余热锅炉学习课件中英文对照

- 格式:ppt

- 大小:9.55 MB

- 文档页数:69

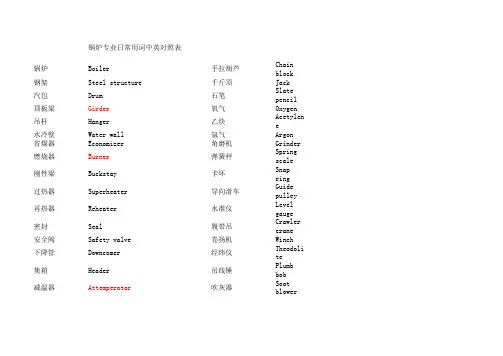

锅炉专业日常用词中英对照表锅炉Boiler手拉葫芦Chain block 钢架Steel structure 千斤顶Jack汽包Drum 石笔Slate pencil 顶板梁Girder 氧气Oxygen 吊杆Hanger 乙炔Acetylene 水冷壁Water wall 氩气Argon 省煤器Economizer 角磨机Grinder燃烧器Burner 弹簧秤Spring scale 刚性梁Buckstay 卡环Snap ring 过热器Superheater 导向滑车Guide pulley 再热器Reheater 水准仪Level gauge 密封Seal履带吊Crawler crane 安全阀Safety valve 卷扬机Winch 下降管Downcomer 经纬仪Theodolite 集箱Header吊线锤Plumb bob 减温器Attemperator 吹灰器Soot blower切圆Tangential减温减压站保温、油漆Heat insulation & Painting 邻炉加热adjacent boiler heating 点火杆、油枪Spark rod & Oil gun 检查孔inspection eye通球试验Ball-passing test 膨胀指示器expansion indicator 旋风分离器Cyclone separator 对空排汽系统Air exhausting system 百叶窗分离器Louver separator 压力表Pressure gauge人孔门Manhole 双色水位计Double-color water gauge 吊挂管Suspension pipe 平衡容器Balance cell 雾化片(雾化门)Atomizing disk取样器SamplerPressure-reducing and desuperheating station。

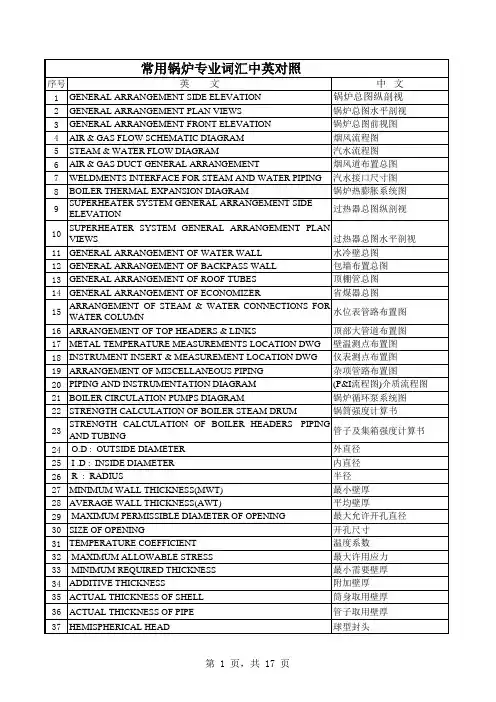

余热锅炉运行培训讲义HRSG Operation Training Material目录Contents1锅炉技术规范 (1)1BOILER TECHNICAL SPECIFICATIONS (1)1.1余热锅炉主要设计参数 (1)1.1M AIN D ESIGN P ARAMETERS (1)1.1.1锅炉概述 (1)1.1.1Boiler Overview (1)1.1.2设计参数 (1)1.1.2Design Parameters (1)1.1.3锅炉汽水品质标准 (3)1.1.3Boiler Steam and Water Quality Standard (3)1.1.4锅炉水容积 (5)1.1.4Boiler Water Capacity (5)1.1.5锅炉安全门设计参数 (5)1.1.5Boiler Safety Valve Design Parameters (5)1.2余热锅炉主要承压部件及受热面 (6)1.2M AIN P RESSURE P ARTS AND H EATING S URFACES OF E XHAUST H EAT B OILER (6)1.2.1锅炉结构 (6)1.2.1Structure (6)1.2.2汽包 (7)1.2.2Drum (7)1.2.3受热面 (11)1.2.3Heating Surface (11)1.2.4减温器设备 (13)1.2.4Desuperheating Device (13)1.2.5本体钢架、主烟囱钢架、平台扶梯 (13)1.2.5Boiler Body Steel Frame, Main Chimney Steel Frame and Platform Handrail (13)1.2.6烟道 (14)1.2.6Flue Gas Duct (14)1.2.7保温和外护板 (14)1.2.7Insulation and External Protective Casing (14)1.2.8柔性膨胀节 (15)1.2.8Flexible Expansion Joint (15)1.2.9三通挡板阀 (15)1.2.9Three-way Damper Valve (15)1.2.10定排扩容器 (16)1.2.10Periodical Blowdown Flash Tank (16)1.2.11连排扩容器 (17)1.2.11Continuous Blowdown Flash Tank (17)1.3辅机设备规范 (17)1.3S PECIFICATION OF A UXILIARIES (17)1.3.1高、低压给水泵设备规范 (18)1.3.1Specifications of High and Low Pressure Feed Water Pump (18)1.3.2高、低压循环泵设备规范 (19)1.3.2Specifications of High Pressure and Low Pressure Circulating Pump (19)1.3.3除氧循环泵设备规范 (20)1.3.3Specifications of Deaerating Circulation Pump (20)1.4保护定值 (21)1.4P ROTECTION S ETTINGS (21)1.4.1水位 (21)1.4.1Water Level (21)1.4.2温度 (23)1.4.2Temperature (23)1.4.3压力 (24)1.4.3Pressure (24)1.4.4流量 (25)1.4.4Flow (25)2余热锅炉启动前的检查和试验 (27)2INSPECTION AND TESTING BEFORE HRSG BOILER STARTUP (27)2.1锅炉检查项目及要求 (27)2.1I NSPECTION I TEMS AND R EQUIREMENTS (27)2.1.1锅炉内部检查 (27)2.1.1Furnace Inside Inspection: (27)2.1.2锅炉外观检查 (27)2.1.2Boiler Visual Inspection (27)2.1.3锅炉高压、低压汽包检查 (27)2.1.3HP/LP Steam Drum Inspection (27)2.1.4除氧器系统的检查 (28)2.1.4Inspection of Deaerating System (28)2.1.5锅炉高压、低压给水泵检查 (29)2.1.5Inspection of Boiler HP & LP Feed Water Pumps (29)2.1.6锅炉高、低压循环泵,除氧循环泵的检查 (29)2.1.6Inspection of Boiler HP & LP Circulating Pump and Deaerating Circulating Pump (29)2.1.7锅炉冷却水系统的检查 (29)2.1.7Inspection of Boiler Cooling Water System (29)2.1.8锅炉补充水系统的检查 (30)2.1.8Inspection of Boiler Makeup Water System (30)2.1.9锅炉压缩空气系统的检查 (30)2.1.9Inspection of Boiler Compressed Air System (30)2.1.10锅炉排污系统的检查 (30)2.1.10Inspection of Boiler Blowdown System (31)2.1.11管道的检查 (31)2.1.11Inspection of Pipelines (31)2.1.12阀门的检查 (31)2.1.12Inspection of Valves (31)2.2主要转动设备的试运行 (32)2.2C OMMISSIONING OF THE M AIN R OTARY M ACHINERY (32)2.2.1转动机械试运行前的检查和准备工作 (32)2.2.1Inspections and Preparations before the Rotary Equipment Commissioning (32)2.2.2试运行的步骤及注意事项 (32)2.2.2Commissioning Procedures and Precautions (32)2.2.3转动设备的试运行方式 (33)2.2.3Commissioning Mode of Rotating Equipment (33)2.2.4转动设备的启动 (33)2.2.4Startup of the Rotating Equipment (33)2.2.5转动机械试运行验收项目 (36)2.2.5Commissioning Items of Rotating Equipment (36)2.2.6转机联锁试验 (38)2.2.6Interlock Test of Rotating Equipment (38)2.2.7电动门及其它执行机构的自动模拟试验 (38)2.2.7Auto Simulation Test of Electric Valve and Other Actuators (38)2.3水压试验 (39)2.3H YDRAULIC T EST (39)2.3.1水压试验规定 (39)2.3.1Hydraulic Test Code Requirements (39)2.3.2水压试验范围 (40)2.3.2Scope of Hydraulic Test (40)2.3.3水压试验前的准备工作 (40)2.3.3Preparations before hydraulic test (40)2.3.4工作水压及超水压试验步骤 (41)2.3.4Procedures of Hydraulic Test under Working Pressure and Over Pressure Cases (41)2.3.5水压试验合格标准 (43)2.3.5Hydraulic Test Criterion (43)2.3.6水压试验后锅炉放水 (43)2.3.6Boiler Water Discharging after Hydraulic Test. (43)2.3.7水压试验注意事项 (43)2.3.7Safety Considerations during Hydraulic Test (43)2.4安全阀校验 (44)2.4C ALIBRATION OF S AFETY V ALVE (44)2.4.1安全阀校验的规定 (44)2.4.1Provisions of Safety Valve Calibration (44)2.4.2安全阀校验的条件 (45)2.4.2Safety Valve Calibration Conditions (45)2.4.3安全阀校验前的检查与准备 (45)2.4.3Inspections and Preparations before Safety Valve Calibration (45)2.4.4安全阀校验方法 (45)2.4.4Method of Safety Valve Calibration (45)3机组启动 (47)3UNIT STARTUP (47)3.1锅炉启动前必须具备的条件 (47)3.1T HE R EQUIRED C ONDITIONS BEFORE B OILER S TARTUP (47)3.2锅炉启动前的检查 (48)3.2I NSPECTION BEFORE B OILER S TARTUP (48)3.3锅炉启动 (49)3.3B OILER S TARTUP (50)3.3.1启动规定 (50)3.3.1Startup Codes (50)3.3.2锅炉上水 (50)3.3.2Boiler Water Filling (50)3.3.3锅炉水冲洗(冷态) (52)3.3.3Boiler Water Flushing (During Cold State) (52)3.3.4冷态启动 (52)3.3.4Cold State Startup (53)3.3.5热态启动 (54)3.3.5Hot Startup (54)3.4锅炉启动后的检查 (56)3.4I NSPECTION AFTER B OILER S TARTUP (56)4锅炉正常运行中的调整与维护 (1)4ADJUSTMENT AND MAINTENANCE DURING BOILER NORMAL OPERATION (1)4.1正常运行中的检查 (1)4.1I NSPECTION DURING N ORMAL O PERATION (1)4.2运行中的调整 (2)4.2A DJUSTMENT DURING O PERATION (2)4.2.1运行调整的任务 (2)4.2.1Task of Operation Adjustment (2)4.2.2锅炉运行调整 (2)4.2.2Boiler Operation Adjustment (2)4.2.3锅炉水位计的运行维护 (5)4.2.3Operation Maintenance of Boiler Level Meter (5)4.2.4锅炉排污 (8)4.2.4Boiler Blowdown (8)4.3正常运行中的定期工作 (9)4.3R EGULAR W ORK DURING U NIT N ORMAL O PERATION (9)5UNIT SHUTDOWN (11)5.1机组停运原则 (11)5.1S HUTDOWN P RINCIPLES (11)5.2正常停运操作: (11)5.2N ORMAL S HUTDOWN O PERATION (11)5.2.1停炉前的准备 (11)5.2.1Preparation before Boiler Shutdown (11)5.2.2停炉操作 (12)5.2.2Shutdown 0peration (12)5.2.3停炉后的热备用 (12)5.2.3Hot Standby after Boiler Shutdown (12)5.2.4停炉后的冷却 (13)5.2.4Cooling after Boiler Shutdown (13)6停炉后的保养 (1)6MAINTENANCE AFTER BOILER SHUTDOWN (1)6.1短期保养(15-30天) (1)6.1S HORT-TERM M AINTENANCE (15-30 DA YS) (1)6.1.1余热烘干法 (1)6.1.1Residual Heat Drying Method (1)6.1.2氨液保养法: (1)6.1.2Ammonia Solution Maintenance Method (1)6.2长期保养(30天以上) (2)6.2L ONG-TERM M AINTENANCE (ABOVE 30 DA YS) (2)6.2.1充氮保护法: (2)6.2.1Nitrogen-filling Maintenance Method: (2)6.2.2干燥剂防腐法: (2)6.2.2Drying Agent Corrosion Protection Method: (2)7余热锅炉事故及故障处理 (1)7RESIDUAL HEAT BOILER FAULTS AND TROUBLESHOOTING (1)7.1事故处理原则 (1)7.1T ROUBLESHOOTING P RINCIPLES (1)7.2紧急停炉的条件 (2)7.2E MERGENCY S HUTDOWN R EQUIREMENTS (2)7.2.1紧急停炉的条件: (2)7.2.1Emergency Shutdown Requirements (2)7.2.2Emergency Shutdown Operation: (3)7.3故障停炉的条件 (3)7.3B OILER S HUTDOWN R EQUIREMENTS (3)7.4事故处理 (4)7.4T ROUBLESHOOTING (4)7.4.1锅炉满水 (4)7.4.1Boiler Full Water (4)7.4.2锅炉缺水 (5)7.4.2BOILER WATER SHORTAGE (5)7.4.3汽水共腾 (6)7.4.3FOAMING (6)7.4.4水冲击故障 (7)7.4.4Water Hammer Faults (7)7.4.5汽包水位计故障 (9)7.4.5Steam Drum Water Level Gauge Faults (9)7.4.6省煤器管、蒸发器管爆破 (11)7.4.6Economizer and Vaporizer Piping Rupture (11)7.4.7过热器管爆破 (12)7.4.7Superheater Rupture (12)7.4.8蒸汽及给水管道损坏 (13)7.4.8Steam and Feedwater Piping Damage (13)7.4.9安全门故障 (14)7.4.9Safety Valve Faults (14)8辅助系统事故处理 (1)8AUXILIARY SYSTEM TROUBLESHOOTING (1)8.1一般处理原则 (1)8.1G ENERAL T REATMENT P RINCIPLES (1)8.2紧急停止转机运行的条件 (1)8.2R OTARY E QUIPMENT E MERGENCY S HUTDOWN R EQUIREMENTS (2)8.3给水泵故障 (2)8.3F EEDWATER P UMP F AULTS (2)8.4循环泵故障 (6)8.4C IRCULATING W ATER P UMP F AULTS (6)8.5仪用空气系统故障 (9)8.5F AILURES OF I NSTRUMENT A IR S YSTEM (9)8.5.1空压机故障、原因及解决方法 (9)8.5.1Malfunctions, Causes and Corrections of Air Compressor (9)8.5.2组合式干燥机故障、及处理方法 (10)8.5.2Failures and trouble shooting methods of combined dryer (10)1 锅炉技术规范1 Boiler Technical Specifications1.1 余热锅炉主要设计参数1.1 Main Design Parameters1.1.1 锅炉概述1.1.1 Boiler Overview型号:NG-S109E-R1Model: NG-S109E-R1形式:无补燃、悬吊立式、正压运行、强制循环余热锅炉Type: exhaust-heat boiler characterized by three pressures, no supplement fuel, verticalsuspended, positive pressure and forced circulation.配套燃机:PG9171EConfigured gas turbine: PG9171E尺寸:锅炉烟囱标高60M,占地面积30.3×14MDimension: chimney elevation 60M covered an area of 424.2 square meters结构:露天塔式布置,全悬吊结构Structure: open-air tower type arrangement with full suspended structure制造商:杭州锅炉厂Manufacturer: Hang Zhou Boiler Corporation1.1.2 设计参数1.1.2 Design Parameters1.1.2.1 烟气参数1.1.2,.1 Flue gas parameters1.1.2.2 余热锅炉蒸汽参数1.1.2.2 Steam parameters1.1.3 锅炉汽水品质标准1.1.3 Boiler Steam and Water Quality Standard 1.1.3.1 给水品质标准1.1.3.1 Feed water quality standard1.1.3.2 凝结水品质标准1.1.3.2 Condensate water quality standard1.1.3.3 炉水品质标准1.1.3.3 Boiler water quality standard1.1.3.4 蒸汽品质标准1.1.3.4 Steam quality standard1.1.4 锅炉水容积1.1.4 Boiler Water Capacity1.1.5 锅炉安全门设计参数1.1.5 Boiler Safety Valve Design Parameters1.2 余热锅炉主要承压部件及受热面1.2 Main Pressure Parts and Heating Surfaces of Exhaust Heat Boiler1.2.1 锅炉结构1.2.1 Structure1.2.1.1 本锅炉为塔式布置,全悬吊管箱结构。

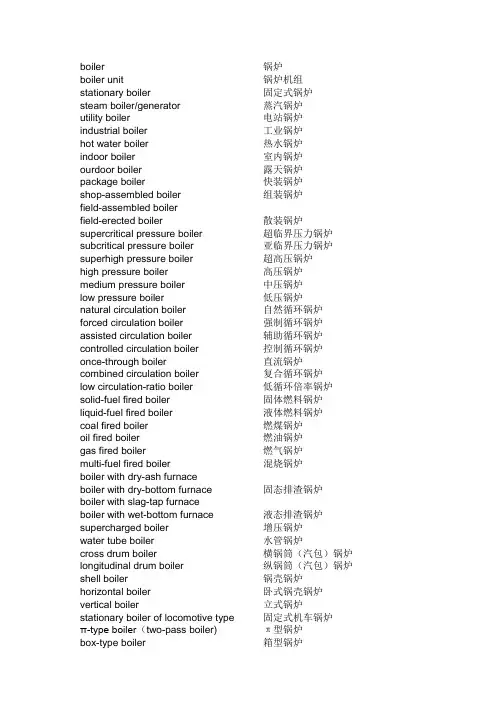

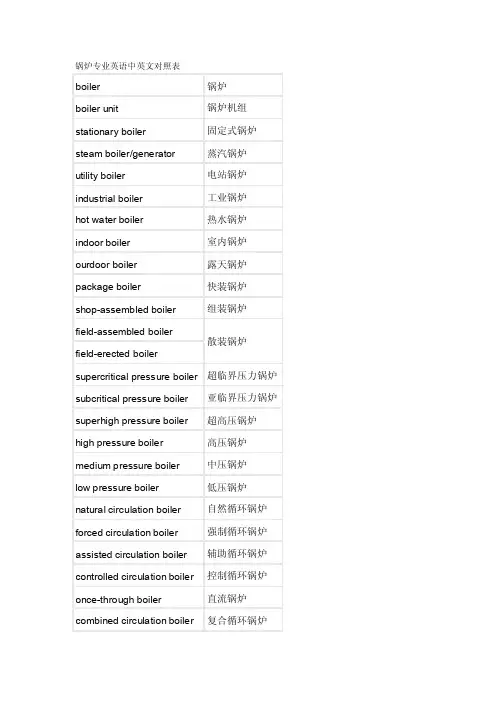

锅炉专业英语中英文对照表火道锅炉Flame tube boiler疏水器、疏水阀steam trap饱和蒸汽saturated steam过热蒸汽superheated steam震动炉篦Oscillating bar grate链条炉蓖Chain grate, travelling grate省煤器economizer减速器speed reducer螺旋除渣机screw slag remover除尘器dust collectorcombustion air fan鼓风机exhausting fan上煤机coal conveyor尖端的、高科技的Hi-tech节能的energy-saving高效的high-efficiency低噪声的low noise耐用的、持久的durable蒸发evaporation额定的rated热效率thermal efficiency碳化物carbide碳化硅silicon carbidemonoxide一氧化碳carbon monoxide二氧化碳dioxide二氧化碳亚临界压力锅炉carbon dioxide subcritical pressure boiler燃煤锅炉coal-fired boiler启动锅炉 start-up boiler炉墙 furnace wall管束(排) tube bundle管屏tube platen下降管 downcomer上升管 riser省煤器管 economizer tube再热器管 reheater tube过热器管 superheated tube蛇形管 coil吊挂管 supporting tube水冷壁管 water wall tubesaturated steam pipe水冷壁 water wall鳍片管finned tube, fin tube, gilled tube 联箱 header锅炉本体 boiler proper锅炉机组 boiler unit炉膛 boiler framework燃烧器 furnace燃烧室 combustion chamber油枪 oil gun torch风门 damper管板 tube plate。

锅炉运行规程Boiler Running Regulations总则General (2)第一章设备结构及布置Equipment structure and layout. 21. 锅炉设计概况Design parameters (2)2 锅炉概述 Boiler overview (7)3. 锅炉整体布臵 Boiler general layout (10)第二章锅炉机组的启动Boiler Starting (11)1.锅炉启动前的检查与试验 Check and test before Start (11)2.锅炉机组的启动 (15)第三章锅炉运行中的监视与调整Monitor and adjustment during Boiler Running (20)1 运行调整任务 Runing control duty (20)2. 锅炉水位调节boiler water level adjustment (21)第四章自动装置的运行Automatic device running (25)1. 自动装臵投撤要求及注意事项:When put in automatic device: (25)2. 汽包水位自动控制 Drum water level automatic control (26)3. DCS分散控制系统的操作注意事项 DCS operator's Matters need attention (26)第五章锅炉停炉操作Handing of Boil Stop (28)总则General本标准规定本项目锅炉设备的规范和特性、运行操作规定、运行维护及事故处理原则。

本标准适用QC余热锅炉及辅机设备运行操作管理的运行操作、定期试验、运行维护及典型事故分析与处理。

This regulations are for boiler and auxiliaries of this project, inclusive of equipment standard and properties、running、regular maintenance and emergency handling.锅炉运行人员和有关领导均应熟悉本规程。

水泥窑余热发电锅炉运行规程Running Regulation of Waste Heat Boiler前言Preface1. 本规程内容包括余热锅炉运行规程和余热锅炉事故处理二个部分,至于涉及原理、说明及维修方面则不在本规程范围。

1. This regulation consists of three parts: Boiler Running Regulation and Boiler Fault Resolution Principles involved, Explanation and Maintenance are not included.2. 本规程被批准后,立即执行,原有默认的操作规定即时作废。

2. This regulation must be executed immediately it is approved. At the same time, the regulation used before is invalid.3. 如果本规程与部颁规程、厂家规定有抵触的地方,以部颁、厂家规定为准。

3. Articles in this regulation should be invalid if they contradict with the regulation by the department and the factory.4. 下列人员必须熟知并严格执行:4. Following staff must familiarize with and implement this regulation strictly:4.1 全体锅炉运行值班人员,锅炉相关、直管的管理人员及有关锅炉检修人员。

4.1 All operators on duty of steam boiler running, management staff and boiler maintenance staff4.2 总工程师、生产技术部、锅炉专职、电站人员、教育培训人员。

A List of Abbreviations and Symbols inEnglish-ChineseA Ash Handling System 除灰系统AH Air Heater 空气预热器AAh Analyzer, Alarm High 分析器,高值报警AIV Air Intake V alve 进气阀ALIGN Alignment 校正ALKF Airlock Feeder 锁气器AP Ash Slurry Pump 灰浆泵A TM Atmosphere 大气AC Air Conditioner 空气调节器AFT Atmosphere Flash Tank 大气扩容器AC Alternating Current 交流电ALM Alarm 报警AMP Ampere 安培AX THR BRG Axis Thrust Bearing 轴向推力,轴承A TMZ Atomizing 雾化AUTO Automation 自动AUX Auxiliary 辅助的BA Bottom Ash 底灰BAH Bottom Ash Hopper 底灰斗BLR Boiler 锅炉BSD Boiler Shut Down 停炉BUSH Bushing 衬套BYPS Bypass 旁路BCP Boiler Circulating Pump 锅炉循环泵BVD Boiler V ents and Drains 锅炉疏水放气BFP Boiler Feed-water Pump 锅炉给水泵BFPTBoiler Feed-water Pump Turbine锅炉给水泵汽机BFW Boiler Feed-water 锅炉给水BM Boiler Master 锅炉主控BMCR Boiler Maximum Continuous Rating 锅炉最大连续出力BFBP Boiler Feed Booster Pump 锅炉给水增压泵BNR Burner 燃烧器BOP Balance Of Plant 电厂辅机设备BPC Blade Pitch Control 叶片带距控制BT Boiler Tube 炉管CH Crusher House 碎煤房COMB Combustion 燃烧COMP Compressed Air 压缩空气CONV Conveyer 输送机CPL Control Panel Local 就地控制盘CPM Control Panel Main 主控盘CRT Cathode Ray Tube 屏幕显示CT Current Transformer 变流器CYCL Cyclone 旋风分离器CAS Casing 缸CB Cut Breaker 开关COMP Complete 完成CCCW Closed Circulating Cooling Water 闭式循环冷却水CCW Closed Cooling Water 闭式冷却水CCWHF Closed Cooling Water Heater 闭式冷却水冷却器CCWP Closed Cooling Water-pump 闭式冷却水泵CS Closed Cooling Water System 闭式冷却水系统CH Coal Handling 煤的装卸CHK VLV Check V alve 逆止阀CIRC Circulation 循环CLR Cooler 冷却器CLSD Closed 闭式CLOW Cooling Water 冷却水CMPR Compressor 压缩机CNDNR Conditioner 调节器CNTL Control 控制CNTLE Controller 控制器COND Condensate 凝结水CONDTY Conductivity 导电率CP Condensate Pump 凝结泵CIR Circuit 回路COUPI Coupling 藕合,连接CP Condensate Polisher 除盐装置CS Control Switch 控制开关CRSV Cold Reheat Safety V alve 再热器冷段安全阀CV Control V alve 控制阀CWP Circulation Water Pump 循环水泵DMPR Damper 挡板DP Difference Pressure 差压DPIC Differential Pressure Indicating Controller 压差指示控制器DPT Differential Pressure Transmitter 压差变速器DRN Drain 疏水DV Drain V alve 疏水阀DC Direct Current 直流电DSH De-super-heater 减温器DCA Drain Cooler Approach 疏水冷却器通道DEAER De-aerator 除氧器DEV Deviation 偏差DIFFRLY Differential Relay 差动继电器DISCH VLV Discharge V alve 排放阀DIST Disturbance 故障DSCH Discharge 排出ECON Economizer 省煤器EP Electrical Static Precipitator 电除尘ECC Eccentric 偏心EFF Efficiency 效率EHC Electric Hydraulic Control 电液控制EO Electric Operate 电气操作EQ Equipment 设备ER Error 误差ES Extraction System 抽气ESC Escape 逃逸ESS Engineering Safety System 保安系统EU Engineering Unit 工程单位EXH Exhaust 排汽EXT Extract 抽出F Fly Ash System 飞灰系统FA Fine Ash 细灰FDR Feeder 给料机FE Flow Element 流量元件FI Flow Indicator 流量指示件FDBK Feedback 反馈FITG Fitting 连接件FLW Flow 流量FO Fail Open 故障时自动开关FT Flow Totalize 流量累加器FT Flow transmitter 流量变送器FV Flow Control V alve 流量控制阀FY Flow Relay or V alve 流量传送器FA Failure Alarm 故障报警FD Forced Draft 强制通风FDF Forced Draft Fan 送风机FDR Feeder 给煤机FIC Flow Indicate Controller 流量指示控制器FLT Flash Tank 扩容箱FLD Field 磁场FLG Flange 法兰FLM Flame 火焰FWH Feed Water Heater 给水加热器FO Fuel Oil 燃油FREQ Frequency 频率FURN Furnace 炉膛FV Flow Control V alve 流量控制阀GLD Gland 密封GRDR Grinder 碎渣机GND Ground 接地GC Generator Cooling 发电机冷却GEN Generator 发电机GESE Gland Steam Condenser Exhauster 轴封抽汽机GMT Generator Main Transformer 发电机变压器GRAD Grandient 梯度GS Gland Steam 轴封蒸汽GSC Gland Steam Condenser 轴封加热器GV Governor V alve 压调门H Heat Conservation 保温HO Heavy Oil 重油HP High Pressure Horse Power 高压马力HS Hand Switch 手动开关HTR Heater 加热器HV Hand Control V alve 手动控制器HY Hand Relay or Transducer 手动继电器(转换器)H Hand 手动的HB Heat Balance 热平衡HD Heater Drain 加热器疏水HD der 联箱HL Heat Loss 热损失HMDY Humidity 湿度HPH High Pressure Heater 压加热器HPR Hooper 漏斗HPT High Pressure Turbine 高压缸HR Hot Reheat 再热器,热段HR Heat Rate 热耗率HSV Hot Reheat Safety V alve 再热器热段安全阀HT Heat 加热HTG Heating 加热HTR Heater 加热器HV AC Heating V entilation & Air Conditioner 加热通风与空气调节HW Hot-well 热井HV Hand Control V alve 手动控制器HYD Hydraulic 液力的INTLK Interlock 联锁IC Instrument and Control 仪表与控制(热工)ICV Intermediate Control V alve 中压控制阀ID Induced Draft 抽风,引风IDF Induced Draft Fan 引风机IGN Ignition 点火装置INLT Inlet 入口IPR Initial Pressure 初压INST Instrument 仪表INVR Inverter 倒相器,转换开关I /O Input/Output 输入/输出IP Intermediate Pressure 中压IPT Intermediate Pressure Turbine 中压缸ISV Intermediate Pressure Turbine Steam V alve中压缸,进汽阀JP Jet Pump 喷射器LG Level Gauge 料位计LUB Lubricate 润滑油LVL Level 水位,液位LA Level Alarm 液体报警LIM(LMIR) Limiter 限制器LKG Leakage 泄漏LP Low Pressure 低压L.P Low Point 低位LPH Low Pressure Heater 低压加热器LS Live Steam 主蒸汽LSH Local Switch Hand 就地开关LUB OIL Lube Oil 润滑油M Mechanical 机械Motor 马达MAG Magnetic 磁性MOD Mode 方式M/A Manual/Automatic 手动/自动MAN Manual 手动MARG Margin 极限MAX Maximum 最大的,最大值的MCR Maximum Continuous Rating最大连续出力MCV Main Control V alve 主控制阀MD Modulation Damper 调节挡板MDBFP Motor Driven Boiler Feed-water Pump 电动给水泵MEAS Measure 测量MFT Master Fuel Trip 主燃料切断MIN Minimal 最小的MKUP (MU) Make-up 补充ML Mill 磨煤机MN Main 主要的M.O. Manual Operate 手操MPT Main Power Transformer 主变压器MS Main Steam 主蒸汽MSV Main Steam V alve 主汽阀NOZ Nozzle 喷嘴NPSH Net Pump Suction Heat 泵的静吸压头OL Overload 过载OLR Overload Relay 过载继电器OPER Operation 运行OSC Oscillograph 示波器OTLT Outlet 出口PA Primary Air 一次风PAF Primary Air Fan 一次风机PAH Pressure Alarm High 高压报警PAL Pressure Alarm低压报警PAS TDBFP A Status 汽动给水泵A 状态PB Push Button 按钮PBS TDBFP B Status 汽动给水泵B 状态PC Power Center 动力中心PC Pressure Controller 压力控制器P.C. Pressure Control 压力控制PCP Precipitator 除尘器PCV Pressure Control V alve 压力控制阀PDI Pressure Differential Indication 差压指示计PDT Pressure Differential Transmitter 差压变送器PED Pdestal 轴承座PERF CALC Performance Calculation 性能计算PF Power Factor 功率因数PHTR Pre-heater 预热器PMP Pump 泵PNEU Pneumatic 气动的PR Pressure Recorder 压力记录计PRG Purge 吹扫PRV Pressure Relief V alve 泄压阀PRO Protection 保护PROGR Program 程序PT Pressure Transmitter 压力变送器PULV pulverizer 磨煤机PVSV Pressure V acuum Safety V alve压力真空安全阀PW Plant Water 厂用水PY Pressure Relay 压力继电器QA Quality 质量,性能RB Run Back 快速降负荷RCV Recovering 回收RCV Reverse Current V alve 逆止阀RECIRC Re-circulation 再循环RECT Rectifier 整流器RED Reducer 减压器RET Return 返回RH Re-heater 再热器RO Restriction Orifice 节流孔板ROT Rotor 转子RTU Remote Telemetry Unit 遥测装置SA Secondary Air 二次风SA T Saturate 饱和的SC Steam Coil Air Heater 暖风器SCA V Scavenge 吹扫SCN Scanner 控制器SD Shut-off Damper 关断挡板Shut-Down 停止运行SEP Separator 分离器SG Switchgear 开关装置SH-DN Shut-Down 切除SH Super-heater 过热器SLS Seals 密封SO Shut Off 关闭SPD Speed 转速SPRA Spray 喷水SPT Support 支持,支架ST Start 启动,开始STD-BY Stand By 备用ST System 系统STM Steam 蒸汽STR Stator 定子STRNR Strainer 滤器SU Start Up 启动SV Solenoid V alve 电磁阀Shut Off V alve 关断阀SUCT Suction 吸入SW Switch 开关Steam Water 汽水SBLWR Soot Blower 吹灰器TBFP Turbine Drive Boiler Feed-water Pump 汽动给水泵TCV Temperature Control V alve 温度控制T.B. Transfer Damper 转换挡板TE Temperature Element 测量元件TG Turbine-generator 汽轮发电机Turbine-gear 汽机盘车THERM Thermal 热力的TMS Turbine Master System 汽机主控TRANS Transfer 转换TRBL Trouble 故障TRKG Tracking 跟踪TRX TURBOMAX 汽机最大热应力控制TT Temperature Transmitter 温度传感器TTD Terminal Temperature Difference 温度端差TURB Turbine 汽机TW Thermo-well 热电偶套管UAM Unit Automatic Master 机组自动系统V AC V acuum 真空V AL V alue 数值VB Vibration 振动VLV V alve 阀门WH Watt-hour 瓦小时WP Work Point 工作点WW Water Wall 水冷壁WX Watt Transducer 功率转换器COVER Crossover 切换管CV Control V alve 控制阀PS Position Switch 状态开关,位置开关PT Position Transmitter 状态变送器BOOSTER PUMP FREE SIDE BEARING TEMP前置泵自由端径向轴承温度BOOSTER PUMP DRIVEN SIDE BEARING TEMP前置泵驱动端径向轴承温度BOOSTER PUMP THRUST BEARING OUTSIDE TEMP前置泵推力轴承外侧温度BOOSTER PUMP THRUST BEARING INSIDE TEMP前置泵推力轴承内侧温度comment 注释,评论module 模块standby 备用proximity 相近,接近,亲近detector 探测器bracket 支架interlocks 互锁,连锁axial 轴向的surge conditions 喘振loss of speed 飞车accessory 附件pulsation 有节奏的跳动,跳动fossil fired 燃煤intent 意图,目的,意向intend 意指,想要,打算consistent 一致的,调和的practice 惯例,实习,实践intrinsic 固有的,内在的procurement 获得,获取fabrication 制作,构成,伪造物vent 通风孔,出烟孔,出口,放出,排出,发泄noncondensible gas 不凝结气体intermittent 间歇的,断断续续的blowdown 排污tank 桶,箱,罐diagram 图表deaerator 除氧器corrosion 侵蚀,腐蚀状态concentration 集中,集合,浓缩,浓度recommend 推荐,介绍,托付,劝告abnormal and normal conditions 变工况和额定工况warm up 暖机acid wash 酸洗scale 范围,水垢,水锈,比例,刻度sludge 污泥,淤泥foreign matter 不相关的物质facilitate 推动,促进,使简化multistage 多级的remote control 遥控safety relief valve 安全卸压阀gauge 量规,量表,测量manhole 人孔,检修孔equivalent 等价物,相等的forging 锻造seat 部位,座socket welding 管座焊接enthalpy 焓estimate 评价,评估,估价parameters 参数,参量correction factor修正系数nominal 名义上的,额定的,标称的MS—Main Steam 主蒸汽Cycle循环Intercept截止Fetting附件Gage规,表,压力计Form factor 形状系数Taps接头test wells测点插孔stress-relieved 应力消除thermometer温度计steam purge system蒸汽吹扫系统centrifugal type pumps离心式泵margin余量friction losses磨擦损失solenoid螺线管modulat调整,调节criteria标准wrenches扳手pipe taps管接头Assemble 集合,集结,组装Group 聚合,成群Vibration 振动audio 声频的,音频的integral 部分,完整,积分,完整的boiler house 锅炉房coal conveyor 输煤装置coal bunker 煤仓coal mill 磨煤机steam boiler water boiler tube蒸汽锅炉,管式锅炉furnace(combustion chamber) 炉膛(燃烧室) water tube 水管ash pit 灰坑super-heater 过热器water pre-heater 水预热器air pre-heater 空气预热器gas duct(flue) 烟气管,烟道dust collecting plant 集尘室electrical precipitation plant 电气除尘室induced draught fan 引风机chimney 烟囱de-aerator 除氧器feed water tank 供水箱boiler feed pump 给水泵switchgear 开关设备cable tunnel 电缆通道cable cellar 电缆槽turbine room 汽轮机室steam turbine with alternator蒸汽汽轮发电机组economizer 省煤器steam drum 汽包surface condenser 表面凝汽low-pressure pre-heater 低压预热器circulating water pipe(pump) 循环水管control room 控制室electrostatic dust remover(precipitator)静电除尘器pulverizer 磨煤机slag pump 灰渣泵thermal cycle 热力循环(net)heat rate (净)热耗率STEAM POWER STA TION 火力发电站锅炉boiler锅炉机组boiler unit固定式锅炉stationary boiler蒸汽锅炉steam boiler电站锅炉power station boiler工业锅炉industrial boiler生活锅炉domestic boiler热水锅炉hot water boiler船用锅炉marine boiler快装锅炉package boiler组装锅炉shop-assembled boiler散装锅炉field-assembled boiler常压热水锅炉atmospheric pressure hot water boiler低压锅炉low pressure boiler中压锅炉medium pressure boiler高压锅炉high pressure boiler超高压锅炉superhigh pressure boiler亚临界压力锅炉subcritical pressure boiler超临界压力锅炉supercritical pressure boiler 超超临界锅炉ultra supercritical boiler自然循环锅炉natural circulation boiler强制循环锅炉forced circulation boiler直流锅炉once-through boiler复合循环锅炉combined circulation boiler低循环倍率锅炉low circulation boiler火管锅炉fire tube boiler水管锅炉water tube boiler固体燃料锅炉solid-fuel fired boiler液体燃料锅炉liquid-fuel fired boiler气体燃料锅炉gas-fuel fired boiler余热锅炉exhaust heat boiler 余热锅炉(HRSG)电热锅炉electric boiler锅壳式锅炉shell boiler水火管锅壳式锅炉water-fire tube shell boiler 卧式内燃锅炉horizontal internal-combustion boiler角管式锅炉corner tube boiler立式锅炉vertical boiler小型锅炉low-capacity boiler铸铁锅炉cast-iron boiler固态排渣锅炉boiler with dry-ash furnace液态排渣锅炉boiler with slag-tap furnace火床燃烧锅炉grate firing boiler链条炉排锅炉traveling grate boiler抛煤机链条炉排锅炉spreader-stoker-fired boiler火室燃烧锅炉suspension firing boiler煤粉燃烧锅炉pulverized coal fired boiler水煤浆燃烧锅炉coal-water slurrty fired boiler流化床燃烧锅炉fluidized bed boiler循环流化床锅炉circulating fluidized bed boiler增压循环流化床锅炉pressurized fluidized bed boiler微正压锅炉pressure fired boiler增压锅炉supercharged boiler辐射式锅炉radiant boiler通用压力锅炉universal-pressure boiler汽水两用锅炉multifunctional boiler (steam and hot water)盘管式锅炉coil tube boiler真空相变热水锅炉vacuum phase-change hot water boiler有机热载体炉organic heat transfer material heater锅炉本体boiler proper受热面heating surface辐射受热面radiant heating surface对流受热面convection heating surface附加受热面auxiliary heating surface受压部件pressure part受压元件pressure part管屏tube panel垂直上升管屏up flow riser tube panel回带式管屏ribbon panel水平围绕管屏spirally-wound tube panel管束tube bank错列布置管束staggered bank顺列布置管束in-line bank对流烟道convection pass并联烟道parallel gas passes风道air duct炉膛(燃烧室)furnace水冷炉膛water cooled furnace绝热炉膛insulating furnace炉胆furnace波形炉胆corrugated furnace回燃室reversal chamber冷灰斗water-cooled hopper bottom卫燃带refractory belt折焰角furnace arch炉拱arch前拱front arch后拱rear arch燃烧器burner煤粉燃烧器powdered coal burner旋流式煤粉燃烧器cyclone type burner直流式煤粉燃烧器impellerless burner低氮氧化物燃烧器low nitrogen oxide burner 点火装置flame ignitor油燃烧器oil burner油雾化器oil atomizer机械雾化油燃烧器(压力雾化油燃烧器)mechanical atomizing burner气流雾化油燃烧器gas atomizing burner气体燃烧器gas burner调风器register炉排grate链条炉排traveling grate stoker 链带式炉排chain belt type grate stoker横梁式炉排crossgirder grate stoker鳞片式炉排flake type grate stoker往复炉排reciprocating grate倾斜式往复炉排inclined reciprocating grate 振动炉排vibrating stoker抛煤机spreader stoker锅筒drum上锅筒steam drum下锅筒water drum锅壳shell筒体cylindrical shell封头head凸形封头convex head椭圆形封头ellipsoidal head半球形封头hemispherical head平封头flat head管板tube plate孔桥(管孔带)ligament人孔manhole手孔handhole集箱(联箱)header端盖head锅筒内部装置drum internals清洗装置steam washer旋风分离器cyclone separator轴流式分离器turbo separator百叶窗分离器corrugated scrubber钢丝网分离器screen separator多孔板perforated distribution plate集汽管dry pipe排污管blowoff pipe下降管downcomer加药管chemical feed pipe蒸发受热面evaporating heating surface水冷壁water-cooled wall膜式水冷壁membrane wall双面水冷壁division wall防渣管(凝渣管)boiler slag screen锅炉管束boiler convection tube bank烟管(火管)fire tube螺纹烟管spirally corrugated tube内螺纹管ribbed tube旗式受热面flag pattern surface过热器superheater辐射式过热器radiant superheater墙式过热器wall superheater屏式过热器platen superheater对流式过热器convection superheater包墙管过热器steam-cooled wall顶棚管过热器(炉顶过热器)steam-cooled roof悬吊式过热器pendant superheater水平式过热器horizontal superheater再热器reheater辐射式再热器radiant reheater对流式再热器convection reheater减温器desuperheater、attemperator表面式减温器drum type surface attemperator 喷水减温器spray type attemperator烟气挡板(旁路档板)smoke damper烟气再循环装置gas recirculation equipment 汽——汽热交换器steam-steam heat exchanger省煤器economizer沸腾式省煤器steaming economizer非沸腾式省煤器nonsteaming economizer钢管式省煤器steel tube economizer鳍片管式省煤器finned tube economizer铸铁肋片管式省煤器cast-iron gilled tube economizer可分式省煤器(独立式省煤器)separated economizer悬吊管pendant tube空气预热器air heater钢管式空气预热器tubular air heater再生式回转空气预热器rotary regenerative air heater受热面转动型再生式空气预热器rotating-plate type regenerative air heater风罩转动型再生式空气预热器stationary-plate type regenerative air heater板式空气预热器plate type recuperative air heater铸铁肋片管式空气预热器cast-iron gilled tube air heater暖风机steam air heater锅炉构架boiler structure支承式锅炉构架bottom-supported structure 悬吊式锅炉构架top-supported structure by hangers框架式锅炉构架frame type boiler structure 桁架式锅炉构架trussed type boiler structure 刚性架buckstay锅炉炉墙boiler setting重型炉墙bottom supported heavy wall轻型炉墙sectional supporting water cooled wall敷管炉墙top supported water cooled wall炉墙护板boiler casing锅炉汽水系统boiler steam and water circuit 锅炉范围内管道boiler external piping安全阀safety valve静重式安全阀direct-loaded safety valve弹簧式安全阀spring-loaded safety valve杠杆式安全阀deadweight safety valve脉冲式安全阀pulsed safety valve电磁控制式安全阀electric relief valve水封式安全装置water-sealed safety equipment水位表water gauge玻璃水位计glass water gauge双色水位计double-colour water gauge高低水位报警器high-low water level alarm 低置水位计remote water level indicator防爆门explosion door排污阀blowdown valve疏水阀(疏水器)bleeder点火程序控制装置ignition control program 熄火保护装置flame failure protection额定蒸发量nominal capacity最大连续蒸发量maximum continuous rating 额定供热量rated heating capacity额定蒸汽参数nominal steam parameter额定蒸汽压力nominal steam pressure额定蒸汽温度nominal steam temperature额定热水温度nominal hot water temperature 给水温度feed watr temperature3.2.2.1.9回水温度return water temperature排污率rate of blowdown锅炉热力计算thermal calculation for boilers 锅炉水动力计算hydrodynamic calculation for boilers锅炉烟风阻力计算flue-gas and air resistance calulation for boilers锅炉受压元件强度计算strength calculation of pressure parts for boilers锅炉水循环boiler circulation循环回路circulation circuit蒸汽品质steam quality蒸汽污染steam contamination机械携带mechanical carry-over溶解携带vaporous carry-over蒸汽净化steam purification蒸汽湿度moisture in steam分段蒸发stage evaporation气温调节steam temperature control给水feed water补给水make-up water锅水boiler water给水品质feedwater condition锅水浓度boiler water concentration总硬度total hardness总碱度total alkalinity悬浮固形物suspended solid matter溶解固形物dissolved solid matter相对碱度relative alkalinity负压燃烧negative-pressure firing压力燃烧pressurized firing自然通风natural draft机械通风mechanical draft平衡通风balanced draft分段送风zone control draft燃料消耗量fuel consumption计算燃料消耗量calculated fuel consumption 理论空气量theoretical air过量空气系数excess air ratio理论燃烧温度theoretical combustion temperature炉膛出口烟气温度furnace outlet gas temperature排烟温度exhaust gas temperature锅炉热效率boiler efficiency保证效率guarantee efficiency燃烧效率combustion efficiency锅炉热损失boiler heat loss排烟热损失heat loss due to exhaust gas气体不完全燃烧热损失heat loss due to unburned gases固体不完全燃烧热损失heat loss due to unburned carbon in refuse散热损失heat loss due to radiation灰渣物理热损失heat loss due to sensible heat in slag飞灰可燃物含量(飞灰含碳量)unburned combustible in flue dust炉渣可燃物含量(炉渣含碳量)unburned combustible in slag漏风系数air leakage factor热风温度hot air temperature一次风(一次空气)primary air二次风(二次空气)secondary air三次风(三次空气)tertiary air炉膛容积热负荷furnace volume heat release rate炉膛截面热强度furnace cross-section heat release rate辐射受热面热流密度(炉壁热流密度)furnace wall heat flux density炉排面积热负荷grate heat release rate炉排通风截面比percentage of air space水动力特性hydrodynamics循环倍率circulation ratio循环水速circulation velocity运动压头available static head有效压头available head质量流速mass velocity质量含汽率steam quality by mass临界含汽率critical steam quality沸腾换热恶化boiling crisis过冷沸腾subcooled boiling计算压力calculated pressure计算壁温calculated metal temperature最高允许工作压力maximum allowable working pressure安全系数safety factor许用应力allowable stress理论计算壁厚theoretical calculated thickness 最小需要壁厚minimum required thickness公称壁厚(名义壁厚)nominal thickness有效壁厚effective thickness应力集中系数stress concentration factor孔桥减弱系数ligament efficiency焊缝减弱系数weld efficiency开孔补强reinforcement of openings表面清理surface cleaning喷丸(砂)处理shot-rain cleaning封头成型head forming冲压成型press forming旋压成型spin forming爆炸成型explosion forming边缘加工edge processing去毛刺deburring卷板plate rolling冷态卷板cold rolling热态卷板hot rolling矫形shape righting矫圆round set板边预弯preliminary rolling弯管tube bending冷态弯管cold bending胀管tube expansion胀管率expansion efficiency成排焊接panel welding成排弯管panel bending不圆度out-of-roundness直线度straightness/alinement偏心度eccentricity管端倾斜度gradient of tube-end通球试验ball passing test锅筒起吊drum lifting砌墙walling烘炉furnace drying煮炉boiling out补炉fetting挖补修理remedy除垢descaling机械除垢mechanical descaling化学清洗chemical cleaning碱煮除垢alkali descaling酸洗除垢acid descaling钝化处理passivating冲管flushing吹管steam-line blowing锅炉改造boiler reforming炉拱改造arch reforming循环系统改造circulation circuit reforming 锅炉启动start-up上水filling水位water level炉内清扫purge点火fire升压raising pressure疏水drain并汽bring a boiler onto the line 启动压力start-up pressure启动流量start-up flow rate滑参数启动variable parameter start-up 排污blowdown定期排污periodic blowdown连续排污continuous blowdown吹灰soot blowing压缩空气吹灰compressed air blowing 蒸汽吹灰steam blowing药物清灰chemical deashing压火banking fire停炉shutdown定压运行constant pressure operation 变压运行variable pressure operation 经济运行economical operation停炉保养preservation湿法保养wet preservation干法保养dry preservation充气保养gas-filled preservation外部检查visual inspection内部检查internal inspection宏观检验macroscopic examination漏风试验air leakage test堵灰clogging常用锅炉专业词汇中英对照序号英文中文1 GENERAL ARRANGEMENT SIDE ELEV A TION 锅炉总图纵剖视2 GENERAL ARRANGEMENT PLAN VIEWS 锅炉总图水平剖视3 GENERAL ARRANGEMENT FRONT ELEV A TION 锅炉总图前视图4 AIR & GAS FLOW SCHEMA TIC DIAGRAM 烟风流程图5 STEAM & WA TER FLOW DIAGRAM 汽水流程图6 AIR & GAS DUCT GENERAL ARRANGEMENT 烟风道布置总图7 WELDMENTS INTERFACE FOR STEAM AND WA TER PIPING 汽水接口尺寸图8 BOILER THERMAL EXPANSION DIAGRAM 锅炉热膨胀系统图9 SUPERHEA TER SYSTEM GENERAL ARRANGEMENT SIDE 过热器总图纵剖视ELEV A TION10 SUPERHEA TER SYSTEM GENERAL ARRANGEMENT PLAN VIEWS 过热器总图水平剖视11 GENERAL ARRANGEMENT OF WA TER WALL 水冷壁总图12 GENERAL ARRANGEMENT OF BACKPASS WALL 包墙布置总图13 GENERAL ARRANGEMENT OF ROOF TUBES 顶棚管总图14 GENERAL ARRANGEMENT OF ECONOMIZER 省煤器总图15 ARRANGEMENT OF STEAM & W A TER CONNECTIONS FOR W A TER COLUMN水位表管路布置图16 ARRANGEMENT OF TOP HEADERS & LINKS 顶部大管道布置图17 METAL TEMPERA TURE MEASUREMENTS LOCA TION DWG 壁温测点布置图18 INSTRUMENT INSERT & MEASUREMENT LOCA TION DWG 仪表测点布置图19 ARRANGEMENT OF MISCELLANEOUS PIPING 杂项管路布置图20 PIPING AND INSTRUMENTA TION DIAGRAM (P&I流程图)介质流程图21 BOILER CIRCULA TION PUMPS DIAGRAM 锅炉循环泵系统图22 STRENGTH CALCULA TION OF BOILER STEAM DRUM 锅筒强度计算书23 STRENGTH CALCULA TION OF BOILER HEADERS PIPING AND TUBING 管子及集箱强度计算书24 O.D : OUTSIDE DIAMETER 外直径25 I .D : INSIDE DIAMETER 内直径26 R : RADIUS 半径27 MINIMUM WALL THICKNESS(MWT) 最小壁厚28 A VERAGE WALL THICKNESS(A WT) 平均壁厚29 MAXIMUM PERMISSIBLE DIAMETER OF OPENING 最大允许开孔直径30 SIZE OF OPENING 开孔尺寸31 TEMPERA TURE COEFFICIENT 温度系数32 MAXIMUM ALLOWABLE STRESS 最大许用应力33 MINIMUM REQUIRED THICKNESS 最小需要壁厚34 ADDITIVE THICKNESS 附加壁厚35 ACTUAL THICKNESS OF SHELL 筒身取用壁厚36 ACTUAL THICKNESS OF PIPE 管子取用壁厚37 HEMISPHERICAL HEAD 球型封头序号英文中文38 FLA T HEAD 平端盖39 LONGITUDINAL PITCH 纵向节距40 CIRCUMFERENTIAL PITCH 环向节距41 DIAGONAL PITCH 斜向节距42 EFFICIENCY OF LIGAMENT 孔桥系数43 EFFICIENCY FOR LONGITUDINAL LIGAMENT 纵向孔桥系数44 EFFICIENCY FOR CIRCUMFERENTIAL LIGAMENT 环向孔桥系数45 EFFICIENCY FOR DIAGONAL LIGAMENT斜向孔桥系数46 EQUIV ALENT LONGITUDINAL EFFICIENCY 当量纵向孔桥系数47 LIMITS OF REINFORCEMENT FOR OPENING 开孔补强范围48 CORRECTION FACTOR FOR PRESSURE STRESS压应力修正系数49 AREA REQUIRED FOR REINFORCEMENT 需要补强面积50 AREA IN EXCESS THICKNESS IN THE SHELL 筒身起加强作用补强面积51 AREA IN EXCESS THICKNESS IN THE NOZZLE 管接头起加强作用补强面积52 ASME CODE SECTION ⅠASME法规第Ⅰ卷53 ASME CODE SECTION Ⅱ,PART D ASME法规第Ⅱ卷D篇54 RULES FOR CONSTRUCTION OF POWER BOILERS 动力锅炉建造规则55 ASME BOILER AND PRESSURE VESSEL CODE ASME锅炉与压力容器法规56 THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS美国机械工程师学会57 COMBUSTION ENGINEERING INCORPORA TION 美国燃烧工程公司58 MITSUBISHI HEA VY INDUSTRIES LIMITED 日本三菱重工业集团59 HARBIN BOILER COMPANY LIMITED 哈尔滨锅炉厂有限责任公司60 MASONEILAN 阀门供货商美国梅索尼兰公司61 DRESSER 阀门供货商美国德莱赛公司62 ANDERSON GREENWOOD 阀门供货商美国安德森格林伍德公司63 CROSBY阀门供货商美国克罗斯比公司64 VELAN阀门供货商加拿大威兰公司65 FISHER阀门供货商美国费舍尔公司66 COPROSIDER 三通供货商意大利考坡罗西得公司67 ALSTOM POWER BOILER GMBH 阿尔斯通公司68 NORTHEAST ELECTRIC POWER DESIGN INSTITUTE 东北电力设计院69 BOILER DESIGN AND DEVELOPMENT DEPARTMENT锅炉设计开发处70 UTILITY BOILER PRESSURE PARTS DESIGN SECTION 电站锅炉受压元件设计室71 CFB BOILER PRESSURE PARTS DESIGN SECTION 流化床锅炉受压元件设计室72 PERFORMANCE DESIGN SECTION 性能设计室73 AIR HEA TER AND DUCT DESIGN SECTION 空气预热器设计室74 STRUCTURAL STEEL DESIGN SECTION 钢架设计室75 STRESS ANALYSIS SECTION 应力分析室76 SECRETARY OFFICE 计划室77 FIRING SYSTEM DESIGN SECTION 燃烧系统设计室78 COMPUTER PROGRAM DESIGN SECTION 计算机程序设计室79 POSTWELD HEA T TREA TMENT 焊后热处理序号英文中文80 CHEMICAL COMPOSITION 化学成分81 MA TERIAL PROPERTIES 材料性能82 MINIMUM TENSILE STRENGTH 最小抗拉强度83 MINIMUM YIELD STRENGTH 最小屈服强度84 MAXIMUM TEMPERA TURE LIMITS(OXIDA TION LIMIT) 最高使用温度(抗氧化温度)85 CREEP RA TE 蠕变数率86 STRESS RUPTURE 断裂应力值87 AUSTENITIC ALLOY STEEL (STAINLESS STEEL ) 奥氏体不锈钢88 FERROUS STEEL 铁素体钢89 COEFFICIENT OF THERMAL EXPANSION 热膨胀系数90 LINEAR THERMAL EXPANSION 线性热膨胀系数91 CONVERSION FACTOR 换算系数92 PERMANENT STRAIN 永久变形93 NP=NOT PERMITTED 不许采用94 FINITE ELEMENT ANALYSES 有限元分析95 ELASTIC DEFORMA TION 弹性变形96 PLASTIC DEFORMA TION 塑性变形97 FURNACE VOLUME 炉膛容积98 FURNACE WIDTH 炉膛宽度99 FURNACE DEPTH 炉膛深度100 MAN HOLE (锅筒)人孔101 TEMPERA TURE PROBE 温度探针102 THERMOCOUPLE 热电偶103 WALL BLOWER 墙式吹灰器104 RETRACTABLE BLOWER 伸缩式吹灰器105 SOOT BLOWING SYSTEM 吹灰系统106 HYDROSTA TIC TEST(HYDRAULIC TEST)水压试验107 HARDNESS TEST 硬度试验108 RADIOGRAPHIC TEST (RT) 射线检查109 MAGNETIC TEST (MT) 磁粉检查110 MA TERIAL PURCHASING REQUISITION 材料申请单111 ACCESS DOOR 检修人孔112 DYE PENETRANT TEST (PT) 着色检查113 ¢:OF BOILER 锅炉中心线114 FW :FIELD WELD工地焊接115 TUBE ENDS SCARFING PER HG04004-98 管端坡口按HG04004-98116 ULTRASONIC INSPECTION (UT) 超声波检查117 DETAIL OF GROOVE 坡口详图118 REDUCER 大小头119 TEE 三通120 ELBOW(锻造) BEND (弯制) 弯头121 SCOPE OF SUPPLY AND TECHNICAL REQUIREMENTS供货范围和技术要求序号英文中文122 CONTRACT NO. 合同号123 A TECHNOLOGY TRANSFER CONTRACT技术转让合同124 BUYER 买方125 SELLER 卖方126 VENDOR 卖主127 SHIPPING MARK 发货标记128 PACKAGE NO. 发货清单号129 CASE NO. 发货件号130 GROSS WEIGHT 毛重131 NET WEIGHT 净重132 KEEP AWAY FROM MOISTURE 防潮133 ETC. 等等134 N.A.=NOT APPLICABLE 不采用135 DITTO 同上136 PACKAGE PER DWG 按图包装137 BUNDLED WITH WIRE & BAR 铁丝捆扎扁钢笼扎138 TWO LABLES FOR ONE PACKAGE 每包两个小标牌139 SUPPLY PER TOTAL LENGTH 按总长供货140 DELIVERY A T A GIVEN LENGTH 分段出厂141 SCALLOPED BAR 梳形板142 HANGER PLA TE 吊挂板143 SUPPORT RACK 撑架144 WOODEN CASE 木箱包装145 HANDLE WITH CARE 小心轻放146 THIS SIDE UP 这侧朝上147 DIMENSIONS (LENGTH ,HEIGHT AND WIDTH ) 尺寸(长、高、宽)148 RECIPIENT 收件人149 CONSIGNEE / RECEIVER 收件人150 REPRESENTA TIVE OF HBC 哈锅代表151 VICE CHIEF ENGINEER 副总师152 DIRECTOR 处长153 SUPERVISOR 室主任/ 组长154 DESIGNED BY 设计155 CHECKED BY校对156 REVIEWED BY审核157 VERIFIED BY审定158 APPROVED BY 批准159 HEADER MANUFACTURING SHALL BE IN ACCORDANCE WITH SPECIFICA TION HG5.2.1.5 集箱制造按技术条件HG5.2.1.5160 TUBE ENDS SCARFING PER 94-0430(Ⅺ) & INNER SCARFING DIAMETER 37mm 管端坡口按94-0430(Ⅺ) 型加工,且内倒角D内=37mm161 CHAMFER 1.5×45°按1.5×45°倒角162 SHOWN 1 OPPOSITE HAND 1 正反各一163 PIECE NO: / MARK NO.件号序号英文中文164 HEA T TREA TMEN TO BE MADE AFTER ALL PARTS WELDED TO THE HEADER 集箱所有零件焊接完毕进行热处理165 RIGHT SIDE SHOWN,LEFT SIDE TO BE SYMMETRICAL 本图仅示出右侧,左侧与之对称166 DIMENSION IN BRACKETS IS THE MIN REQUIRED THICKNESS BY CALCULA TION,IT IS NOT PERMITTED IN ANY CASE THE WALL THICKNESS LESS THAN THIS V ALUE括号内尺寸为理论计算最小壁厚,任何情况下均不得小于该值167 FIN SPLIT TO BE SEAL WELDED AFTER COMPLETING BUTT WELD WITH ADJACENT PANEL A T SITE 管屏在工地对接完工以后,鳍片开缝应焊封168 BIFURCA TE TUBE 分叉管,三叉管169 TUBE ENDS TO BE COA TED WITH VINYL CAPS &COHESIVE TAPE 管子两端均盖以塑料管盖并用胶带密封170 WELDING MA TERIAL 熔焊金属171 QUANTITIES GIVEN ARE FOR ONE BOILER 给出的数量为单台锅炉172 DEVELOPMENT ON OUTSIDE OF SHELL PLA TES筒身按外表面展开图173 MA TCH DRILL 20mm φ HOLES WITH DWG 5541B.142 A T ASSEMBLYΦ20装配时与图5541B.142配钻174 SHARP EDGE IN THE OPENING AREA OF INSIDE SURFACE TO BE GROUND SMOOTHLY IN 2~3mm RADIUS 集箱内表面开孔部位均以R=2~3mm倒圆175 REMOVE ANY BURRS THA T EXIST ON HOLES & WELD SEAM 去除开孔及焊缝的毛刺176 TUBE BUTT WELDING IS NOT PERMITTED WITHIN 250mm FROM ¢OF BUCKSTAY 刚性梁中心线上下250mm以内不准有拼接焊缝177 SHOWN AND OPPOSITE HAND TO BE MADE PER DRA WING 按本图制造正反178 BENDING RADIUS 120mm 弯曲半径120mm179 CUTTING AND SEAL WELDING A T SITE 工地切割焊封180 CHROMIUM 元素Cr181 MOLYBDENUM 元素Mo182 V ANADIUM 元素V183 TITANIUM 元素Ti184 BORON 元素B185 MANGANESE 元素Mn186 CARBON 元素C187 TUNGSTEN 元素W188 NICKLE 元素Ni189 STEEL BILLET 钢坯190 COMPENSA TION CALCULA TION FOR MULTIPLE OPENINGS孔桥补强计算191 THE RADIUS ON OUTSIDE OF THE TEE A T THE JUNCTION OF BRANCH AND RUN SHALL BE EQUAL TO OR GREA TER THAN 120mm 三通外侧主管与支管交接处R应≥120mm 192 THE MIN THICKNESS OF AN UNPIERCED SHELL OF TEE 不开孔三通最小壁厚序号英文中文193 TUBE ENDS SCARFING FOR FIELD WELDING SEE DWG YT15-199,TYPE Ⅱ,D1=4940-0.5,tT=58,F=25 工地焊接坡口按YT15-199Ⅱ型,D1=4940-0.5,tT=58,F=25194 STRENGTH OF THE FILLET WELD IN TENSION 焊缝抗拉强度195 STRENGTH OF THE FILLET WELD IN SHEAR 焊缝抗剪强度196 THE WELD TO BE GROUND SMOOTHLY IN R120mm该焊缝以R120mm打磨光滑。