美国博雷(BRAY)S67(定位器)用于双作用&单作用气动执行器

- 格式:pdf

- 大小:1.43 MB

- 文档页数:5

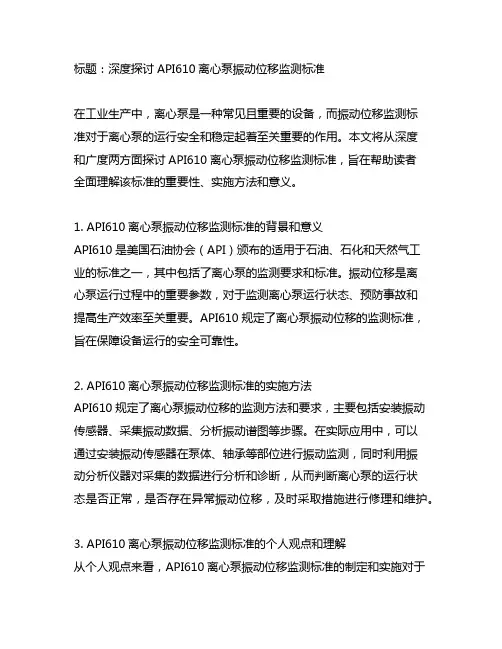

标题:深度探讨API610离心泵振动位移监测标准在工业生产中,离心泵是一种常见且重要的设备,而振动位移监测标准对于离心泵的运行安全和稳定起着至关重要的作用。

本文将从深度和广度两方面探讨API610离心泵振动位移监测标准,旨在帮助读者全面理解该标准的重要性、实施方法和意义。

1. API610离心泵振动位移监测标准的背景和意义API610是美国石油协会(API)颁布的适用于石油、石化和天然气工业的标准之一,其中包括了离心泵的监测要求和标准。

振动位移是离心泵运行过程中的重要参数,对于监测离心泵运行状态、预防事故和提高生产效率至关重要。

API610规定了离心泵振动位移的监测标准,旨在保障设备运行的安全可靠性。

2. API610离心泵振动位移监测标准的实施方法API610规定了离心泵振动位移的监测方法和要求,主要包括安装振动传感器、采集振动数据、分析振动谱图等步骤。

在实际应用中,可以通过安装振动传感器在泵体、轴承等部位进行振动监测,同时利用振动分析仪器对采集的数据进行分析和诊断,从而判断离心泵的运行状态是否正常,是否存在异常振动位移,及时采取措施进行修理和维护。

3. API610离心泵振动位移监测标准的个人观点和理解从个人观点来看,API610离心泵振动位移监测标准的制定和实施对于保障离心泵设备的安全稳定运行具有重要意义。

振动位移作为离心泵运行状态的重要指标,其准确监测和及时分析能够有效地帮助企业预防事故、延长设备的使用寿命,提高生产效率和安全性。

我认为在实际应用中,企业应该严格遵守API610标准,加强离心泵振动位移的监测和分析,从而最大程度地提升设备的可靠性和安全性。

4. 总结和回顾本文对API610离心泵振动位移监测标准进行了深度和广度兼具的探讨,从背景意义、实施方法到个人观点和理解进行了详细阐述。

通过本文的阅读,读者能够全面了解API610标准的重要性、实施方法和意义,进而加强对离心泵振动位移监测的认识和理解。

Products Solutions Services简明操作指南Micropilot FMR67HART雷达物位仪本文档为《简明操作指南》;不得替代设备随箱包装中的《操作手册》。

设备的详细信息请参考《操作手册》和其他文档资料:所有设备型号均可通过下列方式查询:–网址:/deviceviewer–智能手机/平板电脑:Endress+Hauser Operations AppKA01253F/00/ZH/02.1771355420Micropilot FMR67 HART2Endress+HauserMicropilot FMR67 HART 目录Endress+Hauser 3目录1重要文档信息 (4)1.1图标................................................................................41.2术语和缩写..........................................................................61.3注册商标 (7)2基本安全指南 (8)2.1人员要求............................................................................82.2指定用途............................................................................82.3工作场所安全.........................................................................82.4操作安全............................................................................82.5产品安全............................................................................93产品描述 (10)3.1产品设计 (10)4到货验收和产品标识 (11)4.1到货验收...........................................................................114.2产品检验 (11)5储存和运输 (13)5.1储存条件...........................................................................135.2将产品运输至测量点 (13)6安装 (14)6.1安装条件...........................................................................146.2安装:水滴天线,PTFE 材质,口径50 mm / 2"..............................................196.3安装:天线,齐平安装.................................................................206.4FMR67的空气吹扫接口................................................................226.5带保温层的罐体......................................................................256.6旋转变送器外壳......................................................................256.7旋转显示模块........................................................................266.8安装后检查.........................................................................267电气连接 (27)7.1连接条件 (27)8调试(通过操作菜单) (43)8.1显示与操作单元......................................................................438.2操作菜单...........................................................................468.3解锁仪表...........................................................................478.4设置操作语言........................................................................478.5物位测量设置........................................................................488.6用户自定义应用......................................................................49重要文档信息Micropilot FMR67 HART 1 重要文档信息1.1 图标1.1.1 安全图标1.1.2 电气图标1.1.3 工具图标4Endress+HauserMicropilot FMR67 HART重要文档信息1.1.4 特定信息图标1.1.5 图中的图标1.1.6 设备上的图标Endress+Hauser5重要文档信息Micropilot FMR67 HART 1.2 术语和缩写6Endress+HauserMicropilot FMR67 HART 重要文档信息Endress+Hauser 71.3 注册商标HART®HART 通信组织(Austin,美国)的注册商标KALREZ®, VITON®杜邦高性能弹性体公司(Wilmington,美国)的注册商标TEFLON®杜邦公司(Wilmington,美国)的注册商标基本安全指南Micropilot FMR67 HART8Endress+Hauser2基本安全指南2.1人员要求操作人员必须符合下列要求:‣经培训的合格专业人员必须具有执行特定功能和任务的资质。

-posi turn2Sicher und fl exibel –die neue Antriebsgeneration actubar2Operating Instructionsbar-positurn2In this documentation we use different ty-pes of instructions for safety and warning signs:Indicates a real and near dan-ger.To ignore this sign means pos-sible death or serious injury as consequence.Indicates a threat of danger. To ignore this sign means pos-sible serious injury or material damage as consequence.Indicates a possible danger. To ignore this sign means pos-sible material damage as con-sequence.Stands for advice and tips for a better understanding of in-structions or a better handling of the unit.tions are valid for positurn2, a module of the new valve control system bar-vacotrol. They are intended for the operator that me-ans the person that works with the unit. This is not a technical handbook. For que-stions, arising from the contents of this do-cumentation, please contact our customer service department.The unit and this documentation are pro-tected by copyright. Their reproduction wi-thout written permission will be contested in court. We reserve all rights to these operating instructions and their contents thereof, also for their reproduction and/or duplication in whatever imaginable form, e.g. through photocopies, print, on whate-ver data carriers or in whatever translated form. The reprinting of this documentation is only possible via the express written per-mission of bar GmbH. The technical state at the time of delivery of the unit and in-structions is a deciding factor, in case no other information is provided. We reserve the right to technical changes without spe-cial notice in advance. Earlier instructions lose their validity. The General Terms and Conditions for Sales and Delivery as pre-scribed by bar GmbH are to be adhered to.Copyright:DANGER!WARNING!ATTENTION!Operating Instructions bar-positurn2product according to our advertising, the product information and this documentati-on issued by us. Further product features are not promised. We undertake no liability for economy and fault-free function, when the product is used for other purposes, as described in the section …Intended Use“. Damages are generally excluded, except in the case of criminal intent or gross negli-gence committed by bar is proved, or in the case of promised product features being absent. If this product is exposed to non-prescribed environments, for which it is not suitable or does not correspond to the technical standard as stipulated therein, we cannot and will not be held responsible for the consequences.We accept no liability for damages to sy-stems and equipment in whatever form in the surrounding environment around the product, which result from a fault of the product or in this documentation. We are not responsible for injuries to patents and/ or other third party rights outside the Fe-deral Republic of Germany.We cannot be held liable for damages, re-sulting from the incorrect operation and non-adherence to the instructions laid down in this documentation. We are not li-able for losses in profi t and resulting dama-ge thereof from the non-adherence to safe-or consumable products, which have been neither delivered nor certifi ed by bar.The products manufactured by bar GmbHare designed to give a long service life. They correspond to the state of the art for science and technology and are individu-ally tested in all functions before dispatch.The electrical and mechanical construction corresponds to valid standards and guide-lines. bar constantly carries out ongoing tests on the products and the marketplace,to ensure the further development and im-provement of their products.In case of faults and/or technical problems, please contact our service department. Wecan assure you, that immediate appropri-ate measures will be initiated. Valid hereare the Terms of Warranty from bar GmbH, which we will send to you upon request.The positurn2 is a positioner for mountingonto pneumatic actuators of the series known as the actubar series or actuators according to VDI/VDE 3845 with a pivoting angle of max. 180°. With the help of ex-ternal solenoid valves and compressed air,the positurn2 converts analog input signalsinto actuator pivoting movements. Usageas a 3-position control unit with freely se-Designated Usage:3Operating Instructionsbar-positurn2 on indicator without any activation.Any other application of this device is to beconsidered to be outside the designateduse. If you have any questions, or wouldlike to use the unit for another purpose,please contact our customer service de-partment. We will be pleased to help withthe necessary confi gurations.For this device, we undertake the warrantyof faultless condition for a duration of sixmonths within the framework of our Con-ditions of Warranty. Parts subject to wear-and-tear are excluded from this warranty.The claim is invalidated, when tampering iscarried out by persons who are hereby notauthorised by bar GmbH.Inside the warranty period of time, we willrepair damage or faults without cost, whichcan be provenly traced back to a factoryerror, insofar as this is registered by usimmediately upon discovery, at the latesthowever inside a time span of six monthsfollowing the date of delivery. The warrantycover will be made according to our estima-tion, through cost-free repair maintenanceof the faulty part(s) or exchange of thoseparts with faultless parts.Send the units, for which the claim againstwarranty is being made, carriage-paid andfore sending the goods.The owner/operator of this device has toensure that only persons who• k now the rules about safety at work andprevention of accidents• h ave been instructed in the operation ofthis device• h ave completely read and understoodthese instructionscan use and operate this device. Persons,who operate this device, are obliged:• t o observe all rules pertaining to safetyat work and the prevention of accidents• to read these instructions thoroughly.Persons to be seen as authorised, are tho-se with a successfully concluded professi-onal training, technical experience, as wellas knowledge of the appropriate standardsand guidelines, and who are in a position,to appreciate the tasks they are delegated,and lastly to recognise and act upon possi-ble dangers arising.Operators of the positurn2Persons to be seen as authorised, are tho-se who have been instructed in the opera-Guarantee:Obligations of the Customer:Authorised Personnel:4Operating Instructions bar-positurn2Personnel for Installation and Care Persons to be seen as authorised, are tho-se who have been instructed in the impor-tance and consequences of a positioner and have read and fully understood these instructions.In its standard form, the positurn2 is desi-gned & manufactured for actuators with a closing direction for valves in a clockwise manner (cw). The actuator undertakes the basic position with a closed valve. In the case of corresponding units, the basic position corresponds to so-called safety ef-fect ”current-free closed“In the initialisation process, the positioner adjusts to the defined actuator pivoting range. The analog activation is triggered from the control point and effects the pro-portional allocation of the defi ned pivoting angle to the set value (input) signal.In a similar manner, the defi ned pivoting angle is allocated an analog positioning signal.Binary signals are formed additionally at the start and end of the pivoting range. Electrical connection is made at terminal blocks inside the unit. Pneumatic connec-tion is made directly at the external sole-noid valves.• or directly onto actuators type actubar. Solenoid valves are fi tted to standard inter-faces with type-related material.Functional Description:5Operating Instructionsbar-positurn2Pivoting angle10° to 190°Protection Type IP 65Mounting position randomAmbient temperature-20°C to +70°CAmbient humidity10-90%, non-condensingWeight Without valve ca. 0,65 kgVa riant D Mini-valves: ca. 1,0 kg Midi-valves: ca. 1,1 kgVariant S Mini-valves: ca. 1,2 kg Midi-valves: ca. 1,4 kgVariant E Mini-valves: ca. 1,2 kg Midi-valves : ca. 1,4 kg Analog c ontrolsignalEffective direc-tionreversible by sliding switchActuating signal Signal type selectable 4-20 mA, 0-10 V, inverse polarity-protection, proportional to pivoting anglePre-resistor > 1 kOhm at 0-10 V; < 500 Ohm at 20mADead-zone± 2% of nominal pivoting angleTravel s peed Adjustable by t hrottles in solenoid valvesPosition s ignal Signal type selectable 4-20 mA, 0-10 V, nominal, active, inversepolarity protection, proportional pivoting angleResolution < 0,5% of nominal pivoting angleLimit feedback Voltage12-28 VDCSystem Opto-coupler, short-circuit-proof; 1 kOhm series &10 kOhm parallel resistance fittedIndication 3% of nominal pivoting angle b efore initiated endpositionSupply24 VDC (21 bto28 VDC), inverse polarity p rotectionPower Variant D Mini-valves: 1,8 W M idi-valves: 4,2 Wconsumption Variant S Mini-valves: 3,6 W M idi-valves: 7,2 WVariant E Mini-valves: 3,6 W M idi-valves: 7,2 W Terminal strip Clamping range up to 0,75 mm²Cable to P CS7 to 13 mm, 0,5 mm2, random cable lengthBinary inputsignalsON/OFF valves < 10 V for …0“;> 18 V for …1“Operating pres-sure2,5 to8 barAir Quality Filtered air acc. to DIN ISO 8573-1/Class 467Operating Instructionsbar-positurn2Delivery and Unpacking:Pneumatic scheme for positurn2 PN2-D PN2-E (single-acting) PN2-S (double-acting)Please note the unit-specifi c safety descriptions on pages 13 and 14.The unit is dispatched from bar and trans-ported by selected transport companies i.e. parcel services. At the point of arrival on your premises you should check the fol-lowing:• A re the number of packages that arrived the same as on the bar delivery note?• I s the packaging free from visible signs of damage?• A re the unit(s) and the accessories free from visible signs of damage?• A re there any signs of careless handling during transport (e.g. burn marks, scrat-ches, paint)?To be able to present all claims against the transport companies, you should do-cument all possible transport damage (e.g.with photographs and a written report), be-fore you unpack the unit. bar is not respon-sible in any way for transport damage and can not accept responsibility or liability in any way whatsoever.Carefully remove the transport packaging. Please observe all laws and regulations for the disposal of packaging materials.The positurn2 comes supplied with the external solenoid valve version D, S or E – depending on the actuator type and safety concept. There is a mounting bracket for mounting onto actuators with protruding shaft.Check the scope of delivery with the de-livery note and the order documentation.Controlling the Delivery:Scope of Delivery:Pneumatic schemes for the safety-orientated positurn2Operating Instructionsbar-positurn2Mounting, Electrical Connection, Initialising and Commissioning:MountingMounting may only be carriedout by suitably trained skilledpersons. Otherwise there is thedanger of an incorrect installa-tion.• O pen the positurn2 and set it onto theactuator.• T ake special care to avoid the entry ofdust, dirt and moisture getting into theopen housing of the positurn2 duringmounting & commissioning• G uide the base of the positioner into thecorresponding groove at the actuator.WARNING!89Operating Instructionsbar-positurn2Electrical Connection:Positionertake care to see that the symbol position coincides with the valve function.lead-throughs of the protective cover.Electrical installation may only be carried out by suitably quali fi ed & skilled persons.Otherwise there is a real dan-ger of electric shocks.WARNING!Operating Instructionsbar-positurn210Do not damage switch!123564Operating direction switch Potentiometer Initialising switchProgram Switch:1 = P ositioner mode ON = 3-Position modeCurrent / Voltage switches123456Set current / voltage switches according to the signal type for the unit.Initialising (learning the end positions and other specifi c data):Note:When initialising, the operating direction switchmust be set in accordance with the operating direction of the valve actuator, in order to ascertain the real func-tion correctly. In real operation, the operating direction switch may be adjusted when the increase in signal for special cases is to be changed.• Check whether the operating direction switch has been set in accordance with the operating direction of the actuator(L/ccw or R/cw).• Make the electrical connections accor-ding to the connection diagram.• Select program: 1:PositionerOn: 3-Positionmode• Set initialisation switch J0 to …Init“. • Establish power supply.fall 4 Status-LEDs illuminateorternating terminals 1 and 2 with terminal 13 (24 VDC).• T he end positions must be fully reached at least 2 times. Take care to see that the compressed air fl ow comes to a standstill.• C onnect digital input terminal 3. If there is no external digital input available for activating the function “Positioner“, layNot valid for 3-Position mode!• Set sliding switch J0 to …Run“. • S et the middle position at the 3-Position control unit via the integrated potentio-meter.f T he green status-LED illuminates and a yellow LED illuminates depending on the particular end position.Description of Safety Functions: Unit type: PN2-D• Digital Input Terminal 3 missing• C urrent supply Terminal 13 + 14 missing • Analog input Terminal 8 missing • Analog input Terminal 8 < 2mA Unit type: PN2-S• D igital Input Terminal 3 missing• C urrent supply Terminal 13 + 14 missing • Analog input Terminal 8 missing • Analog input Terminal 8 < 2mAUnit type: PN2-E• Digital Input Terminal 3 missing• C urrent supply Terminal 13 + 14 missing • Analog input Terminal 8 missing • Analog input Terminal 8 < 2mA f Valve stays in last positionf Valve stays in last positionf Valve stays in last positionf Valve stays in last positionf Valve moves to safety position f Valve moves to safety position f Valve moves to safety position f Valve moves to safety position f Valve moves to safety position f Valve moves to safety position f Valve moves to safety position f Valve moves to safety positionPositioner mode 4-20 mA:f Valve stays in last position f Valve stays in last position f Valve moves to safety position f Valve moves to safety position f Valve moves to safety position f Valve moves to safety position f Valve moves to safety position f Valve moves to safety positionf Valve stays in last positionf Valve stays in last position f Valve moves to safety position f Valve moves to safety position f Valve moves to safety position f Valve moves to safety position f Valve moves to safety position f Valve moves to safety position• C urrent supply Terminal 13 + 14 missing • Analog input Terminal 8 missing Unit type: PN2-S• Digital Input Terminal 3 missing • C urrent supply Terminal 13 + 14 missing • Analog input Terminal 8 missing Unit type: PN2-E• Digital Input Terminal 3 missing • C urrent supply Terminal 13 + 14 missing • Analog input Terminal 8 missingUnit type: PN2-3P-D• Digital Input Terminal 1, 2 + 3 missing • C urrent supply Terminal 13 + 14 missing Unit type: PN2-3P-S• Digital Input Terminal 1, 2 + 3 missing • D igital Input Terminal 1, 2 + 3 missing Longer than 3 seconds• Current supply Terminal 13 + 14 missing Unit type: PN2-3P-E • D igital Input Terminal 1, 2 + 3 missing • D igital Input Terminal 1, 2 + 3 missing Longer than 3 seconds • C urrent supply Terminal 13 + 14 missing3-Position mode:actuator and valve compo-nents! Set and secure the me-chanical end positions of the actuator.E nd positionadjustment screwsThrottlesUse the throttles at the pneumatic valves to set the actuating speed of the actuator. Standard setting: minimum 5 seconds pivoting time for 90° pivoting angle.• I f so required, shorten the cable in the solenoid valve wiring or coil it together in a tidy manner and bind toge-ther with cable-ties.• I f so required, the coils in the solenoid valves can be ex-changed. Take note here to keep the same cabling sys-tem and to initialise anew. • D o not close the throttle com-pletely; the consequence will be that no actuator function will follow.• W hen using manual operation at the pneumatic valves you have to return them to the in-itial position afterwards.• A fter every change in the end position and re-assembling the actuator, do not forget to make a new initialization.12ATTENTION!2Never use aggressive clea-ners or materials to clean the housing of the positurn2. This can lead to damage to the vie-wing glass or paintwork.• C lean the housing of the positurn2 with a clean, slightly moistened cloth.• I n the case of hardened-on dirt, use a normal household cleaner according to the instructions on the packaging on the cleaner.Never open the protective co-ver above the delicate electro-nics. This can lead to damage to the unit and the loss of all warranty claims.• T he positurn2 works maintenance-free. In case of defects, which take place in-side the warranty time, remove the po-siturn2, and after telephoning us, send it to the address as shown on the rear side.electrical connection data in the operating instructions has to be strictly adhered to.Manufacturer: bar GmbH • Auf der Hohl • 53547 Dattenberg Machine Description: bar-positurn2Machine Type:PN2-D, PN2-E, PN2-S, PN2-3P-D, PN2-3P-E, PN2-3P-S Appropriate EC Guidelines:EMV Guidelines 89/336/EWGUsed Standards and TechnicalSpecifi cations: EN61000-4-1:2001EN 61000-4-2:2001EN 61000-4-3:2001 and A11:2004EN 61000-4-4:2001EN 61000-4-5:2001EN 61000-4-6:2001EN 61000-6-3:2001EN 61000-6-4:2001V DI/VDE 3845 (Interfaces Valves, Actuators,Auxiliary Devices)Dattenberg, 01.02.2011 © bar pneumatische Steuerungssysteme GmbHbar pneumatischeSteuerungssysteme GmbHAuf der Hohl 153547 Dattenberg/Germany Tel. +49 (0) 2644 - 96070Fax +49 (0) 2644 - 960735www.bar-gmbh.de sales@T e c h n i c a l d e v e l o p m e n t a n d c h a n g e o f d a t a s i s r e s e r v e d . © b y b a r G m b H – 03/2011www.bar-gmbh.de。

导航一体机用户手册江苏天泽信息产业股份有限公司2011年5月目录声明事项 (4)注意事项 (5)阅读说明 (5)1概述 (6)1.1技术规格 (6)1.1.1GPS接收性能 (6)1.1.2物理性能 (7)2基本操作 (7)2.1操作方式 (7)2.2系统关机 (7)2.3界面介绍 (8)2.3.1主菜单界面 (8)2.3.2GSM信号和SIM卡检测 (8)2.3.3GPRS连接状态 (9)3具体操作 (9)3.1汽车导航 (9)3.2一键通 (9)3.3扩展应用 (10)3.3.1IC卡登录 (11)3.3.2条形码扫描 (11)3.3.3RFID (12)3.4CAN信息 (13)3.5摄像头 (14)3.6电话短信 (15)3.6.1电话 (16)3.6.2拨号 (17)3.6.3电话簿 (18)3.6.4通话记录 (20)3.6.5短消息 (20)3.6.6写消息 (21)3.6.7收件箱 (23)3.6.8发件箱 (24)3.6.9草稿箱 (25)3.7娱乐 (26)3.7.1视屏播放 (26)3.7.2音乐播放 (28)3.7.3图片浏览 (29)3.7.4电子书阅览 (30)3.8调度信息 (31)3.8.1中心信息 (31)3.8.2救援信息 (32)3.8.3定期定点 (36)3.9收音机 (40)3.10系统设置 (41)3.10.1路径设置 (42)3.10.2背光设置 (43)3.10.3按键声音 (44)3.10.4一键通设置 (44)3.10.5星历信息 (45)3.10.6IP设置 (46)3.10.7系统信息 (46)4软件升级 (48)5附录 (48)5.1运输与存储 (48)5.2保养与维护 (48)声明事项声明1:全球卫星定位系统(GPS)是由美国政府所控制的,也是由美国政府来保证其精确度以及进行维护的。

如果该系统进行改动,将会影响所有GPS设备的精度和性能。