汽车专业英语课文翻译4

- 格式:doc

- 大小:33.50 KB

- 文档页数:4

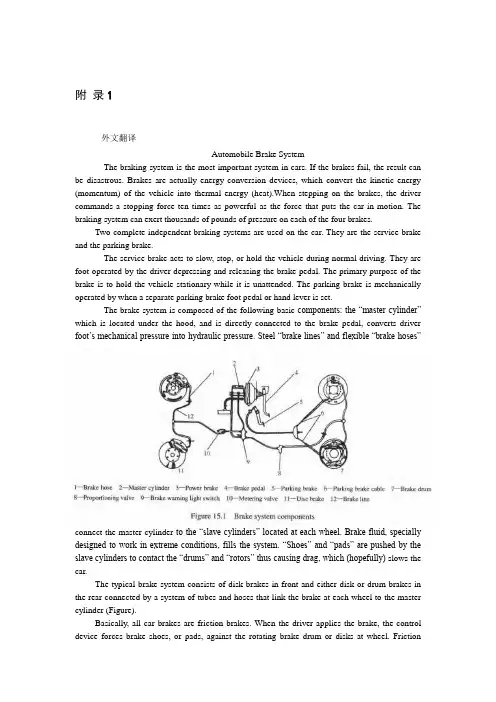

附录1外文翻译Automobile Brake SystemThe braking system is the most important system in cars. If the brakes fail, the result can be disastrous. Brakes are actually energy conversion devices, which convert the kinetic energy (momentum) of the vehicle into thermal energy (heat).When stepping on the brakes, the driver commands a stopping force ten times as powerful as the force that puts the car in motion. The braking system can exert thousands of pounds of pressure on each of the four brakes.Two complete independent braking systems are used on the car. They are the service brake and the parking brake.The service brake acts to slow, stop, or hold the vehicle during normal driving. They are foot-operated by the driver depressing and releasing the brake pedal. The primary purpose of the brake is to hold the vehicle stationary while it is unattended. The parking brake is mechanically operated by when a separate parking brake foot pedal or hand lever is set.The brake system is composed of the following basic components: the “master cylinder” which is located under the hood, and is directly connected to the brake pedal, converts driver foot’s mechanical pressure into hydraulic pressure. Steel “brake lines” and flexible “brake hoses”connect the master cylinder to the “slave cylinders” located at each wheel. Brake fluid, specially designed to work in extreme conditions, fills the system. “Shoes” and “pads” are pushed by the slave cylinders to contact the “drums” and “rotors” thus causing drag, which (hopefully) slows the car.The typical brake system consists of disk brakes in front and either disk or drum brakes in the rear connected by a system of tubes and hoses that link the brake at each wheel to the master cylinder (Figure).Basically, all car brakes are friction brakes. When the driver applies the brake, the control device forces brake shoes, or pads, against the rotating brake drum or disks at wheel. Frictionbetween the shoes or pads and the drums or disks then slows or stops the wheel so that the car is braked.In most modern brake systems (see Figure 15.1), there is a fluid-filled cylinder, called master cylinder, which contains two separate sections, there is a piston in each section and both pistons are connected to a brake pedal in the driver’s compartment. When the brake is pushed down, brake fluid is sent from the master cylinder to the wheels. At the wheels, the fluid pushes shoes, or pads, against revolving drums or disks. The friction between the stationary shoes, or pads, and the revolving drums or disks slows and stops them. This slows or stops the revolving wheels, which, in turn, slow or stop the car.The brake fluid reservoir is on top of the master cylinder. Most cars today have a transparent r reservoir so that you can see the level without opening the cover. The brake fluid level will drop slightly as the brake pads wear. This is a normal condition and no cause for concern. If the level drops noticeably over a short period of time or goes down to about two thirds full, have your brakes checked as soon as possible. Keep the reservoir covered except for the amount of time you need to fill it and never leave a cam of brake fluid uncovered. Brake fluid must maintain a very high boiling point. Exposure to air will cause the fluid to absorb moisture which will lower that boiling point.The brake fluid travels from the master cylinder to the wheels through a series of steel tubes and reinforced rubber hoses. Rubber hoses are only used in places that require flexibility, such as at the front wheels, which move up and down as well as steer. The rest of the system uses non-corrosive seamless steel tubing with special fittings at all attachment points. If a steel line requires a repair, the best procedure is to replace the compete line. If this is not practical, a line can be repaired using special splice fittings that are made for brake system repair. You must never use copper tubing to repair a brake system. They are dangerous and illegal.Drum brakes, it consists of the brake drum, an expander, pull back springs, a stationary back plate, two shoes with friction linings, and anchor pins. The stationary back plate is secured to the flange of the axle housing or to the steering knuckle. The brake drum is mounted on the wheel hub. There is a clearance between the inner surface of the drum and the shoe lining. To apply brakes, the driver pushes pedal, the expander expands the shoes and presses them to the drum. Friction between the brake drum and the friction linings brakes the wheels and the vehicle stops. To release brakes, the driver release the pedal, the pull back spring retracts the shoes thus permitting free rotation of the wheels.Disk brakes, it has a metal disk instead of a drum. A flat shoe, or disk-brake pad, is located on each side of the disk. The shoes squeeze the rotating disk to stop the car. Fluid from the master cylinder forces the pistons to move in, toward the disk. This action pushes the friction pads tightly against the disk. The friction between the shoes and disk slows and stops it. This provides the braking action. Pistons are made of either plastic or metal. There are three general types of disk brakes. They are the floating-caliper type, the fixed-caliper type, and the sliding-caliper type. Floating-caliper and sliding-caliper disk brakes use a single piston. Fixed-caliper disk brakes have either two or four pistons.The brake system assemblies are actuated by mechanical, hydraulic or pneumatic devices. The mechanical leverage is used in the parking brakes fitted in all automobile. When the brake pedal is depressed, the rod pushes the piston of brake master cylinder which presses the fluid. The fluid flows through the pipelines to the power brake unit and then to the wheel cylinder. The fluidpressure expands the cylinder pistons thus pressing the shoes to the drum or disk. If the pedal is released, the piston returns to the initial position, the pull back springs retract the shoes, the fluid is forced back to the master cylinder and braking ceases.The primary purpose of the parking brake is to hold the vehicle stationary while it is unattended. The parking brake is mechanically operated by the driver when a separate parking braking hand lever is set. The hand brake is normally used when the car has already stopped. A lever is pulled and the rear brakes are approached and locked in the “on” position. The car may now be left without fear of its rolling away. When the driver wants to move the car again, he must press a button before the lever can be released. The hand brake must also be able to stop the car in the event of the foot brake failing. For this reason, it is separate from the foot brake uses cable or rods instead of the hydraulic system.Anti-lock Brake SystemAnti-lock brake systems make braking safer and more convenient, Anti-lock brake systems modulate brake system hydraulic pressure to prevent the brakes from locking and the tires from skidding on slippery pavement or during a panic stop.Anti-lock brake systems have been used on aircraft for years, and some domestic car were offered with an early form of anti-lock braking in late 1990’s. Recently, several automakers have introduced more sophisticated anti-lock system. Investigations in Europe, where anti-lock braking systems have been available for a decade, have led one manufacture to state that the number of traffic accidents could be reduced by seven and a half percent if all cars had anti-lock brakes. So some sources predict that all cars will offer anti-lock brakes to improve the safety of the car.Anti-lock systems modulate brake application force several times per second to hold the tires at a controlled amount of slip; all systems accomplish this in basically the same way. One or more speed sensors generate alternating current signal whose frequency increases with the wheel rotational speed. An electronic control unit continuously monitors these signals and if the frequency of a signal drops too rapidly indicating that a wheel is about to lock, the control unit instructs a modulating device to reduce hydraulic pressure to the brake at the affected wheel. When sensor signals indicate the wheel is again rotating normally, the control unit allows increased hydraulic pressure to the brake. This release-apply cycle occurs several time per second to “pump” the b rakes like a driver might but at a much faster rate.In addition to their basic operation, anti-lock systems have two other things in common. First, they do not operate until the brakes are applied with enough force to lock or nearly lock a wheel. At all other times, the system stands ready to function but does not interfere with normal braking. Second, if the anti-lock system fail in any way, the brakes continue to operate without anti-lock capability. A warning light on the instrument panel alerts the driver when a problem exists in the anti-lock system.The current Bosch component Anti-lock Braking System (ABSⅡ), is a second generation design wildly used by European automakers such as BWM, Mercedes-Benz and Porsche. ABSⅡsystem consists of : four wheel speed sensor, electronic control unit and modulator assembly.A speed sensor is fitted at each wheel sends signals about wheel rotation to control unit. Each speed sensor consists of a sensor unit and a gear wheel. The front sensor mounts to the steering knuckle and its gear wheel is pressed onto the stub axle that rotates with the wheel. The rear sensor mounts the rear suspension member and its gear wheel is pressed onto the axle. The sensor itself is a winding with a magnetic core. The core creates a magnetic field around thewinding, and as the teeth of the gear wheel move through this field, an alternating current is induced in the winding. The control unit monitors the rate o change in this frequency to determine impending brake lockup.The cont rol unit’s function can be divided into three parts: signal processing, logic and safety circuitry. The signal processing section is the converter that receives the alternating current signals form the speed sensors and converts them into digital form for the logic section. The logic section then analyzes the digitized signals to calculate any brake pressure changes needed. If impending lockup is sensed, the logic section sends commands to the modulator assembly.Modulator assemblyThe hydraulic modulator assembly regulates pressure to the wheel brakes when it receives commands from the control utuit. The modulator assembly can maintain or reduce pressure over the level it receives from the master cylinder, it also can never apply the brakes by itself. The modulator assembly consists of three high-speed electric solenoid valves, two fluid reservoirs and a turn delivery pump equipped with inlet and outlet check valves. The modulator electrical connector and controlling relays are concealed under a plastic cover of the assembly.Each front wheel is served by electric solenoid valve modulated independently by the control unit. The rear brakes are served by a single solenoid valve and modulated together using the select-low principle. During anti-braking system operation, the control unit cycles the solenoid valves to either hold or release pressure the brake lines. When pressure is released from the brake lines during anti-braking operation, it is routed to a fluid reservoir. There is one reservoir for the front brake circuit. The reservoirs are low-pressure accumulators that store fluid under slight spring pressure until the return delivery pump can return the fluid through the brake lines to the master cylinder.译文汽车制动系统制动系统是汽车中最重要的系统。

INTERNAL COMBUSTION ENGINE引擎燃烧室1. principle of operation 原理Engine and power :Engine is used to produce power. The chemical energy in fuel is converted to heat by the burning of the fuel at a controlled rate. This process is called combustion. If engine combustion occurs with the power chamber. ,the engine is called internal combustion engine. If combustion takes place outside the cylinder, the engine is called an external combustion engine.Engine used in automobiles are internal combustion heat engines. Heat energy released in the combustion chamber raises the temperature of the combustion gases with the chamber. The increase in gas temperature causes the pressure of the gases to increase. The pressure developed within the combustion chamber is applied to the head of a piston to produce a usable mechanical force, which is then converted into useful mechanical power.译:引擎和能量:引擎为汽车提供能量,燃料的化学能通过燃烧,转化为热能,这个过程叫燃烧。

汽车实用英语课文翻译汽车实用英语课文翻译《汽车实用英语》是一本图文并茂介绍汽车构造、维修保养和技术应用的通俗专业英语教材。

全书共分16个单元,每个单元由看图说话、课文、阅读材料、应用写作或科技英语知识组成。

以下是小编整理的汽车实用英语课文翻译,欢迎阅读。

汽车实用英语课文翻译1For many people, driving is A peaceful and easy way to get from point A to point B. Unfortunately, it often takes only a second to turn into a driver's nightmare. As traffic accidents continue to happen on the road, the point is not to go somewhere, but to get somewhere safely.Because of its weight and speed, cars always need to be handled carefully. The number of cars on the road is increasing, and accidents are on the rise. In fact, the Numbers that can be described are already staggering. In Canada, more than 450, 000 traffic accidents are reported every year. Perhaps most disturbing is the main cause of these accidents: about 90 per cent are caused by human error.Car makers share responsibility with drivers who are responsible for keeping roads safe. For years, car makers have designed vehicles to improve. Many of the devices in the vehicle are used to ensure passengers' safety. Braking system, this is the most common kind of safety device. In addition, windscreen is also a safety device. And then the seatbelts, airbags, reverse radar, and so on.When the driver encountered an emergency, he should brake to stop the car. This, of course, is the simplest way to protect a car's passengers. Windscreen, usually a curved glass or othertransparent shielding material, placed in front of the car owner's position to prevent wind. As the basic safeguard equipment of automobile safety, the main function of seat belt is to limit the position of the driver or crew member when the accident occurs, and reduce the injury degree of the accident to the personnel. After special sensors to detect the impact of a very short time, is located in the steering wheel or the airbag will pop up on the dashboard, in order to prevent the people directly by wheels, fender or windshield. Reverse radar, also known as parking ancillary system, or reverse computer warning system. It is when the car parking or reversing safety auxiliary processing it more intuitive to voice or show told the driver around obstructions, lifted the driver parking, before and after the detection of problems, while backing eliminate blind spot, enhance the security of driving.Other traffic safety in the performance of the device are: padded dashboard and masks, built-in fixed child seats, concave type plate, anti-lock braking system, daytime lamp, energy absorption bumper. Every year, new vehicles are introduced, and manufacturers have to stabilize the new system to ensure the safety of driving.对于许多人来说开车是件平静而轻松的从A地到B地的方式。

汽车专业英语翻译Unit 1 Automotive BasicsAutomobiles, trucks, and buses are essential forms of transportation. They are complex machines made up of many parts. These parts can be grouped into a number of systems. An understanding of how the system work will help you understand how the automobile works.轿车、卡车和客车是交通运输的重要组成部分。

它们都是由许多部件组成的复杂机器。

这些部件可以归类为汽车的几个组成系统。

了解这些各个小系统是如何工作的将有助于我们理解整个汽车系统是如何工作。

An automobile can be divided into two basic parts: a body and a chassis. The body is the enclosure that houses the engine, passengers, and cargo. It is the part of the automobile that you see. The chassis is that part of the automobile beneath the body.汽车可以分为两个基本部分:车身和底盘。

车身包围发动机、乘客和行,它是汽车你所看到的部分。

而车身以下的部分就是底盘。

An automobile body is a sheet metal shell with windows, doors, a hood, and a trunk deck built into it. It provides a protective covering for the engine, passengers, and cargo. The body is designed to keep passengers safe and comfortable. For example, insulation in the body reduces noise and protects against heat and cold. The body styling provides an attractive, colorful, modern appearance for the vehicle. It is streamlined to lessen wind resistance and to keep the car from swaying at driving speeds.轿车车身是一个钣金件壳体,它上面有车窗、车门、发送机罩和行舱门等部件,它给发动机、乘客和行提供防护。

Fuel Supply System of Gasoline EngineAll the gasoline engines have substantially identical fuel systems and run on a mixture consisting of fuel vapor and air. The fuel system comprises the units designed to store, clear and deliver fuel, the units intended to clean air and a unit for preparing a mixture from fuel vapor and air.In a fuel system different components are used to supply fuel from the fuel tank into the engine cylinder. Some of the important components are fuel tank, fuel pump, fuel filter, carburetor, intake manifold and fuellines or tubes connecting the tank, pump and the carburetor.The fuel tank is a fuel container used for storing fuel. It is made of sheet metal. It is attached to the vehicle frame with metal traps and is located at the rear of the vehicle. They are mounted in a boot or boot-floor pan in case of front-engined cars and small commercial vehicles. In order to strengthen the tank as well as to prevent surging of fuel when the vehicle rounds a curve of suddenly stops, baffle plates are attached to the inside of the tank.A cap is used to close the filler opening of the tank. The fuel line is attached at or near the bottom of the tank with a filtering element placed at the connection. The other components of the fuel tank are the fuel gauge sending unit, a vent pipe, receiving unit. To prevent the dirt and water from entering the luggage compartment, a sealing strip is fitted between the fuel tank and boot floor pan. Moreover to limit the transmission of frame distortion to the tank giving rise to squeaking as the metal parts get rubbed together, rubber or felt pads are often fitted between the mountings and the tank. Provision is also made against drumming of the tank by these mountings. The tank may be placed at the side of the chassis frame for convenience in case of large commercial vehicles. The length of the connecting lines or tubes from the tank to the carburetor is also restricted by this at the same time.A porous filter is attached to the outlet lines. By drawing fuel from the tank through the filter, any water in the bottom of the tank as well as any dirt into the fuel gathers on the surface of the filter. To keep the fuel always under atmospheric pressure, the filter pipe or tank is vented.In order to prevent dirt in the fuel from entering the fuel pump or carburetor, fuel filters and screens are used in the fuel system. If the dirt is not removed from the fuel, the normal operation of these units will be prevented. The engine performance will also be reduced.The filter is either fitted inside the fuel tank and pump or operates as a separate unit connected between the fuel tank and pump or between pump and carburetor into the fuel lines. Carburetors are also provided filter screens while a filter element is provided in the fuel tank.The fuel filter used is generally a sediment bowl made of glass or metal and a strainer screen. When the fuel drawn from the tank passes through the filter (through the bowl and strainer screen), particles of dirt and water settle in the bottom of the bowl. In certain vehicles, a separate filter either of the disk or ceramic type is used. It is either located between the fuel pump and carburetor or in the fuel line.For connecting the fuel tank to the fuel pump, metallic tubes or synthetic rubber hose used are called fuel lines. They are usually positioned with metallic clips along the frame side members. The tubing or fuel lines are also used to connect fuel pump to the carburetor. In order to absorb vibration as well as prevent breakage of the fuel lines, a short flexible line is used between the fuel pump and the tank.In order to meter and caution the driver of the motor vehicle about the quantity of fuel consumed and left in the tank, a fuel gauge is used. It is generally fitted on dash board for easy reading of the fuel. It is usually a balancing coil type having construction similar to that of an oil gauge. It is generally electrically operated.It consists of a sending unit mounted on the fuel tank and a receiving unit having a caliberated gauge mounted on the instrument panel.A sending unit consists of a float controlled thermostat or variable resistor. With a float and the float arm extending into the fuel tank, the whole unit is mounted on it. The level of fuel in the tank varies the position of the float. The amount of electrical resistance within the variable resistor for controlling the amount of current sent to receiving unit on the instrument panel is determined by the float position.The receiving unit mounted on the dash board indicates the amount of fuel in the tank on a caliberated gauge by the amount of current received from the sending unit.On modern automobiles, two types of fuel gauges; thermostatic type and an electromagnetic type are used.In order to prevent the rapid wear and tear of engine operating components causing reduced performance air cleaner is fitted to the carburetor air intake, it is mounted on thecarburetor air-horn for trapping dirt. Before entering the carburetor, the air must pass through it.To reduce the noise produced by the air rushing into the carburetor, a silencing chamber is built into the air cleaner. In case the engine misfires back through the carburetor, it acts as the flame arrestor.There are in general three types of the air cleaners used in modern automobiles. They are (a) oil bath cleaner (b) oil-wetted mesh air cleaner (c) dry type air cleaner. The first two are also known as heavy duty air cleaner while the third is known as light duty air cleaner.Fuel pumps are the devices used to supply fuel from the fuel tank to the carburetor. There are in general two main types of fuel pumps used in automobiles. They are main types of fuel pumps used in automobiles. They are (a) mechanical fuel pump (b) electric fuel pump.汽油发动机的燃料供给系统所有的汽油发动机具有基本相同的燃料系统和运行的燃料蒸气和空气组成的混合物中。

汽车工程专业英语全文翻译一当今的汽车一般都由15000 多个分散、独立且相互配合的零部件组成。

这些零部件主要分为四类:车身、发动机、底盘和电气设备。

Body:车身Engine:发动机Brakes:制动器Power train :传动系Steering:转向系Electrical:电器及电子设备Suspension:悬架Layout of a passenger car:乘用车总布置Layout of a commercial vehicle :商用车总布置1.1 车身汽车车身是由车窗、车门、发动机罩和行李箱盖焊接在金属板外壳发动机发动机作为动力装置。

最常见的发动机气缸的排列方式称为发动机配置。

直列式发动机的汽缸呈一列布置。

这个设计创造了一个简单的发动机缸体铸造。

在车辆应用中,汽缸数一般是2-6 缸,汽缸中心线与水平面垂直。

当汽缸数增多时,发动机尺寸和曲轴就成为一个问题。

解决这个问题的办法就是采用V 形(汽缸呈两列布置,且两列气缸之间夹角为V 形)发动机。

这个设计使发动机尺寸和曲轴都变得更短且更坚硬。

前置发动机纵向安装,既可前轮驱动也可后轮驱动。

后置发动机是将发动机安装在后轮后面。

发动机可横置或纵置,一般情况下为后轮驱动。

1.4 电气系统电气系统为起动机、点火系统、照明灯具、取暖器提供电能。

该电平由一个充电电路维护。

1.4.1 充电充电系统为所有汽车电子元件提供电能。

充电系统主要包括:蓄电池,交流发电机,电压调节器,即通常是交流发电机上不可或缺的,充电警告或指示灯和金属丝连成一个完整电路。

蓄电池为起动提供电能 ,然后发动机工作,交流发电机就为所有的电子元件提供电能。

同时也给蓄电池充电即用来使发动机起动。

电压调节器有过充保护作用。

1.4.2 起动起动系统包括:蓄电池、电缆、起动机、飞轮和换向器。

起动时,有两个动作同时运行,该起动机齿轮与飞轮齿圈啮合,并起动电机,然后运行传输到发动机曲轴。

起动机电机将起动机安装在发动机缸体上并由电池供电。

第4单元课文B Motronic系统的工作原理在这一部分中,我们来考察一下Motronic系统的工作情况,从而理解Motronic系统是怎样控制喷油、点火和怠速旁通系统,以便获取理想的发动机管理效果的。

1.起动控制1)起动时的燃油控制在大多数Motronic系统中,起动加浓燃油由进气道喷油器而不是单独的起动喷油器/温控定时开关来提供的。

对于起动控制,重要的输入有转速和发动机温度。

控制单元监视着起动转速,还监视着起动开始之后转动的圈数。

喷油脉冲比通常情况下要长些。

而在发动机低温时,控制单元对每一转都要输送几个较短的喷油脉冲,以便改善起动性能。

记住,在一个脉冲周期(即曲轴转动200ms的时间)中有10个毫秒级脉冲。

为了防止溢油,在经过精确的圈数之后,或者在发动机达到与温度相关的一定起动转速(如200~300r/min)之后,燃油量将会下降。

2)起动时的点火正时控制一台低温发动机以低转速起动,其点火正时将会控制在上止点(TDC)附近。

对于正常的起动转速,大的点火提前角会使发动机点火过早,从而损坏起动机。

另外,如果能起动的话,起动也将会很困难。

然而,一台低温发动机以较高转速起动,为了更好地起动,要将点火正时提前。

对于热起动,或在高的进气温度下起动,由于在活塞以起动转速下上升时,热的气缸就能着火,所以应该推迟点火正时。

推迟点火能够防止高压缩比发动机出现爆燃,这种爆燃在起动时会被起动机噪声所掩盖。

3)起动时的空气控制就像在L-Jetronic系统中一样,由于闭合角信号的加长,通常怠速稳定器的开度会加大,以便提供冷态起动所需的额外空气。

2.起动后控制起动后阶段(即在松开钥匙,使钥匙转离“起动”位置之后,发动机保持运转的5~30s 时间)受发动机温度以及控制单元内的定时电路的控制。

发动机温度越低,喷油量就越大。

发动机温度越低,喷油定时越早。

根据起动温度和起动后经过的时间,起动后校正加浓逐渐减小。

怠速稳定器维持转速不变。

汽车特性参数汽车尺寸可以使你了解它的外观,包括轴距、前后轮距、全长、全宽、全高、前悬、后悬、接近角、离去角、内长、内宽、内高、离地距、整备质量、总质量、车门数、乘坐空间和后备箱空间。

汽车的性能是否优良取决于其发动机和底盘。

而发动机是否给力取决于它的类型、排量、压缩比、最大输出功率和扭矩。

更重要的是先进的行驶系、制动方式、传动系统和车轮组成坚固耐用的底盘。

发动机性能参数包括发动机类型,缸径和冲程,排量、压缩比、气门组、功率、扭矩和点火方式。

气缸的直径称作缸径。

排量和压缩比是发动机两个常用的参数,排量表明了发动机的大小,压缩比是汽缸总容积与燃烧室容积之比。

功率指的是正常工作时的速度。

有效功率是指在正常条件下在发动机后部测得的实际功率。

指示功率是理论功率,指的是在理想状态下由发动机获得的最大输出功率。

指示功率是由发动机大小、排量、转速和气缸内压力的基础上通过理论计算得到的。

摩擦功率指的是用来克服在发动机和传动系内的内部摩擦。

摩擦功率来源于轴承、活塞在气缸内滑动、压缩冲程、发电机、风扇、水泵、皮带、空调、变速器、后差速器总成等。

汽车驱动轮上获得的功率称为行驶功率。

扭矩是一种确定工况的方法,指的是扭转力。

扭转力产生于发动机的燃料燃烧。

燃烧将活塞向下推。

而活塞带动曲轴转动,产生扭矩。

而扭转力引起车轮的转动。

底盘的性能参数包括悬架类型,制动器的类型和大小,转向方式和转弯半径,车轮的型号与大小,油箱容积。

发动机工作原理大多数发动机都是内燃机,如图示为往复式四冲程汽油发动机。

但是其他类型的发动机也有使用,比如柴油发动机,转缸式发动机(汪克尔发动机),二冲程发动机和层状充气式发动机。

往复式的意思就是“从上到下”或“从后到前”。

在往复式发动机中动力产生于活塞的上下运动。

几乎所有这种类型的发动机都依赖于一个气缸体。

气缸是由铁或铝铸造出来的,在缸体内有气缸和水套,冷却水在水套内循环。

汽缸盖覆盖在缸体顶部,形成了燃烧室。

缸体底部被油底壳所包覆。

第4单元汽油直接喷射课文A汽油直接喷射(GDI)和线控油门1.汽油直接喷射普通的汽油机设计用电子控制燃油喷射系统替代传统机械汽化系统。

目前,将燃油喷入各个进气道口的多点喷射系统(MPI)是应用最为广泛的系统之一。

尽管MPI大大提高了响应性和燃烧质量,但是由r燃油和空气在进入气缸之前进行混合而形成混合气,这种优越性也会受到限制。

为了进一步提高响应性和燃烧效率,同时降低燃油消耗,提高输出,系统可以采用直接喷射。

汽油直接喷射发动机被设计成将汽油直接喷射进气缸内,喷射的方法与直接喷射式柴油机相似。

直接喷射可设计成具有更大的控制灵活性和更高的精确度,因而提高了燃油经济性。

这一点是通过使许多工况下能够进行超稀薄混合气的燃烧来实现的。

直接喷射的设计还允许采用更高的压缩比,因而提高了动力性,并降低了燃油消耗。

目前,直接喷射汽油机在全世界范围正在在轿车上得到推广应用。

1)三菱GDI三菱汽车公司的目标是取得低油耗、高输出。

MMC (三菱汽车公司)是世界上缸内直接喷射汽油机开发的先驱者。

它的缸内直接喷射汽油机叫做“GDI”,最早安装在1996年款戈兰特轿车上。

GDI系统将燃油直接输送到气缸内。

随着喷油定时的变化,就能形成各种各样的空气-燃油混合气。

利用三菱独到的方法和技术,GDI发动机及降低了燃油消耗,同时又提高了输出。

这种看来相互矛盾而又难以实现的目标通过采用两种燃烧模式而得到实现。

三菱独辟蹊经,使喷油定时的变化与发动机负荷相匹配。

(1)超稀薄燃烧模式在大多数正常行驶条件(车速最高达120knVh)下,三菱GDI发动机运行在超稀薄燃烧模式,从而降低了燃油消耗。

在这种模式时,燃油喷射发生在压缩冲程的后期,点火发生在空燃比30〜40 (包括EGR时为5〜55)的超稀薄混合气中。

(2)高输出模式当GDI发动机在高负荷或高转速工作时,在进气行程中进行喷油。

这样,确保混合气更加均匀且温度较低(减小爆燃的倾向),使燃烧得到了优化。

汽车专业英语课文翻译汽车专业英语是一门涵盖广泛的学科,它涵盖了汽车工程学、汽车设计学、汽车制造学、汽车维修学等多个领域。

学习汽车专业英语是非常有必要的,因为这是一个国际化的语言,同时也是在汽车行业工作所必要掌握的技能之一。

下面是一篇汽车专业英语课文,通过对其进行翻译,可以更好地理解其中的内容。

原文:Car Engine LubricationThe importance of lubrication in the engine of a car cannot be overemphasized. Without proper lubrication, the moving parts of anengine would grind agnst each other, causing unnecessary wear and tearon the engine and ultimately leading to its premature flure.Lubrication is accomplished by an oil pump that circulates oil throughout the engine. The oil serves as a lubricant between the moving parts, reducing friction and preventing metal-to-metal contact. The oil also acts as a cooling agent, carrying away heat generated by the engine.Oil filters are used to remove impurities from the oil, which can cause damage to the engine if not removed. Over time, the oil in an engine becomes contaminated and loses its viscosity, or thickness. It is important to regularly change the oil in a car to ensure that it continues to provide proper lubrication and cooling.Synthetic oils are becoming increasingly popular for use in car engines. Synthetic oils are engineered to provide superior lubrication and are more resistant to breaking down and losing their viscosity overtime. They also provide better protection agnst wear and tear and can improve fuel efficiency.Overall, proper lubrication is essential for the longevity and performance of a car engine. Regularly changing the oil and using high-quality synthetic oils can help to ensure that a car engine remns in top condition.译文:汽车发动机润滑汽车发动机的润滑问题不可忽视。

第4单元课文C 电子控制燃油喷射系统的维修如果怀疑燃油喷射系统有故障,应首先弄清点火开关接通时燃油泵是否运转。

如果不转,应检查线路和继电器,并弄清继电器能否接收到表明发动机将要运转的信号。

在某些发动机上,这种信号来自空气流量计,而在另外的发动机上,这种信号来自点火系统。

接着,检查系统的基本压力、燃油供给系统和喷油器的工作情况。

燃油喷射系统的压力测试和许多其它测试,以及部件的维修和更换,所有这些都要用到下面的程序之一或全部:释放燃油压力,安装压力表,使燃油泵运转但发动机不转。

1.压力测试燃油压力过高会使混合气变浓,而压力过低又会使混合气变稀。

下面的程序用来检测系统的基本压力,以及确定压力不正确的原因。

为了进行压力测试,应释放系统压力并安装压力表。

1)系统压力测试为了检查压力调节功能,系统压力测试分为两个阶段。

在第一个阶段中,在发动机怠速运转的情况下,压力表读数一般应为2巴(29 lbf/in2)左右。

查阅维修手册,找到你的车型的正确的压力规格。

多数压力规定值为2.5巴(36 lbf/in2),容许变化范围为2.3~2.7巴。

但是,应该记住,这是在燃油泵运转而发动机不转的情况下测出的压力值。

因此,这个测试项目是为了检查燃油压力调节器的燃油压力调节功能。

在这项测试的第二个阶段,在发动机仍然怠速运转的情况下,拔下到进气歧管的真空软管并将软管口堵住。

由于压力调节器感受到的是比进气歧管压力高的大气压力,所以,燃油压力应该上升到大约2.5巴(36 lbf/in2)。

这个压力值最有可能就是维修手册规定的压力值。

压力太低或太高表明压力调节器有故障或者是输油量不正确。

应首先按照下面所述的方法,检查压力调节器,然后再检查输油量。

2)检查燃油压力调节器如果在真空管连接的情况下测试系统压力,结果压力并没有低0.5巴,应检查真空管是否泄漏。

如果真空管完好,那么调节器有故障。

如果在两个阶段系统压力都过低,那么可能是压力调节器回油量过大,或者是燃油泵输油量不正确。

原文:Routine brake system maintenanceThe braking system is the most important system on a car. If the brakes don't work properly, the result can be disastrous. So the good brakes are essential for safety.There are two completely independent braking systems on a car. One is the service brake, and the other is parking brake. The service brake acts to slow, stop, or hold the vehicle during normal driving. They are foot-operated by the driver depressing and releasing the brake pedal. The parking brake's purposes are to hold a car stationary while it is unattended, and to keep the car from rolling on unleveled ground. It is also called the handbrake.Basically, all car brakes are friction brakes. When the driver applies the brake, the control device will force brake shoes or pads against the rotating brake drums or discs at wheels. Friction between the shoes or pads and the drums or disks then slows or stops the wheels so that the car is braked.Disc brakeDisc brakes are used on the front wheels of most cars and on all four wheels on many cars.The main components of a disc brake are the brake pads, the caliper which contains a piston, and the rotor which is mounted to the hub.The disc brake is a lot like the brakes on a bicycle. Bicycle brakes have a caliper, which squeezes the brake pads against the wheel. In a disc brake, the brake pads squeeze the rotor instead of the wheel, and the force is transmitted hydraulically instead of through a cable. Friction between the pads and the disc slows the disc down.A moving car has a certain amount of kinetic energy, and the brakes have to remove this energy from the car in order to stop it. The brakes convert the kinetic energy to heat generated by the friction between the pads and the disc, so the car stops.Drum brakeSo if disk brakes are so great, how come we still have cars with drum brakes? The reason is cost. While all most vehicles for many years have disk brakes on the front wheels, drum brakes are cheaper to produce for the rear wheels. Drum brake is shown in Fig.Drum brakes consist of a backing plate, brake shoes, brake drum, wheel cylinder, return springs and an automatic or self-adjusting system. When you apply the brakes, the wheel cylinder pushes the brake shoes into contact with the machined surface on the inside of the drum. When the pressure is released, return springs pull the shoes back to their rest position. As the brake linings wear, the shoes must travel a greater distance to reach the drum. When the distance reaches a certain point, a self-adjusting mechanism automatically reacts byadjusting the rest position of the shoes so that they are closer to the drum.Hydraulic Brake SystemsWhen the operator steps on the brake pedal, the brake pedal operates a hydraulic system.The typical brake system is composed of the following basic components(1) Master cylinder. That is directly connected to the brake pedal, converts your foot's mechanical pressure into hydraulic pressure.(2) Brake lines and brake hoses, they connect the master cylinder to the wheel cylinders located at each wheel.(3) Brake fluid: that is special oil that has special properties. It is designed to withstand cold temperature without thickening as well as very high temperature without boiling.In the brake system, master cylinder contains two separate sections, there is a piston in each section and both pistons are connected to a brake pedal in the driver's compartment. When the brake is pushed down, brake fluid is sent from the master cylinder to the wheels. At the wheels, the fluid pushes shoes, or pads, against revolving drums or disks, which can slow and stop car. This slows or stops the revolving wheels, which, in turn, slow or stop the car.Routine maintenance of automobile brake fluid: Usually brake fluid maintenance period of 2 years or 48,000 km. Recommended brake fluid on the maintenance period, the European car manufacturers generally set a few years; and Japan and the United States car manufacturers are generally in their owner's manual have detailed descriptions. The abs function with anti-lock braking system, brake fluid and timely supplement is especially important. This is mainly due to energy storage in the pollution of dust and moisture of the body will lead to expensive failure, and thus laid security risk when vehicle braking force owners to find weak, you can use brake fluid test strips humidity assisted analysis of whether there is any fault of defect caused by brake fluid. If the brake fluid for the failure of the root causes of lack of sufficient quantity to be added in time brake fluid. By the brake fluid tank vent in a normal infiltration (or when tank lid open non-regular access to) the moisture and dust reduced brake fluid maintenance cycle. Maintenance of the brake fluid in the same time, must not neglect the wheel brake parts.Auto brake pad, brake drum, rotating body, and brake calipers: the current drive vehicle for leading the trend, people are concerned about how to play the 2 / 3 of the front brake lines brake tasks for scientific and effective maintenance. Now, after a variety of drive, all-wheel drive, trucks and suv blossom everywhere, people "before re-light after the" traditional concept has gradually changed.Gradually replace the asbestos linings in the semi-metallic brake pad will cause the whole surface of rotating serious wear and tear. Brake parts on the car wheel or brake pad inspection is a complex task, not simply from a visual look at both sides of the front brakepads wear the middle point. In actual operation, even if the brake caliper of open distance just to let you see both sides of the brake pad, it does not mean we can be handy, unimpeded operation of the. In addition, the popularization of brake shield, and the brake pad of rotating the contact surface is multi-block, hard look. As for the rear wheel with disc brake, it is hidden, is difficult to comprehend the appearance.Typically, the only system in the apparent leak, we will focus on checking brake fluid sealing. The comprehensive system of inspection, including the traditional static checking (that is, to find leaks in situ static) and dynamic checks (ie check the seal during braking). In any case, when the vehicle braking system to maintain up to 48 000 km driving range, they need the vehicle's braking system to conduct a comprehensive professional maintenance Brake rotating body of minor scratches do not cause illness. But since the fastening nut tightening force thickness of inequality and uneven brake rotating body rotation caused by excessive wear and tear will seriously affect the braking performance. To reduce weight, many rotating body size using unconventional structure, which is difficult to meet some of the machine tool clamping the basic requirements. If you find a rotating body has been processed, then follow the same axle of the second rotating body is only the size of its replacement. In theory, you can only replace a rotating body, but to get the best balance between braking effect, or the proposed replacement with two on the same axle rotating body. The proposal also applies to vehicles during braking, brake caliper piston through the experience back movement, we can complete the key features of the automatic brake calipers inspection. If the brake caliper piston back position is unsound, please replace a new brake caliper; If you want to discharge or filling brake fluid, make sure relief valve can be normally open; if the relief valve setting, replace the new The brake caliper.If the asbestos linings have worn 3.175mm, this time even under light loading, the security of driving range has also been very limited. Also, if needed at this time of high load brake, the wear lining weak braking force will make the traffic safety compromised.Some rear disc brake, rear-drive rotary body with a cap, the cap body also acts as a rotary brake drum. There are many car owners often overlook the parking brake will cancel the direct-drive vehicles, the rotating body and the brake shoes in direct metal - metal friction, the result is bound to cause a rotating body, brake pads and brake shoes of serious wear and tear.译文:汽车制动系统的日常维修保养制动系统是汽车上最重要的系统。

1 A 汽车的基本结构01虽然在风格和设计上都有很大的不同,但汽车的结构基本上是相同的。

换句话说,任何汽车都由四部分组成,如发动机、底盘、车身和电气系统。

发动机02发动机是汽车的动力来源。

最常见的类型是内燃机,燃料燃烧的气瓶,将膨胀力的燃烧或爆炸成旋转力,用以推动车辆前进。

03所有发动机都有燃油、排气、冷却和润滑系统。

汽油发动机也有点火系统。

04燃料系统在动力生产过程中起着至关重要的作用,因为它将汽油供应给发动机汽缸。

05排气系统是用来将燃烧的气体排放到车辆后部,进入空气中,安静的排气噪声,并且,在大多数情况下,减少废气中的污染物。

06冷却系统从发动机部件中移除过多的热量07润滑系统是保持发动机运转平稳的重要保证。

机油是系统中使用的润滑剂。

08点火系统提供所需的电火花,以点燃气缸内的空气燃料混合物,从而启动动力冲程。

底盘09底盘是一个框架,用于组装汽车零部件在它。

底盘包括动力车、悬架、转向和制动系统。

10动力传动系统包括从发动机传递扭矩的机构和单位,以及变化的扭矩和转速的大小和方向。

在这些机制和单位是变速器(变速箱),离合器,传动轴,后桥,差速器和车轮。

11悬挂系统的主要目的是支持车辆的重量。

悬挂系统的基本工作是吸收由不规则路面引起的冲击,否则会被传送给车辆及其乘员,从而有助于保持车辆在控制和水平的过程中,不管道路条件。

12转向系统是用来控制车辆的行驶方向,因为它移动。

构成的转向系统的关键部件是方向盘、转向轴、蜗杆、扇形齿轮、转向摇臂、拉杆、转向节臂、主销、转向臂、拉杆、前轴和转向节。

13制动系统是一种通过摩擦来阻止车辆的〖JP〗运动机械和液压平衡的装置。

在结构上,汽车刹车系统包括几个主要部件如制动鼓、刹车蹄、刹车片、汽车等功能,〖JP〗制动系统可分为行车制动装置和停车制动机构。

车身14车身为发动机、乘客和货物提供保护罩。

它的目的是让居住者安全和舒适。

车身一般分为四个部分-前,上部或顶部,后部和底部。

Fuel Supply System of Gasoline Engine(UNIT SEVEN)All the gasoline engines have substantially identical fuel systems and run on a mixture consisting of fuel vapor and air. The fuel system comprises the units designed to store, clear and deliver fuel, the units intended to clean air and a unit for preparing a mixture from fuel vapor and air.In a fuel system different components are used to supply fuel from the fuel tank into the engine cylinder. Some of the important components are fuel tank, fuel pump, fuel filter, carburetor, intake manifold and fuellines or tubes connecting the tank, pump and the carburetor.The fuel tank is a fuel container used for storing fuel. It is made of sheet metal. It is attached to the vehicle frame with metal traps and is located at the rear of the vehicle. They are mounted in a boot or boot-floor pan in case of front-engined cars and small commercial vehicles. In order to strengthen the tank as well as to prevent surging of fuel when the vehicle rounds a curve of suddenly stops, baffle plates are attached to the inside of the tank.A cap is used to close the filler opening of the tank. The fuel line is attached at or near the bottom of the tank with a filtering element placed at the connection. The other components of the fuel tank are the fuel gauge sending unit, a vent pipe, receiving unit. To prevent the dirt and water from entering the luggage compartment, a sealing strip is fitted between the fuel tank and boot floor pan. Moreover to limit the transmission of frame distortion to the tank giving rise to squeaking as the metal parts get rubbed together, rubber or felt pads are often fitted between the mountings and the tank. Provision is also made against drumming of the tank by these mountings. The tank may be placed at the side of the chassis frame for convenience in case of large commercial vehicles. The length of the connecting lines or tubes from the tank to the carburetor is also restricted by this at the same time.A porous filter is attached to the outlet lines. By drawing fuel from the tank through the filter, any water in the bottom of the tank as well as any dirt into the fuel gathers on the surface of the filter. To keep the fuel always under atmospheric pressure, the filter pipe or tank is vented.In order to prevent dirt in the fuel from entering the fuel pump or carburetor, fuel filters and screens are used in the fuel system. If the dirt is not removed from the fuel, the normal operation of these units will be prevented. The engine performance will also be reduced.The filter is either fitted inside the fuel tank and pump or operates as a separate unit connected between the fuel tank and pump or between pump and carburetor into the fuel lines. Carburetors are also provided filter screens while a filter element is provided in the fuel tank.The fuel filter used is generally a sediment bowl made of glass or metal and a strainer screen. When the fuel drawn from the tank passes through the filter (through the bowl and strainer screen), particles of dirt and water settle in the bottom of the bowl. In certain vehicles, a separate filter either of the disk or ceramic type is used. It is either located between the fuel pump and carburetor or in the fuel line.For connecting the fuel tank to the fuel pump, metallic tubes or synthetic rubber hose used are called fuel lines. They are usually positioned with metallic clips along the frame side members. The tubing or fuel lines are also used to connect fuel pump to the carburetor. In order to absorb vibration as well as prevent breakage of the fuel lines, a short flexible line is used between the fuel pump and the tank.In order to meter and caution the driver of the motor vehicle about the quantity of fuel consumed and left in the tank, a fuel gauge is used. It is generally fitted on dash board for easy reading of the fuel. It is usually a balancing coil type having construction similar to that of an oil gauge. It is generally electrically operated.It consists of a sending unit mounted on the fuel tank and a receiving unit having a caliberated gauge mounted on the instrument panel.A sending unit consists of a float controlled thermostat or variable resistor. With a float and the float arm extending into the fuel tank, the whole unit is mounted on it. The level of fuel in the tank varies the position of the float. The amount of electrical resistance within the variable resistor for controlling the amount of current sent to receiving unit on the instrument panel is determined by the float position.The receiving unit mounted on the dash board indicates the amount of fuel in the tank on a caliberated gauge by the amount of current received from the sending unit.On modern automobiles, two types of fuel gauges; thermostatic type and an electromagnetic type are used.In order to prevent the rapid wear and tear of engine operating components causing reduced performance air cleaner is fitted to the carburetor air intake, it is mounted on thecarburetor air-horn for trapping dirt. Before entering the carburetor, the air must pass through it.To reduce the noise produced by the air rushing into the carburetor, a silencing chamber is built into the air cleaner. In case the engine misfires back through the carburetor, it acts as the flame arrestor.There are in general three types of the air cleaners used in modern automobiles. They are (a) oil bath cleaner (b) oil-wetted mesh air cleaner (c) dry type air cleaner. The first two are also known as heavy duty air cleaner while the third is known as light duty air cleaner.Fuel pumps are the devices used to supply fuel from the fuel tank to the carburetor. There are in general two main types of fuel pumps used in automobiles. They are main types of fuel pumps used in automobiles. They are (a) mechanical fuel pump (b) electric fuel pump.汽油发动机的燃料供给系统所有的汽油发动机具有基本相同的燃料系统和运行的燃料蒸气和空气组成的混合物中。