samsung k2200打印机使用说明.ppt

- 格式:ppt

- 大小:2.54 MB

- 文档页数:16

k2200说明书k2200说明书篇一:K2200固件升级说明 US B升级方法:升级前,请查询复印的固件版本号,到官网下载固件。

查询方式就是打印复印机的报告查看。

需要下载固件名称为k2200_v3.07.01.1 4.hd,没有升级前是k2200_v3.07.01.12 U SB连接复印机的执行文件:usb list2.e xe 需要进入工程师维修模式进行设置:1、进入工程师维修模式:2、选择Service Functins3、进入F/Upgrade 4、打开端口选择n5、保持在工程师模式,使用电脑将下好的固件更新文件拖拽到usblist2.exe文件6、电脑提示文件传输完后,复印会出现100%走条,会自动完成升级固件步骤,关机重启。

7、升级完成后,需要进入到工程师维修模式进行设置:8、进入工程师维修模式:9、选择S ervice Fun ctins10、选择 SFE 菜单11、选择数字 5 12、将状态改为 N13、退出工程师维修模式,关机并重新开机。

设备就绪后该问题即可解决。

篇二:银俊门禁一体机IGK2200说明书一、产品简介与性能参数1、产品简介I GK2200是对单门(或通道)出入进行管制的控制主机。

结合门禁管理软件,实现对门(或通道)进行权限设定、管制、数据采集及安全监控。

从而实现门禁管理自动化,安全防范科学化。

2、性能参数卡片类型:I GK2200A/EM使用EM及其兼容卡 IGK2200/T E 使用TEMIC及其兼容卡 IGK2200A/M1 使用m ifare及其兼容卡用户卡容量: 10000张记录容量: 8000条读卡器端口:标准G26/34/36/37/42自适应或RS485接口读卡器输入:四路开关量输入(1路开门按钮、1路门磁、1路报警、1路消防联动)输出:2路1A继电器干接点输出(1路电锁控制、1路报警输出)通讯: RS485/4800~115200bps(默认19200bps)工作电压:D C6~36V(额定D C12V)功耗:3(不包括电锁) 工作温度:-10~60℃体积:126m m×83mm×18m m 重量: 125g 界面:LCD中/英文双语菜单/信息显示键盘: 12键门铃接口:干接点开关输出二、安装说明1、整体安装图2.012、接口图与说明图 2.02 1 3、接线端口说明(4)继电器输出端口(1)电源接口( 2)通讯接口(3)控制信号输入口 25)门铃输出口 6)外接读卡器接口(( 4、接线说明(1)门禁专用电源接线图(2)通用电源(通电开锁型)接线图门禁单元接线图一图2.03 门禁单元接线图二图2.04 3(3)通用电源(断电开锁型)接线图门禁单元接线图三图 2.05 4 5、系统安装说明(1) 单元连接及系统连接示意图图2.06 6、安装注意事项●所有通讯线以及控制线等要单独走管,不能与强电靠近或平行走线。

2200 SERIES COMMON DRIVE PACKAGESpecial Capabilities Specification Sheet 975CottonwoodAve.,POBox20,Hartland,Wisconsin53029-0020,USA||***************COMMON DRIVE CONVEYOR SETUPUp to (4) conveyors can be coupled together and driven from a single gearmotor.• Conveyors move at same relative belt speed.• Creates single lanes for handling parts.• Wide parts or pallets can be carried by each conveyor to allow access from below.• Conveyors can be of different widths and lengths.Uses Standard 2200 Series End Drive Conveyors• Aluminum Extruded Frame with T-slot Construction• Sealed Ball Bearings• V-Guided and Non-V-Guided Belt Compatible• Rack and Pinion Belt Tensioning• Conveyor Widths: 1.75" to 24" wide• Conveyor Lengths: End Drive = 2' to 18' long• Belt Speeds: up to 264 ft/minSee Product Engineering Manual or for details.Common Drive Specifications• Drive up to (4) Conveyors from a Single Drive Gearmotor• Fixed Conveyor Locations• Load Capacity: Contact Factory for Details• Compatible with all Standard End Drive Gearmotor Mounting Packages• Includes Aluminum Extruded Conveyor Tie Bar Assembly with Belt Return Roller• Includes Common Drive Couplings and Guarding• Multiple Conveyor Spacing Options• 2" Belt Edge to Belt Edge• 3" Belt Edge to Belt Edge• 4.75" to 24" Belt Edge to Belt Edge1/4-20 T -N U T S6[52]C o m p a t i b l e w i t h a l l W +Profiles:• All 2200 Series profiles are applicable.See Product Engineering Manual or for details. •Belting:• All 2200 Series belting is applicable.• Finger Splice is preferred, plastic and metal clipper splices are available.See Product Engineering Manual or for details. •Mounting Packages & Gearmotors:• All 2200 Series mounting packages and gearmotors are applicable.See Product Engineering Manual or for details. •Support Stands:• All 2200 Series support stands are applicable.See Product Engineering Manual or for details. •EXPRESS INQUIRY FORM: GENERAL INFORMATIONAlong with completing the Express Inquiry form below, please complete the specific 2200 Series Common Drive Conveyor application questions on the next page to the best of your ability.ContactTechnicalSalesat1-800-259-1510(Press3)***************************************************.CONTACT INFORMATIONCompany: ____________________________________________________________ Date: ____________________ Name: _________________________________________________________________________________________ Phone: __________________________ Fax: ________________________ E-Mail: _________________________ Address: _______________________________________________________________________________________ City: ______________________________________ State: ____________ Zip: ___________________________PRODUCTDescription/Material: ______________________________________________________________________________ Dimensions:_____________________________________________________________________________________ Weight: ____________________________________ Total Weight to be Placed on Conveyor: ____________________ Temperature: ________________________________ Leading Edge Dimension: ______________________________ENVIRONMENTChemicals or Fluids Present: ________________________________________________________________________ Unusual Ambient Temperature Conditions: ______________________________________________________________ Other Concerns: __________________________________________________________________________________Complete individual conveyor specifications on page 6.EXPRESS INQUIRY FORM: GENERAL INFORMATIONPage may need to be copied to communicate multiple conveyorsFAX COMPLETED FORMS TO 800.369.2440 or 262.367.5827BELT SPEED CALCULATORHow to calculate minimum conveyor belt speed:(Part rate in parts per minute) x (part size in inches)12Example (30 parts per minute) x (6" dia. part) = 180 = 15 ft/min. Minimum Belt Speed12 12How to calculate conveyor belt speed incorporating a product spacing:(Part rate in parts per minute) x (desired part spacing in inches + part size in inches)12Example (30 parts per minute) x (6" dia part + 12" spacing between parts) = (30) x (18) = 540 = 45 ft/min. Belt Speed12 12 12Please highlight the conveyor, dimensions, belt flow and motor positions required.Belt Edge to Belt Edge Options:• 2"• 3"• 4.75" to 24"Note: Conveyors over 7' (2134mm) require additional tie-together brackets.。

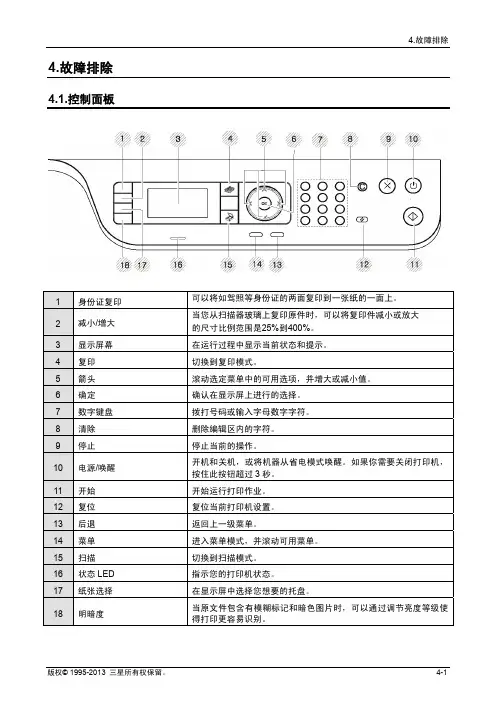

三星K2200K2200N D 放大缩小功能A3缩放为A4操作步骤

三星2200 A3缩放为A4操作步骤

说明:A4纵向放置纸型为 A4LEF

A4横向放置纸型为 A4SEF

1、打开旁路门(机器或资料上均用MP纸盘显示)

2、将A4纸横向放置在旁路上

3、根据显示屏显示操作设置纸型

如果显示A4 SEF就按“确认”键,不是这个尺寸就按停止键

按右键更换纸张尺寸

选择为A4 SEF

点击“确认”键,显示“已保存”。

4、按功能键“缩放扩放”键

选择到70%

按确认键后显示“已保存”

5、按复印键后可从旁路走出A4的缩小复印件。

重点说明:

旁路走完纸后再加入纸张,请将进纸口塑料板手动压下或把旁路关好后再打开方能继续放纸。

纸盒设置与旁路设置纸张方式同理。