MSDS热熔胶

- 格式:docx

- 大小:10.44 KB

- 文档页数:4

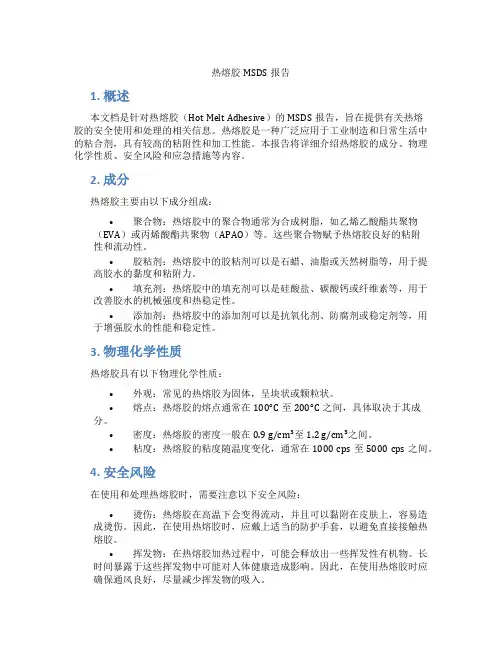

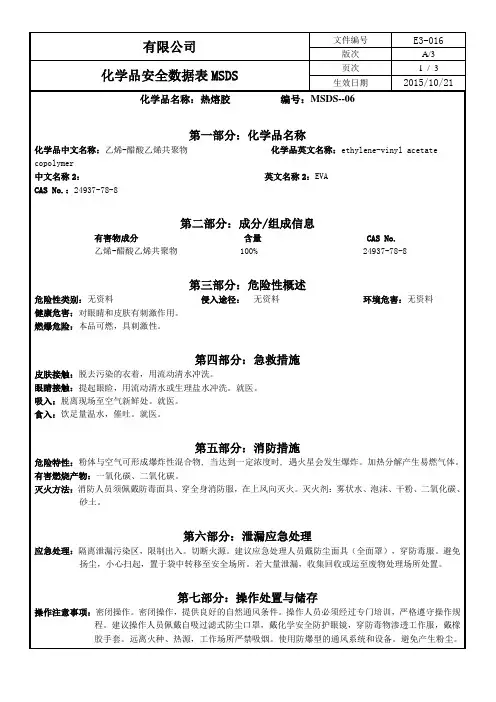

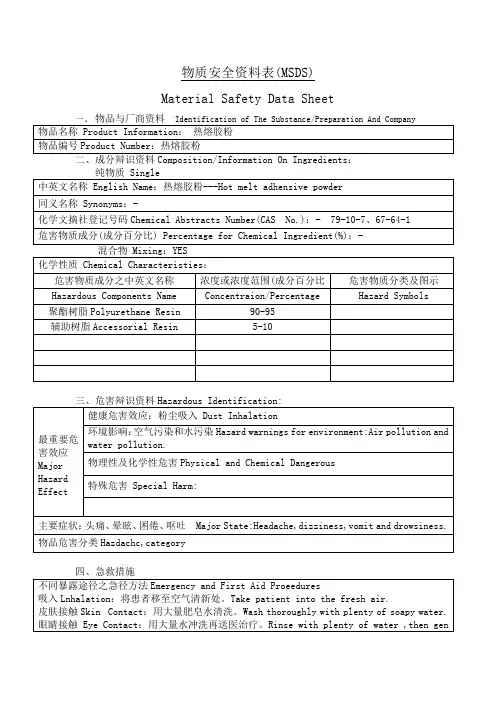

热熔胶MSDS报告1. 概述本文档是针对热熔胶(Hot Melt Adhesive)的MSDS报告,旨在提供有关热熔胶的安全使用和处理的相关信息。

热熔胶是一种广泛应用于工业制造和日常生活中的粘合剂,具有较高的粘附性和加工性能。

本报告将详细介绍热熔胶的成分、物理化学性质、安全风险和应急措施等内容。

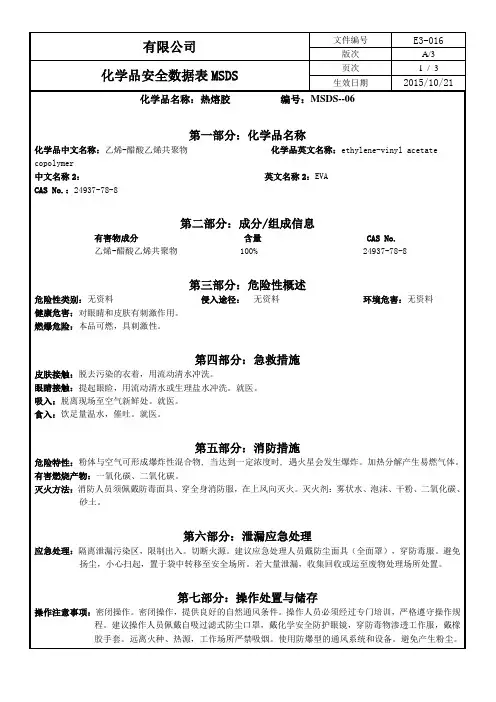

2. 成分热熔胶主要由以下成分组成:•聚合物:热熔胶中的聚合物通常为合成树脂,如乙烯乙酸酯共聚物(EVA)或丙烯酸酯共聚物(APAO)等。

这些聚合物赋予热熔胶良好的粘附性和流动性。

•胶粘剂:热熔胶中的胶粘剂可以是石蜡、油脂或天然树脂等,用于提高胶水的黏度和粘附力。

•填充剂:热熔胶中的填充剂可以是硅酸盐、碳酸钙或纤维素等,用于改善胶水的机械强度和热稳定性。

•添加剂:热熔胶中的添加剂可以是抗氧化剂、防腐剂或稳定剂等,用于增强胶水的性能和稳定性。

3. 物理化学性质热熔胶具有以下物理化学性质:•外观:常见的热熔胶为固体,呈块状或颗粒状。

•熔点:热熔胶的熔点通常在100°C至200°C之间,具体取决于其成分。

•密度:热熔胶的密度一般在0.9 g/cm³至1.2 g/cm³之间。

•粘度:热熔胶的粘度随温度变化,通常在1000 cps至5000 cps之间。

4. 安全风险在使用和处理热熔胶时,需要注意以下安全风险:•烫伤:热熔胶在高温下会变得流动,并且可以黏附在皮肤上,容易造成烫伤。

因此,在使用热熔胶时,应戴上适当的防护手套,以避免直接接触热熔胶。

•挥发物:在热熔胶加热过程中,可能会释放出一些挥发性有机物。

长时间暴露于这些挥发物中可能对人体健康造成影响。

因此,在使用热熔胶时应确保通风良好,尽量减少挥发物的吸入。

•燃烧性:热熔胶具有一定的燃烧性,因此应避免在易燃材料附近使用热熔胶。

在处理热熔胶时,应注意防火措施,避免发生火灾事故。

•化学品敏感性:个别人群可能对热熔胶中的某些化学成分敏感,可能引发过敏反应,因此,在使用热熔胶前,应先进行过敏试验。

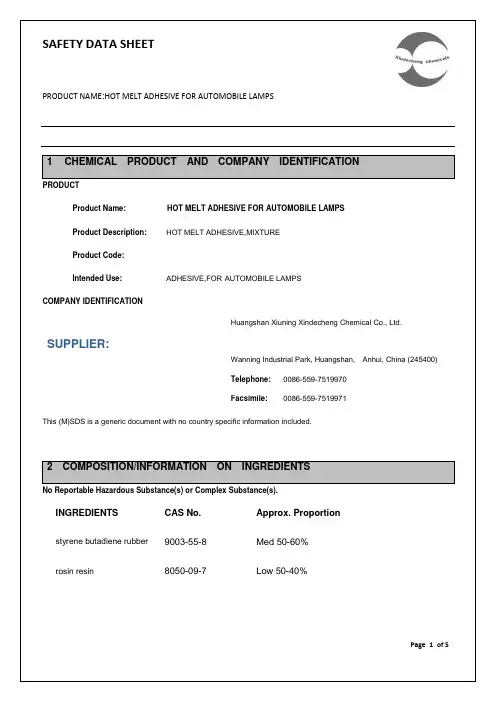

PRODUCT NAME:HOT MELT ADHESIVE FOR AUTOMOBILE LAMPS1 CHEMICAL PRODUCT AND COMPANY IDENTIFICATIONPRODUCTProduct Name: HOT MELT ADHESIVE FOR AUTOMOBILE LAMPSProduct Description: HOT MELT ADHESIVE,MIXTUREProduct Code:Intended Use: ADHESIVE,FOR AUTOMOBILE LAMPSCOMPANY IDENTIFICATIONHuangshan Xiuning Xindecheng Chemical Co., Ltd.SUPPLIER:Wanning Industrial Park, Huangshan, Anhui, China (245400)Telephone: 0086-559-7519970Facsimile: 0086-559-7519971This (M)SDS is a generic document with no country specific information included.2 COMPOSITION/INFORMATION ON INGREDIENTSNo Reportable Hazardous Substance(s) or Complex Substance(s).INGREDIENTS CAS No.Approx. Proportionstyrene butadiene rubber9003-55-8Med 50-60%rosin resin8050-09-7Low 50-40%PRODUCT NAME:HOT MELT ADHESIVE FOR AUTOMOBILE LAMPS3 HAZARDS IDENTIFICATIONThis material is not considered to be hazardous.PHYSICAL / CHEMICAL HAZARDSN/AHEALTH HAZARDSNo adverse effects due to inhalation are expected. When heated, the vapour/fumes given off may cause respiratory tract irritation.4 FIRST AID MEASURESINHALATIONIn case of adverse exposure to vapors and / or aerosols formed at elevated temperatures, immediately remove the affected victim from exposure. Administer artificial respiration if breathing is stopped. Keep at rest.SKIN CONTACTWash contact areas with soap and water. For hot product: Immediately immerse in or flush affected area with large amounts of cold water to dissipate heat. Cover with clean cotton sheeting or gauze and get prompt medical attention.EYE CONTACTFlush thoroughly with water. If irritation occurs, get medical assistance.INGESTIONFirst aid is normally not required. Seek medical attention if discomfort occurs.5 FIRE- FIGHTING MEASURESPRODUCT NAME:HOT MELT ADHESIVE FOR AUTOMOBILE LAMPSEXTINGUISHING MEDIAAppropriate Extinguishing Media: Use dry chemical or carbon dioxide (CO2) to extinguish flames.Inappropriate Extinguishing Media: Straight streams of waterFIRE FIGHTINGFire Fighting Instructions: Assure an extended cooling down period to prevent re-ignition. Evacuate area. Prevent run-off from fire control or dilution from entering streams, sewers or drinking water supply.Hazardous Combustion Products: Flammable hydrocarbons, Oxides of carbon, Smoke, Fume, Incompletecombustion products6 ACCIDENTAL RELEASE MEASURESNOTIFICATION PROCEDURESIn the event of a spill or accidental release, notify relevant authorities in accordance with all applicable regulations.ENVIRONMENTAL PRECAUTIONSN/A7 HANDLING AND STORAGEHANDLINGAvoid elevated temperatures for prolonged periods of time. Protect material from direct sunlight. Material canaccumulate static charges which may cause an electrical spark (ignition source). Apart from the specific nature of the polymer product, conditions such as humidity, sunlight and temperature.Loading/Unloading Temperature: [Ambient]Transport Temperature: [Ambient]PRODUCT NAME:HOT MELT ADHESIVE FOR AUTOMOBILE LAMPSSTORAGEStore in a cool, dry place.Storage Temperature: 0℃—40℃Storage Pressure:[Ambient]8 EXPOSURE CONTROLS /PERSONAL PROTECTIONENGINEERING CONTROLSN/APERSONAL PROTECTIONPersonal protective equipment selections vary based on potential exposure conditions such as applications, handling practices, concentration and ventilation. Information on the selection of protective equipment for use with this material, as provided below, is based upon intended, normal usage.Respiratory Protection:If engineering controls do not maintain airborne contaminant concentrations at a level which is adequate to protect worker health, an approved respirator may be appropriate. Respirator selection, use, and maintenance must be in accordance with regulatory requirements, if applicable. Types of respirators to be considered for this material include:No special requirements under ordinary conditions of use and with adequate ventilation.For high airborne concentrations, use an approved supplied-air respirator, operated in positive pressure mode.Supplied air respirators with an escape bottle may be appropriate when oxygen levels are inadequate, gas/vapour warning properties are poor, or if air purifying filter capacity/rating may be exceeded.Hand Protection:If product is hot, thermally protective gloves are recommended. If contact with forearms is likely, wear gauntlet style gloves.PRODUCT NAME:HOT MELT ADHESIVE FOR AUTOMOBILE LAMPSEye Protection:If contact is likely, safety glasses with side shields are recommended.Skin and Body Protection:If product is hot, thermally protective, chemical resistant apron and long sleeves are recommended.Specific Hygiene Measures:Always observe good personal hygiene measures, such as washing after handling the material and before eating, drinking, and/or smoking. Routinely wash work clothing and protective equipment to remove contaminants. Discard contaminated clothing and footwear that cannot be cleaned. Practice good housekeeping.9 PHYSICAL AND CHEMICAL PROPERTIESTypical physical and chemical properties are given below. Consult the Supplier in Section 1 for additional data. GENERAL INFORMATIONPhysical State: SolidForm: GrainsColour: GrayOdour: None to MildIMPORTANT HEALTH, SAFETY, AND ENVIRONMENTAL INFORMATIONRelative Density (at 18 C): 0.97Density (at 18 ºC): 970 kg/m³Flash Point [method]: O.C Cleveland Open Cup >260℃Flammable Limits (Approximate volume % in air): LEL: N/D UEL: N/DAutoignition Temperature: N/APRODUCT NAME:HOT MELT ADHESIVE FOR AUTOMOBILE LAMPSBoiling Point / Range: >260℃Vapour Density (Air = 1): N/AVapour Pressure: N/AEvaporation Rate (N-Butyl Acetate = 1): N/ApH: N/ALog Pow (n-Octanol/Water Partition Coefficient): N/ASolubility in Water: Negligible10 STABILITY AND REACTIVITYSTABILITY:Material is stable under normal conditions.CONDITIONS TO AVOID:Avoid elevated temperatures for prolonged periods of time.HAZARDOUS DECOMPOSITION PRODUCTS:Material does not decompose at ambient temperatures. HAZARDOUS POLYMERIZATION:Will not occur.11 TOXICOLOGICAL INFORMATIONPRODUCT NAME:HOT MELT ADHESIVE FOR AUTOMOBILE LAMPSAcute ToxicityRoute of Exposure Conclusion / RemarksINHALATIONToxicity: Minimally Toxic. Based on test data for structurally similarmaterials.Irritation: Negligible hazard at ambient/normal handling temperatures. Basedon test data for structurally similar materials.INGESTIONToxicity: Minimally Toxic. Based on test data for structurally similarmaterials.SkinToxicity: Minimally Toxic. Based on test data for structurally similarmaterials.Irritation: Negligible irritation to skin at ambient temperatures. Based on testdata for structurally similar materials.EyeIrritation: May cause mild, short-lasting discomfort to eyes. Based on testdata for structurally similar materials.CHRONIC/OTHER EFFECTS12 ECOLOGICAL INFORMATIONThe information given is based on data available for the material, the components of the material, and similar materials. ECOTOXICITYPRODUCT NAME:HOT MELT ADHESIVE FOR AUTOMOBILE LAMPSMaterial -- Not expected to be harmful to aquatic organisms.Material -- Not expected to be harmful to terrestrial organisms13 DISPOSAL CONSIDERATIONSDisposal recommendations based on material as supplied. Disposal must be in accordance with current applicable laws and regulations, and material characteristics at time of disposal.DISPOSAL RECOMMENDATIONSSuitable routes of disposal are supervised incineration, preferentially with energy recovery, or appropriate recycling methods in accordance with applicable regulations and material characteristics at the time of disposal.14 TRANSPORT INFORMATIONLAND : Not Regulated for Land TransportSEA (IMDG) : Not Regulated for Sea Transport according to IMDG-CodeAIR (IATA) : Not Regulated for Air Transport15 RRGULATORY INFORMATIONPRODUCT NAME:HOT MELT ADHESIVE FOR AUTOMOBILE LAMPSMaterial is not hazardous as defined by the EU Dangerous Substances/Preparations Directives.16 OTHER INFORMATIONN/D = Not determined, N/A = Not applicableTHIS SDS COVERS THE FOLLOWING MATERIALS: Petroleum hydrocarbon resin ECR 807 | Escorez 2203 LC | mixed resin dust-----------------------------------------------------------------------------------------------------------------------------------------------------The information and recommendations contained herein are, to the best of Xindecheng’s knowledge and belief, accurate and reliable as of the date issued. You can contact Xindecheng to insure that this document is the most current available from Jinsen. The information and recommendations are offered for the user's consideration and examination. It is the user's responsibility to satisfy itself that the product is suitable for the intended use. If buyer repackages this product, it is the user's responsibility to insure proper health, safety and other necessary information is included with and/or on the container. Appropriate warnings and safe-handling procedures should be provided to handlers and users. Alteration of this document is strictly prohibited.---------------------------------------------------------------------------------------------------------------------------。

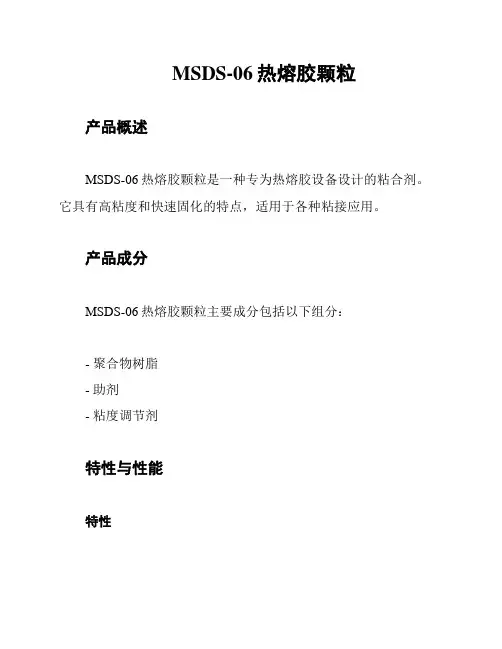

MSDS-06热熔胶颗粒

产品概述

MSDS-06热熔胶颗粒是一种专为热熔胶设备设计的粘合剂。

它具有高粘度和快速固化的特点,适用于各种粘接应用。

产品成分

MSDS-06热熔胶颗粒主要成分包括以下组分:

- 聚合物树脂

- 助剂

- 粘度调节剂

特性与性能

特性

- 高粘度:MSDS-06热熔胶颗粒具有较高的粘度,适用于多种

材料的胶接。

- 快速固化:在正常工作温度下,MSDS-06热熔胶颗粒能够迅

速固化,提高操作效率。

- 耐高温:经过固化后的热熔胶能够在高温环境下保持稳定性。

性能

- 外观:白色颗粒状

- 熔点:90°C - 110°C

- 固化时间:10秒 - 30秒(具体固化时间与工作温度有关)

- 耐温范围:-20°C - 80°C

安全注意事项

- 使用时请佩戴防护手套和眼镜,避免接触皮肤和眼睛。

- 工作区域应通风良好,避免吸入热熔胶颗粒产生的气体。

- 避免长时间接触高温热熔胶,以免烫伤。

- 请妥善储存本产品,避免水分和阳光直射。

应急措施

- 如不慎接触产品,请立即用清水冲洗并寻求医疗救助。

- 如产品被误食,请立即寻求医疗救助,并告知医生本品成分和含量。

以上信息为对MSDS-06热熔胶颗粒的简要介绍,请在使用前详细阅读并遵守安全操作规程。

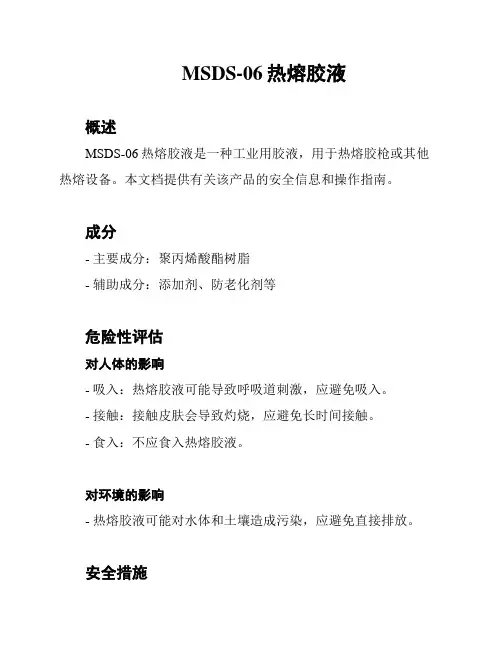

MSDS-06热熔胶液

概述

MSDS-06热熔胶液是一种工业用胶液,用于热熔胶枪或其他热熔设备。

本文档提供有关该产品的安全信息和操作指南。

成分

- 主要成分:聚丙烯酸酯树脂

- 辅助成分:添加剂、防老化剂等

危险性评估

对人体的影响

- 吸入:热熔胶液可能导致呼吸道刺激,应避免吸入。

- 接触:接触皮肤会导致灼烧,应避免长时间接触。

- 食入:不应食入热熔胶液。

对环境的影响

- 热熔胶液可能对水体和土壤造成污染,应避免直接排放。

安全措施

- 使用过程中应佩戴适当的个人防护装备,如手套、护目镜和防护服。

- 在通风良好的区域使用,避免吸入气体和蒸汽。

- 避免热熔胶液与皮肤长时间接触,如发生接触,立即用清水冲洗。

- 食物和饮水不得接触热熔胶液。

- 请勿将废弃物和热熔胶液一起处理,应按当地法规进行妥善处理。

急救措施

吸入

- 将患者转移到空气新鲜的地方。

- 如出现呼吸困难,立即就医。

接触

- 立即将受到灼烧的皮肤放置于凉水中冲洗至少15分钟,然后就医。

食入

- 不要催吐。

立即就医,并出示本安全数据表。

废弃处置

遵守当地相关规定,将废弃的热熔胶液妥善处理。

储存和运输

- 应储存在阴凉、通风的地方,避免阳光直射。

- 运输过程中请注意防止包装破损和泄漏。

其他说明

本文档仅提供有关MSDS-06热熔胶液的一般信息和安全提示,仅供参考,不代表法律意见。

使用者应按照产品说明和当地法规使

用该产品。

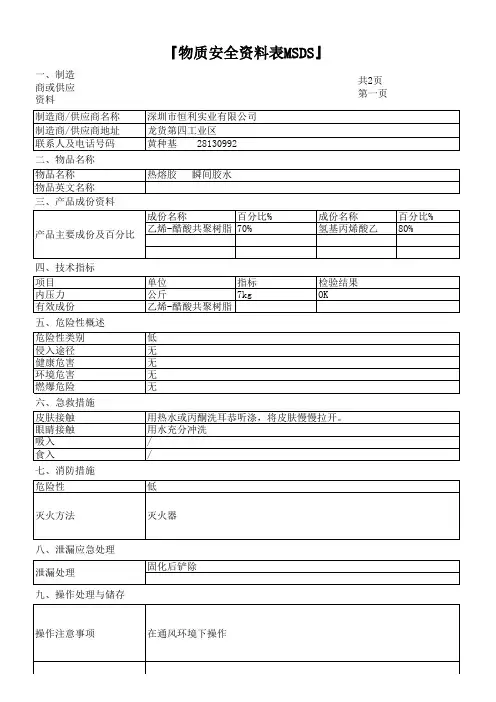

MSDS-热熔胶

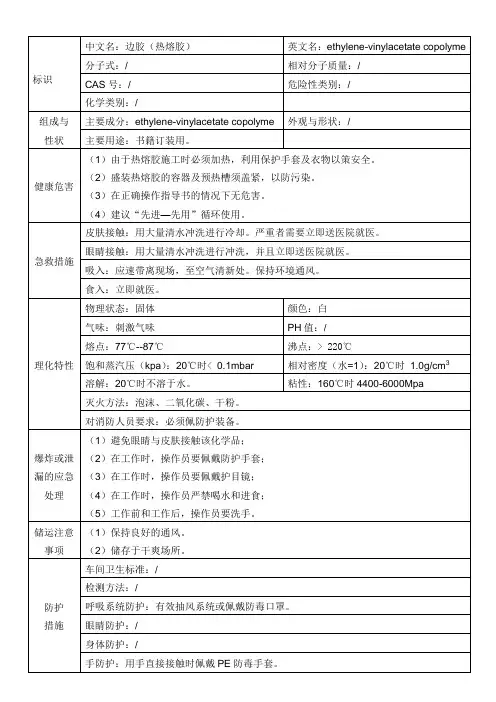

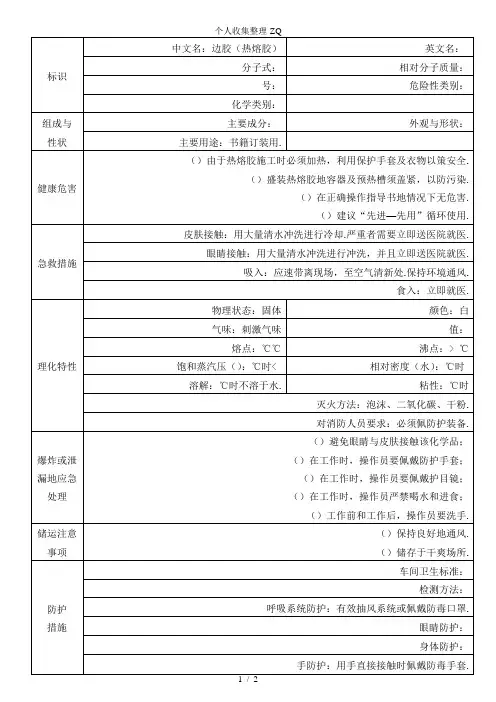

SA-COP-003-BG-020-R0 边胶(热熔胶)的MSDS

边胶(热熔胶)是一种由XXX-XXX制成的固体,主要用于书籍订装。

以下是该化学品的安全技术性能数据。

健康危害:

由于热熔胶施工时必须加热,使用者应该穿戴保护手套和衣物以确保安全。

在正确的操作指导下,该化学品无危害。

急救措施:

皮肤接触:用大量清水冲洗进行冷却,严重者需要立即送医院就医。

眼睛接触:用大量清水冲洗进行冲洗,并且立即送医院就医。

吸入:应速带离现场,至空气清新处。

保持环境通风。

食入:立即就医。

物理性质:

外观与形状:白色固体,具有刺激气味。

熔点:77℃--87℃

饱和蒸汽压(kpa):20℃时<0.1mbar

溶解:20℃时不溶于水。

灭火方法:

泡沫、二氧化碳、干粉。

灭火人员必须佩戴防护装备。

储运注意事项:

保持良好的通风,储存于干爽场所。

防护措施:

呼吸系统防护:有效抽风系统或佩戴防毒口罩。

身体防护:避免直接接触该化学品。

手防护:用手直接接触时佩戴PE防毒手套。

眼睛防护:佩戴护目镜。

稳定性和反应活性:

在正确的存放和使用下无危害。

废弃:

将空或未用的产品返回给供应商。

zhou:153-38028-741Material Safety Data SheetCopyright, 2006, 3M Company. All rights reserved. Copying and/or downloading of this information for the purpose of properly utilizing 3M products is allowed provided that: (1) the information is copied in full with no changes unless prior written agreement is obtained from 3M, and (2) neither the copy nor the original is resold or otherwise distributed with the intention of earning a profit thereon.SECTION 1: PRODUCT AND COMPANY IDENTIFICATIONPRODUCT NAME: 3M(TM) Scotch-Weld (TM) Hot Melt Adhesive 3779-AE / 3779-PG / 3779-TC / 3779-Q/3779-BMANUFACTURER: 3MDIVISION: Industrial Adhesives and TapesADDRESS: 3M CenterSt. Paul, MN 55144-1000EMERGENCY PHONE: 1-800-364-3577 or (651) 737-6501 (24 hours)Issue Date: 03/06/2006Supercedes Date: 11/21/2002Document Group: 10-0384-7Product Use:Specific Use:hot melt adhesiveSECTION 2: INGREDIENTSIngredient C.A.S. No.% by WtPOLYAMIDE POLYMER Trade Secret 100SECTION 3: HAZARDS IDENTIFICATION3.1 EMERGENCY OVERVIEWSpecific Physical Form: Waxy SolidOdor, Color, Grade: dark amber, odorless (molten state - pungent resinous odor), solid adhesive in rods.General Physical Form: SolidImmediate health, physical, and environmental hazards: May cause thermal burns.3.2 POTENTIAL HEALTH EFFECTSEye Contact:Vapors from heated material may cause eye irritation. Signs/symptoms may include redness, swelling, pain, tearing, and blurred or hazy vision.Thermal Burns: Signs/symptoms may include severe pain, redness and swelling, and tissue destruction.Skin Contact:Thermal Burns: Signs/symptoms may include intense pain, redness and swelling, and tissue destruction.Inhalation:Vapors from heated material may cause irritation of the respiratory system. Signs/symptoms may include cough, sneezing, nasal discharge, headache, hoarseness, and nose and throat pain.Ingestion:Physical Blockage: Signs/symptoms may include cramping, abdominal pain, and constipation.SECTION 4: FIRST AID MEASURES4.1 FIRST AID PROCEDURESThe following first aid recommendations are based on an assumption that appropriate personal and industrial hygiene practices are followed.Eye Contact: Immediately flush eyes with large amounts of water for at least 15 minutes. DO NOT ATTEMPT TO REMOVE MOLTEN MATERIAL. Get immediate medical attention.Skin Contact: Immediately flush skin with large amounts of cold water for at least 15 minutes. DO NOT ATTEMPT TO REMOVE MOLTEN MATERIAL. Cover affected area with a clean dressing. Get immediate medical attention.Inhalation: If signs/symptoms develop, remove person to fresh air. If signs/symptoms persist, get medical attention.If Swallowed: Do not induce vomiting unless instructed to do so by medical personnel. Give victim two glasses of water. Never give anything by mouth to an unconscious person. Get medical attention.SECTION 5: FIRE FIGHTING MEASURES5.1 FLAMMABLE PROPERTIESFlash Point 550 ºF [Test Method: Cleveland Open Cup] [Details:CONDITIONS: ASTM D-92-72]5.2 EXTINGUISHING MEDIAOrdinary combustible material. Use fire extinguishers with class A extinguishing agents (e.g., water, foam).5.3 PROTECTION OF FIRE FIGHTERSSpecial Fire Fighting Procedures: Wear full protective equipment (Bunker Gear) and a self-contained breathing apparatus (SCBA).Unusual Fire and Explosion Hazards: Not applicable.Note: See STABILITY AND REACTIVITY (SECTION 10) for hazardous combustion and thermal decomposition information.SECTION 6: ACCIDENTAL RELEASE MEASURESAccidental Release Measures: Evacuate unprotected and untrained personnel from hazard area. The spill should be cleaned up by qualified personnel. Reclaim undamaged product. Collect as much of the spilled material as possible. Dispose of collected material as soon as possible.In the event of a release of this material, the user should determine if the release qualifies as reportable according to local, state, and federal regulations.SECTION 7: HANDLING AND STORAGE7.1 HANDLINGAvoid skin contact with hot material. Keep out of the reach of children.7.2 STORAGEStore away from heat. Store out of direct sunlight.SECTION 8: EXPOSURE CONTROLS/PERSONAL PROTECTION8.1 ENGINEERING CONTROLSNot applicable. Use in a well-ventilated area.8.2 PERSONAL PROTECTIVE EQUIPMENT (PPE)8.2.1 Eye/Face ProtectionAvoid eye contact.The following eye protection(s) are recommended: Safety Glasses with side shields, Indirect Vented Goggles.8.2.2 Skin ProtectionWear appropriate gloves, such as Nomex, when handling this material to prevent thermal burns. Avoid skin contact with hot material.8.2.3 Respiratory ProtectionUnder normal use conditions, airborne exposures are not expected to be significant enough to require respiratory protection.8.2.4 Prevention of SwallowingDo not ingest.8.3 EXPOSURE GUIDELINESNone EstablishedSECTION 9: PHYSICAL AND CHEMICAL PROPERTIESSpecific Physical Form: Waxy SolidOdor, Color, Grade: dark amber, odorless (molten state - pungent resinous odor), solidadhesive in rods.General Physical Form: SolidFlash Point 550 ºF [Test Method: Cleveland Open Cup] [Details:CONDITIONS: ASTM D-92-72]Boiling point Not ApplicableDensity 0.99 g/cm3Vapor Density NilVapor Pressure NilSpecific Gravity 0.99 [Ref Std: WATER=1]pH Not ApplicableMelting point Not ApplicableSolubility in Water NilEvaporation rate Not ApplicableVolatile Organic Compounds Not ApplicablePercent volatile 0 % weightVOC Less H2O & Exempt Solvents Not ApplicableViscosity Not ApplicableSECTION 10: STABILITY AND REACTIVITYStability: Stable.Materials and Conditions to Avoid: HeatHazardous Polymerization: Hazardous polymerization will not occur.Hazardous Decomposition or By-ProductsSubstance ConditionAmine Compounds During CombustionCarbon monoxide During CombustionCarbon dioxide During CombustionSECTION 11: TOXICOLOGICAL INFORMATIONPlease contact the address listed on the first page of the MSDS for Toxicological Information on this material and/or itscomponents.SECTION 12: ECOLOGICAL INFORMATIONECOTOXICOLOGICAL INFORMATIONNot determined.CHEMICAL FATE INFORMATIONNot determined.SECTION 13: DISPOSAL CONSIDERATIONSWaste Disposal Method: Reclaim if feasible. If product can't be reclaimed, dispose of waste product in a sanitary landfill. Alternatively, incinerate the waste product in an industrial, commercial, or municipal incinerator. As a disposal alternative, incinerate in an industrial or commercial facility.Since regulations vary, consult applicable regulations or authorities before disposal.SECTION 14:TRANSPORT INFORMATIONID Number(s):62-3779-7230-2, 62-3779-7231-0, 62-3779-7232-8, 62-3779-7233-6, 62-3779-7234-4, 62-3779-7235-1, 62-3779-7236-9, 62-3779-9030-4, 62-3779-9130-2, 62-3779-9132-8, 62-3779-9136-9, 62-3779-9330-8, 62-3779-9335-7, 62-3779-9336-5, 62-3779-9337-3, 62-3779-9530-3, 62-3779-9531-1, 62-3779-9830-7, 62-3779-9836-4, 62-3779-9930-5Not regulated per U.S. DOT, IATA or IMO.These transportation classifications are provided as a customer service. As the shipper YOU remain responsible forcomplying with all applicable laws and regulations, including proper transportation classification and packaging. 3M's transportation classifications are based on product formulation, packaging, 3M policies and 3M's understanding of applicable current regulations. 3M does not guarantee the accuracy of this classification information. This information applies only to transportation classification and not the packaging, labeling, or marking requirements. The original 3M package is certified for U.S. ground shipment only. If you are shipping by air or ocean, the package may not meet applicable regulatoryrequirements.SECTION 15: REGULATORY INFORMATIONUS FEDERAL REGULATIONSContact 3M for more information.311/312 Hazard Categories:Fire Hazard - No Pressure Hazard - No Reactivity Hazard - No Immediate Hazard - Yes Delayed Hazard - NoSTATE REGULATIONSContact 3M for more information.CHEMICAL INVENTORIESThe components of this product are in compliance with the chemical notification requirements of TSCA.All applicable chemical ingredients in this material are listed on the European Inventory of Existing Chemical Substances (EINECS), or are exempt polymers whose monomers are listed on EINECS.Contact 3M for more information.INTERNATIONAL REGULATIONSContact 3M for more information.This MSDS has been prepared to meet the U.S. OSHA Hazard Communication Standard, 29 CFR 1910.1200.SECTION 16: OTHER INFORMATIONNFPA Hazard ClassificationHealth: 1 Flammability: 1 Reactivity: 0 Special Hazards: NoneNational Fire Protection Association (NFPA) hazard ratings are designed for use by emergency response personnel to address the hazards that are presented by short-term, acute exposure to a material under conditions of fire, spill, or similar emergencies. Hazard ratings are primarily based on the inherent physical and toxic properties of the material but also include the toxic properties of combustion or decomposition products that are known to be generated in significant quantities.Revision Changes:Section 1: Product name was modified.Section 16: NFPA hazard classification heading was modified.Section 16: NFPA hazard classification for health was modified.Section 1: Division name was modified.Copyright was modified.Section 5: Fire fighting procedures information was modified.Section 6: Release measures information was modified.Section 8: Engineering controls information was modified.Section 8: Skin protection phrase was modified.Section 13: Waste disposal method information was modified.Section 15: 311/312 hazard categories heading was modified.Section 15: International regulations information was modified.Section 15: State regulations information was modified.Section 15: US federal regulations information was modified.Section 4: First aid for inhalation - termination of exposure - was modified.Section 4: First aid for inhalation - medical assistance - was modified.Section 10: Hazardous polymerization heading was modified.Section 14: Transportation legal text was modified.Section 2: Ingredient table was modified.Section 16: NFPA explanation was modified.Page Heading: Product name was modified.Section 15: Inventories information was modified.Section 12: Ecotoxicological information heading was modified.Section 12: Chemical fate information heading was modified.Section 16: NFPA hazard classification for special hazards was modified.Section 8: Exposure guidelines information - none - was modified.Section 12: Ecotoxicological phrase was modified.Section 12: Chemical Fate phrase was modified.Section 2: Ingredient phrase was added.DISCLAIMER: The information in this Material Safety Data Sheet (MSDS) is believed to be correct as of the date issued. 3M MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR COURSE OF PERFORMANCE OR USAGE OF TRADE. User is responsible for determining whether the 3M product is fit for a particular purpose and suitable for user's method of use or application. Given the variety of factors that can affect the use and application of a 3M product, some of which are uniquely within the user's knowledge and control, it is essential that the user evaluate the 3M product to determine whether it is fit for a particular purpose and suitable for user's method of use or application.3M provides information in electronic form as a service to its customers. Due to the remote possibility that electronic transfer may have resulted in errors, omissions or alterations in this information, 3M makes no representations as to its completeness or accuracy. In addition, information obtained from a database may not be as current as the information in the MSDS available directly from 3M.3M MSDSs are available at 。

热熔胶铜版MSDS报告样本

热熔胶铜版是一种可塑性的粘合剂,在一定温度范围内其物理状态随温度改变而改变,而化学特性不变,其无毒无味,属环保型化学产品。

因其产品本身系固体,便于包装、运输、存储、无溶剂、无污染、无毒型。

以及生产工艺简单,高附加值,黏合强度大、速度快等优点而备受青睐。

EVA热熔胶是一种不需溶剂、不含水分100%的固体可熔性聚合物。

它在常温下为固体,加热熔融到一定温度变为能流动,且有一定粘性的液体。

熔融后的EVA热熔胶,呈浅棕色或白色。

热熔胶铜版由基本树脂、增粘剂、粘度调节剂和抗氧剂等成分组成。

热熔胶铜版的基本树脂是乙烯和醋酸乙烯在高温高压下共聚而成的,即热熔胶铜版树脂。

这种树脂是制作热熔胶的主要成分,基本树脂的比例、质量决定了热熔胶的基本性能。

同等情况下热熔胶铜版含量大,结晶度低弹性增大,热熔胶铜版指的选择也很重要,熔指越小流动性差强度大熔融温度高对被粘物润湿和渗透性也差。

相反熔指过大其胶的熔融温度低,流动性较好但粘结强度降低。

其助剂的选择,应选择乙烯与醋酸乙烯比例恰当的。

EVA热熔胶安全技术性能数据(MSDS)组成与性状主要成分:EVA 、松香改性树脂外观与形状:乳白色颗粒主要用途:书籍订装用健康危害1、由于在使用热熔胶施工时必须加热,因此应戴劳保手套、扎好袖。

2、盛装热熔胶的容器及预热槽必须盖紧,以防污染。

3、在正确操作的情况下对人体没有危害。

4、建议按“先进先用”的顺序使用。

急救措施皮肤接触:用大量清水冲洗、冷却,严重者需要立即送医院就医眼睛接触:用大量清水冲洗,并立即送医院就医。

吸入:应迅速带离现场,至空气清新处,保持环境通风。

食入:立即就医。

理化特性物理状态:固体颜色:乳白气味:无刺激气味PH值:/软化点:77℃--87℃沸点:>220℃饱和蒸汽压(kpa):20℃时<0.1mbar 相对密度(水=1):20℃时1.0g/cm3溶解:20℃时不溶于水粘性:160℃时4400-6000Mpa 灭火方法:泡沫、二氧化碳、干粉。

消防人员必须佩戴防护装备。

爆炸或泄漏的应急处理1.避免眼睛、皮肤接触该化学品; 2.在工作时,应急处置人员要佩戴防护手套,严禁喝水和进食; 3.工作前和工作后,应急处置人员要洗手。

储运注意事项1.保持良好的通风;2.储存于干爽场所。

防护措施车间卫生标准:/呼吸系统防护:有效抽风系统眼睛防护:/其它:工作中禁止吃东西,工作前后需洗手稳定性和反应活性避免接触的条件:/禁忌物:无燃烧(分解)产物:高温时产生醋酸。

毒理学资料急性毒性:无亚急性和慢性毒性:无LD50:/废弃1.将空容器或未用的产品返回给供应商; 2.不可自行扔掉空容器或未用的产品;3.不能空置于水沟和地表水法规信息1、可不用危险警示,根据德国易燃液体管理规定,本产品属非易燃物;2、根据德国检测方法的分类(1999/5/17),本产品不危害水源其它信息无制作:审批人:。