PPAP检查清单Checklist(中英文)

- 格式:pdf

- 大小:22.84 KB

- 文档页数:1

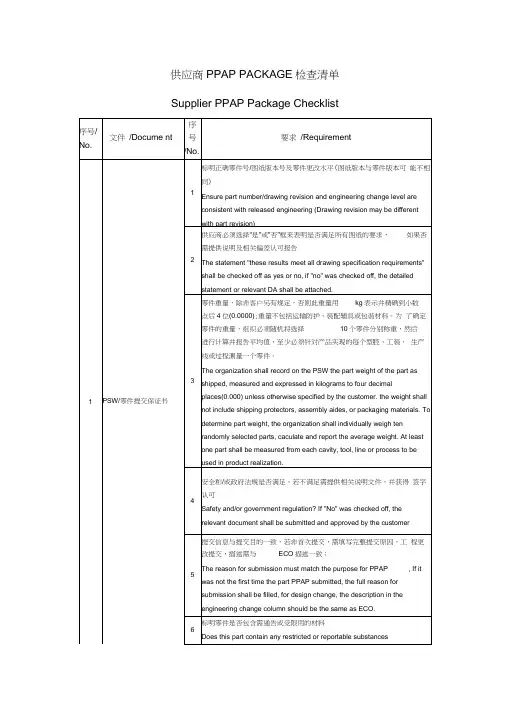

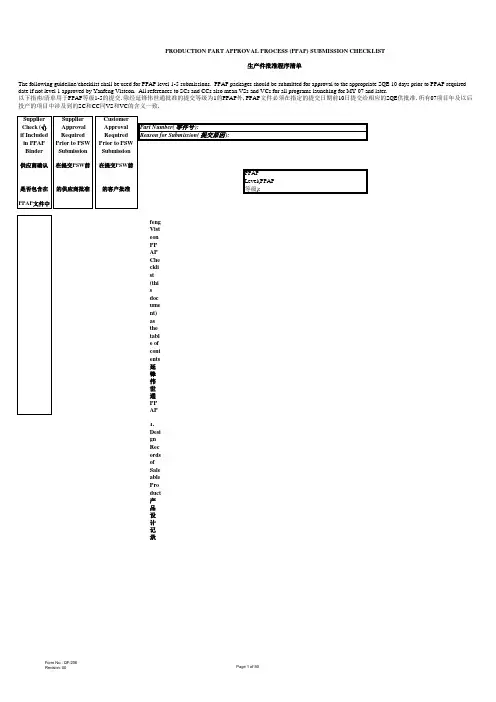

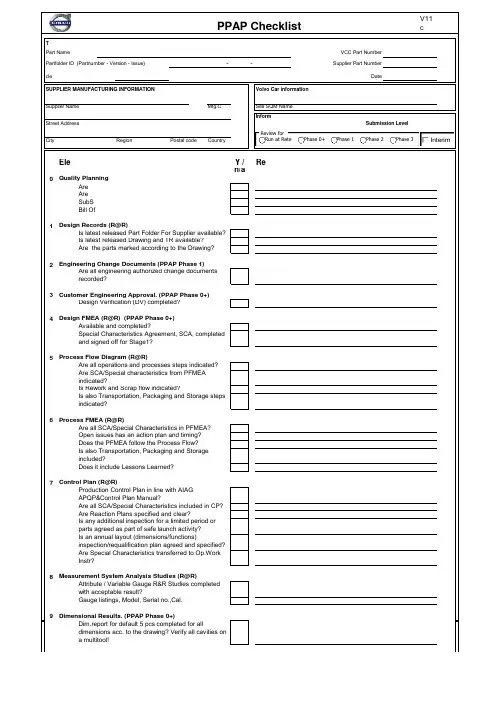

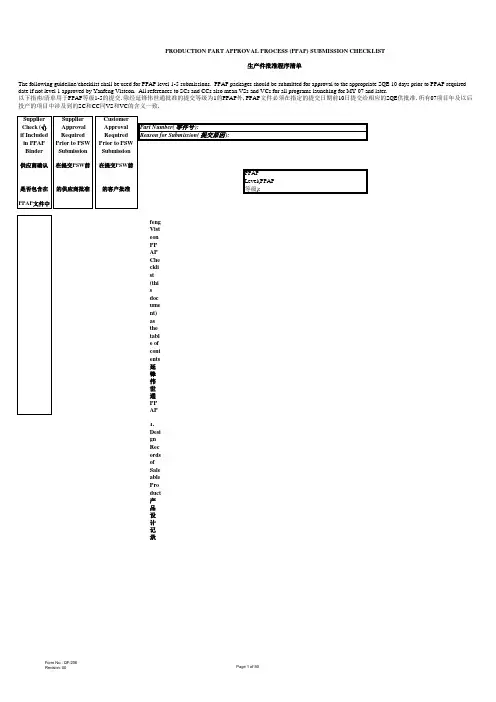

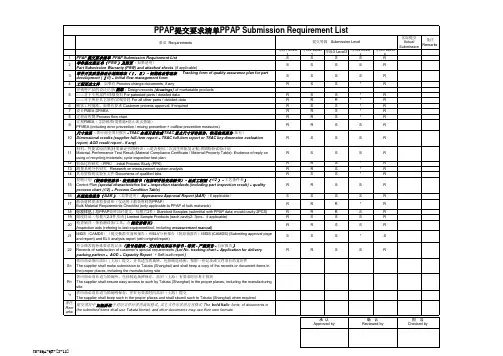

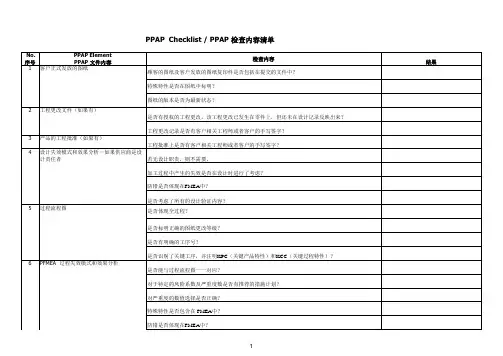

Yanfeng Visteon PPAP Checklist (this document) as the table of contents延锋伟世通PPAP 清单目录1. Design Records of Saleable Product产品设计记录a.Released Engineering Specification/Drawings and drawing notes 工程规范/图纸及图纸注释b.Special Characteristics 特殊特性Special Characteristics Identification Form (SCIF) Model year 2007 and later 特殊特性确认表格c.Interface and performance requirement for defined Black Box part“黑盒子”的零件应当规定接口和性能要求d.Part material composition report, report can be IMDS or other system/method defined by customer零件材质成分报告, 报告可以使用国际材料数据系统或顾客规定的其他系统/方法e.Polymer shall be identified according to ISO sign 聚合物应按ISO符号标识f.E-data, such as CAD/CAM data need hard copy 电子数据, 如CAD/CAM 数据需要打印硬拷贝2. Engineering Change Documents if applicable 授权的工程更改文件SCR approved by all customer functions as specified on SCR forms 批准的供应商变更请求3. Customer Engineering approval, if required 顾客工程批准, 如需要a.Product Engineering Approval(ESER) 产品工程批准(工程样品评估报告)b.Engineering Test Results (ES, Electronic Component) 工程测试结果(工程样品, 电子元件)4. Design FMEA 设计潜在失效模式及后果分析DFMEA must be included if supplier is design responsible 如果供应商有设计责任, 应进行请附DFMEA5. Process Flow Diagrams 过程流程图Detailed Flow Diagram to Yanfeng Visteon's dock 详细的产品流程图6. Process FMEA 过程潜在失效模式及后果分析PFMEA should includ"Handling,Packaging,Warehousing, and Shipping" PFMEA应包括"操作过程, 包装, 仓储和运输"7. Dimensional Results 尺寸结果100% layout for 6 parts for a single line process minimum单线流程最少取6件产品进行100%尺寸测量100% layout for 6 parts for each cavity if the process has 2 cavities per tool minimum如果每个模具有2个穴, 每个穴最少取6件产品进行100%尺寸测量100% layout for 3 parts for each cavity if the process has 3, 4 or 5 cavities per tool minimum如果每个模具有3个, 4个或5个穴, 每个穴最少取3件产品进行100%尺寸测量100% layout for 1 part for each cavity if the process has 6 or more cavities per tool minimum如果每个模具有6个或更多的穴, 每个穴最少取1件产品进行100%尺寸测量a.Tabular Summary Format (according to AIAG manual) - with 100 % in tolerance results 100%在公差范围内的结果Note: Data cannot be older than one year 数据不能过时超过一年b.Any surrogate data must be approved by Yanfeng Visteon's SQE 所有替代的数据必须被延锋伟世通SQE批准Note: Number of layouts may be modified with approval from Yanfeng Visteon. Attach approval if applicable注: 标记出经延锋伟世通批准的修改后的数据, 并附上批准文件8. Records of Material/ Performance test results 材料/性能试验结果的记录Data should be collected from Production Trial Run parts 数据应从试生产产品中收集Any material certification cannot be older than one year 任何材料证明都不能过时超过一年Any surrogate data must be approved by Visteon's Product Engineering 任何代替数据必须被延锋伟世通PD批准Test Results need to include: 试验结果应包括:- Copy of the specifications called out on the drawing 图纸上的材料规范- Material Certification with test results 附有试验结果的材料证明- Approved PV test results by Yanfeng Visteon's PD as required" '- 被延锋伟世通PD批准的PV试验结果9. Initial Process Study 初始过程研究a.At least 100 parts measured and at least 25 subgroups to be considered 最少25个子组并至少取得100个零件测量读数For each SC/VS and CC/VC. Raw data to be included in the PPAP package.应包含每个SC/VS和CC/VC的原始数据b.c.For all SC/VS's and CC/VC's, if any Ppk/Cpk < 1.33, work plan and 100% in process inspection to be implementedas a control method in the Control Plan对于所有的SC/VS及CC/VC项, 如果Ppk/Cpk < 1.33, 则应提交纠正措施计划和包含100%检验的控制计划For all SC/VS's and CC/VC's, if any 1.33 ≤ Ppk/Cpk < 1.67, work plan required对于所有的SC/VS及CC/VC项, 如果1.33 ≤ Ppk/Cpk < 1.68, 则应提交纠正措施计划The following guideline/checklist shall be used for PPAP level 1-5 submissions. PPAP packages should be submitted for approval to the appropriate SQE 10 days prior to PPAP required date if not level 1 approved by Yanfeng Visteon. All references to SCs and CCs also mean VSs and VCs for all programs launching for MY 07 and later.以下指南/清单用于PPAP等级1-5的提交. 除经延锋伟世通批准的提交等级为1的PPAP外, PPAP文件必须在指定的提交日期前10日提交给相应的SQE供批准. 所有07项目年及以后投产的项目中涉及到的SC和CC同VS和VC的含义一致.cumentsForm No.: QF-206Revision: 00Page 1 of 4The following guideline/checklist shall be used for PPAP level 1-5 submissions. PPAP packages should be submitted for approval to the appropriate SQE 10 days prior to PPAP required date if not level 1 approved by Yanfeng Visteon. All references to SCs and CCs also mean VSs and VCs for all programs launching for MY 07 and later.以下指南/清单用于PPAP等级1-5的提交. 除经延锋伟世通批准的提交等级为1的PPAP外, PPAP文件必须在指定的提交日期前10日提交给相应的SQE供批准. 所有07项目年及以后投产的项目中涉及到的SC和CC同VS和VC的含义一致.如果考虑型腔, 则原始数据矩阵应作适当的详细说明* The statistical Capability study must show statistical charts 统计过程能力分析研究应有统计图表* If the study is being done per cavity, at least 100 parts/cavity and at least 25 subgroups should be consideredfor each SC and CC. If less than 30 parts/cavity contact SQE responsible activity to develop a suitable plan.* 如果对每个型腔进行研究, 则对每个型腔的SC及CC项最少要100个数据和至少25个子组。

Yanfeng Visteon PPAP Checklist (this document) as the table of contents延锋伟世通PPAP 清单目录1. Design Records of Saleable Product产品设计记录a.Released Engineering Specification/Drawings and drawing notes 工程规范/图纸及图纸注释b.Special Characteristics 特殊特性Special Characteristics Identification Form (SCIF) Model year 2007 and later 特殊特性确认表格c.Interface and performance requirement for defined Black Box part“黑盒子”的零件应当规定接口和性能要求d.Part material composition report, report can be IMDS or other system/method defined by customer零件材质成分报告, 报告可以使用国际材料数据系统或顾客规定的其他系统/方法e.Polymer shall be identified according to ISO sign 聚合物应按ISO符号标识f.E-data, such as CAD/CAM data need hard copy 电子数据, 如CAD/CAM 数据需要打印硬拷贝2. Engineering Change Documents if applicable 授权的工程更改文件SCR approved by all customer functions as specified on SCR forms 批准的供应商变更请求3. Customer Engineering approval, if required 顾客工程批准, 如需要a.Product Engineering Approval(ESER) 产品工程批准(工程样品评估报告)b.Engineering Test Results (ES, Electronic Component) 工程测试结果(工程样品, 电子元件)4. Design FMEA 设计潜在失效模式及后果分析DFMEA must be included if supplier is design responsible 如果供应商有设计责任, 应进行请附DFMEA5. Process Flow Diagrams 过程流程图Detailed Flow Diagram to Yanfeng Visteon's dock 详细的产品流程图6. Process FMEA 过程潜在失效模式及后果分析PFMEA should includ"Handling,Packaging,Warehousing, and Shipping" PFMEA应包括"操作过程, 包装, 仓储和运输"7. Dimensional Results 尺寸结果100% layout for 6 parts for a single line process minimum单线流程最少取6件产品进行100%尺寸测量100% layout for 6 parts for each cavity if the process has 2 cavities per tool minimum如果每个模具有2个穴, 每个穴最少取6件产品进行100%尺寸测量100% layout for 3 parts for each cavity if the process has 3, 4 or 5 cavities per tool minimum如果每个模具有3个, 4个或5个穴, 每个穴最少取3件产品进行100%尺寸测量100% layout for 1 part for each cavity if the process has 6 or more cavities per tool minimum如果每个模具有6个或更多的穴, 每个穴最少取1件产品进行100%尺寸测量a.Tabular Summary Format (according to AIAG manual) - with 100 % in tolerance results 100%在公差范围内的结果Note: Data cannot be older than one year 数据不能过时超过一年b.Any surrogate data must be approved by Yanfeng Visteon's SQE 所有替代的数据必须被延锋伟世通SQE批准Note: Number of layouts may be modified with approval from Yanfeng Visteon. Attach approval if applicable注: 标记出经延锋伟世通批准的修改后的数据, 并附上批准文件8. Records of Material/ Performance test results 材料/性能试验结果的记录Data should be collected from Production Trial Run parts 数据应从试生产产品中收集Any material certification cannot be older than one year 任何材料证明都不能过时超过一年Any surrogate data must be approved by Visteon's Product Engineering 任何代替数据必须被延锋伟世通PD批准Test Results need to include: 试验结果应包括:- Copy of the specifications called out on the drawing 图纸上的材料规范- Material Certification with test results 附有试验结果的材料证明- Approved PV test results by Yanfeng Visteon's PD as required" '- 被延锋伟世通PD批准的PV试验结果9. Initial Process Study 初始过程研究a.At least 100 parts measured and at least 25 subgroups to be considered 最少25个子组并至少取得100个零件测量读数For each SC/VS and CC/VC. Raw data to be included in the PPAP package.应包含每个SC/VS和CC/VC的原始数据b.c.For all SC/VS's and CC/VC's, if any Ppk/Cpk < 1.33, work plan and 100% in process inspection to be implementedas a control method in the Control Plan对于所有的SC/VS及CC/VC项, 如果Ppk/Cpk < 1.33, 则应提交纠正措施计划和包含100%检验的控制计划For all SC/VS's and CC/VC's, if any 1.33 ≤ Ppk/Cpk < 1.67, work plan required对于所有的SC/VS及CC/VC项, 如果1.33 ≤ Ppk/Cpk < 1.68, 则应提交纠正措施计划The following guideline/checklist shall be used for PPAP level 1-5 submissions. PPAP packages should be submitted for approval to the appropriate SQE 10 days prior to PPAP required date if not level 1 approved by Yanfeng Visteon. All references to SCs and CCs also mean VSs and VCs for all programs launching for MY 07 and later.以下指南/清单用于PPAP等级1-5的提交. 除经延锋伟世通批准的提交等级为1的PPAP外, PPAP文件必须在指定的提交日期前10日提交给相应的SQE供批准. 所有07项目年及以后投产的项目中涉及到的SC和CC同VS和VC的含义一致.cumentsForm No.: QF-206Revision: 00Page 1 of 4The following guideline/checklist shall be used for PPAP level 1-5 submissions. PPAP packages should be submitted for approval to the appropriate SQE 10 days prior to PPAP required date if not level 1 approved by Yanfeng Visteon. All references to SCs and CCs also mean VSs and VCs for all programs launching for MY 07 and later.以下指南/清单用于PPAP等级1-5的提交. 除经延锋伟世通批准的提交等级为1的PPAP外, PPAP文件必须在指定的提交日期前10日提交给相应的SQE供批准. 所有07项目年及以后投产的项目中涉及到的SC和CC同VS和VC的含义一致.如果考虑型腔, 则原始数据矩阵应作适当的详细说明* The statistical Capability study must show statistical charts 统计过程能力分析研究应有统计图表* If the study is being done per cavity, at least 100 parts/cavity and at least 25 subgroups should be consideredfor each SC and CC. If less than 30 parts/cavity contact SQE responsible activity to develop a suitable plan.* 如果对每个型腔进行研究, 则对每个型腔的SC及CC项最少要100个数据和至少25个子组。

Yanfeng Visteon PPAP Checklist (this document) as the table of contents延锋伟世通PPAP 清单目录1. Design Records of Saleable Product产品设计记录a.Released Engineering Specification/Drawings and drawing notes 工程规范/图纸及图纸注释b.Special Characteristics 特殊特性Special Characteristics Identification Form (SCIF) Model year 2007 and later 特殊特性确认表格c.Interface and performance requirement for defined Black Box part“黑盒子”的零件应当规定接口和性能要求d.Part material composition report, report can be IMDS or other system/method defined by customer零件材质成分报告, 报告可以使用国际材料数据系统或顾客规定的其他系统/方法e.Polymer shall be identified according to ISO sign 聚合物应按ISO符号标识f.E-data, such as CAD/CAM data need hard copy 电子数据, 如CAD/CAM 数据需要打印硬拷贝2. Engineering Change Documents if applicable 授权的工程更改文件SCR approved by all customer functions as specified on SCR forms 批准的供应商变更请求3. Customer Engineering approval, if required 顾客工程批准, 如需要a.Product Engineering Approval(ESER) 产品工程批准(工程样品评估报告)b.Engineering Test Results (ES, Electronic Component) 工程测试结果(工程样品, 电子元件)4. Design FMEA 设计潜在失效模式及后果分析DFMEA must be included if supplier is design responsible 如果供应商有设计责任, 应进行请附DFMEA5. Process Flow Diagrams 过程流程图Detailed Flow Diagram to Yanfeng Visteon's dock 详细的产品流程图6. Process FMEA 过程潜在失效模式及后果分析PFMEA should includ"Handling,Packaging,Warehousing, and Shipping" PFMEA应包括"操作过程, 包装, 仓储和运输"7. Dimensional Results 尺寸结果100% layout for 6 parts for a single line process minimum单线流程最少取6件产品进行100%尺寸测量100% layout for 6 parts for each cavity if the process has 2 cavities per tool minimum如果每个模具有2个穴, 每个穴最少取6件产品进行100%尺寸测量100% layout for 3 parts for each cavity if the process has 3, 4 or 5 cavities per tool minimum如果每个模具有3个, 4个或5个穴, 每个穴最少取3件产品进行100%尺寸测量100% layout for 1 part for each cavity if the process has 6 or more cavities per tool minimum如果每个模具有6个或更多的穴, 每个穴最少取1件产品进行100%尺寸测量a.Tabular Summary Format (according to AIAG manual) - with 100 % in tolerance results 100%在公差范围内的结果Note: Data cannot be older than one year 数据不能过时超过一年b.Any surrogate data must be approved by Yanfeng Visteon's SQE 所有替代的数据必须被延锋伟世通SQE批准Note: Number of layouts may be modified with approval from Yanfeng Visteon. Attach approval if applicable注: 标记出经延锋伟世通批准的修改后的数据, 并附上批准文件8. Records of Material/ Performance test results 材料/性能试验结果的记录Data should be collected from Production Trial Run parts 数据应从试生产产品中收集Any material certification cannot be older than one year 任何材料证明都不能过时超过一年Any surrogate data must be approved by Visteon's Product Engineering 任何代替数据必须被延锋伟世通PD批准Test Results need to include: 试验结果应包括:- Copy of the specifications called out on the drawing 图纸上的材料规范- Material Certification with test results 附有试验结果的材料证明- Approved PV test results by Yanfeng Visteon's PD as required" '- 被延锋伟世通PD批准的PV试验结果9. Initial Process Study 初始过程研究a.At least 100 parts measured and at least 25 subgroups to be considered 最少25个子组并至少取得100个零件测量读数For each SC/VS and CC/VC. Raw data to be included in the PPAP package.应包含每个SC/VS和CC/VC的原始数据b.c.For all SC/VS's and CC/VC's, if any Ppk/Cpk < 1.33, work plan and 100% in process inspection to be implementedas a control method in the Control Plan对于所有的SC/VS及CC/VC项, 如果Ppk/Cpk < 1.33, 则应提交纠正措施计划和包含100%检验的控制计划For all SC/VS's and CC/VC's, if any 1.33 ≤ Ppk/Cpk < 1.67, work plan required对于所有的SC/VS及CC/VC项, 如果1.33 ≤ Ppk/Cpk < 1.68, 则应提交纠正措施计划The following guideline/checklist shall be used for PPAP level 1-5 submissions. PPAP packages should be submitted for approval to the appropriate SQE 10 days prior to PPAP required date if not level 1 approved by Yanfeng Visteon. All references to SCs and CCs also mean VSs and VCs for all programs launching for MY 07 and later.以下指南/清单用于PPAP等级1-5的提交. 除经延锋伟世通批准的提交等级为1的PPAP外, PPAP文件必须在指定的提交日期前10日提交给相应的SQE供批准. 所有07项目年及以后投产的项目中涉及到的SC和CC同VS和VC的含义一致.cumentsForm No.: QF-206Revision: 00Page 1 of 4The following guideline/checklist shall be used for PPAP level 1-5 submissions. PPAP packages should be submitted for approval to the appropriate SQE 10 days prior to PPAP required date if not level 1 approved by Yanfeng Visteon. All references to SCs and CCs also mean VSs and VCs for all programs launching for MY 07 and later.以下指南/清单用于PPAP等级1-5的提交. 除经延锋伟世通批准的提交等级为1的PPAP外, PPAP文件必须在指定的提交日期前10日提交给相应的SQE供批准. 所有07项目年及以后投产的项目中涉及到的SC和CC同VS和VC的含义一致.如果考虑型腔, 则原始数据矩阵应作适当的详细说明* The statistical Capability study must show statistical charts 统计过程能力分析研究应有统计图表* If the study is being done per cavity, at least 100 parts/cavity and at least 25 subgroups should be consideredfor each SC and CC. If less than 30 parts/cavity contact SQE responsible activity to develop a suitable plan.* 如果对每个型腔进行研究, 则对每个型腔的SC及CC项最少要100个数据和至少25个子组。

PPAP 零件名称Part name: ******* 零件号Part No. :图号Drawing No.:版本号Version: 01 Supplier Part No.:BC1234客户名称Customer Name: 供应商suppliers:XXXXXXXXXXXX CO ., LTD日期Date: 201X-XX-25零件号:Part No.:**** Part No.:BC1234XXXXXXXXXXXX有限公司 **** ******PPAP提交清单Document submited list 顾客名称 Customer:零件号Part No.:**** Part No.:BC1234PPAP递交日期PPAP递交等级:等级3编制Prepare:****** 日期Date:07/18/2018XXXXXXXXXXXX有限公司**** RUBBER TECHNOLOGY CO.,LTD.制造流程图/PROCESS FLOW CHART客户产品编号\Customer part number : 日期(初版)\Date(Orig.):2018.02.02 日期(修订)\Date(Rev.) :供方产品编号\**** part number :BC1234跨功能小组\Core Team Member: ******流程图编号/Process flow number : BC1234-1部门\Department检验\Inspection 制造\Manufacture 仓库\Warehous 流程说明\Description10 进料检验\ Material incoming inspectionDrying70 涂粘合剂/Adhesive coated80 干燥/DryingNG20 储存\Storage30 备料\Material preparation40 打料\Rubber mixing50 切料\Material cutting90 成型\Molding100 过程检验110磨削\■120 最終檢驗\Final inspectionOkNG返工/报废Rework / scrap●130 包裝\Packaging作业\Operate 检验\Inspection 储存\Storage运输\Transfer第 1 页,共 1 页第 1 页,共 10 页第 2 页,共 10 页第 3 页,共 10 页第 4 页,共 10 页第 5 页,共 10 页第 6 页,共 10 页核准/Approved:审核/Checked:制作/Produced:跨功能小组\Core Team Member全尺寸检验部分尺寸检验XXXXXXXXXXXX 有限公司 ************ CO.,LTD.产品检验报告Product check report检验日期: 2018.04.05Total dimension check Part of dimension checkCheck date:XXXXXXXX 有限公司***** CO.,LTD.TEL: FAX:TEST REPORT / 胶料物性测试报告配方编号:FK080180-A Date:2018.6.10X-Bar 管制图50.180 50.150 50.120 50.090 50.060 50.030 50.000 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20过程能力指数测算表CPKComputation of process capability indices样件\Prototype 试产\Pre-launch 量产\ProductionCustomer part No.:Sampling place : Molding **** part No.: BC1234Measuring tool : Projector Equipment : Molding machine Specification : φ50±0.3 Unit:mmTest date :2018.6.18Data proces-singITEM TIMES123456789101 50.1250.0850.0650.1050.1050.0850.1650.1850.1650.182 50.08 50.10 50.10 50.06 50.08 50.10 50.10 50.06 50.10 50.063 50.10 50.08 50.08 50.08 50.06 50.04 50.14 50.08 50.14 50.08 4 50.08 50.13 50.06 50.14 50.08 50.14 50.16 50.06 50.16 50.065 50.0750.0450.0850.0850.0750.0850.0850.1250.0850.12X 50.090 50.086 50.076 50.092 50.078 50.088 50.128 50.100 50.128 50.100 R0.050 0.090 0.040 0.080 0.040 0.100 0.080 0.120 0.080 0.120ITEM TIMES111213141516171819201 50.1650.1850.1650.1850.1650.1850.1250.1850.1650.182 50.18 50.12 50.10 50.06 50.10 50.06 50.18 50.12 50.10 50.163 50.16 50.14 50.14 50.08 50.14 50.08 50.16 50.14 50.14 50.08 4 50.18 50.12 50.16 50.06 50.16 50.06 50.18 50.12 50.16 50.065 50.1750.0850.0850.1250.0850.1250.1750.0850.0850.12X 50.170 50.128 50.128 50.100 50.128 50.100 50.162 50.128 50.128 50.120 R0.020 0.100 0.080 0.120 0.080 0.120 0.060 0.100 0.080 0.120Calculating theparameters上公差限USL50.300 下公差限LSL 49.700 公差范围T 0.600 公差中心M6.300 分布中心X50.113 平均极差R0.084 样本容量n100标准差估计值(d2=2.33)σ0.036 上控制限UCL=50.221下控制限L CL=50.005Capability exponent calculation and judgement 标准差估计值 σ=R/d 25.1911.45 1.73Operation ability is no problemThe operation need to be adjusted, and to take measures. Tester****Operator****Checker****X-Bar 管制图50.180 50.150 50.120 50.090 50.060 50.030 50.0001234567891011121314151617181920R 管制图0.140 0.120 0.100 0.080 0.060 0.040。

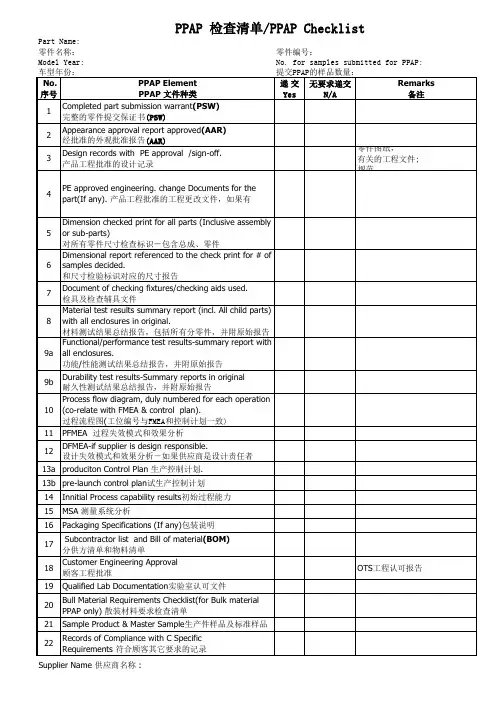

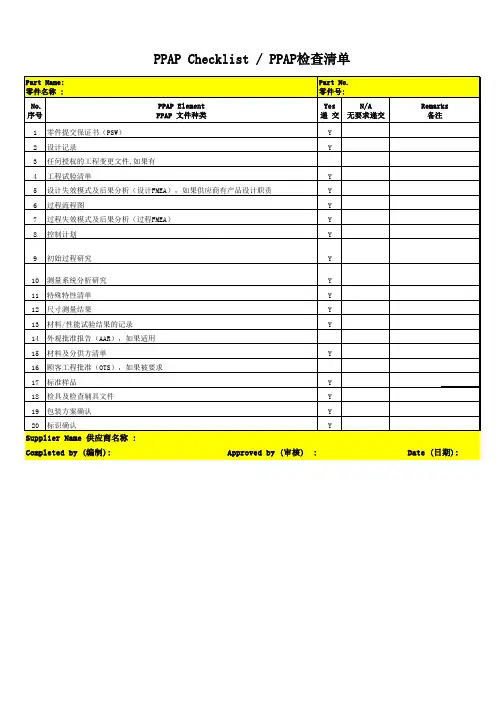

No.

序号

PPAP Element PPAP 文件种类递交Yes 无要求递交N/A Remarks 备注1

Completed part submission warrant (PSW)完整的零件提交保证书(PSW)2

Appearance approval report approved (AAR)经批准的外观批准报告(AAR)3

Design records with PE approval /sign-off.产品工程批准的设计记录零件图纸,有关的工程文件;规范4PE approved engineering. change Documents for the part(If any). 产品工程批准的工程更改文件,如果有5Dimension checked print for all parts (Inclusive assembly or sub-parts)

对所有零件尺寸检查标识-包含总成、零件

6Dimensional report referenced to the check print for # of samples decided.

和尺寸检验标识对应的尺寸报告

7Document of checking fixtures/checking aids used.检具及检查辅具文件

8Material test results summary report (incl. All child parts)with all enclosures in original.

材料测试结果总结报告,包括所有分零件,并附原始报告9a Functional/performance test results-summary report with all enclosures.

功能/性能测试结果总结报告,并附原始报告9b Durability test results-Summary reports in original 耐久性测试结果总结报告,并附原始报告

10Process flow diagram, duly numbered for each operation (co-relate with FMEA & control plan).

过程流程图(工位编号与FMEA 和控制计划一致)11PFMEA 过程失效模式和效果分析

12DFMEA-if supplier is design responsible.

设计失效模式和效果分析-如果供应商是设计责任者13a produciton Control Plan

生产控制计划.13b pre-launch control plan 试生产控制计划

14

Innitial Process capability results 初始过程能力15

MSA 测量系统分析16

Packaging Specifications (If any)包装说明17

Subcontractor list and Bill of material (BOM)分供方清单和物料清单18

Customer Engineering Approval 顾客工程批准OTS 工程认可报告19

Qualified Lab Documentation 实验室认可文件20

Bull Material Requirements Checklist(for Bulk material PPAP only) 散装材料要求检查清单21

Sample Product & Master Sample 生产件样品及标准样品22Records of Compliance with C Specific

Requirements 符合顾客其它要求的记录

车型年份:

提交PPAP 的样品数量:Supplier Name 供应商名称 :

Completed by (编制): Approved by(批准) : Date(日期 ): PPAP 检查清单/PPAP Checklist

Part Name:

Part No.:零件名称:

零件编号:Model Year:

No. for samples submitted for PPAP:。