gambit网格划分的评价标准

- 格式:docx

- 大小:13.85 KB

- 文档页数:1

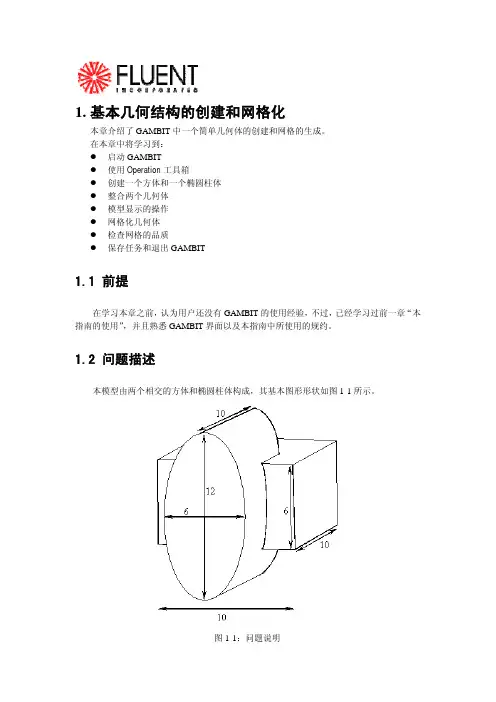

1.基本几何结构的创建和网格化本章介绍了GAMBIT中一个简单几何体的创建和网格的生成。

在本章中将学习到:z启动GAMBITz使用Operation工具箱z创建一个方体和一个椭圆柱体z整合两个几何体z模型显示的操作z网格化几何体z检查网格的品质z保存任务和退出GAMBIT1.1 前提在学习本章之前,认为用户还没有GAMBIT的使用经验,不过,已经学习过前一章“本指南的使用”,并且熟悉GAMBIT界面以及本指南中所使用的规约。

1.2 问题描述本模型由两个相交的方体和椭圆柱体构成,其基本图形形状如图1-1所示。

图1-1:问题说明1.3策略本章介绍使用GAMBIT生成网格的基本操作,特别地,将介绍:z如何使用“top-down”固体建模方法来方便地创建几何体z如何自动生成六面体网格“top-down”方法的意思是用户可以通过生成几何体(如方体、柱体等)来创建几何结构,然后,对它们进行布尔操作(如整合、剪除等),以这种方式,用户不用首先去创建作为基础的点、边和面,就可以快速创建出复杂的几何形体。

一旦创建出一个有效的几何模型,网格就可以直接并且自动地(很多情况下)生成。

在本例子中,将采用Cooper网格化算法来自动生成非结构化的六面体网格。

更复杂的几何结构在生成网格之前可能还需要进行手工分解,这将在后面进行介绍。

本章的学习步骤如下:z创建两个几何体(一个方体和一个椭圆柱体)z整合两个几何体z自动生成网格z检查网格的品质为了使本章的介绍尽量简短,一些必要的步骤被省略了:z调节几何体单边上节点的分布z设置连续介质类型(例如,标识哪些网格区是流体,哪些网格区是固体)和边界类型这些方面的详细内容,也包括其他方面,在随后的章节将涉及到。

1.4步骤输入gambit -id basgeom启动GAMBIT。

这就打开了GAMBIT的图形用户界面(GUI)(图1-2)。

GAMBIT把设定的名称(本例子中为basgeom)作为她将创建的所有文件的词头,如:basgeom.jou。

Fluent计算对网格质量的几个主要要求:1)网格质量参数:Skewness (不能高于0.95,最好在0.90以下;越小越好)Change in Cell-Size (也是Growth Rate,最好在1.20以内,最高不能超过1.40)Aspect Ratio (一般控制在5:1以内,边界层网格可以适当放宽)Alignment with the Flow(就是估计一下网格线与流动方向是否一致,要求尽量一致,以减少假扩散)2)网格质量对于计算收敛的影响:高Skewness的单元对计算收敛影响很大,很多时候计算发散的原因就是网格中的仅仅几个高Skewness的单元。

高长宽比的单元使离散方程刚性增加,使迭代收敛减慢,甚至困难。

也就是说,Aspect Ratio尽量控制在推荐值之内。

3)网格质量对精度的影响:相邻网格单元尺寸变化较大,会大大降低计算精度,这也是为什么连续方程高残差的原因。

网格线与流动是否一致也会影响计算精度。

4)网格单元形状的影响:你在fluent里面用grid quality命令看下,相关的东西可以百度一下;以下为我百度搜索到的东西:可以作为参考:如何检查网格质量,用什么指标来说明网格好不好呢?怎么控制?一般是什么原因造成的? 一般也就是,网格的角度,网格变形的梯度等等吧判断网格质量的方面有很多,不知你用的是什么软件,下面总结的是针对Gambit帮助文件的简单归纳,不同的软件有不同的评价单元质量的指标,使用时最好仔细阅读帮助文件。

Area单元面积,适用于2D单元,较为基本的单元质量特征。

Aspect Ratio长宽比,不同的网格单元有不同的计算方法,等于1是最好的单元,如正三角形,正四边形,正四面体,正六面体等;一般情况下不要超过5:1. Diagonal Ratio对角线之比,仅适用于四边形和六面体单元,默认是大于或等于1的,该值越高,说明单元越不规则,最好等于1,也就是正四边形或正六面体。

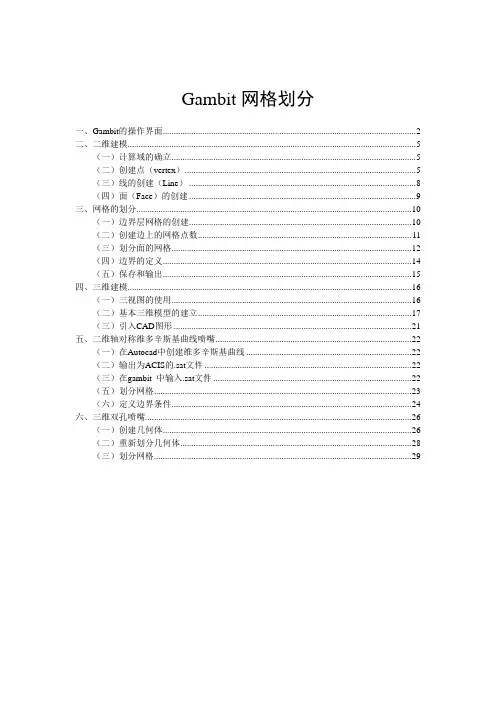

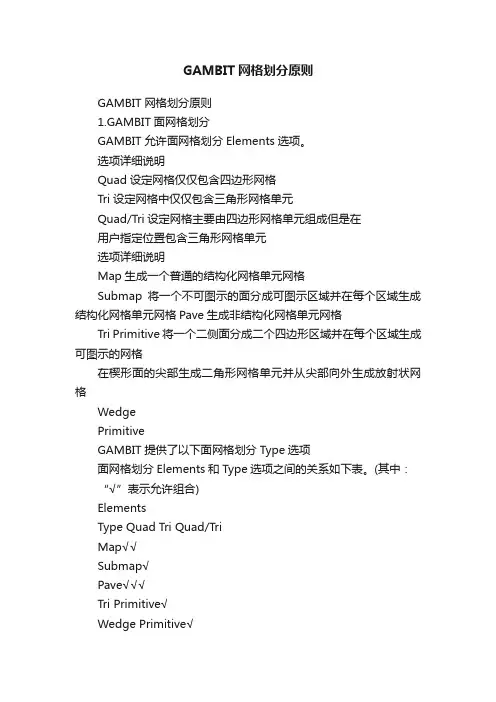

GAMBIT网格划分原则GAMBIT网格划分原则1.GAMBIT面网格划分GAMBIT允许面网格划分Elements选项。

选项详细说明Quad设定网格仅仅包含四边形网格Tri设定网格中仅仅包含三角形网格单元Quad/Tri设定网格主要由四边形网格单元组成但是在用户指定位置包含三角形网格单元选项详细说明Map生成一个普通的结构化网格单元网格Submap将一个不可图示的面分成可图示区域并在每个区域生成结构化网格单元网格Pave生成非结构化网格单元网格Tri Primitive将一个二侧面分成二个四边形区域并在每个区域生成可图示的网格在楔形面的尖部生成二角形网格单元并从尖部向外生成放射状网格WedgePrimitiveGAMBIT提供了以下面网格划分Type选项面网格划分Elements和Type选项之间的关系如下表。

(其中:“√”表示允许组合)ElementsType Quad Tri Quad/TriMap√√Submap√Pave√√√Tri Primitive√Wedge Primitive√2. GAMBIT体网格划分GAMBIT指定的体积网格划分Elements选项。

选项详细说明Hex指定网格仅仅包含六面体网格单元Hex/Wedge指定网格主要有六面体网格单元组成但是也包括在适当地位置的楔形网格Tet/Hybird指定网格主要由四面体网格构成但是在适当的位置可以包含六面体、锥形和楔形网格单元GAMBIT提供了以下体网格划分Type选项选项详细说明Map生成一般六面体结构化网格单元Submap将一个不可图示化体积分割成可图示化区域并在每个区域生成六面体结构化网格单元Tet Primitive将一个四个侧面的体积分成四个六面体区域并在每个区域生成可图示化网格Cooper扫描整个体积的指定的源面的网格节点类型Tet/Hybird指定该网格主要包含四面体网格单元但是在合适的位置也可以包含六面体、锥体和楔形单元Stairstep生成普通六面体网格和一个与原是提及形状近似的平滑的体积体网格划分Elements和Type选项之间的关系如下表。

Gambit网格处理问题一:面合并和interface设置:1、在设置GAMBIT边界层类型时需要注意的几个问题:a、没有定义的边界线如何处理,b、计算域内的内部边界如何处理(2D),gambit默认为wall,一般情况下可以到fluent再修改边界类型。

内部边界如果是split产生的,那么就不需再设定了,如果不是,那么就需要设定为interface或者是internal。

先从机理上分析流动可能的情况,然后再确定网格划分的方法。

流体流动方向与网格的走向相平行,计算结果的精度会好一些。

流动复杂的地方、计算比较关心的地方,网格密一些,其它的区域可以稍微稀疏一些。

流动最复杂的地方加入边界层,边界层的层数及各层的厚度要合理。

对于标准壁面函数,过密的边界层会导致很小的 y+(FLUENT 推荐+12~300),可能会影响计算结果。

为了将计算区域的不同位置划分成不同密度、不同结构的网格,可以用面或线(二维)将整个区域分成多个小区域。

区域之间的分界面(单个面,两个体是相连的。

)可以设为Internal边界条件,或Interface(分界处是两个面分属于两个体,即两个体是不相连的。

)边界条件。

如果设为 Interface 边界条件,在网格文件导入 FLUENT 中开始解算之前,在 Define中仍要进行相应的Grid Interface 设置。

Interface边界条件还可以用于连接运动的区域和静止的区域,例如,涡轮流量传感器叶轮区域和导向架区域。

不同的小区域可以用不同结构和尺度的网格,但两个相邻区域之间的网格尺度过渡要尽可能的平滑,不要超过 3~5 倍。

几何结构规则的区域尽可能用结构化网格(六面体),可以减少网格数量;结构复杂的区域采用非结构化网格(四面体),便于网格生成;四面体网格可以转化成多面体网格。

在gambit划分三维网格时,难免遇见对一模型进行分区划分。

其中不好处理的地方就是在两个体交界面处的网格怎么去处理。

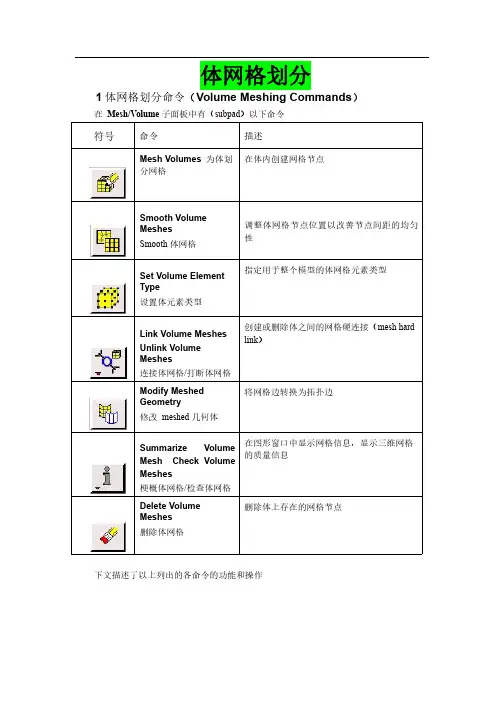

GAMBIT 网格划分第四节体网格划分FEBRUARY 26, 20144.4 体网格划分命令(Volume Meshing Commands)在Mesh/Volume 子面板中有(subpad)以下命令下文描述了以上列出的各命令的功能和操作4.4.1 为体划分网格(Mesh Volumes )Mesh Volumes 命令允许你为一个或多个体创建网格。

当你为一个体划分网格时,GAMBIT 会根据当前设定的参数在整个体中创建网格节点。

要mesh 一个体,需要设定以下参数•待划分网格的体•网格划分方案(Meshing scheme )•网格节点间距(Mesh node spacing )•网格划分选项(Meshing options )指定体(Specifying the Volume)GAMBIT 允许你在网格划分操作中指定任何体,但是,何种网格划分方案(meshing scheme)能应用于这个体,则决定于体的拓扑特性、形状,以及体的面上的顶点的类型。

指定网格划分方案(Specifying the Meshing Scheme)指定网格划分方案需要设定以下两个参数•元素(Elements)•类型(Type)Elements参数用于定义(应用于该体的)体网格元素的形状;Type 参数定义网格划分算法,因此也决定了体中所有网格元素的模式。

下文将介绍上面列出的参数的功能,以及它们对体网格产生的效果。

指定方案元素(Specifying Scheme Elements)GAMBIT 允许你指定下表列出的任何一个体网格Elements(元素)选项以上列出的每个Elements 选项都有一套特定的Type(类型)选项(一个或多个)相对应(见下)指定方案类型(Specifying Scheme Type)GAMBIT 提供以下体网格划分的Type 选项正如上文提到的,每个Elements选项都有一套特定的Type(类型)选项(一个或多个)相对应。

体网格划分1体网格划分命令(Volume Meshing Commands)在Mesh/Volume子面板中有(subpad)以下命令下文描述了以上列出的各命令的功能和操作1.1为体划分网格(Mesh Volumes)Mesh Volumes命令允许你为一个或多个体创建网格。

当你为一个体划分网格时,GAMBIT会根据当前设定的参数在整个体中创建网格节点。

要mesh一个体,需要设定以下参数•待划分网格的体•网格划分方案(Meshing scheme)•网格节点间距(Mesh node spacing)•网格划分选项(Meshing options)指定体(Specifying the Volume)GAMBIT允许你在网格划分操作中指定任何体,但是,何种网格划分方案(meshing scheme)能应用于这个体,则决定于体的拓扑特性、形状,以及体的面上的顶点的类型。

指定网格划分方案(Specifying the Meshing Scheme)指定网格划分方案需要设定以下两个参数•元素(Elements)•类型(Type)Elements参数用于定义(应用于该体的)体网格元素的形状;Type参数定义网格划分算法,因此也决定了体中所有网格元素的模式。

下文将介绍上面列出的参数的功能,以及它们对体网格产生的效果。

指定方案元素(Specifying Scheme Elements)GAMBIT允许你指定下表列出的任何一个体网格Elements(元素)选项以上列出的每个Elements选项都有一套特定的Type(类型)选项(一个或多个)相对应(见下)指定方案类型(Specifying Scheme Type)GAMBIT提供以下体网格划分的Type选项正如上文提到的,每个Elements选项都有一套特定的Type(类型)选项(一个或多个)相对应。

下表示出了体网格划分时Elements选项和Type(类型)选项之间的对应关。

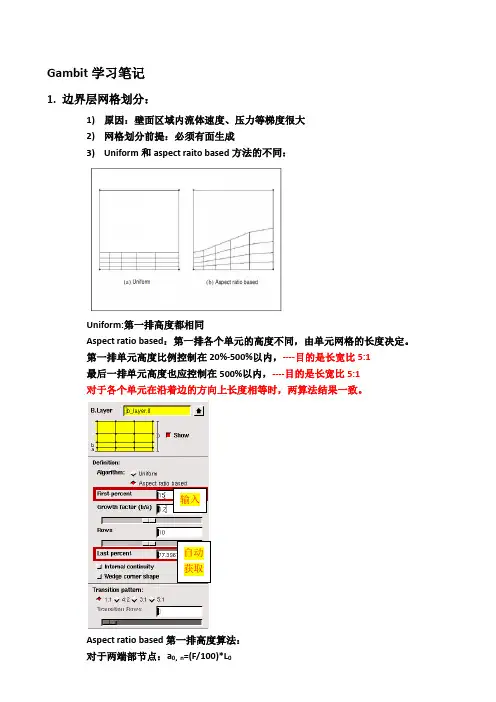

Gambit 学习笔记1. 边界层网格划分:1) 原因:壁面区域内流体速度、压力等梯度很大 2) 网格划分前提:必须有面生成3) Uniform 和aspect raito based 方法的不同:Uniform:第一排高度都相同Aspect ratio based :第一排各个单元的高度不同,由单元网格的长度决定。

第一排单元高度比例控制在20%-500%以内,----目的是长宽比5:1 最后一排单元高度也应控制在500%以内,----目的是长宽比5:1 对于各个单元在沿着边的方向上长度相等时,两算法结果一致。

Aspect ratio based 第一排高度算法: 对于两端部节点:a 0,n =(F/100)*L输入自动获取对于内部节点:a i=i节点两边单元长度和的平均值*比例因子4)Internal Continuity内部连续性:使用区别应该在使用的时候去更好的体会✧壁面边界层印记关系:多个面为壁面时的搭接问题✧网格光滑度和高度自动调整对内部连续性的影响:0/1(0为不起作用,1为起作用)MESH.BLAYER.ANGLE_SMOOTH_FACTORMESH.BLAYER.ADJUST_EDGE_BL_HEIGHT默认值更改方法:edit/default✧内部连续性对网格划分方案type的影响5)边界层楔形角----不能生成✧两条边相交且属于一个面内✧交点类型为corner或reversal型✧每条边单个生成边界层勾选楔形角选项6)边界层第一层高度值确定Y plus理论壁面函数适用于:k-ε型对数定律(Log-law)仅对平衡边界层和充分发展的流动有效,提供了壁面与第一层网格中心可接受间距的上下限,此距离通过无量纲参数y+(≡ρuτy/µ)或y*来表示,当第一层网格位于对数律层内时,y+与y*数值相近,但不同于C1/4µ i.e. ≈0.5.标准和非平衡壁面,每一个近壁面网格中心都应落于Log-law内,30 < y+ < 300,接近于30是最理想的。

G A M B I T软件网格的划分模型的网格划分当用户点击Operation工具框中的Mesh命令按钮时,GAMBIT将打开Mesh 子工具框。

Mesh子工具框包含的命令按钮允许用户对于包括边界层、边、面、体积和组进行网格划分操作。

与每个Mesh子工具框命令设置相关的图标如下。

图标命令设置Boundary LayerEdgeFaceVolumeGroup本章以下部分将详细说明与上面列举的每个命令按钮相关的命令。

3.1 边界层3.1.1 概述边界层确定在与边和/或者面紧邻的区域的网格节点的步长。

它们用于初步控制网格密度从而控制相交区域计算模型中有效信息的数量。

示例作为边界层应用的一个示例,考虑包括一个代表流体流过管内的圆柱的计算模型。

在正常环境下,很可能在紧靠管道壁面的区域内流体速度梯度很大,而靠近管路中心很小。

通过对壁面加入一个边界层,用户可以增大靠近壁面区域的网格密度并减小靠近圆柱中心的网格密度——从而获得表征两个区域的足够的信息而不过分的增大模型中网格节点的总数。

一般参数要确定一个边界层,用户必须设定以下信息:•边界层附着的边或者面•确定边界层方向的面或者体积•第一列网格单元的高度•确定接下来每一列单元高度的扩大因子•确定边界层厚度的总列数用户还可以设定生成过渡边界层——也就是说,边界层的网格节点类型随着每个后续层而变化。

如果用户设定了这样一个边界层,用户必须同时设定以下信息:•边界层过渡类型•过度的列数3.1.2 边界层命令以下命令在Mesh/Boundary Layer子工具框中有效。

图标命令详细说明Create Boundary Layer建立附着于一条边或者一个面上的边界层Modify Boundary Layer更改一个现有边界层的定义Modify Boundary LayerLabel更改边界层标签Summarize BoundaryLayers在图形窗口中显示现有边界层Delete BoundaryLayers删除边界层生成边界层Create Boundary Layer命令允许用户在一条边或者一个面附近定义网格节点步长。

GAMBIT圆柱体的高质量网格划分(钱币划分)(1)先在opteration--geometry-volumn中创建了一个高为100,半径15的圆柱体。

然后再圆柱的底面建立了一个边长为8的正方形,将正方形旋转45度,使正方形的一个顶点跟底面圆的点对齐,然后将圆周分割为4等分,将这4个顶点和正方形的四个顶点连成线,效果如图所示:

(2)然后用这四条线沿Z轴正向的矢量方向长出4个面,效果如图:

(3)用正方形去分割底面圆,注意选择connected选项,再用刚才形成的四个面去分割那个古钱形的底面,把它分成4部分,效果如图所示:

(4)下面就是把对应边划分网格,注意正方形每条边对应的圆弧边划分的网格份数是一样的,效果如图:

(5)划分面网格,选择map结构的四边形网格,效果如:

(6)最后划分体网格,按照cooper方式的六面体网格来划分,效果如图:。

GAMBIT 网格划分第四节体网格划分FEBRUARY 26, 20144.4 体网格划分命令(Volume Meshing Commands)在Mesh/Volume 子面板中有(subpad)以下命令下文描述了以上列出的各命令的功能和操作4.4.1 为体划分网格(Mesh Volumes )Mesh Volumes 命令允许你为一个或多个体创建网格。

当你为一个体划分网格时,GAMBIT 会根据当前设定的参数在整个体中创建网格节点。

要mesh 一个体,需要设定以下参数•待划分网格的体•网格划分方案(Meshing scheme )•网格节点间距(Mesh node spacing )•网格划分选项(Meshing options )指定体(Specifying the Volume)GAMBIT 允许你在网格划分操作中指定任何体,但是,何种网格划分方案(meshing scheme)能应用于这个体,则决定于体的拓扑特性、形状,以及体的面上的顶点的类型。

指定网格划分方案(Specifying the Meshing Scheme)指定网格划分方案需要设定以下两个参数•元素(Elements)•类型(Type)Elements参数用于定义(应用于该体的)体网格元素的形状;Type 参数定义网格划分算法,因此也决定了体中所有网格元素的模式。

下文将介绍上面列出的参数的功能,以及它们对体网格产生的效果。

指定方案元素(Specifying Scheme Elements)GAMBIT 允许你指定下表列出的任何一个体网格Elements(元素)选项以上列出的每个Elements 选项都有一套特定的Type(类型)选项(一个或多个)相对应(见下)指定方案类型(Specifying Scheme Type)GAMBIT 提供以下体网格划分的Type 选项正如上文提到的,每个Elements选项都有一套特定的Type(类型)选项(一个或多个)相对应。

LOW-SPEED CENTRIFUGAL COMPRESSOR9. LOW-SPEED CENTRIFUGAL COMPRESSORThis tutorial employs the configuration of a low-speed, centrifugal compressor blade to demonstrate the use of imported geometry and the turbo volume decomposition operation. It illustrates how to adjust decomposition split points and employs a structured hexahedral mesh.In this tutorial, you will learn how to:•Create a turbo volume based on imported ACIS geometry•Decompose a turbo volume9.1 PrerequisitesTo understand this tutorial, you should review and understand the steps, principles, and procedures outlined in Tutorials 1, 2, 3, 4, and 8.© Fluent Inc., Mar-06 9-1Problem Description LOW-SPEED CENTRIFUGAL COMPRESSOR9.2 Problem DescriptionFigure 9-1 shows the turbomachinery configuration to be modeled and meshed in this tutorial. The configuration represents the rotor of a low-speed centrifugal compressor containing 20 identical, highly skewed blades, each of which is spaced equidistant from the others on the rotor hub. The configuration is designed such that the angles of the inlet and outlet flow directions are offset from each other by 90º.Outlet flowInlet flowFigure 9-1: Low-speed centrifugal compressor rotor9-2 © Fluent Inc., Mar-06LOW-SPEED CENTRIFUGAL COMPRESSOR Strategy9.3 StrategyThe GAMBIT turbo modeling procedure includes seven basic steps:1)Creating or importing edge data that describes the turbo profile2)Creating the turbo profile3)Creating the turbo volume4)Assigning zone types to regions of the turbo volume5)Decomposing the turbo volume6)Meshing the turbo volume7)Viewing the turbo volumeThis tutorial illustrates all of the steps listed above. In this example, the edge data that describes the turbo profile is imported from an ACIS file, and edges of the turbo volume are pre-split in the zone-type assignment step (Step 4) to facilitate decomposition (Step 5). NOTE: In this tutorial, the turbo-volume viewing operation (Step 7, above) is illustrated in conjunction with the mesh examination step (see “Step 10:Examine the Mesh,” below).© Fluent Inc., Mar-06 9-3Procedure LOW-SPEED CENTRIFUGAL COMPRESSOR 9.4 Procedure1.Copy the filepath/Fluent.Inc/gambit2.x/help/tutfiles/lscc-smooth.sat (where 2.x is the GAMBIT version number) from the GAMBIT installation area in the directory path to your working directory.2.Start GAMBIT using the session identifier “LS_Centrifugal_Comp”.Step 1: Select a Solver1.Choose the solver from the main menu bar:Solver → FLUENT 5/6The choice of solver affects the types of options available in the Specify Boundary Types form (see below). For some systems, FLUENT 5/6 is the default solver. The currently selected solver is shown at the top of the GAMBIT GUI.9-4 © Fluent Inc., Mar-06LOW-SPEED CENTRIFUGAL COMPRESSOR Procedure © Fluent Inc., Mar-06 9-5 Step 2: Import ACIS GeometryTo create a turbo model, GAMBIT requires the specification of a set of edges that define the shapes of the turbo hub and casing and the cross-sectional shapes of the turbo blade(s). In this tutorial, the edge specification data is imported from an ACIS file.1. Select the Import ACIS File option from the main menu bar.File → Import → ACISThis command sequence opens the Import ACIS Fileform.2. Click the Browse... button.This action opens the Select File form.Procedure LOW-SPEED CENTRIFUGAL COMPRESSOR9-6© Fluent Inc., Mar-06a)In the Files list, select lscc-smooth.sat.b)On the Select File form, click Accept.3.On the Import ACIS File form, click Accept.GAMBIT reads the information contained in the ACIS file and constructs the geometry shown in Figure 9-2.LOW-SPEED CENTRIFUGAL COMPRESSOR ProcedureBlade cross sectionsHub edgeCasing edgeFigure 9-2: Imported ACIS geometry for low-speed centrifugal compressor© Fluent Inc., Mar-06 9-7Procedure LOW-SPEED CENTRIFUGAL COMPRESSOR 9-8 © Fluent Inc., Mar-06Step 3: Create the Turbo ProfileThe turbo profile defines the basic characteristics of the turbo volume. In GAMBIT , the edges that describe the hub, casing, and blade cross sections are defined by means of their inlet endpoint vertices.1. Specify the hub, casing, and blade-cross-section edges of the turbo profile.TOOLS →TURBO →CREATE PROFILEThis command sequence opens the Create Turbo Profileform.In this step, you will specify vertices that define the hub, casing, and blade cross-sections. In addition, you will specify the axis of revolution for the turbo configu-ration. All instructions listed in this step refer to the vertex labels shown in Figure 9-3.LOW-SPEED CENTRIFUGAL COMPRESSOR Procedure© Fluent Inc., Mar-06 9-9 Casing InletHub InletBlade Tips BA D ECFigure 9-3: Vertices used to specify the turbo profilea) Activate the Hub Inlet list box on the Create Turbo Profile form.b) Select vertex A .c) Activate the Casing Inlet list box.d) Select vertex B .e) Activate the Blade Tips list box.f) Select (in order) vertices C , D , and E .! The order in which the Blade Tips vertices are selected is important to thedefinition of a turbo profile. Specifically, the Blade Tips vertices must beselected in order from hub to casing.g) Click Apply to accept the vertex selections and create the turbo profile.GAMBIT creates the turbo profile shown in Figure 9-4.Procedure LOW-SPEED CENTRIFUGAL COMPRESSORBAFigure 9-4: Turbo profile for low-speed centrifugal compressor blade The turbo profile for this tutorial includes six (real) rail edges and three (virtual) medial edges, each of which corresponds to one of the turbo blade cross sections.9-10 © Fluent Inc., Mar-06Step 4: Modify the Inlet and Outlet Vertex Locations It is often useful to control the shape of the turbo volume such that its inlet and outlet surfaces represent smooth flow transitions to and from the inlet and outlet ends, respectively, of the turbo blade. In GAMBIT, you can control the shape of the turbo volume by adjusting the positions of the medial-edge endpoint vertices prior to con-structing the volume.1.Open the Slide Virtual Vertex form.TOOLS →TURBO →SLIDE VIRTUAL VERTEXThis command sequence opens the Slide Virtual Vertexform.a)Select the inlet endpoint vertex of the medial edge for the hub blade cross section(vertex A in Figure 9-4, above).b)In the U Value field, enter the value 0.962.As an alternative to entering a value in the U Value field, you can select thevertex in the graphics window and drag it along its host rail edge until the UValue field value is 0.962.c)Retain the (default) Move with links option.© Fluent Inc., Mar-06 9-119-12 © Fluent Inc., Mar-06The Move with links option specifies that GAMBIT is to apply the current Slide Virtual Vertex specifications to all medial-edge inlet endpoint vertices in addi-tion to the selected vertex.d) Click Apply to accept the new position of the medial-edge inlet endpoint vertices. e) Select the outlet endpoint vertex of the medial edge for the casing blade crosssection (vertex B ).f) In the U Value field, enter the value 0.981.g) Retain the Move with links option.h) Click Apply to accept the new position of the medial-edge outlet endpoint vertices.The modified turbo profile appears as shown in Figure 9-5.Figure 9-5: Turbo profile with modified inlet and outlet vertex locationsStep 5: Create the Turbo VolumeThe turbo volume characteristics are determined by the turbo profile and by specifi-cation of the number of blades on the rotor (or angle between blades), the tip clear-ance, and the number of spanwise sections. This example does not include either a tip clearance or spanwise sectioning.1.Specify the pitch for the turbo volume.TOOLS →TURBO →CREATE TURBO VOLUMEThis command sequence opens the Create Turbo Volumeform.a)In the Pitch text box, enter 20.b)On the Pitch option button (located to the right of the Pitch text box), select theBlade count option.c)In the Spanwise Sections text box, enter 1.d)Click Apply.Figure 9-6 shows the resulting turbo volume.© Fluent Inc., Mar-06 9-139-14 © Fluent Inc., Mar-06 Casing faceHub faceInlet face Outlet faceBladepressuresideBladesuction sideFigure 9-6: Turbo volume for low-speed centrifugal compressor bladeStep 6: Define the Turbo ZonesThis step assigns standard zone types to surfaces of the turbo volume. The zone-type specifications determine which faces are linked for meshing. In addition to assigning zone types, this step employs pre-decomposition options that presplit periodic surfaces in order to facilitate turbo volume decomposition (see “Step 8:Decompose the Turbo Volume,” below).1.Specify the faces that constitute the hub, casing, inlet, and outlet of the turbo volume,as well as the pressure and suction sides of the turbo blade.TOOLS →TURBO →DEFINE TURBO ZONESThis command sequence opens the Define Turbo Zonesform.a)Activate the Hub list box, and select the bottom (hub) face of the turbo volume.b)Activate the Casing list box, and select the top (casing) face of the turbo volume.c)Activate the Inlet list box, and select the inlet face of the turbo volume.d)Activate the Outlet list box, and select the outlet face of the turbo volume.e)Activate the Pressure list box, and select the front two faces (excluding the flat,trailing-tip face) on the inner-curve (pressure side) of the turbo blade.f)Activate the Suction list box, and select the front two faces (excluding the flat,trailing-tip face) on the outer-curve (suction side) of the turbo blade.© Fluent Inc., Mar-06 9-15The flat edges on the trailing tips of the blade cross sections are not included in the definitions of the pressure and suction surfaces; therefore, they will not be merged into their respective surfaces in the decomposition step.g)In the Pre-decompose section, select both the Link spanwise and Split edges options.The Pre-decompose options specify that GAMBIT is to merge the pressure and suction surfaces of the blade, link the spanwise (hub and casing) faces of the turbo volume, and split the periodic edges of the hub and casing faces to facilitate decomposition of the turbo volume. The split locations for the peri-odic faces are determined by a set of default variables that can be modified by means of the Edit Defaults form (see Section 4.2.4 in the GAMBIT User’s Guide).h)Click Apply.GAMBIT assigns the zone types and splits the blade and periodic edges as shown in Figure 9-7.AEC BDFFigure 9-7: Turbo volume with pre-decomposition splitsBecause the flat trailing edges are not included in the pressure and suction surface definitions, the sharp edges at the trailing tip of the edge are maintained and are used for the turbo decomposition.9-16 © Fluent Inc., Mar-06Step 7: Adjust Edge Split PointsIt is often useful to modify the default split-point locations prior to decomposing the turbo volume. Such adjustments can facilitate success of the decomposition operation and the creation of spanwise faces that can be meshed with high-quality elements.You can adjust the split-point locations either before or after decomposition, but the adjustment process is less time-consuming if it is performed prior to decomposition, because it does not involve updating the face and volume configurations associated with each adjustment.In this step, you will adjust the turbo blade split points such that they are close to, but not coincident with, the leading edge vertex.1.Open the Slide Virtual Vertex form.TOOLS →TURBO →SLIDE VIRTUAL VERTEXThis command sequence opens the Slide Virtual Vertexform.a)Select the suction-side, upstream split-point vertex on the casing face turbo bladecross section (vertex A in Figure 9-7, above).b)In the U Value field, enter the value 0.003.© Fluent Inc., Mar-06 9-17As an alternative to entering a value in the U Value field, you can select thevertex in the graphics window and drag it along its host rail edge until the UValue field value is 0.003.c)Retain the Move with links option.The Move with links option specifies that GAMBIT is to apply the current SlideVirtual Vertex specifications to all linked vertices in addition to the selectedvertex. In this case, the suction-side split-point vertex on the casing face turboblade cross section is linked to a corresponding vertex on the hub face turboblade cross section.d)Click Apply to accept the new split-point location.e)Select the pressure-side, upstream split-point vertex on the casing face turbo bladecross section (vertex B).f)In the U Value field, enter the value 0.997.g)Click Apply to accept the new split-point location.h)Select the pressure-side, upstream split-point vertex on the casing face periodicedge (vertex C).i)Unselect the Move with links option.Because the leading edge of the blade is swept backwards from hub to casing,it is appropriate to move this vertex independently of the corresponding hubvertex (vertex D). This independent movement is accomplished by unselectingthe Move with links option. (NOTE: In all subsequent Slide Virtual Vertexoperations, the Move with links option will remain unselected.) j)In the U Value field, enter the value 0.238.k)Click Apply to accept the new split-point location.l)Select the pressure-side, upstream split-point vertex on the hub face periodic edge (vertex D).m)In the U Value field, enter the value 0.812.n)Click Apply to accept the new split-point location.o)Select the pressure-side, downstream split-point vertex on the casing face periodic edge (vertex E).9-18 © Fluent Inc., Mar-06© Fluent Inc., Mar-06 9-19 p) In the U Value field, enter the value 0.812.q) Click Apply to accept the new split-point location.r) Select the pressure-side, downstream split-point vertex on the hub face periodicedge (vertex F ).s) In the U Value field, enter the value 0.156.t) Click Apply to accept the new split-point location.Figure 9-8 shows the turbo volume configuration with the adjusted split points.Figure 9-8: Turbo volume with adjusted split points9-20 © Fluent Inc., Mar-06 Step 8: Decompose the Turbo VolumeThe decomposition step splits the turbo volume into four geometric volumes the topologies of which are suitable for the creation of structured hexahedral meshes.1. Decompose the turbo volume.TOOLS →TURBO →DECOMPOSE TURBO VOLUMEThis command sequence opens the Decompose Turbo Volumeform.a) Retain the (default ) Type:H option, and click Apply .GAMBITdecomposes the volume as shown in Figure 9-9.Figure 9-9: Decomposed turbo volume for low-speed centrifugal compressorStep 9: Mesh the VolumesThe decomposition step (above) automatically sets the interval count and grading on the edges according to the turbo decomposition defaults. In addition, the decomposi-tion sets face vertex types so that the volume is ready to mesh.1.Mesh all of the volumes.TOOLS →TURBO →MESH EDGES/FACES/VOLUMES RThis command sequence opens the Mesh Volumes form.a)Activate the Volumes list box.b)Select all four volumes.GAMBIT automatically selects the Scheme:Elements:Hex and Scheme:Type:Map options.c)Retain the automatically selected Scheme options.© Fluent Inc., Mar-06 9-219-22 © Fluent Inc., Mar-06d) On the Spacing option button, select Interval size .e) In the Spacing text box, enter a value of 10.f) Click Apply .Figure 9-10 shows the final meshed turbo volume.Figure 9-10: Meshed turbo volume for low-speed centrifugal compressorStep 10: Examine the Mesh1.Select the EXAMINE MESHcommand button at the bottom right of the GlobalControl toolpad.This action opens the Examine Meshform.a)Click Update at the bottom of the Examine Mesh form.© Fluent Inc., Mar-06 9-239-24 © Fluent Inc., Mar-06GAMBIT does not automatically update the graphics display when you open the Examine Mesh form or modify its specifications, such as Display Type or Quality Type . To update the graphics display, you must click the Update pushbutton located at the bottom of the form. GAMBIT displays the Update pushbutton label in red lettering whenever the display needs to be updated to reflect the current Examine Mesh specifications.Some Examine Mesh operations automatically update the graphics display. For example, if you select the Display Type:Range option and click one of the histogram bars, GAMBIT automatically updates the display.The Examine Mesh form allows you to view various mesh characteristics for the 3-D mesh. For example, Figure 9-11 displays hexahedral volume mesh elements for which the EquiSize Skewparameter is between 0.2 and 0.3 for this example.Figure 9-11: Hexahedral mesh elements—EquiSize Skew = 0.2–0.32. Display the casing surface in a cascade turbo view.TOOLS →TURBO →VIEW TURBO VOLUMEThis command sequence opens the View Turbo Volume form.© Fluent Inc., Mar-069-25a) Select the Cascade surface:Casing option.The Cascade surface specifications described above specify a flattened, 2-D display of the casing surface.b) Click Apply .Figure 9-12 displays an enlarged view of the quadrilateral face mesh elements near the blade tip on the casing surface for this example. In this case, the mesh elements are colored to represent the value of the EquiSize Skew parameter. (NOTE: To view the 2-D face elements shown in Figure 9-12, select the Display Type: 2D Element option on the Examine Mesh form, and specify the display of quadrilateral () elements.)9-26© Fluent Inc., Mar-06Figure 9-12: Quadrilateral mesh elements near blade tip—EquiSize Skew = 0–1c) Select the Off option and click Apply to turn off the cascade turbo view beforespecifying zone types.Step 11: Specify Zone TypesYou can use the Specify Boundary Types command to apply solver-specific boundary zone specifications to surfaces of the turbo volume. For some solver options, includ-ing Fluent 5/6, GAMBIT automatically assigns such boundary zone specifications. 1.Check the automatically applied boundary zone types.ZONES →SPECIFY BOUNDARY TYPESThis command sequence opens the Specify Boundary Typesform.© Fluent Inc., Mar-06 9-27Step 12: Export the Mesh and Exit GAMBIT1.Export a mesh file.a)Open the Export Mesh File formFile → Export → Mesh…This command sequence opens the Export Mesh Fileform.i.Enter the File Name for the file to be exported—for example, “ls_cc.msh”.ii.Click Accept.GAMBIT writes the mesh file to your working directory.2.Save the GAMBIT session and exit GAMBITa)Select Exit from the File menu.File → Exitform.This action opens the Exitb)Click Yes to save the current session and exit GAMBIT.9-28 © Fluent Inc., Mar-069.5 SummaryThis tutorial demonstrates the use of ACIS geometry import and turbo decomposition operations in GAMBIT turbo modeling. In this example, edge data imported from an ACIS file were used to define a turbo profile, which, in turn, was used to create a turbo volume representing the flow region surrounding one blade of a low-speed centrifugal compressor. The turbo zones were assigned, the turbo volume was pre-split, and the split-point locations on the blade and periodic edges were adjusted to facilitate decomposition and meshing. The final, decomposed turbo volume consisted of four volumes, each of which could be meshed using a structured, hexahedral meshing scheme.© Fluent Inc., Mar-06 9-29。

Gambit介绍网格的划分使用Gambit软件,首先要启动Gambit,在Dos下输入Gambit <filemane>,文件名如果已经存在,要加上参数-old。

一.Gambit的操作界面如图1所示,Gambit用户界面可分为7个部分,分别为:菜单栏、视图、命令面板、命令显示窗、命令解释窗、命令输入窗和视图控制面板。

文件栏文件栏位于操作界面的上方,其最常用的功能就是File命令下的New、Open、Save、Save as和Export等命令。

这些命令的使用和一般的软件一样。

Gambit可识别的文件后缀为.dbs,而要将Gambit中建立的网格模型调入Fluent使用,则需要将其输出为.msh文件(file/export)。

视图和视图控制面板Gambit中可显示四个视图,以便于建立三维模型。

同时我们也可以只显示一个视图。

视图的坐标轴由视图控制面板来决定。

图2显示的是视图控制面板。

图2 视图控制面板视图控制面板中的命令可分为两个部分,上面的一排四个图标表示的是四个视图,当激活视图图标时,视图控制面板中下方十个命令才会作用于该视图。

视图控制面板中常用的命令有:全图显示、选择显示视图、选择视图坐标、选择显示项目、渲染方式。

同时,我们还可以使用鼠标来控制视图中的模型显示。

其中按住左键拖曳鼠标可以旋转视图,按住中键拖动鼠标则可以在视图中移动物体,按住右键上下拖动鼠标可以缩放视图中的物体。

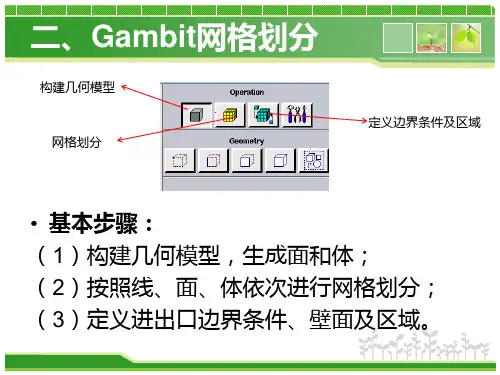

命令面板命令面板是Gambit的核心部分,通过命令面板上的命令图标,我们可以完成绝大部分网格划分的工作。

图3显示的就是Gambit的命令面板。

图3 Gambit的命令面板从命令面板中我们就可以看出,网格划分的工作可分为三个步骤:一是建立模型,二是划分网格,三是定义边界。

这三个部分分别对应着Operation区域中的前三个命令按钮Geometry(几何体)、mesh(网格)和Zones(区域)。

Operation中的第四个命令按钮Tools 则是用来定义视图中的坐标系统,一般取默认值。

如何检查网格质量,用什么指标来说明网格好不好呢?怎么控制?

一般是什么原因造成的?

一般也就是,网格的角度,网格变形的梯度等等吧

判断网格质量的方面有很多,不知你用的是什么软件,下面总结的是针对Gambit帮助文件的简单归纳,不同的软件有不同的评价单元质量的指标,使用

时最好仔细阅读帮助文件。

Area单元面积,适用于2D单元,较为基本的单元质量特征。

Aspect Ratio长宽比,不同的网格单元有不同的计算方法,等于1是最好的

单元,如正三角形,正四边形,正四面体,正六面体等;一般情况下不要超过5:1.

Diagonal Ratio对角线之比,仅适用于四边形和六面体单元,默认是大于或

等于1的,该值越高,说明单元越不规则,最好等于1,也就是正四边形或正六

面体。

Edge Ratio长边与最短边长度之比,大于或等于1,最好等于1,解释同上。

EquiAngle Skew通过单元夹角计算的歪斜度,在0到1之间,0为质量最好,

1为质量最差。

最好是要控制在0到0.4之间。

EquiSize Skew通过单元大小计算的歪斜度,在0到1之间,0为质量最好,1为质量最差。

2D质量好的单元该值最好在0.1以内,3D单元在0.4以内。

MidAngle Skew通过单元边中点连线夹角计算的歪斜度,仅适用于四边形和

六面体单元,在0到1之间,0为质量最好,1为质量最差。

Size Change相邻单元大小之比,仅适用于3D单元,最好控制在2以内。

Stretch伸展度。

通过单元的对角线长度与边长计算出来的,仅适用于四边

形和六面体单元,在0到1之间,0为质量最好,1为质量最差。

Taper锥度。

仅适用于四边形和六面体单元,在0到1之间,0为质量最好,

1为质量最差。

Volume单元体积,仅适用于3D单元,划分网格时应避免出现负体积。

Warpage翘曲。

仅适用于四边形和六面体单元,在0到1之间,0为质量最好,1为质量最差。

另外,在Fluent中的窗口键入:grid quality 然后回车,Fluent能检查网格的

质量,主要有以下三个指标:

1.Maxium cell squish: 如果该值等于1,表示得到了很坏的单元;

2.Maxium cell skewness: 该值在0到1之间,0表示最好,1表示最坏;

3.Maxium 'aspect-ratio': 1表示最好。