卤代酮的合成-060123

- 格式:doc

- 大小:417.00 KB

- 文档页数:13

卤代酮的制备卤代酮是一类重要的有机化合物,它们在有机合成中具有广泛的应用。

卤代酮的制备方法有许多种,下面将介绍其中的几种常见方法。

一、酮的卤代反应酮的卤代反应是一种常见的制备卤代酮的方法。

酮分子中的羰基碳原子与卤素发生取代反应,从而得到卤代酮。

这种方法适用于活性较高的酮,例如酮中的氧化氢原子活性较高或酮分子中存在较强的共轭体系。

具体操作时,可以选择适量的卤素和有机溶剂,在适当的温度下进行反应。

反应完成后,通过适当的方法进行分离纯化,得到纯净的卤代酮产物。

二、酮的卤代还原反应酮的卤代还原反应是制备卤代酮的另一种常用方法。

这种方法首先进行酮的卤代反应,得到卤代酮,然后通过还原反应将卤素原子还原为氢原子,形成卤代酮。

这种方法适用于含有较多卤素的酮,例如三卤代酮。

在反应中,可以选择适量的还原剂和有机溶剂,在适当的温度下进行反应。

反应完成后,通过适当的方法进行分离纯化,得到纯净的卤代酮产物。

三、酮的卤化反应酮的卤化反应是制备卤代酮的另一种常见方法。

在这种反应中,酮分子中的氧化氢原子被卤素取代,形成卤代酮。

这种方法适用于活性较低的酮,例如酮中的氧化氢原子活性较低或酮分子中不存在共轭体系。

具体操作时,可以选择适量的卤素和有机溶剂,在适当的温度下进行反应。

反应完成后,通过适当的方法进行分离纯化,得到纯净的卤代酮产物。

四、酮的酸化卤化反应酮的酸化卤化反应是一种制备卤代酮的有效方法。

在这种反应中,酮分子首先与酸反应生成酸酯,然后再与卤素反应生成卤代酮。

这种方法适用于酮分子中存在较强的羰基活性或活性氢原子。

具体操作时,可以选择适量的酸和卤素,以及适当的有机溶剂,在适当的温度下进行反应。

反应完成后,通过适当的方法进行分离纯化,得到纯净的卤代酮产物。

总结起来,卤代酮的制备方法主要包括酮的卤代反应、酮的卤代还原反应、酮的卤化反应和酮的酸化卤化反应等。

这些方法各有优缺点,适用于不同类型的酮分子。

在实际应用中,可以根据具体情况选择最合适的方法进行制备。

有机合成中的卤代化合物在有机合成领域中,卤代化合物是一类广泛应用的化合物。

卤代化合物是指含有卤素(氟、氯、溴、碘)原子的有机分子。

这些化合物在合成有机化合物、药物和材料等方面起着重要作用。

本文将从卤代化合物的合成方法、反应性质以及应用等方面进行探讨。

一、卤代化合物的合成方法1. 直接卤代反应直接卤代反应是最直接、简单的合成卤代化合物的方法。

它通常将有机物与卤素在适当条件下反应,生成相应的卤代产物。

例如,将溴与苯反应可以得到溴苯。

此类反应条件温和,操作简单。

2.间接卤代反应间接卤代反应是通过先将有机物转化为亲电或亲核试剂,然后再与卤素反应得到卤代产物。

这种方法在选择性、收率和操作性上有一定的优势。

例如,将醇与氯化亚砜反应可以得到氯代醚。

3. 卤化醇反应卤化醇反应指的是醇与卤素(溴、氯)反应生成卤代醇的过程。

这是一种常用的合成卤代化合物的方法,适用于不同类型的醇。

例如,将乙醇与氯气反应可以得到氯乙醇。

二、卤代化合物的反应性质1. 亲电取代反应卤代化合物具有亲电子性,容易进行亲电取代反应。

这类反应中,卤素被替换掉,取代它的官能团进入化合物中。

常见的亲电取代反应包括氢氧化、碱解、还原和取代等反应。

2. 亲核取代反应卤代化合物也可参与亲核取代反应。

在这类反应中,卤代化合物的卤素被亲核试剂所取代。

亲核试剂可以是普通的亲核离子、亲核试剂还可以是亲核试剂及普通亲核离子的中间体。

常见的亲核取代反应有芳香核取代反应、亲核加成反应等。

三、卤代化合物的应用1. 有机合成卤代化合物作为重要的中间体,在有机合成过程中发挥着至关重要的作用。

它们可以作为起始物质用于合成其他有机分子或者在反应中被进一步转化。

例如,乙烯基溴可以参与许多重要的碳碳键形成反应,用于构建分子骨架。

2. 药物研究卤代化合物在药物研究领域中具有广泛的应用。

它们可以用作药物的前体,通过后续的化学转化形成具有特定功能的药物分子。

卤代化合物的引入可以改变药物分子的生物活性、稳定性和吸收性等特性。

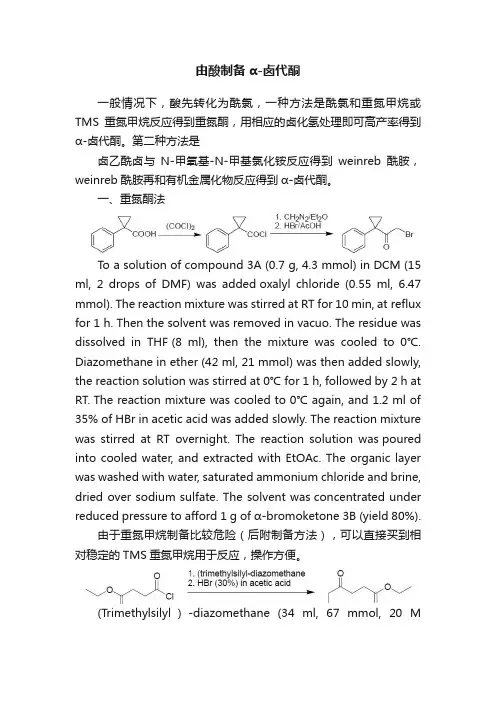

由酸制备α-卤代酮一般情况下,酸先转化为酰氯,一种方法是酰氯和重氮甲烷或TMS重氮甲烷反应得到重氮酮,用相应的卤化氢处理即可高产率得到α-卤代酮。

第二种方法是卤乙酰卤与N-甲氧基-N-甲基氯化铵反应得到weinreb酰胺,weinreb酰胺再和有机金属化物反应得到α-卤代酮。

一、重氮酮法To a solution of compound 3A (0.7 g, 4.3 mmol) in DCM (15 ml, 2 drops of DMF) was added oxalyl chloride (0.55 ml, 6.47 mmol). The reaction mixture was stirred at RT for 10 min, at reflux for 1 h. Then the solvent was removed in vacuo. The residue was dissolved in THF (8 ml), then the mixtu re was cooled to 0℃. Diazomethane in ether (42 ml, 21 mmol) was then added slowly, the reaction solution was stirred at 0℃ for 1 h, followed by 2 h at RT. The reaction mixture was cooled to 0℃ again, and 1.2 ml of 35% of HBr in acetic acid was added slowly. The reaction mixture was stirred at RT overnight. The reaction solution was poured into cooled water, and extracted with EtOAc. The organic layer was washed with water, saturated ammonium chloride and brine, dried over sodium sulfate. The solvent was concentrated under reduced pressure to afford 1 g of α-bromoketone 3B (yield 80%).由于重氮甲烷制备比较危险(后附制备方法),可以直接买到相对稳定的TMS重氮甲烷用于反应,操作方便。

经典化学合成反应标准操作α-卤代酮的合成目录1.前言 (2)2. 直接卤化 (2)3.经重氮酮制备 (4)4.从weinreb 酰胺制备 (6)5.傅克酰基化合成卤代酮 (7)6 其他合成α-卤代酮的方法 (9)1.前言α-卤代酮的合成广泛应用于现代有机合成中, 多用于溴的烷基化、合成咪唑及噻唑等杂环类化合物,其合成方法常用直接卤化、经重氮酮制备、经Weinreb 酰胺制备、傅克酰基化等方法合成。

2. 直接卤化酮的α-氢易被取代,可以直接合成α-卤代酮。

一般操作是将酮与卤素于醋酸、氯仿、DMF 或水中反应。

除卤素外, 硫酰氯、五卤化磷、过溴化吡啶氢溴酸盐(C5H5NH.Br 3)、三卤化三甲基苄基铵盐等也可以做卤化试剂。

对称酮或只有一个取代方向的酮卤代时,可以良好产率(80~90%)生成α-卤代酮。

不对称酮卤代,往往生成α-及α’-卤代酮的混合物。

由于酮卤代的决定步骤是酮的烯醇化,因此,易形成烯醇的方向优先卤代。

例 2-甲基环己酮与亚硫酰氯作用, 多取代的α-氢优先氯代1。

OCH 3OCH 3Cl 2485%若利用双(二甲基乙酰胺基)三溴化氢做溴化剂,可使不对称酮在少取代一边溴代2。

OOBr[(Me 2NCOCH 3)2H]Br 3384%若将不对称酮首先转变成为一定构型的烯醇盐,继而卤代,是区域定向卤代的新方法3。

OH 3COH 3CCl1. i -Pr 2NLi, THFPhCOOEtO CH 3PhOCH 3Br 1. NaH, DMSO另外,甲基酮可用甲基格式试剂与相应的Weinreb 酰胺来制备, 如下例即是先合成甲基酮,后溴化来合成α-溴代酮的4。

NBocO HONBocO NO NBocODCC, D MAP, N HMeOMe MeMgI , e t h er合成实例一 5OOOOOOBrBr 2, AcOH2B 2AA suspension of ketone 2A (700 mg, 2.17 mmol) in acetic acid (15 ml) was heated to 70℃, followed by addition of bromine (347 mg, 2.17 mmol). After the mixture was stirred at 70℃ for 3h, the solvent was evaporated and the residue was purified by column chromatography to give the compound 2B (591 mg, 68%).合成实例二6OMe MeOO Br OMeMeOOBr232C2DBromine (7.99 g, 50 mmol) in CHCl 3 (20 ml) was added in a dropwise manner to a stirred solution of 2, 5-dimethoxy-4-bromoacetophenone 2C (12.95 g, 40 mmol) in CHCl 3 (100 ml) at 5℃. After the addition was completed, the reaction mixture was allowed to warm to room temperature and stirred for an additional 2 h. The mixture was poured onto crushed ice, the organic portion was separated and washed with water, saturated NaHCO 3 solution, and again with water. The solution was dried MgSO 4, and evaporated to dryness under reduced pressure to give a crude product. The product was recrystallized from MeOH to yield 14.70 g (87%) of the desired bromoacetophenone 2D as a white solid.ON NH 2NON NH 2NBr AcOH, 48% aq. HBr and Br 2To a solution of 1-(2-aminopyrimidin-4yl) ethanone (412 mg, 3 mmol) in glacial acetic acid (1 mL) and 48% aq. HBr (0.3 mL), bromine (0.153 mL) in acetic acid (0.4 mL) was added and the resulting orange solution was stirred at RT for1.5 hours. After diluting with ethyl acetate (15 mL), the precipitate was filtered and washed with ethl acetate thus affording the target compound as a whitish solid (580 mg, 65%).合成实例四8O OSiOOSi Br 2E 2FBenzyltrimethylammonium tribromide (4.17 g, 10.7 mmol) was added to a solution of Compound 2E (4.00 g, 10.7 mmol) in CH 2Cl 2-MeOH (5:2, 25 mL). The mixture was stirred at RT for 3 h. At this time the reaction mixture was concentrated in vacuo and H 2O (15 mL) was added. The mixture was extracted with diethyl ether (3 × 20 mL). The combined organic extracts were washed with brine (15 mL), dried over MgSO 4, filtered and concentrated in vacuo. The residue was purified by silica gel chromatography (hexanes:EtOAc, 3:1) to afford to afford Compound 2F (3.97 g, 8.8 mmol, 82%) as a thick yellow oil.3.经重氮酮制备不对称酮卤代时,有时无法得到单卤代产物。

此时,从酰氯或活泼酯经重氮酮合成α-卤代酮可以顺利得到单卤代产物。

重氮酮常用重氮甲烷的醚溶液加到相应的酰氯或活波酯中制得,也可以用三甲基硅重氮甲烷处理相应的酰氯制得。

重氮酮用相应的卤化氢处理即可高产率得到α-卤代酮。

COOH COClO Br(COCl)1. CH2N2/Et2O3A3BTo a solution of compound 3A (0.7 g, 4.3 mmol) in DCM (15 ml, 2 drops of DMF) was added oxalyl chloride (0.55 ml, 6.47 mmol). The reaction mixture was stirred at RT for 10 min, at reflux for 1 h. Then the solvent was removed in vacuo. The residue was dissolved in THF (8 ml), then the mixture was cooled to 0℃. Diazomethane in ether (42 ml, 21 mmol) was then added slowly, the reaction solution was stirred at 0℃for 1 h, followed by 2 h at RT. The reaction mixture was cooled to 0℃again, and 1.2 ml of 35% of HBr in acetic acid was added slowly. The reaction mixture was stirred at RT overnight. The reaction solution was poured into cooled water, and extracted with EtOAc. The organic layer was washed with water, saturated ammonium chloride and brine, dried over sodium sulfate. The solvent was concentrated under reduced pressure to afford 1 g of α-bromoketone 3B (yield 80%).Note: Preparation of diazomethaneSO2NO+ ROH CH2N2+SO2OR+H2OKOHA reaction and distillation apparatus is assembled by connecting an addition funnel and condensor to a 100 ml long-neck distillation flask. Two in series receiving flasks are connected to the apparatus with the second flask containing an induction tube. A solution containing 6 g potassium hydroxide in 10 ml water, and a solution containing 35 ml Carbitol (diethylene glycol monoethyl ether) and 10 ml of ether are placed in the distillation flask. 20~30 ml ether is placed in the second receiving flask makin gsure the induction tube is immersed into the ether. Both receiving flasks are cooled to 0℃. A solution containing p-toluenesulfonyl-N-methyl-N-nitosamide (21.5 g, 0.1 mol) in 140 ml ether is placed in the addition funnel. Heat the distillation flask to 70℃in a warm water bath. As the ether begins to boil, start adding the p-toluenesulfonyl-N-methyl –N-nitrosamide solution dropwise over a 20 minute period. Swirl distillation flask from time to time. About 3 g ofwithout storing it.合成实例二9OOOOOO Cl1. (trimethylsilyl-diazomethane(Trimethylsilyl )-diazomethane (34 ml, 67 mmol, 20 M solution in hexanes) was added dropwise to a solution of ethyl succinyl chloride (5 g, 303 mmol) in acetonitrile (60 ml) over a period of 30 min after the mixture was stirred for 2 h, hydrogen bromide (14 ml, 30% solution in acetic acid) was slowly added over 15 min after the reaction was stirred for an additional 1 h, the solvent was evaporated under vacuum. The residue was dissolved in ethyl acetate and washed with 1 N NaOH and brine. The organic layer was dried with sodium sulfate, filtered, and evaporated under vacuum to yield 4.3 g (64%) of ethyl 5-bromo-4-oxopentanoate4.从weinreb 酰胺制备N -甲氧基-N -甲基酰胺做为易离去基团,可因与有机金属试剂在温和的条件下反应,以良好的收率生成酮。