第3章-工艺及器件仿真工具SILVACO-TCAD教程文件

- 格式:ppt

- 大小:4.38 MB

- 文档页数:118

Silvac o TCA D 半导体仿真工具培训教程_资料手册S ilvac o TCA D 2014.00Win32 1DVD半导体仿真工具Sy nopsy s.Tca d.Sen tauru s.vH-2013.03.Li nux64 3CDSilva co的TC AD 建模服务提供解决方案给那些有特别半导体器件建模需求而内部又没有时间和资源运行TCAD软件的客户。

使用TC AD建模服务,可运用Silva co在半导体物理和T CAD软件操作方面的专长,提供完全、快速和精确的即可使用的解决方案。

Silva co AM S v2010.00 Win32 1CDSil vacoAMS 2008.09 Lin ux3264S ilvac o AMS 2008.09 S olari s 1CDSil vacoAMS 2008.09 Man ual 1CDS ilvac o Icc ad 2008.09 1CDSilv aco I ccad2008.09 Li nux32 64Silva co Ic cad 2008.09 Sol aris1CDSilva co Ic cad 2008.09 Man ual 1CDS ilvac o Log ic 2008.09 1CDSilv aco L ogic2008.09 Li nux32 64Silva co Lo gic 2008.09 Sol aris1CDSilva co Lo gic 2008.09 Man ual 1CDS ilvac o TCA D 2012.00Win32_64 1DVDSilva co TC AD 2010.00 Linu x 1CDSil vacoTCAD2012Linux64 1D VDS ilvac o TCA D 2008.09Solar is 1C DSi lvaco TCAD 2008.09 M anual 1CDSilv aco C ataly st 2008.09 Linu x32 64Si lvaco Cata lyst2008.09 So laris 1CDSilv aco C har 2008.09 Lin ux3264S ilvac o Cha r 2008.09Solar is 1C DSi lvaco Fire bird2008.09 Li nux32 64Silva co Fi rebir d 2008.09Solar is 1C DSi lvaco Mode 2008.09 L inux32 64Silv aco M ode 2008.09 Sol aris1CDSilva co Pa rasit ic 2008.09 Linu x32 64Si lvaco Para sitic 2008.09 S olari s 1CDSil vacoUT 2007.04 Linu x32 64S ilvac o UT2007.04 So laris 1CDSilv aco V WF 2007.04 Linu x32 64S ilvac o VWF 2007.04 S olari s 1CDPar allel Smar tSpic e 1.9.3.E1CD■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□+ 诚信合作,保证质量!!!长期有效: +电话TE L:18980583122 客服 QQ:1140988741■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□Pin nacle产品:Fracp roPT.2007.v10.4.52 1CD(石油工业界的先进压裂软件工具,它提供支撑剂和酸液压裂处理的设计、模拟、分析、执行和优化功能。

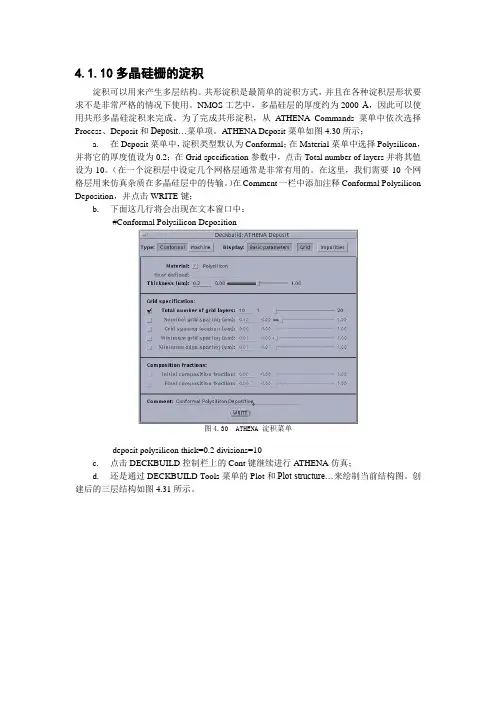

4.1.10多晶硅栅的淀积淀积可以用来产生多层结构。

共形淀积是最简单的淀积方式,并且在各种淀积层形状要求不是非常严格的情况下使用。

NMOS工艺中,多晶硅层的厚度约为2000 Å,因此可以使用共形多晶硅淀积来完成。

为了完成共形淀积,从ATHENA Commands菜单中依次选择Process、Deposit和Deposit…菜单项。

ATHENA Deposit菜单如图4.30所示;a.在Deposit菜单中,淀积类型默认为Conformal;在Material菜单中选择Polysilicon,并将它的厚度值设为0.2;在Grid specification参数中,点击Total number of layers并将其值设为10。

(在一个淀积层中设定几个网格层通常是非常有用的。

在这里,我们需要10个网格层用来仿真杂质在多晶硅层中的传输。

)在Comment一栏中添加注释Conformal Polysilicon Deposition,并点击WRITE键;b.下面这几行将会出现在文本窗口中:#Conformal Polysilicon Deposition图4.30 ATHENA 淀积菜单deposit polysilicon thick=0.2 divisions=10c.点击DECKBUILD控制栏上的Cont键继续进行A THENA仿真;d.还是通过DECKBUILD Tools菜单的Plot和Plot structure…来绘制当前结构图。

创建后的三层结构如图4.31所示。

图4.31 多晶硅层的共形淀积4.1.11简单的几何图形刻蚀接下来就是多晶硅的栅极定义。

这里我们将多晶硅栅极的左边边缘定为x=0.35μm,中心定为x=0.6μm。

因此,多晶硅应从左边x=0.35μm开始进行刻蚀,如图4.32所示。

图4.32 ATHENA Etch菜单a.在DECKBUILD Commands菜单中依次选择Process、Etch和Etch…。

基于Silvaco TCAD的4H-SiC功率BJT器件仿真[摘要] 碳化硅(SiC)作为第三代半导体材料的代表,由于具有宽禁带、高击穿电场、高热导率等优异特性,使其在高温、大功率、高频、抗辐射等领域应用前景广阔,其研究广为关注。

在商用的SiC材料中,4H-SiC具有更高的体迁移率和更低的各向异性,使其更具优势。

大功率4H-SiC BJT是非常具有竞争力的器件种类,可以广泛应用于诸如航空航天、机车牵引、高压直流输电设备、混合动力车辆等国计民生的重要领域。

然而,4H-SiC BJT较低的击穿电压、低的共发射极电流增益、较低的频率响应以及较差的可靠性限制了其在功率系统领域的发展,也使得在这一方面的研究成为热点。

本文首先完善了碳化硅新材料在仿真器Silvaco-TCAD中的物理模型,这包括迁移率模型、禁带宽度变窄模型、杂质不完全离化模型、碰撞电离模型、SRH产生一复合模型与俄歇复合模型等。

然后,讨论了4H-SiC BJT器件制作的工艺流程,并对关键工艺如欧姆接触工艺、刻蚀工艺以及离子注入工艺等进行了简要的介绍。

研究结果表明,仿真器可以正确的模拟碳化硅新材料特性,提出的结构击穿电压由于在结终端处做了优化的终端处理和采用缓冲漂移层,具有更高的耐压能力,更低的功耗和反向泄露电流;采用的P型薄层基区加速了少子在基区的运动,提高了电流增益,所设计结构更能适用于大功率电力电子系统应用。

[关键词] 4H-SIC 功率BJT 器件物理 Silvaco-TCADResearchon4H-SICPowerBJTDevieeSimulationLin ChengNO.2010850060,Electronic science and technology,2014Information Engineering College of Jimei UniversityAbstract:As the representative of the third generation semiconductor material, Silicon Carbide (SiC) is the promising candidate in application of high temperature, high power, high frequency,anti-radiation fields because of its excellent properties such as wide-band gap, high breakdown field, high thermal conductivity. Among the commercially available SiC types, 4H-SiC is the most attractive one due to its higher bulk mobility, lower anisotropy. Continuous research has been done through past decades. High power4H-SiC BJT is very competitive in power device family, which is widely applied in both military and civilian use such as aerospace, traction, HVDC facility, HEV. However, the low blocking voltage, low current gain, low frequency response and weak reliability of 4H-SiC BJT restrict its application in power system.Firstly, the physics models of new materials in simulator Silvaco-TCAD were improved in the paper, including mobility model, band-gap narrowing model, doping incomplete ionization model, impact ionization model, SRH and Auger generation-recombination model;the simulation can be done successfully under the accurate physics models. Then the process flow was discussed, critical processes such as Ohmic contact, pattern etch process and ion implantation are also been discussed.Research results indicate that the simulator is accurate to simulate the SiC material characteristics, the new structure proposed is with blocking voltages 1450V, current gain 52,higher 45% and 30% than traditional structure 1000V and 40 respectively. And the peak electrical field decreases from 3MV/cm to 2.3MVlcm. At the same time, the novel structure is with lower power loss and reverse leakage current, can be applied better in high power system.Finally, the frequency response and power loss are discussed in detail according to physics analysis.Key words: 4H-SiC Power BlT Device Physics Silvaco-TCAD引言 (1)第一章绪论 (2)1.1课题研究背景及意义 (2)1.2碳化硅功率器件发展回顾 (2)1.3碳化硅功率BJT国内外研究现状 (4)1.4主要研究思想和研究内容 (4)第二章 SILVACO-TCAD软件 (5)2.1Silvaco-TCAD简介 (5)2.2Silvaco-TCAD器件仿真中的物理模型 (5)2.2.1 迁移率模型 (6)2.2.2 禁带宽度变窄模型 (6)2.2.3 杂质不完全离化模型 (6)2.2.4 碰撞电离模型 (7)2.2.5 SRH产生一复合模型与Auger复合模型 (8)2.34H-SIC功率BJT设计原则 (9)第三章基于SILVACO TCAD的4H-SIC功率BJT器件仿真 (12)3.1工艺流程 (12)3.2欧姆接触工艺 (13)3.3图形刻蚀技术 (13)3.4离子注入和退火 (14)3.5 器件仿真流程 (14)结论 (20)致谢语 (21)参考文献 (22)附录 (23)电子技术有两大分支,即微电子技术(Mieroelectronies)和电力电子技术(PowerEleetronics)。