法国NF金属及非金属材料标准名称

- 格式:docx

- 大小:36.01 KB

- 文档页数:25

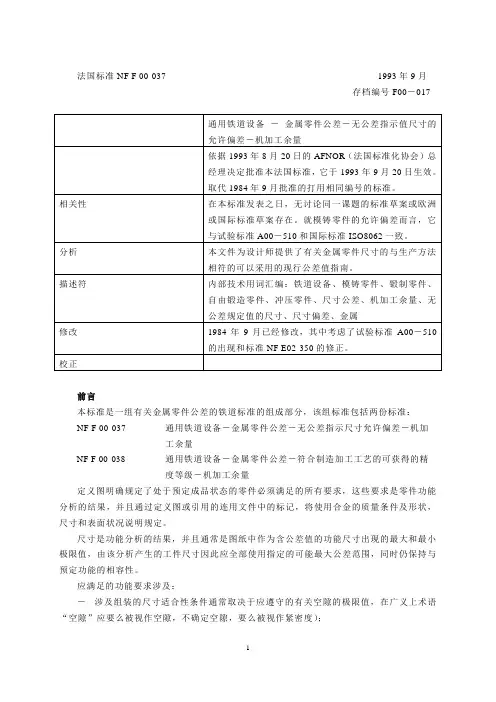

法国标准NF F 00-037 1993年9月存档编号F00-017前言本标准是一组有关金属零件公差的铁道标准的组成部分,该组标准包括两份标准:NF F 00-037 通用铁道设备-金属零件公差-无公差指示尺寸允许偏差-机加工余量NF F 00-038 通用铁道设备-金属零件公差-符合制造加工工艺的可获得的精度等级-机加工余量定义图明确规定了处于预定成品状态的零件必须满足的所有要求,这些要求是零件功能分析的结果,并且通过定义图或引用的连用文件中的标记,将使用合金的质量条件及形状,尺寸和表面状况说明规定。

尺寸是功能分析的结果,并且通常是图纸中作为含公差值的功能尺寸出现的最大和最小极限值,由该分析产生的工件尺寸因此应全部使用指定的可能最大公差范围,同时仍保持与预定功能的相容性。

应满足的功能要求涉及:-涉及组装的尺寸适合性条件通常取决于应遵守的有关空隙的极限值,在广义上术语“空隙”应要么被视作空隙,不确定空隙,要么被视作紧密度);-非涉及组装的尺寸(强度、空间、质量、美学条件等)。

在第一种情况下,尽管功能要求提出了相对狭窄的公差范围,但在第二种情况下,可以以较宽的利用现役生产手段较易实现范围满足那些要求。

此外,在第二种情况下,和在非功能尺寸中,工件定义图的对应尺寸不含指定的个别的公值。

这时,使用的制造加工过程中固有的与规定尺寸的偏差后限于通用公差使,它们与当前的生产相符,但无需高成本的专用预防措施。

因此,本标准的目的是规定在定义图的有关尺寸上未标出公差值时零件尺寸应遵守的通用公差值。

但是,在必须执行高精度要求时,就应依据标准NF F00-038的规定确定该要求,这一标准按生产工艺规定了可实现的精度水平。

就模铸零件的允许偏差而言,本标准以试验标准A00-510为依据,该试验标准-取代了文件资料版本A31-011和A32-012;-与国际标准ISO8062等效,本身提供了表格UIC800 52的依据;-按模铸工艺和合金规定了模铸工件的机加工余量尺寸单位:mm目录前言1. 范围2. 适用条件3. 参考资料3.1 标准类参考资料3.2 非标准类参考资料4. 定义5. 记录斜面零件公差值的原则6. 模铸零件公值-机加工余量6.1 模铸零件公差值6.2 机加工余量7. 利用冲压锻制的钢零件或非铁金属或合金自由锻造零件的公差7.1 利用冲压锻制的钢零件7.2 非铁金属或合金自由锻造零件8. 金属板零件公差等级8.1 钢和非铁金属及合金的拉制零件8.2 切削零件8.3 锤击零件9. 焊接零件和氧气电弧切割零件的公差值9.1 钢、铝和铝合金焊接零件9.2 氧气电弧切割零件10. 机加工零件公差值10.1 线性尺寸10.2 角尺寸11.3 连接边和槽11.4 用于固定设备的冲孔或钻孔1. 范围本标准按行业使用的生产手段规定了铁道设备结构目前需要的通用公差值。

厦门易朔Ecosafene公司NFP92-507防火测试法国M等级NF P92-503,NFP92-501防火测试相关新闻:随着建筑节能工作的深入开展,我国建筑保温材料行业迎来了难得的发展机遇。

不论是技术的创新、产业的融合与升级,还是解决市场、技术、标准、政策等方面存在的问题,都需要集全行业的力量,共同努力。

在推广交流会上,记者获悉,由住房和城乡建设部科技与产业化发展中心发起的、以技术创新和产业化创新为宗旨的中国绿色建材产业化创新联盟经过紧张筹备,即将成立,这对于我国绿色建材产业与绿色建筑产业的协调健康发展是一个好消息。

标准概述:法国政府于2002年11月颁布的条例第3章,以装饰装修材料对火反应特性为依据,定义其级别划分的标准。

NFP92-503 该法规包含建筑和装饰材料防火性能测试方法。

NF P 92-503对防火测试分为M0到M4级,M0为最高等级。

按M1至M4的标准,将各种厚度的硬质材料与厚度超过5毫米的软质材料的燃烧性能进行分级,其依据是NF P 92-501辐射热源试验所得结果。

易朔产品服务有限公司提供专业权威的测试服务。

标准名称:1.NF P92-503:建筑材料—电喷枪试验NF P92-503:Building material—Electrical burner test used for flexible materials2.NF P92-501: 建筑材料—辐射热源试验NF P92-501: Building material—used for rigid material or flexible materials thicker than 5mmNF P92-503:电喷枪试验的相关标准:NF P 92-501:辐射热源试验NF P 92-504:耐火性能试验和火焰蔓延速度测试NF P 92-505:熔滴试验NF P 92-506:铺地材料的发热板试验NF P92-507建筑材料分级测试NF P 92-511:根据材料性质与用途确定试验进行方式NF P 92-512:对火反应耐久度级别划分标准 - 试验。

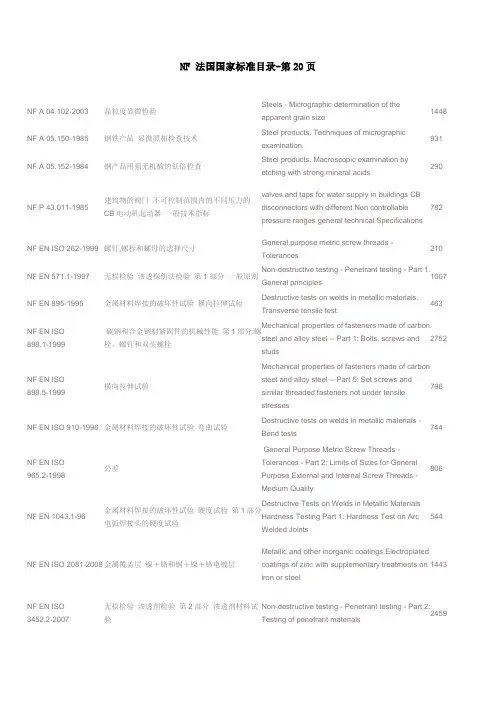

NF 法国国家标准目录-第20页NF A 04.102-2003 晶粒度显微检验Steels - Micrographic determination of theapparent grain size1448NF A 05.150-1985 钢铁产品显微照相检查技术Steel products. Techniques of micrographic examination.931NF A 05.152-1984 钢产品用强无机酸的低倍检查Steel products. Macroscopic examination byetching with strong mineral acids290NF P 43.011-1985 建筑物的阀门不可控制范围内的不同压力的CB电动机起动器一般技术指标valves and taps for water supply in buildings CBdisconnectors with different Non controllablepressure ranges general technical Specifications782NF EN ISO 262-1999 螺钉,螺栓和螺母的选择尺寸General purpose metric screw threads -Tolerances210NF EN 571.1-1997 无损检验渗透探伤法检验第1部分一般原则Non-destructive testing - Penetrant testing - Part 1. General principles1007NF EN 895-1995 金属材料焊接的破坏性试验横向拉伸试验Destructive tests on welds in metallic materials. Transverse tensile test463NF EN ISO 898.1-1999碳钢和合金钢制紧固件的机械性能第1部分:螺栓、螺钉和双头螺栓Mechanical properties of fasteners made of carbonsteel and alloy steel -- Part 1: Bolts, screws andstuds2752NF EN ISO 898.5-1999 横向拉伸试验Mechanical properties of fasteners made of carbonsteel and alloy steel -- Part 5: Set screws andsimilar threaded fasteners not under tensilestresses796NF EN ISO 910-1996 金属材料焊接的破坏性试验弯曲试验Destructive tests on welds in metallic materials - Bend tests744NF EN ISO 965.2-1998 公差General Purpose Metric Screw Threads -Tolerances - Part 2: Limits of Sizes for GeneralPurpose External and Internal Screw Threads -Medium Quality806NF EN 1043.1-96 金属材料焊接的破坏性试验硬度试验第1部分电弧焊接头的硬度试验Destructive Tests on Welds in Metallic MaterialsHardness Testing Part 1: Hardness Test on ArcWelded Joints544NF EN ISO 2081-2008 金属覆盖层镍+铬和铜+镍+铬电镀层Metallic and other inorganic coatings.Electroplated coatings of zinc with supplementary treatments oniron or steel1443NF EN ISO 3452.2-2007 无损检验渗透剂检验第2部分渗透剂材料试验Non-destructive testing - Penetrant testing - Part 2:Testing of penetrant materials2459NF EN ISO 3452.3-2007 无损检验渗透剂检验第3部分校准试验块Non-destructive testing - Penetrant testing - Part 3:Reference test blocks512NF EN ISO 3452.4-2007 无损检验渗透剂检验第4部分设备Non-destructive testing - Penetrant testing - Part 4:Equipment629NF EN ISO 3506.1-1998 耐腐蚀不锈钢紧固件的机械性能第1部分:螺栓、螺钉和螺柱Mechanical properties of corrosion-resistantstainless steel fasteners -- Part 1: Bolts, screwsand studs1920NF EN ISO 3506.2-1998 抗腐蚀不锈钢紧固件的机械性能第2部分Mechanical properties of corrosion-resistantstainless-steel fasteners -- Part 2: Nuts1560NF EN ISO 3506.3-1997 抗腐蚀不锈钢紧固件的机械性能第3部分Mechanical properties of corrosion-resistantstainless-steel fasteners -- Part 3: Set screws andsimilar fasteners not under tensile stress1258NF EN ISO 4759.1-2005 紧固件公差.第1部分:螺栓、螺钉和垫圈和螺母.产品等级A和CTolerances for fasteners -- Part 1: Bolts, screws,studs and nuts -- Product grades A, B and C1852NF EN ISO6157.2-1995紧固件表面不均匀性Fasteners -- Surface discontinuities -- Part 2: Nuts 702NF EN ISO 6506.1-2006 金属材料布氏硬度试验第1部分试验方法Metallic materials - Brinell hardness test - Part 1:Test method982NF EN ISO 6506.2-2006 金属材料布氏硬度试验第2部分试验机器的认证和校准Metallic materials - Brinell hardness test - Part 2:Verification and calibration of testing machines838NF EN ISO 6506.3-2006 金属材料布氏硬度试验第3部分参考块的校准Metallic materials - Brinell hardness test - Part 3:Calibration of reference blocks563NF EN ISO 6506.4-2006 金属材料布氏硬度试验第4部分硬度值表Metallic materials - Brinell hardness test - Part 4:Table of hardness values339NF EN ISO 6507.1-2006 金属材料维氏硬度试验第1部分试验方法Metallic materials - Vickers hardness test - Part 1:Test method961NF EN ISO 6507.2-2006 金属材料维氏硬度试验第2部分试验机器的认证和校准Metallic materials - Vickers hardness test - Part 2:Verification of testing machines1039NF EN ISO 6507.3-2006 金属材料维氏硬度试验第3部分参考块的校准Metallic materials - Vickers hardness test - Part 3:Calibration of the reference blocks777NF EN ISO 6507.4-2006 金属材料维氏硬度试验第4部分硬度值表Metallic materials - Vickers hardness test - Part 4:Tables of hardness values635NF EN ISO 6508.1-2006 金属材料洛氏硬度试验第1部分试验方法Metallic materials - Rockwell hardness test - Part1: Test method1300NF EN ISO 6508.2-2006 金属材料洛氏硬度试验第2部分试验机器的认证和校准Metallic materials - Rockwell hardness test - Part2: Verification and calibration of testing machines1292NF EN ISO 6508.3-2006 金属材料洛氏硬度试验第3部分参考块的校准Metallic materials - Rockwell hardness test - Part3: Calibration of reference blocks884NF EN ISO 7438-2005 金属材料弯曲试验Metallic materials - Bend test 411 NF EN ISO 8493-2004 金属材料管材扩口试验Metallic materials - Tube - Drift-expanding test 285NF EN ISO10484-2004螺母扩孔试验Widening test on nuts 370 NF EN ISO10485-2004螺母锥形保证载荷试验Cone proof load test on nuts 317NF EN 12223-2000 无损检验超声波检验1号校准块规范Non-destructive testing. Ultrasonic examination. Specification for calibration block No.1376NF EN10216.2.A2-2007 承压用无缝钢管交货技术条件Seamless steel tubes for pressure purposes -Technical delivery conditions - Part 2: Non alloyand alloy steel tubes with specified elevatedtemperature properties; German version3074NF EN10217.1.A1-2005 承压用焊接钢管规定室温性能的非合金钢管Welded steel tubes for pressure purposes -Technical delivery conditions - Part 1: Non-alloysteel tubes with specified room temperatureproperties362NF F 18-001-1988 铁路运输车辆.锰钢磨耗板.性能.焊接规定Rolling stock. Wearing plates made ofmanganeses steel. Characteristics. Welding prescriptions950NF F 19-290-2002 铁路设施保护和装饰用的室外涂料系统Railway applications - Outdoor paint systems for conservation and ornementation1380NF E 25.100.0-92 Mechanical properties of fasteners made ofcarbon steel and alloy steelMechanical properties of fasteners made of carbonsteel and alloy steel1666NF E 25.400.0-93 Mechanical properties of corrosion-resistantstainlessMechanical properties of corrosion-resistantstainless983NF E 25-135-1986 固定部件。

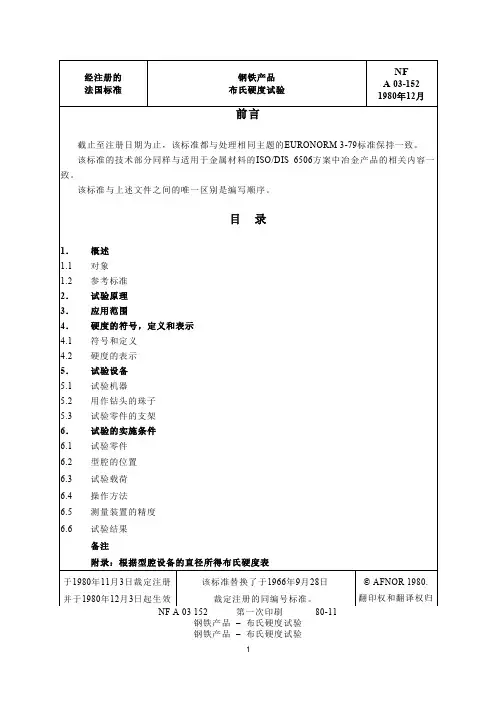

11.概述1.1 对象该标准介绍了钢铁产品的布氏硬度试验并说明了其应用方法。

1.2 参考标准NF A 03-154 《冶金产品–钢铁的维氏硬度试验(载荷为5kgf到100kgf)》。

NF A 03-502 《冶金产品–布氏硬度试验机器的检验》。

NF A 03-505 《冶金产品–布氏硬度试验–硬度参考块的标定》。

NF A 95-422 《冶金产品–硬金属–维氏硬度试验(载荷为98,1到491N)》。

2.试验原理2.1 该试验即在载荷F下将一个直径为D的钢珠或碳化钨珠压印到试验零件中,然后测定去掉载荷后留在表面上的型腔的平均直径d。

2.2 布氏硬度即与试验载荷F的商数成正比的一个数,以牛顿比平方毫米表示,对应球面直径为D的球冠形型腔的面积。

该硬度应由最接近所得商数的整数来表示。

其比例系数为0,102,可根据下列方程获得布氏硬度:布氏硬度根据珠子的属性布氏硬度的符号分别是:- 通过钢珠完成的试验对应符号为HBS。

- 通过碳化钨珠完成的试验对应符号为HBW。

3.应用范围布氏硬度试验的应用范围取决于用作钻头的珠子属性:- 钢珠:试验仅适用于450以下的布氏硬度。

- 碳化钨珠:试验适用于布氏硬度650以下的所有硬度范围。

每种珠子都对应一个硬度级。

对于超过350的布氏硬度这两种级别是不同的。

4.硬度的符号,定义和表示4.1 符号和定义下面的表1中列举了各项符号和定义:中的规定一致的一批珠子中选择新的珠子。

然后在的温度下通过一台精度为的测量装置检验珠子的直径。

5.2.1 钢珠这种珠子必须采用淬火钢制造并具备根据NF A 03-154标准所测定的不小于850 HV 10的维氏硬度。

表2中提供了在98,07牛的载荷在根据钢珠曲率所得维氏型腔的平均对角线最大值。

5.2.2 碳化钨珠这种珠子必须选用碳化钨制造,其化学成分如下:- 碳化钨94%- 钴6%其比重为。

这种珠子必须具备根据NF A 95-422标准所测定的不小于1500 HV 10的维氏硬度。

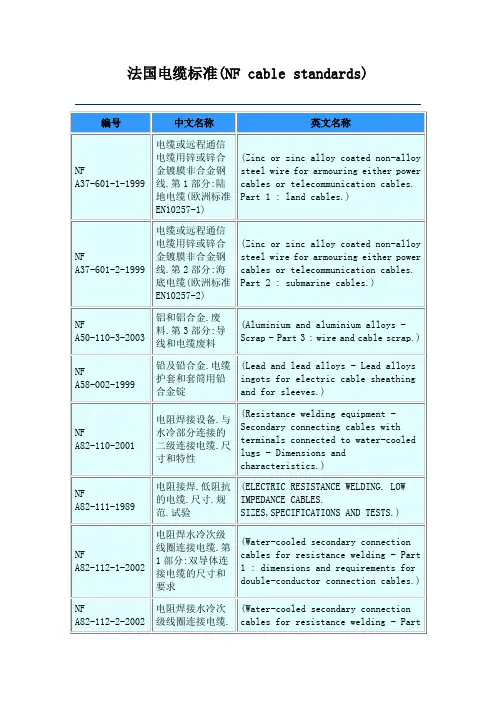

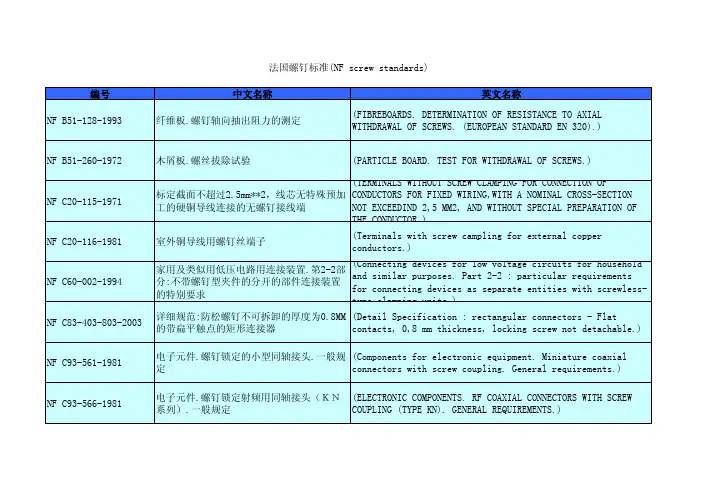

编号中文名称英文名称NF B51-128-1993纤维板.螺钉轴向抽出阻力的测定(FIBREBOARDS. DETERMINATION OF RESISTANCE TO AXIAL WITHDRAWAL OF SCREWS. (EUROPEAN STANDARD EN 320).)NF B51-260-1972木屑板.螺丝拔除试验(PARTICLE BOARD. TEST FOR WITHDRAWAL OF SCREWS.)NF C20-115-1971标定截面不超过2.5mm**2,线芯无特殊预加工的硬铜导线连接的无螺钉接线端(TERMINALS WITHOUT SCREW CLAMPING FOR CONNECTION OFCONDUCTORS FOR FIXED WIRING,WITH A NOMINAL CROSS-SECTIONNOT EXCEEDIND 2,5 MM2, AND WITHOUT SPECIAL PREPARATION OFTHE CONDUCTOR)NF C20-116-1981室外铜导线用螺钉丝端子(Terminals with screw campling for external copper conductors.)NF C60-002-1994家用及类似用低压电路用连接装置.第2-2部分:不带螺钉型夹件的分开的部件连接装置的特别要求(Connecting devices for low voltage circuits for householdand similar purposes. Part 2-2 : particular requirementsfor connecting devices as separate entities with screwless-type clamping units)NF C83-403-803-2003详细规范:防松螺钉不可拆卸的厚度为0.8MM的带扁平触点的矩形连接器(Detail Specification : rectangular connectors - Flatcontacts, 0,8 mm thickness, locking screw not detachable.)NF C93-561-1981电子元件.螺钉锁定的小型同轴接头.一般规定(Components for electronic equipment. Miniature coaxialconnectors with screw coupling. General requirements.)NF C93-566-1981电子元件.螺钉锁定射频用同轴接头(KN系列).一般规定(ELECTRONIC COMPONENTS. RF COAXIAL CONNECTORS WITH SCREWCOUPLING (TYPE KN). GENERAL REQUIREMENTS.)法国螺钉标准(NF screw standards)NF C93-578-1996射频连接件.第20部分:外导线内径为13.56mm(0,534 in)同时带有两条内导线的屏蔽平衡电缆用双头螺钉(3/4-20统(Radio-frequency connectors. Part 25 : two-pole screw (3/4-20 unef) coupled connectors for use with shielded balancedcables having twin inner conductors with inner diameter ofouter conductor1356mm(0534in)(type twhn))NF E02-312-1981钢制规.螺丝孔莫氏锥环规(STEEL GAUGES. MORSE TAPER RING GAUGES.) NF E02-316-1981钢制规.螺丝孔5%锥度环规(STEEL GAUGES. METRIC TAPER RING GAUGES.)NF E03-152-1981用极限量规检验螺纹.螺钉用螺纹规(Thread checking with limit gauges. Threaded gauges for screw.)NF E03-154-1970公制三角螺纹.用极限规检验螺纹.螺钉和螺钉孔光滑度检查器(THREAD CHECKING WITH LIMIT GAUGES. PLAIN GAUGES FOR SCREWSAND NUTS.)NF E04-012-1-1996技术制图.螺钉和螺纹部件.第1部分:通用规范(Technical drawings. Screw threads and threaded parts. Part1 : general conventions.)NF E04-012-2-1996技术制图.螺钉和螺纹部件.第2部分:螺纹嵌镶件(TECHNICAL DRAWINGS. SCREW THREADS AND THREADED PARTS. PART2 : SCREW THREAD INSERTS. (EUROPEAN STANDARD EN ISO 6410-2).)NF E04-012-3-1996技术制图.螺钉和螺纹部件.第3部分:简化表示(TECHNICAL DRAWINGS. SCREW THREADS AND THREADS AND THREADEDPARTS. PART 3 : SIMPLIFIED REPRESENTATION. (EUROPEANSTANDARD EN ISO 6410-3).)NF E22-201-1992滚珠螺钉.第1部分:词汇和命名(Ball screws. Part 1 : vocabulary and designation.)NF E22-202-1992滚珠螺钉.第2部分:公称直径和公称引线.米制系列(Ball screws. Part 2 : nominal diameters and nominal leads.Metric series.)NF E22-203-1993球端螺钉.第3部分:合格条件和合格试验(Ball screws. Part 3 : acceptance conditions and acceptance tests.)NF E25-011-1992紧固件的机械特性.由非亚铁金属制造的螺栓,螺钉,柱螺栓和螺母(MECHANICAL PROPERTIES OF FASTENERS. BOLTS, SCREWS, STUDSAND NUTS MADE OF NON-FERROUS METALS. (EUROPEAN STANDARD EN28839).)NF E25-018-2-1994沉头螺钉.第2部分:十字槽(CONTERSUNK FLAT HEAD SCREWS. PART 2 : PENETRATION DEPTHY OF CROSS RECESSES. (EUROPEAN STANDARD EN ISO 7721-2).)NF E25-021-1994螺钉的十字槽(欧洲标准EN ISO 4757)(Cross recesses for screws.)NF E25-022-1-2001紧固件公差.螺栓、螺钉、双头螺栓和螺母.第1部分:产品等级A、B及C(Tolerances for fasteners - Bolts, screws, studs and nuts -Part 1 : product grades A, B and C.)NF E25-022-1987紧固件.F级螺钉和螺帽公差(精密机械).螺纹直径1到3mm(FASTENERS. TOLERANCES FOR BOLTS,SCREWS AND NUTS PRODUCTGRADE F (FINE MECHANIC). THREAD DIAMETERS FROM 1 UP TO 3MM.)NF E25-023-1992紧固件.螺栓和螺钉的自由尺寸孔(Fasteners. Clearance hole for bolts and screws.)NF E25-100-1-1999碳钢合金制成的紧固件的机械性能.第1部分:螺栓、螺钉和螺柱(Mechanical properties of fasteners made of carbon steeland alloy steel - Part 1 : bolts, screws and studs.)NF E25-100-3-1992紧固件.表面不连续性.第1部分:一般要求的螺栓、螺钉和螺柱(FASTENERS. SURFACE DISCONTINUITIES. PART 1 : BOLTS, SCREWSAND STUDS FOR GENERAL REQUIREMENTS. (EUROPEAN STANDARD EN26157-1).)NF E25-100-4-1992紧固件.表面不连续性.第3部分:特殊要求的螺栓、螺钉和螺柱(FASTENERS. SURFACE DISCONTINUTIES. PART 3 : BOLTS, SCREWAND STUDS FOR SPECIAL REQUIREMENTS. (EUROPEAN STANDARD EN26157-3).)NF E25-100-5-1998碳钢和不锈钢制紧固件的机械性能.第5部分:不处在拉伸应力下的固定螺钉和类似螺纹紧固件(Mechanical properties of fasteners made of carbon steeland alloy steel. Part 5 : set screws and similar threadedfasteners not under tensile stresses.)NF E25-100-6-1998不锈钢紧固件耐腐蚀的机械特性.螺栓,螺丝和双端螺栓(Mechanical properties of corrosion-resistant stainless-steel fasteners. Part 1 : bolts, screws and studs.)NF E25-100-7-1995紧固件的机械性能.第7部分:公称直径1-10mm的螺栓和螺钉的扭力试验和最小扭矩(MECHANICAL PROPERTIES OF FASTENERS. PART 7 : TORSIONALTEST AND MINIMUM TORQUES FOR BOLTS AND SCREWS WITH NOMINALDIAMETERS 1 MM TO 10 MM. (EUROPEAN STANDARD EN 20898-7).)NF E25-100-8-1998不锈钢紧固件耐腐蚀的机械特性.不低于拉伸应力下配套螺钉和类似紧固件(Mechanical properties of corrosion-resistant stainless-steel fasteners. Part 3 : set screws and similar fastenersnot under tensile stress.)NF E25-107-1983金属用螺钉.内部六叶埋头.A级.符号FX(SCREWS. SIX LOBES RECESSED CONTERSUNK HEAD. PRODUCT GRADE A. SYMBOL FX.)NF E25-108-2001半埋头内六角螺钉(Hexalobular socket raised countersunk head screws.) NF E25-109-2001平头内六角螺钉(Hexalobular socket pan head screws.)NF E25-110-2001圆柱头内六角螺钉(Hexalobular socket head cap screws.)NF E25-111-2001凸头内六角螺钉(Hexalobular socket cheese head screws.)NF E25-114-2001六角头螺钉.产品等级A和B(Hexagon head bolts - Product grades A and B.)NF E25-115-2-2001六角头螺钉.产品等级C(Hexagon head screws - Product grade C.)NF E25-116-1983金属用螺钉.方头.标准杆.A和B级.符号Q(Square head screws. Product grades A and B. Symbol Q.) NF E25-117-1983金属用螺钉.方头.全螺纹.A和B级.符号Q(Square head screws. Product grades A and B. Symbol Q.) NF E25-118-1983金属用螺钉.方头.C级.符号Q(Square head screws. Product grade C. Symbol Q.)NF E25-119-1-1994带有H型或Z型的十字槽沉头螺钉(普通头型).产品等级A.第1部分:性能类别4.8的钢(Countersunk flat head screws (common head style) with typeH or type Z cross recessed. Product grade A. Part 1 : steelof property class 4.8.)NF E25-119-2-1994十字槽沉头螺钉(一般头形).等级A.第2部分:8.8类特性钢,不锈钢和有色金属(Cross recessed countersunk flat head scews (common headstyle). Grade A. Part 2 : steel of property class 8.8,stainless steel and non-ferrous metals.)NF E25-120-1994带有H型或Z型的十字槽半沉头螺钉(普通头型).产品等级A(Countersunk raised head screws (common head style) withtype H or type Z cross recessed. Product grade A.)NF E25-121-1994带有H型或Z型十字槽的平圆头螺钉.产品等级A(Pan head screws with type H or type Z cross recess.Product grade A.)NF E25-122-1984金属用螺钉.称作“POLIER“的Z十字槽宽圆头.A级.符号RLZ(SCREWS. CROSS RECESSED MUSHROOM HEAD (POELIERS). PRODUCTGRADE A. SYMBOL RL Z.)NF E25-123-1994一字槽沉头螺钉(普通头型).产品等级A (Slotted countersunk flat head screws (common head style). Product grade A.)NF E25-124-1994一字槽半沉头螺钉(普通头型).产品等级A (Slotted raised countersunk head screws (common head style). Product grade A.)NF E25-126-1997内六角圆头螺钉(HEXAGON SOCKET BUTTON HEAD SCREWS. (EUROPEAN STANDARD EN ISO 7380).)NF E25-128-1994一字槽平圆头螺钉.产品等级A(Slotted pan head screws. Product grade A.)NF E25-130-1986加垫圈的金属用螺钉.锥形光滑压紧垫圈.A级(SCREWS WITH CONICAL SPRING TIGHTENING WASHER. PRODUCTGRADE A.)NF E25-131-1986加垫圈的金属用螺钉.内齿锥形垫圈.A级(SCREWS WITH CONICAL SPRING INTERNAL TOOTHED TIGHTENING WASHER. PRODUCT GRADE A.)NF E25-132-1986加垫圈的金属用螺钉.外齿垫圈.A级(SCREWS WITH SERRATED EXTERNAL OVERLAPED TOOTHED LOCK TIGHTENNING WASHER. PRODUCT GRADE A.)NF E25-133-1987紧固件.螺杆千斤顶用的金属螺钉.短六角头长制动端螺钉.A和B级.符号HZ(Fasteners. Screws for screw-jacks. Small hexagon headscrews with long dog point. Product grades A and B. SymbolHZ.)NF E25-134-1987紧固件.螺杆千斤顶用的金属螺钉.短方头短制动端螺钉.A和B级.符号QZ(Fasteners. Screws for screw-jacks. Small square headscrews with short dog point. Product grades A and B. SymbolQZ.)NF E25-139-1987紧固件.金属用螺钉.Z十字槽宽凸圆柱形头.A级.符号CBLZS(FASTENERS. SCREWS. Z CROSS RECESSED AND SLOTTED PAN HEAD.GRADE A. SYMBOL CBL ZS.)NF E25-142-1991紧固件.电阻焊金属螺钉.缩小头(FASTENERS. RESISTANCE WELDING SCREWS. REDUCED HEAD. SYMBOL Z. SR.)NF E25-149-1998十字槽圆头螺钉(CROSS RECESSED CHEESE HEAD SCREWS. (EUROPEAN STANDARD EN ISO 7048).)NF E25-150-1998带平垫圈的螺钉和垫圈组件.垫圈强度等级为200 HV和300 HV.(Screw and washer assemblies with plain washers. Washerhardness classes 200 HV and 300 HV.)NF E25-151-2001米制细牙螺纹的六角头螺钉.产品等级A和B (Hexagon head screws with metric fine pitch thread -Product grades A and B.)NF E25-160-1992平端开槽调整螺钉(SLOTTED SET SCEWS WITH FLAT POINT. (EUROPEAN STANDARD EN 24766).)NF E25-161-1992锥端开槽调整螺钉(SLOTTED SET SCEWS WITH CONE POINT. (EUROPEAN STANDARD EN 27434).)NF E25-162-1992长制动端开槽调整螺钉(SLOTTED SET SCREWS WITH LONG DOG POINT. (EUROPEAN STANDARD EN 27435).)NF E25-163-1992蝶形端开槽调整螺钉(SLOTTED SET SCEWS WITH CUP POINT. (EUROPEAN STANDARD EN 27436).)NF E25-501-2000紧固件公差.第3部分:螺栓、螺钉和螺母用平垫圈.A级和C级(Tolerances for fasteners - Part 3 : plain washers forbolts, screws and nuts - Product grades A and C.)NF E25-520-1998螺丝和洗衣机组件用水平式洗衣机.小型,常规型和大型系列.A级产品(PLAIN WASHERS FOR SCREW AND WASHER ASSEMBLIES. SMALL,NORMAL AND LARGE SERIES. PRODUCT GRADE A. (EUROPEANSTANDARD EN ISO 10673).)NF E25-525-2000通用米制螺栓、螺钉和螺母用平垫圈.一般示意图(Plain washers for metric bolts, screws and nuts forgeneral purposes - General plan.)NF E25-600-1984紧固件.木螺钉系列标准(FASTENERS. WOOD SCREWS FAMILY STANDARD.)NF E25-601-1984十字槽沉头木螺钉.符号FZ(CROSS RECESSED COUNTERSUNK HEAD WOOD SCREWS. SYMBOL FZ.)NF E25-602-1984十字槽沉头木螺钉.符号FBZ (CROSS RECESSED RAISED COUNTERSUNK HEAD WOOD SCREWS. SYMBOL FBZ.)NF E25-603-1984一字槽圆头木螺钉.符号RZ(CROSS RECESSED ROUND HEAD WOOD SCREWS. SYMBOL RZ.)NF E25-604-1984有槽沉头木螺钉.符号FS(Slotted countersunk head wood screws. Symbol FS.)NF E25-605-1984木螺丝.一字槽沉头.FBS符号(Slotted raised countersunk head wood screws. Symbol FBS.) NF E25-609-1985木螺钉.螺丝眼(WOODSCREWS. SCREW-EYES.)NF E25-609-1985木螺钉.螺丝眼(WOODSCREWS. SCREW-EYES.)NF E25-610-1985木螺钉.螺丝钩(WOODSCREWS. SCREW-HOOKS.)NF E25-610-1985木螺钉.螺丝钩(WOODSCREWS. SCREW-HOOKS.)NF E25-611-1985木螺钉.直角弯头螺丝钩(WOODSCREWS. SQUARE BEND SCREW HOOKS.)NF E25-611-1985木螺钉.直角弯头螺丝钩(WOODSCREWS. SQUARE BEND SCREW HOOKS.)NF E25-650-1-1994热处理钢自攻螺钉.机械性能(Heat-treated steel tapping screws. Mechanical properties.) NF E25-650-2-1999自攻螺钉螺纹(Tapping screw thread.)NF E25-651-2003耐腐蚀不锈钢紧固件的机械特性.第4部分:攻丝螺钉(Mechanical properties of corrosion-resistant stainlesssteel fasteners - Part 4 : tapping screws.)NF E25-652-2001沉头内六角攻丝螺钉(Hexalobular socket countersunk head tapping screws.)NF E25-653-2001半埋头(椭圆形)内六角攻丝螺钉(Hexalobular socket raised countersunk (oval) head tapping screws.)NF E25-654-2001平头内六角攻丝螺钉(Hexalobular socket pan head tapping screws.)NF E25-655-1983内六角圆头自攻螺钉.符号RLX (ROUND HEAD TAPPING SCREWS WITH SIX LOBES RECESS. SYMBOL RLX .)NF E25-656-1994十字槽沉头自攻螺钉(普通头型)(Cross recessed countersunk (flat) head tapping screws (common head style).)NF E25-657-1994十字槽半沉头椭圆头自攻螺钉(Cross recessed raised countersunk (oval) head tapping screws.)NF E25-658-1994十字槽平圆头自攻螺钉(Cross recessed pan head tapping screws.)NF E25-659-1984自攻螺钉.十字槽半沉头.(`Poelier`).符号RLZ(TAPPING SCREWS. CROSS RECESSED MUSHROOM HEAD (“POELIER“). SYMBOL RL Z.)NF E25-664-1986一字槽六角头自攻螺钉.符号HS(HEXAGON SLOTTED HEAD TAPPING SCREWS. SYMBOL HS.)NF E25-666-1987紧固件.自攻螺钉.Z形十字槽和一字槽平圆头螺钉.符号CBL ZS(FASTENERS. TAPPING SCREWS. Z CROSS RECESSED AND SLOTTEDPAN HEAD. SYMBOL CBL ZS.)NF E25-755-1997非硬度钢和奥斯特不锈钢的内螺纹平行螺钉(Parallel pins with internal thread, of unhardened steel and austenitic stainless steel.)NF E25-756-1997金属不锈钢和硬化钢的平行螺钉(Parallel pins, of hardened steel and martensitic stainless steel (Dowel pins).)NF E25-757-1997非硬度钢和奥斯特不锈钢的内螺纹平行螺钉(Parallel pins with internal thread, of hardened steel and martensitic stainless steel.)NF E25-800-1-1994紧固件.波纹钢管用螺栓.第1部分:带法兰或不带法兰,带尖或不带尖的六角头螺钉.产品等级A(FASTENERS. BOLTS FOR CORRUGATED STEEL PIPES. PART 1 :HEXAGON HEAD SCREWS WITH OR WITHOUT FLANGE, WITH OR WITHOUTNIBS. PRODUCT GRADE A.)NF E25-800-2-1994紧固件.波纹钢管用螺栓.第2部分:带尖或不带尖的圆头螺钉.产品等级A(FASTENERS. BOLTS FOR CORRUGATED STEEL PIPES. PART 2 :CHEESE HEAD SCREWS, WITH OR WITHOUT NIBS. PRODUCT GRADE A.)NF E25-851-1987紧固件.滚制螺钉(ISO米制螺纹).特性(FASTENERS. THREAD ROLLING SCREWS (ISO METRIC THREAD). PROPERTIES.)NF E27-163-1972调整螺钉(ADJUSTING SCREW.)NF E27-164-1976锁紧螺钉的垫板(LOCKING SCREW.)NF E27-165-1976锁紧螺钉的穿销(SLIDE FOR LOCKING SCREW.)NF E27-166-1976滚花头锁紧螺钉(LOCKING SCREW WITH KNURLED KNOB.)NF E27-167-1976星形手扭锁紧螺钉(LOCKING SCREW WITH PALM KNOB.)NF E27-168-1976四翼锁紧螺钉(LOCKING SCREW WITH 4 ARMED KNOB.)NF E27-170-1974通用滚花头螺钉(GENERAL PURPOSE KNURLED THUMBS SCREWS.) NF E27-191-1983紧固件.有肩固定螺钉(FASTENERS. SHOULDERED RETAINING SCREWS.)NF E27-214-1976带小提琴紧弦用的蝶形螺母锁紧螺钉(LOCKING SCREW WITH VIOLIN TYPE THUMB NUT.) NF E27-215-1976带六角螺母的锁紧螺钉(LOCKING SCREWS WITH HEXAGON NUT.)NF E27-303-1968有孔球头螺钉(SPHERICAL HOLED HEAD SCREW.)NF E27-853-1989通用金属卡箍.带型,无螺钉,不可重复使用(Metallic hose clamps for general purpose. Band type,without screws, non re-usable. Specifications.)NF E27-854-1982通用金属卡箍.带型,无螺钉,可重复使用的销钉卡箍或轴的卡箍(METAL-HOSE CLAMPS FOR GENERAL PURPOSES ; BAND TYPE,WITHOUTSCREWS,RE-USABLE,PIN OR AXLE CLAMPS.)NF E62-307-1977机床构造标准部件.多轴头.防护装置.28和36卧式防护装置.支架.行程止推螺钉(MODULAR UNITS FOR MACHINE TOOL CONSTRUCTION. MULTI-SPINDLEHEADS. HORIZONTAL TEMPLATES 28 AND 36. SUPPORTS : STOPSCREW.)NF E62-519-2003柱形扁柄刀具用螺钉压紧刀具夹(立铣刀刀夹).第1部分:刀柄驱动系统的尺寸(Tool chucks (end mill holders) wirth clamp screws forflatted cylindrical shank tool - Part 1 : dimensions of thedriving system of tool shanks.)NF E62-520-2003柱形扁柄刀具用螺钉压紧刀具夹(立铣刀刀夹).带7/24锥柄的夹头尺寸(Tools chucks (end mill holders) wirth clamp screws forflatted cylindrical shank tools - Dimensions of chucks with7/24 taper shank.)NF E62-526-2003带7/24外圆锥和莫氏内圆锥缩径套筒和连接螺钉(Reduction sleeves with 7/24 external and Morse internaltaper and incorporated screw.)NF E63-512-1983铸型和挤压器材.金属模型构件.止动螺钉(MOULDING AND EXTRUSION EQUIPMENT. METALLIC MOULDING ELEMENTS. LOCKING SCREWS.)NF E66-103-1993机用螺丝锥和手动螺丝锥(Short machine taps and hand taps.)NF E66-107-2000公称直径由M3-M10的长杆螺丝攻.由回缩的全直径杆型螺丝攻(Long shank taps with nominal diameters from M3 to M10 -Full-diameter shank taps with recess.)NF E66-108-2000公称直径由M3-M24和1/8-1 英寸的长杆螺丝攻.渐减型螺丝攻(Long shank taps with nominal diameters from M3 to M24 and1/8 in to 1 in - Reduced shank taps.)NF E66-120-1975圆柱和锥形管螺纹手用螺丝锥(HAND TAPS FOR PIPE THREADS FOR PARALLEL AND TAPER THREADS.)NF E66-150-1990ISO公制螺纹的手用和机用圆螺丝板牙(Hand- An machine-operated circular screwing dies and hand-operated die stocks.)NF E66-153-1990煤气管道圆柱螺纹手用和机用圆螺丝板牙(Hand-and machine-operated circular screwing dies for parallel pipe threads. G series.)NF E74-303-2001螺钉和螺母组装工具.锻造的和管形套筒扳手.头部外形最大尺寸(Assembly tools for screws and nuts - Forged and tubularsocket wrenches - Maximum outside head dimensions.)NF E74-304-2001螺钉和螺母装配工具.双头开口扳手、双头环形扳手和多用扳手.端部最大宽度(Assembly tools for screws and nuts - Double-headed open-ended wrenches, double-headed ring wrenches and combinationwrenches - Maximum widths of heads.)NF E74-305-2001螺钉和螺母装配工具.双头扳手.尺寸选配(Assembly tools for screws and nuts - Double-ended wrenches - Size pairings.)NF E74-307-2001螺钉和螺母用装配工具.组合扳手.扳手长度和端口最大厚度(Assembly tools for screws and nuts - Combination wrenches- Lengths of wrenches and maximum thickness of heads.)NF E74-310-2001螺钉和螺母用装配工具.工程用双头开口扳手.扳手长度和端口厚度(Assembly tools for screws and nuts - Double-headed open-ended engineers' wrenches - Length of wrenches andthickness of the heads.)NF E74-311-2001螺钉和螺母用装配工具.双头平直套筒扳手和斜口套筒扳手.扳手长度和端口厚度(Assembly tools for screws and nuts - Double-headed, flatand offset, box wrenches - Length of wrenches and thicknessof the heads.)NF E74-313-2001螺钉和螺母用装配工具.双头深斜口套筒扳手和改进的斜口套筒扳手.扳手长度和端口厚度(Assembly tools for screws and nuts - Double-headed, deepoffset and modified offset, box wrenches - Length ofwrenches and thickness of the heads.)NF E74-321-1998螺钉和螺母用装配工具.十字形套筒扳手.尺寸和扭矩试验(ASSEMBLY TOOLS FOR SCREWS AND NUTS. FOUR-WAY SOCKETWRENCHES. DIMENSIONS AND TORQUE TEST.)NF E74-322-1972螺钉螺帽紧固工具.齿条式扳手(ASSEMBLY TOOLS FOR SCREWS AND NUTS.RACK WRENCHES.)NF E74-323-1972螺钉螺帽紧固工具.开槽螺帽用单钩扳手(ASSEMBLY TOOLS FOR SCREWS AND NUTS.HOOK WRENCHES)NF E74-324-2001螺钉和螺母用装配工具.可调扳手(Assembly tools for screws and nuts - Adjustable wrenches.)NF E74-325-2003螺钉和螺母用装配工具.手动转矩工具.设计一致性试验、质量一致性试验和重新校准程序的要求和试验方法(Assembly tools for screws and nuts - Hand torque tools -Requirements and test methods for design conformancetesting, quality conformance testing and recalibrationprocedure)NF E74-331-2003螺钉和螺母用装配工具.内六角扳手(Assembly tools for screws and nuts - Hexagon socket screw keys.)NF E74-351-2002螺钉和螺母用装配工具.一字槽头螺钉用旋具.第2部分:手工操作旋具的一般要求、刀刃长度和标记(Assembly tools for screws and nuts - Screwdrivers forslotted-head screws - Part 2 : general requirements,lengths of blades and marking of hand-operatedscrewdrivers)NF E74-352-1998螺钉和螺母用装配工具.槽螺钉用旋具.第1部分:手工及机械操作用的旋具头(Assembly tools for screws and nuts. Screwdrivers forslotted-head screws. Part 1 : tips for hand- and machine-operated screwdrivers.)NF E74-353-1-2002螺钉和螺母用装配工具.机动旋转头.第1部分:一字槽螺钉旋具(Assembly tools for screws and nuts - Machine-operatedscrewdriver bits - Part 1 : screwdriver bits for slottedhead screws.)NF E74-353-2-2002螺钉和螺母用装配工具.机动旋转头.第2部分:十字槽螺钉旋具头(Assembly tools for screws and nuts - Machine-operatedscrewdrivers bits - Part 2 : screwdriver bits for cross-recessed head screws.)NF E74-353-3-2002螺钉和螺母用装配工具.机动旋转头.第3部分:内六角螺钉用旋具头(Assembly tools for screws and nuts - Machine-operatedscrewdriver bits - Part 3 : screwdriver bits for hexagonsocket screws.)NF E74-354-2002螺钉和螺母用装配工具.螺旋棘轮螺钉旋具头.尺寸(Assembly tools for screws and nuts - Spiral ratchetscrewdriver ends - Dimensions.)NF E74-355-1993十字槽头螺钉用旋转具.第1部分:旋具尖(SCREWDRIVERS FOR CROSS-RECESSED HEAD SCREWS. PART 1 : DRIVERS POINTS.)NF E74-356-1993十字槽头螺钉用旋具.第2部分:手持式旋具的一般要求、旋具头长度和标记(SCREWDRIVERS FOR CROSS-RECESSED HEAD SCREWS. PART 2 :GENERAL REQUIREMENTS, LENGTHS OF BLADES AND MARKING OFHAND-OPERATED SCREWDRIVERS.)NF E74-360-2001螺钉和螺母用装配工具.手动和机动螺丝刀的驱动端和连接部件.尺寸和扭矩试验(Assembly tools for screws and nuts - Drive ends for hand-and machine-operated screwdriver bits and connecting parts- Dimensions, torque testing.)NF E74-360-2001螺钉和螺母用装配工具.手动和机动螺丝刀的驱动端和连接部件.尺寸和扭矩试验(Assembly tools for screws and nuts - Drive ends for hand-and machine-operated screwdriver bits and connecting parts- Dimensions, torque testing.)NF E74-361-1997螺钉和螺母用装配工具.方形旋具.第1部分:手动套筒工具用方形旋具(Assembly tools for screws and nuts. Driving squares. Part1 : driving squares for hand socket tools.)NF E74-362-1997螺钉和螺母用装配工具.方形旋具.第2部分:电动套筒工具用方形旋具(Assembly tools for screws and nuts. Driving squares. Part2 : driving squares for power socket tools.)NF E74-363-1-1997螺钉和螺母用装配工具.方形传动套筒.第1部分:手动套筒.尺寸(Assembly tools for screws and nuts. Square drive sockets.Part 1 : hand-operated sockets. Dimensions.)NF E74-363-2-1997螺钉和螺母用装配工具.方形传动套筒.第2部分:机动“冲击“套筒.尺寸(Assembly tools for screws and nuts. Square drive sockets.Part 2 : machine-operated sockets “impact“. Dimensions.)NF E74-363-3-2001螺钉和螺母用组合工具.方形驱动套筒.第3部分:机器驱动套筒(无冲击).尺寸(Assembly tools for screws and nuts - Square drive sockets- Part 3 : machine-operated sockets (“non impact“) -Dimensions.)NF E74-365-1997螺钉和螺母用装配工具.手动方形传动套筒扳手上的传动件.尺寸和试验(Assembly tools for screws and nuts. Driving parts forhand-operated square drive socket wrenches. Dimensions andtests.)NF E74-366-1997螺钉和螺母用装配工具.手动方形传动套筒扳手上的附件.尺寸和试验(Assembly tools for screws and nuts. Attachments for hand-operated square drive socket wrenches. Dimensions andtests.)NF E74-367-1995螺钉和螺母用装配工具.机动插头扳手的方块传动加长六角插头(Assembly tools for screws and nuts. Square drive extensionhexagon insert, for power socket wrenches.)NF E74-381-1997螺钉和螺母用装配工具.技术规范.第1部分:手动扳手和套筒(Assembly tools for screws and nuts. Technicalspecifications. Part 1 : hand-operated wrenches andsockets.)NF E82-020-1984模压锻造零件.拉紧装置用灯的螺钉.规范(DROP FORGINS. EYEBOLTS FOR TURNBUCKLES. REQUIREMENTS.)NF F01-088-1971铁路运输设备.带有槽端头和螺纹端头的未钻孔轴.头部钻孔的螺钉(RAILWAY TRANSPORT EQUIPMENT. UNBORED AXLES WITH SLOTTEDAND THREADED ENDS. SCREWS WITH DRILLED HEADS.)NF F03-004-1983铁路车辆.金属螺钉. 沉头和半沉头. A级.符号F和FB(Railway rolling stock. Grade A. Countersunk and raisedcountersunk notched head machine screws. Symbols F and FB.)NF F03-005-1983铁路车辆.金属螺钉. 圆柱头和球面圆柱头.A级. 符号C和CR(Railway rolling stock. Grade A. Notched cheese head ornotched dome head machine screws. Symbols C and CR.)NF F03-006-1983铁路车辆.开槽懦半沉头螺钉一螺母. A级.符号FBP(Railway rolling stock. Grade A. Slotted or notched raisedcountersunk head screws nuts. Symbol FBP.)NF F03-016-1983铁路车辆.开槽沉头螺钉, 螺母. A级. FP(Railway rolling stock. Grade A. Slotted countersunk headscrews nuts. Symbol FP.)NF F10-404-1984铁路车辆.0.25MN的联接螺钉(Railway transport equipment. Coupling screw of 0,25 mn.)NF F11-003-1970铁路车辆.手制动. 螺钉和螺母. 螺距和螺纹剖面. 螺钉传动(RAILWAY TRANSPORT EQUIPMENT. HAND BRAKE. SCREWS AND NUTS.PITCHES AND PROFILES. SCREW DRIVES.)NF F50-006-1998铁路固定设备.带可变螺纹的枕木螺丝(Railway fixed equipment. Sleeper screws with variable thread.)NF F55-251-1991铁路固定设备.信号电路.连接和分段器材.螺钉连接部件(RAILWAY FIXED EQUIPMENT. SIGNALLING. CIRCUITS. CONNECTINGAND BREAKING COMPONENTS. SCREW-TYPE TERMINAL BLOCKS.)NF F56-123-1980铁路固定设备.通讯和信号装置架空线路用器材.直径口毫米镀锌方头木螺钉(FIXED RAILWAY INSTALLATIONS. EQUIPMENT FOR OVERHEADTELECOMMUNICATION AND SIGNALLING LINES. GALVANIZED SQUAREHEAD WOOD SCREWS.)NF J41-465-1957造船工业.“金士顿“阀门.螺钉零件(SHIPBUILDING. KINGSTON VALVES. BOLTS AND SCREWS.)NF J46-126-1951造船工业.空气入口.手柄和紧固螺钉(SHIPBUILDING. VENTILATORS. HANDLE AND LOCKING SCREW.) NF L22-063-1970用板手操作的螺母、螺钉和轴的间隙(CLEARANCE FOR WRENCHING NUTS,SCREWS AND PINS.)NF L22-070-1976螺钉的BNAE型十字槽(CROSS RECESS (B.N.A.E.).)NF L22-071-1976NFL 22-070 型螺钉十字槽用螺丝刀头(SCREW-DRIVER END FOR CROSS RECESS ACCORDING TO NF L 22-070.)NF L22-071-1976NFL 22-070 型螺钉十字槽用螺丝刀头(SCREW-DRIVER END FOR CROSS RECESS ACCORDING TO NF L 22-070.)NF L22-072-1991航天建筑.螺丝.920型十字槽(Aerospace construction. Bolts and screws. 92 degrees cruciform recess.)NF L22-090-1966修配用大直径标准螺钉、销和垫圈(STANDARDIZED SCREWS,PINS AND WASHERS WITH INCREASED DIAMETER INTENDED FOR REPAIR WORK.)NF L22-111-1975无销孔六角头螺钉.国际单位制螺纹(Hexagon head bolts without split pin hole. Sim thread (rech.).)NF L22-112-1975带销孔六角头螺钉.国际单位制螺纹(Hexagon head bolts with split pin hole. Sim thread (rech.).)NF L22-121-1975带轻杆无锁孔六角头螺钉.国际单位制螺纹(Hexagon head bolts with waisted shank without split pin hole. Sim thread (rech.).)NF L22-122-1975带轻杆有销孔六角头螺钉.国际单位米制螺纹(Hexagon head bolts with waisted shank with split pin hole.Sim thread.)NF L22-125-1985六角头承拉螺钉ISO 螺纹4h 类(Bolt, hexagonal head, for tensile application, . ISO thread 4H class.)NF L22-126-1985带锁紧孔六角头承拉螺钉.ISO螺纹4h 类(Bolt, hexagonal head, with locking hole, for tensile application. ISO thread 4H class.)NF L22-127-1985带颈杆六角头承拉螺钉.ISO螺 纹4h 类(Bolt, hexagonal head, necked shank, for tensile application. ISO thread 4H class.)NF L22-128-1985带颈杆有锁紧孔六角头承拉螺钉.ISO 螺纹4h 类(Bolt, hexagonal head, necked shank, with locking hole, fortensile application. ISO thread 4H class.)NF L22-129-1985带销孔六角头承拉螺钉.ISO 螺纹4h 类(Bolt, hexagonal head, with split pin hole, for tensile application. ISO thread 4H class.)NF L22-134-1975无销孔六角头槽制螺钉.国际单位制螺纹(Precision hexagon head bolts without split pin hole. Sim thread (rech.).)NF L22-135-1975带销孔六角头槽制螺钉.国际单位制螺纹(Precision hexagon head bolts with split pin hole. Sim thread (rech.).)NF L22-136-1984通用六角头螺钉短螺纹(Bolt, hexagonal head, current use, short thread.)NF L22-137-1984带锁紧孔六角头短螺纹螺钉(Bolt, hexagonal head, with locking hole, short thread.) NF L22-138-1984精密六角头短螺纹螺钉(Bolt, hexagonal head, close tolerance, short thread.)NF L22-139-1984带锁紧孔精密头角头短螺纹螺钉(BOLT,HEXAGONAL HEAD,CLOSE TOLERANCE,WITH LOCKING HOLE,SHORT THREAD.)NF L22-140-1984六角头全螺纹螺钉(Bolt, hexagonal head, threaded to head.)NF L22-141-1984有锁紧孔方角头全螺纹螺钉(Bolt, hexagonal head, with locking hole, threaded to head.)NF L22-142-1984常用有销孔六角头螺钉(BOLT,HEXAGONAL HEAD,WITH COTTER PIN HOLE,CURRENT USE.)NF L22-145-1985六角头承拉螺钉.ISO螺纹4G类(Bolt, hexagonal head, for tensile application, ISO thread 4G class.)NF L22-146-1985有锁紧孔六角头承拉螺钉.ISO螺纹4G类(Bolt, hexagonal head, with locking hole, for tensile application. ISO thread 4G class.)NF L22-147-1985带颈杆六角头承拉螺钉.ISO螺纹4G类(Bolt, hexagonal head, necked shank, for tensile application. ISO thread 4G class.)NF L22-148-1985带颈杆有销紧孔六角头承拉螺钉.ISO螺纹4G类(Bolts, hexagonal head, necked shank, with locking hole,for tensile application. ISO thread 4G class.)NF L22-151-1975开槽圆柱头螺钉和紧固凸圆头螺钉.国际单位制螺纹(Slotted and drilled cheese head screws. Sim thread(rech.).)NF L22-152-1975开槽扁头螺钉.国际单位米制螺纹(Slotted mushroom head screws. Sim thread (rech.).)NF L22-153-197590°埋头开槽螺钉.国际单位米制螺纹(Slotted 90 degrees countersunk head screws. Sim thread (rech.).)NF L22-154-1975120°半圆头开槽埋头螺钉.单际单位米制螺纹(Slotted raised 120 degrees countersunk head screws. Simthread (rech.).)NF L22-156-1975锥顶凸圆头开槽螺钉.国际单位米制螺纹(Slotted raised cheese head screws with cone point. Sim thread (rech.).)NF L22-157-1975锥顶扁头开槽螺钉.国际单位米制螺纹(Slotted mushroom head screws with cone point. Sim thread (rech.).)NF L22-158-1975锥顶90°埋头开槽螺钉.国际单位米制螺纹(Slotted 90 degrees countersunk head screws with cone point. Sim thread (rech.).)NF L22-159-1975锥顶120°半圆头开槽埋头螺钉.国际单位米制螺纹(Slotted raised 120 degrees countersunk head screws withcone point. Sim thread (rech.).)NF L22-161-1984有NF L22-72十字槽的通用100°埋头螺钉(Bolt, 100 degrees countersunk head, current use, nf L 22-072 cross recess.)NF L22-162-1984有NF L22-072十字槽的精密100°全螺纹埋头螺钉(Bolt, 100 degrees countersunk head, close tolerance, nf L22-072 cross recess.)NF L22-163-1984有NF L22-072十字槽的常用100°度全螺纹埋头螺钉(Bolt, 100 degrees countersunk head, threaded to head, nf L22-072 cross recess.)NF L22-167-1984有NF L22-070十字槽的常用100°埋头螺钉(Bolt, 100 degrees countersunk head, current use, nf L 22-070 cross recess.)NF L22-168-1984有NF L22-070 十字槽的紧公差100°沉头螺钉(BOLT,100 DEGREES COUNTERSUNK HEAD,CLOSE TOLERANCE,NF L 22-070,CROSS RECESS.)NF L22-169-1984有 NF L22-070十字槽的100°全螺纹埋头螺钉(BOLT,100 DEGREES COUNTERSUNK HEAD,THREADED TO HEAD,NF L22-070,CROSS RECESS.)NF L22-171-1984有NF L22-072十字槽的常用半圆头螺钉(Bolt, pan head, current use, nf L22-072 cross recess.) NF L22-173-1984有NF L22-072十字槽全螺纹半圆头螺钉(BOLT,PAN HEAD,THREADED TO HEAD,NF L 22-072 CROSS RECESS.)NF L22-176-1984有NF L22-072十字槽锥顶半圆头非磁性螺钉(Bolt, pan head, amagnetic with cone point NF L 22-072 cross recess.)NF L22-177-1984有NF L22-070十字槽常用半圆头螺钉(Bolt, pan head, current use, nf L 22-070 cross recess.) NF L22-179-1984有NF L22-070十字槽全螺纹半圆头螺钉(BOLT,PAN HEAD,THREADED TO HEAD,NF L 22-070 CROSS RECESS.)NF L22-181-1976有BNAE十字槽扁头螺钉.国际单位米制螺纹(MUSHROOM HEAD SCREWS WITH B.N.A.E. CROSS RECESS. SIM THREAD.)NF L22-182-1976有BNAE十字槽90°埋头螺钉.国际单位米制螺纹(90 DEGREES COUNTERSUNK HEAD SCREWS WITH B.N.A.E. CROSSRECESS. SIM THREAD.)NF L22-183-1976有BNAE十字槽90°埋头螺钉.国际单位米制螺纹(RAISED 120 DEGREES COUNTERSUNK HEAD SCREWS WITH B.N.A.E.CROSS RECESS. SIM THREAD.)NF L22-184-1976有BNAE十字槽120°埋头螺钉.国际单位米制螺纹(120 DEGREES COUNTERSUNK HEAD SCREWS WITH B.N.A.E. CROSSRECESS. SIM THREAD.)NF L22-186-1976有BNAE十字槽锥顶扁头螺钉.国际单位米制螺纹(MUSHROOM HEAD SCREWS WITH B.N.A.E. CROSS RECESS AND CONEPOINT. SIM THREAD.)NF L22-187-1976有BNAE十字槽锥顶90°埋头螺钉.国际单位米制螺纹(90 DEGREES COUNTERSUNK HEAD SCREWS WITH B.N.A.E. CROSSRECESS AND CONE POINT. SIM THREAD.)NF L22-188-1976有BNAE十字槽锥顶120°埋头半圆头螺钉单国际单位制米螺纹(RAISED 120 DEGREES COUNTERSUNK HEAD SCREWS WITH B.N.A.E.CROSS RECESS AND CONE POINT. SIM THREAD.)NF L22-189-1976有BNAE十字槽锥顶120°埋头螺钉.国际单位米制螺纹(120 DEGREES COUNTERSUNK HEAD SCREWS WITH B.N.A.E. CROSSRECESS AND CONE POINT. SIM THREAD.)NF L22-201-1984短螺纹精密螺钉.六角头.ISO螺纹(Bolt, hexagonal head, short thread, close tolerance. ISO thread.)。

各国质量认证标志及说明1. CE认证(Conformite Europeenne) 这个标志想必大家都非常熟悉吧!对,它就是CE认证,使用CE认证的产品越拉越广,某产品中如果有CE标志的话,就代表这件产品安全、卫生、环保和消费者保护等一系列欧洲指令所要表达的要求。

如果产品可以符合相关的要求,就可以贴CE标志了,但不符合相关的要求,就与之相反。

(个人觉得CE不是认证,只是自我申明而已,一般出货欧洲会做此声明)C产品认证(China compulsory certification) CCC认证:所谓3C认证,这个认证是2002年5月1日诞生的,CCC是英文China compulsory certification 的缩写,意思是“中国强制认证”。

如果产品被列入国家质量监督检验检疫总局和国家认证认可监督管理委员会发布的《第一批实施强制性产品认证的产品目录》,就要对该产品实施强制性的检测和审核。

如果是列入目录里的产品,没获得指定机构认证的,没进行按规定标贴认证的,就不可以销售、进口和出厂了。

这个标志实施以后,就取代了原本的“长城”标志,“长城”标志自2003年5月1日起就作废了。

需要注意的是,3C标志并不是质量标志,而只是一种最基础的安全认证。

3.CQC认证 中国质量认证中心(CQC),可以获得CQC的认证,再贴上CQC认证标志的产品,就是被国家级认证机构认证的,认证目的为安全的、符合国家响应的质量标准。

4.CB认证 CB体系(电工产品合格测试与认证的IEC体系)是IECEE运作的-个国际体系,IECEE各成员国认证机构以IEC标准为基础对电工产品安全性能进行测试,其测试结果即CB测试报告和CB测试证书在IECEE各成员国得到相互认可的体系。

目的是为了减少由于必须满足不同国家认证或批准准则而产生的国际贸易壁垒。

IECEE 是国际电工委员会电工产品合格测试与认证组织的简称。

5.PCT认证 “要进入俄联邦海关领土的产品都必须要获得俄罗斯国家标准计量委员会颁发的国家标准合格证书(GOST合格证)”俄罗斯中的法律这样规定到。

ISSN O335 – 3931NF F 16 - 1011988年10月法国标准铁路车辆用材料材料在火中的性状材料的选用英语:(略)德语:(略)法国标准的批准:1988年9月由法国标准协会主任批准,自1988年10月执行。

相关性:在本标准公布之日,在铁路系统的范围内,尚无相同主题的国际和欧洲标准。

分析:对于一些铁路车辆用材料,根据它们在火中的性状,本标准给出了一些选用的规定。

描述:国际技术关键词:铁路车辆用材料;非易燃材料;选材;分类;火中的反应;火中性状的实验;材料要求。

修订:校对:铁路车辆用材料NF F 16 – 1011988年10月材料在火中的性状材料的选用通告本标准根据一系列标准化的实验结果,提出了一种对铁路车辆用材料进行分类的方法,不仅确定了所选定的材料,同时还考虑到了它们在火中燃烧的性状,燃烧所产生烟雾的不透明状态和所散发的毒性物质。

实际上,由于铁路运输的增加,其系统的性能也越来越多地引起人们的重视,本标准规定了在火灾中能引起旅客惊慌的、在一些反应中所散发出来的某些易感物质的临界浓度。

在铁路车辆用材料之外的范围,未经预先的实验研究,本标准不能适用。

对于材料在火中的反应和烟雾的不透明程度的评价,使用了一种“整体性能”的方法。

这种方法对毒性评价的基础是对7中气体浓度的测量。

而这种方法的局限性在于,材料燃烧时所释放出来的一种或多种气体的敏感成分。

总之,表中所列气体之外的其他气体,无发进行比对。

对于这种气体的鉴别、其剂量和临界浓度,可依照本标准的思想,建立完善的文本资料。

对于标准FN X 70-100未曾涉及的一些化学成分,本标准也未予以考虑。

可以使用另外的一种方法来确定其允许的浓度,以便建立一种毒性指标,使之能与本标准所确定的指标进行比对。

同样还应意识到,对于各种局部毒性的总体效应,计算常规毒性指标的方案是不能用来表示混合气体整体的实际毒性的。

由于混合气体的协同作用所表现出来的现象会有所发展,因此,只有通过对动物实验所得到的生理反应结果才是可靠的。

法国金属材料与非金属材料标准编号中文名称英文名称NF A03-001-2001 金属材料.拉伸试验.第1部分:常温试验方法(Metallic materials - Tensile testing - Part 1 :method of test at ambient temperature.)NF A03-002-1999 金属材料.静态单轴向试验机的验正.第1部分:拉伸/压缩试验机(Metallic materials - Verification of static uniaxialtesting machines - Part 1 : tension/compressiontesting machines.)NF A03-003-2002 金属材料.用于验证(Metallic materials - Calibration of force-provinginstruments used for the verification of uniaxial单轴向试验机的作用力检验仪的校准testing machines.)NF A03-004-2003 金属材料.单轴向试验用伸长计的校准(Metallic materials - calibration of extensometersused in uniaxial testing.)NF A03-011-1990 金属材料.摆锤式冲击试验.第1部分:试验方法(Metallic materials. Charpy impact test. Part 1 : testmethod.)NF A03-012-1992 金属材料.夏比冲击试验.第2部分:试验机的检定(冲击(Metallic materials. Charpy impact test. Part 2 :verification of the testing machine (pendulumimpact).)摆).(欧洲标准EN 10045-2)NF A03-021-1994 金属材料.硬度试验.第1部分:洛氏表面硬度试验.(15N、30N、45N、15T、30T和45T刻度)(METALLIC MATERIALS. HARDNESS TEST.PART 1 : ROCKWELL TEST (SCALES A, B, C,D, E, F, G, H, K) AND ROCKWELLSUPERFICIAL TEST (SCALES 15N, 30N, 45N,15T, 30T AND 45T). (EUROPEAN STANDARDEN 10109-1).)NF A03-031-1994 金属材料.布氏硬度试验.第1部分:试验方法(ISO6506-81)(METALLIC MATERIALS. BRINELLHARDNESS TEST. PART 1 : TEST METHOD.(EUROPEAN STANDARD EN 10003-1).)NF A03-091-1994 金属材料.管材(全截面).弯曲试验(Metallic materials. Tube (in full section). Bendtest.)NF A03-093-1994 金属材料.管.拉力试验(Metallic materials. Tube. Drift expanding test.)NF A03-096-1994 金属材料.管材.环形拉伸试验(METALLIC MATERIALS. TUBE. RINGTENSILE TEST. (EUROPEAN STANDARD EN10237).)NF A03-152-2-1999 金属材料.布氏硬度试验.第2部分:试验机的验证和校正(Metallic materials. Brinell hardness test. Part 2 :verification and calibration of testing machines.)NF A03-152-3-1999 金属材料.(Metallic materials. Brinell hardness test. Part 3 :布氏硬度试验.第3部分:标准试块的校正calibration of reference blocks.)NF A03-153-2-1999 金属材料.洛氏硬度试验.第2部分:试验机(刻度A, B, C,D, E, F, G,H, K, N,T)的验证和校正(Metallic materials. Rockwell hardness test. Part 2 :verification and calibration of testing machines(scales A, B, C, D, E, F, G, H, K, N, T).)NF A03-153-3-1999 金属材料.洛氏硬度试验.第3部分:标准试块的校正(刻度A, B, C,(Metallic materials. Rockwell hardness test. Part 3 :calibration of reference blocks (scales A, B, C, D,E, F, G, H, K, N, T).)D, E, F, G, H, K, N, T)NF A03-154-1-1998 金属材料.维氏硬度试验.第1部分:试验方法(Metallic materials. Vickers hardness test. Part 1 :test method.)NF A03-154-2-1998 金属材料.维氏硬度试验.第2部分:试验机械的校准(Metallic materials. Vickers hardness test. Part 2 :verification of testing machines.)NF A03-154-3-1998 金属材料.维氏硬度试验.第3部分:标准块的校准(Metallic materials. Vickers hardness test. Part 3 :calibration of reference blocks.)NF A03-155-1-2003 金属材料.硬度和材料参数的仪器压痕试验.第1部分:试验方法(Metallic materials - Instrumented indentation testfor hardness and materials parameters - Part 1 : testmethod.)NF A03-155-2-2003 金属材料.硬度和材料参数的仪器压痕试验.第2部分:试验机的检定和校准(Metallic materials - Instrumented indentation testfor hardness and materials parameters - Part 2 :verification and calibration of testing machines.)NF A03-155-3-2003 金属材料.硬度和材料参数的仪器压痕试验.第3(Metallic materials - Instrumented indentation testfor hardness and materials parameters - Part 3 :calibration of reference blocks.)部分:硬度标准块的校准NF A03-159-2000 金属材料.厚度3mm或小于3mm的板材或带材.反向弯曲试验(Metallic materials - Sheet and strip 3 mm thick orless - Reverse bend test.)NF A03-356-1999 金属材料(Metallic materials.)NF A03-652-2003 金属材料.薄板材和带材.埃里克森压凹试验(Metallic materials - Sheet and strip - Erichsencupping test.)NF A03-750-2000 金属材料.(Metallic materials - Uniaxial creep testing in张力的单轴蠕变试验.试验方法tension - Method of test.)NF A03-760-1-2003 金属材料.拉伸应力松弛试验.第1部分:试验机规程(Metallic materials - Tensile stress relaxation testing- Part 1 : procedure for testing machines.)NF A05-411-2000 金属材料抗腐蚀性防护.大气环境中腐蚀的可能性.大气环境中腐蚀性的分类、确定和评价(Protection of metallic materials against corrosion -Corrosion likelihood in atmospheric environment -Classification, determination and estimation ofcorrosivity of atmospheric environments.)NF A05-412-1-2003 金属材料的防腐.土壤腐蚀的可能性.第1部分:总则(Protection of metallic materials against corrosion -Corrosion likelihood in soil - Part 1 : general.)NF A05-412-2-2003 金属材料的防腐.土壤腐蚀的可能性.第2部分:低合金和非合金黑色金属材料(Protection of metallic materials against corrosion -Corrosion likelihood in soil - Part 2 : low alloyedand non alloyed ferrous materials.)NF A06-352-1995 黑色金属材料的化学分析.钢和铁中砷的测定.分光光度法(欧洲标准EN(Chemical analysis of ferrous materials.Determination of arsenic in steel and iron.Spectrophotometric method.)ISO 10212)NF A06-392-1-2000 黑色金属材料的化学分析.钢和铁中氧的测定.第1部分:取样和制备钢样品用于测定氧(Chemical analysis of ferrous materials -Determination of oxygen in steel and iron - Part 1 :sampling and preparation of steel samples foroxygen determination.)NF A08-328-1989 黑色金属材料的化学分析.钢铁中铬的测定.火焰原子吸收光谱测定法(Chemical analysis of ferrous materials.Determination of chromium in steels and irons.Flame atomic absorption spectrometric method.)NF A09-201-1994 无损检验.用X和γ射线进行金属材料射线检查的一般原则(Non-destructive testing. General principles forradiographic examination of metallic materials byX- and gamma rays.)NF A09-250-3-2002 无损检验.射线检验.第3部分:用X-射线和γ射线进行金属材料射线检验的一般原理(Non-destructive testing - Radioscopic testing - Part3 : general principles of radioscopic testing ofmetallic materials by X- and gamma rays.)NF A49-865-1999 金属材料.重量损失磨损试验(欧洲标准EN10274)(METALLIC MATERIALS. DROP WEIGHTTEAR TEST. (EUROPEAN STANDARD EN10274).)NF A49-866-1999 金属材料.管圈液压试验(METALLIC MATERIALS. TUBE RINGHYDRAULIC PRESSURE TEST. (EUROPEANSTANDARD EN 10275).)NF A50-110-8-2003 铝和铝合金.废料.第8部分:铝分离工艺中切碎工艺产生的有色金属材料组成的废料(Aluminium and aluminium alloys - Scrap - Part 8 :scrap consisting of non-ferrous materials fromshredding processes destined to aluminiumseparation processes.)NF A80-230-1-1998 焊接和合金过程.金属材料几何缺陷的分类.第1部分:熔焊(欧洲标准6520-1)(Welding and allied processes. Classification ofgeometric imperfections in metallic materials. Part1 : fusion welding.)NF A80-230-2-2003 焊接和相关工艺.金属材料中几何缺陷的分类.第2部分:带压焊接(Welding and allied processes - Classification ofgeometric imperfections in metallic materials - Part2 : welding with pressure.)NF A81-331-1984 焊接、硬钎焊和硬焊铝及铝合金用填充金属材料.符号.规范(Filler materials for welding, brazing and brazewelding aluminium and aluminium alloys.Symbolization. Specifications.)NF A88-112-1998 焊接操作人员.焊接操作人员用金属材料全机械化和自动(Welding personnel. Approval testing of weldingoperators for fusion welding and resistance weldsetters for fully mechanized and automatic weldingof metallic materials.)焊接用熔焊和阻焊装置验收试验NF A89-010-1-1992 金属材料焊接工艺与验收规范.第1部分:熔焊一般规则(欧洲标准EN288-1)(Specification and approval of welding proceduresfor metallic materials. Part 1 : general rules forfusion welding.)NFA89-010-10-1996 金属材料焊接工艺的验收和规范.第10部分:电子束焊接工艺规范(SPECIFICATION AND APPROV AL OFWELDING PROCEDURES FOR METALLICMATERIALS. PART 10 : WELDINGPROCEDURE SPECIFICATION FORELECTRON BEAM WELDING. (EUROPEANSTANDARD EN ISO 9956-10).)NFA89-010-11-1996 金属材料焊接工艺的验收和规范.第11部分:激光束焊接工艺规范(SPECIFICATION AND APPROV AL OFWELDING PROCEDURES FOR METALLICMATERIALS. PART 11 : WELDINGPROCEDURE SPECIFICATION FOR LASERBEAM WELDING. (EUROPEAN STANDARDEN ISO 9956-11).)NF A89-010-2-1992 金属材料焊接工艺与验收规范.第2部分:电弧焊焊接程序规范(欧洲标准EN 288-2)(Specification and approval of welding proceduresfor metallic materials. Part 2 : welding procedurespecification for arc welding.)NF A89-010-3-1992 金属材料焊接工艺的验收和(Specification and approval of welding proceduresfor metallic materials. Part 3 : welding proceduretests for the arc welding of steels.)规范.第3部分:钢件电弧焊焊接工艺试验(欧洲标准EN 288-3)NF A89-010-5-1994 金属材料焊接程序的规范和认可.第5部分:使用批准的电弧焊焊条进行认可(Specification and approval of welding proceduresfor metallic materials. Part 5 : approval by usingapproved welding consumables for arc welding.)NF A89-010-6-1994 金属材料焊接程序的规范和认可.第6部分:有关以前试验的认可(SPECIFICATION AND APPROV AL OFWELDING PROCEDURES FOR METALLICMATERIALS. PART 6 : APPROV AL RELATEDTO PREVIOUS EXPERIENCE. (EUROPEANSTANDARD EN 288-6).)NF A89-010-7-1995 金属材料焊接程序的规范和认可.第七部分:使用电弧焊标准接程序进行认可(SPECIFICATION AND APPROV AL OFWELDING PROCEDURES FOR METALLICMATERIALS. PART 7 : APPROV AL BY ASTANDARD WELDING PROCEDURE FOR ARCWELDING. (EUROPEAN STANDARD EN288-7).)NF A89-010-8-1995 金属材料焊接程序的规范和认可.第八部分:利用预生产焊接试验进行认可(SPECIFICATION AND APPROV AL OFWELDING PROCEDURES FOR METALLICMATEIRALS. PART 8 : APPROV AL BY APRE-PRODUCTION WELDING TEST.(EUROPEAN STANDARD EN 288-8).)NF A89-052-2-2001 金属材料焊接程序的规范和合格评定.(Specification and qualification of weldingprocedures for metallic materials - Weldingprocedure specification - Part 2 : gas welding.)焊接程序规范.第2部分:气焊NFA89-057-11-2002 金属材料焊接程序规范和鉴定.焊接程序试验.第11部分:电子和激光射线焊接(Specification and qualification of weldingprocedures for metallic materials - Weldingprocedure test - Part 11 : electron and laser beamwelding.)NF A89-057-8-2002 金属材料焊接程序规范和鉴定.焊接程序试验.第8部分:管对管-板接头的焊接(Specification and qualification of weldingprocedures for metallic materials - Weldingprocedure test - Part 8 : welding of tubes totube-plate joints.)NF A89-101-1-1998 焊接.金属材料焊接推荐.第1部分:电弧焊接的一般指南(WELDING. RECOMMENDATIONS FORWELDING OF METALLIC MA TERIALS. PART1 : GENERAL GUIDANCE FOR ARC WELDING.(EUROPEAN STANDARD EN 1011-1).)NFA89-101-1/A1-2002 焊接.金属材料焊接的推荐规范.第1部分:电弧焊接通用指南(Welding - Recommendations for welding ofmetallic materials - Part 1 : general guidance for arcwelding.)NF A89-101-2-2002 焊接.金属材料焊接的推荐规范.第2部分:铁素体钢的电弧焊(Welding - Recommendations for welding ofmetallic materials - Part 2 : arc welding of ferriticsteel.)NF A89-101-3-2000 焊接.金属材料焊接的推荐方法.第3部分:不锈钢的电弧焊(Welding - Recommendations for welding ofmetallic materials - Part 3 : arc welding of stainlesssteels.)NF A89-101-4-2000 焊接.金属材料焊接的推荐方法.第4部分:铝和铝合金的电弧焊(Welding - Recommendations for welding ofmetallic materials - Part 4 : arc welding ofaluminium and aluminium alloys.)NF A89-101-5-2003 焊接.金属材料焊接的推荐方法.第5部分:包层钢焊接(Welding - Recommendations for welding ofmetallic materials - Part 5 : welding of clad steel.)NF A89-204-2-1996 金属材料焊接的破坏试验.硬度试验.第2部分:焊接接缝的微硬度试验(欧洲标准EN1043-2)(DESTRUCTIVE TESTS ON WELDS INMETALLIC MATERIALS. HARDNESS TEST.PART 2 : MICRO HARDNESS TESTING ONWELDED JOINTS. (EUROPEAN STANDARDEN 1043-2).)NF A89-210-1996 金属材料焊接的破坏试验.断裂试验.(欧洲标准EN1320)(DESTRUCTIVE TESTS ON WELDS INMETALLIC MATERIALS. FRACTURE TEST.(EUROPEAN STANDARD EN 1320).)NF A89-211-1996 金属材料焊接的破坏试验.焊(DESTRUCTIVE TESTS ON WELDS INMETALLIC MATERIALS. MACROSCOPIC ANDMICROSCOPIC EXAMINATION OF WELDS.接的低倍及显微检验(欧洲标准EN1321)(EUROPEAN STANDARD EN 1321).)NF A89-250-1-1994 焊接的质量要求.金属材料的熔焊.第1部分:选择和使用导则(Quality requirements for welding. Fusion weldingof metallic materials. Part 1 : guidelines forselection and use.)NF A89-250-2-1994 焊接的质量要求.金属材料的熔焊.第2部分:全面质量系统(Quality requirements for welding. Fusion weldingof metallic materials. Part 2 : comprehensive qualityrequirements.)NF A89-250-3-1994 焊接的质(Quality requirements for welding. Fusion welding量要求.金属材料的熔焊.第3部分:标准质量要求of metallic materials. Part 3 : standard quality requirements.)NF A89-250-4-1994 焊接的质量要求.金属材料的熔焊.第4部分:基本质量要求(Quality requirements for welding. Fusion weldingof metallic materials. Part 4 : elementary qualityrequirements.)NF A89-500-1997 焊缝的无损检验.金属材料用一般规则(Non-destructive examination of welds. Generalrules for metallic materials.)NFA89-500/A1-2003 焊接无损检验.金属材料的一般规则(Non-destructive examination of welds - Generalrules for metallic materials.)NF A89-573-2003 金属材料焊缝的有损检验.电阻点焊的扭转试验(Destructive tests on welds in metallic materials -Torsion test of resistance spot welds.)NF A89-574-2003 金属材料焊接的无损检验.电阻焊接.电阻缝焊的压力试验(Destructive test on welds in metallic materials -Resistance welding - Pressure test on resistanceseam welds.)NF A89-575-2003 金属材料焊接的无损检验.测量δ铁素体用的取样方法(Destructive tests on welds in metallic materials -Method for taking samples for delta ferritemeasurement.)NF A89-600-1998 焊接.金属(WELDING. ARC STUD WELDING OF材料的弧双端螺栓焊接(欧洲标准EN ISO 14555) METALLIC MATERIALS. (EUROPEAN STANDARD EN ISO 14555).)NF A89-601-2001 焊接.金属材料的摩擦焊接(Welding - Friction welding of metallic materials.)NF A91-474-2001 金属材料上的转化涂层.单位面积涂层质量的测定.重量分析法(Conversion coatings on metallic materials -Determination of coating mass per unit area -Gravimetric methods.)NF A95-301-1977 粉末冶金.硬金属除外的烧结(POWDER METALLURGY. SINTERED METALMATERIALS EXCLUDING HARDMETALS.SAMPLING.)金属材料.取样NF A95-311-1977 粉末冶金.透气烧结金属材料.密度和开气孔率的测定(POWDER METALLURGY. PERMEABLESINTERED METAL MATERIALS.DETERMINA TION OF DENSITY AND OPENPOROSITY.)NF A95-322-2000 硬金属除外的烧结金属材料.拉伸试验块(Sintered metal materials, excluding hardmetals -Tensile test pieces.)NFA95-323/A1-2003 不包括硬质合金的烧结金属材料.横向断裂强度的测定.修(Sintered metal materials, excluding hardmetals -Determination of transverse rupture strength -Amendment 1 : precision statement.)改件1:精确说明NF A95-326-1993 除硬金属外的烧结金属材料.无缺口试件(Sintered metal materials, excluding hardmetals.Unnotched impact test piece.)NF A95-327-1986 粉末冶金.硬金属除外的烧结金属材料.疲劳试验用试件(Powder metallurgy. Sintered metal materialsexcluding hardmetals. Fatigue test pieces.)NF A95-329-1986 粉末冶金.硬金属除外的烧结金属材料.维氏显微硬度的测(POWDER METALLURGY. SINTERED METALMATERIALS EXCLUDING HARDMETALS.MEASUREMENT OF VICKERSMICROHARDNESS.)定NF A95-342-1985 粉末冶金.包括硬金属在内的烧结金属材料.显微照相检查技术(POWDER METALLURGY. SINTEREDMATERIALS INCLUDING HARDMETALS.MICROGRAPHIC EXAMINATIONTECHNIQUES.)NF A95-771-1-1988 烧结金属材料.规范.第1部分:用液体润滑剂浸渍的轴承材料(Sintered metal materials. Specifications. Part 1 :materials, for bearings, impregnated with liquidlubricant.)NF C20-907-2000 固体非金属材料暴露于引燃源的可燃(Flammability of solid non metallic materials whenexposed to flame sources - List of test methods.)性.试验方法清单NF E01-201-4-2003 压力设备.金属材料的技术交货条件的确立(Pressure equipment - Part 4 : establishment oftechnical delivery conditions for metallic materials.)NF E29-492-2002 工业阀门.金属材料的薄片阀(Industrial valves - Diaphragm valves made ofmetallic materials.)NF E29-648-1-1998 可运输储气瓶.储气瓶和阀门材料与气含量的相容性.第1部分:金属材料(Transportable gas cylinders. Compatibility ofcylinder and valve materials with gas contents. Part1 : metallic materials.)NF E29-648-2-2001 可移动式液化气钢瓶.内有气体的钢瓶和阀材料的配合性.第2部分:非金属材料(Transportable gas cylinders - Compatibility ofcylinder and valve materials with gas contents - Part2 : non-metallic materials.)NF L06-387-1991 航天结构用焊接和钎焊组装件.用电子束焊接金属材料组装件(Weldments and brazements for aerospacestructures. Joints of metallic materials by electronbeam welding. Quality of weldments.)NF L06-391-1994 航天结构用焊接和钎焊组装件.用扩散焊接法安装金属材(WELDED AND BRAZED ASSEMBLIES FORAEROSPACE CONSTRUCTION. ASSEMBL Y OFMETALLIC MA TERIALS CARRIED OUT BYDIFFUSION WELDING. QUALITY OF WELDEDASSEMBLIES.)料组装件.焊接组装件的质量NF L06-394-1999 飞行器工业.航空与航天结构的焊接和钎焊. 用TIG方法的金属材料焊接组件.焊接质量(AIRCRAFT INDUSTRIE. WELDMENTS ANDBRAZEMENTS FOR AEROSPACESTRUCTURES. ASSEMBL Y OF METALLICMATERIALS WELDED BY TIG METHOD.QUALITY OF WELDMENTS.)NF L06-850-2001 航空航天系列.非金属材料.设计产品.塑料粒子.技术规范(Aerospace series - Non metallic materials -Projecting products - Plastic particles - Technicalspecification.)NF L10-005-1-2002 航空航天系列.金属材料.第1部分:常规命名(Aerospace series - Metallic materials - Part 1 :conventional designation.)NF L10-006-2002 航空航天系列.金属材料.生产进度表、检验进度表、检验和试验报告.定义、一般原理、制备和验收(Aerospace series - Metallic materials -Manufacturing schedule, inspection schedule,inspection and test report - Definition, generalprinciples, preparation and approval.)NF L10-015-2002 航空航天系列.金属材料.金属半成品产品尺寸标准的起草(Aerospace series - Metallic materials - Rules forthe drafting and presentation of dimensionalstandards for metallic semi-finished products.)和说明规则NF L10-020-1998 航空和航天系列.金属材料.一般结构和标准化.EN标准和其使用型之间的链接(Aerospace series. Metallic materials. Generalorganization of standardization. Links betweentypes of EN standards and their use.)NF L10-100-1991 航空和航天系列.非金属材料分类用耐火性试验方法(Aerospace series. Test methods for the flameresistance rating of non-metallic materials.)NF L17-005-1992 航空航天系列.非金(Aerospace series. Non-metallic materials.Preferred test temperatures.)属材料.优选试验温度NF L17-015-2000 航空系列.非金属材料.质量计划的验收和评价及建立的规则(Aerospace series - Non-metallic materials - Rulesfor the establishement, the evolutions and theacceptance of quality plans.)NF L17-020-1996 航空航天系列.非金属材料.液相色谱法特性(高性能液相色谱法.静挤压色层分离法).分类法(AEROSPACE SERIES. NON-METALLICMATERIALS. LIQUID CHROMATOGRAPHYCHARACTERIZATION (HIGH PERFORMANCELIQUID CHROMATOGRAPHY. STERICEXCLUSION CHROMATOGRAPHY).GENERAL METHODOLOGY.)NF L17-021-1998 航空航天系列.非金属材料.树脂,粘接剂,增强塑料,预浸渍.用液相色谱测定特性(AEROSPACE SERIES. NON-METALLICMATERIALS. RESINS, ADHESIVES,REINFORCED PLASTICS, PREIMPREGNATES.CHARACTERISATION BY LIQUIDCHROMATOGRAPHY.)NF L17-022-1999 航空航天系列.非金属材料.油类、液压油和燃料.液体层析法特征(AEROSPACE SERIES. NON-METALLICMATERIALS. OILS, HYDRAULIC FLUIDS,FUELS. CHARACTERISATION BY LIQUIDCHROMATOGRAPHY.)NF L17-301-1998 航空航天系列.非金属材料.结构胶粘剂.试验方法.低漆厚度(AEROSPACE SERIES. NON-METALLICMATERIALS. STRUCTURAL ADHESIVES.TEST METHODS. DETERMINATION OF THEPRIMER THICKNESS. (EUROPEANSTANDARD EN 2781).)的测定NF L17-310-6-2002 航空航天系列.非金属材料.泡沫结构粘合剂.试验方法.第6部分:吸水性的测定(Aerospace series - Non-metallic materials -Foaming structural adhesives - Test methods - Part6 : determination of water absorption.)NF L19-003-1992 航空航天系列.元件和非金属材料中的管腔蜂窝状材料(AEROSPACE SERIES. HONEYCOMBMATERIALS WITH TUBULAR CELLS INCOMPONENT AND NON-METALLICMATEIRALS. GENERALITIES.)NF L22-031-2003 紧固件.金属材料的选择(Fasteners - Selection of metallic materials.)NF S91-243-2002 牙科用金属材料.抗腐蚀试验方法(Dental metallic materials - Corrosion testmethods.)NF S94-051-2000 外科植入物.金属材料.锻造不锈钢(Implants for surgery - Metallic materials - Wroughtstainless steel.)NF S94-052-1997 外科用植入物.金属材料.第2部分:非金属钛(Implants for surgery. Metallic materials. Part 2 :unalloyed titanium.)NF S94-053-1997 外科植入物.金属材料.第12部分:锻造钴/铬/钼合金(Implants for surgery. Metallic materials. Part 12 :wrought cobalt-chromium-molybdenum alloy.)NF S94-054-1997 外科植入物.金属材料.第4部分:钴铬钼铸造合金(Implants for surgery. Metallic materials. Part 4 :cobalt-chromium-molybdenum casting alloy.)NF S94-055-1997 外科用植入物.金属材料.第5部分:锻制钴-铬-钨-镍合金(Implants for surgery. Metallic materials. Part 5 :wrought cobalt-chromium-tungsten-nickel alloy.)NF S94-056-1998 外科植入物.金属材料.第6部分:锻压的钴镍铬钼合金(Implants for surgery. Metallic materials. Part 6 :wrought cobalt-nickel-chromium-molybdenumalloy.)NF S94-057-1997 外科植入(Implants for surgery. Metallic materials. Forgeable物.金属材料.可锻和冷成型钴铬镍钼铁合金and cold-formed cobalt-chromium-nickel-molybdenum-iron alloy.)NF S94-058-1998 外科植入物.金属材料.第8部分:锻压的钴镍铬钼钨铁合金(Implants for surgery. Metallic materials. Part 8 :wroughtcobalt-nickel-chromium-molybdenum-tungsten-ironalloy.)NF S94-059-1997 外科植入物.金属材料.可锻高氮不锈钢(Implants for surgery. Metallic materials. Wroughthigh nitrogen stainless steel.)NF S94-065-1998 外科植入物金属材料.基于磷酸钙包被(Materials for surgical implants. Determination ofarsenic, mercury, cadmium and lead on coatingsbased on phosphate of calcium.)的砷,汞,铬,铅含量的测定NF S94-066-1998 外科植入物金属材料.磷酸钙钙/磷比数量的测定(Materials for surgical implants. Quantitativedetermination of the Ca/P ratio of calciumphosphates.)NF S94-471-2000 外科设备.金属材料.第1部分:不锈钢(Surgical instruments - Metallic materials - Part 1 :stainless steel.)。