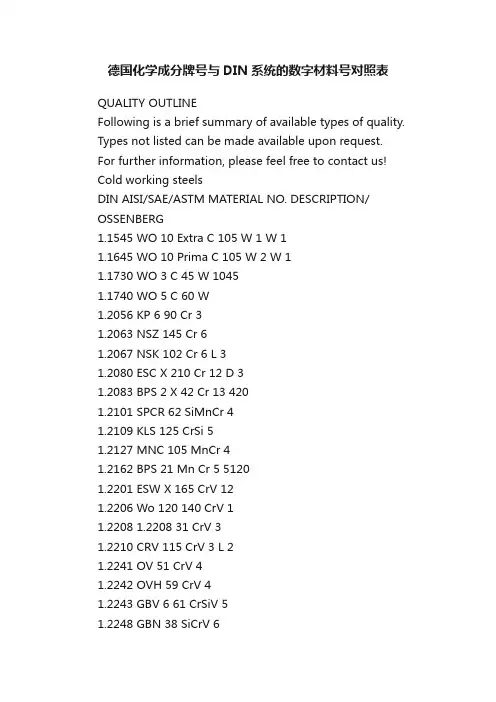

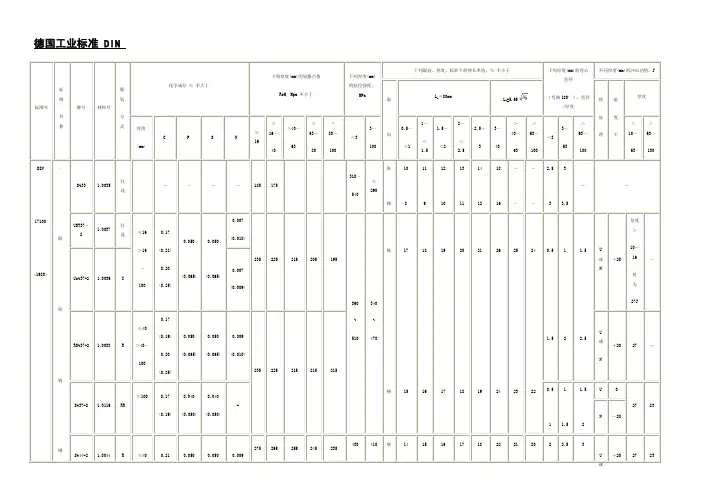

德国标准化学成分对照表

- 格式:xls

- 大小:17.00 KB

- 文档页数:1

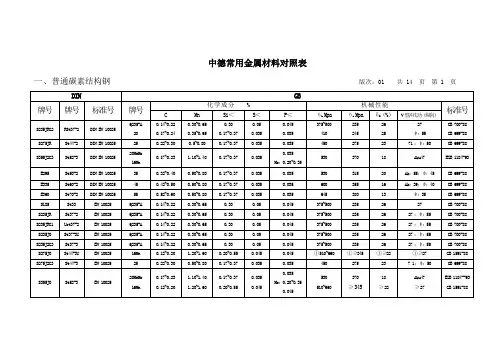

中德常用金属材料对照表

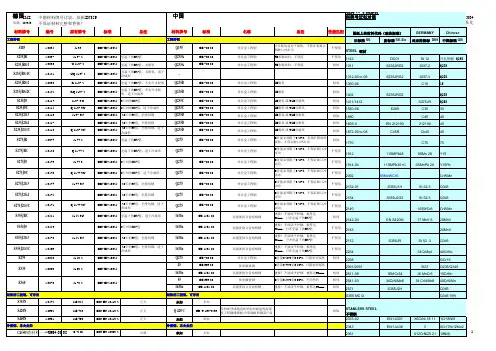

一、普通碳素结构钢版次:01 共 14 页第 1 页

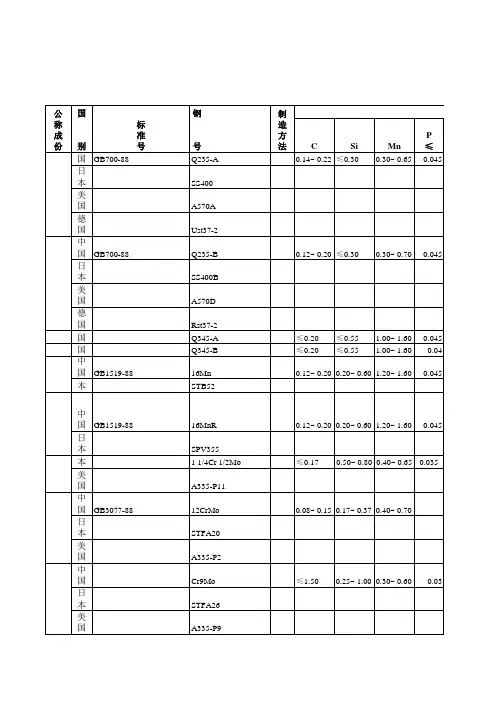

一、碳素结构钢版次:01 共 14 页第 2 页

注:

(a)V:调质处理;

(b)①为调质处理时参数。

一、碳素结构钢版次:01 共 14 页第 3 页

注:

N:正火。

二、合金结构钢版次:01 共 14 页第 4 页

①截面≤100时,调质;②截面≤ 120时,调质;③截面 15时,调质;④截面25时,调质;⑤截面30时,调质。

三、灰口铸铁:球墨铸铁Grey cast iron;nodular cast irou版次:01 共 14 页第 5页

四、铸钢 Casting steel版次:01 共 14 页第 6 页

四、铸钢 Casting steel版次:01 共 14 页第 7 页

注:①正火+回火;②调质。

六、弹簧钢Spring steel 版次:01 共14 页第9 页

七、无缝钢管用碳素钢 Carbon steel for seamless steel tube版次:01 共 14 页第 10 页

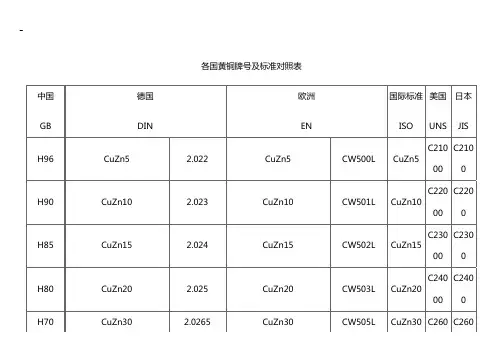

八、有色金属材料 non-ferrous metal maerial 版次:01 共 14 页第11 页

八、有色金属材料 non-ferrous metal maerial版次:01 共 14 页第13 页

注:S—砂型铸造;J—金属型铸造;Li—离心铸造;La—连续铸造

九、轴承钢 Bearing Steel 版次:01 共 14 页第 14 页。

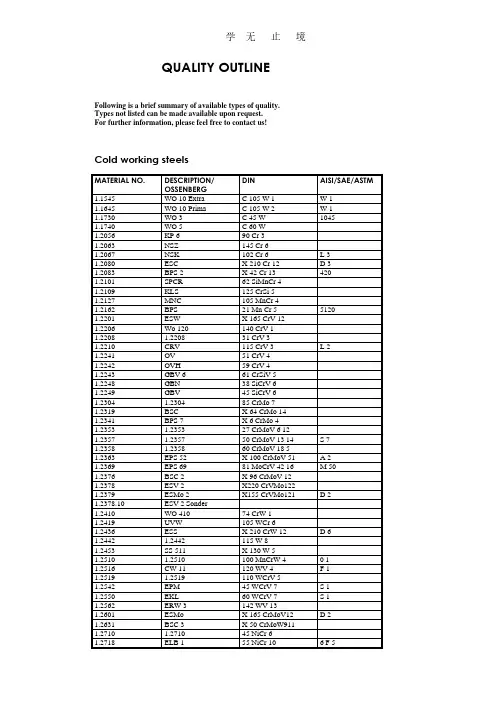

德国化学成分牌号与DIN系统的数字材料号对照表QUALITY OUTLINEFollowing is a brief summary of available types of quality. Types not listed can be made available upon request. For further information, please feel free to contact us! Cold working steelsDIN AISI/SAE/ASTM MATERIAL NO. DESCRIPTION/ OSSENBERG1.1545 WO 10 Extra C 105 W 1 W 11.1645 WO 10 Prima C 105 W 2 W 11.1730 WO 3 C 45 W 10451.1740 WO 5 C 60 W1.2056 KP 6 90 Cr 31.2063 NSZ 145 Cr 61.2067 NSK 102 Cr 6 L 31.2080 ESC X 210 Cr 12 D 31.2083 BPS 2 X 42 Cr 13 4201.2101 SPCR 62 SiMnCr 41.2109 KLS 125 CrSi 51.2127 MNC 105 MnCr 41.2162 BPS 21 Mn Cr 5 51201.2201 ESW X 165 CrV 121.2206 Wo 120 140 CrV 11.2208 1.2208 31 CrV 31.2210 CRV 115 CrV 3 L 21.2241 OV 51 CrV 41.2242 OVH 59 CrV 41.2243 GBV 6 61 CrSiV 51.2248 GBN 38 SiCrV 61.2304 1.2304 85 CrMo 71.2319 BSC X 64 CrMo 141.2341 BPS 7 X 6 CrMo 41.2353 1.2353 27 CrMoV 6 121.2357 1.2357 50 CrMoV 13 14 S 7 1.2358 1.2358 60 CrMoV 18 51.2363 EPS 52 X 100 CrMoV 51 A 2 1.2369 EPS 69 81 MoCrV 42 16 M 50 1.2376 BSC 2 X 96 CrMoV 121.2378 ESV 2 X220 CrVMo1221.2379 ESMo 2 X155 CrVMo121 D 2 1.2378.10 ESV 2 Sonder1.2410 WO 410 74 CrW 11.2419 UVW 105 WCr 61.2436 ESS X 210 CrW 12 D 61.2442 1.2442 115 W 81.2453 SS 511 X 130 W 51.2510 1.2510 100 MnCrW 4 0 1 1.2516 CW 11 120 WV 4 F 11.2519 1.2519 110 WCrV 51.2542 EPM 45 WCrV 7 S 11.2550 EKL 60 WCrV 7 S 11.2562 ERW 3 142 WV 131.2601 ESMo X 165 CrMoV12 D 2 1.2631 BSC 3 X 50 CrMoW9111.2710 1.2710 45 NiCr 61.2718 ELB 1 55 NiCr 10 6 F 51.2721 ELB 50 NiCr 131.2735 NE 35 15 NiCr 141.2764 ECNK X 19 NiCrMo 4 P 211.2766 ELB 3 35 NiCrMo 161.2767 ELB Spezial X 45 NiCrMo 4 6 F 7 1.2823 SP 70 Si 71.2826 SP 2 60 MnSiCr 4 S 41.2833 KP 100 V 1 W 2101.2835 KP Extra 95 V 41.2838 V 35 145 V 331.2842 UVW 2 90 MnCrV 8 0 21.2880 ESS Spezial X 165 CrCoMo12 1.2884 ESS 1 X 210 CrCoW 121.2900 EKL Spezial1.2901 ESSW1.2902 VSC1.2929 Pr?gnant1.2937 KRO 11.2939 He 1Hot working steels1.2323 WPS 2 48 CrMoV 671.2343 EPS 51 X 38 CrMoV 51 H 111.2344 EPS 51 V X 40 CrMoV 51 H 13 1.2345 1.2345 X 50 CrMoV 511.2360 1.2360 X 48 CrMoV 811 Chipper 1.2362 EPS 62 X 63 CrMoV 511.2365 EPS 33 X 32 CrMoV 33 H 101.2367 EPS 53 X 38 CrMoV 53 H 10 + Cr 1.2360.11 1.2360 Sonder1.2362.11 1.2362 Sonder1.2390 1.2390 X 82 CrVMo 8321.2547 EPS 25 45 WCrV 771.2564 EPS 35 X 30 WCrV 411.2567 EPS 45 X 30 WCrV 17-21.2581 EPS X 30 WCrV 93 H 211.2581.01 EPS Sonder1.2603 WPMV 45 CrMoW 581.2606 EPSW 51 X 37 CrMoW 51 H 121.2622 EPD X60 WcrMoV 941.2662 EPSK 2 X 30 WcrCoV 931.2678 1.2678 X45 CoCrWV555 H 191.2709 1.2709 X3NiCoMoTi18951.2713 WPS 55 NiCrMoV 6 L 61.2714 WPS 1 56 NiCrMoV 7 L 61.2726 1.2726 26 NiCrMoV 51.2740 WPS 3 28 NiCrMoV 101.2743 WPS 1 Ni 3 60 NiCrMoV 1241.2744 1.2744 57 NiCrMoV 771.2746 1.2746 45 NiCrMoV 166 6 F 7 + V + Mo 1.2747 1.2747 28 NiMo 171.2782 1.2782 X 16CrNiSi 2520 3141.2786 1.2786 X 13NiCrSi 3616 303301.2885 1.2885 X32CrMoCoV333 H 10 A1.2886 1.2886 X15CrCoMoV101051.2888 1.2888 X20CoCrWMo1091.2889 EPS 71 X45CoCrMoV553 H 19 A1.2906 EPDMo1.2930 1.29301.2932 1.29321.2935 1.29351.2960 1.29601.2965 1.29651.2968 VSW1.2974 1.29741.2978 1.2978High-speed working steels1.3202 K 5 S 12-1-4-5 T 151.3207 K 10 Spezial S 10-4-3-10 T 421.3211 K 3 S 12-1-2-31.3243 DMo 5 Co S 6-5-2-5 M 351.3245 1.3245 S 6-5-2-5 S M 35 + S 1.3246 1.3246 S 7-4-2-5 M 411.3247 1.3247 S 2-10-1-8 M 421.3249 1.3249 S 2-9-2-8 M 331.3255 K 5 W S 18-1-2-5 T 41.3257 K 15 S 18-1-2-151.3265 K 10 S 18-1-2-10 T 51.3302 EH 0000 S 12-1-41.3316 EH 00 S 9-1-21.3318 EH 000 S 12-1-21.3333 EHV S 3-3-21.3342 DMo 5 C SC 6-5-2 M 31.3343 DMo 5 S 6-5-2 M 21.3344 DMo 5 V S 6-5-3 M 3 Class 2 1.3346 BMo 9 S 2-9-1 M 11.3348 1.3348 S 2-9-2 M 71.3355 EH 0018 S 18-0-1 T 11.3357 EH 0018 Mo S 18-1-11.3990 K 18 S 18-12-18Stainless and acid-resistant steels1.4000 1.4000 X 6 Cr 13 410 S1.4001 RF 1 X 7 Cr 14 410 S1.4016 RFS 1 X 6 Cr 17 4301.4021 RF 3 X 20 Cr 13 4201.4024 RF 2 X 15 Cr 13 4031.4034 RF 4 X 46 Cr 13 4201.4057 RFS 4 X 17 CrNi 162 4311.4104 RFS 3 X 14 CrMoS17 430 F 1.4109 1.4109 X 70 CrMo 15 440 A 1.4110 1.4110 X 55 CrMo 141.4111 RFSH 1 X 110 CrMoV151.4112 RFSH 2 X 90 CrMoV18 440 B 1.4116 RFSH 5 X 50 CrMoV151.4120 RF 5 X 20 CrMo 131.4122 RFSH 4 X 39 CrMo 171 431 1.4125 RFSH 6 X 105 CrMo 17 440 C 1.4136 1.4136 X 70 CrMo 2921.4138 1.4138 X 120 CrMo2921.4301 SB 2 X 5 CrNi1810 3041.4305 1.4305 X 10 CrNiS189 303 1.4401 SB 5 X5CrNiMo17122 316 1.4460 SB 9 X4CrNiMoN2752 329 1.4510 RFS 2 X 3 CrTi 17 430 Ti1.4512 1.4512 X 2 CrTi 12 4091.4528 RFSH 7 X105CrCoMo1821.4535 RFSH 3 X90CrCoMoV171.4541 SB 3 X6 CrNiTi 1810 3211.4542 RFS 5 X 5CrNiCuNb164 630 1.4550 SB 4 X6CrNiNb 1810 3471.4571 SB 6 X6CrNiMoTi17122 316 Ti1.4580 SB 7 X6CrNiMoNb17122 316 CBHeat-resistant steels1.3912 Ni 36 Ni 361.3917 Ni 42 Ni 421.4713 Hi 1 X 10 CrAl 71.4721 1.4721 X 215 Cr 121.4724 Hi 2 X 10 CrAl 131.4742 Hi 3 X 10 CrAl 18 4301.4762 Hi 4 X 10 CrAl 24 4461.4821 Hi 10 X 20CrNiSi 254 3271.4828 Hi 21 X 15CrNiSi 2012 3091.4841 Hi 22 X 15 CrNiSi 2520 3101.4842 1.4842 X 12 CrNi2520 310 S1.4845 1.4845 X 12 CrNi 2521 XM 121.4864 Hi 23 X 12 NiCrSi3616 303301.4873 1.4873 X45CrNiW 1891.4878 Hi 20 X 12 CrNiTi189 3211.4885 Hi 24 X12CrNiMoNb20151.4923 1.4923 X22CrMoV 1211.4939 1.4939 X12CrNiMo 12 A 565 (XM32) Constructional and heat-treated steels1.5122 1.5122 37 Mn Si 51.5662 1.5662 X 8 Ni 9 A 333 Grade 8 1.5860 ECN 45 14 NiCr 181.5864 NV 45 35 NiCr 181.6545 1.6545 30 NiCrMo 221.6742 1.6742 20 NiCrMo1461.6926 1.6926 38NiCrMoV73 43371.6958 1.6958 26NiCrMo1461.7006 1.7006 46 Cr 21.7325 1.7325 25 MoCr 41.7335 1.7335 13 Cr Mo 44 A 336 F 12 1.7362 1.7362 12 CrMo 195 A 182-78 F 5 1.7709 1.7709 21 CrMoV 571.7711 1.7711 40 CrMoV 471.7733 1.7733 24 CrMoV551.8161 1.8161 58 CrV 4。

耐热铸钢和热强铸钢标准对照表:

标准内容:

5.3.3 耐热铸钢和热强铸钢*

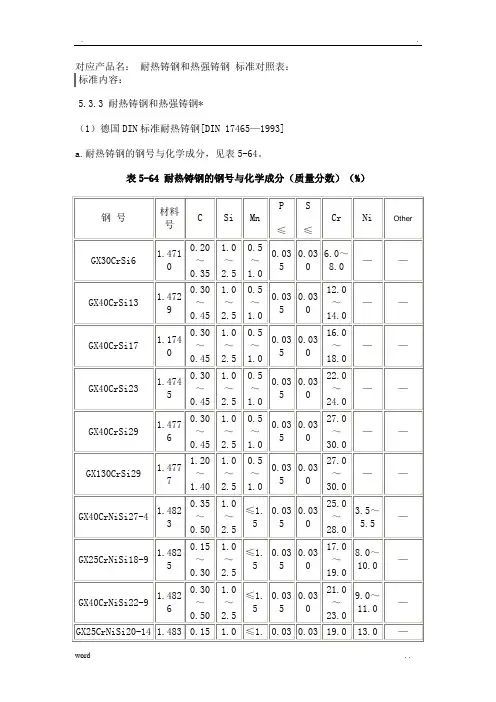

(1)德国DIN标准耐热铸钢[DIN 17465—1993]

a.耐热铸钢的钢号与化学成分,见表5-64。

表5-64 耐热铸钢的钢号与化学成分(质量分数)(%)

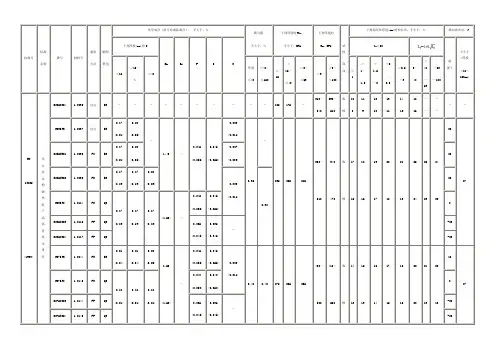

b.耐热铸钢的室温力学性能,见表5-56。

表5-56 耐热铸钢的室温力学性能

c.耐热铸钢的高温力学性能,见表5-66。

表5-66 耐热铸钢的高温力学性能

(2)德国DIN标准铁素体热强铸钢[DIN 17245—1987]

a.铁素体热强铸钢的钢号与化学成分,见表5-67。

表5-67 铁素体热强铸钢的钢号与化学成分(质量分数)(%)

b.铁素体热强铸钢的力学性能,见表5-68。

表5-68 铁素体热强铸钢的力学性能。

标准号标准名称牌号材料号脱氧方法钢的类别化学成分(括号内成品成分),不大于,%碳当量不大于,%下列厚度的R eH,不小于,MPa下列厚度的Rm,MPa试样取向下列标距和厚度(mm)的伸长率,不小于,%纵向冲击功,J 下列厚度(mm)的CMn Si P S NL0=80温度℃不小于(厚度>10~150mm)≤16>16~≤>40厚度≤40>40~≤150≤16>16~≤40>40~≤63<3≥3~≤100≤1>1~1.5>1.5~2>2~2.5>2.5~33~40>40~63>63~100EN 10025(1993)非合金结构钢热轧产品供货技术条件S235J2G4 1.0035自定BS----------185175-310~540290~510纵横1081191210131114121816------S235JR 1.0037自定BS0.17(0.21)0.20(0.25)-1.40-0.045(0.055)0.045(0.055)0.009(0.011)0.35-235225215360~510340470纵横171518161917201821192624252324222027 S235JRG1 1.0036FU BS0.17(0.21)0.20(0.25)0.007(0.009)20 S235JRG2 1.0038FN BS0.17(0.19)0.17(0.19)0.20(0.23)0.009(0.011)0.3820S235J0 1.0114FN QS0.17(0.19)0.17(0.19)0.17(0.19)(1.50)-0.045(0.055)0.045(0.055)0 S235J2G3 1.0116FF QS0.035(0.045)0.035(0.045)--20 S235J2G4 1.0117FF QS-20 S275JR 1.0044FN BS0.21(0.24)0.21(0.24)0.22(0.25)1.50(1.60)-0.045(0.055)0.045(0.055)0.009(0.011)0.400.42275265255430~580410~560纵横141215131614171518162220211920181027 S275J0 1.0143FN QS0.18(0.21)0.18(0.21)0.18(0.21)0.040(0.050)0.040(0.050)0 S275J2G3 1.0144FF QS0.035(0.045)0.035(0.045)--20 S275J2G4 1.0145FF QS-20S355JR 1.0045FN BS0.240.240.241.60 (1.70)0.55(0.60)0.045(0.055)0.045(0.055)0.009(0.011)0.450.47355345335510~680490~630纵横141215131614171518162220211920182027S355J0 1.0553FN QS0.20 (0.23)0.20(0.23)0.22(0.24)0.040(0.050)0.040(0.050)S355J2G3 1.0570FF QS0.035 (0.045)0.035(0.045)--20S355J2G4 1.0577FF QS-20S355K2G3 1.0595FF QS-2040 S355K2G4 1.0596FF QS-20E295 1.0050FN BS-----0.045(0.055)0.045(0.055)0.009(0.011)--295285275490~660470~610纵横12101311141215131614201819171816--E335 1.0060FN BS-----0.045(0.055)0.045(0.055)0.009(0.011)--335325215590~770590~710纵横86971081191210161415131412--E360 1.0070FN BS-----0.045(0.055)0.045(0.055)0.009(0.011)--360355345690~900670~830纵横4354657687111010998--备注:1.表中脱氧方法符号含义为:FU=沸腾钢;FN=不允许用沸腾钢;FF=完全镇静钢,它含有足以将游离氮全部固定的固氮元素(例如含0.020%Al)。

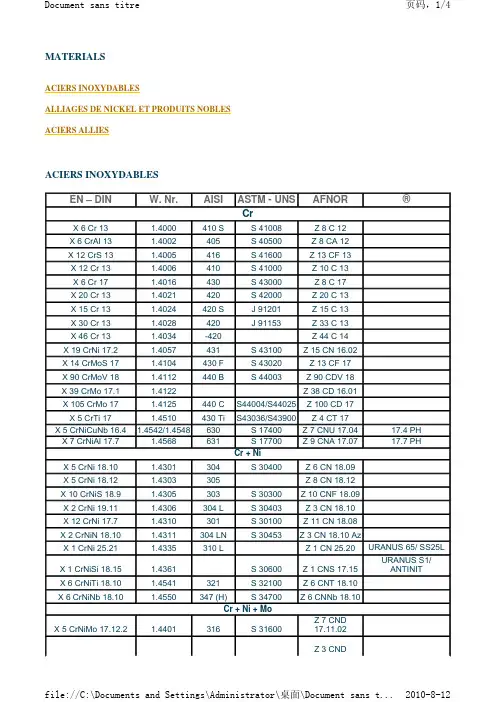

MATERIALSACIERS INOXYDABLESALLIAGES DE NICKEL ET PRODUITS NOBLESACIERS ALLIESACIERS INOXYDABLESEN – DIN W. Nr.AISI ASTM - UNS AFNOR®CrX 6 Cr 13 1.4000410 S S 41008Z 8 C 12X 6 CrAl 13 1.4002405S 40500Z 8 CA 12X 12 CrS 13 1.4005416S 41600Z 13 CF 13X 12 Cr 13 1.4006410S 41000Z 10 C 13X 6 Cr 17 1.4016430S 43000Z 8 C 17X 20 Cr 13 1.4021420S 42000Z 20 C 13X 15 Cr 13 1.4024420 S J 91201Z 15 C 13X 30 Cr 13 1.4028420J 91153Z 33 C 13X 46 Cr 13 1.4034-420Z 44 C 14X 19 CrNi 17.2 1.4057431S 43100Z 15 CN 16.02X 14 CrMoS 17 1.4104430 F S 43020Z 13 CF 17X 90 CrMoV 18 1.4112440 B S 44003Z 90 CDV 18X 39 CrMo 17.1 1.4122Z 38 CD 16.01X 105 CrMo 17 1.4125440 C S44004/S44025 Z 100 CD 17X 5 CrTi 17 1.4510430 Ti S43036/S43900Z 4 CT 17X 5 CrNiCuNb 16.4 1.4542/1.4548630S 17400Z 7 CNU 17.0417.4 PHX 7 CrNiAl 17.7 1.4568631S 17700Z 9 CNA 17.0717.7 PHCr + NiX 5 CrNi 18.10 1.4301304S 30400Z 6 CN 18.09X 5 CrNi 18.12 1.4303305Z 8 CN 18.12X 10 CrNiS 18.9 1.4305303S 30300Z 10 CNF 18.09X 2 CrNi 19.11 1.4306304 L S 30403Z 3 CN 18.10X 12 CrNi 17.7 1.4310301S 30100Z 11 CN 18.08X 2 CrNiN 18.10 1.4311304 LN S 30453Z 3 CN 18.10 AzX 1 CrNi 25.21 1.4335310 L Z 1 CN 25.20URANUS 65/ SS25LX 1 CrNiSi 18.15 1.4361S 30600Z 1 CNS 17.15URANUS S1/ ANTINITX 6 CrNiTi 18.10 1.4541321S 32100Z 6 CNT 18.10 X 6 CrNiNb 18.10 1.4550347 (H)S 34700Z 6 CNNb 18.10Cr + Ni + MoX 5 CrNiMo 17.12.2 1.4401316S 31600Z 7 CND 17.11.02 Z 3 CNDX 2 CrNiMo 17.13.2 1.4404316 L S 3160318.12.02X 2 CrNiMoN 17.12.2 1.4406316 LN S 31653Z 3 CND 17.11AzX 2 CrNiMoN 17.13.3 1.4429316 LN(Mo+)(S 31653)Z 3 CND 17.12AzX 2 CrNiMo 18.14.3 1.4435316 L(Mo+)S 31609Z 3 CND18.14.03X 5 CrNiMo 17.13.3 1.4436316 (Mo+)Z 6 CND 18.12.03X 2 CrNiMo 18.16.4 1.4438317 L S 31703Z 3 CND 19.15.04X 2 CrNiMoN 17.13.5 1.4439317 LNM S 31726Z 3 CND 18.14.05 AzX 5 CrNiMo 17.13 1.4449-317Z 6 CND 17.12.04X 1 CrNiMoN 25.25.2 1.4465N08310/S31050Z 2 CND 25.25AzX 1 CrNiMoN 25.22.2 1.4466S 31050Z 2 CND 25.22AzX 4 NiCrMoCuNb20.18.2 1.4505Z 5 NCDUNb20.18X 5 NiCrMoCuTi 20.18 1.4506Z 5 NCDUT20.18X 1 NiCrMoCuN25.20.6 1.4529N 0892619.25 HMoX 1 NiCrMoCu 25.20.5 1.4539904 L N 08904Z 2 NCDU 25.20URANUS B6 / 2 RK65X 1 CrNiMoCuN20.18.7 1.4547S 31254Z 1 CNDU 20.18Az254 SMOX 1 NiCrMoCu 31.27.4 1.4563N 08028Z 1 NCDU31.27.03SANICRO 28x 2 CrNiMnMoNbN25.18.5.4 1.4565S 345654565 S / 6 Mo X 6 CrNiMoTi 17.12.2 1.4571316 Ti S 31635Z 6 CNDT 17.12X 3 CrNiMoTi 25.25 1.4577Z 5 CNDT 25.25X 6 CrNiMoNb 17.12.2 1.4580316 Cb/Nb S 31640Z 6 CNDNb17.12X 10 CrNiMoNb 18.12 1.4583318Z 6 CNDNb17.13DUPLEX & SUPER-DUPLEXX 2 CrNiN 23.4 1.4362S 32304Z 3 CN 23.04 Az URANUS 35N / SAF23.04X 2 CrNiMoN 25.7.4 1.4410S 32750Z 3 CND 25.06AzURANUS 47 N (+)SAF 25.07X 2 CrNiMoN 27.5.2 1.4460329S 32900Z 5 CN 27.05 Az SS 44X 2 CrNiMoN 22.5.3 1.4462(329 LN)/F51S31803/S32205Z 3 CND 22.05AzURANUS 45N / SAF2205X 2 CrNiMoCuWN25.7.4 1.4501F55S 32760ZERON 100X 2 CrNiMoCuN 25.6.3 1.4507F53S32550/S32520Z 3 CNDU 25.07AzURANUS 52 N (+)C° - 600° -> 1200° CX 10 CrAl 7 1.4713Z 8 CA 7SICROMAL 8 X 10 CrSiAl 13 1.4724Z 13 C 13SICROMAL 9 X 10 CrAl 18 1.4742442S 44200Z 12 CAS 18SICROMAL 10Haut de pageALLIAGES DE NICKEL ET PRODUITS NOBLESX 18 CrN 28 1.4749 446S 44600Z 18 C25SICROMAL 11 / 4 C54 X 10 CrAlSi 24 1.4762Z 12 CAS 25 SICROMAL 12X 20 CrNiSi 25.4 1.4821 327Z 20 CNS 25.04X 15 CrNiSi 20.12 1.4828 302 B / 309 S 30215/30900Z 17 CNS 20.12 X 6 CrNi 22.13 1.4833 309 (S)S 30908Z 15 CN 24.13 X 15 CrNiSi 25.20 1.4841 310 / 314S 31000/31400Z 15 CNS 25.20X 12 CrNi 25.21 1.4845 310 (S)S 31008Z 8 CN 25.20X 12 NiCrSi 35.16 1.4864 330N 08330Z 20 NCS 33.16 INCOLOY DS X 10 NiCrAlTi 32.20 1.4876N 08800Z 10 NC 32.21 INCOLOY 800 (H /HT)X 12 CrNiTi 18.9 1.4878 321 HS 32109Z 6 CNT 18.12X 8 CrNiSiN 21.11 1.4893S 30815253 MAX 6 CrNi Mo 17.13 1.4919 316 H S 31609Z 6 CND 17.12 X 6 CrNi 18.11 1.4948 304 HS 30409Z 6 CN 18.11X 5 NiCrAlTi 31.20 1.4958 N 08810Z 10 NC 32.21INCOLOY 800 H X 8 NiCrAlTi 32.211.4959N 08811INCOLOY 800 HTEN - DINW. Nr.AISI ASTM - UNS AFNOR®Ni & Ni ALLOYSNi 99.2 2.4066 N 02200Ni 99.2NICKEL 200Lc-Ni 99 2.4068 N 02201LC-Ni 99NICKEL 201NiCu 30 Fe 2.4360 N 04400Nu 30MONEL 400NiCu 30 Al 2.4375 N 05500Nu 30 ATMONEL K500NiCr 21 Mo 14 W 2.4602 N 06022 HASTELLOY C22NiCr 30 FeMo 2.4603 N 06030 HASTELLOY G30NiCr 23 Mo 16 Al 2.4605 N 06059 ALLOY 59NiMo 16 Cr 16 Ti2.4610 N 06455 HASTELLOY C4NiMo 28 2.4617 N 10665HASTELLOY B2NiCr 22 Mo 6 Cu 2.4618 HASTELLOY G NiCr 22 Mo 7 Cu 2.4619 N 06985 HASTELLOY G3NiCr 20 Ti 2.4630/2.4951 N 06075NC 20 T NIMONIC 75NiCr 20 TiAl 2.4631/2.4952 N 07080NC 20 TA NIMONIC 80 A NiCr 20 Co 18 Ti 2.4632/2.4969N 07090NC 20 KTANIMONIC 90NiCr 25 FeAl2.4633ALLOY 602 CA NiCo 20 C r15 Mo Al Ti2.4634 N 13021NCKD 20 ATV NIMONIC 105NiCr 29 Fe 2.4642 N 06690NC 30 FeALLOY 690NiCr 20 CuMo 2.4660 N 08020CARPENTER 20 Cb 3NiCr 23 Co 12 Mo 2.4663 N 06617NC 22 KDA INCONEL 617NiCr 22 Fe 18 Mo 2.4665/2.4603N 06002NC 22 FeD HASTELLOY X NiCr 19 NbMo 2.4668 N 07718NC 19 FeNb INCONEL 718NiCr 15 Fe 7 TiAl2.4669 N 07750NC 15 Fe 7 TAINCONEL X-750CoCr 282.4778UMCO 50NiCr 15 Fe 2.4816N 06600NC 15 Fe INCONEL 600 NiMo 16 Cr 15 W 2.4819N 10276NiMo 16 Cr 15HASTELLOY C276 NiCr 23 Fe 2.4851N 06601NC 23 Fe INCONEL 601 NiCr 22 Mo 9Nb 2.4856N 06625NC 22 DNb INCONEL 625NiCr 21 Mo 2.4858N 08825NC 21 FeDU INCOLOY 825Ta - TANTALE - TANTALUM - TANTALHaut de pageACIERS ALLIESTYPE UNS PLATE BAR PIPE WELD FITTINGSALLOY STEELWP-1SA, A-204, GR B SA, A-182 F1SA, A-335 P1SA, A-234WP-5SA, A-387, GR 5SA, A-182 F5SA, A-335 P5SA, A-234WP-9SA, A-387, GR 9SA, A-182 F9SA, A-335 P9SA, A-234WP-11SA, A-387, GR 11SA, A-182 F11SA, A-335 P11SA, A-234WP-12SA, A-387, GR 12SA, A-182 F12SA, A-335 P12SA, A-234WP-22SA, A-387, GR 22SA, A-182 F22SA, A-335 P22SA, A-234LOW-TEMPERATURE STEELWP-L3SA, A-203, GR E SA, A-350 LF3SA, A-333,GR 3SA, A-420WP-L6SA, A-516, GR 70SA, A-350 LF2SA, A-333,GR 6SA, A-420WP-L8SA, A-353SA, A-522SA, A-333,GR 8SA, A-420Haut de page。

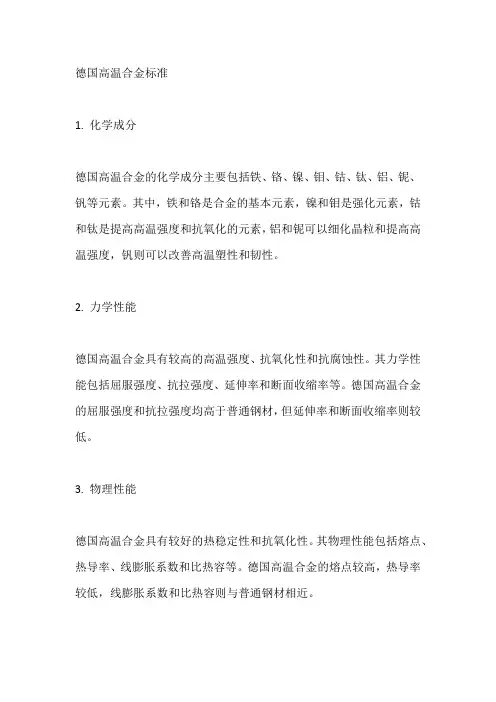

德国高温合金标准1. 化学成分德国高温合金的化学成分主要包括铁、铬、镍、钼、钴、钛、铝、铌、钒等元素。

其中,铁和铬是合金的基本元素,镍和钼是强化元素,钴和钛是提高高温强度和抗氧化的元素,铝和铌可以细化晶粒和提高高温强度,钒则可以改善高温塑性和韧性。

2. 力学性能德国高温合金具有较高的高温强度、抗氧化性和抗腐蚀性。

其力学性能包括屈服强度、抗拉强度、延伸率和断面收缩率等。

德国高温合金的屈服强度和抗拉强度均高于普通钢材,但延伸率和断面收缩率则较低。

3. 物理性能德国高温合金具有较好的热稳定性和抗氧化性。

其物理性能包括熔点、热导率、线膨胀系数和比热容等。

德国高温合金的熔点较高,热导率较低,线膨胀系数和比热容则与普通钢材相近。

4. 耐腐蚀性能德国高温合金具有良好的抗高温氧化性和抗腐蚀性。

其耐腐蚀性能包括表面氧化层、腐蚀速率和抗腐蚀性能等。

德国高温合金的表面氧化层较厚,腐蚀速率较低,抗腐蚀性能较好。

5. 加工制造性能德国高温合金的加工制造性能较差。

其加工制造过程需要较高的温度和压力,且易出现加工硬化和开裂等问题。

因此,在加工制造过程中需要注意控制加工参数和选用合适的加工刀具。

6. 焊接性能德国高温合金的焊接性能较差。

其焊接过程中易出现裂纹、气孔和夹渣等问题。

因此,在焊接过程中需要注意控制焊接参数和选用合适的焊接材料。

同时,在焊接前需要进行预热处理和焊后热处理,以降低焊接应力和提高焊接质量。

7. 质量控制与检验德国高温合金的质量控制与检验非常重要。

在生产过程中需要进行严格的化学成分控制、冶炼和锻造过程的监控以及热处理过程的控制等。

同时,在成品检验过程中需要进行化学成分分析、力学性能测试、金相组织分析、无损检测和焊缝质量检验等。

8. 应用与规范德国高温合金广泛应用于航空航天、能源、汽车等领域。

其应用范围广泛,包括航空发动机涡轮叶片、燃烧室、紧固件等部件,以及能源领域的燃气轮机叶片、核反应堆燃料棒等部件。

在使用过程中需要遵循相关规范和标准,以确保安全可靠的使用。

德标1.4435化学成分标准1. 引言德标1.4435是一种常见的不锈钢材料,具有优良的耐腐蚀性能和机械性能,被广泛应用于化工、制药、食品加工等领域。

为了确保1.4435材料的质量和性能,德国国家标准化组织制定了1.4435化学成分标准,对其成分和性能进行了严格规定。

2. 化学成分标准根据德国标准化组织的要求,1.4435材料的化学成分必须符合以下标准:- 碳含量(C):不超过0.05%- 硅含量(Si):不超过1.00%- 锰含量(Mn):不超过2.00%- 硫含量(S):不超过0.015%- 磷含量(P):不超过0.045%- 铬含量(Cr):16.5%-18.5%- 镍含量(Ni):10.0%-13.0%- 钼含量(Mo):2.0%-2.5%- 铜含量(Cu):不超过0.50%- 钛含量(Ti):不超过0.70%- 铌含量(Nb):0.10%-0.30%- 钙含量(Ca):不超过0.12%- 铁含量(Fe):余量3. 化学成分标准的意义化学成分是决定不锈钢材料性能的关键因素之一。

严格控制1.4435材料的化学成分,可以保证其具有良好的耐腐蚀性能、机械性能和加工性能。

碳含量的控制可以影响材料的强度和硬度,硅、锰、磷、硫等元素的含量则会影响材料的耐蚀性和加工性能。

而铬、镍、钼等元素的含量则是决定不锈钢材料耐腐蚀性能的关键因素。

4. 成分分析方法为了确保1.4435材料的化学成分符合标准要求,需要采用严格的成分分析方法进行检测。

常用的成分分析方法包括化学成分分析、光谱分析、金相分析、显微组织分析等。

通过这些分析方法,可以准确地测定1.4435材料中各种元素的含量,确保其符合标准要求。

5. 结论德标1.4435化学成分标准的制定,对保证1.4435材料的质量和性能起到了至关重要的作用。

通过严格控制材料的化学成分,可以确保其具有优良的耐腐蚀性能和机械性能,满足不同工程领域的需求。

对成分的准确分析也是保证材料质量的重要手段,为材料的生产和应用提供了可靠的保障。

版次:01 共14 页第1、碳素结构钢版次:01 共14页第中德常用金属材料对照表、普通碳素结构钢注:(a) V:调质处理;(b) ①为调质处理时参数。

版次:01 共14页一、碳素结构钢注:N:正火。

版次:01 共14页二、合金结构钢注:①截面<100时,调质;②截面w 120时,调质;③截面15时,调质;④ 截面25时,调质;⑤截面30时,调质版次:01三、灰口铸铁:球墨铸铁Grey cast iron ; nodular cast irou 共14页第5页版次:01 共14页第6四、铸钢Casting steel四、铸钢Casting steel 版次:01 共14页第7注:①正火+回火;②调质。

五、不锈钢版次:01 共14页第8页六、弹簧钢Spring steel七、无缝钢管用碳素钢 Carbon steel for seamless steel tube版次:01 共14页第10页版次: 01 共14页第9页注:①GB8163-87为输送流体用钢管;② GB8162-87为结构用钢管八、有色金属材料non-ferrous metal maerial 版次:01 共14 页第11页八、有色金属材料non-ferrous metal maerial版次:01共14页第12八、有色金属材料non-ferrous metal maerial注:S —砂型铸造;J —金属型铸造;Li —离心铸造;La —连续铸造九、轴承钢 Beari ng Steel版次:01 共14 页第13页版次:01共14页第14页。

德标材质元素含量的标准

在标准中,推荐加热温度范围较宽:1000~1150℃,通常采用1020-1080℃。

考虑具体牌号成分,是铸件还是锻件等情况,在允许范围内,适当调节加热温度。

加热温度低,C-Cr碳化物不能充分溶解,温度太高,也存在晶粒长大,降低耐蚀性问题。

冷却方式:应以较快速度冷却,防止碳化物再析出。

在我国及其它一些国家标准中,标明固溶化后“快冷”,综合不同文献资料和实践经验,“快”的尺度可按如下情况掌握:

•含C量≥0.08%的;含Cr量>22%、Ni量较高的;含C量虽<0.08%,但有效尺寸>3mm的,应水冷;

•含C量<0.08%、尺寸<3mm,可风冷;

•有效尺寸≤0.5mm的可空冷。