视节目1. 在公告版上做广告2. 给作者一些关于写长巴士旅行的意见)3. 一路上没有指示牌4. 他们都有开始,中间和结尾,其中为商业5. 令人兴奋的)Passage 7 在过去的500年......1、食物2、一些商店3、土豆收获不好4、埃塞俄比亚5、阿拉伯人是最开始制造咖啡这种饮料的Passage 8 奥运会1、因为真正的问题是怎么样才可以参加奥林匹克2、希腊队是第一个3、运动员来自很多的国家4、田径赛事5、在1900 年Passage 9 挑战俱乐部1、62、在教练的指导下集中训练3、集中训练的项目4、它可以增加财政收入5、反对的Passage 10 某人开发电脑游戏一年可以赚35000)1、 因为他可以赚到相当高的薪水2、 把薪水收入的钱花掉3、 他编写过一些电脑程序4、他想使用电脑工作,呆在学校不能帮助他5、因为他认为电脑游戏不可能一直畅销下去 Passage 11A (睡觉)D (有时候去散步)C(他们自己)D(频繁)B(保持梦游者安全)Passage 12B(方法)A(深海上航行)C(更多的货物)A(海洋勘探)B(水手王子) Passage 13D(退休问题)D(新的生意)A(价值)B(读者)D(说明)Passage 14C (学院)A(不考虑)B(问题)C(自豪)B(伎俩失败)Passage 15C(病人)D(清洁工)B(严格的规则)A(姐妹)C (聪明)Passage 16B (消失)A (很多人)C(慢性孤独)A(严重的疾病)B (身体问题)Passage 17B(全国)A (著名论文)B(本地事件)D(吸引读者)B(影响政策)Passage 18D(戒烟)D(人的生活)C(肉体上的痛苦)C(学生)A(笑是最好的药)Passage 19C (想清楚)D(无力)C(一个真正的问题)A(焦虑)B (加利福尼亚)Passage 20D (开始工作)B (超市)D(工作)C (更难)B(账户)Passage 21 童年最重要的事情Is interested(感兴趣)stimulate(激发,鼓舞)exercising their imagination(锻炼他们的想象力)from his toys(从玩具中)amusement(娱乐)Passage 22 穿衣......worn inside(穿在里面)in America(在美国)long wearing(常穿)cotton(棉的)a variety(一个品种)Passage 23waking up(醒来)accident(意外broken window(坏窗子)river(河)two kids(两个孩子)Passage 24 发明单词Solved(解决)communicate(沟通)simply sounds(简单的声音) tears(流泪)ordinary(普通)Passage 25Understand (明白)output(输出)advantage(优势)development(发展)economic growth(经济增长) Passage 26 mixed-ability综合素质 Approving(赞成的)advancing(推进)total personality(整体人格) organization(组织)same class(相同班级)Passage 27to grow成长lack of space缺乏空间attitude态度considerably相当的not very higher不是很高 Passage 28 animals动物Good for them对它们是好的flavored调味cultural customs文化习俗surroundings环境balanced diet均衡的饮食Passage 29Requirements需求background背景very young非常年轻psychological 心理changed altogether完全改变Passage 30becoming busier越来越忙hold out stress抵制压力different amount不同数量remove转移cope对付Passage 311. A 一个毫无负担的大城市。

汽轮机组主油泵出口油压波动原因分析发布时间:2022-02-15T02:40:50.054Z 来源:《中国科技人才》2021年第28期作者:孙海山袁国栋王源王鸿亮[导读] 主油泵出口油压的波动严重时会造成调节系统摆动、轴承断油、故障停机等严重后果。

山西华兴铝业有限公司摘要:主油泵是汽轮机设备的一个重要组成部分,其作用为1、向机组各轴承供油,润滑和冷却轴承,2、供给调速系统和保护装置稳定充足的压力油。

主油泵出口油压的波动严重时会造成调节系统摆动、轴承断油、故障停机等严重后果。

文章从人为误操作、热工仪表故障、电网频率波动、滤油器滤网堵塞、射油器故障、油系统泄漏、油箱油位过低、主油泵故障8个方面对主油泵出口油压波动进行了分析,提出了相应的措施。

关键词:汽轮机组;主油泵出口油压波动;原因Analysis of oil pressure fluctuation at the outlet of main oil pump of steam turbine unit Sun HaishanThe main oil pump is an important part of the steam turbine equipment. Its function is 1. Supply oil, lubrication and cooling bearings to the bearings of the unit. 2. Supply stable and sufficient pressure oil to the speed governing system and the protection device. Serious fluctuation of the oil pressure at the outlet of the main oil pump will cause serious consequences such as swing of the regulating system, oil cut-off of the bearing, failure of the machine,etc..This paper analyzes the fluctuation of the oil pressure at the outlet of the main oil pump from eight aspects: Human Error Operation, the malfunction of the thermal instrument, the fluctuation of the frequency of the power network, the blockage of the oil filter, the malfunction of the oil ejector, the leakage of the oil system, the low oil level of the oil tank and the malfunction of the main oil pump, the corresponding measures are put forward.Key Words:Steam Turbine Unit; main oil pump outlet oil pressure fluctuation; Reason主油泵是蜗壳型双吸离心泵,装在前轴承座中的汽轮机转子上,由汽轮机主轴直接驱动,且与汽轮机主轴采用刚性连接。

汽轮发电机:паротурбинный генератор汽轮机、蒸汽涡轮:паровая турбина背压、反压力:противодавлениеI Power station电站1. power station电站2. power plant电站,发电设备3. utility电力部门4.independent power producer (IPP)独立发电项目,独立发电站5.nuclear power station核电站6. thermal power station火电站7. fossil (fired) power plant化石燃料电站,常规火电站8. combined heat power (CHP) plant热电联供机组9. steam power plant蒸汽电站,蒸汽发电设备10. cogeneration power station热电联供电站11. coal fired power plant燃煤电站12. oil fired power plant燃油电站13. gas filed power plant燃气电站14. LNG power plant (liquefied natural gas)燃液化天然气电站15. BoP (balance of plant)电站辅机16. I&C (instrumentation and control)仪表和控制系统II Turbine透平,涡轮17. Turbine透平,涡轮18. steam turbine汽轮机19. gas turbine燃气轮机20. nuclear turbine核电汽轮机21. fossil turbine火电汽轮机22. industrial turbine工业透平23. cogeneration turbine热电联供透平24. condensing turbine凝汽式汽轮机25. back pressure turbine背压式汽轮机26. extraction turbine抽汽式汽轮机27. extraction condensing turbine抽汽凝汽式汽轮机28. single-extraction turbine单抽汽轮机29. double-extraction turbine双抽汽轮机30. mechanical drive turbine机械驱动汽轮机31. HP (IP, LP) turbine高(中、低)压缸32. sub-critical pressure turbine亚临界汽轮机33. super-critical pressure (SC) turbine 超临界汽轮机34. ultra-super critical (USC) pressure turbine超朝临界汽轮机35. BFPT (boiler feed pump turbine)给水泵汽轮机36. steam turbine with air-cooled condenser(air cooled steam turbine)空冷汽轮机37. reheat turbine再热汽轮机38. double-reheat turbine二次再热汽轮机39. wet steam turbine湿蒸汽汽轮机40. saturated steam turbine饱和蒸汽汽轮机41. full-speed turbine全速汽轮机42. half-speed turbine半速汽轮机43. tandem compound turbine单轴汽轮机44. cross compound turbine双轴汽轮机45. super (over)-high pressure turbine过高压汽轮机46. impulse (type) turbine冲动式汽轮机47. reaction (type) turbine反动式汽轮机48. axial flow turbine轴流透平49. radial flow turbine径流透平50. turbine with axial condenser轴向排汽汽轮机51. turbine with horizontal joint带有水平中分面的汽轮机52. turbine with vertical joint带有垂直中分面的汽轮机53. double flow turbine两排汽汽轮机54. triple flow turbine三排汽汽轮机56. single-casing turbine单缸汽轮机57. double-casing turbine双缸汽轮机58. turbine proper汽轮机本体59. oil turbine 油透平60. hydraulic turbine水轮机61. marine steam turbine船用汽轮机62. aeroderivative gas turbine航改式燃气轮机63. stationary steam turbine电站汽轮机64. auxiliary turbine辅助透平III Rotary parts回转件65. rotor转子66. rigid rotor刚性转子67. flexible rotor挠性转子68. solid (forged) rotor (monobloc rotor)整锻转子69. welded rotor焊接转子70. (hollow) drum (type) rotor鼓型转子71. built-up rotor组装转子72. rotor without center bore无中心孔转子73. HP-LP integrated rotor高/低压一体化转子74. shafting (shaft)轴系75. HP (IP, LP) rotor高(中、低)压转子76. thrust collar推力盘77. journal轴颈78. section of rotor转子区段79. (first, second ) critical speed一阶(二阶)临界转速80. extension shaft (spacer)中间轴,延伸段81. coupling联轴节82. flexible coupling挠性联轴节83. rigid coupling刚性联轴节84. semi-flexible coupling半挠性联轴节85. half coupling联轴节半部86. integral (forged) coupling整体(锻制)联轴节87. shrunk-on coupling红套联轴节88. spigot(rabbet)止口89. disk (disc) 叶轮90. rim (steeple)轮缘(枞树型叶根槽)91. hub轮毂92. body(web)轮体93. T (fir tree-type ) groove T型(枞树型)叶根槽94. balance hole (plane, weight, plug)平衡孔(平衡平面,平衡配重,平衡旋塞)95. keyway键槽96. disk of constant stress (conical profile)等强度(锥形)叶轮97. disk of constant thickness等厚度叶轮98. shrunk-on disk红套叶轮99. blade叶片100. moving (rotating, rotor) blade动叶101. bucket 动叶102. straight (tapered, twisted) blade直叶片(变截面叶片,扭曲叶片)103. last stage (last but one, penultimate) blade末级叶轮(次末级叶片)104. last (locking , gate) blade (piece)末叶片(锁紧叶片,锁紧件)105. free-stand blade自由叶片106. integral shroud blade整体围带叶轮107. triple-pin blade三联叶片108. bow blade马刀型叶片109. compound lean blade复合弯扭叶片110. concave (pressure) side内弧(压力侧)111. convex (suction) side 背弧(负压侧)112. tenon铆钉头113. leading (inlet) edge 进汽边114. trailing (outlet, exit) edge出汽边115. blade wake叶片尾流116. convergent-divergent channel (CD passage)缩张通道117. brazed (stellite) shield钎焊(斯太立)防蚀片118. lacing hole拉筋孔119. profile (section of blade)叶型,型线部分(叶片截面)120. reaction(degree)反动度121. cascade叶栅122. blade root叶根123. (three teeth, straight, curved ) fir- tree (blade) root(三齿直线/弧形)枞树型叶根124. ( five finger) fork type (blade) root(五叉)插入式叶根,叉型叶根125. tee (T-type) root T型叶根126. inverted-T (blade) root倒T型叶根127. straddle-type (blade) root 外包叶根128. straddle inverted T-root 外包倒T型叶根129. dovetail root (serrated root)燕尾型(齿型)叶根130. lacing (tie) wire 拉筋131. (lacing) lug (stub) 拉筋凸台132. loose lacing wire松拉筋133. tubular lacing wire管状拉筋134. shroud (band,cover)围带135. whole circle packed (continuously connected) shroud 整圈连接围带136. integral shroud整体围带137. snubber整体围带138. gauging (throat)喉节比(喉部)139. pitch diameter节径,平均直径140. top diameter(叶片)顶部直径IV. Stationary parts静止件141. casing (cylinder)汽缸,缸体142. outer casing外缸143. inner casing内缸144. single-shell casing单层缸145. double-shell casing双层缸146. cover (upper half)上半部147. base (lower half)下半部148. horizontal (split) joint水平中分面149. (massive) flange(厚)法兰150. (casing) bore(汽缸)洼窝151.fastener (bolt, nut, stud, dowel)紧固件(螺栓、螺母、螺柱、定位销)152. vertical flange垂直法兰153. tightness气密性154. inlet进口155. exhaust排汽口156. exhaust hood 排汽缸157. guide plate导流板158. diffuser扩压管159. flange bolt hole法兰螺栓孔160. shrunk-on ring红套箍环161. combined HP-IP casing高中压合缸162. thermal shield (baffle)挡热板163. single (double) flow HP turbine单流(双流)高压缸164. flow path (steam path)通流部分165.center support system滑键系统166. lug ( foot, pawl)猫爪167. thermal insulation保温设施168. enclosure (lagging)罩壳(外壳)169. diaphragm隔板170. blade ring ( diaphragm carrier)叶片持环,隔板套171. outer (inner) ring (of diaphragm)(隔板)外环(内环,隔板体)172. stationary (stator, guide ,nozzle) blade静叶,导叶,喷嘴173. vane (partition) 静叶174. cast-in (welded-in) diaphragm铸造(焊接)隔板rotary diaphragm回转隔板175. nozzle block (chest)喷嘴组(喷嘴室)176. diaphragm deflection隔板挠度177. bearing housing (pedestal)轴承箱178. front bearing housing (standard) 前轴承箱179. rear bearing housing 后轴承箱180. floor(-type) bearing落地式轴承181. bearing轴承182. journal (radial) bearing支持轴承(径向轴承)183. thrust ( axial) bearing推力轴承(轴向轴承)184. tilting pad bearing可倾瓦轴承185. Kingsburg type thrust bearing金斯布里推力轴承186. Babbitt (white metal, bearing metal)巴氏合金187. bearing bush轴承壳体188. bearing body轴承体189. bearing pad轴瓦190. bearing cover (cap) 轴承上半191. 360°bearing整圆轴承192. elliptical bearing椭圆轴承193. three wedge bearing三油楔轴承194. self-aligning bearing自找中轴承195. sleeve bearing套筒式轴承196. sliding bearing滑动轴承197. (oil) pocket (wedge)油袋(油楔)198. oil film油膜199. oil (film) whip油膜振荡200. setting pad (segment)安装瓦块201. working pad (segment)工作瓦块202. oil ring (oil deflector)挡油环203. oil film stiffness油膜刚度204. armored thermocouple铠装式热电偶V. Main Valves主要阀门205. Main (HP) stop valve (MSV)主汽阀206. control (governing) valve (CV, GV)调节阀207. reheat (IP) stop valve(RSV)再热主汽阀208. intercept valve再热调节阀209. Combined main stop/governing valve联合式主汽/调节阀210. butterfly valve蝶阀211. piloted (pre-inlet) valve预启阀212. fast valve快速动作阀213. check (non-return) valve逆止阀214. solenoid valve电磁阀215. motor driven (operated) valve电动阀216.drain valve疏水阀217. diaphragm valve (atmospheric)膜片阀(大气阀)218. relief (exhaust) valve释放阀(放汽阀)219. safety valve安全阀220. extraction valve 抽汽阀221. stop valve截止阀222. flap valve翻板阀223. gate valve闸阀224. steam chest蒸汽室225. (valve) stem阀杆226. (valve) disk (plug)阀碟227. (valve ) seat阀座228. (valve) bonnet (cover)阀帽(阀盖)229. valve casing (chest)阀壳230. (valve) travel (stroke)阀门行程231. cross over (cross under)连通管232. anti-jamming(stick) test防卡涩试验VI. Various systems各种系统(1) Control system (control and protection system)调节系统(调节保安系统)233. Electro-hydraulic control system电液调节系统234. hydro-mechanical control system液压调节系统235. DEH (digital electro-hydraulic control system)数字式电液调节系统236. electro-hydraulic converter电液转换器237. trip跳闸,脱扣238. actuator执行机构239. servomotor油动机240. pilot (slide, spool) valve滑阀241. piston活塞242. piston rod活塞杆243. (oil) cylinder油缸244. (oil) window油口(窗)245. overlap覆盖度246. emergency governor危急遮断器247. speed governor 调速器248. MSV servomotor 主汽阀油动机249. spring support操纵座250. centrifugal stop bolt撞击子251. LVDT (linear variable differential transformer)线性阀位传感器252. safety test box安全试验盒253. relay继电器,继动器254. relay valve继动滑阀255. axial displacement indicator (transducer)轴向位移指示器(传感器)256. overspeed protection超速保护257. differential expansion detector (transducer)差胀检出器(传感器)258 lever杠杆259. (cam type) steam distribution device凸轮式排汽机构260. throttle governing节流调节261. nozzle governing喷嘴调节262. partial admission (degree)部分进汽(度)263.full arc admission全周进汽264. governing (control) stage (Curtis stage) 调节级(复速级)(2) Oil system油系统265. Main oil reservoir (tank)主油箱266. turbine oil透平油267. fire-resistant fluid抗燃油268. lube (lubrication ) oil润滑油269. HP control fluid高压控制油270. pressure (feed) line (pipe)供油管道271. return (relief) line (pipe) 回油管道273. nested pipe (pipe in pipe)system套管式274. demister除油雾器275. fan风机276. mist separator 油污分离器277. oil purifier净油装置,油净化器278. oil filter滤油器279. oil cooler 冷油器280. overflow valve溢流阀281. oil vapour油雾,油气282. main oil pump( shaft driven)主油泵283. impeller(主油泵)叶轮284. switch-over (change-over)切换(3) Gland system汽封系统285. Labyrinth gland 拉别林汽封,迷宫式汽封286. gland housing (casing)汽封体287. gland segment汽封弧段288. gland (sealing) ring 汽封环289. gland strip (comb)汽封片(齿)290. brush sealing刷子汽封291. leaf sealing薄叶汽封292. diaphragm gland隔板汽封293. gland over shroud (tip gland)围带汽封294. shaft gland轴封295. gland steam condenser (cooler)汽封冷却器296. spring-back sealing回弹式汽封297. gland leak-off 漏汽298. gland ejector 汽封抽气器299. packing盘根,填函,汽封300. inner (outer) gland 内侧(外侧)汽封301. gland chamber (pocket) 汽封腔室302. dummy ring (balance piston)平衡环(4) Drain system疏水系统303. (drain) flash tank (疏水)扩容器304. drain port 疏水口305. cascade drain (system)逐级疏水306. drain cooler疏水冷却器(5) Bypass system旁路系统307. capacity容量308. HP (IP) bypass loop高压(中压)旁路回路309. start with bypass system利用旁路系统启动310. desuperheating and reducing device减温减压装置(6) Regenerative system回热系统311. HP heater高压给水加热器(高加)312. LP heater低压给水加热器(低加)deaerator除氧器313. terminal (temperature) difference (TTD) (温度)端差314. drain subcooler approach (DCA)疏水过冷段315. shell side (design pressure)壳侧(设计压力)316. tube side (design pressure)管侧(设计压力)317. condensing zone冷凝区318. drain subcooling zone疏水过冷区319. direct contact (LP) heater混合式(低压)加热器320. U tube U型管(7) Reheat system再热系统321. Cold reheat line再热冷端管道322. hot reheat line 再热热端管道323. MSR (moisture separator reheater)汽水分离再热器324. (single) reheat(一次)再热325. double reheat二次再热VII Auxiliaries辅机(1) Condenser凝汽器326. Shell-tube type heat exchanger壳管式热交换器327. surface condenser 表面式凝汽器328. direct contact condenser混合式凝汽器329. shell壳体330. (divided) water box (chamber)(对分)水室331. tube bundle管束332. tube plate (sheet) 管板333. support plate 支承隔板334. tube cleaner管子清洗器335. sponge ball cleaning system海绵球清洗系统336. double-shell condenser双壳体凝汽器337. single pass condenser单流程凝汽器338. air cooling zone空气冷却区339 air (cooled) condenser空冷凝汽器340. vacuum system真空系统341. evacuate 抽真空342. tube expander胀管器343. condensate冷凝水344. hot well (condensate sump)热井345. cooling rate冷却速率346. cleanness 清洁度347. condensate pump凝结水泵348. (condenser) neck(凝汽器)喉部349. expansion joint膨胀接头350. wave type (bellows) compensator波纹管补偿器351. deaerating capacity除氧能力352. subcooling degree过冷度353. non-condensed (condensable) gas不凝结气体354. booster pump增压泵(2) Oil cooler冷油器355. Filter过滤器strainer滤网356. cartridge滤芯357. vent通风口358. clogging堵塞359. twin-filter双联冷油器360. on-line change-over (switch-over) 在线切换(3) Ejector 抽气器361. Steam jet (air) ejector射汽抽气器362. water jet (air) ejector 射水抽气器363. (water ring) vacuum pump(水环)真空泵364. evacuation 抽真空365. vacuum establishing (forming) 建立真空366. starting ejector启动抽气器367. vacuum breaker真空破坏阀(4) Turning gear (device) or barring gear盘车装置368. Bull gear大齿轮369. driving gear驱动装置370. worm and (worm) gear涡轮蜗杆副371. turning by (every) 180°(每次)盘转180度372. jacking-up oil pump顶轴油泵373. (dis) engagement 啮合(脱开)VIII Operation运行374. Operation mode运行方式Start (up)启动375. (emergency) shut down (紧急)停机376. daily start- stop (DSS) 日启停377. initial start初次启动378. cold (state) start 冷态启动379. warm start 温态启动380. hot start 热态启动381. extreme hot start极热态启动382. base load (unit) 基荷机组383. cyclic load循环负荷384. peak load峰荷385. peak shaving调峰386. two-shift (operation)两班制(运行)387. cyclic duty capacity变负荷能力388. life cycle(使用)寿命389. life expenditure (CLE)寿命消耗390. life extension 寿命延长391. trip(ping)跳闸392. load tracking (following) capacity负荷跟踪能力393. boiler-turbine coordination control锅炉-汽机协调控制394. warming暖机395. loading-up (down)升负荷(降负荷)396. unloading甩负荷397. load throw-off甩负荷398. run up升速399. run away飞车400. idle running惰行,空负荷运行401. speed up升速402 synchronization同步403. synchronizer同步器404. connect to grid并网405. rolling (by steam)冲转(用蒸汽)406. fixed pressure (start)定压(启动)407. sliding pressure (start)滑压(启动)408. combined (hybrid) fixed/sliding pressure operation定压/滑压混合运行方式409. routine inspection日常检查410. planned maintenance计划维修411. overhaul (intervel)大修(间隔期)412. forced outage rate (FOR)强迫停机率413. repair检修414. availability可用率415. reliability可靠性416. control room 控制室417. corrosion腐蚀erosion浸蚀,水涮418. stress corrosion cracking (SCC) 应力腐蚀裂纹419. latch-on (reset)挂闸420. commission调试,试运行,交付使用。

航海及海运专业英语词汇(S10)static circuit 静态电路static condenser 静电控制器static condition 静止状态static control 静态控制static converter 静态变换器static deflection 静载挠度static delivery head 排出静压头static deviation 静态偏差static discharge 静电放电static disturbances 静电干扰static electric fire 静电起火static electricity 静电static electricity 静电;静电学static energy 静电static equilibrium 静平衡static error 静态误差static exciter 静态励磁机static focusing 静电聚焦static force 静力static frequency converter 静止变频器static friction 静摩擦static gain 静态增益static governor 静调速器static hazard 静电危害static head 静压头static heeling angle 静横倾角static impedance 静态阻抗static inductance 静电电感static instability 静不稳定性static inverter 静止逆变器static jet 固定喷嘴static lever arm 静横倾力臂static lift 静升力static list angle 静横倾角static load test 静负荷强度试验static load 静负载static memory 静态存储器static modulator 静态调制器static moment 静力矩static non-accumulator oil 不能积聚静电的油static offset 静态偏差static opening 静压口static parameter 静态参数static pressure compensator 静压补偿器static pressure line 低压输送管static pressure orifice 静压测量孔static pressure regulator 静压调节器static pressure transducer 静压传感器static pressure 静压力static probe 静压探测器static resistance 静态电阻static sea cock 计程仪静压管船底阀static sea valve 计程仪静压管船底阀static sea valve 静压船底阀static self-exciting method 静态自励法static sensitivity 静态灵敏度static sliding-shoe bearing 静压滑瓦轴承static split auto-tracking 静态分离自跟踪static stability 静稳性static state 静态static stress 静应力static temperature 静温static test for cargo gear 起货设备静负荷试验static test stand 静态试验台static test 静力试验static thrust 静推力static torque 静转矩static trail 静力试验static transformer 静态变压器static trim angle 静纵倾角static tube 静压管static unbalance 静不平衡static value 静态值static waterline 静浮水线static yawing stability 偏航静稳定性static 大气干扰static 静电干扰static 静态的static 静态的静力的固定的静电的大气干扰static-moment calculation 静弯矩计算statical balancing machine 静平衡试验机statical equilibrium 静平衡statical heeling angle 静倾角statical heeling moment 静横倾力矩statical load 静负载statical roll 静横倾statical stability diagram 静稳性图statical stability 静稳性statical stress 静应力statical unstability 静不稳性statical 静态的静力的固定的staticelectricity 静电staticinstability 静不稳定性statics of fluid 流体静力学statics 静电干扰statics 静力学statics 静力学静电干扰station address 站地址station bill 部署表station bill 船员部署表station bill 岗位表station bill 应变部署表station break 电台间断station buoy 临时位置浮标station buoy 位置浮标station call letters 电台呼号station call 叫号电话station capacity 电站容量station change-over switch 控制部位转换开关station designator 电台标识station dialling 电台拨号station error 铅垂偏差station from 发报电台station identification 电台识别station identification code 地面站识别码station identification 电台识别station identification 站址识别站址标识station in the space service 对空服务电台station keeping 位置保持性station license 无线电台执照station list 应变部署表station load factor 电站负载系数station number 站号station of category 1 第一类电台station of category 2 第二类电台station of category 3 第三类电台station of category 4 第四类电台station of destination 收报台station of origin 发报台station of origin 首发台station open from sunrise to sunset 白天业务电台station open in the night 夜间业务电台station ordinate 站线纵坐标station pair 台对station pointer 三杆定位仪station pressure 本站气压station selector 选台旋钮station selector 选站开关station serial number 电台流水号station tanker 贮油油船station tanker 驻泊油轮station to station 站到站station to station 站到站站到站station to station 站对站station to 收报电台station transmitting epidemiological bulletins 发送疫菌报告的电台station transmitting medical advice 发送医务通知的电台station transmitting notices to navigators 发送航海通告电台station transmitting regular meteorological bulletins 发送定时气象报告的电台station transmitting standard frequencies 发送标准频率的电台station transmitting time signal 发送报时信号的电台station 电台停车场station 电台停车场厂station 海岸电台车站station 控制部位station 所station 站station 站;位置station-keeping ability 定位能力station-keeping system 定位系统station-pointer fixing 三杆定位法stationarity 平稳性stationary auxiliary gas turbine 固定式辅燃气轮机stationary battery 固定电池stationary blade 导向叶片stationary blade 固定叶片stationary block 定滑车stationary block 绞辘的)定滑车stationary boiler 固定式锅炉stationary cloud 山帽云stationary communication satellite 静止通信卫星stationary contact 固定触点stationary engine 固定式发动机stationary field 恒定场stationary fit 静配合stationary flow 稳定流动stationary front 静止锋stationary increment 平稳增量stationary installation 固定式装置stationary level 稳定级stationary machine 固定式机器stationary member 固定构件stationary motion 定常运动stationary nozzle 固定喷口stationary parallel bench vice 固定式台钳stationary process 平稳过程stationary process 稳恒过程stationary pull 系柱拉力stationary random process 平稳随机过程stationary random sequence 平稳随机序列stationary response method 平稳响应法stationary satellite = prescribed orbit satellite 静止卫星stationary satellite 静止卫星stationary seal ring 静密封环stationary shaft factor 固定轴因数stationary slewing crane 定柱旋臂起重机stationary state 静止状态stationary stochastic process 平稳随机过程stationary stop 固定止块stationary stream 静流stationary vane 固定叶片stationary wave 驻波stationary 固定的stationary 静止的;固定的stationary 稳定的stationary) regime 稳定状态stationing 定位stations bill 应急部署表stations ticket 码头票stations 船体分站stations 船体分站船体分站statisitical analysis 统计分析statisitical wall load analysis 统计壁载荷分布statisitical 统计的statistic 统计量statistical analysis 统计分析statistical average 统计平均statistical confirmation 统计证明statistical decision theory 统计判决理论statistical design value 统计设计值statistical independence 统计独立statistical information 统计资料statistical mechanics 统计力学statistical oceanography 统计海洋学statistical office of the european communities 欧洲共同体统计办公室statistical probability 统计概率statistical wave measure 统计波浪测量statistical 统计的statistics analysis of steel structures 钢结构统计分析statistics of extremes 极值统计statistics of shipping 航海统计statistics 统计statistics 统计;统计数;统计资料statistics 统计学statistics 统计学统计数字statllite switching 卫星转换statllite system 卫星系统statllite telecom with automatic routing 自动转换的卫星通信statohm 静欧stator blade 静叶片stator coil 定子线圈stator contactor 定子接触器stator core 定子铁心stator plates 电容器定片stator reactance starting 定子串电抗起动stator resistance starting 定子串电阻起动stator ring 定子环stator teeth 定子齿部stator vane 静子叶片stator voltage 定子电压stator winding 定子绕组stator 定子statoscope 微动气压计statoscope 微动气压器statue 塑像status alarm unit 工况警报装置status change 状态改变status contact 状态触头status enquiry 状态询问status number 状态编号status of seamen 海员的地位status report of messages 电报状态报告status 地位status 地位状况status 跟踪状态显示status 状态statutable 合法的statute law 成文法statute mile 英里statute mile 英里(5280英尺statute miles to nautical 英里换算为海里statute of limitations for appeal 上诉期限statute of the international tribunal for the law of the sea 国际海洋法法庭规约statute ordinance 法令规则statute theory 法则区别说statute 法令statute 法令章程statute 法律statute-barred 已过法定时效的statutory and certification survey 法定发证检验statutory debt 法定债statutory deck line 勘定甲板线statutory duty 法定责任statutory equipment 法定属具statutory equipment 规定属具statutory freeboard 法定干舷statutory freeboard 勘定干舷statutory inventory 法定属具表statutory law 成文法statutory leave 法定休假statutory lien 法定留置权statutory limitation 法定时效statutory load line 勘定载重线statutory loadline 法定载重线statutory mark 干舷标志statutory presumption fault 法律推定过失statutory right in rem 法定对物权利statutory right of detention and sale 法定滞留和出售权statutory rules and orders 法规与法令statutory staunch 法定的坚实statutory survey 法定检验statutory water level 法定水平面statutory 法定的statutory 法令的statvolt 静伏staubosphere 尘圈stauffer lubricator 滑脂杯润滑器staulog 皮托管水压计程仪staunch ship 坚固船staunch 坚固的staunch 耐航的紧密的stave in 撞破stave off 桶板脱落stave 桶板;(桶stave 狭板staves 桶板stay bolt 撑螺栓stay bolt 支撑螺栓stay foresail 前支索的三角帆stay light 锚灯stay light 前锚灯stay luff 2—1与2—1复绞辘stay luff 双套复滑车组stay luff 与2-1复绞辘与2-1复绞辘stay of execution 停止执行stay of proceedings 中止诉讼stay of ship 船舶停留stay pin 撑档stay pin 链挡链环档stay pin 链环档stay plate 撑板stay proceedings 停止手续stay sail 支索帆stay tackle 支索滑车组stay tube 撑管stay tube 牵条管stay 支索stay 支柱stay 支柱撑条stay 中止诉讼stay-bolt 支撑螺栓stayed mast 支索桅stays 拉索staysail 支索帆steadfast 坚决的固定的steadiness number 航向稳定特征数steadiness number 稳定特征数steadiness of course 航向稳定性steadiness test at maximum continuous rating 持续功率稳定性试验steadiness 定常性steadiness 稳定性steadman system 斯特德曼方式steady arm 定位器steady as she goes! 把定!steady as you go! 把定!steady bearing 方位没有明显变化;支撑轴承steady bearing 方位没有明显变化支撑轴承steady bearing 支撑轴承steady brace 定位销steady center rest 固定中心架steady course 保向保速航行steady course 稳定航向steady creep 等速蠕变steady creep 等速蠕变率steady drift angle 稳定偏航角steady flow turbine 稳流式涡轮steady flow 定流steady flow 稳定流动steady full 继续全速steady heel angle 稳定横倾角steady lift 定常升力steady light 定光steady load 稳定负载steady load 稳恒载荷steady mark 固定传号steady noise 稳态噪声steady operation 稳定工作steady operation 稳定运行steady periodic oscillation 定常周期摇荡steady persistence 长余辉steady perturbation 定常扰动steady pipe 管柱steady pipe 水位计)管柱steady precision of course 航向稳定精度steady precision of depth 深度稳定精度steady precision of trim 纵倾稳定精度steady progress 稳定进展steady pulsation 稳定脉动steady resistance 稳流电阻steady rest 中心架steady roll 稳定横摇steady rotation 稳定旋转steady run 稳定运行steady running condition 稳定运行工况steady running 稳定运行steady running 稳定运转steady sea motion 定常海浪运动steady ship 航向稳定船steady short-circuit condition 稳定短路状态steady short-circuit current 稳定短路电流steady so! 把定!steady speed 稳定速度steady stage 稳定阶段steady state characteristic 稳态特性steady state conditions 稳态条件steady state current 稳态电流steady state deviation 稳态偏差steady state distribution 稳态分布steady state error 稳态误差steady state frequency variation 静态频率变化steady state heat transfer 稳态传热steady state response 稳态特性steady state short circuit current 静态短路电流steady state stability limit 稳态稳定极限steady state stability 静稳定度steady state vibration 稳态振动steady state voltage variiation 静态电压变化steady state 稳定状态steady state 稳态steady steaming 稳定航行steady steering angle 恒定舵角steady the helm 稳舵steady time 稳定时间steady turning motion 稳定回转运动steady turning period 定常阶段steady turning speed 稳定回转速度steady turning 稳定旋回steady vessel 航向稳定船steady! 把定!steady 把定平稳的steady 固定中心架稳定的steady 稳定的steady-speed resistance 稳速阻力steady-state distribution 稳态分布steady-state error 稳态误差steady-state gain 稳态增益steady-state incidence 定常迎角steady-state life 稳态寿命steady-state measurement 稳态测量steady-state oscillation 稳恒态摇荡steady-state performance 稳态特性steady-turning path 稳定旋回航迹steady-turning radius 稳定旋回半径steadying line 稳定索steadying sails 稳定帆steadymotion 稳态运动stealer 合并列板steam meter 蒸汽流量表steam accumulator 储汽器steam admission 进汽steam air heater 蒸汽-空气预热器steam anchor capstan 蒸汽起锚绞盘steam and feed flow diagram 汽水流程图steam and gas 蒸汽与燃气steam and motor 蒸汽和马达steam and water flow controls 汽量和水量调节器steam and water purity test 蒸汽与水纯度试验steam annihilator 蒸汽灭火系统蒸汽灭火装置steam annihilator 蒸汽灭火装置steam assisted pressure jet burner 蒸汽-机械喷油燃烧器steam atomizer 蒸汽雾化器steam atomizing burner 蒸汽雾化燃烧器steam baffle 挡汽板steam blast 蒸汽喷射蒸汽喷净法steam bleeder connection 抽汽接头steam bleedidng 抽汽steam bleeding system 抽汽系统steam bleeding 抽汽steam boat 汽艇steam boiler plant 蒸汽锅炉装置steam boiler 蒸汽锅炉steam bottle 集汽器steam box 蒸汽阀箱steam bubble 汽泡steam by-pass 蒸汽旁通steam calorimeter 蒸汽干度计steam calorimeter 蒸汽量热量steam capability 蒸发能力steam capstan 蒸汽绞缆机steam capstan 蒸汽绞盘steam cargo winch 蒸汽绞车steam cargo winch 蒸汽起货机steam cargo winch 蒸汽起货绞车steam case 蒸汽套steam casing 蒸汽套steam chamber 蒸汽室steam channel 蒸汽通道steam chest 汽柜steam chest 汽室steam chest 蒸汽室steam circle 作用半径steam circle 作用半径;续航务;航行范围steam circuit 蒸汽循环回路steam coal 锅炉用煤steam cock 蒸汽旋塞steam coils 蒸汽盘管steam collector 集汽器steam collier 蒸汽机运煤船steam condenser 蒸汽冷凝器steam condensing zone 蒸汽凝结区steam condition 蒸汽参数steam connection 蒸汽管接头steam connection 蒸汽接管steam consumption meter 蒸汽耗量表steam consumption rate 耗汽率steam consumption 耗汽量steam consumption 蒸汽消耗量steam content 蒸汽含量steam converter 蒸汽转换器steam cooker 蒸汽锅steam cooler 蒸汽冷却器steam cooling 蒸汽冷却steam cushion 汽垫steam cut-off valve 截汽阀steam cut-off valve 停汽阀steam cut-off 截汽steam cutter 小火轮steam cycle 蒸汽循环steam cylinder piston 汽缸活塞steam cylinder 汽缸steam deck machinery 蒸汽甲板机械steam demulsification number 抗蒸汽乳化值steam desaturator 蒸汽干燥器steam discharge pipe 排汽管steam discharge 排汽排汽量steam disengaging surface 蒸发表面steam distillation 蒸汽蒸馏steam distributing system 蒸汽分配系统steam distributing valve 蒸汽分配阀steam distribution adjustment 配汽调整steam distribution device 配汽机构steam distribution 蒸汽配汽steam distributor 蒸汽分配器steam dredger 蒸汽动力挖泥船steam drenching 蒸汽灭火steam drier 蒸汽干燥器steam drive 蒸汽动力传动蒸汽动力传动装置steam driven auxiliaries auxiliary 蒸汽辅机steam driven auxiliaries 蒸汽辅机steam driven generator 蒸汽发电机steam driven reciprocating pump 蒸汽往复泵steam driven turbo-pump 汽轮泵steam driven vessel 蒸汽机船steam driven 蒸汽动力驱动的steam drum 汽鼓steam drum 蒸汽鼓筒steam dryer 蒸汽干燥器steam ejector gas-freeing 喷气驱除油气法steam ejector gas-freeing 喷汽驱除油气法steam ejector 蒸汽抽除器ejector gas-freeing system蒸汽喷射油气抽除装置steam electric propulsion 蒸汽-电力推进steam electric propulsion 蒸汽电力推进steam engine powerplant 蒸汽机动力装置steam engine 蒸汽机steam entrance angle 蒸汽进口角steam escape pipe 浅汽排出管steam escape tube 逸汽管steam escape 放汽steam escape 漏汽steam exhaust 废汽steam expansion 蒸汽膨胀steam extraction 抽汽steam fire smothering system 蒸汽灭火系统steam fire-extinguishing manifold 灭火用蒸汽分阀箱steam fire-extinguishing manifold 消防蒸汽分配阀箱steam fire-extinguishing 蒸汽灭火steam flow 蒸汽流动steam flow 蒸汽流动蒸汽流量steam flowmeter 蒸汽流量表steam flushing 蒸汽清洗steam fog 大风雪steam fog 蒸汽雾steam gas cycle 蒸汽-燃气循环steam gas-freeing system 蒸汽喷射油气抽除装置steam gauge board 蒸汽压力表板steam gauge 蒸汽压力表steam generating plant 蒸汽发生装置steam generation unit 蒸汽发生装置steam generation 蒸发steam generator 蒸汽发生器steam gland 蒸汽填料函压盖steam guy 边索steam hammer 汽锤steam hauling machine 蒸汽绞车steam header 蒸汽联箱steam heated steam generator 蒸汽发生器steam heated steam generator-on a ship-on a ship 蒸汽加热蒸汽产生器steam heated 用蒸汽加热的steam heater 蒸汽加热器steam heater 蒸汽暖气steam heater 蒸汽暖气器steam heating coil 蒸汽加热盘管steam heating pipe 蒸汽加热管steam heating system 蒸汽加热系统steam heating tank 蒸汽加热柜蒸汽加热货油舱steam heating tube 蒸汽加热管steam heating 蒸汽加热steam hoist 蒸汽绞车steam horn 汽笛steam hose 蒸汽软管steam humidity 蒸汽湿度steam hydraulic steering gear 蒸汽-液压操舵装置steam injector 蒸汽喷射器steam inlet 进汽口steam jacket 汽缸套steam jacket 汽套steam jet air ejector 蒸汽喷射式空气抽除器steam jet air pump 蒸汽喷射式空气泵steam jet air-conditioning system 蒸汽喷射空调系统steam jet air-ejector pump 蒸汽喷射式空气抽除泵steam jet ejector 蒸汽喷射式抽除器steam jet exhauser 蒸汽喷射式排气器steam jet mixer 蒸汽喷射混合器steam jet mixer 蒸汽喷射式混合器steam jet pump 蒸汽喷射泵steam jet refrigerating machine 蒸汽喷射制冷机steam jet refrigerating system 蒸汽喷射式制冷系统steam jet 喷汽口steam jet 蒸汽喷射蒸汽喷嘴steam jet 蒸汽喷嘴steam kettle 汽锅steam lance 蒸汽除水器steam lance 蒸汽吹灰器蒸汽除水器steam lap 进汽余面steam launch 汽艇steam lighter 蒸汽动力驳船steam line smothering 蒸汽灭火管系steam line 蒸汽管路steam line 蒸汽管系steam load 蒸汽负荷steam lubrication 蒸汽润滑steam main 蒸汽总管steam manifold 蒸汽总管steam meter 蒸汽流量表steam mist 大风雪steam mist 海上蒸汽雾steam mooring winch 蒸汽系泊绞车steam nozzle 蒸汽喷嘴steam oil atomizer 蒸汽雾化喷油器steam outlet pipe 蒸汽出口管steam outlet 出汽口steam output 蒸发量steam oven 蒸汽锅steam oven 蒸汽灶steam packet company 邮船公司steam packing 汽密steam packing 蒸汽填料steam parameter 蒸汽参数steam passage 蒸汽通路steam path 蒸汽通流部分steam phone 汽笛steam pipe insulating valve 蒸汽管隔离阀steam pipe 蒸汽管steam piping pressure automatic regulating system 蒸汽管系压力自动调节系统steam piping 蒸汽管系steam plunger pump 蒸汽柱塞泵steam port 汽口steam power cycle 蒸汽动力循环steam power plant 蒸汽动力装置steam power plant 蒸汽动力装置蒸汽发电厂steam power plant 蒸汽发电厂steam power 蒸汽动力steam pressure gauge 蒸汽压力计steam pressure regulator 蒸汽压力表steam pressure regulator 蒸汽压力调节器steam pressure 蒸汽压力steam proof 耐蒸汽的steam pump 蒸汽泵steam purging 蒸汽扫气steam purification 蒸汽净化steam purifier 蒸汽净化器steam purity 蒸气纯度steam purity 蒸汽纯度steam quality 蒸汽品质steam radiator 蒸汽散热器steam raising unit 蒸汽发生器steam raising 升汽steam rate test 蒸汽率试验steam rate 耗汽率steam receiver 容汽器steam reciprocating engine 往复式蒸汽机steam reciprocating engine 蒸汽往复机steam reducing valve 减压汽阀steam reducing valve 蒸汽减压阀steam regulating valve 蒸汽调节阀steam regulator 蒸汽调节器steam reheater 蒸汽加热式再热器steam reheater 蒸汽再热器steam return line 蒸汽回路steam riser 上升管steam schooner guy 吊长件货物索具steam seal regulator 汽封调节器steam seal 蒸汽密封steam sealed 蒸汽密封的steam seasoning 蒸干法steam separator 汽水分离器steam separator 蒸汽分离器steam shield 档汽板steam ship 汽船steam ship 汽船蒸汽机船steam shop 锅炉间steam siren 汽笛steam siren 汽笛汽笛steam smothering arrangement 蒸汽窒息灭火装置steam smothering line 蒸汽灭火管系steam smothering line 蒸汽熏舱及蒸汽灭火管路steam smothering system in cargo space 货舱蒸汽灭火系统steam smothering system in machinery space 机舱蒸汽灭火系统steam smothering system 蒸汽灭火系统steam smothering system 蒸汽灭火系统蒸汽灭火装置steam smothering 蒸汽灭火steam space (锅炉steam space 蒸汽空间steam steam generator 蒸汽发生器steam steering engine 蒸汽操舵机steam steering gear 蒸汽操舵机steam steering gear 蒸汽操舵装置steam steering gear 蒸汽舵机steam stop cock 截汽旋塞steam stop valve 截汽阀steam stop valve 停汽阀steam strainer 蒸汽滤器steam stuffing box 汽密填料函steam superheater 蒸汽过热器steam supply pipe 供汽管steam supply valve 供汽阀steam supply 供汽steam syren 汽笛steam syren 汽笛汽笛steam system 蒸汽系统steam table 蒸汽表steam tank ship 蒸汽动力油舶蒸汽动力油船steam tank ship 蒸汽动力油船steam temperature automatic regulating system 蒸汽温度自动调节装置steam temperature control 蒸汽温度调节steam test for leak tightness 蒸汽密封性试验steam test 蒸汽试验steam tight globe 汽密灯罩steam tight 汽密steam tiller 蒸汽操舵机steam tiller 蒸汽舵机steam to-steam generator 蒸汽发生器steam to-water preheater 蒸汽加热水预热器steam towing winch 蒸汽拖缆机steam trap 阻汽器steam trawler 蒸汽动力拖网渔船steam trial 蒸汽动力装置试验steam tug 蒸汽机拖船steam tug 蒸汽机拖轮steam turbine automatic remote control system 汽轮机自动遥控系统steam turbine drive 蒸汽涡轮传动steam turbine gas-freeing system 汽轮机油气抽除装置steam turbine generator 汽轮发电机steam turbine output control 汽轮机功率调节steam turbine plant 汽轮机装置steam turbine power plant 汽轮机动力装置steam turbine room 汽轮机舱steam turbine ship 汽轮机船steam turbine single-cylinder operation 汽轮机单缸运行steam turbine single-up test 汽轮机单缸试验steam turbine stage 汽轮机级steam turbine tanker 汽轮机油船steam turbine 冲动-反动式汽轮机steam turbine 汽轮机steam turbine 汽轮机;蒸汽透平steam turbine 蒸汽轮机steam turbine-driven windlass 汽轮机驱动起锚机steam turbine-electric propulsion apparatus 汽轮机电力推进装置steam turbo-compressor 汽轮压缩机steam turbo-generator 汽轮发电机steam valve 汽阀steam valve 蒸汽阀steam vessel 汽船steam vessel 蒸汽机船steam waste pipe 残汽排出管steam water ejector 蒸汽射水器steam whistle 汽笛steam winch 蒸汽绞车steam winch 蒸汽绞车蒸汽起货机steam windlass 蒸汽锚机steam windlass 蒸汽起锚机steam working pressure 蒸汽工作压力steam yacht 汽艇steam -tight joint汽密接头tightness汽密性steam 蒸汽;蒸发;航行steam 蒸汽a.蒸汽的在蒸汽作用下运行用蒸汽清洗vi.蒸发steam 蒸汽密封的steam 蒸汽蒸汽的steam 蒸汽蒸汽的在蒸汽作用下运行用蒸汽清洗蒸发steam 蒸汽蒸汽汽化蒸汽的在蒸汽作用下运行steam-engine 蒸汽机steam-gas cavity 蒸气燃气空泡steam-gas mixture 蒸汽-燃气混合物steam-generating installation 蒸汽发生装置steam-heating pipe 暖气管steam-return line 蒸汽回路steam-smothering line 蒸汽灭火管路steam-steerage 操舵steam-supply pipe 供汽管steam-tight joint 汽密接头steam-to-water preheater 蒸汽加热水预热器steam-turbine oil 汽轮机油steam-water mixture 汽-水混合物steamboat 汽船steamer line 船舶航线steamer payed dues 船方负担税金steamer pays dues 船方负担税金船方支付费用船方支付税金steamer pays dues 船方负担税金船方支付税金船方支付费用steamer pays dues 船方支付费用steamer 轮船steamer 汽船steaming bours 锅炉工作小时数steaming distance 续航力steaming economizer 蒸发式经济器steaming head to sea 顶浪航行steaming header 沸腾联箱steaming hour 锅炉工作时间steaming light 航行灯steaming light 航行桅灯steaming out line 蒸汽灭火管路steaming out line 蒸汽灭火管系steaming out system 蒸汽灭火管系steaming radius 续航距离steaming range 续航距离steaming range 续航力steaming surface 蒸发表面steaming time 航行时间steaming with the sea on the bow 偏浪航行steaming 蒸发steaming 蒸汽的蒸汽洗舱航行steaming 蒸汽洗舱;蒸汽的;航行steaming-out system 蒸汽清洗系统steamship company 船舶公司steamship freight contract 轮船公司运货契约steamship line 轮船公司steamship mutual underwriting association 船舶互助海上保险协会steamship 汽船steamship 蒸汽机船steamtight 蒸汽密封的stearate 硬脂酸盐stearic acid 硬脂酸stearin pitch 硬脂沥青stearin 甘油硬脂酸酯stearin 硬脂stearin 硬脂甘油硬脂酸酯steatite 块滑石steel alloy 合金钢steel angle 角钢steel ball method of launching 钢珠下水法steel ball 钢球steel ballast 钢压载steel bar 钢条steel bay 钢材堆场steel bellow 钢质波纹管steel belt 钢带steel billet 钢坯steel block 钢滑车钢制滑车steel block 铁滑车steel bloom 钢坯steel boat 钢船steel bottle screw 伸缩螺丝steel bottle 钢瓶steel bottom 钢质舱底steel cable bridle 钢缆牵索steel cable 钢索steel caisson 钢沉箱steel cast 铸钢steel casting 钢铸件steel casting 铸钢件steel chrome 铬钢steel clad switch box 铠装开关箱steel clad 铠装的steel conduit 布线钢管steel container 钢质集装箱steel cord strain gauge 钢弦应变仪steel core 钢芯steel cored aluminium wire 钢芯铝线steel cored copper wire 钢芯钢线steel deck house 钢甲板室steel deck 钢甲板steel figure 钢字码steel filament reinforced plastics 钢丝增强塑料steel file 钢锉steel fire-screen door 钢质挡火网门steel flange 钢法兰steel flat 扁钢steel forged 锻钢steel forgings 钢锻件steel foundry 铸钢厂steel framed structure 钢架结构steel grating 光栅steel grating 铁格子板steel hatch cover 钢质舱口盖steel hawser 钢丝索steel hawser 钢索steel high pressure seamless pipe 高压无缝钢管steel horseboats 马驳steel i-beam 窄缘工字钢梁steel ingot 钢锭steel leg vice 长腿火钳steel liner 钢衬steel magnet 磁钢steel maker 制钢厂steel marline spike 铁笔steel material 钢材steel measuring tape 钢卷尺steel nickel chrome 镍铬钢steel numbers punch 钢字码冲头steel ordering 钢材订购steel pipe 钢管steel plate concave 钢板变凹steel plate convex 钢板凸起steel plate deformed 钢板变形steel plate galvanized 镀锌钢板steel plate lining 钢板衬层steel plate thickness meter 钢板测厚仪steel plate 钢板steel plates 钢板steel pointed marline spike 铁笔steel preheating 钢材预热steel pretreatment 钢材预处理steel products carrier 钢材运输船钢制品船steel products carrier 钢制品船steel protection coaming 钢质防护围槛steel protractor 量角规steel rail 钢轨steel reinforced aluminium cable 钢芯铝电缆steel rigid salvage pontoon 钢壳打捞浮筒steel rope 钢索steel rule 钢尺steel ruler 钢尺steel ruler 钢直尺steel scrap 废钢steel scrap 钢屑steel sections 型钢steel shape 型钢steel sheave pulley block 钢轮滑车steel sheave 铁滑轮steel sheet corner folded 钢板卷角steel sheet edge folded 钢板卷起steel sheet pile 钢板桩steel sheet piling 钢板桩基steel sheet 薄钢板steel sheets 钢板steel ship 钢船steel short link chain 葡萄链;短环链steel shutter 钢质罩带steel sleeve 钢衬套steel socket 钢套节steel spar 空心铁杆steel square 钢角尺steel storm door 钢制防浪门steel strapping 钢带steel strip 带钢steel structural hull 钢结构船体steel structure 钢结构steel swarf 钢屑steel tape 钢卷尺steel taper ring 锥形钢环steel toe rubber boots 铁龟头橡胶长统靴steel tube armor 钢管铠装steel tube badly bent 钢管严重碰弯steel tube piping general 通用钢管管系steel tube piping 钢管管系steel tube 钢管steel turn-buckle 伸缩螺丝steel v. state line steamship co. 斯蒂尔诉州班轮公司案steel vessel 钢船steel wire armor 钢丝铠装steel wire braid armor 编织层镀锌钢丝steel wire broom 钢丝扫帚steel wire brush 钢丝刷steel wire gauge 钢丝线规steel wire oil 钢丝绳油steel wire rope anchor line 钢丝绳锚索steel wire rope clip 钢丝绳轧头steel wire rope cutter 钢丝绳铲刀steel wire rope grip 钢丝绳执持轧头steel wire rope shear 钢丝绳剪刀steel wire rope thimble 钢丝绳索眼心环steel wire rope 钢丝绳steel wire rope 钢丝绳钢索steel wire rope 钢索steel wire tow gear 钢丝拖带装置steel wire 钢丝steel wool 钢丝绒steel work 钢制品steel works 钢厂steel 钢steel 钢钢制的steel-material for decks 钢steel-seal type cell 钢皮密封式电池steeling inserting die 篷夹冲模steelshop 钢材加工车间steelwork design 钢结构设计steelwork outfitting 船体舾装steelwork 钢制件steelworking plant 钢船体加工设施steelyard 秤steep coast 陡岸steep shore 陡岸steep to 陡深steep to 陡深(指海岸steep wave front 陡波前steep 陡的steep 陡削的steeple head rivet 尖头铆钉steeple 尖塔steepness 陡度steer a ship around reefs 驾船绕过暗礁steer a trick 舵工一次轮转值班steer clear of 避开……航驶steer course 采取……航向steer for 向着……前进steer large! 大舵角转向!steer small! 小舵角转向!steer with a large helm! 用大舵角steer with a small helm! 用小舵角steer 操纵steer 航行steer-wheel 舵轮steerability 操舵性能steerability 操纵性steerability 操纵性能steerable antenna null 可控天线零值steerable hydrofoil 可操纵水翼steerable nozzle with rudder 带舵转动导管steerable thruster 可操纵推力器steerable 可操纵的steerage mess 普通舱餐厅steerage mess 统舱餐厅steerage passage 统舱steerage passenger 三等舱旅客steerage passenger 统舱旅客steerage passengers' quarters 统舱旅客舱位steerage way 有舵效的速度steerage 操舵steerage 舵效;船的转向性能;客船统舱steerageway 舵效速率steerer 操舵装置;舵手steerer 舵手操舵装置steering alarm indicator 舵机报警指示器steering alarm indicator 舵机警报指示器steering and sailing rule 驾驶和航行规则steering and sailing rules 驾驶与航行规则steering angle 操舵角steering angular velocity 操舵角速度steering apparatus steerer 操舵装置steering apparatus 操舵装置steering arm 转向臂steering arrangement 操舵布置steering arrangement 操舵装置steering axle 转向轴steering box 操舵箱steering bridge 操舵室steering bridge 驾驶桥楼steering capacity 操舵能力steering chain 舵链steering chain 转舵链steering characteristics 操舵特性steering characteristics 操纵性能steering clutch 转向离合器steering column jacket 转向轴套steering column 操舵台steering column 转向柱steering command 操纵指令steering committee on pilotage 引水员操船指导委员会steering compartment 操舵室steering compartment 舵机舱steering compass course 操舵罗经航向steering compass 操舵罗经steering compass 驾驶罗经steering console 操舵台steering control device 操舵控制器steering control device 操舵控制装置steering control system 操舵系统steering control 操舵steering crutch 舵桨索环steering crutch 橹架steering cut-out manifold 操舵分配阀箱steering cutout manifold 操舵截止阀箱steering cylinder 舵机液缸steering device 操舵装置steering device 转舵装置steering display 操舵显示steering electric rudder indicator 电动舵角指示器steering engine room 舵机舱steering engine valve 舵机滑阀steering engine 舵机steering equipment 操舵装置steering experiment 操纵性试验steering failure 操舵故障。

第19卷第5期 山东理工大学学报(自然科学版) Vol.19No.5 2005年9月 Journal of Shandong University of Technology(Sci&Tech) Sep.2005文章编号:1672-6197(2005)05-0036-04小型背压式汽轮机性能计算软件开发宋桂霞1,曹新忠2,韩才祥3(1.山东理工大学交通与车辆工程学院,山东淄博255049;2.山东理工大学物理学院,山东淄博255049;3.淄博迈特汽轮机有限公司,山东淄博255077)摘 要:针对小型汽轮机性能定量研究相对缺乏的现状,开发了小型背压式汽轮机性能通用计算软件.采用顺序和倒序的计算方法和模块化设计方法,以Windows为工作平台,运用Visual Basic6.0软件开发工具研制开发,界面友好,适用性强,能满足小型背压式汽轮机性能计算要求,、改进和运行良好的辅助计算工具.关键词:汽轮机;性能计算;软件开发中图分类号:T K262文献标识码:ASoft w are development of performance calculation for minitypebackpressure type steam turbineSON G Gui2xia1,CAO Xin2zhong2,HAN Cai2xiang3(1.School of Transportation and Vehicle Engineering,Shandong University of Technology,Zibo255049,China;2.School of Physics,Shandong University of Technology,Zibo255049,China;3.Maite Steam Turbine Co.,L td,Zibo255077,China)Abstract:According to t he act uality t hat is lack of t he quantitative research of minitype steam t urbine relatively,t he universal performance calculation software is developed for mini2 type backp ressure type steam t urbines.The calculational met hods of order and reverse order and modularized design conception,Windows as exploring circumstance and Visual Basic6.0 software designing tool are used to develop t he software,and itπs interface is f riendly,con2 venient and applicable so t hat it can satisfy t he performance calculation work for minitype backpressure type steam t urbine.It is a helpf ul and assistant calculation tool of design,im2 provement and run for t urbine technicians.K ey w ords:steam t urbine;performance calculation;software develop ment收稿日期:20050308作者简介:宋桂霞(1980),女,硕士研究生. 热力性能评价是汽轮机设计、运行和改进的基础.多年来,科技工作者从试验及理论计算方面对这个问题做了许多研究.试验方面,从试验准备、试验进行、试验数据计算整理到提出试验报告的全过程耗用时间长,工作量大,而且要受到测试仪器、仪表和人为因素的影响,试验数据误差大,准确率不高.传统的手工理论计算方面计算公式多、计算量大、计算出错率高,计算出一个机型的性能参数也需要花费很长的时间,况且计算过程中也要受到计算舍入误差和查表读数误差的影响,这对设计、运行和机组改进的指导有很大的制约性.目前在小型汽轮机性能评价方面的研究也尤为欠缺.计算机技术在生产实践中的广泛应用和基于Windows 的软件开发环境软件的强大的开发功能,为汽轮机热经济性的性能计算和分析提供了必要条件,若针对机组编制一套计算程序显然是事半功倍,它可以不受试验仪器和人为误差的影响,大大地提高计算准确率,并且可以让有关人员解脱繁琐的查表和计算,节省人力,缩短计算时间和开发周期,提高工作效率.本计算软件主要由性能计算程序和用户界面程序组成.本软件采用面向对象的Visual Basic 6.0编制系统性能计算程序和用户界面程序.所开发的软件及应用弥补了对小型汽轮机性能评价研究的不足.1 软件系统1.1 软件语言[1,2]软件开发的语言采用Visual Basic 6.0(VB ).VB 是一个可视化的面向对象的程序设计环境,可视化的用户界面设计功能,把程序设计人员从繁琐复杂的界面设计中解脱出来,并且具有语法简单、容易编程,移植性强、功能强、容易掌握和使用方便等优点.1.2 性能计算方法[3,4]选用适当的性能计算方法是软件开发的关键,决定了开发的难易和效率.汽轮机组的核心是以多级“透平”组成的,多级机组如图1所示.本文根据不同的原始条件,分别采用热力计算中的顺序计算和图1 多级机组示意图倒序计算两种基本方法.如果知道级前状态,则采用顺序算法,先假设喷嘴出口和动叶出口的压力,要求计算的喷嘴与动叶的流量值分别与已知的喷嘴和动叶的流量值相等,如果不等就改变压力的假设值,相应改变喷嘴与动叶计算流量值,直至计算与已知相等为止.如果知道级后状态,则采用倒序算法,先假设级的各种损失,如余速损失、湿气损失、摩擦损失、漏气损失、撞击损失等,然后分别对这些损失进行迭代,直至计算值与假设值相等或充分接近为止.但顺序算法不能计算汽轮机级的超临界工况,所以在机组出现超临界工况时必须采用倒序算法.2 软件模块2.1 计算模块计算模块是程序中的最主要模块,汽轮机功率和效率等参数反映汽轮机装置中能量转换的大小和完善程度,是汽轮机组运行过程中需要密切关注的性能参数,为了方便程序的调用和编写,把计算汽轮机功率和效率等参数作为一个模块.在计算中,根据汽轮机排气已知条件不同将其划分为排气为过热蒸气、排气为出口干度已知的湿蒸气和排气为出口焓已知的湿蒸气3种类型.根据不同类型在相应的区域内查h -s 图,得到排气热力参数.本软件在计算时直接调用水蒸气计算模块得到汽轮机的出口热力参数.2.2 水和水蒸气计算模块[5]汽轮机的工质就是水蒸气(简称蒸气),大量的蒸气热力参数计算是在进行汽轮机组设计、核算以及73第5期 宋桂霞,等:小型背压式汽轮机性能计算软件开发83山东理工大学学报(自然科学版)2005年 性能计算中必不可少的一部分.如果采用费时、费力的查表和插值计算法显然是不合时宜的.本系统采用水和水蒸气性质国际联合会(IA PWS)推出的最新的水和水蒸气计算模型,即IA PWS—IF97公式来编制程序.为了便于系统的调用、提高计算速度,编制成计算模块.该模块主要是用来根据任何两个热力参数,由相应的公式计算其他的热力参数.3 软件功能3.1 设计工况计算在确定了结构尺寸如喷嘴数目和安装角度、动叶出气角度、偏转角度以及有关系数如速度系数、蒸气流量系数后能计算出机组的功率、效率等性能参数的值.3.2 变工况性能计算变工况性能计算功能是本软件的核心功能.具体考虑了以下几个变工况:1)入口蒸气压力变化时对汽轮机的效率、功率、气耗和热耗的影响;2)入口蒸气初温度变化时对汽轮机的效率、功率、气耗和热耗的影响;3)出口蒸气压力变化时对汽轮机的效率、功率、气耗和热耗的影响;4)出口蒸气温度变化时对汽轮机的效率、功率、气耗和热耗的影响;5)蒸气流量发生变化时对汽轮机的效率、功率、气耗和热耗的影响;6)汽轮机转速变化时对汽轮机的效率、功率、气耗和热耗的影响;7)冷却水变化时对汽轮机的效率、功率、气耗和热耗的影响;8)以上各参数部分或全部变化时对汽轮机的效率、功率、气耗和热耗的影响.3.3 水和水蒸气热力性质计算水和水蒸气热力性质计算以计算机自动化计算完成,摆脱了手工查取水和水蒸气热力性质图、表的繁琐.并且采用水和水蒸气性质国际联合会(IA PWS)推出的最新的水和水蒸气IA PWS—IF97计算公式,计算机实例计算与水和水蒸气热力性质图、表对照,有相当的准确性和精度,不仅可满足工程计算的要求,也可用于要求更高的分析研究.3.4 数据查询本软件提供给用户一个查询界面,可对以往的各种记录包括各状态参数值和计算结果进行随时查询,实现对历史数据进行查询的功能.3.5 数据存储和打印对输入、输出的数据进行存储,形成历史数据,便于日后查找,也可实现所需数据的打印.4 软件特点及应用1)采用可视化编程语言Visual Basic6.0编制,具有很大的可扩展性,可以不断完善,根据需要增加新的计算内容和功能.2)程序采用物理意义明确的模块化方法,化繁为简,既便于程序管理,又可节省内存,便于系统的灵活调用,并且可扩充新的模块,以适应于不断发展的性能计算方法和机组类型.3)具有友好的用户界面.在Windows系统平台上运行此程序后,将自动进入主界面.人机对话,友好的用户界面,使用方便,容易操作.4)软件所包含的绝大部分计算公式和参数均取自最新的、通用的国家标准、行业设计规范和方法,部分尚无标准可依的常用计算内容均取自行业权威手册或有关科技书籍,计算结果准确,数据可靠,计算精度足以满足工程实际计算的需要.5)本软件在迈特汽轮机厂热力试验和设计计算中得到应用,与以往的传统方法相比,极大地提高了工作效率、计算速度和计算准确度.5 结束语小型背压式汽轮机性能计算实用软件填补了对小型汽轮机性能定量研究的不足,满足目前市场的需要,是一套使用简便、功能丰富且计算速度快、精度高的软件,是热能动力专业工程师、技术人员、热力测试人员的得力助手,可以大大提高工作效率,节省工作时间,让技术人员从繁琐的查表、计算、校核或迭代过程中解脱出来,并能充分发挥个人计算机的潜在功能,能满足汽轮机热力试验和设计的计算工作.参考文献:[1]黄润发,强莎莎.VB 程序设计技术[M ].上海:中国纺织大学出版社,2001.[2]林 永,张乐强.Visual Basic 6.0用户编程手册[M ].北京:人民邮电出版社,2002.[3]曹祖庆.汽轮机变工况特性[M ].北京:水利电力出版社,1991.[4]李维持.汽轮机变工况热力计算[M ].北京:中国电力出版社,2001.[5]The international association for t he properties of water and steam.Release on t he IAPWS International Formulation 1997for t heThermodynamic Properties of Water and Steam[R ].Erlangen Germany ,1997.我校一项课题通过省级技术鉴定2005年7月9日,由我校交通与车辆工程学院杨仲玉老师等主持完成的“汽车、发动机智能燃油消耗测量系统”项目,通过了山东省科技厅组织的技术鉴定。

菲律宾CHECK EPC CONTRACTOR:D.M.CONSUNJI,INC. ENGINEERS CONTRACTORSForward前言This outline is a guidance document for the conducting of commissioning. The detail of commissioning work will be done according to the subsystem and start-up commissioning procedures of every specialty. Due to the fact that not all technical documents which should be submitted by manufacturers are available now, this commissioning outline is second edition. The update edition will be submitted for approval as request.The I&C commissioning procedure will be submitted to DMCI for the checking of the functional test matrix details.本大纲适用于调试工作的指导文件,调试工作的详细步骤仍需按照各专业的分系统及整套调试方案进行,由于设备制造厂提供的技术文件不全,本调试大纲为第二版,升版后的调试大纲将根据需要提交。

我们将向DMCI 提供热控调试方案,以便DMCI依此方案对相关功能试验进行检查。

Contents目录1.Project Description (1)项目描述 (1)2.Purpose (3)目的 (3)3.Applicable Standards (3)应用标准 (3)anization (4)组织机构 (4)missioning Record (7)调试记录 (7)6.Individual Systems Commissioning (8)分系统试运 (8)7.Unit Integrated Startup (46)整套启动 (46)missioning Procedure List (59)调试方案清单 (59)9.Attachments (62)附件 (62)1. Project Description项目描述1.1. G eneral工程概况The project is located in Antique province of the Philippines and is mainly install a Circulating Fluidized Bed Boiler Coal Fired Power Plant by the owner, Semirara Mining Corporation (SMC). The engineering planning capacity is 1×15MW put into production in January, 2014. The Engineering, Procurement and Construction (EPC) contractor shall be D.M. Consunji, Inc. (DMCI) Engineering, Procurement (EP) by CNEEC and The Construction (C), erection works shall be by DMCI本期工程项目位于菲律宾安蒂克省,为业主塞米拉拉矿业公司(SMC)新装循环流化床燃煤电厂。

专利名称:Steam turbine发明人:Linck, Klaus,Schmitt, Bernd, Dipl.-Ing.,Nottrott, Joachim申请号:EP83104256.9申请日:19830430公开号:EP0093990A2公开日:19831116专利内容由知识产权出版社提供专利附图:摘要:the invention relates to a radial position is a major and flying mounted impeller(2) which is at least a wreath with laufachaufeln (4, 30) inand what with a shaft (34) is connected.in order to achieve the wirkungsgradmaximums for thermodynamic reasonsrotordynamisch necessary surface speeds are controlled is proposedthe impeller (2) as a closed, in the direction of the rotation axis (20) narrow slice is trained.the impeller (2) is the laufschaufeln (4, 30) from a piece of and it is also a planverzahnung (32, 33) of the shaft (34) connected.the impeller is a relatively small mass of the points, and using a simple and planverzahnung in an optimal way zentrierende connection is achieved.radial flow turbines are of the kind referred to in series are standardizedwith impellers and waves each matching planverzahnungen) and in the desired manner can be combined.申请人:A.G. Kühnle, Kopp & Kausch地址:Postfach 265 Hessheimer Strasse 2 D-67227 Frankenthal DE国籍:DE代理机构:Klose, Hans, Dipl.-Phys.更多信息请下载全文后查看。

汽轮机低真空供热时轴向推力的变化特性勇1 ,张卫会1 ,曹丽华1 ,栾忠兴2 ,徐立巍2李 (1 东北电力学院动力系 ,吉林 吉林 132012 ;2 营口第一热电厂 ,辽宁 营口 115001)摘要 :首先对现有的汽轮机变工况热力计算方法及变工况下级反动度解析式进行了改进 。

然后 ,利用改进的变工况热力计算方法及反动度解析式对 CC12 汽轮机低真空供热后的最末级反动度及整个汽轮机轴向推力进行了计 算 。

结果表明低真空供热后 ,只要背压在0 . 05M P a 以下 ,不会出现末级反动度和汽轮机轴向推力大于设计值的现 象 。

实际运行结果证明了该结论的正确性 。

关键词 :汽轮机 ;低真空供热 ;反动度 ;轴向推力 分类号 : T K264 . 1 + 1文献标识码 :A文章编号 :100125884 (2003) 0520279203The Changing Characteristic of End Thrust w h ile Steam Turbine Heat Supplyingwit h Low VacuumL I Y o ng 1 , Z HAN G Wei 2hui 1 ,CAO Li 2hua 1 ,L UAN Zho ng 2xing 2 , X U Li 2wei 2(1 No rt h east China Instit u te of Elect r ic Power Engineering , J i lin J ilin 132012 ,China ;2 Y ingko u f irst C ogenerati o n Plant ,Liao n ing Y ingko u 115001 , China )Abstract :In t his p ap er , t he existing t her mal p erfor mance calcu lating met ho ds fo r st eam t ur b ines at off - design co n d iti o n sand t he analytical exp ressio n fo r degree of reactio n are imp r o ved. Then , t h e new t hermal p erfor mance calcu lating met h od s and exp ressio n are used to calcu lat e t he degree of reactio n of t he last st age and t he whole end t hrust of CC12 ty pe steam t u rb ine heat su pplying wit h lo w vacuum. The calcu lating resu lt s ind icat e t h at so lo n g as t h e back p r essure lo wer t h an 0 . 05 M P a , t h e degree of reactio n of t h e last stage and t h e whole end t h rust can ’t be great er t h an t h ese at design co n d itio n s. This co n clusio n is p r o ved by t h e op erating resu lt s in p r actice.K ey w ords :stea m turbine ; h eat supplying w ith lo w v acuum ; d eg ree of reactio n ;en d thrust压差由于反动度的增加而较设计工况加大 ,从而使整个汽轮 机的轴向推力增加 。

蒸汽透平泵操作指南英文回答:Steam Turbine Pump Operating Manual.The steam turbine pump is a vital piece of equipment in many industrial applications. It is used to pump liquids, gases, and vapors in a wide variety of industries,including power generation, oil and gas, and chemical processing.Steam turbine pumps are powered by steam, which is generated by a boiler. The steam is then directed through a turbine, which turns a shaft connected to the pump. The pump impeller then uses the energy of the rotating shaft to move the fluid being pumped.Steam turbine pumps are available in a variety of sizes and configurations to meet the specific needs of each application. They can be used to pump a wide range offluids, including water, oil, gas, and chemicals. Steam turbine pumps are also capable of handling high pressures and temperatures.Operation of a Steam Turbine Pump.The operation of a steam turbine pump is relatively simple. The following steps outline the basic procedure for operating a steam turbine pump:1. Start the boiler. The boiler is used to generate the steam that will power the steam turbine pump.2. Open the steam valve. The steam valve is used to control the flow of steam to the turbine.3. Start the turbine. The turbine is started by turning on the steam valve and allowing the steam to flow throughthe turbine blades.4. Adjust the speed of the pump. The speed of the pumpis controlled by adjusting the flow of steam to the turbine.5. Monitor the pump's performance. The pump's performance should be monitored regularly to ensure that it is operating properly.Maintenance of a Steam Turbine Pump.The maintenance of a steam turbine pump is essential to ensure its long-term operation. The following tasks should be performed regularly to maintain a steam turbine pump:1. Inspect the pump regularly. The pump should be inspected regularly for any signs of wear or damage.2. Lubricate the pump. The pump should be lubricated regularly to reduce friction and wear.3. Replace the pump's bearings. The pump's bearings should be replaced regularly to prevent them from failing.4. Overhaul the pump. The pump should be overhauled periodically to ensure that it is operating at its peakefficiency.Safety Precautions.When operating a steam turbine pump, it is important to follow all safety precautions. The following safety precautions should be observed when operating a steam turbine pump:1. Wear appropriate safety gear. When working on a steam turbine pump, it is important to wear appropriate safety gear, including gloves, safety glasses, and a hard hat.2. Be aware of the hazards. Operators should be aware of the hazards associated with operating a steam turbine pump, including the risk of burns, cuts, and explosions.3. Follow all operating procedures. Operators should follow all operating procedures when operating a steam turbine pump.4. Never work on a steam turbine pump while it is running. Operators should never work on a steam turbine pump while it is running.中文回答:蒸汽透平泵操作指南。

1.Synchronous Machine(同步机)本组件有一选项是可以模拟Q轴的两个阻尼绕组,因此它可以作为隐极极或者凸极机使用。

其速度可以由给“w”输入一个正值直接控制,或者将机械转矩输入到“Tm”上。

使用此组件模拟同步机有许多优势。

对于一般应用,那些标注为“Advanced”的参数可以不用修改直接采用默认值,这样做不会改变设备的特性。

本组件的这些特点主要是为了初始化仿真以及更快的达到期望的稳态。

期望的稳态由潮流可知。

在仿真中一旦达到稳态,可能就要使用故障、扰动等等来看看系统的暂态响应。

2.Squirrel Cage Induction Machine(鼠笼感应电动机)本组件可以运行于“速度控制”或“转矩控制”模式下。

在“速度控制”模式下,电动机按照输入“W”的规定速度运转。

在转矩控制模式下,速度根据设备的惯性、阻尼和输入转矩、输出转矩求得。

通常,此型电动机在启动时采用“速度控制”,输入“W”取值为额定标么转速(0.98),在电动机最初的暂态结束(过渡到稳态)后采用转矩控制。

本组件可以和“Multi-Mass Torsional Shaft Interface”组件配合使用。

3.Wound Rotor Induction Machine(绕线转子感应电动机)此感应电动机可采用“速度控制”和“转矩控制”模式运行。

通常,通常,此型电动机在启动时采用“速度控制”,输入“W”取值为额定标么转速(0.98),在电动机最初的暂态结束(过渡到稳态)后采用转矩控制。

本组件可以和“Multi-Mass Torsional Shaft Interface”组件配合使用。

4.Two Winding DC Machine(两绕组直流电机)本绕组模拟了两绕组直流电机。

如果外部接线正确的话,电枢绕组两端(right side + and -),磁场绕组两端(top + and -)。

这样可以满足孤立励磁机、并联或串联电机仿真的需要。