Safety relay

- 格式:ppt

- 大小:3.37 MB

- 文档页数:33

1Control Relays and TimersSafety Relays40.10Safety RelaysProduct Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2Application Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2Standards and Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Technical Data and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7Note: Supplement to Volume 7—Motor Controls, Logic and Connectivity, CA08100008E, Tab 40.40.10Control Relays and T imersSafety RelaysSafety RelaysContentsDescription PageSafety RelaysProduct Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3Technical Data and Specifications . . . . . . . . . . . . . . . . . 4Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Product DescriptionSafety relays are intended toreliably monitor the signalsfrom safety devices at alltimes and switch off quicklyand reliably in an emergency.Single-channel and dualchannel versions are availablefor the construction of safetyapplications. The internallogic of the safety relaysmonitors the safety circuits(emergency stop, guard door,and so on) and activates theenable paths in a fault-freecondition. Upon actuation ofthe safety device or in theeven of a fault, the enablepaths are switched off. Anyfaults that occur in the controlcircuit, such as ground fault,cross connection fault or wirebreakage are also detected.Application DescriptionEaton’s ESR5 safety relaysprovide optimal safety and ahigh degree of reliability onplant machinery. Applicationsthat meet the highestsafety requirements inaccordance with EN 954-1,EN ISO 13849-1 up to PL eand accordance withIEC 62061 up to SILCL 3can be realized with theESR5 safety relay.Compatible with a widevariety of safety devices:●Emergency stops●Rope pulls●Two-hand control stations●Light curtain (OSSD)●Gate enable device●Safety switchesFeatures●Use for the highestsafety requirements inaccordance with EN 954-1EN ISO 13849-1,IEC 62061 and EC 61508●Suitable for the worldmarket with UL, cULcertifications and TÜVRhineland functionalsafety certifications●Applicable for EN 60204stop categories 0 or 1●Plug-in screw terminalsfor fast and fault-freereplacement●Multi-voltage versions(24–230 Vac/Vdc) for aflexible range of application●Delayed and non-delayedcontact expansionsaccommodate a widevariety of applicationsStandards andCertifications●UL 508; CSA-C22.2 No14-95; CE Marked●UL/cUL file number:E29184●Degree of protection: IP20●TÜV Rhineland certified●UL/cULus listed2340.10Control Relays and TimersSafety RelaysProduct SelectionTechnical OverviewApplication OverviewApplication Overview, continuedNotesᕃLaser scanners or light curtains with OSSD outputs. ᕄ All main units can also be reset automatically or manually.Single ChannelDual ChannelSafety Output (NO)SafetyOutput (NO) (Delayed)Output Delay SignalOutput (NC)Feedback Output Control Voltage RemovableTerminal Blocks Type of UnitCatalog Number ■ —4——1—24 Vac/Vdc ■ Main ESR5-NO-41-24VAC-DC ■ ■ 2——1—24 Vac/Vdc ■ Main ESR5-NO-21-24VAC-DC ■ ■ 3——1—24 Vac/Vdc ■ Main ESR5-NO-31-24VAC-DC ■ ■ 3——1—230 Vac ■ Main ESR5-NO-31-230VAC ■ ■ 3——1—24–230 Vac/Vdc ■ Main ESR5-NO-31-AC-DC ■■ 220.1–30s——24 Vdc ■ Main ESR5-NV3-30—■ 2——1—24 Vac/Vdc ■ Main ESR5-NZ-21-24VAC-DC ■ —5——1124 Vac/Vdc ■ Expansion ESR5-NE-51-24VAC-DC ■ ——40.3–3s 1124 Vdc■ ExpansionESR5-VE3-42Emergency Stop SafetySwitchesLight Curtain/OSSD ᕃTwo-Hand Control(EN 574 Type III C)ContactExpansion Off-Delayed Cross Circuit Recognition MonitoredManual Reset ᕄCatalog Number ■ ■——————ESR5-NO-41-24VAC-DC ■ ■ ————■ —ESR5-NO-21-24VAC-DC ■ ■————■ —ESR5-NO-31-24VAC-DC ■ ■ ————■ ■ ESR5-NO-31-230VAC ■ ■————■ ■ ESR5-NO-31-AC-DC ■■ ■——■■ ■ESR5-NV3-30—■—■——■—ESR5-NZ-21-24VAC-DC ————■———ESR5-NE-51-24VAC-DC ————■■——ESR5-VE3-42SingleChannelDual Channel Stop Category EN 60204Control Category to EN 954-1Achievable PL per ISO 13849-1Achievable SIL per EN IEC 62061Catalog Number ■ —02PL d SIL 3ESR5-NO-41-24VAC-DC ■ ■ 04PL e SIL 3ESR5-NO-21-24VAC-DC ■ ■ 04PL e SIL 3ESR5-NO-31-24VAC-DC ■ ■ 04PL e SIL 3ESR5-NO-31-230VAC ■ ■ 04PL e SIL 3ESR5-NO-31-AC-DC ■■ 0/14PL e SIL 3ESR5-NV3-30—■04PL e SIL 3ESR5-NZ-21-24VAC-DC ■ —04PL e SIL 3ESR5-NE-51-24VAC-DC ■—13PL dSIL 2ESR5-VE3-42Safety Relays40.10Control Relays and TimersSafety RelaysTechnical Data and SpecificationsSafety RelayDescription Unit ESR5-NO-21_ESR5-NO-41_ESR5-NO-31-24VAC-DC ESR5-NZ-21_GeneralStandards EN ISO 13849-1, IEC 62061,IEC 61508, DIN EN 50178,UL/CUL listedEN ISO 13849-1, IEC 62061,IEC 61508, DIN EN 50178,UL/CUL listedEN ISO 13849-1, IEC 62061,IEC 61508, DIN EN 50178,UL/CUL listedEN ISO 13849-1, IEC 62061,IEC 61508, DIN EN 50178,UL/CUL listedType-dependent standards———EN 574 Part no. IIIC Lifespan, mechanical—c (contacts)x 10610101010Maximum operating frequency Ops/h3600360036003600Climatic proofing Cold according toEN 60068-2-1, dry heataccording to EN60068-2-2,damp heat according toEN 60068-2-3Dry heat according toEN60068-2-2, damp heataccording to EN 60068-2-3Cold according toEN 60068-2-1, dry heataccording to EN60068-2-2,damp heat according toEN 60068-2-3Dry heat according toEN60068-2-2, damp heataccording to EN 60068-2-3Ambient temperature°F (°C)–4° to 131° (–20° to 55°)–4° to 131° (–20° to 55°)–4° to 131° (–20° to 55°)–4° to 131° (–20° to 55°) Ambient temperature storage°F (°C)–13° to 167° (–25° to 75°)–13° to 167° (–25° to 75°)–13° to 167° (–25° to 75°)–13° to 167° (–25° to 75°) Mounting position Any Any Any AnyVibration resistance (IEC/EN 60068-2-6)2g, frequency: 10–150 Hz,amplitude: 0.15 mm2g, frequency: 10–150 Hz,amplitude: 0.15 mm2g, frequency: 10–150 Hz,amplitude: 0.15 mm2 g, frequency: 10–150 Hz,amplitude: 0.15 mm Shock resistance (IEC 60068-2-27)————Protection typeHousing IP20IP20IP20IP20Terminals IP20IP20IP20IP20Protection against direct contact whenactuated from front (IEC 0106 Part 100)Finger- and back-of-handproofFinger- and back-of-handproofFinger- and back-of-handproofFinger- and back-of-handproofWeight kg0.170.220.170.22Terminal capacitySolid or flexible mm2 1 x (0.2–2.5)2 x (0.2–1)1 x (0.2–2.5)2 x (0.2–1)1 x (0.2–2.5)2 x (0.2–1)1 x (0.2–2.5)2 x (0.2–1)Flexible with ferrule mm2 1 x (0.25–2.5)2 x (0.25–1)1 x (0.25–2.5)2 x (0.25–1)1 x (0.25–2.5)2 x (0.25–1)1 x (0.25–2.5)2 x (0.25–1)Solid or stranded AWG24–1224–1224–1224–12Terminal screwPozidriv screwdriver Size2222Flat-blade screwdriver mm0.6 x 3.50.6 x 3.50.6 x 3.50.6 x 3.5Max. tightening torque Nm0.60.60.60.6Main ContactsRated impulse withstand voltage—U imp Vac6000400040006000Overvoltage category/pollution degreeOutside III/2III/2III/2III/2Inside————Rated insulation voltage—U i Vac250250250250Rated operating voltage—U e Vac230230230230Rated operation currentAC-15230V (360 ops./h)—I e A5454230V (3600 ops./h)—I e A3333DC-1324V (360 ops./h)—I e A646424V (3600 ops./h)—I e A3 2.53 2.5Max. summation current of all poles24 Vac/Vdc devices A72727272230 Vac devices A————Square of the total current(and total current)of all current paths72 A2 (6 + 6)72 A2 (4.2 + 4.2 + 4.2 + 4.2)72 A2 (4.9 + 4.9 + 4.9)72 A2 (6 + 6)Short-circuit protectionMax. fuse A gG/gL1061064540.10Control Relays and TimersSafety RelaysSafety Relay, continuedDescriptionUnitESR5-NO-21_ESR5-NO-41_ESR5-NO-31-24VAC-DCESR5-NZ-21_Power Supply Circuit Actuating voltage 50/60 Hz Vac 24242424Actuating voltage—U sVdc 24242424Voltage tolerance pick-up voltage x e 0.85–1.10.85–1.10.85–1.10.85–1.1Power consumption AC operated 50/60 Hz VA ————AC operated 50/60 Hz W 3.4 3.4 3.43DC operatedW1.61.61.61.5Fuse for control circuit supply 24V Short-circuit proof Short-circuit proof Short-circuit proof Short-circuit proof 115/230V ————Control Circuit Rated output voltage Vdc 24242424Rated operational current mAS12, S22: 30, S34: 45S12: 65, S34: 40S12, S22: 30, S34: 45S11, S21: 60, Y2: 45Resistance—R 50225022Short-circuit current A 2.3 2.3 2.3 2.3Response time ms 1006510050Recovery timems ————Response time with reset monitoring—t A1ms ————Response time without reset monitoring—t A2ms 1006510050Reset time—t R /t R1ms Single-channel 45;dual-channel 1045Single-channel 45;dual-channel 1020Minimum on duration—t M ms ————Recovery time—t Wms Approx. 1000Approx. 1000Approx. 1000Approx. 1000Synchronous monitoring time—t Sms ———500Electromagnetic Compatibility (EMC)Emitted interference EN 61000-6-4EN 61000-6-4EN 61000-6-4EN 61000-6-4Interference immunityAccording to EN 61000-6-2,EN 62061According to EN 61000-6-2According to EN 61000-6-2,EN 62061According to EN 61000-6-240.10Control Relays and TimersSafety RelaysSafety Relay, continuedDescription Unit ESR5-NO-31-230VACESR5-NO-31-24V-230VAC-DC ESR5-NV3_ESR5-VE3_ESR5-NE-51_GeneralStandards EN ISO 13849-1, IEC 62061,IEC 61508, DIN EN 50178,UL/CUL listedEN ISO 13849-1, IEC 62061,IEC 61508, DIN EN 50178,UL/CUL listedEN ISO 13849-1, IEC 62061,IEC 61508, DIN EN 50178,UL/CUL listedEN ISO 13849-1, IEC 62061,IEC 61508, DIN EN 50178,UL/CUL listedEN ISO 13849-1, IEC 62061,IEC 61508, DIN EN 50178,UL/CUL listedType-dependent standards EN 60204(if applicable)EN 60204(if applicable)EN 60204(if applicable)——Lifespan, mechanical—c (contacts)x 1061010101010Maximum operating frequency Ops/h3600360036009003600Climatic proofing Dry heat according toEN60068-2-2, damp heataccording to EN 60068-2-3Dry heat according toEN60068-2-2, damp heataccording to EN 60068-2-3Cold in accordance with:EN 60068-2-1, dry heat inaccordance with EN60068-2-2, humiditystorage test in accordancewith 60068-2-78Dry heat according toEN60068-2-2, damp heataccording to EN 60068-2-3Dry heat according toEN60068-2-2, damp heataccording to EN 60068-2-3Ambient temperature°F (°C)–4° to 131° (–20° to 55°)–4° to 131° (–20° to 55°)–4° to 113° (–20° to 45°)–4° to 131° (–20° to 55°)–4° to 131° (–20° to 55°) Ambient temperature storage°F (°C)–13° to 167° (–25° to 75°)–13° to 167° (–25° to 75°)–13° to 167° (–25° to 75°)–13° to 167° (–25° to 75°)–13° to 167° (–25° to 75°) Mounting position Any Any Any Any AnyVibration resistance (IEC/EN 60068-2-6)2g, frequency: 10–150 Hz,amplitude: 0.15 mm2g, frequency: 10–150 Hz,amplitude: 0.15 mm2g, frequency: 10–150 Hz,amplitude: 0.15 mm2g, frequency: 10–150 Hz,amplitude: 0.15 mm2g, frequency: 10–150 Hz,amplitude: 0.15 mm Shock resistance (IEC 60068-2-27)—————Protection typeHousing IP40IP40IP20IP20IP20Terminals IP20IP20IP20IP20IP20Protection against direct contact whenactuated from front (IEC 0106 Part 100)Finger- and back-of-handproofFinger- and back-of-handproofFinger- and back-of-handproofFinger- and back-of-handproofFinger- and back-of-handproofWeight kg0.30.30.170.170.22Terminal capacitySolid or flexible mm2 1 x (0.2–2.5)2 x (0.2–1)1 x (0.2–2.5)2 x (0.2–1)1 x (0.2–2.5)2 x (0.2–1)1 x (0.2–2.5)2 x (0.2–1)1 x (0.2–2.5)2 x (0.2–1)Flexible with ferrule mm2 1 x (0.25–2.5)2 x (0.25–1)1 x (0.25–2.5)2 x (0.25–1)1 x (0.25–2.5)2 x (0.25–1)1 x (0.25–2.5)2 x (0.25–1)1 x (0.25–2.5)2 x (0.25–1)Solid or stranded AWG24–1224–1224–1224–1224–12Terminal screwPozidriv screwdriver Size22222Flat-blade screwdriver mm0.6 x 3.50.6 x 3.50.6 x 3.50.6 x 3.50.6 x 3.5Max. tightening torque Nm0.60.60.60.60.6Main ContactsRated impulse withstand voltage—U imp Vac60006000400040004000Overvoltage category/pollution degreeOutside III/2III/2III/2III/2III/2 Inside—————Rated insulation voltage—U i Vac250250250250250Rated operating voltage—U e Vac230230*********Rated operation currentAC-15230V (360 ops./h)—I e A44—54230V (3600 ops./h)—I e A33333DC-1324V (360 ops./h)—I e A44—6424V (3600 ops./h)—I e A 2.5 2.533 2.5Max. summation current of all poles24 Vac/Vdc devices A5050495050230 Vac devices A5050———Square of the total current(and total current)of all current paths50 A2 (4 + 4 + 4)50 A2 (4 + 4 + 4)50 A2 (4 + 4 + 4)49 A2(3.5 + 3.5 + 3.5 + 3.5)50 A2(3.7 + 3.7 + 3.7 + 3.7+ 3.7)Short-circuit protectionMax. fuse A gG/gL66101066740.10Control Relays and TimersSafety RelaysSafety Relay, continuedDimensionsApproximate Dimensions in Inches (mm)Safety Relays, Contact Expansion Modules ESR5_ 24 Vac/VdcESR5_ 230 VacDescriptionUnitESR5-NO-31-230VACESR5-NO-31-24V-230VAC-DCESR5-NV3_ESR5-VE3_ESR5-NE-51_Power Supply Circuit Actuating voltage 50/60 Hz Vac 23024–230——24Actuating voltage—U sVdc —230242424Voltage tolerance pick-up voltage x e 0.85–1.10.85–1.10.85–1.10.85–1.10.8–1.1Power consumption AC operated 50/60 Hz VA —————AC operated 50/60 Hz W 5.8 5.8—— 2.2DC operatedW2.9 2.91.822.2Fuse for control circuit supply 24V —Short-circuit proof ———115/230V Short-circuit proofShort-circuit proof———Control Circuit Rated output voltage Vdc 2424242424Rated operational current mAS10, S12, S22: 35, S34,S35: 45S10, S12, S22: 35, S34, S35: 45S12, S22: 3.5, S34, S35: 7A1, A2: 84, K1/K2: 5A1, A2: 92Resistance—R 1111500——Short-circuit current A 0.70.70.1——Response time ms 2502501502020Recovery timems —————Response time with reset monitoring—t A1ms 60601502020Response time without reset monitoring—t A2ms 2502501502020Reset time—t R /t R1ms 202020 (non-delayed enable paths); 100 (min. delayed enable paths)0.3–3 s (+50%)adjustable20Minimum on duration—t M ms —————Recovery time—t Wms Approx. 1000Approx. 1000Approx. 330Approx. 1000—Synchronous monitoring time—t S ms—————Electromagnetic Compatibility (EMC)Emitted interference EN 61000-6-4EN 61000-6-4EN 61000-6-4EN 61000-6-4EN 61000-6-4Interference immunityAccording to EN 61000-6-2According to EN 61000-6-2According to EN 61000-6-2,EN 62061According to EN 61000-6-2According toEN 61000-6-2Eaton CorporationElectrical Sector1111 Superior Ave. Cleveland, OH 44114United States877-ETN-CARE (877-386-2273) ©2011 Eaton CorporationAll Rights ReservedPrinted in USAPublication No. CA04902001E / Z10889 March 2011Eaton is a registered trademark of Eaton Corporation. All oher trademarks are property of their respective owners.Eaton’s Electrical Sector isa global leader in power distribution, power quality, control and automation, and monitoring products. When combined with Eaton’s full-scale engineering services, these products provide customer-driven PowerChain™ solutions to serve the power system needs of the data center, industrial, institutional, public sector, utility, commercial, residential, IT, mission critical, alternative energy and OEM markets worldwide.PowerChain solutions help enterprises achieve sustainable and competitive advantages through proactive management of the power system as a strategic, integrated asset throughout its life cycle, resulting in enhanced safety, greater reliability and energy efficiency. For more information, visit /electrical.。

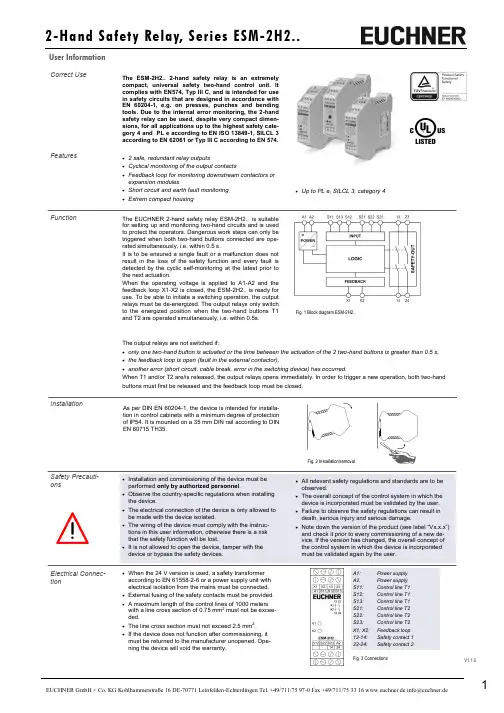

• Up to PL e, SILCL 3, category 4Correct UseThe ESM-2H2.. 2-hand safety relay is an extremely compact, universal safety two-hand control unit. It complies with EN574, Typ III C, and is intended for use in safety circuits that are designed in accordance with EN 60204-1, e.g. on presses, punches and bending tools. Due to the internal error monitoring, the 2-hand safety relay can be used, despite very compact dimen-sions, for all applications up to the highest safety cate-gory 4 and PL e according to EN ISO 13849-1, SILCL 3 according to EN 62061 or Typ III C according to EN 574.Features• 2 safe, redundant relay outputs• Cyclical monitoring of the output contacts• Feedback loop for monitoring downstream contactors orexpansion modules• Short circuit and earth fault monitoring • Extrem compact housingFunctionThe EUCHNER 2-hand safety relay ESM-2H2.. is suitable for setting up and monitoring two-hand circuits and is used to protect the operators. Dangerous work steps can only be triggered when both two-hand buttons connected are ope-rated simultaneously, i.e. within 0.5 s.It is to be ensured a single fault or a malfunction does not result in the loss of the safety function and every fault is detected by the cyclic self-monitoring at the latest prior to the next actuation.When the operating voltage is applied to A1-A2 and the feedback loop X1-X2 is closed, the ESM-2H2.. is ready for use. To be able to initiate a switching operation, the output relays must be de-energized. The output relays only switch to the energized position when the two-hand buttons T1 and T2 are operated simultaneously, i.e. within 0.5s.Fig. 1 Block diagram ESM-2H2..InstallationAs per DIN EN 60204-1, the device is intended for installa-tion in control cabinets with a minimum degree of protection of IP54. It is mounted on a 35 mm DIN rail according to DIN EN 60715 TH35.Fig. 2 Installation/removalElectrical Connec-tion• When the 24 V version is used, a safety transformeraccording to EN 61558-2-6 or a power supply unit with electrical isolation from the mains must be connected. • External fusing of the safety contacts must be provided. •A maximum length of the control lines of 1000 meters with a line cross section of 0.75 mm 2 must not be excee-ded.•The line cross section must not exceed 2.5 mm2. •If the device does not function after commissioning, it must be returned to the manufacturer unopened. Ope-ning the device will void the warranty.A1: Power supply A2. Power supply S11: Control line T1 S12: Control line T1 S13: Control line T1 S21: Control line T2 S22: Control line T2 S23: Control line T2 X1; X2: Feedback loop 13-14: Safety contact 1 23-24:Safety contact 2The output relays are not switched if:• only one two-hand button is actuated or the time between the actuation of the 2 two-hand buttons is greater than 0.5 s, • the feedback loop is open (fault in the external contactor),• another error (short circuit, cable break, error in the switching device) has occurred.When T1 and/or T2 are/is released, the output relays opens immediately. In order to trigger a new operation, both two-hand buttons must first be released and the feedback loop must be closed.ESM-2H2..The arrangement of the two-hand buttons must be designed in accordance with the standard EN 574 such that accidental actuation or simple bypassing of the safety function is excluded.The ESM-2H2.. unit is provided for the connection of 2-hand push-buttons, with one normally open or one normally colsed contact.Figur 1 shows the wiring of the ESM-2H2.. with a 2-hand push-buttons:ApplicationsFig. 1:Wiring of the ESM-2H2.. with a 2-hand push -buttonsFig. 2: Feedback loopContactors connected to the ESM-2H2.. or the basic devices are monitored via the feedback loop of the basic device. K A and K B are the positively driven contacts of the connected contactor or expansion module.Feedback loopNote: The items listed under “Electrical connection” must be observed during commissioning. Commissioning Procedure1. Wiring ESM-2H2..:Wire the ESM-2H2.. With the 2-hand push button according to your application (see Fig. 1).2. Wiring feedback loop:Wire the feedback loop as shown in Fig. 2.3. Wiring power supply:Connect the power supply to terminals A1 and A2.Warning: Wiring only in de-energized state.4. Starting the device:Switch the operating voltage on.5. Switch to working condition:Press the two buttons T1 and T2 simultaneously, or within 0.5 seconds.The positive-guided relay switches.6. Switch into hibernation:Release the two buttons T1 and T2. The positive-guided relay swiches off.Jumper X1-X2: See descriptionX1 X2InstallationAvoiding unintentional actuation or bypassing of the safety deviceThe arrangement of the two-hand buttons must be designed in accordance with the standard EN 574 such that accidental actuation or simple bypassing of the safety function is excluded.The operation of both buttons using one hand must be prevented by an adequate distance (at least 260 mm) or by a sepa-rating wall. Actuation using forearm, elbow, knee, hip or other parts of the body can be effectively prevented by a further increase in the distance between the two buttons, adequate distance from the floor and/or covers and/or separating walls. Distance from the two-hand buttons to the danger areaIt is necessary to maintain a minimum distance between the buttons for the two-hand circuit and the danger area on themachine or plant so that, after the release of one or both buttons, the machine or plant can only be reached once the dange-rous movement has been interrupted or completed. According to the standard DIN EN ISO 13855, the distance is calculated with the following equation:S = (K · T) + CS : Minimum distance from the nearest pushbutton (two-hand button) to the danger area.K : Parameter in mm/s, derived from data on the approach speeds of the body or parts of the body, for two-hand circuits 1600 mm/s.T : The overtravel of the overall system in seconds, that is the time from releasing the two-hand button to the end of the dan gerous movement.C : Additional distance in mm that based on entry into the danger area prior to the triggering of the safety device. For twohand circuits this is 250 mm, this distance can also be set to 0 mm given an adequate cover on the buttons, however then S must be at least 100 mm.ExampleThe overtravel time for the entire system is 90ms. Then the above equation gives for the minimum distance: S = (1600 mm/s · 0.09 s) + 250 mm S = 144 mm + 250 mm = 394 mmIf a suitable cover is used, S can be reduced to 144mm (see above).MaintenanceWhat to Do in Once per month, the device must be checked for proper function and for signs of tampering and bypassing of the safety function (to do this, check the wiring of the device and activate the emergency stop function. Check the delay time).The device is otherwise maintenance free, provided that it was installed properly.Note:Additional data can be requested from the manufacturer for applications that deviate from these conditions.SafetyCharacteristics According to EN ISO 13849-1The device is certified according to EN ISO 13849-1 up to a Performance Level of PL e.Safety characteristics according to EN ISO 13849-1 for all variants of ESM-2H2.. Load (DC-13; 24 V) <= 0.1 A <= 1 A <= 3 A T10d [years] 20 20 20 Category: 4 4 4 PLe e e PFHd [1/h]: 1.2E-08 1.2E-08 1.2E-08 nop [cycle / year]<= 400,000<= 100,000<= 22,500Case of a Fault?If the fault still exists, perform the steps listed under “Commissioning Procedure”.If these steps do not remedy the fault either, return the device to the manufacturer for examination.Opening the device is impermissible and will void the warranty.Device does not switch on:• Check whether the 2-hand button of correct function. • Check whether the wiring.• Check the supply voltage on A1 and A2 • Is the feedback loop closed?Dimension DrawingS u b j e c t t o t e c h n i c a l m o d i f i c a t i o n s , n o r e s p o n s i b i l i t y i s a c c e p t e d f o r t h e a c c u r a c y o f t h i s i n f o r m a t i o n . © E U C H N E R G m b H + C o . K G 109071-06-02/16 (T r a n s l a t i o n o f t h e O r i g i n a l O p e r a t i n g I n s t r u c t i o n s ) Fixed TerminalsPlug-In Terminals。

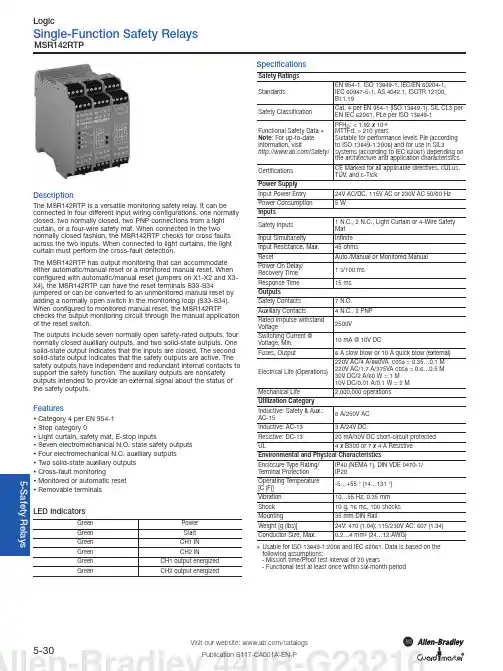

Single-Function Safety Relays5-30Visit our website: /catalogsPublication S117-CA001A-EN-PMSR142RTPDescriptionThe MSR142RTP is a versatile monitoring safety relay. It can be connected in four different input wiring configurations: one normally closed, two normally closed, two PNP connections from a light curtain, or a four-wire safety mat. When connected in the two normally closed fashion, the MSR142RTP checks for cross faults across the two inputs. When connected to light curtains, the light curtain must perform the cross-fault detection.The MSR142RTP has output monitoring that can accommodate either automatic/manual reset or a monitored manual reset. When configured with automatic/manual reset (jumpers on X1-X2 and X3-X4), the MSR142RTP can have the reset terminals S33-S34 jumpered or can be converted to an unmonitored manual reset by adding a normally open switch in the monitoring loop (S33-S34). When configured to monitored manual reset, the MSR142RTP checks the output monitoring circuit through the manual application of the reset switch.The outputs include seven normally open safety-rated outputs, four normally closed auxiliary outputs, and two solid-state outputs. One solid-state output indicates that the inputs are closed. The second solid-state output indicates that the safety outputs are active. The safety outputs have independent and redundant internal contacts to support the safety function. The auxiliary outputs are nonsafety outputs intended to provide an external signal about the status of the safety outputs.FeaturesCategory 4 per EN 954-1Stop category 0Light curtain, safety mat, E-stop inputsSeven electromechanical N.O. state safety outputsFour electromechanical N.C. auxiliary outputsTwo solid-state auxiliary outputsCross-fault monitoringMonitored or automatic resetRemovable terminalsLED IndicatorsGreen PowerGreen StartGreen CH1 INGreen CH2 INGreen CH1 output energizedGreen CH2 output energized SpecificationsSafety RatingsStandardsEN 954-1, ISO 13849-1, IEC/EN60204-1,IEC60947-5-1, AS4042.1, ISOTR12100,B11.19Safety ClassificationCat. 4 per EN 954-1 (ISO 13849-1), SIL CL3 perEN IEC 62061, PLe per ISO 13849-1Functional Safety Data 1Note: For up-to-dateinformation, visit/Safety/PFH D: < 1.92 x 10-9MTTFd: > 210 yearsSuitable for performance levels Ple (accordingto ISO 13849-1:2006) and for use in SIL3systems (according to IEC 62061) depending onthe architecture and application characteristics CertificationsCE Marked for all applicable directives, cULus,TÜV, and c-TickPower SupplyInput Power Entry24V AC/DC, 115V AC or 230V AC 50/60 Hz Power Consumption 5 WInputsSafety Inputs1 N.C.,2 N.C., Light Curtain or 4-Wire SafetyMatInput Simultaneity InfiniteInput Resistance, Max.45 ohmsReset Auto./Manual or Monitored ManualPower On Delay/Recovery Time1 s/100 msResponse Time15 msOutputsSafety Contacts7 N.O.Auxiliary Contacts 4 N.C., 2 PNPRated Impulse withstandVoltage2500VSwitching Current @Voltage, Min.10 mA @ 10V DCFuses, Output 6 A slow blow or 10 A quick blow (external) Electrical Life (Operations)220V AC/4 A/880VA cosφ= 0.35…0.1 M220V AC/1.7 A/375VA cosφ= 0.6…0.5 M30V DC/2 A/60 W = 1 M10V DC/0.01 A/0.1 W = 2 MMechanical Life2,000,000 operationsUtilization CategoryInductive: Safety & Aux.:AC-156 A/250V ACInductive: AC-13 3 A/24V DCResistive: DC-1320 mA/30V DC short-circuit protectedUL 4 x B300 or 7 x 4 A ResistiveEnvironmental and Physical CharacteristicsEnclosure Type Rating/Terminal ProtectionIP40 (NEMA 1), DIN VDE 0470-1/IP20Operating Temperature[C(F)]-5…+55° (14…131°)Vibration10…55 Hz, 0.35 mmShock10 g, 16 ms, 100 shocksMounting35 mm DIN RailWeight [g (lbs)]24V: 470 (1.04); 115/230V AC: 607 (1.34) Conductor Size, Max.0.2…4 mm2(24…12 AWG)1Usable for ISO 13849-1:2006 and IEC 62061. Data is based on the following assumptions:- Mission time/Proof test interval of 20 years- Functional test at least once within six-month periodSingle-Function Safety Relays5-31Visit our website: /catalogsMSR142RTP5-S a f e t y R e l a y sProduct SelectionAccessoriesDimensions are shown in mm (in.). Dimensions are not intended to be used for installation purposes.Block DiagramTypical Wiring DiagramsL1K1L2L3MActiveClosedLIght Curtain, Monitored Manual Reset,Monitored Output Single Channel Safety Gate, Auto Reset,No Output MonitoringL1K1L2K2L3M+24V DCActiveClosedDual Channel E-Stop, Monitored Manual Reset, Monitored Output Safety Mat, Automatic Reset, No Output MonitoringApproximate DimensionsSafety Applications and Wiring DiagramsSafety Valve & E-Stop—Air Supply Release10-30Visit our website: /catalogsPublication S117-CA001A-EN-P800F, MSR142, Pneumatic Safety ValveCircuit StatusThe e-stop button is released, the MSR142 safety relay outputs are off and the pneumatic valve is closed.Operating PrincipleSTARTING: Press the reset button to energize the output contacts of the safety relay. The two solenoids in the valve energize and allow air to flow from the Air Supply to the Air Outlet.STOPPING: Pressing the e-stop button de-energizes the safety outputs of the MSR142, which in turn drops out the solenoids of the safety valve. The valve closes the Air Supply and releases the air pressure to the Air Exhaust. Releasing the e-stop button does not cause the valve to turn back on.Fault DetectionUpon successful completion of internal checks on power up, the MSR142 checks the e-stop status. If an open or short circuit is detected, the MSR142 will not energize its outputs. If both input circuits are properly closed, the MSR142 checks the status of the safety valve. If one or both solenoids of the safety valve are energized, the Status contact will be open, and the MSR142 will not energize its outputs. If both solenoids are de-energized, Status contact will be closed and the MSR142 will turn on its Ready LED. Pressing the Reset button energizes the MSR142 safety outputs and opens the safety valve.The safety valve performs its own internal checks. If one of the valves remains actuated, gets stuck or moves too slowly, the Air Outlet flow will be re-directed to the exhaust. To clear the fault condition, both valves must be de-energized and the valve reset button pressed.+24V DCRatingsThe safety function initiated by the 800F e-stop button meets the safety performance requirements of SIL CL 3 per IEC 62061:2005 and has Category 4structure that can be used in systems requiring Performance Levels up to PLe per ISO 13849-1: 2006. The MSR142 has seven safety rated outputs. To maintain the highest safety levels, these outputs must drive redundant actuators which must be monitored for proper performance. This example circuit performs a Stop Category 0 function (coast to stop).Allen-Bradley 440R-G23216。

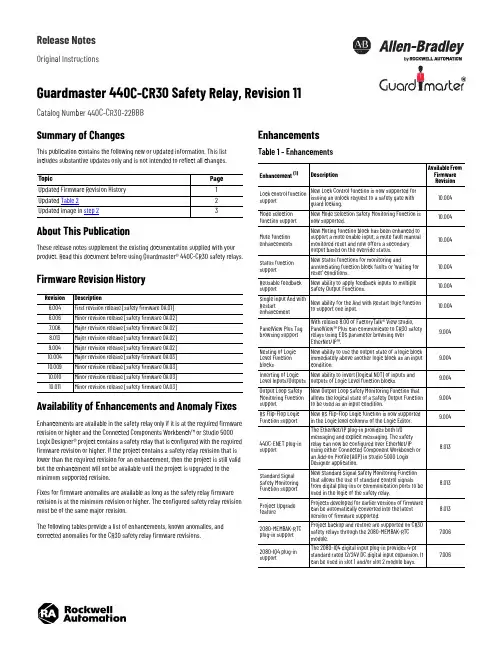

Release NotesOriginal InstructionsGuardmaster 440C-CR30 Safety Relay, Revision 11Catalog Number 440C-CR30-22BBBSummary of ChangesThis publication contains the following new or updated information. This list includes substantive updates only and is not intended to reflect all changes.About This PublicationThese release notes supplement the existing documentation supplied with your product. Read this document before using Guardmaster® 440C-CR30 safety relays.Firmware Revision HistoryAvailability of Enhancements and Anomaly FixesEnhancements are available in the safety relay only if it is at the required firmware revision or higher and the Connected Components Workbench™ or Studio 5000 Logix Designer® project contains a safety relay that is configured with the required firmware revision or higher. If the project contains a safety relay revision that is lower than the required revision for an enhancement, then the project is still valid but the enhancement will not be available until the project is upgraded to the minimum supported revision.Fixes for firmware anomalies are available as long as the safety relay firmware revision is at the minimum revision or higher. The configured safety relay revision must be of the same major revision.The following tables provide a list of enhancements, known anomalies, and corrected anomalies for the CR30 safety relay firmware revisions.EnhancementsTopicPage Updated Firmware Revision History 1Updated Table 22Updated image in step 23Revision Description6.004First revision release [safety firmware 0A.01]6.006Minor revision release [safety firmware 0A.02]7.006Major revision release [safety firmware 0A.02]8.013Major revision release [safety firmware 0A.02]9.004Major revision release [safety firmware 0A.02]10.004Major revision release [safety firmware 0A.03]10.009Minor revision release [safety firmware 0A.03]10.010Minor revision release [safety firmware 0A.03]10.011Minor revision release [safety firmware 0A.03]Table 1 - EnhancementsEnhancement (1)DescriptionAvailable From Firmware RevisionLock control function support New Lock Control function is now supported forissuing an unlock request to a safety gate withguard locking.10.004Mode selection function support New Mode Selection Safety Monitoring Function is now supported.10.004Mute function enhancements New Muting function block has been enhanced to support a mute enable input, a mute fault manual monitored reset and now offers a secondary output based on the override status.10.004Status function supportNew Status functions for monitoring andannunciating function block faults or ‘waiting for reset’ conditions.10.004Reusable feedback supportNew ability to apply feedback inputs to multiple Safety Output Functions.10.004Single input And withRestartenhancement New ability for the And with Restart logic function to support one input.10.004PanelView Plus Tag browsing support With release 8.00 of FactoryTalk® View Studio, PanelView™ Plus can communicate to CR30 safety relays using EDS parameter browsing over EtherNet/IP™.9.004Nesting of Logic Level Function blocksNew ability to use the output state of a logic block immediately above another logic block as an input condition.9.004Inverting of Logic Level Inputs/Outputs New ability to invert (logical NOT) of inputs and outputs of Logic Level function blocks.9.004Output Loop Safety Monitoring Function support New Output Loop Safety Monitoring Function that allows the logical state of a Safety Output Function to be used as an input condition.9.004RS Flip-Flop Logic Function support New RS Flip-Flop Logic function is now supported in the Logic level columns of the Logic Editor.9.004440C-ENET plug-in supportThe EtherNet/IP plug-in provides both I/O messaging and explicit messaging. The safety relay can now be configured over EtherNet/IP using either Connected Component Workbench or an Add-on Profile (AOP) in Studio 5000 Logix Designer application.8.013Standard Signal Safety Monitoring Function support New Standard Signal Safety Monitoring Function that allows the use of standard control signals from digital plug-ins or communication ports to be used in the logic of the safety relay.8.013Project Upgrade featureProjects developed for earlier versions of firmware can be automatically converted into the latest version of firmware supported.8.0132080-MEMBAK-RTC plug-in support Project backup and restore are supported on CR30 safety relays through the 2080-MEMBAK-RTC module.7.0062080-IQ4 plug-in supportThe 2080-IQ4 digital input plug-in provides 4-pt standard rated 12/24V DC digital input expansion. It can be used in slot 1 and/or slot 2 module bays.7.0062Rockwell Automation Publication 440C-RN001H-EN-P - December 2020Guardmaster 440C-CR30 Safety Relay, Revision 11 Release NotesAnomalies2080-OB4 plug-in support The 2080-OB4 digital output plug-in provides 4-pt standard rated 12/24V DC sourcing output expansion. It can be used in slot 1 and/or slot 2 module bays.7.0062080-OW4I plug-in supportThe 2080-OW4I relay output plug-in provides 4-pt standard rated relay output, individually isolated, 2A expansion. It can be used in slot 1 and/or slot 2 module bays.7.006Unique function block name supportUnique names can be assigned to the Safety Monitoring Function blocks and the Safety Output Function blocks. These names are stored in the project that is loaded to the safety relay and can be recovered by an upload.7.006Password protection Software connections including Upload, Download,and Connect can be restricted through passwordprotection.7.006(1)For more information, see publication 440C-UM001.Table 2 - Known and Corrected AnomaliesAnomalyDescriptionAffected Firmware Revisions Corrected Firmware Revision Discrepancy Fault on Power-upDevices with pulse testing outputs would sometimes cause a discrepancy fault in the CR30 safety relay upon power-up. On power-up, the Channel Test during the first logic scan when transitioning from self-test to run mode has been removed to help prevent the discrepancy fault.See publication 440C-UM001 for details.6.0046.0067.0068.0139.00410.00410.00910.01010.011Memory Module Incompatibility Safety relay fails to recognize 2080-MEMBAK-RTC memory modules that are manufactured on or after 2016/02/11.APBC000280011 6.0046.0067.0068.0139.00410.00410.00910.010Memory Module Update When updating a safety relay from a previous firmware revision to firmware 10 using thememory module the restore operation must be performed twice (the first process updates thefirmware, the second process restores the user configuration). 6.004 6.0067.0068.0139.004Configuration loss on power cycleDuring specific power down conditions, the safety relay could be interrupted while writing a fault condition to its nonvolatile memory. On power up, the memory is evaluated as corrupted and the user configuration is discarded.APBC00026898 6.0046.0067.0068.0139.00410.00410.009Connection failure with Add-on Profile (AOP) major revision 1The safety relay rejects an I/O connection that originates from the safety relay AOP (versions 1.013 and versions 1.014) when Compatible Keying and Major Revision 8 or later is configured.APBC000271569.00410.004Download faultA download could result in a major fault on the safety relay, Type 06, Code 20 – Configuration Fault.APBC000251087.0068.0139.00410.004Download over Ethernet faultA download over Ethernet to the safety relay could result in a Type 05, Code 00 – Internal Safety Synch Fault.APBC000236608.0139.00410.004Unexpected disconnect from safety relay Occasionally Connected ComponentsWorkbench software would unexpectedly disconnect while connected to a password protected safety relay.APBC000248668.0139.004Table 1 - Enhancements (Continued)Enhancement (1)DescriptionAvailable From Firmware RevisionLocked by another connection error Attempts to connect to the safety relay arerejected and erroneously reports “CR30 has been locked by another, new connection is not allowed.”APBC000248678.0139.004No reconfiguration after EEPROM fault After the safety relay experiences a memory fault (Type 5 Code 00), the safety relay does not accept a new download.APBC00024866 6.0046.0067.0068.0139.004Muting L-Type reports incorrect fault description Under specific configuration conditions, the Muting T Type function block incorrectly reports a mute sensor timing fault when actually a sequence fault occurred.APBC000237318.0139.004Network address changes require power cycle Changes to the 440C-ENET Ethernet portsettings, duplicate IP address detection, and DHCP vs. static IP address settings may require a power cycle to take effect.APBC000241338.0139.004Power-up faultVariations in 24V DC supply power to the CR30 safety relay during power-up could lead to power fault: Type 04, Code 01.APBC000244266.0046.0067.0068.013Discrepancy fault after power-upVariations in 24V DC supply power to the CR30 safety relay during power-up could lead to adiscrepancy fault on any dual channel Safety Monitoring Function: “One channel open after reset” 6.0046.0067.0068.013Empty fault logModbus reporting of the fault log always returns 0, indicating no fault, even if faults are present in the log.APBC00025011 6.0046.0067.0068.013Incorrect Mode The safety relay will return to Run Mode after downloading a valid configuration to a unit that has experienced a nonrecoverable fault.APBC000257716.0046.0067.0068.013Modbus fault state cleared in Program Mode The safety relay does not report faultinformation over Modbus once the safety relay is placed in Program Mode.6.0046.0067.0068.013Memory module firmware update failure The memory module is unable to upgrade a firmware revision 7 safety relay to version 8 or later 7.006L-Type muting override conditionOverride for L-Type muting cannot be initiated when only the light curtain is interrupted (no mute sensors).6.0046.0067.006Two Hand Control at power up Two Hand Control does not fault at power up if buttons are pressed. 6.0046.0067.006Override conditionsFor muting applications, mute sensor interrupted or timing faults should be only conditions that allow override to be initiated.6.0046.0067.006Serial port doesnot shutdownWhen the serial port is configured as shutdown,it still responds to Modbus messages.APBC00020590 6.0046.0067.006Input filters greater than 200 ms create nonrecoverable fault When an input filter of greater than 200 ms is configured on any Safety Monitoring function, a nonrecoverable fault is generated when the configuration is downloaded to the safety relay.APBC00020589 6.0046.0067.006Missing plug-in slot 1 without fault log entry A missing plug-in module configured in slot 1 and not actually present results in a fault but no fault log entry is created.APBC00018493 6.0046.0067.006Plug-inmismatch with duplicate fault log entriesA mismatch between the plug-in present on slot 1 and the actual plug-in present results in duplicate entries in the fault log.APBC000205086.0046.0067.006Plug-in outputs fail to configure When Plug-in outputs terminals are selected asoutputs for Safety Output Functions, they fail toturn on when the corresponding Safety OutputFunction turns on.APBC000201036.004 6.006Table 2 - Known and Corrected Anomalies (Continued)AnomalyDescriptionAffected Firmware Revisions Corrected Firmware RevisionRockwell Automation Publication 440C-RN001H-EN-P - December 20203Guardmaster 440C-CR30 Safety Relay, Revision 11 Release NotesUse DMK FilesFirmware for the CR30 safety relay beginning with firmware revision 10.009 uses a new file format called *.DMK. These files are named for easy identification, for example: 440C-CR30-22BBB_10.009.dmk.ControlFLASH™ software, version 13 or later, supports the format. ControlFLASH software is automatically installed as part of Studio 5000 Logix Designer application installation, version 28 or later. You can download ControlFLASH software from the Rockwell Automation Product Compatibility and Download Center (PCDC - rok.auto/pcdc ) separately, if necessary.You are not required to install the new firmware file format. When you download *.DMK files from the Rockwell Automation PCDC, ControlFLASH softwareautomatically saves the folder location where the *.DMK files were downloaded. As a result, ControlFLASH software can easily locate *.DMK files.You can use the Browse option to access and configure the folders that ControlFLASH software monitors as shown:Upgrade Safety Relay FirmwareThis procedure shows you how to update the firmware in a CR30 safety relay using ControlFLASH. To download the latest CR30 safety relay firmware revision, go to the PCDC (PCDC - rok.auto/pcdc ) and select your desired revision.On CR30 safety relays, you can upgrade your safety relays through the Ethernet port on the 440C-ENET plug-in module and the USB.Through USB1.Verify successful RSLinx® Classic communications with you CR30 safety relay by USB using RSWho. The CR30 safety relay uses the AB_VBP-x driver.2.Start ControlFLASH (Start > All Programs > FLASH Programming Tools > ControlFlash) and click Next >.3.Select the catalog number of the CR30 safety relay (440C-CR30-22BBB) that you are updating and click Next >.4.Select the safety relay in the browse window and click OK.Communication fault without fault log entryIf the host microprocessor within the CR30safety relay loses communication with the safety processors a fault is generated but no fault log entry is createdAPBC00020302 6.0046.006Fault log index changes after power cycleAfter a power cycle of the safety relay,previously detected faults index by one within the fault log.APBC000186376.004 6.006Inverted image of downloadprogram notcompared After performing a download, the inverted datais sent back from the safety relay to Connected Components Workbench software but not compared as an additional diagnostic check.APBC00020430 6.004 6.006Download through virtual image failsDownload of a program to the safety relay occasionally fails due to connection timeout when downloading through a virtual image.6.004 6.006ATTENTION: All Ethernet settings are reverted to factory default after a ControlFLASH firmware update.Table 2 - Known and Corrected Anomalies (Continued)AnomalyDescriptionAffected Firmware Revisions Corrected Firmware Revision IMPORTANTTo update your safety relay successfully, it must be in Program Mode or BOOT Loader mode. The safety relay can be placed into Program Mode from the Graphic Overview screen in Connected Component Workbench software, the Logic Configuration tab in the Logix Designer module profile or placed in BOOT Loader mode by holding the MEM/ID button located below the USB port on the safety relay during power-up.Publication 440C-RN001H-EN-P - December 2020 | Supersedes Publication 440C-RN001G-EN-P - April 2016Copyright © 2020 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400 EEE Yönetmeliğine UygundurAllen-Bradley, Connected Components Workbench, ControlFLASH, expanding human possibility, FactoryTalk, Guardmaster, PanelView,Rockwell Automation, RSLinx, and Studio 5000 Logix Designer are trademarks of Rockwell Automation, Inc.EtherNet/IP is a trademark of ODVA, Inc.Trademarks not belonging to Rockwell Automation are property of their respective companies.Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form at rok.auto/docfeedback .For technical support, visit rok.auto/support.Waste Electrical and Electronic Equipment (WEEE)Rockwell Automation maintains current product environmental compliance information on its website at rok.auto/pec .At the end of life, this equipment should be collected separately from any unsorted municipal waste.5.Verify the revision, and click Next > to continue.6.Click Finish.7.Click Yes to initiate the update.The next screen shows the download progress.If you see the following error message, verify that the safety relay is in Run mode. If so, change to Program or BOOT Loader mode by pressing theMEM/ID switch during power-up of the CR30 safety relay, click OK, and try again.When the update is complete, you see a screen similar to the following.Click OK to complete the update.。

航海及海运专业英语词汇(S1)s chair 双套结s point 船首基线s seconds signs silvers slips slows starboards switchs-bend s形弯管s-generation 第二代s-hook s形钩s-link s形连接件s-pole s极s-shackle s形卸扣s-wrench s形扳手s.s.s. clutch 自动同步滑动离合器sa safe arrivalsa subject to approvalsaaret 岛saari saaret 群)岛saari 岛sabathecycle 等容等压混合加热循环sabik =ηophiuchi 宋sables 黑貂皮sabotage 破坏sabotage 破坏的行为;怠工sac 袋状凹湾sack cargo 袋装货sack conveyor 袋装货运输带sack of coals 麦哲伦云sack 包布袋sack 包布袋袋装材料sack 布袋sack 袋sack 装sack-cloud 麦哲伦云sacriffice of ship 牺牲船舶sacrifice of cargo 货物牺牲sacrifice of freight 运费牺牲sacrifice of ship 牺牲船舶sacrifice property 牺牲财产sacrifice 牺牲sacrifice 牺牲;亏本出售sacrificial anode cathodic protection 牺牲阳极阴极保sacrificial anode protection 牺牲阳极法sacrificial anode 牺牲阳极sacrificial anodic protection 牺牲阳极保sacrificial corrosion 阴极保腐蚀sacrificial 牺牲的saddle back 鞍板saddle cut-out 鞍座断流器saddle hatch 鞍形舱口saddle hatch 鞍形舱口saddle joint 鞍架接合saddle key 鞍形键saddle plate 鞍板saddle seat 鞍座saddle support 鞍形支承saddle 鞍;鞍形物;凹座;凹谷;鞍型低压;圆枕木锅炉座saddle 海底鞍形支架saddle 支架saddlehill 马鞍峰sae number sae号数sae viscosity sae粘度sae 汽车工程师学会safe access 船内安全通道safe aground 安全搁浅safe allowable load 安全容许载荷safe allowable load 安全许可载荷safe allowable stress 安全容许应力safe allowable stress 安全许用应力safe anchorage 安全锚地safe arrival 安全到达safe arrival 安全抵达safe berth clause 安全泊位条款safe berth 安全泊位safe berth 安全泊位安全锚泊safe berth 安全锚泊safe carriage of grain 谷物安全装运safe carriage 安全运载safe carrying capacity 安全载流量safe conduct 安全条例safe container 安全集装箱safe current carrying capacity 安全载流量safe current 安全电流safe deck load height 上甲板载货安全高度safe design 安全设计safe distance of approachsafe distance of approach会遇安全距离safe distance 安全距离safe drip pan 承油盘safe factor 安全系数safe guard 保safe handling of cargo 货物安全装卸safe handling of dangerous goods 危险货物的安全装卸safe handling 安全操作safe handling 安全运转safe haven 安全的避风港safe injection 安全喷射safe limit 安全界限safe load calculator 配载仪safe load 安全负载力safe load 安全载荷safe loading 安全装载safe management and operation of ship 船舶安全管理和操作safe management of ship 船舶的安全管理safe navigable speed 安全航速safe navigation 安全航行safe navigational procedure 安全导航程序safe offing 为安全而驶出海面safe operation area of loading or discharging of dangerous goods 危险货物装卸安全作业区safe operation 安全操作safe operation 安全运行safe operation 安全运营safe operation 安全作业safe overhead clearance 安全净空高度safe passing 安全通过safe place 安全地点safe port 安全港safe port 安全港口safe prosecution of voyage 安全完成航程safe prosecution of voyage 安全续航safe range of stress 安全应力范围safe reliability 安全可靠性safe roadstead 安全锚地safe securing 安全系固safe shipment 安全载运safe shut-down 安全停safe speed 安全航速safe storage of dangerous goods 危险货物的安全存放safe stowage 安全积载safe stress 安全应力safe transport of dangerous goods 危险货物的安全运输safe transport 安全运输safe voltage 安全电压safe water mark 安全水域标志safe water marks 安全水域标safe working load 安全负载力safe working load 安全工作负荷safe working load 安全工作载荷safe working load 安全使用负荷safe working load 安全有效载荷safe working pressure 安全工作压力safe working strength 安全工作强度safe working stress 安全工作应力safe working temperature 安全工作温度safe 安全的safe-load computer 安全负载计算机safe-working load 安全工作载荷safeguard and alarm 保措施和报警器safeguard clause 保障条款safeguard 安全设备safeguard 保装置safeguard 保险板safeguarding duties 保性关税safekeeping fee 保管费safekeeping life 安全储存期限safekeeping 保safekeeping 保妥善保管safekeeping 妥善保safest 最安全的safety alarm 安全报警器safety allowance 安全裕量safety ampparatus 安全装置safety and interlock device 安全联锁装置safety and limit control 安全和极限控制safety and limit protection 安全和极限保safety angle 安全角safety apparatus 安全装置safety appliance 安全设备safety approval plate 安全合格牌照safety assessment 安全鉴定书safety assurance system 安全保证系统safety at sea international 《国际海上安全》safety at sea 海上安全safety basin 安全水域safety belt 安全带safety bolt 安全螺栓safety brake 安全闸safety brake 安全制动器safety buoy 救生圈safety buoyancy 储备浮力safety buoyancy 预备浮力safety call 安全呼叫safety cap 安全帽safety car 救生吊车safety catch 安全掣子safety catch 保险扣safety certificate 安全证书safety chain 安全链safety chain 安全链备用电路safety chain 备用电路safety clamp 安全夹safety clearance 安全间隙safety clip 熔断器接线端safety clip 熔丝夹safety clntrol 安全控制safety clutch 安全离合器safety cock 安全旋塞safety code 安全码safety coefficient 安全系数safety collar 安全环safety communication 安全通信safety construction certificate 安全构造证书safety construction certificate 安全结构证书safety control 安全保障safety coupling 安全联轴节safety coupling 安全联轴器safety cup 安全帽safety cut-off 安全开关safety cut-out device 安全切断装置safety cut-out 安全断流器safety cut-out 保安器safety cutout circuit 安全断开电路safety deck 安全甲板safety device 安全装置safety dog 安全轧头safety earthing 安全接地safety earthing 保接地safety engineering 安全工程技术safety equipment certificate 安全设备证书safety equipment certificate 安全设备证书安全设备证书safety equipment certificate 设备安全证书safety equipment 安全设备safety et screw 安全止动螺钉safety exhaust 安全排气阀safety factor 安全系数safety factor 安全因数safety fairway 安全航道safety falling velocity 安全降落速度safety feature test 安全性能试验safety flap 安全瓣safety fuel 安全燃料safety fuse 保险丝safety gear 安全装置safety glass 不碎玻璃safety goggles 安全护目镜safety governor 安全调速器safety guard 安全板safety guard 保险板safety hardener 安全固化剂safety hatch 安全舱口safety hatch 太平舱口safety height of ullage 油面安全高度safety hook 安全钩safety injection system 安全注射系统safety inspection of vessels in inland waters 内河船舶安全检查safety inspection 安全检查safety interlock for running direction 转向安全联锁装置safety interlock 安全联锁装置safety keel 龙骨翼板safety lamp 安全灯safety latch hook 自锁安全吊货钩safety latch 安全闩safety law 安全规则safety lever 保险杆safety lighting 安全照明safety limit 安全界限safety line 安全绳索safety line 安全索safety load 安全负荷safety load 安全载荷safety locker 保险箱safety locking wire 安全锁线safety loop 保险圈safety management system 安全管理系统safety margin 安全余地safety margin 安全裕度safety match 安全火柴safety measure 安全措施safety measures 安全措施safety mechanism 安全机构safety mechanism 保险机构safety meeting 两船安全会遇safety message 安全信文safety net provision10% 安全网条款safety net 安全网safety net 安全网;安全信息网safety net 保网safety nut 安全螺母safety of crew 船员安全safety of human life 人命安全safety of life at sea 海上人命安全safety of life of person on board 船上人命安全safety of maritime navigation 航海安全safety of navigation 航行安全safety of property at sea 海上财产安全safety of ship 船舶安全safety of ships law 船舶安全法safety officer 安全员safety pad 安全垫safety passing distance 安全通过距离safety performance 安全性能safety pin 安全销safety plug socket 安全塞座safety plug 保险塞safety plug 插塞式熔断器safety pole 安全杆safety precaution 安全防护safety precaution 安全预防措施safety protection program 安全保程序safety protection system 安全保装置safety provision 安全措施safety radiotelegraphy certificate 无线电设备安全证书safety radiotelephony certificate 无线电话安全证书safety rail 安全栏杆safety rail 安全拦杆安全栏杆safety regulation 安全调节safety regulations for offshore installations 海上平台安全规则safety regulations 安全规程safety relay 保安继电器safety requirement 安全要求safety ring 安全环safety ring 保险环safety rod 安全棒safety rope 安全绳safety rules 安全条例safety service 安全业务safety set screw 安全止动螺钉safety signal 安全信号safety slip clutch 安全滑动离合器safety spark gap 安全火花间隙safety speed 安全速度safety standard 安全标准safety standards 安全标准safety stay 安全牵条safety stop device 安全止动装置safety stop 安全限制器safety stop 安全止动器safety supervision department 安全监督处safety support vessel 安全支持船safety switch 安全开关safety switch 保险开关safety system 安全保系统safety tackle 安全绞辘safety tap 安全旋塞safety temperature 安全温度safety traffic 安全通信safety tread 防滑板safety trip level 保安断路水平safety trip 安全脱口器safety type dispensing valve 安全型分配阀safety valve complement 安全阀总成safety valve operation test 安全阀调整试验safety valve setting 安全阀压力较定safety valve spring 安全阀弹簧safety valve 安全阀safety voltage 安全电压safety washer 安全垫圈safety working boots 安全工作靴safety working shoes 安全工作鞋safety zone 安全区safety 安全safety 可靠性safety-type panel 安全型配电板safty construction certificate 《安全结构证书》safty fairway 安全航道sag resistance 拖索中垂阻力sag to leeward 向下风漂流sag 下垂sag 下陷下沉sag 中垂;下降;倾斜;垂弛;垂度;压向下风sagging condition 中垂状况sagging condition 中垂状态sagging gaff 向下风舷侧斜的斜桁sagging moment 中垂力矩sagging stress 中垂应力sagging stresses 中垂应力sagging 流挂;中垂sagging 弯曲sagging 下垂sagging 中垂sagittarius = archer 人马星座sagittarius 人马星座said by shipper to contain 内容据发货人报称said to be 1 000 mts 重量据称为1千公吨said to be 据称said to contain 据说装有said to weigh 据称重量;自报重量said to weigh 据说重量said to weight 据称重量sail angle 帆角sail area 帆面积sail area 受风面积sail assisted ship 风帆船sail bag 风帆罩sail batten 硬帆横支撑条sail before the mast 普通水手sail broad 顺风驶帆sail cabin 帆具舱sail cloth 帆布sail free 顺风驶帆sail ho! 看见船了!sail hook 缝帆钩sail in ballast 压载航行sail in 入港sail large 顺风驶帆sail locker 帆缆舱sail loft 帆布品制造车间sail loft 帆布制品间sail needle 缝针sail number 帆船号码sail on a bowline 紧抢航驶(收紧缭绳sail on an even keel 等吃水航行sail on one's bottom 自己负责航行;独立经营sail out 出航sail out 开航sail plan 帆装置图sail propulsion 风帆推进sail room spaces 帆缆舱sail room 帆具舱sail training vessel 驶帆训练船sail twine 帆线sail 出海sail 帆;航行sail 帆vi.航行启航sail 帆航行sail-assited bulk carrier 帆助散货船sailboat 帆船sailcatamaran 双体帆船sailcloth 帆布sailed 已出航sailed 已开航已开航的sailer 帆船sailer 帆船海员sailfree 顺风驶帆sailing advice 开航通知sailing area 航区sailing barge 平底帆船sailing board 开航公告牌sailing boat 帆船sailing chart 航行图sailing club 帆船俱乐部sailing coaster 沿海帆船sailing condition 航行情况sailing conditions 航行条件sailing craft 小帆船sailing date 船期开航日期sailing date 船期起航日sailing date 开航日期sailing date 启航日sailing direction 《航路指南》sailing directions 航路指南sailing distance 帆航距离sailing draft 出港时船的吃水sailing drifter 漂网小渔船sailing driver 漂网小渔船sailing exercise 舢板驶风练习sailing free 顺风驶帆sailing gear 驶风工具sailing ice 稀疏漂冰sailing ice) 浮冰sailing in ballast 压载航行sailing in the direction of a fairway 顺航道行驶sailing instruction 开航通知sailing instruction 开航指示sailing large 顺风驶帆sailing list 船期表sailing on her ear 满帆倾斜行驶sailing on her own bottom 私营商船sailing on the port tack 左舷戗风航行sailing order 出航命令sailing order 船舶开航通知单sailing order 船舶开航通知单开航通知sailing order 开航通知sailing permit 开航许可证sailing plan 航行计划sailing quality 航海性能sailing raft 帆筏sailing region 航区sailing rights in inland water 内水航行权sailing route 航线sailing routes in inland waters 内河航路sailing schedule 船期表sailing schedule 航行时间表sailing ship fitted with auxiliary motor 机帆船sailing ship 帆船sailing speed 单船航速sailing telegram 船舶启航电报sailing telegram 开航电报sailing term 驶帆术语sailing to 驶往sailing tonnage length 帆艇量吨长度sailing trim 出航纵倾sailing trim 适航纵倾sailing trims 适航纵倾sailing vessel fitted with auxiliary engines 机帆船sailing vessel fitted with auxiliary motor 机帆船sailing vessel underway 在航帆船sailing vessel 帆船sailing zone 航区sailing 航海;航行计算方法;航行;驶风sailing 航行sailing 航行开船扬帆行驶a.航行的sailing-boat 帆船saillarge 顺风驶帆sailless 无帆的sailmaker 制帆厂sailmaker's eye splice 顺纹眼环插接sailmaker's needle 缝针sailmaker's palm 缝帆顶针sailmaker's seaming 制帆缝法sailmaker's splice 顺纹插接sailmaker's tools 缝帆工具;制帆工具sailmaker's whipping 帆工式扎绳头sailmaking 制帆术sailor 船员sailor 水兵sailor 水手sailor 水手海员sailor's knot 平结sailor's quarters 水手舱sailor's room 水手室sailor's shore pass 船员登陆证sailor's union of the pacific 太平洋海员工会sailorchest 水手柜sailorhome 海员之家sailorizing 船艺实习sailorknot 一结sailorless 无船员的sailorman 水手sailorpocket knife 水手刀sailors' home 海员俱乐部sailors' mess 水手餐室sailorwhipping 扎绳头sailorworking suit 水手工作服saint elmols fire(st.elmo's fire 桅上电火saint hilaire method 天文定位)高度差法saint 圣saint 圣……saint 圣地saint 圣圣……圣地sainte 圣地saki 岬sal log 一种船底计程仪一种水压计程仪salary 薪金sale and purchase broker 买卖经纪商sale and purchase 买卖sale by auction 拍卖sale by instalments 分期分批出售sale by proxy 代销sale commission 出售佣金sale of ship 卖船sale or transfer clause 出卖或转让条款sale or transfer clause 售卖或转让条款sale 卖sale 销售saleform 船舶销售协议备忘录标准格式saler 卖方sales book 《销售手册》sales by description 凭文字说明买卖sales by sample 凭样品买卖sales confirmation 销售证明书sales contract 买卖合同sales contract 买卖契约sales contract 销货合同sales discount 销货折扣sales voucher 售货凭证salescrap'87 1987年拆船交易标准合同salicylate liniment 水杨酸甲酯搽剂salient angle 凸角salient features 主要性能salient instrument 凸装型仪表salient mounting 凸装salient pole alternator 凸极式交流发电机salient pole generator 凸极发电动salient pole generator 凸极发电机salient pole machine 凸极电机salient pole machine 凸极式电机salient pole machine 显极电机salient pole synchronous induction motor 塌极式同步感应电动机salient pole type field 凸极式磁场salient pole 凸极salient 突出salient 显著的salimeter ice flower 冰花salimeter 盐度表salimeter 盐度计saline deposit 盐分沉淀物saline waters 海水域saline 盐的saline 有盐分的salinity bridge 测定盐度用电桥salinity gradient 盐度梯度salinity indication equipment 盐分测定装置salinity indicator 盐度指示器salinity meter 盐度计salinity sensor 盐度传感器salinity table 盐度表salinity temperature depth recorder 海水盐度温度深度记录器salinity 含盐量salinity 盐度salinity 盐分salinometer cock 盐度计旋塞salinometer port 盐度计箱salinometer sensor 盐度传感器salinometer 调浓器盐度计salinometer 盐度表salinometer 盐度计salinometer 盐度计调浓器sallying 摇摆船身(小船上船员集中在两舷同时左右来回奔跑salmon and crab floating cannery 鲑蟹罐头加工船salmon tail 运河舵salometer =salimeter盐度计salometer 盐度计saloon deck 餐厅甲板saloon deck 餐厅甲板;一等客舱甲板saloon deck 客舱甲板saloon keeper 酒吧间经营人saloon master 餐厅主任saloon passenger 头等舱旅客saloon stores 船上小卖部saloon 餐厅saloon 大厅餐厅一等客舱saloon 厅salt 盐salt air 盐雾salt atmosphere 盐雾salt bath quenching 盐浴淬火salt brine 盐水salt cake 芒硝salt carrier 运盐船salt content 盐分salt door 泥渣孔salt filtration 盐雾过滤salt flower 冰花salt fog test 盐雾试验salt gauge 盐水比重计salt gauge 盐水相对密度计salt haze 盐霾salt liquor 盐溶液salt liquor 盐水salt marsh 盐碱地盐咸滩salt marsh 盐咸滩;咸沼salt meter 盐浮计salt mist test 盐雾试验salt pan 盐田salt pans 盐田salt provisions 咸货salt rock 岩盐salt water activated battery 海水电池salt water arrival draught 抵港时海水吃水salt water circulating distiller 循环海水制淡装置salt water circulating pump 盐水循环泵salt water contamination 海水污染salt water cooling system 海水冷却系统salt water density correction 海水密度校正salt water draught 海水吃水salt water evaporator 海水蒸发器salt water heater 海水加热器salt water ice 海上制成的冰块salt water ingestion tset 喷盐雾试验salt water loadline 海水吃水线salt water pump 海水泵salt water sanitary pump 海水卫生泵salt water soap 海水皂salt water 海水salt water 海水盐水salt water 盐水salt 盐salt 盐类salt-logoon 咸水湖salt-water circulating distiller 循环海水式制淡装置salt-water corrosion 海水腐蚀salt-water draft 海水吃水salt-water oil cooler 海水油冷却器saltern 盐田saltings 盐碱地saltings 盐碱地盐咸滩saltmarsh 盐沼泽saltpetre 硝石saltpetre 硝酸钾saltwater system 海水系统saltwater-activated battery 海水电池salute 敬礼;放礼炮saluting by fire 放礼炮saluting gun 礼炮salutis gratia 为安全而牺牲salvage agreement 救助契约salvage anchor 救助锚salvage and rescue ship 打捞救助船salvage and rescue ship 海难救助船salvage and salvage charge 救助与救助费salvage and wreck removal 打捞清除salvage appliance 救难设备salvage appliance 救助工具salvage appliance 救助设备salvage association 海难救助联合会salvage association 海难救助协会salvage at sea 海上救助salvage at sea 救助捞救salvage award 救助报酬salvage barge 救捞驳船salvage boat 救助船salvage boat 救助船救捞船salvage bond 海难救助合同salvage bond 救助契约salvage bureau 海难救助打捞局salvage by contract 按约救助salvage by sister-ships 姊妹船救助salvage by stowage 救助拖带salvage by tow 拖救salvage by voluntary action 自愿救助salvage charge 救助费salvage charge 救助费救助费用salvage charges 救助费salvage charges 救助费用salvage clause 救助报酬条款salvage clause 救助条款salvage company 打捞公司salvage company 救捞公司salvage contract upon the principle of no cure-no pay 无效果-无报酬救助合同salvage contract 救助合同salvage convention 救助公约salvage convoy 救助护航salvage corps 救难队救助队salvage corps 消防队salvage craft tender 救援艇供应船salvage craft 救助船salvage crane 救险起重机salvage crew 救助船员salvage cruiser 救生快艇salvage department 海难救助处salvage dock 救难船坞salvage expenses 救助费用salvage fee 救助费salvage fee 救助费用salvage firm 救助商salvage for preservation of human life. 人命救助报酬salvage gear 救助工具salvage gear 救助设备salvage gear 救助装置salvage has a useful result 救助有效果salvage hawser 大型轮船必须携带的)应急拖缆应急拖缆salvage hawser 应急拖缆salvage in stages 阶段救助salvage lien 救助留置权salvage life craft 救助打捞船salvage liftcraft 救难打捞船salvage lifting vessel 浮力打捞船salvage lifting vessel 浮力打捞船救助打捞船salvage lifting vessel 救助打捞船salvage loss 海难损失salvage loss 救助损salvage loss 救助损失salvage loss 救助损失(被救财产所遭受的损失salvage loss 救助损失(指被救财产遭受的损失salvage master 打捞监督salvage money 救助费salvage money 救助费救助费用salvage money 救助费用salvage of life 人命救助salvage of property 财产救助salvage officer 海难救助员salvage operation 海难救助作业salvage operation 救助作业salvage operations carried out by public authorities 公共当局从事的救助作业salvage operations controlled by public authorities 公共当局控制的救助作业salvage performed by several salvors 共同救助salvage pipe 海难救助管salvage pontoon 打捞浮筒salvage prize 救助报酬salvage pump 救助泵salvage pump 应急排水泵salvage remuneration 救助报酬salvage repair 海损修理salvage service 救助服务机构salvage service 救助机构salvage ship 救助船salvage suction hose 救求软吸管salvage suction hose 救助泵吸入软管salvage suction hose 救助泵吸软管salvage suction hose 救助软吸管salvage tug 海难救助拖轮salvage tug 救助打捞拖船salvage tug 救助拖船salvage tug 救助拖船救助拖轮salvage tup 救助拖船salvage under contract 签约救助salvage value 海难后的残余财产价值salvage vessel 海难救助船salvage vessel 海难救助船海难救助船salvage vessel 救助船salvage waist band 救生带salvage winc 救助绞车salvage winch 救助绞车salvage work boat 海难救助船salvage work 救助工作salvage wotrk 救助作业salvage 打捞salvage 打捞海难救助salvage 海难救助salvage 海上救助;救助费用;被救船舶;打捞salvage 海上救助沉船打捞救助费salvageable 可打捞的salvageboat 救助船salvagee strap 绕匝索套salvagerescue 海难救助或救生salvages 被救船、货salvaging 海难救助作业salvaging 救助工作salvation association 海难救助协会salve 打捞salve 救助salved property 获救财产salved value 获救价值salved value 获救价值;原子动力遇难船除污染费用salvee 被救助人salver 救难者salvesen-tuck-faltinsen method 萨-托-福船舶纵向运动估算法salvge operation 救助作业salving vessel 救助船salvo 保留条款salvo 齐发salvor of human life 人命救助人salvor 救难者salvor 救助船salvor 救助人;救助船salvor's expense 救助人的费用salvor's misconduct 救助人的过失salvorial negligence 救助过失salvorial relation 救助关系salvors ordinary negligence liability system 救助人一般过失责任制same case 相同情况same date 同日same force 同等效力same frequency repeater 同频增音机same frequency 相同频率same level of safety 同样的安全水平same name 同名same sea and coast 同一海域和同一海岸同一海域及海岸same sea and country or coast 同一海域和国家或海岸same sea and country 同一海域和地区same sea and country 同一海域和地区同一海域和同一国家同一海域及国家same sea and country 同一海域和同一国家同一海域及国家same validity 同等效力same 同一的samephase horizontal antenna 同相水平天线samephase vertical antenna 同相垂直天线sampan 舢板sampan 舢舨sample analysis 取样分析sample and hold amplifier 取样与保持放大器sample and hold circuit 取样维持电路sample average 样本均值sample central moments 样本中心矩sample characteristics 样本特征sample collector 试样收信sample correlation coefficient 样本相关系数sample correlation matrix 样本相关矩阵sample covariance 样本协方差sample data control system 取样数据控制系统sample design 样品设计sample details 油样细节sample devices 取样装置sample discharge arrangement 样水排放装置sample fair ship 展览船sample function 样本函数sample interval 抽样间隔取样间隔sample mean 样本均值sample mode 样本众数sample moment of order r 样本r阶矩sample number 样品号码sample of no value 免费货样sample of oil 油样sample operating system 样本操作系统sample percentiles 样本百分位数sample program 抽样程序sample program 取样程序sample ship 试样船sample space 取样空间sample variance 样本方差sample water piping system 样水管路系统sample workpiece 样件sample 试用sample 样品sample-hold circuit 采样-保持电路sampled data system 取样数据系统sampled data 取样数据sampled data 样本数据sampled phase-locked loop 抽样锁相环sampled signal 取样信号sampled 取样的sampler 采样器sampler 电子取样器;快速转换器;脉冲调制器sampling analysis 取样分析sampling arrangement 取样装置sampling circuit 取样电路sampling counter clear 取样计数器复位sampling counter maximum 取样限数计数器sampling counter 取样计数器sampling decoder 取样译码器sampling device 取样器sampling error 取样误差sampling frequency 采样频率sampling frequency 取样频率sampling function 取样函数sampling gate 取样门sampling inspection 抽样检查sampling inspection 取样检查sampling instruction 抽样说明sampling interval 抽样区间sampling line 取样管道sampling normal distribution 取样正态分布sampling oscilloscope 取样示波器sampling point 采样点sampling procedure 抽样程序sampling procedure 取样程序sampling process 取样过程sampling switch 取样转换器;取样交换机sampling system 取样系统sampling test 取样试验sampling theorem 取样定理sampling time 采样时间sampling tube 取样管sampling 取样samson knee 缆桩倒肘samson line 一种由2或3股大麻纤维制成的轻白麻绳samson post 吊杆柱samson post 吊杆柱将军柱samson post 将军柱san francisco 旧金山san 大山圣地圣地sanction of custom 按惯例的制裁sanction 制裁sand accretion 淤沙sand anchor 沙地锚sand and gravel foreshore 沙砾混合滩sand and mud foreshore 泥沙混合滩sand and mud 沙与泥底sand ballast 砂压载sand ballast 沙压载sand bank 沙滩sand bar 拦江沙sand blast 喷砂sand blasting 喷砂sand blasting 喷砂处理sand block 砂箱墩sand blower 喷砂器sand box 砂箱sand bucket 砂箱sand carrier 砂运输船运砂船疏浚船sand carrier 运沙船sand casting 砂型铸造sand cay 沙洲sand cloth 砂布sand core 砂型心sand dredger 疏浚船sand dune 砂丘sand dyke 沙堤sand ejector 喷砂器sand filter 砂过滤器sand fluke 瘦尖形锚爪sand foreshore 沙滩sand glass 沙漏sand heap 沙包sand hill 砂丘sand hole 砂眼sand inclusion 夹砂sand jack 砂箱墩sand lead 撇缆头sand mold 砂型sand molding 砂造型sand paper 砂纸sand pillar 沙卷sand pump bucket dredger 自扬链斗挖泥船sand pump dredger 砂泵挖泥sand pump dredger 砂泵挖泥船sand pump 泥浆泵sand pump 砂泵sand scouring flow 走沙水sand shovel 砂铲sand spit 沙咀sand spraying device 喷砂器sand stone 沙石sand storm 沙暴sand strake 龙骨翼板sand sucker 砂泵挖泥船sand sucker 吸泥机sand sucker 吸扬式挖泥船sand trap 沉砂槽sand wave 沙纹sand 沙sand 沙铺沙砂磨sand 沙沙沙底sand 沙沙沙丘沙岗sand-and-canvas 用黄沙与帆布擦洗sand-sucker 吸扬式挖砂船泥泵sandbar 拦江沙sandbar 沙堤sandbar 沙洲sandblast apparatus 喷砂装置sandblast cleaning 喷砂清理sandblast cleaning 喷沙清理sandblast device 喷砂设备sandblast machine 喷砂机sandblast n. 喷砂sandblast n. 喷砂喷砂清除法喷矿器vt. sandblast 喷砂sandblaster 喷砂器sandblasting 喷砂处理sander 喷砂器sandhill 沙丘沙岗sandhills 沙丘sanding 喷砂清洗sanding 砂磨sandpaper 砂纸用砂纸擦sandpump 泥浆泵sandscratcher 水手sandstorm or duststorm 沙暴或尘暴sandstorm 尘暴沙暴sandstorm 沙暴sandsweeping 喷砂清洗sandwave 洲浪底sandwaves 波浪形沙丘sandwich construction 夹层结构sandwich cylinder 夹层圆筒sandwich laminate 夹层板sandwich type element 式壳体sandwich wound 分层绕的sandwich 夹层sandy beach 沙滩sandy bottom 沙底sandy chore 沙岸sandy coast 沙岸sandy shore 沙岸sanitary accomodation 卫生间sanitary authority 检疫部门sanitary certificate 卫生证书sanitary control system 卫生水柜控制sanitary control system 卫生水柜控制系统sanitary customhouse regulation 海关卫生条例sanitary discharge 卫生水管sanitary drainage 卫生水管系sanitary ejector 卫生水喷射器sanitary fixture 卫生设备sanitary fixtures 卫生设备sanitary flushing system 卫生水冲洗系统sanitary installation 卫生装置sanitary line 卫生管道sanitary measures 卫生处理sanitary outfit 卫生设备sanitary outfit 盥洗设备sanitary passage 疫情证(港口检疫部门发给从传染病嫌疑船登岸的旅客sanitary pipe 卫生水管sanitary pipe 畲洗水管sanitary pipe 盥洗水管sanitary plumbing 卫生管道sanitary pressure tank 卫生水压力柜sanitary pump 卫生泵sanitary pump 卫生水泵sanitary pumping system 卫生水泵唧系统sanitary rules 卫生规则sanitary system 卫生管系sanitary system 卫生水管系sanitary tank 卫生水柜sanitary treating arrangement 污水处理装置sanitary treatment arrangement 污水处理装置sanitary 卫生的sanitation system 卫生系统sanitation 排水设备sanitation 卫生卫生设备sanitation 盥洗设备sansan 云冠sansar 桑萨风sansar 桑萨风伊朗东北风santa ana 圣塔阿那风(焚风的地方名称santa 圣地圣地圣地santi 圣地santo 圣地圣地圣地sao 圣地sap rot 干枯sap 白木质saponification equivalent 皂化当量saponification value 皂化值saponification 皂化saponifier 皂化剂saponifying 皂化sapphire cap 蓝宝石帽sar mission coordinator 搜救任务协调员sar point of contact 搜救联络地点sar unit 搜救单位sardine oil 沙丁鱼油sardines 沙丁鱼sargasso sea 藻海(北大西洋中央区域sargasso weed 马尾藻sargasso 大量浮在海面的海藻sargassun 马尾藻sargo ship safety equipment certificate 《货船安全设备证书》saros 沙罗周期(月龄周期的一种sarsar 桑萨风伊朗东北风sarsar 伊朗东北风sash knob 窗框把手sash knob 门框上球形把手sash tool 框刷sash 框sasse 船闸sastrugi 雪被风吹成的沟和脊zastrugi 的复数复数)雪被风吹成的沟和脊satan 尘旋satellite acquisition 卫星获得satellite aided navigation 卫生导航satellite anchoring 卫星定锚位satellite asset 卫星装置satellite automatic monitoring system 卫星自动监控系统satellite automatic monitoring system 卫星自动监视系统satellite automatic system 卫星自动化系统satellite automation system 卫星自动系统satellite availability 卫星可用率satellite aximuth 卫星方位角satellite broadcasting 卫星广播satellite business system 卫星商业系统satellite channel 卫星通路satellite charge 卫星费用satellite circuit noise 卫星线路噪音satellite circuit 卫星电路satellite cloud picture 卫星云图satellite collection of buoy observations 卫星收集观测浮标数据satellite communication agency 卫星通信局satellite communication agency 卫星通信局卫星通信社satellite communication agency 卫星通信社satellite communication center 卫星通信中心satellite communication control office 卫星通信控制室satellite communication controller 卫星通信控制器satellite communication system 卫星通信系统satellite communication terminal 卫星通信终端satellite communication 卫生通信satellite communications control facility 卫星通信控制设施satellite communications terminal 卫星通信终端satellite communications 卫星通信satellite computer 卫星计算机satellite configuration 卫星配置satellite control center 卫星控制中心satellite control facility 卫星控制设备satellite control network 卫星控制网络satellite control network 卫星控制网卫星控制网络satellite coupling 卫星接合satellite coverage areas 卫星覆盖区域satellite coverage 卫星覆盖范围satellite data communication system 卫星数据通信系统satellite data communications system 卫星数据通信系统satellite data modulator 卫星数据调制器satellite data reduction processor system 卫星数据简化处理系统satellite data system 卫星数据系统satellite data system 卫星资料系统satellite day 卫星白天satellite designation 卫星名称satellite digital and analog display 卫星数字-模拟显示satellite digital and analog display 卫星数字和模拟显示satellite doppler navigation system 卫星多普勒导航系统satellite early warning system 卫星预警系统satellite earth station hongkong 香港卫星地面站satellite earth station 卫星地面站satellite educational and informational television 卫星教育和。