欧米茄表使用说明书

- 格式:doc

- 大小:51.00 KB

- 文档页数:8

如何确定我购买的是正宗欧米茄腕表?遵循如下步骤可以确定您购买的是正宗欧米茄腕表:- 只在欧米茄指定经销商处购买欧米茄腕表。

- 申请一张信用卡大小的保修卡,完整填写8位系列编号、手表编号以及经销商的完整姓名和地址。

- 如果您想确定腕表是否正宗,请携同欧米茄腕表及保修卡到指定的维修中心,让我们的维修服务员确定您购买的是否为正宗欧米茄腕表。

客户服务网络返回页首计时表(CHRONOGRAPH)与瑞士官方天文台认证腕表(CHRONOMETER)有何区别?计时表(CHRONOGRAPH)带有显示时、分和秒的指针,它们与机械系统一起透过中央计时指针测定逝去时间,可以记录到秒,并且具有30分钟和12小时定时装置。

瑞士官方天文台认证腕表(CHRONOMETER)是以不同角度,成功通过温度、精确度和防水功能测试后,获得COSC(瑞士官方天文台)正式颁发的等级证书的腕表。

通过这些测试至少需要15天时间。

返回页首计时腕表上的按钮具有什么功能?位于2点钟位置的按钮可以启动或停止计时功能,位于4点钟位置的按钮用于重新计时。

返回页首海马系列专业计时腕表的排氦气阀门具有什么功能?排氦气阀门由欧米茄为职业潜水员专门研发。

在深海潜水过程中,潜水员往往会在潜水钟内进行数天作业。

在到达水平面之前,潜水钟内充满氦气和氧气的混合气体。

氦气分子轻于空气,可以渗入手表,并在大气压力的作用下将水晶镜面推出。

在到达水平面之前打开氦气排放阀可以将氦气排放,从而防止手表进水。

返回页首自动上链机芯与手动上链机芯有何区别?自动上链机芯与手动上链机芯的区别在于上链方式的不同。

手动上链腕表需要每天人工上链,而自动上链腕表则具有内部摩打,利用手腕的运动来自动上链。

自动上链腕表通常具有至少40小时的动力储存,即使不佩戴手表,仍然能够备有足够的能量储存以保持稳定的运行。

返回页首欧米茄腕表是否具有防振功能?是。

欧米茄腕表可以承受重量为5000克的振动。

返回页首欧米茄腕表是否具有防磁性能?是。

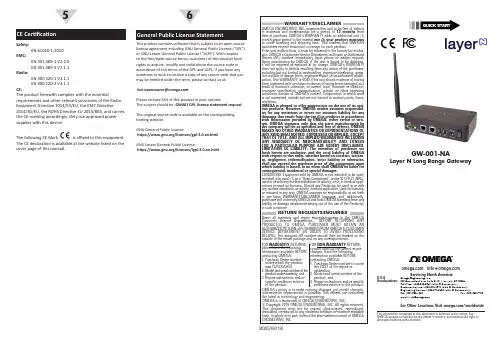

WARRANTY/DISCLAIMEROMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and shipping time. T his ensures that OMEGA’s customers receive maximum coverage on each product.If the unit malfunctions, it must be returned to the factory for evalua-tion. OMEGA’s Customer Service Department will issue an Authorized Return (AR) number immediately upon phone or written request.Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling, improper interfacing, opera-tion outside of design limits, improper repair, or unauthorized modifi-cation. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not limited to contact points, fuses, and triacs.OMEGA is pleased to offer suggestions on the use of its vari-ous products. However, OMEGA neither assumes responsibil-ity for any omissions or errors nor assumes liability for any damages that result from the use if its products in accordance with information provided by OMEGA, either verbal or writ-ten. OMEGA warrants only that the parts manufactured by the company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY W ARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warran-ty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical appli-cations or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally,purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s)in such a manner.RETURN REQUESTS/INQUIRIESDirect all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RE URNING ANY PRODUC (S) O OMEGA, PURCHASER MUS OB AIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPART MENT (IN ORDER T O AVOID PROCESSING DELAYS). T he assigned AR number should then be marked on the outside of the return package and on any correspondence.FOR WARRANTY RETURNS, please have the following information available BEFORE contacting OMEGA:1. Purchase Order numberunder which the product was PURCHASED, 2. Model and serial number of the product under warranty, and 3. Repair instructions and/or specific problems relativeto the product.FOR NON-WARRANTY REPAIRS, consult OMEGA for current repair charges. Have the following information available BEFOREcontacting OMEGA:1. P urchase Order number to cover the COST of the repair or calibration,2. Model and serial number of the product, and 3. R epair instructions and/or specific problems relative to the product.OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and engineering.OMEGA is a trademark of OMEGA ENGINEERING, INC.© Copyright 2019 OMEGA ENGINEERING, INC. All rights reserved. T his document may not be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.MQS5749/1120GW-001-NALayer N Long Range Gateway***********************The information contained in this document is believed to be correct, butOMEGA accepts no liability for any errors it contains, and reserves the right to alter specifications without notice.Servicing North America:U.S.A. Omega Engineering, Inc.Headquarters: 800 Connecticut Ave. Suite 5N01, Norwalk, CT 06854 Toll-Free: 1-800-826-6342 (USA & Canada only)Customer Service: 1-800-622-2378 (USA & Canada only) Engineering Service: 1-800-872-9436 (USA & Canada only) Tel: (203) 359-1660 Fax: (203) 359-7700 e-mail:**************For Other Locations Visit /worldwide65This product contains software that is subject to an open source license agreement including GNU General Public License (“GPL”) or GNU Lesser General Public License (“LGPL”). With respect to the free/open source terms, customers of this product have rights to acquire, modify and redistribute the source code in accordance of the terms of the GPL and LGPL. If you have any questions or wish to receive a copy of any source code that you may be entitled under the term, please contact us at:*************************Please include SKU of this product in your request.The subject should be: GW001 GPL license statement request The original source code is available on the corresponding hosting website.GNU General Public License:https:///licenses/gpl-3.0.en.html GNU Lesser General Public License:https:///licenses/lgpl-3.0.en.htmlSafety: EN 61010-1:2010EMC: EN 301 489-1 V2.2.0 EN 301 489-3 V2.1.1Radio: EN 300 320-1 V3.1.1 EN 300 220-2 V3.1.1CE:The product herewith complies with the essentialrequirements and other relevant provisions of the Radio Equipment Directive 2014/53/EU, the EMC Directive2014/30/EU, the ROHS Directive EU 2015/863, and carries the CE-marking accordingly. Only use approved power supplies with this device.The following CE Mark is affixed to this equipment.The CE declaration is available at the website listed on the cover page of this manual.In the Web UI, you can add external accessories by clicking on th e sign. Follow the dropdown bar selections and fill out all fields as required.While your GW-001 is connected to the Internet, the Gateway UI can be accessed by typing: http://X.X.X.X (where X is the IP address of the gateway) OR by typing: 234START HEREUse this Quick Start Guide to set up your Layer N GW-001Gateway. For additional information regarding your GW-001, refer to the User Manual available on the Omega website.• Layer N GW-001 Unit • Quick Start Guide • 12 V Power Adapter • Ethernet Cable • AntennaAdditional Materials Needed• Access to an Ethernet port on your network -Network must have Internet connectivity • A registered user account with • A Layer N compatible device that will connect to the gateway• Any device with web browser accessThe GW-001 Gateway contains an internal UI that can be used to upgrade various firmwares and configure the external accessories.To setup your Layer N Gateway, you must first create and register a Layer N Cloud account. Using any device with a web browser, complete the following steps:Step 1: Open your browser to Step 2: Click Sign Up and complete the registration process.Registered Email: _________________________________New User Password: ______________________________Once your user credentials are verified, you can sign in and you will be presented with the Layer N Cloud homepage.Note: See the section below for instructions on how to create and register a Layer N Cloudaccount.Sign in to your Layer N Cloud account using any device with a web browser. Once you are logged in, register your new gateway by following these steps:Step 1: From the cloud homepage, click Add Gateway .Note: The label containing your Gateway ID and Registration ID is located on the bottom ofthe gateway unit.Step 3: Type in the Registration ID on your gateway label and click Register .Step 4: Once you have successfully registered your gateway, a icon will appear next to your registered device. You can now change the name of your gateway.Note: The icon will disappear once theregistered gateway is powered on.The GW-001 Series gateways offer the following measurement interface options:• Smart Sensor one-button pairing • 2x USB 2.0 connectors• Serial data and alarm connector • Ethernet RJ45 connectorOnce your gateway is registered to your Layer N Cloud account, follow these instructions to power on your gateway:Step 1: Connect antenna included with your gateway to the side of the Gateway housing.Your gateway can now accept connections from a Layer N Smart Sensor, wired sensors, controller devices such as TCP ModBus or Serial Modbus depending on the gateway model you have purchased.Pin Description Pin 1TX (D+)Pin 2RX (D-)Pin 3GND Pin 4Alarm (N/O)Pin 5Alarm (N/O)Serial Data and Alarm ConnectorThe 5-pin screw terminal can accept RS232 or RS485 inputs from authorized OMEGA accessories and devices such as OM240, CN6161A, and DP612. The 5-pin screw connector on the gateway is labeled as follows:Contact Omega or visit our website to see othercompatible devices.Step 2: Type in the Gateway ID.Step 6: The LED light on the Pairing Button will blink red to indicate that it is booting up.Smart Sensor PairingPairing a Layer N Smart Sensor to your Layer N Gateway is made easy with one-button pairing. Simply press the pairing button on your gateway and press the pairing button on your sensor to connect the two. Your Smart Sensor will now be visible on your Layer N Cloud interface.Note: It is recommended that you only use Layer N Cloud to upgrade firmware for theGateway.Ethernet ConnectorA second Ethernet port for Modbus TCP devices and Power over Ethernet is available on certain models.Note: Layer N GW-001 Series connectivityinterfaces vary with each model.Step 2: Connect the DC 12V adapter to the back of the gateway.Step 3: Connect the included Ethernet cable to the port labeled Ethernet 1 on the gateway.Step 4: Connect the other side of the Ethernet cable to a router or LAN that will provide Internet access.Step 5: Turn the power switch on the gateway to the ON position.Once it is connected to the Internet, the light will stay a solid green.Gateway IDRegistration IDUSB 2.0 ConnectorsThe USB 2.0 connectors are used to connect Layer NSmart Probes with an IF-001 Smart Interface Cable directly to your Gateway.I nterfaces available vary with modelImportant: Do not power on the Gateway or Smart Sensor before Gateway registration iscomplete.Step 1: Enter the password located on the label of your gateway unit.Step 2: Enter the same password from Step 1 under Existing Password , and then follow the instructions to create a new password.http://omegaiotgatewayXXXX.local(where XXXX are the last 4 digits of your Gateway MAC Address ). This will only work if your browser/computer has Bonjour Service installed. For either method, the computer and gateway must be on the same local area network.Once you have access to the gateway internal UI, you will be prompted to enter a password. Follow these instructions:。

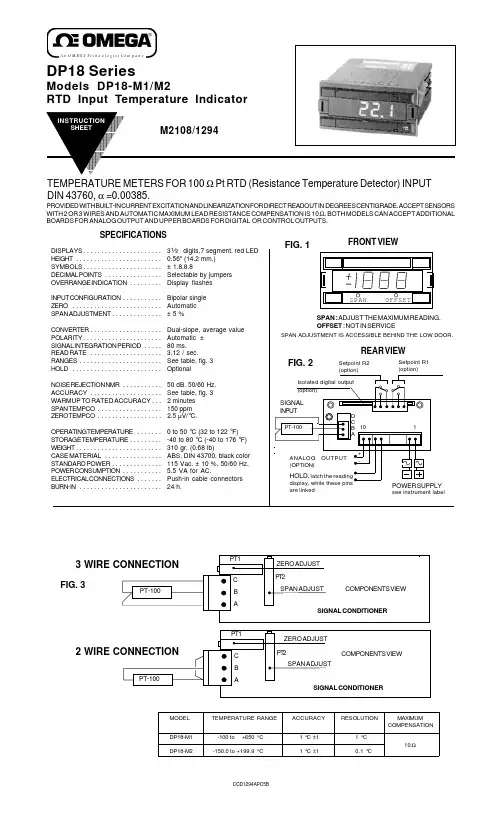

An OMEGA Te c h n o l o g i e s Co m p a n y DP18 SeriesModels DP18-M1/M2RTD Input Temperature IndicatorCCD1294APC5BSPECIFICATIONSTEMPERATURE METERS FOR 100 Ω Pt RTD (Resistance Temperature Detector) INPUT DIN 43760, α =0.00385.PROVIDED WITH BUILT-IN CURRENT EXCITATION AND LINEARIZATION FOR DIRECT READOUT IN DEGREES CENTIGRADE. ACCEPT SENSORS WITH 2 OR 3 WIRES AND AUTOMATIC MAXIMUM LEAD RESISTANCE COMPENSATION IS 10 Ω. BOTH MODELS CAN ACCEPT ADDITIONAL BOARDS FOR ANALOG OUTPUT AND UPPER BOARDS FOR DIGITAL OR CONTROL OUTPUTS.FIG. 3MODEL TEMPERATURE RANGE ACCURACY RESOLUTIONMAXIMUM COMPENSATIONDP18-M1-100to+650°C1 °C ±1 1 °C DP18-M2-150.0to +199.9°C1 °C ±10.1 °C10 ΩOPTIONS AND POWER SUPPLIES AVAILABLE FOR DP18 SeriesCONTROL O UTPUT/COMMUNICATIONS O PTIONS Select a maximum of one option from each columnPOWER SUPPLY OPTIONSServicing USA and Canada: Call OMEGA Toll FreeUSA CanadaOne Omega Drive, Box 4047976 BergarStamford, CT 06907-0047Laval (Quebec) H7L 5A1Telephone: (203) 359-1660Telephone: (514) 856-6928FAX: (203) 359-7700FAX: (514) 856-6886Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA SM Customer Service: 1-800-622-2378 / 1-800-622-BEST SM Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN SMTELEX: 996404 EASYLINK: 62968934 CABLE: OMEGAServicing Europe: One OMEGA Drive, River BendThecnology CentreNorthbank, Irlam, ManchesterM44 5EX , EnglandTelephone: 44 (161) 777-6611 FAX: 44 (161) 777-6622RETURN REQUESTS / INQUIRIESDirect all warranty and repair requests/inquiries to the OMEGA ENGINEERING Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA'S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package and on any correspondence.OMEGA's policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and engineering.OMEGA is a registered trademark of OMEGA ENGINEERING, INC.© Copyright 1998 OMEGA ENGINEERING, INC. All rights reserved. This documentation may not be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without prior written consent of OMEGA ENGINEERING, INC.FOR WARRANTY RETURNS, please have the following information available BEFORE contacting OMEGA:1.P.O. number under which the product was PURCHASED.2.Model and serial number of the product under warranty, and3.Repair instructions and/or specific prob-lems relative to the product.WARRANTY/DISCLAIMEROMEGA warrants this unit to be free of defects in materials and workmanship and to give satisfactory service for a period of 13 months from date of purchase.OMEGA Warranty adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA's customers receive maximum coverage on each product. If the unit should malfunction, it must be returned to the factory for evaluation.OMEGA's Customer Service Department will issue an Authorized Return (AR) number imme-diately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at no charge. However, this WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of being damaged as a result of excessive corrosion; or current; heat; moisture or vibration; improper specification;misapplication; misuse or other operating conditions outside of OMEGA's control. Components which wear or which are damaged by misuse are not warranted. These include contact points,fuses and triacs..OMEGA is pleased to offer suggestions on the use of its various products.However OMEGA neither assumes responsability for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or written.OMEGA only warrants that the parts manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTA-TIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no even shall OMEGA be liable for consequential, incidental or special damages.CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a "Basic Component" under 10 CFR 21 (NRC), used in or with any nuclear installation or activity;or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used in humans, or misused in any way.OMEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER lan-guage, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmlees from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.FOR NON-WARRANTY REPAIRS, consult OMEGA for current repair charges. Have the following information available BEFORE contacting OMEGA:1.P.O. number to cover the COST of therepair,2.Model and serial number of product, and3.Repair instructions and/or specificproblems relative to the product.。

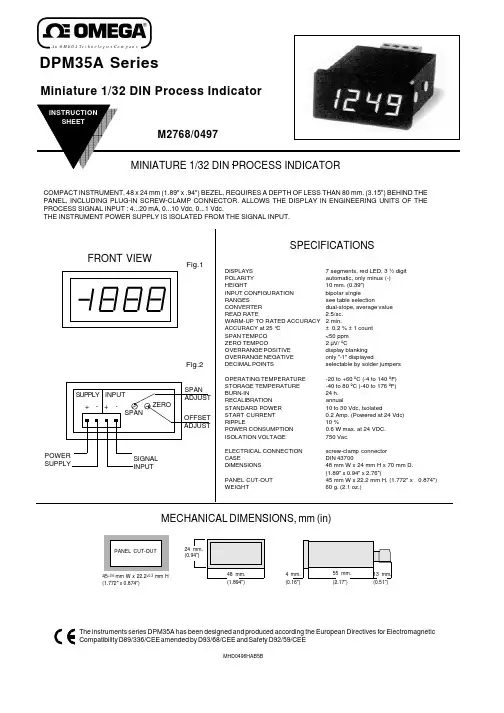

An OMEGA Te c h n o l o g ie s Co m p a n yMECHANICAL DIMENSIONS, mm (in)45+0.6 mm W x 22.2+0.3 mm H (1.772" x 0.874")MHD0496HAB5BDPM35A SeriesMiniature 1/32 DIN Process IndicatorFeatures a decimal point that can be set independently of signal range.For instance : 1 Vdc. signal on a ±2 Vdc meter can be displayed as 1.000, 10.00, 100.0, or 1000 for different engineering units. (in this example 1.000 V 10.00 mA.100.0% or 1000 mV)Fig.4a b c1 XX . X 1X . XX 1 . XX XDecimal pointposition Close Solder PadDisplay Board Components ViewDECIMAL POINT SELECTIONSignal Input Impedance ΩClose Jumpers0/4...20mA 182 1 & 20/10...50mA 68 1 & 30...2/10Vdc 200 K 10...10/200Vdc1 MNone*lower table, in function of signal input.Offset course : from -1000 to +1000To know the maximum negative Offset value, according to the Span value to be displayed apply this formula :((R3/S3) x S1) -1000.Span course for signal input :in Current, minimum 100 counts and maximum 3000 countsin Voltage, minimum 100 counts and maximum 2000 counts*Standard signal input for all orders unless specified otherwise.Display is adjusted to read 100.0WARRANTY/DISCLAIMEROMEGA warrants this unit to be free of defects in materials and workmanship and to give satisfactory service for a period of 13 months from date of purchase.OMEGA Warranty adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA's customers receive maximum coverage on each product. If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA's Customer Service Department will issue an Authorized Return (AR)number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at no charge. However, this WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of being damaged as a result of excessive corrosion; or current; heat; moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA's control. Components which wear or which are damaged by misuse are not warranted. These include contact points, fuses and triacs..OMEGA is pleased to offer suggestions on the use of its various products.However OMEGA neither assumes responsability for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or written.OMEGA only warrants that the parts manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRE-SENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EX-CEPT THAT OF TITLE AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PUR-POSE ARE HEREBY DISCLAIMED.LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no even shall OMEGA be liable for consequential,incidental or special damages.CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used:(1) as a "Basic Component" under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used in humans, or misused in any way. OMEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmlees from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.Servicing USA and Canada: Call OMEGA Toll FreeUSA CanadaOne Omega Drive, Box 4047976 BergarStamford, CT 06907-0047Laval (Quebec) H7L 5A1Telephone: (203) 359-1660Telephone: (514) 856-6928FAX: (203) 359-7700FAX: (514) 856-6886Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA SM Customer Service: 1-800-622-2378 / 1-800-622-BEST SM Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN SMTELEX: 996404 EASYLINK: 62968934 CABLE: OMEGAServicing Europe: One OMEGA Drive, River BendThecnology CentreNorthbank, Irlam, ManchesterM44 5EX , EnglandTelephone: 44 (161) 777-6611 FAX: 44 (161) 777-6622RETURN REQUESTS / INQUIRIESDirect all warranty and repair requests/inquiries to the OMEGA ENGINEERING Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PUR-CHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA'S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS).The assigned AR number should then be marked on the outside of the return package and on any correspondence.FOR WARRANTY RETURNS, please have the following information available BE-FORE contacting OMEGA:1.P.O. number under which the product was PURCHASED.2.Model and serial number of the product under warranty, and3.Repair instructions and/or specific problems relative to the product.FOR NON-WARRANTY REPAIRS, consult OMEGA for current repair charges. Have the following information available BEFORE contacting OMEGA:1.P.O. number to cover the COST of therepair,2.Model and serial number of product, and3.Repair instructions and/or specificproblems relative to the product.OMEGA's policy is to make running changes, not model changes, whenever an improve-ment is possible. This affords our customers the latest in technology and engineering.OMEGA is a registered trademark of OMEGA ENGINEERING, INC.© Copyright 1998 OMEGA ENGINEERING, INC. All rights reserved. This documentation may not be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without prior written consent of OMEGA ENGINEERING, INC.ADJUSTMENT AND CALIBRATION PROCEDUREDetermine the lowest input (S1); highest input (S2); lowest reading (R1) and highest reading (R2).S3 = S2 - S1R3 = R2 - R11.-Select the Signal Input type installing the Jumpers according to Table2.2.-Connect a calibrator to the signal input terminals.3.-Power up the instrument with the appropriate power supply.4.-Adjust the calibrator until it generates 0 mA. or 0 Vdc.5.-Turn the "ZERO" trimmer (P1) until the display shows "0000".6.-Adjust the calibrator until it generates the S3 value (difference between the highest and lowest signal).7.-Turn the "SPAN" trimmer (P2) until the display shows the R3 value (difference between the highest and lowestreading).The adjustment procedure is finished, but if the lowest signal is different of 0 then follows with the next point.8.-Adjust the calibrator until it generates the low signal S1. (i.e. 4 mA).9.-Turn the "ZERO" trimmer (P1) until the display shows the lowest reading R1. The reading for lowest signalcan be modified as much times as wanted. The value of R3 will not be affected.10.-Close the jumper for the decimal point, according to the required decimals, see table 1.Example :Signal Input : 4...20 mA; Display Reading : 0...125.0Determine the value of S3 and R3.S3 = 20-4 = 16 mA R3 = 1250-0 = 12501.-Close Jumpers 1 &2.2.-Connect the calibrator and power up the instrument.3.-Adjust the calibrator at 0 mA and turn the trimmer P1 until the display shows "0000"4.-Adjust the calibrator at 16 mA and turn the trimmer P2 until the display shows "1250"5.-Adjust the calibrator at 4 mA and turn the trimmer P1 until the display shows "0000"6.-Close the Solder Pad "a".GENERAL CONSIDERATIONSINSTALLATIONPRECAUTIONS.- The installation and the future use of this unit must be done by suitable qualified personnel. The unit has not DC(mains) switch, neither internal protection fuse, it will be in operation as soon as power is connected. The installation mustincorporate an external mains switch with a protection fuse and also the necessary devices to protect the operator andthe process when using the unit to control a machine or process where injury to personnel or damage to equipment orprocess, may occur as a result of failure of the unit.SAFETY PRESCRIPTIONS.- The unit has been designed and tested under UNE 20553 rules and is delivered in good condition. This data sheet contains useful information for electrical connections. Do not make wiring signal changes or connections when power is applied to the unit. Make signal connections before power is applied and, is reconnection is required, disconnect the DC (mains)power before such wiring is attempted.Install the unit in a places with a good ventilation to avoid the excessive heating. And far from electrical noise source or magnetic field generators such as power relays, electrical motors, speed controls etc...The unit cannot be installed in open places. Do not use until the installation is finished.POWER SUPPLY.- The power supply must be connected to the adequate terminals (see the connection instructions). The characteristics of the power supply are showed on the side label. Please make sure that the unit is correctly connected to a power supply of the correct voltage and frequency.Do not use other power supply otherwise permanent damage may be caused to the unit. Do not connect the unit to power sources heavily loaded or to circuits which power loads in cycle ON-OFF or to circuits which power inductive loads.WARNING.- The power supply is dc voltage, be careful with the polarity indicated for each terminal.SIGNAL WIRING.- Certain considerations must be given when install the signal input wires. If the wires are longs can act like an antenna and introduce the electrical noise to the unit, therefore :Do not install the signal input wires in the same conduit with power lines, heaters, solenoids, SCR controls etc...and always far from these elements.SAFETY CONSIDERATIONSPRESCRIPTIONS.- Before starting any operation of adjustment, replacement, maintenance or repair, the unit must be disconnected from any kind of power supply.Keep the unit clean , to assure good functioning and performance.To prevent electrical or fire hazard, do not expose the unit to excessive moisture.Do not operate the unit in the presence of flammable gases or fumes, such an environment constitutes a definite safety hazard. The unit is designed to be mounted in a metal panel.If the unit shows signs of damage, or is not able to show the expected measures, or has been stored in a bad conditions or a protection failure can occur, then do not attempt to operate and keep the unit out of service.IN CASE OF FIRE1.- Disconnect the unit from the power supply.2.- Give the alarm according to the local rules.3.- Switch off all the air conditioning devices.4.- Attack the fire with carbonic snow, do not use water in any case.WARNING : In closed areas do not use systems with vaporized liquids.Signal Input :Lowest (S1) = 4 mAHighest (S2) =20 mAReading :Lowest (R1) =200Highest (R2) =1700S3 = S2 - S1 = 20 - 4 =16 mA R3 = R2 - R1= 1700 - 200 = 1500Signal Input 4...20 mAEXAMPLES OF ADJUSMENT AND CALIBRATION PROCEDUREA.- Without offsetSignal Input :Lowest (S1) =0 mAHighest (S2) =20 mAReading :Lowest (R1) =0Highest (R2) = 1700S3 = S2 - S1=20 - 0 = 20 mA R3 = R2 - R1=1700 - 0 = 17001700200020 mAD i s p l a yInput Signal Input 0...20 mA Display Reading 0 (1700)B.- With Negative OffsetSignal Input :Lowest (S1) = 4 mAHighest (S2) =20 mAReading :Lowest (R1) =0Highest (R2) =1700S3 = S2 - S1= 20 - 4 =16 mA R3 = R2 - R1= 1700 - 0 =1700Signal Input 4...20 mA Display Reading 0 (1700)C.- With Positive Offset。

e-mail:**************For latest product manuals:User’s GuideShop online atLDP63000Large Display MeterLP0687AOMEGAnet®Online ServiceInternet e-mail **************Servicing North America:U.S.A.: One Omega Drive, P.O. Box 4047ISO 9001 Certified Stamford, CT 06907-0047TEL: (203) 359-1660 FAX: (203) 359-7700e-mail:**************Canada: 976 BergarLaval (Quebec) H7L 5A1, CanadaTEL: (514) 856-6928 FAX: (514) 856-6886e-mail:*************For immediate technical or application assistance:U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA®Customer Service: 1-800-622-2378/1-800-622-BEST®Engineering Service: 1-800-872-9436/1-800-USA-WHEN®Mexico: En Español: (001) 203-359-7803 e-mail:*****************FAX: (001) 203-359-7807 **************.mxServicing Europe:Czech Republic: Frystatska 184, 733 01 Karviná, Czech RepublicTEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114T oll Free: 0800-1-66342e-mail:*****************Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, GermanyTEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29T ollFreeinGermany************e-mail:*************United Kingdom: One Omega Drive, River Bend T echnology CentreISO 9002 Certified Northbank, Irlam, ManchesterM44 5BD United KingdomTEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622T oll Free in United Kingdom: 0800-488-488e-mail:**************.ukIt is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMIregulations that apply. OMEGA is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.The information contained in this document is believed to be correct, but OMEGA accepts no liability for anyerrors it contains, and reserves the right to alter specifications without notice.WARNING : These products are not designed for use in, and should not be used for, human applications.● LARGE LED DISPLAY READABLE TO 70 FEET● VARIOUS ANALOG INPUT MODULES;DC VOLTAGE AND CURRENTPROCESS SIGNALSTRUE RMS VOLTAGE AND CURRENTTHERMOCOUPLE OR RTD● ALARMS, ANALOG OUTPUT, AND COMMUNICATION● CUSTOM UNITS LABEL WITH BACKLIGHT● PROGRAMMABLE USER INPUTS● PROGRAMMABLE FUNCTION KEYS● UNIVERSAL AC/DC POWERED MODELS● PROGRAMMING SOFTWARE● NEMA 4/IP65● FIELD INSTALLABLE OUTPUT CARDS (Optional) GENERAL DESCRIPTIONThe LDP63000 Display is a versatile display that can increase productivityby offering the plant floor or production area a large visual display of theircurrent status. Whether your measurement is temperature, weight, or flow, theLDP63000 can satisfy your requirement. With the use of a units label andbacklighting, the display can be tailored to show the actual engineering unit,which further enhances the display. The LDP63000 display accepts variousanalog inputs through the use of input modules which allow the unit to adapt tomost any application. Additional plug-in option cards can add alarms, analogoutput, and communication/bus capabilities, making the LDP63000 a trulyIntelligent Panel Meter.1.0 ASSEMBLING THE DISPLAYOnce assembled, the LDP63000 has all the same functions and capabilities of our DP63x00 Series Intelligent Panel Meters. Therefore, you will find the appropriate wiring and programming information in a separate manual packed with your LDP63000 Display. Simply follow the instructions to wire and program the display for your application.2.0 INSTALLING THE DISPLAY3.0 WIRING AND PROGRAMMING THE DISPLAYWARRANTY/DISCLAIMEROMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 25 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal two (2) year product warranty to cover handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not limited to contact points, fuses, and triacs.OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.RETURN REQUESTS/INQUIRIESDirect all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package and on any correspondence.The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and engineering.OMEGA is a registered trademark of OMEGA ENGINEERING, INC.© Copyright 2006 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without theprior written consent of OMEGA ENGINEERING, INC.FOR WARRANTY RETURNS, please have the following information available BEFORE contacting OMEGA:1. Purchase Order number under which the product was PURCHASED,2. Model and serial number of the product under warranty, and3. Repair instructions and/or specific problems relative to the product.FOR NON-WARRANTY REPAIRS, consult OMEGA for current repair charges. Have the following information available BEFORE contacting OMEGA:1. Purchase Order number to cover the COST of the repair,2. Model and serial number of the product, and3. Repair instructions and/or specific problems relative to the product.Where Do I Find Everything I Need for Process Measurement and Control?OMEGA…Of Course!Shop online at TEMPERATURE]Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies]Wire: Thermocouple, RTD & Thermistor]Calibrators & Ice Point References]Recorders, Controllers & Process Monitors]Infrared PyrometersPRESSURE, STRAIN AND FORCE]T ransducers & Strain Gages]Load Cells & Pressure Gages]Displacement T ransducers]Instrumentation & AccessoriesFLOW/LEVEL]Rotameters, Gas Mass Flowmeters & Flow Computers]Air V elocity Indicators]T urbine/Paddlewheel Systems]T otalizers & Batch ControllerspH/CONDUCTIVITY]pH Electrodes, T esters & Accessories]Benchtop/Laboratory Meters]Controllers, Calibrators, Simulators & Pumps]Industrial pH & Conductivity EquipmentDATA ACQUISITION]Data Acquisition & Engineering Software]Communications-Based Acquisition Systems]Plug-in Cards for Apple, IBM & Compatibles]Datalogging Systems]Recorders, Printers & PlottersHEATERS]Heating Cable]Cartridge & Strip Heaters]Immersion & Band Heaters]Flexible Heaters]Laboratory HeatersENVIRONMENTALMONITORING AND CONTROL]Metering & Control Instrumentation]Refractometers]Pumps & T ubing]Air, Soil & Water Monitors]Industrial Water & Wastewater T reatment]pH, Conductivity & Dissolved Oxygen Instruments M4492/0613。

e-mail:**************For latest product manuals: FPD3100-D and FPD3100-D-A S eries12mm LC Digital Display with AnalogOutput OptionsShop online at ®User’s Guide***********************Servicing North America:U.S.A.:Omega Engineering, Inc., One Omega Drive, P.O. Box 4047S tamford, CT 06907-0047 USAToll-Free: 1-800-826-6342 (USA & Canada only)Customer Service: 1-800-622-2378 (USA & Canada only)Engineering Service: 1-800-872-9436 (USA & Canada only)Tel: (203) 359-1660 Fax: (203) 359-7700e-mail:**************For Other Locations Visit /worldwideThe information contained in this document is believed to be correct, but OMEGA accepts no liability for any errors it contains, and reserves the right to alter specifications without notice.WARNING: These products are not designed for use in, and should not be used for, human applications.Product Overview………………………………………………………….General Product Functionality Page 4 Type FPD3100-D Digital Register………………………………………………………….Program Overview Page 5………………………………………………………….Set-up Functions Page 6………………………………………………………….Wiring Diagram Page 7………………………………………………………….Parts Listing Page 7………………………………………………………….Technical Specifications Page 8Type FPD3100-D-A Digital Register………………………………………………………….Program Overview Page 10………………………………………………………….Set-up Functions Page 11-13………………………………………………………….Wiring Diagram Page 13………………………………………………………….Outputs Page 14………………………………………………………….Parts Listing Page 15Technical Specifications Page 16-17………………………………………………………….………………………………………………………….List Configuration Settings Page 18………………………………………………………….Wall Mount Bracket Dimensions Page 19The following keys are available:Functions of the keysThis key is used to program and save new values or settings. It is also used to gain access to SETUP-level.This key is used to SELECT the display defaults, ACC.TOTAL, RATE, TOTAL, BATCHThe key is also used in the setup program to scroll through the base levels and options in each levelPressing both keys simultaneously to CLEAR the value for total and batch then press P for NO or S for YES to clear the total/batch.In the setup mode pressing both keys simultaneously whilst in the upper levels of each ofthe functions will allow modification of the setting and pressing again will save setting.SYSTEM DESCRIPTION OF THE G X 012PFunctions and featuresThe flow rate / totalizer model FPD3100 series is a microprocessor driven instrument designed to display flow rate, total and accumulated total.This product has been designed with a focus on:ultra-low power consumption to allow long-life battery powered applications.The glass reinforced polypropylene housing offers IP65 environmental protection.Configuration of the unitThe FPD3100 Series has been designed to be implemented in many types of applications. For that reason, a SETUP-level is available to configure your FPD3100 according to your specific requirements.It includes several important features, such as K-factors, measurement units etc. All setting are stored in EEPROM memory and will not be lost in the event of power failure.Display informationThe unit has a large transflective LCD with a range of symbols and digits to display measuring units, status informa-tion, trend-indication and key-word messages.Flow rate and totals can be displayed by using the S button to move through the various options.. A backup of the total and accumulated total in EEPROM memory is made every minute.OPERATIONALGENERALThis chapter describes the daily use of the FPD3100–D / -D-A Series Digital Register. This instruction is meant fo cu sers / operators. CONTROL PANELPlease read and retain this instruction manual to assist you in the operation of this product.This Instruction Manual provides a instruction guide on the set-up and programming of the Type FPD3100-D and FPD3100-D-A, 12mm LCD Digital Register.GENERALConfiguration of the FPD3100-D is done at SETUP-level. SETUP-level is reached by pressing the PROG/ENTER key for7 seconds; at which time, setup will be displayed. In or-der to return to the operator level, PROG will have to be pressed for three seconds. Alternatively, if no keys are pressed for 2 minutes, the unit will exit SETUP automati-cally.SETUP can be reached at all times while the register remains fully operational.The FPD3100 unit cam only accept a reed switch input, this sensor has been selected as the most common sensor and requires very little power with small effect on battery life.The 2 position terminal block is not polarity conscious so the reed switch wires can be connected in any order.Connecting any other sensor type could cause damage to theelectronics modulePROGRAMMING SETUP-LEVELGENERALConfiguration of the FPD3100-D-A is done at SETUP-level. SETUP-level isreached by pressing the PROG/ENTER key for 7 seconds; at which time, setupwill be displayed. In order to return to the operator level, PROG will have to bepressed for three seconds. Alternatively, if no keys are pressed for 2 minutes,the unit will exit SETUP automatically.SETUP can be reached at all times while the register remains fully operational.Type DRA DIGITAL REGISTER Wiring DiagramExample for scaled 1 pulse per litre the output must be programmed as follows: In menu 7.1 set 2222.22In menu 7.2 set 10 or more (10mS or more if needed) In menu 7.3 set 1.00Example Pulse/Alarm Output SetupPassive 4-20mA setup910Pulse OutputFPD3100-D-A DIGITAL REGISTER Parts DescriptionNOTESThe FPD3100 series is available with a Wall Mount Bracket option for applications requiring remote mount display. Both the models -D and –D-A are available with this option.Following is a dimensional drawing for the wall mount bracket.WARRANTY/DISCLAIMEROMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not limited to contact points, fuses, and triacs.OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED W ARRANTIES INCLUDING ANY W ARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY /DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and engineering.OMEGA is a registered trademark of OMEGA ENGINEERING, INC.© Copyright 2013 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.FOR WARRANTY RETURNS, please have the following information available BEFORE contacting OMEGA:1. P urchase Order number under which the product was PURCHASED,2. M odel and serial number of the product under warranty, and3.Repair instructions and/or specific problems relative to the product.FOR NON-WARRANTY REPAIRS, consult OMEGA for current repair charges. Have the followinginformation available BEFORE contacting OMEGA:1.Purchase Order number to cover the COST of the repair,2.Model and serial number of the product, and3.Repair instructions and/or specific problems relative to the product.RETURN REQUESTS/INQUIRIESDirect all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETU RNING ANY PRODU CT(S) TO OMEGA, PU RCHASER MU ST OBTAIN AN AU THORIZED RETU RN (AR) NU MBER FROM OMEGA’S CU STOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package and on any correspondence.The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.Where Do I Find Everything I Need for Process Measurement and Control?OMEGA…Of Course!Shop online at SMTEMPERATUREM U Thermocouple, RTD & Thermistor Probes, Connectors, Panels & AssembliesM U Wire: Thermocouple, RTD & ThermistorM U Calibrators & Ice Point ReferencesM U Recorders, Controllers & Process MonitorsM U Infrared PyrometersPRESSURE, STRAIN AND FORCEM U Transducers & Strain GagesM U Load Cells & Pressure GagesM U Displacement TransducersM U Instrumentation & AccessoriesFLOW/LEVELM U Rotameters, Gas Mass Flowmeters & Flow ComputersM U Air Velocity IndicatorsM U Turbine/Paddlewheel SystemsM U Totalizers & Batch ControllerspH/CONDUCTIVITYM U pH Electrodes, Testers & AccessoriesM U Benchtop/Laboratory MetersM U Controllers, Calibrators, Simulators & PumpsM U Industrial pH & Conductivity EquipmentDATA ACQUISITIONM U Data Acquisition & Engineering SoftwareM U Communications-Based Acquisition SystemsM U Plug-in Cards for Apple, IBM & CompatiblesM U Data Logging SystemsM U Recorders, Printers & PlottersHEATERSM U Heating CableM U Cartridge & Strip HeatersM U Immersion & Band HeatersM U Flexible HeatersM U Laboratory HeatersENVIRONMENTALMONITORING AND CONTROLM U Metering & Control InstrumentationM U RefractometersM U Pumps & TubingM U Air, Soil & Water MonitorsM U Industrial Water & Wastewater TreatmentM U pH, Conductivity & Dissolved Oxygen InstrumentsM-5428/0816。

K-19Ejemplos de pedidos: LVU-2001, transmisor de nivel ultrasónico con regulador LVCN-51, LVU-2001, transmisor ultrasónico.EspECifiCaCioNEs Rango: 15,2 cm a 3,7 m (0,5 a 12') precisión: ±0,25% de intervalo en aire Resolución: 3 mm (0,125")frecuencia: 50 kHz frecuencia de impulsos: 3 por segundo anchura del haz: 8° cónica Banda muerta: 15,2 cm (0,5') en condiciones estándar mín.Tensión de suministro: 12 a 36 Vcc Resistencia del bucle: 600 Ω a 36 Vcc salida de señal: 4 a 20 mA U M edición de nivel precisa y fiable desde 15,2 cm a 3,7 m (0,5 a 12')U R ango fijo; no requiere programaciónU s olución de bajo coste para fabricantes de equipos originales y aplicaciones de procesosU T amaño compacto y transductor de 5 cm (2") para tanques pequeñosU C arcasa de pp clasificada como NEMa 4X (ip65) con transductor de pVDfU L a inteligencia a prueba de fallos garantiza la máxima seguridad en los procesosserie LVU-2001Diag. a prueba de fallos: Vuelve a 22 mA indicación LED: Alimentación y a prueba de fallos Temp. nominal: de -40 a 60 °C (de -40 a 140 °F)Comp. de temp.: En toda la gama presión nominal: 2 bares (30 psig) @ 25 °C, reducida @ 113 bares (1.667 psig) por °C por encima de 25 °C Clasificación de la carcasa: NEMA 4X (IP65)Material de la carcasa: PP (U.L. 94 VO)Material del transductor: PVDF Roscas de montaje: 2 NPT o 2 G Conec. de conducto: NPT de 1⁄2 Junta de montaje: FKM para LVU-2002de alta frecuencia tres veces por segundo. La onda de sonido se refleja en el medio de proceso inferior y vuelve al transductor. La electrónica por microprocesador mide el tiempo de vuelo entre la generación y la recepción del sonido y traduce esta figura en la distancia entre el transmisor y el medio de proceso inferior.El transmisor de nivel ultrasónico de dos hilos con tanque para almacenamiento a granel se monta a través de la pared superior del tanque y realiza mediciones sin contacto de hasta 3,7 m (12'). El rango es fijo: 4 mA = 144" o 12' (distancia hasta el sensor) y 20 mA = 6" o 0,5'. No requiere programación. Gracias a su tecnología sin contacto, el transmisor es una opción excelente para aplicaciones con líquidos sucios y corrosivos de recubrimiento. Su diseño compacto tiene el tamaño perfecto para las aplicaciones con un tanque pequeño.Desde la base del transductor se emite una onda de sonido ultrasónicaTransmisor de nivel ulTrasónicoEl modelo LVU-2001 se muestra en un tamaño inferior al real.。

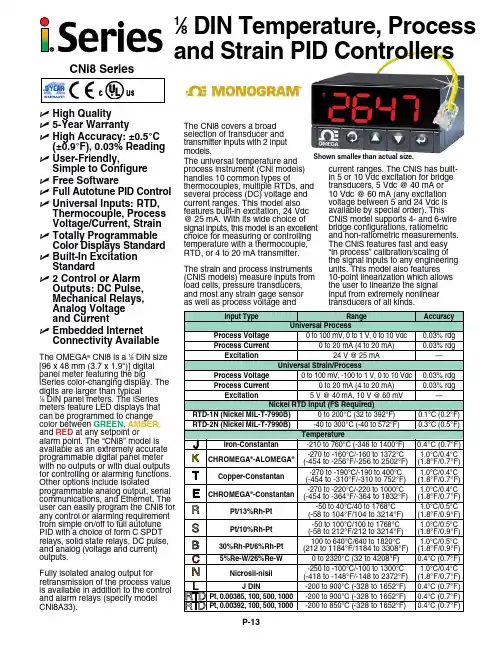

U High QualityU 5-Year WarrantyU H igh Accuracy: ±0.5°C(±0.9°F), 0.03% Reading U U ser-Friendly,Simple to Configure U Free SoftwareU Full Autotune PID ControlU U niversal Inputs: RTD,Thermocouple, Process Voltage/Current, StrainU T otally ProgrammableColor Displays Standard U B uilt-In ExcitationStandard U 2 Control or AlarmOutputs: DC Pulse, Mechanical Relays, Analog Voltage and CurrentU E mbedded InternetConnectivity Available The OMEGA ®CNi8 is a 1⁄8 DIN size[96 x 48 mm (3.7 x 1.9")] digital panel meter featuring the big iSeries color-changing display. The digits are larger than typical 1⁄8 DIN panel meters. The iSeriesmeters feature LED displays that can be programmed to change color between GREEN, AMBER,and RED at any setpoint oralarm point. The “CNi8” model is available as an extremely accurate programmable digital panel meter with no outputs or with dual outputs for controlling or alarming functions. Other options include isolated programmable analog output, serial communications, and Ethernet. The user can easily program the CNi8 for any control or alarming requirement from simple on/off to full autotune PID with a choice of form C SPDT relays, solid state relays, DC pulse, and analog (voltage and current) outputs.Fully isolated analog output for retransmission of the process value is available in addition to the control and alarm relays (specify model CNi8A33). The CNi8 covers a broad selection of transducer and transmitter inputs with 2 input models.The universal temperature and process instrument (CNi models) handles 10 common types of thermocouples, multiple RTDs, and several process (DC) voltage and current ranges. This model also features built-in excitation, 24 Vdc @ 25 mA. With its wide choice of signal inputs, this model is an excellent choice for measuring or controlling temperature with a thermocouple, RTD, or 4 to 20 mA transmitter.The strain and process instruments (CNiS models) measure inputs from load cells, pressure transducers, and most any strain gage sensor as well as process voltage and current ranges. The CNiS has built-in 5 or 10 Vdc excitation for bridge transducers, 5 Vdc @ 40 mA or 10 Vdc @ 60 mA (any excitation voltage between 5 and 24 Vdc is available by special order). This CNiS model supports 4- and 6-wire bridge configurations, ratiometric and non-ratiometric measurements. The CNiS features fast and easy “in process” calibration/scaling of the signal inputs to any engineering units. This model also features 10-point linearization which allows the user to linearize the signal input from extremely nonlineartransducers of all kinds.1⁄8 DIN Temperature, Process and Strain PID Controllers Shown smaller than actual size.Ordering Examples: CNi8A22, 1⁄8 DIN temperature/processcontroller with isolated analog output and 2 SSR outputs. CNiS833, 1⁄8 DIN strain/process controller with 2-relay outputs.*2 “-DC”, “-C24”, and “-C4EIT” not available with excitation.*3 Analog output is not available with “-AL” units.*4 CNi8A0x-AL contains 1 alarm and 1 analog retransmission.*5 20 to 36 Vdc for CNi8A, CNi8-C4EIT and CNi8-EIT.*6 “-SM” option not available on CNiS strain models.at any setpoint PatentedUniversal Temperature and Process Input (DPi/CNi Models)Accuracy: ±0.5°C temp; 0.03% rdg Resolution: 1°/0.1°; 10 µV process Temperature Stability: RTD: 0.04°C/°C TC @ 25°C (77°F): 0.05°C/°C Cold Junction Compensation Process: 50 ppm/°C NMRR: 60 dB CMRR: 120 dB A/D Conversion: Dual slope Reading Rate: 3 samples/s Digital Filter: Programmable Display: 4-digit 9-segment LED 10.2 mm (0.40"); i32, i16, i16D, i8DV 21 mm (0.83"); i8 10.2 mm (0.40") and 21 mm (0.83"); i8DH RED , GREEN, and AMBER programmable colors for process variable, setpoint and temperature units Input Types: Thermocouple, RTD, analog voltage, analog current Thermocouple Lead Resistance: 100 Ω max Thermocouple Types (ITS 90): J, K, T, E, R, S, B, C, N, L (J DIN)RTD Input (ITS 68): 100/500/1000 Ω Pt sensor, 2-, 3- or 4-wire; 0.00385 or 0.00392 curve Voltage Input: 0 to 100 mV, 0 to 1V, 0 to 10 Vdc Input Impedance: 10 M Ω for 100 mV 1 M Ω for 1 or 10 Vdc Current Input: 0 to 20 mA (5 Ω load)Configuration: Single-ended Polarity: Unipolar Step Response: 0.7 sec for 99.9%Decimal Selection: Temperature: None, 0.1 Process: None, 0.1, 0.01 or 0.001Setpoint Adjustment: -1999 to 9999 counts Span Adjustment: 0.001 to 9999 counts Offset Adjustment: -1999 to 9999Excitation (Not Included with Communication): 24 Vdc @ 25 mA (not available for low-power option)Universal Strain and Process Input (DPiS/CNiS Models)Accuracy: 0.03% reading Resolution: 10/1µV Temperature Stability: 50 ppm/°C NMRR: 60 dB CMRR: 120 dB A/D Conversion: Dual slope Reading Rate: 3 samples/s Digital Filter: Programmable Input Types: Analog voltage and current Voltage Input: 0 to 100 mVdc, -100 mVdc to 1 Vdc, 0 to 10 Vdc Input Impedance: 10 M Ω for 100 mV;1 M Ω for 1V or 10 Vdc Current Input: 0 to 20 mA (5 Ω load)Linearization Points: Up to 10 Configuration: Single-ended Polarity: Unipolar Step Response: 0.7 sec for 99.9%Decimal Selection: None, 0.1, 0.01 or 0.001Setpoint Adjustment: -1999 to 9999 counts Span Adjustment: 0.001 to 9999 counts Offset Adjustment: -1999 to 9999Excitation (Optional In Place Of Communication): 5 Vdc @ 40 mA;10 Vdc @ 60 mA Control Action: Reverse (heat) or direct (cool)Modes: Time and amplitude proportional control; selectable manual or auto PID, proportional, proportional with integral, proportional with derivative and anti-reset Windup, and on/off Rate: 0 to 399.9 s Reset: 0 to 3999 s Cycle Time: 1 to 199 s; set to 0 for on/off Gain: 0.5 to 100% of span; setpoints 1 or 2Damping: 0000 to 0008Soak: 00.00 to 99.59 (HH:MM), or OFF Ramp to Setpoint: 00.00 to 99.59 (HH:MM), or OFF Auto Tune: Operator initiated from front panel Control Output 1 and 2Relay: 250 Vac or 30 Vdc @ 3 A (resistive load); configurable for on/off, PID and ramp and soak Output 1: SPDT, can be configured as alarm 1 output Output 2: SPDT, can be configured as alarm 2 output SSR: ******************.5A (resistive load); continuous DC Pulse: Non-isolated; 10 Vdc @ 20 mA Analog Output (Output 1 Only):Non-isolated, proportional 0 to 10 Vdc or 0 to 20 mA; 500 Ω max Output 3 Retransmission: Isolated Analog Voltage and Current Current: 10 V max @ 20 mA output Voltage: 20 mA max for 0 to 10 V output Network and Communications Ethernet: Standards compliance IEEE 802.3 10 Base-T Supported Protocols: TCP/IP, ARP, HTTPGET RS232/RS422/RS485: Selectable frommenu; both ASCII and MODBUS protocol selectable from menu; programmable 300 to 19.2 Kb; complete programmable setup capability; program to transmit current display, alarm status, min/max, actual measured input value and status Common Specifications (Alli/8, i/16, i/32 DIN)RS485: Addressable from 0 to 199Connection: Screw terminals Alarm 1 and 2 (Programmable)Type: Same as output 1 and 2Operation: High/low, above/below,band, latch/unlatch, normally open/normally closed and process/deviation; front panel configurations Analog Output (Programmable):Non-isolated, retransmission 0 to 10 Vdcor 0 to 20 mA, 500 Ω max (output 1 only); accuracy is ± 1% of FS when following conditions are satisfied: input is not scaled below 1% of input FS, analog output is not scaled below 3% of output FS General Power: 90 to 240 Vac ±10%, 50 to 400 Hz *, 110 to 300 Vdc, equivalent voltage Low Voltage Power Option: 24 Vac **, 12 to 36 Vdc for DPi/CNi/DPiS/CNiS; 20 to 36 Vdc for dual display, ethernet and isolated analog output from qualified safety approved source Isolation Power to Input/Output: 2300 Vac per 1 minute test For Low Voltage Power Option: 1500 Vac per 1 minute test Power to Relay/SSR Output: 2300 Vac per 1 minute test Relay/SSR to Relay/SSR Output:2300 Vac per 1 minute test RS232/485 to Input/Output:500 Vac per 1 minute test Environmental Conditions: All Models: 0 to 55°C (32 to 131°F) 90% RH non-condensing Dual Display Models: 0 to 50°C (32 to 122°F), 90% RH non-condensing (for UL only) Protection: D Pi/CNi/DPiS/CNiS32,16,16D, 8C: NEMA 4X/Type 4 (IP65) front bezel DPi/CNi/DPiS/CNiS8, 8DH, 8DV: NEMA 1/Type 1 front bezel Approvals: UL, C-UL, CE per 2014/35/EU, FM (temperature units only)Dimensions i /8 Series: 48 H x 96 W x 127 mm D (1.89 x 3.78 x 5") i/16 Series: 48 H x 48 W x 127 mm D (1.89 x 1.89 x 5") i/32 Series: 25.4 H x 48 W x 127 mm D(1.0 x 1.89 x 5")Panel Cutouti /8 Series: 45 H x 92 mm W (1.772 x 3.622"), 1⁄8 DIN i/16 Series: 45 mm (1.772") square,1⁄16 DINi/32 Series: 22.5 H x 45 mm W (0.886 x 1.772"), 1⁄32 DIN Weighti /8 Series: 295 g (0.65 lb) i/16 Series: 159 g (0.35 lb) i/32 Series: 127 g (0.28 lb)* No CE compliance above 60 Hz. ** Units can be powered safely with 24 Vac。

e-mail:**************For latest product manuals:BLOCK HEATERShop online atUser’sGuideCL-200 SeriesServicing North America:U.S.A.:Omega Engineering, Inc., One Omega Drive, P.O. Box 4047ISO 9001 CertifiedStamford, CT 06907-0047 USA Toll Free: 1-800-826-6342TEL: (203) 359-1660FAX: (203) 359-7700e-mail:**************Canada:976 BergarLaval (Quebec), Canada H7L 5A1Toll-Free: 1-800-826-6342TEL: (514) 856-6928FAX: (514) 856-6886e-mail:*************For immediate technical or application assistance:U.S.A. and Canada:Sales Service: 1-800-826-6342/1-800-TC-OMEGA ®Customer Service: 1-800-622-2378/1-800-622-BEST ®Engineering Service: 1-800-872-9436/1-800-USA-WHEN ®Mexico:En Español: 001 (203) 359-7803FAX: (001) 203-359-7807**************.mxe-mail:*****************Servicing Europe:Benelux :Managed by the United Kingdom Office Toll-Free: 0800 099 3344TEL: +31 20 347 21 21FAX: +31 20 643 46 43e-mail:**************Czech Republic:Frystatska 184733 01 Karviná, Czech Republic Toll-Free: 0800-1-66342TEL: +420-59-6311899FAX: +420-59-6311114e-mail:*****************France:Managed by the United Kingdom Office Toll-Free: 0800 466 342TEL: +33 (0) 161 37 29 00FAX: +33 (0) 130 57 54 27e-mail:**************Germany/Austria:Daimlerstrasse 26D-75392 Deckenpfronn, Germany Toll-Free************TEL: +49 (0) 7059 9398-0FAX: +49 (0) 7056 9398-29e-mail:*************United Kingdom:OMEGA Engineering Ltd.ISO 9001 CertifiedOne Omega Drive, River Bend Technology Centre, Northbank Irlam, Manchester M44 5BD England Toll-Free: 0800-488-488TEL: +44 (0)161 777-6611FAX: +44 (0)161 777-6622e-mail:**************.ukOMEGAnet ®Online ServiceInternet e-mail **************It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMIregulations that apply. OMEGA is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.The information contained in this document is believed to be correct, but OMEGA accepts no liability for any errors it contains, and reserves the right to alter specifications without notice.WARNING: These products are not designed for use in, and should not be used for, human applications.BEFORE USE:Please read the following instructions:Examine the integrity of the box before open. If box is broken, please check whether the instrument damaged.If so, please call your local distributors immediately. Do not try to plug into power outlet!Read the Manual first before operating the instrumentFor indoor use onlyUse in a well-ventilated areaAmbient temperature range +5°C to +40°CRelative humidity not exceeding 80%Temperature Adjustment supply fluctuation not exceeding 10%WarningALL UNITS MUST BE GROUNDEDCheck the line supply is sufficient to meet the power requirement of the unit!OverviewCL‐201 and CL‐202 are designed to accommodate three different format aluminum blocks. And it comes with block handling tool (see Figure 2) and glass thermometer.CL‐201 has the digital display and simple operation buttons to fit the needs of users in the lab and has two lights to indicate the status of the operation and process.OperationFor the digital: CL‐201, CL‐204, CL‐205 and CL‐207:1. Put the block into the blocks compartment (see Figure 1A), use block handling tool (Fig‐ure 1B) to add and remove the block2. Plug the power cord to the source, and make sure that the plug is firmly pressed. Turning on the switch on the back, and the light in the front will be on. The light will be flashing until the temperature reaches equilibrium. Use thermometer measuring the temperature, turn the knob to adjust temperature. Leave the Heated Block on to keep the temperature at sta‐ble level. It takes sometimes to reach the equilibrium.ALWAYS KEEP THE MACHINE AWAY FROM DRAFTY AREA TO AVOID THE EFFECT OF THE ENVIRONMENTAL TEMPERAURE ON THE TEMPERATURE CONTROL OF THE BLOCK HEATERS!Figure1A.Figure1B. Removing Tool CL‐200‐RT2. Plug the power cord to the source, and make sure that the plug is firmly pressed. Turn onthe machine by switching the on/off switch (see Figure 2).Figure 2: The rear view of the Block Heater. 1, on/off switch; 2, IEC power inlet; 3,fuse holder3. When turning on the machine, the display will immediately shows “_ _ _ _”, and thenshows the actual temperature in Celsius. The “power” light is off at this time, and when theblock temperature is over 50 ˚C, the “heat” light is on, otherwise, it is off, too.Figure 3: the front panel view of the CL‐2014. To set the temperature, press the “Set” key, and turn the “Temperature Adjustment”knob to desired temperature point, and release the “Set” button.5. Press “Start/stop” button to start the operation. The “power” light is on and “heat” lightis flashing at this point. When reaching the equilibrium, the “heat” light is steady on. The equilibrium point is set @ 0.1 degree of the accuracy. It might take longer time to reach.Caution: when putting the cold test tubes or other vials, it may cause the tubes/vials tobreak!6. When running, i.e. the “power” light on, the set point of the heated block could not be changed. To change the set point of the temperature, press “Start/stop” button to stop the run (the “power” light will go off), and then change the set point as indicated in the step 4.7. The CL‐201 always shows the actual temperature reading. To see the set point tempera‐ture, press the “Set” button, and the LED will show the set point temperature.8. After use, wait until the block cool down to below 50 degree (the “heat” light is off) and turn off the block heater.CalibrationThe digital types of Block Heaters can easily be calibrated to show any blocks/vials and tubes’ temperature in the displayed LED. Due to the differences in the mass of the various aluminum blocks, environmental air temperature, thermal radiation, and many other factors, the Block Heater may need to be re‐calibrated when switching different blocks and when the environmental changed. The CL‐201 has been calibrated based on 16 mm Blocks.CL‐201 can be calibrated using one to five points. The calibration steps are described in the followings:1. Prepare the thermistor, or thermometer temperature measurement devices. You can calibrate the block or even the temperature of the solution in the vials/tubes. Make surethe thermistor or sensor well contacted with the blocks or vials/tubes solution.2. Calibration could not be made during running (i.e. the “Power” light on). Press“Start/stop” button first to stop run if the machine is running.3. Press “Temperature Adjustment” turning knob (please note that it should be “press” not “turn”)first, then press “Start/stop” button, simultaneously release both, the display will show “C _ _ X”, which X indicates the stage of the calibration. For example, in the first cali‐bration, it willdisplay “C _ _ 1”.4. Press “set” button, and turn the “Temperature Adjustment” turning knob to the desired temperaturecalibration point, release the “set” button, and press “Temperature Adjustment” to start the calibration. In this time, the “power” light will be on, and the “heat” light will be flashing. The display showed “C _ _ X” flashing.5. When reaching the equilibrium set temperature, the display will stop flashing. In this stage, you can enter the actual block or vial temperature from reading the block or vial temperature from external temperature measurement device: Press “set” button and turning the “Temperature Adjustment” knob to the actual temperature value, release the “set” button, and press the “Temperature Adjustment” knob. The machine will take the real value to take effect in the next run. In this case the CL‐201 will display “C _ _ X+1” (X + 1 in‐dicates the next number of thecalibration stage) and continue to flash: Repeat the step 4 to enter the next calibration set temperature.The maximum calibration point is five. When finishing five point of the calibration, the machine will automatically exit from the calibration program and return to the pre‐start status: the “power” light will go off and the “heat” light will go “on” when temperature is over 50 ˚C.6. The calibration can be interrupted anytime by pressing “Start/stop” button and “Tem‐perature Adjustment” knob as indicated in step 3: If the process interrupted before the completion of thecalibration stage, the machine will only take the previous calibration point. For example, if the process interrupted between the first and second point calibration stages, then the machine will take the first calibration point and becomes one‐point calibration; If the process interrupted between stage 4 and 5, then the machine will take the previous 4 points data as the calibrated value, and becomes 4‐points calibration.7. During calibration, the calibration set point could not be changed unless interrupting the process by pressing the “Start/stop” and “Temperature Adjustment” knob as indicated in the step 3.8. Always using the same type of the block to avoid the discrepancy. The calibrated displayed value only accurately indicates the value of the block/vial that actually measured from external temperature measurement device.For CL‐205:Figure 4: CL‐205 Overview: Ch1: The left hand side (with six holes block); Ch2: The right hand side with 20 holes block)Figure 5: the front panel view of the CL‐205Please make sure that the correct channel corresponding to the designated block before to do the operation. The CL‐205 comes with additional LED display and “sel” button for users to select the channel. All operation and calibration is the same as in CL‐201, but before to do that, please press the “sel” button to select the channel (the LED light will be ON when the channel got selected).Selection of the Aluminum BlocksWe provide various aluminum blocks to accommodate different vials/tubes:Part Number Tube size (Diameter or ml) Number of the holes Hole sizes (Diameter X Depth)in mmCL‐200‐B1 27 mm 6 26.75 X 48CL‐200‐B2 0.5 ml 30 7.9 X 15.6 + 11.2, 9° taper CL‐200‐B3 0.2 ml 96 6.0 X 17.3, 9° taper CL‐200‐B5 1.5 ml 20 10.7 X 22.5 + 13, 9° taper CL‐200‐B6 50 ml Flat bottom 2 45 X 46CL‐200‐B7 10 mm 20 10.8 X 35CL‐200‐B9 2 ml 20 10.5 X 33CL‐200‐B10 13 mm 20 13.5 X47CL‐200‐B13 1.5 ml 20 10.7 X 14, 9° taper CL‐200‐B15 12 mm 20 12.5 X 47DB 0015‐33 12 mm 20 12.5 X 33CL‐200‐B16 16 mm 12 16.5 X 47CL‐200‐B17 2 ml 20 10.5 X 47CL‐200‐B18 19 mm Block 8 19.5 X 47CL‐200‐B19 33 mm Block 4 33.5 X 47T echnical SpecificationWorking temperature range Ambient +5°C to 200°C Settable temperature range 0.0°C to 200.0°C Temperature stability ±0.1°C at 40°CTemperature stability ±0.15°C at 100°CTemperature display 4 digit LEDSet point resolution 0.1°CSet point to accuracy ±1°CElectrical supply Voltage Cycles Power230V 50Hz‐60Hz 650W or110V‐120V 50Hz‐60Hz 650WWARRANTY/DISCLAIMEROMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 36 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to normal three (3) year product warranty to cover handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not limited to contact points, fuses, and triacs.OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.RETURN REQUESTS/INQUIRIESDirect all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package and on any correspondence.The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.FOR WARRANTY RETURNS, please have the following information available BEFORE contacting OMEGA:1.Purchase Order number under which the productwas PURCHASED,2.Model and serial number of the product underwarranty, and3.Repair instructions and/or specific problemsrelative to the product.FOR NON-WARRANTY REPAIRS,consult OMEGA for current repair charges. Have the following information available BEFORE contacting OMEGA: 1. Purchase Order number to cover the COSTof the repair,2.Model and serial number of the product, and3.Repair instructions and/or specific problemsrelative to the product.OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and engineering.OMEGA is a registered trademark of OMEGA ENGINEERING, INC.© Copyright 2009 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,Where Do I Find Everything I Need for Process Measurement and Control?OMEGA…Of Course!Shop online at SMTEMPERATUREThermocouple, RTD & Thermistor Probes, Connectors, Panels & AssembliesWire: Thermocouple, RTD & ThermistorCalibrators & Ice Point ReferencesRecorders, Controllers & Process MonitorsInfrared PyrometersPRESSURE, STRAIN AND FORCETransducers & Strain GagesLoad Cells & Pressure GagesDisplacement TransducersInstrumentation & AccessoriesFLOW/LEVELRotameters, Gas Mass Flowmeters & Flow ComputersAir Velocity IndicatorsTurbine/Paddlewheel SystemsTotalizers & Batch ControllerspH/CONDUCTIVITYpH Electrodes, Testers & AccessoriesBenchtop/Laboratory MetersControllers, Calibrators, Simulators & PumpsIndustrial pH & Conductivity EquipmentDATA ACQUISITIONData Acquisition & Engineering SoftwareCommunications-Based Acquisition SystemsPlug-in Cards for Apple, IBM & CompatiblesDatalogging SystemsRecorders, Printers & PlottersHEATERSHeating CableCartridge & Strip HeatersImmersion & Band HeatersFlexible HeatersLaboratory HeatersENVIRONMENTALMONITORING AND CONTROLMetering & Control InstrumentationRefractometersPumps & TubingAir, Soil & Water MonitorsIndustrial Water & Wastewater TreatmentpH, Conductivity & Dissolved Oxygen InstrumentsM-5364/1113。