AIAG-VDA-PFMEA分析范例

- 格式:xls

- 大小:33.00 KB

- 文档页数:1

aiag vda pfmea例子

AIAG(汽车行业行动组)和VDA(德国汽车工业协会)合作制定了一种统一的PFMEA(过程失效模式和影响分析)标准,以确保汽车制造过程中的质量和安全。

以下是一个关于AIAG-VDA PFMEA的示例:

在汽车制造过程中,某公司决定对其发动机装配线进行PFMEA 分析。

首先,团队收集了有关发动机装配过程的数据,包括从零部件到最终装配的所有步骤。

然后,团队识别了潜在的失效模式,例如零部件装配不当、零部件缺陷、工具磨损等。

接下来,团队评估了每种失效模式可能对产品质量和安全性造成的影响,以及当前的控制措施是否足够有效。

团队还分配了严重性、发生频率和探测能力的评分,以确定优先级。

最后,团队提出了改进措施,例如改进装配工艺、增加检查步骤、提高员工培训等,以减少潜在的失效和提高质量水平。

这个示例展示了AIAG-VDA PFMEA的应用,通过系统性的分析和改进,可以帮助汽车制造公司识别和管理潜在的质量问题,从而提高产品质量和可靠性。

通过这种方法,公司可以确保其产品符合行业标准,并满足客户的需求和期望。

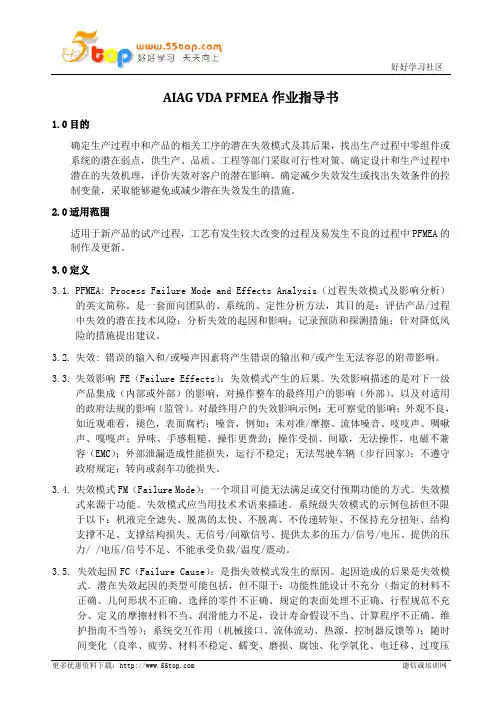

AIAG VDA PFMEA作业指导书1.0目的确定生产过程中和产品的相关工序的潜在失效模式及其后果,找出生产过程中零组件或系统的潜在弱点,供生产、品质、工程等部门采取可行性对策。

确定设计和生产过程中潜在的失效机理,评价失效对客户的潜在影响。

确定减少失效发生或找出失效条件的控制变量,采取能够避免或减少潜在失效发生的措施。

2.0适用范围适用于新产品的试产过程,工艺有发生较大改变的过程及易发生不良的过程中PFMEA的制作及更新。

3.0定义3.1.PFMEA: Process Failure Mode and Effects Analysis(过程失效模式及影响分析)的英文简称。

是一套面向团队的、系统的、定性分析方法,其目的是:评估产品/过程中失效的潜在技术风险;分析失效的起因和影响;记录预防和探测措施;针对降低风险的措施提出建议。

3.2.失效:错误的输入和/或噪声因素将产生错误的输出和/或产生无法容忍的附带影响。

3.3.失效影响FE(Failure Effects):失效模式产生的后果。

失效影响描述的是对下一级产品集成(内部或外部)的影响,对操作整车的最终用户的影响(外部),以及对适用的政府法规的影响(监管)。

对最终用户的失效影响示例:无可察觉的影响;外观不良,如近观难看,褪色,表面腐朽;噪音,例如:未对准/摩擦、流体噪音、吱吱声、啁啾声、嘎嘎声;异味、手感粗糙、操作更费劲;操作受损、间歇,无法操作,电磁不兼容(EMC);外部泄漏造成性能损失,运行不稳定;无法驾驶车辆(步行回家);不遵守政府规定;转向或刹车功能损失。

3.4.失效模式FM(Failure Mode):一个项目可能无法满足或交付预期功能的方式。

失效模式来源于功能。

失效模式应当用技术术语来描述。

系统级失效模式的示例包括但不限于以下:机液完全滤失、脱离的太快、不脱离、不传递转矩、不保持充分扭矩、结构支撑不足、支撑结构损失、无信号/间歇信号、提供太多的压力/信号/电压、提供的压力/ /电压/信号不足、不能承受负载/温度/震动。

aiag vda pfmea例子全文共四篇示例,供读者参考第一篇示例:团队确定了该产品的设计和生产过程中的所有关键步骤,例如电动机的组装、充电系统的安装等。

然后,团队开始识别可能的故障模式和效果。

电动机可能会因为某个零部件装配不当而导致断电;充电系统可能会出现过热导致短路等问题。

团队将这些问题列为潜在的故障模式。

接下来,团队对每个潜在的故障模式进行评估,确定其对产品质量和安全性的影响程度(严重性)、故障发生的频率(发生性)以及故障被发现的可能性(检出性)。

电动机断电的影响程度可能很大,因此被评为高严重性;但由于装配工艺比较成熟,发生频率较低,被评为低发生性。

团队将制定预防措施和控制措施来降低这些故障模式的风险。

他们可能会制定更严格的装配规程,增加对关键零部件的检测频率等。

制定完措施后,团队还需要对这些措施的效果进行评估,并不断改进。

第二篇示例:AIAG VDA PFMEA是指根据国际汽车行业标准组织(AIAG)和德国汽车工程师协会(VDA)共同制定的一种过程失效模式及影响分析方法。

这种方法是为了帮助汽车行业的供应链伙伴在产品设计和生产过程中识别和解决潜在的故障模式,从而提高产品质量和可靠性。

在本文中,我们将以实际案例为例,介绍AIAG VDA PFMEA的具体应用及其重要性。

故障模式及影响分析(FMEA)是一种常见的质量管理工具,其目的是通过系统性地识别和排除产品和过程中的潜在故障模式,以确保产品的质量和可靠性。

在汽车行业,产品设计和生产过程中存在着各种各样的潜在故障模式,如设计错误、工艺不当、零部件失效等,这些故障模式可能会导致产品的功能失效、安全性降低,甚至对用户造成伤害。

AIAG VDA PFMEA是结合了AIAG和VDA两个国际汽车行业标准组织的最佳实践而制定的一种FMEA方法。

它强调了全面性和系统性,要求参与方从产品设计、制造、测试、维修等全过程来考虑潜在故障模式,并评估其可能的影响程度和频率。

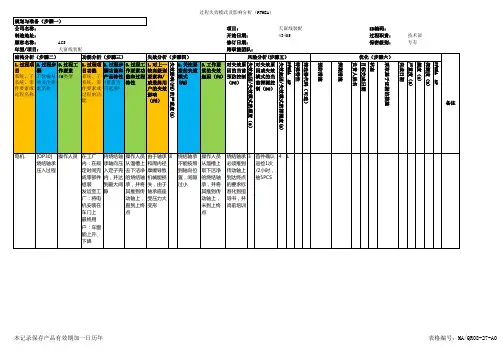

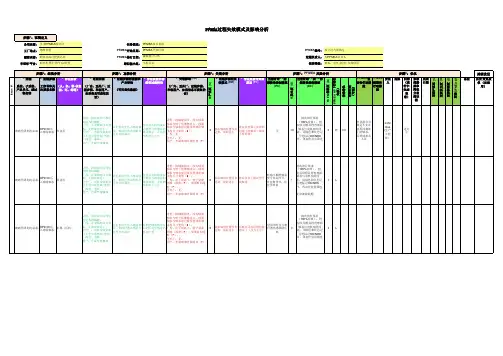

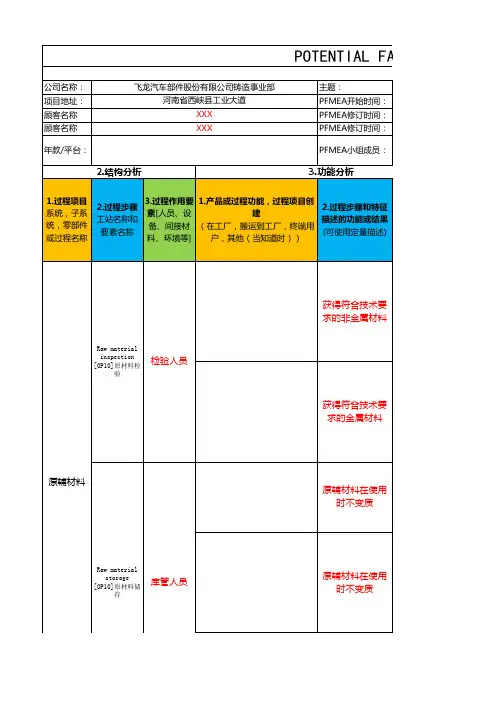

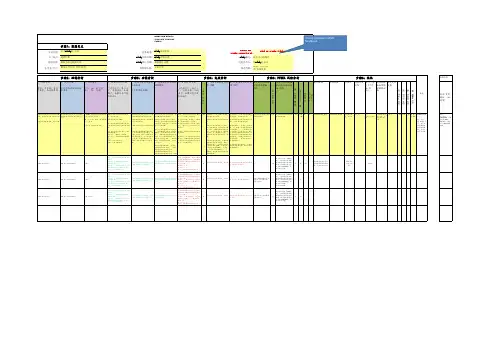

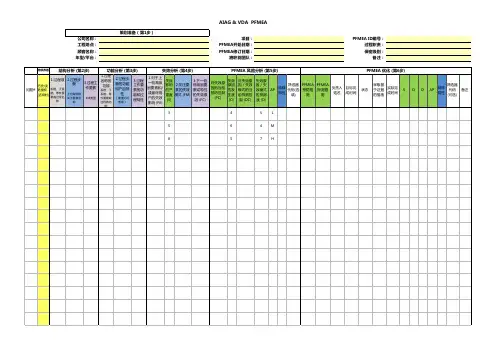

Process Failure Mode and Effects Analysis (Process FMEA)Company Name:Name of company responsiblefor PFMEA Subject:Name of PFMEA projectSystem/sub-system/component/Plant Location:Geographical location PFMEA Start Date:Date PFMEA project started PFMEA ID Number:Determined by the companyCustomer Name:Name of customer (s) or [product family ]PFMEA Revision Date:Date of most recent change Process Responsibility:Name of PFMEA ownerModel Year / Platform:Customer application orcompany model / style Cross-Functional Team:Team Roster needed Confidentiality Level:[ Business Use,Confidential,Propriotary, etc. ]CONTINUOUSIMPROVEMENT1.Process ItemSystem, Subsystem, Part Element or Name of Process 2.Process StepStation No. and Name of FocusElement3.Process Work Element[ Man, Machine, Material(Indirect), Milieu(Environment), etc. ]1.Function of the Process Item[ In-plant, Ship to plant,Process Item, Vehicle Enduser, when known ]2.Function of the Process Stepand Product Characteristic( Quantitative value isoptional )3.Function of the Process WorkElement and ProcessCharacteristic1.Failure Effects (FE)[In-plant, ship to plant,process item, vehicle enduser, when know]OriginalSeverity(S)ofFE 2.Failure Mode (FM) of theProcess Element3.Failure Cause (FC) of the WorkElementCurrent PreventionControl (PC) of FCOccurrence(O)ofFCCurrent DectectionControls (DC) of FC orFMDetection(D)ofFC/FMActionPriority(AP)SpecialProductCharFilterCode(optional)Prevention Action Detection Action ResponsiblePersonTargetCompletionDate (TCD)Status:Open,Completed,DiscardedAction Takenwith Pointerto EvidenceCompletionDateSeverity(S)Occurrence(O)Detection(D)ActionPriority(AP)History / ChangeAuthorization(As Applicable)The name of the process being analyzed e.g. electrical motor assembly line which is the end result of all successfully completed process stepsmay also be a non-direct manufacturing process e.g. shipping The operation or station to beanalyzed that produces theProcess Item e.g. OP30Sintered bearing Press-inprocessUse the 4M's to identity typesof variation that have aninfluence on the operation orstation being analyzed4M Types:Man, Machine, Material(indirect), Milieu(Environment)List a single "M" for eachline.Types may vary by companyA description of what theProcess Item is expected toachieve broken down intoseveral categoriesSome categories maybe unknownand listed as Not Applicable(NA)These expectations can bereferred to when completingFailure Effects (FE)These expected results mayapply for the entire ProcessItem e.g. electrical motorassembly lineIn-plant:Avoid rework andscrapShip to plant Installation ofwindow lifter electrical motorto vehicle doorProcess Item.:Shaft installedinto pole house assemblyVehicle.:Window raises andlowersA description of what theoperation or station mustachieve e.g. Axial positionsintered bearing in polehousingThis is the positive ProductCharacteristic and must bedetectable in the productThe Failure Mode or FailureModes will be the negative ornegatives of the positiveProduct Characteristic.The Product Characteristic canbe written stating the entirepositive ProductCharacteristic, e g within gaptolerance, or using separatelines, considering over andunder tolerance, e g , notgreater then max tolerance,not less than min tolerance.It may also consider magnitudeof out to tolerance if iteffects the Failure Effectse.g. gap not greater then maxtolerance by 0~3mm or gap notA positive description of howthe work is completedincluding the positive processcharacteristic related to each4MThe negative of thesepositives will be used for theFailure Cause column The moredetail used here will producemore Failure Cause i.e. eachline is a unique positiveproducing a unique negative,i.e. a Failure CauseInstead of “Get correctsintered bearing from partrack and place into fixture”Use “Get correct sinteredbearing” and “Fully placebearing into fixture”Thisidentifies of two separateFailure Causes, i.e.. “wrongpart picked” “Bearing notfully set into fixture” Themore detail used, the moreCauses can be captured in thedocumented for risk analysis.How the Vehicle, System orSubsystem could fail toperform the Function describedat the Next Higher levelWhen considering Effects,consider items listed in “Function of the Process Item”and the "Failure Mode” endhow they can Effect the 3areas being considered (In-Plant, Ship to plant. ProcessItem, Vehicle End User)Include potential effects tothe vehicle (End User) levelend regulations. as applicableIt is recommended to list theSeverity Rank next to each ofthe 3 areas being consideredand use the highest Rank forthe Severity Rank. One area,such as End User. may notalways have the highestSeverity Rank1~10Failure mode must bedetectable in the product(defect)The Failure Mode will be thenegative or negatives of thepositive ProductCharacteristic.Considering each side of thespecification of ProductCharacteristic ifspecification of ProductCharacteristic has a range,list Failure Mode for eachside of the specification,i.e., “Torque Bolt to spec”,the Failure Modes will be “Torque loss then spec”, “Torque more than spec” Eachmay have a different SeverityRank.Considering magnitude of outof specification If themagnitude of out ofspecification can affect theSeverity Rank. It should helisted, i.e., “No stampingThe Failure Cause is thenegative of the positivelisted in “Function of theProcess Work Element andProcess Characteristic”Cause must be detectable inthe process (error) and leadto the Failure ModeNew Failure Causes - Whileconsidering “Failure Causes”, new 'Function of theProcess Work Element andProcess Characteristic”, “Product Characteristic andmaybe generated, i.e. listing.“Scratched top surface whilepicking part from rack” cangenerate “Pick part from partrack without scratching thetop surface”, may generateand a new “ProductCharacteristics”, “Topsurface scratch tree” and anew Failure Mode “Top surfacescratched”Failure Analysis can beginInitial State - Pastcontrols proven and /or controls committedto1~10Initial State - Pastcontrols proven and /or controls committedto1~10H, M,L, NALL Additional Actionsneeded to reduceOccurrenceAdditional Actionsneeded to improveDetectionName, nottitle ordepartmentmm yy or ddmm yyOptional:Decisionpending,Implementation pendingDescriptionof actiontaken anddocumentnumber,report nameand date,etc.mm yy or ddmm yy1~101~101~10H, M,L, NAFor PFMEA teamuseExamples:A design change:DCN0983885A managementreview:MR07-NOV-2017A customerreview:CR02-FEB-2018Electrical Motor[OP 30] Sintered bearing press Operator Process Item: Convertelectrical energy intomechanical energy (acc.control signal)In Plant: Assembly ofcomponents within cycle time,without scrap or reworkShip to Plant: Assembly ofmotor to vehicle door withoutline stoppage, sort orcontainmentEnd User Window raises andlowers Press in sintered bearing toachieve axial position in polehousing to max gap per printOperator takes clean sinteredbearing from chute and push itonto the press-in shaft untilthe upper stopProcess Item: Loss ofmechanical energy because oftoo much friction betweenbearing and shaft, innerdiameter of the bearingdeformed because off too muchseating stressIn Plant: NoneShip to Plant NoneEnd User: Window raises andlowers with difficulty8Axial position of sinteredbearing is not reached, gaptoo smallOperator inserts a sinteredbearing which was dropped tothe ground floor before(contaminated with dirt)No Prevention control10Lot release Protectobjective(effectiveity 100%)Visual Gaugeinspection of axialgap of bearing to polehousing eat byoperator (check thechecker:N/A)Dectection indicator:OK/NOK (RED/GREENarea) and operatorseparate the NOK part2H CC The definition of awork instructionand a workinstruction for"fallingcomponents" andcontents of theregularTraining curricularthe operator andfinishing staffJohn Doe(ProductionEngineer)DD.MM.YYYY In-progress832LElectrical Motor[OP 30] Sintered bearing press Machine (press machine)Process Item: Convertelectrical energy intomechanical energy (acc.control signal)In Plant: Assembly ofcomponents within cycle time,without scrap or reworkShip to Plant: Assembly ofmotor to vehicle door withoutline stoppage, sort orcontainmentEnd User Window raises and Press in sintered bearing toachieve axial position in polehousing to max gap per printMachine has to press in thesintered bearing into the polehousing seat until the definedaxial positionProcess Item: Loss ofmechanical energy because oftoo much friction betweenbearing and shaft, innerdiameter of the bearingdeformed because off too muchseating stressIn Plant: NoneShip to Plant NoneEnd User: Window raises andlowers with difficulty8Axial position of sinteredbearing is not reached, gaptoo smallMachine stops before reachingfinal position (too lessforce)Selected press withforce monitoring andposition controlsensor3Lot release Protectobjective(effectiveity 100%)Visual Gaugeinspection of axialgap of bearing to polehousing eat byoperator (check thechecker:N/A)2M3Electrical Motor[OP 30] Sintered bearing press Machine (press machine)Process Item: Convertelectrical energy intomechanical energy (acc.control signal)In Plant: Assembly ofcomponents within cycle time,without scrap or reworkShip to Plant: Assembly ofmotor to vehicle door withoutline stoppage, sort orcontainmentEnd User. Window raises andlowers Press in sintered bearing toachieve axial position in polehousing to max gap per printMachine has to press in thesintered bearing into the polehousing seat until the definedaxial positionProcess Item: NoneIn Plant: Assembly of shaft isnot possible because clearancetoo small (scrap 7),excessive line cycle time (7)Ship to Plant: n/aEnd User: n/a7axial position of sinteredbearing is not reached, gaptoo largeMachine stops before reachingfinal position (too lessforce)Selected press withforce monitoring andposition controlsensor3Lot release Protectobjective(effectiveity 100%)Visual Gaugeinspection of axialgap of bearing to polehousing eat byoperator (check thechecker:N/A)Dectection indicator:OK/NOK (RED/GREENarea) and operatorseparate the NOK part3M3OPTIMIZATION (Step 6)RemarksSCOPE DEFINITION (Step 1)Name of system elementSTRUCTURE ANALYSIS (Step 2)FUNCTION ANALYSIS (Step 3)FAILURE ANALYSIS (Step 4)RISK ANALYSIS (Step 6)missed contexts in draft handbook。

AIAG-VDA失效模式与影响分析(新版PFMEA)课程大纲课程介绍:根据最新发布的AIAG-VDA FMEA(第一版)要求,从实际的应用案例,系统的讲解新版FMEA的背景,重要变化点及企业如何应对等,并针对性极强地讲解PFMEA 的内容、要求、内部逻辑、实施步骤和方法,对新的AIAG-VDA FMEA “六步法”进行提前分解,帮助企业相关职能部门负责人及主管工程师们能够快速聚焦变更,透彻理解OEM对潜在失效分析并进行预防,解决产品设计和过程设计可能出现的问题,在产品实现过程的前期确保法律法规,系统的,过程的,以及产品的相关的失效模式及风险得到考虑并实现有效预防和控制,从而实现稳健的产品和过程设计和公司的持续经营。

参加人员:设计、制造、质量等相关部门经理、主管以及工程师以上人员,以及从事质量体系管理及标准化等工作,以及企业的一方和或二方审核员等相关人员。

课程收益:1、全面了解AIAG-VDA FMEA 第一版背景及主要变化点;2、掌握AIAG-VDA FMEA 推荐的方法和工具;3、获得有效实施FMEA的方法和思路;4、识别目前FMEA的差距并采取纠正行动,降低企业运营的风险;课程大纲:第一章:FMEA介绍第一节:AIAG-VDA FMEA 背景及主要变化点第二节:FMEA目的和描述第三节:FMEA开发过程及里程碑第四节:FMEA的对象和局限性第五节:如何与公司现况进行整合1、FMEA相关的法律法规2、管理承诺3、D/FMEA的知识保护4、客户和供应商之间的协议5、FMEA的再使用6、现有FMEA的处理第六节:产品FMEA和过程FMEA1、设计FMEA2、过程FMEA3、设计FME和过程FMEA之间的信息流第七节:FMEA的策划1、FMEA的团队2、FMEA的时机3、FMEA的意图4、FMEA的工具5、FMEA的任务第二章:过程FMEA的执行第一节:PFMEA第一步:范围定义1、目的第二节:PFMEA第二步:结构分析1、目的2、过程流程图3、结构树第三节:PFMEA第三步:功能分析1、目的2、功能3、要求4、功能关系可视化第四节:PFMEA第四步:失效分析1、目的2、失效3、失效链4、故障网络与链分析5、失效影响6、失效模式7、失效原因8、总结第五节:PFMEA第五步:风险分析1、目的2、现行预防控制3、过程策划4、生产过程5、现行探测控制6、现行预防和探测控制7、评价8、严重度9、发生度10、探测度11、优先措施第六节:PFMEA第六步:优化1、目的2、职责分配3、措施的现状4、措施有效性评估5、持续改进第七节:FMEA结果文件化。