丙烷脱氢(PDH)介绍 PPT

- 格式:ppt

- 大小:5.40 MB

- 文档页数:38

2015/7/24丙烷脱氢工程经验介绍PROPANE DEHYDROGENATION (PDH) PROJECT EXPERIENCEsnec丙烷脱氢工程经验介绍PROPANE DEHYDROGENATION (PDH) PROJECT EXPERIENCE概况INTRODUCTION宁波海越丙烷与混合碳四利用项目是浙江省和宁波市“十二五”重点建设项目,项目位于浙江省宁波市北仑青峙工业园区,主要工艺装置有:气分、丙烷脱氢、甲乙酮、异辛烷及配套的锅炉、罐区、循环水场、空分等设施。

其中,丙烷脱氢装置是该项目的核心工艺装置,也是目前国内外已建成的同类最大规模装置之一。

概况INTRODUCTION装置概况如下:生产能力:60万吨/年(单线);产品纯度≥99.6wt%;小时产量:75吨/小时。

操作弹性:60~110%操作时数:连续运行8000小时/年。

技术来源:美国CB&I LUMMUS公司CATOFIN丙烷脱氢工艺。

设计及总承包方:中石化宁波工程公司采取EPC总承包模式,承担丙烷脱氢装置的工程设计(基础工程设计+详细工程设计)、采购、施工(含大型设备吊装)和开车服务等各项工作。

工艺技术及流程TECHNOLOGY & PROCESS本装置引进美国CB&I LUMMUS公司的CATOFIN丙烷脱氢工艺。

该工艺以丙烷为原料,采用高效的铬系脱氢催化剂在八台固定床反应器中进行脱氢反应,再经低温回收及产品精制后,得到聚合级丙烯产品。

该工艺具有丙烷转换率高、丙烯选择性好、原料适应性强及装置在线率高等优点。

⏹反应单元⏹产品压缩单元⏹低温回收单元⏹产品精制单元⏹丙烯制冷单元⏹乙烯制冷单元⏹废水汽提单元•按照工艺流程的要求、物料介质的特性和设备的类型进行布置。

•PDH工艺装置占地长×宽:320m×110m 占地面积:35200平方米注:装置占地不包括配套的公用工程、变电所、仪表机柜间、循环水场等。

丙烷脱氢副产氢摘要:一、丙烷脱氢概述二、丙烷脱氢副产氢的工艺过程三、丙烷脱氢副产氢的应用领域四、丙烷脱氢副产氢的发展前景五、总结正文:一、丙烷脱氢概述丙烷脱氢(PDH,Propane Dehydrogenation)是一种重要的石油化工工艺,其主要目的是通过脱氢反应将丙烷(C3H8)转化为丙烯(C3H6)。

在这个过程中,副产物氢气(H2)被同时产生。

丙烷脱氢副产氢在全球范围内得到了广泛关注,因为它具有较高的经济价值和环保意义。

二、丙烷脱氢副产氢的工艺过程丙烷脱氢副产氢的工艺过程主要包括以下几个步骤:1.原料准备:将丙烷作为原料,经过过滤、干燥等预处理,确保原料的纯净度。

2.脱氢反应:将预处理的丙烷送入脱氢反应器,在高温(约400-600℃)和催化剂的作用下,丙烷发生脱氢反应,生成丙烯和氢气。

3.产物分离:反应产物经过冷却、分离,将丙烯和氢气分离出来。

4.氢气提纯:对副产物氢气进行提纯,以满足不同应用领域的纯度要求。

5.产品应用:将提纯后的氢气应用于各个领域,如石油精炼、化学工业、燃料电池等。

三、丙烷脱氢副产氢的应用领域1.石油精炼:丙烷脱氢副产氢可用于石油精炼过程中的加氢脱硫、加氢裂化等工艺。

2.化学工业:丙烷脱氢副产氢可用于生产氨、甲醇、合成橡胶等化学品。

3.燃料电池:氢气作为燃料电池的燃料,具有高能量密度、无污染等优点。

4.氢能交通:氢气作为新能源汽车的燃料,可实现零排放,有利于改善环境质量。

四、丙烷脱氢副产氢的发展前景随着全球对环保和能源转型的关注,丙烷脱氢副产氢的发展前景十分广阔。

一方面,丙烷脱氢副产氢可以缓解石油资源短缺问题,提高石油化工行业的可持续发展能力;另一方面,丙烷脱氢副产氢有助于推动氢能产业的发展,实现能源结构的优化。

五、总结丙烷脱氢副产氢作为一种清洁、高效的能源,具有广泛的应用前景。

通过优化丙烷脱氢副产氢的工艺过程,提高氢气纯度和产量,有望为我国能源化工行业注入新的活力。

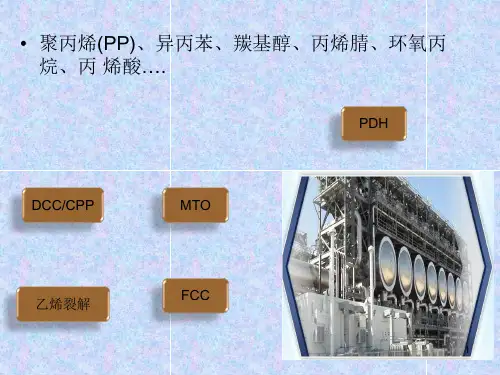

丙烷脱氢2020年1月PROPANE DEHYDROGENATION一、丙烷脱氢反应机理二、轻烃催化脱氢历史变迁三、丙烷脱氢催化剂四、丙烷脱氢主要工艺技术五、丙烷脱氢的工程特点提纲丙烯生产技术FCC DCC/CPP MTO PDH乙烯裂解一、丙烷脱氢反应机理从丙烷脱氢到丙烯•反应表观方程式:C3H8 C3H6+ H2•热裂解脱氢:传统的蒸汽热裂解装置(乙烯装置),C-C和C-H打断,生产乙烯和丙烯。

温度800~920℃,转化率~93%,乙烯收率~42%,丙烯~17%。

•催化脱氢:所谓的“丙烷脱氢”,温度590~630℃,单程转化率33%~44%,选择性~86%。

一、丙烷脱氢反应机理丙烷脱氢制丙烯反应•平衡反应:C3H8C3H6+ H2(吸热)•反应产物、副产物:H2, CH4, C2H4, C2H6, C3H6, C3H8, C4+•热力学性质决定:(1)吸热反应;(2)平衡常数随温度的升高而增大;适当适当的高的反应温度(3)分子数增加的可逆反应;反应压力越低越有利.因此,提高反应温度和降低压力有利于反应向正方向进行;但反应温度过高将造成非催化热裂和深度脱氢反应加剧,导致选择性降低。

通常催化脱氢反应温度控制在590~630 ℃。

温度-热裂解副反应曲线一、丙烷脱氢反应机理轻烃催化脱氢历史变迁•催化剂相同,脱氢温度不同。

•上世纪60年代,正丁烷脱/异丁烷脱氢盛极一时,以获得丁二烯/异丁烯;随着热裂解制乙烯/丙烯并副产丁二烯/异丁烯(即统称的乙烯装置)的发展,催化脱氢制烯烃渐渐退出市场。

•近年来随着乙烯装置原料轻质化,丙烯相对的缺口增大,丙烷脱氢开始兴起。

异丁烷脱氢制异丁烯正丁烷脱氢制丁二烯异丁烷脱氢制异丁烯二、轻烃催化脱氢历史变迁三、丙烷脱氢催化剂丙烷脱氢催化主要有以下几种:铬系催化剂,如Catofin工艺采用的催化剂;铂系催化剂,如Olefex工艺采用的催化剂;氧化脱氢类催化剂。

(氧化脱氢是指在催化剂作用下采用适当的氧化剂与丙烷反应生成丙烯与水,其焓变小于零,为放热反应,无需外界加热、节省能源,与催化脱氢过程相比,可以克服热力学平衡的限制并降低催化剂的减活作用。

丙烷脱氢单原子pt催化剂Propane dehydrogenation (PDH) is a process that involves the removal of a single hydrogen atom from propane to produce propylene. This reaction is typically catalyzed by platinum (Pt) catalysts. In this response, I will provide a detailed explanation of the PDH process, discussing its importance, reaction mechanism, catalyst requirements, and potential challenges.Firstly, it is important to understand the significance of propane dehydrogenation. Propylene is a key building block in the petrochemical industry, used in the production of various products such as plastics, synthetic fibers, and rubber. The PDH process allows for the conversion of propane, a readily available and relatively inexpensive feedstock, into a more valuable product. This makes it an economically attractive process for propylene production.The reaction mechanism of propane dehydrogenation involves the removal of a hydrogen atom from propane,resulting in the formation of propylene. This reaction is typically carried out at high temperatures (around 500-600°C) to facilitate the breaking of the carbon-hydrogen bonds. The platinum catalyst provides the necessary activation energy for the reaction to occur at these temperatures. It acts as a surface for the adsorption and activation of propane molecules, promoting the removal of a hydrogen atom.The choice of platinum as a catalyst for propane dehydrogenation is based on its unique properties. Platinum is known for its high catalytic activity and selectivity towards the dehydrogenation reaction. It has a high surface area, allowing for a greater number of active sites for propane adsorption and reaction. Additionally, platinum exhibits excellent thermal stability, maintaining its catalytic activity even at high temperatures. These characteristics make platinum an ideal catalyst for PDH.However, the use of platinum catalysts in propane dehydrogenation also presents some challenges. One major challenge is the deactivation of the catalyst due to carbondeposition. During the reaction, carbonaceous species can adsorb onto the platinum surface, blocking the active sites and reducing the catalytic activity. To overcome this issue, catalyst regeneration methods, such as oxidative or steam treatments, are employed to remove the carbonaceousdeposits and restore the catalyst activity.Another challenge in PDH is the control of selectivity. While platinum catalysts are highly selective towards propylene formation, there is also a tendency for side reactions, such as cracking and hydrogenation, to occur. These side reactions can lead to the formation of undesired byproducts and decrease the overall yield of propylene. Catalyst design and optimization, along with appropriate reaction conditions, are crucial in achieving highselectivity towards propylene.In conclusion, propane dehydrogenation with Ptcatalysts is a vital process for the production of propylene. It offers a cost-effective and efficient routefor converting propane into a valuable chemical building block. The platinum catalyst provides the necessarycatalytic activity and selectivity for the dehydrogenation reaction. However, challenges such as catalyst deactivation and control of selectivity need to be addressed for the successful implementation of PDH. Overall, PDH with Pt catalysts plays a significant role in the petrochemical industry and contributes to the production of various essential products.。