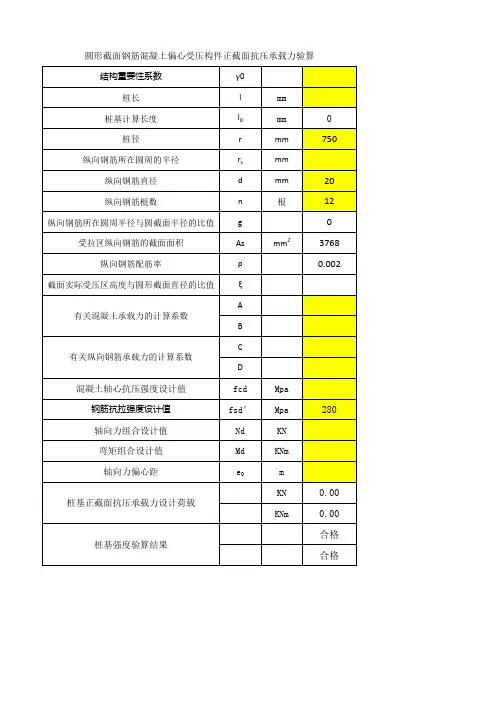

圆形截面钢筋混凝土偏压构件正截面抗压承载力计算系数

- 格式:xlsx

- 大小:16.14 KB

- 文档页数:2

C.O.2沿用边均匀配筋的圆形截面钢筋混凝土偏心受压构件,其正截面抗压承载力可用查表法(表C.0.2)并按下列规定计算求得:1当对构件承载力进行复核验算时1)由本规范公式(5.3.9-1)和(5.3.9-2)解得轴向力的偏心距:'0'g cd sd cd sd Bf D f e r Af C f ρρ+=+(C.0.2-1)2)已知cd f 、'sd f 、ρ、r ,设定ξ值,查表C.0.2,将查得的系数A、B、C、D值代入公式(C.0.2-1)计算0e 值。

若此0e 值与实际计算偏心距/d d M N η相符(允许偏差在2%以内),则设定的ξ值为所求者;若不相符,重新设定ξ值,重复上述计算,直到相符为止;3)将最后确定的ξ相应的A、B、C、D值代入规范公式(5.3.9-1)或(5.3.9-2)进行构件正截面承载力的复核验算。

2当对构件进行配筋设计时1)由公式(C.0.2-1)变换得截面配筋率:0'cd sd o f Br Ae f Ce Dgr ρ−=•−(C.0.2-2)2)已知cd f 、'sd f 、0e 、r ,设定ξ值,查表C.0.2,将查得的系数A、B、C、D值代入公式( C.0.2-2)计算ρ值,计算时式中的0e 应乘以偏心距增大系数η;再再把ρ和A、C值直代入规范公式(5.3.9-1)算得轴向力值。

若此轴向力值与实际作用的轴向力设计值相符(允许偏差在2%以内),则该ξ值及依此计算的ρ值为所求者;若不相符,重新设定ξ值,重复上述计算,直至相符为止。

3)以最后确定的ρ值代入下列公式计算纵向钢筋截面面积:2s A r ρπ=(C.0.2-3)所得钢筋配筋率应符合最小配筋率的要求。

表C.O.2圆形截面钢筋混凝土偏压构件正截面抗压承载力计算系数ξA B C D ξA B C DξA B C D0.200.32440.2628-1.52961.4216 0.210.34810.2787-1.46761.4623 0.220.37230.2945-1.40741.5004 0.230.39690.3103-1.34861.5361 0.240.42190.3259-1.29111.5697 0.250.44730.3413-1.23481.6012 0.260.47310.3566-1.17961.6307 0.270.49920.3717-1.12541.6584 0.280.52580.3865-1.07201.6843 0.290.55260.4011-1.01941.7086 0.300.57980.4155-0.96751.7313 0.310.60730.4295-0.91631.7524 0.320.63510.4433-0.86561.7721 0.330.66310.4568-0.81541.7903 0.340.69150.4699-0.76571.8071 0.350.72010.4828-0.71651.8225 0.360.74890.4952-0.66761.8366 0.370.77800.5073-0.61901.8494 0.380.80740.5191-0.57071.8609 0.390.83690.5304-0.52271.8711 0.400.86670.5414-0.47491.8801 0.410.89660.5519-0.42731.8878 0.420.92680.5620-0.379818943 0.430.95710.5717-0.33231.8996 0.440.98760.5810-0.28501.9036 0.451.01820.5898-0.23771.9065 0.461.04900.5982-0.19031.9081 0.471.07990.6061-0.14291.9084 0.481.11100.6136-0.09541.9075 0.491.14220.6206-0.04781.9053 0.501.17350.6271-0.00001.9018 0.51 1.20490.63310.0480 1.8971 0.52 1.23640.63860.0963 1.8909 0.53 1.26800.64370.1450 1.8834 0.54 1.29960.64830.1941 1.8744 0.55 1.33140.65230.2436 1.8639 0.56 1.36320.65590.2937 1.8519 0.57 1.39500.65890.3444 1.8381 0.58 1.42690.66150.3960 1.8226 0.59 1.45890.66350.44851,8052 0.60 1.49080.66510.5021 1.78560.64 1.61880.66610.7373 1.67630.65 1.65080.66510.8080 1.63430.66 1.68270.66350.8766 1.59330.67 1.71470.66150.9430 1.55340.68 1.74660.6589 1.0071 1.51460.691.77840.6559 1.06921.47690.70 1.81020.6523 1.1294 1.44020.71 1.84200.6483 1.1876 1.40450.72 1.87360.6437 1.2440 1.36970.73 1.90520.6386 1.2987 1.33580.74 1.93670.6331 1.3517 1.30280.75 1.96810.6271 1.4030 1.27060.76 1.99940.6206 1.4529 1.23920.77 2.03060.6136 1.5013 1.20860.78 2.06170.6061 1.5482 1.17870.79 2.09260.5982 1.5938 1.14960.80 2.12340.5898 1.6381 1.12120.81 2.15400.5810 1.6811 1.09340.82 2.18450.5717 1.7228 1.06630.83 2.21480.5620 1.7635 1.03980.84 2.24500.5519 1.8029 1.01390.85 2.27490.5414 1.84130.98860.86 2.30470.5304 1.87860.96390.87 2.33420.5191 1.91490.93970.88 2.36360.5073 1.95030.91610.89 2.39270.4952 1.98460.89300.90 2.42150.4828 2.01810.87040.91 2.45010.4699 2.05070.84830.92 2.47850.4568 2.08240.82660.93 2.50650.4433 2.11320.80550.94 2.53430.4295 2.14330.78470.95 2.56180.4155 2.17260.76450.96 2.58900.4011 2.20120.74460.97 2.61580.3865 2.22900.72510.98 2.64240.3717 2.25610.70610.99 2.66850.3566 2.28250.68741.002.69430.3413 2.30820.66921.012.71120.3311 2.33330.65131.022.72770.3209 2.35780.63371.032.74400.3108 2.38170.61651.042.75980.3006 2.40490.59971.082.82000.26092.49240.53561.092.83410.25112.51290.52041.102.84800.24152.53300.50551.112.86150.23192.55250.49081.122.87470.22252.57160.47651.132.88760.21322.59020.46241.142.90010.20402.60840.44861.152.91230.19492.62610.43511.162.92420.18602.64340.42191.172.93570.17722.66030.40891.182.94690.16852.67670.39611.192.95780.16002.69280.38361.202.96840.15172.70850.37141.212.97870.14352.72380.35941.222.9886O.13552.73870.34761.232.99820.12772.75320.33611.243.00750.12012.76750.32481.253.01650.11262.78130.31371.263.02520.10532.79480.30281.273.03360.09822.80800.29221.283.04170.09142.82090.28181.293.04950.08472.83350.27151.303.05690.07822.84570.26151.313.06410.07192.85760.25171.323.07090.06592.86930.24211.333.07750.06002.88060.23271.343.08370.05442.89170.22351.353.08970.04902.90240.21451.363.09540.04392.91290.20571.373.10070.03892.92320.19701.383.10580.03432.93310.18861.393.11060.02982.94280.18031.403.11500.02562.95230.17221.413.11920.02172.96150.16431.423.12310.01802.97040.15661.433.12660.01462.97910.14911.443.12990.01152.98760.14171.453.13280.00862.99580.13451.463.13540.00613.00380.12751.473.13760.00393.01150.12061.483.13950.00213.01910.11400.61 1.52280.66610.5571 1.76360.62 1.55480.66660.6139 1.73870.63 1.58680.66660.6734 1.7103 1.05 2.77540.2906 2.42760.58321.06 2.79060.2806 2.44970.56701.07 2.80540.2707 2.47130.5512 1.49 3.14080.007 3.02640.10751.503.14160.00003.03340.10111.513.14160.00003.04030.09505.3.9沿周边均匀配置纵向钢筋的圆形截面钢筋混凝土偏心受压构件(图5.3.9),其正截面抗压承载力计算应符合下列规定:图5.3.9沿周边均匀配筋的圆形截面偏心受压构件计算22'0d cd sdN Ar f C r f γρ≤+(5.3.9-1)33'00d cd sd N e Br f D gr f γρ≤+(5.3.9-2)式中0e ——轴向力的偏心距,0/d d e M N =,应乘以偏心距增大系数η,η可按第5.3.10条的规定计算;A、B——有关混凝土承载力的计算系数,按附录C 的迭代法由表C.O.2查得;C、D——有关纵向钢筋承载力的计算系数,按附录C 的迭代法由表C.O.2查得;r ——圆形截面的半径;g ——纵向钢筋所在圆周的半径s r 与圆截面半径之比,/s g r r =;ρ——纵向钢筋配筋率,2/s A r ρπ=。

C.O.2沿用边均匀配筋的圆形截面钢筋混凝土偏心受压构件,其正截面抗压承载力可用查表法(表C.0.2)并按下列规定计算求得:1当对构件承载力进行复核验算时1)由本规范公式(5.3.9-1)和(5.3.9-2)解得轴向力的偏心距:'0'g cd sd cd sd Bf D f e r Af C f ρρ+=+(C.0.2-1)2)已知cd f 、'sd f 、ρ、r ,设定ξ值,查表C.0.2,将查得的系数A、B、C、D值代入公式(C.0.2-1)计算0e 值。

若此0e 值与实际计算偏心距/d d M N η相符(允许偏差在2%以内),则设定的ξ值为所求者;若不相符,重新设定ξ值,重复上述计算,直到相符为止;3)将最后确定的ξ相应的A、B、C、D值代入规范公式(5.3.9-1)或(5.3.9-2)进行构件正截面承载力的复核验算。

2当对构件进行配筋设计时1)由公式(C.0.2-1)变换得截面配筋率:0'cd sd o f Br Ae f Ce Dgr ρ−=•−(C.0.2-2)2)已知cd f 、'sd f 、0e 、r ,设定ξ值,查表C.0.2,将查得的系数A、B、C、D值代入公式( C.0.2-2)计算ρ值,计算时式中的0e 应乘以偏心距增大系数η;再再把ρ和A、C值直代入规范公式(5.3.9-1)算得轴向力值。

若此轴向力值与实际作用的轴向力设计值相符(允许偏差在2%以内),则该ξ值及依此计算的ρ值为所求者;若不相符,重新设定ξ值,重复上述计算,直至相符为止。

3)以最后确定的ρ值代入下列公式计算纵向钢筋截面面积:2s A r ρπ=(C.0.2-3)所得钢筋配筋率应符合最小配筋率的要求。

表C.O.2圆形截面钢筋混凝土偏压构件正截面抗压承载力计算系数ξA B C D ξA B C DξA B C D0.200.32440.2628-1.52961.4216 0.210.34810.2787-1.46761.4623 0.220.37230.2945-1.40741.5004 0.230.39690.3103-1.34861.5361 0.240.42190.3259-1.29111.5697 0.250.44730.3413-1.23481.6012 0.260.47310.3566-1.17961.6307 0.270.49920.3717-1.12541.6584 0.280.52580.3865-1.07201.6843 0.290.55260.4011-1.01941.7086 0.300.57980.4155-0.96751.7313 0.310.60730.4295-0.91631.7524 0.320.63510.4433-0.86561.7721 0.330.66310.4568-0.81541.7903 0.340.69150.4699-0.76571.8071 0.350.72010.4828-0.71651.8225 0.360.74890.4952-0.66761.8366 0.370.77800.5073-0.61901.8494 0.380.80740.5191-0.57071.8609 0.390.83690.5304-0.52271.8711 0.400.86670.5414-0.47491.8801 0.410.89660.5519-0.42731.8878 0.420.92680.5620-0.379818943 0.430.95710.5717-0.33231.8996 0.440.98760.5810-0.28501.9036 0.451.01820.5898-0.23771.9065 0.461.04900.5982-0.19031.9081 0.471.07990.6061-0.14291.9084 0.481.11100.6136-0.09541.9075 0.491.14220.6206-0.04781.9053 0.501.17350.6271-0.00001.9018 0.51 1.20490.63310.0480 1.8971 0.52 1.23640.63860.0963 1.8909 0.53 1.26800.64370.1450 1.8834 0.54 1.29960.64830.1941 1.8744 0.55 1.33140.65230.2436 1.8639 0.56 1.36320.65590.2937 1.8519 0.57 1.39500.65890.3444 1.8381 0.58 1.42690.66150.3960 1.8226 0.59 1.45890.66350.44851,8052 0.60 1.49080.66510.5021 1.78560.64 1.61880.66610.7373 1.67630.65 1.65080.66510.8080 1.63430.66 1.68270.66350.8766 1.59330.67 1.71470.66150.9430 1.55340.68 1.74660.6589 1.0071 1.51460.691.77840.6559 1.06921.47690.70 1.81020.6523 1.1294 1.44020.71 1.84200.6483 1.1876 1.40450.72 1.87360.6437 1.2440 1.36970.73 1.90520.6386 1.2987 1.33580.74 1.93670.6331 1.3517 1.30280.75 1.96810.6271 1.4030 1.27060.76 1.99940.6206 1.4529 1.23920.77 2.03060.6136 1.5013 1.20860.78 2.06170.6061 1.5482 1.17870.79 2.09260.5982 1.5938 1.14960.80 2.12340.5898 1.6381 1.12120.81 2.15400.5810 1.6811 1.09340.82 2.18450.5717 1.7228 1.06630.83 2.21480.5620 1.7635 1.03980.84 2.24500.5519 1.8029 1.01390.85 2.27490.5414 1.84130.98860.86 2.30470.5304 1.87860.96390.87 2.33420.5191 1.91490.93970.88 2.36360.5073 1.95030.91610.89 2.39270.4952 1.98460.89300.90 2.42150.4828 2.01810.87040.91 2.45010.4699 2.05070.84830.92 2.47850.4568 2.08240.82660.93 2.50650.4433 2.11320.80550.94 2.53430.4295 2.14330.78470.95 2.56180.4155 2.17260.76450.96 2.58900.4011 2.20120.74460.97 2.61580.3865 2.22900.72510.98 2.64240.3717 2.25610.70610.99 2.66850.3566 2.28250.68741.002.69430.3413 2.30820.66921.012.71120.3311 2.33330.65131.022.72770.3209 2.35780.63371.032.74400.3108 2.38170.61651.042.75980.3006 2.40490.59971.082.82000.26092.49240.53561.092.83410.25112.51290.52041.102.84800.24152.53300.50551.112.86150.23192.55250.49081.122.87470.22252.57160.47651.132.88760.21322.59020.46241.142.90010.20402.60840.44861.152.91230.19492.62610.43511.162.92420.18602.64340.42191.172.93570.17722.66030.40891.182.94690.16852.67670.39611.192.95780.16002.69280.38361.202.96840.15172.70850.37141.212.97870.14352.72380.35941.222.9886O.13552.73870.34761.232.99820.12772.75320.33611.243.00750.12012.76750.32481.253.01650.11262.78130.31371.263.02520.10532.79480.30281.273.03360.09822.80800.29221.283.04170.09142.82090.28181.293.04950.08472.83350.27151.303.05690.07822.84570.26151.313.06410.07192.85760.25171.323.07090.06592.86930.24211.333.07750.06002.88060.23271.343.08370.05442.89170.22351.353.08970.04902.90240.21451.363.09540.04392.91290.20571.373.10070.03892.92320.19701.383.10580.03432.93310.18861.393.11060.02982.94280.18031.403.11500.02562.95230.17221.413.11920.02172.96150.16431.423.12310.01802.97040.15661.433.12660.01462.97910.14911.443.12990.01152.98760.14171.453.13280.00862.99580.13451.463.13540.00613.00380.12751.473.13760.00393.01150.12061.483.13950.00213.01910.11400.61 1.52280.66610.5571 1.76360.62 1.55480.66660.6139 1.73870.63 1.58680.66660.6734 1.7103 1.05 2.77540.2906 2.42760.58321.06 2.79060.2806 2.44970.56701.07 2.80540.2707 2.47130.5512 1.49 3.14080.007 3.02640.10751.503.14160.00003.03340.10111.513.14160.00003.04030.09505.3.9沿周边均匀配置纵向钢筋的圆形截面钢筋混凝土偏心受压构件(图5.3.9),其正截面抗压承载力计算应符合下列规定:图5.3.9沿周边均匀配筋的圆形截面偏心受压构件计算22'0d cd sdN Ar f C r f γρ≤+(5.3.9-1)33'00d cd sd N e Br f D gr f γρ≤+(5.3.9-2)式中0e ——轴向力的偏心距,0/d d e M N =,应乘以偏心距增大系数η,η可按第5.3.10条的规定计算;A、B——有关混凝土承载力的计算系数,按附录C 的迭代法由表C.O.2查得;C、D——有关纵向钢筋承载力的计算系数,按附录C 的迭代法由表C.O.2查得;r ——圆形截面的半径;g ——纵向钢筋所在圆周的半径s r 与圆截面半径之比,/s g r r =;ρ——纵向钢筋配筋率,2/s A r ρπ=。

混凝土结构设计规范(附录)附录A钢筋的公称直径、公称截面面积及理论重量表AO1钢筋的公称直径、公称截面面积及理论重量表A.0.2钢绞线的公称直径、公称截面面积及理论重量表A.0.3钢丝的公称直径、公称截面面积及理论重量附录B近似计算偏压构件侧移二阶效应的增大系数法B.0.1在框架结构、剪力墙结构、框架-剪力墙结构及筒体结构中,当采用增大系数法近似计算结构因侧移产生的二阶效应(P—△效应)时,应对未考虑P-△效应的一阶弹性分析所得的柱、墙肢端弯矩和梁端弯矩以及层间位移分别按公式(Bo1-I)和公式(BO1—2)乘以增大系数ηs:[B.0.1-1]∆=3[B.0.1-2]式中:Ms——引起结构侧移的荷载或作用所产生的一阶弹性分析构件端弯矩设计值;Mns——不引起结构侧移荷载产生的一阶弹性分析构件端弯矩设计值;∆1——一阶弹性分析的层间位移;ηs——P-△效应增大系数,按第B.0.2条或第B.0.3条确定,其中,梁端ηs 取为相应节点处上、下柱端或上、下墙肢端ηs的平均值。

B.0.2在框架结构中,所计算楼层各柱的ηs可按下公式计算:式中:D——所计算楼层的侧向刚度。

在计算结构构件弯矩增大系数与计算结构位移增大系数时,应分别按本规范第B.0.5条的规定取用结构构件刚度;Nj——所计算楼层第j列柱轴力设计值;HO——所计算楼层的层高。

B.0.3剪力墙结构、框架-剪力墙结构、简体结构中的ηs可按下列公式计算:[B.0.3]式中:∑G——各楼层重力荷载设计值之和;EcJd——与所设计结构等效的竖向等截面悬臂受弯构件的弯曲刚度,可按该悬臂受弯构件与所设计结构在倒三角形分布水平荷载下顶点位移相等的原则计算。

在计算结构构件弯矩增大系数与计算结构位移增大系数时,应分别按本规范第B.0.5条规定取用结构构件刚度;H——结构总高度。

B.0.4排架结构柱考虑二阶效应的弯矩设计值可按下列公式计算:(B.0.4-2)(B.0.4-3)(B.0.4-4)式中:ζc——截面曲率修正系数;当Q>1.0时,取«=1.0。

3.2 下部结构钻孔灌注桩、双柱式桥墩的计算3.2.1 设计资料1、设计标准及上部构造 设计荷载:公路-Ⅱ级; 桥面净空:净-8+2×1m ;标准跨径:13b L m ,梁长12.96m ; 上部构造:预应力简支空心板。

2、水文地质条件冲刷深度:最大冲刷线为河床线下6.88m 处;按无横桥向的水平力(漂流物、冲击力、水流压力等)计算。

3、材料钢筋:盖梁主筋用HRB335钢筋,其它均用R235钢筋 混凝土:盖梁、墩柱用C30,系梁及钻孔灌注桩用C25 4、桥墩尺寸图3-17:尺寸单位cm5、设计依据《公路桥涵地基与基础设计规范》(JTG D63-2007) 3.2.2 盖梁计算 (一)荷载计算1、上部结构永久荷载见表3-15:表3-152、盖梁自重及作用效应计算(1/2盖梁长度)图3-18表3-16:盖梁自重产生的弯矩、剪力效应计算1q +2q +3q +4q +5q =190.07KN 3、可变荷载计算(1)可变荷载横向分布系数计算:荷载对称布置时用杠杆法,非对称布置用偏心受压法。

○1公路-I 级 a 、单车列,对称布置(图3-19)时:图3-19b 、双车列,对称布置(图3-20)时:图3-20c 、单车列,非对称布置(图3-21)时:图3-21由()∑±=22/1a ea i i ηη,已知6=n ,185.3=e ,则460.02930.06199.42955.3185.3611=+=⨯+=η d 、双车列,非对称布置(图3-21)时: 已知:6=n ,635.1=e ,∑=99.4222a(2)按顺桥向可变荷载移动情况,求得支座可变荷载反力的最大值(图3-22)图3-22公路-I 级双孔布载单列车时: 双孔布载双列车时: 单孔布置单列车时: 单孔布载双列车时:(3)可变荷载横向分布后各梁支点反力(计算的一般公式为i i B R η=),见表3-17表3-17:各板支点反力计算(4)各板永久荷载、可变荷载反力组合:计算见表3-18,表中均取用各板的最大值,其中冲击系数为:表3-18:各板永久荷载、可变荷载基本组合计算表(单位:KN )4、双柱反力i G 计算(图3-23)所引起的各梁反力表3-19:图3-23:尺寸单位cm表3-19:双柱反力1G 计算由上表知应取组合○6控制设计,此时KN G G 07.277821== (二)内力计算1、恒载加活载作用下各截面的内力 (1)弯矩计算(图3-23)截面位置见图3-23,为求得最大弯矩值,支点负弯矩取用非对称布置时的数值,跨中弯矩取用对称布置时数值。