伟创电气BU20制动单元使用说明书

- 格式:pdf

- 大小:15.16 MB

- 文档页数:15

电气操作说明书安装和使用本设备时,请详细阅读说明书,熟悉电气线路及各按钮的功能。

线路图参见附图。

1 安装说明:本设备的电源为380V三相5线制(包括火线、零线和地线),整机额定功率为48KW,接入电源线要求不低于10mm2,最好用16 mm2,务必将火线L1/L2/L3接到380V主电源空气开关上,零线接到零线位置上,地线接到地线排上,工厂应在接入电源侧安装额定电流100A以上的漏电保护断路器,加强用电安全。

2 参数设定:根据用户需要,水温最高不超过55°,实际设定值建议为50-55°。

当水温温度低于设定值时,在水位处于“满水”和开启加热的情况下,系统加热启动,在达到设定值时,停止加热,当水温低于设定值3°时,再次加热,如此循环。

当设定温度为50°时,如当前水温为48°或者高于47°时,启动加热后,系统不会立即加热,要等到水温低于设定值3度(也即37°)时,才会加热。

当水箱水位处于低位时,为保护水泵和加热管,系统将自动停止水泵和加热,请注意保持水箱的水位。

磕蛋和清洗频率的设定,磕蛋频率最高为35HZ,清洗频率最高为18HZ,用户可根据使用情况,调整参数。

磕蛋和清洗状态相互切换。

用户设定的设备参数,在设备通电状态下,可以持续保存和使用,在设备完全断电的情况下,PLC的保存期为4-5天,超过时间后,数据会丢失,在数据丢失后,系统将使用默认的开机参数,每次开机前请注意核对开机参数,及时调整到工厂需要的设定值。

系统默认值为水温50°,磕蛋频率为25HZ,清洗频率为15HZ。

水温设定的范围是最高55°,磕蛋频率的最高设定值为35,清洗频率的最高设定值为18。

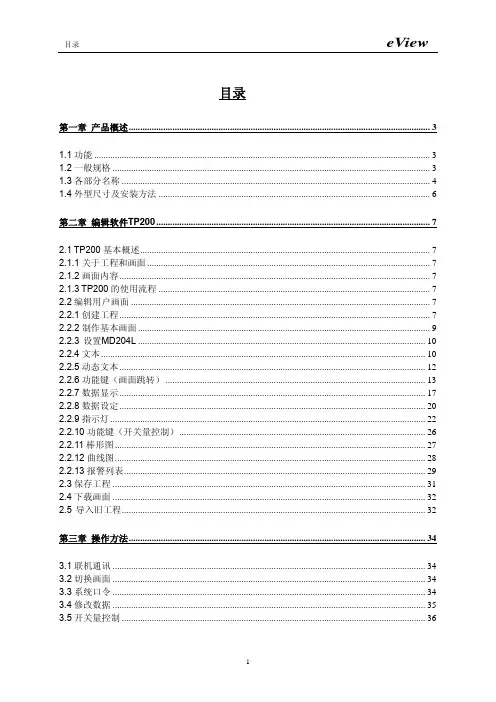

3 页面设置:开机进入“首页”画面如下:点击:“进入”,进入选择画面。

在此页可以选择“首页”、“流程”、“参数”、“操作”画面。

“流程”画面如下:在“流程”画面中,没有需要操作的项目,显示整个设备的基本模型,有三个指示灯,分别是“Estop”(急停),“Water”(指清洗水箱的水位),“Full”(水位在满水状态),“Empty”(水位在低水状态)。

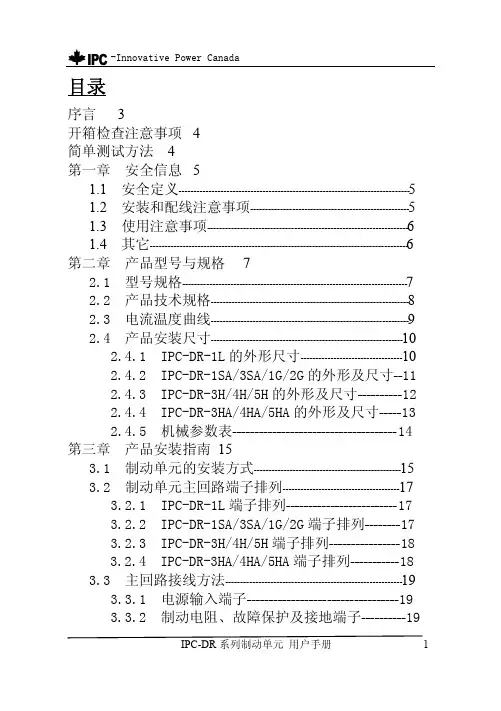

IPC-DR 系列制动单元用户手册1目录序言3开箱检查注意事项4简单测试方法4第一章安全信息51.1安全定义-----------------------------------------------------------------------------51.2安装和配线注意事项-----------------------------------------------------51.3使用注意事项-------------------------------------------------------------------61.4其它--------------------------------------------------------------------------------------6第二章产品型号与规格72.1型号规格---------------------------------------------------------------------------72.2产品技术规格------------------------------------------------------------------82.3电流温度曲线------------------------------------------------------------------92.4产品安装尺寸----------------------------------------------------------------102.4.1IPC-DR-1L 的外形尺寸----------------------------------102.4.2IPC-DR-1SA/3SA/1G/2G 的外形及尺寸--112.4.3IPC-DR-3H/4H/5H 的外形及尺寸----------122.4.4IPC-DR-3HA/4HA/5HA 的外形及尺寸-----132.4.5机械参数表-------------------------------------14第三章产品安装指南153.1制动单元的安装方式-------------------------------------------------153.2制动单元主回路端子排列---------------------------------------173.2.1IPC-DR-1L 端子排列-------------------------173.2.2IPC-DR-1SA/3SA/1G/2G 端子排列--------173.2.3IPC-DR-3H/4H/5H 端子排列----------------183.2.4IPC-DR-3HA/4HA/5HA 端子排列-----------183.3主回路接线方法-----------------------------------------------------------193.3.1电源输入端子----------------------------------193.3.2制动电阻、故障保护及接地端子----------192IPC-DR 系列制动单元用户手册3.3.3辅助电源端子----------------------------------193.3.4变频器的直流母线端子的辩认------------203.4主回路接线规格---------------------------------------22第四章操作面板说明234.1操作面板示意图------------------------------------------------------------234.2状态指示区---------------------------------------------------------------------234.3数据显示区说明---------------------------------------244.4按钮说明-------------------------------------------------254.5并联插座与主从模式的切换-----------------------25第五章制动单元的选型275.1一般性负载快速选型--------------------------------------------------275.2周期性制动负载的选型---------------------------------------------29第六章常见故障的排除31第七章质量保证32IPC-DR 系列制动单元用户手册3序言感谢您购买和使用加能公司生产的IPC-DR 系列能耗制动单元。

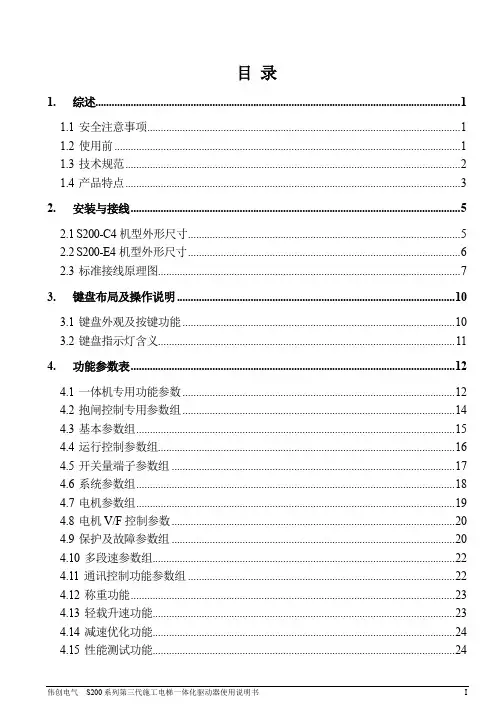

目录1.综述 (1)1.1安全注意事项 (1)1.2使用前 (1)1.3技术规范 (2)1.4产品特点 (3)2.安装与接线 (5)2.1S200-C4机型外形尺寸 (5)2.2S200-E4机型外形尺寸 (6)2.3标准接线原理图 (7)3.键盘布局及操作说明 (10)3.1键盘外观及按键功能 (10)3.2键盘指示灯含义 (11)4.功能参数表 (12)4.1一体机专用功能参数 (12)4.2抱闸控制专用参数组 (14)4.3基本参数组 (15)4.4运行控制参数组 (16)4.5开关量端子参数组 (17)4.6系统参数组 (18)4.7电机参数组 (19)4.8电机V/F控制参数 (20)4.9保护及故障参数组 (20)4.10多段速参数组 (22)4.11通讯控制功能参数组 (22)4.12称重功能 (23)4.13轻载升速功能 (23)4.14减速优化功能 (24)4.15性能测试功能 (24)伟创电气S200系列第三代施工电梯一体化驱动器使用说明书I4.16监控代码 (24)5.故障诊断与对策 (27)5.1故障类型 (27)5.2故障、预警信息及详细内容 (27)6.配件推荐选型 (30)6.1制动电阻 (30)6.2操作台规格尺寸 (31)6.3销轴传感器 (32)6.4笼顶操作盒&坠落测试盒 (33)6.5编码器选型及安装指导 (34)7.定期检查与维护 (35)7.1检查 (35)7.2维护 (36)8.品质保证 (37)8.1保证期限与范围 (37)8.2责任免除 (37)8.3产品适用范围 (37)附录一:操作说明 (38)附录二:升降机常见故障及对策 (39)II 伟创电气S200系列第四代施工电梯一体化驱动器使用说明书伟创电气 S200系列第四代施工电梯一体化驱动器使用说明书 11综述1. 综述1.1 安全注意事项为保证安全、合理的使用本产品,请在完全理解本手册所述的安全注意事项后再使用该产品。

第一章 安全及注意事项为了确保您的人身、设备及财产安全,在使用变频器之前,请务必认真阅读本章内容。

并在搬运、安装、调试、运行及检修过程中遵照执行。

1.1 安全定义危险:如果不按要求操作,会引起危险发生,可能导致人身严重损害或死亡。

注意:如果不按要求操作,会引起危险发生,可能导致人身轻度或中度伤害或设备损坏。

提示:表示一些对操作和使用有用的信息。

1.2安全注意事项危险1.只有训练有素的人员允许操作本装置,使用前请务必详细阅读本说明书中有关安全、安装、操作和维护部分。

本设备的安全运行取决于正确的选型、运输、安装、操作和维护。

危险1.接线前,请确认输入电源已切断,否则有触电危险。

2.应由专业电气工程人员施工配线,否则有触电危险。

3.请按标准要求正确接地,否则有触电危险。

4.绝不可将交流电源接至变频器输出端子U、V、W,否则会引起变频器损坏。

5.不要将螺钉、垫片及金属棒、导线之类的异物掉进变频器内部,否则有引起火灾及变频器损坏的危险。

危险1.在接通电源后,不可打开外罩,不可实施配线,检查等作业,否则可能引起触电危险。

2.本装置在通电后,请勿接触内部线路板及其元器件, 否则可能引起触电危险。

3.不要用湿手操作和触摸变频器,否则可能引起触电危险和变频器损坏。

注意1.请勿以拉闸方式(断电)停机,等电机运行停止后才可断开变频器电源,否则可能造成变频器损坏。

2.变频器使用中避免有异物掉入设备中,否则可能造成变频器损坏。

第二章 购入检查及产品技术指标2.1 购入检查1.开箱前请检查产品的包装是否因运输不慎而造成损伤。

2.产品的规格、型号是否与所订购机种相符。

3.AC20系列变频器在出厂之前均已经过严格的测试和品质检验。

请检查有无合格证、产品使用说明手册及保修卡。

4.检查机器内部是否有任何损坏。

如有明显损坏,请不要操作和使用机器,并及时联络本公司或经销厂商,以免造成事故。

1.铭牌说明输出电源规格变频器型号输入电源规格生产控制序号2. 型号说明变频器系列A C 20 - S 2 - R 75代号电压等级2220V 3380V代号电压等级T 三相S 单相代号R 40R 751R 52R 23R 7A C 20迷你型0.4k W 0.75k W 适配电机功率(k W )1.5k W2.2k W3.7k W第三章 安装3.1 安装环境要求1.环境温度-10℃—40℃,通风良好或有换气装置的室内场所,超过40℃以上需降额使用。

MOTORR/L1S/L2T/L3U V WIMSymbol for groundingBraking resistorCircuit breaker for wiring(MCCB)T erminal block for main circuitPower sourceMotorFunctions of Terminals for Main CircuitIMCircuit breaker for wiring(MCCB)MotorBraking resistorL1L2P/DB+N-DB-U V W3-phase 400V type 0.75 to 15kWSpecification of potentiometer for frequency setting:select a potentiometer of “10 kΩ, 1/4 W or higher” rating. Relay output specification:1c contact (contact capacity 230V AC, 0.3A; 30V DC 0.3A resistive load).Open-collector Output specification: max. rating 50 VDC/50 mA.Please refer to the User Manual for the SOURCE status terminal arrangement diagram and the functions of various terminals.Terminal No.Terminal NameExplanation of terminal functionR/L1,S/L2,T/L3U,V,W P/DB+,DB-N-×2Power supply for Main circuit Inverter outputBraking resistor connection Internal DC voltage (negative)GroundFor 1-phase 200 V type, connect to terminal L1 and L2.Connect to 3-phase motor.Connect to braking resistor.Negative terminal of internal DC voltage.Ground terminal.1-phase 200 V: ground resistance 100Ω or less 3-phase 400 V: ground resistance 10Ω or less Ground the neutral of power source.VF200 SERIESPanasonic Industrial Devices SUNX Suzhou Co., Ltd.No.97, Huoju Road, New District Suzhou, Jiangsu province, ChinaSINKSOURCESW1SW2SW3SW4SW5NONC COMRelay output(TR1、TR2)Specifications are subject to change without notice.Please contact...........Simple Vector Control InverterHigh-efficiency Operation, Outstanding PerformanceCommon terminalsCommon terminalsAnalog output (Note)4 to 20mA 0 to 20mA 4 to 20mA0 to 20mA4 to 20mA 0 to 20mA(Note)(Note)RS485communication terminal(0 to 10V)0 to 5V 0 to 10V0 to 5V 0 to 10VRun /Stop Forward /ReverseNote) a built-in 200 Ω resistor should be set between terminal No.24 and a common terminal. If analog input signal of 4 to 20mA/0 to 20mA is used, external resistor connection can be eliminated by connecting terminal No.24 to No.14 or No.16. For external connection, it is recommended to use a resistor of 200 Ω, 1/4 W.All Rights Reserved Panasonic Industrial Devices SUNX Suzhou Co., Ltd. 2013■Telephone: +81-512-6843-2580 ■Facsimile: +81-512-6843-2590■No.97.Huoju Road, New District Suzhou, Jiangsu province, China P.R.215009Panasonic Industrial Devices SUNX Suzhou Co., Ltd.PowerfulTurntableInjection moldingmachineCopy parameters Operation panelcan be prolongedUse vector control to output higher torqueat low-speedNetworkEquip with standard RS485 SerialCommunication InterfaceCorresponding Functions forWire Winding MachinesToughIncorporate with Output Short-CircuitProtection CircuitsEquip with High-speed CurrentLimiting Protection function EasyApply large-scale operation panelto further improve the operabilityDetachable operation panelControl PanelComputerRS485 (Max. 500m)New Operation ModeDuring ONThe winding mode control function operates at the frequencies of atriangle wave as shown below.Repeated operation around the Winding SpindleSpinnerApply to most textile equipmentsin which inverters are used.During OFFVF200VF200VF200VF200CopyCopy11 kW(400V)15 kW(400V)5.5 kW(400V)7.5 kW(400V)2.2 kW(200V)2.2 kW(400V)3.7 kW(400V)0.2 kW(200V)0.4 kW(200V)0.75 kW(200V)1.5 kW(200V)0.75 kW(400V)1.5 kW(400V)Higher torque can be generated at low-medium speed (1Hz→150%) bymaking use of our Company’s original vector control technology. Equipmentswith great fluctuation in loads and requiring a sufficient starting torque, forexample conveyor belts and turntables on which there are large numbersof semi-finished products, can be operate smoothly. In addition, the vectorcontrol technology also plays a significant role in the operation of the cannedfoods caulking machines, punching machines, injection molding machines,as well as other machines that require low-speed torque. Inverter with highercapacity is not needed in this case, which contributes greatly to the reductionof cost and installation space.It is also equipped with auto-tuning function which can conduct simple andappropriate parameter settings thus giving a full play to the motor characteristic.Highly visible 7-segment large format display;Ease-to-use large volume knob;Easy recognizable operation key.Parameter can be easily copy to another unit.Have a dimension of 72mm×72mm, it is attractive even if it is mounted on the panel surface.Standard LAN cables (max. 5m), which can be bought easily from the market,are used to realize the connection between the operation panel andthe host. It has the characteristics of ease purchase and affordable price.31 unitsCan control up to 31 VF200 units via the RS485 serial communicationlines. VF200 is also installed with two protocols : Modbus-RTU andMEWTOCOL, that allow control, data collection/monitoring viacomputer or PLCs.The FP series PLCs produced by our Company support both Modbus-RTU and MEWTOCOL.Which can be connected directly to the touchscreen GT series to provide you with a convenientoperating environment. For example, you mayconduct various operations such as monitoring,setting and operation via the screen.·Random swing mode: can effectively prevent the accumulation ofwires at the same point·Winding Wire Length Stop Mode: it will automatically stop after thelength of the winding wire had accumulated to the specified value.·Pulse Input Controlled length Calculation Mode: easily indicate theaccumulated length of the winding wire, and the results can be transmitted.·Two-point Mode: the reference frequency can be ultimately changed toa secondary frequency with the smooth running of the winding wire.With built-in short-circuit protectioncircuitsFaultshort-circuitVF200 can detect an over-current resulting from a short circuit dueto a fault in the electric motor as a result of over-load, in this case,it will instantaneously disconnect the output to protect the circuit,therefore, you can rest assured that it is safe.VF200 will not trip and keep operating even if instantaneous over-current is caused by a change in loads, thus improve the productivity.It is also applicable to the rapid increase in the speed of a heavyturntable and the stirring of materials with a higher viscosity such asbread and noodles.TripOutput CurrentOutput Frequency Output FrequencyOutput CurrentUpperPeak ValueSettingFrequencyLowerPeak ValueStar/StopRandom ModeCommon ModeRandomly swing within thespecified rangeWastewater beingdischargedfrom canteenkitchensFlowmeter ①Filter Flowmeter ②4-20mAAnalog input4-20mAAnalog inputControl panelWater used forindustrial useControl terminals(①-③)0-10VAnalog outputFP-XAFPX-C30T AFPX-A21Main body Operation PanelUnit: mm3-phase 400 V input typeNote) The cooling fan is not mounted on 0.75 kW model.※Please process the mounting platebased on the dimensions of the panelcut-out.The appropriate thickness of the platePanel Cut-outDimensions ofPanel Cut-out (A View)1-phase 200 V input type Unit: mmNote) Cooling fan is not mounted on 0.2 kW~0.75 kW model.0.2, 0.4kW100 112 130 143 120 52.2kW130 143 130 143 5160InvertercapacityW1W H1H D Φd0.75, 1.5kW 100 112 130 143 51500.75, 1.5kW2.2,3.7kW5.5, 7.5kW11, 15kWInvertercapacityW1W H1H DΦd5557100130150112163143130130190143143203150150179179204 223 2652831-phase, 200 to 230V AC (proportional to power supply voltage)1-phase, 200 to 230V AC, 50/60 Hz±5% of rated input frequency0.2 to 2.2kW150% of rated output current for 1 minute+10% and –15% of rated input AC voltageOperation continues when voltage is above 165V AC.Operation continues for 15 ms when voltage drops below 165V AC.3-phase, 380 to 460V AC (proportional to power supply voltage)3-phase, 380 to 460V AC, 50/60 Hz±5% of rated input frequency0.75 to 15kW150% of rated output current for 1 minute+10% and –15% of rated input AC voltageOperation continues when voltage is above 323V AC.Operation continues for 15 ms when voltage drops below 323V AC.Rated VoltageNumber of phases,voltage and frequencyAllowable frequency fluctuationStandard output of applicablemotor (kW)Over-load Current RatingAllowable voltage fluctuationInstantaneous voltagedrop ride-through capabilityInputpowersupplyInputpowersupplyRated VoltageNumber of phases,voltage and frequencyAllowable frequency fluctuationStandard output of applicablemotor (kW)Over-load Current RatingAllowable voltage fluctuationInstantaneous voltagedrop ride-through capabilityRatedOutputRatedOutputNote 5: the AVF200-REM1 operation panel is applicable to both the 200V and 400V types.Composition of PLC5SpecificationsUse the small-sized PLC [FP-X] and VF200of Our Company to control the tank pump pressureDecompositiontankSetting tank Storage tankControl unit C30TAnalog I/O card(Mounting holes)(Mounting holes)Unit: mmUnit: mmC o n t r o lPID function Automatic tuningSlip compensation control Cooling fan ON/OFF controlCommunication functionB r a k i n gRegenerative braking torque DC braking O u t p u t s i g n a lAnalog outputOpen-collector outputRelay outputD i s p l a yOperation/control statusDetails of abnormality P r o t e c t i o nCurrent limit Trip (stop)Stall prevention functionE n v i r o n m e n tAmbient temperature and humidity Storage temperature and humidity Vibration Altitude LocationEnclosure Cooling methodNote 1: it is -10 to +40°C when multiple inverters are installed side-by-side.Frequency range Frequency display Frequency accuracy Frequency resolutionInverter control mode Carrier frequencyO p e r a t i o nStart/StopForward/Reverse run JOG operation Stop mode Reset function Start frequency Stop frequencyRide-through restart select Speed search Retry functionC o n t r o lFrequency setting signalFrequency/voltage characteristics Torque boostAcceleration/deceleration timeAcceleration/deceleration characteristics The 2nd function select Multi-speed frequency settingSkip frequency setting Upper frequency limit setting Lower frequency limit settingO u t p u t F r e q u e n c ySeries name: VF200Applicable motor capacity:002 :0.2 kW004 :0.4 kW 007 :0.75 kW 015 :1.5 kW022 :2.2 kW 037 :3.7 kW Voltage class: Panel type:12341-phase 200V type: 0.2 to 2.2kW; 3-phase 400V type: 0.75 to 15 kW055 :5.5 kW075 :7.5 kW 110 :11 kW150 :15 kW A VF200 007 2 □12342 for 1-phase 200 V type; 4 for 3-phase 400V typewithout marks: operation panelP: simple panelProduct Ordering SystemBias/gain frequency setting External stop function Automatic tuning of motor constant Available Available·Protocols : MEWTOCOL-COM/Modbus (RTU) (switchable)·Communication pattern: Half duplex Output functions: operation signal, arrival signal, overload alarm, frequency detection, abnormal reverse run signal Output functions: operation signal, arrival signal, overload alarm, frequency detection, Output voltage, internal DC voltage, setting frequency, communication station No., operation(setting value, measured value and output value), progress of automatic tuning, accumulative operation time and accumulative operation time of fanOvercurrent and overvoltage stall preventionIndoor areas free of corrosive gases, flammable gases, oil mist or dust PID control mode (optional)·Interface : RS485 serial communication·Communication speeds : 4800/9600/19200/38400 bps (switchable)·Maximum number of connected units: 31·Maximum transmission distance: 500 m (in total)·200 V 0.2 kW: 100% or higher; 0.4 kW: 80% or higher; 0.75 to 2.2 kW: 20% or higher ·400 V 0.75 to 15 kW: 20% or higher Operate at the frequency below stop frequency ·Braking torque level: 0 to 100 (20 steps adjustable)·Braking time: adjustable from 0.1 to 120 sOutput specification: 0 to 10V DC (max. 1 mA)Output function: output frequency and output current proportion (switchable)Output specification: max. rating 50V DC/50 mAalarm, current detection, timer OFF signal and output frequency/current proportion PWM signal (cycle: 1 ms) (switchable)Output specification: 1c contact (contact capacity 230 VAC, 0.3 A resistive load)abnormal reverse run signal alarm, current detection and timer OFF signal (switchable)Output frequency, linear speed display (switchable) and rotation directiontimes of timer, alarm type, control circuit terminal status (I/O signal), operation status, PID Specific symbol is indicated when the protection function is activated (the latest four abnormalities are stored.)Current limit can be set within 1 to 200% of rated output current.Instantaneous overcurrent (SC1-6) and abnormal temperature (OH)Overcurrent (OC1-3), overload and electronic thermal relay (OL), undervoltage (LU),overvoltage (OU1-3), cooling fan fault (FAN), external fault (AU), operation fault (OP) and CPU fault (CPU)-10 to +50°C (Note 1) (without freezing) and below 90%RH (without condensation)-25 to +65°C and below 95%RH 5.9m/s 2 (0.6G) or lower 1000m or lowerIP20 cabinet-mounted·400 V 0.75 kW: self-cooling; 1.5 to 15 kW: air-cooling·200 V 0.2 to 0.75 kW: self-cooling; 1.5 to 2.2 kW: air-cooling Bias frequency: adjustable from -99 to 250%Gain frequency: adjustable from 0 to 500%External fault stop/coast-to-stop (switchable)·Volume (10 kΩ, 1/4 W or higher)·0 to 5 V DC 、0 to 10 V DC·4 to 20 mA, 0 to 20 mA (An external resistor of 200 Ω/1/4 W or higher is connected.)·PWM signal (cycle: 0.9 to 1100 ms)·Frequency rise SW/reduction SW/storage SW signalDigital displayAnalog setting: within ±0.5% of maximum setting frequency (25°C±10°C)Digital setting: within ±0.01% of maximum setting frequency (-10°C to +50°C)Digital setting: 0.1 HzAnalog setting: 0.1 Hz (in 50/60 Hz mode)High carrier frequency sinusoidal PWM control (V/F control or simple vector control is available.)·V/F control setting: 7 options can be selected (adjustable from 0.8 to 10 kHz).·Simple vector control setting: 4 options can be selected (adjustable from 2.5 to 10 kHz).(0.8,1.1,1.6,2.5,5.0,7.5,10.0kHz)·1a contact signal and 3-wire input (1a and 1b contact signals) can be selected.·Operation panel buttons·RS485 communication·Operation panel buttons·1a contact signal (reverse run can be disabled.)·RS485 communication·Wait time (0.1 to 100 s) can be set.Operation frequency: adjustable from 0.5 to 400 Hz; acceleration/deceleration time: adjustable from 0.04 to 3600sRamp-to-stop / coast-to-stop (switchable)Stop signal reset/external reset/panel reset (optional) / power supply reset Adjustable from 0.5 to 60 Hz Adjustable from 0.5 to 60 Hz0 Hz restart/operation frequency restart/speed search restart (switchable)Speed search Operation during startup (optional)Retry select: validity of function, details of retry faults Retry times: adjustable from 1 to 10 timesPanel setting (operation panel): volume and digital setting Analog setting signal input from external control :Digital setting signal input from external control:Communication setting: RS485 communicationBase frequency: fixed at 50/60 Hz, adjustable from 45 to 400 Hz In 3-point V/F mode: adjustable voltage and frequency V/F curve: constant/square torque mode (switchable)Adjustable from 0 to 40%/auto torque boost (switchable)0.04 to 3600 s (independent acceleration/deceleration setting)Linear and S-shaped acceleration/deceleration (switchable)The 2nd function select (acceleration/deceleration time, torque boost, V/F characteristics (base frequency/3-point V/F mode), electronic thermal and analog frequency setting)·Multi-speed operation: up to 16 speed settings (No limitation to frequency setting)·Timer operation: up to 8 speed settings (No limitation to frequency setting)·Pulse input operation: up to 8 speed settings (No limitation to frequency setting)It can be linked with acceleration/ deceleration time.Up to 3 settings (skip frequency band adjustable from 1 to 10 Hz)Adjustable from 0.5 to 400 Hz Adjustable from 0.5 to 400 Hz0.5 to 400Hz SpecificationsSpecifications。

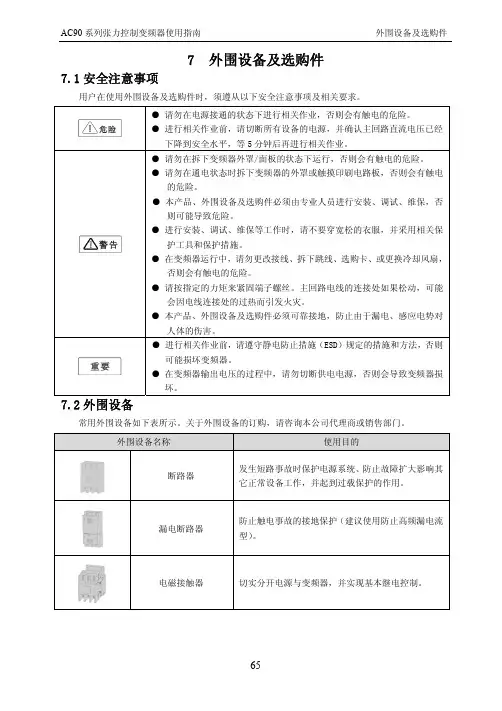

7 外围设备及选购件7.1安全注意事项用户在使用外围设备及选购件时,须遵从以下安全注意事项及相关要求。

● 请勿在电源接通的状态下进行相关作业,否则会有触电的危险。

● 进行相关作业前,请切断所有设备的电源,并确认主回路直流电压已经下降到安全水平,等5分钟后再进行相关作业。

● 请勿在拆下变频器外罩/面板的状态下运行,否则会有触电的危险。

● 请勿在通电状态时拆下变频器的外罩或触摸印刷电路板,否则会有触电的危险。

● 本产品、外围设备及选购件必须由专业人员进行安装、调试、维保,否则可能导致危险。

● 进行安装、调试、维保等工作时,请不要穿宽松的衣服,并采用相关保护工具和保护措施。

● 在变频器运行中,请勿更改接线、拆下跳线、选购卡、或更换冷却风扇,否则会有触电的危险。

● 请按指定的力矩来紧固端子螺丝。

主回路电线的连接处如果松动,可能会因电线连接处的过热而引发火灾。

● 本产品、外围设备及选购件必须可靠接地,防止由于漏电、感应电势对人体的伤害。

● 进行相关作业前,请遵守静电防止措施(ESD)规定的措施和方法,否则可能损坏变频器。

● 在变频器输出电压的过程中,请勿切断供电电源,否则会导致变频器损坏。

7.2外围设备 常用外围设备如下表所示。

关于外围设备的订购,请咨询本公司代理商或销售部门。

外围设备名称 使用目的断路器发生短路事故时保护电源系统、防止故障扩大影响其它正常设备工作,并起到过载保护的作用。

漏电断路器 防止触电事故的接地保护(建议使用防止高频漏电流型)。

电磁接触器 切实分开电源与变频器,并实现基本继电控制。

交流输入电抗器提高电源侧功率因数,隔离电源侧噪声信号对变频器的干扰。

直流电抗器 抑制高次谐波,改善电源功率因数。

输入侧噪音滤波器降低变频器对电源的干扰,同时有效降低来自电网的干扰。

制动电阻器 电气制动的被动能量消耗单元。

能耗制动单元电气制动控制单元,用于控制制动电阻器有效消耗电机的再生电能。

输出侧噪音滤波器 降低变频器输出侧电线的电磁干扰。

3.3 基本操作面板(BOP 20)控制电机BOP20(Basic Operator Panel 20)是一个带有背景灯显示和6个按键的基本操作面板。

BOP20可以直接安装在SINAMICS S120的控制单元(CU310 或CU320,固件版本2.4或以上)上进行操作。

3.3.1 BOP 20概述使用BOP20可以在调试的过程中实现对SINAMICS S120实现以下功能:•改变驱动对象,启动或停止驱动轴•实现参数的修改和显示•显示故障信息并复位故障在一个应用简单并使用SINAMICS S120的场合,使用BOP20是一个经济有效的选择。

图3.7 BOP20面板1. BOP20的LED 显示状态如下表所示:表3.2 BOP的LED显示状态2. BOP20的按键信息如下表所示:运行表3.3 BOP的按键信息3. BOP20的功能如下表所示:表3.4 BOP的功能表4. BOP20的相关参数:•对于控制单元➢r0000 BOP20运行显示➢p0003 BOP20访问等级➢p0004 BOP20参数显示过滤➢p0007 BOP20背景灯设置➢p0008 BOP20传动对象选择➢p0009 设备调试,参数过滤➢p0011 BOP20密码输入➢p0012 BOP20密码确认➢r0019 BOP20控制字➢p0977 保存所有参数•对于所有驱动对象➢p0005 BOP20运行显示选择➢p0006 BOP20运行显示模式➢p0013 BOP20用户定义参数➢p0971 保存传动对象参数•对于所有控制单元(如:servo,vector,infeed,TM31)➢p0010 调试参数过滤此外,通过BOP20实现的重要功能有:•工厂复位通过设置控制单元CU上的参数完成工厂复位➢p0009 = 30➢p0976 = 1•Copy RAM to ROM在CU上可以初始化所有参数,并保存在非易失性内存中(CF卡)➢按住P键3秒或➢p0009 = 0➢p0977 = 1•LED识别驱动器对象的主要组成部分(如,电机模块)可以通过参数p0124指数来识别。

伟创变频器AC20说明书AC20 变频器说明书1.引言1.1 目的本文档旨在向用户提供对伟创变频器AC20的详细了解,并指导用户正确、安全地使用该产品。

1.2 背景AC20 变频器是伟创公司最新推出的高性能变频器,具有广泛的应用领域,包括工业自动化、机械设备、电力系统等。

1.3 目标读者本文档面向伟创变频器AC20的最终用户、安装维护人员以及相关技术人员。

2.产品概述2.1 产品特点伟创变频器AC20采用先进的变频控制技术,具有以下特点: - 高效节能:采用先进的PWM调制技术,能够实现高效能量转换,降低系统能耗。

- 高性能:具有高响应速度、精确控制和可靠性,适用于多种工业应用。

- 多功能:支持多种控制模式、多种输入输出接口,可满足不同应用的需求。

- 易操作:具有友好的人机界面和简便的操作方式,方便用户操作和调试。

2.2 技术参数伟创变频器AC20的主要技术参数如下:- 电源电压: AC220V/380V/440V- 控制方式: V/F控制、矢量控制等- 额定电流: 根据型号不同,范围为0.5A-1000A- 额定功率: 根据型号不同,范围为0.4KW-1000KW- 工作温度范围: -10℃-40℃- 本体重量: 根据型号不同,范围为2kg-100kg3.安装与调试3.1 安装要求在安装伟创变频器AC20之前,请确保满足以下要求:- 电源电压稳定,接地条件良好。

- 安装位置通风良好,避免阳光直射。

- 安装位置无振动、无异物,且远离腐蚀性气体、蒸汽和灰尘等。

3.2 连接与接线安装伟创变频器AC20时,请按以下步骤进行连接与接线:1.将变频器与电源连接;2.将变频器与电机连接;3.根据实际需求,连接控制信号线;4.检查接线是否牢固、正确。

3.3 参数设置与调试安装完成后,需对伟创变频器AC20进行参数设置与调试。

具体步骤如下:1.打开变频器的电源,并按照说明书上的指引进行参数设置;2.进行基本的运行测试,检查各功能是否正常;3.根据实际需求,对控制参数进行调整;4.完成参数设置和调试后,保存参数设置。

制动单元DBU-1030/4045/4200用户手册1.综述DBU系列制动单元的作用是将马达在减速的过程中产生的再生能量,以热能的形式消耗在制动电阻上,从而改善变频器的制动性能及缩短变频器的制动时间。

在使用DBU系列制动单元之前,请仔细阅读本说明,如有疑问,请与我公司联系。

本说明对你的日常维护,维修;故障检测,检修提供了有力的帮助。

1.1购入检查所有制动单元在出厂前,均经过严格仔细的检验,测试;在你开箱验收时,请确认如下事项.如有异常,请与我公司业务部联系.。

检查项目检查方法与订购的产品是否一致? 查看CDBR的型号.所收物品是否有损伤? 查看整体外观,检查制动单元是否在运输中损伤1.2 制动单元型号说明1.3 DBU 系列制动单元技术条件ED :表示制动率在一个制动周期为120sS 时,制动时间所占比率.如下图可表示为ED=t1/t2=10%.t表1.41为ED=10%时的配置表,普通机械、10层一下电梯、起重机大小车选用。

AC200V~AC300V AC380V~AC460V 制动单元型号-DBU 2015 2022 2030 4030 4045 4220 4300 峰值电流(A) 50 75 90 50 75 300 500 额定电流(A) 15 25 30 15 25 85120配线 mm 24-64-66-84-64-616-36 25-50制动起始电压(V) 380V ±5VDC630/DC660/DC690/DC730/DC760V ±10V 最大回滞误差 约8V约16V 输入输出特性同步信号可多台并机,推鉴不超过3台。

电源 直流母线电压DC 243-400V DC 460~800V散热器过热 温度开关+85℃保护故障输出 RELAY 接点0.6A125V AC/2A30VDC(Ta,Tb,Tc) 外接电源R,S 端子4220、4300两款需外接380V AC 电源于R,S 端子,有外接电源时,红色POWER 指示灯亮散热风机工作条件 制动单元,能量吸收电阻板温升超过+45℃时风机工作,低于+45℃风机停止工作电源指示PCB 上直流母线输入端子有电压(大于50V )输入,红色上电“POWER ”指示灯亮指示功能运行指示制动单元工作时,绿色“BRAKING ”指示灯亮 环境温度 -10℃~+40℃(无冰冻) 存储温度 -10℃~+50℃ 湿度 90%RH(无凝霜)环境条件振动10~20HZ 为1G, 20~50HZ 可达0.2G 机械构造壁挂式IP20变频器功率KW 制动单元型号 制动单 元 数 量 电阻配置 电阻数量 制动转矩 (10%ED) 0.4 DBU-4015 1 70W 750Ω 1230 0.75 DBU-4015 1 70W 750Ω 1 130 1.5 DBU-4015 1 260W 400Ω 1 125 2.2 DBU-4015 1 260W 250Ω 1 135 3.7 DBU-4015 1 390W 150Ω 1 135 5.5 DBU-4015 1 520W 100Ω 1 135 7.5 DBU-4015 1 780W 75Ω 1 130 11 DBU-4015 1 1040W 50Ω 1 135 15 DBU-4015 1 1560W 40Ω 1 125 18.5 DBU-4030 1 4800W 32Ω 1 125 22 DBU-4030 1 4800W 27.2Ω 1 125 30 DBU-4030 1 6000W 20Ω 1 125 37 DBU-4045 1 9600W 16Ω 1 125 45 DBU -4045 1 9600W 13.6Ω 1 125 55 DBU -4030 2 6000W 20Ω 2 135 75 DBU -4045 2 9600W 13.6Ω 2 145 110 DBU -4030 3 9600W 20Ω 3 100 160 DBU -4220 1 40KW 3.4Ω 1 140 220 DBU -4220 1 60KW 3.2Ω 1 110 300 DBU -4220 2 40KW4.5Ω 2 110 600DBU -4220360KW3Ω3130ED : 表示制动率在一个制动周期为120s 时,制动时间所占比率,如下图可表示为ED=t1/t2=20%.。