Cirrus Pro云雾室型极早期火灾探测器设计使用手册

- 格式:pdf

- 大小:1.85 MB

- 文档页数:26

•All installations should comply with local regulations•For detectors approved to UL268refer to NFPA72for installation guidance.In such installations,it is advised that the maximum distance of Detector and Reflector from the ceiling must be 10%of the distance between floor and ceiling•For installations covering less than 18m,the Short Range Mask must be used•Position beam as high as possible,but with a minimum distance of 0.5m from Detector and Reflector to ceiling.•Mount Detector and Reflector directly opposite each other•Do NOT position Detector where personnel or objects can enter the beam path •Do NOT position 2Detectors facing each other •Detector LED indicator must face downward•Do NOT install the Detector or Reflector in environments where condensation or icing are likely tooccur18—50m =150—100m =48—18m =1Use Short RangeMaskEnsure clear line ofsight from Detector to ReflectorMount on solid surfaces (structural wall or girder)1.General Information2.Fitting the ProductClip PCB intobaseInsert DetectorcableLED indicator must face downward3.Wiring DiagramsWiring two Detectors onto two Zones:To Detector 1To Detector 2EOL EOLDET 1DET 2N/OCOMN/CN/OCOMN/CN/OCOMN/CN/OCOMN/C14V -36V DC123123123Con C Zone 1-Zone 1+Zone 2+Zone 2-Supply +Ext Reset Supply -Con A Con B see note 1see note 1ExtReset123Con D •Note 1:This component is the fire resistor.Its value is specified by the Fire Control Panel manufacturer.For U.S.installations it is typically a short circuit •ALWAYS use a separate 2-core cable for each Detector head•CAUTION:For system monitoring -Do not use looped wire under any terminals.Break wire run to provide monitoring of connections •Components not supplied:•End Of Line ('EOL')component -supplied by Fire Control Panel manufacturer •Fire Resistor•After installation,check operation of Fire and Fault connection on Fire Panel•Apply a voltage of 5V to 40V to ‘Ext Reset’contact for at least 2seconds to clear a latched fire conditionFireFaultFire Fault3.Wiring Diagrams (continued)Relay connections for wiring the two Detectors of one Controller onto one Zone:For wiring to other types of Fire Control Panel,or to wire multiple Controllers onto one Zone,refer to additional installation instructions supplied with the productEOLN/O COM N/C N/O COM N/CN/OCOMN/CN/OCOMN/C123123123Con C Zone 1-Zone 1+Con A Con B see note 1123Con D Fire Fault FireFault5seconds5secondsNOTE:One System Controller can be used to control and monitor up to two Detector heads.The ‘#’symbol in this guide is used to represent the number of the Detector currently selected (1or 2).4.Apply power•Commissioned system:•Detectors have been found but the selected Detector is not aligned:•Detector is connected butnot ‘Found’(normal on uncommissionedsystem):•Communications fault,or no Detector connected:Pressfor Pass Codescreen:•Default PassCode:1234•Change digit •Move between digits •Accept•An incorrect Pass Code will return the display to the Pass Code entry screen•Three incorrect attempts will lock access for three minutes5.Enter Pass Code to Access Engineering Menu6.Find Detectors•Press to enable ‘Found’Detectors at any point during 60s countdown•Any unused Detector channels are switched off •Press to re-scan if number is incorrect•‘Find’is automatically displayed the first time this process is run.‘Find’can also be accessed in the System Controller settings menu.Find must be performed when adding or removing a detector to an already ‘Found’system.•In‘Hi A’mode(default),during normal operation the system will take5.5mA if one Detector is connected or8mA if two Detectors are connected. During Laser targeting,Auto, Hand and Home functions,the system will take36mA.•In‘Lo A’mode(selected via the System Controller settings menu),the system will take 5.5mA or8mA in ALL modes of operation.The Detector will move more slowly during Align, Laser targeting and Home,so it is recommended to leave the system set to‘Hi A’if the current isavailable.7.Select Power Mode8.Select Detector•Select Detector to be accessed•All Detectors need to be aligned separately•Steps9to129.Select Distance between Detector and Reflector •Select8-50m(default)or100m(Set for eachDetector)SER TargetingThe system will signal Fault while in this modeThe LASER is used to align the Detector with the Reflector.It is an approximate alignment tool only.After Auto-Align the LASERwill not necessarily be pointing on the Reflector •Use to move the LASER as close to the Reflector as possible •One press of an arrow key results in one movement of the Detector head •Press or to turn off the LASER and return to the Settings menu•Refer to Additional Detector Information for troubleshooting if LASER is not visible11.‘Auto’Alignment•Select ‘Auto’to automatically align the infrared beam •Signal Strength will be shown during Alignment•If the LASER is turned on it will not necessarily be pointing on the Reflector after ‘Auto’is run -this is normal•If ‘Auto’ends with an error code ‘E-’,refer to troubleshootingHiA:2minutes LoA:25minutes•When ‘Set’is displayed press whilst the Reflector is still uncovered•When ‘S-00’is displayed,cover the Reflector with a non-reflective material and leave covered,then press•When ‘S-01’is displayed,uncover the Reflector and leave uncovered,then press •Repeat Steps 8to 12for any other Detectors found during the ‘Find’process12.‘Set’0/100(Calibrate)13.System is Aligned•Green LED on Detector will flash every 10seconds,and Signal Strength should be between 99%and 101%•Default values:35%Fire Threshold,10second delay to Fire and Fault,Non-Latching mode14.Manual Fire and Fault TestsAfter installation or cleaning,it is recommended that a manual Fire and Fault test is performed:Fire Test:Cover the Reflector slowly so that it takes longer than 5seconds to cover.The System Controller will signal Fire to the Fire Control Panel after the delay to fire has expired (10s default)Fault Test:Cover the Reflector completely within 2seconds.The System Controller will signal Fault back to the Fire Control Panel after the delay to fault has expired (10s default)Detector Fire LED Test Detector will signal Fire,System Controller will stay Normal.Press to exitwithout performing the testRelay/Controller Wiring Test System Controller signals ‘Fire’to Fire Control Panel Press or to exitIt is possible to perform a Fire Test from the System Controller,to test the wiring to the Fire Control PanelNOTE:The Remote Fire Test is acceptable for Fire Authority Acceptance and Routine Maintenance per UL268-515.Remote Fire TestThis setting is the threshold at which the Detector will detect a fire Default factorysetting=35%(Set for each Detector)16.Fire ThresholdComplies with EN54-12for sensitivity levels between 25%and 35%with a maximum delay to fire of 20seconds•Sensitivity can be adjusted in 1%steps by pressing up or down keys •Press to accept setting EN Approved Sensitivity Ranges:to move between icons in theDetector Menu,shownDelay 1(Fire)These settings are the delays that the System Controller uses before signalling a FIRE or FAULT condition respectively to the Fire Control Panel.Default factory setting=10seconds Delay 2(Fault)In Latching Mode the system will stay in Fire condition after the fire clears.In Non-Latching Mode the system will automatically return to normal condition after the fire clears(Set for each Detector)17.Fire/Fault Delaytching/Non-Latching ModeTo clear a latched fire,apply 5-40V to the External Reset terminal,enter the passcode,or power cycle for 20s(Set for each Detector)19.Cleaning the SystemThe system will automatically compensate for dust build-up by changing the Compensation Level.However,it is recommended that the Detector lenses and the Reflector are cleaned periodically with a soft lint-free cloth.If the Compensation Level for a particular Detector remains above130for several days,this indicates that cleaning should take place on that Detector.The system should be isolated from the Fire Control Panel before cleaning takes place.After cleaning,verify that the system is operating normally:If the Signal Strength is between92%and108%-leave the system to compensate back to100%(this should take no more than12hours)If the Signal Strength is above108%-reduce Compensation Level until Signal Strength is92—108%,and wait for system to compensate back to100%If the Signal Strength is below92%-perform LASER Targeting,Auto-Align,and Set.How to change Compensation Level:20.Troubleshooting21.1.Multiple Zone WiringWhen using more than one System Controller on a single zone of a conventional Fire Control Panel (FCP),it is important to choose the correct method of wiring.Incorrect wiring may result in a Controller isolating subsequent devices on that zone if it enters a Fault condition,and may prevent these subsequent devices signalling a Fire condition back to the FCP .If the FCP monitors for point detector removal,it is possible to use the following wiring diagrams which use diodes to provide zone continuity in the event of a Fault state on any Controller.Two Detectors connected to Controller:Single Detector connected to Controller on “Det 1”:Note 1–This component is the Fire Resistor.Its value is specified by the FCP manufacturer,and is not supplied with the System Controller.For U.S.installations it is typically a short circuit.Note 2–Recommended diode type:Schottky,60Volt,1Amp;must be UL listed for installations meeting NFPA72.Con C Fire Con D FaultFire Con A Fault Con BCon C Fire Con D FaultFire Con A Fault Con B1.Multiple Zone Wiring(continued)If the FCP does not monitor for detector removal,it is recommended that the following wiring diagram be used.For installations conforming to UL268and NFPA72,the following diagram MUST be used when wiring multiple Controllers onto one zone.Note1–This component is the Fire Resistor.Its value is specified by the FCP manufacturer, and is not supplied with the System Controller.For U.S.installations it is typically a short circuit.EOL–End of Line component.This is supplied with the FCP,and not supplied with the System Controller.Do NOT wire to any unused relay pairs.Con A and Con B are the relay outputs for Detector1;Con C and Con D are the relay outputs for Detector2.2.Event LoggerThe System Controller contains a logging function which will store information for the most recent 50events on each Detector.For each Fire or Fault activation,the controller will store:If there have been power-cycle events on the controller,all timing information will be lost for those events that occurred prior to the most recent of the power-cycles.To erase and restart the event logger,press and hold ‘left’and ‘right’keys together when displaying any of the event log entries.Press ‘tick’when prompted by ‘SurE’.To access the event log,press tick on the Event Logger icon when the relevant detector is highlighted:Event Number01is the most recent event 02is the event before 0103is the event before 02,and so on•The event code –This is the same as the error code (E-__)that would be displayed during the Fault,or one of the following:•99-Log erased •98-Power cycle •97-Fire Detected•96-Remote Fire Test initiated •95-AUTO initiated •94-LASER activated •93-‘Home’initiated•The elapsed time since the event occurred •The duration of the event•The signal strength when the event occurred (if applicable)•The AGC value when the event occurred (if applicable)2.Event Logger(continued)Press left to access olderevents,and right to accessnewer events.When therelevant event is selected,press down to accessfurther information about theevent.Time elapsed since eventstarted.‘—‘will be displayedif the event occurred prior tothe most recent power cycle.Duration of event.‘—‘will bedisplayed if the event is stilloccurring,or if a power cycleoccurred while the eventwas in progress,or if thereis no duration associatedwith the event type(e.g.power-on)Signal strength when theevent occurred.If the signalstrength could not be readduring the event‘—‘will bedisplayed.AGC value when the eventoccurred.If the AGC valuecould not be read during theevent‘—‘will be displayed.3.Troubleshooting-LASER not visibleIf it is not possible to see the LASER because of the installation environment(for example,if you cannot see the Reflector from the System Controller or there is high ambient light)then use‘Hand’Alignment.This option displays the signal strength value returned by the Detector, and allows the user to move the beam1.Start‘Auto’Alignment and press after two seconds to exit.(this will maximise infrared power)2.Select‘Hand’alignmente to steer the beam until the signal strength is above800.There is no auto-repeat function on any key.To move the motor in any given direction more than once, press the key multiple times4.Cover the Reflector.If the Signal Strength does not drop by more than half,the beam is not aligned to the Reflector,so repeat Step35.Perform‘Auto’alignment,followed by‘Set’4.Troubleshooting-HOMEIf it is not known where the beam is pointing,use Home Position to automatically steer the infrared beam to approximately the centre of its range of movement.•Press or to exit this function•This will take up to3minutes to complete•When complete the display will return to the Engineering Menu5.Display and Indicators -LCD Icon LayoutD e g r e e s F i r e T r a n s m S i g n a l R e c e i v S i g n a l %/VS y s t e F i r e L A S E R S e t B a r G r a p hS y s t e m L o c k e d /U n l o c k e dW a r n i n gB u s yM e t r e s6.Display and Indicators -Detector and System ControllerStatus Indicators123•PressinthismenutoenterthePassCode•PresstoputthesystemintoSleep ControllerStatusSystemControllerSoftwareVersionDetectorSoftwareVersionDetectorStatus8—5mor5—1m8.Menu Layout -Engineering Menu•T h e P a s s C o d e m u s t b e e n t e r e d t o a c c e s s t h e E n g i n e e r i n g M e n u •T h e m e n u i s n a v i g a t e d b y u s i n g k e y s t o m o v e t h e c u r s o r .•I t e m s a r e s e l e c t e d b y u s i n g •P r e s s i n g e x i t s t h i s m e n u a n d r e t u r n s t h e s y s t e m t o a ‘l o c k e d ’s t a t eS e t t i n g s E v e n t L o g F i r e T e s t D e l a y9.**Gain**1% SetDetector10.System Controller SettingsCodePower Mode•Change Pass Code Use to access each digit Use to change the digit Press to save the new Pass Code and return to the settings menu Press to cancel the change and return to the Engineering menuDetectors。

CIRRUS PRO火灾侦测器使用者手册目录1.0简介 (2)1.1型号和设备 (3)1.2UL及ULC信息Pro100, 200, 200+, 200D, 200D+, 200DSC及200DSC+ (4)1.3Pro X4之UL及ULC信息 (6)2.0 定期检修 (8)2.1 定期检查 (8)2.1.1 每天检查 (8)2.1.2 三个月检查 (8)2.1.3 年度检查 (9)3.0 使用者指引 (9)3.1 面板指示和控制 (9)3.2 面板显示 (9)3.2.1 主功能选单 (11)3.2.2 实时图形表示 (12)3.2.3 单位/管显示 (12)3.2.4 事件讯息 (12)3.2.5 历史图形 (13)3.2.6 密码 (13)3.2.7 维修讯息 (14)4.0 侦错 (15)4.1 错误讯息列表 (15)4.2 侦测单元上的错误码 (15)5.0 侦测器规格 (15)1.0简介本手册详述Cirrus Pro Series Aspirating Fire Detectors的安装,测试及服务使用方法。

背景当材料过热时会产生比可见光波长还小的粒子已是众所皆知的事,而且其数量远远超过在正常环境下存的粒子数。

Cirrus Pro侦测器利用Wilson的云雾室理论来侦测火的早期及其它各阶段所产生的次微粒子。

经过过滤的空气样本经由离心风扇传送到侦测器,其中一部份被送入一个增湿器中。

在接近100%的相对湿度下,空气样本被吸入云雾室。

因为真空样本迅速的膨胀、降温,并使水气凝结在小粒子表面而造成”云雾”。

因此,这些由温度变化产生的粒子造成了许多小水滴而形成云,这些小水滴会被云雾室的测量系统侦测。

云的密度会以相称的粒子数量来表现。

侦测的结果是一个连续的讯号,其相对应于粒子的浓度,且此讯号用来提供有4个顺序的警报。

Cirrus Pro侦测器有自我管理系统,会持续的监视其正常的操作。

任何问题会立即有面板灯号、蜂鸣器及失误继电器发出警告。

火焰探测器设计手册(设计院)一、产品概述防爆红外、红紫外复合火焰探测器(以下简称探测器)属于智能型火灾探测设备,它运用了先进的多红外传感技术(MIR)和复合探测技术,采用多通道火焰传感器设计。

本探测器能够对日光、闪电、电焊、人工光源、环境(人等)、热辐射、电磁干扰、机械振动等干扰有很好的抑制,从而实现了对火焰信号的快速响应和准确识别。

本探测器采用非接触式探测,灵敏度现场可调,提供无源接点、标准电流输出和总线接口与火灾报警系统相连接。

本探测器适用于无烟液体和气体火灾、产生烟的明火以及产生爆燃的场所。

例如:航天工业、飞机库、飞机修理场、化学工业、公路隧道、弹药和爆炸品仓库、油漆工厂、石油化工企业、制药企业、发电站、印刷企业、易燃材料仓库等可燃物含碳物质的其他场合。

本探测器根据GB3836.1-2000《爆炸性气体环境用电气设备第1部分:通用要求》、GB3836.2-2000《爆炸性气体环境用电气设备第2部分:隔爆型“d”》的规定,制成隔爆型结构,其防爆标志:ExdⅡCT6。

适用于工厂具有ⅡA、ⅡB、ⅡC级,引燃温度组别为T1~T6组的1区、2区可燃性气体或蒸气与空气形成的爆炸性混合物的场所。

二、产品系列介绍三、火焰探测器型号注释JTGB ―□□―□□ □□□(□□)―□□/□□□产品类别组特征代号传感器特征及传输方式代号厂家代号产品代号Ex 防爆标志IR 红外火焰探测器UV 紫外火焰探测器UV/IR 红紫外复合火焰探测器IR2双波段红外火焰探测器IR3三波段红外火焰探测器四、产品资料※JTGB-UH-YC103-IR2 隔爆双波段红外火焰探测器 ●产品简介防爆多波段红外火焰探测器(以下简称探测器)属于智能型火灾探测设备,它运用了先进的多红外传感技术(MIR ),使用两只具有窄带滤波的不同波长的红外传感器,其中一只传感器工作在反映火焰信息的中心波长,另外一只传感器监视环境中的其他红外辐射,结合火焰的闪烁特征,通过高性能的微处理器和先进的数学算法模型进行运算分析,使得只有符合火焰特征的辐射频谱才会被确认为火警,而其他的干扰因素形成的假火警信号则会被排除。

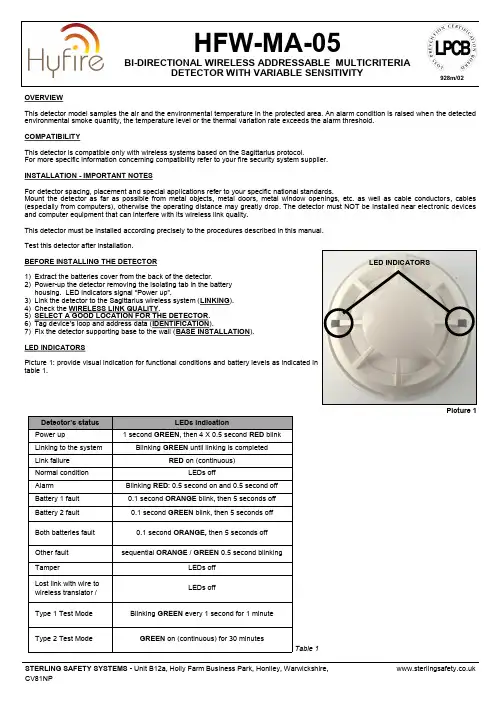

OVERVIEWThis detector model samples the air and the environmental temperature in the protected area. An alarm condition is raised when the detected environmental smoke quantity, the temperature level or the thermal variation rate exceeds the alarm threshold.COMPATIBILITYThis detector is compatible only with wireless systems based on the Sagittarius protocol.For more specific information concerning compatibility refer to your fire security system supplier.INSTALLATION - IMPORTANT NOTESFor detector spacing, placement and special applications refer to your specific national standards.Mount the detector as far as possiblefrom metal objects,metal doors, metal window openings, etc. as well as cable conductors, cables (especially from computers), otherwise the operating distance may greatly drop. The detector must NOT be installed near electronic devices and computer equipment that can interfere with its wireless link quality.This detector must be installed according precisely to the procedures described in this manual.Test this detector after installation.BEFORE INSTALLING THE DETECTOR1) Extract the batteries cover from the back of the detector.2) Power -up the detector removing the isolating tab in the battery housing. LED indicators signal “Power up ”.3) Link the detector to the Sagittarius wireless system (LINKING ). 4) Check the WIRELESS LINK QUALITY .5) SELECT A GOOD LOCATION FOR THE DETECTOR . 6) Tag device ’s loop and address data (IDENTIFICATION ).7) Fix the detector supporting base to the wall (BASE INSTALLATION ).LED INDICATORSPicture 1: provide visual indication for functional conditions and battery levels as indicated in table 1.HFW -MA -05BI -DIRECTIONAL WIRELESS ADDRESSABLE MULTICRITERIADETECTOR WITH VARIABLE SENSITIVITYLED INDICATORS Picture 1928m/02LINKINGrefer to the translator ’s or the Wirelex configuration software ’s literature):1) Move the link switch ’call it BLANK, since it carries no indication). LED indicators signal “system ” (picture 2).Linking is successful when: a) the translator indicates so (check translator ’s literature)ORb) the Wirelex software indicates so (check the Wirelex ’s literature).If linking is unsuccessful:2) Check if evident mistakes were made.3) Perform the LINKING RECOVERY .LINKING RECOVERY1) Take out both batteries from their holders2) Move alternatively the link switch to ON / BLANK five times (picture 2) 3) Move the link switch to ON4) Reinsert both batteries into their holders, oriented as per polarity marks5) Perform the LINKING procedure.DETECTOR SENSITIVITY SETTINGSDuring installation using the Wirelex software it ’s possible to set the smoke sensitivity and the heat class of the detector (see tables 4 and 5). Otherwise if the installation is performed manually through the translator keyboard, default setting will be applied.WIRELESS LINK QUALITYIt is possible to check wireless link quality between the detector and its linked -to translator or expander in this way:1) Move the link switch to the ON position.2) LED indicators will start blinking according to the following table:3) NOTE: Ensure the link switch is returned to the "BLANK" (operational) position on completion of testing.SELECT A GOOD LOCATION FOR THE DETECTORChoose for the detector a placement position that:- compliances with your specific standards- is reached by a strong wireless signal from its linked -to translator or expander module- is not interfered by environmental factors.IDENTIFICATIONFor identification purposes, analogue loop number and device ’address can be recorded on the plastic tag supplied with base (picture 3).base.**********************.ukL20-LMCXX -1400 (vA.2)Picture 3Assessment Device ’s indicationDuring the linking phase, the detector must be positionedclose to the aerial (within a few centimeters) of the translator or expander to which it is being linked. Picture 2 Link switchBASE INSTALLATIONFix the base to the wall with the provided screws (picture 4).DETECTOR PLACEMENT1)Install the batteries cover.2)Position the detector centrally on the baseensuring it is level.3)Rotate clockwise applying gentle pressure.The detector will drop into its keyed location.4)Continue to rotate clockwise a few degreesuntil the detector has fully engaged in thebase.5)When the detector is firmly engaged, checkthe alignment of the raised reference markson the detector and on the base (picture 5).DETECTOR LOCKINGTo lock the detector to the base, screw in the provided security screw; screw entry is locat-ed on the side of the detector’s base (picture 6).TAMPER DETECTIONWhen the detector is detached from the base a tamper message event is sent to the control panel.TESTINGTest this detector after installation.After each test reset the fire security system from the control panel, as per your control panel in-structions.TEST MODESTest modes make the HFW-MA-05 more reactive to aerosol stimulus; two test mode types are provided:Type 1 Test Mode -almost instantaneously alarm agent reactive.Type 2 Test Mode -makes the detector as reactive to smoke as an optical smoke detector, simulating it.TEST 1 - MAGNET TEST1) Hold a suitable magnet in correspondence of the indicated area (picture 7)2) LED indicator will signal “Type 1 Test Mode”3) Apply again the magnet in correspondence of the indicated area (picture 7)4) LED indicator will signal “Alarm”TEST 2 - AEROSOL TESTUse only suitable aerosol testers supplied by approved manufacturers.1) Hold a suitable magnet in correspondence of the indicated area (picture 7)2) LED indicator will signal “Type 1 Test Mode”3) By following its specific instructions, apply the aerosol test device to the detector4) Wait a few seconds5) LED indicator will signal “Alarm”TEST 3 - AEROSOL TESTUse only suitable aerosol testers supplied by approved manufacturers.1) Remotely activate the detector’s green LED from the Wirelex program2) LED indicator will signal “Type 2 Test Mode”3) By following its specific instructions, apply the aerosol test device to the detector4) Wait a few seconds5) LED indicator will signal “Alarm”TEST 4 - HEAT TESTUse only suitable heat test devices from approved manufacturers.1) By following its specific instructions, apply the heat test device to the detector.2) Wait a few seconds.3) LED indicator will signal “Alarm”.Picture 5Dust covers DO NOT providecomplete protection againstcontamination: detectorsshould be removed before construc-tion, major re-decoration or other dustproducing work is started.Dust covers MUST be removed beforethe system can be made operational.Picture 4Picture 6Picture 7MAINTENANCE - CLEANING1) Remove the detector from its base.2) Smoke entry areas and thermistor area: use asoft bristle brush to dislodge any obvious such as insects, spider webs, hairs, etc.3) Smoke entry areas and thermistor area: use a blow any remaining small particles away.4) damp, lint -free cloth to remove any surface film that later attract airborne contaminants.5) Install the detector onto its base again.6) Test the detector. MAINTENANCE - BATTERY REPLACEMENTWhen a low battery condition is indicated, both batteries must be changed altogether.During this procedure the linking switch must NOT be touched at all !1) Detach the detector from its base.2) Extract the batteries cover.3) Extract the batteries.4) Insert the new batteries into their holders, oriented as per polarity marks.5) Reinstall the batteries cover.6) Reinstall the detector onto its base.7) Test the detector.**********************.ukL20-LMCXX -1400 (vA.2)Table 3Table 4Table 5* When a low battery condition is indicated, both batteries must be changed for new cells. Lifespan of batteries indicated is subject to standard environmental conditions, default monitor settings and excellent link quality.** Check latest version of document TDS -LMCXX for further data, obtainable from your supplier.。

Cirrus Pro IFD 云雾室极早期火灾报警系统计算机数据中心解决方案展径贸易(上海)有限公司目录一.计算机数据中心极早期火灾防范的重要性二.计算机数据中心极早期火灾防范特点三.传统点式烟雾探测设备的局限性四.Cirrus Pro IFD云雾室极早期火灾报警器`的工作原理五.Cirrus Pro IFD在计算机数据中心的应用优势六.CirrusPro IFD网络结构七.云雾室型与激光型探测器性能比较八.IFD探测器主要技术指标和参数一.计算机数据中心极早期火灾防范的重要性随着社会的发展和进步,以及现代科技及信息产业的飞速发展,人们对书籍、资料和数据(印刷版本、电子版本、电脑数据库等)的兴趣和需求越来越强烈,已经成为我们日常工作和生活当中的重要组成部分,为我们提供了知识和乐趣、资料和数据以及信息等服务。

我们对其的依赖也变得日趋强烈。

与过去的情况相比,计算机数据中心的设施越来越先进,功能越来越完备,造价也变得越来越昂贵,所以这些场所内部设施的一次很小的火灾都将造成非常严重的灾害。

其中不但包括建筑物及设施本身的损失,而由此引发的包括珍贵的文史图书、资料和数据的损毁以及信息服务中断所带来的损失将是不可估量的。

因此,计算机数据中心的安全,特别是火灾防范,已经变成保障此类场所中有形及无形资产安全,确保服务正常进行的首要问题。

但是,传统形式的火灾报警设备已经远远不能达到计算机数据中心这一类物品价值高、设施精密,有些部门还不能间断服务的场合的防护需求,为了计算机数据中心火灾防范问题,必须要有一种比现有设备更加先进,更加灵敏,更加稳定无误报,能够较好的适应这些场所特殊环境的新一代极早期火灾报警探测系统。

二. 计算机数据中心极早期火灾防范特点相对一般意义的火灾防范,计算机数据中心有着自身的特点,主要表现在以下几个方面: 1.易燃物品种类繁多--与过去相比,现代化的计算机数据中心内安置有大量计算机、电源及功能完备、价格昂贵的仪器设备、电线电缆及各种存储介质,其中设备内部的元器件,电缆绝缘外套多采用石碳酸纤维,聚氯乙烯等易燃材料,极易燃烧造成灾难性后果。

Cirrus Pro IFD云雾室极早期火灾探测系统计算机数据中心解决方案展径贸易(上海)有限公司目录一.计算机数据中心极早期火灾防范的重要性二.计算机数据中心极早期火灾防范特点三.传统点式烟雾探测设备的局限性四.Cirrus Pro IFD云雾室极早期火灾探测器`的工作原理五.Cirrus Pro IFD在计算机数据中心的应用优势六.Cirrus Pro IFD网络结构七.云雾室型与激光型探测器性能比较八.IFD探测器主要技术指标和参数一.计算机数据中心极早期火灾防范的重要性随着社会的发展和进步,以及现代科技及信息产业的飞速发展,人们对书籍、资料和数据(印刷版本、电子版本、电脑数据库等)的兴趣和需求越来越强烈,已经成为我们日常工作和生活当中的重要组成部分,为我们提供了知识和乐趣、资料和数据以及信息等服务。

我们对其的依赖也变得日趋强烈。

与过去的情况相比,计算机数据中心的设施越来越先进,功能越来越完备,造价也变得越来越昂贵,所以这些场所内部设施的一次很小的火灾都将造成非常严重的灾害。

其中不但包括建筑物及设施本身的损失,而由此引发的包括珍贵的文史图书、资料和数据的损毁以及信息服务中断所带来的损失将是不可估量的。

因此,计算机数据中心的安全,特别是火灾防范,已经变成保障此类场所中有形及无形资产安全,确保服务正常进行的首要问题。

但是,传统形式的火灾报警设备已经远远不能达到计算机数据中心这一类物品价值高、设施精密,有些部门还不能间断服务的场合的防护需求,为了计算机数据中心火灾防范问题,必须要有一种比现有设备更加先进,更加灵敏,更加稳定无误报,能够较好的适应这些场所特殊环境的新一代极早期火灾报警探测系统。

二.计算机数据中心极早期火灾防范特点相对一般意义的火灾防范,计算机数据中心有着自身的特点,主要表现在以下几个方面:1.易燃物品种类繁多--与过去相比,现代化的计算机数据中心内安置有大量计算机、电源及功能完备、价格昂贵的仪器设备、电线电缆及各种存储介质,其中设备内部的元器件,电缆绝缘外套多采用石碳酸纤维,聚氯乙烯等易燃材料,极易燃烧造成灾难性后果。

极早期空气采样烟雾探测器JB-BK06安装使用说明书目录一:概述-------------------------------------------------------- 2二:特点-------------------------------------------------------- 2三:技术特性---------------------------------------------------- 2四:结构介绍---------------------------------------------------- 3五:面板说明---------------------------------------------------- 4六:探测器编程-------------------------------------------------- 8 1:时间设置-------------------------------------------------- 8 2:工作模式等设置------------------------------------------ 10 3:灵敏度设置------------------------------------------ 104:环境自学习---------------------------------------------- 12七:维护------------------------------------------------------- 12过滤器更换―――――――――――――――――――――12八:常见问题与解决--------------------------------------------- 12九:注意事项--------------------------------------------------- 13一:概述:极早期空气采样烟雾探测器(以下简称探测器)是基于先进的激光光学空气监测技术和微处理器控制技术的烟雾采样探测装置。

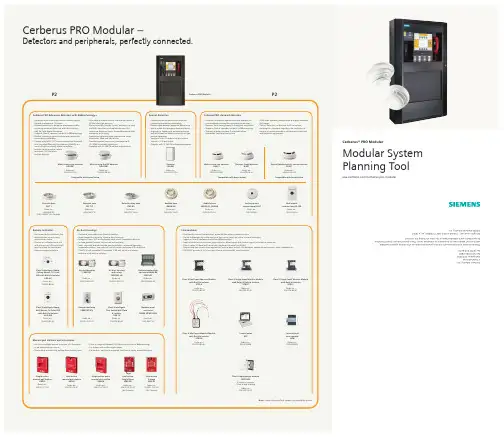

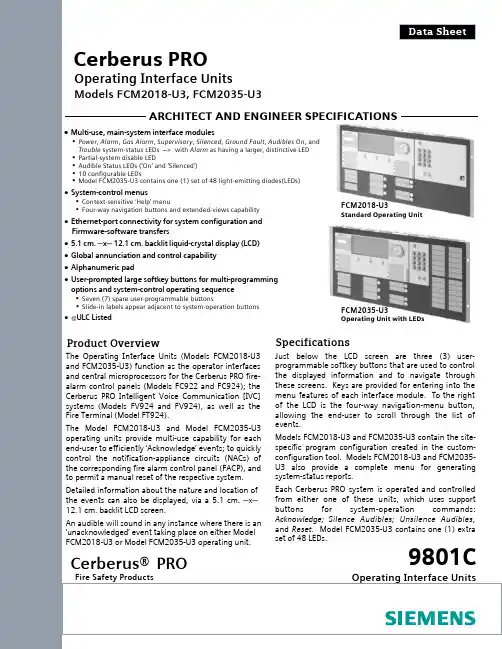

ARCHITECT AND ENGINEER SPECIFICATIONSFCM2018-U3Standard Operating UnitFCM2035-U3Operating Unit with LEDss Cerberus® PRONOT I CE ─ The information contained in this data-sheet document is intended onlyas a summary, and is subject to change without notice. The devices described here have specific instruction sheets that cover various technical, limitation and liability information.Copies of these instruction sheets and the General Product Warning and Limitations document, which also contains important information, are provided with the product and, are available from the Manufacturer.I nformation contained in these documents should be consulted before specifying or using the product. For further information or assistance concerning particular problems contact the Manufacturer.Siemens ─ Canada, Limited1577 North Service Road East • E. Oakville, Ontario L6H 0H6 / CanadaTel: (905) 799-9937 • Fax: (905) 799-9858 Web: /Cerberus-PROBuilding Technologies Division S CL ─ Fire SafetyMay 2017 ─ Supersedes sheet dated 8/2013(Rev. 4)Specifications – (continued)Models FC I 2016-U1 and FC I 2017-U1 provide connection for power and communication of the periphery boards.With the use of the custom-configuration tool, Models FCM2018-U3 and FCM2035-U3 can provide global functionality by annunciation and control of multiple Cerberus PRO systems. Moreover, the programming software is held in flash electrically erasable programmable read-only memory (EEPROM).The display screen for each interface module categorizes events by type, providing a separate event tab for Fire Alarm , Gas Alarm , Supervisory , Trouble and Test events.Each event can have a custom message of up to 40 characters describing the event’s location. In addition to the text message, the system displays the category of the active event: (e.g. – Automatic Alarm , Water Flow , Manual , etc) – the category means more to responding officials than model numbers.Up to eight (8) events can be displayed at a time. When more than eight (8) events are present, the four-way navigation-menu buttons allow the end-user to scroll up and down the list of events.A progress meter on the right side of the list indicates the size of the list of events and the location in the list. New, ‘unacknowledged’ events are indicated by a flashing exclamation point ('!'). Once ‘acknowledged’, the exclamation point changes to a non-flashing check mark (‘√ ’).A Maintenance Menu contains options for adjusting the contrast and brightness for the LCD screen, as well as supplying options for diagnostics and system-configuration programming.Once beyond the password-protected initial screen in ‘Menu’ view, system-configuration functions allow the end-user to enable, disable, or test alarms; activate / deactivate switches; report, control and maintain data. The soft-key buttons allow the end user to scroll down, allowing for further information to be displayed on a given event. This data can be vital to an authority-having-jurisdiction (AHJ), or any fire official responding to an Alarm system command.Models FCM2018-U3 and FCM2035-U3 also provide a complete menu for generating system-status reports. Each operating interface unit provides the user with seven (7) extra programmable buttons that can be programmed for a variety of usages. Models FCM2018-U3 and FCM2035-U3 mount to the inner door of the enclosure (Model FHD2004-U1).The operating interface units also support the following optional modules:▪ SafeDL I NK / Cnet network module for ‘peer-to-peer’networking of Cerberus PRO FACPs▪ RS −485 module (Model FCA2016-U1) forconnection to remote-display terminals (RDTs) and / or remote peripheral modules (RPMs) for printersTemperature and Humidity RangeOperating I nterface Units areULC Listed for indoor dry locations within a temperature range of 120+/-3°F (49+/-2°C) to 32+/-3°F (0+/-2°C) and a relative humidity of 93+/-2% a temperature of 90 +/-3°F (32+/-2°C).Details for OrderingModelPart NumberDescriptionF C M2018-U3 S 54400-C 40-A2Operating I nterface Unit for the Cerberus PRO FACPF C M2035-U3 S 54400-C 140-A1Siemens − Canada Operating I nterface Unit [w/ LED module]for the fire-only Cerberus PRO FACPs, and I ntelligent Voice (I VC) systems。

IFD Cirrus Pro极早期火警预警系统操作手册目录第一章一般操作 (1)第二章异常操作 (6)第三章查询 (9)第一節事件检视 (9)第二節历史曲线图 (11)第三節数据库查询 (12)第四節历史数据查询 (13)第五節图面打印 (14)第四章CirrusPro控制器操作 (15)第一節组件选项 (15)第二節灵敏度设定 (16)第三節编辑文字 (16)第四節输入输出设定 (17)第五節管之进气流 (18)第六節保修信息 (18)第七節制造信息 (19)第八節清除事件线图 (20)第九節展示模式 (20)第五章数据设定 (21)第一節树状窗口操作 (21)第一項监控计算机 (22)第二項F-NET (25)第三項区域 (30)第四項CPD(CirrusPro控制器) (33)第二節图片窗口操作 (36)第一項新增 (36)第二項删除 (36)第三項更改属性 (37)第四項CPD位置调整 (37)第六章登入 (39)第七章使用者管理 (40)第一節使用者权限 (40)第二節新增使用者 (41)第三節修改使用者 (41)第四節删除使用者 (42)第一章一般操作进入极早期火警预警系统, 屏幕显示如下:窗口说明:树状窗口极早期火警预警系统之数据为树状结构,以监控计算机图标开始,第二层为区域侦测网络(F-NET) ,每一个区域侦测网络包含区域(第三层),每一个区域包含极早期火警预警控制器(CPD) (最后一层)。

树状显示窗口如下: 图控树状窗口 图片窗口讯息窗口 CPD 状态窗口图示说明:监控计算机区域侦测网络(F-NET)区域极早期火警预警控制器(CPD)讯息窗口依CPD的状态显示该异常CPD之相关讯息。

图片窗口显示目前选定区域图片。

在树状窗口节点上按下鼠标左键, 即可快速切换至该区域或极早期火警预警控制器图片。

鼠标光标图标说明:鼠标游标在图面上移动时之图示。

当鼠标游标在图面时按下鼠标左键时之图标,此时移动鼠标可拖曳图面。

1.3 火灾探测器1.3.1 OT502智能光电感烟火灾探测器概述OT502探测器采用红外散射原理设计,内置先进的MCU微处理器,具有强大的现场数据采集和分析判断能力。

完善的火灾判定智能模型和漂移自动补偿技术,有效确保了探测器报警的准确性和工作的稳定性。

外形尺寸性能特点; 美国Microchip微处理器,内含Flash存储器,功能强大,性能可靠。

; 德国Siemens红外光电管,内含日光滤波器,有效滤除环境光线干扰。

;特殊的光学迷宫结构,响应快,一致性好。

; 先进的自动编址功能,无需电子编码器人工编址,节约工程施工时间。

; 环境自动补偿,独特的自诊断技术,对环境变化(温度、湿度、灰尘污染)的漂移量具有 自动修正补偿功能,极大地降低了系统的误报率。

; 内含智能软件,与控制器双向分布智能,最大限度地保证了报警的准确性。

; 二总线电流量脉宽数字化信号传输技术,通讯可靠,抗干扰性能强。

; 总线无极性,避免了由于接线不当而引起的系统损坏。

; 具有过流保护功能,可监测其供电电压,并可在控制器上显示出来,方便工程调试。

; 先进的SMT贴片工艺、可靠的屏蔽措施,对电磁环境恶劣场所有很强的抗干扰能力。

; 特殊三防处理,防霉防潮防盐雾,抗潮湿性能强。

;平时绿灯闪亮,报火警时红灯闪亮。

; 可做为编码探测器使用,也可做为普通探测器使用。

; 超薄流线外形,美观大方。

主要技术参数工作电压 标准值DC24V,范围DC20~28V监视电流 典型值200uA,最大值350uA报警电流 20mA(红灯闪亮时)风速 <10 m/s保护面积 60~80m2编码方式 自动编码,范围1~192线制 两总线,无极性适用底座 ODZ5004、ODZ5006、ODZ300C技术标准 GB4715-93安装与接线* 在天花板上预埋86H50型标准或其它孔距为40~85mm的预埋盒。

* 确认探测器类型与底座要求的类型一致。

* 将探测器底座用两个M4的螺丝安装在预埋盒上或直接安装在天花板上。