J-STD-020D(中英文对照版)

- 格式:pdf

- 大小:475.38 KB

- 文档页数:13

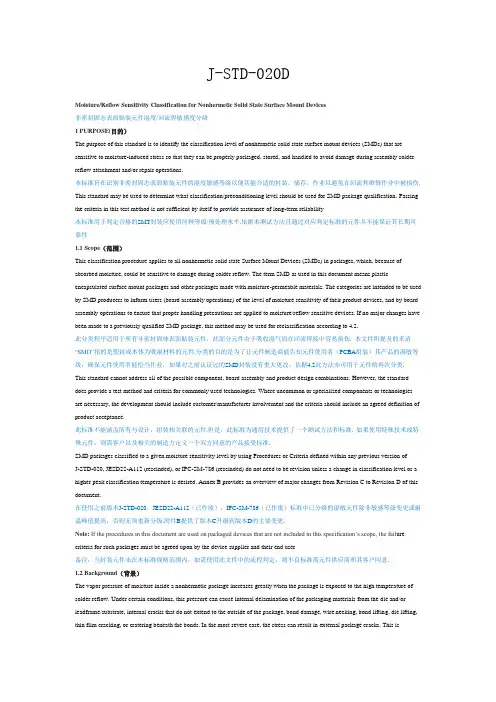

J-STD-020DMoisture/Reflow Sensitivity Classification for Nonhermetic Solid State Surface Mount Devices非密封固态表面贴装元件湿度/回流焊敏感度分级1 PURPOSE(目的)The purpose of this standard is to identify the classification level of nonhermetic solid state surface mount devices (SMDs) that are sensitive to moisture-induced stress so that they can be properly packaged, stored, and handled to avoid damage during assembly solder reflow attachment and/or repair operations.本标准旨在识别非密封固态表面贴装元件的湿度敏感等级以便其能合适的封装,储存,作业以避免在回流和维修作业中被损伤. This standard may be used to determine what classification/preconditioning level should be used for SMD package qualification. Passing the criteria in this test method is not sufficient by itself to provide assurance of long-term reliability本标准用于判定合格的SMT封装应使用何种等级/预处理水平.依据本测试方法且通过对应判定标准的元件并不能保证其长期可靠性1.1 Scope(范围)This classification procedure applies to all nonhermetic solid state Surface Mount Devices (SMDs) in packages, which, because of absorbed moisture, could be sensitive to damage during solder reflow. The term SMD as used in this document means plastic encapsulated surface mount packages and other packages made with moisture-permeable materials. The categories are intended to be used by SMD producers to inform users (board assembly operations) of the level of moisture sensitivity of their product devices, and by board assembly operations to ensure that proper handling precautions are applied to moisture/reflow sensitive devices. If no major changes have been made to a previously qualified SMD package, this method may be used for reclassification according to 4.2.此分类程序适用于所有非密封固体表面贴装元件,此部分元件由于吸收湿气而在回流焊接中容易损伤. 本文件所提及的术语“SMD”指的是塑封或本体为吸湿材料的元件.分类的目的是为了让元件制造商能告知元件使用者(PCBA组装)其产品的湿敏等级,确保元件使用者能恰当作业,如果对之前认证过的SMD封装没有重大更改,依据4.2此方法亦可用于元件的再次分类.This standard cannot address all of the possible component, board assembly and product design combinations. However, the standard does provide a test method and criteria for commonly used technologies. Where uncommon or specialized components or technologies are necessary, the development should include customer/manufacturer involvement and the criteria should include an agreed definition of product acceptance.此标准不能涵盖所有与设计,组装相关联的元件.但是,此标准为通用技术提供了一个测试方法和标准. 如果使用特殊技术或特殊元件,则需客户以及相关的制造方定义一个双方同意的产品接受标准.SMD packages classified to a given moisture sensitivity level by using Procedures or Criteria defined within any previous version ofJ-STD-020, JESD22-A112 (rescinded), or IPC-SM-786 (rescinded) do not need to be revision unless a change in classification level or a higher peak classification temperature is desired. Annex B provides an overview of major changes from Revision C to Revision D of this document.在使用之前版本J-STD-020,JESD22-A112(已作废),IPC-SM-786(已作废)标准中已分级的湿敏元件除非敏感等级变更或耐温峰值提高,否则无须重新分级.附件B提供了版本C升级到版本D的主要变更.Note: If the procedures in this document are used on packaged devices that are not included in this specification’s scope, the fail ure criteria for such packages must be agreed upon by the device supplier and their end user备注:当封装元件未在本标准规格范围内,如需使用此文件中的流程判定,则不良标准需元件供应商和其客户同意.1.2 Background(背景)The vapor pressure of moisture inside a nonhermetic package increases greatly when the package is exposed to the high temperature of solder reflow. Under certain conditions, this pressure can cause internal delamination of the packaging materials from the die and/or leadframe/substrate, internal cracks that do not extend to the outside of the package, bond damage, wire necking, bond lifting, die lifting, thin film cracking, or cratering beneath the bonds. In the most severe case, the stress can result in external package cracks. This iscommonly referred to as the ‘‘popcorn’’ phenomenon because the internal stress causes the package to bulge and then crack wit h an audible ‘‘pop.’’ SMDs are more susceptible to this problem than through-hole parts because they are exposed to higher temperatures during reflow soldering. The reason for this is that the soldering operation must occur on the same side of the board as the SMD device. For wave-soldered through-hole devices, the soldering operation occurs under the board that shields the devices from the hot solder through-hole devices, the soldering operation occurs under the board that shields the devices from the hot solder Throughhole devices that are soldered using intrusive soldering or ‘‘pin in paste’’ processes may experience the same type of moisture-induced failures as SMT devices.非密封元件封装在回流高温条件下,其内部水蒸气压力猛增.在某一件下,压力将导致封装从内部分层或者内裂,邦定受损。

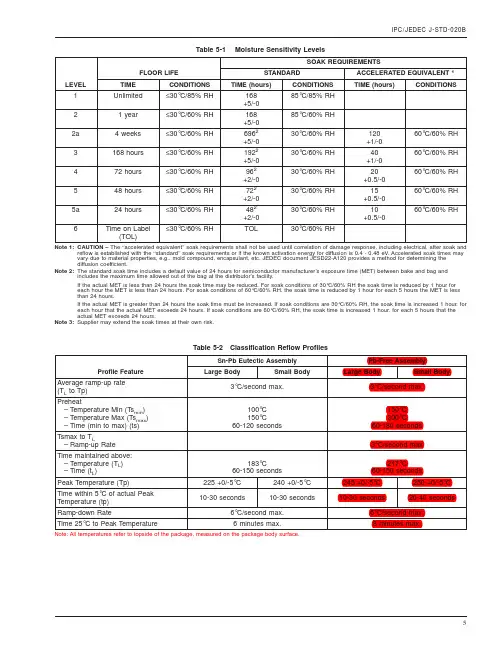

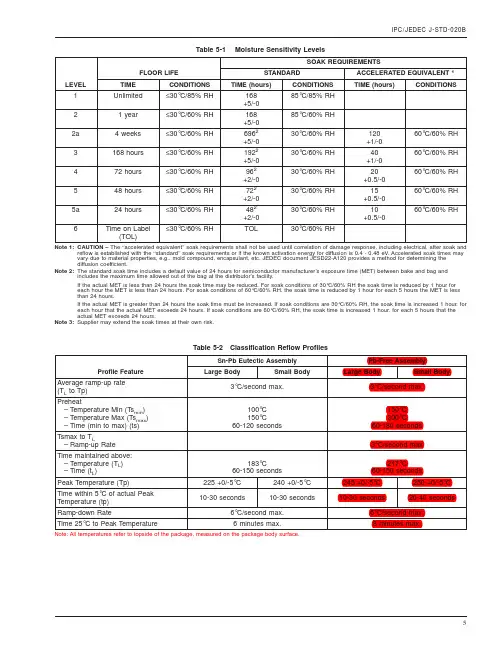

Table 5-1Moisture Sensitivity LevelsLEVELFLOOR LIFESOAK REQUIREMENTSSTANDARDACCELERATED EQUIVALENT 1TIMECONDITIONSTIME (hours)CONDITIONSTIME (hours)CONDITIONS1Unlimited ≤30°C/85%RH 168+5/-085°C/85%RH 21year ≤30°C/60%RH 168+5/-085°C/60%RH 2a 4weeks ≤30°C/60%RH 6962+5/-030°C/60%RH 120+1/-060°C/60%RH 3168hours ≤30°C/60%RH 1922+5/-030°C/60%RH 40+1/-060°C/60%RH 472hours ≤30°C/60%RH 962+2/-030°C/60%RH 20+0.5/-060°C/60%RH 548hours ≤30°C/60%RH 722+2/-030°C/60%RH 15+0.5/-060°C/60%RH 5a 24hours ≤30°C/60%RH 482+2/-030°C/60%RH 10+0.5/-060°C/60%RH6Time on Label(TOL)≤30°C/60%RHTOL30°C/60%RHNote 1:CAUTION –The ‘‘accelerated equivalent’’soak requirements shall not be used until correlation of damage response,including electrical,after soak andreflow is established with the ‘‘standard’’soak requirements or if the known activation energy for diffusion is 0.4-0.48eV.Accelerated soak times may vary due to material properties,e.g.,mold compound,encapsulant,etc.JEDEC document JESD22-A120provides a method for determining the diffusion coefficient.Note 2:The standard soak time includes a default value of 24hours for semiconductor manufacturer’s exposure time (MET)between bake and bag andincludes the maximum time allowed out of the bag at the distributor’s facility.If the actual MET is less than 24hours the soak time may be reduced.For soak conditions of 30°C/60%RH the soak time is reduced by 1hour for each hour the MET is less than 24hours.For soak conditions of 60°C/60%RH,the soak time is reduced by 1hour for each 5hours the MET is less than 24hours.If the actual MET is greater than 24hours the soak time must be increased.If soak conditions are 30°C/60%RH,the soak time is increased 1hour.for each hour that the actual MET exceeds 24hours.If soak conditions are 60°C/60%RH,the soak time is increased 1hour.for each 5hours that the actual MET exceeds 24hours.Note 3:Supplier may extend the soak times at their own risk.Table 5-2Classification Reflow ProfilesProfile FeatureSn-Pb Eutectic Assembly Pb-Free AssemblyLarge BodySmall BodyLarge BodySmall BodyAverage ramp-up rate (T L to Tp)3°C/second max.3°C/second max.Preheat–Temperature Min (Ts min )–Temperature Max (Ts max )–Time (min to max)(ts)100°C 150°C60-120seconds150°C 200°C60-180seconds Tsmax to T L–Ramp-up Rate 3°C/second maxTime maintained above:–Temperature (T L )–Time (t L )183°C60-150seconds217°C60-150secondsPeak Temperature (Tp)225+0/-5°C 240+0/-5°C 245+0/-5°C 250+0/-5°C Time within 5°C of actual Peak Temperature (tp)10-30seconds10-30seconds10-30seconds20-40secondsRamp-down Rate6°C/second max.6°C/second max.Time 25°C to Peak Temperature6minutes max.8minutes max.Note:All temperatures refer to topside of the package,measured on the package body surface.IPC/JEDEC J-STD-020B5。

Table 5-1Moisture Sensitivity LevelsLEVELFLOOR LIFESOAK REQUIREMENTSSTANDARDACCELERATED EQUIVALENT 1TIMECONDITIONSTIME (hours)CONDITIONSTIME (hours)CONDITIONS1Unlimited ≤30°C/85%RH 168+5/-085°C/85%RH 21year ≤30°C/60%RH 168+5/-085°C/60%RH 2a 4weeks ≤30°C/60%RH 6962+5/-030°C/60%RH 120+1/-060°C/60%RH 3168hours ≤30°C/60%RH 1922+5/-030°C/60%RH 40+1/-060°C/60%RH 472hours ≤30°C/60%RH 962+2/-030°C/60%RH 20+0.5/-060°C/60%RH 548hours ≤30°C/60%RH 722+2/-030°C/60%RH 15+0.5/-060°C/60%RH 5a 24hours ≤30°C/60%RH 482+2/-030°C/60%RH 10+0.5/-060°C/60%RH6Time on Label(TOL)≤30°C/60%RHTOL30°C/60%RHNote 1:CAUTION –The ‘‘accelerated equivalent’’soak requirements shall not be used until correlation of damage response,including electrical,after soak andreflow is established with the ‘‘standard’’soak requirements or if the known activation energy for diffusion is 0.4-0.48eV.Accelerated soak times may vary due to material properties,e.g.,mold compound,encapsulant,etc.JEDEC document JESD22-A120provides a method for determining the diffusion coefficient.Note 2:The standard soak time includes a default value of 24hours for semiconductor manufacturer’s exposure time (MET)between bake and bag andincludes the maximum time allowed out of the bag at the distributor’s facility.If the actual MET is less than 24hours the soak time may be reduced.For soak conditions of 30°C/60%RH the soak time is reduced by 1hour for each hour the MET is less than 24hours.For soak conditions of 60°C/60%RH,the soak time is reduced by 1hour for each 5hours the MET is less than 24hours.If the actual MET is greater than 24hours the soak time must be increased.If soak conditions are 30°C/60%RH,the soak time is increased 1hour.for each hour that the actual MET exceeds 24hours.If soak conditions are 60°C/60%RH,the soak time is increased 1hour.for each 5hours that the actual MET exceeds 24hours.Note 3:Supplier may extend the soak times at their own risk.Table 5-2Classification Reflow ProfilesProfile FeatureSn-Pb Eutectic Assembly Pb-Free AssemblyLarge BodySmall BodyLarge BodySmall BodyAverage ramp-up rate (T L to Tp)3°C/second max.3°C/second max.Preheat–Temperature Min (Ts min )–Temperature Max (Ts max )–Time (min to max)(ts)100°C 150°C60-120seconds150°C 200°C60-180seconds Tsmax to T L–Ramp-up Rate 3°C/second maxTime maintained above:–Temperature (T L )–Time (t L )183°C60-150seconds217°C60-150secondsPeak Temperature (Tp)225+0/-5°C 240+0/-5°C 245+0/-5°C 250+0/-5°C Time within 5°C of actual Peak Temperature (tp)10-30seconds10-30seconds10-30seconds20-40secondsRamp-down Rate6°C/second max.6°C/second max.Time 25°C to Peak Temperature6minutes max.8minutes max.Note:All temperatures refer to topside of the package,measured on the package body surface.IPC/JEDEC J-STD-020B5。

J-STD-020DMoisture/Reflow Sensitivity Classification for Nonhermetic Solid State Surface Mount Devices非密封固态表面贴装元件湿度/回流焊敏感度分级1 PURPOSE(目的)The purpose of this standard is to identify the classification level of nonhermetic solid state surface mount devices (SMDs) that are sensitive to moisture-induced stress so that they can be properly packaged, stored, and handled to avoid damage during assembly solder reflow attachment and/or repair operations.本标准旨在识别非密封固态表面贴装元件的湿度敏感等级以便其能合适的封装,储存,作业以避免在回流和维修作业中被损伤. This standard may be used to determine what classification/preconditioning level should be used for SMD package qualification. Passing the criteria in this test method is not sufficient by itself to provide assurance of long-term reliability本标准用于判定合格的SMT封装应使用何种等级/预处理水平.依据本测试方法且通过对应判定标准的元件并不能保证其长期可靠性1.1 Scope(范围)This classification procedure applies to all nonhermetic solid state Surface Mount Devices (SMDs) in packages, which, because of absorbed moisture, could be sensitive to damage during solder reflow. The term SMD as used in this document means plastic encapsulated surface mount packages and other packages made with moisture-permeable materials. The categories are intended to be used by SMD producers to inform users (board assembly operations) of the level of moisture sensitivity of their product devices, and by board assembly operations to ensure that proper handling precautions are applied to moisture/reflow sensitive devices. If no major changes have been made to a previously qualified SMD package, this method may be used for reclassification according to 4.2.此分类程序适用于所有非密封固体表面贴装元件,此部分元件由于吸收湿气而在回流焊接中容易损伤. 本文件所提及的术语“SMD”指的是塑封或本体为吸湿材料的元件.分类的目的是为了让元件制造商能告知元件使用者(PCBA组装)其产品的湿敏等级,确保元件使用者能恰当作业,如果对之前认证过的SMD封装没有重大更改,依据4.2此方法亦可用于元件的再次分类.This standard cannot address all of the possible component, board assembly and product design combinations. However, the standard does provide a test method and criteria for commonly used technologies. Where uncommon or specialized components or technologies are necessary, the development should include customer/manufacturer involvement and the criteria should include an agreed definition of product acceptance.此标准不能涵盖所有与设计,组装相关联的元件.但是,此标准为通用技术提供了一个测试方法和标准. 如果使用特殊技术或特殊元件,则需客户以及相关的制造方定义一个双方同意的产品接受标准.SMD packages classified to a given moisture sensitivity level by using Procedures or Criteria defined within any previous version ofJ-STD-020, JESD22-A112 (rescinded), or IPC-SM-786 (rescinded) do not need to be revision unless a change in classification level or a higher peak classification temperature is desired. Annex B provides an overview of major changes from Revision C to Revision D of this document.在使用之前版本J-STD-020,JESD22-A112(已作废),IPC-SM-786(已作废)标准中已分级的湿敏元件除非敏感等级变更或耐温峰值提高,否则无须重新分级.附件B提供了版本C升级到版本D的主要变更.Note: If the procedures in this document are used on packaged devices that are not included in this specification’s scope, the fail ure criteria for such packages must be agreed upon by the device supplier and their end user备注:当封装元件未在本标准规格范围内,如需使用此文件中的流程判定,则不良标准需元件供应商和其客户同意.1.2 Background(背景)The vapor pressure of moisture inside a nonhermetic package increases greatly when the package is exposed to the high temperature of solder reflow. Under certain conditions, this pressure can cause internal delamination of the packaging materials from the die and/or leadframe/substrate, internal cracks that do not extend to the outside of the package, bond damage, wire necking, bond lifting, die lifting, thin film cracking, or cratering beneath the bonds. In the most severe case, the stress can result in external package cracks. This iscommonly referred to as the ‘‘popcorn’’ phenomenon because the internal stress causes the package to bulge and then crack wit h an audible ‘‘pop.’’ SMDs are more susceptible to this problem than through-hole parts because they are exposed to higher temperatures during reflow soldering. The reason for this is that the soldering operation must occur on the same side of the board as the SMD device. For wave-soldered through-hole devices, the soldering operation occurs under the board that shields the devices from the hot solder through-hole devices, the soldering operation occurs under the board that shields the devices from the hot solder Throughhole devices that are soldered using intrusive soldering or ‘‘pin in paste’’ processes may experience the same type of moisture-induced failures as SMT devices.非密封元件封装在回流高温条件下,其内部水蒸气压力猛增.在某一件下,压力将导致封装从内部分层或者内裂,邦定受损。

j std 020标准J STD 020标准。

J STD 020标准是一项电子组件可靠性测试的标准,旨在确保电子元件在各种环境条件下的可靠性和稳定性。

该标准是由美国电子工业联合会(EIA)和美国国防部(DOD)共同制定的,适用于各种类型的电子元件,包括集成电路、电容器、电阻器等。

J STD 020标准的制定对于保障电子设备的可靠性和稳定性具有重要意义,也对电子行业的发展起着积极的推动作用。

首先,J STD 020标准对电子元件的存储条件和包装要求进行了详细规定。

在电子元件的存储过程中,各种环境因素都会对其性能产生影响,因此需要在特定的环境条件下进行存储,并且采取合适的包装措施,以确保元件在存储期间不受到损坏或腐蚀。

J STD 020标准明确了存储条件的温度、湿度要求,以及包装材料和方法的规定,从而有效保护了电子元件的质量和稳定性。

其次,J STD 020标准还对电子元件的焊接可靠性进行了严格的测试要求。

焊接是电子元件组装过程中至关重要的一环,焊接质量的好坏直接影响到整个电子设备的可靠性和稳定性。

J STD 020标准规定了电子元件在不同环境条件下的焊接测试方法和标准,包括热冲击测试、湿热循环测试等,以确保元件在焊接过程中不会出现损坏或失效,从而提高了电子设备的可靠性。

此外,J STD 020标准还对电子元件的可靠性试验进行了全面的规定。

可靠性试验是评估电子元件在各种环境条件下性能稳定性的重要手段,通过对元件进行高温、低温、湿热等试验,可以有效地检测元件的可靠性和稳定性。

J STD 020标准明确了各种试验的具体方法和要求,确保了试验结果的准确性和可靠性,为电子元件的可靠性评估提供了有力的支持。

总的来说,J STD 020标准的制定对于提高电子元件的可靠性和稳定性具有重要意义,为电子行业的发展提供了有力的支持。

通过对电子元件的存储条件、焊接可靠性和可靠性试验进行严格的规定,J STD 020标准有效地保障了电子设备的质量和稳定性,为电子行业的可持续发展提供了有力保障。

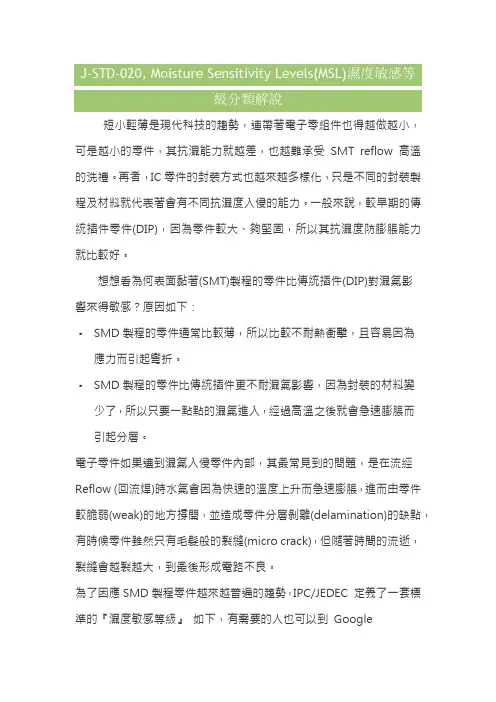

短小輕薄是現代科技的趨勢,連帶著電子零組件也得越做越小,可是越小的零件,其抗濕能力就越差,也越難承受SMT reflow 高溫的洗禮。

再者,IC零件的封裝方式也越來越多樣化,只是不同的封裝製程及材料就代表著會有不同抗濕度入侵的能力。

一般來說,較早期的傳統插件零件(DIP),因為零件較大、夠堅固,所以其抗濕度防膨脹能力就比較好。

想想看為何表面黏著(SMT)製程的零件比傳統插件(DIP)對濕氣影響來得敏感?原因如下:▪SMD製程的零件通常比較薄,所以比較不耐熱衝擊,且容易因為應力而引起彎折。

▪SMD製程的零件比傳統插件更不耐濕氣影響,因為封裝的材料變少了,所以只要一點點的濕氣進入,經過高溫之後就會急速膨脹而引起分層。

電子零件如果遭到濕氣入侵零件內部,其最常見到的問題,是在流經Reflow (回流焊)時水氣會因為快速的溫度上升而急速膨脹,進而由零件較脆弱(weak)的地方撐開,並造成零件分層剝離(delamination)的缺點,有時候零件雖然只有毛髮般的裂縫(micro crack),但隨著時間的流逝,裂縫會越裂越大,到最後形成電路不良。

為了因應SMD製程零件越來越普遍的趨勢,IPC/JEDEC 定義了一套標準的『濕度敏感等級』如下,有需要的人也可以到Google找J-STD-020。

不過要注意的是,這份標準該主要在幫助IC製造廠確定其所生產的元器件對潮濕的敏感性,並列出幾種潮濕等級分類與其停留於車間的使用期限。

1) TOL means ‘Time on Label’, or the time indicated on the label of the packing.2) The standard soak time is the sum of the default value of 24H for the semiconductor manufacturer’s exposure time (MET) between bake and bag and the floor life or maximum time allowed out of the bag at the end user or distributor’s facility. Forexample, an MSL 3 package will require a standard soak time of 192 hours, which is 168 hours of floor life plus 24 hours between bake and bag at the semiconductor manufacturer.『濕度敏感等級』MSL (Moisture Sensitivity levels),由小排到大,數字越小的表示其抗濕度能力越好;數字越大的,表示其可以曝露於環境濕氣的時間要越短。

ECN HISTORY LISTREV DATE DESCRIPTION APPROVED CHECKED DRAWN 1.018/06/20新發行羅宜春梁周虎許靜備注B:Dimension BxC.C:Type Standard.D:Inductance R10=0.1uh,1R0=1.0uh,100=10uh,101=100uh,102=1000uh. E:Inductance Tolerance K=±10%,L=±15%,M=±20%,N=±25%,Y=±30%F:Code Marking:Black.100and1536(15YY,36WW,follow production date).5.Specification1.Test frequency:Ls:100KHz/1.0V.2.All test data referenced to25℃ambient.3.Testing Instrument(or equ):L:HP4284A,CH11025,CH3302,CH1320,CH1320S LCR METER/Rdc:CH16502,Agilent33420A MICRO OHMMETER.4.Heat Rated Current(Irms)will cause the coil temperature rise approximatelyΔT of40℃5.Saturation Current(Isat)will cause L0to drop approximately30%.6.The part temperature(ambient+temp rise)should not exceed125℃under worst case operating conditions.Circuit design,component,PCB trace size andthickness,airflow and other cooling provisions all affect the part temperature.Part temperature should be verified in the end application.7.Special inquiries besides the above common used types can be met on your requirement.6.Material List7.Reliability and Test ConditionItemPerformanceTest ConditionOperating temperature-40~+125℃(Including self-temperature rise)Storage temperature1.-10~+40℃,50~60%RH (Product with taping )2.-40~+125℃(on board)Electrical Performance TestInductanceRefer to standard electrical characteristics list.HP4284A,CH11025,CH3302,CH1320,CH1320S LCR Meter.DCRCH16502,Agilent33420A Micro-Ohm Meter.Saturation Current (Isat)Approximately △L30%.Saturation DC Current (Isat)will cause L0to drop △L(%)Heat Rated Current (Irms)Approximately △T40℃Heat Rated Current (Irms)will cause the coil temperature rise △T(℃).1.Applied the allowed DC current2.Temperature measured by digital surface thermometerReliability TestLife TestAppearance :No damage.Impedance :within ±15%of initial value Inductance :within ±10%of initial valueQ :Shall not exceed the specification value.RDC :within ±15%of initial value and shall not exceed the specification valuePreconditioning:Run through IR reflow for 2times.(IPC/JEDECJ-STD-020DClassification Reflow Profiles)Temperature :125±2℃(Inductor)Applied current :rated current Duration :1000±12hrsMeasured at room temperature after placing for 24±2hrs.Load HumidityPreconditioning:Run through IR reflow for 2times.(IPC/JEDECJ-STD-020DClassification Reflow Profiles)Humidity :85±2﹪R.H,Temperature :85℃±2℃Duration :1000hrs Min.with 100%rated currentMeasured at room temperature after placing for 24±2hrs.Moisture ResistancePreconditioning:Run through IR reflow for 2times.(IPC/JEDECJ-STD-020DClassification Reflow Profiles)1.Baked at50℃for 25hrs,measured at room temperature after placing for 4hrs.2.Raise temperature to 65±2℃90-100%RH in 2.5hrs,and keep 3hours,cool down to 25℃in 2.5hrs.3.Raise temperature to 65±2℃90-100%RH in 2.5hrs,and keep 3hours,cool down to 25℃in2.5hrs,keep at 25℃for 2hrs then keep at -10℃for 3hrs4.Keep at 25℃80-100%RH for 15min and vibrate at the frequency of 10to 55Hz to 10Hz,measure at room temperature after placing for 1~2hrs.Thermal shockPreconditioning:Run through IR reflow for 2times.(IPC/JEDECJ-STD-020DClassification Reflow Profiles)Condition for 1cycleStep1:-40±2℃30±5min Step2:25±2℃≦0.5minStep3:125±2℃30±5minNumber of cycles :500Measured at room fempraturc after placing for 24±2hrs.VibrationPreconditioning:Run through IR reflow for 2times.(IPC/JEDECJ-STD-020DClassification Reflow Profiles)Oscillation Frequency:10~2K ~10Hz for 20minutes Equipment :Vibration checker Total Amplitude:1.52mm±10%Testing Time :12hours(20minutes,12cycles each of 3orientations)。

SMD温湿度敏感元件作业,运输,储存,包装标准1.前言SMD零件的出现直接带来了新的挑战,而这些挑战的重心又在于包装的品质和可靠性。

本文讲述了floorlife在作业,包装,运输,的等级标准。

J-STD-020说明了湿敏元件级别,JEP113说明了标签要求周围环境中的湿气会通过包装材料渗透到包装内部,并在不同材料的表面聚结。

在组装工艺中,SMD 元件贴装在PCB上时会经历超过200℃,在焊接时,湿气的膨胀会造成一些列的焊接品质问题。

2.目的本文旨在为使用,运输,存储,包装SMD湿敏元件提供标准。

通过本文内的方法,可以避免零件受潮和零件在过IR后可靠性下降。

通过本文的各个程序,可以达到无害回焊。

热烘可以使SMD零件得到长达12个月的包装存储寿命。

3.范围3.1包装3.1.1本标准适用于PCBA中无需密封SMD零件的作业,其中包括聚合分子材料和塑胶材料3.1.2密封包装大零件无湿气风险,不必作防潮3.2组装制程3.2.1本标准适用于PCBAIR,VPR等制程,不适用于波峰焊3.2.2本标准亦适用于受潮零件的烘烤或重工3.2.3本标准不适用于不过回焊炉的零件3.3可靠性3.3.1内容描述中的方法可以保证PCBA的成品可靠性是可评估的(标准J-STD-020和JESD22-A113)3.3.2本文不对焊接可靠性作评述4.涉及文件4.1EIAJEDECEIA-541静电放电敏感元件包装要求EIA-583湿气敏感元件包装要求EIA-625静电放电敏感设备操作要求JEP-113湿气敏感设备标识JESD22-A113不气密包装可靠性测试条件要求4.2防护部分MIL-B-131阻湿材料(隔绝湿气,不透气的)-MIL-B-81705透气的,无静电的,可加热处理的MIL-D-3464活性干燥剂,MIL-I8835指示,湿度卡5.定义活性干燥剂:全新干燥剂或是经过依照推荐标准进行烘烤恢复原始规格的干燥剂6.包装6.1包装要求详见下表16.2零件包装前的烘烤6.2.1湿敏级别在2a 到5a 之间的零件在做防潮包装之前必须要做烘烤处理。

SMD温湿度敏感元件作业,运输,储存,包装标准1.前言SMD零件的出现直接带来了新的挑战,而这些挑战的重心又在于包装的品质和可靠性。

本文讲述了floor life 在作业,包装,运输,的等级标准。

J-STD-020说明了湿敏元件级别,JEP113说明了标签要求周围环境中的湿气会通过包装材料渗透到包装内部,并在不同材料的表面聚结。

在组装工艺中,SMD元件贴装在PCB上时会经历超过200℃,在焊接时,湿气的膨胀会造成一些列的焊接品质问题。

2.目的本文旨在为使用,运输,存储,包装SMD湿敏元件提供标准。

通过本文内的方法,可以避免零件受潮和零件在过IR后可靠性下降。

通过本文的各个程序,可以达到无害回焊。

热烘可以使SMD零件得到长达12个月的包装存储寿命。

3.范围3.1 包装3.1.1 本标准适用于PCBA中无需密封SMD零件的作业,其中包括聚合分子材料和塑胶材料3.1.2 密封包装大零件无湿气风险,不必作防潮3.2 组装制程3.2.1本标准适用于PCBA IR,VPR等制程,不适用于波峰焊3.2.2 本标准亦适用于受潮零件的烘烤或重工3.2.3 本标准不适用于不过回焊炉的零件3.3 可靠性3.3.1 内容描述中的方法可以保证PCBA的成品可靠性是可评估的(标准J-STD-020 和JESD22-A113)3.3.2 本文不对焊接可靠性作评述4. 涉及文件4.1 EIA JEDECEIA-541 静电放电敏感元件包装要求EIA-583 湿气敏感元件包装要求EIA-625 静电放电敏感设备操作要求JEP-113 湿气敏感设备标识JESD22-A113 不气密包装可靠性测试条件要求4.2 防护部分MIL-B-131 阻湿材料(隔绝湿气,不透气的)- MIL-B-81705 透气的,无静电的,可加热处理的MIL-D-3464 活性干燥剂,MIL-I8835 指示,湿度卡5. 定义活性干燥剂:全新干燥剂或是经过依照推荐标准进行烘烤恢复原始规格的干燥剂6.包装6.1 包装要求详见下表1湿敏级别烘干元件防潮袋干燥剂湿敏级别标签警告贴纸1 随意随意随意随意220℃时不必标示,235℃时必需标示2 随意必需必需必需必需2a-5a 必需必需必需必需必需6 随意随意随意必需必需6.2 零件包装前的烘烤6.2.1 湿敏级别在2a到5a之间的零件在做防潮包装之前必须要做烘烤处理。

……………………………………………………………最新资料推荐…………………………………………………中国联通M2M车载UICC卡技术规范China Unicom Machine to Machine automotive equipment UICC CardTechnical Specification(V1.0)中国联通公司发布目次目次 (I)前言 (1)1范围 (2)2规范性引用文件 (2)3缩略语和定义 (2)3.1 缩略语 (2)3.2 定义 (3)4概述 (3)5使用环境定义 (3)5.1 环境属性分类 (3)5.2工作和存储温度(TX) (3)5.3湿度/回流焊 (4)5.4 湿度(HX) (4)5.5 腐蚀(CX) (4)5.6 震动(VX) (5)5.7 接触腐蚀(FX) (5)5.8 冲击(SX) (5)5.9 数据保留时间(RX) (5)5.10 最小更新次数(UX) (5)6M2M车载UICC物理特性 (6)6.1 M2M车载UICC卡一般物理特性 (6)6.2 M2M车载UICC卡特定物理特性 (6)7UICC和终端之间电气规格和逻辑规格 (8)7.1 电压支持 (9)8设备匹配机制 (9)8.1 安全通道匹配 (9)8.2 CAT应用匹配 (9)附录A:针对MFF的PCB布局 (9)前言本标准是中国联通GSM/WCDMA数字蜂窝移动通信网M2M车载 UICC卡标准。

本标准中,M2M 车载UICC卡要求能兼容2G业务,卡容量达到64k及以上。

本标准是在国际标准和行业标准的基础上,根据中国联通业务发展需要而制定的,是对国际标准和行业标准的扩展、加强和补充。

随着业务对卡要求的拓展以及技术的发展,还会对本标准进行适时的补充和修订。

本标准由中国联通公司集团客户部提出。

本标准由中国联通公司技术部归口。

本标准主要起草单位:中国联通集团客户部联通兴业公司本标准主要起草人:毛建庄高丹枫匡威于胜军刘骞马志玲顾菲伏京生本标准的修改和解释权属中国联通公司中国联通M2M车载UICC卡技术规范 v1.01 范围本标准明确规定了中国联通的GSM/WCDMA M2M 车载UICC卡的物理特性、电气特性,并定义了M2M车载UICC卡外形尺寸、使用环境,并提供了与使用M2M车载UICC卡产品设备的配合机制。

J-STD-020DMoisture/Reflow Sensitivity Classification for Nonhermetic Solid State Surface Mount Devices非密封固态表面贴装元件湿度/回流焊敏感度分级1 PURPOSE(目的)The purpose of this standard is to identify the classification level of nonhermetic solid state surface mount devices (SMDs) that aresensitive to moisture-induced stress so that they can be properly packaged, stored, and handled to avoid damage during assembly solderreflow attachment and/or repair operations.本标准旨在识别非密封固态表面贴装元件的湿度敏感等级以便其能合适的封装,储存,作业以避免在回流和维修作业中被损伤.This standard may be used to determine what classification/preconditioning level should be used for SMD package qualification. Passingthe criteria in this test method is not sufficient by itself to provide assurance of long-term reliability本标准用于判定合格的SMT封装应使用何种等级/预处理水平.依据本测试方法且通过对应判定标准的元件并不能保证其长期可靠性1.1 Scope(范围)This classification procedure applies to all nonhermetic solid state Surface Mount Devices (SMDs) in packages, which, because ofabsorbed moisture, could be sensitive to damage during solder reflow. The term SMD as used in this document means plasticencapsulated surface mount packages and other packages made with moisture-permeable materials. The categories are intended to be usedby SMD producers to inform users (board assembly operations) of the level of moisture sensitivity of their product devices, and by boardassembly operations to ensure that proper handling precautions are applied to moisture/reflow sensitive devices. If no major changes havebeen made to a previously qualified SMD package, this method may be used for reclassification according to 4.2.此分类程序适用于所有非密封固体表面贴装元件,此部分元件由于吸收湿气而在回流焊接中容易损伤. 本文件所提及的术语“SMD”指的是塑封或本体为吸湿材料的元件.分类的目的是为了让元件制造商能告知元件使用者(PCBA组装)其产品的湿敏等级,确保元件使用者能恰当作业,如果对之前认证过的SMD封装没有重大更改,依据 4.2此方法亦可用于元件的再次分类.This standard cannot address all of the possible component, board assembly and product design combinations. However, the standarddoes provide a test method and criteria for commonly used technologies. Where uncommon or specialized components or technologiesare necessary, the development should include customer/manufacturer involvement and the criteria should include an agreed definition ofproduct acceptance.此标准不能涵盖所有与设计,组装相关联的元件.但是,此标准为通用技术提供了一个测试方法和标准. 如果使用特殊技术或特殊元件,则需客户以及相关的制造方定义一个双方同意的产品接受标准.SMD packages classified to a given moisture sensitivity level by using Procedures or Criteria defined within any previous version ofJ-STD-020, JESD22-A112 (rescinded), or IPC-SM-786 (rescinded) do not need to be revision unless a change in classification level or ahigher peak classification temperature is desired. Annex B provides an overview of major changes from Revision C to Revision D of thisdocument.在使用之前版本J-STD-020,JESD22-A112(已作废),IPC-SM-786(已作废)标准中已分级的湿敏元件除非敏感等级变更或耐温峰值提高,否则无须重新分级.附件B提供了版本C升级到版本D的主要变更.ureNote: If the procedures in this document are used on packaged devices that are not included in this specification’s scope, the fail criteria for such packages must be agreed upon by the device supplier and their end user备注:当封装元件未在本标准规格范围内,如需使用此文件中的流程判定,则不良标准需元件供应商和其客户同意.1.2 Background(背景)The vapor pressure of moisture inside a nonhermetic package increases greatly when the package is exposed to the high temperature ofsolder reflow. Under certain conditions, this pressure can cause internal delamination of the packaging materials from the die and/orleadframe/substrate, internal cracks that do not extend to the outside of the package, bond damage, wire necking, bond lifting, die lifting,thin film cracking, or cratering beneath the bonds. In the most severe case, the stress can result in external package cracks. This ish ancommonly referred to as the ‘‘popcorn’’ phenomenon because the internal stress causes the package to bulge and then crack wit-hole parts because they are exposed to higher temperaturesaudible ‘‘pop.’’ SMDs are more susceptible to this problem than throughduring reflow soldering. The reason for this is that the soldering operation must occur on the same side of the board as the SMD device.For wave-soldered through-hole devices, the soldering operation occurs under the board that shields the devices from the hot solderthrough-hole devices, the soldering operation occurs under the board that shields the devices from the hot solder Throughhole devices thatmay experience the same type of moisture-induced failures as SMTare soldered using intrusive soldering or ‘‘pin in paste’’ processesdevices.非密封元件封装在回流高温条件下,其内部水蒸气压力猛增.在某一件下,压力将导致封装从内部分层或者内裂,邦定受损。