ProLab_Testing_Suite_Release_Notes

- 格式:pdf

- 大小:250.24 KB

- 文档页数:18

Document Name:Global Outside Lab QualificationProcedureDate Revised:21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden.Appendix to GES-0128:Outside Lab Capability AssessmentREQUIREMENTSREPORT FORMCOMMENTS CARDCOPYRIGHT © 2008 WHIRLPOOL CORPORATIONDocument Name:Global Outside Lab QualificationProcedureDate Revised:21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden. TABLE OF CONTENTSPage Foreword ....................................................................................................................................... 11 Auditee Preparation Guidelines ...................................................................................................... 11-12Suggested Outside Lab Capability Assessment Agenda ................................................................. 13 Outside Lab Capability Assessment Topics .................................................................................... 13 Requirement Statements and Guidelines ........................................................................................ 14-15 Auditee Final Assessment Status ................................................................................................... 16 Outside Lab Capability Assessment Requirements ......................................................................... 17 L1 - Quality Systems (equipment & data integrity)................................................................. 18 L2 - Materials Testing .......................................................................................................... 19 L3 - Codes & Regulatory Requirements ............................................................................... 20 L4 - Test Specifications & Procedures .................................................................................. 21 L5 - Test Plans .................................................................................................................... 22-23 L6 - Reliability ………………………………………………………………24 L7 - Lab Product Approval Process ...................................................................................... 25-26L8 – Lab Personnel Experience ………………………………….…………..27-28 L9 – Product Experience and Market Experience (29)Glossary of Terms …………………………………………………...30-31 Outside Lab Assessment Report .................................................................................................... 33 Assessment Individual Key Scores and Findings ............................................................................ 33-35 Comments Card ............................................................................................................................ 36 Comments & Suggestions ..............................................................................................................37Document Name:Global Outside Lab QualificationProcedureDate Revised:21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden.FOREWORDThe purpose of this document is to define the proper standard for the assessment of outside labs for potential data source(s) to support Whirlpool Corporation ’s product approval process. It is expected that any outside lab providing data will do so in a manner consistent with Whirlpool ’s Product Approval and Lab Operation process; thus, this Whirlpool ’s assessment is based upon the same “18 PALO Keys to Lab Improvement ” as is used internally at Whirlpool.This Outside Lab Assessment is to be used under the direction of a trained Product Approval representative.The contents of this document explain the necessary steps involved when going through a Whirlpool Outside Lab Assessment. The first section in this package is the “Outside Lab Audit Assessment Guidelines,” which are recommendations on how and what to prepare for the official assessment. Following that is the “Suggested Assessment Agenda .” This agenda is supplied to help the outside lab understand approximately how the time is allocated throughout the day while conducting the assessment. It is only a suggested agenda and does not take into account the size or complexity of the location beingassessed. The section “Guidelines for Use ” contains information about how to use this document. The biggest and most important section called “Assessment Requirements,” lists all the assessment requirements that will be used to evaluate the Outside Lab ’s Capabilities. This section is the core of the assessment process and the assessment team will evaluate the outside lab based upon this material. The sections have been organized to allow a natural flow or progression of questions while performing the Outside Lab Assessment. Finally, the last section called “Outside Lab Assessment Results &Comments Card ,” is a copy of the forms used to write the final assessment report. It includes a copy of a survey that may be filled out by the outside lab after the assessment is complete. It is through this feedback that we can continue to make the assessment process more valuable.This document shall provide all the necessary information to complete an Outside Lab Assessment and Final Report. If any more information is required, the outside lab shall contact the lead assessor. This person can answer any remaining questions.It is our intent that this process will provide Global Whirlpool Technology and Procurement personnel with a solidunderstanding of each Outside Lab ’s capabilities such that enlightened decisions can be made regarding potential testing outsourcing.AUDITEE PREPARATION GUIDELINESAUDITEE: This checklist is provided as an aid to help prepare you for your upcoming Outside Lab Capability Assessment . Basically, a Whirlpool team will be assessing your lab capabilities relative to specific Whirlpool needs and requirements. The key to a successful and efficient audit is preparation, both on the part of the auditee and the audit team. Your responsibility, as Auditee, is to make sure that the following items have been addressed and available as needed.A. Has the agenda for the day(s) of the audit been established and communicated? This is the responsibility ofWhirlpool Lead Assessor. If not complete, please contact the Lead Assessor.Document Name:Global Outside Lab QualificationProcedureDate Revised:21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden.B. Have you reviewed the Outside Lab assessment standard, understand the requirements and used them toperform a self-evaluation prior to the official visit? Have you sent a copy of your self-assessment to the Whirlpool Lead assessor? C. Do you understand the scoring system?D. Is your documentation and supporting evidence readily available? Suppliers should prepare for the assessmentby gathering initial documentation & evidence by key, summarize it, organize it in a manner that the information can be rapidly selected for discussion, and prepare for additional background evidence should the Lead Assessor desire additional material.Key Point: The audit can be conducted in a much more efficient manner if the supporting documentation isarranged in a sequence corresponding to the Whirlpool requirements.The audit documentation can be flowcharted according to your design process. You may arrange the evidence in that order and notify the lead auditor of the desired flow and the lead auditor will follow your recommendations by re-arranging the assessment keys in the order you have recommended (note: all keys must be completed).E. Have you identified the key contact person (Lab Manager or equivalent) to represent your organization andinterface with the lab assessment team? F. Do you have lead people identified for specific sections of the audit (i.e. reliability, equipment calibration,personnel experience, document management, planning, etc.)? Are they “ready ” when called upon? G. Has a conference room been reserved for the audit team to use? H. Is a telephone available? I.Given the expected complexity of the audit and the size of the facility, has the overall time duration of the audit been estimated and consideration given to necessary breaks, including lunch arrangements, if needed? (Note: In the interest of time, a quick working lunch brought to the audit location is typically preferred.)J. Is any safety equipment required (i.e. safety glasses, steel toe shoes, hearing protection, etc.)?Finally, if you have any other questions or concerns they can and should be resolved with the Whirlpool Certified Lead Assessor prior to the actual audit day.Document Name:Global Outside Lab QualificationProcedureDate Revised:21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden.SUGGESTED ASSESSMENT AGENDAACTIVITIES:EST. DURATIONIntroduction (Team members/Auditee representatives) .................................................................. 10 - 20 min. Auditee overview of Lab Operation & Facilities .............................................................................. 30 min. Lab Facility Tour ........................................................................................................................... 30 min - 1 Hr. Lab Capability Assessment ............................................................................................................ 4 - 6 Hrs. Scoring & Report Development (Whirlpool Team Only) ................................................................... 30 min – 1 Hr. Closure Meeting ............................................................................................................................ 30 - 45 min.Note: This suggested agenda does not take into account the size or complexity of the location being assessed. The estimated duration should be seen as a guideline only. A typical assessment can take anywhere from 5.0 hr. to 9.0 hrs .Outside Lab Capability Assessment TopicsKey No.KEY NAMEL1 QUALITY SYSTEMS (equipment & data integrity) L2 MATERIALS TESTINGL3 CODES & REGULATORY REQUIREMENTS L4 TEST SPECIFICATIONS & PROCEDURES L5 TEST PLANS L6 RELIABILITYL7 LAB PRODUCT APPROVAL PROCESS L8 LAB PERSONNAL EXPERIENCEL9PRODUCT EXPERIENCE AND MARKET EXPERIENCEDocument Name:Global Outside Lab QualificationProcedureDate Revised:21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden.REQUIREMENT STATEMENTS AND GUIDELINESAs mentioned in the Foreword, this audit was designed to evaluate all three dimensions of a lab ’s capability; the Personnel , Equipment, and Documentation . To achieve this, each assessment page is laid out in the following manner: The “KEY ” statements are the first statements written in “Bold ” letters on top of every page in the assessment. The keyDocument Name:Global Outside Lab QualificationProcedureDate Revised:21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden.Key ScoringAs indicated above, all keys have as a scoring technique a series of incremental points. Within each point are a number of ‘criteria statements ’ that correlate directly with increased compliance to the requirements of the key. From point-to-point these criteria build upon each other in a progressive manner toward excellence in the “Key ” subject matter.For the purposes of scoring, to achieve the “point being evaluated ” the auditee must, in the opinion of the Lead Assessor , meet or exceed all of the criteria based statements assigned to it . Only after meeting the current ‘point ’ requirements may the assessor look toward the next level of incremental criteria. Also, as noted above, to aid in scoring decisions, half-point scores (0.5, 1.5, or 2.5) are permissible.If all of the criteria are not met, the score shall be recorded at the previous “point ” level or, as appropriate, at the half-point score between the previous score and the next incremental score. Key ScoringPOINTSCRITERIA0 Non-Existent – System requirements have not been addressed; there is essentially no evidence of implementation or compliance.1 Traditional - System requirements may informally exist but they are unstructured and potentially inefficient. There is minimal compliance toward required standards.2 Learning - Adequate awareness and understanding of the preferred approach with basic proficiency and implementation levels, reasonable documentation.3 Leading – Full awareness and understanding of the preferred approach with effective and efficient implementation levels, solid documentation, an operational model.Lead Assessor QuestionsThe Lead Assessor Questions shown with each key are intended only as “thought provokers ” or “response generators ”. Their sole purpose is to stimulate supplier discussion on the key topic in a manner applicable to the key ’s scoring criteria. They are not meant to be “all inclusive ”; thus a supplier should focus their attention on the scoring criteria and not the lead assessor questions.Overlap of Key ContentFrom time-to-time it is fully expected that the content of various “Keys ” will overlap with the content of similar keys. To a degree, this is planned into the assessment. The repetition of seeing a topic in multiple areas of this assessment simply signifies the importance of its content.While this may spark some discussion regarding fairness of scoring if the auditee has a particular weakness in the duplicated area; it needs to be recognized as well that if the auditee has strength in this area, their strength will be likewise be multiplied throughout the assessment.Document Name:Global Outside Lab QualificationProcedureDate Revised:21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden.None, No, Some, Occasional, Most, Majority, All and Always in Criteria Statements:Many of the Results Oriented criteria statements are specifically designed to probe the level of results that the design system should create. There are four levels of evaluation for these questions that contain results oriented requirements. These four levels can be recognized by the use of the words “None, Some, Most and All ” (and their synonyms) in the evaluation criteria. The meaning of these words can be reasonably quantified as shown in the following table:LEVEL RANGE None, no 0 – 5 % Some, occasional 6 - 50 % Most, majority 51 - 85 % All, always86 - 100 %Multiple Outside Lab OperationsIf an Outside Lab has multiple lab operations (i.e. an automotive lab, an appliance lab, a lab for all others, etc.) for the purpose of managing development, cost, and efficiency, the Whirlpool Outside Lab Assessment shall be applied to the section of the Outside Lab ’s business that would typically be utilized to test Whirlpool parts and product.ASSESSMENT STATUSAuditee Status:In addition to the assessment scores, auditees are classified under one of the four different status choices. This status is with regard only to the capability assessment. Additional reviews of specific facility, equipment, fixtures, and test procedure reviews are necessary for final determination of qualification level. These four status choices are Full Qualification , Conditional Qualification, Qualification in Process, and No Qualification . See matrix below:Assessment StatusCriteria(assumes all Keys are being assessed)Full Qualification Assessment that has a minimum score of 2 points or more for each key.Conditional Qualification Assessment that has less than a minimum score of 2 points for any key, but has documented an improvement plan that is acceptable to Whirlpool, with regard to quality and schedule.Qualification InProcessAssessment that is not complete, but plans are in place.No QualificationNo plans or desire to qualify currently.Document Name:Global Outside Lab QualificationProcedureDate Revised:21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden.OUTSIDE LABASSESSMENTREQUIREMENTSDocument Name:Global Outside Lab QualificationProcedureDate Revised:21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden.KEY #L1 - QUALITY SYSTEM (EQUIPMENT & DATA INTEGRITY)Description: This ‘Key ’ is designed to understand the process for maintaining integrity of their test equipment, test and equipment procedures (work instructions), and test records. Lead Assessor Questions:1. What is your process to calibrate & update laboratory test equipment?2. What is your process for updating test / equipment procedures or work instructions?3. What is your document control process for test records?4. What independent lab certifications or accreditations do you currently hold? (ie. ISO-17025, UL, etc.) 0 pts There is no evidence of test equipment calibrationNo evidence of a process to maintain control of test procedures (work instructions) andtest records.1 ptSome evidence of acceptable test equipment calibration; some examples of expiredcalibration tagsAn informal process to maintain control of test data & documentation exists (procedures,work instructions, etc.).Some test procedures are out-of-date or do not match actual practice2 ptsMost equipment has acceptable calibration and measurement systems analysis evidenceavailableA formal process to maintain control of test data & documentation exists (procedures,work instructions, etc.).Most test procedures are up-of-date and match actual practiceThere exists evidence that key test procedures are reviewed periodically3 ptsThe lab is currently ISO-17025 accredited OR meets the following requirements:All equipment has acceptable calibration and measurement systems analysisevidence availableAll test data (records) is stored in an easily accessible location, controlled through aformal document control system, and are kept for set periods of time (e.g. records retention)All test procedures are up-of-date and match actual practiceAll test procedures are reviewed per schedule or process trigger (evidence required) Equipment is calibrated based upon MSE / MSA needs or control chartingNotes* - calibratedbased upon factual, demonstrated evidence that ‘control ’ has been lost in the measurement device as opposed to calibration based upon a selected time interval.Document Name: Global Outside Lab QualificationProcedureDate Revised: 21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden.KEY #L2 – MATERIALS TESTINGDescription: The Auditee may be expected to have a fully equipped materials testing lab to analyze and test materials for proper formulation and material properties analysis during design and development. Expected scope would be materials applicable to the industry of the products being tested.Lead Assessor Questions:1. What material testing capability do you have at this location?2. Do you have all the material testing equipment needed for your products?3. Do you have plans to update the materials testing lab? 0 pts There are no materials testing capabilities at this locationAll materials are contracted out for testing and/or analysis1 ptsSome material testing is completed at this locationThe more difficult material testing is contracted outMost auditee test personnel have less than (2) years of test experienceMost materials testing is done based upon informal, unapproved procedures2 pts Most materials testing is completed at this locationMost material testing is completed with formal, detailed test procedures and analysisreports.Most test result records are archived for future referenceSome auditee test personnel have greater than (5) years of test experienceSome test personnel have (2) or more years of formal college training3 pts All material testing is completed with formal, detailed test procedures and analysisreports.All test result records are archived for future referenceAll test result records are archived and easily retrieved for future referenceSome auditee test personnel have greater than (10) years of test experienceMost test personnel are degreed engineersNotesDocument Name: Global Outside Lab QualificationProcedureDate Revised: 21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden.KEY #L3 – CODES & REGULATORY REQUIREMENTSDescription: This ‘Key ’ is intended to understand how codes and regulatory requirements are implemented and validated at the auditee ’s facility. It also is intended to assess the competency of personnel associated with the codes and regulatory operations.Lead Assessor Questions:1. Please describe the methods used in your product development group to ensure adherence to regulatory agency codesand product safety requirements.2. Please describe your level of certification (of lab and technicians) by appropriate codes agencies (e.g. UL, CSA, IEC,etc.).0 pts No identified codes function at this design locationNo codes agency certification of lab and/or technicians Auditee expects all codes & regulatory requirements to be their customer ’s responsibility 1 ptSome engineering change notice approvals include a sign-off from a codes/safety standpoint There is some evidence that outside codes houses are leveraged to minimize the risk that regulatory gaps may exist 2 ptsSome codes engineer(s) are in place at auditees design facility Some codes agency certification of auditees lab and/or technicians – or - some evidence that outside codes houses are leveraged Most engineering change notices are reviewed and signed-off by a codes/safety expert Most codes requirements are completed by product release Most code engineer test requirements are fully documented 3 ptsLead codes engineer has more than 5 years experience in the Product Approval and Lab Operations All engineering change notices AND temporary change authorizations have a codes/safety sign-off All appropriate labs and technicians are certified by regional appropriate codes agency All codes requirements are completed by product release All code engineer test requirements are fully documented NotesDocument Name: Global Outside Lab QualificationProcedure Date Revised: 21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden.KEY #L4 - TEST SPECIFICATIONS & PROCEDURESDescription: Test specifications and procedures are the backbone of the testing and validation process. Their accuracy and use drive the verification and fitness for use decisions that must be made for new and revised products. This key investigates the auditee ’s test specification management system.Lead Assessor Questions:1.What is your process to develop and update test specifications? 1.Is there linkage of test specifications to customer needs? 2.How is data from the field used to create or improve specifications? 3.Who reviews newly created specifications prior to formal release? What is their authority? 4.How are specifications / test procedures reviewed over time? 5. What independent lab certifications or accreditations do you currently hold? (ie. ISO-17025, UL, etc.)0 ptsThere is no process to develop or update test specifications 1 pt There is limited input from design, customer, and field test results into test specificationcreationTest specifications are informally written by individuals who individually put them to useProcedures / test specifications are informally reviewed2 pts A formal process exists for the development and updating of test specifications; however, itmay not always be used as individually generated test specifications still occasionally existThere is some input from ‘the customer ’ and ‘field test results ’ into test specificationdevelopmentThere is some collaboration between design and the lab organizations in test specificationcreationReleased procedures / test specifications are formally reviewed to ensure correctness;review schedule is variable3 pts The lab is currently ISO-17025 accredited OR meets the following requirements:A formal, approved process for the development and updating of specifications existsand its use is a business requirement.Most specifications are developed based upon customer intended functions and are tiedto customer needs / benefits with historical data from the fieldA great deal of collaboration exists between design and lab organizations in testspecification creationReleased procedures / test specifications are regularly reviewed by a cross-functionaltechnical team according to a developed scheduleNotesDocument Name: Global Outside Lab QualificationProcedureDate Revised: 21-May-08© 20yy – 20yy Whirlpool Corporation. The subject matter shown hereon is disclosed in confidence to the extent it is original with Whirlpool.Disclosure to other parties except in filling Whirlpool orders is forbidden.KEY #L5 – TEST PLANSDescription: This ‘Key ’ evaluates the process used to develop and implement test plans for testing and approving products that meet customer requirements. It includes how test plans are continuously improved with new requirements such that results achieved from approved product lead to better products.Lead Assessor Questions:1.How are test plans for new features / products developed? Who has input to their creation? 2.Please describe how DFMEA ’s provide directional content to the creation of your test plans. 3.Is there a standardized template used for test plan development? 4.When in the development cycle are test plans created and how are they linked to the customer specifications? 5.Are new tests developed when new specifications are created? 0 ptsAuditee has no formal test plans - they do minimal testing Auditee does not create their own test plans (customer assumes this responsibility) 1 pt Evidence shows only standard tests are used and minimal or no critical thought is given for newtests.Tests plans are typically created close to product launch (reacting to the timetable)The Product Approval Group & Design Engineering only occasionally interact in test plandevelopmentThere is evidence that DFMEA ’s are used in some test plan creation.2 pts Test plans are based on prior test documents; no specific regional /global template is usedNew, unique tests are developed for unique features or new product based upon customerinsightsSome test plans are developed early in the process.Test plans are jointly developed between the Product Approval Group and Design EngineeringGroup with the Product Approval Group having the overall authority on most test plan content.There is some test plan coordination / interaction with customers (i.e. effect on other customerparts).There is evidence that DFMEA ’s are used in most test plan creation.3 ptsTest plan development template (w/standard tests) used to drive critical thought for all projecttest plans.There is clear evidence of new tests proactively developed and based upon customer insights.These tests are shown to be linked to newly developed product specificationsTest plans are jointly developed with the Product Approval Group and Design Engineering, andit is clearly documented that the Product Approval engineer has the final authority on all test plan content.There is considerable test plan coordination / interaction with customers (i.e. effect on othercustomer parts).There is evidence that DFMEA ’s are used in all test plan creation.Most test plans are developed early in the process.。

初次使用此软件的朋友,看了猫版的介绍,再加上这个指南文件,上手应当很轻松了。

献给部分英文比我还糟的朋友,呵呵Using this tutorial 如何使用此指南This tutorial is meant to be used as a step-by-step guide to certain operations in TuneL ab Pro. 本指南将一步一步的指导您在TuneLab Pro中的操作. Many of these operations i nvolve the keyboard.有相当一部分操作涉及到键盘的使用。

However, the keys that you press when this tutorial is displayed do not always go to TuneLab Pro.然而,当此帮助页面显示时,您按下键盘键并不总是能够回到TuneLab Pro操作界面。

In fact, every time y ou call this tutorial and every time you click in it, the tutorial acquires the "focus" of t he keyboard.实际上,每当您查看本指南或者在本指南显示的区域内操作鼠标时,焦点总是被当前的指南页面获得的。

To make the keys go to TuneLab Pro, you need to give the focus back to TuneLab Pro. 要想使用键盘来控制TuneLab Pro的操作,您需要使焦点回到TuneLab Pro界面中。

You can do that by clicking anywhere inside the TuneLab Pro win dow. 您可使用鼠标点击TuneLab Pro窗口来实现。

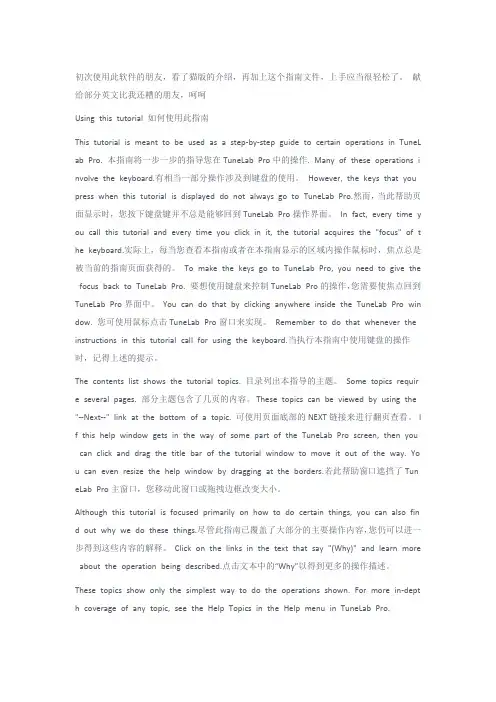

注意:这个说明没有多少说明文字,请仔细看清安装过程中的选择LMS TesLLabVVWW」E contactus b rowse cd .exit LMS Test Lab 13A License ServerSoftware License Terms and Conditions Read the release notesRead the installation manualInstall LMS b now...Read the end users guide in stall RLM License server now.-.LMS Viewer and Smart ControlInstall LMS Data Plugin for Active Pictures now. Install LMS Scadas Smart C ontrol now..-■:5 LMS InlernaLiOiial Adobe Aerob臼t Reader Install reader RD叽A Siemens &usin«s选择In stall LMS b now ••安装软件LMS b ISA SetuiWelcome to the Prerequisites WizardThe setup has determined that some of the prerequisites needed torun this program are missing. This wizard will assist you in gettingand installing those prerequisites. Click Next to continue to the list ofprerequisitesClick Finish at any time to completely skip the installation ofprerequisites and jump to the installation of the main program. ClickCancel to cancel the installation and sxit the Setup Wizard.A Siemens Business[<上一^6”帀一步00 >]「题][翊P LMS b 12A SetupPrerequisitesThese programs are needed for the applies b on to run. Click on the check box next to aprerequisite to select it for install or to skip it.□K上一步⑻II下一步闪)R ~矽 LMS Unit System 2.0 Setup< Back 11 Next > ] [~Cancel劃 LMS Unit System 2.0 SetupEnd-User License AgreementPlease read the following license agreement carefullyThe use of this software program requires that you accept on behalf of the company that ordered this ■ software program (the "LICENSEE r ) the terms and conditions of following Software License Terms and Conditio ns. By cicking the *1 agree r ・button below. they will be fuly applicable unless and to the extent otherwise agreed in writing with LMS International NV ・If you doni agree with these terms and conditions, dont push the x l agreed-button. In such case, neither installation nor use of the software program will be allowed and you wil have to contact the response line of one of the LMSofficesSOFTWARE LICENSE TERMSAND CONDITIONS< BackCancel肝 i_nm□ I—MS*A Siewons BusinessWelcome to the LMS Unit System 2.0 Setup WizardThe Setup Wizard will install LMS Unit System 2.0 on your computer. Click "Next' to continue or "Cancel" to exit the Setup Wizard.o I accept the terms in the License AgreementI do not accept the terms in the License Agreement<_Back | Next > Cancel<_Back | Next > CancelInstallation TypeChoose the installation type.Install LMS Unit System 2.0 for:Only for me (Joy) o Everybody (all users)|― Bock || Next a ] | CancelSelect Installation FolderThis is the folder where LMS Unit System 2.0 will be installed.To install in this folder, click ,,Next ,f . To install to a different folder, enter it below or click ,,Browse ,1.Folder:|cAProgram Files (x86)\LMS\觀 LMS Unit System 2.0 SetupBrowse...AOtnlrxmLMS Unit System 2.0 Setup < Back |Install CancelUser Configuration Folder;|C:\LMS\The Group Con figuration Folder is a folder used to provide specific configuration settings to several users. For instance, company templates placed in that folder will be accessible to several Test.Lob users ・ If you don't need such o folder, please leave the field as is. Group Configuration Folder:|C:\LMS\[—< Back 11 Next a ~| CancelLM& Unit System 2.0 SetupClick M Install M to begin the installation. If you v/ant to review or change any of your installation settings, click "Back". Click "Cancel" to exit the wizard ・出J LMS Unit System 2.0 Setup< BackFinish1CancelASiome^s BusinessCompleting the LMS UnitSystem 2.0 Setup WizardClick the "Finish" button to exit the Setup Wizard£3 LMS Tes-tLab 13A SetupIA Siemens BusinessThe Setup Wizard will install LM5 b 13A on your computer. Click ^Next" to continue or "Cancer* to exit the Setup Wizard ・Welcome to the LMS b 13ASetup WizardCancel< Back日 LMS TestLab 13A SetupNew license mechanism introduced based on RLMLMS b Rev. 12A SL1 and higher use a new licensing mechanism that is incompatible with earlier versions ・ You therefore need a new license file. If your installation uses a license server^ you must also instaII a new one. This new license server does not support older versions of LMS TestLab.Please contact your local LMS office and request a new RLM ficense file before installing this version.Please read the installation guide for more details on how to install the new license serverS3 LMS TestLab 13A SetupPlease read the following document carefully. It contains important information about your rights and obligations, as well as limitations and exclusions concerning the use of this software program.A Wnwn> (hAlnoaThe us-e of this software program requires that you accept on behal 1 of the company that ordered this software program (the 'LICENSEE ) the terms and conditions of following Saftv/are License Terms and Conditions. By clicki ng the M l agree*-button below, they will be fully applicable unless and to the extent otherwise agreed in wrting with LMS International NV.If you don't agree with these terms and con<jrtions f dont push the -lagfefr r -button. In such case ・ n either installation nor use of the software program will be allowed and you will have io contact the response Ime of one of the LMS-offices.SOFTWARE LICENSE TERMS AND CONOITIONSThese Software License Terns and Conditions (hereinafter: the Terms and Conditions) s&t forth the terms and conditions according to which LMS Inter national NV (herei natter LMS) agrees to grant to I ICPMQ 匚匚 a e A I IC"O H-e e aro rwrr^/inr*4-e I I-IQ «ort/t I ICPM Q 匚匚 ar-oa e ■♦hoO I agree with the Software Licerse Terms and ConditionsIdo not agree wth the Software LicenseTernrs and ConditionsCancel ]< BackNext >Cancel ]A SWTwrnOl LMS Test Lab 13A Setup貝 i_zimThe system wll set the instanation features based on all .be files in the provried directory. The automatic selection of features based on a license file is optional and can be skipped. If skipped, all products will be selected for installation. In either case you can still change the selected products ually. Automatic license selectionYes t us-e automatic product selection 0 No, do not use automatic product selection Licensn directory path; CABrowse...Please note that if any token features are present in any license file. 9l products wfl be selected.Cancel£3 LMS TestLab 13A SetupProduct SelectionPlease select the products to install▲ { )▼ LMS b Appbcationsi 十产 Desktop Standard & AdvancedAcoustic匸^▼ Environmental ( General Processing and Recording(Rotating Mach in ary 二^▼ Structures Acquisition▼ Structures Analysisi Turbine Testing i_ ▼ Data ServerX p TL-DTP.60.2 LMS [>ata Server th at is part of LMS b Data Management Se 厶b DocumentationHelp(Theory丫 v b Demo DatainCancelLicense Based Automatic Feature Selection (aptron^l) Please enter the path to the license fife.t>t > tSome LMS Te$b workbooks require specific hardware and drivers to be installed・ Please follow installation instructions before connecting thehardware to your computer.LMS HD acoustic camera (HDcam—drivers—installabon.pdf)LMS 3D Solid Sphere array (3Dcam_drivers_installation.fxif)LMS 3D Photo Geometry Scanner (3Dcam_drivers_instalation pdf)These documents are available on the b installation DVD in the Documents folder.Next> Cancel泛 LMS b 13A SetupABwJhnn*Desktcp - Standard (Product cirfe; TL-DTR20.1 rd Desktop - Ad .■ a need (Pro duct cade : TL-DTP.21.1)盘 LMS La b J3A 舁tupSUMS'A 弘”rHbRvilMMl Do you wiah LUS TeatiLafr 1 SAto add exceptions to the Win lows Firewfill?4 H DYes., EPI a bletrs exceptions to tne 'jVindaws. Firewall during the mslalljtion. (Reccnunendedj< Back || Nexti | Cancel 这里选择NO□ LMS Testlab 13A SetupI - j MOMSelect Installation FolderThis is the folder where LMS b 13A will be instaled.To install n this folder, click HexT. To install to a different folder, enter t below or click •Browse**.Install LMS b in the folder:C:\Program Files (x86)\LMSBrowse...£3 LMS Test. Lab 13A SetupSelect User Configuration FolderThis folder will be used for configuration files (project templates, layout, configurate)n,.・・) saved by the user.To use this folder, click m NexT. To use a different folder, enter t below or click "Browse"Important: make sure that you choose a folder on which the user will have read and write permissionsb user configuration folder (*): C:\LM®C)This folder wi be the base folder, used for al user configurations. b will appe nd \UserConfiguration\SLOGN\b 13A\to the folder specified.Browse...Cancel< Back CancelA Stctncrn、Q LMS Test Lab 13A SetupSelect Group Configuration FolderPlease specify whether you want b to use a group folderA Siemens BuUnr%>A group folder is a folder where an administrator can place files which are in common for a group of busers・ These files include project templates, documentation :emplates. print formats, layout files andconfiguration files.9 No, de not use a group configuration folderYes, use a group con figurati on fold erb group configuration tolder (f):C:\LMSX BrowseFile access priority:When accessing files, prioritize the Local folderC)This folder wil be the base foldef. u&ed for all group configuratiom. b wil append\GroupConfiguraton\LMS b 13A\ tothe folder specified.«Bacc I Next > Cancel£3 LMS Test Lab 13A SetupA S'emens RuMnws.Please specify in what way you would like to use the ASAM/ODS data driver on ths machine. You can access ASAM/ODS data using a Corba Names server. In that case, please provide the server name and port numtoer Corba Names Servera Mo. do not use a Corba Names ServerYes. use a Corba Names Server[vBadc ||ASAM/ODS ConfigurationPlease specify the ASAM/ODS configuraOon to useCancel完成后选择安装“ In stall RLM Lice nse server now …”JLMS Tesl.L^b UA ^etupj■A Siemens Busi nessCompleting the LMS b 13A SetupWizardLMS b 13A is installed successftjly. Please dick thf ^Finish" button to exit ttie 虫tup Wizard.Back | FinistiC.anc el岀 LMS RLM 10.0.1 License server SetupSelect License RleSetup v\il use the license file specified below ・ If left empty, you have to copy the license file hter to the daU folder that you specify below.|G: gLM _License_Server V-MS.lic© Configure the license server to look for license files in Cr^rogramData^LMSpcensing and copy the license file to thslocation ・ RecommendedConfigure the license server to look for license files in a specific directory and copy the license file to this location:Browse...<Back Next >CancelLMS RLM 10.0.1 License server SetupDefine the options2l Do not allow to shut down the license server from a remote computerPleaseO specfy the path f&r the server logfile CRLMLOG.txt): |C!^LNJ-icense_ServerV-MSDIog .txt\ Please specify the path for the daemon logfile (LMSLOG.DLOG): |C^LM_License_Server\|ms .dlog.dlog<BackNext >CancelA 5icfncm (knl nenBrowse...劃LMS RLM 10.0.1 Lkens-e server SetupFirewall settings必i_zim Adapt the firewall exclusions...Ifsdected f the installation will modify the firewall settings on your computer, such that the communication between your computer rnd the license server will not x prohibited.[/ Adapt the fireball settings to allow the licensing daemon to pass< Bad [ Next > ] 「Cancel ]上¥ _M& RLM LO.O.l Licence server SetupReady to IiistBllTlhe Setup V/izard is ready to begin the LMS RLM UO.O.lUoenBe server instil日lionL'c /?i5ta ' LKec'il'ie irst-zlatic. It /c_. -ai\ :a e -匚,c卜己】匚亡■亍江LJ「installation settings, dick 'B日ck*. Click r Cancd r bo exit the wizard.< Sack Install匚 ancel 安装结束后将crack\RLM_License_Server目录下的所有文件复制到C:\Program Files (x86)\LMS\LMS RLM 10.0.1 Lice nseserver\Licensing\Bin目录内覆盖掉安装文件,重启电脑即可。

//重点:两个三层交换机之间可以通过Vlan 1 进行路由退出的命令的运用在神州数码的视图下是没有quit的命令的,但并不代表不能用quit,在大多数的视图下,都可以用quit命令退回上一级视图,当然用exit也可以,看个人喜好,但有视图也是例外的,例如:# spanning-tree mst configuration视图下就要用它专用的退出命令:abrotNAT配置:1、配置acl允许通过的网段;//一般用标准acl2、配置地址池;ip nat pool+名字+起始IP+终止IP+子网掩码3、配置nat转换那个网段;Ip nat inside source list +acl名字pool +地址池名字4、配置int接口和out接口;【接口试图】ip nat inside【接口试图】ip nat insideNAT server:# ip nat inside source static tcp + 服务的IP地址+ 服务端口+ 要转换成公网的IP地址+ 端口号在发布FTP的时候最好把21和20的都发布出去DNS一定要使用UDP服务路由器enable用户密码和时间配置:1、enable password 0/7(不验证和验证)+密码level+权限(默认不配置的时候是15)2、date(接下来按照指示配置就OK了)配置语言:1、路由器Chinese2、交换机language ChineseOSPF路由协议的配置:1、router id的配置,可以选择配置,配置的时候,要指向路由器接入的端口上的IP地址2、router ospf +数字(可以随意)network +使能的网段+子网掩码+area +区域号(ospf 分单区域和多区域两种,单区域的配置要注意每一个使能的网段后面的区域号都要一致,多区域配置两个区域相交的那路由器使能网段的时候要配置和对端相对应的区域号)3、ospf的虚连接配置(ospf的虚连接是只多个不能直接相连接的区域通过建立逻辑的上虚拟连接,建立邻居关系):area +本网段的区域号+ virtual-link + 相同区域对端的路由器的router id(虚连接链路的配置是运用在至少3个不同区域的ospf上,而且其中两个区域,分别和第三个区域连接)4、可以使用neighbor + 邻接路由的IP地址Ping命令有趣使用:问题:ping 1.0.0.1 可以学成ping 1.001 ,写成1.1也能ping通因为ping 的协议的编写时采用了IPV6的机制的,中间是出现连续两个0的情况的话,可以合并,可以可以不写。

labsolutions使用流程English Response:Introduction.LabSolutions is a comprehensive software suite designed to enhance the efficiency and accuracy of laboratory analyses. Developed by Shimadzu, a leading manufacturer of analytical instrumentation, it empowers users with advanced features and intuitive functionality.Key Features.Data Acquisition and Control: LabSolutions seamlessly integrates with a wide range of analytical instruments, enabling seamless data acquisition and control. Users can remotely monitor and adjust instrument parameters, ensuring optimal performance and minimizing the risk of errors.Data Processing and Analysis: Robust data processingtools allow users to perform a comprehensive range of operations, including peak integration, smoothing, and baseline correction. Advanced statistical analysis capabilities enable the extraction of meaningful information from complex data sets.Chromatography Management: LabSolutions provides comprehensive chromatography management features, including peak identification, retention time alignment, and qualitative and quantitative analysis. It supports various chromatography techniques, including HPLC, GC, LC-MS, and GC-MS.Method Development and Validation: LabSolutions streamlines method development and validation processes. Users can create and optimize methods in a user-friendly environment, ensuring compliance with regulatory standards and enhancing analytical accuracy.LIMS Integration: The software can integrate with Laboratory Information Management Systems (LIMS), enabling seamless data transfer and eliminating the risk of manualerrors.User Interface: LabSolutions features an intuitive and customizable user interface that simplifies data handling and analysis. Its configurable layouts and customizable toolbars allow users to tailor the software to their specific workflows.Benefits.Enhanced efficiency and productivity.Improved data accuracy and reliability.Time savings and reduced operating costs.Simplified compliance with regulatory standards.Increased confidence in analytical results.中文回答:简介。

MyLab Accessibility Best Practices GuideStriving to ensure every learner succeeds MyLab course materials Alternative course materials Accessible eTextbooks Alternate format text AccessText Network Braille and large print MyLab accessibility features Turning on Accessibility Platform and navigation Assignments and assessments Question bank for homework and tests Custom Question Builder Microsoft PowerPoint decks Alternate text Videos Discipline-specific media In your MyLab course: New considerations Support and documentation VPATs and other accessibility status documents Table of Contents112222344456789910101010Introduction/OverviewStriving to ensure every learner succeedsMyLab course materialsEmpowering learners will always be central to Pearson’s mission and values. That includes designing instructional content for MyLab® to be fully accessible to students with disabilities while continually improving usability.By honoring the following best practices together, we can enable a wider array of students to thrive through their learning journey — and prepare everyone to prosper.Pearson’s investment in accessible product design and remediation is significant and ongoing as we strive to meet and exceed Web Content Accessibility Guidelines (WCAG 2.1 AA standards) for all our educational materials including those designed for MyLab courses.If for any reason any Pearson eTextbook doesn’t meet a student’s need, Pearson is prepared to provide other course material options. To save everyone time and effort, we’ve partnered with top providers and accessibility experts to expand our capabilities.Alternative course materialsAccessible eTextbooksPearson’s newest eTextbook platform, Pearson+, supports the majority of WCAG 2.1 AA standards and we are continuously updating to improve both accessibility and usability as well as compatibility with assistive technologies. Keep in mind that the most recent edition of each title will provide the most accessible user experience.Pearson+ eTextbooks can be accessed in two ways:1. Using a MyLab courseIf your course uses Pearson MyLab online learning platforms, students may already have access to an accessible eTextbook. To open, go to the MyLab course menu in your browser and select the eTextbook option.2. Logging in to Pearson+ directlyFor classes that do not use MyLab, students can log in to Pearson+ to access eTextbooks from a computer or mobile device (iOS and Android), even when offline.Please email us at ****************************** for title-specific details or if you encounter any issues.Alternate format textIf a Pearson+ eTextbook is not fully accessible for a student based on their needs, an alternate format text can be found within the Pearson VitalSource accessible digital textbooks library.You may purchase Pearson titles as eTextbooks from VitalSource and get instant access to eTextbooks through the VitalSource Bookshelf platform.Learn more about accessible digital eTextbooks from Pearson and get answers to common questions about them.AccessText NetworkPearson partners with the AccessText Network to ensure that students with print-based disabilities that would be better addressed by a non-digital textbook also have that option. Upon request and at no added cost, additional Pearson titles are available for qualified students who buy or rent our print or eTextbook versions through AccessText Network, a clearinghouse for files from all major higher education publishers.A disability services representative must make these title requests from the school who must register with the AccessText Network. The alternative text file will be delivered typically as an untagged PDF (meaning not fully accessible for digital consumption).This method is ideal for:• Schools intending to produce their own braille or large format documents• Students requiring a printed textbook versus digital book as a result of a disability Braille and large printPearson and Allyant, the leading provider of accessible textbook formats in North America, partnered to significantly reduce the turnaround time and cost of providing top-selling Pearson titles in braille and reflowed large print.T-Base can deliver top-selling braille or reflowed large-print textbooks within 10 business days at a substantial cost reduction to institutions. Purchasing accessible textbooks through this new, more efficient process enables educators to focus on helping students succeed in their studies. Explore the ever-expanding Allyant Catalog. Order textbooks in braille or reflowed large print by emailing Allyant at: **************** or calling: 1-800-563-0668.Platform and navigationAll MyLab website pages are screen reader and keyboard-accessible including student pages like Calendar, Homework and Tests, Results, Announcements, and Study Plan.The platform’s interface works with common screen magnifiers. Browser- or device-based contrast settings are respected.*Note: When the student is using keyboard-only navigation or assistive technology within MyLab, the Accessibility Mode is required to complete assignments. (Explore the command-line language students can use to type symbols when Accessibility Mode is turned on.)Assignments and assessments Question bank for homework and testsWhen giving students with disabilities any assignments, be sure their eTextbooks display a copyright year of 2014 or later, and keep in mind that all Pearson business products published in 2016 or later also have accessible eTextbooks.Contact ****************************** for questions about other eTextbooks. Accessible questions are noted with an icon to help instructors select accessible assessmentsand require alternative text.Pearson is actively and consistently increasing the number of accessible questions.Accessible questions and items are:• Screen reader and keyboard accessible• Compatible with common screen magnifiers• Contrast-optimized for vision-impaired access• Created with accessible media such as video with captions and/or video descriptions and images with alternative textCustom Question BuilderWhen editing existing questions or composing your own, remember to:• Add alternative text for images• Use only captioned media• Format fonts for optimal readability• Weigh the use of static vs algorithmic questions for ease of editing and to accommodate student needs• Want to learn more? Watch our MyLab Create Your Own Questions video.• Use questions from other texts and the new enhanced book search. Watch our MyLab Enhanced Book Search video.Microsoft PowerPoint decksMicrosoft PowerPoint decks copyrighted 2018 or later are accessible and include: • Slides that use a clear, simple language and layout• Slides that use accessible fonts of a minimum size• Defined reading order• Accessible color contrast ratios (4.5:1) for text and images of text and color combinations that can be read by students with color blindness• Alternative text descriptions for images• Accessible math, where applicable• Slide titles in the title placeholder for each slide that are unique and concise• Meaningful text or raw URLs to describe hyperlinks• Lists that are built as structured lists• Columns that are created with defined reading order• Tables that are created with PowerPoint’s table feature, are simple grids with predictable rows and columns, and are free of merged cells• Slides that are free of background images and flickering imagesAlternative Text• Alternative text (“Alt Text”) is a written description that conveys visual content of images to students who are blind or have low vision. Pearson eTextbooks with a copyright year of 2018 or later have alternative text for images.• Alternative text is read aloud by screen readers and other assistive technology devices.For complex images, a long description may also be provided via hyperlink to fullydescribe the image.VideosVideos:• Are navigable using screen readers and keyboards• Offer closed captioning in most Business, Reading & Writing, and Math & Statistics products. Note: MIS titles and products released prior to 2010 may vary.• Provide access to certain transcripts via the video player. (See the Further Problem Solving example.) Activate this feature in “Settings.” Some transcripts are available as supplemental materials within the course and do not require a request.• Will include audio descriptions in future releases of visual details on screen that are not apparent from the audio alone.In your MyLab course: New considerations Support and documentationVPATs and other accessibility status documents• Link an HTML eBook directly to its own tab.• Use screen-reader compatible questions. If using Skill Builder, select only the screen reader questions.• Extend testing time by 50% by using the individual student settings.• VPATs and Accessibility Conformance and Remediation Forms (ACC&R) are available for many products upon request and organized and described by feature and status. • To request this information, contact Pearson Disability Support .• Learn more about Pearson’s Accessibility online or contact your Pearson Sales Representative.Discipline-specific mediaMany MyLab products feature discipline-specific media (e.g.: animations, simulations, experiments, flashcards, etc.). For updated details on their accessibility, refer to discipline-specific accessibility status flyers.。

reportlab basedoctemplate -回复[ReportLab based Octemplate],以中括号内的内容为主题,写一篇1500-2000字文章,一步一步回答ReportLab 是一个用于生成丰富且可定制的电子文档的Python 库。

它具有强大的功能,可以用于创建报告、表格、图表等各种类型的文档。

而Octemplate 是ReportLab 的一个扩展,用于创建模板化的文档。

本文将一步一步地介绍如何使用ReportLab 和Octemplate 创建模板化的电子文档。

第一步:安装ReportLab 和Octemplate首先,确保已经安装了Python 解释器。

然后,打开命令行界面,并通过以下命令安装ReportLab:pip install reportlab接下来,通过以下命令安装Octemplate:pip install octemplate安装完成后,我们就可以开始使用ReportLab 和Octemplate 了。

第二步:创建一个模板首先,创建一个名为"template.odt" 的空白OpenDocument 文档。

这将作为我们的模板。

打开一个文本编辑器,将以下内容复制到"template.odt" 中:Hello, [name]!Today is [date].Here is a list of your tasks for the day:1. [task1]2. [task2]3. [task3]Have a great day!在该模板中,我们使用了占位符(用方括号括起来的内容),这些占位符将在后续步骤中被替换为实际的值。

第三步:创建一个Python 脚本现在,我们需要创建一个Python 脚本,用于生成基于模板的文档。

打开一个文本编辑器,将以下内容复制到脚本中,并将文件保存为"generate_document.py":pythonfrom octemplate import Renderer# 创建一个Renderer 对象renderer = Renderer("template.odt")# 填充占位符data = {"name": "Alice","date": "2022-01-01","task1": "完成报告","task2": "开会讨论","task3": "编写代码"}renderer.set_vars(data)# 生成文档renderer.render("output.docx")在以上脚本中,我们首先导入了Octemplate 的Renderer 类。

LAB1 熟悉实验板与开发环境1. 熟悉实验板1.1 实验板使用注意1.Basys 3只接受5V直流输入,通过USB供电,也可以通过EXT供电,供电方式下面会讲到;2.Basys 3在上电后,不得插拔USB线,不得去动跳线开关;3.Basys 3远离水源;4.不要触碰实验板上的芯片,尤其是在上电时;5.拿实验板时,手拿实验板边缘;1.2 实验板使用介绍1.2.1概述实验板出厂后,会有一个用户手册详细记录实验板的外设以及芯片引脚与外设的连接关系。

实验板正面如图1.2-1所示。

图1.2-1 实验板顶视图图1.2-1标号对应的外设如下:表1.2-1 实验板外设标号1.2.2 供电方式实验板的供电方式有两种:USB供电或者EXT外部供电,通过供电配置跳线来完成选择。

供电配置跳线在示意图中16号位置,配置如图1.2-2所示。

图1.2-2 供电配置图1.2-3 上电加载将实验板正放,跳线开关接上面两根引脚时为外部供电EXT,接下面两根引脚时为USB供电,在本实验中,实验板都采用USB供电。

1.2.3 上电加载方式实验板在上电后,FPGA芯片会首先去找有没有相应的下载文件,如果有则开始运行,上电加载模式一共有三种:QSPI模式:QSPI是一种Flash存储器,实验板中的FPGA与QSPI相连接。

设置为QSPI模式后,FPGA在上电后会首先在QSPI里读配置文件(程序经过编译后的二进制代码)。

USB模式:上电后,FPGA会到⑪接口去找配置文件。

JTAG模式:上电后通过⑬加载配置文件。

在试验中,始终按下图选一配置,如图1.2-3所示。

1.2.4 其他另外,用户手册还详细描述了各个外设的接口和FPGA芯片引脚的连接情况,这个在开发FPGA时,是非常重要的信息,开发者在FPGA芯片中生成的数字电路的接口需要与FPGA引脚相连接,这样就可以操控不同的外设。

2. 熟悉开发环境2.1 开发环境介绍实验板的FPGA芯片属于Xilinx公司的ATRIX 7系列,其对应的开发环境是Xilinx 推出的Vivado套件。

MPLAB® Code Configurator SMPS Library Release NotesWhat is the MPLAB Code Configurator SMPS LibraryThe MPLAB Code Configurator SMPS Library allows quick and easy configuration, and code generation for 8-bit PIC SMPS applications.System Requirements1.MPLAB® X IDE v5.40 or later2.MCC v4.0.1 or later3.MCC Core v5.0.0 or later4.MCC PIC10 / PIC12 / PIC16 / PIC18 MCU Library 1.81.6 or later5.XC8 compiler v2.20 or laterRelated Hardware and Documentation SupportMPLAB Code Configurator Switch Mode Power Supply Library User's GuideCIP Hybrid Power Starter KitInstalling the MPLAB Code Configurator SMPS Library1.To install the MPLAB® Code Configurator Plugin:1.1.In the MPLAB X IDE, select Plugins from the Tools menu1.2.Select the Available Plugins tab1.3.Check the box for the MPLAB® Code Configurator v4, and click on Install2.To install the SMPS Library:2.1.In the MPLAB X IDE, select Options from the Tools menu2.2.Select the MPLAB® Code Configurator 4.x tab from Plugins option2.3.Click on Install Library/Open Library Folder2.4.Add SMPSPowerLibrary_vX.X.X.jar2.5.Restart MPLAB X IDE (optional)3.To load different SMPS Library version:3.1.Open MPLAB® Code Configurator v4 from the Tools menu3.2.Expand the Versions tab under Software/SMPS Power Library (loaded version is indicated by thegreen mark)3.3.Right click on the desired version of the library and select Mark for load3.4.Click on the Load Selected Libraries button to load the libraryWhat’s New•v1.4.0–Compatibility update with MCC Plugin v4.0.1 and MCC Core v5.0.0–Various output pin fixes•v1.3.0–Added CIP Hybrid Starter Kit (PCMC/VMC) Demo modules–Added a CIP SEPIC LED Driver Demo module•v1.2.1–Removed local peripheral modules–Added dependency to the MCC 8bit PIC Library•v1.2.0–Added support for PIC16(L)F176x devices–Updated the Compensator Block module with an override setting–Updated the Fault Block module with CIN- pin options–Updated the PCMC Control Mode module with LED dimming options –Added the Pulse Modulator Block module–Added the SEPIC_LED Topology module–Added up to four instances of each SMPS Library module•v1.0.0–Initial release with support for a Synchronous Buck Topology moduleSupported Families•8-bit Families–PIC16(L)F177x–PIC16(L)F176xTable of ContentsWhat is the MPLAB Code Configurator SMPS Library (1)1.System Requirements (1)2.Related Hardware and Documentation Support (1)3.Installing the MPLAB Code Configurator SMPS Library (1)4.What’s New (1)5.Supported Families (2)The Microchip Website (4)Product Change Notification Service (4)Customer Support (4)Microchip Devices Code Protection Feature (4)Legal Notice (5)Trademarks (5)Quality Management System (6)Worldwide Sales and Service (7)The Microchip WebsiteMicrochip provides online support via our website at /. This website is used to make files and information easily available to customers. Some of the content available includes:•Product Support – Data sheets and errata, application notes and sample programs, design resources, user’s guides and hardware support documents, latest software releases and archived software•General Technical Support – Frequently Asked Questions (FAQs), technical support requests, online discussion groups, Microchip design partner program member listing•Business of Microchip – Product selector and ordering guides, latest Microchip press releases, listing of seminars and events, listings of Microchip sales offices, distributors and factory representativesProduct Change Notification ServiceMicrochip’s product change notification service helps keep customers current on Microchip products. Subscribers will receive email notification whenever there are changes, updates, revisions or errata related to a specified product family or development tool of interest.To register, go to /pcn and follow the registration instructions.Customer SupportUsers of Microchip products can receive assistance through several channels:•Distributor or Representative•Local Sales Office•Embedded Solutions Engineer (ESE)•Technical SupportCustomers should contact their distributor, representative or ESE for support. Local sales offices are also available to help customers. A listing of sales offices and locations is included in this document.Technical support is available through the website at: /supportMicrochip Devices Code Protection FeatureNote the following details of the code protection feature on Microchip devices:•Microchip products meet the specifications contained in their particular Microchip Data Sheet.•Microchip believes that its family of products is secure when used in the intended manner and under normal conditions.•There are dishonest and possibly illegal methods being used in attempts to breach the code protection features of the Microchip devices. We believe that these methods require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data Sheets. Attempts to breach these codeprotection features, most likely, cannot be accomplished without violating Microchip’s intellectual property rights.•Microchip is willing to work with any customer who is concerned about the integrity of its code.•Neither Microchip nor any other semiconductor manufacturer can guarantee the security of its code. Code protection does not mean that we are guaranteeing the product is “unbreakable.” Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our products.Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act.If such acts allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.Legal NoticeInformation contained in this publication is provided for the sole purpose of designing with and using Microchip products. Information regarding device applications and the like is provided only for your convenience and may be superseded by updates. It is your responsibility to ensure that your application meets with your specifications.THIS INFORMATION IS PROVIDED BY MICROCHIP “AS IS”. MICROCHIP MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED, WRITTEN OR ORAL, STATUTORY OR OTHERWISE, RELATED TO THE INFORMATION INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF NON-INFRINGEMENT, MERCHANTABILITY, AND FITNESS FOR A PARTICULAR PURPOSE OR WARRANTIES RELATED TO ITS CONDITION, QUALITY, OR PERFORMANCE.IN NO EVENT WILL MICROCHIP BE LIABLE FOR ANY INDIRECT, SPECIAL, PUNITIVE, INCIDENTAL OR CONSEQUENTIAL LOSS, DAMAGE, COST OR EXPENSE OF ANY KIND WHATSOEVER RELATED TO THE INFORMATION OR ITS USE, HOWEVER CAUSED, EVEN IF MICROCHIP HAS BEEN ADVISED OF THE POSSIBILITY OR THE DAMAGES ARE FORESEEABLE. TO THE FULLEST EXTENT ALLOWED BY LAW, MICROCHIP'S TOTAL LIABILITY ON ALL CLAIMS IN ANY WAY RELATED TO THE INFORMATION OR ITS USE WILL NOT EXCEED THE AMOUNT OF FEES, IF ANY, THAT YOU HAVE PAID DIRECTLY TO MICROCHIP FOR THE INFORMATION. Use of Microchip devices in life support and/or safety applications is entirely at the buyer’s risk, and the buyer agrees to defend, indemnify and hold harmless Microchip from any and all damages, claims, suits, or expenses resulting from such use. No licenses are conveyed, implicitly or otherwise, under any Microchip intellectual property rights unless otherwise stated.TrademarksThe Microchip name and logo, the Microchip logo, Adaptec, AnyRate, AVR, AVR logo, AVR Freaks, BesTime, BitCloud, chipKIT, chipKIT logo, CryptoMemory, CryptoRF, dsPIC, FlashFlex, flexPWR, HELDO, IGLOO, JukeBlox, KeeLoq, Kleer, LANCheck, LinkMD, maXStylus, maXTouch, MediaLB, megaAVR, Microsemi, Microsemi logo, MOST, MOST logo, MPLAB, OptoLyzer, PackeTime, PIC, picoPower, PICSTART, PIC32 logo, PolarFire, Prochip Designer, QTouch, SAM-BA, SenGenuity, SpyNIC, SST, SST Logo, SuperFlash, Symmetricom, SyncServer, Tachyon, TempTrackr, TimeSource, tinyAVR, UNI/O, Vectron, and XMEGA are registered trademarks of Microchip Technology Incorporated in the U.S.A. and other countries.APT, ClockWorks, The Embedded Control Solutions Company, EtherSynch, FlashTec, Hyper Speed Control, HyperLight Load, IntelliMOS, Libero, motorBench, mTouch, Powermite 3, Precision Edge, ProASIC, ProASIC Plus, ProASIC Plus logo, Quiet-Wire, SmartFusion, SyncWorld, Temux, TimeCesium, TimeHub, TimePictra, TimeProvider, Vite, WinPath, and ZL are registered trademarks of Microchip Technology Incorporated in the U.S.A.Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any Capacitor, AnyIn, AnyOut, BlueSky, BodyCom, CodeGuard, CryptoAuthentication, CryptoAutomotive, CryptoCompanion, CryptoController, dsPICDEM, , Dynamic Average Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial Programming, ICSP, INICnet, Inter-Chip Connectivity, JitterBlocker, KleerNet, KleerNet logo, memBrain, Mindi, MiWi, MPASM, MPF, MPLAB Certified logo, MPLIB, MPLINK, MultiTRAK, NetDetach, Omniscient Code Generation, PICDEM, , PICkit, PICtail, PowerSmart, PureSilicon, QMatrix, REAL ICE, Ripple Blocker, SAM-ICE, Serial QuadI/O, SMART-I.S., SQI, SuperSwitcher, SuperSwitcher II, Total Endurance, TSHARC, USBCheck, VariSense, ViewSpan, WiperLock, Wireless DNA, and ZENA are trademarks of Microchip Technology Incorporated in the U.S.A. and other countries.SQTP is a service mark of Microchip Technology Incorporated in the U.S.A.The Adaptec logo, Frequency on Demand, Silicon Storage Technology, and Symmcom are registered trademarks of Microchip Technology Inc. in other countries.GestIC is a registered trademark of Microchip Technology Germany II GmbH & Co. KG, a subsidiary of Microchip Technology Inc., in other countries.All other trademarks mentioned herein are property of their respective companies.© 2020, Microchip Technology Incorporated, Printed in the U.S.A., All Rights Reserved.ISBN:Quality Management SystemFor information regarding Microchip’s Quality Management Systems, please visit /quality.Worldwide Sales and Service。

RELEASE NOTESLabWindows /CVI Version 7.1These release notes introduce LabWindows/CVI 7.1. Refer to thisdocument for system requirements, installation and activation instructions, and information about new features in LabWindows/CVI.Minimum System RequirementsTo run LabWindows/CVI, you must have the following items:•Personal computer using a Pentium 600 or higher microprocessor •Windows 2000/NT Service Pack 6/XP •800 × 600 resolution (or higher) video adapter •Minimum of 128 MB of RAM, 256 MB recommended •150 MB free hard disk space for full installation •Microsoft-compatible mouse •Microsoft Internet Explorer 5.0 or later, typical installationInstallation InstructionsNote If you have a previous version of LabWindows/CVI installed on your machine, be sure to install version 7.1 in a different directory or uninstall the older version before installing this version.1.Insert the LabWindows/CVI CD into the CD drive. If the CD does not run automatically, open Windows Explorer, right-click the CD driveicon, and select AutoPlay .2.Select Install LabWindows/CVI on the National InstrumentsLabWindows/CVI screen.™™3.In the User Information panel, enter the serial number found on yourCertificate of Ownership card.4.Continue to follow the instructions on the screen. Activation InstructionsComplete the following steps to activate LabWindows/CVI:unch LabWindows/CVI.2.The LabWindows/CVI – Unlicensed Version message box opens whenyou launch LabWindows/CVI for the first time. Click ActivateLicense, which launches the NI Activation Wizard.3.In the NI Activation Wizard, select a method to acquire the activationcode and click Next:–Automatically activate through a secure Internetconnection—Automatically receive an activation code.–Use a Web browser, email client, telephone, or fax machine toacquire an activation code—Contact National Instruments toobtain an activation code. You will then enter the code in theNI Activation Wizard to activate LabWindows/CVI.–Apply a 20-character activation code previously acquired forthis computer—Enter a code you have obtained to activateLabWindows/CVI.4.Enter or verify your serial number. Click Next.5.Continue to follow the instructions on the screen.6.When you successfully activate LabWindows/CVI, click Finish. What’s New in LabWindows/CVI7.1?This section includes information about changes and enhancements inLabWindows/CVI 7.1.Digital Graph ControlUse the digital graph control to plot and display arrays of data as lines orbuses. As with all other LabWindows/CVI controls, you can create a digitalgraph programmatically or in the User Interface Editor.You can find examples for using the digital graph control in the samples\newexamples.cws workspace.LabWindows/CVI Release For more information about the digital graph control, refer to the LibraryReference»User Interface Library»Controls»Control Types»DigitalGraph Control section of the LabWindows/CVI Help.Splitter ControlUse the splitter control to resize different components of your graphicaluser interface. You also can use the splitter control as a line decoration. Youcan create this control programmatically or in the User Interface Editor.You can find examples for using the splitter control in the samples\newexamples.cws workspace.For more information about the splitter control, refer to the LibraryReference»User Interface Library»Controls»Control Types»SplitterControl section of the LabWindows/CVI Help.Remote DebuggingWith remote debugging, the LabWindows/CVI debugger and the programyou are debugging can be on different computers. The debugger anddebuggee communicate over a TCP/IP network connection. To configureremote debugging, select Run»Configure Remote Debugging.For more information about remote debugging, refer to UsingLabWindows/CVI»Debugging Tools»Remote Debugging in theLabWindows/CVI Help.Debugging on RT TargetsUsing remote debugging, you can debug LabWindows/CVI-built DLLs ona remote LabVIEW Real-Time system.For more information about how to debug a DLL on an RT target, refer tothe Using LabWindows/CVI DLLs in LabVIEW Real-Time Applicationsapplication note, available through the LabWindows/CVI Bookshelf.Command Line InterfaceUse the LabWindows/CVI command line compiler, compile.exe, tocompile files and build projects from the command line. You can use thisfeature to automate builds. The command line compiler does not launch theLabWindows/CVI environment.© National Instruments Corporation3LabWindows/CVI Release NotesTry compiling a LabWindows/CVI sample project. compile.exe islocated in the National Instruments\CVI71 folder.For more information about compiling from the command line, refer toCommand Line Compiler in the LabWindows/CVI Help index.Function Panels in WorkspaceYou can edit and operate function panels from within the WindowConfinement Region of the Workspace window.Variable and Watch Windows in WorkspaceYou can view the Variable and Watch windows from within the DebuggingRegion in the Workspace window.Code Completion EnhancementsLabWindows/CVI includes the following enhancements in the Sourcewindow:•Launch function panel customization dialog boxes. For example, typeLoadPanel in a Source window. After you type the openingparentheses and the first parameter, notice the ... button next toFilename in the function prototype tooltip. Click the button or press<Ctrl-Shift-Enter> to view the Open dialog box.•Select constant values. Parameters with predefined values, attributes,and attribute values have a ... button in the function prototype tooltipwhen they are active. For example, type OpenComConfig in a Sourcewindow. You can select a value for COMPort by clicking the ... buttonor pressing <Ctrl-Shift-Enter>. To see an example of selecting anattribute, type SetCtrlAttribute in a Source window. You canselect an attribute for the ControlAttribute parameter and select anattribute value.•Declare variables. As you type values for the parameters, press<Ctrl-D> to declare a variable. LabWindows/CVI inserts thedeclaration code at the top of the function.•View function and parameter help. As you type the function, you canpress <F1> or click the question mark button in the function prototypeto view help for the active function or parameter.For more information about code completion enhancements, refer toSource Code Completion Options in the LabWindows/CVI Help index. LabWindows/CVI Release TCP/IP EnhancementsThe LabWindows/CVI TCP Support Library contains several newfunctions:•RegisterTCPServerEx—Includes a parameter in which you canspecify the address of the localhost network interface to use for theconnection.•UnregisterTCPServerEx—Includes a parameter in which you canspecify the address of the localhost network interface to use for theconnection.•ConnectToTCPServerEx—Includes a parameter in which you canspecify the port number to use for the client on the localhost.•GetAllTCPHostAddresses—Returns all of the network interface IPaddresses of the computer on which your program is currently running.For more information about the new functions in the TCP Support Library,refer to the function panel help.Internet LibraryThe LabWindows/CVI Internet Toolkit is now a LabWindows/CVI library.Use this library to complete the following actions:•Send and receive files to and from a remote FTP server•Send commands to and get output from a remote Telnet server•Send email to any internet email address•Send commands to and retrieve email from POP3 servers•Ping network machines to see if they are available•Launch the default Web browserYou can find examples for using the Internet Library in the samples\newexamples.cws workspace.For more information about the Internet Library, refer to the LibraryReference»Internet Library section of the LabWindows/CVI Help.DIAdem Connectivity LibraryUse this library to save test data in National Instruments DIAdem fileformat. DIAdem is a powerful tool for interactive visualization, analysis,and management of test data. You also can use this library toprogrammatically read DIAdem files.You can find examples for using the DIAdem Connectivity Library in thesamples\newexamples.cws workspace.© National Instruments Corporation5LabWindows/CVI Release NotesFor more information about this library, refer to the Library Reference»DIAdem Connectivity Library section of the LabWindows/CVI Help.Pre- and Post-Build StepsSpecify actions to execute before and after you build a project inLabWindows/CVI. To add build steps to your project, select Build»BuildSteps.You can use build steps to remove manual steps from your build process.For example, if your build process consists of synching to the latest sourcefiles in your source code control program, running a batch file, buildingyour project, and then checking the project back into your source codecontrol program, you can add these items as build steps. When you buildyour project, LabWindows/CVI will complete these steps.For more information about build steps, refer to Build Steps in theLabWindows/CVI Help index.Event Interface for LabWindows/CVI COM ServerLabWindows/CVI 7.1 includes support for COM events in theLabWindows/CVI ActiveX server. This feature allows ActiveX clients thatautomate LabWindows/CVI to be notified about important state changes,completion of asynchronous tasks, and so on. LabWindows/CVI ResourcesHow do I get started?Read the Getting Started with LabWindows/CVI manual, which provides atutorial of the LabWindows/CVI environment.Are there known issues or late-breaking information?Refer to the LabWindows/CVI ReadMe, which you can access fromStart»Programs»National Instruments»LabWindows CVI»LabWindows CVI ReadMe. The ReadMe contains information aboutknown issues.Where can I find reference information?The LabWindows/CVI Help contains complete reference information. Thehelp file includes the following sections:•Using LabWindows/CVI describes the LabWindows/CVI developmentenvironment and features.LabWindows/CVI Release •Library Reference provides information about functions you can callin LabWindows/CVI.•Programmer Reference provides information to help you developapplications.•Tools Library provides information about the LabWindows/CVIToolslib controls.Where can I find examples?Find examples with the NI Example Finder, which you can access byselecting Help»Find Examples.Is there a list of LabWindows/CVI documentation?The LabWindows/CVI Bookshelf contains all the LabWindows/CVIdocumentation, including manuals, application notes, and white papers, inelectronic format. You can launch the Bookshelf from Start»Programs»National Instruments»LabWindows CVI»LabWindows CVIBookshelf.Where else can I go for LabWindows/CVI information?Visit the LabWindows/CVI Web site and NI Developer Zone at forthe most up-to-date information about LabWindows/CVI.© National Instruments Corporation7LabWindows/CVI Release NotesCVI™, DIAdem™, LabVIEW™, National Instruments™, NI™, ™, and NI Developer Zone ™ are trademarks of National Instruments Corporation. Product and company names mentioned herein are trademarks or trade names of their respective companies. For patents covering National Instrumentsproducts, refer to the appropriate location: Help»Patents in your software, the patents.txt file on your CD, or /patents. For a listing of the copyrights, conditions, and disclaimers regarding components used in USI (Xerces C++, ICU, and HDF5), refer to the USICopyrights.chm.© 2003–2004 National Instruments Corp. All rights reserved. Printed in Ireland.323607B-01Sep04 *323607B-01*。

pnetlab使用-回复关于pnetlab 使用的步骤和指南。

这篇文章将详细介绍pnetlab 的安装、配置和使用过程。

我们将逐步回答您在文章主题中提到的问题,并提供有关pnetlab 的相关信息和使用技巧。

第一步:安装pnetlab安装pnetlab 是使用它的第一步。

pnetlab 是一个基于Python 的网络实验模拟平台,因此首先需要确保具备以下环境和依赖项:1. Python:确保您的计算机已经安装了Python。

推荐使用Python 3.x 版本。

2. pip:pip 是Python 的软件包管理器。

检查您的Python 安装中是否包含pip。

如果没有,您可以通过运行以下命令来安装它:python get-pip.py3. pnetlab:通过pip 安装pnetlab。

运行以下命令来安装pnetlab:pip install pnetlab这将自动安装pnetlab 并其所需的依赖项。

第二步:配置pnetlab安装完pnetlab 后,需要进行一些必要的配置,以确保其顺利运行。

1. 网络设备镜像:为了模拟网络设备的行为,pnetlab 需要相应的网络设备镜像文件。

您可以从官方供应商处获取这些镜像文件(如Cisco IOS 镜像),并将它们放置在一个单独的文件夹中。

确保该文件夹的路径易于访问,以便将来在配置中引用。

2. 网络拓扑:在使用pnetlab 前,您需要根据您的需求创建网络拓扑。

可以使用pnetlab 提供的图形界面工具或编程API 来创建和修改网络拓扑。

pnetlab topology create mytopology这会创建一个名为"mytopology" 的新拓扑。

3. 设备导入:为了使pnetlab 能够管理网络设备实例,您需要将网络设备导入到拓扑中。

您可以使用pnetlab 提供的设备库或导入自定义设备。

以下是一个示例命令,用于将一个Cisco 设备导入到拓扑中:pnetlab topology import_device mytopology device cisco_ios name router1这将在名为"mytopology" 的拓扑中导入一个名为"router1" 的Cisco 设备。