A plasticity and anisotropic damage model for plain concrete

- 格式:pdf

- 大小:611.60 KB

- 文档页数:27

ABAQUS学习笔记一.AQUS-.inp编码介绍(一).ABAQUS头信息文件段(1-4)1.*PREPRINT 输出求解过程所要求的信息(在dat文件中)ie:*PREPRINT, ECHO=YES, HISTORY=YES, MODEL=YES2.*HEADING 标题输出文件(出现在POST/VIEW窗口中,且出现在结果输出文件中)ie:*HEADINGSTRESS ANALYSIS FOR A PLATE WITH A HOLE3.*RESTART 要求abaqus/standard输出其POST/view模块所需要的.res文件。

其中的FREQ =?控制结果在每次迭代(或载荷步)输出的次数。

ie:*RESTART, WRITE, FREQ=14.*FILE FORMAT 要求abaqus/standard输出到.fil中的某些信息。

它也用于post。

对于在后处理中得到x-y形式的诸如应力-时间、应力-应变图有用!ie: *FILE FORMAT, ZERO INCREMENT(二).ABAQUS网格生成段定义结点、单元,常用的命令有:结点定义(*NODE,*NGEN),单元定义(*ELEMENT,*ELGEN等)。

1.*NODE 定义结点,其格式为:*NODE结点号,x轴坐标,y轴坐标,(z轴坐标)2.*NGEN 在已有结点的基础上进行多个结点的生成,一般是在两结点间以某种方式(直线、圆)产生一定分布规律的结点。

如:*NGEN, LINE=C, NSET=HOLE,119, 1919, 100, 101 在两结点(结点号为119,1919)间以圆弧形式生成多个结点,100为任意相邻结点的单元号增量,101为圆弧形成时圆心位置的结点(对于直线形式生成没有此结点)。

所有这些生成的结点(包括119,1919)被命名成HOLE的集合(这样做的目的是以后的命令中使用到它,比如说对这些结点施加同等条件的边界条件或载荷等,HOLE就是这些结点的代称)。

定义材料属性单词Density 密度1、general Depvar 用户子程序相关;因变量;独立变量Regularization ˌ[ˌregjələrɪ'zeɪʃən] 正规化;规则化Elastic 弹性带hyperelastic 超弹性Hyperfoam 泡沫Low density foam 低密度硅胶发泡Elasticity Hypoelastic 亚弹性弹性 Porous elastic 多孔材料弹性模型2、mechanical Viscoelastic 粘弹性力学的Plastic 塑料Cap plasticityCast iron plasticity 铸铁塑性Clay plasticity 黏土塑性Concrete damaged plasticity混凝土塑性损伤Concrete smeared cracking弥散裂缝模型Plasticity crushable foam可压扁泡沫塑性drucker prager 德鲁克普拉格准则Mohr coulomb plasticity摩尔哥伦布塑性准则Porous metal plasticity多孔塑性Creep 蠕变Swelling 膨胀Viscous 粘性Ductile damage 延性损伤下屈服点Johnson-cook damageShear damage 剪切破柔软的坏剪切损伤Damage for ductile metals FLD damage对韧性金属的损伤FLSD damageM-K damageMDFLD damage2、mechanical quade damage二次名义应力准则Damage for traction Maxe damage 最大Separation laws 名义应变准则牵引分离损伤法Quads damage 二次名义应变准则Maxs damage 最大名义应力准则Maxpe damageMaxps damageDamage for fiber-reinforced composites纤维增强复合材料的损伤Damage for elastomers t弹性体损伤Deformation plasticity 塑变单元Damping 阻尼Expansion 膨胀Brittle cracking 脆性材料断裂属性设置Viscosity 粘性Conductivity 传导率电导率传热性Heat generation 热生成量产热率Inelastic heat fraction 热弹性分数无弹性小数分数3、thermal joule heat fraction 焦耳热量分数热力热量latent heat 潜热Specific heat比热容Electrical conductivity 电导率Dielectric (electrical permittivity)介电常数;绝4、electrica l 介电常数缘的magnetic Piezoelectric 压电的Magnetic permeability 磁导率5、field variable 场变量 compression 压力tension 张力youngs modulus杨氏模量 strain 应变 strain-rate-dependent 应变率相关 yieldStress 屈服应力 plastic strain 塑性应变6、mooney-rivlin 材料常数;超弹性模型 strain energy potential 应变比能 isotropic 各向同性的 anisotropic 各向异性的 input source输入源 Coefficients 系数创建并赋予截面特性Homogeneous 同类的同质的均匀的 Generalized plane strain广义平面应变solid eulerian 欧拉欧拉模型Composite 复合材料Homogeneous 同类的同质的C omposite 复合材料shell membrane 隔膜膜结构Surface 曲面表面7、create section General shell stiffness 一般壳体硬创建截面度BeamBeam横梁 truss 桁架网格划分mesh controlsHex 六面体 hex-dominated 六面体占优 tet 四面体 wedge 锲形 define cutting plane定义切割面 use mapped meshing where appropriate映射网格virtual topology虚拟拓扑 appropriate适当的恰当的Explicit显示的清楚地(显示分析) standard规范的标准的(适合隐试分析) 3D stress 三维应力 continuum连续体continuum shell实体壳薄壳 quadratic二次的二次曲线optimization 最优化 equivalent plastic strain等效塑性应变parameter 参数参量 dynamic 动态的 implicit隐式的 symmetry 对称性 displacement位移 velocity速度速率 angular velocity 角速度incrementation增长 mass scale质量缩放 tangential切线的friction coefficient摩擦系数 create reference point创建基准点connector assignment连接器 connector section 连接器截面 sketch planar partition草绘平面分区 linear perturbation线性扰动线性摄动线性轨道扰动 displacement 位移取代 freeze boundary condition region冻结边界条件区 create design response创建设计响应 create objective function创建目标函数 minimize design response values减少设计的响应值 fraction碎片片段 a fraction of the initial value初始值的一小部分 static静态的 geostatic静地压的node region 节点区域 slave surface从接触面 symmetry对称Antisymmetric非对称的 encastre 完全约束端部固定deformation scale factor 变形比例因子 tangential behavior主要定义摩擦系数等摩擦属性 friction 摩擦 frictionless不考虑摩擦Pentalty主要定义摩擦系数 stress component 应力分量 beam section orientation梁截面方向ALE1、transient 瞬时的2、Deformations变形3、Arbitrary 随意的,任意角度的。

elasticitytheory of elasticity homogeneous state ofstressstress invariant strain invariant strain ellipsoid homogeneous state ofstrainequation of strain compatibilityLame constants isotropic elasticityrotating circular diskwedgeKelvin problemBoussinesq problemAiry stress functionKolosoff-Muskhelishvili methodKirchhoff hypothesisPlateRectangular plate Circular plate Annular plate Corrugated plate Stiffened plate,reinforced弹性力学 弹性理论 均匀应力状态 应力不变量 应变不变量 应变椭球 均匀应变状态应变协调方程拉梅常量各向同性弹性旋转圆盘楔开尔文问题布西内斯克问题 艾里应力函数 克罗索夫―穆斯赫利什维 利法基尔霍夫假设板 矩形板 圆板 环板 波纹板 加劲板PlatePlate of moderate thickness Stress function of bendingShell Shallow shell Revolutionary shell Spherical shell Cylindrical shell Conical shell Toroidal shell Closed shell Corrugated shell Stress function of torsionWarping function semi-inverse method Rayleigh-Ritz method Relaxation methodLevy method Relaxation Dimensional analysis self-similarity Influence surface Contact stress Hertz theory Conforming contact Sliding contact Rolling contact中厚板 弯[曲]应力函数壳 扁壳 旋转壳 球壳 [圆]柱壳锥壳 环壳 封闭壳 波纹壳 扭[转]应力函数翘曲函数 半逆解法 瑞利―里茨法松弛法 莱维法 松弛 量纲分析 自相似[性]影响面 接触应力 赫兹理论 协调接触压入Indentation各向异性弹性Anisotropic elasticity 颗粒材料Granular material散体力学Mechanics of granular media 热弹性Thermoelasticity超弹性Hyperelasticity粘弹性Viscoelasticity对应原理Correspondence principle 褶皱Wrinkle塑性全量理论Total theory of plasticity 滑动Sliding微滑Microslip粗糙度Roughness非线性弹性Nonlinear elasticity 大挠度Large deflection突弹跳变snap-through有限变形Finite deformation格林应变Green strain阿尔曼西应变Almansi strain弹性动力学Dynamic elasticity运动方程Equation of motion准静态的Quasi-static气动弹性Aeroelasticity水弹性Hydroelasticity颤振Flutter弹性波Elastic wave简单波Simple wave柱面波Cylindrical wave水平剪切波Horizontal shear wave 竖直剪切波Vertical shear wave 体波body wave无旋波Irrotational wave 畸变波Distortion wave膨胀波Dilatation wave瑞利波Rayleigh wave等容波Equivoluminal wave 勒夫波Love wave界面波Interfacial wave 边缘效应edge effect塑性力学Plasticity可成形性Formability金属成形Metal forming耐撞性Crashworthiness结构抗撞毁性Structural crashworthiness 拉拔Drawing破坏机构Collapse mechanism回弹Springback挤压Extrusion冲压Stamping穿透Perforation层裂Spalling塑性理论Theory of plasticity 安定[性]理论Shake-down theory 运动安定定理kinematic shake-downtheoremStatic shake-down theorem rate dependent theoremload factor Loading criterion Loading function Loading surface Plastic loading Plastic loading waveSimple loading Proportional loadingUnloading Unloading wave Impulsive load step load pulse load limit load nentral loading instability in tension acceleration wave constitutive equation complete solution nominal stress over-stress true stress equivalent stressflow stress stress discontinuity静力安定定理 率相关理论 载荷因子 加载准则 加载函数 加载面 塑性加载 塑性加载波 简单加载 比例加载 卸载 卸载波 冲击载荷 阶跃载荷 脉冲载荷 极限载荷 中性变载 拉抻失稳 加速度波 本构方程 完全解 名义应力 过应力 真应力 等效应力 流动应力 应力间断stress space principal stress space hydrostatic state of stresslogarithmic strain engineering strain equivalent strain strain localizationstrain ratestrain rate sensitivitystrain space finite strain plastic strain incrementaccumulated plastic strainpermanent deformationinternal variable strain-softening rigid-perfectly plasticMaterialrigid-plastic materialperfectl plastic material stability of material deviatoric tensor of strain deviatori tensor of stress spherical tensor of strain spherical tensor of stresspath-dependency linear strain-hardening应力空间 主应力空间 静水应力状态 对数应变 工程应变 等效应变 应变局部化 应变率 应变率敏感性 应变空间 有限应变塑性应变增量累积塑性应变永久变形 内变量 应变软化 理想刚塑性材料刚塑性材料 理想塑性材料 材料稳定性 应变偏张量 应力偏张量 应变球张量 应力球张量 路径相关性strain-hardening kinematic hardening isotropic hardening strain-hardening moduluspower hardening plastic limit bendingMomentplastic limit torque elastic-plastic bending elastic-plastic interface elastic-plastic torsionViscoplasticityInelasticityelastic-perfectly plasticMaterial limit analysislimit design limit surface upper bound theorem upper yield point lower bound theorem lower yield point bound theorem initial yield surface subsequent yield surface convexity of yield surface shape factor of cross-section应变强化 随动强化 各向同性强化 强化模量 幕强化 塑性极限弯矩塑性极限扭矩 弹塑性弯曲 弹塑性交界面 弹塑性扭转粘塑性非弹性理想弹塑性材料极限分析 极限设计 极限面 上限定理 上屈服点 下限定理 下屈服点 界限定理 初始屈服面 后继屈服面 屈服面[的]外沙堆比拟屈服屈服条件屈服准则屈服函数屈服面塑性势能量吸收装置能量耗散率塑性动力学塑性动力屈曲塑性动力响应塑性波运动容许场静力容许场流动法则速度间断滑移线滑移线场移行塑性铰塑性增量理论米泽斯屈服准则普朗特―罗伊斯关系特雷斯卡屈服准则sand heap analogyYieldyield conditionyield criterionyield functionyield surfaceplastic potential energy absorbing device energy absorbing device dynamic plasticity dynamic plastic buckling dynamic plastic response plastic wave kinematically admissibleFieldstatically admissibleFieldflow rule velocity discontinuityslip-linesslip-lines field travelling plastic hinge incremental theory ofPlasticityMises yield criterion prandtl- Reuss relation Tresca yield criterion洛德应力参数莱维―米泽斯关系亨基应力方程赫艾一韦斯特加德应力空间洛德应变参数德鲁克公设盖林格速度方程结构力学结构分析结构动力学拱三铰拱抛物线拱圆拱穹顶空间结构空间桁架雪载[荷]风载[荷]土压力地震载荷弹簧支座支座位移支座沉降Lode stress parameterLevy-Mises relation Hencky stress equation Haigh-Westergaardstress space Lode strain parameter Drucker postulateGeiringer velocityEquation structural mechanics structural analysis structural dynamicsArchthree-hinged archparabolic archcircular archDomespace structurespace trusssnow loadwind loadearth pressureearthquake loadingspring support support displacementsupport settlementdegree of indeterminacy kinematic analysis method of joints method of sectionsjoint forces conjugate displacementinfluence line three-moment equation unit virtual force stiffness coefficient flexibility coefficientmoment distributionmoment distribution methodmoment redistribution distribution factor matri displacement method element stiffness matrix element strain matrix global coordinates Betti theorem Gauss-Jordan eliminationMethod buckling mode mechanics of compositescomposite materialfibrous composite unidirectional composite超静定次数 机动分析 结点法 截面法 结点力 共轭位移 影响线 三弯矩方程 单位虚力 刚度系数柔度系数力矩分配力矩分配法 力矩再分配 分配系数 矩阵位移法 单元刚度矩阵 单元应变矩阵 总体坐标 贝蒂定理 高斯一若尔当消去法屈曲模态复合材料力学 复合材料foamed composite particulate compositeLaminate sandwich panel cross-ply laminate angle-ply laminatePlycellular solid ExpansionDebulk Degradation DelaminationDebond fiber stress ply stress ply strain interlaminar stress specific strength strength reduction factor strength -stress ratio transverse shear modulustransverse isotropyOrthotropyshear lag analysis chopped fiber continuous fiber fiber direction泡沫复合材料 颗粒复合材料层板 夹层板 正交层板 斜交层板 层片 多胞固体 膨胀 压实 劣化 脱层 脱粘 纤维应力 层应力 层应变层间应力比强度强度折减系数 强度应力比 横向剪切模量 横观各向同性 正交各向异 剪滞分析 短纤维 长纤维fiber break fiber pull-out fiber reinforcementDensification optimum weight design netting analysis rule of mixture failure criterion Tsai-W u failure criterionDugdale model fracture mechanics probabilistic fractureMechanicsGriffith theory linear elastic fracturemechanics, LEFMelastic-plastic fracturemecha-nics, EPFMFracture brittle fracturecleavage fracture creep fracture ductile fracture inter-granular fracture quasi-cleavage fracture trans-granular fractureCrack纤维断裂 纤维拔脱 纤维增强 致密化 最小重量设计 网格分析法 混合律 失效准则 蔡一吴失效准则 达格代尔模型断裂力学概率断裂力学格里菲思理论线弹性断裂力学弹塑性断裂力学断裂 脆性断裂 解理断裂 蠕变断裂 延性断裂 晶间断裂 准解理断裂 裂纹Flaw Defect Slit MicrocrackKinkelliptical crack embedded crack penny-shape crackPrecrack short crack surface crack crack blunting crack branching crack closure crack front crack mouthcrack opening angle,COAcrack opening displacement,CODcrack resistancecrack surfacecrack tipcrack tip opening angle,CTOAcrack tip openingdisplacement, CTOD crack tip singularity裂缝 缺陷 割缝 微裂纹 折裂 椭圆裂纹 深埋裂纹 [钱]币状裂纹预制裂纹 短裂纹 表面裂纹 裂纹钝化 裂纹分叉 裂纹闭合 裂纹前缘 裂纹嘴 裂纹张开角 裂纹张开位移裂纹阻力裂纹面裂纹尖端 裂尖张角裂尖张开位移Fieldcrack growth rate stable crack growth steady crack growth subcritical crack growthcrack retardation crack arrest arrest toughness fracture mode sliding mode opening mode tearing mode mixed mode Tearingtearing modulus fracture criterionJ-integral J-resistance curve fracture toughness stress intensity factor Hutchinson-Rice-RosengrenFieldconservation integraleffective stress tensor strain energy density energy release ratecohesive zone裂纹扩展速率 稳定裂纹扩展 定常裂纹扩展 亚临界裂纹扩展 裂纹[扩展]减速 止裂 止裂韧度 断裂类型 滑开型 张开型 撕开型 复合型 撕裂 撕裂模量 断裂准则 J 积分 J 阻力曲线 断裂韧度 应力强度因子HRR 场守恒积分 有效应力张量 应变能密度 能量释放率塑性区plastic zone张拉区stretched zone热影响区heat affected zone, HAZ延脆转变温度brittle-ductile transitiontempe- rature剪切带shear band 剪切唇shear lip无损检测non-destructive inspection双边缺口试件double edge notchedspecimen, DEN specimen 单边缺口试件single edge notchedspecimen, SEN specimen 三点弯曲试件three point bendingspecimen, TPB specimen 中心裂纹拉伸试件center cracked tensionspecimen, CCT specimen 中心裂纹板试件center cracked panelspecimen, CCP specimen 紧凑拉伸试件compact tension specimen,CT specimen 大范围屈服large scale yielding 小范围攻屈服small scale yielding 韦布尔分布Weibull distribution 帕里斯公式paris formula空穴化Cavitation应力腐蚀stress corrosion概率风险判定probabilistic riskassessment, PRAdamage mechanicsDamagecontinuum damage mechanics microscopic damage mechanicsaccumulated damage brittle damage ductile damage macroscopic damage microscopic damage microscopic damagedamage criteriondamage evolution equationdamage softeningdamage strengtheningdamage tensor damage threshold damage variable damage vector damage zone Fatigue low cycle fatigue stress fatigue random fatigue creep fatigue corrosion fatigue fatigue damage 损伤力学 损伤 连续介质损伤力学 细观损伤力学 累积损伤 脆性损伤 延性损伤 宏观损伤 细观损伤 微观损伤损伤准则损伤演化方程损伤软化 损伤强化 损伤张量 损伤阈值 损伤变量 损伤矢量 损伤区 疲劳 低周疲劳 应力疲劳 随机疲劳 蠕变疲劳 腐蚀疲劳fatigue failure fatigue fracture fatigue crack fatigue life fatigue rupture fatigue strength fatigue striations fatigue threshold alternating load alternating stress stress amplitudestrain fatiguestress cyclestress ratio safe life overloading effect cyclic hardening cyclic softening environmental effectcrack gage crack growth, crackPropagation crack initiationcycle ratio experimental stressAnalysisactive[strain] gage疲劳失效 疲劳断裂 疲劳裂纹 疲劳寿命 疲劳破坏 疲劳强度 疲劳辉纹 疲劳阈值 交变载荷 交变应力应力幅值应变疲劳应力循环 应力比 安全寿命 过载效应 循环硬化 循环软化 环境效应 裂纹片 裂纹扩展裂纹萌生 循环比工作[应变]片backing material stress gage zero shift, zero drift strain measurementstrain gage strain indicator strain rosette strain sensitivity mechanical strain gage rectangular rosetteExtensometertelemetering of strain transverse gage factor transverse sensitivity weldable strain gage balanced bridge bonded strain gage bonded foiled gage bonded wire gage bridge balancing capacitance strain gage compensation technique compensation techniquereference bridge resistance strain gageself-temperature compensating gage基底材料 应力计 零[点]飘移 应变测量 应变计 应变指示器 应变花 应变灵敏度 机械式应变仪 直角应变花弓I 伸仪 应变遥测 横向灵敏系数 横向灵敏度 焊接式应变计 平衡电桥 粘贴式应变计 粘贴箔式应变计 粘贴丝式应变计桥路平衡 电容应变计 补偿片 补偿技术 基准电桥 电阻应变计semiconductor strainGageslip ring strain amplifier fatigue life gage inductance [strain] gagePhotomechanics Photoelasticity Photoplasticity Young fringe birefrigent effect contour of equal Displacement dark fringefringe multiplication interference fringeIsochromatic Isoclinic isopachic stress- optic lawIsostatic light fringe optical path differencephoto-thermo -elasticityphotoelastic coatingMethodphotoelastic sandwich半导体应变计集流器 应变放大镜 疲劳寿命计 电感应变计 光[测]力学光弹性 光塑性 杨氏条纹 双折射效应 等位移线暗条纹 条纹倍增 干涉条纹 等差线 等倾线 等和线 应力光学定律 主应力迹线亮条纹光程差热光弹性 光弹性贴片法Methoddynamic photo-elasticityspatial filtering spatial frequencyPolarizerreflection polariscope residual birefringentEffectstrain fringe valuestrain-optic sensitivitystress freezing effectstress fringe valuestress-optic pattern temporary birefringentEffect pulsed holographytransmission polariscope real-time holographic interfero - metrygrid methodholo-photoelasticityHologram Holographholographic interferometry holographic moire techniqueHolography whole-field analysis动态光弹性 空间滤波 空间频率 起偏镜 反射式光弹性仪 残余双折射效应应变条纹值应变光学灵敏度应力冻结效应应力条纹值 应力光图 暂时双折射效应脉冲全息法 透射式光弹性仪 实时全息干涉法网格法 全息光弹性法全息图 全息照相 全息干涉法 全息云纹法 全息术散斑干涉法speckle interferometry 散斑Speckle错位散斑干涉法speckle-shearinginterferometry,shearography散斑图Specklegram 白光散斑法white-light speckle method 云纹干涉法moire interferometry [叠栅]云纹moire fringe[叠栅]云纹法moire method 云纹图moire pattern离面云纹法off-plane moire method 参考栅reference grating试件栅specimen grating分析栅analyzer grating面内云纹法in-plane moire method脆性涂层法brittle-coating method 条带法strip coating method坐标变换transformation ofCoordinates计算结构力学computational structuralmecha-nics加权残量法weighted residual method 有限差分法finite difference method 有限[单]元法finite element method 配点法point collocation里茨法Ritz method广义变分原理generalized variationalPrinciple 最小二乘法least square method胡[海昌]一鹫津原理Hu-Washizu principle赫林格-赖斯纳原理Hellinger-ReissnerPrinciple修正变分原理modified variationalPrinciple约束变分原理constrained variationalPrinciple混合法mixed method杂交法hybrid method边界解法boundary solution method有限条法finite strip method半解析法semi-analytical method协调兀conforming element非协调兀non-conforming element混合元mixed element杂交元hybrid element边界元boundary element强迫边界条件forced boundary condition自然边界条件natural boundary condition离散化Discretization离散系统discrete system连续问题continuous problem广义位移generalized displacement广义载荷generalized load广义应变generalized straingeneralized stress interface variable node, nodal pointElement corner node mid-side node internal node nodeless variablebar element truss element beam elementtwo-dimensional elementone-dimensional elementthree-dimensional element axisymmetric elementplate element shell elementthick plate element triangular element quadrilateral element tetrahedral element curved element quadratic element linear element cubic element quartic element isoparametric element广义应力 界面变量 节点 [单]元 角节点 边节点 内节点 无节点变量杆元 桁架杆元梁元二维元一维元 三维元 轴对称元厚板元 三角形元 四边形元 四面体元 曲线元 二次元 线性元 三次元 四次元 等参[数]super-parametric element sub-parametric element variable-number-nodeelement Lagrange element Lagrange family serendipity element serendipity family infinite element element analysis element characteristicsstiffness matrixgeometric matrixequivalent nodal forcenodal displacementnodal load displacement vectorload vector mass matrix lumped mass matrix consistent mass matrixdamping matrix Rayleigh damping assembly of stiffnessMatricesconsistent mass matrix assembly of mass matrices assembly of elements超参数元 亚参数元 节点数可变元 拉格朗日元 拉格朗日族 巧凑边点元 巧凑边点族 无限元 单元分析 单元特性刚度矩阵几何矩阵等效节点力节点位移 节点载荷 位移矢量 载荷矢量 质量矩阵 集总质量矩阵 相容质量矩阵 阻尼矩阵 瑞利阻尼 刚度矩阵的组集载荷矢量的组集 质量矩阵的组集local coordinate systemlocal coordinate area coordinates volume coordinates curvilinear coordinates static condensation contragradienttransformation shape function trial function test function weight function spline function substitute function reduced integration zero-energy mode p-convergenceh-convergenceblended interpolation isoparametric mapping bilinear interpolationpatch test incompatible modenode number element number band width banded matrix profile matrix局部坐标系 局部坐标 面积坐标 体积坐标 曲线坐标 静凝聚合同变换 形状函数 试探函数 检验函数 权函数 样条函数 代用函数 降阶积分 零能模式P 收敛H 收敛 掺混插值 等参数映射 双线性插值 小块检验 非协调模式 节点号 M 二 口. 单兀号minimization of band widthfrontal method subspace iteration method determinant search methodstep-by-step methodNewmark Wilsonquasi-Newton method Newton-Raphson method incremental method initial straininitial stresstangent stiffness matrixsecant stiffness matrix mode superposition method equilibrium iterationSubstructure substructure techniquesuper-element mesh generationstructural analysis programpre-processing post-processing mesh refinement stress smoothing composite structure带宽最小化 波前法 子空间迭代法 行列式搜索法逐步法 纽马克法 威尔逊法 拟牛顿法 牛顿-拉弗森法增量法初应变初应力切线刚度矩阵 割线刚度矩阵 模态叠加法 平衡迭代 子结构 子结构法 超单元 网格生成 结构分析程序前处理 后处理 网格细化 应力光顺。

HANDBOOK OF MATERIALS BEHAVIOR MODELSCONTENTSForeword(E.van der Giessen)Introduction(J.Lemaitre)Chapter1Background on mechanics of materialsChapter2Elasticity,viscoelasticityChapter3Yield limitChapter4PlasticityChapter5ViscoplasticityChapter6Continuous damageChapter7Cracking and fractureChapter8Friction and wearChapter9Multiphysics coupled behaviorsChapter10Composite medias,biomaterialsChapter11GeomaterialsCHAPTER1Background on mechanics of materials1.1Background on modelingJ.Lemaitreiii Contents1.2Materials and process selectionY.Brechet1.3Size effect on structural strengthZ.BazantCHAPTER2Elasticity,viscoelasticity2.1Introduction to elasticity and viscoelasticityJ.Lemaitre2.2Background on nonlinear elasticityR.W.Ogden2.3Elasticity of porous materialsN.D.Cristescu2.4Elastomer modelsR.W.Ogden2.5Background on ViscoelasticityK.Ikegami2.6A nonlinear viscoelastic model based onfluctuating modesR.Rahouadj,C.Cunat2.7Linear viscoelasticity with damageR.SchaperyCHAPTER3Yield limit3.1Introduction to yield limitsJ.Lemaitre3.2Background on isotropic criteriaD.Drucker3.3Yield loci based on crystallographic textureP.Van HoutteContents iii3.4Anisotropic yield conditionsM.Zyczkowski3.5Distortional model of plastic hardeningT.Kurtyka3.6A generalised limit criterion with application tostrength,yielding and damage of isotropic materialsH.Altenbach3.7Yield conditions in beams,plates and shellsD.DruckerCHAPTER4Plasticity4.1Introduction to plasticityJ.Lemaitre4.2Elastoplasticity of metallic polycrystals by theself-consistent modelM.Berveiller4.3Anisotropic elasto-plastic model based oncrystallographic textureA.M.Habraken,L.Ducheˆne,A.Godinas,S.Cescotto4.4Cyclic plasticity model with non-linear isotropicand kinematic hardening-No LIKH modelD.Marquis4.5Multisurface hardening model for monotonic andcyclic response of metalsZ.Mroz4.6Kinematic hardening rule with critical state ofdynamic recoveryN.Ohno4.7Kinematic hardening rule for biaxial ratchettingH.Ishikawa,K.Sasaki4.8Plasticity in large deformationsY.F.Dafalias4.9Plasticity of polymersJ.M.Haudin,B.Monasse4.10Rational phenomenology in dynamic plasticityJ.R.Klepaczko4.11Conditions for localization in plasticity andrate-independent materialsA.Benallal4.12An introduction to gradient plasticityE.C.AifantisCHAPTER5Viscoplasticity5.1Introduction to viscoplasticityJ.Lemaitre5.2A phenomenological anisotropic creep model forcubic single crystalsBertram,J.Olschewski5.3Crystalline viscoplasticity applied to single crystalG.Cailletaud5.4Averaging of viscoplastic polycristalline materialswith the tangent self-consistent modelA.Molinari5.5Fraction models for inelastic deformationJ.F.Besseling5.6Inelastic compressible and incompressible,isotropic,small strain viscoplasticity theory basedon overstress(VBO)E.Krempl,K.Ho5.7An outline of the Bodner-Partom(BP)unifiedconstitutive equations for elastic-viscoplastic behaviorS.Bodner5.8Unified model of cyclic viscoplasticity based on thenon-linear kinematic hardening ruleJ.L.Chaboche5.9A model of non-proportional cyclic viscoplasticityE.T anaka5.10Rate-dependent elastoplastic constitutive relationsF.Ellyin5.11Physically-based rate and temperature dependantconstitutive models for metalsS.Nemat-Nasser5.12Elastic-viscoplastic deformation of polymersE.M.Arruda,M.BoyceCHAPTER6Continuous damage6.1Introduction to continuous damageJ.Lemaitre6.2Damage equivalent stress-fracture criterionJ.Lemaitre6.3Micromechanically inspired continuous models ofbrittle damageD.Krajcinovic6.4Anisotropic damageC.L.Chow,Y.Wei6.5Modified Gurson modelergaard,A.Needleman6.6The Rousselier Model for porous metal plasticityand ductile fractureG.Rousselier6.7Model of anisotropic creep damageS.Murakami6.8Multiaxial fatigue damage criteriaD.Sauci6.9Multiaxial fatigue criteria based on amultiscale approachK.Dang Van6.10A probabilistic approach to fracture in highcycle fatigueF.Hild6.11Gigacycle fatigue regimeC.Bathias6.12Damage mechanisms in amorphous glassypolymers:crazingR.Schirrer6.13Damage models for concreteG.Pijaudier-Cabot,J.Mazars6.14Isotropic and anisotropic damage law of evolutionJ.Lemaitre,R.Desmorat6.15A two scale damage model for quasi brittle andfatigue damageR.Desmorat,J.LemaitreCHAPTER7Cracking and fracture7.1Introduction to cracking and fractureJ.Lemaitre7.2Bridges between damage and fracture mechanicsJ.Mazars,G.Pijaudier-Cabot7.3Background on fracture mechanicsH.D.Bui,J.B.Leblond,N.Stalin-Muller7.4Probabilistic approach to fracture:the Weibull modelF.Hild7.5Brittle fractureD.Franc¸ois7.6Sliding crack modelD.GrossContents vii7.7Delamination of coatingsH.M.Jensen7.8Ductile rupture integrating inhomogeneitiesin materialsJ.Besson,A.Pineau7.9Creep crack growth behavior in creep ductile andbrittle materialsT.Yokobori Jr.7.10Critical review on fatigue crack growthT.Yokobori7.11Assessment of fatigue damage on the basis ofnon-linear compliance effectsH.Mughrabi7.12Damage mechanics modelling of fatiguecrack growthX.Zhang,J.Zhao7.13Dynamic fractureW.G.Knauss7.14Practical applications of fracture mechanics-fracture controlD.BroekCHAPTER8Friction and wear8.1Introduction to friction and wearJ.Lemaitre8.2Background on friction and wearY.Berthier8.3Models of frictionA.Savkoor8.4Friction in lubricated contactsJ.Freˆne,T.Ciconeviii Contents 8.5A thermodynamic analysis of the contact interfacein wear mechanicsH.D.Bui,M.Dragon-louiset,C.Stolz8.6Constitutive models and numerical methods forfrictional contactM.Raous8.7Physical models of wear,prediction of wear modesK.KatoCHAPTER9Multiphysics coupled behaviors9.1Introduction to multiphysics coupled behaviorJ.Lemaitre9.2Elastoplasticity and viscoplasticity coupledto damageA.Benallal9.3A fully anisotropic elasto-plastic-damage modelS.Cescotto,M.Wauters,A.M.Habraken,Y.Zhu9.4Model of inelastic behavior coupled to damageG.Z.Voyiadjis9.5Thermo-elasto-viscoplasticity and damageP.Perzyna9.6High temperature creep-deformation andrupture modelsD.R.Hayhurst9.7A coupled diffusion-viscoplastic formulation foroxidasing multi-phase materialsE.P.Busso9.8Hydrogen attackE.van der Giessen,S.Schlo¨gl9.9Hydrogen transport and interaction with materialdeformation:implications for fractureP.Sofronis9.10Unified disturbed state constitutive modelsC.S.Desai9.11Coupling of stress/strain,thermal andmetallurgical behaviorsT.Inoue9.12Models for stress-phase transformation couplingsin metallic alloysS.Denis,P.Archambault,E.Gautier9.13Elastoplasticity coupled with phase changesF.D.Fisher9.14Mechanical behavior of steels during solid-solidphase transformationsJ.B.Leblond9.15Constitutive equations of shape memory alloyunder complex loading conditionsM.T okuda9.16Elasticity coupled with magnetismR.Billardon,L.Hirsinger,F.Ossart9.17Physical ageing and glass transition of polymersR.Rahouadj,C.CunatCHAPTER10Composite media,biomechanics10.1Introduction to composite mediaJ.Lemaitre10.2Background on micromechanicsE.van der Giessen10.3Non linear composites-secant methods andvariational boundsP.Suquet10.4Non local micromechanical modelsJ.Willis10.5Transformationfield analysis of composite materialsG.Dvorak10.6A damage mesomodel of laminate compositesdeve`ze10.7Behavior of ceramix-matrix composites underthermomechanical cyclic loading conditionsF.A.Leckie,A.Burr,F.Hild10.8Limit and shakedown analysis of periodicheterogeneous mediaG.Maier,V.Carvelli,A.T aliercio10.9Flow induced anisotropy in shortfiberscompositesA.Poitou,F.Meslin10.10Elastic poperties of bone tissueG.A.Cowing10.11Bimechanics of soft tissueS.C.HolzapfelCHAPTER11Geomaterials11.1Introduction to geomaterialsJ.Lemaitre11.2Background of the behaviour of geomaterialsF.Darve11.3Models for geomaterialsN.D.Cristescu11.4Behaviour of granular materialsI.Vardoulakis11.5Micromechanically-based constitutive model forfrictional granular materialsS.Nemat-NasserContents xi11.6Linear poroelasticityJ.W.Rudnicki11.7Non linear poroelasticity for liquid non saturatedporous materialsO.Coussy,P.Dangla11.8An elastoplastic constitutive model for partiallysaturated soilsB.A.Schreffler,L.Simoni11.9Sinfonietta classica a strain-hardening model forsoils and soft rocksR.Nova11.10A generalized plasticity model for dynamicbehaviour of sand including liquefactionM.Pastor,O.C.Zienkiewicz,A.H.C.Chan11.11A critical state bounding surface model for sandsM.T.Manzari,Y.F.Dafalias11.12Lattice model for fracture analysis of brittledisordered materials like concrete and rockJ.G.M.van Mier。

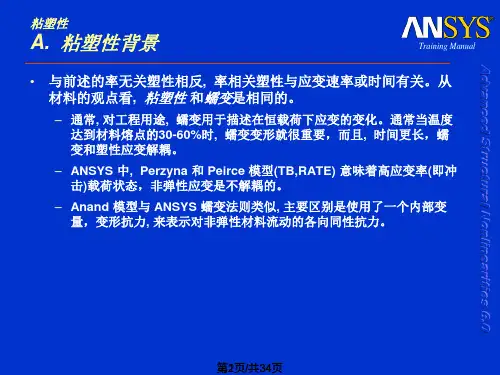

ANSYS树形结构的材料模型库(第一级第二级第三级第四级第五级)(一)Linear:材料的线性行为(1)Elastic:弹性性能参数1, Isotropic:各向同性弹性性能参数 ,2,Orthtropic:正交各向异性弹性性能参数,3, Anisotropic:各向异性弹性性能参数(二)Nonlinear:材料的非线性行为(1)Elastic:非线性的弹性模型1, Hyperelastic:超弹材料模型(包含多个模型)(1) Curve Fitting:通过材料实验数据拟合获取材料模型(2)Mooney-Rivilin:Mooney-Rivilin模型(包含 2 、3、 5 与 9 参数模型)(3) Ogden:Ogden模型(包含1~5 项参数模型与通用模型)(4)Neo-Hookean:Neo-Hookean(胡克)模型(5)Polynomial Form:Polynomial Form(多项式)模型(包含 1~5 项参数模型与通用模型)(6)Arruda-Boyce:Arruda-Boyce:模型(7) Gent:Gent模型(8) Yeoh:Yeoh模型(9) Blatz-Ko(Foam):Blatz-Ko (泡沫)模型(10)Ogden(Foam) Ogden:(泡沫)模型(11) Mooney-Rivlin(TB,MOON):Mooney-Rivlin(TB,MOON) 模型, 2, Multilinear Elastic:多线性弹性模型(2) Inelastic:非线性的非弹性模型1, Rate Independent:率不相关材料模型( 1) Isotropic Hardening Plasticity:各向等向强化率不相关塑性模型1, Mises Plasticity:各向等向强化的 Mises 率不相关塑性模型Bilinear:双线性模型Multilinear:多线性模型Nonlinear:非线性模型2 ,Hill Plasticity:各向等向强化的 Hill 率不相关塑性模型Bilinear:双线性模型Multilinear:多线性模型Nonlinear:非线性模型( 2 )Generalized Anisotropic Hill Potenial:广义各向异性 Hill 势能率不相关模型(3)Kinematic Hardening Plasticity:随动强化率不相关塑性模型1,Mises Plasticity:随动强化的Mises率不相关塑性模型Bilinear:双线性模型Multilinear(Fixed table):多线性模型Nonlinear(General) :非线性模型Chaboche Chaboche:模型2, Hill Plasticity:随动强化的 Hill 率不相关塑性模型Bil inea:双线性模型Mult ilinear(Fixed table):多线性模型Nonl inear(General):非线性模型Chabo che Chaboche:模型(4)Combined Kinematic and Isotropic Hardening Plasticity:随动强化塑性与各向等向强化的率不相关塑性混合模型1,Mises Plasticity:等向强化的 Mises 率不相关塑性模型Chaboche and Bilinear Isotropic:Chaboche模型与双线性等向强化混合模型Chaboche and Multilinear Isotropic:Chaboche模型与多线性等向强化混合模型Chaboche and Nonlinear Isotropic:Chaboche模型与非线性等向强化混合模型2,Hill Plasticity:各向等向强化的 Hill 率不相关塑性模型Chaboche and Bilinear Isotropic:Chaboche模型与双线性等向强化混合模型Chaboche and Multilinear Isotropic:Chaboche模型与多线性等向强化混合模型Chaboche and Nonlinear Isotropic:Chaboche模型与非线性等向强化混合模型2 , Rate dependent:率相关材料模型(1) Visco-plasticity:粘塑模型1, Isotropic Hardening Plasticity:等向强化率相关塑性模型Mises Plasticity:等向强化的 Mises 率相关塑性模型Bi linear:双线性模型Mu ltilinear:多线性模型nlinear:非线性模型Hill Plasticity:等向强化的 Hill 率相关塑性模型Bi linear:双线性模型Mu ltilinear:多线性模型No nlinear:非线性模型2, Anand’Model:Anand 模型(2) Creep蠕变/徐变模型1, Creep only:蠕变模型(1) Mises Potential:Mises 势蠕变模型1, Explicit:Mises 势显式蠕变模型2, Implicit:Mises 势隐式蠕变模型Strain Harding(Primary)2: Time Harding(Primary)3: Generalized Exponential(Primary)4: Generalized Graham(Primary)5: Generalized Blackburn(Primary)6: Modified Time Harding(Primary)7: Modified Strain Harding(Primary)8: Generalized Garofalo(Secondary)9: Exponential Foam(Secondary)10: Norton(Secondary)Harding(Primary+Secondary)12: Rational polynomial(Primary+Secondary)(2) Hill potential:Hill 塑性蠕变模型Implicit:Hill 塑性隐式蠕变模型(略,包含 Creep only>Mises Potential> Implicit 相同模型)2, With Isotropic Hardening Plasticity:等向强化塑性蠕变模型(1) With Mises Plasticity:Mises 等向强化塑性蠕变模型1, Bilinear:双线性蠕变模型Explicit:Mises 等向强化塑性的双线性显式蠕变模型Implicit:Mises 等向强化塑性的双线性隐式蠕变模型(略,包含Creep only>Mises Potential> Implicit相同模型)2, Multilinear:多线性蠕变模型Explicit Mises:等向强化塑性的多线性显式蠕变模型Implicit Mises:等向强化塑性的多线性隐式蠕变模型(略,包含Creep only>Mises Potential> Implicit相同模型)3,Nonlinear:非线性蠕变模型Explicit Mises:等向强化塑性的非线性显式蠕变模型Implicit Mises:等向强化塑性的非线性隐式蠕变模型(略,包含 Creep only>Mises Potential> Implicit相同模型)(2) With Hill Plasticity:Hill 等向强化塑性蠕变模型1, Bilinear:双线性蠕变模型Explicit:双线性显式蠕变模型Implicit:双线性隐式蠕变模型(略,包含Creep only>Mises Potential> Implicit 相同模型)2, Multilinear:多线性蠕变模型Explicit:多线性显式蠕变模型Implicit:多线性隐式蠕变模型(略,包含Creep only>Mises Potential> Implicit 相同模型)3, Nonlinear:非线性蠕变模型Explicit:非线性显式蠕变模型Implicit:非线性隐式蠕变模型(略,包含Creep only>Mises Potential> Implicit 相同模型)3, With Kinematic Hardening Plasticity:随动强化塑性蠕变模型(1) With Mises Plasticity:Mises 随动强化塑性蠕变模型1, Bilinear:双线性蠕变模型1, Implicit Mises:随动强化塑性的双线性隐式蠕变模型(略,包含 Creep only>Mises Potential> Implicit相同模型)(2) With Hill Plasticity:Hill 随动强化塑性蠕变模型1, Bilinear:双线性蠕变模型1, Implicit 双线性隐式蠕变模型(略,包含Creep only>Mises Potential> Implicit 相同模型)4, With Swelling:融涨模型Explicit:显式融涨模型3, Non-metal Plasticity:非金属塑性模型Concrete:混凝土模型Drucker-Prager:D-P 模型Failure Criteria:复合材料失效模型 Gasket:垫片材料模型General Parameters:广义参数模型Compression:压缩模型Linear Unloading:线性卸载模型Nonlinear Unloading:非线性卸载模型 4, Cast-Iron:铸铁材料模型Plasticity Poisson’s Ratio:广义参数模型Uniaxial Compression:单轴压缩模型Uniaxial Tension:单轴拉伸模型5, Shape Memory Alloy形状记忆合金(3) Viscoelastic:非线性的粘弹模型Curve FittingMaxwell:Maxwell 模型(麦克斯韦)Prony:Prony 模型(普罗尼)Shear Response:剪切响应模型Volumetric Response:体积响应模型Shift Function:转换函数模型(三)Density:材料的密度(五)Thermal Expansion Coef:材料的热膨胀系数 Isotropic:各向同性材料的热膨胀系数 Orthtropic:正交各向异性材料的热膨胀系数(六)Damping:材料的阻尼(七)Friction Coefficient:材料的摩擦系数User Material Options:用户自定义材料模型。

abaqus基准手册abaqus基准手册(一)abaqus点滴采用abaqus的cae进行力学问题的分析,其对模型的处理存在很多的技巧,对abaqus的一些分析技巧进行一些概述,希望对大家有所帮助。

abaqus的多图层绘图abaqus的cae默认一个视区仅仅绘出一个图形,譬如contor图,变形图,x-y曲线图等,其实在abaqus里面存在一个类似于origin里面的图层的概念,对于每个当前视区里面的图形都可以建立一个图层,并且可以将多个图层合并在一个图形里面,称之为Overlay Plot,譬如你可以在同一副图中,左边绘出contor图,右边绘出x-y图等等,并且在abaqus里面的操作也是很简单的。

1.首先进入可视化模块,当然要先打开你的模型数据文件(.odb)2.第一步要先创建好你的图形,譬如变形图等等3.进入view里面的overlay plot,点击creat,创建一个图层,现在在viewport layer里出现了你创建的图层了4.注意你创建的图层,可以看到在visible 下面有个选择的标记,表示在视区里面你的图层是否可见,和autocad里面是一样,取消则不可见current表示是否是当前图层,有些操作只能对当前图层操作有效,同cad name是你建立图层的名称,其他的属性值和你的模型数据库及图形的类型有关,一般不能改动的。

5.重复2-4步就可以创建多个图层了6.创建好之后就可以选择plot/apply,则在视区显示出所有的可见的图层子结构的概述1.什么是子结构子结构也叫超单元的(两者还是有点区别的,文后会谈到),子结构并不是abaqus里面的新东东,而是有限元里面的一个概念,所谓子结构就是将一组单元组合为一个单元(称为超单元),注意是一个单元,这个单元和你用的其他任何一种类型的单元一样使用。

2.为什么要用子结构使用子结构并不是为了好玩,凡是建过大型有限元模型的兄弟们都可能碰到过计算一个问题要花几个小时,一两天甚至由于单元太多无法求解的情况,子结构正是针对这类问题的一种解决方法,所以子结构肯定是对一个大型的有限元模型的,譬如在求解非线性问题的时候,因为对于一个非线性问题,系统往往经过多次迭代,每次这个系统的刚度矩阵都会被重新计算,而一般来说一个大型问题往往有很大一部分的变形是很小的,把这部分作为一个子结构,其刚度矩阵仅要计算一次,大大节约了计算时间。

多样化的材料模型库LS-DYNA核心拥有超过150种材料模型数据库,使用者可以自行定义材料模型库,具有十分强大的扩充性。

1. Elastic2. Orthotropic Elastic (Anisotropic-solids)3. Plastic Kinematic/Isotropic4. Elastic Plastic Thermal5. Soil and Foam6. Linear Viscoelastic7. Blatz-Ko Rubber8. High Explosive Burn9. Null Material10. Elastic Plastic Hydro(dynamic)11. Steinberg: Temp. Dependent Elastoplastic12. Isotropic Elastic Plastic13. Isotropic Elastic Plastic with Failure14. Soil and Foam with Failure15. Johnson/Cook Plasticity Model16. Pseudo TENSOR Geological Model17. Oriented Crack (Elastoplastic with Fracture)18. Power Law Plasticity (Isotropic)19. Strain Rate Dependent Plasticity20. Rigid21. Orthotropic Thermal (Elastic)22. Composite Damage23. Temperature Dependent Orthotropic24. Piecewise Linear Plasticity (Isotropic)25. Inviscid Two Invariant Geologic Cap26. Honeycomb27. Mooney-Rivlin Rubber28. Resultant Plasticity29. Fore Limited Resultant Formulation30. Closed Form Update Shell Plasticity31. Frazer-Nash Rubber32. Laminated Glass (Composite)33. Barlet Anisotropic Plasticity34. Fabric35. Plastic Green-Naghdi Rate36. 3-Parameter Barlat Plasticity37. Transversely Anisotropic Elastic Plastic38. Blatz-Ko Foam39. FLD Transversely Anisotropic40. Nonlinear Orthotropicer Defined Materials51. Bamman (Temp/Rate Dependent Plasticity)52. Bamman Damage53. Closed Cell Foam (Low Density Polyurethane)54. Composite Damage With Chang Failure55. Composite Damage with Tsai-Wu Failure57. Low Density Urethane Foam58. Laminated Composite Fabric59. Composite Failure (Plasticity Based)60. Elastic with Viscosity (Viscous Glass)61. Kelvin-Maxwell Viscoelastic62. Viscous Foam (Crash Dummy Foam)63. Isotropic Crushable Foam64. Rate Sensitive Powerlaw Plasticity65. Zerilli-Amstrong (Rate/Temp Plasticity)66. Linear Elastic Discrete Beam67. Nonlinear Elastic Discrete Beam68. Nonlinear Plastic Discrete Beam69. SID Damper Discrete Beam70. Hydraulic Gas Damper Discrete Beam71. Cable Discrete Beam (Elastic)72. Concrete Damage73. Low Density Viscous Foam75.Bilkhu/Dubois Foam (Isotropic)76.General Viscoelastic (Maxwell Model)77.Hyperelastic and Ogden Rubber78.Soil Concrete79.Hysteretic Soil (Elasto-Perfectly Plastic) 81.Plasticity with Damage (Elasto-Plastic)83.Fu Chang Foam84.Winfrith Concrete85.Winfrith Concrete Reinforcement86.Orthotropic Viscoelastic87.Cellular Rubber88.MTS89.Plasticity/Polymer90.Acoustic91.Soft Tissue96.Brittle Damage97.Simplified Johnson Cook98.Simplified Johnson Cook100.Spotweld101.GEPLASTIC Srate2000a102.Inv Hyperbolic Sin103.Anisotropic Viscoplastic104.Damage 1105.Damage 2106.Elastic Viscoplastic Thermal110.Johnson Holmquist Ceramics 111.Johnson Holmquist Concrete112.Finite Elastic Strain Plasticity yered Linear Plasticity115.Unified Creepposite Layupposite Matrixposite Direct120.Gurson123.Modified Piecewise Linear Plasticity 124.Plasticity Compression Tension 126.Modified Honeycomb127.Arruda Boyce Rubber128.Heart Tissue129.Lung Tissue130.Special Orthotropie139.Modified Force Limited150.CFDposite MSC191.Seismic Beam192.Soil Brick193.Drucker Prager194.RC Shear Wall195.Concrete BeamDS1 Spring Elastic (Linear)DS2 Damper Viscous (Linear)DS3 Spring Elastoplastic (Isotropic)DS4 Spring Nonlinear ElasticDS5 Damper Nonlinear ViscousDS6 Spring General NonlinearDS7 Spring Maxwell (Three Parameter Viscoelastic) DS8 Spring Inelastic (Tension or Compression)。

前段时间一直采用anasys模型来分析结构,由于结构所涉及到的非线性较多(预应力、接触、混凝土),结果总是不如人意,查阅网上所有资料均说abaqus非线性性能要比ansys好。

老一辈的人总说:“办法总比困难多”,在这句话的激励下,在ansys分析模型到达穷途末路的时候,想到了将ansys中的模型倒入abaqus中进行计算。

初始接触abaqus有点害怕,有点茫然。

原因之一为abaqus的学习资料少,会用的人少,精通的人更少,学习起来困难。

于是乎,看书,看帮助,打电话求教,磕磕碰碰走到今。

为了减少有志学习abaqus后生的学习难度,在此将abaqus初级关键词的用法与格式进行解释,并与ansys进行对照(虽然采用python语言编写的.inp文件更加简洁明朗,但对于初始学者,关键词也是一种快速入门的捷径)。

由于学习的时间不长(三天左右吧),难免有不知或不正确的地方,如有意请各看官加以指正与补充,在此先行谢过了。

(一)总规则1、关键词必须以*符号开头,且关键词前无空格;2、**为解释行,它可以出现在文件中的任何地方;2、当关键词后带有参数时,关键词后必须采用逗号相隔;3、参数间采用逗号相隔;4、关键词可以采用简写的方式,只要程序能够识别就可以了;5、没有隔行符,如果参数比较多,一行放不下,可以另起一行,只要在上一行的末尾加逗号便可以;(二)建模部分关键词在我的学习过程中,是将ansys的模型倒入abaqus的,最简单的方法就是在ansys中提取单元与节点信息,将提取出来的信息在abaqus中形成有限元模型。

因此首先从节点的关键词来开始吧。

1、*heading描述行这是.inp文件的开头语,相当于你告诉abaqus,我要进行工程建模与分析了。

另起一行可以对模型进行描述,这个描述可有可无,只是为了以后阅读的方便。

abaqus中对每个模块没有清晰的界定,根据关键词的不同来判别进入哪个模块。

而在ansys中对模块要求比较严格,如/prep7为前处理模块,/solu为求解模块,/post26为后处理模块。

第二部分 ANSYS/LS-DYNA 程序的使用方法1 概述ANSYS/LS-DYNA 程序系统是将非线性动力分析程序LS-DYNA 显式积分部分与ANSYS 程序的前处理PREP7和后处理POST1、POST26连接成一体。

这样既能充分运用LS-DYNA 程序强大的非线性动力分析功能,又能很好地利用ANSYS 程序完善的前后处理功能来建立有限元模型与观察计算结果,它们之间的关系如下。

ANSYS/LS-DYNA 程序系统的求解步骤为: 1.1 前处理Preprocessor 建模(用PREP7前处理解算器)1.设置Preference(Main Menu:Preference)选项置Structural LS-DYNA explicit 。

这样,以后显示的菜单完全被过滤成ANSYS/LS-DYNA 的输入选项。

再定义一种显式单元类型,即可激活LS-DYNA 求解。

GUI: Main Menu>Preferencesa.选择Structural.b.选择LS-DYNA Explicit.c.OK.2.定义单元类型Element Type和Option(算法)和实常数Real Constant。

3.定义材料性质Material Properties。

4.建立结构实体模型Modeling。

5.进行有限元网格剖分Meshing。

6.定义接触界面Contact。

1.2 加载和求解Solution1.约束、加载和给定初始速度。

2.设置求解过程的控制参数。

3.选择输出文件和输出时间间隔。

4.求解Solve(调用LS-DYNA)。

1.3 后处理POST1(观察整体变形和应力应变状态)和POST26(绘制时间历程曲线),也可连接LSTC公司的后处理程序LS-TAURUS。

在各程序模块之间传递数据的文件有:(1)A NSYS数据文件数据库文件(Database File)-Jobname.DB 二进制文件图形数据文件(Results File)-Jobname.RST 二进制文件时间历程数据文件-Jobname.HIS 二进制文件输出文件(Output File)-Jobname.OUT ASCII文件命令文件(Log File)-Jobname.LOG ASCII文件(2)L S-DYNA数据文件输入数据文件(Iuput file)-Jobname.K ASCII文件重起动文件(Dump File)-D3DUMP随机文件图形数据文件(Plot File)-D3PLOT随机文件时间历程文件-D3THDT随机文件由于ANSYS前处理程序还不能满足LS-DYNA程序系统的全部功能,用户可以生成LS-DYNA的输入数据文件Jobname.K,经过编辑、修改后,再直接调用LS-DYNA程序求解,其计算结果图形数据文件仍然可以连接ANSYS后处理程序POST1和POST26以及LS-DYNA的后处理程序LS-TAURUS观察计算结果。

A plasticity and anisotropic damage model forplain concreteUmit Cicekli,George Z.Voyiadjis *,Rashid K.Abu Al-RubDepartment of Civil and Environmental Engineering,Louisiana State University,CEBA 3508-B,Baton Rouge,LA 70803,USAReceived 23April 2006;received in final revised form 29October 2006Available online 15March 2007AbstractA plastic-damage constitutive model for plain concrete is developed in this work.Anisotropic damage with a plasticity yield criterion and a damage criterion are introduced to be able to ade-quately describe the plastic and damage behavior of concrete.Moreover,in order to account for dif-ferent effects under tensile and compressive loadings,two damage criteria are used:one for compression and a second for tension such that the total stress is decomposed into tensile and com-pressive components.Stiffness recovery caused by crack opening/closing is also incorporated.The strain equivalence hypothesis is used in deriving the constitutive equations such that the strains in the effective (undamaged)and damaged configurations are set equal.This leads to a decoupled algo-rithm for the effective stress computation and the damage evolution.It is also shown that the pro-posed constitutive relations comply with the laws of thermodynamics.A detailed numerical algorithm is coded using the user subroutine UMAT and then implemented in the advanced finite element program ABAQUS.The numerical simulations are shown for uniaxial and biaxial tension and compression.The results show very good correlation with the experimental data.Ó2007Elsevier Ltd.All rights reserved.Keywords:Damage mechanics;Isotropic hardening;Anisotropic damage0749-6419/$-see front matter Ó2007Elsevier Ltd.All rights reserved.doi:10.1016/j.ijplas.2007.03.006*Corresponding author.Tel.:+12255788668;fax:+12255789176.E-mail addresses:voyiadjis@ (G.Z.Voyiadjis),rabual1@ (R.K.AbuAl-Rub).International Journal of Plasticity 23(2007)1874–1900U.Cicekli et al./International Journal of Plasticity23(2007)1874–19001875 1.IntroductionConcrete is a widely used material in numerous civil engineering structures.Due to its ability to be cast on site it allows to be used in different shapes in structures:arc,ellipsoid, etc.This increases the demand for use of concrete in structures.Therefore,it is crucial to understand the mechanical behavior of concrete under different loadings such as compres-sion and tension,for uniaxial,biaxial,and triaxial loadings.Moreover,challenges in designing complex concrete structures have prompted the structural engineer to acquire a sound understanding of the mechanical behavior of concrete.One of the most important characteristics of concrete is its low tensile strength,particularly at low-confining pres-sures,which results in tensile cracking at a very low stress compared with compressive stresses.The tensile cracking reduces the stiffness of concrete structural components. Therefore,the use of continuum damage mechanics is necessary to accurately model the degradation in the mechanical properties of concrete.However,the concrete material undergoes also some irreversible(plastic)deformations during unloading such that the continuum damage theories cannot be used alone,particularly at high-confining pressures. Therefore,the nonlinear material behavior of concrete can be attributed to two distinct material mechanical processes:damage(micro-cracks,micro-cavities,nucleation and coa-lescence,decohesions,grain boundary cracks,and cleavage in regions of high stress con-centration)and plasticity,which its mechanism in concrete is not completely understood up-to-date.These two degradation phenomena may be described best by theories of con-tinuum damage mechanics and plasticity.Therefore,a model that accounts for both plas-ticity and damage is necessary.In this work,a coupled plastic-damage model is thus formulated.Plasticity theories have been used successfully in modeling the behavior of metals where the dominant mode of internal rearrangement is the slip process.Although the mathemat-ical theory of plasticity is thoroughly established,its potential usefulness for representing a wide variety of material behavior has not been yet fully explored.There are many research-ers who have used plasticity alone to characterize the concrete behavior(e.g.Chen and Chen,1975;William and Warnke,1975;Bazant,1978;Dragon and Mroz,1979;Schreyer, 1983;Chen and Buyukozturk,1985;Onate et al.,1988;Voyiadjis and Abu-Lebdeh,1994; Karabinis and Kiousis,1994;Este and Willam,1994;Menetrey and Willam,1995;Grassl et al.,2002).The main characteristic of these models is a plasticity yield surface that includes pressure sensitivity,path sensitivity,non-associativeflow rule,and work or strain hardening.However,these works failed to address the degradation of the material stiffness due to micro-cracking.On the other hand,others have used the continuum damage theory alone to model the material nonlinear behavior such that the mechanical effect of the pro-gressive micro-cracking and strain softening are represented by a set of internal state vari-ables which act on the elastic behavior(i.e.decrease of the stiffness)at the macroscopic level (e.g.Loland,1980;Ortiz and Popov,1982;Krajcinovic,1983,1985;Resende and Martin, 1984;Simo and Ju,1987a,b;Mazars and Pijaudier-Cabot,1989;Lubarda et al.,1994). However,there are several facets of concrete behavior(e.g.irreversible deformations, inelastic volumetric expansion in compression,and crack opening/closure effects)that can-not be represented by this method,just as plasticity,by itself,is insufficient.Since both micro-cracking and irreversible deformations are contributing to the nonlinear response of concrete,a constitutive model should address equally the two physically distinct modes of irreversible changes and should satisfy the basic postulates of thermodynamics.1876U.Cicekli et al./International Journal of Plasticity23(2007)1874–1900 Combinations of plasticity and damage are usually based on isotropic hardening com-bined with either isotropic(scalar)or anisotropic(tensor)damage.Isotropic damage is widely used due to its simplicity such that different types of combinations with plasticity models have been proposed in the literature.One type of combination relies on stress-based plasticity formulated in the effective(undamaged)space(e.g.Yazdani and Schreyer,1990; Lee and Fenves,1998;Gatuingt and Pijaudier-Cabot,2002;Jason et al.,2004;Wu et al., 2006),where the effective stress is defined as the average micro-scale stress acting on the undamaged material between micro-defects.Another type is based on stress-based plastic-ity in the nominal(damaged)stress space(e.g.Bazant and Kim,1979;Ortiz,1985;Lubliner et al.,1989;Imran and Pantazopoulu,2001;Ananiev and Ozbolt,2004;Kratzig and Poll-ing,2004;Menzel et al.,2005;Bru¨nig and Ricci,2005),where the nominal stress is defined as the macro-scale stress acting on both damaged and undamaged material.However,it is shown by Abu Al-Rub and Voyiadjis(2004)and Voyiadjis et al.(2003,2004)that coupled plastic-damage models formulated in the effective space are numerically more stable and attractive.On the other hand,for better characterization of the concrete damage behavior, anisotropic damage effects,i.e.different micro-cracking in different directions,should be characterized.However,anisotropic damage in concrete is complex and a combination with plasticity and the application to structural analysis is straightforward(e.g.Yazdani and Schreyer,1990;Abu-Lebdeh and Voyiadjis,1993;Voyiadjis and Kattan,1999;Carol et al.,2001;Hansen et al.,2001),and,therefore,it has been avoided by many authors.Consequently,with inspiration from all the previous works,a coupled anisotropic dam-age and plasticity constitutive model that can be used to predict the concrete distinct behavior in tension and compression is formulated here within the basic principles of ther-modynamics.The proposed model includes important aspects of the concrete nonlinear behavior.The model considers different responses of concrete under tension and compres-sion,the effect of stiffness degradation,and the stiffness recovery due to crack closure dur-ing cyclic loading.The yield criterion that has been proposed by Lubliner et al.(1989)and later modified by Lee and Fenves(1998)is adopted.Pertinent computational aspects con-cerning the algorithmic aspects and numerical implementation of the proposed constitu-tive model in the well-knownfinite element code ABAQUS(2003)are presented.Some numerical applications of the model to experimental tests of concrete specimens under dif-ferent uniaxial and biaxial tension and compression loadings are provided to validate and demonstrate the capability of the proposed model.2.Modeling anisotropic damage in concreteIn the current literature,damage in materials can be represented in many forms such as specific void and crack surfaces,specific crack and void volumes,the spacing between cracks or voids,scalar representation of damage,and general tensorial representation of damage.Generally,the physical interpretation of the damage variable is introduced as the specific damaged surface area(Kachonov,1958),where two cases are considered:iso-tropic(scalar)damage and anisotropic(tensor)damage density of micro-cracks and micro-voids.However,for accurate interpretation of damage in concrete,one should con-sider the anisotropic damage case.This is attributed to the evolution of micro-cracks in concrete whereas damage in metals can be satisfactorily represented by a scalar damage variable(isotropic damage)for evolution of voids.Therefore,for more reliable represen-tation of concrete damage anisotropic damage is considered in this study.The effective(undamaged)configuration is used in this study in formulating the damage constitutive equations.That is,the damaged material is modeled using the constitutive laws of the effective undamaged material in which the Cauchy stress tensor,r ij,can be replaced by the effective stress tensor, r ij(Cordebois and Sidoroff,1979;Murakami and Ohno,1981;Voyiadjis and Kattan,1999):r ij¼M ijkl r klð1Þwhere M ijkl is the fourth-order damage effect tensor that is used to make the stress tensor symmetrical.There are different definitions for the tensor M ijkl that could be used to sym-metrize r ij(see Voyiadjis and Park,1997;Voyiadjis and Kattan,1999).In this work the definition that is presented by Abu Al-Rub and Voyiadjis(2003)is adopted:M ijkl¼2½ðd ijÀu ijÞd klþd ijðd klÀu klÞ À1ð2Þwhere d ij is the Kronecker delta and u ij is the second-order damage tensor whose evolution will be defined later and it takes into consideration different evolution of damage in differ-ent directions.In the subsequence of this paper,the superimposed dash designates a var-iable in the undamaged configuration.The transformation from the effective(undamaged)configuration to the damaged one can be done by utilizing either the strain equivalence or strain energy equivalence hypoth-eses(see Voyiadjis and Kattan,1999).However,in this work the strain equivalence hypothesis is adopted for simplicity,which basically states that the strains in the damaged configuration and the strains in the undamaged(effective)configuration are equal.There-fore,the total strain tensor e ij is set equal to the corresponding effective tensor e ij(i.e.e ij¼ e ijÞ,which can be decomposed into an elastic strain e eij (= e eijÞand a plastic straine p ij(= e p ijÞsuch that:e ij¼e eij þe p ij¼ e eijþ e p ij¼ e ijð3ÞIt is noteworthy that the physical nature of plastic(irreversible)deformations in con-crete is not well-founded until now.Whereas the physical nature of plastic strain in metals is well-understood and can be attributed to the generation and motion of dislocations along slip planes.Therefore,in metals any additional permanent strains due to micro-cracking and void growth can be classified as a damage strain.These damage strains are shown by Abu Al-Rub and Voyiadjis(2003)and Voyiadjis et al.(2003,2004)to be minimal in metals and can be simply neglected.Therefore,the plastic strain in Eq.(3) incorporates all types of irreversible deformations whether they are due to tensile micro-cracking,breaking of internal bonds during shear loading,and/or compressive con-solidation during the collapse of the micro-porous structure of the cement matrix.In the current work,it is assumed that plasticity is due to damage evolution such that damage occurs before any plastic deformations.However,this assumption needs to be validated by conducting microscopic experimental characterization of concrete damage.Using the generalized Hook’s law,the effective stress is given as follows: r ij¼E ijkl e eklð4Þwhere E ijkl is the fourth-order undamaged elastic stiffness tensor.For isotropic linear-elas-tic materials,E ijkl is given byE ijkl¼2GI dijkl þKI ijklð5ÞU.Cicekli et al./International Journal of Plasticity23(2007)1874–19001877where I dijkl ¼I ijklÀ13d ij d kl is the deviatoric part of the fourth-order identity tensorI ijkl¼12ðd ik d jlþd il d jkÞ,and G¼E=2ð1þmÞand K¼E=3ð1À2mÞare the effective shearand bulk moduli,respectively,with E being the Young’s modulus and m is the Poisson’s ratio which are obtained from the stress–strain diagram in the effective configuration.Similarly,in the damaged configuration the stress–strain relationship in Eq.(4)can be expressed by:r ij¼E ijkl e eklð6Þsuch that one can express the elastic strain from Eqs.(4)and(5)by the following relation:e e ij ¼EÀ1ijklr kl¼EÀ1ijklr klð7Þwhere EÀ1ijkl is the inverse(or compliance tensor)of the fourth-order damaged elastic tensorE ijkl,which are a function of the damage variable u ij.By substituting Eq.(1)into Eq.(7),one can express the damaged elasticity tensor E ijkl in terms of the corresponding undamaged elasticity tensor E ijkl by the following relation:E ijkl¼MÀ1ijmnE mnklð8ÞMoreover,combining Eqs.(3)and(7),the total strain e ij can be written in the following form:e ij¼EÀ1ijkl r klþe p ij¼EÀ1ijklr klþe p ijð9ÞBy taking the time derivative of Eq.(3),the rate of the total strain,_e ij,can be written as _e ij¼_e eijþ_e p ijð10Þwhere_e eij and_e p ij are the rate of the elastic and plastic strain tensors,respectively.Analogous to Eq.(9),one can write the following relation in the effective configuration:_e ij¼EÀ1ijkl _ rklþ_e p ijð11ÞHowever,since E ijkl is a function of u ij,a similar relation as Eq.(11)cannot be used. Therefore,by taking the time derivative of Eq.(9),one can write_e ij in the damaged con-figuration as follows:_e ij¼EÀ1ijkl _r klþ_EÀ1ijklr klþ_e p ijð12ÞConcrete has distinct behavior in tension and compression.Therefore,in order to ade-quately characterize the damage in concrete due to tensile,compressive,and/or cyclic loadings the Cauchy stress tensor(nominal or effective)is decomposed into a positive and negative parts using the spectral decomposition technique(e.g.Simo and Ju, 1987a,b;Krajcinovic,1996).Hereafter,the superscripts‘‘+”and‘‘À”designate,respec-tively,tensile and compressive entities.Therefore,r ij and r ij can be decomposed as follows:r ij¼rþij þrÀij; r ij¼ rþijþ rÀijð13Þwhere rþij is the tension part and rÀijis the compression part of the stress state.The stress tensors rþij and rÀijcan be related to r ij byrþkl ¼Pþklpqr pqð14ÞrÀkl ¼½I klpqÀPþijpqr pq¼PÀklpqr pqð15Þ1878U.Cicekli et al./International Journal of Plasticity23(2007)1874–1900such that Pþijkl þPÀijkl¼I ijkl.The fourth-order projection tensors Pþijkland PÀijklare definedas follows:Pþijpq ¼X3k¼1Hð^rðkÞÞnðkÞi nðkÞj nðkÞpnðkÞq;PÀklpq¼I klpqÀPþijpqð16Þwhere Hð^ rðkÞÞdenotes the Heaviside step function computed at k th principal stress^rðkÞof r ij and nðkÞi is the k th corresponding unit principal direction.In the subsequent develop-ment,the superscript hat designates a principal value.Based on the decomposition in Eq.(13),one can assume that the expression in Eq.(1) to be valid for both tension and compression,however,with decoupled damage evolution in tension and compression such that:rþij ¼Mþijklrþkl; rÀij¼MÀijklrÀklð17Þwhere Mþijkl is the tensile damage effect tensor and MÀijklis the corresponding compressivedamage effect tensor which can be expressed using Eq.(2)in a decoupled form as a func-tion of the tensile and compressive damage variables,uþij and uÀij,respectively,as follows:Mþijkl ¼2½ðd ijÀuþijÞd klþd ijðd klÀuþklÞ À1;MÀijkl¼2½ðd ijÀuÀijÞd klþd ijðd klÀuÀklÞ À1ð18ÞNow,by substituting Eq.(17)into Eq.(13)2,one can express the effective stress tensor as the decomposition of the fourth-order damage effect tensor for tension and compression such that:r ij¼Mþijkl rþklþMÀijklrÀklð19ÞBy substituting Eqs.(14)and(15)into Eq.(19)and comparing the result with Eq.(1), one can obtain the following relation for the damage effect tensor such that:M ijpq¼Mþijkl PþklpqþMÀijklPÀklpqð20ÞUsing Eq.(16)2,the above equation can be rewritten as follows:M ijpq¼Mþijkl ÀMÀijklPþklpq þMÀijpqð21ÞOne should notice the following:M ijkl¼Mþijkl þMÀijklð22Þoru ij¼uþij þuÀijð23ÞIt is also noteworthy that the relation in Eq.(21)enhances a coupling between tensileand compressive damage through the fourth-order projection tensor Pþijkl .Moreover,forisotropic damage,Eq.(20)can be written as follows:M ijkl¼Pþijkl1ÀuþþPÀijkl1ÀuÀð24ÞIt can be concluded from the above expression that by adopting the decomposition of the scalar damage variable u into a positive u+part and a negative uÀpart still enhances adamage anisotropy through the spectral decomposition tensors Pþijkl and PÀijkl.However,this anisotropy is weak as compared to the anisotropic damage effect tensor presented in Eq.(21).U.Cicekli et al./International Journal of Plasticity23(2007)1874–190018793.Elasto-plastic-damage modelIn this section,the concrete plasticity yield criterion of Lubliner et al.(1989)which was later modified by Lee and Fenves(1998)is adopted for both monotonic and cyclic load-ings.The phenomenological concrete model of Lubliner et al.(1989)and Lee and Fenves (1998)is formulated based on isotropic(scalar)stiffness degradation.Moreover,this model adopts one loading surface that couples plasticity to isotropic damage through the effective plastic strain.However,in this work the model of Lee and Fenves(1998)is extended for anisotropic damage and by adopting three loading surfaces:one for plastic-ity,one for tensile damage,and one for compressive damage.The plasticity and the com-pressive damage loading surfaces are more dominate in case of shear loading and compressive crushing(i.e.modes II and III cracking)whereas the tensile damage loading surface is dominant in case of mode I cracking.The presentation in the following sections can be used for either isotropic or anisotropic damage since the second-order damage tensor u ij degenerates to the scalar damage vari-able in case of uniaxial loading.3.1.Uniaxial loadingIn the uniaxial loading,the elastic stiffness degradation variables are assumed asincreasing functions of the equivalent plastic strains eþeq and eÀeqwith eþeqbeing the tensileequivalent plastic strain and eÀeq being the compressive equivalent plastic strain.It shouldbe noted that the material behavior is controlled by both plasticity and damage so that, one cannot be considered without the other(see Fig.1).For uniaxial tensile and compressive loading, rþij and rÀijare given as(Lee and Fenves,1998)rþ¼ð1ÀuþÞE eþe¼ð1ÀuþÞEðeþÀeþpÞð25ÞrÀ¼ð1ÀuÀÞE eÀe¼ð1ÀuÀÞEðeÀÀeÀpÞð26ÞThe rate of the equivalent(effective)plastic strains in compression and tension,eÀep and eþep,are,respectively,given as follows in case of uniaxial loading:1880U.Cicekli et al./International Journal of Plasticity23(2007)1874–1900_eþeq ¼_e p11;_eÀeq¼À_e p11ð27Þsuch thateÀeq ¼Z t_eÀeqd t;eþeq¼Z t_eþeqd tð28ÞPropagation of cracks under uniaxial loading is in the transverse direction to the stress direction.Therefore,the nucleation and propagation of cracks cause a reduction of the capacity of the load-carrying area,which causes an increase in the effective stress.This has little effect during compressive loading since cracks run parallel to the loading direc-tion.However,under a large compressive stress which causes crushing of the material,the effective load-carrying area is also considerably reduced.This explains the distinct behav-ior of concrete in tension and compression as shown in Fig.2.It can be noted from Fig.2that during unloading from any point on the strain soften-ing path(i.e.post peak behavior)of the stress–strain curve,the material response seems to be weakened since the elastic stiffness of the material is degraded due to damage evolution. Furthermore,it can be noticed from Fig.2a and b that the degradation of the elastic stiff-ness of the material is much different in tension than in compression,which is more obvi-ous as the plastic strain increases.Therefore,for uniaxial loading,the damage variable can be presented by two independent damage variables u+and uÀ.Moreover,it can be noted that for tensile loading,damage and plasticity are initiated when the equivalent appliedstress reaches the uniaxial tensile strength fþ0as shown in Fig.2a whereas under compres-sive loading,damage is initiated earlier than plasticity.Once the equivalent applied stressreaches fÀ0(i.e.when nonlinear behavior starts)damage is initiated,whereas plasticityoccurs once fÀu is reached.Therefore,generally fþ¼fþufor tensile loading,but this isnot true for compressive loading(i.e.fÀ0¼fÀuÞ.However,one may obtain fÀ%fÀuin caseof ultra-high strength concrete.3.2.Multiaxial loadingThe evolution equations for the hardening variables are extended now to multiaxial loadings.The effective plastic strain for multiaxial loading is given as follows(Lubliner et al.,1989;Lee and Fenves,1998):U.Cicekli et al./International Journal of Plasticity23(2007)1874–19001881_e þeq ¼r ð^ r ij Þ^_e p maxð29Þ_e Àeq ¼Àð1Àr ð^ r ij ÞÞ^_e p min ð30Þwhere ^_e p max and ^_e p min are the maximum and minimum principal values of the plastic strain tensor _e p ij such that ^_e p 1>^_e p 2>^_e p 3where ^_e p max ¼^_e p 1and ^_e p min ¼^_ep 3.Eqs.(29)and (30)can be written in tensor format as follows:_j p i ¼H ij ^_e p jð31Þor equivalently _e þeq 0_e Àeq8><>:9>=>;¼H þ0000000H À264375^_e p 1^_e p 2^_e p 38><>:9>=>;ð32ÞwhereH þ¼r ð^ rij Þð33ÞH À¼Àð1Àr ð^ r ij ÞÞð34ÞThe dimensionless parameter r ð^ rij Þis a weight factor depending on principal stresses and is defined as follows (Lubliner et al.,1989):r ð^ r ij Þ¼P 3k¼1h ^ r k i P k ¼1j ^ r kj ð35Þwhere h i is the Macauley bracket,and presented as h x i ¼1ðj x j þx Þ,k ¼1;2;3.Note that r ð^ rij Þ¼r ð^r ij Þ.Moreover,depending on the value of r ð^r ij Þ,–in case of uniaxial tension ^ r k P 0and r ð^ r ij Þ¼1,–in case of uniaxial compression ^ rk 60and r ð^ r ij Þ¼03.3.Cyclic loadingIt is more difficult to address the concrete damage behavior under cyclic loading;i.e.transition from tension to compression or vise versa such that one would expect that under cyclic loading crack opening and closure may occur and,therefore,it is a challenging task to address such situations especially for anisotropic damage evolution.Experimentally,it is shown that under cyclic loading the material goes through some recovery of the elastic stiffness as the load changes sign during the loading process.This effect becomes more sig-nificant particularly when the load changes sign during the transition from tension to com-pression such that some tensile cracks tend to close and as a result elastic stiffness recovery occurs during compressive loading.However,in case of transition from compression to tension one may thus expect that smaller stiffness recovery or even no recovery at all may occur.This could be attributed to the fast opening of the pre-existing cracks that had formed during the previous tensile loading.These re-opened cracks along with the new cracks formed during the compression will cause further reduction of the elastic stiffness that the body had during the first transition from tension to compression.The1882U.Cicekli et al./International Journal of Plasticity 23(2007)1874–1900consideration of stiffness recovery effect due to crack opening/closing is therefore impor-tant in defining the concrete behavior under cyclic loading.Eq.(21)does not incorporate the elastic stiffness recovery phenomenon as well as it does not incorporate any coupling between tensile damage and compressive damage and,therefore,the formulation of Lee and Fenves(1998)for cyclic loading is extended here for the anisotropic damage case.Lee and Fenves(1998)defined the following isotropic damage relation that couples both tension and compression effects as well as the elastic stiffness recovery during transi-tion from tension to compression loading such that:u¼1Àð1Às uþÞð1ÀuÀÞð36Þwhere sð06s61Þis a function of stress state and is defined as follows: sð^ r ijÞ¼s0þð1Às0Þrð^ r ijÞð37Þwhere06s061is a constant.Any value between zero and one results in partial recovery of the elastic stiffness.Based on Eqs.(36)and(37):(a)when all principal stresses are positive then r=1and s=1such that Eq.(36)becomesu¼1Àð1ÀuþÞð1ÀuÀÞð38Þwhich implies no stiffness recovery during the transition from compression to tension since s is absent.(b)when all principal stresses are negative then r=0and s¼s0such that Eq.(36)becomesu¼1Àð1Às0uþÞð1ÀuÀÞð39Þwhich implies full elastic stiffness recovery when s0¼0and no recovery when s0¼1.In the following two approaches are proposed for extending the Lee and Fenves(1998)model to the anisotropic damage case.Thefirst approach is by multiplying uþij in Eq.(18)1by the stiffness recovery factor s:Mþijkl ¼2½ðd ijÀs uþijÞd klþd ijðd klÀs uþklÞ À1ð40Þsuch that the above expression replaces Mþijkl in Eq.(21)to give the total damage effecttensor.Another approach to enhance coupling between tensile damage and compressive dam-age as well as in order to incorporate the elastic stiffness recovery during cyclic loading for the anisotropic damage case is by rewriting Eq.(36)in a tensor format as follows:u ij¼d ijÀðd ikÀs uþik Þðd jkÀuÀjkÞð41Þwhich can be substituted back into Eq.(2)to get thefinal form of the damage effect tensor, which is shown next.It is noteworthy that in case of full elastic stiffness recovery(i.e.s=0),Eq.(41)reducesto u ij¼uÀij and in case of no stiffness recovery(i.e.s=1),Eq.(41)takes the form ofu ij ¼uÀijþuþikÀuþikuÀjksuch that both uþijand uÀijare coupled.This means that duringthe transition from tension to compression some cracks are closed or partially closed which could result in partial recovery of the material stiffness(i.e.s>0)in the absence U.Cicekli et al./International Journal of Plasticity23(2007)1874–19001883。