薯类去皮机的结构设计

- 格式:doc

- 大小:836.50 KB

- 文档页数:20

马铃薯去皮机毕业设计马铃薯去皮机毕业设计在现代社会中,机器的应用已经渗透到了我们生活的方方面面。

无论是生产制造,还是日常生活,机器的存在都给我们带来了极大的便利。

而今天,我将为大家介绍的是一款特殊的机器——马铃薯去皮机。

一、背景介绍马铃薯作为一种重要的农作物,广泛种植于世界各地。

然而,马铃薯的去皮过程一直是一个耗时耗力的工作。

传统的去皮方法往往需要人工操作,不仅效率低下,而且容易导致皮肤被浪费。

因此,设计一款高效、智能的马铃薯去皮机成为了当务之急。

二、设计原理马铃薯去皮机的设计原理主要基于机械力学和电子控制技术。

首先,机器通过传感器检测马铃薯的大小和形状,然后根据这些参数进行智能化的去皮操作。

去皮过程中,机器利用旋转刀片和水流的组合,将马铃薯的皮层迅速剥离,同时确保不会损伤到马铃薯的内部结构。

整个去皮过程完全自动化,减少了人工操作的需求,提高了效率。

三、技术创新为了提高马铃薯去皮机的性能和稳定性,设计者在技术方面进行了一系列创新。

首先,采用了先进的图像识别技术,能够准确地识别马铃薯的大小和形状,从而调整去皮机的工作参数。

其次,马铃薯去皮机配备了高速旋转的刀片和高压水流,能够快速而彻底地去除马铃薯的皮层。

此外,机器还配备了智能控制系统,能够根据实时数据进行自动调整和优化,确保每个马铃薯都能够得到最佳的去皮效果。

四、应用前景马铃薯去皮机的应用前景非常广阔。

首先,它可以广泛应用于食品加工行业。

无论是马铃薯片、薯条还是马铃薯泥,都需要去除皮层,而马铃薯去皮机可以大大提高生产效率,降低成本。

此外,马铃薯去皮机还可以应用于餐饮业和家庭生活中,为人们提供更加便捷的烹饪体验。

最后,马铃薯去皮机还可以推广到农田中,帮助农民提高马铃薯的产量和品质。

五、总结马铃薯去皮机作为一款创新的机器设备,将为我们的生活带来更多便利和效益。

通过智能化的设计和先进的技术应用,马铃薯去皮机能够高效、准确地去除马铃薯的皮层,提高生产效率,降低成本。

![毕业设计马铃薯去皮机设计(附带中英文文献)[管理资料]](https://uimg.taocdn.com/29d5f271e53a580217fcfebc.webp)

毕业设计马铃薯去皮机的设计目录摘要 (I)Abstract (II)第一章引言 (1) (1) (2) (2) (2) (2) (3)国内外马铃薯去皮设备简介 (3) (3)蒸煮装置 (4)化学去皮装置 (5)第二章马铃薯去皮机的结构设计 (7)马铃薯去皮机的设计及特点 (7) (10) (10) (10) (11) (11) (11)第三章马铃薯去皮机的参数确定 (13)物料在工作圆筒内的受力分析 (13) (14) (15) (17)第四章主要零件的结构设计与计算 (18)V带轮结构设计计算 (18)4.2传动主轴的结构设计计算 (19) (20) (21) (21)第五章主要零件的校核 (22) (22) (22) (22) (23) (24) (24)总结 (25)致谢 .................................................................................................................. 错误!未定义书签。

参考文献 . (26)摘要:马铃薯去皮是所有马铃薯制品加工工艺过程的重要环节,目前存在的各种去皮方法都各自有其一定的局限性。

随着马铃薯产业的发展和我国社会经济的进步,如何寻找一种优质、高效、节能几环保的马铃薯剥皮方法己成为马铃薯加工工艺过程中迫切需要解决的问题。

本文主要介绍了以摩擦原理为基础的、适合食品加工工厂等场所使用的大型马铃薯去皮机的设计要点、工作原理和设备组成。

关键词:去皮机;摩擦;设计;马铃薯Abstract: Peeling is an important annulet in potato processing, Methods of peeling which have been used at present all has their limitation. Along with the development of potato processing industry and the progress of our society and economy, it has become an urgent task for finding an efficient, economical and no pollution method of potato peeling. This paper introduced the large-scale machine for peeling potatoes which is designed by the principle of friction and suited to the factory of food processing, and it presented the key of design,working principle and the composition of the large-scale machine.Keywords:Peeling machine; friction; design; potato第一章引言目前,世界79%的国家种植马铃薯,总面积2000万hm,左右,总产量3亿多吨,仅在小麦、玉米、水稻之后,居第四位。

马铃薯立式去皮机结构设计

殷建国;刘滨

【期刊名称】《中国农机化学报》

【年(卷),期】2015(36)1

【摘要】设计了一种高效率的立式马铃薯去皮机。

该去皮机主要包括外筒体、第一和第二两层可升降内筒体、波浪形圆盘、驱动装置、喷淋装置、加料和卸料装置等。

该机结构紧凑、制造容易、工作可靠,马铃薯去皮均匀、清洁度好、剥离损失小于3%,生产效率高,是一种较理想的农产品加工设备。

【总页数】3页(P171-173)

【关键词】马铃薯;去皮;农产品加工;设备

【作者】殷建国;刘滨

【作者单位】南京工业职业技术学院机械工程学院

【正文语种】中文

【中图分类】S226.4

【相关文献】

1.新型立式马铃薯连续去皮机仿真设计 [J], 苗红涛;夏晶晶

2.马铃薯连续机械式去皮机优化与试验 [J], 孟庆书;朱立学;黄键裕;詹旭峰

3.真空包装机/糖衣机/冲洗灌装旋盖机/油水一体调温式油炸机/螺杆式制冷压缩机/立式超微粉碎机/高速斩拌机/马铃薯切片机/瓜子炒干机/山海关膨化机械厂 [J],

4.立式半夏去皮机的设计与研究 [J], 张淑娟;吴海平

5.马铃薯去皮机的设计 [J], 朱颖

因版权原因,仅展示原文概要,查看原文内容请购买。

HEBEINONGJI摘要:土豆放置在一个圆柱式的容器内,转盘调节到一个合适的速度旋转,容器内的士豆在重力、摩擦力等共同力的作用下,利用土豆和转盘间的速度不一样而产生的离心力,最终实现土豆脱皮,在这时向容器内加入大量的水,就能将土豆产生的碎屑冲洗干净。

该方法由于整个过程是在温室下进行的,所以具有耗能低、成本低、产品破损少、产品表面整洁平滑等优点。

同时,还可以在加工出口放置一个多刀口切割机,根据不同的市场需求采取不同的切割方式,既方便又快捷。

关键词:土豆;去皮清洗;摩擦;食品机械;设计一种土豆去皮机的设计德州学院机电工程学院王丽萍王志坤1国内外研究情况伴随着食品加工业的发展,食品深加工已经越来越受到关注,特别是快餐的出现,让保鲜脱水工业快速发展起来,这要求原料深造方面需要更加地方便快捷。

近年来国家推出_系列惠农政策,提高了人们种植土豆的积极性,扩大了土豆的种植面积,同时,也让以其为原料的产品在中国得到更广泛的推广。

土豆的深加工是非常被重视且发展迅速的产业之一。

中国每年的土豆产量在世界各国中也是名列前茅的,年种植面积和总产量在世界上首屈一指,但由于在加工时不能充分利用原材料,从而导致大量土豆积压,大大增加了冬季收藏的难度,同时也极大地降低了它的营养价值。

其很大一部分原因就是没有一种合适的并且高效的去皮机器。

从国外引入设备价格相对较高,生产成本昂贵,导致在中国该产业发展缓慢。

在发达国家中,美国的薯产品在国内外极其有名,快餐食品占据了大部分的世界市场。

近20年来,越来越多的国家投身于研究土豆深加工机械化。

土豆中含有丰富的淀粉、维生素和糖,能满足人们对各种营养成分的需求,在提高人体机能和满足正常营养等方面有很大的作用。

土豆所含的营养成分十分丰富,因此,土豆深加工具有广阔的前景,设计土豆去皮机也是大势所趋。

2土豆去皮机的结构设计土豆摩擦去皮过程中需要考虑的因素主要有以下几点:土豆去皮后表面要光滑、无破坏层、去皮过程没有污染、去皮成本低。

毕业设计(论文)-土豆马铃薯去皮机设计(含全套CAD图纸)由于部分原因,说明书已删除大部分,完整版说明书,CAD图纸等,联系153893706土豆去皮机设计学生:指导老师:摘要:马铃薯去皮是所有马铃薯制品加工工艺过程的重要环节,现有的各种去皮方法都各自有一定的局限性。

随着马铃薯产业的发展和我国社会经济的进步,如何寻找一种优质、高效、节能、环保的马铃薯去皮方法己成为马铃薯加工工艺过程中迫切需要解决的问题。

去皮多用于水果和蔬菜的加工中以除去不需要或不可食的物质,并改善成品的外观。

主要考虑的因素包括:减少去掉的部分以及可能降低的能源、劳力和物质成本来降低总成本。

这里介绍摩擦去皮的方法:马铃薯放置在工作圆筒中,磨盘以一定的速度旋转,工作室内的土豆在离心力、重力和摩擦力共同作用下,利用土豆相对于工作磨盘间的相对速度差,将土豆的皮去掉,又被大量的水冲洗干净。

该方法的优点是由于整过过程是在室温下进行,因而具有能源消耗及成本低、无热损伤,食品外观良好的优点。

关键词:马铃薯;去皮机;摩擦;设计The Design on Potato Peeling MachineStudent:Tutor:1(College of engineering, Hunan Agricultural University, Changsha 410128, China)Abstract:Peel potatoes is the important part of the process of all potato products processing technology, and all kinds of available methods of peeling potato skin each have some limitations. Along withthe development of the potato industry and China's social and economic progress, how to search for a high quality, highly effective, energy-conservationly, environmentally method of peeling potatoes has becomethe machining process of the urgent need to address the problem.Peeling skins is more applicated in fruits and vegetables processing, to remove don't need or not food material, and to improve the appearance of the finished product. The main consideration factors include: reduce removed part of the energy, and may reduce the labor and material costs to lower overall costs. Here introduces the method of peeling skin by friction: potatoes are placed in the working cylinder, with certain rotation speed applications, the potatoes in working interior is under the joint action of the centrifugal force, gravity, and the friction, using the relative speed between the chute and potatoes, take out the potatoes leather , and rinsed clean by the amount of water . The advantage of the method is due to the whole process is over at roomtemperature, thus has the energy consumption and low cost, no heat damage, and good food appearance.Key words: Potato; Peeled and machines;Friction;Design1 前言1.1 研究的目的与意义马铃薯是高产稳产作物,它有很高的营养价值,我国的马铃薯种植面积居世界第二,我国丰富的马铃薯资源至今没有很好开发利用,绝大部分只用作杂粮和饲料,每[1]年的霉烂损失甚大,用于加工的尚不到5%,主要是制作淀粉、粉丝和酒精。

摘要马铃薯为植物的块茎,形状为圆形或椭圆形,其结构由表皮层、形成层、外果肉和内果肉四部分。

马铃薯品种可分两大类,一类是淀粉含量较高的,适宜于作为生产淀粉的原料,另一类是蛋白质含量较高,适宜作为蔬果或制成多种食品[1]。

马铃薯营养丰富,除直接食用外,还可以加工成食品、全粉、淀粉等经济价值较高的食品,通过加工可以大幅度提高鲜薯的商品价值[2]。

鉴于马铃薯的很多特点,马铃薯得到了广泛的利用。

a.马铃薯可鲜食,鲜食用马铃薯主要用作家庭餐馆烹调,我国主要用来制作菜肴、面点小吃等大众食品。

果外除蒸烤鲜马铃薯作主食外,还有咖哩饭、炖薯快以及色拉凉拌菜。

马铃薯可制成方便食品、快餐食品、休闲食品,如马铃薯粉、马铃薯全粉、脱水马铃薯片(条)、速冻薯条(薯泥)、蒸薯条、罐装和去皮马铃薯、马铃薯脆片、马铃薯膨化小食品等;b,加工成淀粉及相关产品:由于马铃薯淀粉的优良特性,不仅是制作高级方便面、面类最为理想的添加淀粉,而且还是肉制品、鱼糜制品等的添加剂或原料。

马铃薯淀粉也是粉条的优质原料。

出马铃薯淀粉外,也可得到相关产品,包括各种变性淀粉、饴糖、葡萄糖、膳食纤维制品等。

C,其他制品:马铃薯提取淀粉后的残渣可制成马铃薯发酵饲料、提取蛋白等[5]。

去皮(peeling)用于多种水果和蔬菜的加工中以除去不需要或不可食的物质,并改善成品的外观。

主要的考虑因素包括通过尽可能减少去掉的部分以及可能降低能源、劳力和物质成本来降低总成本。

这里,介绍摩擦去皮方法:食品被放置在金刚砂滚轴上或内壁排列着金刚砂的转筒中,在磨损力的表面除去食品的表皮后又被大量的水冲洗干净。

该方法的优点是由于过程是在温室下进行而具有的能源成本低以及资本成本低、无热损伤,食品外观良好的优点,不规则食品表面(如马铃薯上的“孔眼”)会破坏去皮产品的外观,需要手工去除[3]。

关键词:马铃薯、去皮清洗、农产品、食品机械AbstractPotato tuber for plants for circular or elliptic shape, structure, by cuticular layer and layer, the pulp and pulp within four parts. Potato varieties can be divided into two kinds, one kind is starch content high, suitable for the production of raw materials as starch content of protein, another kind is higher, suitable for various fruits or food..Potato nutrition is rich, besides direct edible, but also can be processed into food, powder, starch, etc, the economic value of higher food processing can be greatly improved through the value of fresh chips.In view of many of the characteristics of the potato, potato has been widely used. a. can be fresh potatoes, fresh potatoes used mainly for cooking the family restaurant, China is mainly used to create dishes such as pasta snack food of the public.In addition to fresh fruit outside the potato for food, there are curry rice, stew and potato salad cold fast food. Potatoes can be made from convenience foods, fast foods, snack foods, such as potato flour, potato powder, dehydrated potato chips (article), frozen French fries (potato mud), steamed potato chips, canned and peeled potatoes, potato crisps , extruded snacks such as potato; b, processed into starch and related products: potato starch as a result of the excellent features, not only is the production of high-level instant noodles, flour add the most ideal type of starch, but also meat, surimi products such as additives or raw materials . Potato starch is also of high quality raw materials. The potato starch, but also related products available, including a variety of modified starch, maltose, glucose, dietary fiber products. C, other products: potato residue after starch extraction can be made from potato fermented feed, extract proteinSkin peeling (for) of fruits and vegetables processing to remove need not eat or not, and improve the physical appearance of the product. The main factors including through minimize removed part and may reduce the labor and material costs energy, reduce the total cost. Here introduces friction peel method: food is placed on the walls or emery roller drum lined up in the emery, wear away the food of skin surface by the amount of water after washing clean. The advantage of this method is due process is conducted in greenhouse with low cost and the energy of capital cost is low, no heat, the advantages of good food appearance, irregular food surfaces (such as potato "holes) destroys peel product appearance, need manual removal.Key words: Potatoes、Peel cleaning、Agricultural、Food machinery目录前言 .............................................................................................................................. - 1 - 1.马铃薯去皮机工作原理 ........................................................................................... - 2 -1.1去皮清理的原理 .............................................................................................. - 2 -1.2去皮设备 .......................................................................................................... - 2 - 2.轴的设计 ............................................................................................................ - 5 - 2.1轴的材料 ....................................................................................................... - 5 - 2.2轴的强度计算 ............................................................................................... - 5 - 2.3轴的结构尺寸初步确定 ............................................................................... - 6 - 3.滚动轴承的设计 ....................................................................................................... - 8 -3.1.滚动轴承类型的选择 ...................................................................................... - 8 -3.2.滚动轴承部件的组合设计. ............................................................................. - 9 -4.电动机的选择. ........................................................................................................ - 10 -5.齿轮的结构设计 ..................................................................................................... - 11 -5.1.齿轮材料及热处理 ........................................................................................ - 11 -5.2.齿轮相关参数的初步确定 ............................................................................ - 12 -5.3.校核齿轮强度 ................................................................................................ - 12 -6.圆筒的结构设计 ..................................................................................................... - 15 -7.轴承座的结构设计 ................................................................................................. - 16 -8.圆盘的结构设计 ..................................................................................................... - 18 - 参考文献 .............................................................................................................. - 19 - 致谢 ............................................................................................................................ - 20 -前言综观食品加工业对加工技术的要求,食品加工技术的发展趋势大致如下:第一,提高原料的利用率。

小型马铃薯去皮机的设计发布时间:2022-06-13T06:54:13.528Z 来源:《时代教育》2022年4期作者:张增男[导读] 针对市面上马铃薯去皮机具有去皮不完整、维修困难、皮屑在机体堆积等问题,本文设计了一款适合于中小型张增男山东协和学院工学院,山东济南)[摘要] 针对市面上马铃薯去皮机具有去皮不完整、维修困难、皮屑在机体堆积等问题,本文设计了一款适合于中小型饭店的马铃薯去皮机。

该去皮机在圆盘设置波纹凸起同时涂上金刚砂,在筒壁内侧做成可拆卸式的金刚砂砂纸增加摩擦从而节约成本,维修更简便。

在圆盘下方制作刮板,通过搅拌达到均匀分散作用进行高效去皮且能防止马铃薯皮在下方堆积,实现了在不停机的情况下排料。

[关键词] 去皮机;摩擦;马铃薯马铃薯通常情况下,人们也将其称之为土豆,是一种常见的家常菜之一。

而且马铃薯这种美食的做法多种多样,在形状上,既可以将其切成丝状,也可以将其切成片状或者是块状,在做法上,既可以炒着吃,还可以蒸着吃或者是炸着吃。

受到人们的普遍欢迎。

不管做成什么样式,大家都很爱吃。

而且它也是厨房必备品之一。

在当今的社会下,需要制造出一台更具有优势,去皮效率更高的机器来满足需求。

1.国内外研究现状最初在英国,人们是通过简单的设备将土豆去皮,由于去皮时容易将土豆弄脏,因此,他们大多都在河边进行加工。

在这样的生产需要下1765年第一台来自德国的符合需求的半自动马铃薯去皮机研制成功了,尽管该产品是一台半自动机器,但是在那时却可以有效降低人工成本,经过6年的努力,他又研制出一款先进的去皮机械,该机械依靠回转动力进行去皮。

不仅提高了加工效率,其适用范围也进一步扩大。

马铃薯去皮机的发明和发展,也促进了与马铃薯外形相似食品机械的发展。

在19世纪,该去皮机基本是是当时唯一可以对马铃薯进行去皮的机械。

对于马铃薯来说,将其制作成美味佳肴需要多个步骤,然而去皮是第一个而是最重要的一环,经过多年的发展,现在已经形成多种对马铃薯去皮的方法。

毕业设计马铃薯去皮机的设计目录摘要 (I)Abstract (II)第一章引言 (1)1.1目的意义和国内外现状概况 (1)1.2马铃薯原料加工预处理工艺流程简介 (2)1.2.1马铃薯的分级 (2)1.2.2马铃薯的清洗 (2)1.2.3马铃薯的去皮 (2)1.2.4马铃薯的护色 (3)1.3 国内外马铃薯去皮设备简介 (3)1.3.1机械装置 (3)1.3.2 蒸煮装置 (4)1.3.3 化学去皮装置 (5)第二章马铃薯去皮机的结构设计 (7)2.1 马铃薯去皮机的设计及特点 (7)2.2摩擦式马铃薯去皮机基本结构 (10)2.2.1工作圆筒 (10)2.2.2工作转盘 (10)2.2.3传动系统 (11)2.2.4其他 (11)2.3工作原理 (11)第三章马铃薯去皮机的参数确定 (13)3.1 物料在工作圆筒内的受力分析 (13)3.2工作转盘转速的确定 (14)3.3马铃薯去皮机功率的确定 (15)3.4整机主要参数指标 (17)第四章主要零件的结构设计与计算 (18)4.1 V带轮结构设计计算 (18)4.2传动主轴的结构设计计算 (19)4.2.1轴上零件的周向定位 (20)4.2.2确定轴上圆角和倒角尺寸 (21)4.3滚动轴承的初步选择 (21)第五章主要零件的校核 (22)5.1滚动轴承的寿命计算 (22)5.2轴的计算和校核 (22)5.2.1作出轴的计算简图 (22)5.1.2轴的强度校核计算 (23)5.1.3按弯扭合成应力校核轴的强度 (24)5.1.4轴的扭转刚度校核计算 (24)总结 (25)致谢 (26)参考文献 (27)摘要:马铃薯去皮是所有马铃薯制品加工工艺过程的重要环节,目前存在的各种去皮方法都各自有其一定的局限性。

随着马铃薯产业的发展和我国社会经济的进步,如何寻找一种优质、高效、节能几环保的马铃薯剥皮方法己成为马铃薯加工工艺过程中迫切需要解决的问题。

本文主要介绍了以摩擦原理为基础的、适合食品加工工厂等场所使用的大型马铃薯去皮机的设计要点、工作原理和设备组成。

马铃薯去皮机的毕业设计1. 引言马铃薯作为全球重要的粮食作物之一,在农业生产中起着重要的角色。

然而,传统的马铃薯去皮过程通常需要大量的人力和时间,效率低下且易出现误伤等问题。

为了提高马铃薯去皮的效率和质量,本毕业设计旨在设计一台能够自动去皮的马铃薯去皮机。

2. 设计目标本毕业设计旨在设计一台能够高效、准确地去除马铃薯表面皮层的机器。

具体设计目标如下:•自动化:实现全自动化操作,减少人力成本。

•高效性:能够在短时间内完成对多个马铃薯的去皮工作。

•精确性:确保去除皮层时不损伤马铃薯肉质。

•安全性:避免对操作人员和周围环境造成伤害。

3. 设计原理3.1 马铃薯表面特点分析在设计去皮机之前,首先需要分析马铃薯表面的特点。

马铃薯表面通常覆盖着一层皮,皮的厚度不均匀,并且有时会存在凹凸不平的部分。

因此,设计去皮机需要考虑到这些特点,以确保去皮过程的准确性和稳定性。

3.2 设计思路基于对马铃薯表面特点的分析,我们可以采用以下设计思路来实现自动化去皮:1.马铃薯输入:通过一个进料系统将马铃薯送入去皮机。

2.机械去皮:设计一套刀具系统,能够精确地去除马铃薯表面的皮层。

刀具系统应具备一定的灵活性,以适应不同形状和大小的马铃薯。

3.皮屑处理:设计一个排渣系统,将被切割下来的马铃薯皮屑及时清理出去。

4.马铃薯输出:设计一个出料系统,将已去除皮层的马铃薯送出去皮机。

4. 设计方案4.1 进料系统进料系统是将待处理的马铃薯送入去皮机的关键部分。

可以采用传送带的形式,通过电机驱动,将马铃薯从输入端输送到去皮区域。

4.2 刀具系统刀具系统是实现去皮的核心部分。

可以设计多个旋转刀片,围绕着马铃薯进行旋转运动。

刀片的形状和尺寸应根据马铃薯的特点进行合理设计,以确保能够准确地去除皮层。

4.3 排渣系统排渣系统用于清理被切割下来的马铃薯皮屑。

可以设计一个集渣槽,在机器运行过程中及时收集和排出皮屑,以保持清洁。

4.4 出料系统出料系统用于将已去除皮层的马铃薯送出去皮机。

2018.05 农村实用技术农业机械一种摩擦式马铃薯去皮机的设计马兴飞(商丘工学院,河南 商丘 476000)1 去皮机的结构设计1.1 去皮机的设计及特点马铃薯的清洗是去皮之前必不可少的一道工序,因此选用搅戈式机械清洗机,该清洗机在国内生产车间普遍使用。

机器的铣槽形状为梯形,最上部是喷水装置,原料放入充水的铣槽里,在电机带动下,搅龙快速旋转,喷水装置不断喷水,冲洗块茎得以洗净。

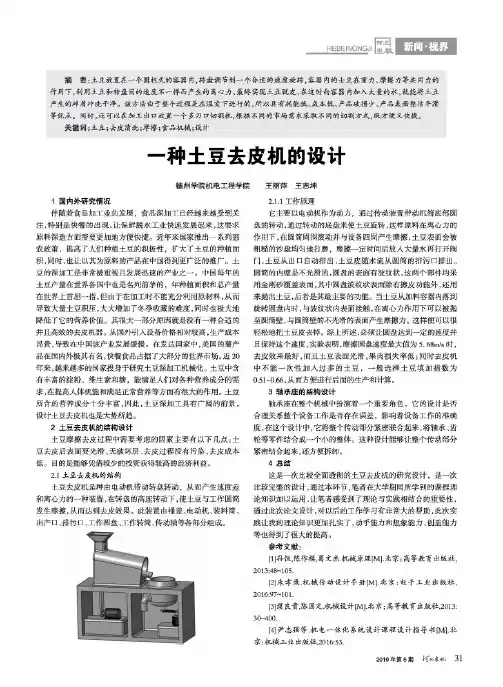

摩擦式机械去皮机结构如图1.1所示。

圆桶壁部有弹板,工作转盘中低边高,呈波浪形,在电机驱动下,采用V带传动,传动轴带动工作转盘做高速旋转运动,圆筒内马铃薯依靠力的相互作用实现去皮,该机工作时注入清水,皮屑随水流沿转盘和筒内壁的间隙排出机体,无皮马铃薯通过出料口排出。

该机器作业过程无污染,皮屑可二次利用,符合设计要求。

图1.1 摩擦式去皮机结构图1-机架 2-排渣管 3-出料口 4-圆筒 5-加料斗盖 6-反转螺帽 7-进水孔 8-转盘 9-挡水环 10-V带 11-小带轮 12-电机13-大带轮 14-轴 15-键1.2 去皮机基本结构如上图1.1所示,去皮机基本结构包括:立式机型、机架、工作圆筒、传动机构和转盘。

1.2.1 工作圆筒去皮设备要求安全、耐用、卫生等特性。

因此圆筒材质应选取具有高硬度、摩擦系数小的不锈钢制品,内壁用棕刚玉掺环氧树脂浇注制成粗糙表面,圆筒侧壁安装出料口和排渣口。

1.2.2 工作转盘工作转盘是去皮过程中马铃薯产生相互运动的主要部件。

根据设计要求,增大转盘表面的粗糙程度,确定转盘形状为圆盘形,表面具有中低、边高、波纹凸起等特性,表面采用棕刚玉掺环氧树脂浇注,下方的橡胶挡板起到挡水环的作用。

转盘结构示意图如图1.2所示。

图1.2 工作转盘结构示意图1.反转螺帽 2.转盘 3.挡水环 4.传动轴1.2.3 传动系统采用V带传动,具有成本低、保护工件、传动比较小等特性。

1.2.4 其他摘 要:针对目前马铃薯去皮方法的局限性,研究一款小成本、高效、环保马铃薯去皮机。

1 英文文献翻译1.1 英文文献原文题目Potatoes Potatoes peeled peeled peeled structure structure structure design designAbstract: Abstract: the the the graduation graduation graduation design design design is is is mainly mainly mainly studied studied studied on on on the the the bas bas is is of of of the the the principle principle principle of of of friction friction friction of of of potato potato potato peeling peeling peeling machine machine machine d d esign, esign, working working working principle principle principle and and and the the the composition composition composition of of of the the the equipment equipment . . Through Through Through the the the analysis analysis analysis of of of original original original data, data, data, project project project demonstratio demonstratio n n and and and related related related data data data analysis analysis analysis and and and calculation, calculation, calculation, the the the overall overall overall des des ign ign of of of a a a complete complete complete potato potato potato peeler peeler peeler to to to peel peel peel and and and mechanical mechanical mechanical stru stru cture cture is is is a a a new new new form, form, form, to to to better better better serve serve serve the the the fruits fruits fruits and and and vegeta vegeta bles bles to to to the the the development development development of of of leather leather leather industry, industry, industry, better better better adapt adapt adapt to to the the demand demand demand of of of the the the market market market both both both at at at home home home and and and abroad, abroad, abroad, so so so has has the the good good good market market market prospect. prospect.Keywords: Keywords: potatoes potatoes potatoes peeled peeled peeled structure; structure; structure; Friction Friction Friction ; ; ; drive drive 1 1 the the the domestic domestic domestic research research research status statusTechnology Technology is is is to to to measure measure measure whether whether whether an an an enterprise enterprise enterprise has has has the the the advan advan ced ced nature, nature, nature, whether whether whether have have have market market market competitiveness, competitiveness, competitiveness, whether whether whether can can keep keep ahead ahead ahead of of of competitors' competitors' competitors' important important important index. index. index. With With With the the the rapid rapid rapid d d evelopment evelopment of of of domestic domestic domestic potato potato potato peeling peeling peeling agency agency agency market, market, market, the the the core core of of the the the related related related production production production technology technology technology and and and research research research and and and devel devel opment opment will will will certainly certainly certainly has has has become become become the the the focus focus focus of of of the the the industry industry enterprises. enterprises. Understand Understand Understand the the the potato potato potato peeling peeling peeling machine machine machine in in in the the the pro pro duction duction of of of the the the core core core technology technology technology research research research and and and development development development at at at h h ome ome and and and abroad, abroad, abroad, process process process equipment, equipment, equipment, technology, technology, technology, application application application and and trend, trend, for for for an an an enterprise enterprise enterprise to to to improve improve improve product product product technical technical technical speci speci fication, fication, improve improve improve the the the market market market competitiveness competitiveness competitiveness is is is critical. critical. Potato Potato products products products the the the main main main varieties varieties varieties of of of potatoes, potatoes, potatoes, potato potato potato chips,chips, dehydrated dehydrated mashed mashed mashed potatoes, potatoes, potatoes, etc. etc. etc. No No No matter matter matter what what what kind kind kind of of of pr products, oducts, its its its processing processing processing technology technology technology requirements requirements requirements of of of raw raw raw material material s s to to to deal deal deal with with with the the the peel peel peel potatoes, potatoes, potatoes, to to to guarantee guarantee guarantee the the the quality quality of of the the the products, products, products, ensure ensure ensure its its its appearance, appearance, appearance, color color color and and and taste. taste. taste. P P eel eel potatoes potatoes potatoes peeled peeled peeled methods methods methods mainly mainly mainly include include include artificial, artificial, artificial, chemica chemica l l peeling, peeling, peeling, mechanical mechanical mechanical peeling, peeling, peeling, etc. etc. etc. Artificial Artificial Artificial to to to skin skin skin peelin peelin g g effect effect effect is is is better, better, better, but but but low low low efficiency, efficiency, efficiency, high high high loss loss loss rate, rate, rate, obv obv iously iously can can can not not not adapt adapt adapt to to to the the the needs needs needs of of of the the the development development development of of of th th e e potato potato potato industrialization; industrialization; industrialization; Chemical Chemical Chemical peeling peeling peeling a a a hot hot hot alkaline alkaline alkaline o o r r peel peel peel and and and low low low temperature temperature temperature liquid liquid liquid method method method in in in two two two forms, forms, forms, main main ly ly rely rely rely on on on the the the strong strong strong alkali alkali alkali solution solution solution and and and liquid liquid liquid chemical chemical chemical p p eeling eeling effect, effect, effect, softening softening softening and and and relaxation relaxation relaxation potato potato potato skins skins skins and and and body body -to -to keep, keep, keep, then then then use use use high high high pressure pressure pressure water water water jet, jet, jet, peeled. peeled. peeled. This This This me me thod thod the the the flushing flushing flushing process process process of of of before before before and and and after after after peeling peeling peeling the the the d d emand emand is is is higher, higher, higher, and and and liquid liquid liquid alkali, alkali, alkali, peel peel peel or or or consumption consumption consumption is is too too large, large, large, the the the cost cost cost is is is higher, higher, higher, and and and this this this way way way the the the serious serious serious in in fluence fluence the the the taste taste taste of of of the the the product. product. product. Mechanical Mechanical Mechanical peeling peeling peeling is is is fric fric tion tion peel peel peel form, form, form, the the the main main main dependence dependence dependence between between between potato potato potato and and and potat potat o o and and and potato potato potato with with with silicon silicon silicon carbide carbide carbide or or or rubber rubber rubber friction friction friction between between role role and and and achieve achieve achieve the the the goal goal goal of of of peel, peel, peel, good good good effect effect effect of of of this this this a a pproach pproach to to to skin, skin, skin, reduce reduce reduce the the the production production production cost, cost, cost, reduced reduced reduced environm environm entalpollution, pollution, simple simple simple operation, operation, operation, fast fast fast speed, speed, speed, can can can one one one person person person opera opera tion, tion, high high high energy energy energy efficiency efficiency efficiency to to to maximize maximize maximize the the the interests interests interests of of of th th e e products. products.2. 2. the the the working working working principle principle principle of of of the the the potato potato potato peeler peelerThe The potato potato potato peeling peeling peeling machine machine machine adopts adopts adopts horizontal horizontal horizontal machine, machine, machine, mainly mainly including including working working working cylinder, cylinder, cylinder, work work work table, table, table, frame frame frame and and and transmission transmission parts parts (see (see (see diagram). diagram). diagram). When When When to to to work work work in in in the the the potato potato potato peeling peeling peeling m m achine, achine, wheel wheel wheel rotation, rotation, rotation, the the the material material material by by by a a a bucket bucket bucket shape shape shape inlet inlet, , material material material fall fall fall on on on the the the surface surface surface of of of a a a rotating rotating rotating brush brush brush roller roller corrugated corrugated bulge, bulge, bulge, the the the effect effect effect of of of the the the centrifugal centrifugal centrifugal force force force by by by the the brush brush roller roller roller tangent tangent tangent upward upward upward movement, movement, movement, material material material constant constant constant alon alon g g the the the motion motion motion for for for a a a cylindrical cylindrical cylindrical wall, wall, wall, rise rise rise to to to the the the top, top, top, was was at at the the the top top top of of of the the the block block block back back back into into into the the the working working working surface surface surface of of the the plate. plate. plate. Into Into Into the the the rough rough rough surface surface surface and and and friction friction friction brush brush brush roll.roll. The The reciprocating reciprocating reciprocating movement movement movement of of of the the the material material material in in in this this this process,process, by by violent violent violent agitation, agitation, agitation, and and and formed formed formed with with with a a a brush brush brush roller, roller, roller, wall wall and and between between between particles particles particles is is is given given given priority priority priority to to to with with with flip, flip, flip, rubb rubb ing ing friction, friction, friction, impact impact impact of of of comprehensive comprehensive comprehensive mechanical mechanical mechanical effects, effects, effects, so so as as to to to achieve achieve achieve the the the aim aim aim of of of the the the skin. skin. skin. At At At the the the same same same time time time of of of f f riction riction peel, peel, peel, from from from inject inject inject water water water into into into the the the hole, hole, hole, in in in a a a timely timely manner manner will will will be be be wiped wiped wiped off off off the the the skin skin skin of of of the the the through through through brush brush brush b b rush rush roll roll roll and and and roll roll roll gap gap gap to to to discharge discharge discharge mouth mouth mouth eduction eduction eduction body. body. body. In In the the case case case of of of non-stop, non-stop, non-stop, open open open the the the discharge discharge discharge valve valve valve of of of mouth, mouth, material material by by by dial dial dial discharged discharged discharged through through through the the the discharge discharge discharge port. port. port. After After peeling peeling potatoes potatoes potatoes peel peel peel by by by institutions institutions institutions discharging discharging discharging chute chute chute into into the the auxiliary auxiliary auxiliary body, body, body, after after after screening screening screening and and and other other other auxiliary auxiliary auxiliary wor wor k k again again again into into into the the the next next next procedure. procedure.3. 3. summary summaryBelieve Believe in in in the the the near near near future, future, future, once once once the the the product product product is is is applied applied applied to to the the actual, actual, actual, will will will greatly greatly greatly save save save the the the working working working time, time, time, improve improve improve wo wo rk rk efficiency, efficiency, efficiency, improve improve improve the the the economic economic economic benefit, benefit, benefit, at at at the the the same same same tim tim e e will will will make make make a a a great great great contribution contribution contribution for for for the the the mass mass mass production, production, production, g g iving iving impetus impetus impetus to to to the the the development development development of of of potato potato potato industry industry industry better better better a a nd nd faster. faster. faster. Mechanical Mechanical Mechanical peeling, peeling, peeling, powered powered powered by by by motor, motor, motor, through through through the the pulley pulley drive drive drive cylinder cylinder cylinder at at at the the the bottom bottom bottom of of of the the the spinning spinning spinning l. Low Low middle, middle, middle, high high high edge edge edge mill mill mill wheel wheel wheel surface, surface, surface, undulate. undulate. undulate. Tubers Tubers to to join join join the the the cylinder, cylinder, cylinder, each each each other other other due due due to to to centrifugal centrifugal centrifugal force forceand and the the the friction friction friction effect, effect, effect, within within within the the the cylinder cylinder cylinder up, up, up, down, down, down, lef lef t, t, right right right turn, turn, turn, and and and constantly constantly constantly rolling; rolling; rolling; And And And the the the rubber rubber rubber cylind cylind er er lining, lining, lining, will will will rebound rebound rebound tuber, tuber, tuber, in in in the the the mill mill mill and and and the the the cylinder cylinder wall wall under under under the the the function function function of of of rubber rubber rubber potato potato potato tuber tuber tuber is is is grinding grinding to to the the the skin skin skin evenly, evenly, evenly, achieve achieve achieve the the the goal goal goal of of of potato potato potato peeling. peeling. peeling. T T o o skin skin skin with with with clear clear clear water, water, water, and and and then then then open open open the the the side side side door, door, door, tube tube r r discharge discharge discharge from from from a a a side side side door, door, door, dander dander dander with with with flow flow flow from from from the the the di di scharge scharge gap gap gap around around around the the the millstone. millstone. millstone. The The The machine machine machine for for for batch batch batch prod prod uction, uction, peeling peeling peeling machine, machine, machine, mill mill mill rotate rotate rotate at at at a a a certain certain certain speed, speed, speed, rol rol ler ler potato potato potato in in in under under under the the the action action action of of of centrifugal centrifugal centrifugal force, force, force, gravity gravity and and the the the friction, friction, friction, using using using potato potato potato work work work relative relative relative to to to the the the mill,mill, the the relative relative relative speed speed speed difference difference difference between between between the the the potato potato potato skin skin skin remov remov ed.1.2中文翻译马铃薯去皮结构设计马铃薯去皮结构设计摘要摘要::本次毕业设计主要研究了以摩擦原理为基础的马铃薯去皮机的设计要点、工作原理工作原理 及设备的组成。

中国地质大学长城学院本科毕业设计题目马铃薯去皮结构设计系别专业学生姓名学号指导教师职称2015年04月20日摘要马铃薯去皮是马铃薯进行深加工的主要工序之一。

目前,马铃薯去皮虽然已经开始依靠机械进行生产,但劳动的强度也比较大、生产效率低下。

结合当前对马铃薯去皮技术的调研和分析,在目前技术和消费条件允许的情况下研究和设计改造一款操作更加简单安全,使用寿命更长的马铃薯去皮机,使之生产效率更高,以便于节省人力资源。

本文设计了一种基于摩擦原理的小型机械式马铃薯去皮结构设备。

该设备主要由电动部分、传动部分和存储部分组成,该系统通过电动机连接一级减速器带动滚刷和传动结构摩擦旋转,由进料口把物料放入滚筒进行工作,通过卸料口卸出物料,从而达到对马铃薯去皮的目的,该设计通过对现有设备的数据进行分析、方案的研究和数据的计算,完成了该马铃薯去皮机构的总体设计,通过马铃薯去皮机的设计主要工作系统,这样马铃薯去皮机可以更安全,稳定和正常运行,提高马铃薯去皮过程的机械化程度。

关键词:马铃薯去皮机;摩擦;传动;去皮ABSTRACTThe potato skin is one of the main processes, deep processing of potato at present, peel the potatoes have begun to rely on mechanical production, but the production efficiency is low, and the labor intensity is relatively large. Combined with the mechanical knowledge of our university and the potato peeler to master technology, research and design a more simple and safe operation in the current technology and consumption conditions allow, potato peeling machine is longer, the higher production efficiency, in order to save human resources. This paper describes the design of a small friction principle of mechanical equipment based on the potato skin structure. The device is mainly composed of a power part, transmission part and the storage part, when the motor is energized, through a speed reducer drives the rolling brush and transmission structure of friction spinning, and feeding the materials into the cylinder to work, after work is completed, through the discharge port of discharge, so as to achieve the purpose of potato peel the design, calculation and analysis, research and data solutions through the existing equipment data, complete the overall design of the potato peeling mechanism, through the design of the main system of potato peeling machine, such as potato to skin machine can be more secure, stable and normal operation, improve the degree of mechanization of potato peeling process. The design of a reasonable structure, carried out at room temperature, the safe and reliable operation, low energy consumption, low cost, no damage, can protect the good food appearance, high rate of production material.Key words:The potato peeling machine;Friction;Peel;drive目录1绪论 (1)1.1 马铃薯加工产业现状与发展态势 (1)1.2 马铃薯原料加工预处理工艺流程简介 (1)1.2.1马铃薯的分级 (1)1.2.2马铃薯的清洗 (1)1.2.3马铃薯的去皮 (2)2马铃薯清洗去皮机的结构设计 (2)2.1 工作原理 (2)2.2 基本结构 (3)2.2.1去皮机构 (3)2.2.2 清洗机构 (3)3 拨料盘和刷辊的设计 (4)3.1拨料盘部件的设计 (4)3.1.1螺旋机输送量的确定 (5)3.1.2 螺旋机功率的确定 (5)3.1.3 螺旋直径的确定 (5)3.1.4 螺旋轴转速的确定 (6)3.1.5螺距的确定 (7)3.1.6物料输送速度的确定 (7)3.2刷辊部件的设计 (8)4 电动机的计算选型 (9)4.1电动机的选择 (9)4.1.1选择电动机类型和结构型式 (9)4.1.2 选择电动机的容量 (9)4.2传动装置的运动和动力参数的计算 (9)4.2.1各轴转速 (10)4.2.2 各轴输入功率 (10)4.2.3 各轴输出功率 (11)4.2.4 各轴输入转矩 (11)4.2.5 各轴输出转矩 (11)5 减速器设计计算 (12)5.1 齿轮设计 (12)5.2减速器结构设计 (16)5.2.1机体结构 (16)5.2.2铸铁减速器机体的结构尺寸 (16)5.3轴设计 (17)5.3.1 计算齿轮受力 (18)5.3.2 计算支承反力 (19)5.3.3画轴转矩图 (19)5.3.4许用应力 (20)5.3.5校核轴径 (20)5.4轴承的选型 (20)5.5键的选型 (21)5.5.1输入轴轴与带轮的联接 (21)5.5.2输出轴与大齿轮的联接 (22)参考文献 (24)致谢 (25)1 绪论1.1马铃薯加工产业现状与发展态势目前, 世界上有超过79%的国家种植马铃薯,种植面积达到2000万公顷,产量3亿吨,居小麦、玉米、水稻产量之后位于世界第四名,马铃薯种植在我国分布很广,主要集中在山西、甘肃、四川、云南、黑龙江、内蒙古、河北、陕西、贵州等地,根据2010年的统计数据,中国的马铃薯种植近7900万亩,产量8200万吨,居世界第一。

红薯去皮机的设计摘要:在很多时候表皮是一种我们不需要,但是又去不掉的一种多余部分,我们通常希望的就是能够在不需要的时候去掉它,同时可以减少能源物质的消耗,通过减少一定的时间工作量,然后就可以达到降低总成本的目的。

此次介绍了一种摩擦去皮,目的就是通过进行摩擦的方式去掉表皮,主要工作特点就是把这种食品直接放置在一个金刚砂的滚轮上通过其内壁上的一个排列有金刚砂的旋转轮上,然后通过运用摩擦力来去除掉蔬菜和水果表面的多余表皮,并且在此时进行大量水冲,将成品清洗干净。

用摩擦去皮这种方式的主要优点之一就是在生产过程中进行温室操作,可以有效地减少了能源成本,并对资本也可减少而且不会直接对蔬菜水果等产品进行外观上的破坏,对此我们可以说它是一件良好的优质产品。

但是假如是不规则的蔬菜水果进行去除表皮,因为其不规则性,就是需要去手工进行去除,比如蔬菜水果上的孔眼等。

关键词:去皮设计红薯Abstract: In many cases, skin is a kind of unnecessary part thatwe don't need, but we can't get rid of it. What we usually hope is to remove it when we don't need it, and reduce the consumption of energy and substances. By reducing the workload of a certain amount of time, the total cost can be reduced Peel the paper introduces a friction,the purpose is through to remove skin friction way, maincharacteristics is to make the food placed directly on a emery wheel through them to the walls of an arrangement with the rotation of the emery wheel, and then by using friction to remove excess skin on the surface of the vegetable and fruit, and a large number of water atthis time, will be finished Wash clean. One of the main advantages of this method of friction peeling is that it can effectively reduce the energy cost, reduce the capital and do not directly damage theappearance of vegetables and fruits and other products. For this, we can say that it is a good quality product But if be irregular vegetable fruit undertakes purify skin, because its are irregular sex, need to go to undertake purify manually namely, wait for the hole on vegetable fruit for instanceKey words:Peeling Design sweet potato1 绪论在当今世界蔬菜水果得到了绝大多数人的肯定和追求,因其具有很多我们人类所需要的物质,而对于蔬菜水果其保质期时间较短,故此对水果蔬菜我们产生了很多的物质加工处理进行长时间保存。

学校代码:10410学号:20050426本科毕业设计题目:轻型立式薯类去皮机结构设计学院:工学院姓名:金道煌学号:20050426专业:机械设计制造及自动化年级:2005级指导教师:张庐陵二OO九年五月摘要马铃薯为植物的块茎,形状为圆形或椭圆形,其结构由表皮层、形成层、外果肉和内果肉四部分。

马铃薯品种可分两大类,一类是淀粉含量较高的,适宜于作为生产淀粉的原料,另一类是蛋白质含量较高,适宜作为蔬果或制成多种食品[1]。

马铃薯营养丰富,除直接食用外,还可以加工成食品、全粉、淀粉等经济价值较高的食品,通过加工可以大幅度提高鲜薯的商品价值[2]。

鉴于马铃薯的很多特点,马铃薯得到了广泛的利用。

a.马铃薯可鲜食,鲜食用马铃薯主要用作家庭餐馆烹调,我国主要用来制作菜肴、面点小吃等大众食品。

果外除蒸烤鲜马铃薯作主食外,还有咖哩饭、炖薯快以及色拉凉拌菜。

马铃薯可制成方便食品、快餐食品、休闲食品,如马铃薯粉、马铃薯全粉、脱水马铃薯片(条)、速冻薯条(薯泥)、蒸薯条、罐装和去皮马铃薯、马铃薯脆片、马铃薯膨化小食品等;b,加工成淀粉及相关产品:由于马铃薯淀粉的优良特性,不仅是制作高级方便面、面类最为理想的添加淀粉,而且还是肉制品、鱼糜制品等的添加剂或原料。

马铃薯淀粉也是粉条的优质原料。

出马铃薯淀粉外,也可得到相关产品,包括各种变性淀粉、饴糖、葡萄糖、膳食纤维制品等。

C,其他制品:马铃薯提取淀粉后的残渣可制成马铃薯发酵饲料、提取蛋白等[5]。

去皮(peeling)用于多种水果和蔬菜的加工中以除去不需要或不可食的物质,并改善成品的外观。

主要的考虑因素包括通过尽可能减少去掉的部分以及可能降低能源、劳力和物质成本来降低总成本。

这里,介绍摩擦去皮方法:食品被放置在金刚砂滚轴上或内壁排列着金刚砂的转筒中,在磨损力的表面除去食品的表皮后又被大量的水冲洗干净。

该方法的优点是由于过程是在温室下进行而具有的能源成本低以及资本成本低、无热损伤,食品外观良好的优点,不规则食品表面(如马铃薯上的“孔眼”)会破坏去皮产品的外观,需要手工去除[3]。

关键词:马铃薯、去皮清洗、农产品、食品机械AbstractPotato tuber for plants for circular or elliptic shape, structure, by cuticular layer and layer, the pulp and pulp within four parts. Potato varieties can be divided into two kinds, one kind is starch content high, suitable for the production of raw materials as starch content of protein, another kind is higher, suitable for various fruits or food..Potato nutrition is rich, besides direct edible, but also can be processed into food, powder, starch, etc, the economic value of higher food processing can be greatly improved through the value of fresh chips.In view of many of the characteristics of the potato, potato has been widely used. a. can be fresh potatoes, fresh potatoes used mainly for cooking the family restaurant, China is mainly used to create dishes such as pasta snack food of the public.In addition to fresh fruit outside the potato for food, there are curry rice, stew and potato salad cold fast food. Potatoes can be made from convenience foods, fast foods, snack foods, such as potato flour, potato powder, dehydrated potato chips (article), frozen French fries (potato mud), steamed potato chips, canned and peeled potatoes, potato crisps , extruded snacks such as potato; b, processed into starch and related products: potato starch as a result of the excellent features, not only is the production of high-level instant noodles, flour add the most ideal type of starch, but also meat, surimi products such as additives or raw materials . Potato starch is also of high quality raw materials. The potato starch, but also related products available, including a variety of modified starch, maltose, glucose, dietary fiber products. C, other products: potato residue after starch extraction can be made from potato fermented feed, extract proteinSkin peeling (for) of fruits and vegetables processing to remove need not eat or not, and improve the physical appearance of the product. The main factors including through minimize removed part and may reduce the labor and material costs energy, reduce the total cost. Here introduces friction peel method: food is placed on the walls or emery roller drum lined up in the emery, wear away the food of skin surface by the amount of water after washing clean. The advantage of this method is due process is conducted in greenhouse with low cost and the energy of capital cost is low, no heat, the advantages of good food appearance, irregular food surfaces (such as potato "holes) destroys peel product appearance, need manual removal.Key words: Potatoes、Peel cleaning、Agricultural、Food machinery目录前言 .............................................................................................................................. - 1 - 1.马铃薯去皮机工作原理 ........................................................................................... - 2 -1.1去皮清理的原理 .............................................................................................. - 2 -1.2去皮设备 .......................................................................................................... - 2 - 2.轴的设计 ............................................................................................................ - 4 - 2.1轴的材料 ....................................................................................................... - 4 - 2.2轴的强度计算 ............................................................................................... - 4 - 2.3轴的结构尺寸初步确定 ............................................................................... - 5 - 3.滚动轴承的设计 ....................................................................................................... - 6 -3.1.滚动轴承类型的选择 ...................................................................................... - 6 -3.2.滚动轴承部件的组合设计. ............................................................................. - 7 -4.电动机的选择. .......................................................................................................... - 7 -5.齿轮的结构设计 ....................................................................................................... - 8 -5.1.齿轮材料及热处理 .......................................................................................... - 9 -5.2.齿轮相关参数的初步确定 .............................................................................. - 9 -5.3.校核齿轮强度 ................................................................................................ - 10 -6.圆筒的结构设计 ..................................................................................................... - 11 -7.轴承座的结构设计 ................................................................................................. - 12 -8.圆盘的结构设计 ..................................................................................................... - 13 - 参考文献 .............................................................................................................. - 15 - 致谢 ............................................................................................................................ - 16 -前言综观食品加工业对加工技术的要求,食品加工技术的发展趋势大致如下:第一,提高原料的利用率。